Installation Instructions

CurrentWatch™ ECS7 Series Current Switches

Self-Calibrating AC Current Switch with Solid State Outputs

WARNING

IN ORDER TO AVOID ELECTRIC SHOCK OR OTHER POSSIBLE INJURY:

• DO NOT USE THIS PRODUCT FOR HUMAN SAFETY APPLICATIONS.

IT WAS NOT DESIGNED, TESTED OR RECOMMENDED FOR THIS

USE.

• DO NOT USE THIS PRODUCT IN HAZARDOUS LOCATIONS (E.G.

EXPLOSIVE ATMOSPHERES). IT WAS NOT DESIGNED, TESTED OR

RECOMMENDED FOR THIS USE.

• ENSURE THE PRODUCT IS PROPERLY WIRED FOR THE

APPLICATION. REFER TO THE SPECIFICATIONS AND WIRING

DIAGRAMS IN THIS MANUAL.

MODELS COVERED IN THIS MANUAL

Catalog Number Description

ECS701SC Solid Core, N.O., Over/Under Load

ECS700SC Solid Core, N.O., Overload Only

ECS702SC Solid Core, N.O., Underload Only

ECS711SP Split Core, N.O., Over/Under Load

ECS710SP Split Core, N.O., Overload Only

ECS712SP Split Core, N.O., Underload Only

INTRODUCTION

The CurrentWatch™ ECS7 Series current

switches are designed for overload,

underload or operating window applications.

Upon sensing an average operating current,

the ECS7 Series self-learns and establishes a

limit-alarm trip point based on plus or minus

15 percent of the average expected current

being monitored. The ECS7 Series is available

in solid or split core housing styles.

The ECS7 Series magnetically isolated solid state output contacts are

rated for 0.30A @ 135V AC/DC. This “universal” output makes this

product especially well suited for PLC control systems or a variety of

load connections.

Eaton’s current sensor family encompasses a broad range of products

for cost-effective monitoring, status, and predictive maintenance.

Downtime and costly repairs can be avoided by utilizing Eaton’s

products and technology in your control systems.

Note: Unless otherwise specifi ed, the term “load” refers to the

current being monitored.

P51922 Rev 04

695000107

INSTALLATION

Considerations for all ECS7 Series models…

• Run wire to be monitored through the aperture (opening) in the

switch body.

• These switches can be located in the same environment as

motors, contactors, heaters, pull-boxes and other electrical

enclosures.

• Mounting can be done in any position or hung directly on a wire

with a wire tie.

• Be sure to leave at least one inch distance between sensor and

other magnetic devices.

Considerations for split-core models only…

• Press the tab in the direction

shown in the diagram to the right.

• After placing the wire in the

aperture, press the hinged portion

fi rmly downward until a click is

heard and the tab pops out fully.

• Keep split-core contact areas

clean. Silicon grease is factory applied on the mating surfaces to

prevent rust and improve performance. Be careful not to allow

grit or dirt into the grease in the contact area, particularly on core

mating surfaces of split core models. Sensor operation could be

impaired if mating surfaces do not have good contact. Check

visually before closing.

QUICK INSTALL GUIDE

The below steps can be followed to quickly install a CurrentWatch™

ECS7 Series switch.

1. Run the wire to be monitored through the aperture

2. Mount the sensor

3. Connect output wire to the solid state relay terminals

a. Use up to 14 AWG copper wires

b. Don’t exceed output rating

4. Slide the Function Switch from “CLR” to “RUN”

5. Turn load “on”, equipment is now energized and sensor is

calibrated

• Note: Refer to the LED Indication table on page two for switch

operation.

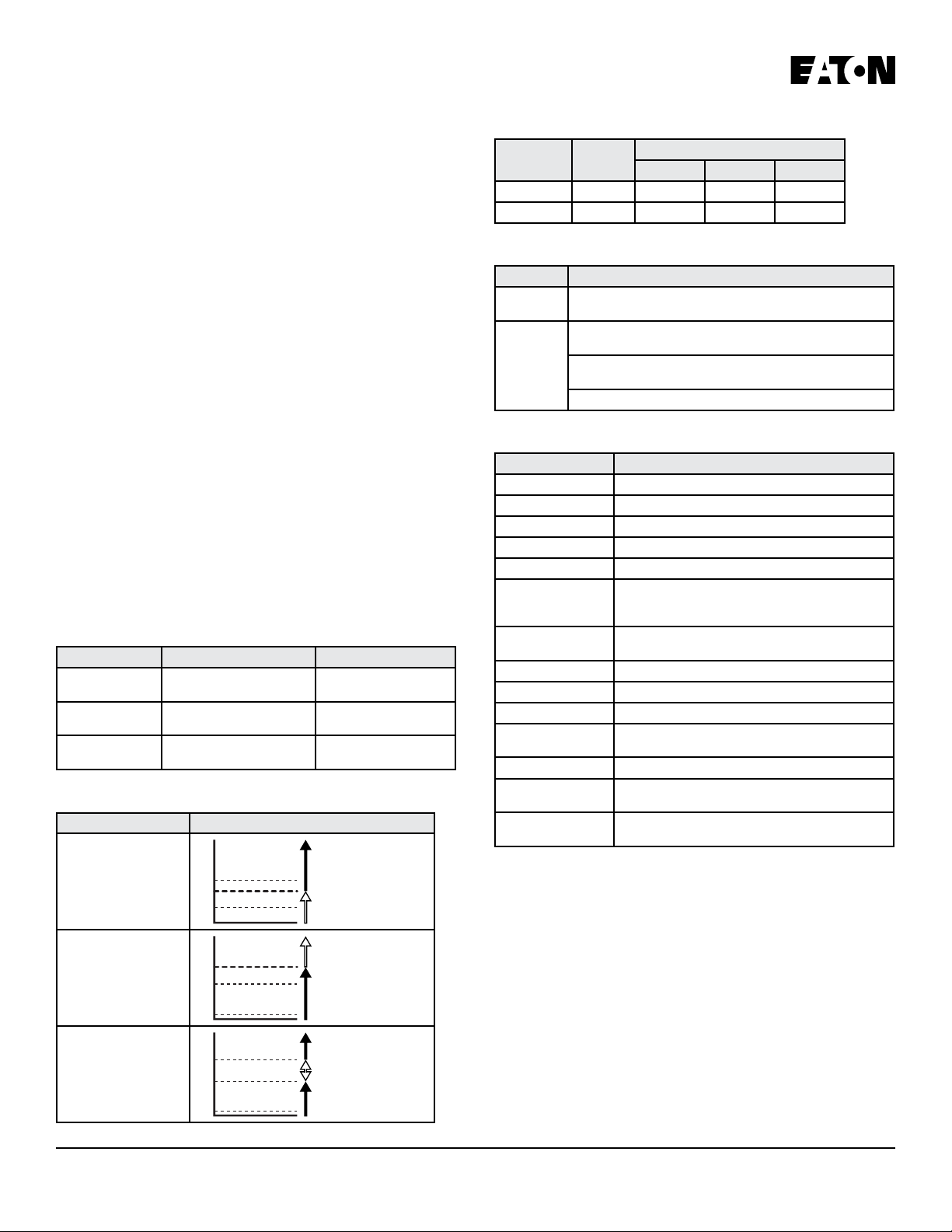

WIRING DIAGRAM

Connect control or monitoring wires to the sensor. Use up to 14 AWG

copper wire and tighten terminals to 7 inch-pounds torque. Be sure the

output load does not exceed the solid state output rating.

CAUTION! Incandescent lamps can have “cold fi lament inrush”

current of up to ten times their rated amperage. Use caution when

switching lamps.

AC or DC

Power

Monitored

Wire

AC or DC

Electrical Equipment Load

Important:

Keep contact areas clean

Use caution when

switching lamps

To open:

Press tab inward

towards hinge

Effective: April 2010 Page 1

Questions? Call our Sensor Application Engineers at (800) 426-9184.

P51922 Rev 04

695000107

SETPOINT ADJUSTMENT

The CurrentWatch™ ECS7 Series has an internal microprocessor

that “learns” your load characteristics and calibrates the setpoint and

setpoint window.

Initial Calibration

1. This product is shipped from the factory with Function Switch in

the “CLR” position, which clears the memory.

2. After installation is complete and the output is connected properly,

slide this switch into the “RUN” position.

3. Turn on the load. The LED indicator marked “CALIB/ALARM”

will fl ash slowly (about one fl ash every two seconds) during the

learning period. When this LED goes out, the sensor has been

calibrated.

Re-Calibration

If the load or conditions change, you may need to recalibrate the sensor.

Below are the steps for doing so.

1. Safety fi rst—turn load power off before recalibrating.

2. Slide the Function Switch to the “CLR” position.

3. Turn the load power back on for fi ve seconds, then turn it off. This

clears the memory.

4. Slide the Function Switch to the “RUN” position.

5. Turn the load back on. The sensor is now re-calibrated.

• Note: For special situations, re-calibration can be performed while

the load is running. Exercise extreme caution when placing your

hands into a high voltage environment! With the load running,

fl ip the Function Switch to the “CLR” position, wait fi ve seconds,

then move the Function Switch back to the “RUN” position. The

sensor will then re-calibrate.

LED INDICATION

State Contact LED Calibration LED

Off Load off or below threshold.

Slow Flash (Once

Every Two Seconds)

Fast Flash (About Two

Flashes Per Second)

Caution! Load power may be on!

Output open, normal state. Sensor is learning the load and

Switch is tripped, output closed. Calibration error. Perform

Sensor is operating normally

or is off.

self-calibrating.

re-calibration.

CURRENT SWITCH OPERATION

Model Output Diagram

Underload Only Models

Output Open (LED Fast)

Amps

Output Closed (LED Slow)

Output Open (LED Off)

Calibration Point

RANGES AND MAXIMUM AMPS

Maximum Amps

Housing Range

Solid Core 1.5-150A 500A 500A 1,000A

Split Core 2.8-150A 500A 500A 1,000A

Continuous 6 sec. 1 sec.

TROUBLESHOOTING

Problem Solution

Switch is

always tripped

Switch will

not trip

Switch may have been overloaded and contacts are burned out. Check the

output load, remembering to include inrush on inductive loads (coils, motors).

For split core models, the core contact area may be dirty. Open the sensor

and clean the contact area.

Switch may have been overloaded and contacts are burned out. Check the

output load, remembering to include inrush on inductive loads (coils, motors).

Make sure function switch is in “RUN” mode.

SPECIFICATIONS

Specifi cation Value

Power Supply Self Powered–No Power Supply Needed

Output Magnetically Isolated Solid State Switch

Output Rating Normally Open (N.O.) Models: 0.30A @ 135V AC/DC

Off-State Leakage < 10 µA

Response Time 200 ms

Setpoint Overload Only Models: +15% of Load

Setpoint Ranges Solid Core: 1.5-150A

Hysteresis Approx. 5% of Setpoint

Isolation Voltage UL Listed to 1,270V AC, Tested to 5,000V AC

Frequency Range 6-100Hz

Sensing Aperture Solid Core Models: 0.75 in. (19mm) dia.

Housing UL94 V0 Flammability Rated

Environmental Operating Temperature: -58 to +149° F (-50 to +65° C)

Approvals UL and ULC Listed

Underload Only Models: -15% of Load

Over/Underload Models: ±15% of Load (Operating Window)

Split Core: 2.8-150A

Split Core Models: 0.85 in. (21.7mm) sq.

Humidity: 0-95% RH, Non-Condensing

CE Certifi ed

Overload Only Models

Over/Underload Models

Amps

Amps

Output Closed

Output Open

Output Closed

Output Open

Output Closed

Effective: April 2010 Page 2

(LED Slow)

115% of Calibration Point

Calibration Point

(LED Fast)

(LED Off)

(LED Slow)

115% of Calibration Point

(LED Fast)

85% ofCalibration Point

(LED Slow)

(LED Off)

Questions? Call our Sensor Application Engineers at (800) 426-9184.

Loading...

Loading...