CustomAir DualWet User and maintenance manual

Dual Wet Vacuum System

Installation, Operation and Care Manual

Table of Contents

Section I Introduction

Specifications ......................................................................................................................... 2

Features/Benefits .................................................................................................................. 2

Section II Pre-installation

Site Requirements ................................................................................................................ 3

Typical Installation Options ................................................................................................4

Section III Installation

Water Supply Line ................................................................................................................ 5

Vacuum Line .......................................................................................................................... 5

Waste Line ............................................................................................................................. 6

Electrical Connection Assembly........................................................................................6

Intake/Exhaust Hose Connections ................................................................................... 7

Section IV Illustrated Parts Breakdown

Cabinet Assembly .................................................................................................................8

1 HP Dual Pump Assembly .................................................................................................9

2 HP Dual Pump Assembly .............................................................................................. 10

Intake Manifold Assembly, Dual ...................................................................................... 11

Waste Manifold Assembly, Dual...................................................................................... 12

Electrical Box ..................................................................................................................... 13

Section V Repair Parts

Water Control Assembly ................................................................................................. 14

Vacuum Control Assembly .............................................................................................. 15

Vacuum Gauge and Adapter ............................................................................................ 15

In-line Filter Assembly ...................................................................................................... 15

Anti-Siphon Valve Assembly ............................................................................................ 16

Water Solenoid Valve Assembly ..................................................................................... 16

Section VI Operation & Care

General Operation ........................................................................................................... 17

Maintenance Schedule ................................................................................................ 17-18

Section V User Ser vice Information

Service Instruction ............................................................................................................ 19

Trouble Shooting Charts ............................................................................................ 19-21

Relay Box ............................................................................................................................ 21

Alternate Voltage Connection ........................................................................................ 21

Wiring Schematic .............................................................................................................. 22

Air/Water Flow Circulation Diagram ........................................................................... 22

Pump Removal ................................................................................................................... 23

Vacuum Pump System Repair Procedure ............................................................... 23-27

Product Support Services ..................................................................................... 28

Dual Wet Vacuum System

1

Section I Introduction

Dual Wet Vacuum System

This manual contains installation, operation, care

and repair instructions and user service information

®

for the CustomAir

201/MC-202).

The Dual Wet Vacuum System is designed to provide

trouble-free service when installed, operated and cared

for according to the procedures set forth in this manual.

Dual Wet Vacuum System (MC-

Specifications

MC-201 MC-202

Motor

Power Rating: 1 HP 2 HP

Amps (each motor): 7.5 15

Running Speed: 3450 RPM

Ambient Temperature: 40°C/104°F

Voltage: 208/230

Cycle: 60 Hz.

Phase: Single

Max. Oper. Noise Level: 70-75 dB

Vacuum

Mercury Pull (Sealed Sys.): Approx. 20-25" Hg. Adjust.

One Pump Operation

Usable CFM: 15 30

Use factor (Number of

high-volume hoses

open simultaneously): 1.5 3

Two Pump Operation

Usable CFM: 30 60

Use factor (Number of

high-volume hoses

open simultaneously): 3 6

Dimensions

Height: 23"

Width: 24"

Depth: 15-5/8"

Features/Benefits

Spread Voltage The Dual Wet Vacuum

system can be wired directly to 208 and 230

VAC electrical circuits, eliminating the need for

buck and boost transformers.

Swing Check Valve Eliminates the need for

inconvenient manual shut-off valves and

provides a positive seal for one pump operation.

Secondary Filter Traps any materials too

large to pass through the pump and features

easy-to-clean convenience.

Pump Controls For convenience, all con-

trols are located on the outside front of the

unit. Dual-lighted switches allow for individual

activation of each pump. Vacuum adjustments

can be easily made and checked with the

adjustment control and gauge.

External Vacuum Adjustment For conve-

nient and accurate vacuum adjustment when

needed.

Rugged Frame and Enclosure Designed

for strength and easy access to all assemblies.

Instrumentation Vacuum level at a glance.

Two Quiet-Running Motor/Pump Assem-

blies For back-up protection. Motors are

designed for continuous operation and long life.

Pumps are solid brass castings, precision machined for long and trouble-free service not

affected by modern dentistry chemicals. 1 HP

and 2 HP motors are available. Both pumps can

be operated during peak work periods.

Pre-Wired for Remote Switch Allows

quick pick-up of third wire for a remote lighted

operatory switch.

Shipping W eight: 180 lbs. 210 lbs.

Approvals:

Standard Models, 115 VAC only:

UL Listed: File E34585

CSA Certified: File LR67707

Installation, Operation and Care Manual

2

Easy Disconnect Designed for easy servic-

ing all connections to motor/pump assembly

can be easily removed for fast service.

Two-Year Warranty Longer warranty

reduces maintenance cost.

Section II Pre-installation

The following Pre-installation information will assist

in making a quick, easy and quality installation. However, if there are any questions, contact a CustomAir

technical service representative at 1-866-DTE-INFO.

Site Requirements

Before the Dual Wet Vacuum System can be properly

installed, the following utilities must be supplied:

Electrical

All electrical supply lines and control wiring should

be supplied and installed by a licensed electrician

according to local building codes. The Dual Wet

Vacuum System requires two separate circuits

(one for each pump motor) of the correct voltage for

the system ordered. In addition to the thermal overload

protection built into the motors, each circuit must be

provided with a circuit breaker, time delay fuse or

standard fuse. See the Motor Protection Chart below

for recommended breaker or fuse amperage.

Motor Protection Chart

epyTnoitcetorP

)rotomhcae(

rekaerBtiucriCspmA02spmA03

esuFyaleDemiTspmA21spmA02

102-CM

V032

202-CM

V032

Water

Water line must be installed by a plumber according

to local building codes. Terminate water line in 1/2"

FIP gate valve.

Waste

— CAUTION —

A free-flowing discharge system is required for

proper operation of the vacuum system. Dual

pump systems may leak at the anti-siphon valve

if the discharge system is restricted. Ensure the

vacuum system is installed and cleaned in accor-

dance to the instructions in this manual.

Waste line must be installed by a plumber according

to local building codes. For requirements, see Typical

Installation Options, Page 4 and Waste Line, Page 6.

V acuum Lines

Vacuum lines be installed by a plumber according to

local building codes. Vacuum lines and risers to be

IPS, PVC, Schedule 40, unless local codes require

another material such as copper. Slope all vacuum

lines toward the vacuum producer 1 inch for every

20 foot run. Make all vacuum line connections using

long radius sweep fittings.

atSspmA52spmA04

esuFdradn

Low Voltage Control Line (Optional)

If remote low voltage is desired, a licensed electrician

should install 18-3 thermostat wire for lighted switch or

18-2 thermostat wire for non-lighted switch from the pump

location to the operatory switch located up to 150 feet

away. If the operatory switch is over 150 feet away from

the pump location, use 16-3 thermostat wire for lighted

switch or 16-2 thermostat wire for non-lighted switch.

— IMPORTANT —

All vacuum systems must be installed according

to local building and electrical codes.

Water Line

(1/2" Gate Valve

Reduced to

3/8" FIP)

Vacuum Line

(IPS, PVC,

Schedule 40)

W aste Line

(Drain)

Low V oltage Line

(24V) (Optional)

Dual Wet Vacuum System

Electrical

(230V)

Connection

Boxes (2)

3

Section II Pre-installation

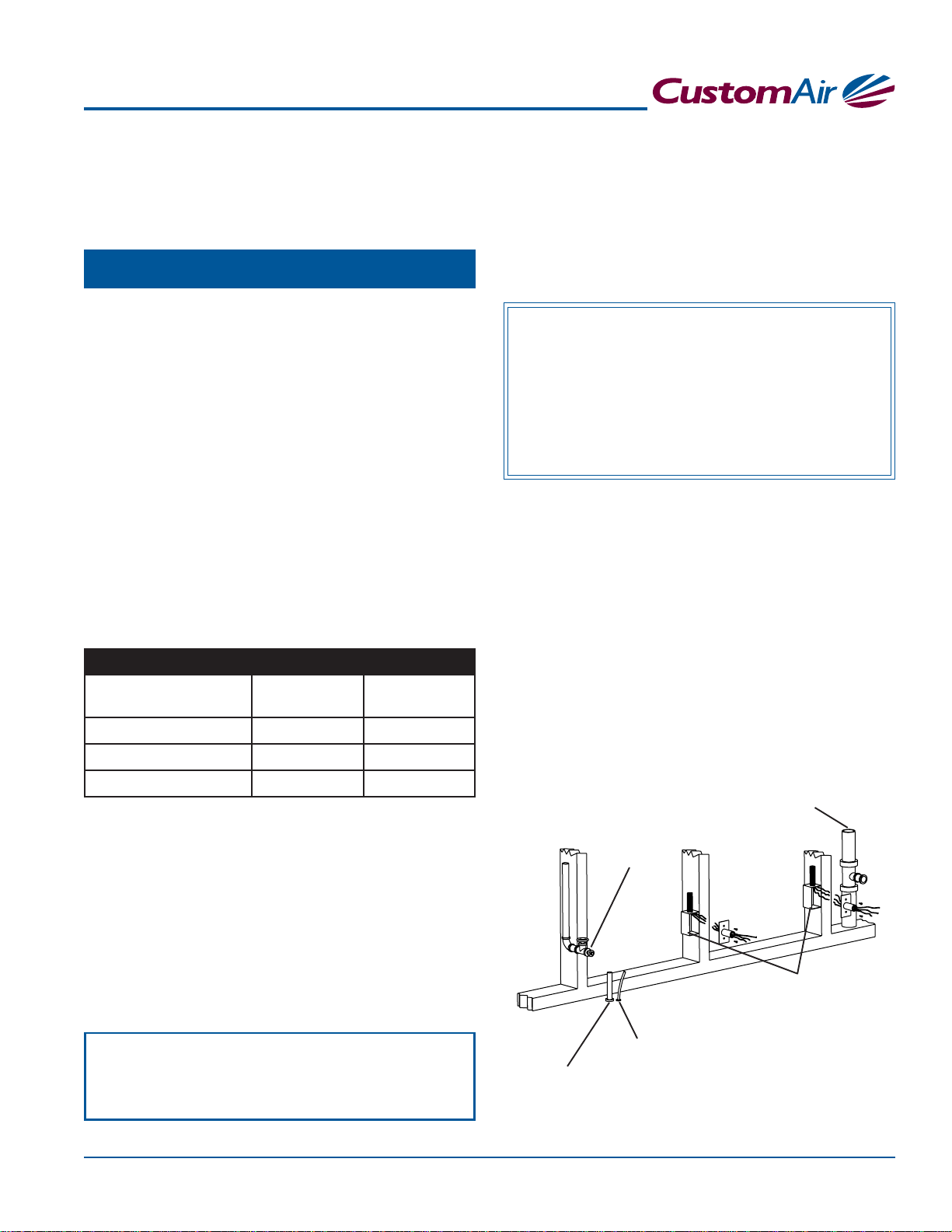

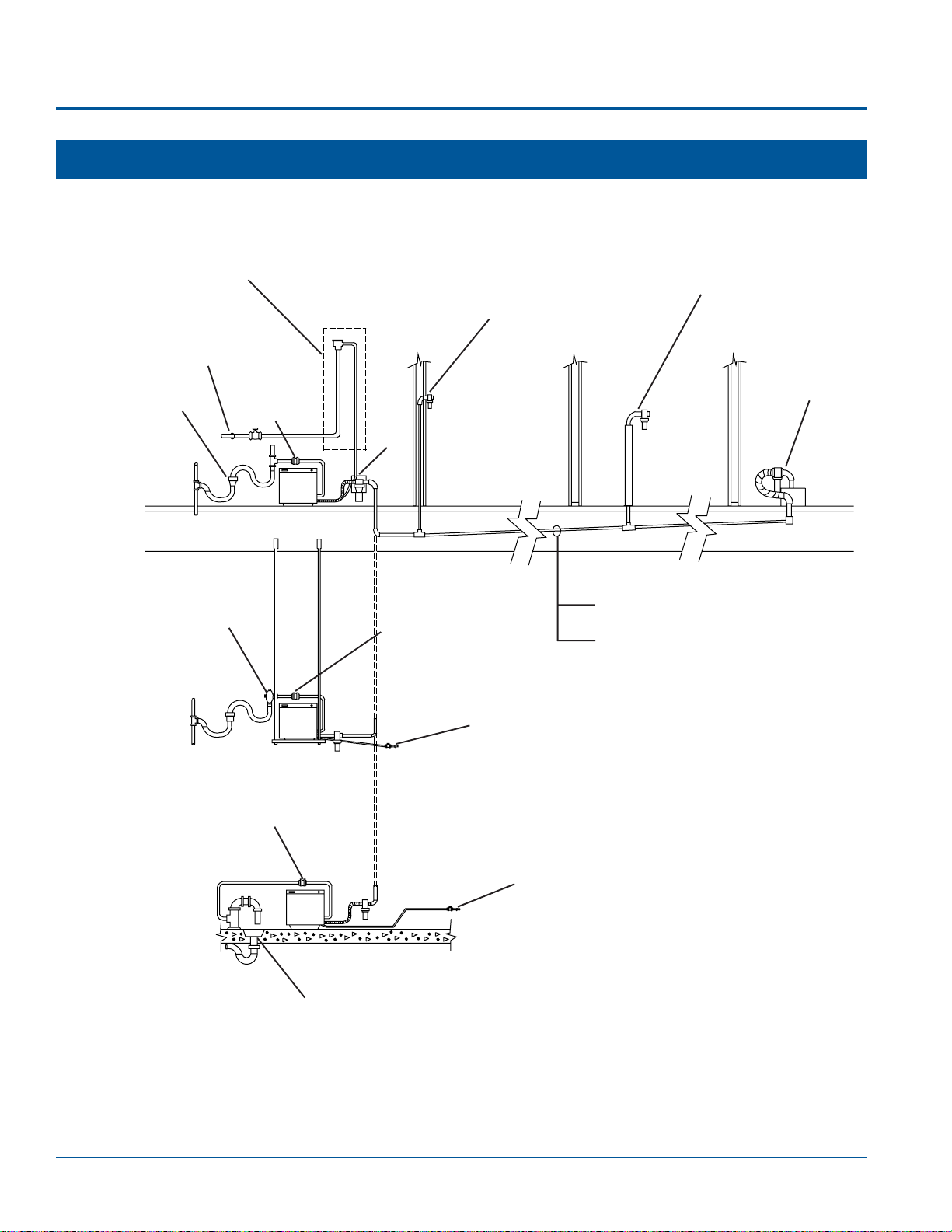

Typical Installation Options

Dual Wet Vacuum System

1" Air Gap Per

Local Code

OPTION

NO . 1

Required only when specified by

local plumbing code.

Water

Supply

Muffler*

Air/Water

Separator

In-Wall Manifold and Filter

Assembly

In

Line

Filter

Muffler*

Floor Stand and Filter

Assembly

Junction

Box Filter

Assembly

IPS, PVC, SCH. 40

1" Slope Per 20' towards

vacuum producer

OPTION

NO . 2

OPTION

NO . 3

Water Supply

Muffler*

Water Supply

Floor Sink

with Adapter

*Position of muffler shown

for illustration clarity only.

Installation, Operation and Care Manual

4

Section III Installation

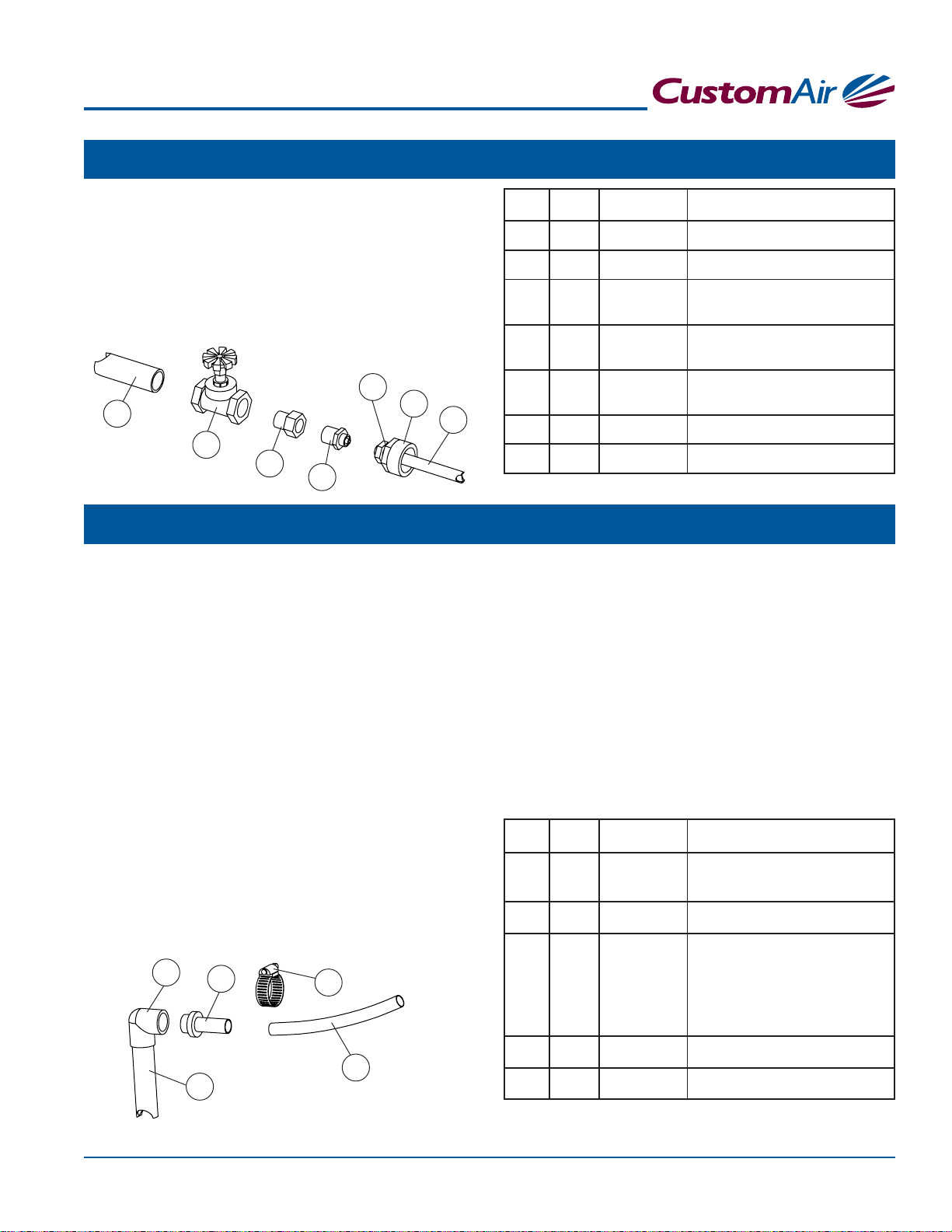

Water Supply Line

The water going to the unit acts as a pump sealant

and cooling agent. When the Vacuum System is in

operation, the water supply must be on at all times.

The plumber supplies and installs a 1/2" gate valve

on the water supply line. Connect the 3/8" nylon

tubing and fittings, which are supplied with the unit,

as illustrated.

5

1

6

7

2

3

4

V acuum Line

Vacuum lines must be installed by a local plumber

according to local building codes. All vacuum lines

and risers are recommended to be IPS, PVC, SCH.

40. Type M copper should be used if local code

does not allow the use of PVC.

Care should be taken to slope the lines 1" for every

20' of run toward the vacuum pump(s). This allows

waste and liquids to flow with gravity, contributing

to the efficiency of the vacuum system.

Make all connections using long radius sweep fittings. To promote unrestricted flow of air and waste

liquids through the vacuum lines, directional flow

connections should be used.

Using 45º elbows for turns or avoiding obstructions

is best; however, do not make a trap in the line,

doing so will decrease the efficiency of the system.

2

3

4

.oN.ytQ.oNtraPnoitpircseD

11

21

31 14061546

41 76040546

51 70001646

61 72097546ebuTnolyN,"8/3,ssarB,tuN

7.tf464081646"8/3,nolyN,ebuT

*

*

eniLretaW

"2/1,ssarB,etaG,evlaV

xPIM"2/1,ssarB,gnihsuB

PIF"8/3

xPIM"8/3,ssarB,retpadA

ebuT"8/3

,noisserpmoC,eveelS

"8/3,ssarB

* Plumber Supplies

All elbows and tees should be sized for the main line

and sized down with busing reducers to accommodate smaller lines.

Avoid sagging lines, which cause the formation of

traps in the system and prevent good air and waste

liquid flow.

Connect the evacuation system to the vacuum line

using the hose and fittings supplied in the installation

kit. The vacuum line can be installed from the right

or left side of the cabinet.

.oN.ytQ.oNtraPnoitpircseD

1

2

1

3

1ro

*

*

20140546

10140546

04.HCS

knahS"2/1-1

knahS"2/1-1

,CVP,SPI,eniLmuucaV

04.HCS,CVP,SPI,woblE

xPIM"1CVP,retpadA

xPI

M"2/1-1,CVP,retpadA

41 40072546esoH"2/1-1,pmalC

5

1

5.tf691026546"2/1-1,esoH

* Plumber Supplies

Dual Wet Vacuum System

5

Section III Installation

Waste Line

The waste line carries water and liquid waste from

the operatory to the building's sewer system.

The waste line should follow the most direct path to

the sewer connection with a minimum of bends and

elevations, and must be installed according to local

building and plumbing codes.

The waste line can be installed from the right or left

side of the cabinet.

The exhaust connection should be made by either of

two methods, floor sink connection or direct connection to P trap, depending on local code and building facilities.

Dual Wet Vacuum System

— IMPORTANT NOTE —

No part of the waste line should be more than

three (3) feet above the level of the waste

connection on the vacuum pump.

DIRECT CONNECTION T O “P” TRAP

Use P trap-air gap, if required by local code. Install

as illustrated.

1

FLOOR SINK CONNECTION

Use floor sink adapter SA-200, Part No. 6-4504-013.

Install as illustrated.

4

3

2

1

.oN.ytQ.oNtraPnoitpircseD

11 31040546

21 20140546

31 30072546"2/1-1,leetSs

4.tf691026546"2/1-1,tsuahxE,esoH

knahS

tresnIdebraB

selniatS,pmalC

"1,kniSroolF,CVP,retpadA

"2/1-1xPIM"1,CVP,retpadA

Electrical Connection Assembly

Right

1

2

2

.oN.ytQ.oNtraPnoitpircseD

1.tf691026546"2/1-1,tsuahxE,esoH

21 30072546"2/1-1,leetSsselniatS,pmalC

31

41

51

61

71

81

*

*

*

*

*

*

"2/1-1woblE

"2/1-1,elppiN

A,retpadA

"2,paGri

"2/1-1x"2,lleB,recudeR

esolCx"2/1-1,elppiN

"2/1-1,”P”,parT

Complete the electrical hook-up as the electrical

codes require through the 1/2" conduit knockouts in

the outer box.

Left

3

Installation, Operation and Care Manual

6

.oN.ytQ.oNtraPnoitpircseD

11 12031546wercSetalPrevoC

21 48448526xoB-J,etalPrevoC

31 06011646wercSdnuorG

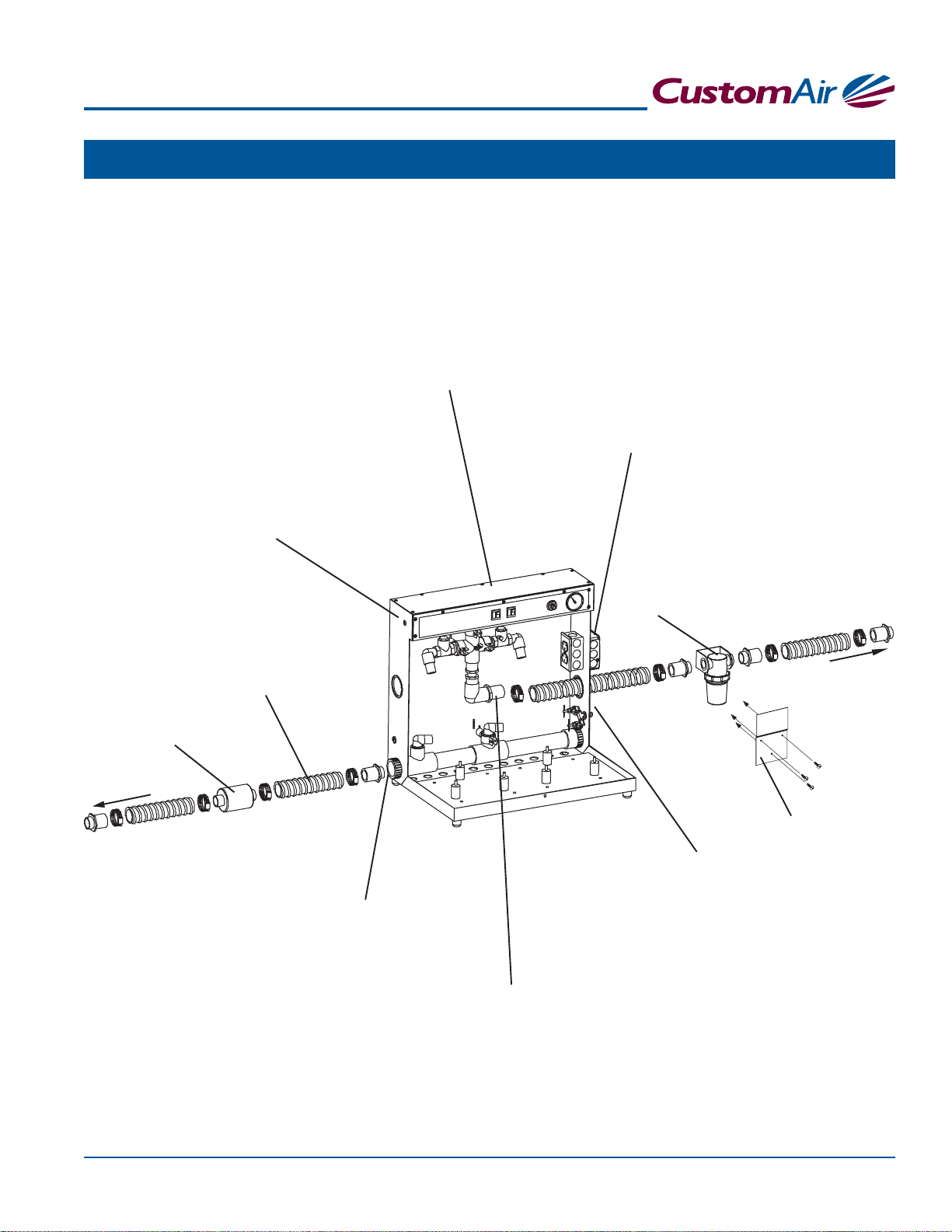

Section III Installation

Intake/Exhaust Hose Connections

Evaluate the installation site and determine which

side the various hoses will enter the pump frame and

the location for the water supply connector.

Connect remote control

wiring at switch location

Install low-voltage remote

control thermostat wiring:

— 18-3 for lighted switch

— 18-2 for non lighted

— Use 16 gauge when distance

from pump exceed 150'

Optional: Install water

re-circulator between

muffler and manifold.

in cabinet.

Place the hoses on their appropriate manifold hose

adapters and secure them using the hose clamps.

Complete the water supply hook-up using the poly

flow tubing and fittings supplied in the installation kit.

Provide two separate

electrical circuits

(one for each pump motor).

Connect to vacuum lines:

— Filter, hoses & fittings

provided

Filter

Assembly

— 1" or 1-1/2" FNPT

fitting required

Muffler

Connect to sewer line:

— Muffler, tubing and

clamps provided

— 1-1/2" FNPT fitting

required

Connect to waste

manifold 1-1/2"

FNPT fitting (left or

right installation).

Connect water supply line:

— 3/8" nylon tubing and

fittings provided

— 1/2" gate valve (1/2"

FNPT) required

Connect hose to intake

manifold (left or right

installation).

Mount filter

to wall using

bracket and

screws

provided.

Dual Wet Vacuum System

7

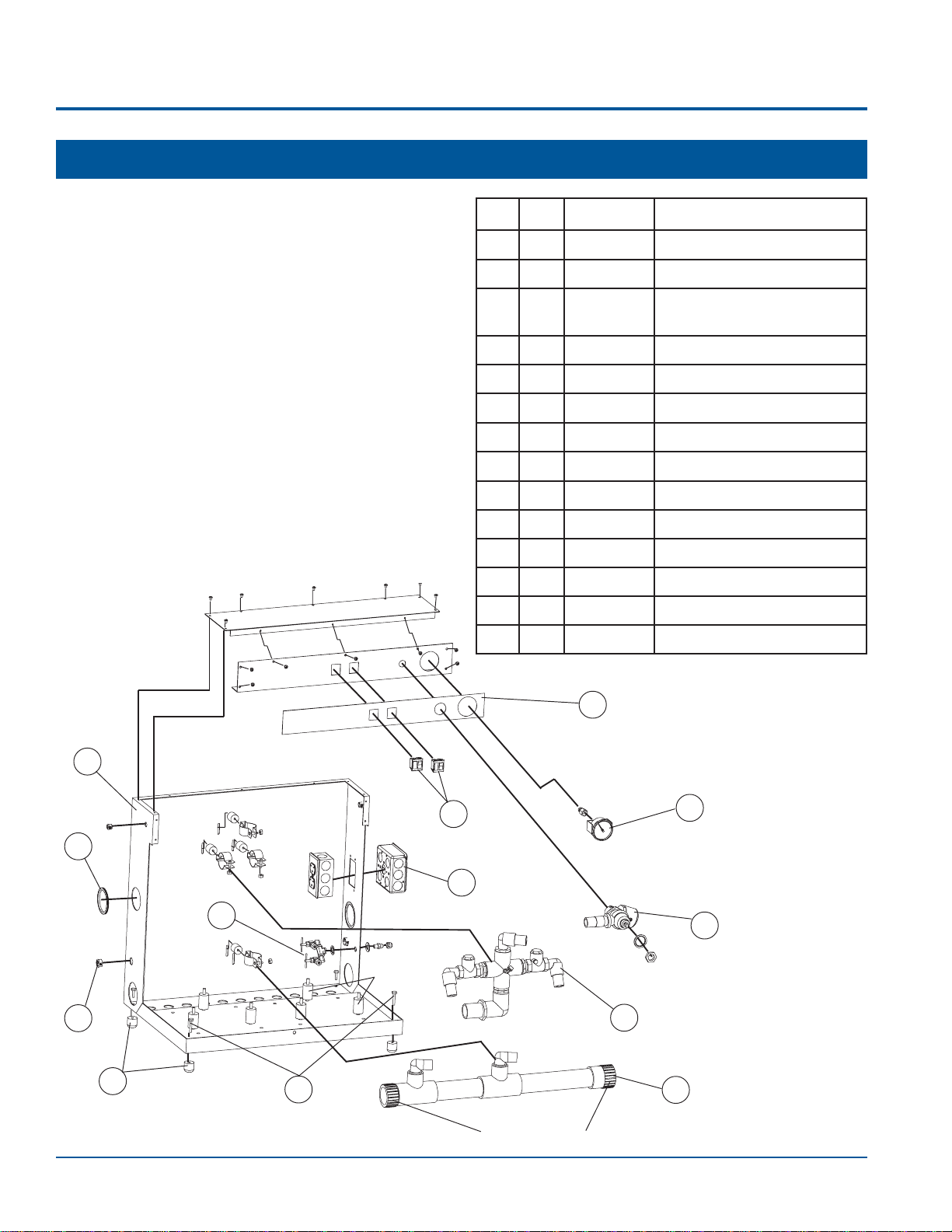

Section IV Illustrated Parts Breakdown

Cabinet Assembly

Dual Wet Vacuum System

The various assemblies of the CustomAir Dual Wet

Vacuum System are attached to the frame, back panel

and control panel of the cabinet, forming a selfcontained vacuum system. The table identifies each

assembly and the drawing indicates its location in the

cabinet.

.oN.ytQ.oNtraPnoitpircseD

11 50082546etelpmoc,erusolcnE

21 60110546ylbmessAdlofinaMekatnI

1

3

1

41 431865

52 23186546hctiwSrekcoR

61 36186546ylbmessAdlofinaMretaW

74 16186546tooFCVPlauD

82 72011646"4/1-1,wercSlauDt

a82 52011646"4/3,wercSlauDraeR

91 26186546ylbmessAdlofinaMetsaW

012 20065546"8/5,temmorG

111 41065546kcalB,dedurtxE,

211 76086546tiKnoitallatsnIlacirtcelE

311 07110546ylbmessAlortnoCmuucaV

46eguaGmuucaV

99192546

00292546

norF

rolaceD102CM

laceD202CM

temmorG

11

10

3

1

5

4

12

6

13

Motor

Mounts

2

7

8

9

Plug

(Left or Right)

Installation, Operation and Care Manual

8

Loading...

Loading...