CustomAir 800-Series User and maintenance manual

LubeFree Compressors

800 Series

Installation, Operation and Care Manual

Low voltage box

The low voltage relay box also called the control box is already installed on this compressor. The purpose

of the control box is for the end use to install all remotely Master Control Panel (24 Volt operated) that

can control the air from one location. By means of ONE switch the compressor can be turned off in the

dental office instead of going to the utility room. By having the control box/low voltage relay installed on

the compressor, you have all that is required for any future additions.

Table of Contents

Section I Introduction

Specifi cations .......................................................................................................................... 3

Model CA-812 / CA-822 ..................................................................................................... 4

Model CA-813D / CA-823D .............................................................................................. 5

Model CA-825 ....................................................................................................................... 6

Model CA-825D .................................................................................................................... 7

Model CA-827D .................................................................................................................... 8

Model CA-829D .................................................................................................................... 9

Model CA-8212T ................................................................................................................10

Section II Pre-installation

Unpacking .............................................................................................................................. 11

Placement .............................................................................................................................. 11

Section III Installation

Unit Connections ................................................................................................................ 12

Grounding Instructions ...................................................................................................... 13

Extension Cords .................................................................................................................. 14

Section IV Operation

General Operation ........................................................................................................15-16

Automatic Reset Protector ............................................................................................... 16

Section V Care

Maintenance Schedule ........................................................................................................ 17

Cleaning Compressor......................................................................................................... 17

Inspecting Dryer .................................................................................................................. 18

Checking for Leaks .............................................................................................................. 18

Testing Safety Valves ............................................................................................................ 19

Replacing Intake Filter ........................................................................................................ 19

Replacing Dryer Filters ...................................................................................................... 20

Cleaning Non-return Valve ................................................................................................ 20

Section VI User Service Information

Service Instruction .............................................................................................................. 21

Troubleshooting Chart ....................................................................................................... 22

Section VII Parts List / Diagrams

Model CA-812 / CA-822 Parts List / Diagram ....................................................... 24-25

Model CA-813D / CA-823D Parts List / Diagram ................................................ 26-27

Model CA-825 Parts List / Diagram .........................................................................28-29

Model CA-825D Parts List / Diagram ...................................................................... 30-31

Model CA-827D Parts List / Diagram ...................................................................... 32-33

Model CA-829D Parts List / Diagram ...................................................................... 34-35

Model CA-8212T Parts List / Diagram ....................................................................36-37

Product Support Services .................................................................................. 38

800 Series Compressors

1

Section I Introduction

This manual contains installation, operation and care instructions and user service information for the

CustomAir® 800 Series Compressors.

The LubeFree 800 Series Compressors are designed to provide trouble-free service when installed, operated

and cared for according to the procedures set forth in this manual.

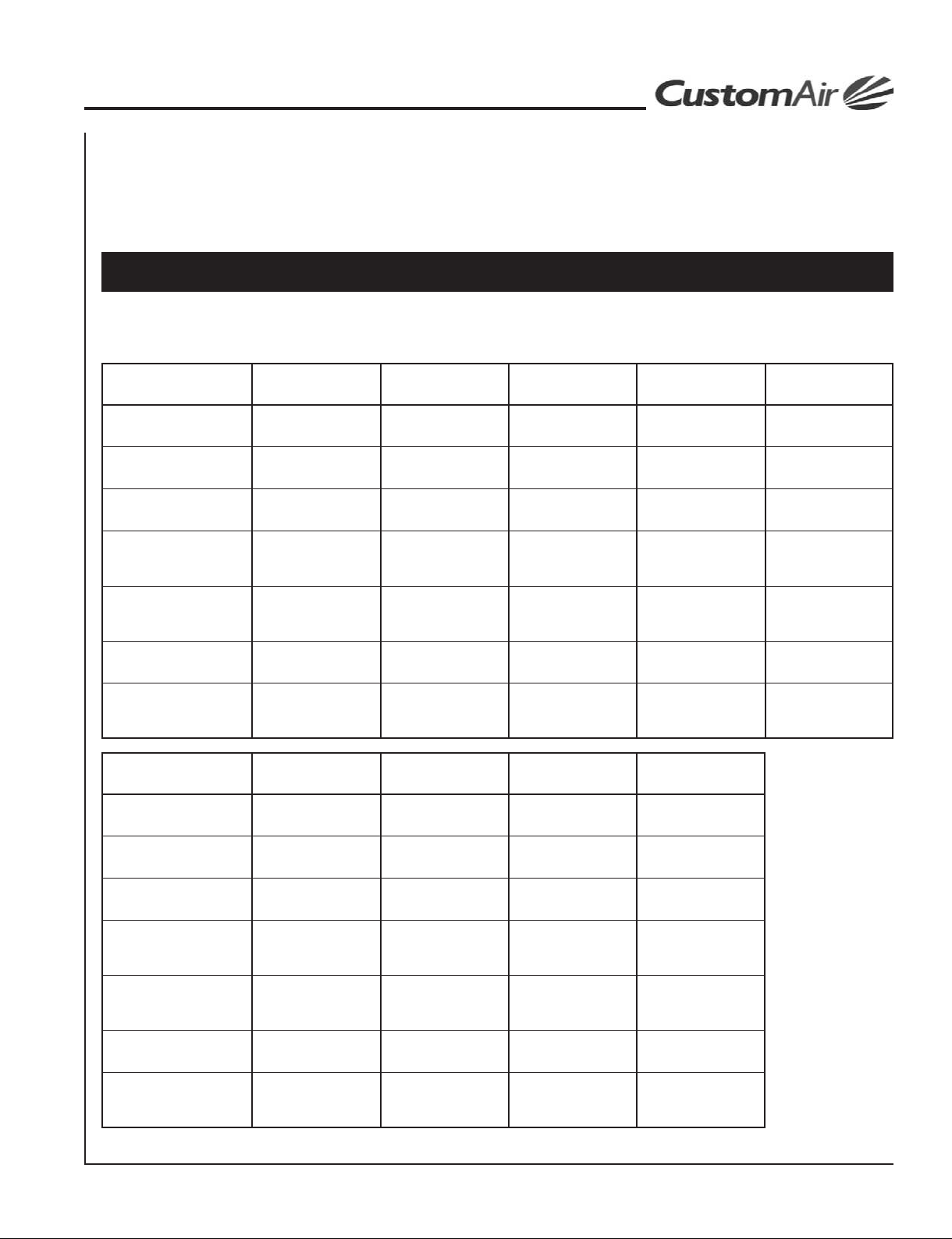

Specifi cations

Specifi cations

NOTE: The dimensions for each model are illustrated on Pages 3 through 10.

NOTE: The pressure dew point for all 800 series units is -40º C/-40°F.

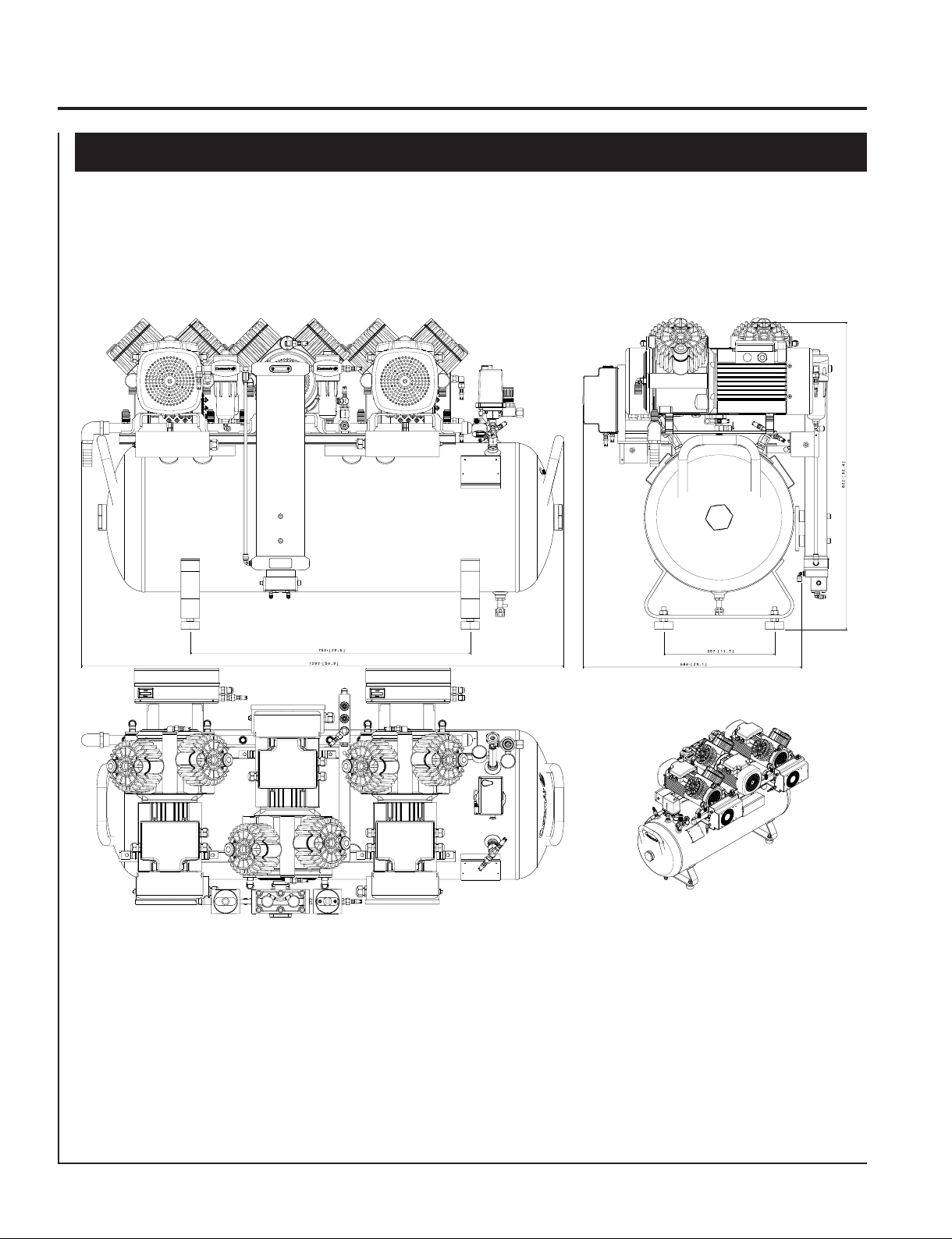

Model CA-812 CA-822 CA-813D CA-823D CA-825

Users (max.) 2 2 3 3 5

Voltage (V/Hz) 120/60 230/60 120/60 230/60 230/60

Power (amps.) 9.75 5.4 15.0 8.2 8.3

Weight: (kg.) 49 49 43 43 61

(lbs.) 108 108 95 95 134

Dimensions: (mm) 522x478x619 522x478x619 603x533x632 603x533x632 535x496x663

LxWxH (in.) 20.5x18.8x24.4 20.5x18.8x24.4 23.8x21x24.9 23.8x21x24.9 21.1x19.5x26.1

Noise level (db) 72 72 69 69 74

Pump Time (sec.) 210 210 190 190 160

0-120 psi

Model CA-825D CA-827D CA-829D CA-8212T

Users (max.) 5 7 9 12

Voltage (V/Hz) 230/60 230/60 230/60 230/60

Power (amps.) 10.8 13.4 16.2 24.9

Weight: (kg.) 79 91 97 167

(lbs.) 174 201 214 368

Dimensions: (mm) 709x562x652 709x582x652 710x551x644 1288x637x788

LxWxH (in.) 27.9x22.1x25.7 27.9x22.9x25.7 27.9x21.7x25.4 50.7x25.1x31

Noise level (db) 74 75 75 77

Pump Time (sec.) 160 105 80 190

0-120 psi

NOTE: Pump Time plus/minus 10%. Average at 20°C/68°F motor start temperature

800 Series Compressors

3

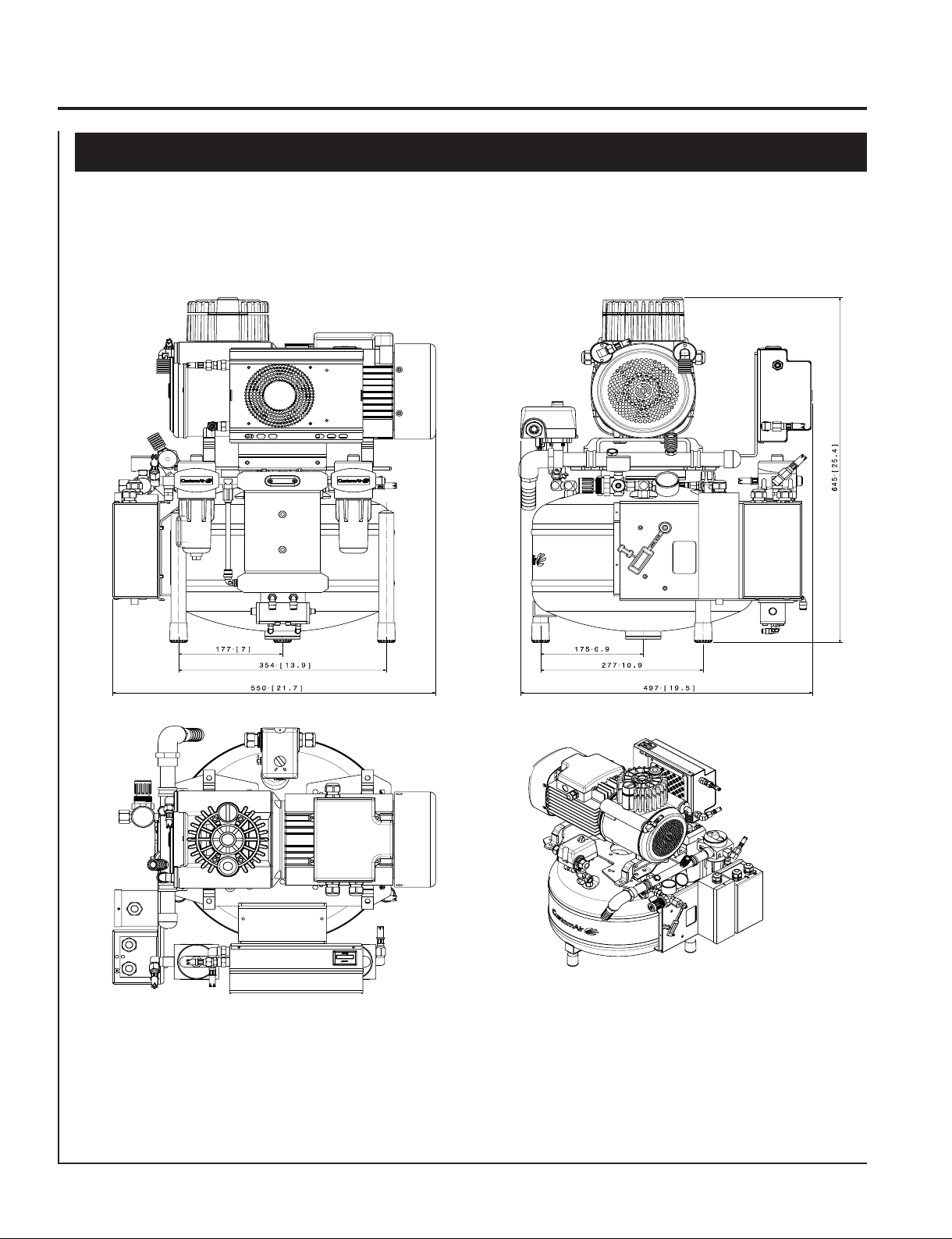

Section I Introduction

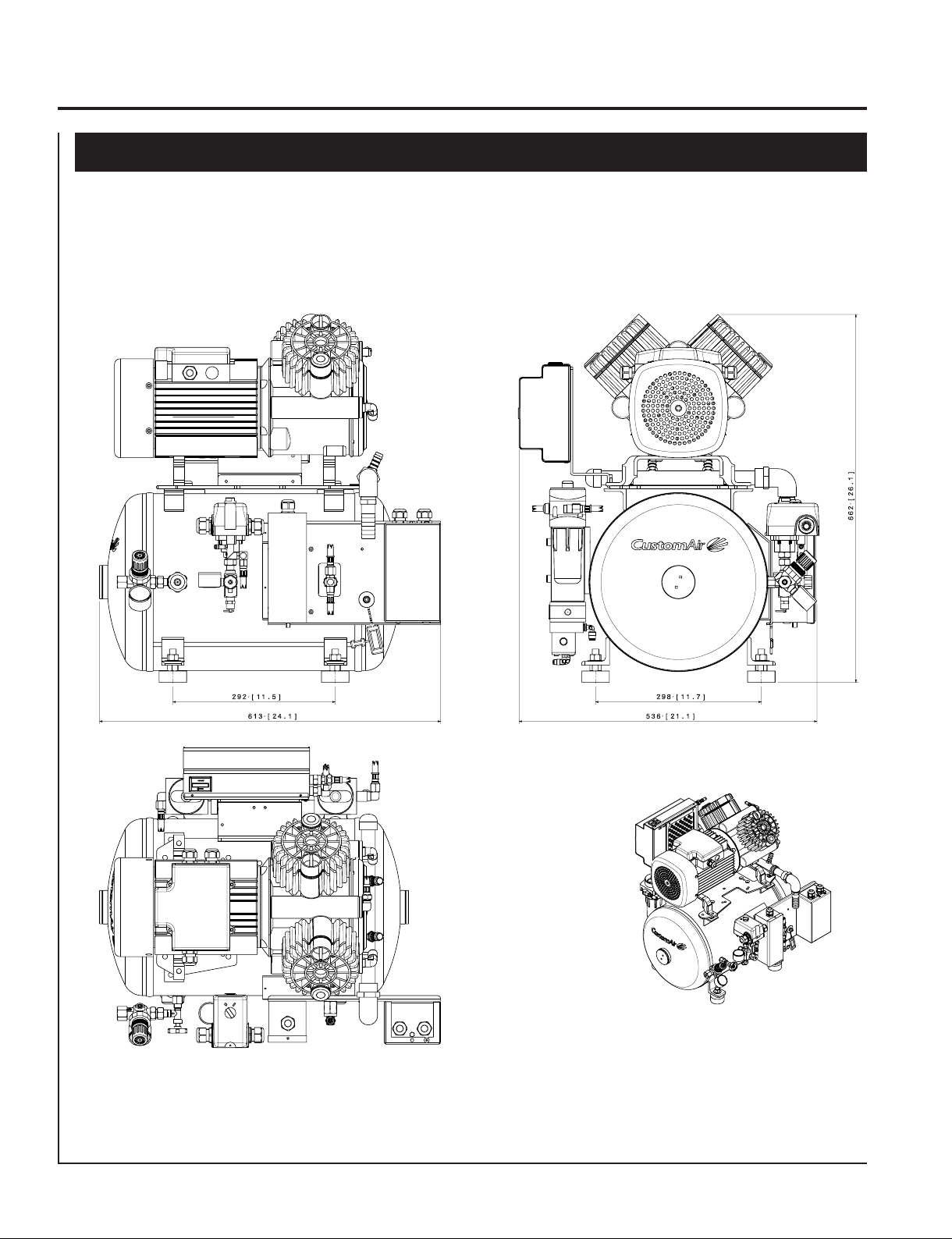

Model CA-812 / CA-822

800 Series Compressors

4 Installation, Operation and Care Manual

Section I Introduction

Model CA-813D / CA-823D

800 Series Compressors

5

Section I Introduction

800 Series Compressors

Model CA-825

6 Installation, Operation and Care Manual

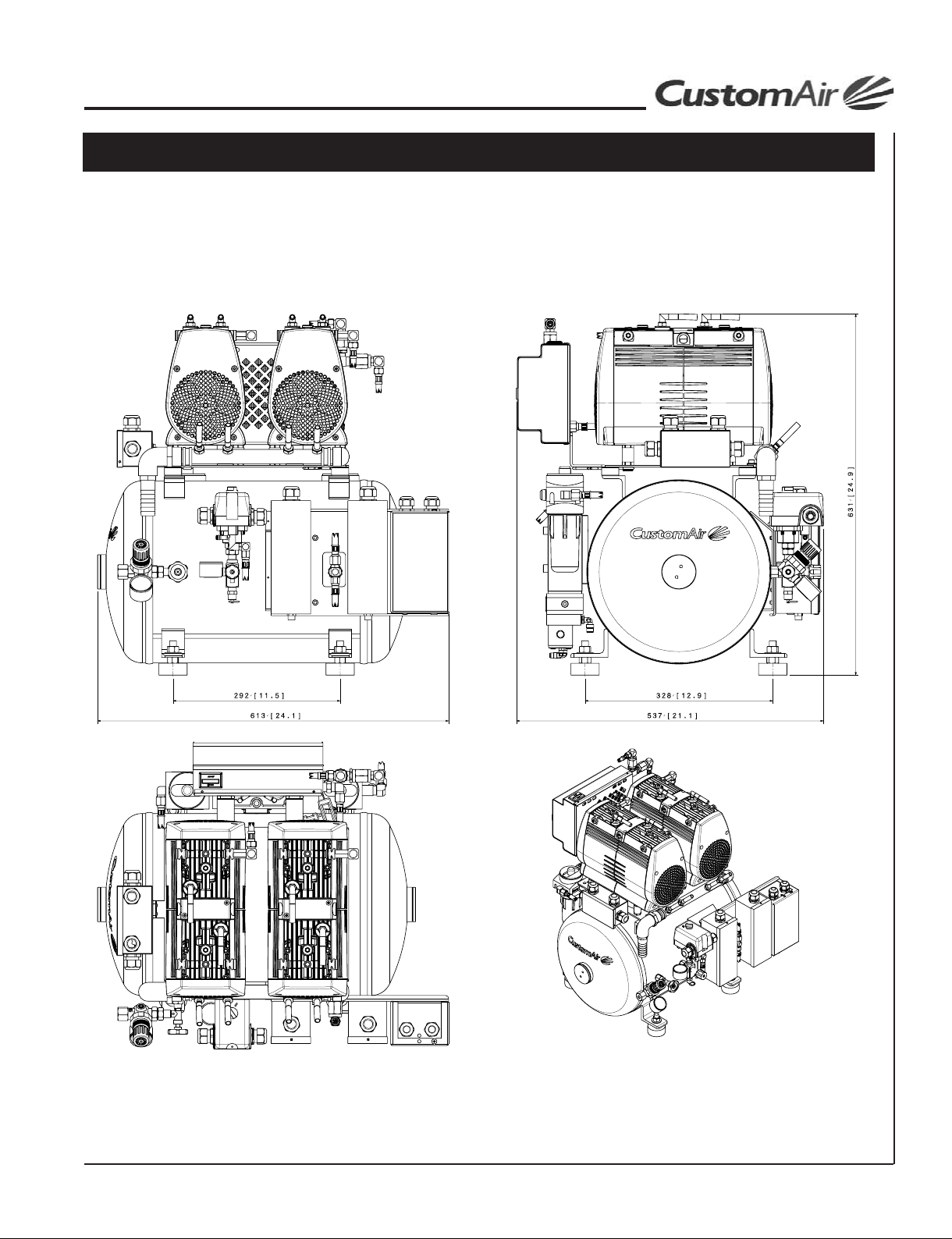

Section I Introduction

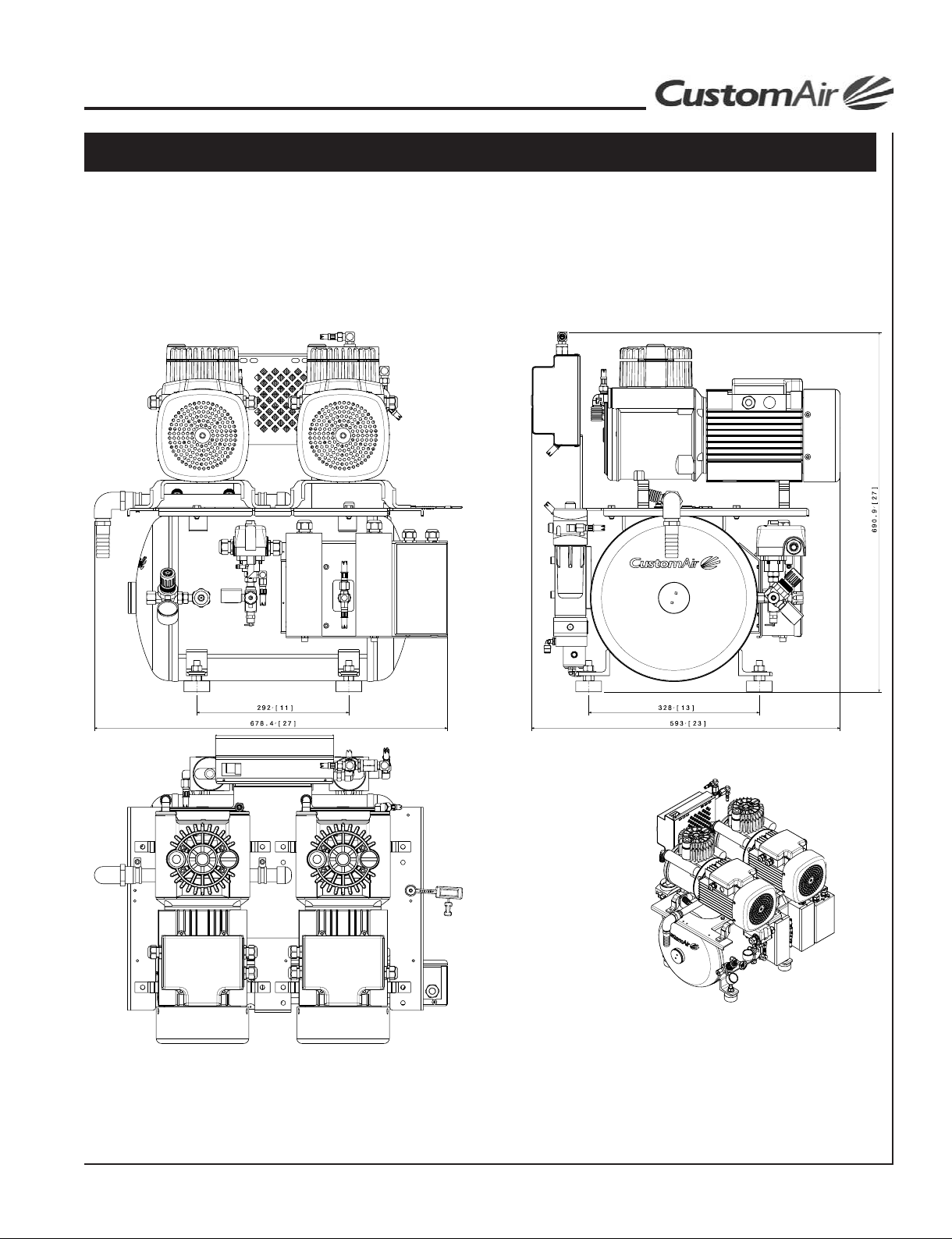

Model CA-825D

800 Series Compressors

7

Section I Introduction

Model CA-827D

800 Series Compressors

8 Installation, Operation and Care Manual

Section I Introduction

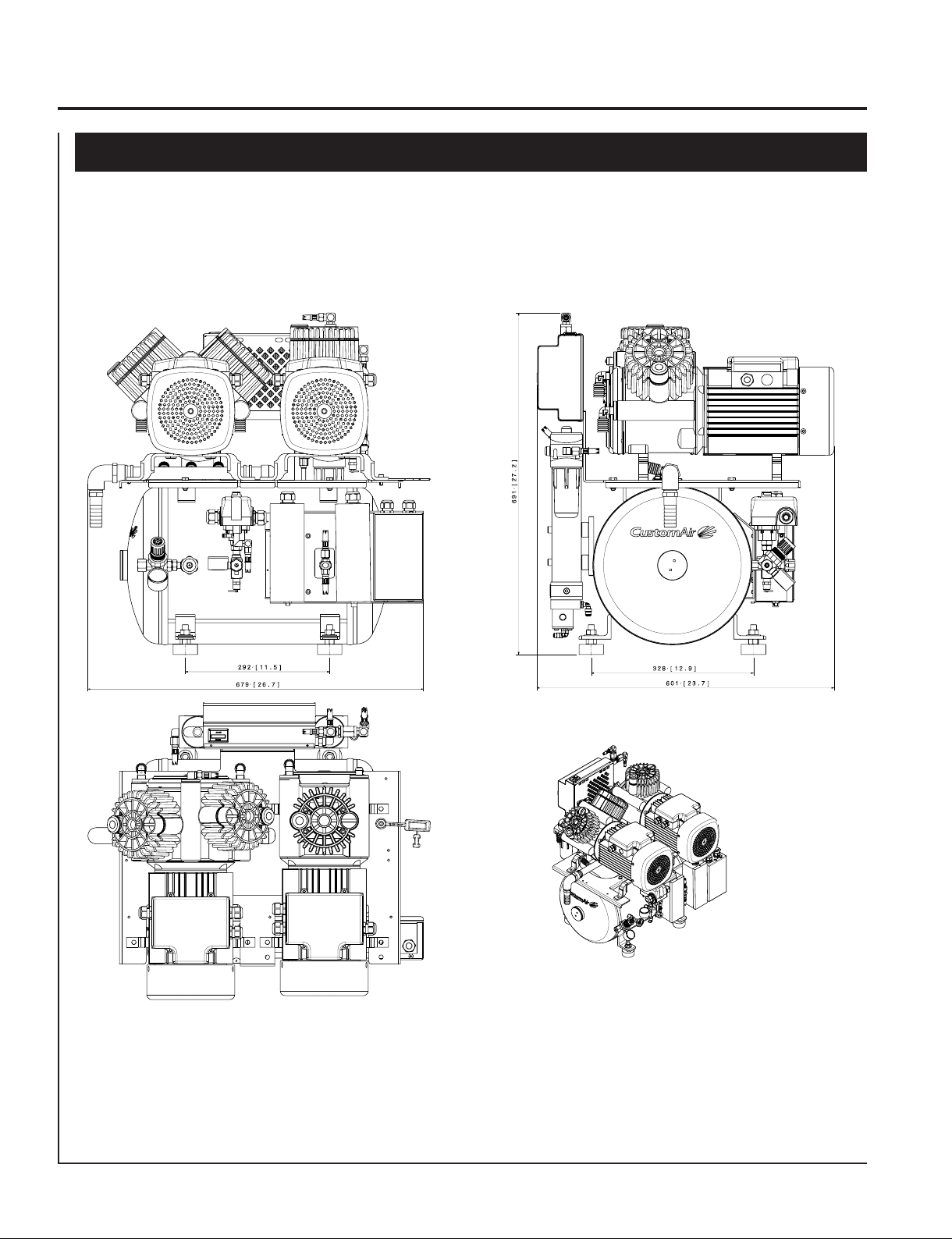

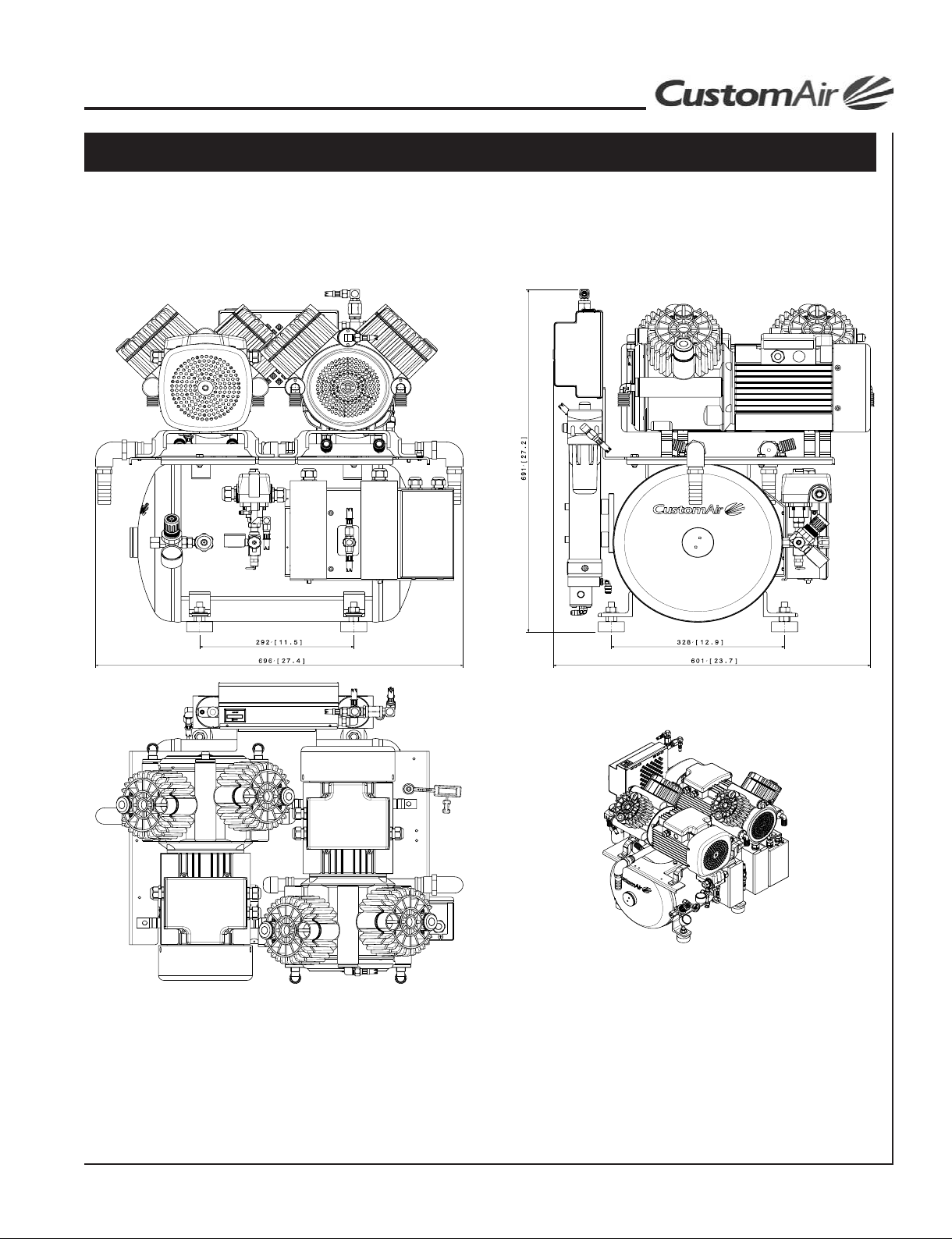

Model CA-829D

800 Series Compressors

9

Section I Introduction

Model CA-8212T

800 Series Compressors

10 Installation, Operation and Care Manual

Section Il Pre-installation

Unpacking

1. Carefully remove the compressor from its shipping carton.

2. Visually inspect the unit for shipping damage. Contact the freight

carrier and supplier immediately if the unit has shipping damage.

(See Product Support Services, Page 40.)

Placement

1. Place the compressor in a dust-free, dry, cool and frost-free room.

— CAUTION —

The compressor is for indoor use only --

NOT FOR OUTDOOR USE!

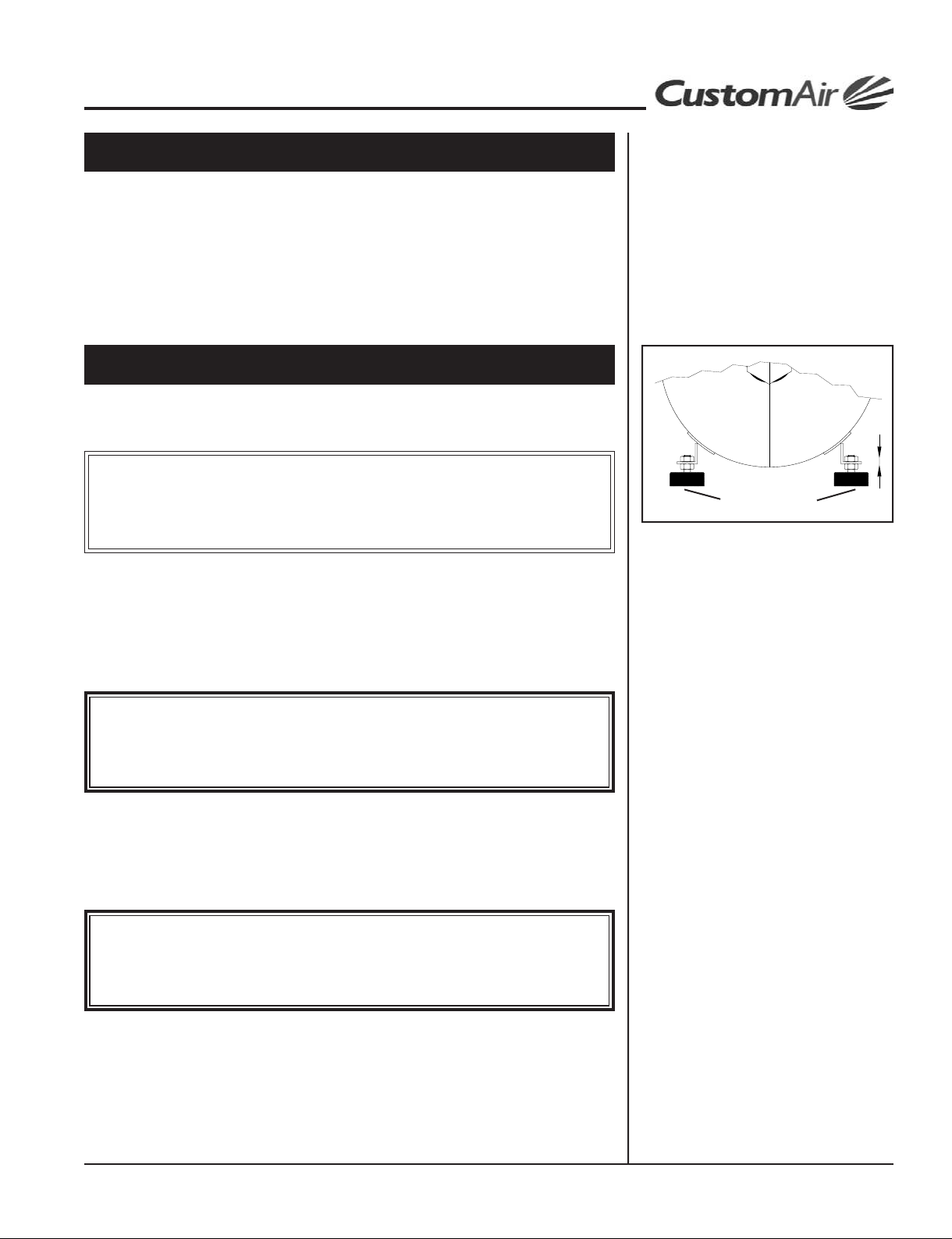

Rubber Feet

2. Do not install the compressor in a closed cupboard, unless

adequate openings for ventilation are available at the top and

2

bottom of the unit (minimum 500 cm

remote air intake is connected to ambient air source.

/77.5 in2 each). And

— WARNING —

When spraying fl ammable liquid, there may be danger of fi re

or explosion, especially in closed rooms.

3. Models CA-813D, CA-823D, CA-825, CA-825D, CA-827D,

CA-829D and CA-8212T have four adjustable rubber feet to

assure the unit stands fi rmly on the fl oor. (See illustration at left.)

— WARNING —

Place the compressor out of children's reach and never leave

children unattended when the compressor is in use.

800 Series Compressors

11

Section Ill Installation

The following information will assist in making a quick, easy and quality installation. However, if there are any questions, contact a CustomAir

technical service representative at 1-866-DTE-INFO (1-866-383-4636).

Unless directions are followed and the original spare parts used,

800 Series Compressors

Unit Connections

— WARNING —

physical injury or property damage may result.

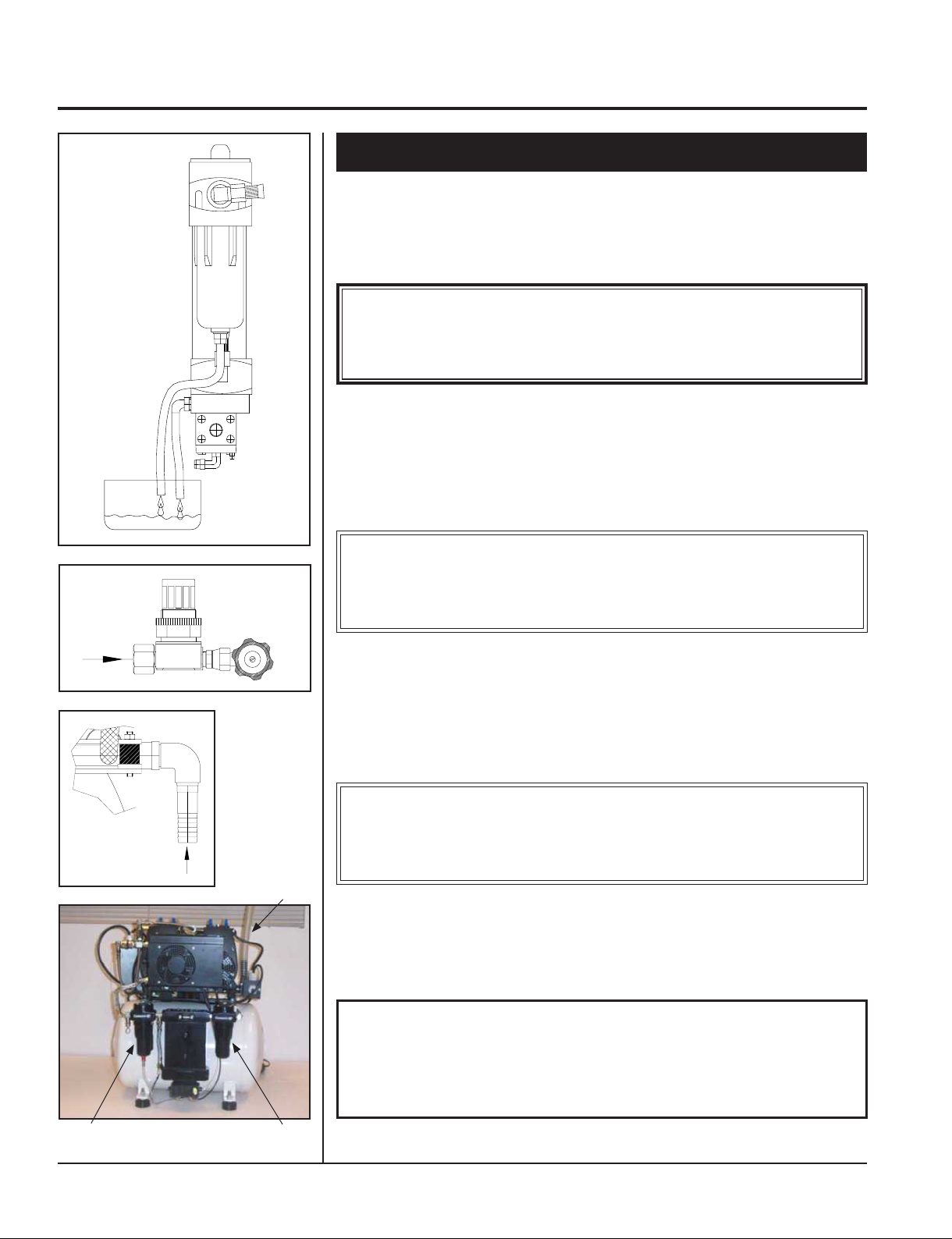

1. Lead the hoses from the fi lter and dryer to an outlet or a bottle to

collect possible water.

2. Make sure the operating voltage of the compressor corresponds to

the voltage of the socket. (Refer to Specifi cations, Page 2.)

Remote Fresh

Air Intake

— CAUTION —

Only connect the compressor to installations with the correct

voltage stated on the motor plate

3. Connect the plug and cable and make sure the circuit is properly

protected. (See Grounding Instructions, Page 13.)

IMPORTANT NOTE: e air consumption of the equipment used

with the compressor must be sized properly to the compressor/number of users.

— CAUTION —

Only connect equipment suitable for the maximum pressure

stated on the tank pressure gauge.

4. Connect the pressure hose to the regulator.

5. Connect the remote air intake on the connecting piece on the

intake to an ambient air source.

When using the compressor in connection with vital

equipment, an alternative air source should be available in

Moisture

Drain Tube

12 Installation, Operation and Care Manual

Dual Column Disiccant Dryer with

Coalescing Filters and moisture

— NOTICE —

case of a defect in the compressor.

Loading...

Loading...