Page 1

THERMOPRO BREWERS

TROUBLESHOOTING GUIDE

Service & Sales

1-800-421-6150

MODELS: TP15T10A1100, TP15S10A1500

www.wilburcurtis.com

Page 2

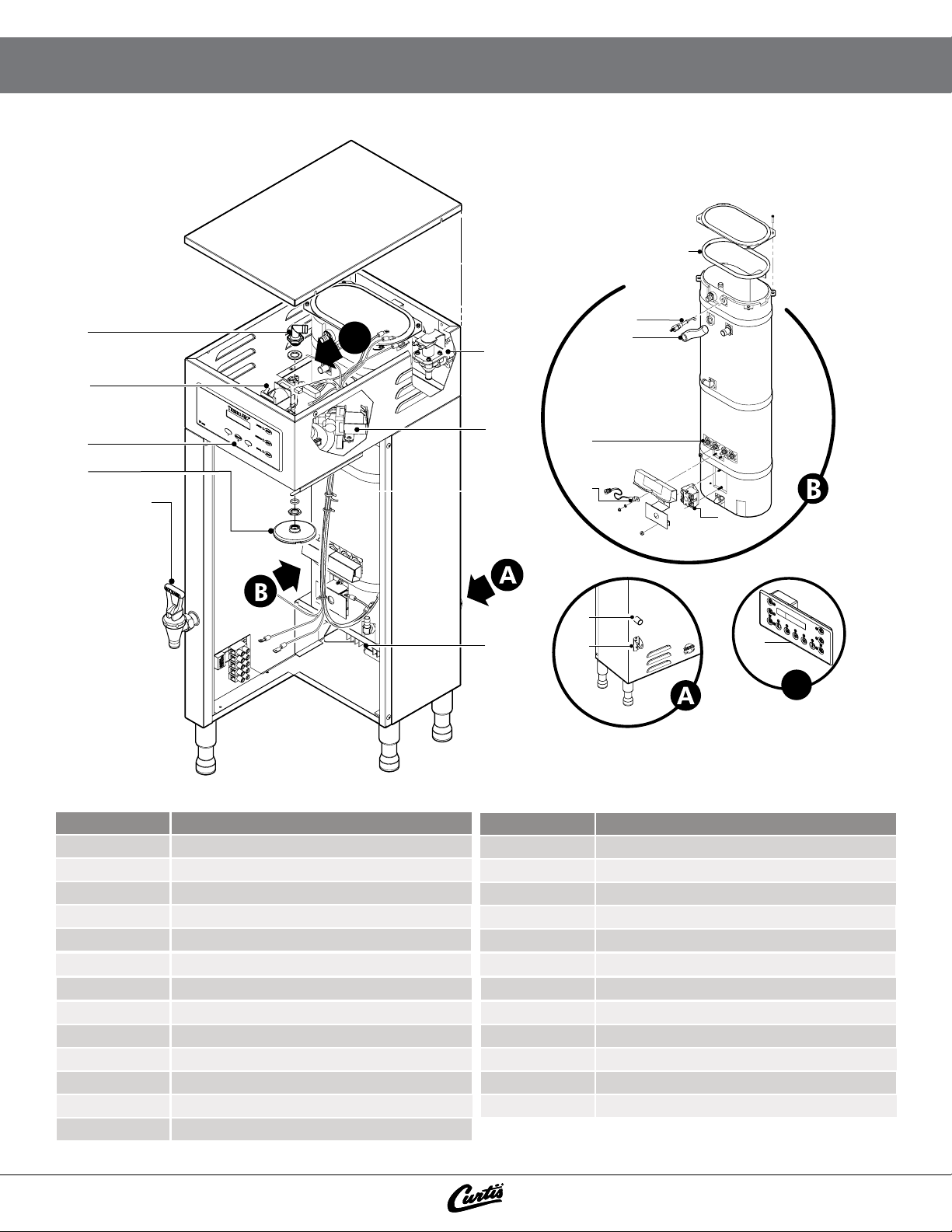

TP15S10A1500 SINGLE BREWER PARTS IDENTIFICATION

20

21

12

C

6

11

1

2

8

14

5

9

18

16

7

10

17

19

C

PART #

1. WC- 844-101 VALVE, ADJ BY-PASS

2. WC-39444 LABEL, UCM OVERLAY TP2S 3-BATCH

3. WC-39417 LABEL, UCM OVERLAY TP2S 1-BATCH

4. WC-39416 LABEL, UCM OVERLAY TP2S 2-BATCH

5. WC-29050 SPRAYHEAD ASSY, ADVANCED FLOW

6. WC- 847 VALVE, WATER INLET 2GPM 120V 10W

7. WC-1501 FUSE HOLDER W/5A FUSE

8. WC-37122 KIT, DUMP VALVE BREW RIGHT

9. WC-1825 FAUCET ASSY, HOT WATER TP2S/2T

10. WC-8559 RELAY, SOLID STATE 40A W/HEAT SINK

11. WC-5350 TUBE, ½ ID x 1/8W SILICONE

12. WC-5502-01 KIT, PROBE, ASSY WATER LEVEL

13. WC-5310 TUBING, 5/16” ID X 1/8” W SILICONE

Service & Sales

Service & Sales

1-800-421-6150

1-800-421-6150

DESCRIPTION

PART #

14. WC- 904-04 ELEMENT, HEATING 1.6KW 120V W/JAM NUTS

15. WC- 906-04 ELEMENT, HEATING 2KW 220V W/JAM NUTS

16. WC- 522 THERMOSTAT, RESET

17. WC- 103 SWITCH, TOGGLE 25A 125/250VAC RST

18. WC-1438-101 SENSOR, HEATING TANK

19. WC- 723 CONTROL MODULE, 120V TP2S/TP2T

20. WC-43062 GASKET, TANK LID

WC-2977-101K

21.

22. WC-37317 9MM STRAIGHT FITTING

23. WC-37357 12MM STRAIGHT FITTING

24. WC-37365 INLET FITTING

25. WC-37266 OVERFLOW FITTING

DESCRIPTION

KIT, SPRAYHEAD FITTING ULTEM

www.wilburcurtis.com

www.wilburcurtis.com

Page 3

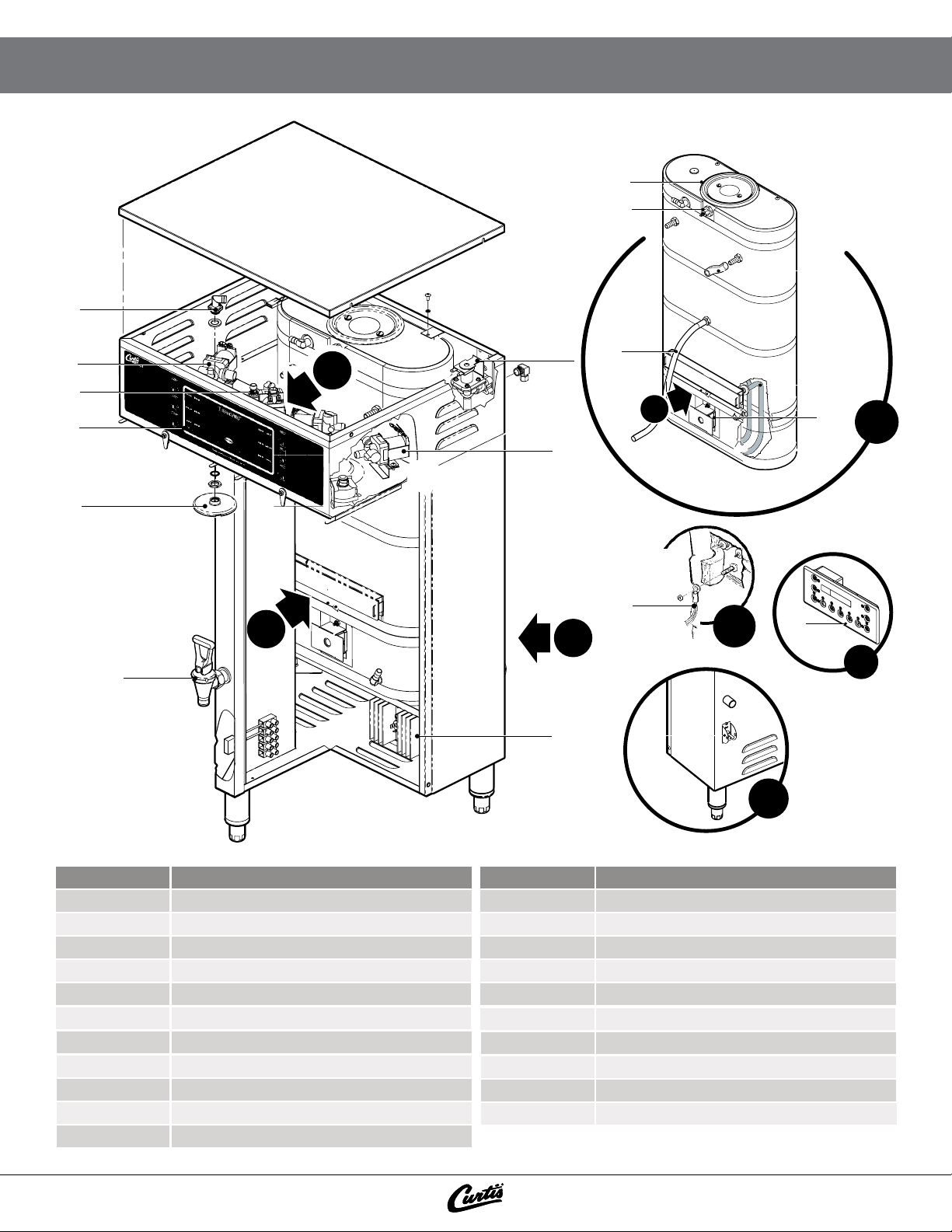

TP15T10A1100 TWIN BREWER PARTS IDENTIFICATION

26

2

2

B

C

A

30

12

13

6

D

C

11

16

31

B

18

D

33

C

PART #

1. WC- 844-101 VALVE, ADJ BY-PASS

5. WC-29050 SPRAYHEAD ASSY, ADVANCED FLOW

6. WC- 847 VALVE, WATER INLET 2GPM 120V 10W

8. WC-37122 KIT, DUMP VALVE BREW RIGHT

9. WC-1825 FAUCET ASSY, HOT WATER TP2S/2T

10. WC-8559 RELAY, SOLID STATE 40A W/HEAT SINK

11. WC-5350 TUBE, ½ ID x 1/8W SILICONE

13. WC-5310 TUBING, 5/16” ID X 1/8” W SILICONE

16. WC- 522 THERMOSTAT, RESET

18. WC-1438-101 SENSOR, HEATING TANK

19. WC- 723 CONTROL MODULE, 120V TP2S/TP2T

DESCRIPTION

32

A

PART #

20. WC-43062 GASKET, TANK LID

WC-2977-101K

21.

26. WC- 37121 KIT, DUMP VALVE BREW LEFT

27. WC-39442 LABEL, UCM OVERLAY TP2T TWIN 3-BATCH

28. WC-39415 LABEL, UCM OVERLAY TWIN 2-BATCH

29. WC-39414 LABEL, UCM OVERLAY TWIN 1-BATCH

30. WC-37008 KIT, TANK LID ROUND

31. WC- 934-04 ELEMENT, HEATING 2.5 KW 220V W/JAM NUTS

32. WC- 102 SWITCH, TOGGLE 125/250 VAC RESISTIVE

33. WC-37176 KIT, UCM & LABEL INSTRUCTIONS THERMOPRO

DESCRIPTION

KIT, SPRAYHEAD FITTING ULTEM

Service & Sales

Service & Sales

1-800-421-6150

1-800-421-6150

www.wilburcurtis.com

www.wilburcurtis.com

Page 4

TXSG1501S600 THERMAL SERVER PARTS IDENTIFICATION

34

39

35

46

36

44

37

38

40

41

47

42

43

45

PART #

34. WC-37387 KIT, CAP, TETHER & SCREW TXSG

35. WC-2025 GLASS, GAUGE 8” TLXSG10

36. WC-2063 BRACKET, GAGE GLASS RING

37. WC-1939-101 NUT, FLANGED

38. WC-1938 SHANK, PLASTIC

39. WC-2005 WASHER, SHIELD CAP 1/8”

40. WC-1903 NUT, UNI0N SHANK

Service & Sales

Service & Sales

1-800-421-6150

1-800-421-6150

DESCRIPTION

PART #

41. WC-1906 C’ RING .917 x .760 x .090

42. WC-3705 KIT, FAUCET REPAIR

43. WC-1841 FAUCET, ESP BLACK LOCKING

44. WC-2456 ELBOW, SILICONE STRT SIDE SRV

45. WC-36076 BRUSH, GAGE GLASS

46. WC-37396 KIT, GLASS GAUGE 10” 3PK TXSG15

47. WC-37395 KIT, GAUGE ASSY 10” BLK TXSG15

DESCRIPTION

www.wilburcurtis.com

www.wilburcurtis.com

Page 5

PARTS IMAGES

1

WC- 844-101

VALVE, ADJ BY-PASS

5

WC-29050

SPRAYHEAD ASSY, ADVANCED FLOW

9

2

WC-39444

LABEL, UCM OVERLAY TP2S 3-BATCH

6

WC- 847

VALVE, WATER INLET 2GPM 120V 10W

10

3

WC-39417

LABEL, UCM OVERLAY TP2S 1-BATCH

7

WC-1501

FUSE HOLDER W/5A FUSE

11

4

WC-39416

LABEL, UCM OVERLAY TP2S 2-BATCH

8

WC-37122

KIT, DUMP VALVE BREW RIGHT

12

FAUCET ASSY, HOT WATER TP2S/2T

WC-1825

13

WC-5310

TUBING, 5/16” ID X 1/8” W SILICONE

17

WC- 103

SWITCH, TOGGLE RST

21

RELAY, SOLID STATE 40A W/HEAT SINK

WC-8559

14

WC- 904-04

ELEMENT, HEATING 120V W/JAM NUTS

18

WC-1438-101

SENSOR, HEATING TANK

22

WC-5350

TUBE, ½ ID x 1/8W SILICONE

15

WC- 906-04

ELEMENT, HEATING 220V W/JAM NUTS

19

WC- 723

CONTROL MODULE, 120V TP2S/TP2T

23

WC-5502-01

KIT, PROBE, ASSY WATER LEVEL

16

WC- 522

THERMOSTAT, RESET

20

WC-43062

GASKET, TANK LID

24

WC-2977-101K

KIT, SPRAYHEAD FITTING ULTEM

Service & Sales

1-800-421-6150

WC-37317

9MM STRAIGHT FITTING

WC-37357

12MM STRAIGHT FITTING

WC-37365

INLET FITTING

www.wilburcurtis.com

Page 6

PARTS IMAGES

25

WC-37266

OVERFLOW FITTING

29

WC-39414

LABEL, UCM OVERLAY TWIN 1-BATCH

33

26

WC- 37121

KIT, DUMP VALVE BREW LEFT

30

WC-37008

KIT, TANK LID ROUND

34

27

WC-39442

LABEL, UCM TP2T TWIN 3-BATCH

31

WC- 934-04

ELEMENT, HEATING W/JAM NUTS

35

28

WC-39415

LABEL, UCM OVERLAY TWIN 2-BATCH

32

WC- 102

SWITCH, TOGGLE RESISTIVE

36

WC-37176

KIT, UCM & LABEL

37

WC-1939-101

NUT, FLANGED

41

WC-1906

C’ RING .917 x .760 x .090

45

WC-37387

KIT, CAP, TETHER & SCREW TXSG

38

WC-1938

SHANK, PLASTIC

42

WC-3705

KIT, FAUCET REPAIR

46

WC-2025

GLASS, GAUGE 8” TLXSG10

39

WC-2005

WASHER, SHIELD CAP 1/8”

43

WC-1841

FAUCET, ESP BLACK LOCKING

47

WC-2063

BRACKET, GAGE GLASS RING

40

WC-1903

NUT, UNI0N SHANK

44

WC-2456

ELBOW, SILICONE STRT SIDE SRV

BRUSH, GAGE GLASS

Service & Sales

1-800-421-6150

WC-36076

KIT, GLASS GAUGE 10” 3PK TXSG15

WC-37396

KIT, GAUGE ASSY 10” BLK TXSG15

WC-37395

www.wilburcurtis.com

Page 7

TROUBLESHOOTING INSTRUCTIONS

HEATING ISSUES

Not heating:

LCD reads “Heating”

1

2

3

4

Verify 220 volts between L1-L2 on the

power block. If yes, proceed to #2. If no,

verify that the unit is plugged in correctly,

and that the panel breaker is turned on.

Verify 220 volts between #2 & #4 on the

Manual Reset Thermostat.

If yes, proceed to #3, if no, reset or

replace the Manual Reset Thermostat.

Verify 220 volts across the Toggle Switch.

If yes, proceed to #4. If no, replace the

toggle switch.

Verify 220 volts across the Heating

Elements. If yes, proceed to #5. If no,

verify 5 VDC on the SSR. If yes, replace the

Solid State Relay, if no, replace the UCM.

Overheating:

LCD reads “Heating”

Verify that the resistance on the Temperature

Sensor is less than 10k ohms with a hot tank

(200+ degrees) If no, verify correct mounting and

that the walls of the tank are free of mineral deposits. If yes, bypass the sensor using a jumper

with a 5k ohm resistor. If the LCD reads “ready”

and the unit stops heating, replace the temperature sensor, if not, replace the UCM.

LCD reads “Ready to Brew”

Check the A.C. side of the SSR for continuity. if

continuity is present, replace the SSR, if no

continuity, replace UCM.

5

Is the water turned on?

Yes:

Yes:

No:

Yes:

No:

Verify 19 ohm across each active Heating

Element, and replace any Heating

Element that reads “OPEN”

Verify 120 volts at inlet valve coil.

Replace Inlet Valve

Remove Orange wire from the Water

Level Probe. Does the Tank Fill?

Replace Water Level Probe.

Replace UCM

TANK FILLING ISSUES

Overlling:Not lling:

Does the tank continue to fill after the

toggle switch has been turned off ?

Yes:

No:

Yes:

No:

Replace Water Inlet Valve.

Remove the Orange wire from the Water

Level Probe and connect it to ground.

Does the tank stop lling?

Replace the Water Level Probe

Replace the UCM

Service & Sales

1-800-421-6150

www.wilburcurtis.com

Page 8

TROUBLESHOOTING INSTRUCTIONS - continued

BREWING ISSUES

LCD does not read “Brewing”

If the LCD reads “Ready to Brew” and no

response when Brew Button is pressed, replace

the UCM.

LCD reads “Brewing”

No water ow from the sprayhead:

Does water ow from the hot water faucet?

If yes, verify 120 volts at the dump valve coil.

If voltage is present at the dump valve coil,

replace the dump valve.

If 120 volts is not present at the dump valve

coil, conrm continuety of wiring between molex

connector and Dump Valve.

If okay, replace the UCM. (Verify the resistance

on the dump valve coil to be open in one direction, and under 2k ohm in the other direction

BEFORE REPLACING THE UCM).

If water does not ow from the hot water faucet,

replace the Water Level Probe.

*Ensure correct alignment of the sprayhead

tting and that the tubing is routed properly to

allow for maximum water ow.

Short Pots:

Verify that the Dump Valve outlet tting on the

tank, the tubing between the tank outlet and the

Sprayhead tting, the Sprayhead, and Dump

Valve are clear of obstructions.

Ensure correct alignment of the sprayhead

tting and that the tubing is routed properly to

allow for maximum water ow.

Verify that the Hot Water Tank is lling correctly.

If not, replace the Water Level Probe.

If all the above are okay, replace the Dump

Valve.

Overowing the Pots:

Ensure that the Sprayhead has not been

removed. Replace as needed.

Ensure that the Hot Water Tank is not overowing

(See Tank Filling Issues).

Ensure Cold Brew Lock is set to 5 degrees.

Ensure that Lime / Debis are not a factor If all

the above are okay, replace the Dump Valve.

*Ensure that the sprayhead is free of mineral

deposits, in good repair, and properly conected.

Wilbur Curs Co., Inc.

6913 Acco Street, Montebello CA 90640

Customer Service: 800.421.6150 | 323.837.2300

csrassistance@wilburcurs.com

Tech Support: 800.995.0417

www.wilburcurs.com

JUNE/2014 M54_TS_WC_TP_revNC

Loading...

Loading...