Page 1

Models Included

u TPC15T

u TPC2T

IMPORTANT: Equipment

to be installed to comply

with applicable federal,

state, or local plumbing/electrical

codes having jurisdiction.

CAUTION: Please use

this setup procedure

before attempting to use

this brewer. Failure to follow the

instructions can result in injury or the

voiding of the warranty.

CAUTION: DO NOT

connect this brewer to

hot water. The inlet valve

is not rated for hot water.

Wilbur Curtis Company, inC.

Milano Twin Brewer – Service Manual

Important Safeguards/Symbols

This equipment is designed for commercial use. Any servicing other than cleaning and routine maintenance should be performed by an

authorized Wilbur Curtis Company Service Technician.

• DO NOT immerse the unit in water or any other liquid

• To reduce the risk of re or electric shock, DO NOT open service panels. There are no user serviceable parts inside.

• Keep hands and other items away from hot areas of the unit during operation.

• Never clean with scouring powders or harsh chemicals.

Symbols:

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Sanitation Requirements

The Curtis ThermoPro Brewer is Factory Pre-Set and Ready to Go… Right from the Carton.

Following are the Factory Settings for your Coffee Brewing System:

• Brew Temperature = 200°F • Water Bypass = On for LARGE & MEDIUM Brew Only

• Brew Volume = Set to Vessel Requirement. • Sleep Mode = Off

System Requirements:

• Water Source 20 – 90 PSI (Minimum Flow Rate of 1 GPM)

• Electrical: See attached schematic for standard model or visit www.wilburcurtis.com for your model.

SETUP STEPS

The unit should be level (left to right and front to back), located on a solid counter top. Connect a water line from the water lter to the

brewer.

NOTE: A water ltration system must be used to help maintain trouble-free operation. Air must be purged from the cartridge prior to

connection to equipment. In areas with extremely hard water, we highly recommend the use of a Curtis approved water lter. For our

full line of lters, please log on to www.wilburcurtis.com.

NSF International requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) is required so that the unit can be moved

for cleaning.

2. This unit must be installed with adequate back-ow protection to comply with applicable federal, state and local codes.

3. Water pipe connections and xtures directly connected to a potable water supply shall be sized, installed and maintained

in accordance with federal, state, and local codes.

1. A 3/8” NPT x 3/8” Flare elbow has been supplied for water line connection. Use tubing sized sufciently to provide a minimum of 1.0

GPM.

2. To hookup the InterLock grinder, Locate the jack labeled “Class 2 Wiring Only” on brewer and grinder. Connect the two with the cable

plug.

3. Connect the unit to an appropriate electrical power circuit.

4. Turn on the toggle (STANDBY/ON) switch behind the unit. The heating tank will start to ll. When the water level in the tank rises

to the correct volume, the heating elements will energize automatically. With ADS Systems there is no danger of element burnout

caused by an empty tank.

5. The heating tank will require 20 to 30 minutes to reach operating temperature (200°F). You will be notied when READY-TO-BREW

appears on the control panel LCD screen.

6. Prior to brewing, dispense 12 ounces of hot water through the hot water faucet.

7. Brew a cycle of at least 12 ounces, to purge the water lines of any air that may be trapped after lling.

WARNING TO AVOID

SCALDING, Do not

remove brewcone while

brew light is ashing.

BREWING INSTRUCTIONS

1. Brewer should be ON (Conrm at rear toggle switch, then press the ON/OFF button). Ready-to-Brew should read on the LCD screen. If

connected to an InterLock grinder, grinder should be on. Grind coffee at this time.

2. Place an empty Milano server under the brewcone.

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO., INC.

6913 West Acco Street

Montebello, CA 90640-5403

For the latest information go to

www.wilburcurtis.com

3. Place a clean lter into

the brewcone.

Tel: 800-421-6150

Fax: 323-837-2410

4. Fill brewcone with

ground coffee.

5. Transfer lled

brewcone to brewer.

6. Press Brew button.

Brewing will begin

immediately.

1

Page 2

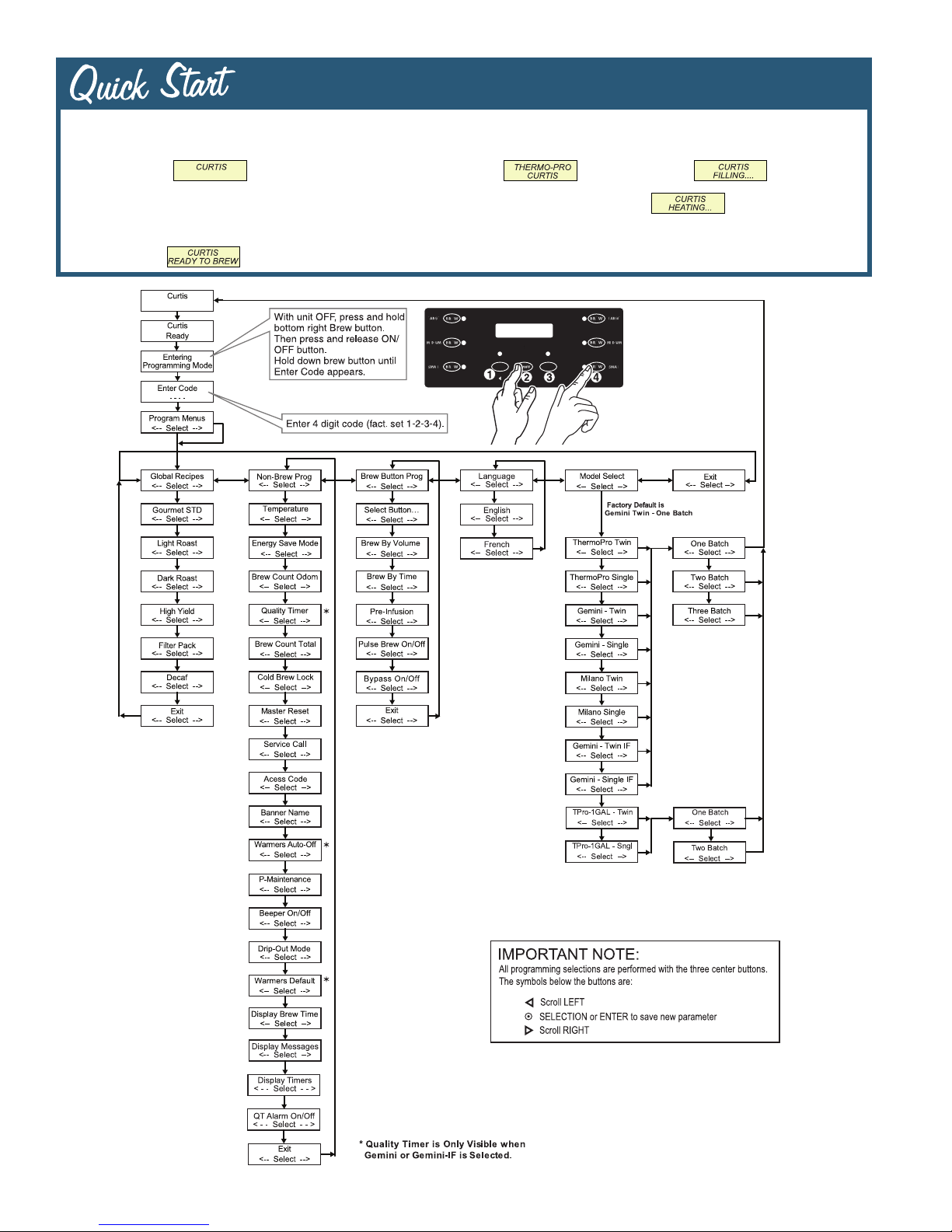

Your Curtis ADS System is Factory Pre-Set for Optimum Performance.

After connection to water and power; the rear toggle switch must be on. You will hear a beep sound, indicating power is available to the controller.

The control displays . Press ON/OFF button and the screen will display . After three seconds, is displayed.

Water will ll the tank (approximately 2-3 minutes depending on water ow rate). When the proper level is reached will appear on the

screen. It takes approximately 20 minutes to reach setpoint temperature of 200°F.

Control will display when temperature reaches the setpoint (200°F). Unit is now ready to brew.

2

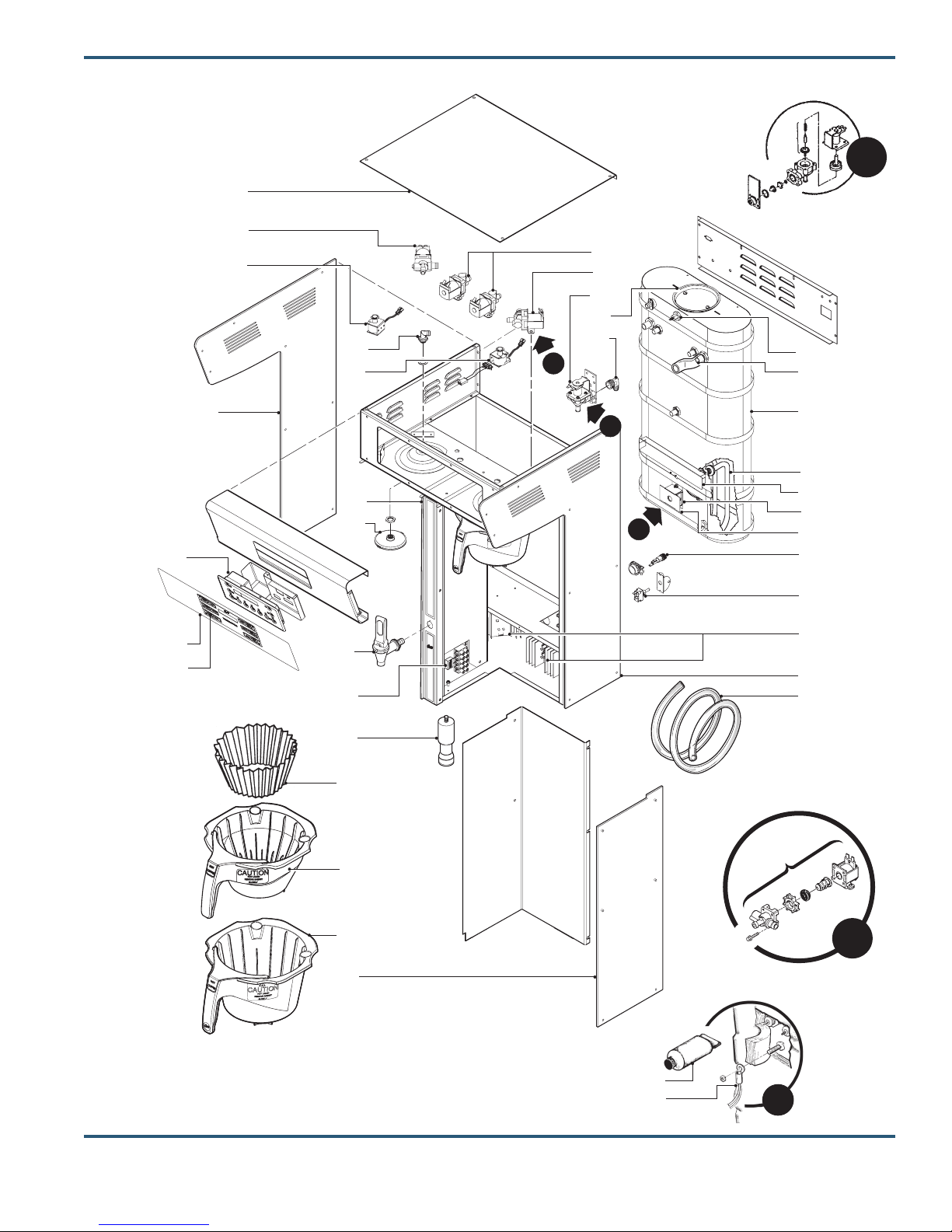

Page 3

ILLUSTRATED PARTS

1

2

3

35

A

18

19

20

21

5

3

B

22

23

24

15

16

17

4

25

A

26

27

28

29

30

31

32

33

34

14

8

9

10

11

11A

12

6

7

C

12A

13

36

37

B

C

3

Page 4

Parts List

Item №

1

2

2A

3

3A

4

5

6

7

8

9

10

11

11A

12

12A

13

14

15

15A

16

17

18

18A

19

19A

20

20A

21

22

23

24

25

26

27

28

29

30

31

31A

32

33

34

35

36

37

Part № Description

WC-61289

WC-37121*

WC- 859

WC- 442

WC- 446

WC-61284

WC-2977-101K*

WC-61286

WC-29050*

WC-1853

WC-8591*

WC-3528

GEM-6

GEM-6-101

WC-3417

WC-3422

WC-61287

WC-37132*

WC- 37176

WC- 728

WC-39496-101

WC-39496

WC- 844-101*

WC- 844-102

WC-37122*

WC- 854

WC- 847*

WC- 883

WC-37008

WC-2402P

WC-5502-01*

WC-5350*

WC-62030

WC- 934-04*

WC-4382

WC- 522*

WC-43055

WC-1501

WC- 102*

WC- 103

WC-8559

WC-61285

WC-5310*

WC-3765L*

WC-5231*

WC-1438-101*

COVER, TOP WRAP

KIT, DUMP VALVE LEFT 120V 14W

VALVE, INLET .35GPM 240V 10W

SOLENOID, LOCK BREWCONE RIGHT/LEFT 120V TP2T/TP2S/GEM

SOLENOID, LOCK BREW CONE RIGHT 220V THERMOPRO/GEMT

PANEL, L’ SHAPE LEFT

KIT,SPRAYHEAD FITTING PLASTIC

PANEL, CENTER SECTION LEFT

SPRAYHEAD, AMBER ADVANCED FLOW

FAUCET, ASSEMBLY TPC

CAPACITOR

LEG, 4” ADJUSTABLE

FILTER, 500PK 12½ x 4 GEMSS/GEMTS/TP

FILTER, PAPER 15 X 5-½” ALTRA 4-3/4” H USED ON WC-3422

BREW CONE ASSY, W/SPLASH POCKET BROWN HOT COFFEE

BREW CONE,ASSY W/SPLASH PCKT BRN STYLIZED HIGH VOL

PANEL, CENTER SECTION RIGHT

KIT, VALVE REPAIR USE ON WC-37122 & WC-37121

KIT, UCM & LABEL INSTRUCTIONS TP

CONTROL MODULE, 220V TP2S/TP2T GEMSS/GEMTS

LABEL, UCM OUTER MILANO

LABEL, UCM OVERLAY MILANO 3-BATCH

VALVE, BY-PASS W/RESISTOR

VALVE, BY-PASS, 220V NON-ADJUS TABLE W/ RESTRICTOR

KIT, DUMP VALVE RIGHT 120V 14W

VALVE, BREW DUMP RIGHT 240V 12W GEM12D/TP/TPC

VALVE, WATER INLET 2GPM 120V 10W

VALVE, INLET 2 GPM 240V 10W

KIT, TANK LID ROUND

ELBOW, 3/8”FL x 3/8” NPT PLATED

KIT, PROBE, ASSY WATER LEVEL W/HEX FITTING, O-RING & NUT

TUBE, ½” ID x 1/8W SILICONE

TANK, COMPLETE TP2T ULTEM FITTINGS

KIT,ELEMENT HEATING 2.5KW 220V W/ JAM NUT & WASHERS

GUARD, SHOCK HEATING ELEMENTS

THERMOSTAT, RESET

GUARD, SHOCK RESET THERMOSTAT

FUSE HOLDER ASSY W/5A FUSE

SWITCH, TOGGLE NON-LIT SPST 15A 125/6A 250VAC RESISTIVE

SWITCH, TOGGLE NON-LIT DPST 25A 125/250VAC RESISTIVE

RELAY, SOLID STATE W/INTEGRATED HTSNK

PANEL, L’ SHAPE RIGHT

TUBE, 5/16” I.D. X 1/8” SILICONE

KIT, VALVE REPAIR WATER INLET

COMPOUND, SILICONE

SENSOR, HEATING TANK

4

* Recommended parts to stock.

Page 5

Electrical Schematic

5

Page 6

TLCG1509S Milano 1.5 Gallon Server Instructions

BREWING INTO SERVERS

Use only coffee or water in the insulated dispenser. Do not use the thermoserver to dispense any other

beverage. Preheating is recommended.

1. Place a clean and empty server centered under the brewcone of the Milano brewer.

2. Make sure the screen reads READY TO BREW.

3. Fill brewcone with the correct measure of ground coffee for the volume of coffee you wish to brew.

4. Press the desired brew button on the side of the brewer with server you wish to brew into.

5. Allow coffee in the brewcone to drip completely before removing the insulated server.

WARNING – SERVERS MAY BE HEAVY WHEN FILLED.

CARE MUST BE TAKEN WHEN TRANSPORTING TO AVOID DROPPING OR SPILLING.

SERVICING

Completely drain the unit of any coffee. Allow server to cool. Unscrew and remove the lid and tube assembly.

REPLACING THE GAUGE GLASS

The gauge glass can be removed for maintenance and cleaning.

1. Remove the gauge glass shield by pulling upward.

2. Carefully, pull up on the gauge glass to free it from the silicone base gasket that sits on the faucet assembly.

3. Pull off the silicone cap on top of the tube.

4. Scrub inside the glass with a tube cleaning brush and mild detergent solution. Inspect the glass tube

for cracks or chips.

WARNING – If gauge glass was broken, carefully remove all traces of glass. Brush out the silicone

base. From inside the liner, brush out the faucet shank. Run clear water through the shank to make

sure any glass shards have been washed from the faucet and base.

5. Checkthetopcapandbottomsiliconebase.Cleanthesettings,makingsuretheyarenotleaking.

Replace if necessary.

6. Once clean and dry, replace all parts that were serviced.

SERVICING THE FAUCET

The faucet will require periodic cleaning and maintenance.

2. Disassemble the faucet. Unscrew the bonnet from the body of the faucet.

3. Remove the faucet handle by pressing inward on the seat cup (see illustration, right) then unhooking

the handle from the center shaft.

4. The seat cup, center shaft and spring will now separate from the bonnet.

5. You may now clean the parts of the faucet (illustration, bottom right). Check the seat cup for tearing or

splitting. Make sure that the faucet spring is free of corrosion. Replace these items if necessary.

HANDLE

BONNET

SPRING

SHAFT

SEAT CUP

Cleaning and Sanitizing Instructions for TLCG15

These cleaning and sanitizing instructions are only a guide line to be used for the cleaning and sanitizing of

the TLCG15. Your current in-house cleaning and sanitizing methods may be just as effective.

ForcleaningandsanitizingoftheTLCG15,thethreesinkmethodisrecommended.Thismethodconsistsofasinkofwaterlled

withadetergentandwatersolution,afreshwaterrinse,andasinklledwithanaqueoussanitizingsolution.

Immersion of parts in commercial BarTabs/Sani-Tabs sanitizing solution is recommended. The solution must be warm (75°F.) Let

the parts soak at least one minute.

CAUTION

Do not immerse in water.

Do not place in dishwasher.

Do not use harsh powders or cleansers containing chlorine.

Do not use a wire brush or pot scour to clean inside liner.

1. Daily, Rinse the unit after use.

a. Rinse unit with hot water.

b. Fill unit with hot water.

c. Open unit and empty contents completely.

6

Page 7

Cleaning and Sanitizing Instructions for TLCG15 . . . Continued

2. Clean and sanitize the lid assembly.

a. Remove lid from unit and submerse it in cleaning solution, cleaning thoroughly.

b. Usingatubecleaningbrush,cleaninsidethellingtube.

c. Rinse with clean water.

d. Submerse in sanitizing solution for 5 minutes then air dry completely.

3. Cleaning and sanitizing body assembly.

a. Fill the unit with cleaning solution. With a sponge brush, thoroughly clean inside liner.

b. Rinse the unit with a fresh water rinse.

c. Fill unit with sanitizing solution. Allow to sit for 5 minutes then drain through the faucet.

d. Wipe outside of unit with clean cloth moistened with cleaning solution.

e. Place body assembly upside down on rack to thoroughly air dry.

4. Cleaning the faucet parts.

a. Unscrew the bonnet/handle assembly from the faucet and disassembly removing spring, seat cup and shaft.

b. Clean and rinse parts. Place in sanitizing solution for 5 minutes, remove and air dry.

c. From inside the liner use a tube brush soaked in cleaning solution inserted through the faucet shank. Rinse by pouring

waterfrominsidetheunit,allowingrinsewatertoowintoasinkuntilwaterrunsclear.

5. When all pieces are completely dry reassemble for use.

Timer Instructions

Every Milano server comes with a brew quality timer attached at the top of the gauge glass cover. It is intended to

keep track of the coffee holding time. The brew quality timer should be started as soon as the brew cycle is

completed.

Initially, you must determine the ideal holding time for the coffee you are brewing. Enter this into the timer. Flashing

bars will notify you when this time has elapsed and the coffee is no longer considered fresh.

I. Functions of Buttons

START/STOP: When the START/STOP button is pressed, the previously

set time will display. By pressing a second time, the timer will start to count up the time. If no value has been

entered or if the time has been cleared, this button will not function.

HOUR: The HOUR button sets hours, starting from left. Each time you press this button, a set of four outline

bars will be added, starting from left to right. This button will not operate while timer is in the timing mode.

MINUTE: The MINUTE button sets minutes. Each time you press the MINUTE button, an outline bar will be added. Each bar represents 15 minutes,

starting from bottom to top. This button is locked and will not operate during the timing mode.

HOUR + MINUTE: Pressing the HOUR and MINUTE buttons simultaneously, clears the time setting and the screen is blank.

II. Time Alarm Set

1. Turning on the timer at the START/STOP button, all bars will be displayed for 0.5 seconds, then go blank. Set the time by pressing the HOUR and

MINUTE buttons.

2. Press START/STOP button to start counting up the time. The outline bar on the left bottom will start to ash rst. The other bars will keep the previous

static status. When the time period is completed, the solid bars of the initial time setting will display on the screen. Solid bars indicate the time that

has passed, the outline bars show the total programmed alarm time.

3. The HOUR and MINUTE buttons will be locked after the time count-up mode starts.

4. Pressing START/STOP button while in the count-up mode will return you to the previous setting.

III. Alarm Signal

1. Alarm range: 15 minutes to 3 hours

2. All 3 columns of solid bars will ash for 30 minutes once the preprogrammed time is reached.

During the alarming count-up time, press START/STOP button to stop and return to the previous setting.

IV. Power Save

After 30 minutes of inactivity under time set up mode, the power save state will activate. The LCD screen will be off. Return to the previous setting by

pressing any control button. After 30 minutes alarming, the timer will enter the time set up mode.

IV. LCD Display

Icon Style: Total 3 columns of 4 bars each. Each column represents an hour, and each bar represents 15 minutes.

The bars are in 4 formats:

1. A static outlined bar represents a 15 minute preset time increment.

2. A ashing outlined bar represents the countdown of a 15 minute increment.

3. A static solid bar represents a 15 minute increment that has already passed.

4. All 3 columns of solid bars ashing is the alarm signaling.

7

Page 8

Product Warranty Information

The Wilbur Curtis Company certies that its products are free from defects in material and workmanship under normal use. The following limited

warranties and conditions apply:

3 Years, Parts and Labor, from Original Date of Purchase on digital control boards.

2 Years, Parts, from Original Date of Purchase on all other electrical components, ttings and tubing.

1 Year, Labor, from Original Date of Purchase on all electrical components, ttings and tubing.

Additionally, the Wilbur Curtis Company warrants its Grinding Burrs for Forty (40) months from date of purchase or 40,000 pounds of coffee,

whichever comes rst. Stainless Steel components are warranted for two (2) years from date of purchase against leaking or pitting and replacement parts are warranted for ninety (90) days from date of purchase or for the remainder of the limited warranty period of the equipment in which

the component is installed.

All in-warranty service calls must have prior authorization. For Authorization, call the Technical Support Department at 1-800-995-0417. Effective

date of this policy is April 1, 2003.

Additional conditions may apply. Go to www.wilburcurtis.com to view the full product warranty information.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no responsibility for substitute replacement parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company, Inc. The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The warranty

does not cover and is void under the following circumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or uctuating water ow rate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the

responsibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the carrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for variation

in equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

8) Replacement of items subject to normal use and wear: This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets,

silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

9) Repairs and/or Replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner. Charges incurred by

delays, waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner

of the equipment. This includes institutional and correctional facilities. The Wilbur Curtis Company will allow up to 100 miles, round trip, per

in-warranty service call.

RETURN MERCHANDISE AUTHORIZATION: All claims under this warranty must be submitted to the Wilbur Curtis Company Technical

Support Department prior to performing any repair work or return of this equipment to the factory. All returned equipment must be repackaged

properly in the original carton. No units will be accepted if they are damaged in transit due to improper packaging. NO UNITS OR PARTS WILL

BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CARTON

OR SHIPPING LABEL. All in-warranty service calls must be performed by an authorized service agent. Call the Wilbur Curtis Technical Sup-

port Department to nd an agent near you.

ECN 15688 . 3/4/14@14.5 . revE

ECN 15461 . 11/11/13@12.8 . revD

ECN 15323 . 9/11/13@15.5 rev C

ECN 14883 . 5/22/13@15.3

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Support Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techsupport@wilburcurtis.com

Web Site: www.wilburcurtis.com

Printed in U.S.A. 3/2014 F-3514 Rev E

Loading...

Loading...