Page 1

More

Page 2

More

Page 3

More

Page 4

Page 5

HI-FLO® 52

AUTOMATIC WATER SOFTENERS

SPECIFICATIONS AND OPERATING DATA

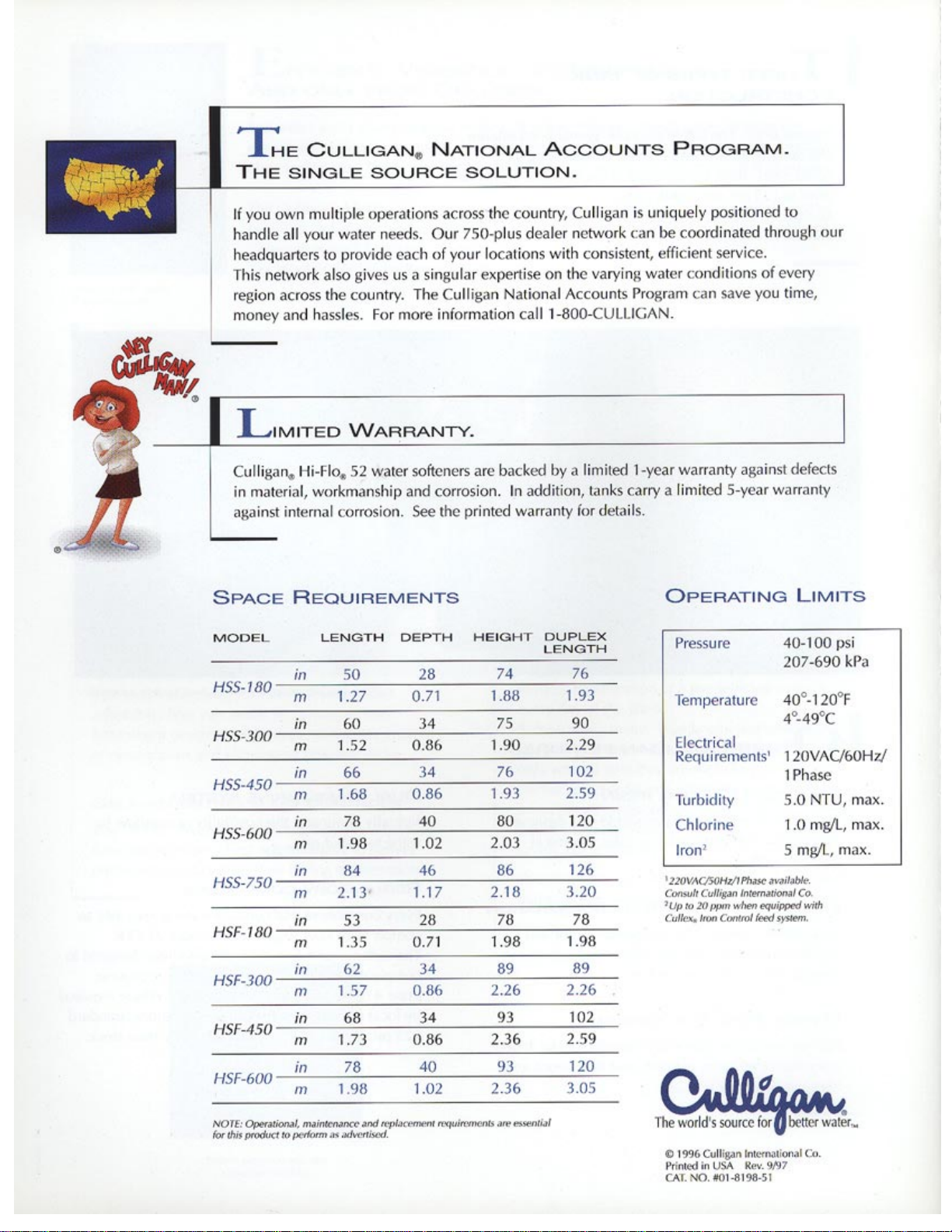

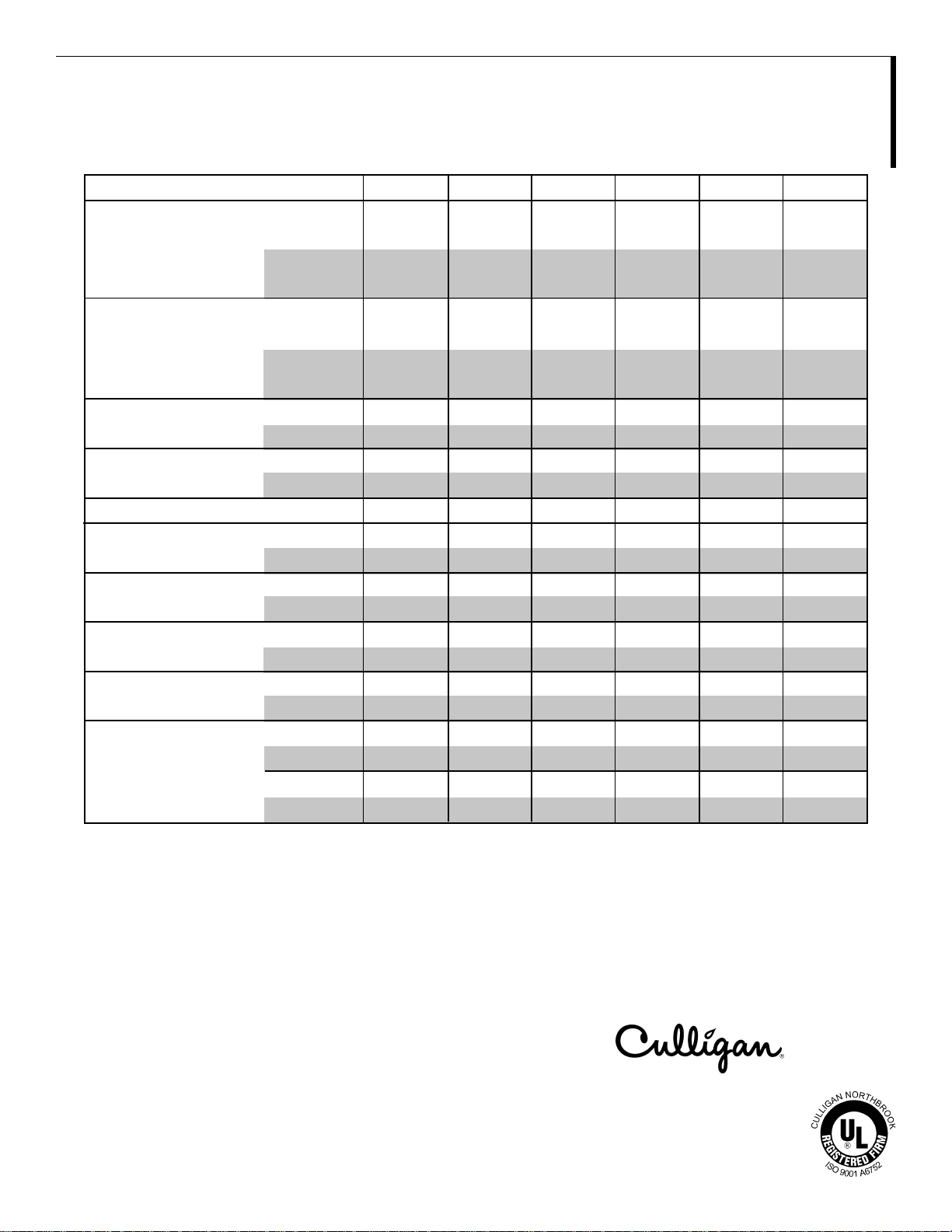

MODELS Model 180 Model 300 Model 450 Model 600 Model 750 Model 900

Capacity

Maximum pounds 90 150 225 30 0 375 450

@ Salt Dosage grams @ 11,664 19,440 29,160 38,879 48,599 58,320

Capacity1, grains @ 120,000 200,000 300,000 400,000 500,000 600,000

Minimum pounds 36 60 90 120 150 180

@ Salt Dosage grams @ 7,776 12,960 19,440 25,920 32,400 38,880

Service Flow,

Continuous m

Service Flow, gpm 9 5 108 12 0 125 123 125

Peak

Pipe Size, NPTI i n 2 2 2 2 2 2

Resin Volume cu. ft. 6 10 15 20 25 30

Media Tank, dia. x ht. in 20 x 54 24 x 54 30 x 54 36 x 60 36 x 60 42 x 60

Steel cm 51 x 137 61 x 137 76 x 137 91 x 152 91 x 152 107 x 152

Fiberglass in 21 x 69 24 x 72 30 x 72 36 x 72 NA NA

Brine Tank, in 24 x 48 30 x 48 30 x 48 36 x 48 42 x 48 42 x 48

dia. x ht. cm 61 x 122 76 x 122 76 x 122 91 x 122 107 x 122 107 x 122

Ship. Wt., approx. pounds 730 1050 1580 2050 2400 2750

Steel kilograms 330 480 720 940 1090 1 195

Fiberglass pounds 570 860 1250 1600 NA NA

1

, grains @ 180,000 300,000 450,000 600,000 750,000 900,000

kilograms 4 1 68 102 136 170 20 4

kilograms 1 6 27 41 54 68 82

2

34

gpm 67 78 90 97 95 104

3

/hr 15 18 20 22 22 24

m3/hr 22 25 27 28 28 28

liters 170 283 425 566 7 08 850

cm 53 x 175 61 x 183 76 x 183 91 x 183 NA NA

kilograms 260 390 570 730 NA NA

1 Exchange capacities based on treating water containing 10 grains per gallon of hardness (expressed as calcium carbonate), free of color, oil, turbidity and at

a continuous flow rate of approximately 50 percent of the peak flow rate. These are nominal capacities and will vary with influent water characteristics, water

temperature, and other factors.

2 Continuous flow at 15 psi (103 kPa) pressure drop.

3 Peak flow at 25 psi (172 kPa) pressure drop.

4 Operation of a softener at peak flow rate for extended periods of time may result in a slight reduction of softening capacity. This is due to premature

hardness breakthrough.

NOTE: Operational, maintenance and replacement requirements are essential for this product as advertised.

Commercial Systems

©2000 Culligan

1-800-CULLIGAN

www.culligan.com

Printed in USA Rev. 4/00

DCO 992587

SL-0075

Moore Part No.46945

Page 6

Page 7

Hi-Flo 52

More

CAD File: Soft_HF52_stl.dwg

Page 8

Hi-Flo 52

CAD File: Soft_HF52_frp.dwg

Page 9

ENGINEER’S SPECIFICATION

More

AUTOMATIC WATER SOFTENER

HI-FLO® 52

1.0 SCOPE

1.1 Provide as indicate d a vertical pressure t ype water softener system com plete with pressure vessel, softening

resin, control valve, brine maker and electronic controller. The system will be of an approved design as

fabricated by a manufacturer regularly engaged in the production of water treatment eq uipment. All equipm ent

and material will be suppli ed in compliance with t he specifications as intended for a com plete and operationa l

system.

¨ (Open Bidding Arrangement)

1.2 Qualified manuf acturers of water treatm ent equi pment of the type spec ified ar e Culligan Internati onal C ompan y

or the Engineer’s approved equal.

¨ (Closed Bidding Arrangement)

1.2 Qualified manufactur ers of water sof tener equipment must be engag ed in the m anufac ture of this equ ipm ent for

a period of not less than fifteen (15) years. Accepta bl e manufacturers are Cul ligan Int er nat ion al Company or the

Engineer’s approved equal.

2.0 GENERAL DESCRIPTION

¨ (Selection for statement of specific model)

2.1 The system specifications are based on Culligan International model ________________________________.

The purpose of the Cu lligan Interna tional Series H i-Flo

hardness from a known water supply to a level not to exc eed ________ mg/l, as determ ined by an accepted

ASTM or EDTA test method, when the system is operated at ________ gpm and in accordance with the

operating instructio ns. The system will be capable of suppl ying ________ gallons of sof tened water between

regenerations based on the influent water analysis listed in Section 3.1 of this equipment specification.

CUSTOMER:

DATE:

52 automatic water softener will be to r emove mineral

®

The systems perf ormance is rated at a desig n flow rate of ______ gpm with a rated pressur e drop of ______

psi, and will be cap able of a p eak flow ra te of _____ _ gpm for sustained periods of 90 m inutes with a pressur e

drop of ______ psi.

There shall be a quantity of ________ of the above described systems.

¨ (Selection for general statement)

2.1 The system, in compliance wi th the equipment specificati on, is described as an autom atic _______________

water softener system meeting the performance and design data requirements as hereinafter specified.

3.0 PERFORMANCE AND DESIGN DATA

3.1 INFLUEN T WATER ANALYSIS

Calcium, Ca:

Magnesium, Mg:

Total Hardness:

(Constituents above are expressed in ppm or mg/l as CaCO3 or as otherwise specified.)

Iron, Fe:

Manganese, Mn:

Total Dissolved Solids, TDS:

(Constituents above are expressed in ppm or mg/l.)

Turbidity, NTU:

Color:

pH:

Page 10

3.2 DESIGN PARAMETERS

More

Normal System Flow & Pressure Drop: gpm @ 15 PSI

Maximum System Flow & Pressure Drop: gpm @ 25 PSI

Backwash/Rinse Flow: gpm

Backwash Volume: gallons nominal

Daily Water Usage: gallons per day (gpd)

Daily Hours of Water Demand:

Operating Temperature Range: 40°–120°F

Operating Pressure Range (System): 30–100 PSI

Electrical Requirements: 120 Volt, 60 Hz, 1 phase (receptacle required)

System Dimension (L x W x H): ”L x

¨ (ASTM soap test method)

3.3 EFFLUENT WATER QUALITY ZERO GPG HARDNESS

¨ (Hardness EDTA test method)

3.3 EFFLUENT WATER QUALITY MG/L HARDNESS

4.0 EQUIPMENT SPECIFICATIONS

4.1 SOFTENER TANK(S)

Each system shall include ____ _ tank(s). Each sof tener tank shall be ___ __ inches in diam eter. The sideshell

height shall be _____ inches, suf ficient to allow for proper f reeboard space above the res in bed for adequate

expansion of the resin during backwashing.

”W x ”H

4.1.0 Tank Construction

¨ (Standard vessel)

Tank(s) shall be electrical welded pressure vessel quality low carbon steel construction rated for 100 psig

working pressure.

¨ (ASME vessel)

Tank(s) shall be electrical welded pressure vessel quality low carbon steel construction rated for 125 psig

working pressure and hydrostatic ally tested at 50% i n excess of the work ing pressure. Tank construction shall

conform to the latest edition of Section VIII for ASME Code pr essure vessels and shall be so stamped and

certified.

¨ (Fiberglass vesse l)

Tank(s) shall be manufactur ed of polyester reinforc ed by a continuous rov ing glass filam ent overwrap. T he top

opening will be 4”-8 UN threaded and the tank bottom will be supported on a molded structural base.

4.1.1 Access Openings

¨ (Steel and ASME vessel)

Each tank will be equipped with openings for mineral filling and periodic inspection.

4.1.2 Tank Supports

¨ (Steel and ASME vessel)

Tank supports shall be struc tural steel legs that perm it skid mounting a nd comply wit h Seismic Zone 4 loading

requirements, UBC importance factor 1.0.

¨ (Steel vessel)

4.1.3 Tank Finish – Exterior

Tank finish on the exterior shall be a h ig h so lids p olyurethane monoc hr omatic gloss en amel applied to a 1 .25 to

1.50 mils DFT over a 1.00 to 1.25 mil DFT prime coat.

Culligan Hi-Flo® 52 Softener Engineer’s Specification Page 2

Page 11

¨ (Steel vessel)

More

4.1.4 Tank Finish – Interior

Tank interior shall have near white sa ndb last and be coated to 8 to 10 mil DFT with an epoxy phenolic designed

specifically as a high chemical resistant, non toxic, odorless protective coating. The lining shall meet the

requirements of the US Federal Register, Food and Drug Regulations, Title 21, Chapter 1, Paragraph 175.300.

4.2 INTERNAL DISTRIBUTION

4.2.1 The upper distribution s ystem shall be of the baf fle type to dispense water laterally to avoi d channeling within

the resin bed.

¨ (20” models, 24” FG models)

4.2.2 The lower distribution system shall be of the s ingle point distributor t ype, constructed of PVC pipe a nd a fine

slotted strainer to provide even flow distribution through the resin bed. The distribution system shall be

embedded in a two layer subfill of washed inorganic material to support the resin bed.

¨ (24” steel models, 30” and larger models)

4.2.2 The lower distribution system s hall b e of the hub and radial arm type, constructed of PVC pi pe, a h ub r a dia l a nd

individual distributors arranged for even flow distribution through the resin bed. No distributor slots will face

upwards to minimize the opportu nity for channelin g. The distribution s yst em shall be embedded in a s i ng le layer

subfill of washed inorganic material to support the resin bed.

4.3 MAIN OPERATING VALVE

The main operating valve shall be of a top mount design constructed of corrosion resistant allo y material and

sized with 2 inch NPTI inlet and outlet connections. The main operating valve will have provision for either left-to

right or right-to-left plumbing flow to simplify installation while maintaining a forward facing timer for ease of

service.

Hard-coat anodizat ion of the valve shall be m andatory. The hard-anodized layer will be 2 mil in th ickness or

greater and shall be final coated with a flouroplate pol ymer to further enhanc e corrosion resis tance. The valve

shall be capable of passing a 1000 hour/5 per cent salt spra y test without sig ns of cor rosion. The valve f inishing

process shall be co nsidered b y the USEPA t o be an enviro nmentall y friendl y process. T he valv e body m aterial

shall be considered as generally safe by the USFDA.

The main operating valve will provide water to service through two smooth-port diaphragm valves. The

diaphragm valves shall be slow opening and closing, free of water hammer. Regeneration will be controlled

through two (2) plastic pistons operating through Teflon® seals.

The main operating valve sha ll incorporate self adjusti ng flow regulat ors to control the r ate of flow and prevent

resin loss during b ac k wash, br i ne/r ins e a nd f as t r inse /r ef ill s teps of r ege nerat ion, regardless of system press ur e

fluctuations between 30 and 100 psi.

The main operating valve s hall be des igne d and m anuf actured b y the s am e manuf actur er as the wat er so ften er

system.

¨ (Single units only – hard water bypass)

The unit shall be supplied so that the valve will allow aut omatic bypass of untreated water durin g regeneratio n.

The bypass shall be integral to the main operating valve body and be capable of being easily modified to

prevent hard water bypass.

¨ (Single units only – NO hard water bypass)

The unit shall be supplied so that the valve will not allow automatic bypass of untreated water during

regeneration. The bypass shall be integral to the main operating valve bod y and be capable of being easil y

modified to allow hard water bypass.

Culligan Hi-Flo® 52 Softener Engineer’s Specification Page 3

Page 12

4.4 CONTROLS

More

A fully integrated pr ogrammable m icro-process or driven electronic c ontroller shall be provided to au tomatically

cycle the main operating valve through the regeneration sequence.

The electronic controller shall be des igned and m anuf actured b y the s am e manuf acturer as the wat er treatm ent

equipment.

The controller sha ll sequence all s teps of an autom atic regenerat ion and autom atically r eturn the s oftener to a

service or stand-by mode. The init iating tim e and/or v olume s etpoints sh all autom aticall y reset up on initi ation of

the regeneration sequence.

The controller shall allow for a manual initiation of the automatic regeneration sequence by utilizing a

regeneration button on the face of the controller.

The controller sha ll be h oused in an enclosure c ons truc t ed t o NE MA 3 e nc losur e s tand ards . The controller s hall

include a keypad, cap able of programming a ll controller functi ons, located ins ide the enclosure. Also included

with the keypad shall be a fluoresc ent alpha-numeric dis play capable of sho wing all inform ation necessary for

programming the controller and operating the softener.

4.4.1 System control options

¨ (Time Clock, Single Unit)

An operator selec ted program of a tim e-initiated regener ation for single u nits shall be available. The controll er

shall be capable of being entirely programmed in the field without additional interface devices. The operator

shall be able to sel ect regeneration to occur after a specified number of days. The electronic controller shall

indicate various functions that include time of day, time of regeneration, number of regenerations in the last

fourteen (14) days, number of days since the last regeneration and unit in regeneration.

¨ (Meter Initiated, Single Unit)

An operator selected program of immediate or delayed volum e initiated regeneration for s ingle units shall be

available. The contr oller shall be capab le of being entirel y programmed in the field witho ut additional interface

devices. The electronic controller shall indicate various functions that include time of day, time of delayed

regeneration, insta ntaneous flow rate, v olume remaining bef ore next reg eneration, num ber of regenerat ions in

the last fourteen (14) days, number of days since the last regeneration and unit in regeneration.

¨ (Aqua-Sensor® Initiated, Single Unit)

An operator selected program of immediate or delayed hardnes s initiated rege neration for s ingle units shal l be

available. An Aqua-Sensor® control probe will be inserted into the resin bed and will sense the need for

regeneration based on the differential water hardness reading and will signal the circuit board to initiate

regeneration. The s ystem will com pensate f or variat ions in water hard ness and temper ature and will requir e no

field adjustments when operat ed within the normal temperature range of the sof tener. The controller shall be

capable of being e ntirely program med in the field without addit ional interf ace devices. The electronic controller

shall indicate various f unctions tha t include tim e of da y, time of dela yed regeneration, number of regenerations

in the last fourteen (14) days, number of days since the last regeneration and unit in regeneration.

¨ (Time Clock, Parallel Twin Unit)

An operator selected program of a time initiated regener ation for par allel twin c onfigurations shall be avail able.

The controller shall be capable of being programmed in the field without additional interface devices. The

electronic controller shall indicat e various functions that include time of day, time of regeneration, num ber of

regenerations in the last fourteen (14) days, number of days since the last regeneration and unit in

regeneration. The controller must communicate via a single pre-wired cable assembly, simultaneous

regenerations shall not be poss ible.

¨ (Meter Initiated, Parallel Twin Unit)

An operator selected program of immediate or delayed volume initiated regeneration for parallel twin

configurations shall be available. The controller shall be capable of being programmed in the field without

additional interface devices. The controller shall indicate various functions that include time of day, time of

delayed regeneration, instantaneous flow rate dis play, volume rem aining before next regener ation, number of

regenerations in the l as t f our teen (14) d a ys, t he days since the last re gen er ati on and indicat io n if the s of tener is

in regeneration. The controller must communicate via a single pre-wired cable assembly, simultaneous

regenerations shall not be poss ible.

Culligan Hi-Flo® 52 Softener Engineer’s Specification Page 4

Page 13

¨ (Meter Initiated, Alternating Twin Unit)

More

An operator selected program of immediate volume initiated regeneration for alternating twin configurations

shall be available. The contro ller shall be c apable of being programmed in t he field without ad ditional inter face

devices. The contro ller shall indicate various functions that incl ude tim e of day, ins tantaneo us flo w rate displa y,

volume remaining bef ore next regeneration, number of regenerations in the last fourteen (14) days, the d ays

since the last regenerat ion and indication if the softener is in stand-by or reg eneration. No exter nal alternatin g

devices will be acceptable. T he alternating function m ust be contained in the sequenc ing controller and each

controller must c ommunicate via a single pre-wired c able assembly, simultaneous reg enerations shall not be

possible.

¨ (Aqua-Sensor® Initiated, Parallel Twin Unit)

An operator selected program of immediate or delayed hardness initiated regeneration for parallel twin

configurations sha ll be available. An Aqua-Sensor® c ontrol probe will be inserted in to the resin bed and will

sense the need for regeneration based on the differential water hardness reading and will signal the circuit

board to initiate reg eneration. The system will compens ate for variations in water hardness and temperature

and will require no field adjustments when operated within the normal temperatur e range of the softener. The

controller shall be capable of bei ng programmed in the f ield without add itional interface de vices. The contr oller

shall indicate various f unctions tha t include tim e of da y, time of dela yed regeneration, number of regenerations

in the last fourteen (14) days, the days since the last regeneration and indication if the softener is in

regeneration. The controller must communicate via a single pre-wired cable assembly, simultaneous

regenerations shall not be poss ible.

¨ (Aqua-Sensor® Initiated, Alternating Twin Unit

An operator selec ted program of immediate har dness initiated regenerat ion for alternating twin c onfigurations

shall be available. An Aqua-Sensor® control probe will be inserted into the resin bed and will sense the need for

regeneration based on the differential water hardness reading and will signal the circuit board to initiate

regeneration. The s ystem will com pensate f or variat ions in water hard ness and temper ature and will requir e no

field adjustments when operat ed within the normal temperature range of the sof tener. The controller shall be

capable of being programmed in the field without additional interface devices. The controller shall indicate

various functions that include time of day, number of regenerations in the last fourteen (14) days, the days since

the last regeneration and indic at ion if the soften er is in st an d-by or regeneration. No externa l al ter na tin g d ev ices

will be acceptable. The alternati ng function m ust be contained in the sequencing c ontroller and e ach controller

must communicate via a single pre-wired cable assembly, simultaneous regenerations shall not be possible.

4.4.2 In addition the following functions shall be provided as part of the system controller:

Memory back-up protection: The controller shall have memory back-up protection via at least two methods,

each capable of retaining the selected operating program and its default settings indefinitely.

Regeneration sequenc e timers: The control ler shall allow control of up to three individua l regeneration c ycles,

each programmable from 0 - 99 minutes.

Lockout function: T he con tr ol ler s ha ll include a lockout to prevent unauthori zed pers onn el f r om altering progra m

data.

Regeneration override: The controller shall include a function to direct pre-programmed regeneration after 3

days without input signal (European requirement).

¨ (Included with metered unit and flow sensor selection – following two options)

Flow rate indication: T he controller sha ll include a flow rate indicator. T he flow rate shall be displayed t hrough

the controller display.

Totalizer: The controller shall include a totalizer function. The totalizer value shall be displayed through the

controller display.

Culligan Hi-Flo® 52 Softener Engineer’s Specification Page 5

Page 14

¨ (Meter Initiated systems ONLY)

More

4.4.3 Flow Sensor(s)

¨ (1.5” Plastic Turbine Meter)

A flow sensor package shall be provided consisting of an turbine-type Hall Effect; the package shall include a

total of _____ flow sensors with fittings.

The fitting provided shall be a 1-1/2 inch threaded Noryl housing. A 4-foot length of cable shall be provided for

direct connection to the system controller.

The flow sensor package provided shall be functional within the flow range of 1 to 60 gpm.

The operating temperature/pressure range of flow sensor fittings shall be 34°F - 100°F at 140 psi max.

The wetted surfaces of the flow sensor shall be constructed of non-corroding materials.

The flow sensor shall have an accuracy to 2% over full range.

¨ (2.0” Meter)

A flow sensor package shall be provided consisting of an insertion-type Hall Effect flow transducer with an

appropriately sized installation fitting; the package shall include a total of _____ flow sensors with fittings.

The fitting provided shall be 2.0 inches, compatible with the specified piping. It will be designed to allow ease of

removal of the sensor for inspection without modification of the piping system. A 25-foot length of cable shall be

provided for direct connection to the system controller.

The flow sensor package provided shall be functional within the flow range of 3 to 275 gpm and will be provided

with a threaded tee flow sensor installation fitting.

The operating temperature/pressure range of flow sensor fittings shall be 34°F - 100°F at 140 psi max.

The wetted surfaces of the flow sensor shall be constructed of non-corroding materials such as polypropylene,

black Polyvinylidene (PVDF) and titanium.

The flow sensor shall have an accuracy to 1.5% over full range.

4.5 EXCHANGE RESIN

The ion exchange resin shall be virgin high capacity “standard mesh” of sulfonated polystyrene type stable over

the entire pH range with good resistance to bead fracture from attrition or osmotic shock. Each cubic foot of

resin will be capable of removing 30,000 grains of hardness as calcium carbonate when regenerated with 15

lbs. of salt. The resin shall be solid, of the proper particle size of 20-50 mesh, U.S. standard screen and will

contain no agglomerates, shells, plates or other shapes that might interfere with the normal function of the water

softener. The resin shall be manufactured to comply with the food additive regulation 21 CFR 173.25 as set

forth by the USFDA.

The system shall include _____ cubic feet of exchange resin per vessel and a total of _____ cubic feet of resin

for the system.

4.6 BRINE SYSTEM

Provide a complete brine system consisting of a plastic tank, salt platform, brine well, an automatic brine valve

and all necessary fittings for operation with the water softening system. The system shall consist of a combined

brine measuring and salt storage tank with salt platform. The tank will be sized ____ inches x _____ inches; the

system will include a total of _____ brine tank(s).

The brine tank will be equipped with a float operated non-corrosive field serviceable brine float valve for

automatic control of brine withdrawal and fresh water refill.

The brine valve will automatically open to admit brine to the resin tank during eduction and close automatically

providing positive shut-off to prevent air from entering the system. The brine valve will also regulate the flow of

soft water into the brine tank during refill. The brine valve works with the timed fill feature of the main operating

Culligan Hi-Flo® 52 Softener Engineer’s Specification Page 6

Page 15

valve controls to admit the correct volume of fresh water to the brine tank in accordance with the salt dosage

setting on the controls. The brine valve will include a float operated safety shut-off valve as a back up to the

timed refill from the main operating valve control to prevent brine tank overflow.

4.7 ACCESSORIES

(All Optional selections)

4.7.1 ¨ Water test kits for hardness tests will be supplied.

4.7.2 ¨ Pressure Gauges for hard water inlet and soft water outlet.

4.7.3 ¨ Sampling Cocks for hard water inlet.

4.7.4 ¨ Vacuum Breaker for protecting Fiberglass tanks from vacuum.

5.0 INSTRUCTIONS

_____ complete sets of installation, operating and maintenance manuals shall be provided.

6.0 FIELD SERVICE

The services of a factory authorized service representative can be made available to supervise, inspect and

provide operator training as required for initial start-up and system operation. Contact your local Culligan dealer

for service rates and scheduling.

7.0 WARRANTY

A single written warranty must be provided from the manufacturer of the water softener system covering

workmanship and materials.

Rev. 10/01

Culligan Hi-Flo® 52 Softener Engineer’s Specification Page 7

Loading...

Loading...