Cutler Hammer, Div of Eaton Corp NEMA Contactors, NEMA Starters Application Information

February 2007

NEMA Contactors & Starters

Freedom

Relays — Thermal Overload

33-113

Contents

Description Page

Thermal Overload Relays

Product Description . . . . . . 33-113

Features . . . . . . . . . . . . . . . 33-113

Operation . . . . . . . . . . . . . . 33-113

Technical Information . . . . 33-113

Technical Data . . . . . . . . . . 33-114

Factory Modifications . . . . 33-115

Accessories. . . . . . . . . . . . . 33-115

Replacement Parts . . . . . . . 33-115

Dimensions. . . . . . . . . . . . . 33-116

Product Selection. . . . . . . . 33-117

Heater Pack Selection . . . . 33-117

32A Overload

Cat. No. C306DN3B

Product Description

C306 Overload Relays are designed for

use with CE or CN non-reversing and

reversing contactors. Four sizes are

available for overload protection up

to 144A.

Features

■ Selectable Manual or Automatic

Reset operation.

■ Interchangeable Heater Packs

adjustable ±24% to match motor

FLA and calibrated for use with 1.0

and 1.15 service factor motors.

Heater packs for 32A overload relay

will mount in 75A overload relay —

useful in derating applications such

as jogging.

■ Class 10 or 20 heater packs.

■ Load lugs built into relay base.

■ Bimetallic, ambient compensated

operated. Trip free mechanism.

■ Electrically isolated NO-NC contacts

(pull RESET button to test).

(Electrical Ratings see Table 33-160

on Page 33-114).

■ Overload trip indication.

■ Shrouded or fingerproof terminals

to reduce possibility of electrical

shock.

■ Meets UL 508 single-phasing

requirements.

■ UL listed, CSA certified, NEMA

compliance and CE mark.

Operation

C306 Overload Relay Setting

1.0

Service

Factor

A

Example of 12.0 FLA setting for

heater pack number H2011B showing

position for 1.0 or 1.15

service factor motors.

Figure 33-43. FLA Dial Adjustment

For motors having a 1.15 service factor, rotate the FLA adjustment dial to

correspond to the motor’s FLA rating.

Estimate the dial position when the

motor FLA falls between two letter

values as shown in the example.

For motors having a 1.0 service factor,

rotate the FLA dial one-half position

counterclockwise (CCW).

Example of setting for

Figure 33-44. Manual/Automatic Reset

The overload relay is factory set at M

for manual reset operation. For automatic reset operation, turn the reset

adjustment dial to the A position as

shown in the illustration.

Automatic reset is not intended for

two-wire control devices.

1.15

Service

Factor

BC

A

M

manual reset.

D

Test for Trip Indication

To test overload relay for trip indication when in manual reset, pull out the

blue reset button. An orange flag will

appear indicating that the device has

tripped. Push reset button in to reset.

Warning — To provide continued protection against fire or shock hazard,

the complete overload relay must be

replaced if burnout of the heater

element occurs.

Technical Information

General

“Overload relays are provided to protect motors, motor control apparatus

and motor-branch circuit conductors

against excessive heating due to

motor overloads and failure to start.

This definition does not include:

1) motor circuits over 600V, 2) short

circuits, 3) ground faults and 4) fire

pump control.” (NEC Art. 430-31)

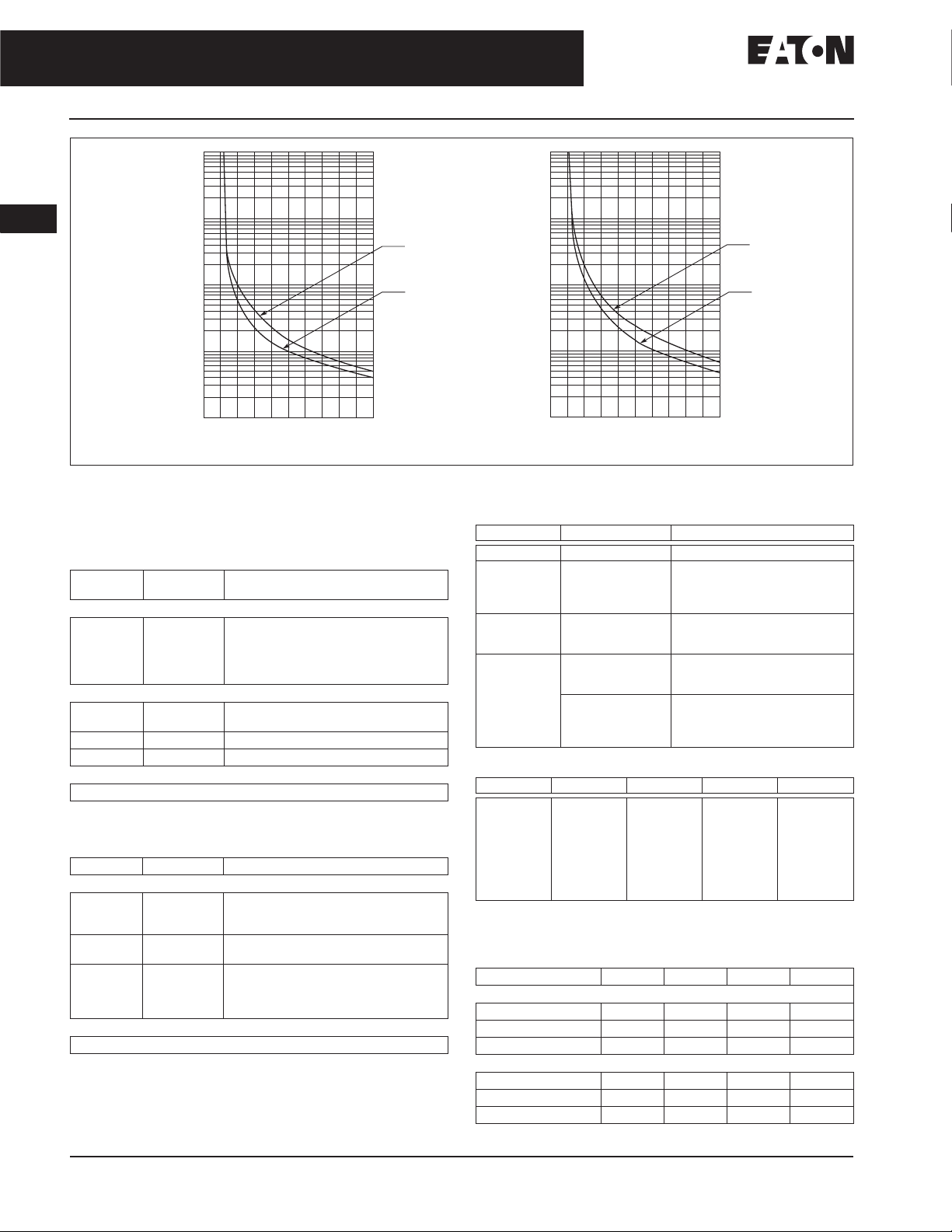

Time Current Characteristics

The time-current characteristics of an

overload relay is an expression of performance which defines its operating

time at various multiples of its current

setting. Tests are run at Underwriters

Laboratories (UL) in accordance with

NEMA Standards and the NEC. UL

requires:

■ When tested at 100 percent of its

current rating, the overload relay

shall trip ultimately.

■ When tested at 200 percent of its

current rating, the overload relay

shall trip in not more than 8

minutes.

■ When tested at 600 percent of the

current rating, the overload relay

shall trip in not more than 10 or 20

seconds, depending on the Class

of the relay.

“Current Rating” is defined as the

minimum current at which the relay

will trip. Per NEC, an overload must

ultimately trip at 125% of FLA current

(heater) setting for a 1.15 service factor

motor and 115% FLA for a 1.0 service

factor motor.

“Current Setting” is defined as the FLA

(Full Load Amperes) of the motor and

thus the overload heater pack setting.

Example: 600% of current rating is

defined as 750% (600 x 1.25) of FLA

current (heater) setting for a 1.15 service factor motor. A 10A heater setting

must trip in 20 seconds or less at 75A

motor current for a Class 20 relay.

33

CA08102001E For more information visit: www.eaton.com

33-114

NEMA Contactors & Starters

Freedom

February 2007

Relays — Thermal Overload

33

10,000

5000

4000

3000

2000

1000

500

Trip Time

(Seconds)

400

300

200

100

50

40

30

20

10

5

4

3

2

1

0

246810

Multiples of Current Setting

Class 10 Overload Relay 25°C Open Rating

From

Cold Start

From

Hot Start

Figure 33-45. Class 10 and Class 20 Trip Curves

Technical Data

Table 33-156. Wire (75°C) Sizes — AWG or kcmil — NEMA Sizes 00 – 2,

IEC A – K — Open

IEC

Size

Power Terminals — Line

A, B, C

D, E, F

G, H, J, K

Power Terminals — Load — Cu Only (Stranded or Solid)

Catalog

Number

C306DN3B 32A 14 – 6 AWG

C306GN3B 75A 14 – 2 AWG

Control Terminals — Cu Only

12 – 16 AWG Stranded, 12 – 14 AWG Solid

Two compartment box lug.

Table 33-157. Wire (75°C) Sizes — AWG or kcmil — NEMA Sizes 3 – 8,

IEC L – N — Open

IEC Size NEMA Size Wire Size

Power Terminals — Line and Load

L

M

N

— 4 Open — 3/0 – 8 Cu

—5

Control Terminals — Cu Only

12 – 16 AWG Stranded, 12 – 14 AWG Solid

NEMA

Cu Only

Size

00

0

1

2

12 – 16 Stranded, 12 – 14 Solid

8 – 16 Stranded, 10 – 14 Solid

8 – 14 Stranded or Solid

3 – 14 (Upper) and/or 6 – 14

Terminal Wire Size

3

—

—

1/0 – 14 Cu/Al

1/0 – 8 Cu/Al

3/0 – 8 Cu/Al

Enclosed — 250 kcmil — 6 Cu/Al

750 kcmil — 2 or

6 – 7

8

(2) 250 kcmil — 3/0 Cu/Al

(2) 750 kcmil — 3/0 Cu/Al

(2) 750 kcmil — 1/0 Cu/Al

(Lower) Stranded or Solid

10,000

5000

4000

3000

2000

1000

500

Trip Time

(Seconds)

400

300

200

100

50

40

30

20

10

5

4

3

2

1

0

246810

Multiples of Current Setting

Class 20 Overload Relay 25°C Open Rating

From

Cold Start

From

Hot Start

Table 33-158. Power Terminal Torque Line and Load Terminals

Terminal Catalog Number Torque in lb-in

32A C306DT3B 20

75A C306GT3B 35 (14 – 10 AWG)

40 (8 AWG)

45 (6 – 4 AWG)

50 (3 – 2 AWG)

105A C306KN3

(Socket Head

Screw)

144A C306NN3

(Socket Head

Screw)

C306NN3

(Slotted Head

Screw)

120 (3/16)

200 (1/4)

250 (5/16)

120 (3/16)

200 (1/4)

250 (5/16)

35 (14 – 10 AWG)

40 (8 AWG)

45 (6 – 4 AWG)

50 (3 – 1/0 AWG)

Table 33-159. Plugging and Jogging Service Horsepower Ratings

NEMA Size 200V 230V 460V 575V

00

0

1

2

3

4

5

6

Maximum horsepower where operation is interrupted more than 5

—

125

15

25

60

1-1/2

3

7-1/2

150

10

20

30

75

1/2

1-1/2

3

150

300

1/2

2

5

15

30

60

1/2

2

5

15

30

60

150

300

times per minute or more than 10 times in a 10 minute period. NEMA

standard ICS 2-1993 table 2-4-3.

Table 33-160. Overload Relay UL/CSA Contact Ratings Control Circuit

AC Volts 120V 240V 480V 600V

NC Contact B600

Make and Break Amps 30 15 7.5 6

Break Amps 3 1.5 .75 .6

Continuous Amps 5 5 5 5

NO Contact C600

Make and Break Amps 15 7.5 3.375 3

Break Amps 1.5 .75 .375 .3

Continuous Amps 2.5 2.5 2.5 2.5

DC ratings cover Freedom Series coils only.

For more information visit: www.eaton.com CA08102001E

Loading...

Loading...