Page 1

I.L. 15569C

Installation Instructions for Vari-Depth Handle Mechanism on

GC/GHC/GD and GMCP Circuit Breakers

WARNING

TO PREVENT ELECTRICAL SHOCK, DISCONNECT

FROM POWER SOURCE BEFORE INSTALLING OR

SERVICING. INSTALL IN SUITABLE ENCLOSURE.

KEEP FREE FROM CONT AMINANTS. TURN OFF AND

LOCK-OFF ALL POWER SOURCES. FAILURE TO DO

SO CAN RESULT IN DEATH, SEVERE PERSONAL

INJURY, OR SUBSTANTIAL PROPERTY DAMAGE.

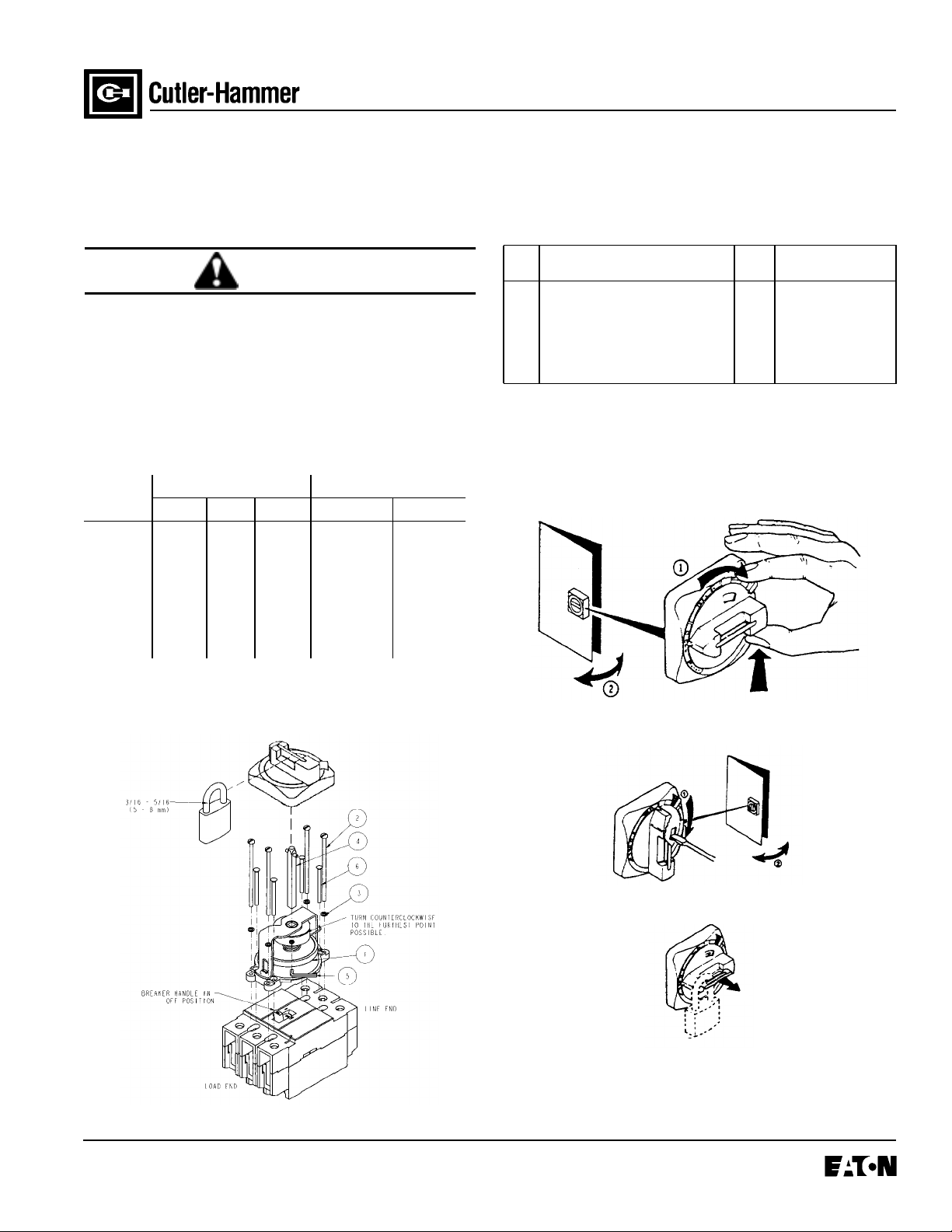

G-FRAME VARI-DEPTH HANDLE MECHANISM

Complete

Cat. #

HRGCV11L Black HRGSL HRGCV1 NEMA 1 GC/GHC/GD

HRGCV31L Yellow HRGSL HRGCV1 NEMA 1 GC/GHC/GD

HRGCV14L Black HRGSL HRGCV1 NEMA 3R/12/4 GC/GHC/GD

HRGCV34L Yellow HRGSL HRGCV1 NEMA 3R/12/4 GC/GHC/GD

HRGMV11L Black HRGSL HRGMV1 NEMA 1 GMCP

HRGMV31L Yellow HRGSL HRGMV1 NEMA 1 GMCP

HRGMV14L Black HRGSL HRGMV1 NEMA 3R/12/4 GMCP

HRGMV34L Yellow HRGSL HRGMV1 NEMA 3R/12/4 GMCP

➀ Black Handle NEMA 1 Cat # HRG11

Consisting of: For Use With:

Handle➀ Shaft Operator Enclosure Breaker

Black Handle NEMA 3R/12/4 Cat # HRG14

Yellow Handle NEMA 1 Cat # HRG31

Yellow Handle NEMA 3R/12/4 Cat # HRG34

ITEM DESCRIPTION BACK

1 SHAFT SUPPORT ASSEMBLY 1 1

2 PAN HEAD SCREW 6-32 X 3.25 LG ➁ 40

3 LOCK WASHER #6 4 0

4 SHAFT 1 1

5 ALLEN WRENCH 1 1

6 HI-LO SCREW 6-19 X 1.75 LG ➂ 04

➀ For DIN Rail or Snap-In Base Plate Application, carefully remove the exist-

ing cover screws from the circuit breaker without breaking the catalog warranty nameplate and replace with Item 6.

➁ Do not exceed a torque of 2.0 lb.-in.

➂ Do not exceed a torque of 4.0 lb.-in.

DINRAIL OR SNAP-IN

PAN

BASE PLATE ➀

HANDLE FEATURES

Handle Off - Open or Close Enclosure

Effective November 1997

Handle On - Open or Close Enclosure

Lock Handle Off With Enclosure Door Interlock

➀

➁

Page 2

Page 2

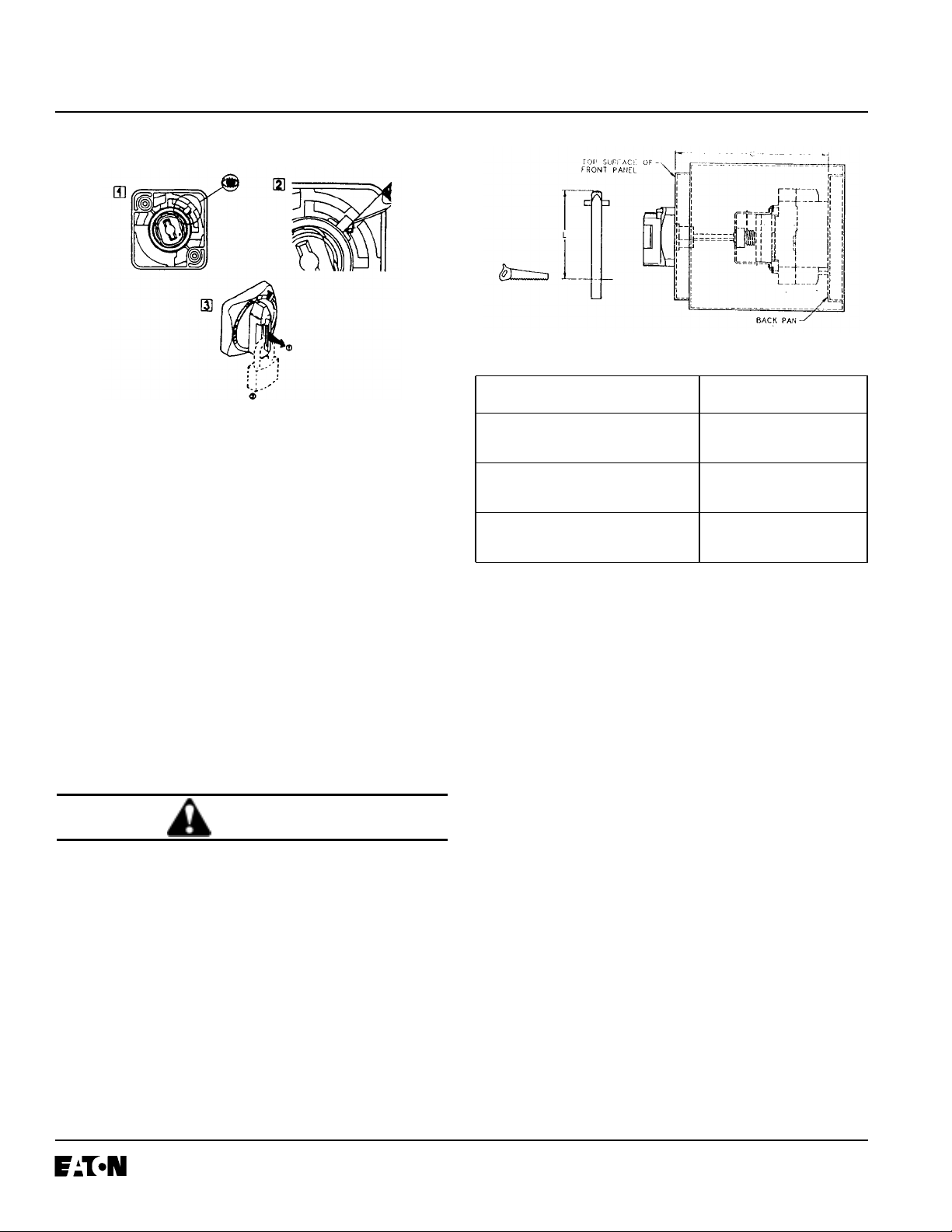

Lock Handle On With Enclosure Door Interlock

I.L. 15569C

2. Cut shaft to length.

BREAKER MOUNTING LENGTH OF SHAFT

INSTALLATION INSTRUCTIONS

1. Place circuit breaker in off position. Position the shaft

support assembly in the Off position by turning the

mechanism counterclockwise until at a solid stop.

Place the mechanism onto the circuit breaker such

that the slot on the slider on the mechanism mates

into the breaker handle. Mount the breaker and

mechanism per the customer's application using the

necessary hardware (as shown in the chart on page

1). Evenly tighten the screws to the giv en torques (as

shown below chart on page 1).

NOTE: Before mounting the shaft support assembly

and breaker to the back pan, see installation instruction item 4 to be certain to acquire minimum front

panel dimensions for door clearance.

If mounting the breaker directly to the back of the

pan, see the figure on page 1 for mounting hole

dimensions.

CAUTION

BE CERTAIN TO CORRECTLY ASSEMBLE SHAFT

SUPPORT TO THE CIRCUIT BREAKER. FAILURE TO

DO THIS WILL CAUSE IMPROPER OPERATION AND

BREAKAGE OF PANS.

DO NOT EXCEED TORQUE LIMITS ON SCREWS.

HIGHER TORQUES COULD CAUSE CRACKING ON

THE SHAFT SUPPORT ASSEMBLY AND IMPROPER

OPERATION.

SCREW INTO BACK PAN L = C -106

L = C - 4 3/16 IN.

DIN RAIL L = C -119 MM

L = C - 4 11/16 IN.

SNAP-IN BASE PLATE L = C -108 MM

L = C - 4 1/4 IN.

Note: Dimension C is the measurement from the back

pan to the top surface of the front panel.

3. Place the shaft into the shaft support assembly as

shown on page 1 and tighten the set screw on the

collar.

4. Measure the distance from the hinge to the center of

the shaft. Measure the distance perpendicular to the

last measurement from the center of the shaft to one

of the sides of the enclosure. With the front panel

door open, mark the inside panel door with these

measurements and drill a 5/16 Dia. hole. Carefully

close the panel door and check to see if the hole is

center to shaft. From inspection of the 5/16 dia. hole,

drill a 3/8 Dia. (35mm) hole.

MM

Effective November 1997

Page 3

I.L. 15569C

Page 3

5. After drilling, close the door of the front panel and

place the full size cutout template on the front panel.

Center the template over the shaft and align the top

edge of the template so that it is parallel with the line

end of the breaker . Mark the handle screw holes and

drill (2) 7/32 Dia. (5.5mm) holes as indicated on the

template.

6. Apply the mounting screws to door and handle.

7. With main power Off, check the mechanism opera-

tion in the On, Off, and reset positions.

Effective November 1997

Page 4

Page 4

I.L. 15569C

Cutler-Hammer

Pittsburgh, Pennsylania U.S.A.

Style No. 8698C43H04 Effective November 1997

Printed in U.S.A./CCI

Loading...

Loading...