Culligan CSM Series, CSM-362R, CSM-242R, CSM-302R, CSM-202D Installation, Operating And Service Instructions

...Page 1

Cat. No. 01016449

Rev. B 03/04/14

DCO # 014223

Installation,

Operating and

Service

Instructions

CULLIGAN® CSM SERIES

Commercial Filters

©2014 Culligan International Com pa ny

Printed in USA

Page 2

Attention Culligan Customer:

Your local independently operated Culligan dealer employs trained service and maintenance personnel who are experienced

in the installation, function and repair of Culligan equipment. This publication is written specifically for these individuals and is

intended for their use.

We encourage Culligan users to learn about Culligan products, but we believe that product knowledge is best obtained by

consulting with your Culligan dealer. Untrained individuals who use this manual assume the risk of any resulting property

damage or personal injury.

NOTICE Please send any suggestions for improving this manual to productmanuals@culligan.com

WARNING! Electrical shock hazard! Prior to servicing equipment, disconnect power supply to prevent

electrical shock.

WARNING! If incorrectly installed, operated, or maintained, this product can cause severe injury.

Those who install, operate, or maintain this product should be trained in its proper use,

warned of its dangers, and should read the entire manual before attempting to install,

operate, or maintain this product. Failure to comply with any warning or caution that

results in any damage will void the warranty.

CAUTION! This product is not to be used by children or persons with reduced physical, sensory or

mental capabilities, or lack of experience or knowledge, unless they have been given

supervision or instruction.

CAUTION! Children should be instructed not to play with this appliance.

CAUTION! If the power cord from the transformer to the unit looks or becomes damaged, the cord

and transformer should be replaced by a Culligan Service Agent or similarly qualified

person in order to avoid a hazard.

WARNING! This device complies with Part 15 of the FCC rules subject to the two following conditions:

1) This device may not cause harmful interference, and 2) This device must accept all

interference received, including interference that may cause undesired operation.

This equipment complies with Part 15 of the FCC rules. Any changes or modifications not expressly approved by the

manufacturer could void the user’s authority to operate the equipment. Changes or modifications not expressly approved by

the party responsible for compliance could void the user’s authority to operate the equipment.

CAUTION! To reduce the risk of fire, use only No. 26 AWG or larger telecommunications line cord.

NOTE This system is not intended for use with water that is microbiologically unsafe or of unknown quality

without adequate disinfection either before or after the system.

NOTE Check with your public works department for applicable local plumbing and sanitation codes. Follow local

codes if they differ from the standards used in this manual. To ensure proper and efficient operation of the

Culligan equipment to your full satisfaction, carefully follow the instructions in this manual.

Products manufactured and marketed by Culligan International Company (Culligan) and its affiliates are protected by patents

issued or pending in the United States and other countries. Culligan reserves the right to change the specifications referred to

in this literature at any time without prior notice. Culligan, Aqua-Sensor, Tripl-Hull, and SoftMinder are trademarks of Culligan

International Company or its affiliates.

Culligan International Company

9399 West Higgins Road, Suite 1100

Rosemont, Illinois 60018

1-847-430-2800

www.culliganmatrixsolutions.com

Page 3

Installation,

Operating and

Service

Instructions

CULLIGAN® CSM SERIES

Commercial Filters

Contents

Introduction ........................................................................ 1

Performance Specications ............................................... 2

Basic Principles ................................................................. 4

Flow Diagram .................................................................... 5

Controller Features ............................................................ 7

Operation ........................................................................... 9

Installation ....................................................................... 10

Schematic ........................................................................ 25

Programming ................................................................... 32

Statistical Data................................................................. 44

Final Start-up ................................................................... 45

Suggested Preventative Maintenance ............................. 47

Appendix A Flow Device K-Factor Data ....................... 74

Appendix B Separate Source Assembly ...................... 75

Program Log .................................................................. 78

Diagnostics ....................................................50

Service .........................................................55

Service Parts ................................................................... 62

Cat. No. 01016449

i

Page 4

This page intentionally left blank.

ii Culligan® CSM Series Filters

ii Cat. No. 01016449

Page 5

Introduction

Read this Manual First

Before you operate the Culligan CSM Water Filter, read this manual to become familiar with the device and

its capabilities.

The Culligan CSM Water Filters are tested and certified by WQA against NSF/ANSI 372 for low

lead requirement.

About this Manual

This manual:

• Familiarizes the operator with the equipment

• Explains installation and setup procedures

• Provides basic programming information

• Explains the various modes of operation

• Gives specifications and troubleshooting information

Safe Practices

Throughout this manual there are paragraphs set off by special headings.

Notice

Notice is used to emphasize installation, operation or maintenance information which is important, but does not present

any hazard. For example,

NOTICE The nipple must extend no more than 1 inch above the cover plate.

Caution

Caution is used when failure to follow directions could result in damage to equipment or property. For example,

CAUTION! Disassembly while under water pressure can result in flooding.

Warning

Warning is used to indicate a hazard which could cause injury or death if ignored. For example,

WARNING! Electrical shock hazard! Unplug the unit before removing the timer mechanism or

cover plates!

The CAUTION and WARNING paragraphs are not meant to cover all possible conditions and situations that may occur. It

must be understood that common sense, caution, and careful attention are conditions which cannot be built into the equipment. These MUST be supplied by the personnel installing, operating, or maintaining the system.

Be sure to check and follow the applicable plumbing codes and ordinances when installing this equipment. Local codes

may prohibit the discharge of sanitizing or descaling solutions to drain.

Use protective clothing and proper face or eye protection equipment when handling chemicals or power tools.

NOTE The Culligan CSM Water Filter is not intended for use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection either before or after the system.

NOTE Check with your public works department for applicable local plumbing and sanitation codes. Follow

local codes if they differ from the standards used in this manual. To ensure proper and efficient

operation of the Culligan CSM Water Filter to your full satisfaction, carefully follow the instructions in

this manual.

Cat. No. 01016449

Introduction 1

Page 6

Performance Specifications

When selecting and sizing a CSM filter for a specific application, the backwash flow rate should be taken into account

prior to determining if the service flow rate is adequate. This is the most important function in the proper operation of a

filter. Periodically, the accumulated impurities (iron, sediment, etc.) must be removed (backwashed) from the filter. Backwash flow rates are always much higher than service flow rates and therefore limit the size of filter that can be installed.

As a general rule in sizing filters, select the largest filter that can be backwashed with the flow rate available at the point

of filter installation. Then note the service flow rate for the filter selected. If it is not adequate for the flow to be treated, a

twin or triple filter installed in parallel is required. A parallel installation will increase the service flow and yet permit each

filter to be backwashed separately with the existing water supply.

Superior water quality is recommended for most filtering applications under all operating conditions. Operating at these

service flow rates allows for the best quality of water, maximum time on line between backwashing, lowest pressure loss

and recommended is for influent suspended solids loads up to and greater than 300 ppm.

High water quality is recommended for many filtering applications. Operating at these service flow rates allows for very

good quality water, moderate time on line between backwashing, increased pressure loss and is recommended for influent suspended solids loads less than 300 ppm.

Utility water quality is operating at the peak design service flow rates of the filter system and operating at higher flow rates

are not recommended. Operating at these service flow rates allows for satisfactory quality water, shorter time on line

between backwashing, higher pressure loss and is recommended for influent suspended solids loads less than 150 ppm.

In order to function properly, some operational parameters must be followed. They include:

• An operating water pressure between 30 and 100 psi. If water pressure is greater, a pressure regulating valve

should be installed ahead of the system. If water pressure is lower, additional equipment will be required to maintain a 30 psi minimum operating pressure.

• Operating temperature between 40° and 120°F or 4.4° to 48° C.

Multi-layered filters are capable of 10 micron effluent water quality or better, whereas, all other filter types are capable of

40 micron effluent water quality or better.

All pressure drop figures are based on new filter media and a water temperature of 60ºF.

NOTE The tanks are available with Non-A.S.M.E. code steel tanks (NC) or with A.S.M.E. code steel tanks (CD).

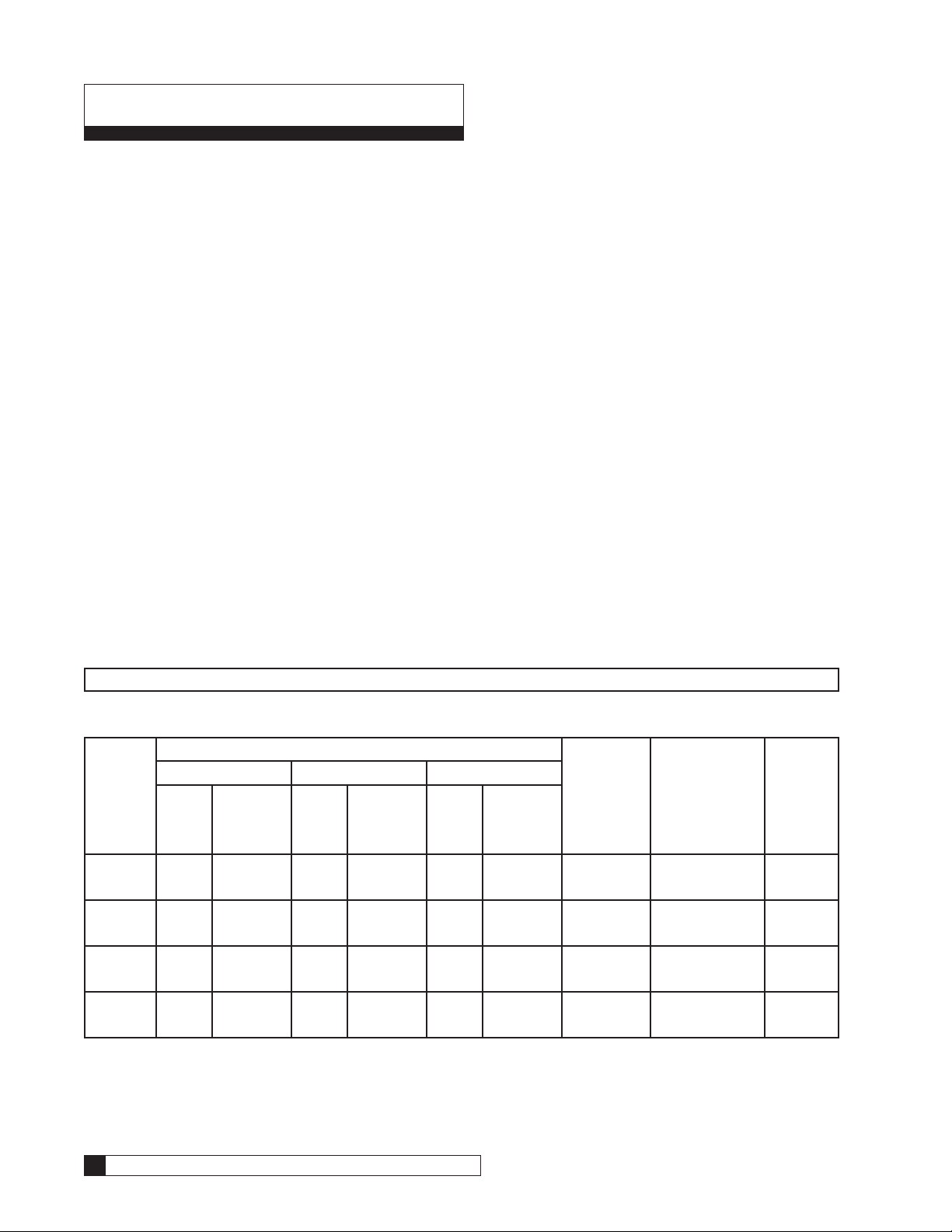

Table 1. Specifications Table for Activated Carbon Commercial Water Filters

Model Water Quality Backwash

Superior High Utility

Flow

Rate

(gpm)

CSM-242R 13 2 19 3 26 5 30

CSM-302R 20 3 30 4 40 6 46

CSM-362R 29 2 42 4 57 7 69

CSM-422R 39 3 58 6 77 9 95

Pressure

Loss

(psi)

Flow

Rate

(gpm)

Pressure

Loss

(psi)

Flow

Rate

(gpm)

Pressure

Loss

(psi)

Flow

Rate

(gpm)

Media Tank

Size & Floor

Space

Required

LxWxH

(inches)

24 x 54

25x33x74

30 x 60

31x40x90

36 x 60

37x46x90

42 x 60

43x53x92

Face

Piping

Size

(inches)

2

2

2

2

2 Culligan® CSM Series Filters

2 Cat. No. 01016449

Page 7

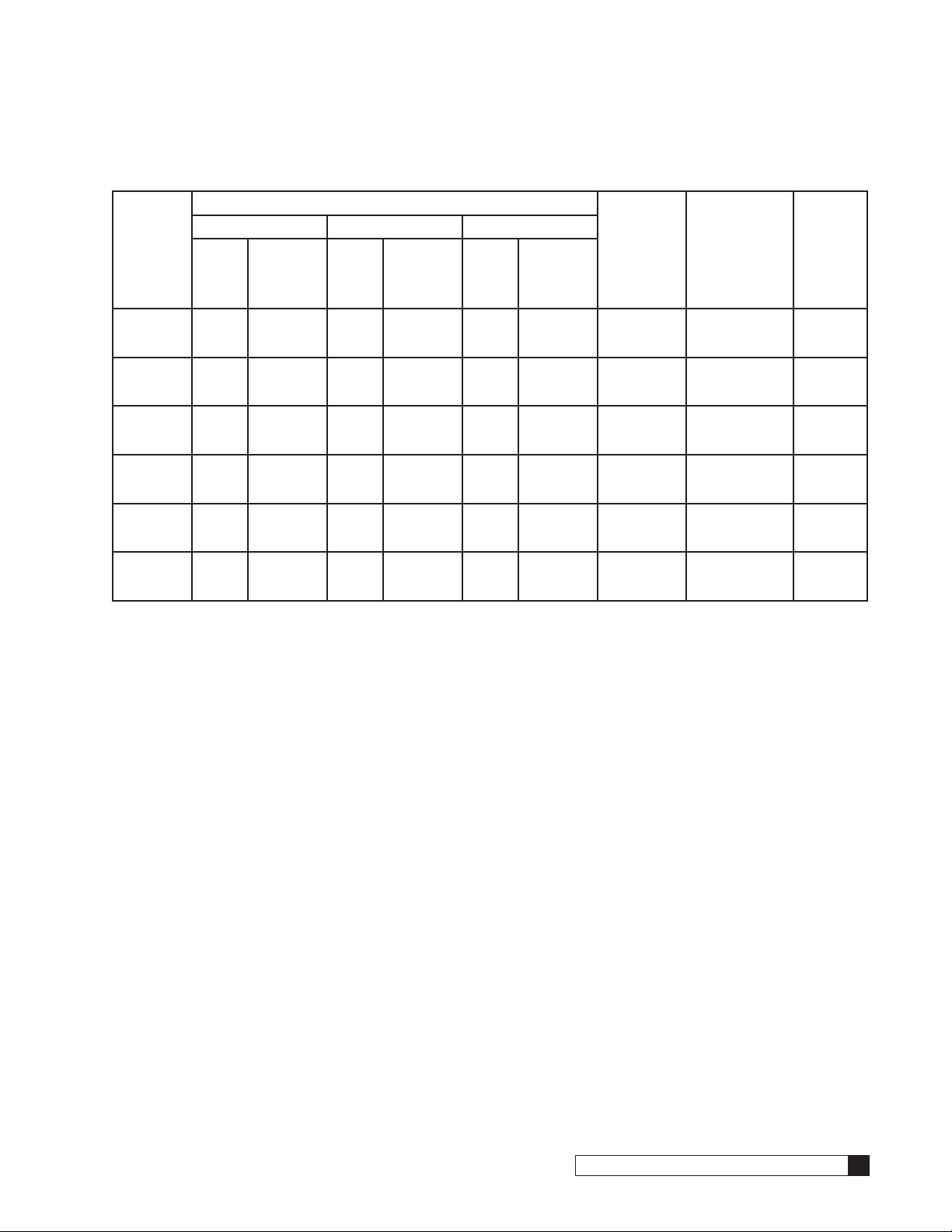

Table 2. Specifications Table for Depth Commercial Water Filters

Model Water Quality Backwash

Superior High Utility

Flow

Rate

(gpm)

CSM-202D 22 3 33 5 44 8 30 20 x 54

CSM-242D 32 4 48 8 63 13 46 24 x 54

CSM-302D 50 6 74 13 99 20 76 30 x 60

CSM-362D 71 9 107 17 142 27 105 36 x 60

CSM-422D 97 11 145 22 193 33 150 42 x 60

CSM-423D 97 6 145 11 193 16 150 42 x 60

Pressure

Loss

(psi)

Flow

Rate

(gpm)

Pressure

Loss

(psi)

Flow

Rate

(gpm)

Pressure

Loss

(psi)

Flow

Rate

(gpm)

Media Tank

Size & Floor

Space

Required

LxWxH

(inches)

21x29x72

25x33x74

31x40x90

37x46x90

43x53x92

43x54x92

Face

Piping

Size

(inches)

2

2

2

2

2

3

Cat. No. 01016449

Performance Specifications 3

Page 8

Basic Principles

Activated Carbon Filter

“Carbocleer” filters reduce unpleasant taste and odors from the water supply. In normal operation, the water passes

through the multi-port valve into the top of the media tank. As it flows down through the mineral bed, sediment in the water is filtered out and objectionable dissolved gases are absorbed into the mineral. The clear water that leaves the bottom

of the media tank and goes into the service lines is free from many disagreeable tastes and odors.

To keep the filter operating properly, it is necessary to periodically remove the accumulated sediment from the mineral

bed. This is done by a three step cleaning process:

Backwash

The direction of flow through the tank is reversed and the mineral bed is “backwashed”. This action expands and agitates

the bed, releasing the sediment which is then carried up and out to the drain.

Settle

The media tank is allowed to set idle to allow the Activated Carbon to settle. Water flow to drain will be present during the

duration of this step.

Fast Rinse

A fast down flow “flush” repacks the mineral bed and washes out traces of sediment not removed by backwash.

Generally, backwashing once a week is adequate, however, more frequent cleaning is recommended for waters with high

turbidity. Filters operated semi-automatically or automatically should be backwashed when the pressure drop across the

bed is 8 to 10 psi higher than a normal clean filter bed.

Depth Filter

Depth filters filter both heavy sediment and suspended matter from the water supply. In normal operation, the water

passes through the multi-port valve and into the top of the media tank. As the water flows down through the mineral bed,

sediment in the water is filtered out, The clear water that leaves the bottom of the media tank and goes through the service lines is free from most sediment and suspended matter.

To keep the filter operating properly, it is necessary to periodically remove the accumulated sediment from the mineral

bed. This is done by a three step cleaning process:

Backwash

The direction of flow through the bed is reversed and the mineral bed is “backwashed”. This action expands and agitates

the bed, releasing the sediment which is then carried up and out to the drain.

Settle

The tank is allowed to set idle to allow the different types of media to restratify and settle. Water flow to drain will be present during the duration of this step.

Fast Rinse

A fast down flow “flush” repacks the mineral bed and the filter is again ready for service.

It is recommended that this cleaning process take place at least once a week. On units with pressure gauges, the differential pressure across the filter can be monitored. A depth filter should be cleaned when the differential pressure across

the filter increases by 8-10 psi over the pressure differential across a clean filter bed.

4 Culligan® CSM Series Filters

4 Cat. No. 01016449

Page 9

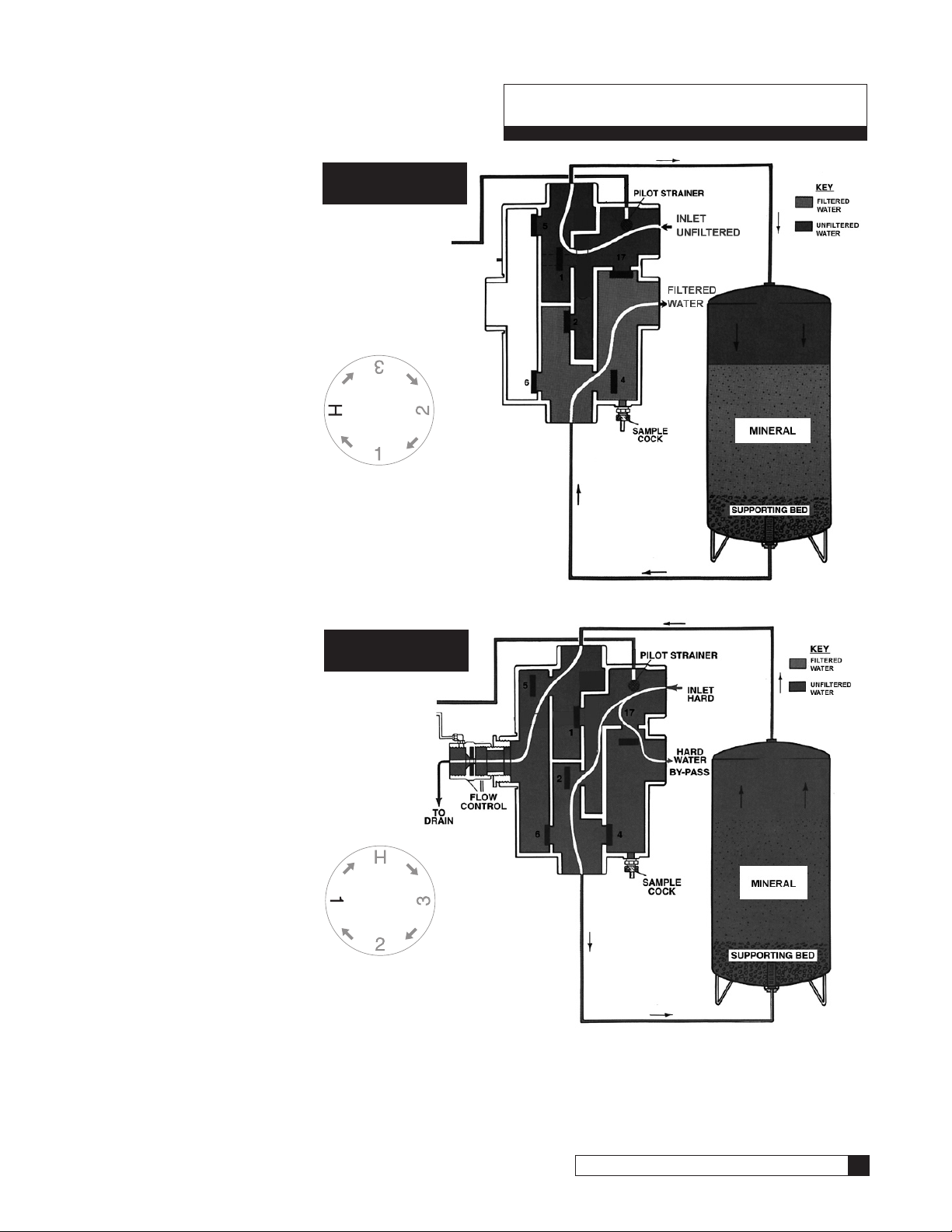

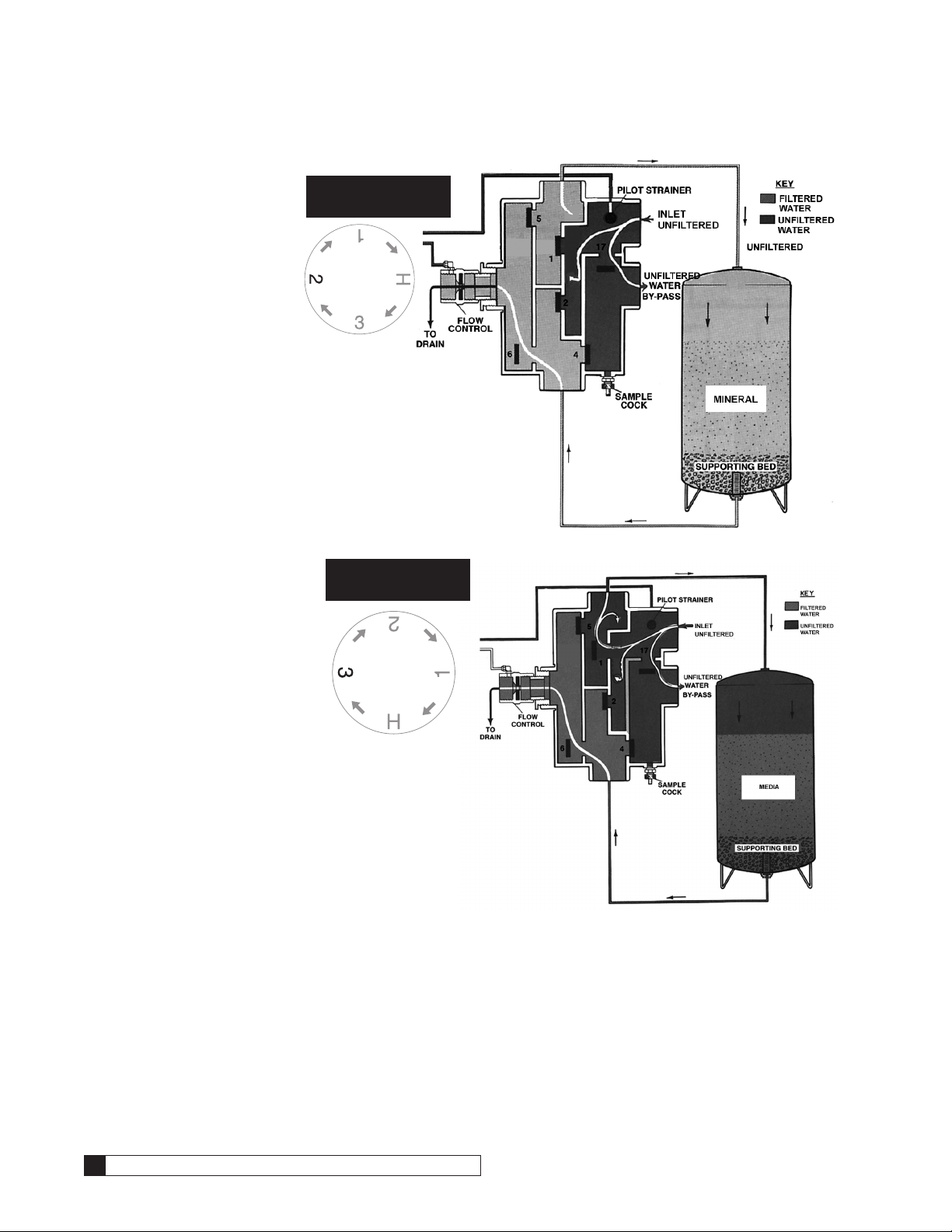

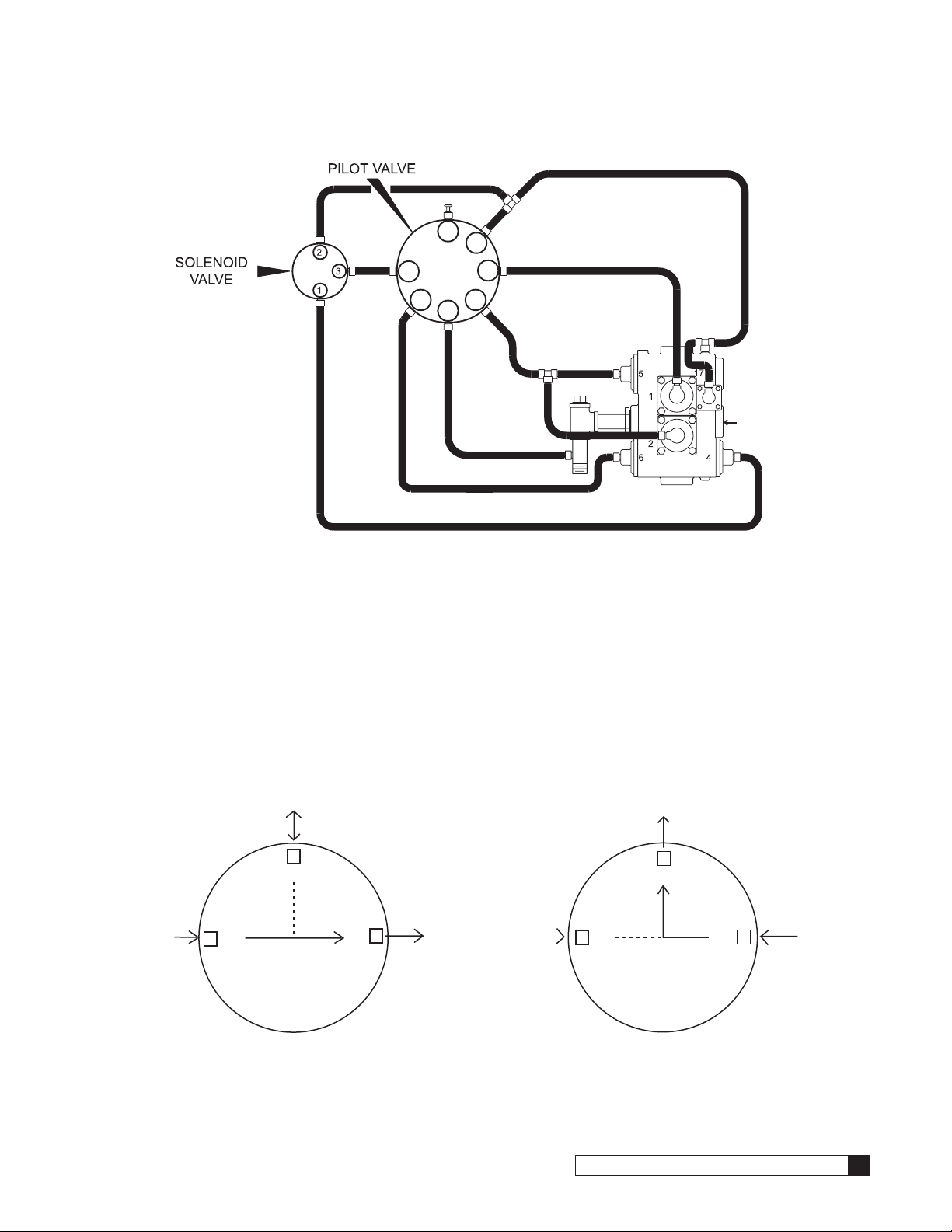

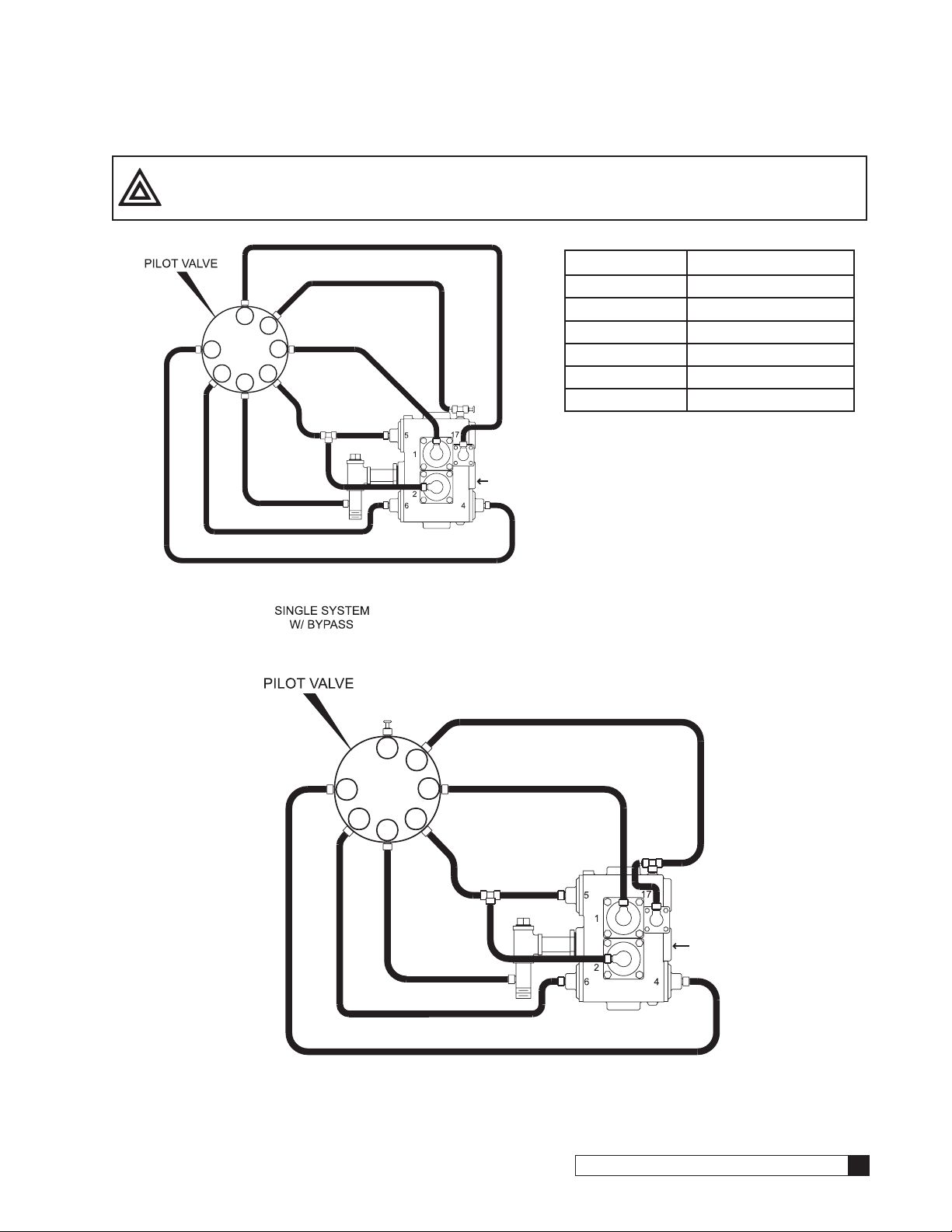

Flow Diagram

Flow Diagram -

Service Step

(H Position)

1. These diagrams illustrate the simplicity of

the Brunermatic valve

and positive control of

flow direction.

2. Note that only diaphragm valves 1 & 4

are open and flow is

directed to the top of

media tank, through

media bed, out bottom

of tank into service

line.

3. Pressure is directed

to pilot valve which

distributes pressure to

other valves.

Flow DiagramBackwash Step

(Position 1)

1. Expands and cleans the

resin bed.

2. Pilot valve changes

ports to direct water

into bottom of resin bed

and out the top of tank.

Diaphragm valves 2, 5,

and 17* are open.

3. Flow to drain is controlled by automatic

backwash flow control

assembly.

The backwash flow control assembly is accurate

over a range of 30-100

psi and insures against

media loss.

*Single tank systems requiring

bypass of unfiltered water.

SERVICE

Position

Dial

Figure 1.

BACKWASH

Position

Dial

Figure 2.

Cat. No. 01016449

Flow Diagram 5

Page 10

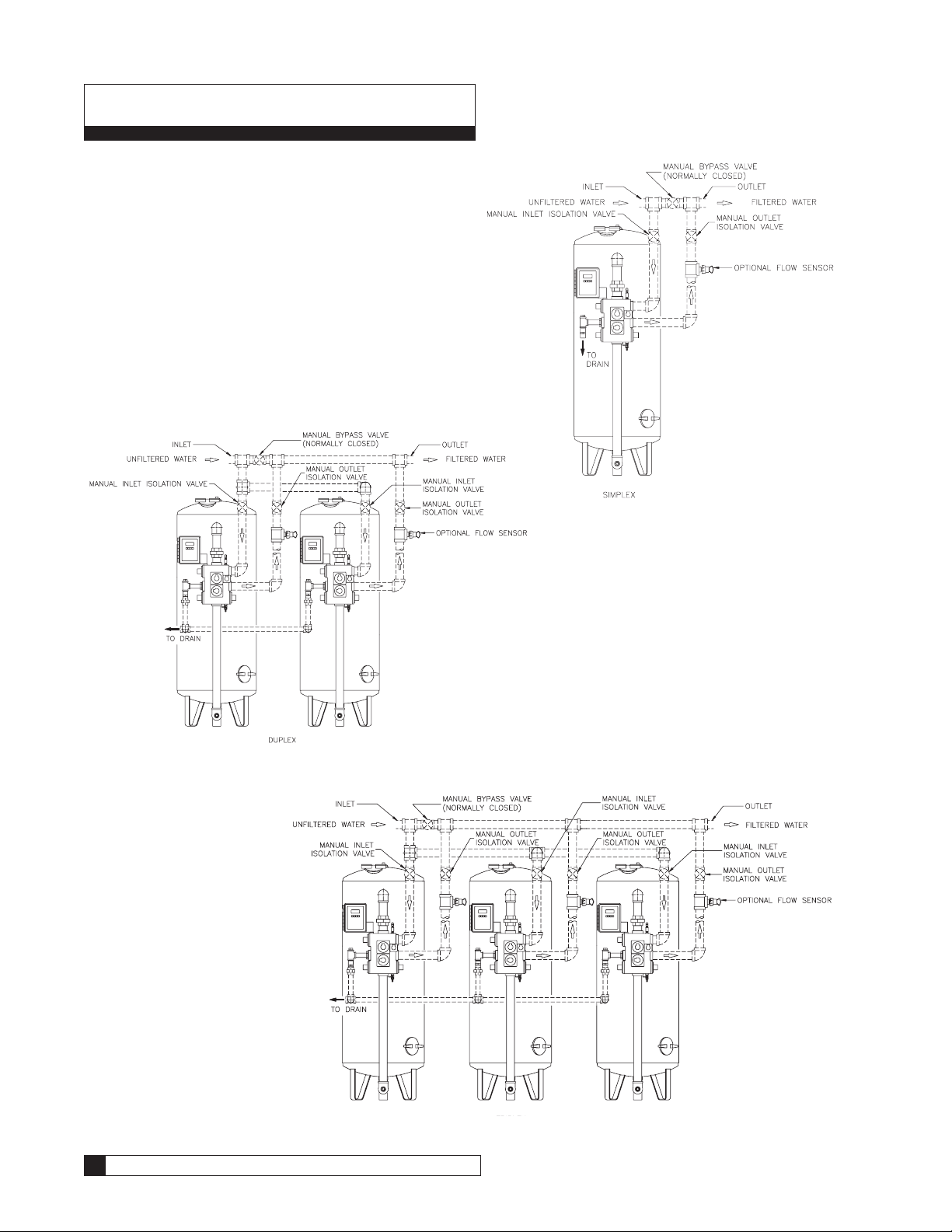

Flow Diagram -

Settle Step

(Position 2)

1. Diaphragm valve #6

opens.

2. Note that only two valves

are open in this cycle

(No. 6 and No. 17*).

3. Pressure directed through

pilot valve holds other

valves closed.

*Single tank systems requiring

bypass of unfiltered water.

Flow Diagram -

Flush Step

(Position 3)

1. Diaphragm valve # 6 opens.

2. Note that only two valves

are open in this cycle (No. 6

and No. 17*).

3. Pressure directed through

pilot valve holds other

valves closed.

SETTLE

Position

Dial

Figure 3.

FLUSH

Position

Dial

*Single tank systems requiring bypass of unfiltered water.

6 Culligan® CSM Series Filters

Figure 4.

6 Cat. No. 01016449

Page 11

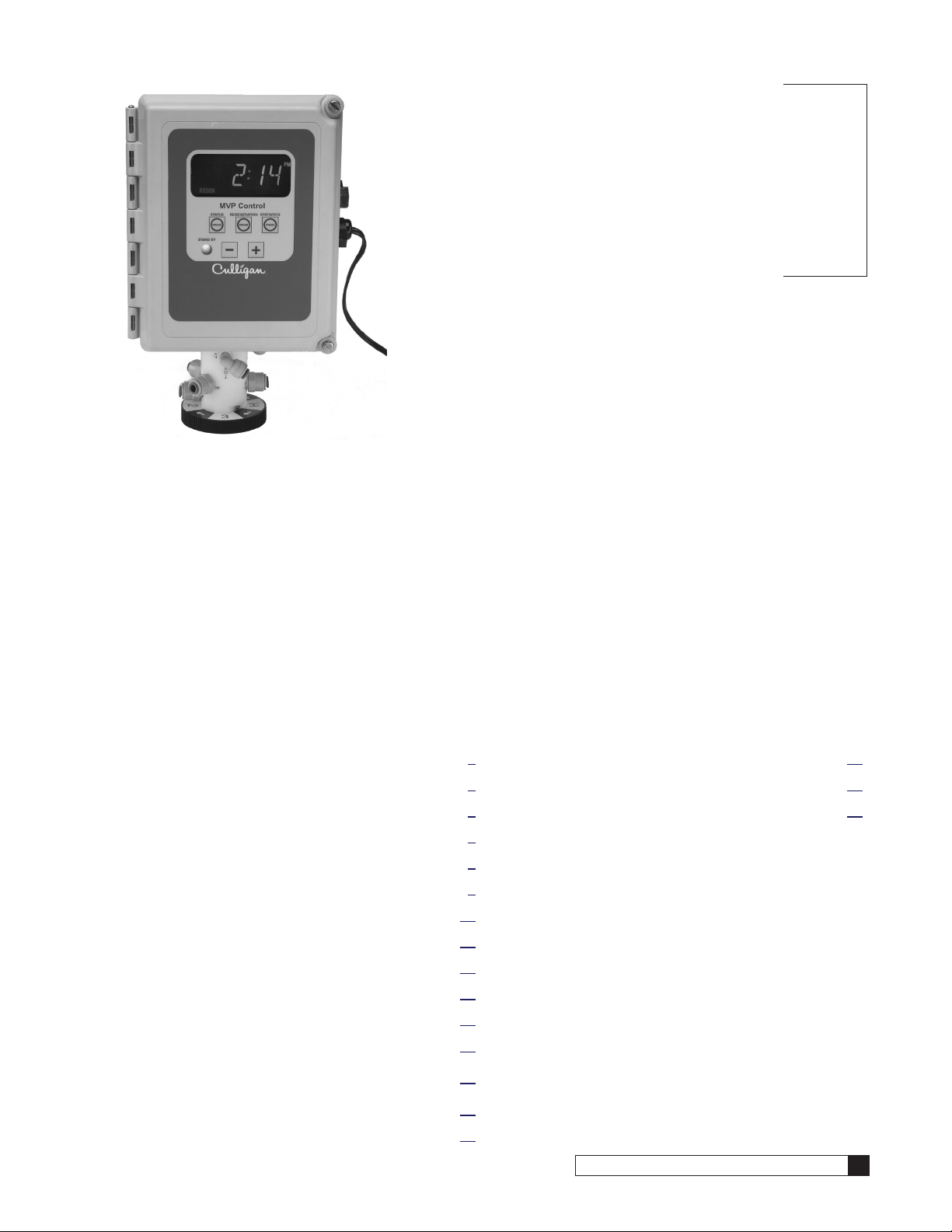

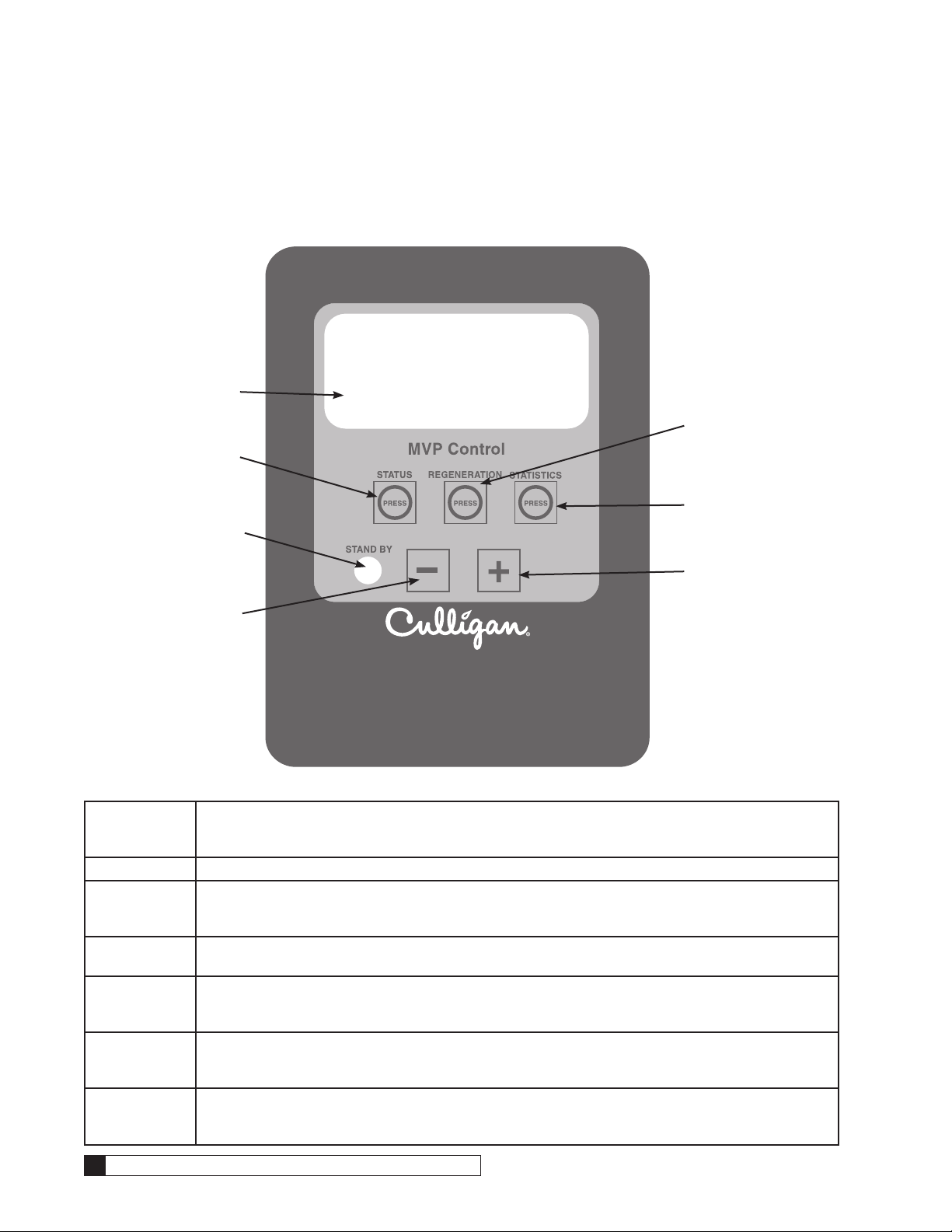

The Culligan MVP control’s (Figure 5) primary function is to initiate and

control the regeneration process via methods that are most convenient and

cost effective for the customer while offering many operation features and

benefits.

Features

Power Source

Electrical power required for the control is 24-Volt 50/60 Hz AC current. A

plug-in transformer (120v/24v) is provided

Battery Backup

Battery backup is available as an optional field add-on. The battery backup

will maintain the time of day for a minimum of 4 weeks using a 3.6V 1/2AAlithium type battery as supplied by Culligan.

EEPROM

Saves programmed and statistical functions.

AC Outputs

Four AC outputs are found within the controller for the following purposes:

• Motor control

• Blocking Valve (blocks the flow of water to service)

• Two programmable outputs for various optional accessories

Controller Features

Figure 5.

One-Touch Program Update

Multiple controls can have their programs updated simply through the touch of a button on the primary or “Master” control

eliminating the need to the programming process for each subsequent control in a system.

Lock/Unlock

Allows the control to be easily locked out from inadvertent program changes or abuse. This feature can be disabled if

desired.

Time of Day

Displays current time in either 12 hour (AM/PM) or 24 hour format.

Current Day of Week Regeneration

This feature is available for single, time clock operated systems.

Regeneration Interval

Provides an ability to initiate a time clock operated system on a number of days (range from 1 to 99 days), hours (range 1

to 24 hours), or a specific day of the week (single, time clock systems).

Progressive Flow Trip Point

Use of this patented feature allows multiple tank systems operating with water meters to be brought on-line or off-line as

facility flow demands increase or decrease.

Regeneration Start Delay

Allows a user determined number of hours (up to 9) to be input into the control for the purpose of increasing the amount

of time between multiple regeneration initiations.

Cat. No. 01016449

Controller Features 7

Page 12

Program Beeper

Emits an audible beep when key pads are depressed to help identify valid (short beep) or invalid (3 short beeps) key pad

touches. Can be enabled or disabled as desired.

Screen Blanking

The screen can be programmed to go blank once programming is complete (After 5 minutes of no keypad activity).

Flow Meter/Sensor Input

Various types of Hall effect flow sensors can be used to measure the amount of treated water provided and initiate a

regeneration sequence.

Auxiliary Input

The auxiliary input is capable of accepting a remote signal from a dry contact device such as an operator push-button for

the purpose of initiating the regeneration sequence.

Home and Position Switch Inputs

The home and position switch inputs work to automatically detect the cycle position of the valve and properly configure

the circuit board for operation with either a four or five-cycle valve. The inputs also assist the operator to troubleshoot

many types of service problems.

Multiple Unit Communication Input/Output (RS485)

The communication input/output feature routinely recognizes when another controller within a multiple controller system is

in a regeneration sequence, prohibiting the chance of multiple units regenerating simultaneously. Additionally, the Communication input/output feature provides the means to operate the controller in the Progressive Flow mode.

8 Culligan® CSM Series Filters

8 Cat. No. 01016449

Page 13

Operation

Modes of Operation

Time Clock

The controller will initiate a regeneration based upon a time schedule of either hours (between 1 to 24 hours), intervals of

days (i.e., every 3 days) or on a specific day of week schedule (i.e., Mondays, Wednesdays and Saturdays).

Differential Pressure

When combined with an optional differential pressure device, the Culligan MVP controller has the ability to initiate a backwashing sequence when the pressure differential across the media bed reaches a preset amount (usually 8 to 10 psi).

Progressive Flow

Used with up to six and as few as two mineral tanks in a system, the Progressive Flow mode allows more than one tank

in a system to either be on-line or off-line depending upon the downstream flow demand. If flow demand is greater than

the flow capability of the tank on-line, another tank can be brought on-line to help satisfy the excess demand. Once the

demand has decreased, the second tank is returned to a standby mode and the system reverts to just one tank on-line

providing treated water.

The progressive flow mode of operation relies on a user programmable set point or Trip Point. The Trip Point is a unit of

flow (gallons or liters) on a per minute basis. Once attained the trip point will cause the second unit (in multiple resin tank

system) to come on-line. Each additional resin tank in the system will subsequently be brought on-line as multiples of the

trip point are attained. (Example: a 3 tank system with a trip point of 50 gpm will bring have two tanks on-line once the

facility flow demands is equal to or greater than the 50 gpm trip point. Should the flow demand reach 100 gpm or more,

the third tank shall be brought on-line.

Additional tanks shall be returned to stand-by once the facility flow demand is <95% of the trip point for two tank systems,

<95% of 2X the trip point for triplex systems and <95% of 3X the trip point for quad systems, and remains there for 60

seconds.

Utilizing the progressive flow feature may allow the owner to use smaller water softening models, resulting in the potential

for reduced capital and operation costs.

The Progressive Flow setting may be used in combination with differential pressure device.

Cat. No. 01016449

Operation 9

Page 14

Installation

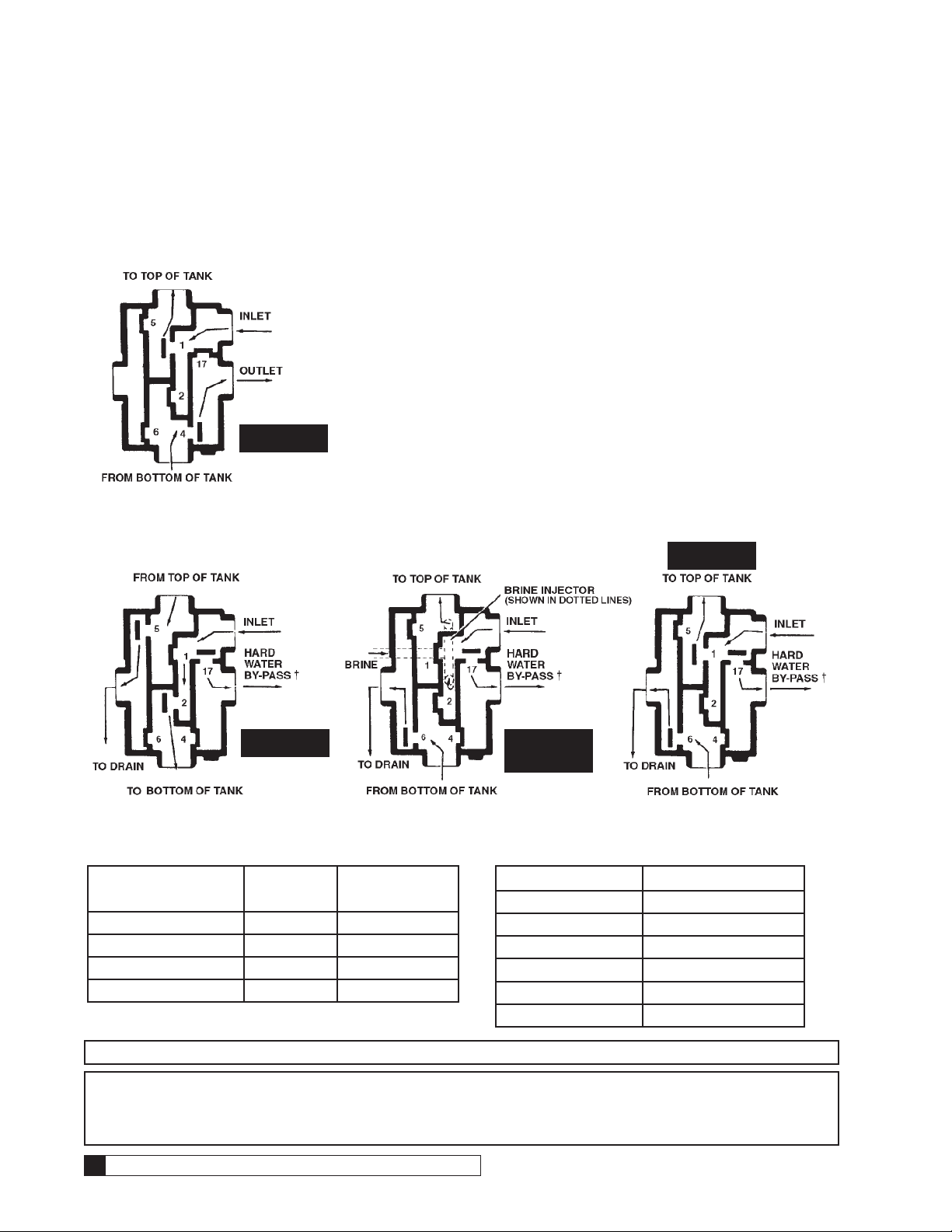

Figure 6.

Figure 7.

10 Culligan® CSM Series Filters

Figure 8.

10 Cat. No. 01016449

Page 15

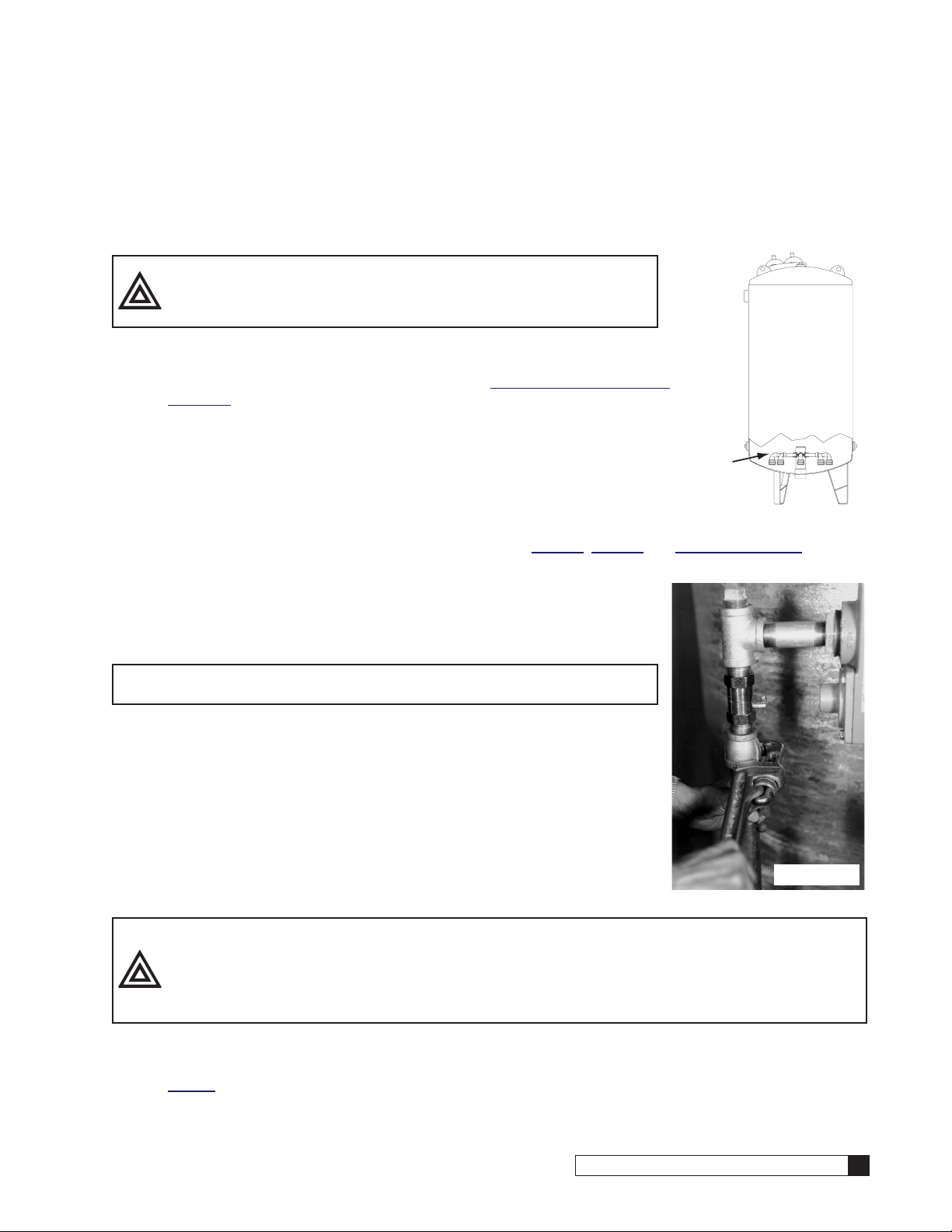

Make certain to follow each step carefully to insure that the filter runs trouble free. Also, be sure all plumbing practices

conform to local plumbing codes.

Locate Filter

1. Check inside the tank to make sure that all of the plastic distributors and laterals (Figure 9) are tight.

CAUTION! Do Not Proceed if any distributors or laterals are broken.

Consult Culligan for assistance. If any are loose, hand

tighten only. Do not use a wrench.

2. If the tank drain valve option kit was purchased, install it at this time.

3. Select a position near a floor drain that has adequate carrying capacity to han-

dle the filter’s backwash flow rate. Refer to section, “Performance Specifications”

on page 2 for specific backwash flow rate.

4. Erect the resin tank on a level firm foundation, preferably concrete. The valve

and piping normally face the front for easy access.

5. Level the system.

Figure 9.

DISTRIBUTORS

AND LATERALS

Install Piping

1. Depending on the type of filter system (i.e. single, twin, etc.) and installation parameters, required pipe lengths

and piping accessories will vary. Sample layout drawings (Figure 6, Figure 7 and Figure 8 on page 10) are

provided to aid the installation. If the layout drawings are not sufficient for your application, consult the equipment provider for specific installation guidelines.

The use of unions on the inlet and outlet isolation valves is recommended to

facilitate service of the softener unit. It is recommended that a full flow by-pass

line be provided.

NOTE All pipe fittings and assemblies should follow good plumbing practices

for installation.

They are:

• Check the threads and make certain that they are clean and free of foreign

matter.

• Fittings must be free of cracks or chips.

• Prepare threads with either a pipe dope sealant or Teflon tape.

• Make certain that the fittings are not cross threaded during the assembly

process.

• Do not over-tighten fitting or threaded pipe being inserted into a cast or

forged part.

CAUTION! Never connect two dissimilar metals (such as copper pipe and aluminum valves) togeth-

er when plumbing the vale to the piping system. The use of unions (dielectric unions

if piping to cast iron valves) on copper or galvanized steel pipe followed by schedule

80PVC or CPVC short nipples to attach the piping to the control valve is strongly recommended to reduce the potential of corrosion by galvanic reaction.

2. Pipe a drain line from the backwash flow control assembly (left side of the Brunermatic valve) to the drain. Use

a minimum of elbows and increase or decrease the pipe size in order to make a connection to the backwash

flow control assembly. (see Figure 10) DO NOT install a valve in this line or use pipe smaller than listed in the

Table 3:

Figure 10.

Cat. No. 01016449

Installation 11

Page 16

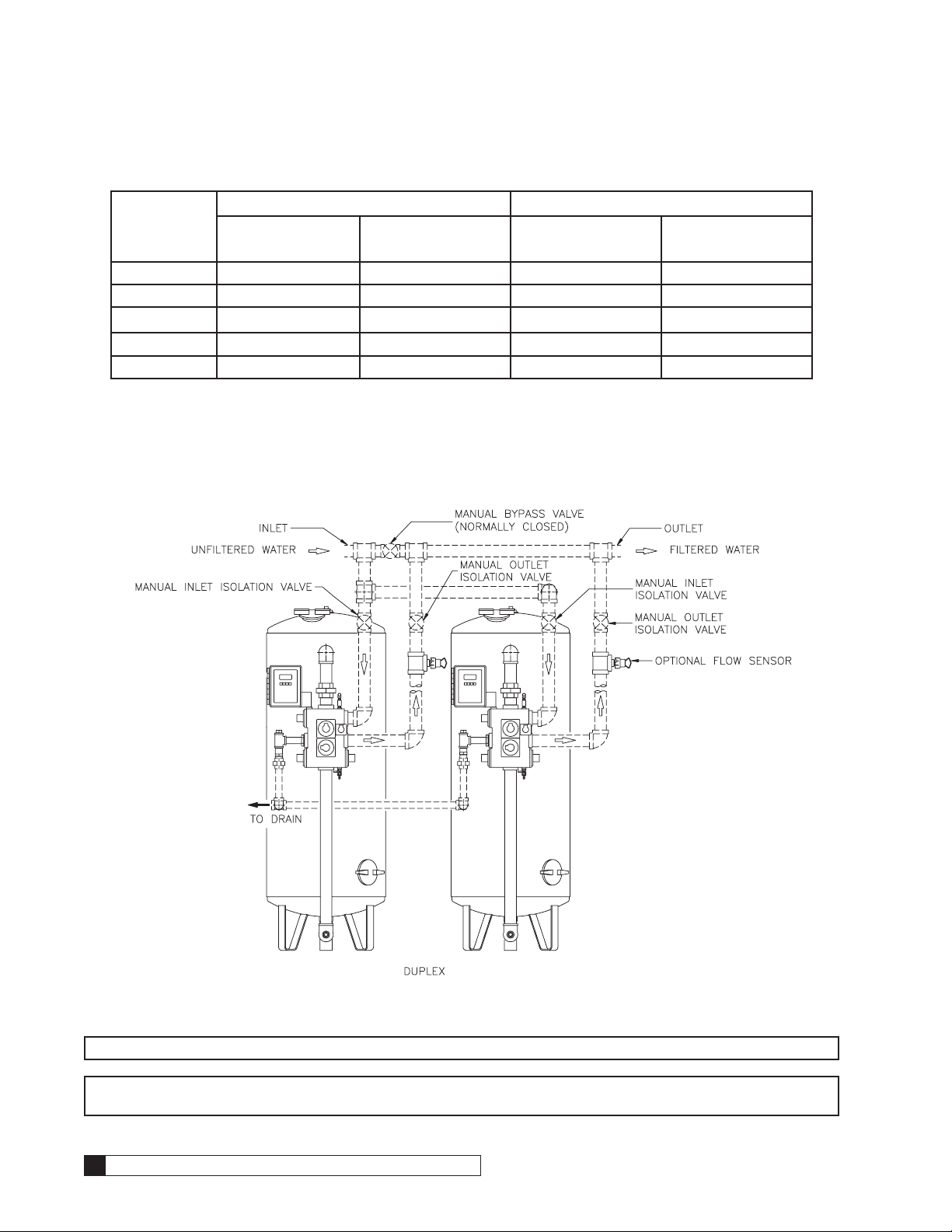

Table 3.

Carbon Filters Depth Filters

Tank Size

20 x 54 20 1-1/4 30 1-1/4

24 x 54 30 1-1/4 46 2

30 x 60 46 2 76 2-1/2

36 x 60 69 2 105 3

42 x 60 95 2-1/2 150 3

3. Install a union near the backwash flow control assembly to facilitate service when required.

DO NOT make a direct connection to the drain. Provide an air gap of at least four times the diameter of the drain

pipe or conform to local sanitation codes and to permit the observation of the drain flow.

Backwash Rate

(gpm)

Drain Line Size

(in.)

Backwash Rate

(gpm)

Installation of the Flow Measuring Device (Option)

Drain Line Size

(in.)

Figure 11.

NOTE *interconnecting piping, bypass valve and isolation valves are not supplied.

NOTE Time or initiated regenerated systems do not necessarily require the use of a flow-measuring device.

Therefore your system may not utilize this portion of the manual.

12 Culligan® CSM Series Filters

12 Cat. No. 01016449

Page 17

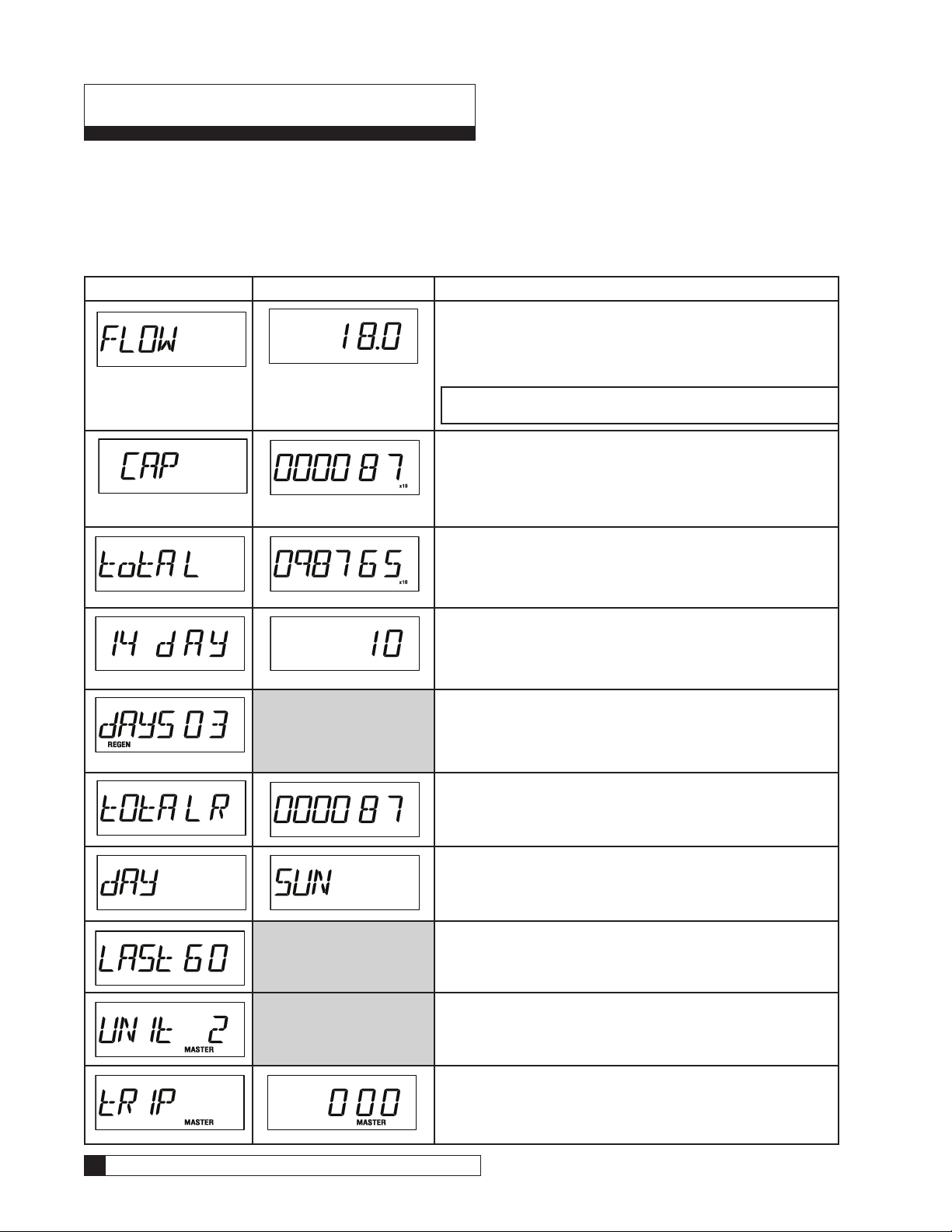

Two popular types of flow measuring devices can be used with the controller; paddlewheel flow sensors or the Culligan

Valve Prior to Flow Sensor

in-line turbine meter. Please refer to the following chart for the number of meters required for your system configuration.

Table 4.

System Configuration Paddlewheel Flow Sensor Turbine Meter

Single 1 1

Duplex Parallel/Progressive Flow 2 2

Duplex Alternating 1 1

Triplex Parallel/Progressive Flow 3 3

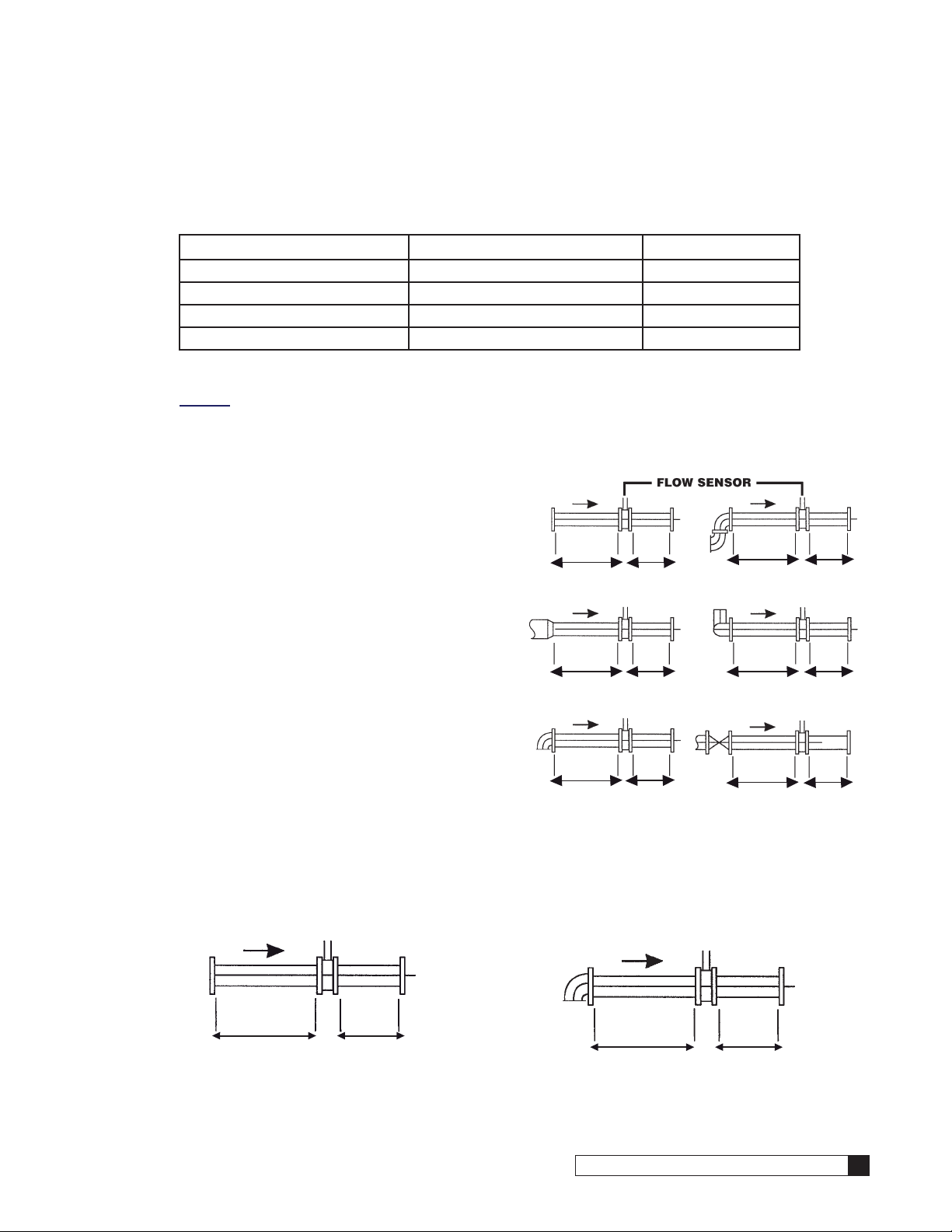

To properly measure flow accurately, the paddlewheel flow sensor(s) must be installed with a certain amount of straight

pipe both before and after the paddlewheel flow sensor. The proper installation for these types of systems is shown on

below and page 14. Turbine meters do not have the same installation requirements and therefore may be positioned

immediately following the Brunermatic valve if the system is a single or parallel configuration or at any point in the common outlet header for alternating configurations.

Location of the Paddlewheel Flow Sensor Package

The flow sensor is to be mounted on the outlet piping of each

filter for single and duplex and triplex parallel systems and in the

common outlet piping of duplex alternating systems.

The piping that the flow sensor is being connected to should

be the same diameter as the mounting fitting. The flow sensor

must also be located in a free-flowing straight run of pipe. This

straight run includes the upstream piping and downstream piping of the flow sensor.

The proper length of upstream and downstream straight piping

is a minimum of 10 pipe diameters of free-flowing straight pipe

upstream of the flow sensor and 5 pipe diameters of free-flowing

straight pipe downstream.

EXAMPLE: A flow sensor that is installed on a length of 2” diameter straight pipe (see Figure 13).

Major obstructions will require considerably longer straight runs

of upstream piping, due to the turbulence created by their presence.

EXAMPLE: A flow sensor on a length of 2” diameter pipe that

has a 90° elbow upstream from the desired location (see Figure 14).

The examples below are intended as guide lines for the proper length of straight pipe required both upstream and downstream of the flow sensor installation point.

These recommendations are minimum requirements (see Figure 12).

10 x D5 x D

Straight Pipe Two Elbows in Same Plane

15 x D 40 x D

Reducer Prior to Flow Sensor Two Elbows in Different Planes

20 x D

Single Elbow Prior to Flow Sensor

5 x D

Figure 12.

25 x D

50 x D

5 x D

5 x D

5 x D5 x D

Figure 13. Example: D = 2”

Cat. No. 01016449

10 x D = 20”

5 x D

= 10”

5 x D

20 X D = 40”

Figure 14. Example: D = 2”

= 10”

Installation 13

Page 18

Position of the Flow Sensor Package

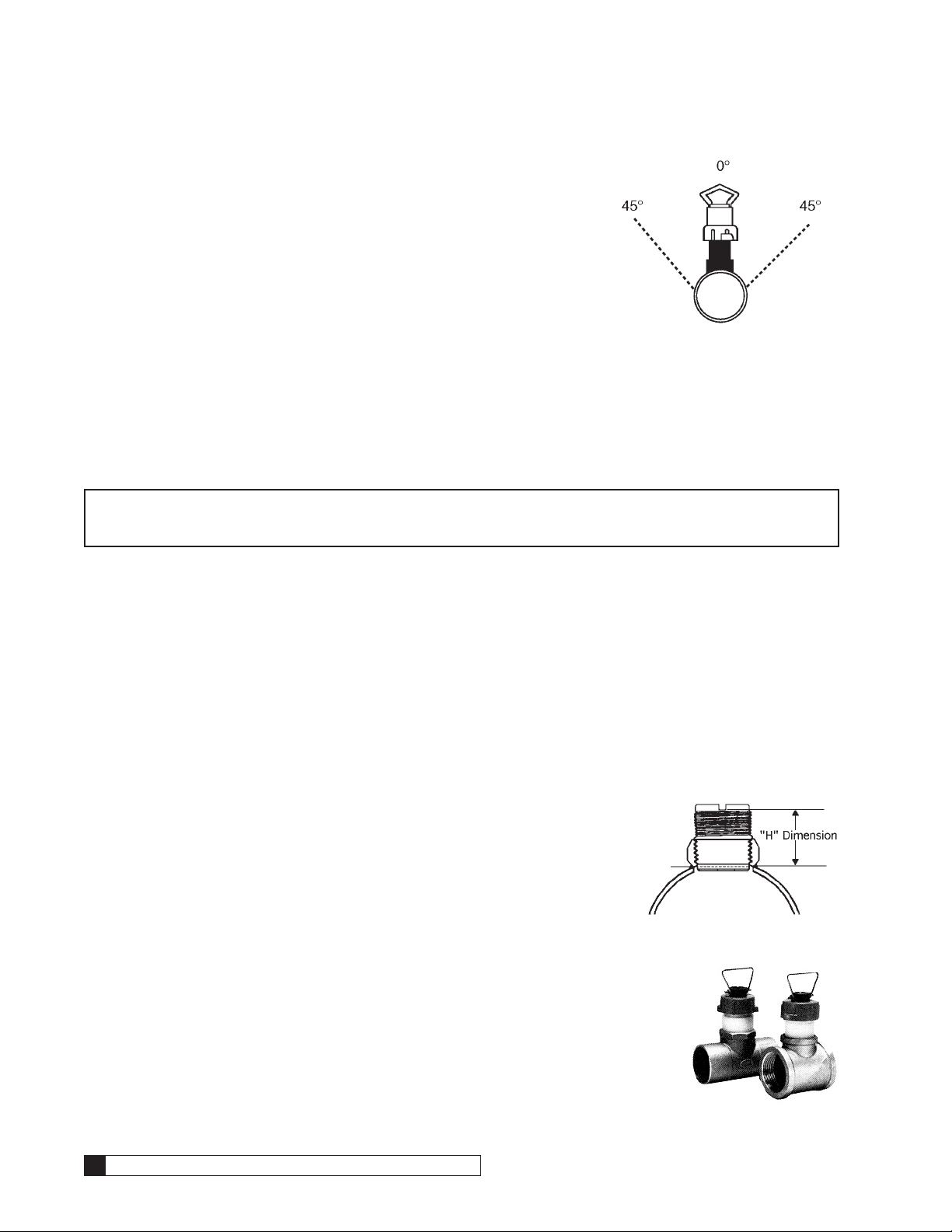

The flow sensor position is also important to the accuracy of the output signal. When

installing the flow sensor in a horizontal pipe, the optimum position of the flow sensor

in the pipe is at 0 or 180 degrees, assuming the pipe is always full of liquid and contains no suspended solids. Air pockets or sediment in the pipe will disturb the rotation

of the flow sensor, causing inaccuracy in the output signal.

Because of certain installation requirements due to space restrictions, it may be necessary to tilt the flow sensor slightly, (max. 45° angle). Excessive angles will cause

bearing drag on the flow sensor rotor at lower flow rates (see Figure 15).

On a vertical pipe run, it is preferable to locate the flow sensor where the flow is

upward. But, if downward flow is necessary, the system must be designed to prevent

air/water vapor pockets from developing in the pipe which will affect the performance of the flow sensor.

The maximum distance that the flow sensor can be located from the MVP controller is 500’. Paddlewheel type flow sensors should be supported in the piping as required by local plumbing codes; typically 18” before and after each joint (in a

horizontal run of pipe).

Figure 15.

Signet Flow Sensor Installation

NOTE Signet flow sensors must be installed as indicated. Failure to follow these instructions may result in

improper operation. Please refer to any supplemental instructions accompanying the flow sensor for

additional information.

1. Once you have located the flow sensor package and confirmed it is the correct size and material type for the

equipment at the site, proceed with installing the flow sensor mounting package.

2. You should follow good plumbing practices for all the installations. They are:

• Check the threads and make certain that they are clean and free of foreign matter.

• Fittings must be free of cracks and chips.

• Prepare threads with either a pipe sealant or Teflon tape.

• Make certain that the fittings are not cross threaded during the assembly process.

• Do not over-tighten the fittings or the threaded pipe that is being threaded into a casting or forging.

• Follow proper soldering processes as outlined in the plumbing code.

3. For each of the different types of installations, certain requirements must be followed to assure a proper installation.

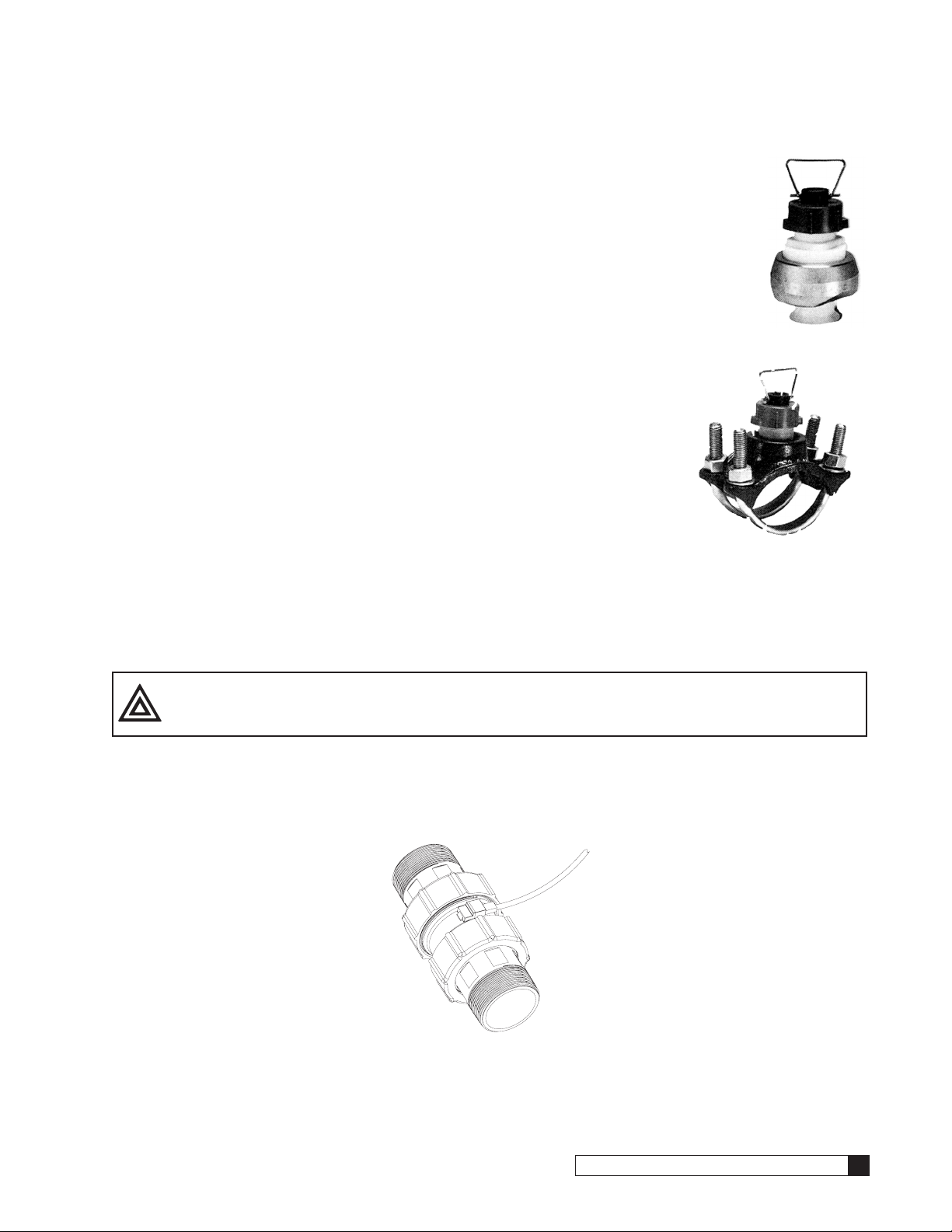

a. Copper sweat tee - for use on copper tubing sizes. 1” 1-1/4”, 1-1/2”

and 2”. With the exception of the 1” copper sweat tee, all of the copper tees include a plastic insert which the flow sensor will attach to.

This insert should be removed in order to properly solder the tee into

the correct position. A tag is attached to the fitting to indicate the proper “H” dimension of the plastic insert when reassembling. This dimension is critical to the proper calibration of the flow sensor. Note the

location of the notch to the pipe (see Figure 16).

b. Threaded galvanized tee - for use on galvanized/iron pipe sizes 1”, 1-1/4”,

1-1/2” and 2”. All tees are threaded with NPT threads and have a plastic

insert to attach flow sensor. This insert is factory installed and should not

be removed. It is necessary for determining the proper location for the flow

sensor wheel when inserted into the fitting. Again this insert should not be

removed from the tee assembly (see Figure 17).

Figure 16.

14 Culligan® CSM Series Filters

Figure 17.

14 Cat. No. 01016449

Page 19

c. Copper brazolet - for use on copper pipe sizes 2-1/2” and 3”. The copper brazolet

should be installed by a certified welder. A hole will need to be drilled in the pipe at

the desired location as described in this section. The hole size should be 1-7/16” and

must be completely deburred and free of any projections. Prior to welding the brazolet, the plastic insert must be removed. A special tool is provided with each brazolet

assembly for the removal and the replacement of the plastic insert. When the plastic

insert is replaced (after the welding is complete), Teflon tape should be used on the

threads. There is a special card that is attached to the insert, this card indicates the

proper “H” dimension for the insert depth when you reassemble the insert back into

the brazolet. This dimension is critical to the proper calibration of the flow sensor.

Note the location of the notch to the pipe (see Figure 18).

d. Iron saddle - for use on steel pipe 2”, 2-1/2” and 3”. A 1-7/16” hole will

need to be drilled in the pipe at the desired location as described in this

section. The assembly comes complete with a plastic insert which is factory installed and should not be removed. The assembly also comes with

a rubber washer which must be installed between the clamp and pipe.

Coat the rubber washer with a silicon lubricant and place it on the inside

of the saddle and form it around the raised groove. With the flat side of

the rubber washer facing the pipe surface, insert the plastic insert and

saddle to the drilled hole. Using the saddle clamps, tighten the saddle

into place.

e. PVC socket weld tee - for use on sizes 1”, 1-1/4”, 1-1/2”, 2”, 2-1/2”, 3”

and 4” schedule 80 PVC pipe. All tees are socket welded with a NPT

threaded port containing a plastic insert to attach the flow sensor. This insert is factory installed and

should not be removed. It is necessary in determining the proper location for the flow sensor wheel

when inserted into the fitting. Again, this insert should not be removed from the tee assembly. Once

the flow sensor installation is completed, locate the warning decal attached to the flow sensor. Apply

the decal to a visible location near the flow sensor in the event service is required.

Figure 19.

Figure 18.

CAUTION! Be certain there is no pressure in pipe BEFORE removing or installing flow sensor.

Turbine Meter Installation

Turbine meters are less sensitive to position. They can be mounted horizontally or vertically but straight runs before and

after the meter are best for accuracy. If mounted vertically, the water flow must be upward. Turbine meters however must

be supported as required by local plumbing codes; typically 18” before and after each joint (in a horizontal run of pipe).

Figure 20.

Cat. No. 01016449

Installation 15

Page 20

Loading the Media Tank

Installing the Gravel Support Bed

1. Verify that the correct type and amount of gravel for the system is on site. The proper amount of gravel is

indicated in the following table. If the correct type and amount of gravel is not on site, DO NOT load the tank.

Contact the equipment provider for assistance.

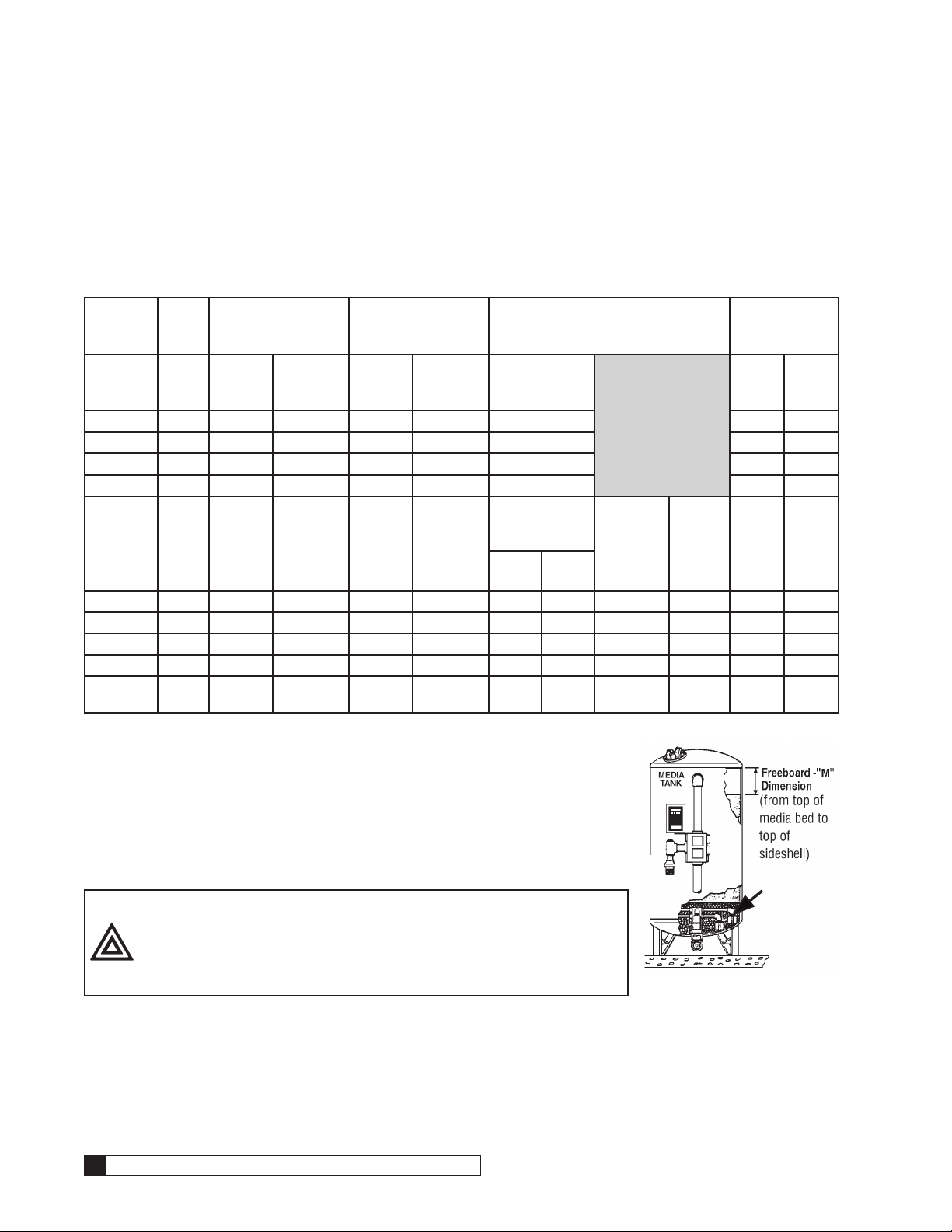

Table 5.

Underbedding, lbs.

Non-Code Tanks

Part Number (Qty)

Size

Size

Layer 1

Med.

Gravel

Layer 1

Med.

Gravel

Layer 2

Cullsan U

Layer 2

Cullsan U

Carbon

Tank

Filters

CSM-242R 24 x 54 100 100 125 100 220 18.00 19.00

CSM-302R 30 x 60 150 150 200 150 330 26.25 26.50

CSM-362R 36 x 60 250 250 350 250 495 24.50 25.00

CSM-422R 42 x 60 350 350 550 350 660 25.50 25.00

Depth

Tank

Filters

CSM-202D 20 x 54 100 50 100 50 100 100 165 150 17.50 19.00

CSM-242D 24x 54 100 100 150 100 150 250 220 250 16.50 16.25

CSM-302D 30 x 60 200 150 250 150 200 200 330 350 25.00 25.50

CSM-362D 36 x 60 300 200 450 200 250 250 495 500 26.00 25.50

CSM-422D

CSM-423D

42 x 60 450 300 700 300 350 350 660 700 19.00 24.50

Underbedding, lbs.

ASME-Code Tanks

Part Number (Qty)

Layer 1

Med.

Gravel

Layer 1

Med.

Layer 2

Cullsan U

Layer 2

Cullsan U

Gravel

Filter Media, lbs.

Part Number (Qty)

Layer 3

Cullar D+

Layer 3

Cullsan G50

NonCode

ASME

Code

Layer 4

Cullsan A

Layer 5

Cullcite

Freeboard

Dimension

“M” (in.)

Non

ASME

Code

Non

ASME

Code

Code

Code

2. Make sure all manual valves are closed. To prevent damage to the distribution system, add approximately 2 feet of water to the media tank with a hose

(Figure 21). It is not recommended that the media tank be entered to receive

and load the gravel. With water in the media tank, carefully pour the gravel

slowly into the media tank, leveling as loading progresses. On media tanks

with only a handhole in the top, it is recommended that a funnel be used to

load the gravel into the media tank to help prevent spillage. When properly

loaded, the gravel should cover the distributor system in the bottom of the

tank. If it does not, contact your Culligan dealer before proceeding to Step 3.

Distributor

System

CAUTION! Should it be necessary to enter the media tank, it is

recommended that a respirator be worn by any person

entering the tank to load gravel. Wet the bags of gravel

to reduce the amount of dust caused by the loading

procedure.

Figure 21.

16 Culligan® CSM Series Filters

16 Cat. No. 01016449

Page 21

3. Level the Gravel Support Bed. An easy way to determine the levelness of the gravel support bed is to add water

(Figure 22) to the surface of the gravel. It may be necessary to add or remove

water to insure that the water level is at or near the same height of the gravel

level. Make certain that no foreign materials are left in the tank. This includes the

bags that the gravel is shipped in.

Installing Activated Carbon Filter Media

1. Before adding the Activated Carbon, verify that the correct type and amount of

Activated Carbon for the filter you are installing is on site. If the correct type and

amount (Table 5) of Activated Carbon is not on site, contact the Culligan Dealer

that sold you the filter.

2. Slowly pour in the Activated Carbon. It is recommended that a funnel be used on

those units with spin top and handhole covers, when loading Activated Carbon into the media tank. Make certain that no foreign material is left in the media tank.

3. With the MVP controller unpowered, rotate the position dial to the Backwash (#1) position. Slowly open the inlet

isolation valve and allow the media tank to slowly fill up with water until the water level covers the mineral bed.

The freeboard dimension should be checked at this time. If the freeboard dimension is correct, rotate the position dial to the Home (H) position at this time.

4. Do not install the spin top, handhole or manhole cover(s) at this time. Allow 24 hours for the air to escape from

the media tank.

Figure 22.

Installing Depth Filter Media

1. Before loading the different types of media, verify that the correct type and amount (Table 5) of each media for

the filter you are installing is on site. If the correct type and amount of each media is not on site, contact the

Culligan Dealer that sold you the filter. The media must be loaded into the mineral tank in the proper order to

assure proper filter operation. It is recommended that a funnel be used on those units with spin top and handhole covers, when loading each layer of media into the media tank.

2. Layer 2 - Slowly pour in the 8-12 mesh garnet. Make certain that no foreign material is left in the media tank.

Carefully level this layer of media. With the MVP controller unpowered, rotate the position dial to the Backwash

(#1) position. Slowly open the inlet isolation valve and allow the media tank to slowly fill up with water until the

water level is just at the top of this layer of media. Close the inlet isolation valve and verify that this layer of

media is level.

3. Layer 3 - Slowly pour in the 30-40 mesh garnet. Make certain that no foreign material is left in the media tank.

Carefully level this layer of media. Slowly open the inlet isolation valve and allow the media tank to slowly fill up

with water until the water level is just at the top of this layer of media. Close the inlet isola-tion valve and verify

that this layer of media is level.

4. Layer 4 - Slowly pour in the 0.35-0.45mm red flint sand. Make certain that no foreign material is left in the media

tank. Carefully level this layer of media. Slowly open the inlet isolation valve and allow the media tank to slowly

fill up with water until the water level is just at the top of this layer of media. Close the inlet isolation valve and

verify that this layer of media is level.

5. Layer 5 - Slowly pour in the 6-16 mesh carbon. Make certain that no foreign material is left n the media tank.

Carefully level this layer of media. Slowly open the inlet isolation valve and allow the media tank to slowly fill up

with water until the water level is just at the top of this layer of media. Close the inlet isolation valve and verify

that this layer of media is level.

6. The freeboard dimension should be checked at this time. If the freeboard dimension is correct, rotate the posi-

tion dial to the Home (H) position at this time.

7. Do not install the spin top, handhole or manhole cover(s) at this time.

Cat. No. 01016449

Installation 17

Page 22

Controller Mounting

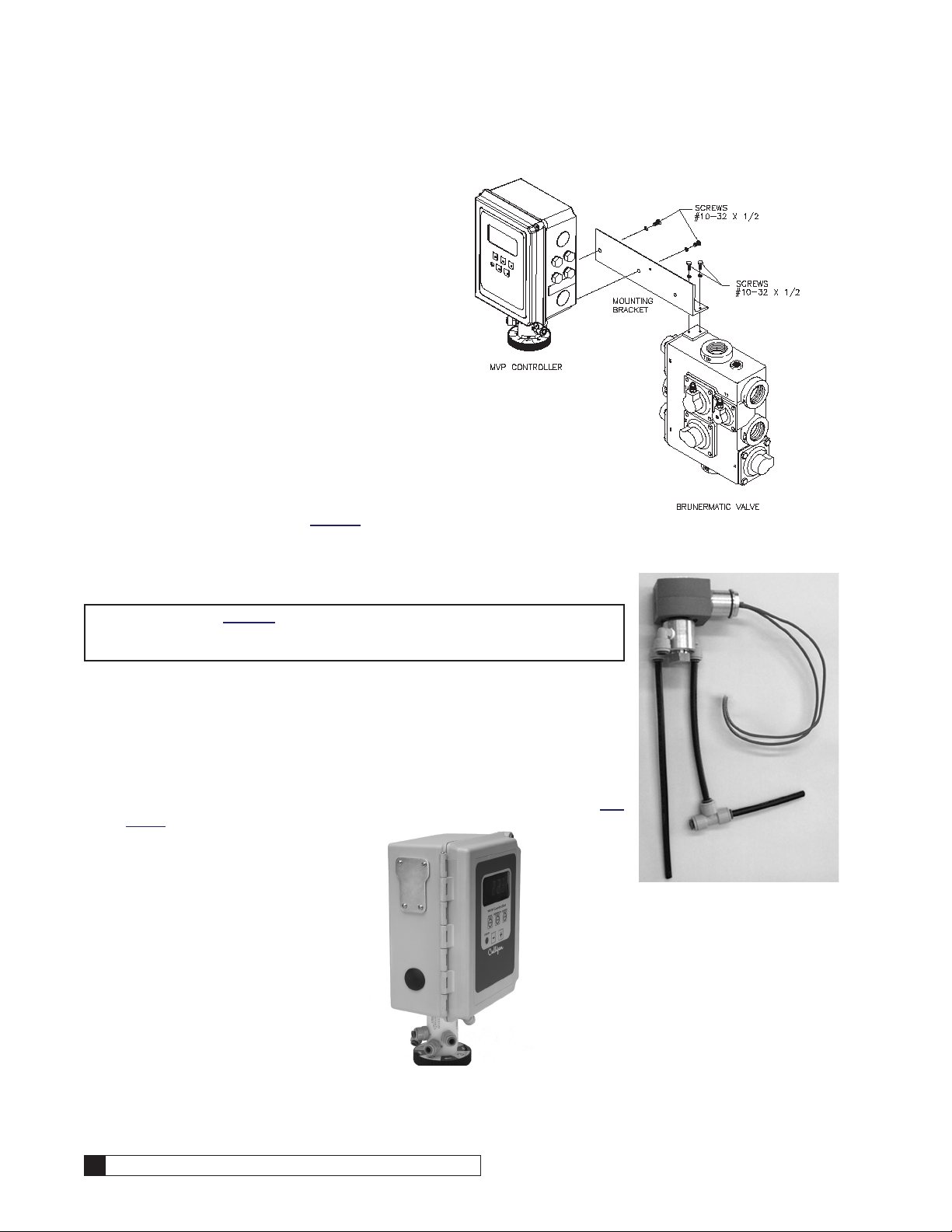

The MVP controller is shipped in its own box, complete

with transformer assembly, tubing assembly, mounting

bracket, and hardware.

1. Remove the controller mounting bracket from

the shipping carton. If the conditioning cartridge

option kit was ordered, follow the instructions

included with the kit to install the cartridge

assembly on the mounting bracket.

2. Install the controller to the mounting bracket

using the supplied hardware. Refer to Figure

23.

3. Install the bracket mounted controller to the

Brunermatic valve using the supplied hardware.

4. Retain the other items in the shipping carton for

future use.

5. If a solenoid blocking valve kit was shipped with

the system (for use in twin alternating systems),

install to the controller. Follow instruction steps

in following section and on page 28.

Figure 23.

Installation and Operation of the Blocking Solenoid Valve for Multi- Tank

Alternating Operation

NOTE Proceed to page 20 if your system is a single tank configuration.

The solenoid valve is only required for multiple unit alternating or

progressive flow systems.

The purpose of the solenoid valve (Figure 24) is to assist the controller in providing

automatic alternation of multiple tank systems. Each Brunermatic multiport valve in the

system will require its own solenoid valve. The solenoid should be mounted to the left

side of the controller (see Figure 25). These solenoids are tubed as follows:

• From solenoid valve port number 1 to Brunermatic multiport valve port number 4.

• From solenoid valve port number 2, tee into the tubing that attaches to the “IN”

port on the pilot valve body.

• From solenoid valve port number 3 to port number 4 on the pilot valve body (Fig-

ure 26).

Blocking Solenoid for

Alternating Operation

18 Culligan® CSM Series Filters

Figure 24. Solenoid

Valve Kit

Figure 25.

18 Cat. No. 01016449

Page 23

6

IN

DR

1

3/4

2

5

Brunermatic

Valve

Figure 26. Alternating/Progressive Flow Parallel System w/ Plugged Bypass

Sequence of Operation

When a filter is in standby or a regeneration cycle, the MVP controller sends a signal to the P7 SOL-VIV terminal of the

primary circuit board, activating the solenoid valve. The orange LED will be on at this time. When the solenoid valve is

electrically activated, ports #1 and #2 of the solenoid (Figure 27) become common. This will direct pressure from the

constant IN pressure supply to Brunermatic diaphragm valve #4, which prohibits the flow of water through the outlet of the

Brunermatic valve.

Once the controller signals the unit to return to a Service status, the signal from P7Solvlv is removed and the solenoid

valve is deactivated. When the solenoid valve is electrically deactivated, ports #1 and #3 of the solenoid become common. The orange LED will not be on at this time. This will vent pressure, from Brunermatic diaphragm valve to port #4 on

the pilot valve body and then to drain. Brunermatic valve #4 opens which allows filtered water to flow through the outlet of

the Brunermatic valve.

From

"IN"

on

Pilot Valve

Body

(pressurized)

Cat. No. 01016449

To port #2 on Pilot Valve Body

(pressurized during regen,

no pressure in standby mode)

3

N

/

O

2

/

C

N

Solenoid Valve

Solenoid Valve Energized

When Tank

in Regen or Standby

To port #2 on Pilot Valve Body

3

N

/

O

1

/N

O

To

Port #4

(pressurized)

From

"IN"

on

Pilot Valve

Body

(pressurized)

N

2

/

C

N

/

1

O

(no pressure)

From

Port #4

on

Brunermatic

Valve

(no pressure)

Solenoid Valve

Solenoid Valve Not Energized

When Tank "Online"

Figure 27.

Installation 19

Page 24

Figure 28.

Tubing Installation

The tubing assembly is shipped in the same carton as the controller. The tubing is suppled in lengths pre-cut to connect

up to a 3” Brunermatic valve.

1. Using the tubing supplied, interconnect the controller, Brunermatic valve, and any accessory kits ordered with

the system. Refer to Figure 31, Figure 32, and Figure 33 for system tubing diagrams.

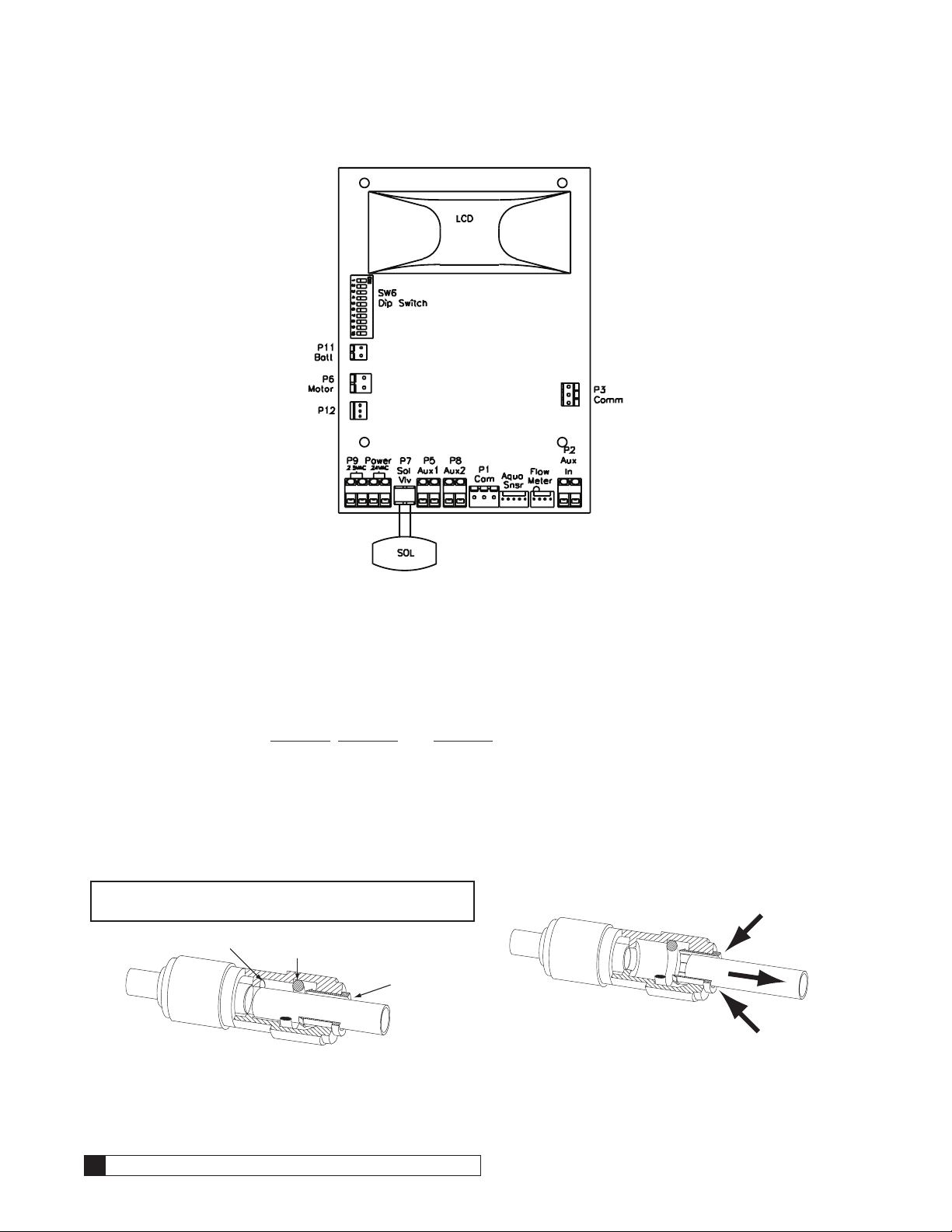

2. For ease of installation, some tube fittings on the system are the push-in type. Tubing is simply inserted into the

fitting collet to make a secure, leak free connection. Refer to Figure 29 and Figure 30 for details on proper connection and disconnection.

CONNECTION

To make a connection, simply push the tubing in by hand.

NOTE The fitting will grip before it seals. Make certain

the tubing is fully pushed into the tube stop.

TUBE STOP

Figure 29.

20 Culligan® CSM Series Filters

O -RING

COLLET

DISCONNECTION

To disconnect tubing, push in the collet against the face

of the fitting. With the collet held against the face of the

fitting, the tubing can be removed.

Figure 30.

20 Cat. No. 01016449

Page 25

CAUTION! The port numbers on the Brunermatic valve may not coincide with the ports on the

Brunermatic

MVP pilot valve. Refer to Table 6 for cross-reference information.

Table 6. Cross Reference Port Chart

Pilot Valve Brunermatic Valve

1 1

6

IN

DR

1

3/4

Valve

2

5

3 2

2 4

4 5

5 6

6 17

Figure 31.

6

IN

DR

1

3/4

Brunermatic

Valve

2

5

Figure 32. PARALLEL (Non-Progressive Flow) SYSTEM W/PLUGGED BYPASS

Cat. No. 01016449

Installation 21

Page 26

6

IN

DR

1

3/4

Brunermatic

Valve

2

5

Figure 33. ALTERNATING/PROGRESSIVE FLOW PARALLEL SYSTEM W/PLUGGED BYPASS

Electrical Installation

CAUTION! Observe the precautions listed below before electrical installation of your MVP control-

ler. Failure to do so may cause permanent damage to the controller.

• Follow the local electrical code requirements.

• Be sure electrical power is off and disconnected at the source before completing any wiring/cabling connections.

• Provide a dedicated 120-volt circuit for the MVP system to ensure maximum electrical protection.

• DO NOT include the MVP wiring cables in any conduit or raceway containing other 120-volt or higher circuits.

• Maintain a distance of at least 10 feet between the MVP controller and any electrical distribution panels, raceways

carrying 300 volts or more, and electrical motors of 1 horsepower or more.

• Use the cabling provided. Failure to do so may effect performance of the MVP controller adversely.

NOTE One transformer is required for each controller in the system. Do not attempt to operate multiple con-

trollers without a dedicated transformer for each or your system will experience operational difficulties.

22 Culligan® CSM Series Filters

22 Cat. No. 01016449

Page 27

Wiring Procedures and Diagrams

Preparation:

1. Loosen the two screws securing the controller

access cover (Figure 34) on each controller provided.

2. Using a small screwdriver, loosen all the terminal

strip binding screws on the main circuit board that

do not contain wires by turning counterclockwise

until the wire clamp has been fully opened (see

Figure 35).

Figure 35.

Figure 34.

Cat. No. 01016449

Installation 23

Page 28

Cable Routing

All input and output connections to the circuit board are 24 volt or less. Non-shielded type cable is provided for installation.

It is imperative that the correct type of cable is used to reduce the possibility of radiated electrical noise from entering the

wiring. This precaution will insure reliable operation of the controller.

Although the cables do not have to be run in conduit, it is necessary that long runs of cable be supported or protected by

strapping them to the equipment piping. If conduit will be used to route the shielded cables, three factors must be considered:

• DO NOT share the same conduit or raceway with 120 volt or higher circuits.

• Keep cables at least 6 inches away from 120 volt or higher electrical circuits.

• GROUND the conduit (if metallic) to a known “earth ground” location.

A series of holes are located on the sides of the controller (see Figure 36). Strain relief fittings are provided with the controller enclosure for interconnecting wiring. Install the plastic fittings as needed. Remove the compression nut and rubber

sleeve from each fitting. Prior to connection of the shielded cable wires to the circuit board, slide the compression nut and

sleeve over the cable for the wiring connections. When wiring is completed, apply a small amount of silicone to the rubber

sleeve and reassemble. This will assure all wiring is secure and assist in making the tightening of the fitting easier. Insert

the plugs provided to block any holes not used for wiring or other accessories.

Right Side View

Brine Reclaim Solenoid

Left Side View

Input Connection

for Flow Sensor

Output Connection

for Remote Accessories

Input Connection

for Remote Accessories

24 Volt Power

Input Connection

Blocking Solenoid for Alter-

nating Operation

Figure 36.

24 Culligan® CSM Series Filters

24 Cat. No. 01016449

Page 29

Circuit Board Layout

Outputs

The circuit board supports four outputs:

• Motor control (P6 Motor)

• Blocking valve (P7 Sol Vlv)

• Two programmable auxiliary outputs (P5 Aux 1 and P8 Aux 2)

• Controller interface (communication between multiple controllers) (P3 Comm).

CAUTION! Do not connect the P3 communication cable to the P12 circuit board connection. Doing

so will damage the circuit board.

CAUTION! Connecting 24V to the 2.5VAC connection on the circuit board will damage the circuit

board.

Schematic

Cat. No. 01016449

Figure 37.

Schematic 25

Page 30

24V Transformer

The MVP control is powered by a 24V/50VA transformer. If there are multiple controls in the system being installed, each

control will require its own transformer. It is recommended that the transformer be plugged into a dedicated 120V circuit.

CAUTION! Connecting 24V to the 2.5V connection on the circuit board will damage the circuit board

1. Connect one of the wires from the 24V cable to one of the outermost 24V transformer screw terminals

(Reference Figure 39). The other end of the wire should be connected to one of the 24 VAC terminals on the

MVP control circuit board (Figure 38).

2. Repeat the process for the other 24V power supply cable attaching the second wire to the opposite terminal.

24V transformer connection

Power Supply

ONE transformer is required for each Control

Figure 38.

Power to circuit board 24V

26 Culligan® CSM Series Filters

Power to circuit board 2.5VAC only required for Aqua-Sensor installations. Not used for filtration systems.

Figure 39.

26 Cat. No. 01016449

Page 31

Communication Cable and Blocking Solenoids - Multiple Units

NOTE Disregard this information and proceed to flow sensor schematic (optional) information when install-

ing single tank configurations.

CAUTION! Do not connect P3 communication cable to P12 circuit board connection. Doing so will

damage the circuit board.

Multiple units will require a communication cable. Refer to the following table for the quantity and cable part number

required for your system configuration.

Table 7.

System Configuration Cable Part Number Qty Required

Alternating Duplex 01016342 1

Duplex Parallel/Progressive 01016327 1

Triplex Parallel/Progressive 01016327 2

Cat. No. 01016449

Figure 40.

Schematic 27

Page 32

To Flow Meter Connection

To P3 Comm Port

on MVP Circuit Board, #1

(on MVP Circuit Board).

To P3 Comm Port

on MVP Ciruit Board, #1

To P3 Comm Port

on MVP Ciruit Board, #2

Flow Meter Connector

(from meter).

Figure 41. Duplex Alternating Cable (P/N 01016342)

To P3 Comm Port

on MVP Circuit Board, #2

PARALLEL

CABLE 01016327

Figure 42. Parallel/Progressive Cable (P/N 01016327)

Blocking Solenoid - Alternating/Progressive Systems

Refer to page 18 for installation of the blocking valve to the

MVP controller enclosure.

The end connector on the solenoid valve wiring attaches to the

Sol Vlv (P7) output connection on the primary circuit board. See

Figure 43.

On twin alternating systems, part number 01016369 duplex installation kit will be required. This kit contains:

• One (1) interconnect cable with end connectors.

• Two (2) solenoid valves with tubing and fittings.

To Flow Meter Connection

on MVP Circuit Board.

Additional communication

cable connections

are used when there

are 3 or more controls.

Connect end of

2nd-(01016327) cable

to this connector and

other end of cable

to P3 Comm Port on

3rd MVP Circuit Board.

28 Culligan® CSM Series Filters

Figure 43.

28 Cat. No. 01016449

Page 33

Flow Sensor Meter Schematic (optional)

The MVP controller is capable of detecting the signal from a Hall effect sensor device to provide flow rate information,

totalization and volume based regeneration initiation. The flow meter device is automatically detected when connected to

the controller.

There are several different types of flow measuring devices and differences in the wiring of the devices to the MVP circuit

board do exist. Refer to the following Figure 44.

Cat. No. 01016449

Figure 44.

Schematic 29

Page 34

Auxiliary Output #1 & #2

The Auxiliary Output #1 & #2 (P5 Aux 1 & P8 Aux 2 - reference Figure 45) are output triacs that can be programmed to

provide power to a “normally open” (normally no power to auxiliary output until power required) or a “normally closed”

contact (user choice). These 24 vac outputs can be used for energizing a relay coil only.

Refer to the section on Programming (page 40) for additional information on the uses of this feature.

30 Culligan® CSM Series Filters

Figure 45.

30 Cat. No. 01016449

Page 35

Auxiliary Input

One auxiliary input (P2 Aux In) input is provided for optional signal devices such as remote push buttons, differential pressure switches, hardness monitors, turbid meters, etc. for the purpose of receiving a regeneration signal.

Select an UN-POWERED contact within the remote device that will close when regeneration is desired. The duration of

the switch closure can be as low as 0 seconds; 6 seconds is the recommended minimum and default but can be as long

as 999 seconds. The contact must automatically open following the start of a regeneration sequence. Connect this contact

to the P2 Aux In terminal shown in Figure 46.

LCD

SW6

Dip Switch

P11

Batt

Motor

P12

P6

P9 Power

24VAC2.5VAC

P7

Sol

Vlv

Differential

Pressure

Switch

P5

Aux1

P8

Aux2

P1

Cam

Aqua

Snsr

Flow

Meter

P3

Comm

P2

Aux

In

Cat. No. 01016449

Figure 46.

Schematic 31

Page 36

Programming

Programming

NOTE Do not apply power to the controller(s) until instructed to do so. If power has been applied, simply

unplug the controller(s).

DIP Switches

The Culligan MVP controller uses a series of ten (10) DIP Switches to streamline the programming process. Figure 47

shows the DIP Switch strip placement on the circuit board and the abbreviated text indicating the function of each switch.

32 Culligan® CSM Series Filters

Figure 47. Dip Switches

32 Cat. No. 01016449

Page 37

Switch Definitions

The circuit board is shipped with all DIP switches in the off position. Prior to programming the controller some DIP

switches may need to be moved to the ON position. Because each switch serves a specific purpose, please review the

following information, moving the required switches to an ON position as necessary for each controller in the system. The

definitions and purpose are as follows:

Table 8. Switch Definitions

Switch # Abbreviation Definition Purpose

1 R/T Run/Test Off - Allows controller to function in a normal, operational mode.

2 0/00 Times 10/

Times 100

3 P/A Parallel/

Alternating

4 D/I Delayed/

Immediate

5 12/24 12 Hour

Clock/ 24

Hour Clock

6 -/TCB Time Clock

Backup

Disabled/

Enabled

7 SO/FI Softener/Filter Off - The unit shall be operated as a softener. Default time programmed for cycle

8 D/H Days/Hours Off - Time clock initiated regenerations will be programmed with an interval of

9 -/M Master Off/

Master On

10 -/BR Brine Reclaim

Off/On

On - Places controller in test mode to verify operation of the board components.

Off - The Maximum Capacity (maximum amount of water that can be treated),

Batch Sizes (volume of water to be treated), Batch (capacity) remaining and Total

Volume of Flow through the unit are displayed and should be multiplied by 10. The

X10 icon in the display will be illuminated.

On - The Maximum Capacity (maximum amount of water that can be treated),

Batch Sizes (volume of water to be treated), Batch (capacity) remaining and Total

Volume of Flow through the unit are displayed and should be multiplied by 100.

The X100 icon in the display will be illuminated.

Off - Allows multiple units to be capable of being online simultaneously. This

switch must be in the off position if the progressive flow feature is desired or if a

parallel mode of operation is required.

On - Indicates the controller will work with another to place one tank in standby at

any given time. If more than 2 units are connected one unit will be offline (standby)

at all times.

Off - Regeneration of a unit will occur at a user-selected time of day.

On - Regeneration shall occur immediately upon a controller receiving a valid regeneration initiation signal, regardless of the time of day.

Off - All time keeping functions shall be based on an AM/PM basis. The AM or PM

icon shall be lit in the display as appropriate.

On - Time keeping functions shall work on a 24-hour clock (military time). The

AM/PM display icons will be disabled.

Off - The time clock backup option is disabled.

On - Allows the user to enable the time clock function of the control as a backup

regeneration initiation option. This feature is used as a back up to a primary device

such as a flow meter, Aqua-Sensor or auxiliary input to ensure a regeneration is

initiated after a user specified period of time if the primary device does not initiate

the regeneration first.

#2 shall be 60 minutes. (If AquaSensor is connected default shall be 99 minutes.)

On - The unit shall function as a filter. The default time programmed for cycle #2

shall be 2 minutes

days (ranging from 1 to 99).

On - Time clock initiated regenerations will be programmed with an interval of

hours (ranging from 1 to 24). (Day of the week disabled)

Off - Single system operation only. Anytime multiple units are connected, one unit

must have the switch set to ON

On - Enables the progressive flow feature and multiple communication setup.

Only one controller in a multiple system should be designated as

the Master control.

Off - Brine reclaim option not enabled. Cycle two shall have a default value of 60

minutes (if Aqua-Sensor is connected default shall be 99 minutes).

On - Brine reclaim option is enabled. Cycle two shall be displayed as three sub-cycles; BR1 - Brine Draw/Slow Rinse (10 minute default time); BR2 - Brine Reclaim/

Slow Rinse (10 minute default time); BR3- Slow Rinse (10 minute default time).

Once the DIP switches have been properly selected for each controller, power may be applied and programming of the control(s) continued.

Cat. No. 01016449

Programming 33

Page 38

Programming - Key Pad Familiarization

Once the DIP switch settings have been established the Culligan MVP control is ready to accept user input. User input

is done through the keypad on the front of the MVP circuit board. Refer to Figure 48 for a description of the layout of the

keypad.

Display

Regeneration Key

Status Key

Statistics Key

Stand By Indicator

Toggle Up

Toggle Down

Figure 48.

Table 9.

Display Back lit LCD display. Six 12 segmented alpha-numeric characters with a decimal separating the first

and second character, a colon separating the second and third character positions and AM, PM, REGEN, Lock, x10, x100, RECLAIM, AUX 1, AUX 2, and MASTER icons.

Status Key Depress to enter and move through the programming steps.

Regeneration

Key

Statistics Key Each time depressed, the Statistics key will display statistical information such a flow rate, time of

Toggle Down

Key

Toggle Up Key In the programming mode this key will move the user through the programming function in an ascend-

Stand By

Indicator

34 Culligan® CSM Series Filters

Press and hold the key for five (5) seconds to initiate an immediate regeneration. When pressed during programming the time of day or time of regeneration, this key will allow the user to toggle between

the hours and minutes setting of timing program segments.

day. Use with the Toggle Down key to display other statistical information.

In the programming mode this key will move the user through the programming function in a descending mode. If depressed for greater than three seconds, the rate at which the display scrolls through

data will increase.

ing mode. If depressed for greater than five seconds, the rate at which the display scrolls through the

data will increase.

This key will also allow the user to manually step through the cycles of regeneration. When lit, indicates the controller is in an off line or stand by mode. If lit and the display shows the REGEN icon,

then the system is in a regeneration mode of operation.

34 Cat. No. 01016449

Page 39

Multiple Unit Communication Setup

Anytime two or more units are connected, each must have a specific ID # assigned. When new, a circuit board does not

have an ID #. Once used, a board will have an ID # assigned and saved in EEPROM. Please refer to the appropriate

paragraph concerning the establishment or re-establishment of a board ID#.

Boards With No ID# Established (Initial Programming)

1. Verify communication cable is properly connected to each board in the system.

2. One (and only one) circuit board in the system should have the #9 DIP switch (MASTER) setting turn to the ON

position.

3. On the Master unit, press Statistics once and then press “-” until “Unit 1 Master” is displayed. Wait a few sec-

onds for all other units to display, “Set ID”. This will be followed by the term “take 2” in the display.

4. Press Status on the second unit. The second unit display will show “ID 2” which indicates it now has a recog-

nized ID#. Once this occurs, the Master unit will display “Unit 2 Master” and all remaining units needing an ID #

will display “take 3”.

5. Repeat step four for each unit in the system and until all units have ID#’s and the Master unit shows all other

units accounted for.

6. When done assigning ID #’s, press Statistics once on the Master unit. This returns all other controllers back to

a time clock display.

7. The Master unit can now be programmed.

Establishing a New ID#

When adding a board to a new or existing system follow these steps to re-establish an ID# if the existing ID# matches that

of another board. (Multiple boards with identical ID#’s will initiate an error code of “ERR 4” in the display of the offending

board).

1. “ERR 4” will be displayed. On this unit, press and hold Status for (10) seconds. This will reset the board,

remove the error from the display and erase the ID# from EEPROM.

2. The board can now accept a new ID#.

3. Press Statistics once on the Master unit, then press “-” until “Unit # Master” is displayed (‘#’ represents how

many units are connected). After a few moments all units that require an ID# will display “Set ID” followed by

the display, “take #”. Those units that have an ID# will display “net ID” followed by “ID#”.

4. Pressing Status on the unit that requires an ID# will assign one.

5. Repeat the process for each unit requiring an ID#.

6. When done assigning ID #’s, press Statistics once on the Master unit. This returns all other controllers back to

a time clock display.

7. The Master unit can now be programmed.

Single Unit Communication Set Up

Erasing an ID# from a board to be used to operate a single unit.

1. If attached, disconnect communication cable from the desired unit. (If that unit happens to be the one with the

#9 DIP switch ON, then switch it off).

2. Wait 60 seconds (If the MASTER icon was indicated in the display, it will disappear).

3. Press the Statistics key once and then press “-” until “Unit 1 MASTER” is displayed.

4. Press and hold the Regeneration key for (3) seconds. The unit will home and the ID# will have been success-

fully erased.

Cat. No. 01016449

Programming 35

Page 40

Program Data Input

There are a couple of items to note that can make the programming the Culligan MVP control a little easier. They are:

Slew Rates This term refers to the speed at which the display moves through the input of material. For exam-

ple, holding down the “+” key for (5) seconds when inputting minutes for Time of Day will cause

the minutes to pass in (10) minute blocks of time. Pressing the “+” or “-” keys for shorter periods

(less than 5 seconds) will slow the rate. To move through the programming slowly, do not hold

down the “+” or the “-” keys.

Beeper A beeper is available (normally on) to assist the user by providing an audible tone (about 70

decibels) to signify valid (one beep) and invalid (three beeps) key presses. The beeper can be

deactivated in the programming mode. (If error occurs, beep will still be ON even if set to “NO”

programming.)

Programming Mode

Timeout

Program Input

Acceptance

NOTE Program steps marked with an asterisk (*) will be saved in EEPROM.

To begin programming, be sure all previous steps have been followed. Be sure power is supplied to the controller. Press

the Status key to begin and to move on from one completed programming step to another.

1. Time of Day* - (Always available)

Establishes the current time of day. The display indicates “tod” as shown

in Figure 49 before changing to “12:00 PM”.

To adjust the minutes or the hour setting, depress the Regeneration key

until the appropriate digits flash (Figure 50) then use the “-” or “+” keys

to scroll to the desired time. Pressing the “-” or “+” keys for 5 seconds

or more will cause the digits to scroll rapidly and at intervals greater than

one at a time. Pressing the Status key will save the setting and move to

the next programming step.

2. Time of Regeneration* - (Delay mode only, DIP switch 4 off or DIP 4 on

when DIP 6 is off.)

For delayed regeneration purposes. The display indicates “tor” as shown

in Figure 51. The default time is 2:00 AM. This function is adjustable in

30-minute increments.

To adjust the minutes or the hour setting, depress the Regeneration key

until the appropriate digits flash then use the “-” or “+” keys to scroll to

the desired time. Pressing the “-” or “+” keys for 3 seconds or more will

cause the digits to scroll rapidly and at intervals greater than one at a

time. Pressing the Status key will save the setting and move to the next

programming step.

3. Meter “K” Factor* - (Only active when a flow meter is attached)

Data input is the number of pulses a flow device emits to represents a

volume of water (gallons or liters). Initial display is “METEr” (Figure 52).

Refer to the information in Appendix A on page 73 for the appropriate

“K” factor for the flow-measuring device being used. The default setting is

50.0.

To adjust the “K” factor setting, depress the Regeneration key until the

appropriate digits flash (Figure 53) then use the “-” or “+” keys to scroll

to the desired setting. (Adjustable from 0.5 to 500). Pressing the “-” or “+”

keys for 3 seconds or more will cause the digits to scroll rapidly and at

intervals greater than one at a time. Pressing the Status key will save the

setting and move to the next programming step.

If there is no keypad activity for a (3) minute period while in the programming mode, the controller will exit the programming mode and return to a Time of Day display. Any setting that was

changed prior to the control timing out will revert back to the original value. Pressing the status

key saves the setting.

For programming information to be accepted, the Status key must be depressed prior to Programming mode timeout.

Figure 49.

Flashing Minutes

Figure 50.

Figure 51.

Figure 52.

Figure 53.

36 Culligan® CSM Series Filters

36 Cat. No. 01016449

Page 41

4. Auxiliary Input Delay* - (All modes)

“AUX IN” (Figure 54) programming is required only if the AUX In terminal

is being used (Such as with a differential pressure switch). This establishes the uninterrupted period of time (in seconds) that a signal must

be received through the auxiliary input before the controller is to react

by initiating a regeneration sequence. The default time is (6) seconds.

Figure 54.

Note that this feature is ignored if nothing is connected to the AUX input

terminal.

To adjust the seconds setting, use the “-” or “+” keys to scroll to the

desired number of seconds. (Adjustable from 0 to 999 seconds). Pressing

the “-” or “+” keys for 3 seconds or more will cause the digits to scroll rap-

idly and at intervals greater than one at a time. Pressing the Status

key will save the setting and move to the next programming step.

Figure 55.

5. Cycle 1 Time* - (All modes)

The backwash cycle is represented by “bw 10” (Figure 55) in the display.

The default duration of cycle 1 is 10 minutes. To adjust the minutes setting, use the “-” or “+” keys to scroll to the desired number of minutes.

(Adjustable from 1 to 99 minutes). Pressing the “-” or “+” keys for 3 seconds or more will cause the digits to scroll rapidly and at intervals greater

Figure 56.

than one at a time. Pressing the Status key will save the setting and move

to the next programming step.

6. Cycle 2 Time* - (All modes except if Brine Reclaim DIP switch 10 is set

to ON)

The brine/slow rinse cycle is represented by “br 60” (Figure 56) in the

display. The default duration of cycle 2 is 60 minutes if the DIP switch #7

is OFF (softener) or 2 minutes if DIP switch #7 is ON (filter). To adjust the

Figure 57.

minutes setting, use the “-” or “+” keys to scroll to the desired number of

minutes. Pressing the “-” or “+” keys for 3 seconds or more will cause the digits to scroll rapidly and at intervals

greater than one at a time. Pressing the Status key will save the setting and move to the next programming step.

7. Cycle 3 Time* - (All modes)