Page 1

CULLIGAN

Cat. No. 01021161

Rev. A 10/16/08

DCO # 010703

Installation,

Operating and

Service

Instructions

®

Global Electronic (GBE)

Softener & Filter Controller

For Commercial/Industrial Applications

Models from 2008

©2008 Culligan International Company

Printed in USA

Page 2

Read this Manual First

Before you operate the Culligan Global Controller, read this manual to become familiar with the device and

its capabilities.

Watch for Special Paragraphs

Please read the special paragraphs in this manual. Examples are shown below.

NOTE A Note provides information or highlights a procedure.

CAUTION

A Caution tells how failing to follow instructions might cause

injury or damage the equipment in some way.

About this Manual

Contents

This manual:

• familiarizes the operator with the equipment

• explains installation and setup procedures

• provides basic programming information

• explains the various modes of operation

• gives specifications and troubleshooting information

WARNING! Electrical shock hazard! Unplug the unit before removing the cover or accessing any internal control parts.

WARNING! This device complies with part 15 of the FCC rules subject to the two following conditions: 1) This device may

not cause harmful interference 2) this device must accept all interference received including interference that may cause

undesired operation.

CAUTION! To reduce the risk of fire, use only No. 26 AWG or larger telecommunicaitons line cord.

This equipment complies with Part 15 of the FCC rules. Any changes or modifications not expressly approved

by the manufacturer could void the user’s authority to operate the equipment. Changes or modifications not

expressly approved by the party responsible for compliance could void the user’s authority to operate

the equipment.

Products manufactured and marketed by Culligan International Company (Culligan) and its affiliates are protected by patents issued or pending in the United States and other countries. Culligan reserves the right to change the specifications referred to in this literature at any time,

without prior notice. Culligan, AquaSensor, Tripl-Hull, and SoftMinder are trademarks of Culligan International Company or its affiliates.

The product is covered by the following patents:

Softener and/or filter: US 5073255, 5273070, 6457698, 4534867: Israel 095754

Sensor option: US 5699272

Other US and foreign patents pending.

i CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 3

Installation,

Operating and

Service

Instructions

®

CULLIGAN

GLOBAL ELECTRONIC (GBE) SOFTENER

& FILTER CONTROLLER

Table of Contents . . . . . . . . . . . . . . . .Page

Important Safety Information ....................................... i

Controller Features ..................................................1-2

Operation ....................................................................3

Installation ...............................................................4-6

Wiring Schematics .................................................7-17

Circuit Board Layout ..............................................7

Transformer ........................................................8-9

Brine Refill Valve ................................................. 10

Communication Cable ......................................... 11

Progressive/ Parallel Flow ...................................12

Alternating ...........................................................13

Flow Meters .........................................................14

Aqua-Sensor ........................................................15

Aux Outputs .........................................................16

Aux Input .............................................................17

Programming .......................................................18-20

Key Pad Operation .............................................19-20

Overview...................................................................21

Commercial Setup .................................................... 22

First Time Setup ..................................................23-27

Customizing the Setup ........................................28-32

Progressive Flow .................................................29

Regeneration .......................................................30

Cycle Times .........................................................31

Regeneration Triggers .........................................32

Installation of Accessories ...................................33-45

Aqua-Sensor ........................................................33

Beeper Mode .......................................................33

Smart brine Tank Sensor ....................................34

Wireless Remote ............................................35-37

Modem ............................................................37-41

Low Meter ............................................................41

Progressive Flow ............................................41-42

Brine Reclaim .................................................42-43

Service Phone Number ......................................44

Auxiliary Boards ..................................................46-48

Manual Regeneration ...............................................49

Manual Cycling ......................................................... 50

System Information .............................................51-52

Error & Alert Codes ..................................................53

Diagnostics / Statistics ........................................54-57

Check Sensors ....................................................55-57

Menu Lockout ........................................................... 58

Menu Flow Chart .................................................59-62

Appendix A - Meter K-Factors ..................................63

Appendix B - Parts & Accessories ..........................64

Appendix C - PLC Output....................................65-68

Appendix D - Control Settings ..................................69

Index .........................................................................70

TABLE OF CONTENTS ii

Page 4

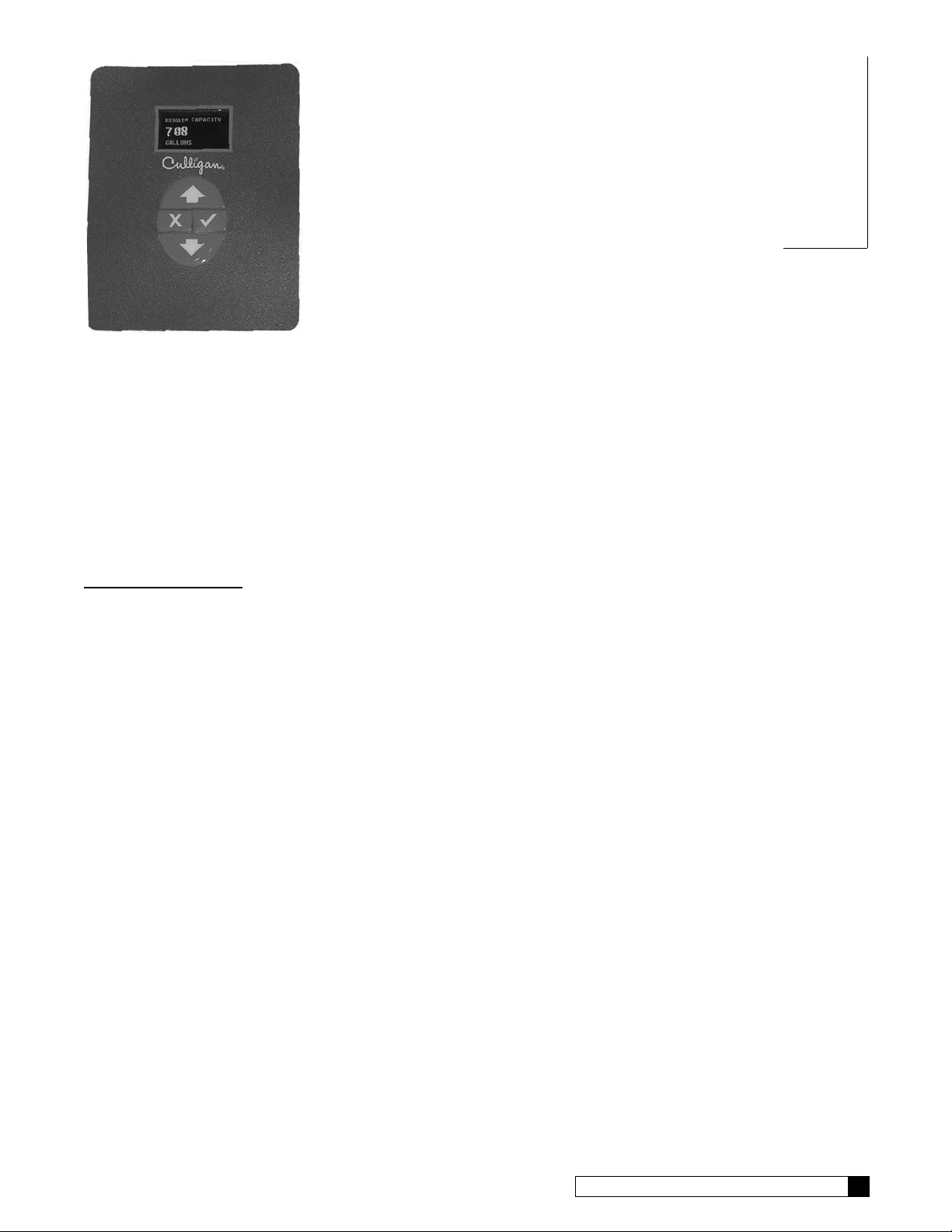

Controller Features

The Culligan Global Electronic control (GBE) primary function is to

initiate and control the regeneration process via methods that are most

convenient and cost effective for the customer while offering many

operational features and benefits. The controller is designed to operate a

wide range of existing and new softener and filtration valves.

Take control of your system and your productivity

The Culligan Global Electronic Controller (GBE) is an advanced design

engineered to handle regeneration and monitoring of your water

treatment equipment. It offers powerful programming options that

can be used to operate and monitor any softener or filter system. It

also provides sensing capabilities, expanded communications and a

multifunction keypad—all in one simple to use unit.

GBE Controller Features

Advanced Lighted OLED Display

•

The user is guided through brightly lit graphical menu screens

with clear, multi-line, full text prompts

Membrane Keypad

•

The keypad uses sealed contacts for programming. No buttons to get dirty

Program Beeper

•

Emits an audible beep when keys are depressed to help identify

valid (short beep) or invalid (3 short beeps) pushes. Can be

enabled or disabled.

Power Source

•

Electrical power required is 24 Volt 50/60 Hz AC current. A UL

listed plug-in transformer (120V/24V) is provided.

Time of Day

•

Displays current time of day in either 12-hour or 24 hour format

Real Time Clock with a 5 Year Battery Back-up

•

Keeps accurate time even during a power outage. Updates

automatically when the GBE is equipped with optional modem

capability

English or Metric Values

•

Displays can be set to either English or Metric

Regeneration Interval

•

Provides the ability to initiate a time clock regeneration based on a number of days (1 to 99) or a specific

day of the week.

Regeneration Start Delay

•

Allows a user determined number of hours (0-9) to be set for the purpose of increasing the amount of

time between regenerations in a multi unit installation.

Auxiliary Input

•

Capable of accepting a remote signal from a dry contact device such as an operator push button for the

purpose of initiating a regeneration sequence

Auxiliary Output on Alarm

•

Capable of sending a signal when an alarm/error is recognized

Expansion Board for Additional Outputs

•

o Control blocking valves

o Control external solenoids or chemical feeders

Figure 1

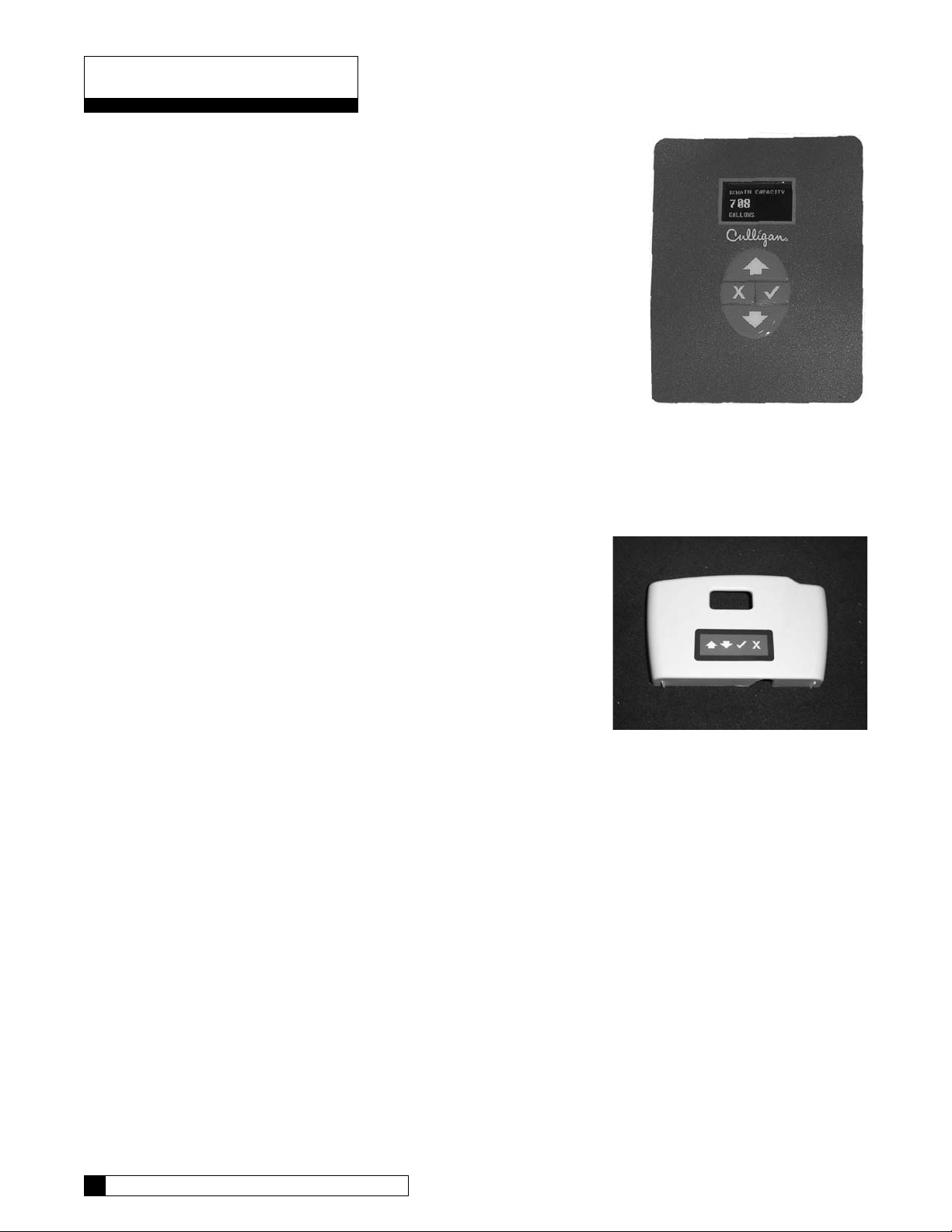

Figure 2

1 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 5

Progressive Flow Trip Point

•

Allows multiple tank systems operating with flow meters to bring tanks on-line or off-line as facility flow

demands increase or decrease

Multiple Unit Communication

•

A communication cable interconnects multiple units to operate the controller in the Progressive Flow

mode and prohibits them from regenerating at the same time.

Diagnostics

•

The user can check the operation of sensors, progressive flow communication, motor positions, or an

optional wireless display

Transformer is UL and CUL Listed

•

RoHS Compliant

•

Optional GBE Features

Flow Meter/Sensor Input

•

Supports various types of Hall effect flow sensors using a programmable “K” factor to initiate a

regeneration sequence

AquaSensor Input

•

Supports the patented digital Culligan AquaSensor technology used to efficiently initiate and control a

regeneration sequence

Telephone Modem

•

o Calls in reports on regenerations and alarm conditions

o Automatically updates time and date when calling in

o Automatically checks for and installs and firmware updates when calling in

Wireless Remote Display

•

Displays the current status of the unit. It can be located up to 200 feet away from the GBE controller

(depending on building and interference). The telephone modem can optionally be installed in the remote

display

Smart Brine Tank Probe

•

This probe monitors conditions inside the brine tank.

o Predicts when more salt is needed

o Detects the presence of a salt bridge

o Detects eductor line plugging

o Signals brine tank overfilling condition

Controller Features

CONTROLLER FEATURES 2

Page 6

Operation

Modes of Operation

Time Clock

The controller will initiate a regeneration based upon a time schedule of intervals of days (i.e., every 3 days) or

on a specific day of week schedule (i.e., Mondays, Wednesdays and Saturdays). Because regeneration will

occur at the prescribed schedule regardless of water use, this method is usually the most inefficient method of

water softener operation.

Flow Meter/Sensor

When a flow meter or sensor is connected to the controller circuit board, the controller has the ability to measure

the amount of water treated and initiate a regeneration sequence based upon the gallon capacity of the water

treatment equipment. The controller can delay the regeneration signal until a convenient time of day (known as

a delayed regeneration) or act and initiate the regeneration sequence as soon as the signal is received (known

as immediate regeneration).

When installing an alternating duplex system (one tank on-line, the other in standby), only one flow measuring

device is required to be installed in the common outlet header of the system. Parallel systems (multiple tank systems, all on-line simultaneously) require one flow device for each mineral tank in the system.

This method is a proven, cost effective means to operate a water softening system.

Aqua-Sensor (Softener use only)

The Aqua-Sensor detects when a softener resin bed has reached its point of exhaustion and, as a result, initiate

a regeneration sequence. This is the most cost-effective method of operation and may be combined with any of

the operational modes previously described.

Progressive Flow

The Progressive Flow mode is used with up to six and as few as two mineral tanks in a system. It allows more

than one tank in a system to either be on-line or off-line depending upon the downstream flow demand. If flow

demand is greater than the flow capability of the tank on-line, another tank can be brought on-line to help satisfy

the excess demand. Once the demand has decreased, the second tank is returned to a standby mode and the

system reverts to just one tank on-line providing treated water.

The progressive flow mode of operation relies on a user programmable set point or Trip Point. The Trip Point

is a unit of flow (gallons or liters) on a per minute basis. Once attained the trip point will cause the second unit

(in multiple resin tank system) to come on-line. Each additional tank in the system will subsequently be brought

on-line as multiples of the trip point are attained. (Example: a 3 tank system with a trip point of 50 gpm will bring

two tanks on-line once the facility flow demands is equal to or greater than the 50 gpm trip point. Should the flow

demand reach 100 gpm or more, the third tank shall be brought on-line.)

Additional tanks shall be returned to stand-by once the facility flow demand is <95% of the trip point for two

tank systems, <95% of 2X the trip point for triplex systems and <95% of 3X the trip point for quad systems, and

remains there for 60 seconds.

Utilizing the progressive flow feature may allow the owner to use smaller units, resulting in the potential for

reduced capital and operation costs.

Differential Pressure (Filters only)

When combined with an optional differential pressure device, the Culligan MVP controller has the ability to

initiate a backwashing sequence when the pressure differential across the media bed reaches a preset amount

(usually 8 to 10 psi).

3 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 7

Installation

ELECTRICAL INSTALLATION

CAUTION!

Observe the precautions listed below before electrical installation of your GBE controller.

Failure to do so may cause permanent damage to the controller.

1. Follow the local electrical code requirements.

2. Be sure electrical power is off and disconnected at the source before completing any wiring/cabling

connections.

3. Provide a dedicated 120-volt circuit for the GBE system to ensure maximum electrical protection.

4. DO NOT include the GBE wiring cables in any conduit or raceway containing other 120-volt or higher

circuits.

5. Maintain a distance of at least 10 feet between the GBE controller and any electrical distribution

panels, raceways carrying 300 volts or more, and electrical motors of 1 horsepower or more.

6. Use the cabling provided. Failure to do so may effect performance of the GBE controller adversely.

Note: One transformer is required for each controller in the system. Do not attempt to operate multiple

controllers without a dedicated transformer for each or your system will experience operational

difficulties.

Installation 4

Page 8

Installation

WIRING PROCEDURES AND DIAGRAMS

Preparation

1. Loosen the screws or latches securing the controller access cover (Figure 3 or 4) on each controller

provided.

2. Using a small screwdriver, loosen all the terminal strip binding screws on the main circuit board that do

not contain wires by turning counterclockwise until the wire clamp has been fully opened (see Figure 5).

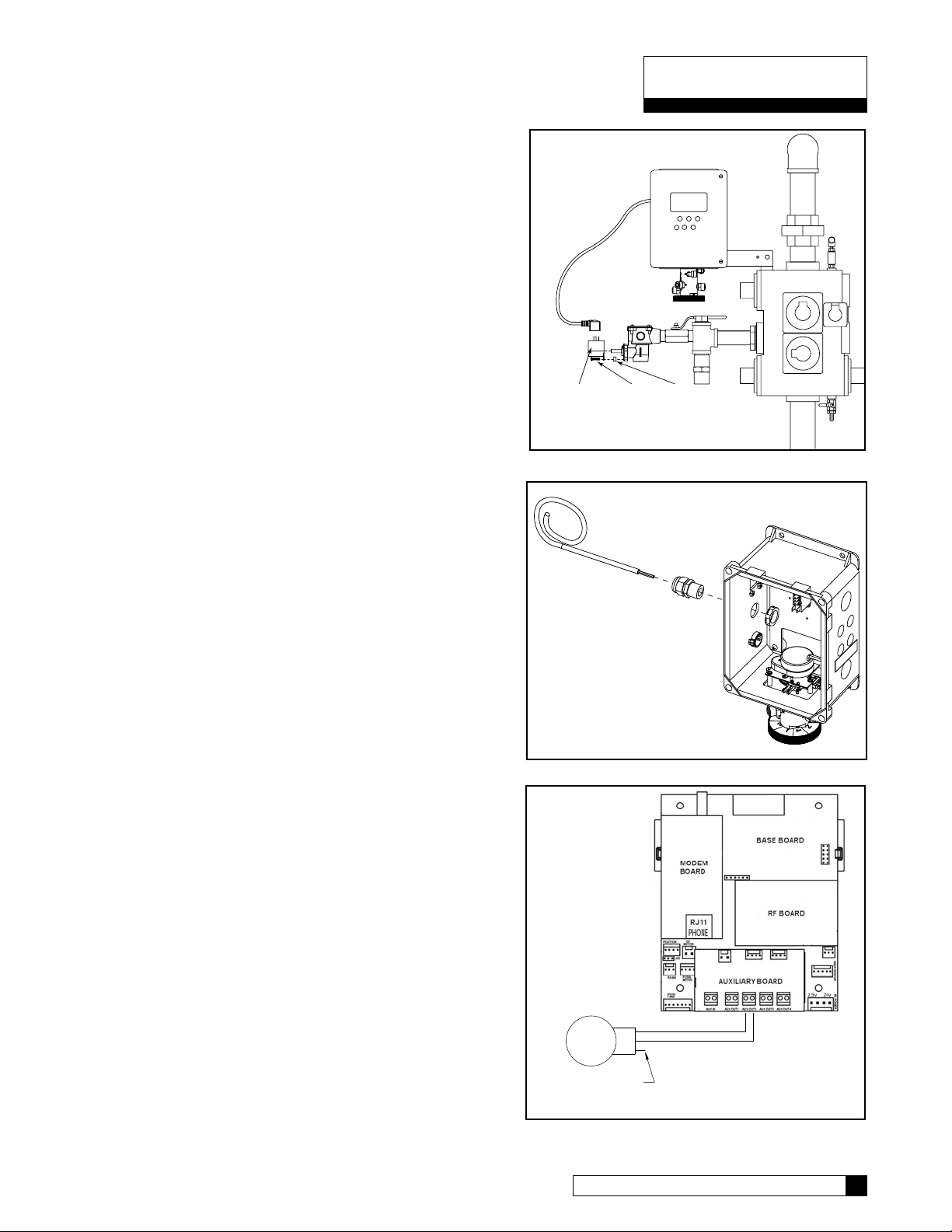

Figure 3

Figure 4

Figure 5

5 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 9

Installation

Cable Routing

All input and output connections to the circuit board are 24 volt or less.

Although the cables do not have to be run in conduit, it is necessary that long runs of cable be supported or

protected by strapping them to the equipment piping. If conduit will be used to route the shielded cables, three

factors must be considered:

1. DO NOT share the same conduit or raceway with 120 volt or higher circuits.

2. Keep cables at least 6 inches away from 120 volt or higher electrical circuits.

3. GROUND the conduit (if metallic) to a known “earth ground” location.

A series of holes are located on the sides of the controller (see Figure 6 and 7). Strain relief fittings are provided

with the controller enclosure for interconnecting wiring. Install the plastic fittings as needed. Remove the compression nut and rubber sleeve from each fitting. Prior to connection of the cable wires to the circuit board, slide

the compression nut and sleeve over the cable for the wiring connections. When wiring is completed, apply a

small amount of silicone to the rubber sleeve and reassemble. This will assure all wiring is secure and assist

in making the tightening of the fitting easier. Insert the plugs provided to block any holes not used for wiring or

other accessories.

Right Side View

Left Side View

Brine Reclaim Solenoid

(optional)

Input Connection

for Flow Sensor

Output Connection

for Remote

Accessories

Input Connection

for Remote

Accessories

24 Volt Power

Input Connection

Brine Reclaim Solenoid

(optional)

Brine Refill Valve

Figure 6 Figure 7

Blocking Solenoid for

Alternating Operation

Installation 6

Page 10

Schematic

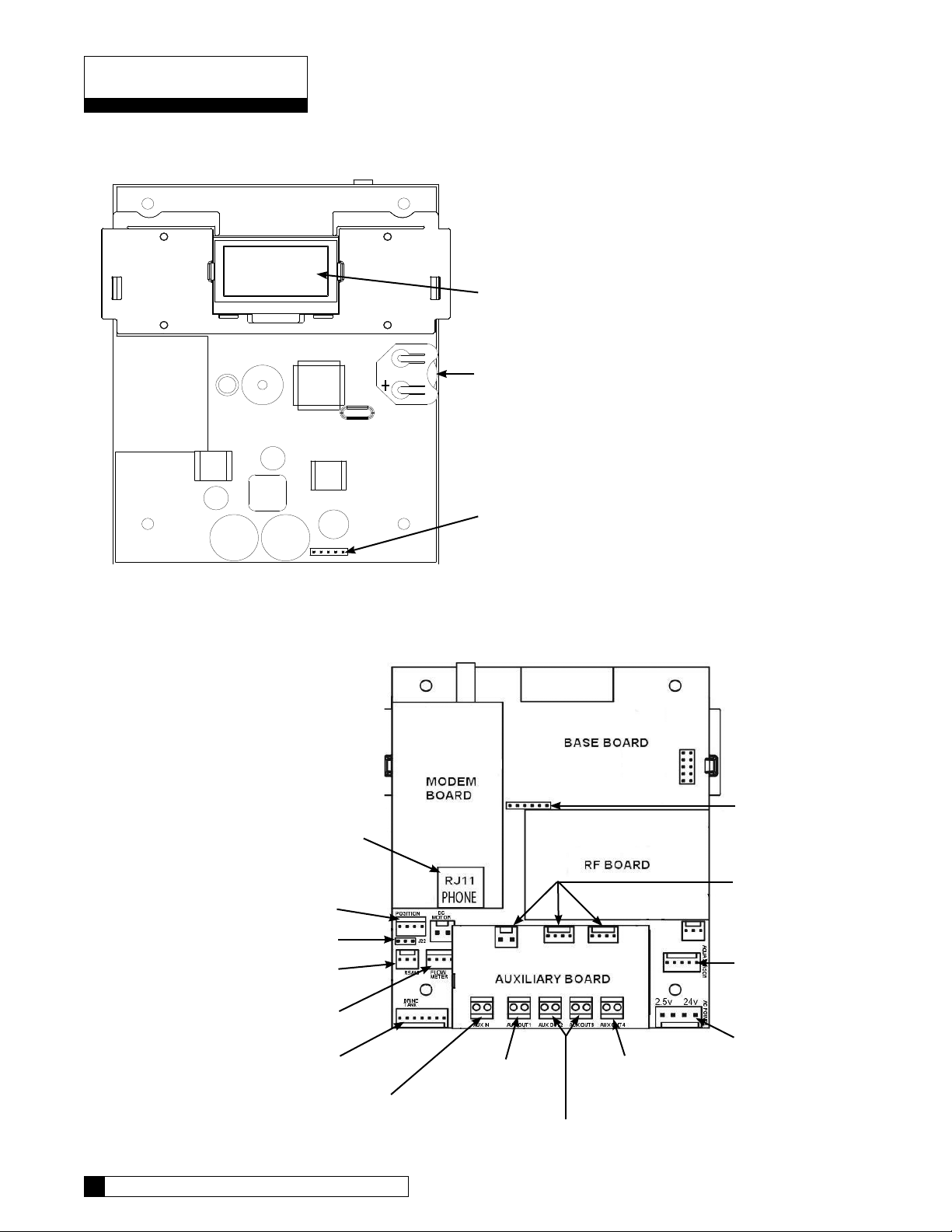

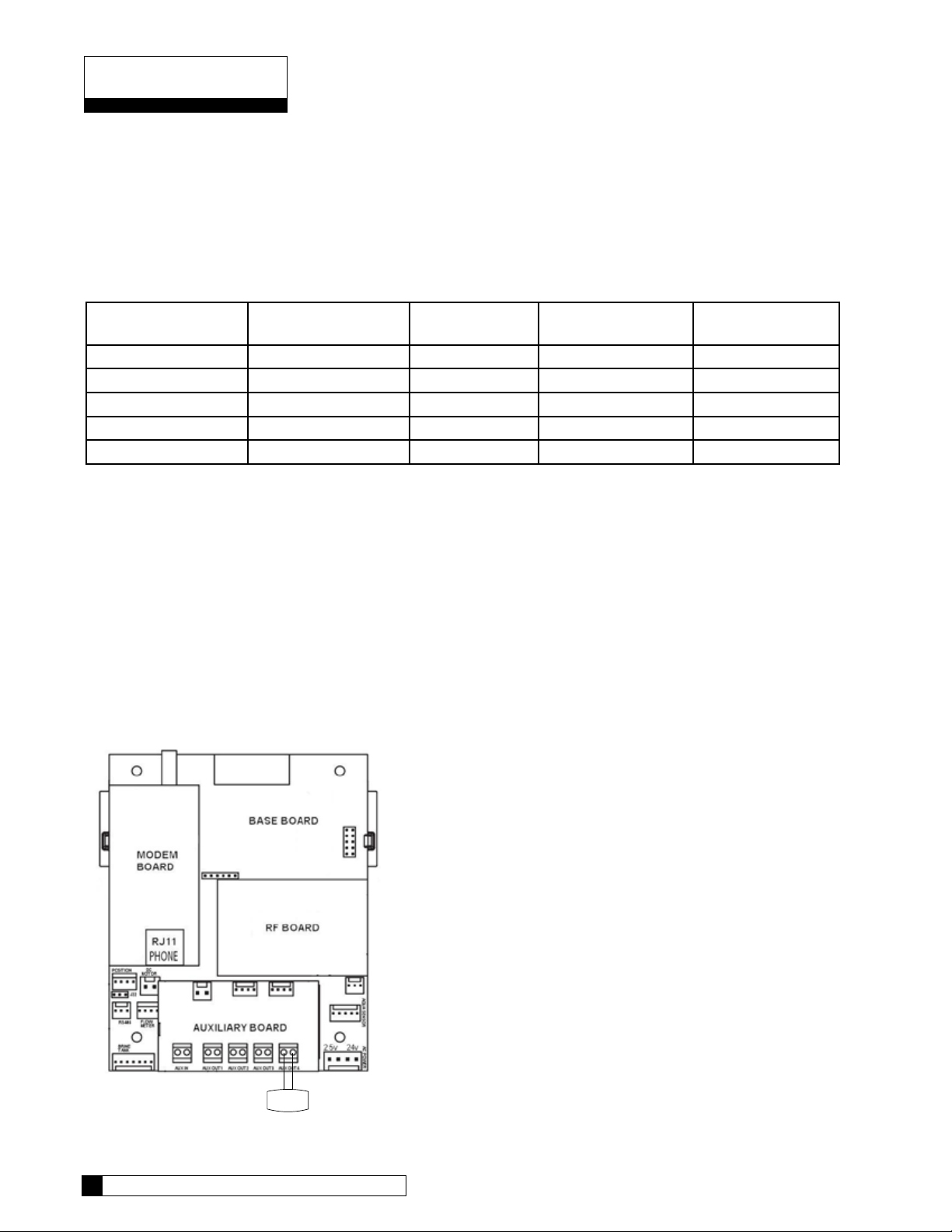

GBE Circuit Board Layout–Front

OLED Display

Battery

CR2032 (Postitive Side Up)

Keypad connector

Figure 8

GBE Circuit Board Layout–Back

Phone line

connection

(optional)

Motor position cable

Multiple unit jumper

Communication cable (optional)

Flow meter cable

(optional)

Smart Brine Tank cable (optional)

External regeneration

signal connection (optional)

Figure 9

7 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Motor

connection

Programmable outputs (optional)

Blocking valve

connection (optional)

Data port

Future use

Do not connect

anything to these.

Aqua-Sensor

cable (optional)

Power cable

from transformer

Page 11

Outputs

Schematic

CAUTION

Connecting 24V to the 2.5v

connection on the circuit board

will damage the circuit board.

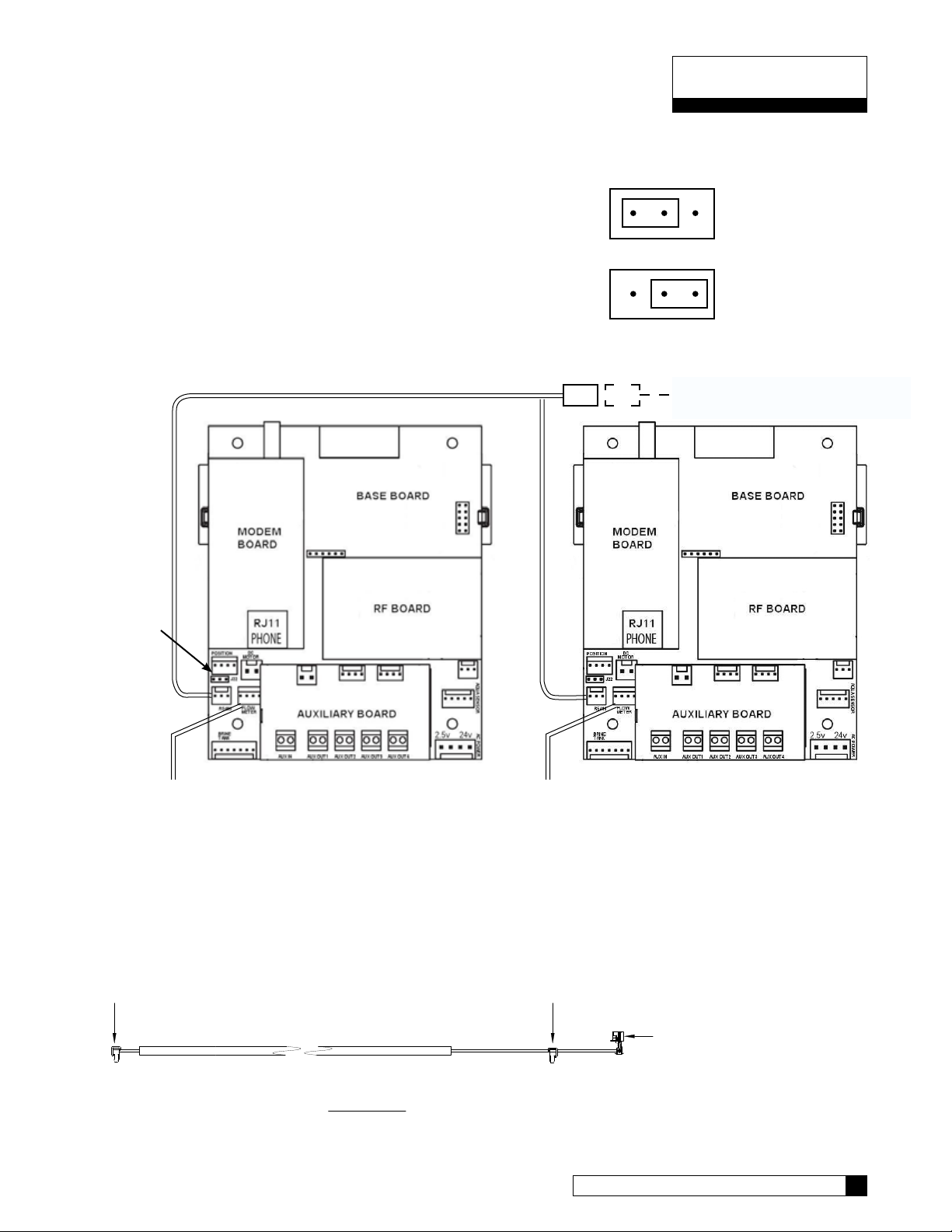

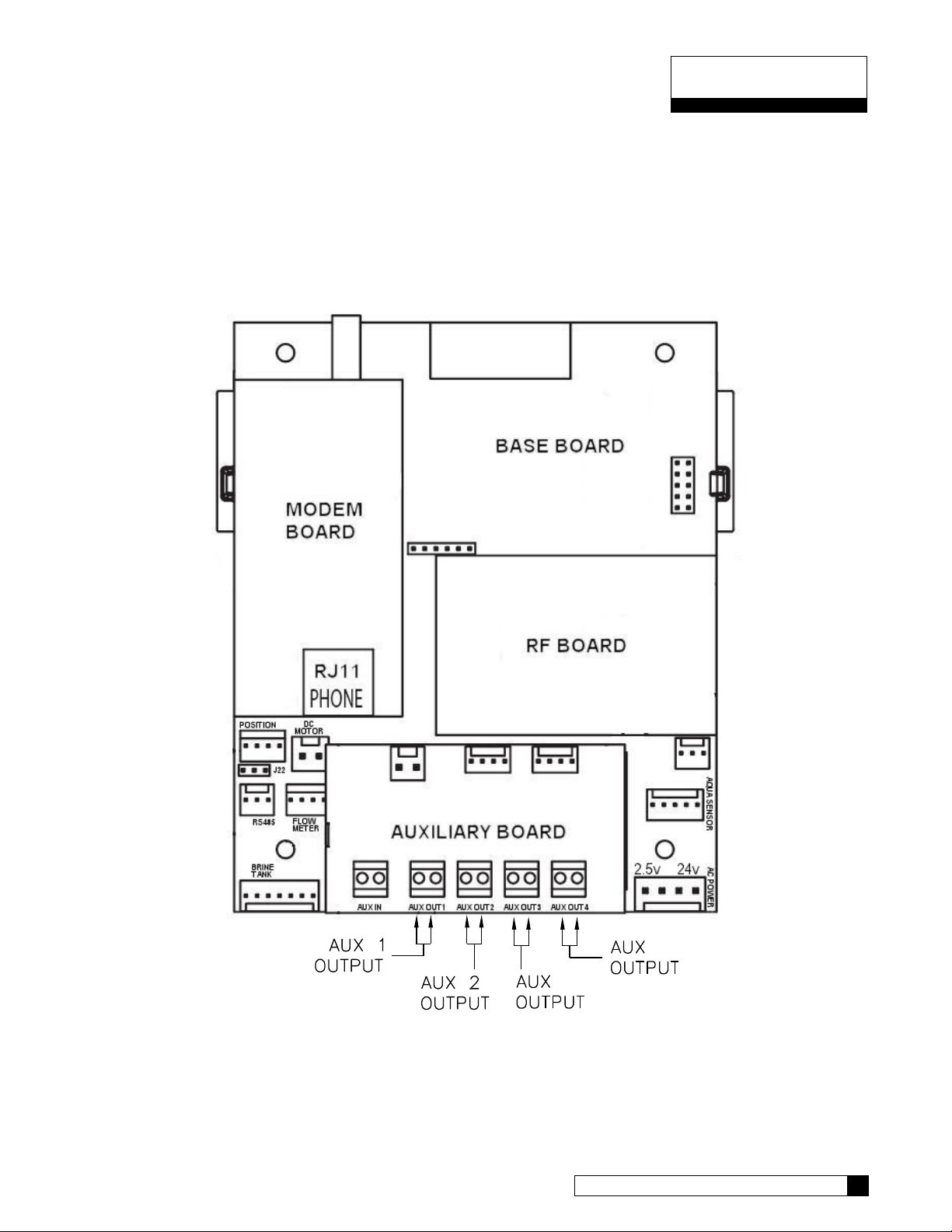

The circuit board supports four outputs:

• Motor control (DC Motor)

• Blocking valve (Use Aux Out 4)

• Four programmable auxiliary outputs (Aux Out 1

through 4)

• Controller interface (communication between multiple controllers) (RS485).

Note: If you are using Aqua-Sensor, you should run the 2.5v wiring now as the cable is run through the same cord grip.

See page 15 for details.

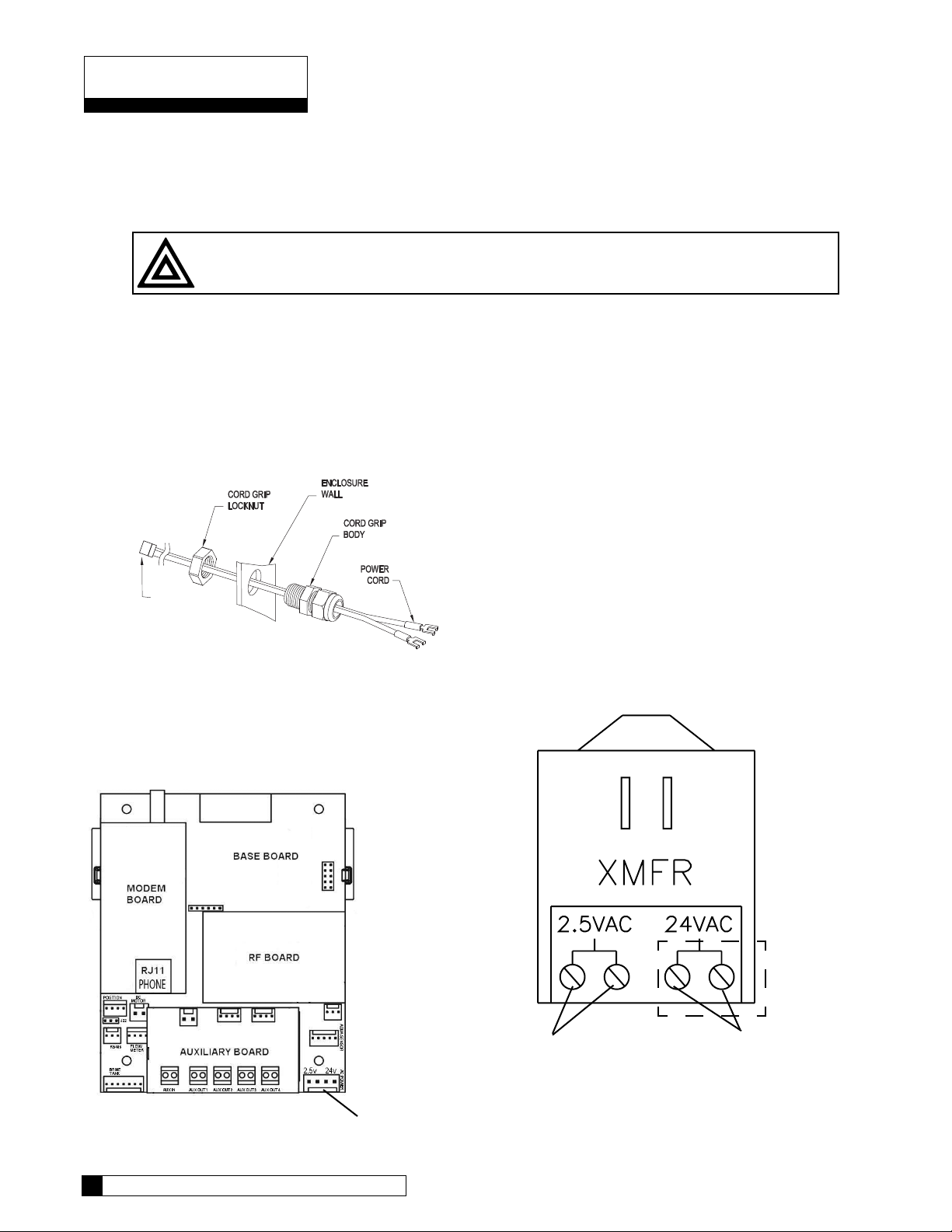

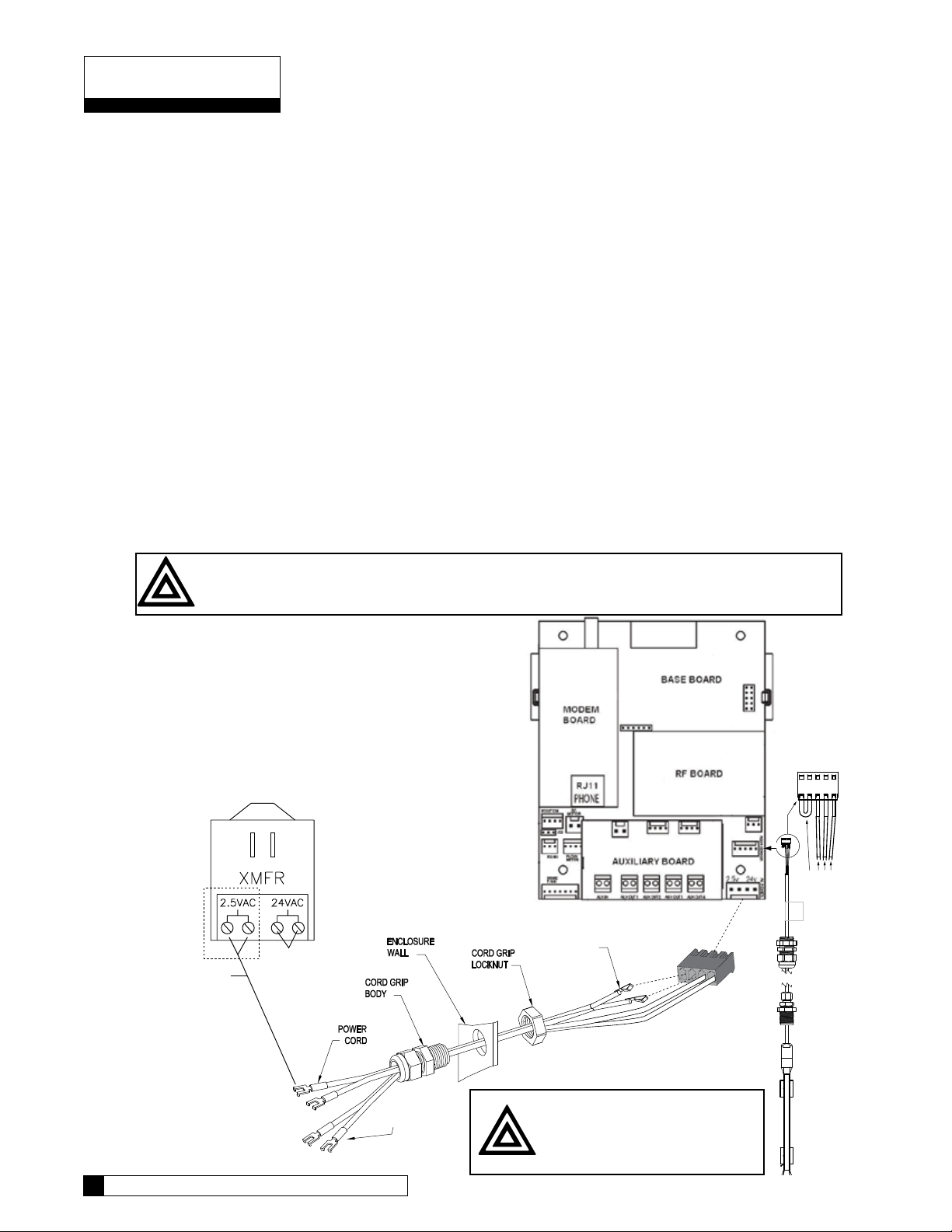

1. Locate the power cord among the controller parts. It has a white connector on one end and two spade connectors on the

other.

2. Locate the cord grip among the parts.

3. To assemble the power cord, first run the cord grip nut over the spade terminal end of the power cord.

4. Next, run the spade terminals through a hole in the side of the controller FROM THE INSIDE. See figure 10.

5. Finally, run the cable through the bottom end of the cord grip, and assemble the grip to the controller wall.

6. Plug the board connector to the board where it says “24v”. The connector has four (4) connections but only two wires are

connected. The other end of the power cord (with spade terminals) should be connected to the two 24VAC terminals on

the transformer (see figure 12).

DO NOT PLUG THE TRANSFORMER INTO THE WALL UNTIL ALL WIRING IS COMPLETED.

Repeat the process for any additional units in the system.

Schematic 8

Page 12

Schematic

METAL TABS

Connect to white connector

on main power cord

If using Aqua-Sensor,

plug metal tabs at end

of cord into connector

24V Transformer

The GBE control is powered by a 24V/50VA transformer. If there are multiple controls in the system being

installed, each control will require its own transformer. It is recommended that the transformer be plugged into a

dedicated 120V circuit.

CAUTION

Connecting 24V to the 2.5V connection on the circuit board will damage the circuit board

1. Connect one wire from the 24V cable to the outermost 24VAC transformer screw terminal

(Reference Figure 12). The other end of the wire should be connected to one of the 24V terminals

on the GBE control circuit board (Figure 11) by way of the white connector.

2. Repeat the process for the other 24V power supply wire attaching the second wire to the opposite

terminal on the transformer and next to the other wire connected to the 24V pins on the GBE board.

24V Power Connection

Figure 10

Transformer connection

Figure 11

9 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

POWER SUPPLY

ONE transformer is required for each Control

2.5VAC Aqua-Sensor

Power Terminals

24VAC Power

Terminals

Figure 12

Page 13

Brine Refill Valve Wiring

Solenoid

Coil

Screw

Plastic

Spacer

2.5VAC

P9 Power

24VAC

Vlv

Aux1

Sol

P7

Aux2

P8P5

Cam

P1

P10

Snsr

Aqua

Meter

P4

Flow

In

P2

Aux

LCD

TRIM OFF

GREEN WIRE

BLACK

WHITE

REFILL

SOLENOID

VALVE

CIRCUIT BOARD

MVP

*This only applies to Culligan CSM Softeners.

1. Installation of the solenoid coil and connector

Locate the solenoid coil and connector cord. Assemble it

to the brine refill valve as shown in Figure 13.

Schematic

Figure 13

2. Installation of the cord grip

Remove the hole plug from the left side of the MVP

controller enclosure. Locate the cord grip fitting and nut.

Assemble them through the open hole and thread the

solenoid coil cord through the cord grip fitting as shown

in Figure 14. Tighten the cord grip onto the cord.

3. Wiring

Wire the valve to Aux Out 2 as shown in the diagram in

Figure 15. The wires can be trimmed to a suitable length.

Figure 14

Figure 15

Schematic 10

Page 14

Schematic

SO L

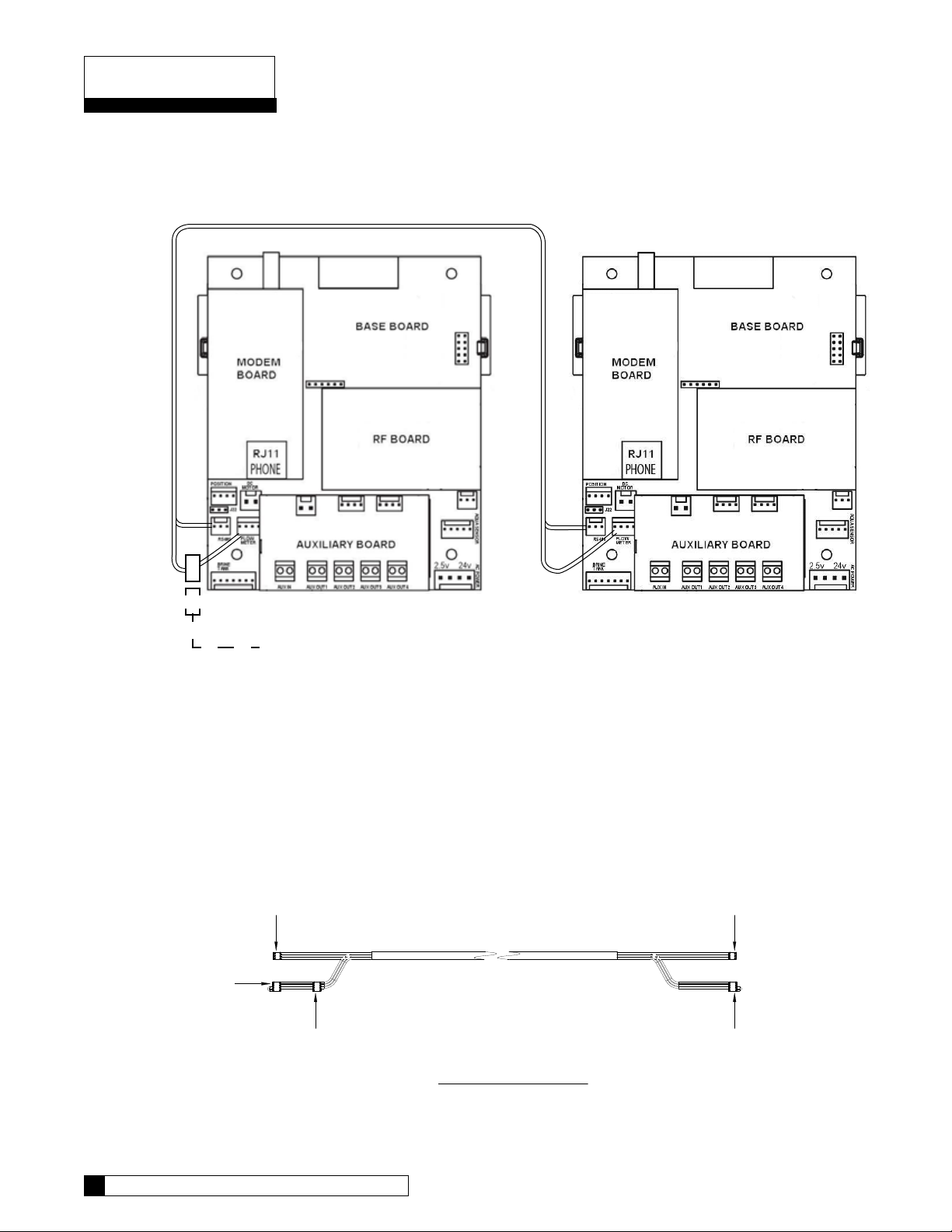

Communication Cable - Multiple Units

NOTE: Disregard this information and proceed to flow sensor schematic (optional) information when installing

single tank configurations.

Multiple units require a communication cable between each unit. Refer to the table below for the cable type, part

number and quantity required. Cables are attached to the RS485 terminal of the circuit board.

Table 2

System

Configuration

Duplex Alternating 01016342 1 01016369 2

Duplex Parallel 01016327 1 N/A 0

Triplex Parallel 01016327 2 N/A 0

Duplex Progressive 01016327 1 01016333 2

Triplex Progressive 01016327 2 01016334 3

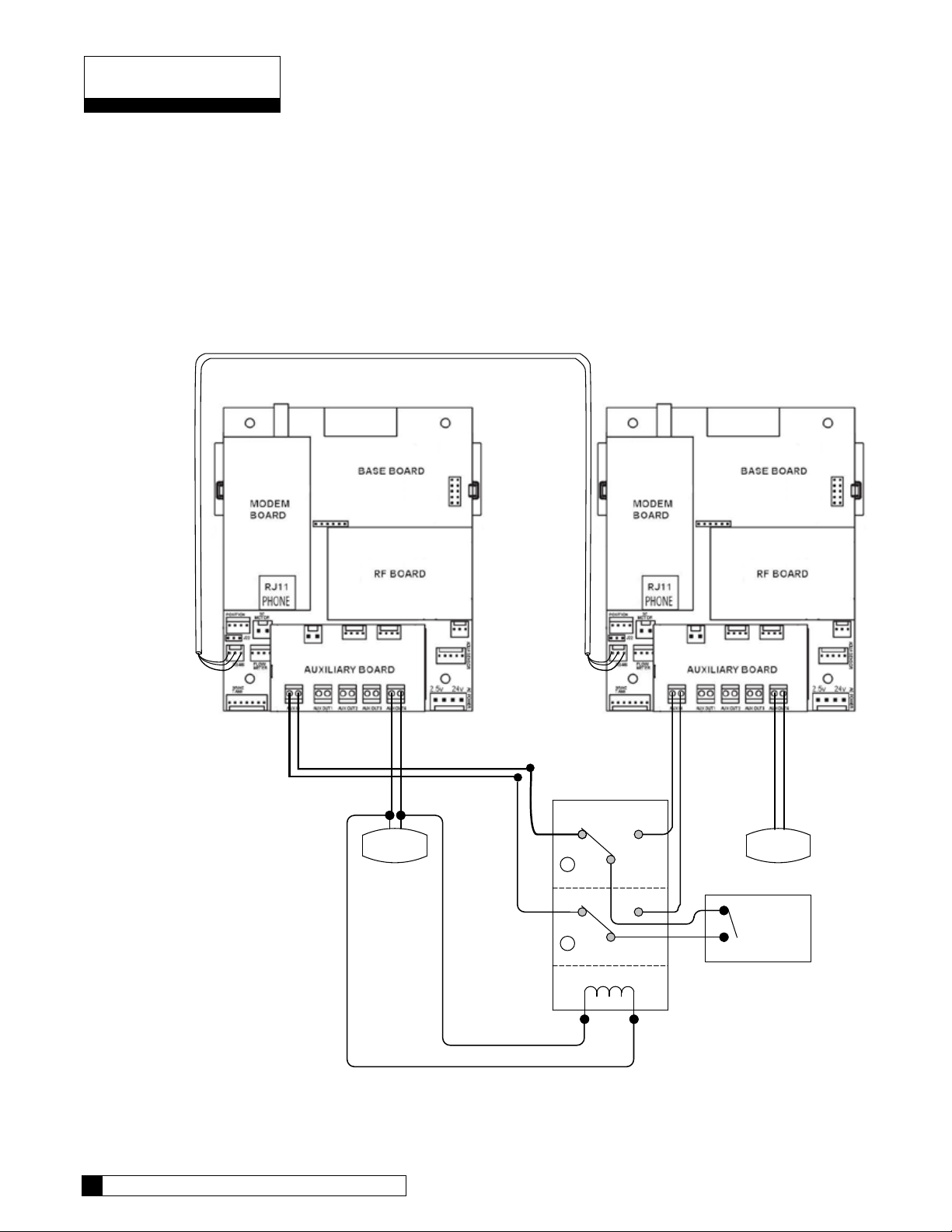

Multiple units can be set up as progressive flow, alternating or parallel operation. Refer to the instructions and

schematics below and on the following pages for connection to the circuit board.

Cable Part Number Qty of Cables

required

“Kit” Part Number Qty of blocking

solenoids used.

Most multiple tank configurations will also require blocking valves (with the exception of the Hi-Flo 3e softener).

These are used to hold tanks offline until needed. Based on the chart above, you can determine how many

blocking solenoids are used. These solenoids are included in the alternating and progressive flow kits.

Blocking Solenoid Connection (used on Alternating and Progressive flow systems)

The solenoid valve wiring attaches to the Aux Out 4 output connection on the auxiliary circuit board. See

Figure 16 .

Figure 16

11 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 15

Progressive Flow or Parallel Flow

To RS 485 Comm Port

on GBE Circuit Board, #1

CABLE 01016327

To RS 485 Comm Port

on GBE Circuit Board, #2

PARALLEL

Additional communication cable

connections are used when there

are 3 or more controls. Connect

end of 2nd-(01016327) cable

to this connector and other end of

cable to RS 485 Comm Port on

3rd GBE Circuit Board.

IMPORTANT

Setting the Jumpers for Progressive Flow

For progressive flow to operate properly, the first and last units must

have the jumpers set to pins 1 and 2 (see figure at right). All middle

units should have the jumpers on pins 2 and 3 (see figure at right).

The diagram below (figure 17) shows duplex connections. Repeat the

connections on any additional systems.

1 2 3

Schematic

Jumper location for

first and last units

(end units).

Jumper location for

middle units.

Jumper

Location

Communication Cable 01016327

To Additional Units

(if necessary)

Unit 1 Unit 2

Flow Meter Flow Meter

Figure 17

Progressive/Parallel Communication Cable 01016327

Schematic 12

Page 16

Schematic

To RS 485Comm Port

on GBE Ciruit Board, #1

To Flow Meter Connection

on GBE Circuit Board.

CABLE 01016342

Flow Meter Connector

(from meter).

To Flow Meter Connection

(on GBE Circuit Board).

To RS 485Comm Port

on GBE Ciruit Board, #2

DUPLEX ALTERNATING

Duplex Alternating with Meter option

Communication Cable 01016342

Unit 1 Unit 2

Flow meter

Figure 18

For triplex, quad, etc alternating, you must use a meter on each unit and connect the same way as

progressive flow.

Duplex Alternating Cable 01016342

13 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 17

(optional)

2535 & 2536

Signet

Black

Shield

Red

Black

Green

Red

Paddle Wheel

(optional)

Seametrics

Green

Red

Black

White

SINGLE OR PROGRESSIVE

Bare

Red

Green

Black

Red

Black

Wht/Clear

2" Autrol Turbine Meter

(optional)

Black

White

Red

2"Clack Meter

(optional)

Schematic

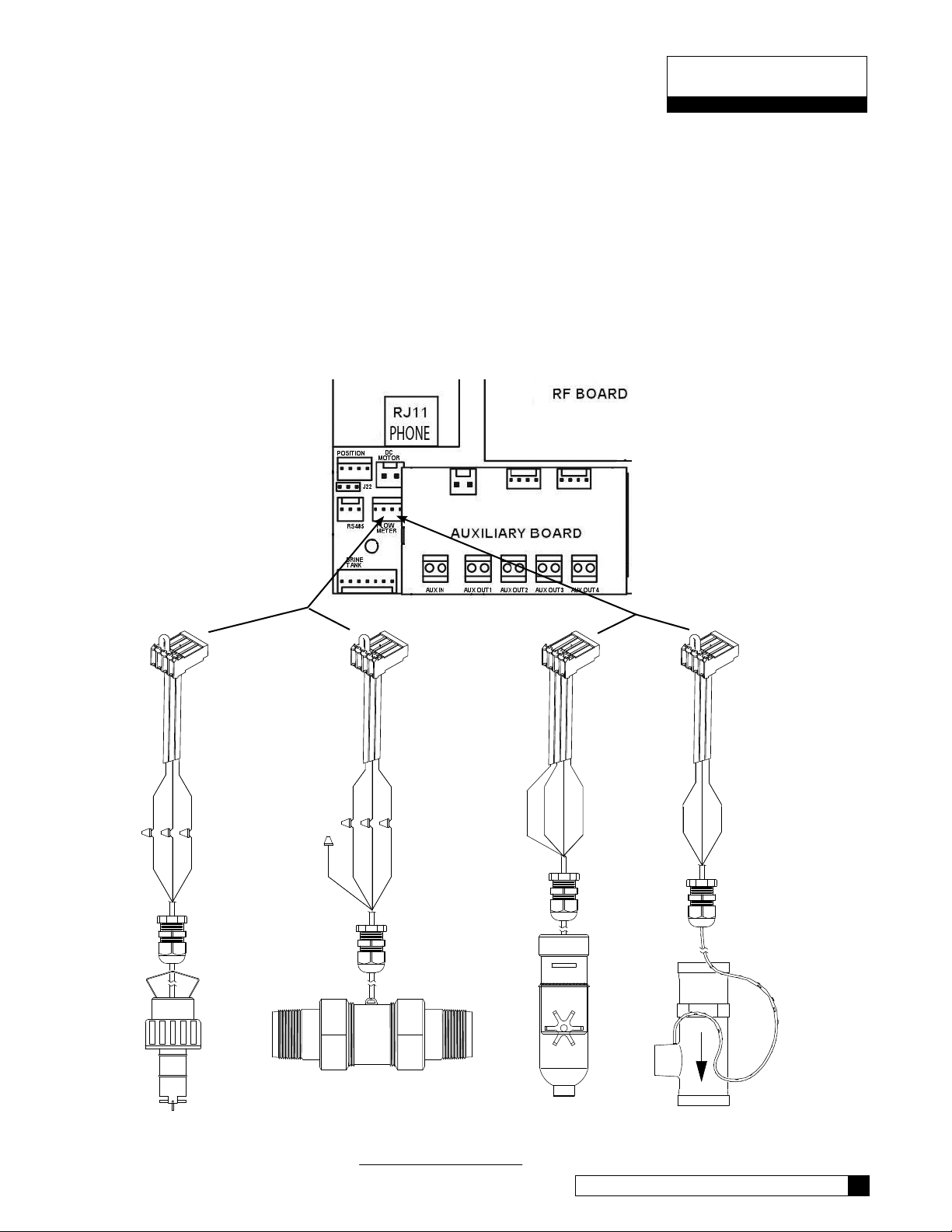

Flow Sensor Meter Connections (Optional)

The GBE Controller is capable of detecting the signal from a Hall effect sensor device to provide flow rate information, totalization and volume based regeneration initiation.

There are several different types of flow measuring devices and differences in the wiring of the devices to the

GBE circuit board do exist. Refer to the drawings below.

For all but duplex alternating, a meter needs to be connected to each circuit board at the location shown below

in the drawing. For duplex alternating meter connection, please refer back to page 13, Duplex Alternating with

meter option.

SEE PAGE 41 FOR PROGRAMMING AND PAGE 63 FOR K FACTORS.

Figure 19

Connector

01010255 included

with controller

Connector

located at

end of meter

cable

Schematic 14

Page 18

2.5V

METAL TABS

Connect to white

connector on main

power cord

24VAC

on TRANSFORMER

Power to circuit

board 2.5VAC

only required

for Aqua-Sensor

installations

Power to circuit

board 24V

Schematic

Red

Black

Blue

White

Aqua-Sensor Schematic (Optional)

The Aqua-Sensor device requires a 2.5 VAC power source. This source is provided via two of the posts on the

24VAC/2.5VAC transformer (see figure 20). The two leads from the transformer are run through the same cable

grip as the 24VAC and then must be pushed into the white power connector for connection to the 2.5v power

pins on the GBE circuit board.

The wire connector from the Aqua-Sensor probe is then routed through the included cable grip and plugged into

the Aqua-Sensor terminal on the GBE circuit board. See below.

Aqua-Sensor

If you are going to install an Aqua-Sensor, you can set up the 2.5V power now.

1. Locate the power cord packed with the Aqua-Sensor. It has two spade terminals on one end of the cable

and two metal “slip in” tabs on the other.

2. Locate the cord grip.

3. The cable can be run through the cable grip and wall from either end of the cable. Make sure the end with

the metal tabs goes INSIDE the controller. The spade terminals should be coming out the top end of the

grip.

4. Locate the connector at the end of the power cord. You may have already plugged it into the board.

5. Press the two metal tabs on the end of the power cord into the open slots on the connector. They will connect to the pins labeled “2.5V’ on the Base Board.The other end of the power cord with the spade terminals

should be connected to the two 2.5VAC terminals on the transformer (see figure 20).

CAUTION - Verify wiring from terminals to circuit board are correct before applying power to

control. 24vac power must not be applied to the 2.5 vac terminals of the circuit board.

2.5V Aqua-Sensor Power Connection

Figure 20

POWER SUPPLY

ONE transformer is

required for each Control

15 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

CAUTION

Connecting 24V to the 2.5V

connection on the circuit board

will damage the circuit board.

Page 19

3

4

Schematic

Auxiliary Outputs (Optional)

The Auxiliary Outputs - reference Figure 21) are output triacs that can be programmed to provide power to a

“normally open” (normally no power to auxiliary output until power required) or a “normally closed” contact (user

choice). These 24VAC outputs can be used for energizing a relay coil only. (2.1 Amp maximum power draw)

Refer to the section on Programming (page 46) for additional information on the uses of this feature.

Figure 21

Schematic 16

Page 20

NC NO

1

POLE

NC NO

2

POLE

C

C

SOL

Regen Signal

EXTERNAL

SOURCE

24V DPDT

RELAY

DUPLEX ALTERNATING WITH EXTERNAL SOURCE

SOL

Communication Cable

01016327

Schematic

Auxiliary Input (Optional)

One auxiliary input is provided for optional signal devices such as remote push buttons, differential pressure

switches, hardness monitors, turbid meters, etc. for the purpose of receiving a regeneration signal.

Select an UN-POWERED contact within the remote device that will close when regeneration is desired. The

duration of the switch closure can be as low as 0 seconds; 6 seconds is the recommended minimum and default

but can be as long as 999 seconds. The contact must automatically open following the start of a regeneration

sequence. Connect this contact to the Aux In terminal shown in Figure 22. The illustration below is an example

of how to use an external source to initiate regeneration.

Figure 22

17 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 21

Programming

Programming

The programming process requires various types of data input. The following information pertains to calculating

the softening capacity of the water softening system. Filters do not have a capacity setting so this section can be

skipped when programming a filter.

Capacity Settings

The capacity of a water softener is determined by two factors; resin amount and water chemistry.

Single Tank Systems

Normally a single tank system has enough resin capacity to soften water for a minimum period of 24 hours.

Time of regeneration is usually set to occur very early in the morning or at a time when no softened water is

required. This is because when the softener is regenerating, hard water is typically bypassed through the system

and into the facility if a demand for water if present.

If regeneration is desired at a time of day when there is no water usage then the system must have a “reserve”

capacity which must last an entire day if the regeneration signal (time clock, Aqua-Sensor and/or meter) occurs

at the beginning of the day. Subtract this reserve capacity from the total capacity to determine “capacity to signal”.

Note: If the reserve capacity is more than 1/3 of the total capacity,

a meter system may not reduce salt consumption relative to

a timeclock system.

Multiple Tank Systems

Multiple tank systems offer the benefit of continuous soft water supply. When using the Aqua-Sensor to initiate

a regeneration sequence, the system capacity may be set for the maximum amount the system is capable of

producing. However multiple tank systems using only water meters and or time clock as the basis for regeneration initiation are recommended to be set up with a 10% reserve capacity. The purpose of the reserve capacity

in multiple tank systems is to allow for subtle changes in water chemistry. You will be able to get the reserve

capacity during programming.

Determining Batch Set Point

To determine the batch set point for programming the Culligan GBE controller, use the following formula:

Total Capacity - Reserve Capacity

Gallons = Hardness

The GBE will calculate this for you automatically. you can use the formula above to verify the setting.

For more information on programming multi-tank systems, see page 41.

Programming 18

Page 22

Programming

Program Data Input

There are a couple of items to note that can make the programming of the Culligan GBE control a little easier.

They are:

Slew Rates This term refers to the speed at which the display moves through the input of material. For

example, holding down the up arrow key for (5) seconds when inputting minutes for Time

of Day will cause the minutes to pass in (10) minute blocks of time. Press the up arrow

or down arrow keys for shorter periods (less than 5 seconds) will slow the rate. To move

through the programming slowly, do not hold down the up arrow or the down arrow keys.

Beeper A beeper is available to assist the user by providing an audible tone (about 70 decibels) to

signify valid (0ne beep) and invalid (three beeps) key presses. The beeper can be deactivated in the programming mode. (If error occurs, beep will still be ON even if set to “No”

programming.)

Programming

Mode Timeout

Program Input

Acceptance

If there is no keypad activity for a (3) minute period while in the programming mode, the

controller will exit the programming mode and return to the main display. Any setting that

was changed prior to the control timing out will revert back the original value. Pressing the

check mark key saves the setting.

For programming information to be accepted, the check mark key must be depressed prior

to programming mode timeout.

19 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 23

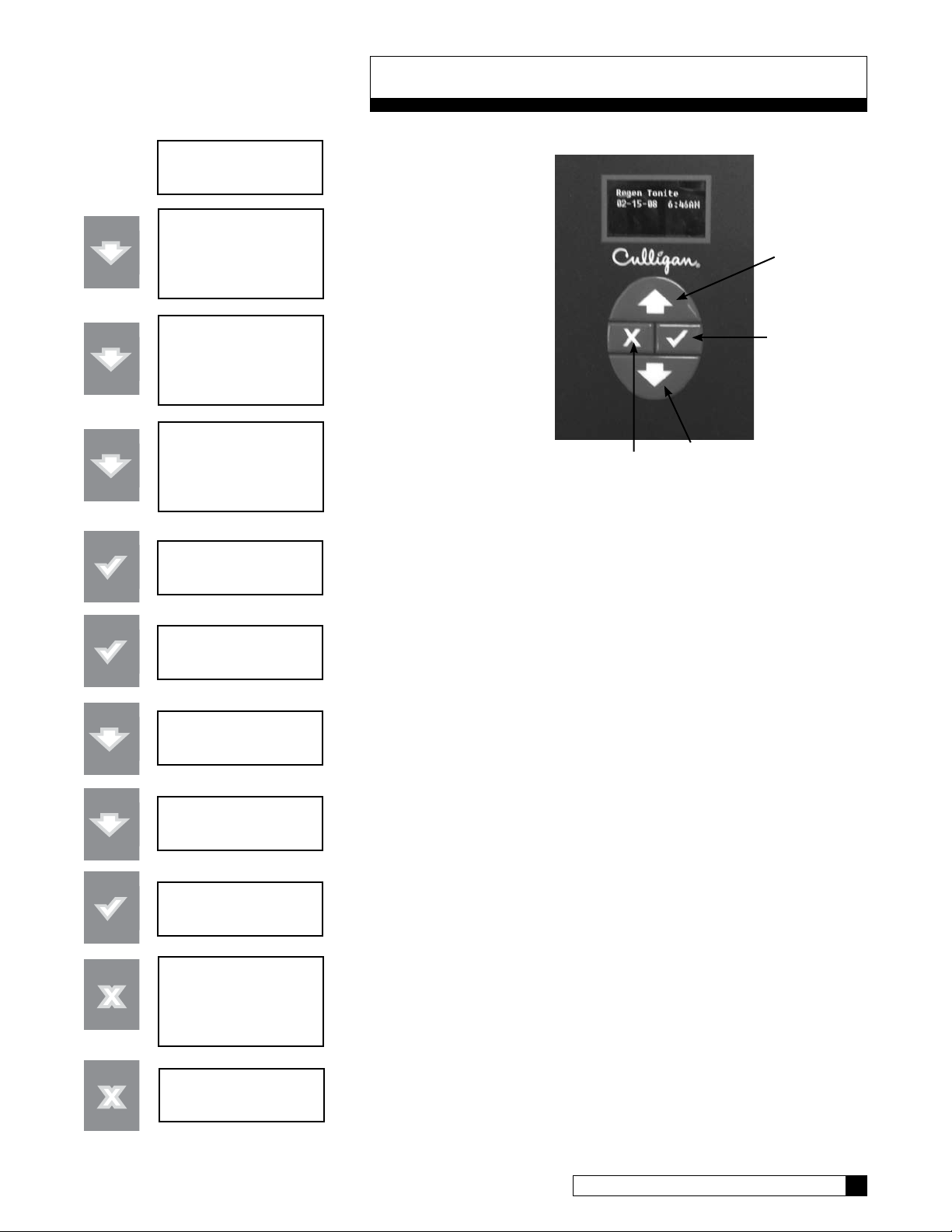

Navigating the Menus and Keypad

system ok

9:17 am 1-17-08

> 1) information

2) bypass

3) regenerate

4) set time and date

1) information

> 2) bypass

3) regenerate

4) set time and date

1) information

2) bypass

> 3) regenerate

4) set time and date

regeneration

off

This is the “home” screen.

Press any key except

CANCEL (“x”) takes you to

the main menu.

This is the main menu. The

pointer shows where you are

in the menu. The UP and

DOWN arrows move thru

the menu.

CANCEL button

Pressing the CHECKMARK key

selects that item on the menu.

UP button

CHECK MARK

or OK button

DOWN button

regeneration

>

off

regeneration

>

now

regeneration

> tonite

regeneration

tonite

> 1) information

2) bypass

3) regenerate

4) set time and date

regeneration tonite

9:18 Am 1-17-08

Here we see the current value for “regeneration”

is “OFF”. Press the CHECK MARK turns on the

pointer symbol. The pointer indicates that you

can change the current value using the arrow

keys.

The arrow keys allow you to scroll thru the

available options.

Pressing the CHECK MARK key to select the new

setting. The pointer symbol turns off to show this

is the selected value.

Pressing the CANCEL button from inside the

menu always takes you one step closer to the

“home” screen.

Now we are back to the home screen. Note that

the display has changed to show that regeneration

is now scheduled for tonight.

Navigating the Menus and Keypad 20

Page 24

Programming

GBE Controller Programming

The programming for the GBE controller is all menu based. There are 5 top level menus with additional options

below each. The top 5 are:

1) INFORMATION

2) MANUAL MODE

3) SET DATE / TIME

4) ACCESSORIES

5) ADVANCED SETUP

Here is a brief explanation of what you will find under each menu

1) INFORMATION

Selecting this menu item will scroll through the operating information for the unit.

2) MANUAL MODE

Use this menu item to initiate a manual regeneration.

3) SET TIME / DATE

Use this menu item to make changes to the time and/or date. This is initially done during first time set up

and the information is saved in memory even in the event of a power outage.

4) ACCESSORIES

Use this menu item to set up any installed accessories. This includes meters, Aqua-Sensor, Smart Brine

Tank probe, Modem, Wireless Remote, Aux In and Aux Outs.

5) ADVANCED SETUP

This menu item allows customization of the unit. There are 5 sub-menus which offer customization

settings.

1) SYSTEM SETUP

This menu allows customization of many of the initial setup information. Water Hardness, Iron,

Salt Type, Resin Volume are among the settings.

2) REGENERATION SETUP

This menu allows customization of the salt dosage, reserve capacity, regeneration time and

regeneration mode.

3) CYCLE TIMES

This menu allows customization of the units cycle times.

4) REGERATION TRIGGER

This menu allows customization of what can trigger regeneration, the regeneration interval,

predict mode and days of regeneration.

5) DIAGNOSTICS

This menu allows diagnostics to be performed on sensors, wireless, progressive flow, motor

control, data port, phone line (modem) and advanced statistics.

21 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 25

Programming

Typical Commercial Setup

Setting up the GBE for a commercial installation requires a few additional steps. Follow the outline below to

make sure everything is covered.

1) Run the first time setup (see pages 24 to 27)

2) Set up accessories (see pages 33) This includes:

• Water Meter (remember to set K Factor)

• Aqua-Sensor

• Aux In

• Aux Outs (needed for multi-tank, brine reclaim and refill on 4-cycle valves)

• Smart Brine Tank Sensor

• Wireless Remote

• Modem

• Service Phone

• External Filter

3) You must tell the controller if it is a multi-tank system. This is under Advanced Setup/System Setup (see

pages 29). The MultiTank System setting is set to PROG FLOW for ALL multi-tank systems. Trip point

settings will determine how unit operates (progressive, parallel or alternating - page 42).

4) If you are using immediate regeneration, you must change the Reserve Capacity setting under Advanced

Setup/REGEN SETUP and the REGEN MODE. See pages 30.

5) Set/Review Cycle Times – This is under Advanced Setup/Cylce Times. Especially check the Brine Draw/

Slow Rinse (BD/RINSE) and the Fast Rinse. 5-cycle valves have separate refill. See pages 31.

6) You need to do this setup procedure on each control in the system. You may want to write down

the settings you change.

7) Refer to Appendix D for a quick programming chart.

Programming 22

Page 26

First Time Setup Process

First Set-up Procedure

If at any time you need to re-run First Time Setup - refer to instruction on page 58.

After completing the plumbing connections to the water softener, follow these steps to turn

on and program the softener controller.

STEP 1: Plug in the wall transformer

STEP 2: Perform the on-display “First Time Setup” process (below)

„ Moves up the menu

‰ Moves down the menu

P Changes the display, accept desired change

X Cancel or exit

1. When a new controller is first turned on, the display shows the following:

First Time Setup

Hit Down Arrow

Controller

Remote

Press the down arrow to move tot he next question.

2. Electronic Serial Number

S/N: 00000123

This screen is very important as it shows the electronic ID number of the controller.

Note: If this unit will be installed with a modem, it is required that this electronic ID number

is reported back to Culligan on the IQR form.

Press the DOWN arrow button to change the display to read “Set Month”.

3. Set Month

Set Month

Jan

• If the default selection is correct, press the DOWN arrow to accept that value and move to the next

question.

• If the value displayed is NOT correct then press the CHECK MARK button to change the display to

show a “>” symbol next to the displayed value.

23 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 27

First Time Setup Process

Set Month

> FEB

• Once the desired value is displayed accept the value by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

4. Set Day

Set Day

• The “>” symbol indicates that this value may be changed by pressing the

UP and DOWN arrow buttons. For example, pressing the DOWN arrow

while the “>” mark is displayed changes the display from “JAN” to “FEB”.

1

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

5. Set Year

Set Year

2008

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

6. Set 12 Hour or 24 Hour Clock

12 hr or 24 hr clock

12

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

First Time Setup Process 24

Page 28

First Time Setup Process

7. Set Hour

Set hour

7

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

8. Set Minute

Set minute

32

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

9. Set AM or PM

Set am or pm

7:32 am

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

10. Set Valve Type (4-cycle or 5-cycle)

valve type

4-cycle

CSM and Hi-Flo 50 are 4-cycle valves and Hi-Flo 22 and Hi-Flo 3e are 5-cycle valves.

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

25 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 29

First Time Setup Process

11. Set Units (US-inch or metrics)

units

us-inch

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

12. Set Softener or Filter

is this a softener or filter?

softener

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

13. Set Water Hardness

water hardness

10 grains

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

Press the DOWN arrow to accept that value and move to the next question.

14. Set Softener Resin Volume

resin volume?

1.0 cu-ft

• If the value displayed is NOT correct, pressing the “CHECK MARK” button will change the display, to show

a “>” symbol next to the displayed value. Use the UP or DOWN arrow to change the setting. Once the

desired value is displayed, this value can be accepted by pressing the “CHECK MARK” button.

This value is found in the products installation manual in the specification table.

Press the DOWN arrow to accept that value and move to the next question.

First Time Setup Process 26

Page 30

First Time Setup Process

15. Setup is Complete

system ok

7:32 am 2-1-08

The circuit board microprocessor automatically calculates softener capacity. The control then automatically homes.

Contact your Culligan Man if the settings need to be customized.

Note: For all commercial applications, you must adjust the cycle times. Most important is refill time. Refer to the

Brine System charts in the product’s installation manual for cycle settings.

27 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 31

Customizing the Setup

The controller is designed to simplify the setup and installation process by making some default recommendations

during the Initial Setup. The default settings are designed to be appropriate for most common installations.

Default Settings

Downflow Brining

•

Standard Mesh Resin

•

Blue/Beige Eductor

•

0.45 GPM Brine Flow Control

•

0 PPM Iron

•

> 40 psi water pressure1

•

NaCl Salt

•

Time of Regen = 2:00 AM

•

Regen Time = Delayed

•

Dosage (calculated)

•

Predict Mode ON

•

30% Reserve Capacity

•

Time Clock Backup = OFF

•

Day-of-week Regen = OFF

•

Pre-Rinse Mode = OFF1

•

1

= these items are changed on the Main Menu / Advanced / System Setup Menu

2

= these items are changed on the Main Menu / Advanced / Regen Setup Menu

3

= these items are changed on the Main Menu / Advanced / Regen Trigger Menu

1

2

1

1

1

1

2

2

2

3

2

3

3

There may be times when the installer would prefer to override the default regeneration selections. See

Advanced Setup Menu, Regeneration Setup Menu or Regeneration Trigger Menu for information on changing

default selections.

Advanced System Set-up Menu

• Press the UP „ or DOWN ‰ arrow to scroll to menu item

• Press the CHECKMARK P key to select a menu item

• Press the UP „ or DOWN ‰ arrow to change a selection

• Press the CHECKMARK P key to save your selection

Default Values are shown for each selection

system ok

7:32 am 2-1-08

> 5) Adv Setup

> 1) system Setup

Scroll to ADV SETUP and select

Select SYSTEM SETUP

Customizing the Setup 28

Page 32

Customizing the Setup

valve type

4-cycle

resin type

standard

hardness gpg

25

dial-a

softness a

iron

present 0 ppm

line pressure

above 40 psi

salt type

nacl

The GBE controller can operate several types of valves. Select from 4-CYCLE, 5-CYCLE or GBV.

For Softeners: For Filters:

CSM and Hi-Flo 50 are 5-CYCLE All are 4-CYCLE

Hi-Flo 22 and Hi-Flo 3e are 4-CYCLE

The type of resin changes how the GBE calculates capacity. Select from STANDARD or FINE.

Unless you change from the standard Cullex®, leave this at STANDARD.

Enter the water hardness (softeners only). This can be from an onsite test or from a water analysis.

Enter in the units shown on screen. For US-INCH, enter the hardness in grains per gallon (gpg).

This does NOT APPLY to commercial valves. Leave this set to A.

Enter the amount of iron present. This value can come from an onsite test or a water analysis.

Enter the value in ppm (mg/l).

This setting is either ABOVE or BELOW 40 PSI. If the pressure is below 40 psi, the brine

rinse time will be extended. This can be overridden by setting the brine rinse time manually by

going to 5) ADV SETUP, then 3) CYCLE TIMES.

Either standard sodium chloride (NACL) salt or potassium chloride (KCL) salt can be used. The

GBE needs to know which type is being used.

multitank system

single

brine refill flow

0.45 gpm

resin volume

1.00 cu/ft

units

us inch

prerinse mode

off

rinse if no flow

>for 24 hours

rinse for

>5 minutes

Select either SINGLE tank or PROGRESSIVE. Selecting PROGRESSIVE implies a multi-tank

system. Please refer to page 41 for details on setting up a multi-tank system.

THIS CAN BE IGNORED FOR COMMERCIAL APPLICATIONS.

Enter the volume of resin in the tank. This information can be found in the product’s installation

manual on the specifications page. Enter in the units shown. For US-INCH, enter the value in

cubic feet.

Select either US INCH or METRIC units. This will change the units when entering programming

values such as resin volume and flow rates. If you change this to METRIC, please review your

input for accuracy.

Set this to ON or OFF. This setting will tell the unit to rinse to drain at the time intervals and

duration set.

IF PRERINSE MODE IS SET TO ON

Select a prerinse time value from 1 to 240 hours. This tells the unit to rinse to drain if no flow is

detected for this duration.

Select the number of minutes the unit should rinse to drain when the NO FLOW duration has

passed.

This concludes the Advanced System Set-Up Menu. Continue to press the X key to return to the Main Menu.

29 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 33

Customizing the Setup

Regeneration Set-up

• Press the UP „ or DOWN ‰ arrow to scroll to menu item

• Press the CHECKMARK P key to select a menu item

• Press the UP „ or DOWN ‰ arrow to change a selection

• Press the CHECKMARK P key to save your selection

Default Values are shown for each selection

system ok

7:32 am 2-1-08

> 5) Adv Setup

> 2) regen Setup

salt dosage

9.0 lbs

reserve capacity

30%

Time of regen

2:00 AM

regen mode

delayed

Scroll to ADV SETUP and select

Select REGEN SETUP

This value is the salt dosage in pounds (LBS) for US INCH (total number of pounds of salt used

per regeneration). The salt dosage contributes to calculating the resin capacity and is also used

when a Smart Brine Tank Sensor is installed to help calculate salt usage and salt remaining. The

higher the salt dosage the higher the capacity. Refer to the appendix of the unit’s installation

manual for information on setting the salt dosage.

For example, for a CSM 300-2 (10 ft³ of resin), and a desired capacity of 250,000 grains, the

chart in the manual shows the dosage at 102 pounds.

This setting is generally used for a single-delay system. For a multi-tank system, reserve capacity is

not necessary and should be set to zero (0). If you do not change this value in a multi-tank system,

your unit will regenerate when 30% of the capacity remains.

This setting is used for time clock regeneration. This is the time of day that the unit will regenerate

when needed.

Select either DELAYED or IMMEDIATE. For multi-tank systems, this is normally set to

IMMEDIATE. If immediate is selected, be sure to change the Reserve Capacity setting.

Regen lockout

for 0 hours

This concludes the Regeneration Set-Up section. Continue to press the X key until reaching the Main Menu.

Use this setting to prevent back-to-back regenerations on multi-tank systems, if necessary. When

one unit is done regenerating, the next regeneration cannot begin until the set amount of time has

passed.

Customizing the Setup 30

Page 34

Customizing the Setup

Cycle Times

• Press the UP „ or DOWN ‰ arrow to scroll to menu item

• Press the CHECKMARK P key to select a menu item

• Press the UP „ or DOWN ‰ arrow to change a selection

• Press the CHECKMARK P key to save your selection

Default Values are shown for each selection

system ok

7:32 am 2-1-08

> 5) Adv Setup

> 3) cycle times

cycle times

>use defaults

backwash time

10 minutes

brine draw-rinse

71 minutes

fast rinse

7 minutes

Scroll to ADV SETUP and select

Select CYCLE TIMES

Select either USE DEFAULTS or CUSTOM. When USE DEFAULTS is selected, the program calculates the cycle times based on hardness and resin volume. When CUSTOM is

selected, you can set custom cycle times.

Use this setting to adjust the number of minutes for backwash. You generally will not

need to change this setting.

For commercial applications, this value can normally be set to 60 minutes. It can be

extended if you find the brine is not being rinsed out properly within this time.

This value is calculated for household units. For commercial units, you should adjust this

value to 10 minutes, but it is not required.

fill Time

7 minutes

This will only show if you have selected a 5-cycle valve. This is the refill time. This value

can be found in the unit’s installation manual. For example, if you have a Hi-Flo 22 WS90 water softener (3 ft³) and you want to set a capacity of 60,000 grains, then using

the chart in Appendix A of the Hi-Flo 22 manual show a time setting of 12 minutes.

For a 4-cycle valve, the refill is controlled by AUX OUTPUT 2 and the refill time is set

there. See page 46.

This concludes the Cycle Times section. Continue to press the X key to return to the Main Menu.

31 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 35

Customizing the Setup

Regeneration Triggers

• Press the UP „ or DOWN ‰ arrow to scroll to menu item

• Press the CHECKMARK P key to select a menu item

• Press the UP „ or DOWN ‰ arrow to change a selection

• Press the CHECKMARK P key to save your selection

Default Values are shown for each selection

system ok

7:32 am 2-1-08

> 5) Adv Setup

> 4) Regen Trigger

flow meter

can trigger

Aqua sensor

can trigger

regen intervals

number of days: 0

predict mode

>

off

Scroll to ADV SETUP and select

Select REGEN TRIGGER

This setting requires an optional flow meter (except Hi-Flo 22) or optional Aqua-Sensor.

Use this setting to tell the controller whether the optional flow meter or Aqua-Sensor is

used to trigger a regeneration. If set to CAN TRIGGER, the flow meter is used to count

the gallons of soft water until the batch value is reached, at which time a regeneration

is triggered. You can install water meter and use it just to monitor flow rate and total

usage, and not use it to trigger the regeneration. An Aqua-Sensor device (softeners) or

differential pressure switch (filters) can be used to trigger the regeneration. You can have

both the water meter and Aqua-Sensor/differential pressure installed and able to trigger regeneration. Either one can trigger the regeneration and everything is reset when

regeneration is complete.

Use this setting if using time clock regeneration only or if you would like to have a time

clock backup for the installed trigger device. It is common to set this at 3 days, although

not necessary.

The Predict Mode is used in the flow meter mode to determine the optimum regeneration

point. Before the regeneration starts, the control will compare the remaining capacity

value with the average daily water use. If the average daily water usage is less than the

remaining capacity, the controller will wait 24 more hours be3fore regeneration. If the

remaining capacity is less than the average daily water usage, the control will initiate

regeneration. This works in delay mode only. At any time, if the total capacity value is

reached, the control will initiate an immediate regeneration.

regeneration on monday

>off

Use this setting to select the days of the week to regenerate. This is most useful when

running the system as time clock only. For commercial multi-tank systems, leave all days

to OFF.

regeneration on monday, ...

>off

The program will go through the rest of the days of the week to set regeneration on or

off.

This concludes the Regeneration Trigger section. Continue to press the X key to return to the Main Menu.

Customizing the Setup 32

Page 36

Installation of Accessories

Installation of the Aqua-Sensor Probe

After installing the Aqua-Sensor kit 01008779 - CSM, Hi-Flo 50 or the 01018959 - Hi-Flo

22, it is necessary to configure some settings.

The Aqua-Sensor probe should be installed prior to loading the resin in the tank. Run the

probe lead through the opening in the top of the tank. Systems with fiberglass tanks will

have a tank plug on the cord. Systems with steel tanks require a 3/4” x 1/2” reducing

bushing (included in kit) for the cord grip. Run the probe through the bushing prior to

inserting into tank. Use a supplied strain relief to run the connector into the controller. Plug

the connector into the circuit board at the position labeled Aqua-Sensor. Figure 23.

system ok

7:32 am 2-1-08

> 4) accessories

> 1) aqua sensor

aqua sensor

>installed

From the home screen, press the DOWN arrow to ACCESSORIES. Press the CHECK

MARK button.

From the ACCESSORIES screen, press the CHECK MARK button at AQUA SENSOR.

Press the CHECK MARK button to change AQUA SENSOR setting. Press the UP or

DOWN arrow to change from NOT INSTALLED to INSTALLED. Press the CHECK

MARK when the correct AQUA SENSOR mode is displayed.

Figure 23

Connect Aqua-Sensor connector

here at lower right corner of circuit

board

Beeper Mode

system ok

7:32 am 2-1-08

> 4) accessories

> 2) beeper

beeper mode

>always off

displayed.

Always ON Always Always

Always OFF Never Never

12 hour mode Never Between 8AM-8PM

24 hour mode Never Always

From the home screen, press the DOWN arrow to ACCESSORIES. Press the CHECK

MARK button.

Press the DOWN arrow button to scroll to BEEPER. Press the CHECK MARK button at

BEEPER.

Press the CHECK MARK button to change BEEPER MODE setting. Press the UP or

DOWN arrow to change from ALWAYS OFF, ALWAYS ON, 12 HR WARNINGS

OR 24 HR WARNINGS. Press the CHECK MARK when the correct BEEPER MODE is

key Press Beeps Beeps on Alarm

33 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 37

Installation of Accessories

Installing the Smart Brine Tank (SBT Probe) in to the Brine Tank

1. Place the smart brine probe on top of the brine plate as shown in Figure 24 .

2. Loop the two zip ties thru the holes in the probe housing and loop the zip ties around the outside of the brine well as shown

in Figure 25. IMPORTANT! Tighten zip ties securely to prevent movement.

3. Use zip tie to snug the top of the brine tank probe against the top of the brine well.

4. Route the smart brine tank probe cable to an appropriate opening in the valve control housing. Use the strain-relief plug

provided with the SBT probe for installation.

5. Plug the SBT probe connector into the circuit board at the position labeled “Brine Tank” - Figure 26.

Figure 24 Figure 25 Figure 26

Installation of the Smart Brine Tank (SBT) Probe

After the Smart Brine Tank Probe is installed, it is necessary to configure some settings.

system ok

7:32 am 2-1-08

> 4) accessories

> 5) sbt sensor

sbt sensor

>installed

brine tank area

>500 sq/in

18 x 38 Brine Tank - 250 sq in 39 x 48 Brine Tank - 1190 sq in

24 x 40 Brine Tank - 450 sq in 42 x 48 Brine Tank - 1380 sq in

24 x 50 Brine Tank - 450 sq in

30 x 50 Brine Tank - 700 sq in

From the home screen, press the DOWN arrow to ACCESSORIES. Press the CHECK

MARK button.

Press the DOWN arrow key to scroll to SBT SENSOR. Press the CHECK MARK button at

SBT SENSOR.

Press the CHECK MARK button to change SBT SENSOR setting. Press the UP or DOWN

arrow to change from NOT INSTALLED to INSTALLED. Press the CHECK MARK when

the correct SBT SENSOR mode is displayed.

Press the CHECK MARK button to set BRINE TANK AREA setting. Press the UP or

DOWN arrow to change AREA SQ/IN. See chart below for correct BRINE TANK

AREA:

Press the CHECK MARK when the correct BRINE TANK AREA is displayed.

salt geometry

>pellet

Press the CHECK MARK button to change SALT GEOMETRY setting. Press the UP or

DOWN arrow to change from PELLET, ROCK OR BRICK. Press the CHECK MARK

when the correct SALT GEOMETRY is displayed.

Installation of Accessories 34

Page 38

Installation of Accessories

Installing the Wireless Remote

Select a location for the wireless remote monitor (Figure 27). The location must be near an electrical outlet. If a modem is

1.

to be used in the remote, then the location should also be near a standard RJ-11 type telephone wall jack.

Use the “Hole Drilling Template” as a guide to drilling two holes to mount the remote monitor. If drilling into wall board,

2.

drill two 5/16” dia holes and insert the plastic drywall anchors into the holes securing them with the two #10 screws

provided. If drilling into a solid surface, drill two 7/32” holes into the surface and screw the two #10 screws into the

holes. In either case, leave a gap of approximately 3/32” between the head of the screw and the wall.

Caution! Do not touch any surfaces of the circuit board. Electrical static discharges may cause damage to the

board. Handle the circuit board by holding only the edges of the circuit board. Keep replacement boards in their

special anti-static bags until ready for use. Mishandling of the circuit board will void the warranty.

(Optional) If a modem is to be installed into the remote monitor, refer to page 37 for installation and setup.

3.

Connect the power cord to the bottom of the remote monitor. If a modem is to be used in the remote, plug a standard

4.

telephone extension cord into the bottom of the remote monitor.

Hang the remote monitor on the two screws.

5.

Disconnect power to the softener. Open the control and connect the RF board into the controller circuit board. Make sure

6.

the RF board is fully seated into all of the sockets (Figure 28). Reconnect power.

Install RF board into unit controller. Line up pins in RF board and press firmly into black connectors. Note orientation of RF

7.

board (Figure 28).

Follow the directions on the next page to program BOTH the main and remote monitor units to communicate with each

8.

other. If modem has been installed in the remote, it is also necessary to follow the directions in the next section of this

manual to configure the main controller to use the modem in the remote.

5 3/8”

SCREWS

Figure 27a

MODEM CONNECTION

POWER CONNECTION

Figure 27b

Back of GBE Board

RF Board (Note orientation)

Figure 28

35 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 39

Control Valve Set-up

system ok

7:32 am 2-1-08

Installation of Accessories

> 4) accessories

> 6) wireless rem

remote display

>installed

channel #

>1

rf frequency

>915 mhz

From the home screen, press the DOWN arrow to ACCESSORIES. Press the CHECK MARK

button.

Press the DOWN arrow to scroll to WIRELESS REM.

Press the CHECK MARK button to change REMOTE DISPLAY setting. Press the UP or DOWN

arrow to change from NOT INSTALLED to INSTALLED. Press the CHECK MARK when the

correct REMOTE DISPLAY mode is displayed.

Press the CHECK MARK button to change CHANNEL # setting. Press the UP or DOWN arrow

to change CHANNEL #. Press the CHECK MARK when the correct CHANNEL# is displayed.

NOTE: The CHANNEL # for the control valve must be

the same as the CHANNEL # for the Remote Display.

NOTE: Do not change RF FREQUENCY for North

American installations.

Wireless Remote Set-up

system ok

7:32 am 2-1-08

> 4) setup

> 1) RF SETUP

channel #

>1

rf frequency

>915 mhz

Continue to press X to return to Home Screen.

From the home screen, press the DOWN arrow to SETUP. Press the CHECK MARK button.

From the SETUP screen, press the CHECK MARK button at RF SETUP.

Press the CHECK MARK button to change CHANNEL # setting. Press the UP or DOWN arrow

to change CHANNEL #. Press the CHECK MARK when the correct CHANNEL# is displayed.

NOTE: The CHANNEL # for the control valve must be the same as the

CHANNEL # for the Remote Display.

NOTE: Do not change RF FREQUENCY for North American installations.

Installation of Accessories 36

Page 40

Installation of Accessories

Check Signal Strength

Check the signal strength once the control valve and wireless remote are setup. On the Softener Controller, go to the Main

Menu/Advanced setup/Diagnostics/Test Wireless to check signal strength. The signal strength indicator (SSI) will show a

value of between 0 and 8. If the SSI is at least 4, then the installation is complete. It the SSI drops below 4, then it may be

necessary to select an alternate location for the wireless remote.

system ok

7:32 am 2-1-08

> 5) adv setup

> 5) diagnostics

> 3) test wireless

wireless test

230/230 rssi=8

From the home screen, press the DOWN arrow to ADV SETUP. Press the CHECK MARK

button.

Press the DOWN arrow to scroll to DIAGNOSTICS.

Press the DOWN arrow to scroll to TEST WIRELESS.

From the TEST WIRELESS screen, press the CHECK MARK button to test.

Installing the Modem (optional)

Note: The modem can be installed into either the back of the main controller or the back of the remote control board. The

functionality of the modem is the same in either installation with the important exception that automatic firmware updating is

ONLY available on units which have the modem installed on the main controller.

Before installing the modem into the back of the GBE board or the back of the remote, the GBE circuit board or the

1.

remote must first be powered off.

When handling all circuit boards, take care to only touch the edges of the circuit boards – not the metal pins. The

2.

electronics on all circuit boards can be damaged by static electricity.

Make sure all of the pins at all four connectors are aligned between the modem board and the main controller board.

3.

Make sure that the modem board is fully seated into all four sockets.

When all connections have been made restore power.

4.

37 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 41

Installation of Accessories

Installing in GBE Board

Open the controller cover and locate the modem connection on the back of the board (see figure 29). Insert line modem board

(P/N 01020307) into the socket on the back of the board. Make sure that all of the pins in all four connectors are aligned and

make sure the modem is fully seated into all of the sockets.

Figure 29

Modem Board

Back of GBE Board

Installing in Remote

Open the remote monitor housing by removing the two screws and squeezing the sides of the monitor housing slightly. Insert

the modem board (P/N 01020307) into the socket on the back of the remote board (Figure 30). Make sure that all of the pins

in all four connectors are aligned and make sure the modem is fully seated into all of the sockets. Snap the two halves of the

remote housing back together using light finger pressure and insert the two screws.

Figure 30

Modem Board

Back of Remote Circuit Board

Modem Setup - GBE

system ok

7:32 am 2-1-08

Installation of Accessories 38

Page 42

Installation of Accessories

> 4) accessories

MARK button.

From the home screen, press the DOWN arrow to ACCESSORIES. Press the CHECK

> 7) Modem

Telephone modem

>installed

Press the DOWN arrow to scroll to MODEM.

If necessary, press the CHECK MARK button to change TELEPHONE MODEM setting.

Press the UP or DOWN arrow to change from NOT INSTALLED to INSTALLED.

Press the CHECK MARK when the correct TELEPHONE MODEM mode is displayed.

If necessary, press the CHECK MARK button to change MODEM LOCATION

Modem location

>in main control

Call frequency

>every 10 regens

setting. Press the UP or DOWN arrow to select IN MAIN CONTROL VALVE or

IN REMOTE. Press the CHECK MARK when the correct MODEM LOCATION is

displayed.

If necessary, press the CHECK MARK button to change CALL FREQUENCY setting.

Press the UP or DOWN arrow to increase or decrease CALL FREQUENCY. Press the

CHECK MARK when the desired CALL FREQUENCY is displayed.

The default value of EVERY 10 REGENS can be changed from 1 to 99 successful regenerations. If set to 1, the

unit will call in the following morning after each regeneration. The interval can also be set to 0, meaning the unit

would NEVER call in, unless there was a problem detected. It is recommended for a typical installation the default

value of EVERY 10 REGENS is used.

time zone

Press the CHECK MARK button to change TIME ZONE setting. Press the UP or

DOWN arrow to increase or decrease TIME ZONE. Press the CHECK MARK when

>00:00

the correct TIME ZONE is displayed.

When using a modem, the control will occasionally access the internet to synchronize the date and time. In order

to do this correctly, the control must be told which time zone it is installed in. The time zone is specified as so

many hours ahead or behind GMT time. The “GMT offset” for some common cities are listed below:

GMT Offset

New York -5:00 (and anywhere in EST)

Chicago -6:00 (CST)

Denver -7:00 (MST)

Los Angeles -8:00 (PST)

London 0:00

Paris 0:00

Rome +1:00

39 CULLIGAN GLOBAL ELECTRONIC CONTROLLER

Page 43

Installation of Accessories

dealer id

>00000

Press the CHECK MARK button to change DEALER ID setting. Press the UP or

DOWN arrow to increase or decrease each digit of the DEALER ID. Press the

CHECK MARK to move to the next digit. Press the CHECK MARK when the correct

DEALER ID is displayed. The dealer ID is your dealership’s account number. Enter with

leading zeroes, if necessary.

data phone #

Press the CHECK MARK button to change DATA PHONE # setting. Press the UP or

DOWN arrow to increase or decrease each digit of the DATA PHONE #. Press the

>18884137028

CHECK MARK to move to the next digit. Press the CHECK MARK when the correct

DATA PHONE # is displayed. Use a local number whenever possible.

It is necessary to provide a telephone number to be called by the unit. Typically, it is

desired that the unit call a local access number. These local access numbers, for nearly

every area code around the globe, can be found from the www.myculligan.com website

at http://www.myculligan.com/technical/tech_ref-gbe-boards.asp. The unit can also

be programmed with the default toll-free access number. Use a local number whenever

possible.

Test Modem

This menu attempts to send in a “test message”. The screen indicates whether or not this process is successful.

Sending a “test message” will also update the time and date on the GBE controller to the correct time. If the

modem is installed on the main controller (as opposed to installed in the remote control) then this testing process

will also check to see if there is an updated version of firmware available on the Culligan servers.

After conducting a phone line test, it is important to verify that the new time and date settings on the controller are

correct. If the new time setting has the incorrect value for the “hours” it is likely that the time zone setting on the

control is incorrect. The time zone setting is found under the Main

Menu / Accessories / Modem screen and is displayed in the format of GMT +/- X hours. (See the section of this

manual called “Installing the modem”

system ok

7:32 am 2-1-08

> 5) adv setup

> 5) diagnostics

> 5) test phoneline

modem test

emailing now please wait...

From the home screen, press the DOWN arrow to ADV SETUP. Press the CHECK

MARK button.

Press the DOWN arrow to scroll to DIAGNOSTICS.

Press the DOWN arrow to scroll to TEST PHONELINE.

From the TEST PHONELINE screen, press the CHECK MARK button to TEST.

Installation of Accessories 40

Page 44

Installation of Accessories

modem email

success

modem test time

set success

modem test

checking for new fw

modem test

no new fw

POSSIBLE RESULTS