Page 1

Professional

Shop Handbook

4x4 Utility Vehicle w/Kohler Engine

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outd oor power

equipment of the kind described in this publication, and are no t intended for use by untrained or inexperienced individu als.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2006 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-03026

12/2006

Page 2

Page 3

Table of Contents

Chapter 1: Introduction.....................................................................................................1

Chapter 2 - Drive Sytem: CVT and Transfer Case............................................................9

Kohler Enclosed CVT Addendum..............................................................................63

Caterpillar Enclosed CVT Addendum........................................................................75

Chapter 3 - Drive System: Drive Shafts and Differentials................................................89

Chapter 4 - Front Suspension and Steering..................................................................123

Chapter 5 - Rear Suspension........................................................................................159

Chapter 6 - Hydraulic Brakes........................................................................................173

Chapter 7 - Kohler Engine Service Access and Fuel System........................................195

Kohler Engine Speed and Throttle Adjustment Addendum.....................................215

Chapter 8 - Caterpillar Engine and Related Systems....................................................219

Chapter 9 - Electrical.....................................................................................................275

Addendum - Front Drive System Differential Gearcase: Hillard.....................................323

1

Page 4

Page 5

CHAPTER 1: INTRODUCTION

Chapter 1: Introduction

1. INTRODUCTION: PRODUCT LINE

6X4

Cub Cadet entered the utility vehicle market in the

2003 season with a 6X4 vehicle having fully independent suspension and Honda power (20 H.P.). The Big

Country 6X4 continues in production with evolutionary

changes and a switch to Kohler power. See Figure 1.1.

Big Country 6X4

Figure 1.1

Steel-bed 4X2

In 2004, a 4X2 vehicle was introduced. The 4X2

shares the 6X4 front suspension, has an 18 H.P.

Honda engine and a push-button controlled transmission. Evolutionary changes include a switch to Kohler

power. See Figure 1.2.

Poly bed 4X2

For 2005, a lighter-duty version of the 4X2 was introduced, using a plastic cargo box and a 9.5 H.P. drives

system sourced from Kawasaki. See Figure 1.3.

4X2 “Poly Bed”

Figure 1.3

All of these first-generation utility vehicles share a common structure from the cargo box forward. The 6X4

carries a fully enclosed rear structure with swing-arm

suspension. The 4X2s carry the engine and transaxles

on a pivoting cradle that acts as the rear suspension.

4X4

The 4X4 vehicle that is the subject of this handbook

represents a complete departure from the first generation vehicles. See Figure 1.4.

4X2 Steel Bed

Figure 1.2

New 4X4

Figure 1.4

1

Page 6

Chapter 1: Introduction

2. UNDERSTANDING UTILITY VEHICLE MODEL NUMBERS

e.g.: 37AJ467D710

• 37 - - - - - - - - - indicates that this is a U.V.

• - - A - - - - - - - - indicates the engineering level

• - - - J - - - - - - - indicates the engine type

• - - - - 4 - - - - - - indicates the number of wheels

• - - - - - 67 - - - - indicates the series and trim

• - - - - - - - D - - - indicates the type of tires

• - - - - - - - - 710 indicates that it is Cub Cadet

2.1. Engine type detail:

• B = Kohler Command 18 H.P. V-twin

• C = Kohler Command 20 H.P. V-twin

• J = Caterpillar Diesel 20 H.P. liquid cooled

• N = Kawasaki 9.5 H.P. single, inclined

• R = Honda 18 H.P. V-twin

• S = Honda 20 H.P. V-twin

3. PROFESSIONAL SHOP MANUAL INTENT

This Manual is intended to provide service dealers with

an introduction to the mechanical aspects of the new

vehicle.

This Professional Shop Manual covers the second

generation Cub Cadet Utility Vehicles more specifically,

and in greater depth than the origanal Shop Handbook.

• The content in this manual supersedes any content in the handbook.

• Detailed service information about the engine

will be provided by the engine manufacturer, in

most cases.

Disclaimer: This manual was written using second

generation vehicle. The information contained in this

handbook is correct at the time of writing. Both the

product and the information about the product are subject to change without notice.

About the text format:

NOTE: is used to point-out information that is

relevant to the procedure, but does not fit as a

step in the procedure.

2.2. Series detail:

• 1 = poly-bed 4 x 2

• 3 = steel bed 4 x 2

•4 = 6 x 4

•6 = 4 x 4

2.3. Trim detail:

• 0 = yellow on 6 x 4 and 4 x 2

• 1 = camouflage on 6 x 4 and 4 x 2

• 2 = fire rescue red on 6 x 4 and 4 x 2

• 6 = yellow on 4 x 4

• 7 = camouflage on 4 x 4

2.4. Tires

• A = turf tires

• B = knobby tires

• C = heavy-duty tires

• D = trail tires

• E = Fire Rescue: f. run-flat tires, r. trail tires

CAUTION: is used to point-out potential danger

to the technician, operator, bystanders, or surrounding property.

• Bullet points: indicate sub-steps or points.

Disclaimer: This Professional Shop Manual is

intended for use by trained, professional technicians.

• Common sense in operation and safety is

assumed.

• In no event shall MTD or Cub Cadet be liable for

poor text interpretation, or poor execution of the

procedures described in the text.

• If the person using this manual is uncomfort able

with any procedures they encounter , they shou ld

seek the help of a qualified technician or Cub

Cadet Technical Support.

• G = poly-bed trail tires

2

Page 7

Chapter 1: Introduction

Fasteners:

• Most of the fasteners used on the vehicle are

sized in fractional inches. Some are metric.

For this reason, wrench sizes are frequently

identified in the text, and measurements are

given in U.S. and metric scales.

• If a fastener has a locking feature that has

worn, replace the fastener or apply a small

amount of releasable thread locking compound

such as Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use

items that are not to be reused.

Other fasteners such as lock washers, retaining

rings, and internal cotter pins (hairpin clips) may

be reused if the do not show signs of wear or

damage. This manual leaves that decision to

the judgement of the technician.

Assembly:

Torque specifications may be noted in the part of the

text that covers assembly, they may also be summarized in tables along with special instructions regarding

locking or lubrication.

Whichever method is more appropriate will be used. In

many cases, both will be used so that the manual is

handy as a quick-reference guide as well as a step-bystep procedure guide that does not require the user to

hunt for information.

4. LIFTING AND SUPPORTING

CAUTION: Use common sense and safety when

lifting and supporting any equipment:

• Always work on a firm, level surface that will

support the load to be placed on it.

• Never leave equipment supported by hydraulic

means: hydraulic jacks are for lifting. Once

lifted, the equipment should be positioned on

and supported by jack stands of sufficient capacity to ensure safety.

• Confirm that the equipment is firmly seated on

the jack stands before doing any work that

results in exposure to falling or crushing hazard.

• Use caution when positioning jacks and jack

stands, so as not to damage any fuel lines,

brake lines, electrical conduits, or linkages.

• Do not lift or support the vehicle by the cradle

that the engine and transfer case are mounted

to. It is vibration-isolated from the rest of the

vehicle. The rubber isolator mounts are not

designed to support the weight of the vehicle.

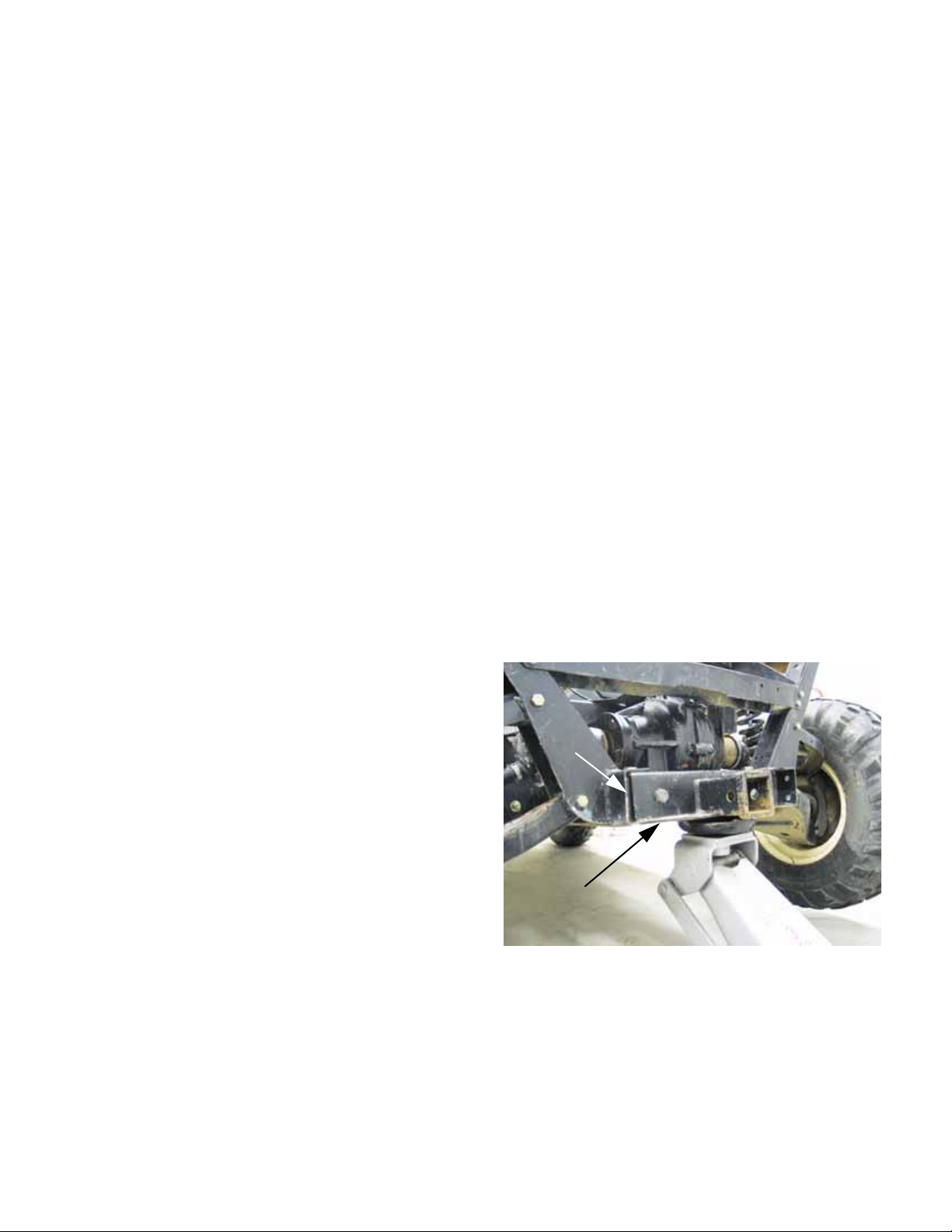

The utility vehicle may be lifted from the rear by placing

a jack under the rear-most cross-member. This crossmember also provides a mounting point for the 2” class

1 hitch receiver. See Figure 1.5.

The level of assembly instructions provided will be

determined by the complexity and of reassembly, and

by the potential for unsafe conditions to arise from mistakes made in assembl y.

Some instructions may refer to other parts of the manual for subsidiary procedures. This avoids repeating

the same procedure two or three times in the manual.

Rear cross-member

Accessory

receiver

Figure 1.5

3

Page 8

Chapter 1: Introduction

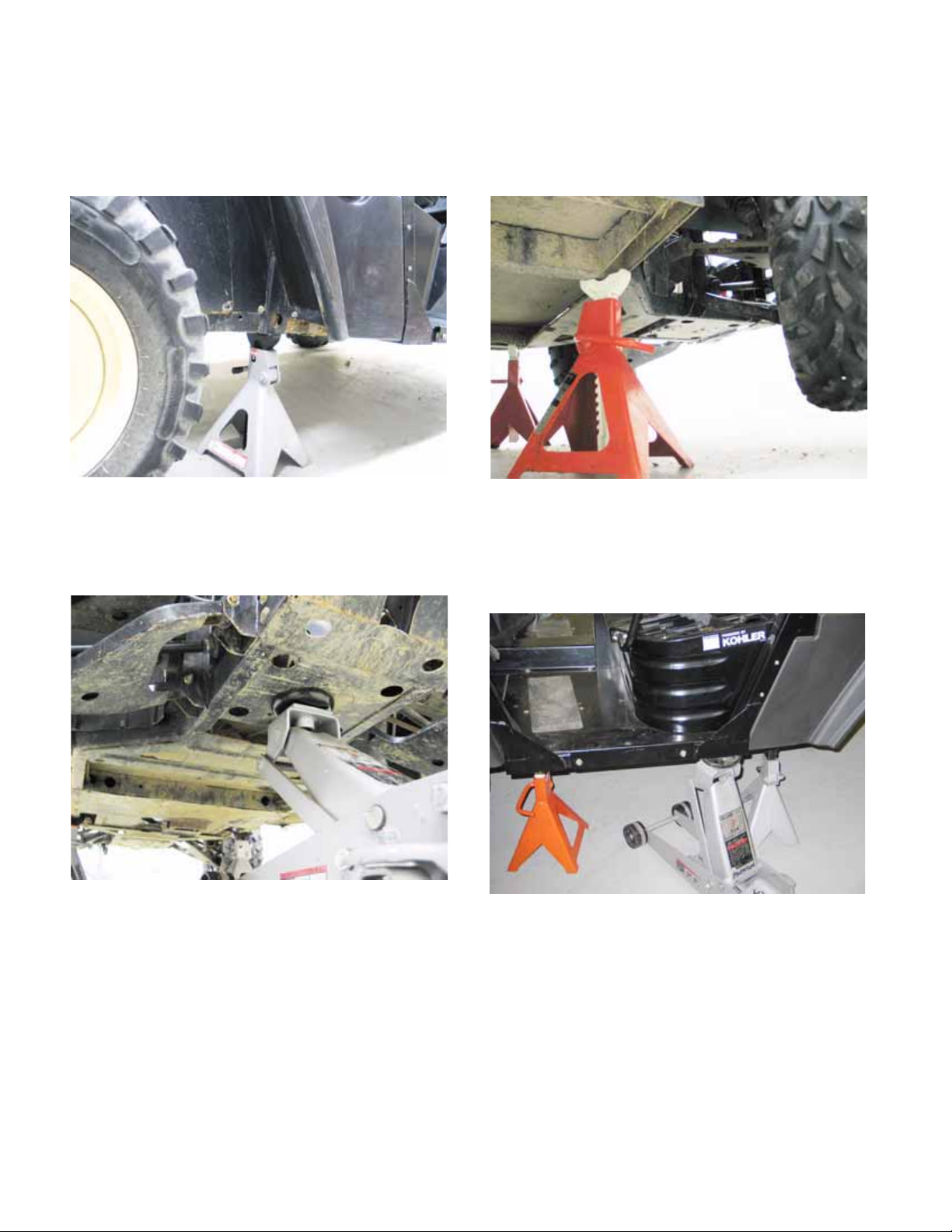

Jack stands can safely be positioned beneath the upright frame members that are roughly even with the

centerline of the tray that supports the engine and

transfer case. See Figure 1.6.

Figure 1.6

The front of the vehicle may be safely lifted by placing a

jack directly under the mounting point where the front

differential joins the frame. See Figure 1.7.

Jack stands will safely support the front of the vehicle if

positioned beneath the frame, where the front out-rigger extends to meet the base of the OPS.

See Figure 1.8.

Figure 1.8

Alternatively, the vehicle may be lifted by positioning a

jack along the outer frame channel, where the rear

out-rigger extends to meet the base of the OPS .

See Figure 1.9.

Figure 1.7

Figure 1.9

NOTE: The center of gravity for the vehicle is

beneath the seat support structure.

NOTE: The outer frame channel will support the

vehicle without damage.

4

Page 9

Chapter 1: Introduction

5. DRIVE SYSTEM DESCRIPTION

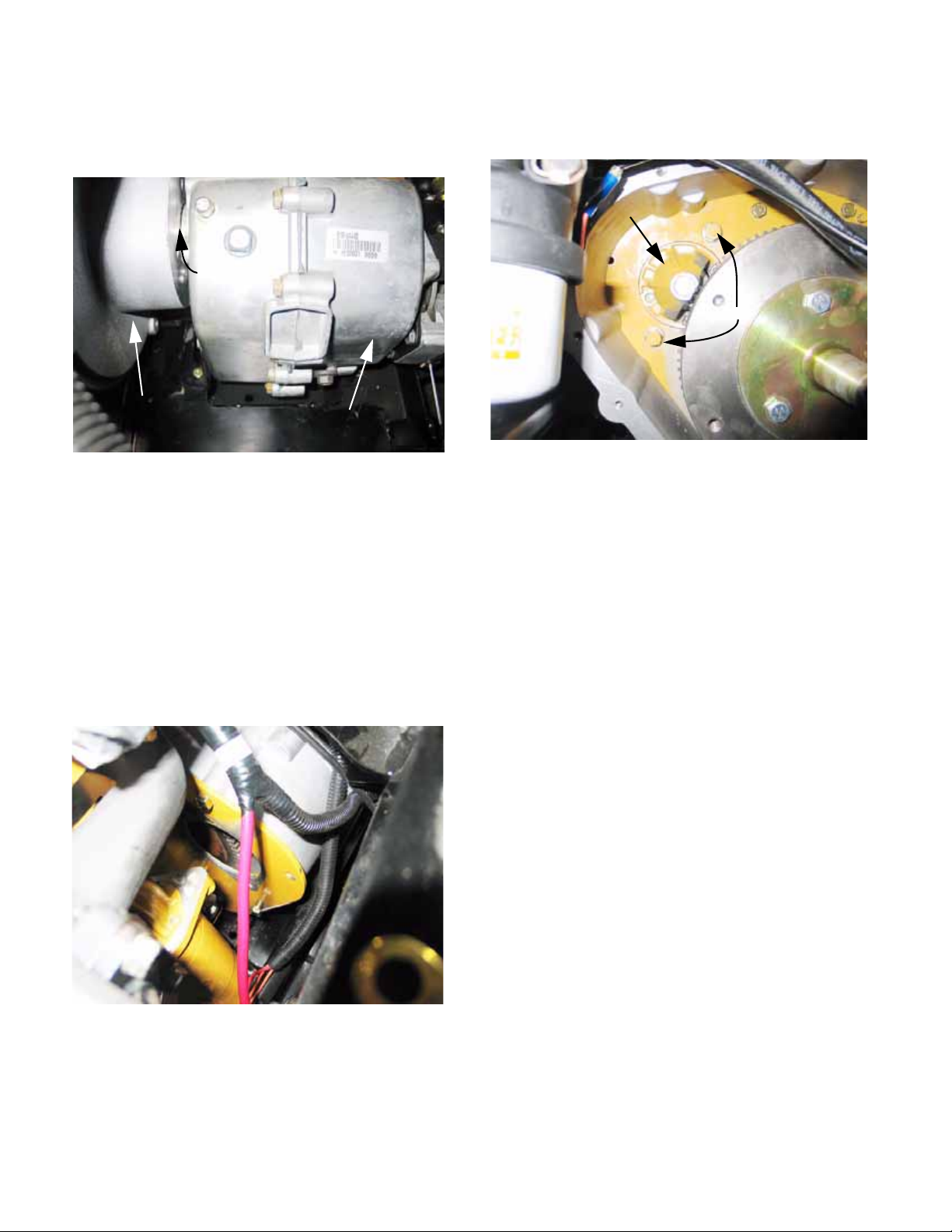

• A belt-type CVT (Continuously Variable Transmission) system carries power from the engine

crankshaft to the transfer case.

See Figure 1.10.

CVT driven

element

CVT belt

CVT driving element

Figure 1.10

• The CVT range provides strong torque and

acceleration, limiting speed to 25 MPH (40

KPH).

• The driving clutch on the engine crankshaft uses

centrifugal force to operate a mechanism that

pulls the sheaves closer together.

The faster the engine spins, the closer the

sheaves get.

As the sheaves close-down on the belt, the belt

is forced outward.

As the belt is forced outward, the drive ratio

decreases so that fewer crankshaft revolutions

equate to more input shaft revolutions at the

input shaft of the transfer case.

•The transfer case is mounted adjacent to the

engine, with the input shaft running fore-and-aft

in the frame. See Figure 1.11.

Transfer

case

Figure 1.11

• The transfer case contains two forwar d ratios,

neutral, and reveres.

• Gear selection is controlled by rods and a selector lever sourced from Hurst®.

Drive shafts with Hooke/Spicer type universal joints

extend fore and aft from the output shafts of the transfer case to drive the front and rear differentials.

The rear differential has a cast iron housing and a

cable-actuated locking feature. See Figure 1.12.

Differential lock

actuator

Rear differential

NOTE: A lower numeric ratio results is frequently referred to as a “steeper” or “taller” d rive

ratio, yielding in increased top speed.

• As the effective diameter of the driving pulley

increases, the belt has less available length to

reach the driven pulley.

The sheaves of the driven pulley is springloaded so that it can absorb the additional tension.

An additional effect is that the belt is drawn

deeper into the sheaves, reducing the effective

diameter of the driven pulley.

Reducing the diameter of the driven pulley further reduces the drive ratio.

Figure 1.12

5

Page 10

Chapter 1: Introduction

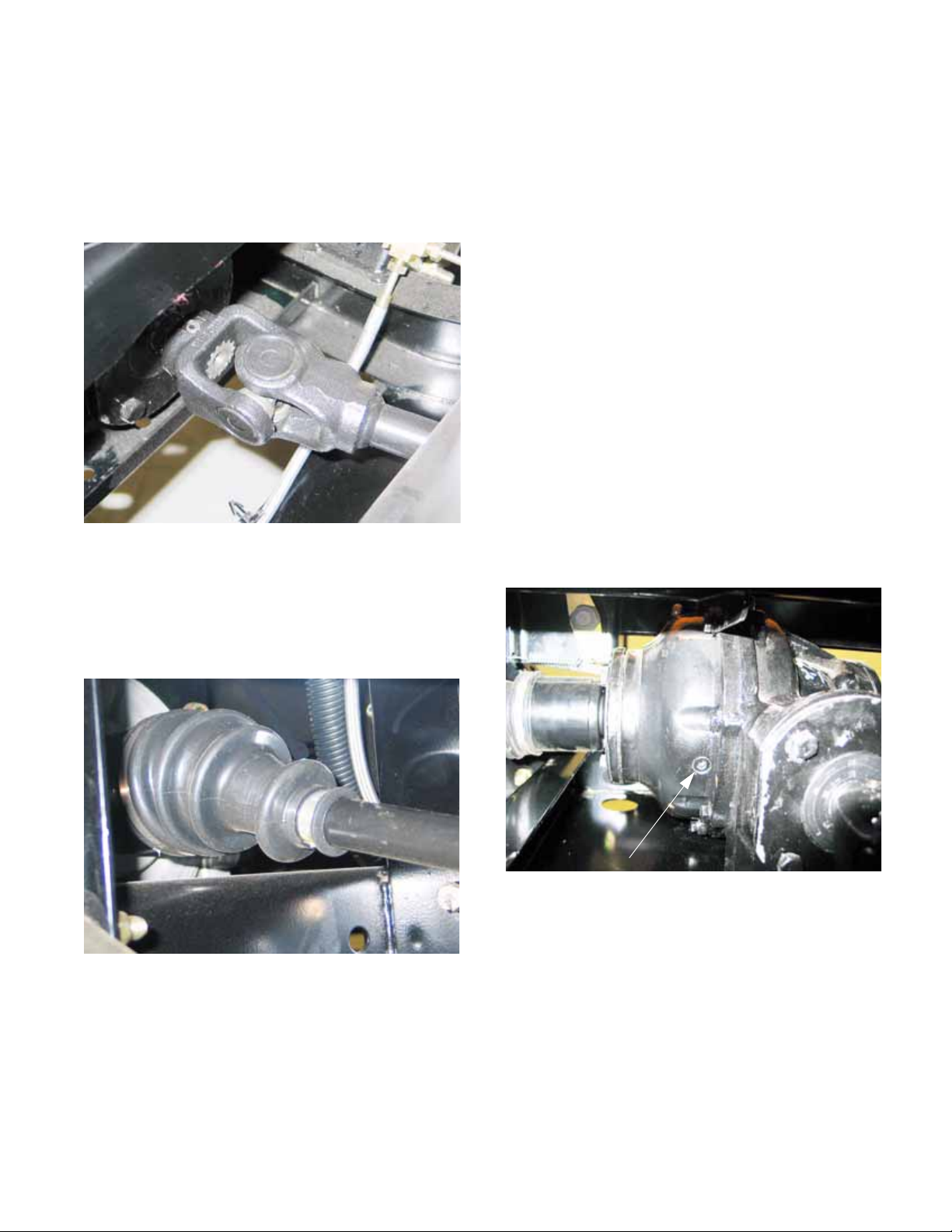

The front differential has an aluminum housing, and

an electronically controlled, slip sensing Auto-Lok®

feature. See Figure 1.13.

Front differential

• The front differential is engaged or disengaged

using a rocker switch on the dashboard.

Each differential transfers power to the drive hubs

through a drive shaft with Rzeppa-type constant velocity joints at each end.

Electrical connection for

Auto-Lok® feature

Figure 1.13

6. SERVICE INTENT

The transfer case is manufactured by Cub Cadet. If it

fails during the first year, it should be removed and

replaced as a complete unit.

• In the event of a failure, the transfer case will be

called back for engineering analysis.

• If the failure is warrantable, Cub Cadet will cover

the cost of replacement.

• If the failure is not warrantable, replacement will

be at the customer’s expense.

• Beyond the first year, but within the first two

years, the decision whether to repair or replace

the transfer case will be based on economic feasibility and the availability of parts and assemblies.

• Beyond the warranty period, the dealer can

repair or replace the transfer case at their own

discretion.

The remainder of the drive system (CVT, drive shafts,

axles, differentials) is purchased from outside vendors.

• If any of these items fail in the first two years,

they should be removed and replaced with a

complete unit. The only exception to this may be

the axles. Rzeppa (Constant Velocity) joints

may be available to repair rather than replace

axles. Service intent has not been decided as

this manual goes to print.

• In the event of a failure, the component will be

called back for engineering analysis and vendor

recovery.

• If the failure is warrantable, Cub Cadet will cover

the cost of replacement.

• If the failure is not warrantable, replacement will

be at the customer’s expense.

• Beyond the warranty period, internal parts for

the differentials will be made available so that

the dealer can repair or replace them at their

own discretion.

Kohler Engines will be serviced as they are in the rest

of the Cub Cadet product Line. They are seen as an

integral part of the Cub cadet product, with parts and

warranty coverage provided through Cu b Cad e t.

Caterpillar Engines in Cub cadet equipment will continue to be serviced exclusively by CAT dealers.

6

Page 11

Chapter 1: Introduction

7. SPECIAL TOOLS

NOTE: There are many specialized tools that

will make servicing the Cub Cadet 4X4 easier.

There are only a couple of tools that are not

likely to be in a technician’s normal tool assortment that necessary to service the 4X4.

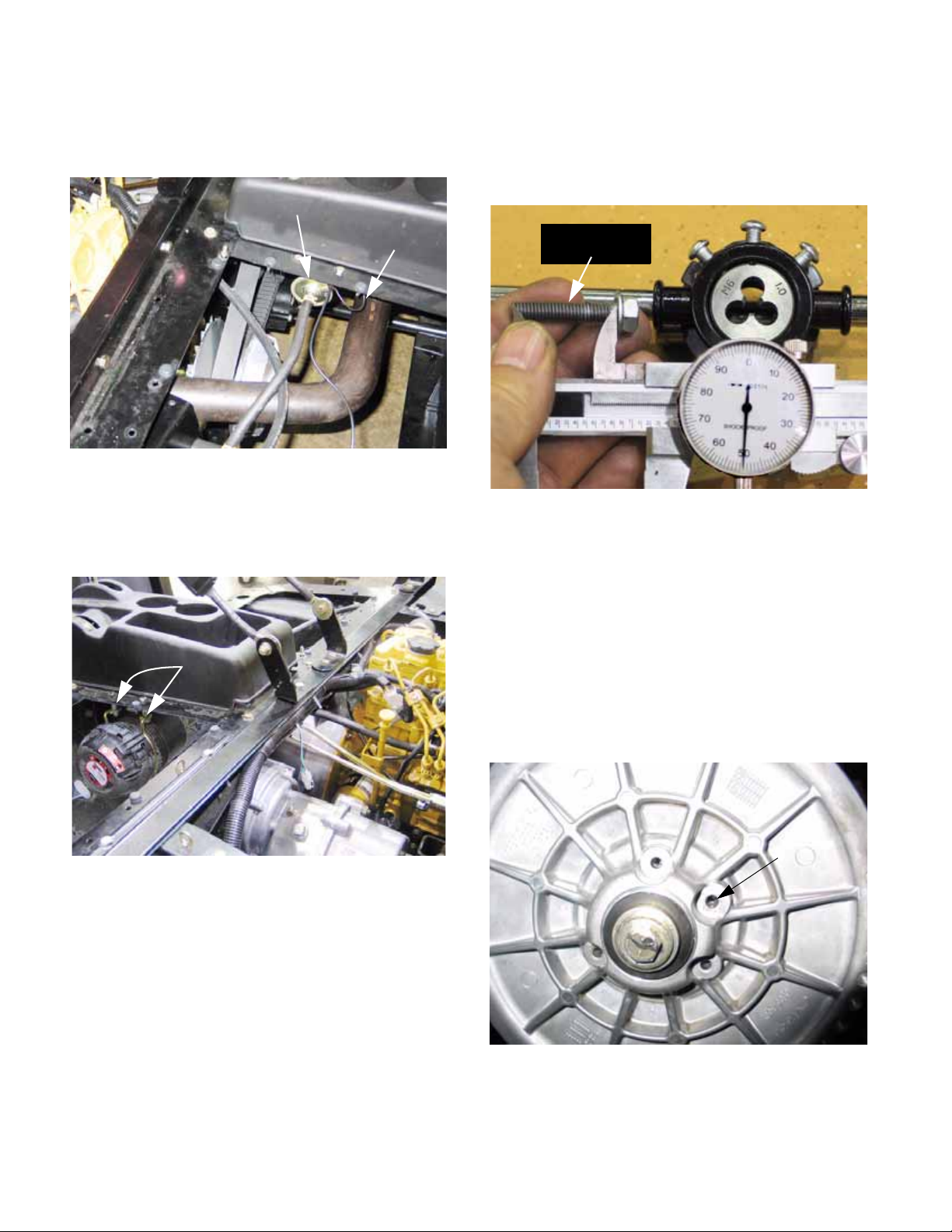

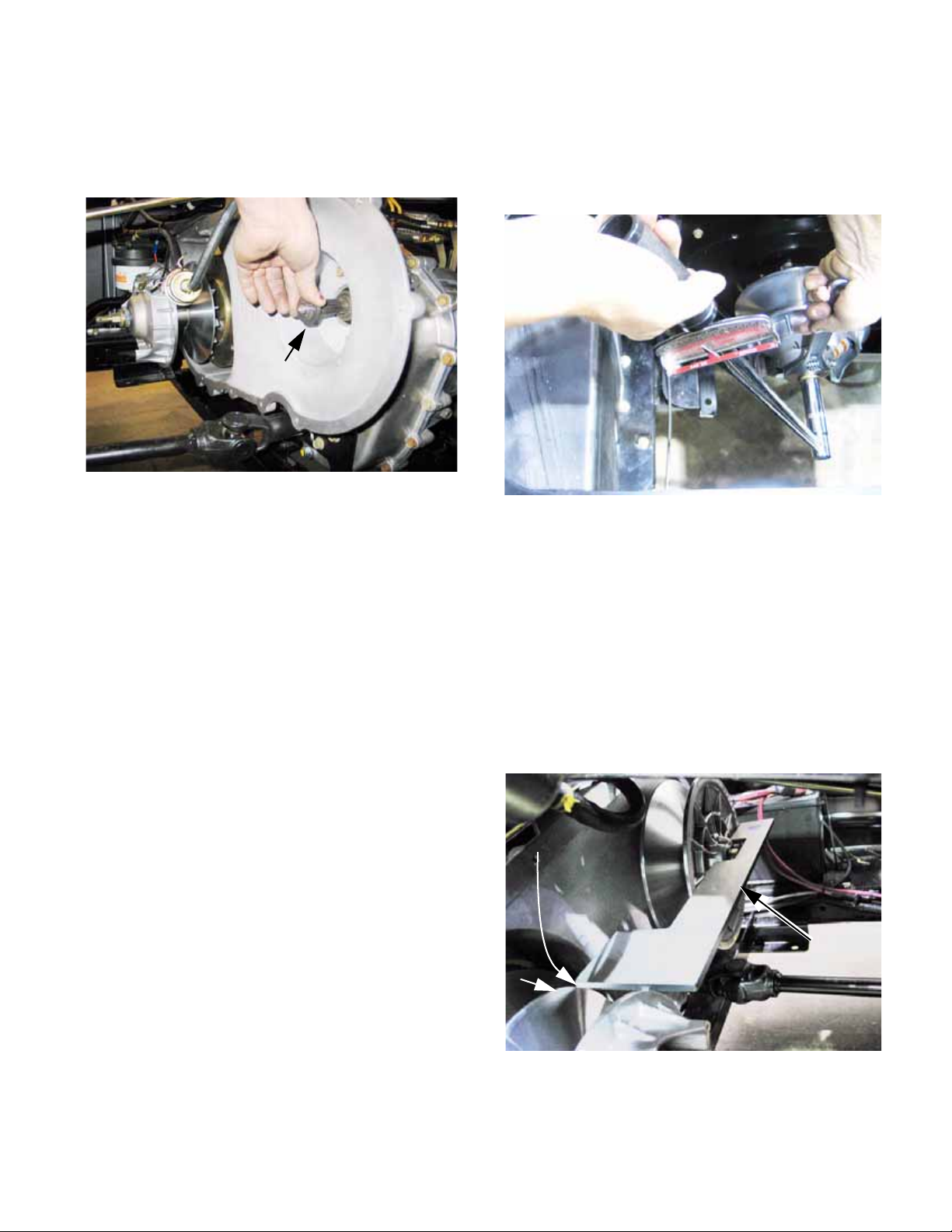

7.1. A small metric screw (6m/1.0) (size/thread pitch)

having a minimum thread length of 1.15” (2.9cm)

can be used to spread the sheaves of the driven

clutch. This is necessary if the belt is to be

replaced without removing both pulleys. The

screw can be purchased locally and modified

using a thread die. See Figure 1.14.

7.3. A pulley alignment tool should be used to check

the alignment of the drive pulley and driven pulley after any procedure that may have disturbed

the alignment, or if unusual belt wear occurs.

See Figure 1.16.

Alignment tool

P/N: 707-04878

Figure 1.16

Figure 1.14

7.2. The second tool that is necessary to service the

drive system is a puller that draws the driving

clutch off of the engine crankshaft.

See Figure 1.15.

Driving pulley removal tool:

Part number: 759-04111

Figure 1.15

7

Page 12

Chapter 1: Introduction

8

Page 13

Chapter 2- Drive System: CVT and Transfer Case

CHAPTER 2- DRIVE SYSTEM: CVT AND TRANSFER CASE

DRIVE SYSTEM: SERVICE INTENT

1. The transfer case is manufactured by Cub

Cadet. If it fails during the first two years, it

should be removed and replaced as a complete

unit.

• In the event of a failure, the transfer case will be

called back for engineering analysis.

• If the failure is warrantable, Cub Cadet will cover

the cost of replacement.

• If the failure is not warrantable, replacement will

be at the customer’s expense.

• Beyond the warranty period, internal parts will be

made available so that the dealer can repair or

replace the transfer case at their own discretion.

2. The remainder of the drive system (CVT, drive

shafts, axles, differentials) is purchased from

outside vendors.

• If any of these items fail in the first two years,

they should be removed and replaced with a

complete unit.

• In the event of a failure, the component will be

called back for engineering analysis and vendor

recovery.

CVT AND TRANSFER CASE OPERATION

1. The transfer case contains a relatively conventional three-shaft gear-set providing Neutral,

Reverse, Forward, and Forward Low-range.

2. The variation in drive speed within each gear is

created by a combination of engine RPM and a

CVT belt drive system.

3. The CVT belt drive system consists of :

See Figure 2.1.

• Driving element = driving pulley = centrifugal

torque converter mounted to the crankshaft.

• Driven element = driven pulley = pulley sheaves

mounted to the input shaft of the transfer case

that react to the motion of the driving element.

• A special belt that transfers power from the driv-

ing element to the driven element.

Driving element Driven element

• If the failure is warrantable, Cub Cadet will cover

the cost of replacement.

• If the failure is not warrantable, replacement will

be at the customer’s expense.

• Drive system components other than the CVT

and transfer case are covered in gr eater depth in

the Drive shafts, Axles, and Differentials chapter

of this manual.

Belt

Figure 2.1

4. Common parts:

4a. The belt and driven element are the

same on both models of the current Cub

Cadet 4X4.

4b. The driving elements are different for

gas and diesel versions. The gas engine

and diesel engines have different torque

curves and maximum operating speeds.

9

Page 14

Chapter 2- Drive System: CVT and Transfer Case

4c. The driving elements are tuned to get the

best vehicle performance out of each

model engine, taking into account: engine

power band and top speed, vehicle

weight, maximized vehicle pulling power,

maximized vehicle acceleration, and a 25

MPH (40 KPH) maximum speed.

5. Operation:

5a. At rest (engine OFF or at low idle) the

sheaves of the driving element (on the

engine crankshaft) are at the widest point

of their travel. The belt rests on a central

bearing surface, but no significant power

is transmitted to the driven element at idle

speed. See Figure 2.2.

Low idle speed

Driving element released

(spread)

5b. At about 1,400 RPM, the sheaves move

closer to each-other. As they do, they

touch the sides of the belt and begin to

transmit power. See Figure 2.3.

Low RPM:

Driving element

beginning to engage belt

Belt deep in sheave

Figure 2.3

• The sheaves are moved by fly-weights within the

driving element housing. Centrifugal force

drives the fly-weights out. The fly-weights are

levered against the sheave, forcing it inward.

Figure 2.2

5c. As the engine RPMs increase, the

sheaves close further, forcing the belt outward on the sheaves. See Figure 2.4.

Moderate engine speed

Driving pulley partially closed-down

Belt partially shifted-out

Figure 2.4

10

Page 15

Chapter 2- Drive System: CVT and Transfer Case

• The further the drive point (contact patch

between the belt and the sheaves) is from the

crankshaft, the greater the effective circumference of the driving pulley (element).

• The greater the effective circumference of the

driving pulley, the more linear motion is transferred to the belt for each crankshaft revoluti on.

• This increases the drive speed, but reduces the

amount of torque the engine transfers to the

drive system.

• If the engine is over-loaded by a combination of

grade and cargo weight while operating at full

throttle, the RPMs will be pulled-down. As the

engine RPMs are reduced, the drive ratio will

automatically shift in the numerically higher

direction, increasing the amount of torque available to the wheels, at the expense of ground

speed.

5d. As the belt is forced outward on the

sheaves of the driving element, the driven

element spread allowing the belt to be

drawn deeper-in. See Figure 2.5.

Driven pulley at speed

Sheaves

Belt deep in sheaves

5f. At about 3,000 RPM (Kohler) or 2,500

RPM (Caterpillar) the driving element

reaches the end of its travel.

See Figure 2.6.

Driven element fully

drawn together:

Belt at outer

edge

Figure 2.6

• Any increase in vehicle speed beyond the end o f

CVT travel is due only to an increase in engine

speed. The rate of vehicle acceleration will

level-off.

IDLE SPEED AND TOP NO-LOAD SPEED

Belt

Figure 2.5

5e. As the belt is drawn deeper into the driven

pulley, two things are accomplished:

• Belt tension is held constant, even though the

effective size of the driving pulley changes.

• The range of available drive ratios is widened.

1. The Kohler and CAT engines should idle at

1,200 RPM. See Figure 2.7.

Belt still

Sheaves

spread

Clutch spinning

at idle speed

Figure 2.7

11

Page 16

Chapter 2- Drive System: CVT and Transfer Case

• Slower idle speeds will result in poor idle quality,

reduced flow of cooling air, and reduced oil flow.

• Higher idle speeds will result in harsh gear

selector action and possible internal damage to

the transfer case.

2. Top no-load speed should be 3 ,600 RPM fo r th e

Caterpillar and 3,850 RPM for the Kohler:

See Figure 2.8.

Sheaves

closed

Engine at

max. RPM

Figure 2.8

• Slower top no-load speeds will result in diminished performance.

• Higher top no-load speeds will result in unsafe

operating conditions and possible over-speed

engine failure.

3. If the idle speed and top-no-load speed do not

fall into this range, refer to the appropriate

engine chapter for adjustment procedures

• Caterpillar related systems Chapter 8

• Kohler engine service access and fuel system

Chapter 7

Belt spinning

DRIVE SYSTEM SERVICE ACCESS, SAFETY, AND

TIPS

1. When working on the belt, block the wheels to

prevent the UV from rolling.

2. Place the transmission in neutral.

3. When working on any components (like the

CVT) that rotate with the engine, disable the

engine:

3a. Disconnect and ground the spark plug

wires on a gasoline engine.

3b. Unplug the fuel shut-off solenoid on a die-

sel engine.

3c. Remove the key from the key switch.

3d. Preferably, disconnect the ground cable

from the negative terminal of the battery.

4. Unless a procedure specifically requires the

engine to be running, the engine should be

turned-off for all maintenance, adjustments, and

repair.

5. To reach the CVT, fold the seats forward and

secure them with shock cords. Release the

Camloc® fasteners and lift the parcel bin out

from beneath the driver’s seat

6. Once accessed, the driving element, the driven

element, and the belt can be removed. There

are some simple but specialized tools r equir ed

to loosen the belt and remove the driving element

•A small screw can be used to spread the

sheaves of the driven element so that the belt

can be removed. Specific dimensions are given

in the belt removal section of this chapter.

•A clutch puller is needed to pull the driving ele-

ment off of the tapered crankshaft.

NOTE: The belt may be remove d independently,

or the CVT may be removed complete with the

belt.

12

Page 17

Chapter 2- Drive System: CVT and Transfer Case

DRIVE SYSTEM ADJUSTMENTS:

1. CVT spacing and alignment:

• Sp acing and alignment are critical to pr oper CVT

performance and belt longevity.

• In normal service, these items should not be an

issue on this vehicle. The engine and transfer

case are firmly tied to each-other by the engine /

transmission plate that holds proper spacing and

alignment.

2. Adjustment of the driving element and driven

element:

• The CVT is tuned to maximize performance of

the vehicle. It should require no adjustment in its

normal service life.

• While it is mechanically possible to disassemble

the driving and driven elements, individual parts

will not be available through Cub Cadet.

CVT SERVICE

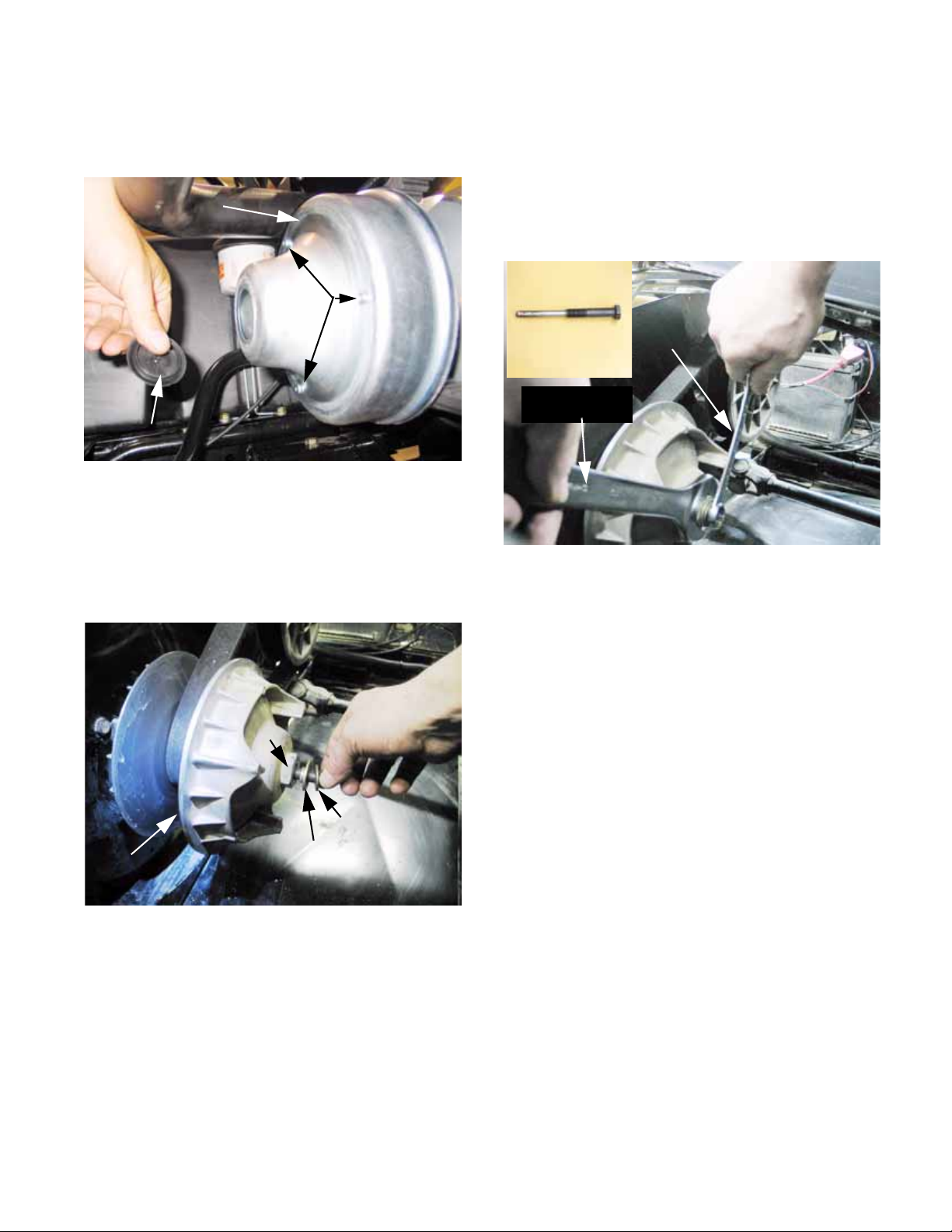

1. BELT REMOVAL

NOTE: The procedure to remove the belt is the

same for the Kohler and the Caterpillar engines.

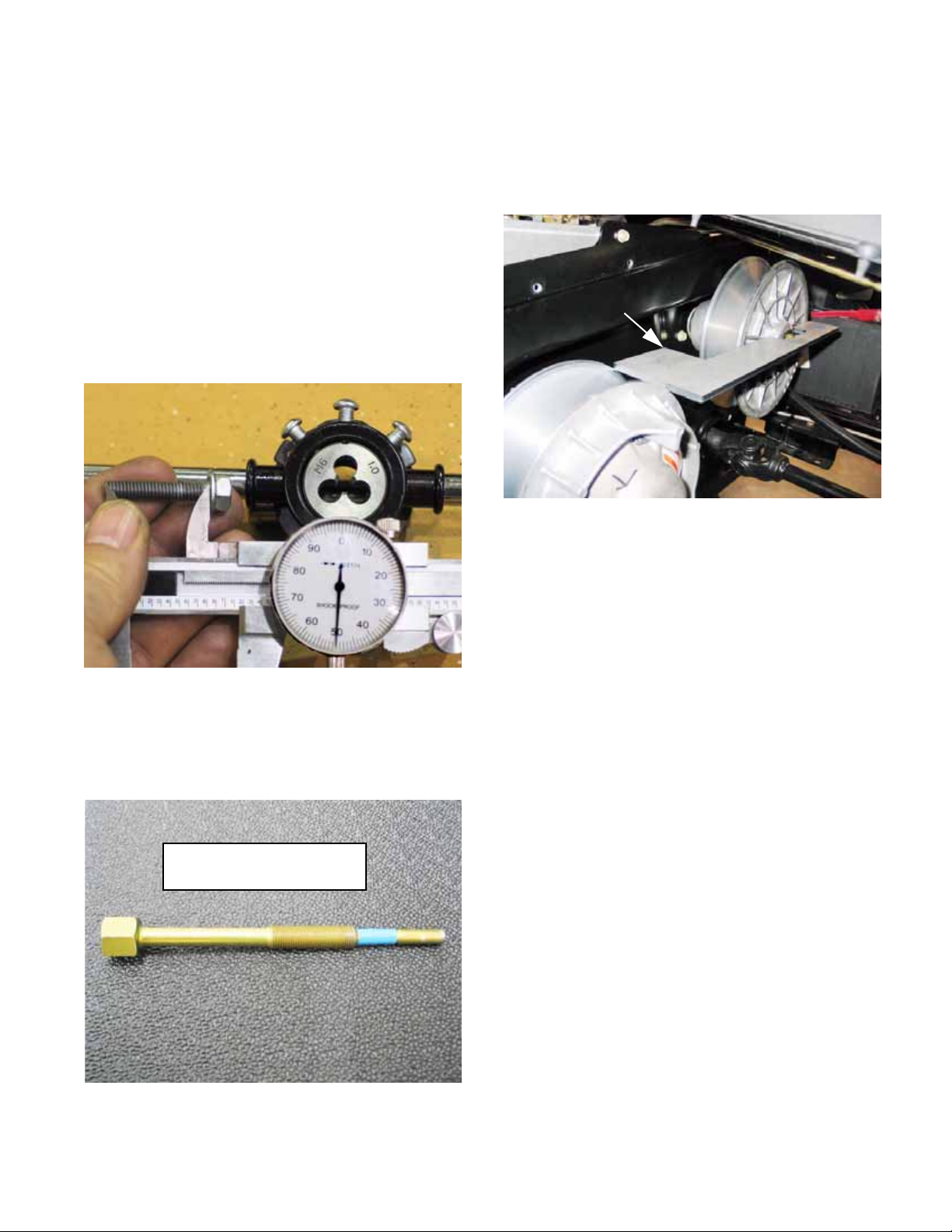

1a. When new, the belt measures 1.335”

+

.031” (33.9 + .8mm) across the wide flat

outside surface of the belt. The belt is

considered worn when the measurement

is 1.20” (30.5mm) or less. some degradation of performance may begin to occur as

belt is worn to less than 1.275” (32.4mm).

See Figure 2.9.

1b. To remove the belt, a 6mm/1.0 screw with a

minimum thread length of 1.15" (2.9cm)

will be required. See Figure 2.10.

1.15” (2.9cm)

thread length

Figure 2.10

NOTE: A 6mm screw with a thread pitch of 1.0

may be purchased locally. The minimum thread

length needed is longer than the threads of a

standard screw of this size. It will be necessary

to cut threads further up the shank of the screw

using a thread-cutting die.

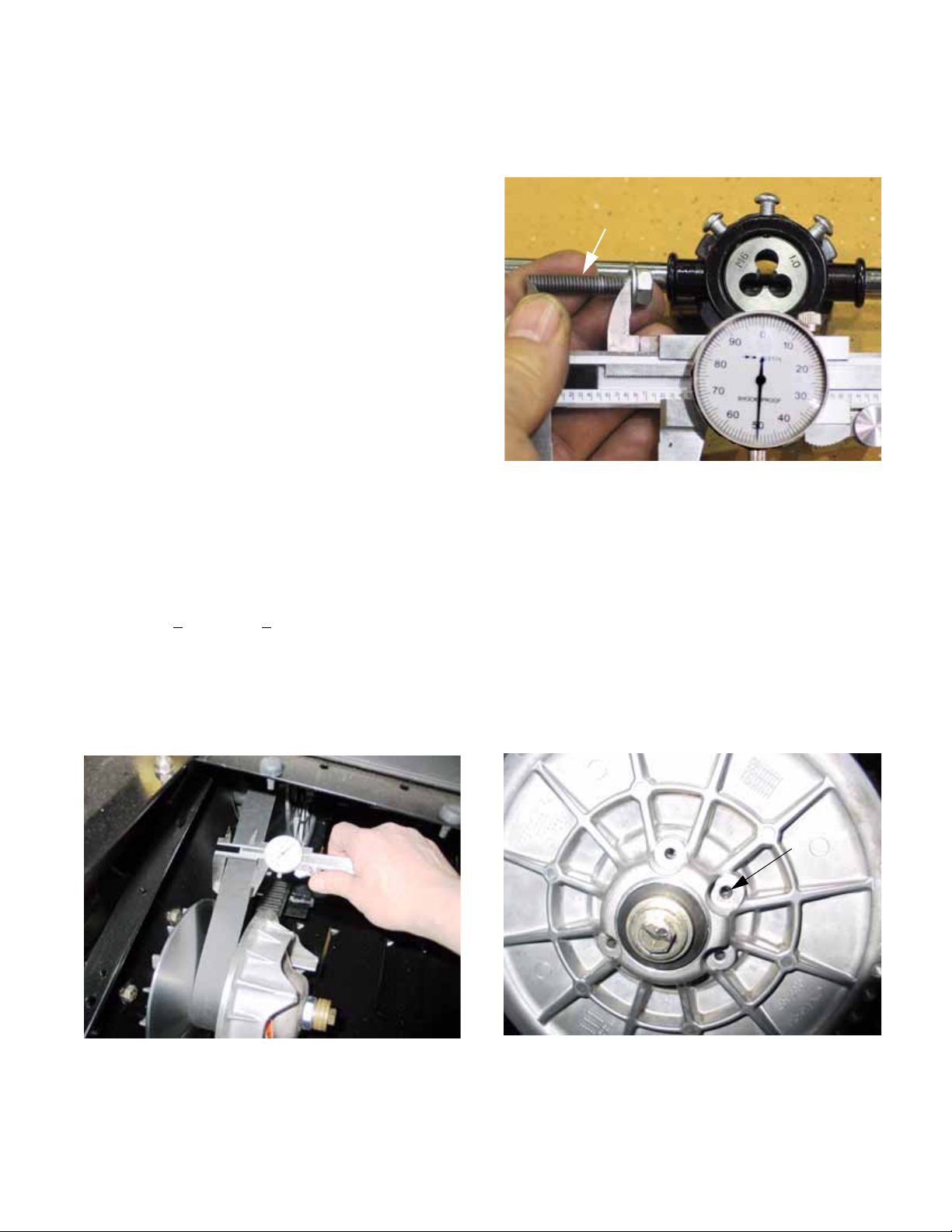

1c. There are 4 holes in the face of the driven

element. Three of them are close

together, one is 180 degrees away from

the others. The middle hole of the set of

three is threaded.

See Figure 2.11.

New: 1.335”

(33.9mm)

Worn: 1.20”

(30.5mm)

Figure 2.9

Tapped hole

Figure 2.11

13

Page 18

Chapter 2- Drive System: CVT and Transfer Case

1d. Thread the screw into the tapped h ole in the

outer half of the driven element sheave.

The end of the screw will press against

the inner half of the sheave, spreading the

two apart. See Figure 2.12.

Screw maintains

distance between

sheaves

Figure 2.12

NOTE: It is common practice among snowmobil-

ers to carry a spare belt. Belt life on this vehicle

should not be an issue, but if the utility vehicle is

operated in very remote areas, it may provide

some peace-of-mind for the operator. If they

choose to carry a spare belt, a suitable screw

and a 10mm wrench should be kept with it.

1e. As the sheaves are spread, the tension on

the belt will be relieved, and the belt can

be rolled-off of the driven element (pulley).

See Figure 2.13.

2. Removal of the Driving element

NOTE: On the Caterpillar engines, The belt may

be harder to roll off the sheave, but it will roll off.

1f. The belt can easily be installed by revers-

ing the removal process. See Figure 2.14.

Figure 2.14

NOTE: When the belt is installed, remove the

screw before operating the vehicle

NOTE: It may be necessary to start the vehicle, ,

and rev the engine in neutral to seat the belt.

NOTE: The driving element is most easily

removed after the belt is taken- off.

NOTE: The driving element can be removed

with the belt in place, but installation may require

the driven element sheaves to be spread unless

all three parts of the CVT are installed together,

as described later in this section.

Figure 2.13

NOTE: The bolt that holds the driving element to

the crankshaft can be reached by removing the

plastic cap from the end of the driving element.

If the driving element spins the crankshaft when

the tool is tightened it will be necessary to hold

the CVT or lock the crankshaft. One means of

holding the CVT involves removing the cover.

That is the technique described in this section.

2a. Disconnect and ground the spark plug

leads (Kohler) or un-plug the fuel shut-off

solenoid (Caterpillar).

14

Page 19

Chapter 2- Drive System: CVT and Transfer Case

2b. Remove the three screws holding the

cover in place, then remove the co v e r.

See Figure 2.15.

Driving element cover

Screws

Plastic cap

Figure 2.15

2c. Hold the large nut with a 30mm wrench

while loosening the crankshaft bolt with a

5/8” wrench.

2d. Withdraw the bolt, washers, and shoulder

spacer. See Figure 2.16.

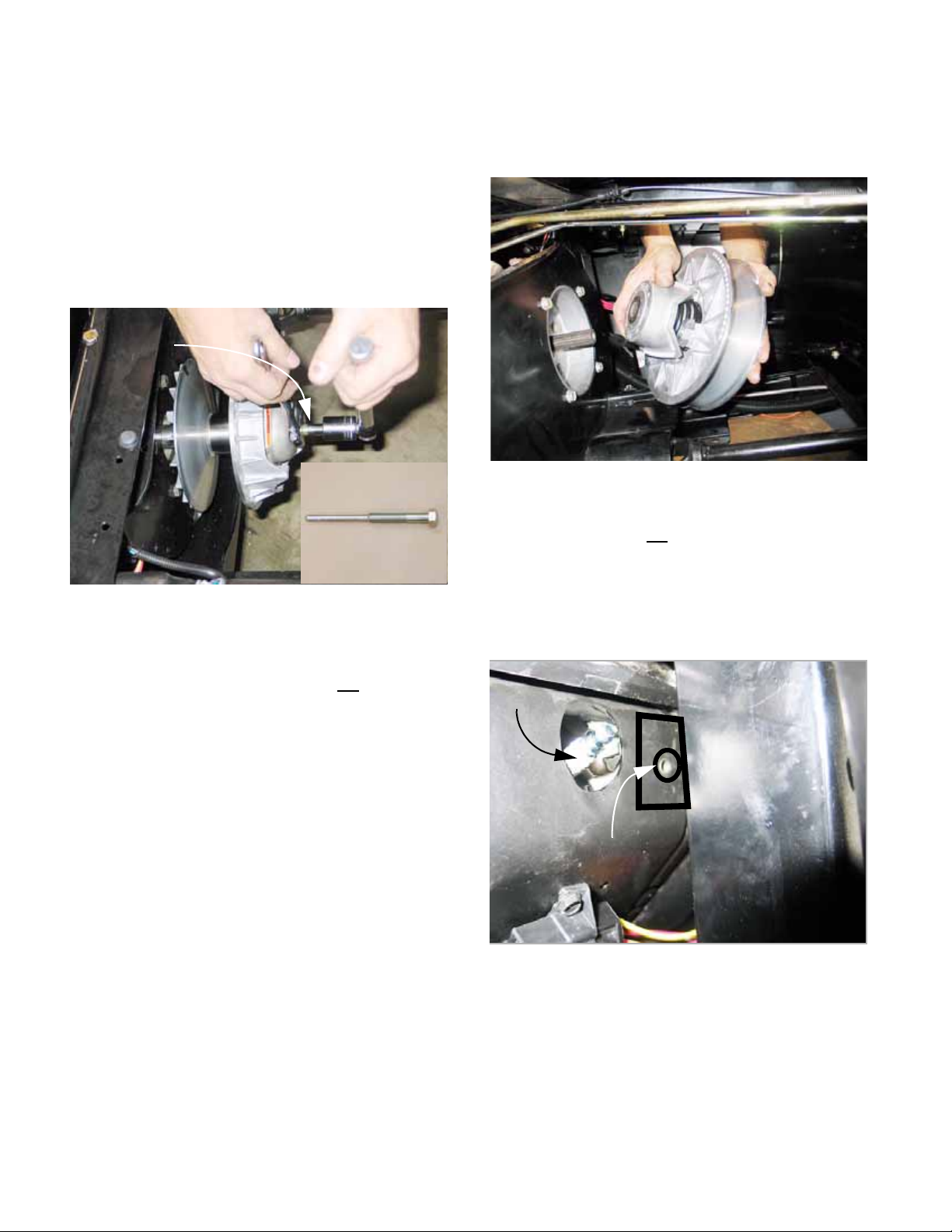

3. Install the clutch removal tool (M14 - 2.O) by

threading it into the clutch, pressing against the

crankshaft.

3a. Hold the pulley with a 30mm wrench, and

turn the tool using a 22mm wrench. This

will force the driving element off of the

crankshaft. See Figure 2.17.

Inset:

clutch tool

One wrench

to turn the

tool

One wrench to

hold the clutch

Figure 2.17

CAUTION: There is a tapered fit between the

driving element and the crankshaft. Applying

force to the perimeter of the driving element will

break it.

Driving

element

Nut

Shoulder washer

Figure 2.16

Flat washer(s)

3b. If the belt was not previously removed, it

can be taken-off as the driving element is

removed.

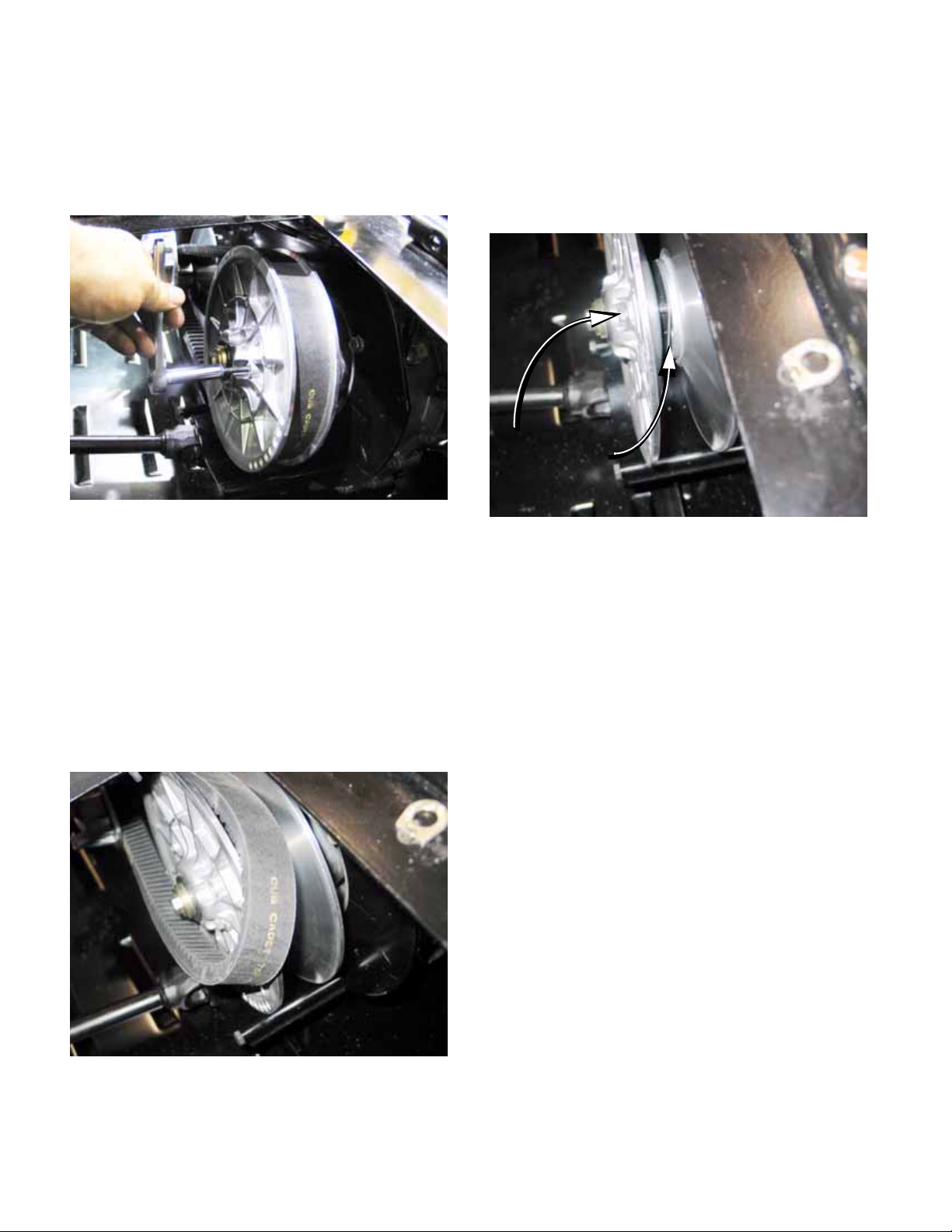

4. Removal of the driven element

4a. Remove the belt.

NOTE: The driving element fits on a tapered

shaft. It can be removed with the belt in-place

because the tapered shaft provides freedom of

movement as soon as the driving element

comes loose.

The driven element fits on a splined shaft. As the

driven element is drawn off the shaft, the belt will

tighten, making removal difficult even with the

sheaves spread. The belt should be removed

before taking-off the driven element.

15

Page 20

Chapter 2- Drive System: CVT and Transfer Case

4b. Place the transfer case in H position, and

set the parking brake.

4c. Loosen the bolt that holds the driven ele-

ment to the input shaft using a 9/16”

wrench.

NOTE: Hold the driven element from rotating

using a pin spanner, if needed.

4d. Remove the bolt and washers.

See Figure 2.18.

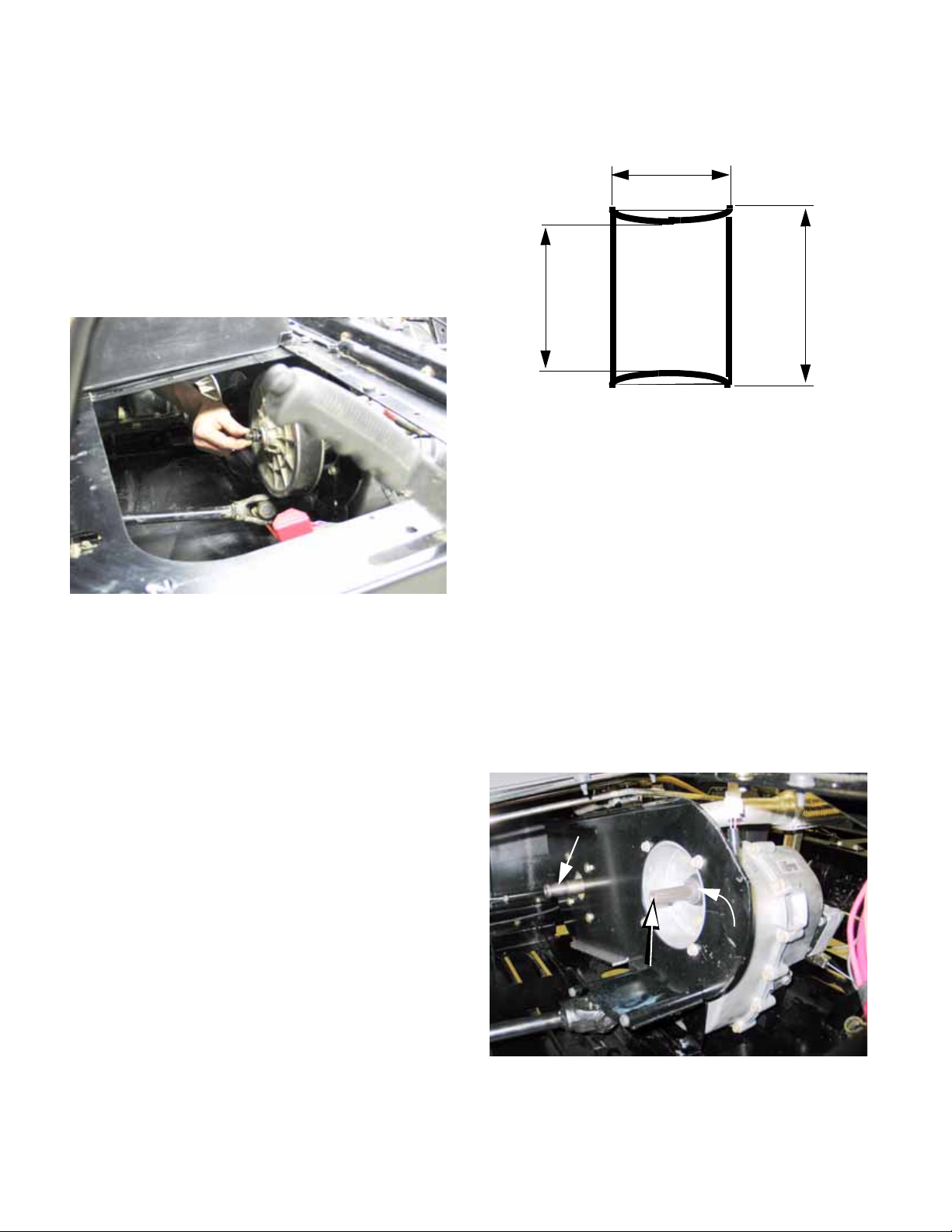

6. Make the wood block spacer as described in the

accompanying illustration. See Figure 2.19.

3-1/2” (8.9CM)

4-3/8”

(8.6CM)

NOTE: BLOCK ENDS MAY BE

V-SHAPED OR CURVED

Figure 2.19

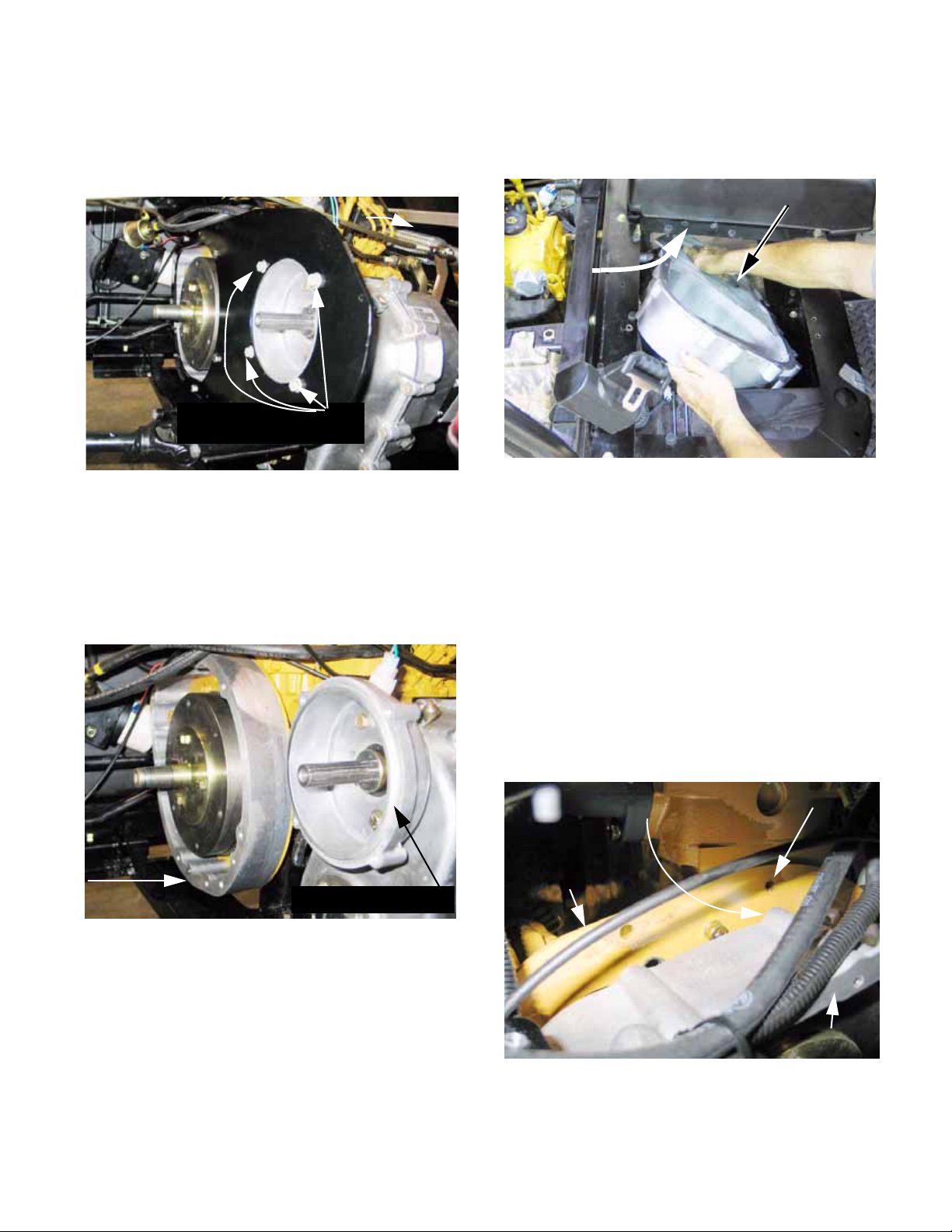

6a. Prepare the CVT for installation:

See Figure 2.20.

• Clean the shafts and the surrounding area

before installing the CVT.

5-1/8”

(13.1CM)

Figure 2.18

4e. At this point, the driven element may be

slipped off of the transfer case input sha ft.

5. CVT Installation

NOTE: The driving element and driven element

can be installed individually, then the belt can be

rolled-on as described in the belt removal section of this chapter.

Alternatively, both elements and the belt can be

installed all-at-once using a simple wood-block

tool. This method is described in the following

steps.

Preparation and torque specs remain the same

for both methods.

• Confirm the presence of the .060” (1.5mm)

spacer on the shaft between the driven element

and the transfer case housing.

• A small amount of anti-seize compound may be

used on the splined joint between the input shaft

of the transfer case and the driven element.

• The tapered joint between the driving element

and the crankshaft must be clean and dry.

Tapered shaft

Spacer

Splined shaft

16

Figure 2.20

Page 21

Chapter 2- Drive System: CVT and Transfer Case

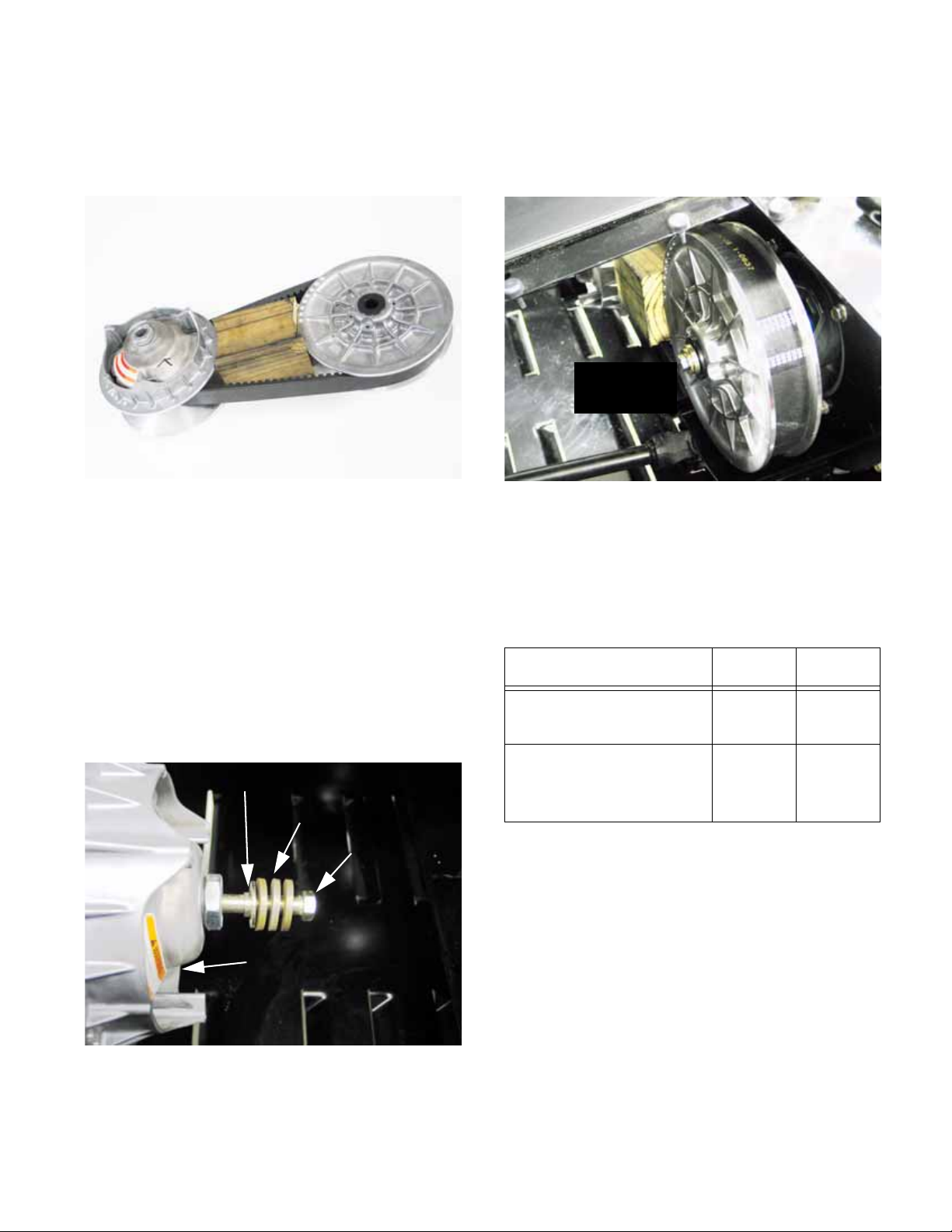

6b. Install the belt around the pulleys and insert

the wood block tool between the pulleys

to establish correct spacing.

See Figure 2.21.

Wooden tool sets

spacing and holds

assembly together

for installation

Figure 2.21

6c. Install the belt and pulleys, with the wood

block between them, onto the crankshaft

of the engine and the input shaft of the

transfer case.

6d. Apply a small amount of thread locking

compound such as Loctite® 262 (red) to

the bolts that secure each pulley.

6e. Secure the driving element to the crank-

shaft using the bolt, washers, and shoulder spacer previously removed. Do not

tighten fully at this time. See Figure 2.22.

Shoulder spacer

Washers

6f. Secure the driven element to the input shaft

using the bolt, washer, and shoulder

spacer previously removed. Do not

tighten fully at this time. See Figure 2.23.

CVT installed

all at once

Figure 2.23

6g. Tighten the bolts securing the pulleys to

their respective shafts in even steps,

drawing the pulleys into place.

6h. Once seated, tighten the bolts to the spec-

ified torque:

Item ft-lbs N-m

Driving element to

32-36** 43-49**

engine crankshaft

Driven element to

70-80** 95transfer case input

shaft

109**

Bolt

Driving element

Figure 2.22

** Install with permanent thread locking compound

such as Loctite®

17

262 (red).

Page 22

Chapter 2- Drive System: CVT and Transfer Case

6i. Remove the wood block tool.

See Figure 2.24.

Tighten bolts

and remove

block

Figure 2.24

6j. Test the operation of the drive system in a

safe area, then allow the exhaust system

to cool before final assembly.

6k. Final assembly: install the cover and plug

on the driving element and replace the

parcel bin under the passenger’s seat.

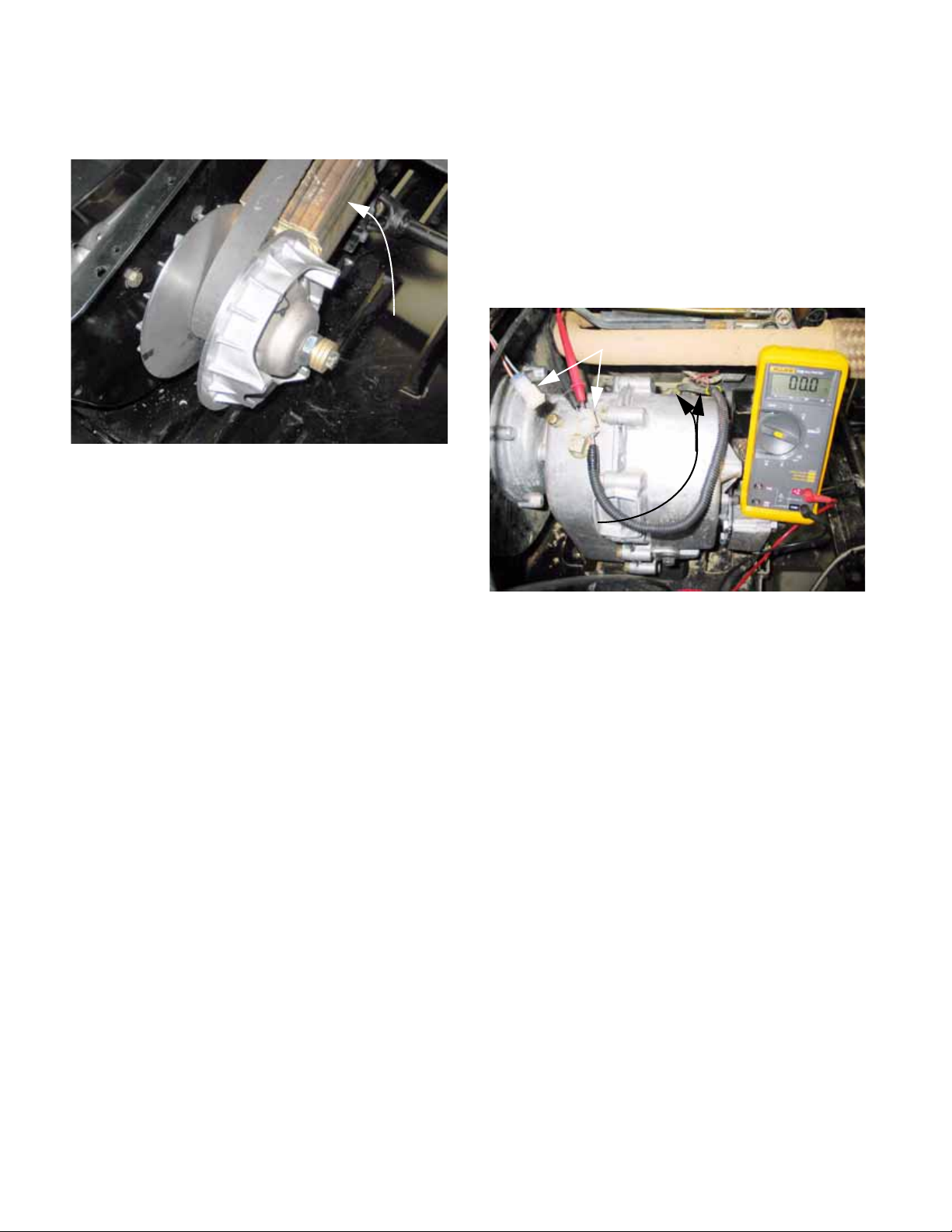

DRIVE SYSTEM ADJUSTMENTS:

TRANSFER CASE SHIFT LINKAGE

1. Before attempting any linkage repair of adjustment, confirm whether the problem at hand is in

the linkage or elsewhere in the system.

2. A handy quick-check to confirm that the transfer

case is in neutral when the gear selector is in

neutral can be made using the two safety

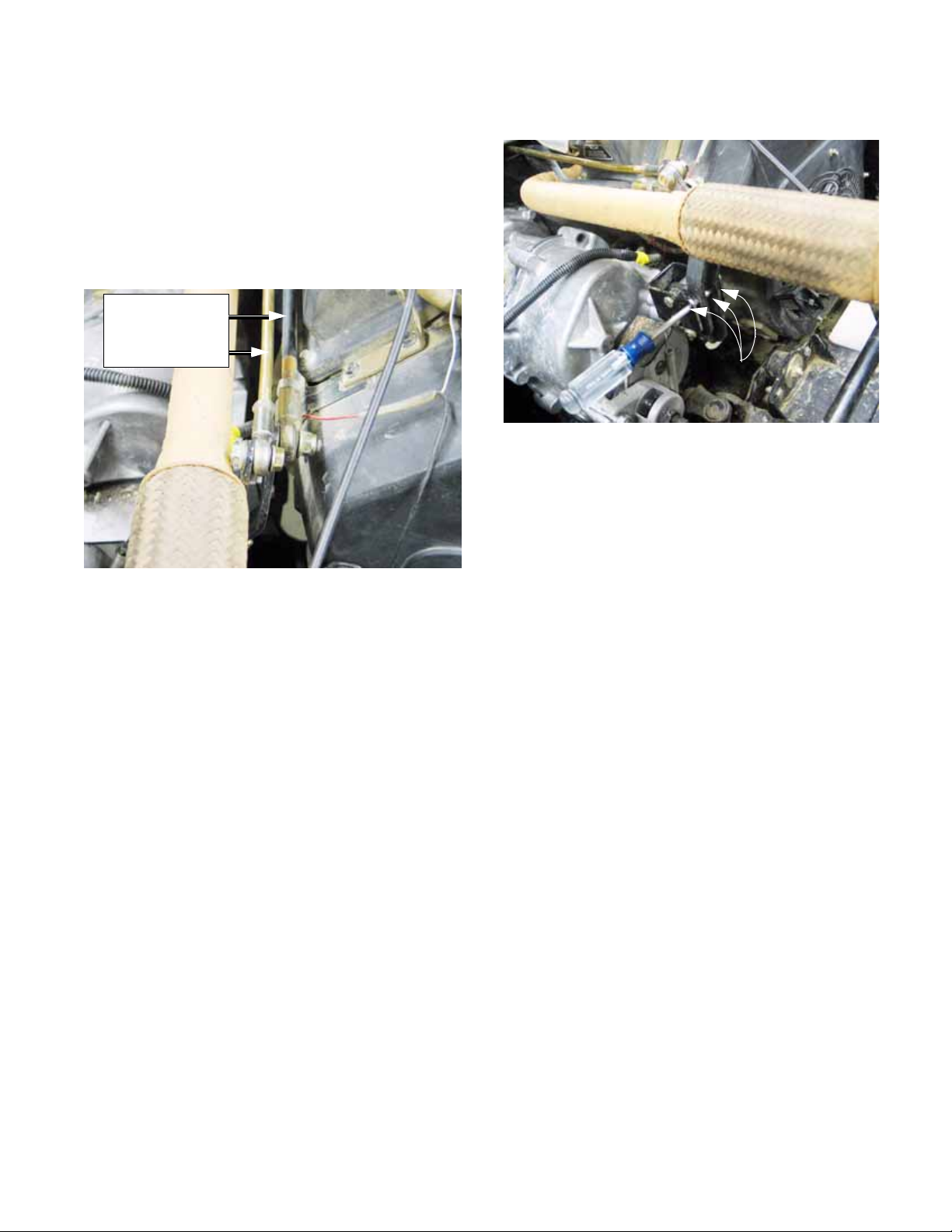

switches in the starter circuit: See Figure 2.25.

Switch harness unplugged

Both switches

in series:

contacts closed

Figure 2.25

2a. Locate and disconnect the harness that

leads to the neutral safety switches.

2b. Connect a DVOM or continuity light to the

pair of terminals on the disconnected harness.

2c. When the transfer case is in neutral, there

should be continuity (0.0 Ω) between the

two wires in the terminal.

NOTE: There are two sets of shift forks within

the transfer case. Each shift fork has a safety

switch associated with it. When both shift forks

are in the neutral position, the contacts of both

switches will be closed. The switches are connected in series, so the closure of both switches

completes the circuit.

3. The correct operation of the switch can be confirmed by rotating the transfer case input shaft

and observing the reaction of the output shafts.

4. After correct internal operation of the transfer

case is confirmed, check the linkage. Correct

any internal problems before proceeding. If the

transfer case has internal damage, no amount of

external adjustment will fix it.

18

Page 23

Chapter 2- Drive System: CVT and Transfer Case

NOTE: Methodology: start at the source (the

transfer case), and work toward the control input

(the gear selector).

5. Operate the gear selector through its full range

of motion (high range forward, low range forward, neutral, and reverse). Look for the following issues: See Figure 2.26.

Forward-Neutral Reverse rod

Low-range rod

7. Centering the linkage: See Figure 2.27.

Neutral

alignment

holes

Figure 2.27

7a. With the linkage disconnected, the shift

forks are centered in the neutral position

by detent springs.

Figure 2.26

• Lost motion

• Loose hardware

• Mechanical interference

• Unintended bends in the linkage

• Excessive linkage bowing under load

• Engagement of the gear that is selected

6. Correct any of these initial problems before proceding with adjustment.

NOTE: It is possible to make a damaged linkage

work better by compensating for the damage

with adjustment. This should not be considered

complete repair.

7b. At this point the shift arms can be locked

into the neutral position by inserting a 3/

16” (or 5mm) dowel rod through the alignment holes in the shift lever bracket and

shift arms located on the back of the

transfer case housing.

7c. The center-point of neutral position at the

Hurst gear selector lever corresponds

with the center of the range where the

shift lever can move from the high-neutralreverse gait into the neutral-low gait.

7d. Find the point were the Hurst lever moves

left and right between the two gates. This

is the center-point of it’s range of travel.

19

Page 24

Chapter 2- Drive System: CVT and Transfer Case

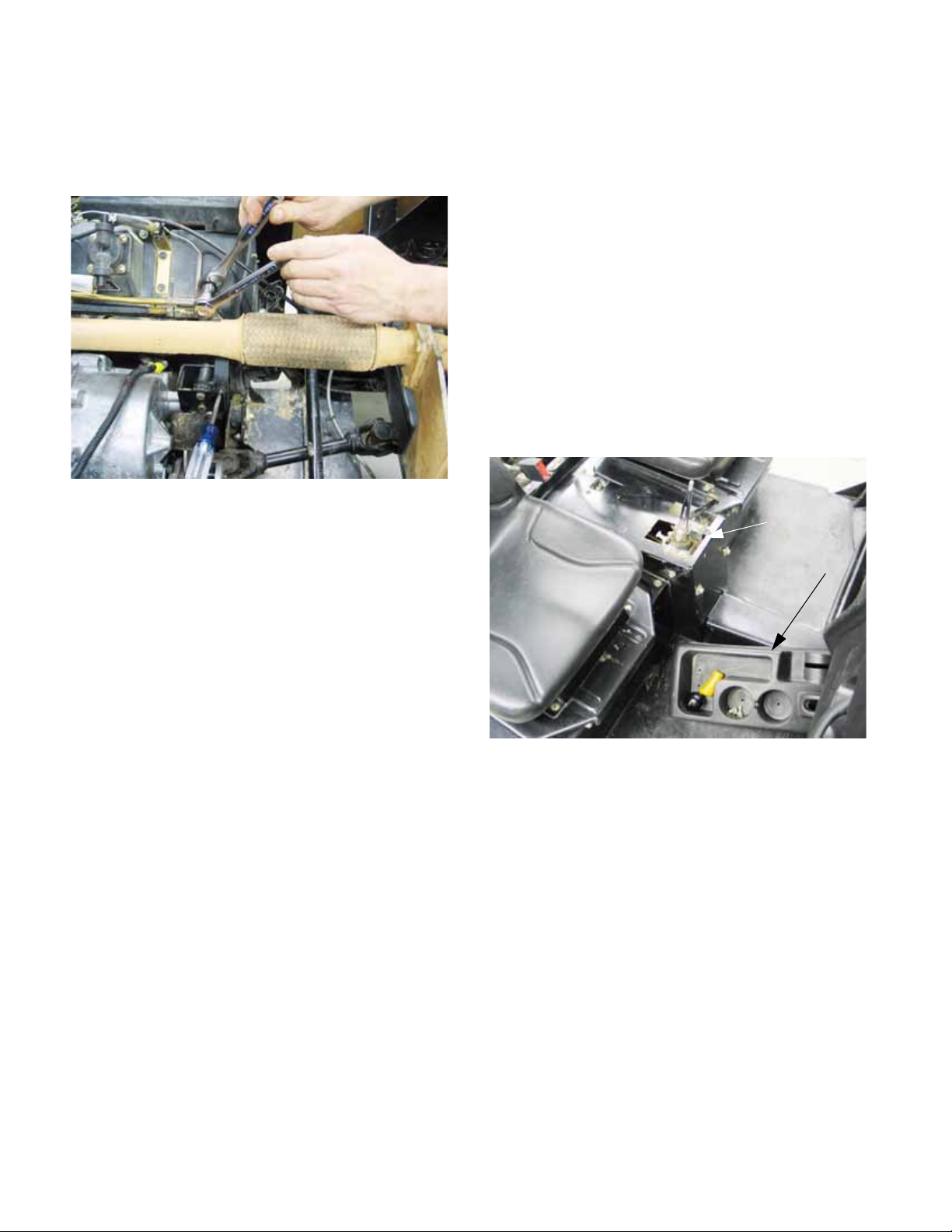

8. Rod adjustment is made by lengthening or shortening the shift rods to make neutral at the Hurst

gear selector lever correspond with neutral

within the transfer case. See Figure 2.28.

Disconnecting linkage

to make low-range adjustment

Figure 2.28

8a. The heavier rod that is connected to the

shift arm nearest the engine controls forward (high range), neutral, and revers e

functions.

8b. Loosen the jam nut, then disconnect the

rod to adjust it using a pair of 9/16”

wrenches.

10. After the rod adjustment is done, operate the

linkage to confirm that the shift forks move fully

to their engaged detent positions.

• If there is insufficient travel, the stops on the

Hurst shift mechanism can be moved out.

• If the linkages are over-throwing the shift fork

travel, the stops on the Hurst shift mechanism

can be moved in.

• The stops are unlikely to need adjustment in the

normal service life of the utility vehicle. The

most likely reason for the stops to be out of

adjustment would be tampering by unqualified

technicians.

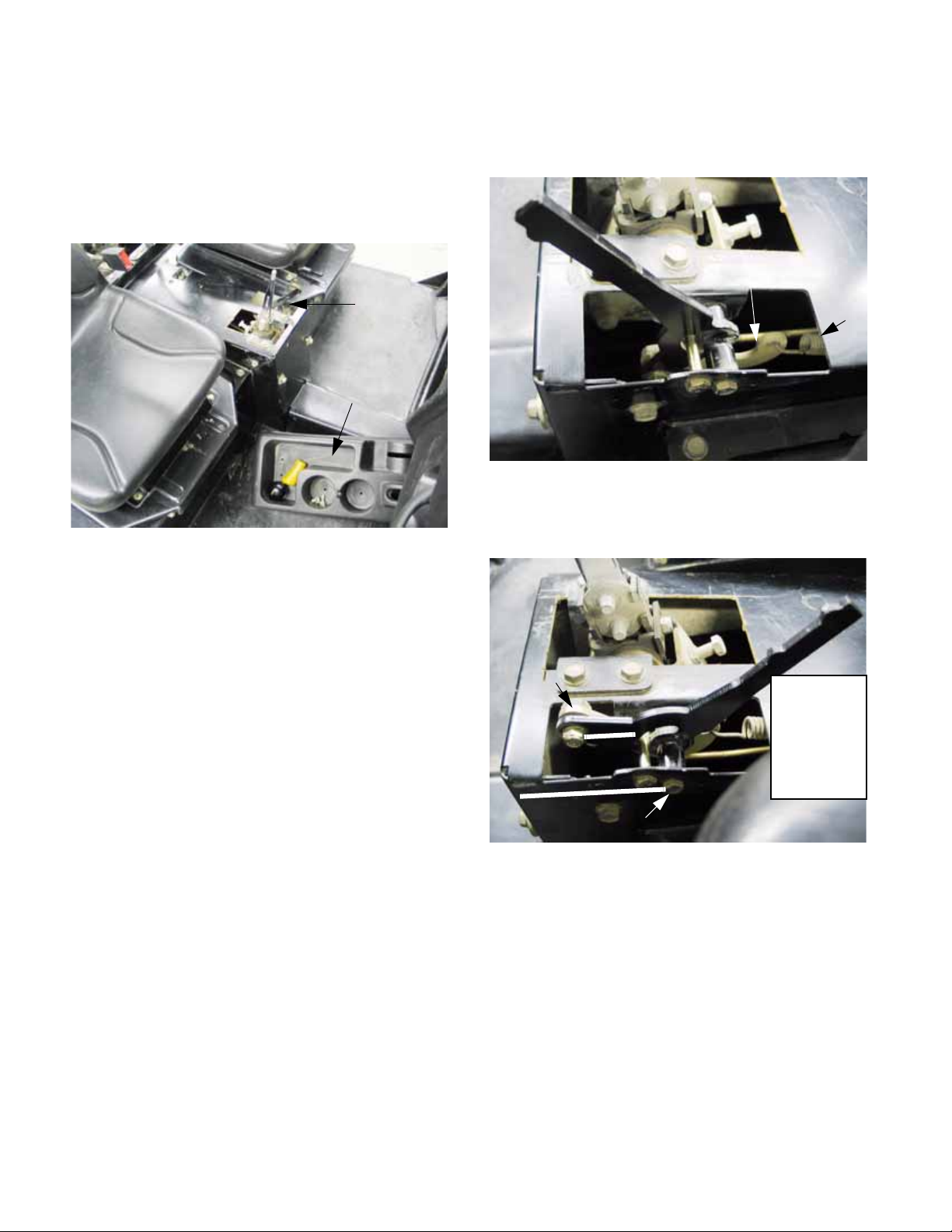

10.1. Remove the console cover / cup holder to gain

access to the stop adjustments.

See Figure 2.29.

Hurst shift

linkage

exposed

Console cover /

cup holder

removed

8c. Thread the rod-end up or down the length

of the threads for adjustment.

8d. The lighter rod that is connected to the shift

arm farthest from the engine shifts the

transfer case between neutral and low

range forward.

8e. Loosen the jam nut using a 1/2” wrench

and a 7/16” wrench, then disconnect the

transfer case end of the rod using a pair of

1/2” wrenches.

9. Snug the jam nuts and remove the locking do wel

after rod adjustment is completed.

Figure 2.29

10b. Remove the knob from the Hurst gear sh if t

by turning it counter-clockwise.

10c. Remove the grip from the differential lock

control lever by pulling upward from the

base of the grip. A blow gun may be used

to force the grip off of the lever by shooting compressed air into the hole at the top

of the grip while lifting upward.

20

Page 25

Chapter 2- Drive System: CVT and Transfer Case

10d. Unbolt the console cover / cup holder using

a 9/16” wrench to remove the two screws

that hold the back of the console cover . A

9/16” wrench can also be used to loosen

the two screws that secure the front edge

of the cover through slotted holes.

10e. Lift the cover off to remove it.

11. Push the Hurst lever straight forward to engage

high-range forward gear.

12. Pulling gently back on the lever to take-up play

in the linkage, there should be 1/16” (1.5mm) of

clearance between the lever and the tip of the

forward stop bolt (mounted at the rear of the

mechanism).

NOTE: A 1/16” or 1.5mm allen wrench makes a

suitable feeler gauge, positioned so that the flats

(not the peaks) are spanning the gap between

the stop bolt and the lever.

NOTE: Do not adjust the travel to make-up for

out-of adjustment shift rods. Travel stop adjustment is merely for confirmation and is not likely

to need adjustment in the normal life of the vehicle.

13. If adjustment is necessary, loosen the jam nut

and tighten or loosen the bolt using a 9/16”

wrench. See Figure 2.30.

14. When adjustment is complete:

14a. Snug the jam nut.

14b. Move the lever into reverse

14c. Repeat the adjustment in the opposite

direction on the reverse stop bolt.

15. Test the operation of the drive system in safe

area. Confirm that:

15a. The vehicle does not try to move in neutral

15b. The gear selector lever works smoothly

and easily, providing solid “feel” for each

gear.

15c. Each gear engages fully. A partially

engaged gear may “jump out” when

power is applied.

NOTE: Other mechanical causes may cause the

vehicle to jump out of gear , e.g.: worn or missing

detent spring, damaged shift fork, damaged shift

dogs. Of those issues, only the detent balls and

springs can be reached without removing the

transfer case from the vehicle.

16. Install the console cover / cup holder, gear

selector knob, and rear differential lock control

lever grip.

Shift linkage

travel stop

adjustment

Figure 2.30

21

Page 26

Chapter 2- Drive System: CVT and Transfer Case

DRIVE SYSTEM ADJUSTMENT: PARKING BRAKE

NOTE: The parking brake is mounted to the

transfer case, and its operation is completely

independent of the hydraulic service brakes.

1. The parking brake has two functions:

1a. It should prevent the vehicle from rolling

when it is applied.

1b. It should not drag when released.

2. Parking brake operation should be checked at

each oil change interval. If the operator notices

any change in operation of the parking brake, it

should be checked before any further use.

NOTE: When the engine is turned-off, the CVT

will not stop the vehicle from rolling, even if the

transfer case is left in gear . The parking brake is

essential to safe operation of the vehicle.

3. Visual inspection of the brake system should

accompany adjustment. Look for:

• Indications of dragging brake:

- burning smell

- discolored park brake rotor

- sluggish performance

- accelerated brake pad wear

- slack cable when brake is released.

• Indications of impending failure

- corroded or frayed cable

- excessive travel on park brake lever before

- brakes engage

- worn brake pads: <

thick ness (<

- burnt, kinked, or chafed cable housing

- loose hardware or damaged brackets

- mechanical damage to rotor or caliper

.762mm)

.030” friction material

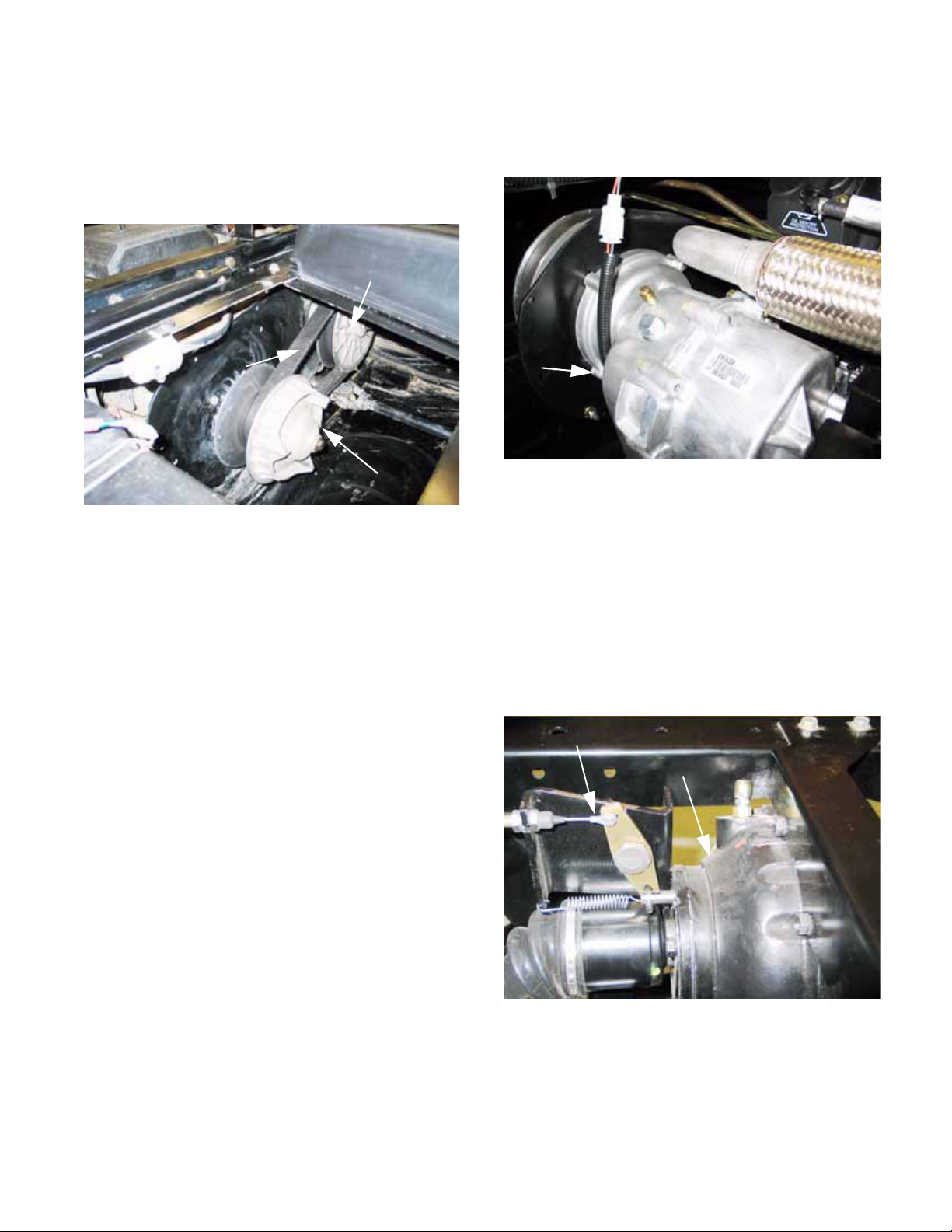

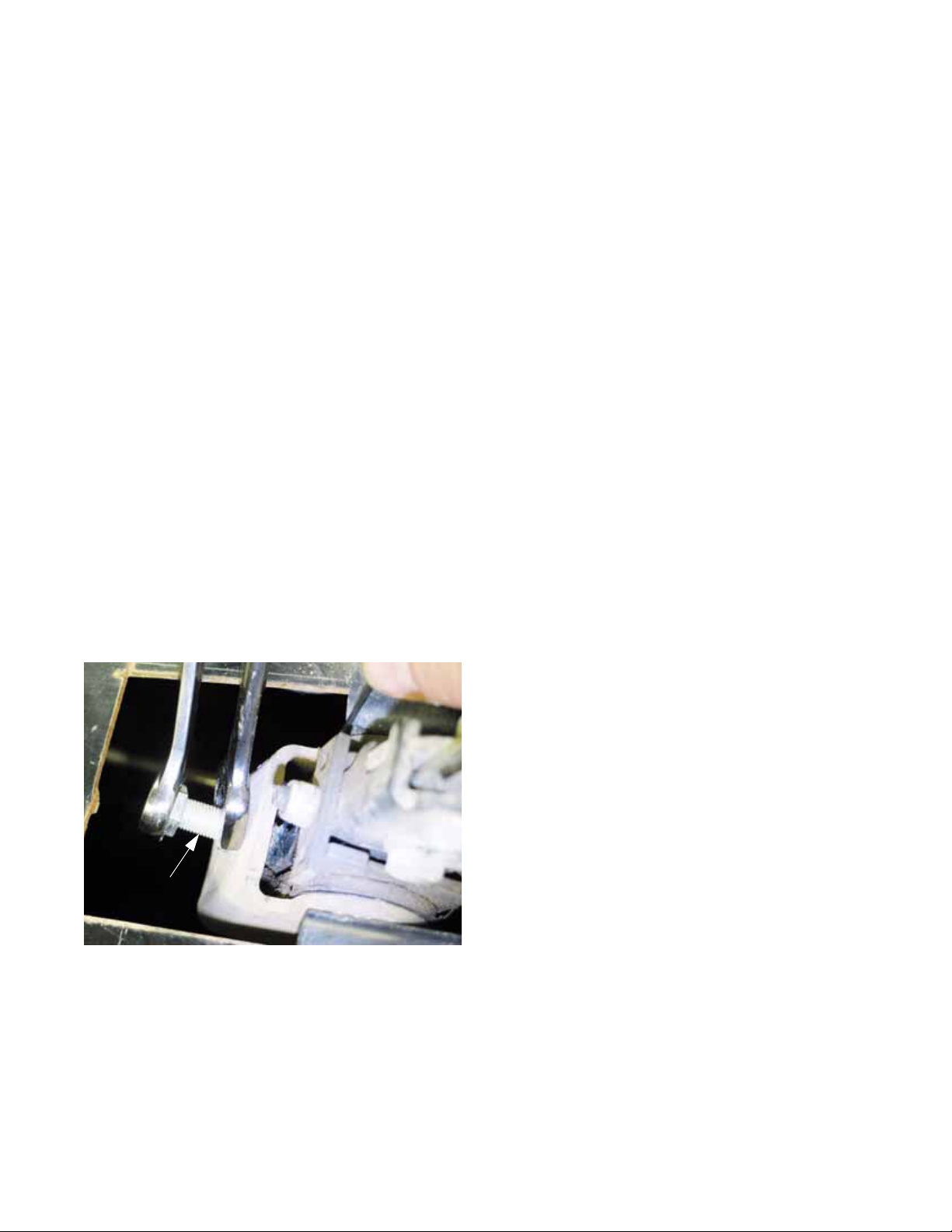

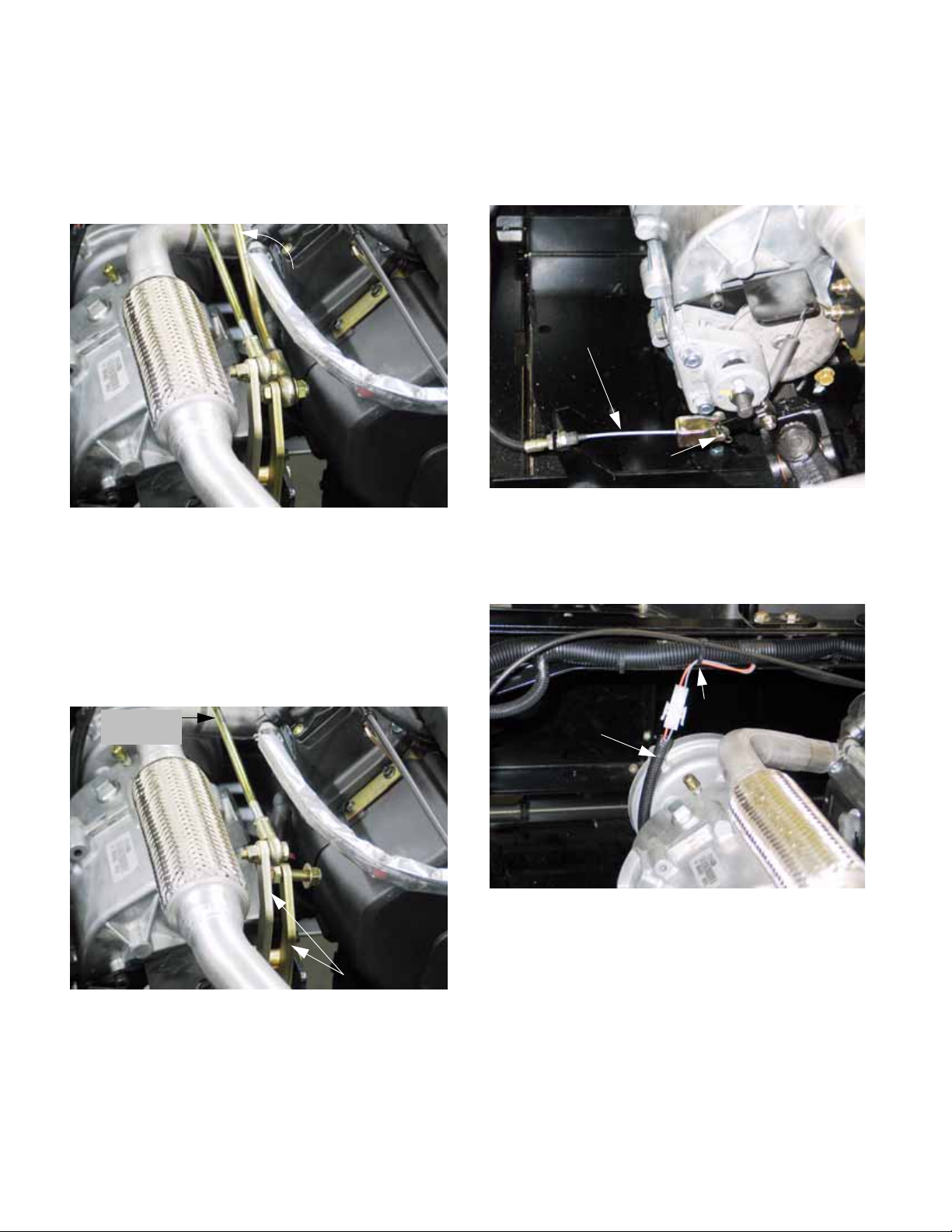

5. Checking caliper adjustment: See Figure 2.31.

Feeler gauge

Parking brake

caliper

5a. Chock the wheels so that the vehicle will

not roll.

5b. Release the parking brake.

5c. Confirm that the return spring has drawn

the arm on the caliper all the way against

the stop.

5d. Use a feeler gauge to check the clear ance

between the parking brake rotor and one

of the pads. It may be necessary to wig-

gle the rotor slightly , forcing the p ads back

from the rotor.

5e. Clearance should be between .010” and

.013” (.254mm-.330mm).

5f. Adjust the caliper if it is not in this range.

.010-.013 (.254-.330mm)

Adjustment screw

and jam nut

Figure 2.31

4. Repair any of these issues before proceeding

with adjustment. Adjustment should be checked

after any service to the parking brake caliper of

linkage.

22

Page 27

Chapter 2- Drive System: CVT and Transfer Case

6. The caliper can be adjusted using the screw and

jam nut on the caliper. Us a 7/16” wrench and an

11/16” wrench. See Figure 2.32.

Park brake

caliper

adjustment

Figure 2.32

6.1. After the caliper is in correct adjustment, the linkage that operates it can be adjusted properly.

6.2. The parking brake lever pulls on the cable to

engage the brake when the lever is pulled

upward. See Figure 2.33.

• There is a park brake switch mounted beneath

the lever. The con tact s within the switch are normally closed. As the lever is pulled-up, the

plunger extends from the switch, closing the

contacts.

• Contact closure = 2 notches.

7. Correct adjustment results in full engagement of

the parking brake before the 5th notch, but

allows the lever to come up far enough to close

the contacts in the switch.

8. Checking adjustment: See Figure 2.34.

Park brake light

Park brake lever

in released position

Park brake

switch

Park brake

cable

Figure 2.33

• It moves up in steps that correspond to notches

in a lock plate that the brake lock passes over in

its travel. Full travel = 5 notches.

Figure 2.34

8a. Make the adjustment with the key switch

turned on, but the engine not

the wheels chocked.

8b. Release and reapply the parking brake.

8c. As the bake lever passes the second

notch, the brake light on the instrument

cluster should illuminate. If the transfer

case is not in neutral, an alarm should

sound as well. At this point the slack

should be out of the parking brake cable,

and the arm on the caliper just beginning

to move.

9. By the third notch, drag should be noted when

the drive shaft leading to the rear differential is

turned.

running, and

23

Page 28

Chapter 2- Drive System: CVT and Transfer Case

10. By the fourth notch, it should be impossible to

rotate the drive shaft. See Figure 2.35.

Correct adjustment =

fourth “click” on handle +

tight cable +

brake fully engaged

Figure 2.35

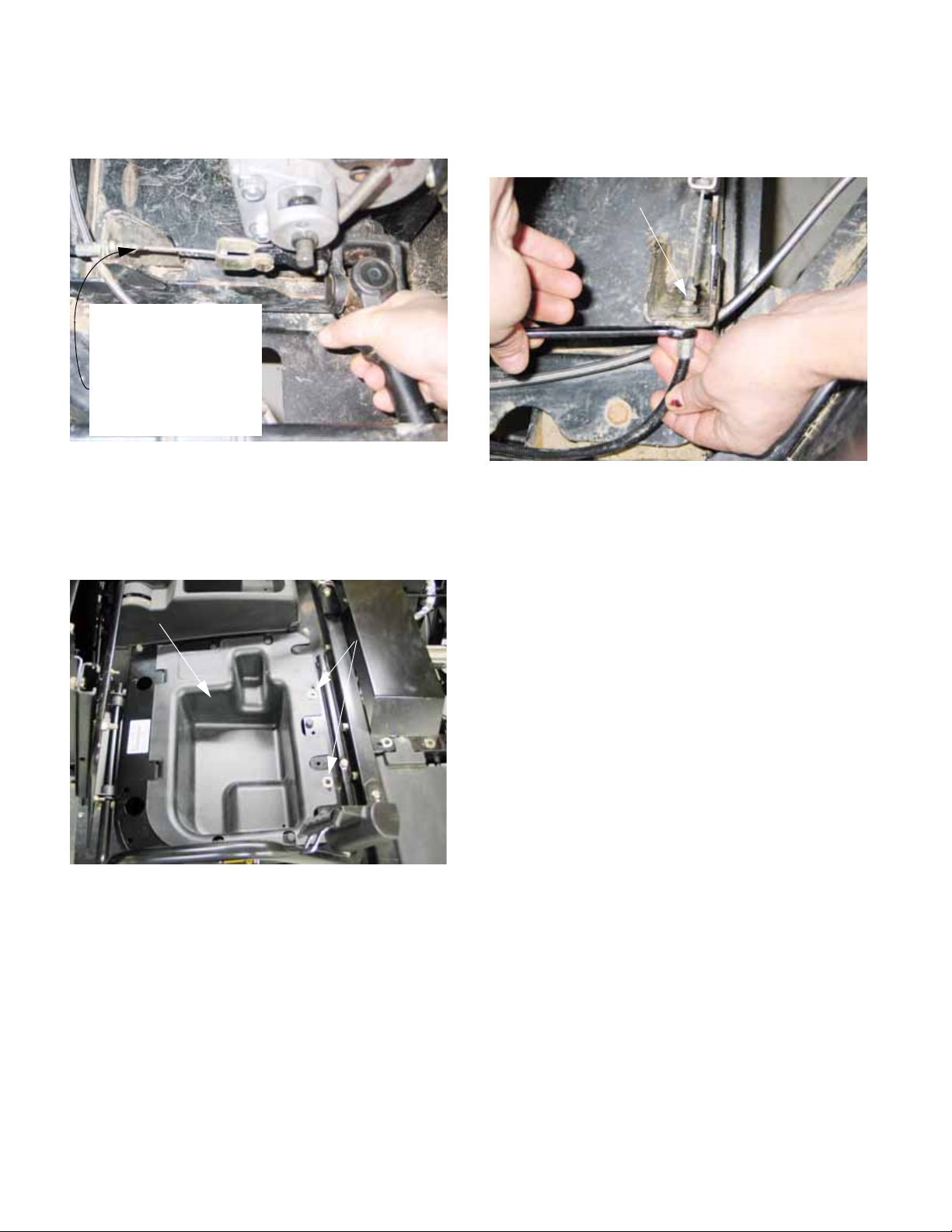

11. To reach the adjustment point for the parking

brake, release the Camloc

fasteners and

R

remove the parcel bin that is located ben eath the

driver’s seat. See Figure 2.36.

Parcel bin

Camloc

R

fasteners

11.1. Adjustment can be made using a pair of 1/2”

wrenches at the anchor point of either end of the

cable. See Figure 2.37.

Adjustment at caliper

end of cable

Figure 2.37

12. Lock the adjustment by snugging the jam nut

against the mounting bracket.

13. Test the operation of the parking brake in a safe

area before returning the vehicle to service. It

should remain stationary with a full load on a 15

degree slope with the parking brake engaged.

NOTE: While this is an extremely capable vehicle, 15 degrees is the maximum angle of operation specified in the Operator’s Manual.

Figure 2.36

CAUTION: Make sure the cover is firmly in place

on the positive battery terminal before adjusting

the cable. Contact between a wrench and the

terminal can short out the battery, causing

potential injury from heat burns, chemical burns,

and battery explosion.

24

Page 29

Chapter 2- Drive System: CVT and Transfer Case

DRIVE SYSTEM SERVICE: LUBRICATION

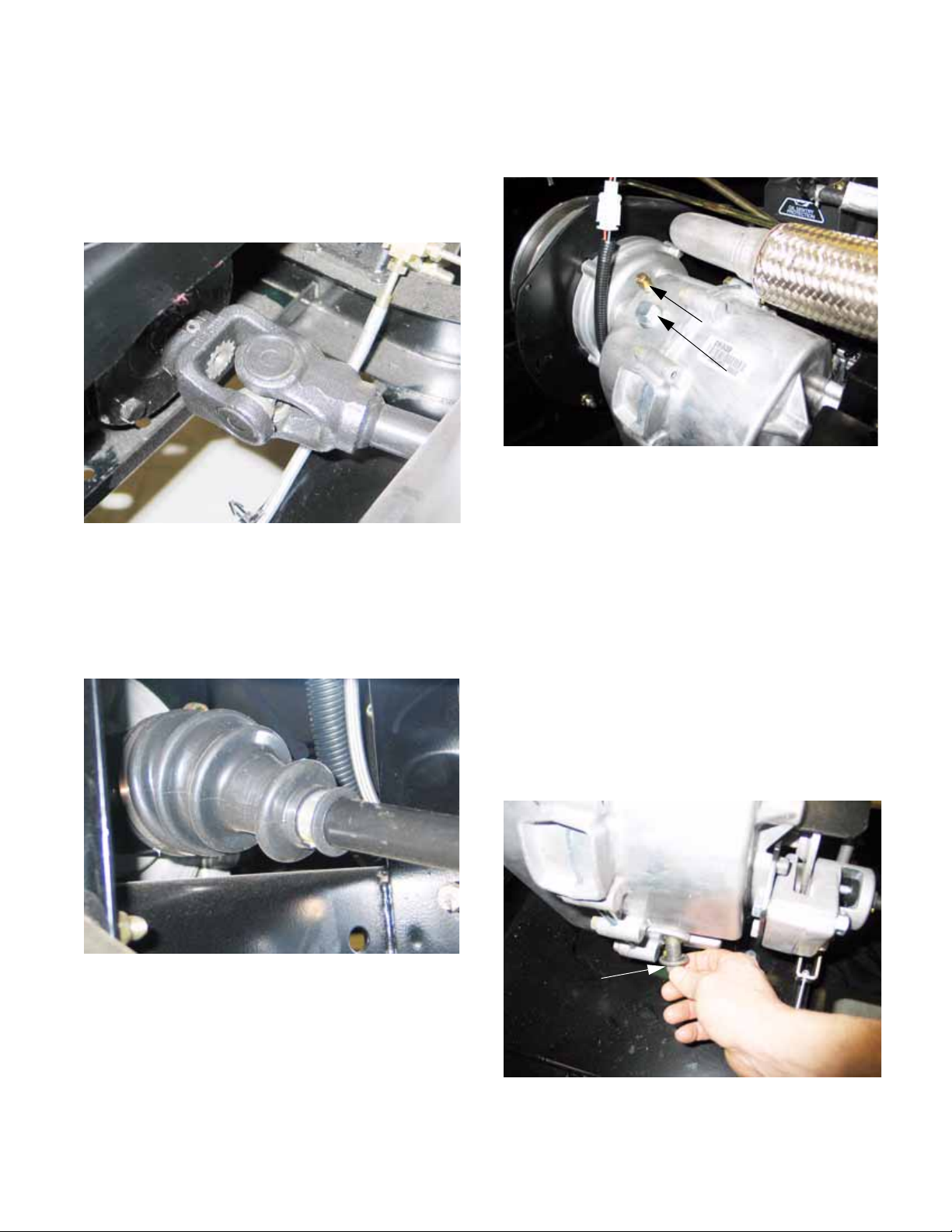

1. The universal joints in the drive shafts that connect the transfer case to the front and rear differentials are lubricated on assembly, and should

not need further lubrication in their normal service life. See Figure 2.38.

Figure 2.38

3. The transfer case contains 64 fl.oz. (1.9 l.) of

80W-90 Low Foam Oil (Cub Cadet P/N: 737-

04040). See Figure 2.40.

Vent

Fill plug

Figure 2.40

• The transfer case oil should be changed after

the first 5 hrs. of use, 50 hrs. of use, and at 500

hr. intervals thereafter.

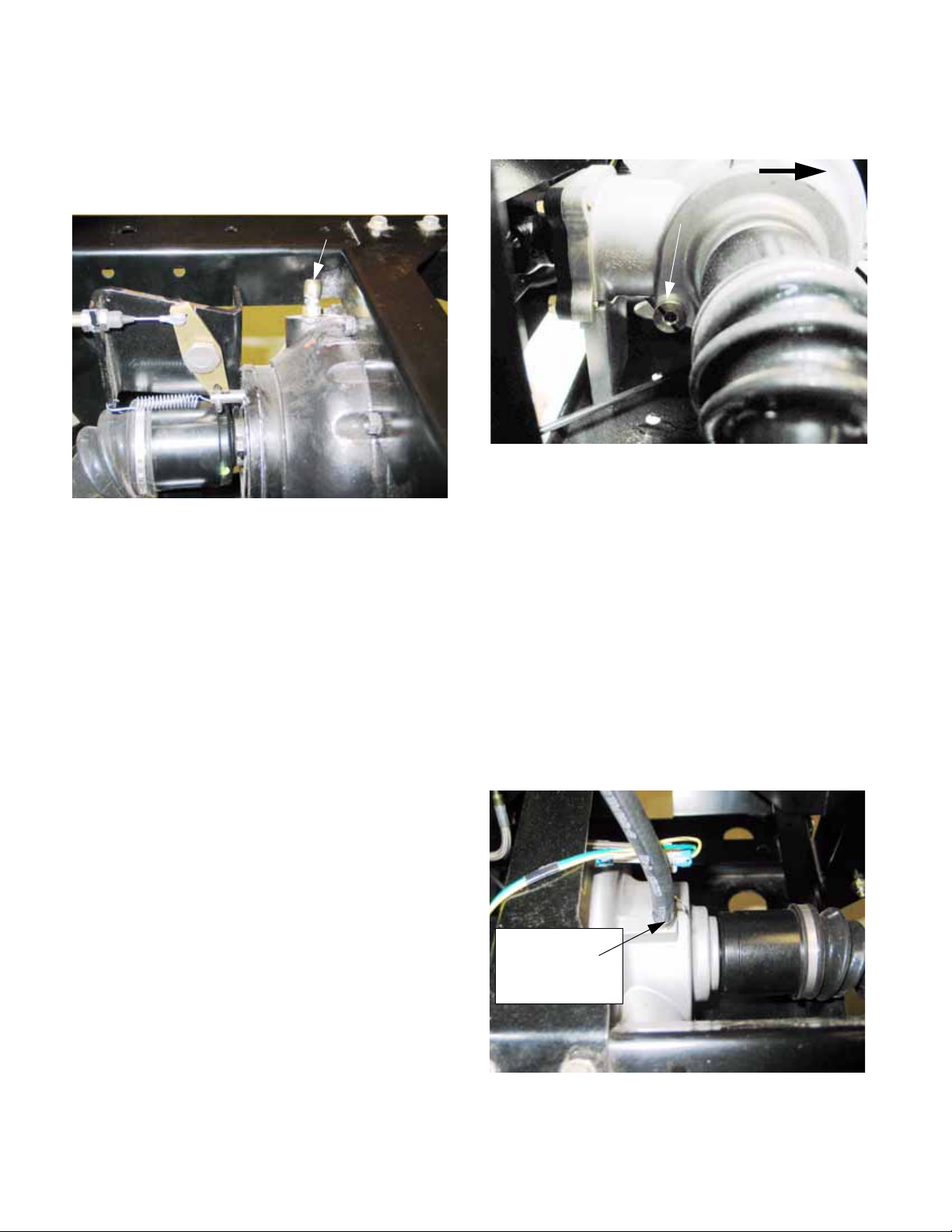

2. The constant velocity (Rzeppa type) joints in

the axle shafts that drive the wheels are lubricated on assembly, and should need no further

lubrication in their normal service life.

See Figure 2.39.

Figure 2.39

NOTE: Grease is contained in the constant

velocity joint boots. If a boot is damaged, the

grease will get contaminated. Once the grease

is contaminated, accelerated wear and joint failure will occur. Replace any damaged boot as

soon as possible. Clean and inspect the boots

regularly.

• Inspect the transfer case vent at 100 hr. intervals. A blocked vent will cause fluid loss.

• The transfer case gear lube should be checked

at 100 hr. intervals, or more frequently if fluid

loss is noticed.

• In the event of fluid loss, identify and repair the

leak as soon as possible to prevent catastrophic

failure of the transfer case, disabling the vehicle.

4. To check the fluid in the transfer case:

See Figure 2.41.

Transfer case

level plug

Figure 2.41

25

Page 30

Chapter 2- Drive System: CVT and Transfer Case

5. 13.4. Transfer case, continued...

5a. Park the vehicle on a firm level surface.

5b. Allow the engine and drive system to cool

to ambient temperature.

5c. Tilt the cargo box up.

5d. Release the Camloc

away the engine cover.

5e. Clean the area surrounding the fill plug and

level plug.

5f. Remove the level plug using a 5/8”

wrench, and check for the presence of

fluid at a level even with the bottom of the

threads.

5g. Clean the plug and inspect the o-ring seal.

Replace the o-ring if it is suspect.

6. If the fluid level is low, gear lube may be added

through the fill plug near the top of the transfer

case housing. See Figure 2.42.

Fill plug

fasteners and lift

R

6a. The fill plug can be removed with a 5/8”

open-end wrench.

6b. Inspect the gear lube for debris or metal

chafe, then dispose of it properly.

6c. Add gear lube until it begins to dribble out

of the level plug hole.

6d. Replace the fill and level plugs. Snug the

fill plug, and tighten the level plug to at

torque of 10 ft-lbs. (13.5 N-m).

6e. Replace the engine cover.

7. To change the lube in the transfer case, follow

the guidelines for checking the fluid. The case

may be drained of lube by removing the plug

using a 5/8” wrench. See Figure 2.43.

Inset: drain plug

O-ring

seal

Level plug

Drain plug access

from beneath vehicle

Figure 2.43

Figure 2.42

26

Page 31

Chapter 2- Drive System: CVT and Transfer Case

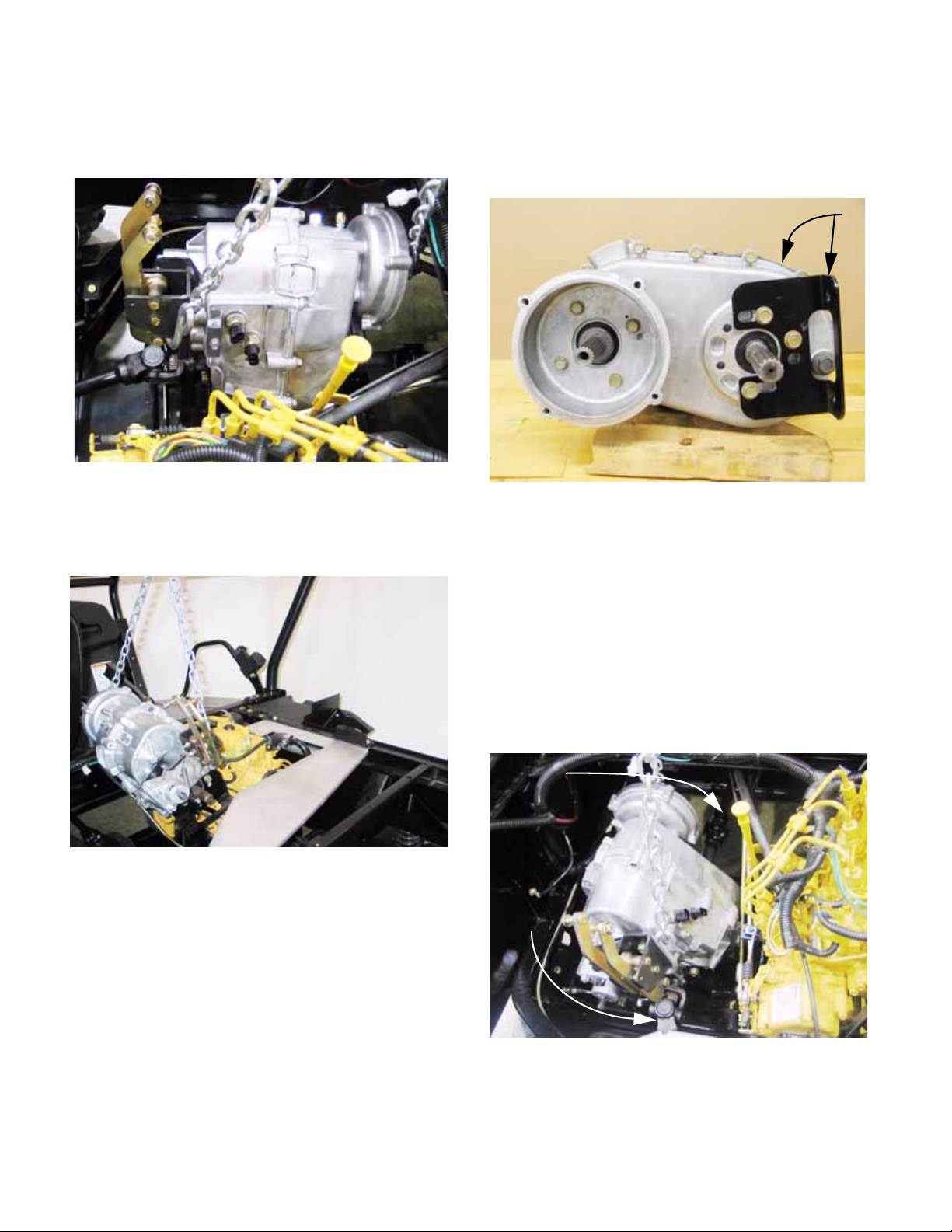

DRIVE SYSTEM SERVICE: TRANSFER CASE

REMOVAL WITH KOHLER ENGINE

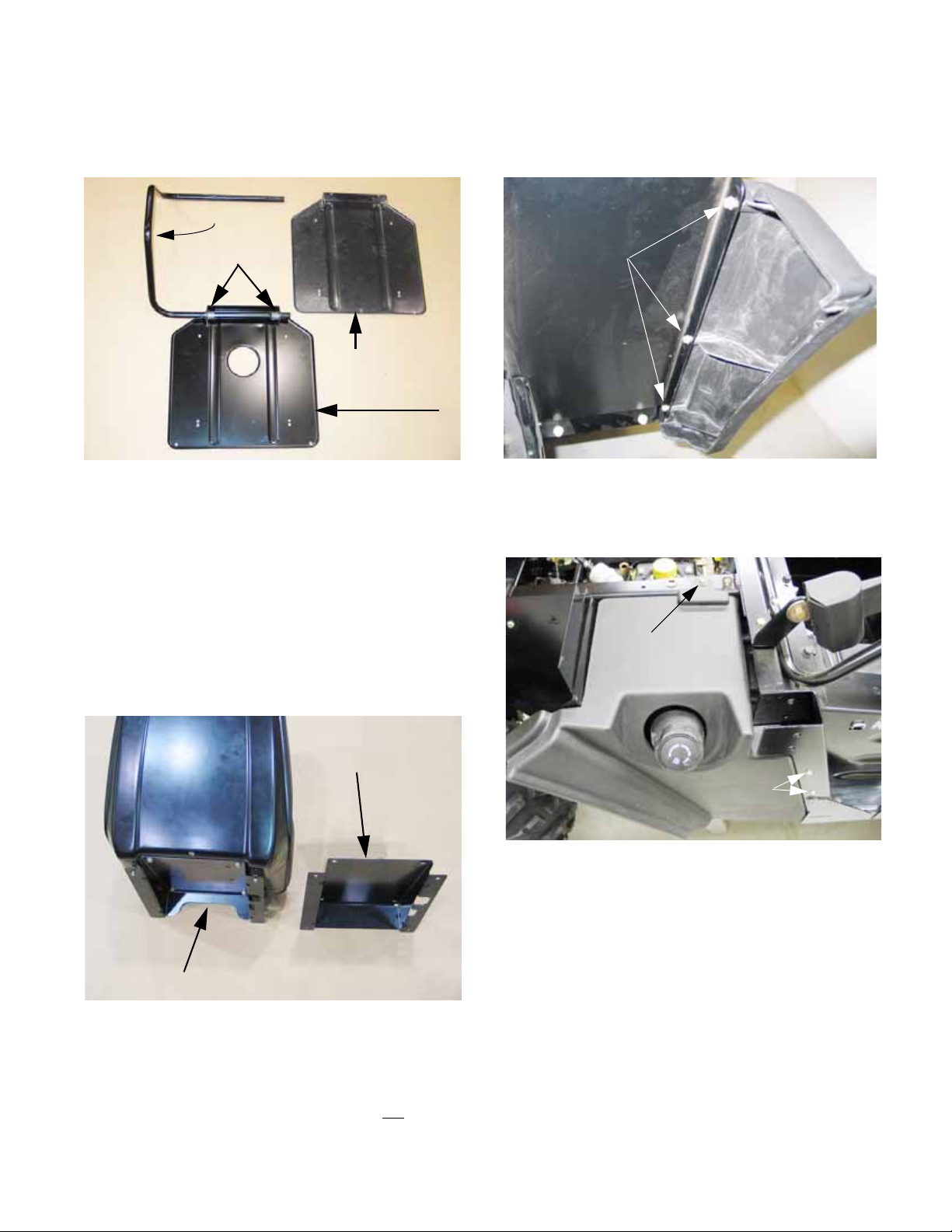

1. Remove the cargo box from the vehicle:

See Figure 2.44.

Attachment clip

Lift assist

cylinder

Cargo box

hinge bolt

(1 per side)

Figure 2.44

1a. Lift and support the cargo box.

1b. Pry-off the retainer that holds the lift assist

cylinder to the cargo box.

1c. Carefully lower the cargo box. Use a length

of 2X4 dimensional lumber to block the

latch that normally secures the cargo box

in the down position.

1d. Remove the nuts and bolts that secure the

cargo box to the frame using a pair of 9/

16” wrenches.

1e. With the help of an assistant or a mechani-

cal lifting device, slide the cargo box off

the back of the frame and remove it from

the vehicle.

4. Disconnect the black cable from the negative

terminal on the battery using a 10mm wrench.

5. Remove the CVT belt and pulleys as described

in the DRIVE SYSTEM: CVT BELT AND PULLEYS section of this manual. See Figure 2.45.

CVT

removed

Figure 2.45

6. Remove the four bolts that hold the heavy steel

engine / transmission plate using a 1/2” wrench.

7. Remove the four bolts that hold the engine /

transmission plate to the engine using a 9/16”

wrench. The bolts pass through a spacer

between the plate and the engine.

NOTE: It is not necessary to remove the universal joint guard from the plate.

8. Carefully lift the plate out of the engine bay. It is

most easily removed through the opening under

the passenger’s seat. See Figure 2.46.

2. Lift and safely support the vehicle.

3. Release the Camloc

engine cover and remove the engine cover.

fasteners that secure the

R

Figure 2.46

27

Page 32

Chapter 2- Drive System: CVT and Transfer Case

9. Confirm that the transfer case is in neutral.

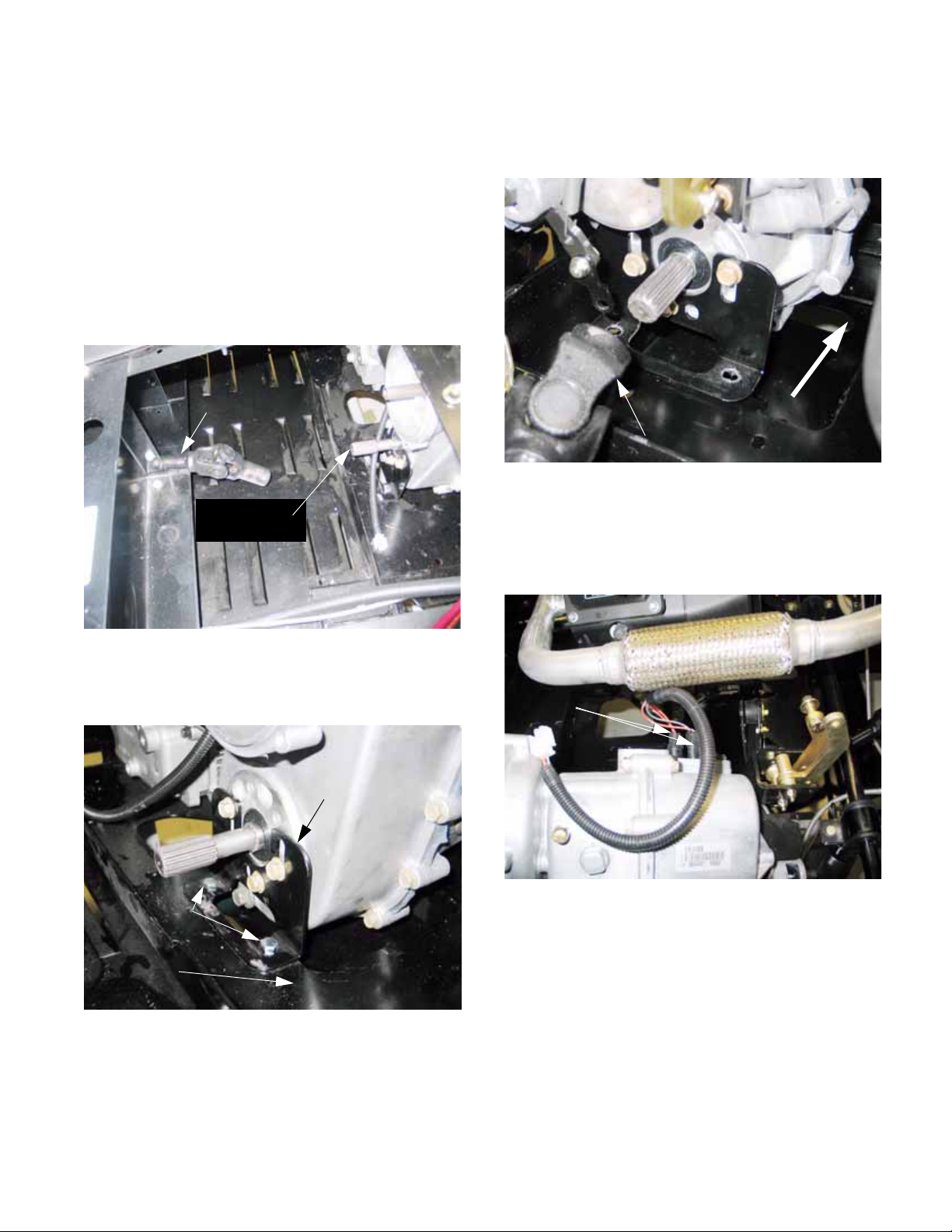

10. Disconnect the heavy Forward-Neutral-Reverse

shift rod from the shift arm mounted to the transfer case. use a pair of 9/16” wrenches.

See Figure 2.47.

ForwardNeutralReverse

rod

Figure 2.47

11. Disconnect the front of the Forwar d- Ne ut ra lReverse shift rod from the Hurst shift mechanism by removing the hairpin clip and tugging

the rod toward the right side of the vehicle.

14. Confirm that the parking brake is released.

15. Disconnect the parking brake cable from the

parking brake caliper by removing the hairpin

clip and clevis pin. See Figure 2.49.

Parking brake

cable

Clevis pin

Figure 2.49

16. Disconnect the transfer case safety switch harness (orange and gray wires) from the main harness. See Figure 2.50.

12. Disconnect the lighter Low-range shift rod from

the shift arm mounted to the transfer case. Use

a pair of 1/2” wrenches. See Figure 2.48.

Low-range

shift rod

Transmission

shift arms

Figure 2.48

13. Disconnect the front of the Low-range shift rod

from the Hurst shift mechanism by removing the

hairpin clip and tugging the rod toward the left

side of the vehicle.

Main harness

Transfer case

switch harness

Figure 2.50

NOTE: Wire routing outboard of the flange that

surrounds the transfer case input shaft. This

keeps the wires well away from the exhaust system.

NOTE: Do not lose the plastic bushings.

28

Page 33

Chapter 2- Drive System: CVT and Transfer Case

17. Lift and safely support the utility vehicle, as

described in the LIFTING AND SUPPORTING

section of this manual.

18. Drain the transfer case lube into an appropriate

container, as described in the DRIVE SYSTEM

SERVICE: LUBRICATION section of this manual.

19. Disconnect the front drive shaft, as described in

the DRIVE SYSTEM SERVICE: DRIVE SHAFT

TO FRONT DIFFERENTIAL section of this manual. See Figure 2.51.

Front drive shaft

Output shaft

(transfer case)

21. Slide the transfer case forward to disengage the

drive shaft that connects it to the rear differ ential.

See Figure 2.53.

Transfer

case

Rear drive shaft

Figure 2.53

22. Tilt the transfer case rearward, so that the shift

linkages clear the bottom of the exhaust system,

and slide it to the left of the vehicle.

See Figure 2.54.

Figure 2.51

20. Unbolt the transfer case brackets from the tray

using a pair of 1/2” wrenches. See Figure 2.52.

Transfer case

mounting bracket

Unbolt here

Engine/ transmission

mounting tray

Figure 2.52

NOTE: The nuts are easily accessible through

access slots in the bottom of the cradle.

Neutral switches

(2X)

Figure 2.54

NOTE: Do NOT unbolt the transfer case from

the brackets that connect it to the tray.

29

Page 34

Chapter 2- Drive System: CVT and Transfer Case

23. Disconnect the transfer case wiring harness

from the two neutral safety switches, and

remove it. This will prevent the harness and

switches from being damaged when the transfer

case is removed.

24. Carefully lift the transfer case and brackets out

of the vehicle.

25. If the transfer case is to be disassembled, it is

best to simply leave the brackets attached to the

housing, so that their position is not disturbed.

26. If the transfer case is to be replaced, matchmark the position of each mounting bracket so

that it can be installed in an identical position on

the new transfer case. See Figure 2.55.

27a. Place the transfer case in the engine bay

with sufficient access to connect the

transfer case wiring harness, and install

the harness.

27b. Move the transfer case into it’s mounting

position in the drive system tray, connecting the rear drive shaft to the rear output

shaft in the process.

27c. Secure the transfer case with the four sets

of 5/16” -18 nuts and bolts, but do not fully

tighten the fasteners.

27d. Connect the front drive shaft to the front

output shaft of the transfer case, and reattach the front differential as descr ibed in

the DRIVE SYSTEM SERVICE: DRIVE

SHAFT TO FRONT DIFFERENTIAL section of this manual.

27e. Apply a small amount of thread locking

compound such as Loctite

all of the screws that hold the engine /

transmission plate to the engine and the

transfer case.

242 (blue) to

R

Figure 2.55

27. Installation Notes: Transfer Case Alignment and

Positioning.

Item ft-lbs N-m

CVT driving element 32-36 43-49

CVT driven element 70-80 95-109

Engine / transmission

12 16

plate to transmission

Engine / transmission

18 24

plate to engine

Transmission brack-

32-36 43-49

ets to engine tray

Lug nuts 65-75 88-102

27f. Position the plate, along with the spacer

that fits between the plate and the mounting boss on the engine, and secure it with

one screw to the engine and one screw to

the transfer case.

27g. Confirm that the plate is properly seated

over the mounting boss on the transfer

case, and that the screw holes are properly aligned, then install all the screws that

secure the plate and spacer. Tighten

them to the torque specified in table....

27h. Tighten all the fasteners that hold the

transfer case to the drive system cradle.

Refer to the accompanying table for

torque specifications.

28. Installation Notes: Drive Connections

28a. Apply a sparing amount of anti-seize com-

pound to the splined joint at each end or

the rear driveshaft.

NOTE: If too much anti-seize compound is

applied to the splined connection on the back of

the transfer case, centrifugal force will sling it

onto the parking brake rotor when the vehicle is

in motion.

28b. Secure the rear driveshaft to the rear diffe r-

ential using a new tension pin.

30

Page 35

Chapter 2- Drive System: CVT and Transfer Case

28c. Install the CVT as described in the DRIVE

SYSTEM SERVICE:CVT BELT AND

PULLEYS section of this manual.

29. Make the remaining electrical and mechanical

connections:

29a. Connect the transfer case safety switch

harness to the main harness, confirming

that it is properly routed.

29b. Install the two gear shift rods.

NOTE: Both bolts that connect the shift rods to

the shift arms should be installed with the heads

between the arms. Both nuts should be installed

outboard of each arm.

NOTE: Both shift rods attach to the side of their

shift arm that is nearest the engine.

29c. Connect the parking brake cable.

29d. Connect the negative battery cable.

30. Make the final pre-operational checks:

30a. Confirm that the transfer case contains

64fl. oz. (1.9l.) of Shell Dentax 80W-90

Low Foam Oil, as described in the DRIVE

SYSTEM SERVICE: LUBRICATION section of this manual.

30b. The gear selector should operate properly,

as described in the DRIVE SYSTEM

ADJUSTMENTS: TRANSFER CASE

SHIFT LINKAGE section of this manual.

30c. The parking brake should operate properly ,

as described in the DRIVE SYSTEM

ADJUSTMENT: PARKING BRAKE section of this manual.

31. Install the rear wheel and tire that were previously removed. Apply the parking brake and

tighten the lugs to the specified torque.

32. Confirm that no unsafe conditions will result from

the operation of the engine and drive system.

32a. Run, test, and adjust the drive system if

needed.

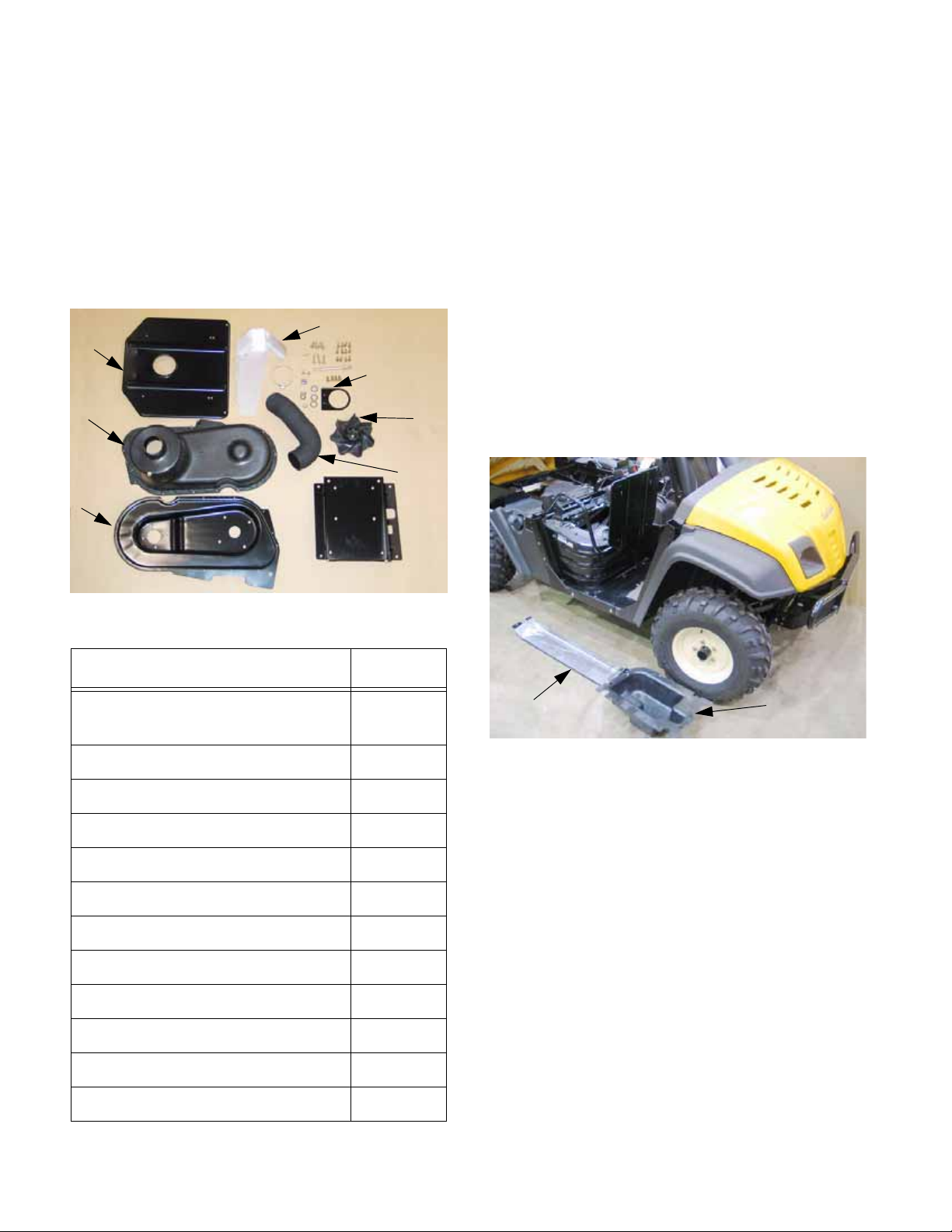

DRIVE SYSTEM SERVICE: TRANSFER CASE

REMOVAL WITH CATERPILLAR ENGINE

1. Remove the cargo box from the vehicle:

See Figure 2.56.

Attachment clip

Lift assist

cylinder

Cargo box

hinge bolt

(1 per side)

Figure 2.56

1a. Lift and support the cargo box.

1b. Pry-off the retainer that holds the lif t assi st

cylinder to the cargo box.

1c. Carefully lower the cargo box. Use a

length of 2X4 dimensional lumber to block

the latch that normally secures the cargo

box in the down position.

1d. Remove the nuts and bolts that secure the

cargo box to the frame using a pair of 9/

16” wrenches.

1e. With the help of an assistant or a mechan-

ical lifting device, slide the cargo box off

the back of the frame and remove it from

the vehicle.

2. Lift and safely support the vehicle.

3. Release the Camloc® fasteners that secure the

engine cover and remove the engine cover.

32b. Check for any fluid leaks.

32c. Install the cargo box.

32d. Make a visual inspection of all relevant

hardware before lowering the vehicle to

the ground and returning it to service.

31

Page 36

Chapter 2- Drive System: CVT and Transfer Case

4. Disconnect the black cable from the negative

terminal on the battery using a 10mm wrench.

5. Remove the CVT belt and pulleys as described

in the DRIVE SYSTEM: CVT BELT AND PULLEYS section of this manual. See Figure 2.57.

CVT

removed

Figure 2.57

6. Remove the four bolts that hold the heavy steel

engine / transmission plate using a 1/2” wrench.

7. Remove the four bolts that hold the engine /

transmission plate to the engine using a 9/16”

wrench. The bolts pass through a spacer

between the plate and the engine.

10. Disconnect the heavy Forward-Neutral-Reverse

shift rod from the shift arm mounted to the transfer case. use a pair of 9/16” wrenches.

See Figure 2.58.

Forward-Neutral-Reverse

shift rod

Figure 2.58

11. Disconnect the lighter Low-range shift rod from

the shift arm mounted to the transfer case. Use

a pair of 1/2” wrenches. See Figure 2.59.

Low-range shift rod

NOTE: It is not necessary to remove the universal joint guard from the plate.

8. Carefully lift the plate out of the engine bay. It is

most easily removed through the opening under

the passenger’s seat.

9. Confirm that the transfer case is in neutral.

Figure 2.59

12. Move the shift rods out of the way.

13. Confirm that the parking brake is released.

32

Page 37

Chapter 2- Drive System: CVT and Transfer Case

14. Disconnect the parking brake cable from the

parking brake caliper by removing the hairpin

clip and clevis pin. See Figure 2.60.

Parking brake

cable

Clevis pin

Figure 2.60

15. Disconnect the transfer case safety switch harness (orange and gray wires) from the main harness. See Figure 2.61.

16. Lift and safely support the utility vehicle, as

described in the LIFTING AND SUPPORTING

section of this manual.

17. Drain the transfer case lube into an appropriate

container, as described in the DRIVE SYSTEM

SERVICE: LUBRICATION section of this manual.

18. Unbolt the transfer case brackets from the tray

using a pair of 1/2” wrenches. See Figure 2.62.

Unbolt here

Transfer case

bracket

Main harness

Transfer case

switch harness

Figure 2.61

NOTE: Wire routing outboard of the flange that

surrounds the transfer case input shaft. This

keeps the wires well away from the exhaust system.

Figure 2.62

NOTE: The nuts are easily accessible through

access slots in the bottom of the cradle.

NOTE: Do NOT unbolt the transfer case from

the brackets.

19. Slide the transfer case slightly away from the

engine, and disconnect the transfer case wiring

harness from the two neutral safety switches,

and remove the harness. See Figure 2.63.

Safety switches

33

Figure 2.63

Page 38

Chapter 2- Drive System: CVT and Transfer Case

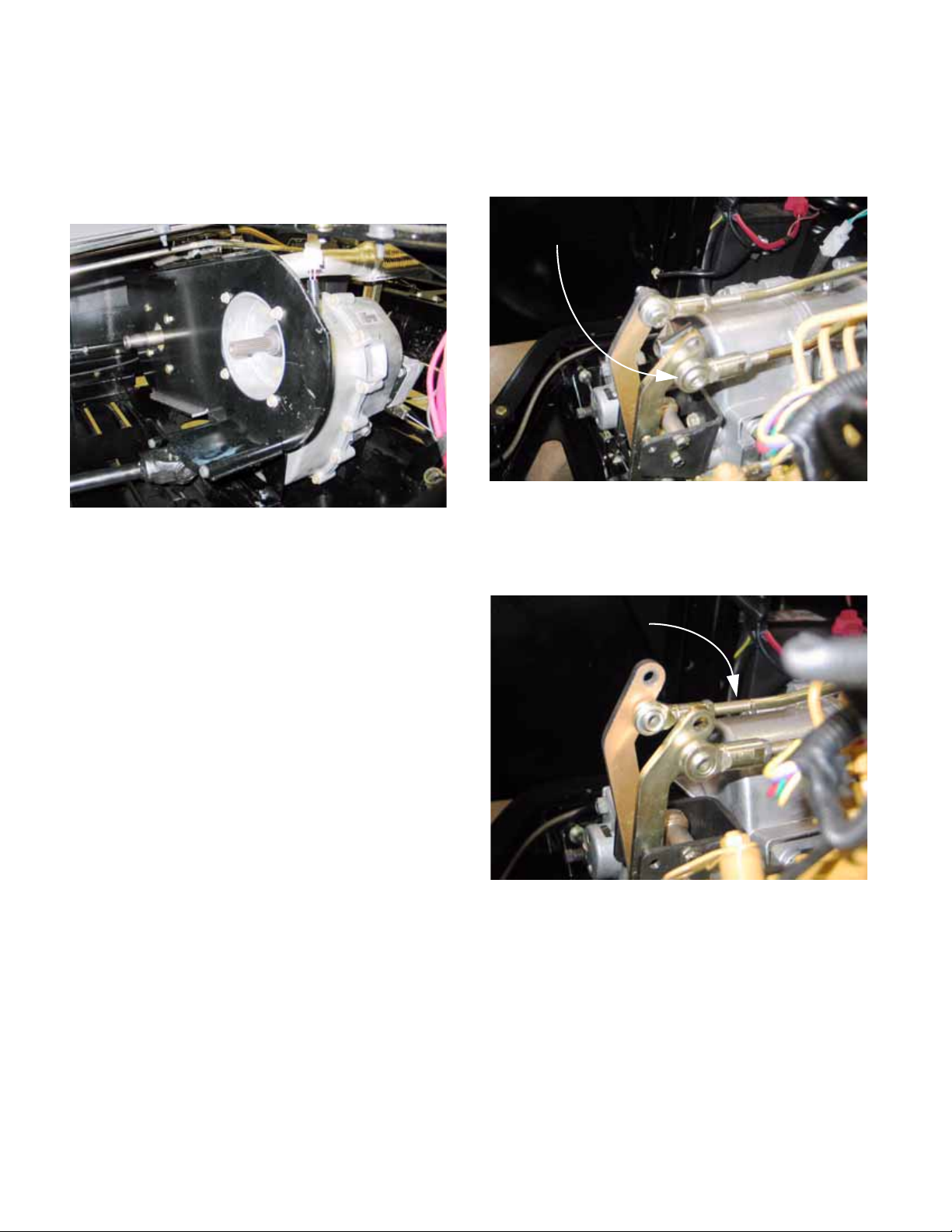

20. Attach a lifting apparatus to the transfer case,

being careful not to fowl the linkages.

See Figure 2.64.

Figure 2.64

21. Carefully lift the transfer case and brackets out

of the vehicle, disconnecting the driveshafts as it

comes up. See Figure 2.65.

23. If the transfer case is to be replaced, matchmark the position of each mounting bracket so

that it can be installed in an identical position on

the new transfer case. See Figure 2.66.

Transfer case

Figure 2.66

24. Installation Notes: T ransfer Case Alig nme nt and

Positioning.

Mounting bracket

Figure 2.65

22. If the transfer case is to be disassembled, it is

best to simply leave the brackets attached to the

housing, so that their position is not disturbed.

24a. Apply a sparing amount of anti-seize

compound to the splined joints at the

transfer case end of each driveshaft.

24b. Use a lifting apparatus to suspend the

transfer case in the engine bay.

24c. Carefully lower the transfer case into posi-

tion, connecting the front and rear driveshafts as it is lowered. See Figure 2.67.

Front drive shaft

Rear drive

shaft

34

Figure 2.67

24d. Connect the transfer case wiring harness

to the two neutral safety switches before

securing the transfer case to the tray.

Page 39

Chapter 2- Drive System: CVT and Transfer Case

24e. Move the transfer case into it’s mounting

position in the drive system tray.

24f. Secure the transfer case with the four sets

of 5/16” -18 nuts and bolts, but do no t fully

tighten the fasteners.

24g. Apply a small amount of thread locking

compound such as Loctite® 242 (blue) to

all of the screws that hold the engine /

transmission plate to the engine and the

transfer case.

24h. Position the plate, and secure it with one

screw to the engine and one screw to the

transfer case.

24i. Confirm that the plate is properly seated

over the mounting boss on the transfer

case, and that the screw holes are properly aligned, then install all the screws that

secure the plate and spacer. Tighten

them to the torque specified in table.

24j. Tighten all the fasteners that hold the

transfer case and the engine/transfer

case in position. Refer to the accompany-

ing table for torque specifications.

Item ft-lbs N-m

26. Make the remaining electrical an d me ch a nic al

connections:

26a. Connect the transfer case safety switch

harness to the main harness, confirming

that it is properly routed.

26b. Connect the two gear shift rods.

NOTE: Both bolts that connect the shift rods to

the shift arms should be installed with the heads

between the arms. Both nuts should be installed

outboard of the arms.

NOTE: Both shift rods attach to the side of their

shift arm that is nearest the engine.

26c. Connect the parking brake cable.

26d. Connect the negative battery cable.

27. Make the final pre-operational checks:

27a. Confirm that the transfer case contains

64fl. oz. (1.9l.) of 80W-90 Low Foam Oil,

as described in the DRIVE SYSTEM

SERVICE: LUBRICATION section of this

manual.

27b. The gear selector should operate properly,

as described in the DRIVE SYSTEM

ADJUSTMENTS: TRANSFER CASE

SHIFT LINKAGE section of this manual.

CVT driving element 32-36 43-49

CVT driven element 70-80 95-109

Engine / transmission

12 16

plate to transmission

Engine / transmission

18 24

plate to engine

Transmission brack-

32-36 43-49

ets to engine tray

Lug nuts 65-75 88-102

25. Install the CVT as described in the DRIVE SYSTEM SERVICE:CVT BELT AND PULLEYS section of this manual.

27c. The parking brake should operate prop-

erly, as described in the DRIVE SYSTEM

ADJUSTMENT: PARKING BRAKE section of this manual.

28. Install the rear wheel and tire that were previously removed. Apply the parking brake and

tighten the lugs to the specified torque.

29. Lower the vehicle to the groun d.

30. Confirm that no unsafe conditions will result from

the operation of the engine and drive system.

30a. Run, test, and adjust the drive system if

needed.

30b. Check for any fluid leaks.

30c. Install the cargo box.

30d. Make a visual inspection of all relevant

hardware before lowering the vehicle to

the ground and returning it to service.

35

Page 40

Chapter 2- Drive System: CVT and Transfer Case

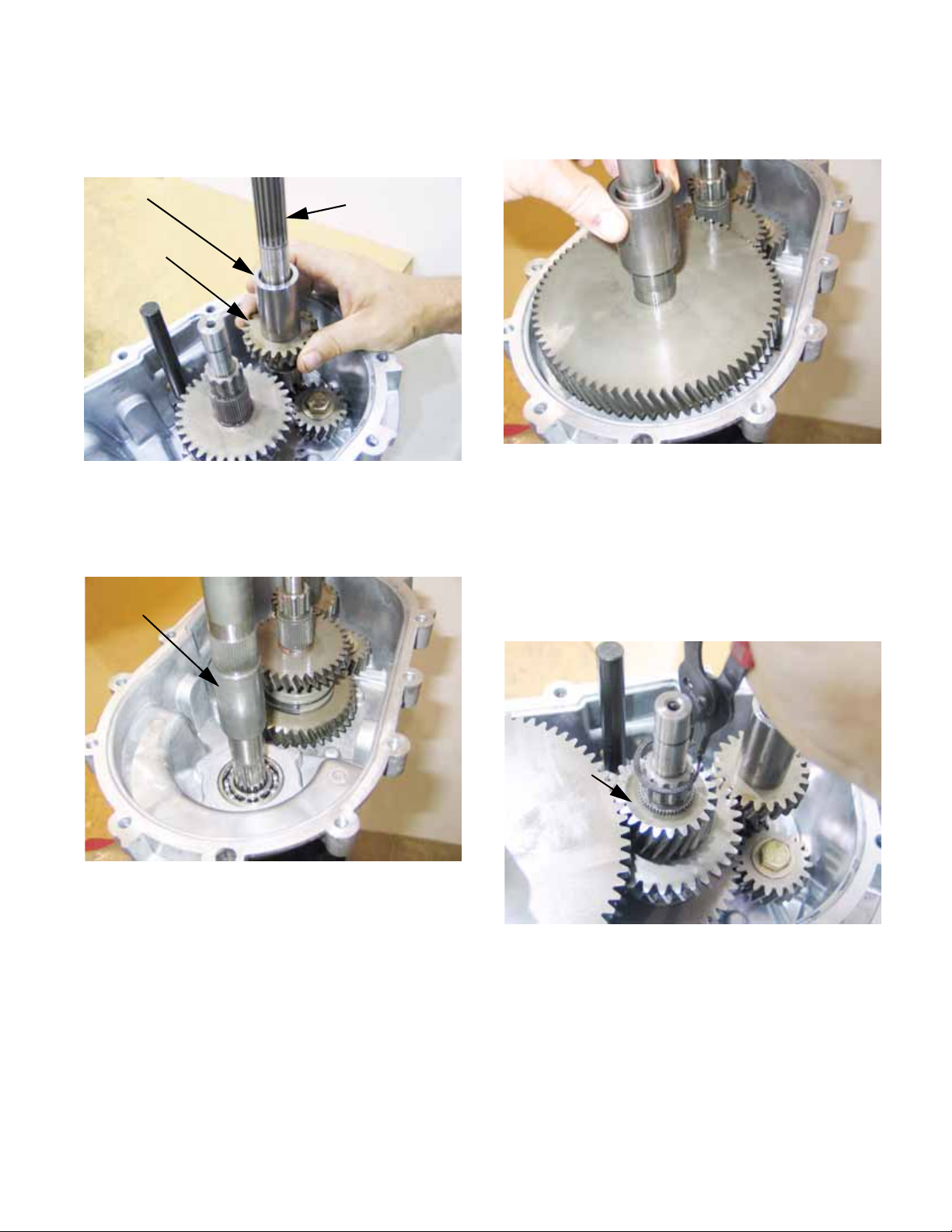

DRIVE SYSTEM BENCH SERVICE:

TRANSFER CASE DISASSEMBLY

1. Preliminary steps:

1a. Clean-up and visually examine the transfer

case for wear and damage that may make

it unfeasible to repair.

1b. Unless there is a specific reason to

remove the mounting brackets, they are

best left in place.

1c. If the gear lube was not previously

drained, remove the drain plug using a

13mm wrench and allow the fluid to drain

into a clean pan. See Figure 2.68.

1e. Examine the contents of the drain pan and

the residue that is stuck to the magnetic

tip of the drain plug. See Figure 2.70.

Residue inside

transfer case

Figure 2.70

1f. If not previously removed, take the washer

and spacer off of the input shaft.

See Figure 2.71.

Drain plug

Gasket

magnetic tip

Figure 2.68

1d. Remove the fill plug from the side of the

transfer case using a 5/8” wrench. This

will let air enter the case faster, speeding

the draining process. See Figure 2.69.

Level plug

(O-ring seal)

Spacer

Washer

Input shaft

Figure 2.71

Figure 2.69

36

Page 41

Chapter 2- Drive System: CVT and Transfer Case

2. If the parking brake is being remove d for transfer

to a replacement transfer case:

2a. Remove the screws that hold the caliper

bracket to the transfer case housing using

a T-45 driver. See Figure 2.72.

Brake caliper

bracket screws

Figure 2.72

2b. Draw-out and pivot the caliper and rotor as

an assembly so that they clear the shift

arm assembly , an d remove them from the

transfer case. See Figure 2.73.

3. If the parking brake is being removed for brake

replacement or other service:

NOTE: The inner brake pad is epoxied into the

caliper. Because the inner pad cannot be

replaced, the caliper is offered only as a complete assembly. Individual parts are not available.

3a. Unhook and remove the return spring.

See Figure 2.74.

Long end

goes up

Unhook the

bottom end

first

Figure 2.74

Figure 2.73

2c. Installation is essentially the reversal of

the removal process.

• The friction surfaces of the pads and rotor must

be clean and in good condition.

• Tighten the nuts according to the torque table

that accompanies this section of the chapter.

3b. Remove the two nuts that hold the caliper

to the caliper bracket using a pair of 9/16”

wrenches. See Figure 2.75.

Bracket

Bolts

Shims

Caliper

Nuts

Figure 2.75

37

Page 42

Chapter 2- Drive System: CVT and Transfer Case

3c. Remove the outer caliper housing.

See Figure 2.76.

Outer caliper

housing

Figure 2.76

3d. Slip the rotor off of the brake shaft. It will

clear the shift arm assembly.

See Figure 2.77.

3e. Slide the inner caliper housing off of the

two bolts that locate it. See Figure 2.78.

Inner caliper

housing

Figure 2.78

3f. Installation is essentially the reversal of

the removal process.

4. Parking brake operation and construction:

Brake rotor:

flat side out

Figure 2.77

• The friction surfaces of the pads and rotor must

be clean and in good condition.

• Tighten the nuts according to the torque table

that accompanies this section of the chapter.

NOTE: Caliper operation: See Figure 2.79.

Cam arm

“Bullet”: flat side visible

Brake backing plate

Brake pad

Long

side

Long

side

short side

Figure 2.79

Short side

Long

side

• The caliper is actuated by a cam-arm that forces

a steel “bullet” against a heavy steel backing

plate.

• The backing plate and pad are “doubleD”

shaped, although one flat is longer than the

other.

38

Page 43

Chapter 2- Drive System: CVT and Transfer Case

• The adjustment screw acts by moving the contact point that the cam arm pivots against.

See Figure 2.80.

Cam arm

“Bullet”

Figure 2.80

NOTE: The brake pads are thick enough that

they will have a long service life. While service

brakes are used to stop the vehicle, parking