Page 1

Service Manual

Cub Cadet Z-Force

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

This Service Manual is not a substitute for the Operator’s Manual. You must read, understand

and follow all of the directions in this manual as well as the Operator’s Manual before working

on this power equipment.

CUB CADET LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA

FORM NO.769-00967

(11/2003)

Page 2

Page 3

TABLE OF CONTENTS

Deck Leveling....................................................................................................1

Deck Removal...................................................................................................2

Deck Belt Removal............................................................................................3

Spindle Removal............................................................................................... 3

Spindle Inspection.............................................................................................4

Tracking and Neutral Adjustment...................................................................... 5

Lap Bar..............................................................................................................9

Brakes...............................................................................................................10

Reverse Cutout Switch Adjustment...................................................................12

Electrical System...............................................................................................14

Deck Lift Shaft...................................................................................................19

Steering Input Shaft...........................................................................................23

Pivot Bar............................................................................................................25

Engine............................................................................................................... 27

Z-Force Model Lineup....................................................................................... 30

Page 4

Page 5

Z Force

1. DECK LEVELING

1.1. Park the mower on a flat paved surface, engage

the parking brake, shut off engine, remove the

key from ignition switch, disconnect the spark

plug wires.

1.2. Check front tire pressure. Adjust as necessary to

20-25 psi.

1.3. Check rear Drive tire pressure. Adjust as necessary to 8-10 psi.

NOTE: Tire pressure can effect blade height as

much as a 1/4 “

1.4. Measure the distance from the right rear corner

of the transmission mounting bracket to the

ground. Repeat on the left side. See Figure 1.4.

1.6. To make side to side level adjustment align

blades across the width of the deck, perpendicular to with center line of the mower.

See Figure 1.6.

Measure blade height

Figure 1.6

1.7. Measure height of the outer tip of the right blade.

1.8. Measure height of the outer tip of the left blade.

Figure 1.4

1.5. Adjust tire pressure within specified range, to

equalize the left and right measurements. This

will level the frame right to left.

1.9. Adjust the threaded link at the left side of the

deck, using two 3/4” wrench, so the height of the

blade tips match. The right side link is not

adjustable. See Figure 1.9.

Deck height

adjustment nuts

Figure 1.9

1

Page 6

Z Force

1.10. To do fore and aft pitch adjustment, align the

blades front to back. See Figure 1.10.

Measure

blade height

Figure 1.10

1.11. Measure blade height distance of the rear tip of

either outer blade.

1.12. Measure the blade height of the front tip of the

center blade.

NOTE: The blade height of the rear tips should

be 1/8” to 1/4” higher than the front tip.

1.13. Adjust blade pitch using a 7/8” wrench to

lengthen or shorten the front lift rods.

See Figure 1.13.

1.16. Tighten inner jam nut to lock the adjustment.

1.17. Double-check side-to-side and pitch measurements before returning the unit to service.

2. DECK REMOVAL

2.1. Position the mower on a shop lift, turn off the

engine, and remove the key from the key switch.

2.2. Raise deck to the highest position.

2.3. Raise the lift.

2.4. Move deck cart under lift.

2.5. Lower lift so that deck is BARELY touching cart

2.6. Using deck lift handle, lower deck on to cart.

2.7. Unhook the belt tensioning lever on the left side

of the deck, and swing the lever outward to

relieve tension on the deck belt and the PTO

belt.

2.8. Remove PTO belt.

Front lift rods

Jam nuts

Figure 1.13

1.14. Using a 7/8” socket loosen or tighten the outer

jam nuts to obtain proper measurement.

1.15. Check for “slack” in front lift rods. If one rod is

looser than the other, deck vibration will be

amplified.

2.9. Remove either linch pin from the lift rod cross

bar, and withdraw the bar. See Figure 2.9.

Lynch pin

Lift rod

cross bar

Front lift rod

Figure 2.9

NOTE: As the cross bar clears each lift rod, it

can be easily unhooked from the deck and

removed.

2

Page 7

Z Force

2.10. Remove both front lift rods.

2.11. Pull the J-pins outward to release rear deck lift

hangers. Rotate the J-pins to lock them in the

out position

2.12. Raise lift. Confirm that none of the belts or linkages will interfere with removal of the cutting

deck.

2.13. Pull cart from under lift.

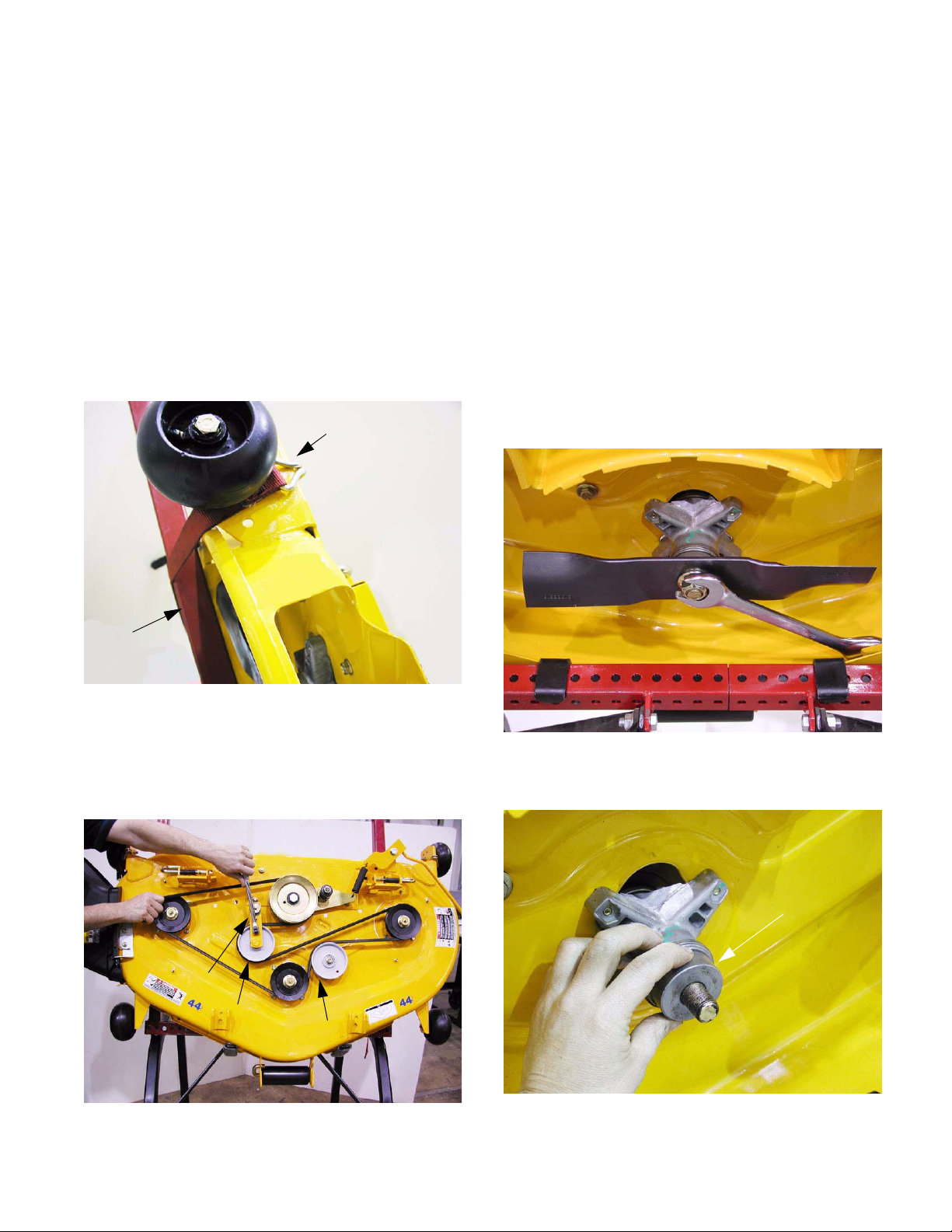

3. DECK BELT REMOVAL

CAUTION: Before doing any work to the deck, it

needs to be safely secured so that it will not fall.

See Figure 3.0.

Strap

3.2. Pull the belt below the flat idler and remove the

belt from the spindle assemblies and stack pulley.

4. SPINDLE REMOVAL

4.1. Strap deck to cart.

4.2. Tilt top of cart until securely locks in place.

4.3. Using two 1 1/8” wrenches remove blade nut

from spindle shaft. See Figure 4.3.

Deck service

cart (Heftee)

Figure 3.0

3.1. Insert a 3/8” breaker bar into the hole on idler

arm assembly. Rotate the idler arm to the left

while rolling belt off of the flat idler pulley.

See Figure 3.1.

Idler

arm

Flat idler

(tensioning)

Stationary

idler

Figure 4.3

4.4. Remove blade and spacer. See Figure 4.4.

Spacer

Figure 3.1

Figure 4.4

3

Page 8

Z Force

4.5. Remove the spindle shaft and pulley from the

spindle housing. See Figure 4.5.

Spindle pulley

Hex head on

spindle shaft

Figure 4.5

NOTE: If the spindle is to be removed from the

deck, rather than serviced in-situ, the pulley and

shaft must be removed before the spindle housing can be removed from the deck.

4.6. Using a 1/2” socket and extension remove the

four bolts holding the spindle housing to the

deck. See Figure 4.6.

5. SPINDLE

NOTE: Spindles can be rebuilt while attached to

deck, or they can be removed for service.

5.1. If the spindle is removed from the deck, carefully

fixture it in a bench vice.

5.2. Remove covers. See Figure 5.2.

Bearing cover (bottom)

Figure 5.2

5.3. Using soft drift, remove the bottom bearing from

the spindle housing. See Figure 5.3.

Spindle

bolts

Figure 4.6

Tapered roller bearing

Spindle housing

seen from top

NOTE: The seal will come out with the bearing

5.4. Remove the spacer that fits between the bearings.

5.5. Repeat bearing and seal removal on the second

bearing in the spindle housing.

Insert drift

Figure 5.3

Seal

Note: lip

faces out

4

Page 9

Z Force

5.6. Clean and inspect all of the components.

Replace any that exhibit wear or damage. Evaluate the feasibility of repair versus complete

spindle replacement.

5.7. If a roller bearing is damaged, drive the bearing

race out of the housing and replace it as well.

Do not over-look the bearing race at the inspection stage. See Figure 5.7.

Cover

Seal

Bearing

Seal

Cover

Spacer

5.11. The double pulley that transfers drive from the

PTO belt to the deck belt has two different size

sheaves. The PTO belt rides in the top sheave,

which is the wider of the two, to accommodate

the angularity that results from different cutting

heights. See Figure 5.11.

PTO Belt

(wide sheave)

deck belt

(narrow sheave)

Figure 5.11

Figure 5.7

5.8. Drive new bearing races into the spindle housing

if required, using a heavy hammer or press, and

and appropriate driver.

5.9. Pack the bearings with grease and assemble the

spindle.

5.10. Install the seals with the lips facing outward,

using an appropriate driver.

NOTE: Failure to install the double pulley in the

right orientation will result in belt loss and premature belt failure.

6. TRACKING AND NEUTRAL ADJUSTMENT

6.1. For preliminary checks, park the mower on a

flat paved surface, engage the parking brake,

shut off engine, remove the key from ignition

switch.

6.2. Check front tire pressure. Adjust as necessary to

20-25 psi.

6.3. Measure distance from the right rear corner of

the transmission mounting bracket to the

ground. Measure the distance from the left rear

corner of the transmission mounting bracket to

the ground. If the measurements are not equal,

the air pressure in the tires will need to be

adjusted to level the frame.

6.4. Check rear Drive tire pressure. Adjust as necessary within the range of 8-10 PSI.

NOTE: This adjustment may be redundant if the

deck has recently been leveled.

5

NOTE: Tire pressure will effect tire circumfer-

ence, which will effect tracking.

Page 10

Z Force

6.5. Check the IHT (Integrated Hydrostatic transmission) release the levers to be sure the transmissions are fully engaged. See Figure 6.5.

Release rod for right

hand side IHT, seen at

rear of frame.

Released position; lift

and push in to engage

Figure 6.5

6.6. Check steering linkage for wear and damage.

i.e.; loose ball joint ends, worn bellcrank bushings, and loose or bent hardware.

IHT release rod

IHT release

lever

Forward end of the same

rod, connected to lever on

right hand side IHT.

6.11. Turn the engine off and remove the key from the

switch.

6.12. If there is wheel movement in neutral, disconnect the control linkage from the transmission

that is driving that wheel.

NOTE: If both wheels “creep” then both control

linkages need to be disconnected.

6.13. Using two 1/2” wrenches, remove the Nylock nut

holding steering link rod end to the return-toneutral mechanism. See Figure 6.13.

Steering

Return-to-neutral mechanism

link rod end

6.7. Replace any worn or damaged components

before attempting to make a tracking adjustment.

6.8. After the preliminary items have been covered,

check the neutral adjustment.

6.9. Raise rear wheels off ground and support the ZForce by the frame.

6.10. Start the engine and release parking brake, do

not move the lap bars from the start position.

Neither the rear wheels nor the brake rotors

should move. See Figure 6.10.

Leave the lap bar in the

“START” position

notch. This will hold

the lap bar in neutral.

Parking brake

released

Figure 6.13

6.14. With the steering link rod disconnected, start the

engine, release the parking brake, and check for

wheel and brake rotor movement.

6.15. If “creep” has been eliminated by disconnecting

the linkage, then only the linkage must be

adjusted to eliminate the “creep”. If “creep” still

exists, then the return-to-neutral mechanism on

the transmission must be adjusted.

Figure 6.10

6

Page 11

Z Force

6.16. To adjust the return-to-neutral mechanism,

loosen the socket head cap screw that locks the

indexing plate on the return-to-neutral mechanism in position using a 1/4” allen wrench. It

should be possible to move the indexing plate

with light effort. See Figure 6.16.

Rotate entire mechanism to adjust

Socket head

cap screw

Figure 6.16

Indexing plate

6.19. Start the engine. Carefully rotate the return-toneutral mechanism until a position is found that

results in no “creep”.

6.20. Tighten socket head cap screw. Confirm that the

adjustment did not shift as the screw was tightened.

6.21. Repeat the procedure on the second IHT, if necessary

6.22. Turn the engine off, and remove the key from the

key switch.

6.23. Reattach steering link rod.

6.24. Enable the seat safety switch.

6.25. The steering link rods can be lengthened or

shortened to adjust tracking.

6.26. Loosen the jam nuts on the link that connects

the bellcrank to the return-to-neutral mechanism.

See Figure 6.27.

6.17. Temporarily disable the seat safety switch.

Because the plug has a double-safety, simply

unplugging the switch has no effect. Applying

pressure to the part of the seat normally occupied by the operator’s gluteus maximus will

extend the three tabs. Clamping one of those

tabs with a pair of alligator clips or a similar tool

will hold the switch in the actuated position.

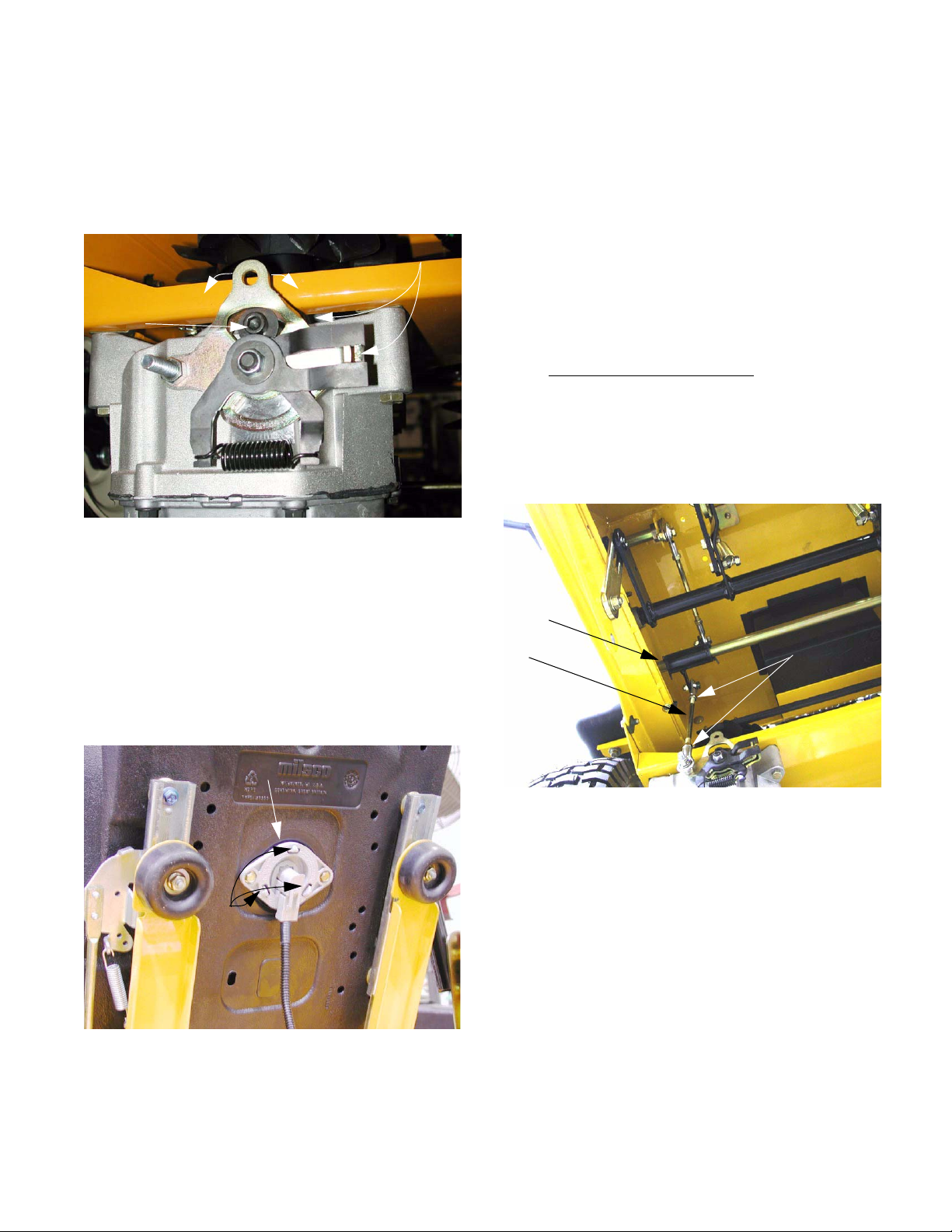

See Figure 6.17.

Seat safety switch

tabs

Bellcrank

Link

Figure 6.26

NOTE: One end of the steering link rod has a

right hand thread, the other end has a left hand

thread. When both jam nuts are loose, the steering link rod can be rotated to make a length

adjustment.

NOTE: When adjusting the steering link rods,

maintain sufficient engaged thread length within

the rod end.

Jam nuts

Figure 6.17

6.18. Insure that no unsafe conditions will be created

by starting the engine and operating the drive

system.

7

Page 12

Z Force

6.27. Clamp the fingers on the return-to-neutral mechanism so that they hold the tab on the control

quadrant to the tab on the indexing plate.

See Figure 6.27.

Rotate link

to adjust

NOTE: This will effectively lock the return-toneutral mechanism positively into neutral.

6.28. Rotate the steering link rod to lengthen or

shorten it until the lap bar is centered in the

notch at the neutral position.

6.29. Tighten the jam nuts on the steering link rod to

lock-in the adjustment.

6.30. Remove the clamp.

6.31. Repeat the procedure on the second IHT if necessary.

6.32. Lower the Z-Force to the ground and test-run it

in a safe area.

6.33. With the lap bars pushed forward or pulled back

an equal amount, the Z-Force mower should

track straight.

6.34. After the steering link rods are adjusted, set the

lap bar stop bolts.

6.35. Loosen the jam nuts on both lap bar stop bolts.

Control quadrant

Indexing

plate

C clamp

Figure 6.27

6.36. With the engine turned off, push each lap bar

gently forward until it reaches the end of the

travel allowed by the return-to-neutral mechanism. See Figure 6.36.

Steering pivot

bracket

Jam nut

Stop bolt

Figure 6.36

6.37. If there is a difference in the travel of the two lap

bars, adjust the stop bolt on the lap bar with the

least travel so that it just contacts steering pivot

bracket as the lap bar reaches the end of its

travel.

6.38. Adjust the second lap bar so that it matches the

first.

NOTE: If the mower does not track straight after

these adjustments are complete, particularly on

a slight grade, internal wear of the transmission

on the side that it tends to track toward may be

the cause.

NOTE: For the first two years of residential use,

or one year of commercial use, the IHTs are

within their warranty period, and will be replaced

as complete units if a warrantable failure

occurs. Beyond the warranty period, complete

service procedures for the Hydro-Gear 31-2400

IHT are outlined in Hydro-Gear publication: BLN-

51134.

NOTE: Replacement IHTs are shipped dry

because of ICC regulations. Prior to installation,

they must be filled with 79 fl.oz. or 20W50 motor

oil. When properly filled, the level should reach

a point 1 7/8” down from the TOP of the transmission housing.

Lap bar

8

Page 13

NOTE: Fill the IHT and check the fluid level

through the vent port at the top off the housing.

NOTE: The IHT may be spun with a drill motor

and purged prior to installation, or they may be

purged after installation.

NOTE: To purge:

• With the engine running and the by-pass valve

open (release rod pulled-out), slowly stroke the

directional control to its full travel in both directions 5 or 6 times.

• Turn off the engine and check the fluid level in

the IHT.

Z Force

7.2. Before tightening the bolts, pivot each lap bar on

the steering pivot bracket to fit the operator.

7.3. Position both lap bars in their respective notches

at the start position. They should align with each

other when swung inward from the start position

slot.

7.4. Tighten the bolts that hold the lap bars to the

steering pivot brackets. See Figure 7.4.

• Repeat the procedure with the by-pass valve

closed (release rod pushed all the way in).

• Repeat until the IHT performs at normal operating speed and cavitation wine has subsided.

7. LAP BAR

NOTE: Lap bars should be adjusted so the oper-

ators upper arm are relaxed and approximately

vertical, and operators forearms should horizontal.

NOTE: Lap bar adjustment should be performed

after tracking and neutral control has been confirmed to be correct.

7.1. Using a 1/2” socket and 1/2” wrench, adjust lap

bars up and down by installing the bolts that hold

the lap bar to the steering pivot bracket in a different set of holes. Install the bolts snugly

enough that each lap bar can pivoted on the

lower mounting bolt with light effort.

See Figure 7.1.

Paired mounting holes

Lap bar reach

adjustment

Figure 7.4

Figure 7.1

Lap bar

height adjustment

9

Page 14

Z Force

8. BRAKES

NOTE: While the mower is in motion, all braking

is performed dynamically through the hydraulic

pumps and traction motors within the IHTs. This

is controlled by the lap bars. When parked, with

the engine off, the hydraulic system locks the

drive wheels.

8.1. To push the unit, you must release the hydraulic

brake. Locate the release levers at the rear of

the transmission mounting bracket. Pull them

toward the rear and lower the wide area of the

rod into the keyhole slot.

8.4. Prior to adjustment, check the condition of the

parking brake cables. See Figure 8.4.

• The cables should not be chafed, kinked, burnt,

or corroded. They should move freely.

• The springs should not be over-stretched or corroded.

Check condition of:

cables

springs

return springs

Figure 8.4

Figure 8.1

8.2. Lift and safely support the rear of the mower.

8.3. Remove the lug nuts from the rear wheels using

a 3/4” socket, and remove the wheels.

8.5. Unbolt the left side control console using a 3/8”

socket, and remove the console.

NOTE: Disconnect the left neutral switch to

avoid damaging electrical components.

8.6. Inspect the lever end of the cables. The Z-fitting

on the lever end of the cable should not be damaged. The cable housing ends should lock

securely into the bracket. See Figure 8.6.

Cable bracket

Cable ends

Cable cores

Parking brake

Z-fittings

lever

10

Figure 8.6

Page 15

Z Force

8.7. Check the brake lever mounting hardware.

See Figure 8.7.

Parking brake lever

Spring

Spacer

Nut

Friction washer

Flat washer

Capscrew

Figure 8.7

8.8. Prior to adjustment, check the brake pawls and

rotors. See Figure 8.8.

Brake rotor

Adjustment point

8.9. Prior to adjustment, check the brake pawls and

rotors. See Figure 8.9.

Shoulder

Right side brake rotor:

Shoulder out.

Figure 8.9

• The teeth on the pawls and rotors should not be

worn, chipped or rounded.

• Both ends of the brake shaft on each transmission are splined. The brakes are mounted to the

outside of each transmission.

Brake pawl

Figure 8.8

• The teeth on the pawls and rotors should not be

worn, chipped or rounded.

• Both ends of the brake shaft on each transmission are splined. The brakes are mounted to the

outside of each transmission.

• The right side brake rotor fits on the brake shaft

with the shoulder facing the transmission.

• The shoulder on the pawl should face in the

same direction as the shoulder on the rotor that

it engages. The pawl should not bind on the

shoulder of the bolt that it pivots on.

• The left side brake rotor fits on the brake shaft

with the shoulder facing the wheel.

• The shoulder on the pawl should face in the

same direction as the shoulder on the rotor that

it engages. The pawl should not bind on the bolt

that it pivots on.

8.10. Pull out both hydro. pump rods to disengage the

hydraulic brakes.

8.11. Install the left side control console.

8.12. Move the parking brake lever to the ON position.

8.13. Check for full tooth engagement between each

brake pawl and rotor. If they are not fully

engaged, move the corresponding rear hub

slightly to align the teeth.

11

Page 16

Z Force

8.14. Move the parking brake lever to the OFF position. There should be roughly 1/16” clearance

between the lowest tooth on each brake pawl

and the nearest tooth on the rotor.

See Figure 8.14.

Left side brake rotor:

Shoulder in

Figure 8.14

8.15. If brake adjustment is necessary, loosen the jam

nuts that hold the threaded end of the cable

housing into the bracket.

8.16. Thread the nuts up or down the length of the

threaded end as necessary to achieve correct

adjustment.

9. REVERSE CUT-OUT SWITCH ADJUSTMENT

NOTE: There are two reverse switches in the

wiring harness of the Z-Force.

NOTE: Both reverse switches are normally

closed and wired in parallel to feed power to the

electric PTO clutch. When both lap bars are

pulled back into neutral or reverse position, the

plungers on the switches are depressed, breaking the contacts within the switches. When either

switch is closed, but the other remains open,

power reaches the PTO clutch. When both sets

of contacts are open, the PTO clutch gets no

power, and turns off.

9.1. Unbolt control consoles using a 3/8” socket, and

remove the consoles.

NOTE: The consoles can be carefully set-aside

without disconnecting the throttle cable or the

neutral switches that are attached to each one.

9.2. Use a bungee cord or similar means to apply

light rearward force to the lap bar on the side

that is not being adjusted. This is will actuate the

switch not being adjusted, opening the contacts. With one switch actuated, the switch

being adjusted will control the PTO clutch.

See Figure 9.2.

Bungee cord

8.17. After adjustment is complete, install the wheels

and lower the rear of the unit to the ground.

8.18. Torque lug nuts to 40 ft. lbs.

8.19. Release hydro. pump rods from the small side of

the keyhole slot, and push them forward to

engage the hydros.

8.20. Test run the unit in a safe area before returning it

to service.

NOTE: If tracking is out of adjustment, biased in

the reverse direction, the brake pawl will wedge

into the brake rotor with force. This force is sufficient to over-come the force of the brake return

spring. If one or both brakes jam in the on position, and the linkage appears to work normally,

check the tracking adjustment.

Figure 9.2

12

Page 17

Z Force

9.3. To adjust the reverse switch bracket, loosen the

machine screws that hold the reverse switch

bracket to the control housing using a 5/16”

wrench. See Figure 9.3.

Reverse switch bracket

screw (accessible

from outside)

Blue wires

Reverse switch bracket

screw (only accessible by

removing control console)

Figure 9.3

NOTE: There is one screw on each switch that is

accessible from outside the control console, and

one that cannot be reached without removing

the control console

9.8. Repeat this adjustment on the opposite side

reverse switch.

One screw is accessible

from outside the control

console

Switch adjustment range

The other screw must be

reached from inside the

control console.

Figure 9.8

9.9. If shop noise prevents the technician from

clearly identifying the “click” from the electric

PTO clutch, a 12V test light may be installed in

the lead that connects to the PTO clutch.

See Figure 9.9.

NOTE: The switch being adjusted should be just

loose enough to allow the reverse switch bracket

to be moved with light pressure.

9.4. Turn the key switch to the “ON” position, but do

not start the engine.

9.5. Pull forward on the lap bar that operates the

reverse switch to be adjusted. Pull forward just

far enough to take-up any play in the linkage, so

that the control quadrant on the IHT is just at the

“forward” edge of the neutral range.

9.6. Pivot the reverse switch bracket back, until an

audible “click” is heard, as the PTO clutch disengages.

9.7. Tighten the screws, and double-check the

adjustment. See Figure 9.8.

Green ground wires

Install test light here if unable to

hear the PTO clutch because of

background noise.

Blue wires from

reverse switches

PTO clutch

Figure 9.9

9.10. Install both control consoles when adjustment is

complete.

NOTE: install the control consoles with two bolts

each for testing purposes. After correct operation is confirmed, install all of the mounting bolts

in each control console.

13

Page 18

Z Force

9.11. Test the operation of the mower and reverse

safety circuits in a safe area before returning the

unit to service. With the engine running, and the

PTO switch turned on:

• The blades should turn when both lap bars are in

the forward position.

• The blades should turn when one lap bar is in

the forward position, and the other is in neutral

or reverse.

• The blades should stop turning when both lap

bars are in non-forward (neutral or reverse) position.

• The blades should begin turning again when

either lap bar is moved to the forward position.

• The Z-Force is unique in the Cub Cadet product

line in that the PTO switch does not need to be

re-set after a safety switch PTO shut-down. As

soon as at least one lap bar is pushed forward,

the blades will begin turning.

NOTE: Because this procedure involves safety

switch testing and adjustment, extreme caution

should be used in testing the operation of the ZForce.

10. ELECTRICAL SYSTEM COMPONENTS

This section is intended to help technicians identify the

location and function of specific components in the ZForce electrical system. In diagnosing an electrical

problem, this section may be used for reference in conjunction with a wiring diagram.

10.1. The Seat Safety Switch is located in the seat

assembly. The contacts in the switch are normally closed (N.C.). When the seat is unoccupied, the contacts close, energizing relay #2 and

relay # 3. When relay #2 is energized, and relay

#1 is energized by the release of the parking

brake, a ground path is completed to the magneto, turning off the engine.

See Figure 10.1.

Seat switch

Figure 10.1

NOTE: A pair of contacts are built into the har-

ness side of the plug, so that customers cannot

defeat the seat safety switch by simply unplugging it. It will default into a closed circuit condition if unplugged. for diagnostic purposes, the

seat safety switch may be temporarily disabled

by a servicing dealer by pressing on the seat

directly above the switch. This will extend three

tabs. One of the tabs can be held in the

extended position using an alligator clip or similar device. Care must be taken not to return the

Z-Force to the customer with the seat safety

switch defeated.

14

Page 19

Z Force

10.2. The Parking Brake Switch is located on the right

side of the control housing. It is accessible by

removing the right side control console. The

switch is actuated by a retainer spring that

moves with the parking brake lever.

See Figure 10.2.

Parking brake lever

Parking brake switch

Retainer spring

Figure 10.2

• One set of contacts (orange wire and orange

wire with white trace) prevents the starter motor

from turning unless the parking brake has been

set.

• The second set of contacts (red wire and red

wire with white trace) provide power to relay #1.

When relay #1 is energized, a potential ground

path is created to the magneto, through the neutral switches that are activated by each lap bar.

If relay #1 is energized (parking brake set) and

the lap bars are moved from the start position

notch, the ground path is completed, turning-off

the engine.

10.6. The two park (neutral) switches are located in

the control console on each side of the Z-Force.

Each is actuated by the movement of a lap bar

into or out of the start position notch.

See Figure 10.6.

Start position notch

10.3. The parking brake lever must be moved out of

the way, and retainer spring removed to provide

clearance for removal of the parking brake

switch.

10.4. Inside the control housing, the squeeze the tabs

to remove the switch. The harness connector

may be separated either before or after the parking brake switch is removed from the control

housing. See Figure 10.4.

Red wires

Power to relay #1

Starter inhibit

circuit

Orange wires

Orange wires

(starter inhibit circuit)

Yellow and green wires

(magneto ground circuit)

Figure 10.6

Park

switch

Figure 10.4

10.5. There are two sets of contacts in the parking

brake switch. Both sets are normally open

(N.O.).

15

Page 20

Z Force

10.7. Each park switch contains two sets of contacts.

One set of contacts in normal closed (N.C.). The

other set of contacts is normally open (N.O.).

• The orange wires (one with black trace on the

right side, one with a white trace on the left side)

are in the starter inhibit circuit. They pass power

through the normally open set of contacts only

when the lap bars are in the “Start” position,

depressing the plungers and closing the contacts.

• The yellow and green wires are in the magneto

ground circuit. When relay #1 is energized by

the application parking brake, the normally

closed contacts will complete a ground path to

the magneto when the lap bars are moved from

the “Start” position, releasing the plunger and

closing the contacts.

10.8. The reverse safety switches are located on the

control housing, accessible by removing the left

and right control consoles. (see previous section)

10.9. Each reverse switch is located “down-stream” of

the PTO switch. They are normally closed

(N.C.). If the contacts of both switches are

opened (lap bars in non-forward position) power

is interrupted to the PTO clutch, stopping the

blades. See Figure 10.9.

PTO Switch

Key switch

Park (neutral)

safety switch

Relay #3 Relay #2 Relay #1

Figure 10.10

10.11. Relay #1: See Figure 10.13.

• Terminal A: 2 yellow wires. One goes to the

magneto, the second goes to the M terminal on

the key switch.

• Terminal B: red wire, white trace. Energizes

windings when parking brake is applied.

• Terminal C: 2 yellow wires with white traces.

Each leads to the N.C. terminal on one neutral

switch via terminal E on the PTO switch. If either

lap bar is moved from the “start” position (notch)

while the relay is energized (brake applied) terminal C will have continuity with terminal A, providing a ground path to the magneto, turning off

the engine.

Figure 10.9

10.10. The three relays are positioned under the right

side control console. See Figure 10.10.

• Terminal D: Green wire. Constant ground to

windings

• Terminal E: Yellow wire with black trace. Connects to terminal A on relay 2. Terminal E connects to terminal A when relay #1 is not

energized.

10.12.Relay #2: See Figure 10.13.

16

Page 21

Z Force

s

• Terminal A: Yellow wire with black trace from

relay #1, terminal E. When relay #2 is energized, Terminal A has contact with Terminal E.

Terminal A has contact with terminal C when

relay #2 is not energized.

• Terminal B: 2 black wires. Power is provided to

the windings through the seat switch, when the

seat is unoccupied. Second black wire is a

jumper to terminal B on relay #3.

• Terminal C: 2 green wires. One is a jumper to

terminal D on relay #2. The second one is a

ground path through the G terminal on the key

switch. When relay #1 is not energized (parking

brake off) and relay #2 is energized (seat

vacant), a ground path is provided for the magneto, turning off the engine.

• Terminal D: 2 green wires. One is a jumper from

terminal C, the other is a ground path. The G

terminal on the key switch finds it’s ground

through the jumper wire.

• Terminal E: Empty.

10.13.Relay #3: See Figure 10.13.

• Terminal A: Yellow wire with black trace, from

terminal B on the PTO switch. Terminal A has

continuity with terminal C when relay #3 is energized by the absence of a butt in the seat. When

the PTO switch is on, and the seat is empty, the

magneto is grounded, turning off the engine.

85 = D

86 = B

87 = C

Figure 10.13

10.14.The key switch is located in the right side control

console. The terminal locations are clearly

marked on the back of the switch. The switch

f u n c t i o n s a s f o l l o w s : S e e F i g u r e 1 0 . 1 4 .

• Off: terminals G, M, and R, have continuity.

• Run: terminals B,R, and L, have continuity.

• Start: terminals B, S, and L, have continuity.

N.C. terminals

N.O. terminals

Common

terminal

30 = A

87A = E

• Terminal B: Black jumper wire from Terminal B

on relay #2. Provides power to the windings of

both relays when the seat is occupied.

• Terminal C: 2 Green wires. One is a jumper wire

to Terminal D. The second green wire leads to

the neutral switches, providing a ground path for

them through jumper to terminal D.

• Terminal D: Two green wires. One is a jumper to

terminal C. The other is a constant ground for

the relay #3 windings and terminal C.

• Terminal E: Empty.

Figure 10.14

17

Page 22

Z Force

10.15.The PTO switch is located just behind the key

switch.

• Terminal A (Common) to G: Orange wire with

white trace leads to parking brake switch from

terminal A. The N.O. contacts in the parking

brake close when the parking brake is applied,

completing the path to trigger the solenoid. The

orange wire with black trace provides power to

terminal G when the N.O. contacts of both neutral switches are closed by moving the lap bars

into the “start” position. Starter inhibit circuit.

• Terminal B (common) to terminal E: Yellow wire

with black trace leads from terminal B to terminal

A on relay #3, where it completes a path to

ground if the relay is energized by the seat

switch. Terminal E has 2 yellow wires with white

traces. Each one leads to the N.C. contacts on

one of the 2 neutral switches. If the PTO switch

is turned on, and the seat is empty, a ground

path is completed to the magneto, turning off the

engine.

• Terminal C (common) to terminal F: A red wire

provides power to terminal C from the L terminal

on the key switch. When the PTO switch is in

the ON position, contacts are closed to terminal

F. 2 blue wires on terminal F provide power to

the PTO clutch via the 2 reverse switches.

10.16. The starter solenoid is located near the right

rear corner of the control console.

See Figure 10.16.

10.17.The voltage regulator / rectifier is located near

the left front corner of the engine, adjacent to the

starter motor. See Figure 10.17.

Regulator/

rectifier

A.C. out-put

from stator

Magneto ground

Fuse (20A)

Regulated out-put

Figure 10.17

10.18.To test stator out-put, disconnect the plug from

the regulator / rectifier. Start the engine, and run

it at full throttle. Checking A.C. voltage at each

white wire should yield a reading of roughly 11

volts. See Figure 10.18.

Black probe from

DVOM to ground

Stator out-put leads

Red probe

from DVOM

STARTER SOLENOID

Figure 10.16

Figure 10.18

18

Page 23

Z Force

10.19.Checking the out-put from the regulator / rectifier, by probing the red wire with the red lead of a

DVOM set to read D.C. voltage while grounding

the black DVOM lead will show a reading of system voltage. See Figure 10.19.

System voltage

Figure 10.19

10.20.To get a true reading of regulated rectified D.C.

voltage from the alternator, it would be necessary to remove the red wire from the molded

connector. A much more useful measurement is

D.C. Amperage. Because many DVOMs cannot

measure beyond 2 or 3 amps D.C., an additional

tool called a shunt must be used.

10.21.To check DC output from the regulator / rectifier

utilize a Brigs and Stratton DC shunt (B&S part

number 19359) installed on the negative battery

post so that it is in series with the negative battery cable. Set DVOM to the 300mV scale. The

red test lead should be connected from the Volts

and Ohms plug on the DVOM to the test connection on the shunt that is closer to the negative

battery post. The black test lead should be connected from the “COM” plug on the DVOM to the

test connection on the shunt that is nearest the

battery ground cable connection. Start and run

the engine at maximum speed (3,600 R.P.M.).

10.22.The reading on the DVOM will vary with the state

of charge of the battery. The charging system is

rated at 13 Amps. If the battery is in need of

charge, the reading on the DVOM may be as

high as 11 Amps D.C., if the battery is fully

charged, a reading in the vicinity of 3 amps DC

is likely. See Figure 10.22.

Shunt

Figure 10.22

11. DECK LIFT SHAFT ASSEMBLY

11.1. Remove the deck as described in the “Deck

Removal” section of this manual.

11.2. Disconnect the negative battery cable using a

pair of 7/16” wrenches. See Figure 11.2.

Battery box

19

Steering link

Figure 11.2

NOTE: Generous access to the steering link

rods, bellcranks, and steering bellcrank shaft

can be obtained by removing the battery completely.

Page 24

Z Force

11.3. Take note of or mark the orientation of the steering bellcrank assemblies. See Figure 11.3.

Bellcrank

Short arm

(inside)

Figure 11.3

NOTE: The long arm of each bellcrank connects

to the link leading to the hydro. The short arm on

each bellcrank connects to the steering input

shaft assembly.

NOTE: There are different part numbers for the

left and right bellcranks. The arms are farther

apart from each other on the right bellcrank. The

arms on the left bellcrank are about 1/4” apart.

11.4. Disconnect the steering link rod that connects

each bellcrank to it’s steering input shaft assembly using a pair of 1/2” wrenches. Disconnect the

steering link rods at the steering input shaft

assembly end.

Long arm (outside)

11.5. Remove the cotter pins that hold each of the

bellcranks in position on the shaft.

See Figure 11.5.

Flat washers

Bushings

Cotter pins

removed

Figure 11.5

11.6. Remove the bolts that hold each control console

to the frame using a 3/8” socket.

11.7. Lift the left side control housing over the brake

lever, and set it out of the way.

NOTE: The throttle cable will still be attached to

the control housing. Be careful no to damage it.

NOTE: Disconnect any electrical components

that inhibit the movement of the control console.

11.8. Remove the right control console in similar fashion.

11.9. Remove the bolt that holds the steering

bellcrank shaft assembly to the frame using a

1/2” wrench. See Figure 11.9.

Bellcrank shaft

20

Figure 11.9

Page 25

Z Force

11.10. Withdraw the shaft, catching the washers. Allow

the bellcranks and steering link rods to hang

down from the hydros. See Figure 11.10.

Figure 11.10

11.11. If the bellcranks are to be removed (eg. for bushing replacement), disconnect the control links

from the IHTs, and remove them. They can be

easily serviced on the bench.

11.12. Move the deck height control to the highest position.

11.13. Remove the nuts from the ends of the long bolts

that connect the lift handle arms to the lift shaft

assembly using a pair of 1/2” wrenches.

11.16. Remove the short bolt that connects each lift

handle arm to the lift shaft assembly using a 1/2”

wrench.

11.17. Spread the ends of the lift rod index apart and

disengage it from the lift shaft assembly.

See Figure 11.17.

Figure 11.17

11.18. Separate the lift handle arms from the lift shaft

assembly.

11.19. Unbolt the lift hub assembly from each side of

the control housing using a 1/2” wrench.

See Figure 11.19.

11.14. Using an appropriate tool, disconnect the extension springs from each lift handle arm.

See Figure 11.14.

Short

bolt

Lift handle

arm

Lift shaft assembly

Figure 11.14

11.15. Remove the second nut from each long bolt, and

remove the bolts completely.

Long bolt

(first nut removed)

Lift hub bolts

Figure 11.19

21

Page 26

Z Force

11.20. Loosen the bolts that hold the back of the gas

tank to the frame at least three turns using a

9/16” wrench. See Figure 11.20.

Rear fuel tank mounting bolts

Figure 11.20

11.21. Loosen the bolts that hold the back of the utility

bin to the frame at least three turns using a

9/16” wrench.

11.22. Remove the bolts that hold the front of the fuel

tank and the utility bin to the front tank mounting

bracket using a 9/16” wrench. See Figure 11.22.

11.23. Remove the bolts that hold the control housing

to the frame using a 3/8” socket.

See Figure 11.23.

Control housing bolts

Figure 11.23

NOTE: There are three bolts along the front

edge that come down from the top. Two bolts are

accessible from the bottom on each side. Two

bolts are accessible from above on the rear corners of the control housing.

11.24. Lift the front of the control housing and support it

with a 4 X 4 or similar dimensional lumber.

See Figure 11.24.

Front fuel tank mounting bolts

Figure 11.22

Frame

J-nuts

Figure 11.24

11.25. Push the lift shaft assembly up into the top of the

control housing, allowing the arms to hang

straight down.

NOTE: Do not cock the lift shaft assembly when

manipulating it, or it will get stuck.

22

Control housing

Page 27

Z Force

11.26. Note the orientation of the lift links, and pivot

them to remove them from the arms on the lift

shaft assembly. The slotted hole goes up. The

adjustment nuts on the right side link face the

inside of the machine. See Figure 11.26.

Lift links

Figure 11.26

11.27. Pivot the lift links to free them from the T-bolt

heads on the lift shaft assembly, and remove

them.

11.28. Note the orientation of the lift shaft assembly.

The T-bolt heads angle downward to the front.

The small holes in the outer arms of the lift shaft

assembly go toward the top.

11.29. Lower the lift shaft assembly and both lift hub

assemblies through the gaps in the bottom lip of

the control housing. See Figure 11.29.

Frame

Lift shaft assembly

11.30. Slide the lift shaft assembly forward and out from

beneath the control housing. See Figure 11.30.

Figure 11.30

11.31. Reverse the removal process to install the lift

shaft assembly.

NOTE: Lubricate the inside of the lift hub assemblies with anti-seize compound before installation.

12. STEERING INPUT SHAFT ASSEMBLY

12.1. Remove the deck as described in the “Deck

Removal” section of this manual.

12.2. Disconnect the negative battery cable using a

pair of 7/16” wrenches.

NOTE: Generous access to the steering link

rods, bellcranks, and steering bellcrank shaft

can be obtained by removing the battery box

See Figure 12.2.

Edge of gap in

base of control

housing

Battery and

battery box

removed

Lift hub

assembly

Figure 11.29

Figure 12.2

23

Page 28

Z Force

12.3. Lift the control housing over the brake lever, if

working on the left side control console, and set

it out of the way.

NOTE: The throttle cable will still be attached to

the left side control console. Be careful no tot

damage it.

NOTE: Disconnect any electrical components

that inhibit the movement of the control console.

12.4. Remove the nut and socket head cap screw that

hold the pivot bracket to the steering input shaft

using a 1/4” Allen wrench and a 1/2” wrench.

See Figure 12.4.

Socket head

cap screw

Pivot bracket

Steering input

shaft

12.7. Remove the outer bushing, and push the inner

bushing out of the hexagonal hole that it resides

in. See Figure 12.7.

Steering input shaft

Outer

bushing

Figure 12.7

12.8. Maneuver the steering input shaft into a vertical

position so that it and the inner bushing can be

removed. See Figure 12.8.

Figure 12.4

12.5. Slide the lap bar and pivot bracket assembly off

of the steering input shaft.

NOTE: If the socket head cap screw has left a

burr on the steering input shaft, de-burr the shaft

before attempting to remove it.

12.6. Push the steering input shaft into the control

housing far enough to allow the removal of the

outside bushing.

Inner hex bushing

Inner bracket

Figure 12.8

12.9. Replace any parts that are worn or damaged,

and install the steering input shaft by reversing

the removal process.

24

Page 29

Z Force

13. PIVOT BAR

13.1. Lift and safely support the Z-Force by the frame

in front of the deck. See Figure 13.1.

Figure 13.1

13.2. Wheel removal can be done with two 3/4”

wrenches. Remove the nut and withdraw the

axle bolt.

13.5. If the pivot bar is to be removed, the foot rest

bracket must be removed first, using a pair of

1/2” wrenches. See Figure 13.5.

Foot rest bracket

Figure 13.5

NOTE: The deck need not be removed.

13.6. Remove at least one caster wheel assembly

using a 9/16” wrench. See Figure 13.6.

13.3. There is a spacer that fits over each side of the

wheel bearing, keeping the wheel centered

between the caster wheel mounting bracket.

See Figure 13.3.

Axle

bushing

Spacer

Figure 13.3

13.4. The roller bearings in the wheel ride on the axle

bushing. Other than regular lubrication with

grease, the bearing is non-serviceable.

Figure 13.6

25

Page 30

Z Force

13.7. The bushings can be driven out and replaced if

necessary. See Figure 13.7.

Upper bushing

Grease zirch

Pivot bar

Figure 13.7

13.8. The pivot bolt can be removed using a pair of

1 1/2” wrenches. See Figure 13.8.

Really big Crescent wrench

13.9. The pivot bar can be withdrawn once the pivot

bolt is removed. See Figure 13.9.

Long side of

pivot hub

Forward

Figure 13.9

NOTE: The pivot bar is off-set to the front. This

provides room for the caster wheels to swivel

without deck interference.

13.10.The bushings that support the pivot bar can be

easily driven out for replacement.

Short side of

pivot hub

Figure 13.8

NOTE: On installation, tighten the pivot bar nut

and bolt until front-back play is gone from the

pivot bar, but not so tight that movement is inhibited by friction.

13.11. When installing the pivot bar, tighten the nut until

a slight bind is placed on the pivoting action,

then loosen the bolt until the bind just goes

away.

26

Page 31

Z Force

Idle throttl

14. ENGINE ADJUSTMENTS (KAWASAKI FH451V)

14.1. The air filter cover is easily removed by releasing the cam action latches at each side of the

cover. A wing nut holds the air filter element in

place. See Figure 14.1.

Element

Foam pre-filter

Air filter cover

NOTE: It is not necessary to remove the air filter

for many carburetor adjustments. It will be leftoff in this manual for the sake of visibility.

14.2. The carburetor is equipped with a bowl drain for

off season storage as well as draining of contaminated or stale fuel. See Figure 14.2.

Fuel pump

Latches

Figure 14.1

Wing

nut

Bowl vent

14.3. If the control bracket is removed for any reason,

it must be adjusted on installation.

See Figure 14.3.

e stop

Slotted control

bracket mounting

Choke

adjustment

Cable clamp

Figure 14.3

14.4. Adjust the position of the control bracket and

control cable so that the full range of control

actuation is available. The bracket is adjustable

using a 10 mm wrench. The position of the

cable in the clamp can be adjusted using a 6mm

driver or a screwdriver.

14.5. Set the idle throttle stop screw so that the engine

turns 1,000 to 1,100 R.P.M. when the throttle

arm on the carburetor is held against the end of

the screw with light finger pressure.

See Figure 14.5.

Fuel line

Crankcase vent

Bowl drain

Choke / throttle cable

Figure 14.2

NOTE: Air filter housing completely removed for

figure 14.2

Screwdriver

Adjustment

screw

Throttle

arm

Figure 14.5

NOTE: It is necessary to insert phillips head

screwdriver through the label on the engine

blower shroud to reach the throttle stop screw.

27

Page 32

Z Force

14.6. Set the governed idle to 1,550 R.P.M. using the

screw at the lower right hand corner of the control bracket. See Figure 14.6.

Governed idle

adjustment screw

Figure 14.6

14.7. With the governed idle and idle throttle stop

adjusted, the engine should maintain a 1,550

R.P. M. idle, but should not fall below 1,000

R.P.M. unless the engine is over-loaded.

14.8. Top no-load speed should be adjusted to within

the range of 3,600 to 3,650 R.P.M. This is done

by slightly bending the arm on the control

bracket that pulls on the governor spring.

14.9. Adjust the choke using the screw on the control

bracket. See Figure 14.9.

Choke

actuator arm

Adjustment

screw

14.10.With the engine turned-off, insert a 1/4” pin in the

round hole when the throttle is set for top noload speed. This will lock the linkage in that

position.

14.11. Using a phillips head screwdriver inserted from

behind the left corner of the control bracket, set

the choke adjustment screw to leave a .199” gap

between the tip of the screw and the point where

it contacts the arm that actuates the choke rod.

Insert 1/4” pin

.100” gap

(2.7mm)

Figure 14.9

Governor

spring

Adjust here

Figure 14.8

NOTE: If high speed governor response is slug-

gish, check for interference between the governor rod and the governor spring.

NOTE: If high speed performance is weak, confirm that the choke is not closing prematurely.

Governor rod

(to throttle on

carburetor)

Governor arm

14.12.After all carburetion adjustments are made, run

the engine to double check the idle speed, throttle stop, top no-load speed, and unimpeded linkage movement.

NOTE: Because the Z-Force engine is not

equipped with a fuel shut-off solenoid, afterboom may occur if it is turned-off at idle speed.

This will cause no harm, but customers may find

it objectionable. To avoid after-boom, the engine

should be throttled-up slightly at the moment of

shut-down. The opening of the throttle plate will

reduce the vacuum level in the intake manifold,

preventing the ingestion of a rich fuel air mixture

from the idle jet on over-run. After the ignition

(spark) is turned-off, the inertia of the engine will

pump unburned fuel and air into the hot muffler.

The presence of this mixture in the hot muffler is

the source of after-boom.

28

Page 33

Z Force

14.13.Turn the engine off, and confirm correct choke

adjustment. Remove the air filter cover and air

filter to confirm that the choke plate is fully

closed when the choke is applied, and fully open

at the full-throttle position. See Figure 14.13.

Figure 14.13

14.14.The valve lash should be checked after every

300 hours of use.

14.20.Rotate the engine in its normal direction of operation until the piston in the first cylinder to be

adjusted is at top dead center on the compression stroke (both valves closed).

14.21.Check the valve lash. Clearance between the

stem of the intake valve and the intake rocker

arm should be .004” - .006” (.10mm - .15mm).

Clearance between the stem of the exhaust

valve and the exhaust rocker arm should also be

be .004” - .006”.

14.22.If necessary, adjust the clearance using a 3mm

allen wrench to loosen the locks crews, and a

14mm wrench to move the adjusting nut.

See Figure 14.22.

Intake valve

Spark

plug hole

Adjusting nuts

Check

lash

here

Locks crews

14.15.If the Z-Force has been run recently, allow the

engine to cool before adjusting the valves.

14.16.Clean the engine and surrounding area before

beginning the valve lash adjustment.

14.17.Disconnect and ground the spark plug wires.

14.18.Remove the spark plugs using a 3/4” spark plug

socket.

14.19.Remove the valve covers using a 10mm wrench.

See Figure 14.19.

Valve covers

H.T. lead

Exhaust

valve

Figure 14.22

14.23.Torque the locks crews to 61 in-lb. (6.9 N-m),

and re-check adjustment.

14.24.When adjustment is complete on the first cylinder, turn the crankshaft to bring the second piston to top dead center on the compression

stroke, and repeat the adjustment procedure on

the second cylinder.

14.25.Install the valve covers using new valve cover

gaskets. Install the screws through the valve

covers before positioning them on each cylinder

head. The gaskets are most easily positioned

on the valve covers rather than the cylinder

head. They will be held in the correct position by

the screws. Sealant should not be necessary.

14.26.Torque the valve covers screws to 17 in-lb. (.20

N-m).

Figure 14.19

14.27.Check compression for consistency between

cylinders. Optional: check leak-down. If more

than 10% difference is found, cylinder head

reconditioning may be necessary.

29

Page 34

Z Force

14.28.Inspect and gap (or replace) the spark plugs

prior to installation.

14.29.Spark plugs: Champion RC8Y or equivalent,

gapped to .030” (.75mm).

14.30.Oil capacity: 1.6 U.S. qts. (1.5L) without filter

replacement. Use 1.8 U.S. qts. (1.7L) with filter

replacement.

14.31.Oil type: API Service Classification SF, SG, SH,

or SJ.

14.32.Oil viscosity: SAE30 will be suitable for most

operating conditions (32 deg.f. to 90 deg.f.).

Where temperatures exceed 100dg. f. SAE40 is

an acceptable alternative (68 deg. f. and up). If

multi-grade oils are used, an increase in oil consumption is to be expected, and the oil must be

checked more frequently.

15. THE Z-FORCE MODEL LINE-UP

15.1. There are three engine and deck combinations

av a i l a b le on the Z-Force fo r 2 0 0 4 .

See Figure 15.1.

• 42” two blade cutting deck with an 18.5 H.P.

Briggs and Stratton Intek single cylinder engine

15.3. The cutting decks are all similar to those offer

elsewhere in the Cub Cadet model line, with the

exception of the mounting method and drive orientation (front Vs. rear engine). See Figure 15.3.

Figure 15.3

• 44” three blade cutting deck with a 20 H.P.

Briggs and Stratton Intek V-twin engine

• 48” three blade cutting deck with a 22 H.P. Brigs

and Stra t ton Int e k V- tw in e n gin e .

Figure 15.1

15.2. We have chosen to cover some service information that applies to the Kawasaki engine offered

the 2003 Z-Force because it is likely to be less

familiar to technicians than the Briggs and Stratton products.

30

Loading...

Loading...