Page 1

Professional Shop Manual

2010 and Newer Log Splitter

NOTE: These materials are for use by trained technicians who are experien ced in th e service an d re pair of outdoo r po wer

equipment of the kind described in this publication, a nd are n ot intende d for use by un trained or ine xper ien ced individu als.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and tr ained p rofessional. Read, understan d, and follo w all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as co mpl ete and accu rate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2010 MTD Products Inc. All Rights Reserved

Page 2

Page 3

Table of Contents

Chapter 1: Introduction ............................................................................................1

Professional Service Manual Intent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description of the 2010 log splitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Understanding model and serial numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2: Engine And Pump................................................................................. 5

Horizontal shaft engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vertical shaft engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Engine coupler gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pump removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3: Hydraulic Diagnosis ............................................................................11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Understanding the hydraulic flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Log splitter test procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

What to do about failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

System drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Log Splitter Hydraulic System Work Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 4: Control Valve .......................................................................................31

Control valve removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Control valve spring cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Control valve lever bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 5: Cylinder .................................................................................................37

Cylinder removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cylinder rebuilding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 6: Wedge And Beam ................................................................................47

Wedge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 7: Tank And Tires .....................................................................................51

Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Wheel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Fenders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Oil filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Vertical locking rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Horizontal locking rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

I

Page 4

Chapter 8: Maintenance .........................................................................................61

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Beam and wedge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Engine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Servicing the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Hydraulic oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Wheel bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

II

Page 5

Introduction

CHAPTER 1: INTRODUCTION

Professional Service Manual Intent

This Manual is intended to provide serv ice dealers with an intro duction to the mechanical aspects of the log sp lit-

ters introduced for the 2010 model year.

• Detailed service information about the engine will be provided by the engine manufacturer, in most cases.

Disclaimer: The information contained in this manual is correct at the time of writin g. Both the prod u ct an d th e inf or mation about the product are subject to change without notice.

About the text format:

NOTE: is used to point out information that is relevant to the procedure, but does not fit as a step in the pr oce dure.

• Bullet points: indicate sub-steps or points.

! CA UTION! CA UTION

! WA RNI NG! WA RNI NG

! DANGER! DANGER

1. Numbered steps indicate specific things that should be done, and the order in which they should be done .

1a. Substeps will be lettered and nested within steps. Two or more substeps may be combined to describe

the actions required to complete a step.

Disclaimer: This manual is intended for use by trained, professional technicians.

• Common sense in operation and safety is assumed.

• In no event shall MTD be liable for poor text interpretation or poor execution of the procedures described

in the text.

Caution is used to point out potential danger to the technician, operator, bystanders, or surrounding property.

Warning indicates a potentially hazardous situation that, if not avoided, could result in death

or serious injury.

Danger indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations

• If the person using this manual is uncomfortable with any procedures they encounter, they should seek

the help of a qualified technician or MTD Technical Suppor t.

Safety

This Service Manual is meant to be used along with the Operator’s Manual. Read the Operator’s Manual and

familiarize yourself with the safety and operational instructions for the equipment being worked on. Keep a copy of

the Operator’s Manual for quick reference. Operator’s manuals may be viewed for free at the brand support website.

It will be necessary to have the complete model and serial number for the equipment.

1

Page 6

2010 Log Splitters

! CAUTION! CAUTION

• Be prepared in case of emergency:

Keep a fire extinguisher nearby

Keep a first aid kit nearby

Keep emergency contact numbers handy

• Replace any missing or damaged safety labels on shop equipment.

• Replace any missing or damaged safety labels on equipment being serviced.

• Grooming and attire:

! WARNING! WARNING

! CAUTION! CAUTION

Do not wear loose fitting clothing that may become entangled in equipment.

Long hair should be secured to prevent entanglement in equipment.

Jewelry is best removed.

• Protective gear: includes, but is not limited to

Clear eye protection ................................ while working around any machinery

Protective gloves ..................................... where necessary

Armored footwear.................................... when working around any machinery

Hearing protection ................................... in noisy environments

Chemically resistant gloves..................... when working with chemicals or solvents

Respirator................................................ when working with chemical or solvents

Appropriate tinted eye protection............. when cutting or welding

Flame resistant headgear, jacket, chaps. when cutting or welding

• Remember that some hazards have a cumulative effect. A single exposure may

cause little or no harm, but continual or repeated exposure may cause very serious

harm.

• Clean spills and fix obviously dangerous conditions as soon as they are noticed.

! DANGER! DANGER

2

• Lift and support heavy objects safely and securely.

• Be aware of your surroundings and potential hazards that are inherent to all power

equipment. All the labels in the world cannot protect a technician from an instant of

carelessness.

• Exhaust fumes from running engines contain carbon monoxide (CO). Carbon

monoxide is a colorless odorless gas that is fatal if inhaled in sufficient quantity.

Only run engines in well ventilated areas. If running engines indoors, use an

exhaust evacuation system with adequate make-up air ventilated into the shop.

• Hydraulic fluid under high pressure can be dangerous. A high-pressure hydraulic fluid leak or spray can penetrate the skin. If this happens, seek immediate

medical attention to reduce the risk of blood poisoning leading to death or limb

amputation.

Page 7

Introduction

Fasteners

• Most of the fasteners used on these log splitters are sized in fractional inches. The engine fasteners are

metric. For this reason, wrench sizes are frequently identified in the text, and measurements are given in

U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of re leasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners, like cotter pins, are single-use items that are not to be reused. Other fasteners such as

lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

Assembly instructions

• Torque specifications may be noted in the part of the text that covers assembly. They may be summa-

rized in tables along with special instructions regarding locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a step-by-step procedure guide that does not require the user to hunt for information.

• Lubricant quantity and specification may be noted in the part of the text that covers maintenance, and

again in the section that covers assembly. They may also be summarized in tables along with special

instructions. Whichever method is more appropriate will be used. In many cases, the information will be

found in several places in the manual so that the manual is handy as a quick-r eference g uide as we ll as a

step-by-step procedure guide that does not require the user to hunt for information.

• The level of assembly instructions provided will be determined by the complexity of reassembly, and by

the potential for damage or unsafe conditions to arise from mistakes made in assembly.

• Some instructions may refer to other parts of the manual for subsidiary pr ocedures. Th is avoids repeating

the same procedure two or three times in the manual.

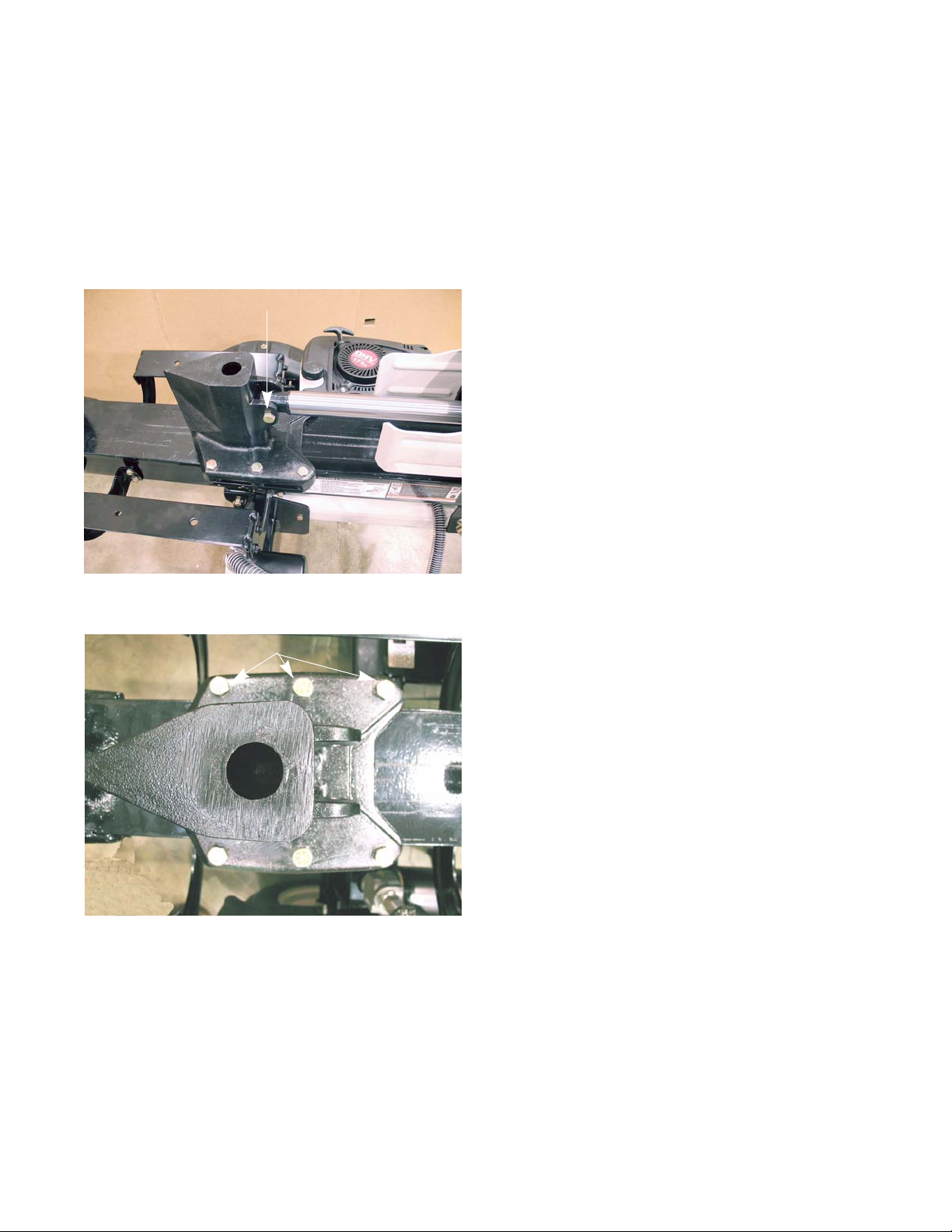

Description of the 2010 log splitters

For the 2010 model year, MTD re-designed its log splitter line.

The re-designed models can be identified by:

2009 and

older

Beam I-beam style U-channel

with a fabricated top

plate

Wedge Adjustable

No gibs

gibs

Figure 1.1

Fittings NPT O-ring face

2010

3

Page 8

2010 Log Splitters

WWWMTDPRODUCTSCOM

-4$,,#

0/"/8

#,%6%,!.$/(

Understanding model and serial numbers

The model number of a the compact log splitter described

in this manual is 24AA5DMK029. This manual is likely to

carry useful information for a range of similar log splitters

that may carry a variety of MTD and private brand names.

0HHWV$16,%6DIHW\6WDQGDUG

0RGHO1XPEHU 6HULDOQXPEHU

$$'0.-*

Figure 1.2

The break down of what the model number

means is as follows:

• 24 - - - - - - - - - - - - - - - - - - - - - - - - -indicates that this is a chore performer.

• - - A - - - - - - - - - - - - - - - - - - - - - - - -“A” means no hydraulic fluid included. “B” means filled at the plant.

• - - - -A5- - - - - - - - - - - - - - - - - - - - - -indicates the tank size and style

• - - - - - - D - - - - - - - - - - - - - - - - - - - -indicates the tonnage

• - - - - - - - -MK - - - - - - - - - - - - - - - - -indicates the engine

• - - - - - - - - - - - 029- - - - - - - - - - - - - -indicates the customer

The serial number is 1J056G10005. The serial number

reads as follows:

• 1 - - - - - - - - - - - - - - - - - -engineering level

• - J - - - - - - - - - - - - - - - - - -month of production (J = October)

• - - - 05- - - - - - - - - - - - - - - -day of the month

• - - - - - 6 - - - - - - - - - - - - - - -last digit of the year

• - - - - - - G - - - - - - - - - - - - - -plant it was built in

• - - - - - - - - 1 - - - - - - - - - - - - -assembly line number

• - - - - - - - - - -0005 - - - - - - - - - -number of unit built

Additional technical and service information may also be available to our company authorized service center personnel through our company corporate offices, regional parts distributors and regional service center field support

personnel. Please contact the designated support office in your area or our corporate offices directly should further

service information be needed.

MTD Products LLC

P.O. Box 368022

Cleveland, OH 44136

Telephone: (800) 800-7310

www.mtdproducts.com

4

Page 9

Engine and pump

CHAPTER 2: ENGINE AND PUMP

MTD log splitters are available with a variety of horizontal and vertical shaft engines. This manual covers procedures that are the same for all engine models available. Specific engine procedures are covered in the engine’s service manual.

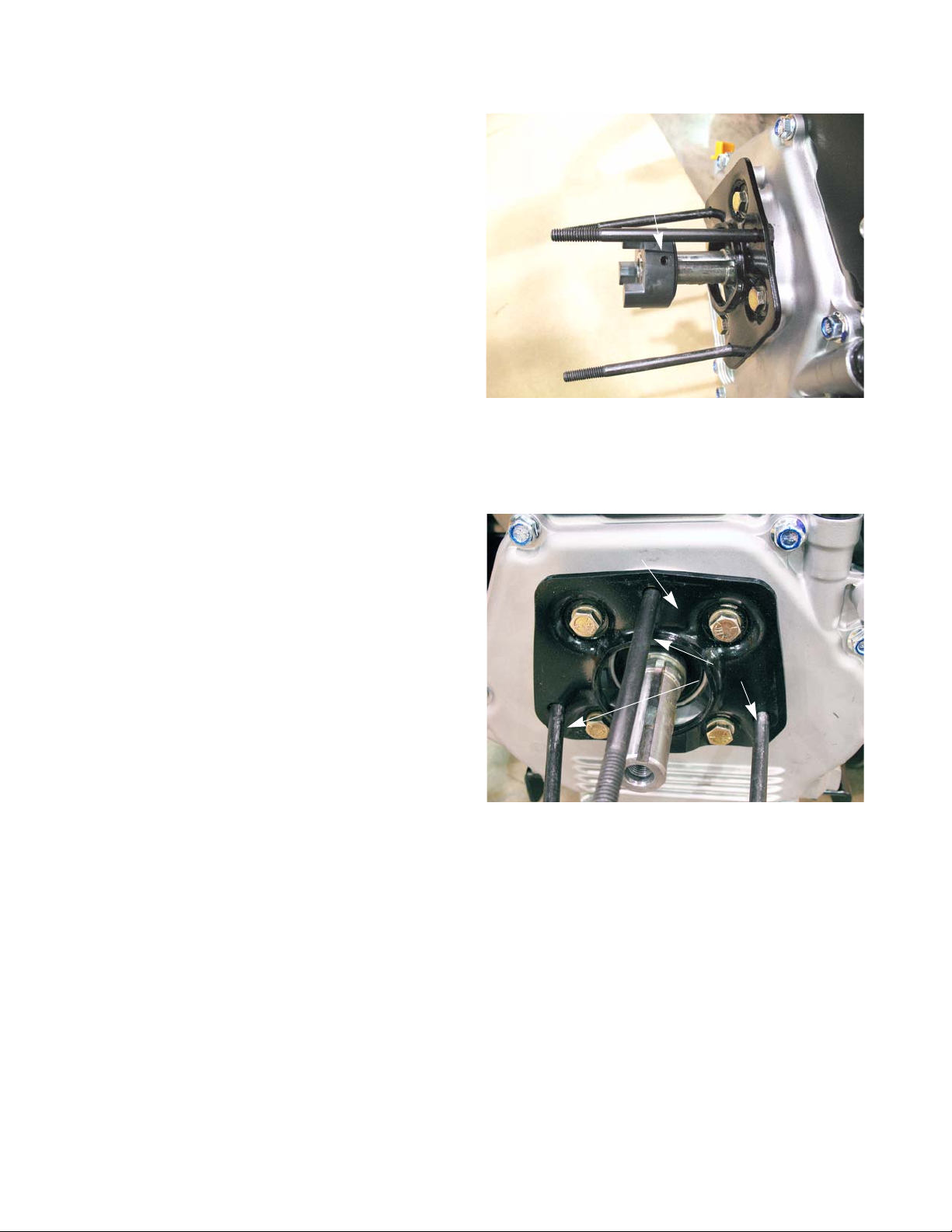

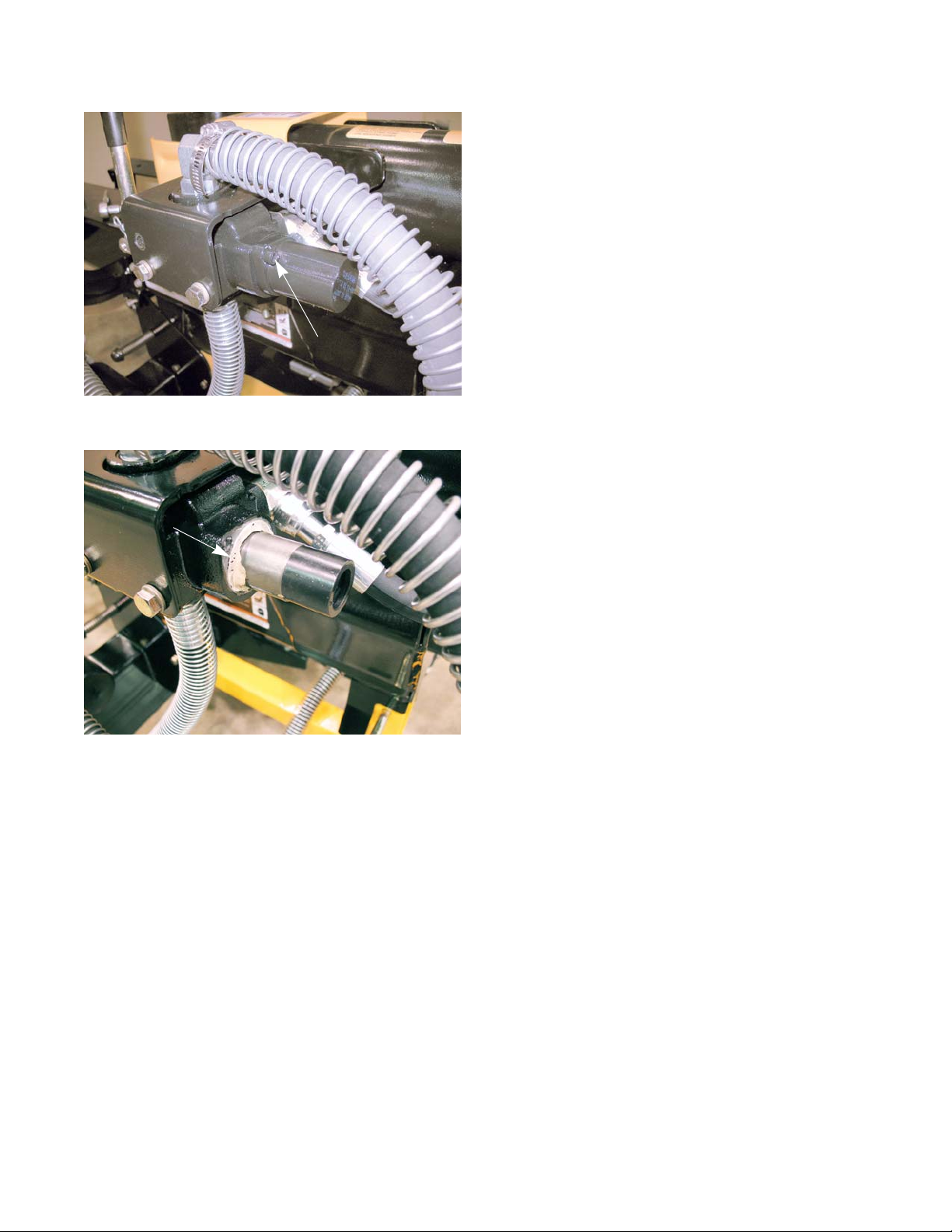

Horizontal shaf t engines

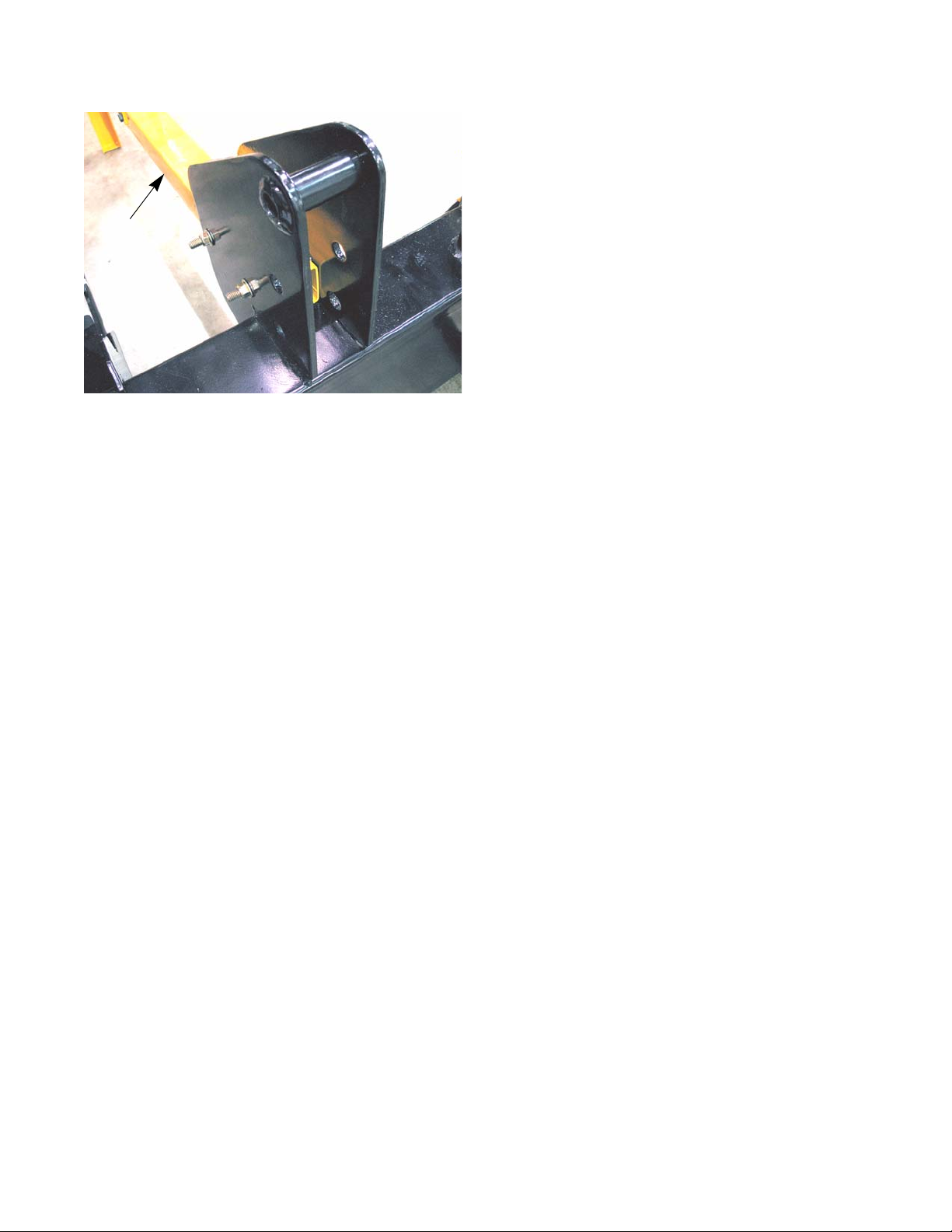

Spacer shield

Nuts

Thin headed

wrench

coupling support bracket

Figure 2.1

To remove/replace the en g ine :

1. Remove the three coupling support bracket nuts

using a pair of 1/2” wrenches.

NOTE: A thin headed wrench (like a tappet wrench) is

needed to fit between the engine and the coupling

support bracket.

2. Slide the pump and the coupling support bracket off

as one assembly.

NOTE: support the pump. DO NOT let the pump hang by

the hoses.

3. Remove the spider from the engine coupling.

4. Remove the spacer shield.

5. Remove the four engine mounting screws using a 9/

16” wrench.

6. Remove the engine from the log splitter.

See Figure 2.1.

Engine mounting

screws

Figure 2.2

5

Page 10

2010 Log Splitters

NOTE: If the engine is not being replaced, skip to

step 10.

7. Remove the set screw in the engine coupling using

a 1/8” hex key.

NOTE: When installing the engine coupling, apply a

small amount of releasable thread locking

compound such as Loctite® 242 (blue ) to

the set screw and tighten it to a torque of 78

in lbs (9 Nm)

8. Remove the engine coupling and key.

NOTE: If the pump shows any signs of an impact,

check the coupling support bracket. If the

bracket is bent, replace the bracket and the

bolts. A bent bracket or bolts may put a side

load on the pump input shaft, damaging the

bearings.

9. Remove the front coupling support bracket using a

1/2” wrench.

10. Install the engine by following the previous steps in

reverse order.

NOTE: The three long bolts must be in the front

coupling support bracket before it is

attached to the engine.

See Figure 2.3.

See Figure 2.4.

Set screw

Figure 2.3

Front coupling support bracket

Long bolts

NOTE: Tighten the engine mounting screws to a

torque of 325 - 450 in lbs (37 - 51 Nm).

1 1. Adjust the engine coupler gap by following the steps

described in the engine coupler gap section of this

chapter.

12. Test run the log splitter before returning it to service.

Figure 2.4

6

Page 11

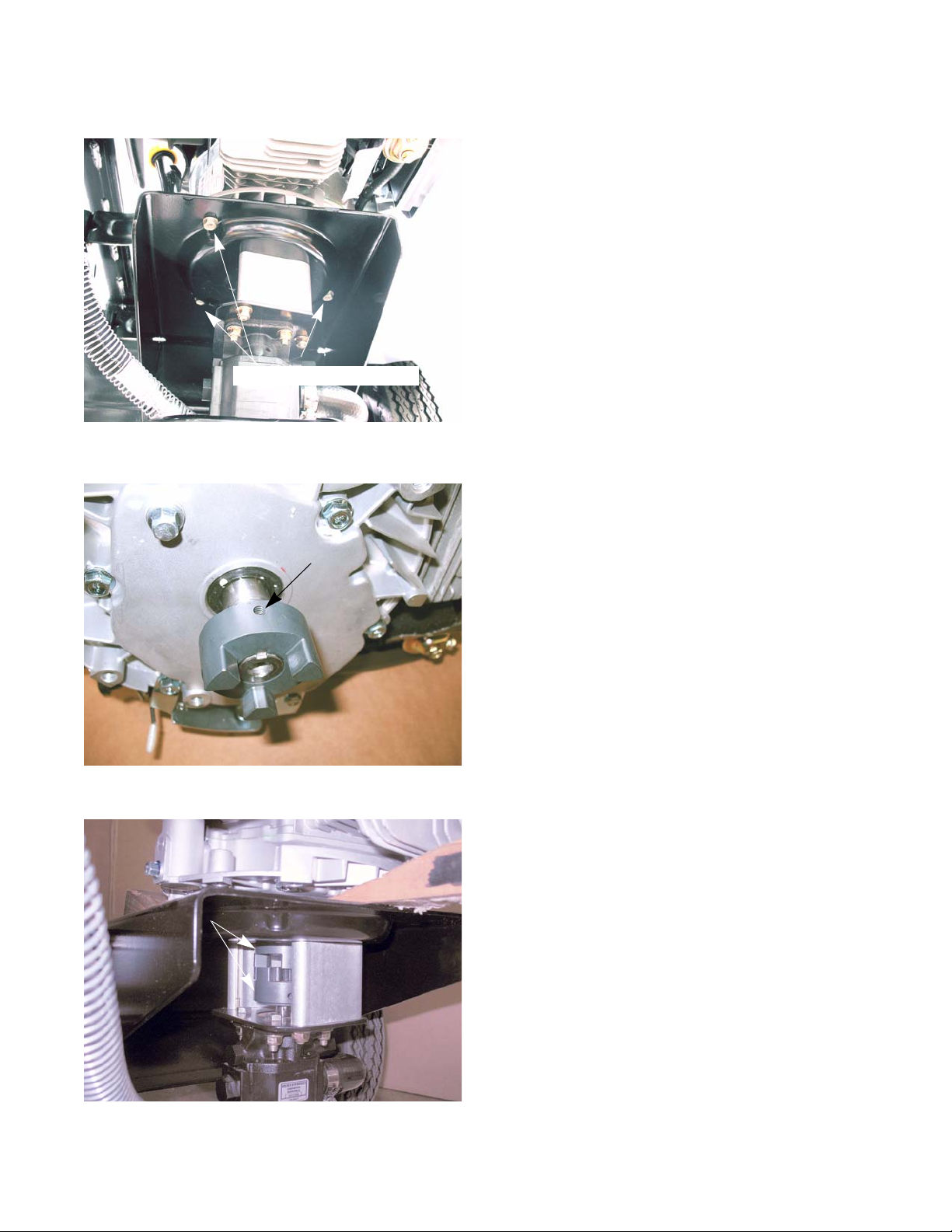

Vertical shaft engines

Engine and pump

To remove/replace the engine:

1. Remove the three engine mounting screws using a

1/2” wrench.

2. Remove the engine from the log splitter.

NOTE: If the engine is being replaced, continue to step 3.

3. Remove the set screw in the engine coupling using a

1/8” hex key.

4. Remove the engine coupling and key.

Engine mounting screws

Figure 2.5

To install a vertical shaft engine:

Set screw

Figure 2.6

Engine coupler halves

1. Install the spider in the pump coupler half.

2. Install the key in the crankshaft’s keyway.

3. Slide the engine coupler half onto the crankshaft.

NOTE: The end of the crankshaft should be flush with the

coupling half.

4. Apply a small amount of releasable thread locking

compound such as Loctite® 242 (blue) to the set

screw.

5. Install the set screw and tighten it to a torque of 78 in

lbs (9 Nm).

NOTE: If installing a new engine, Thread the self tapping

screws into the engine mounting holes to cut the

threads, then remove them.

6. Hold the engine over the engine mount and pump

assembly.

7. Align the engine coupler halves. See Figure 2.6.

NOTE: The wooden wedges were used to hold the engine

for the picture. They are not needed for this step.

See Figure 2.6.

Figure 2.7

8. Lower the engine onto the engine mount.

9. Install the engine mounting screws and tighten them

to a torque of 325 - 450 in lbs (37 - 51 Nm).

10. Adjust the engine coupler gap by following the steps

described in the engine coupler gap section of this

chapter.

11. Test run the log splitter before returning it to service.

7

Page 12

2010 Log Splitters

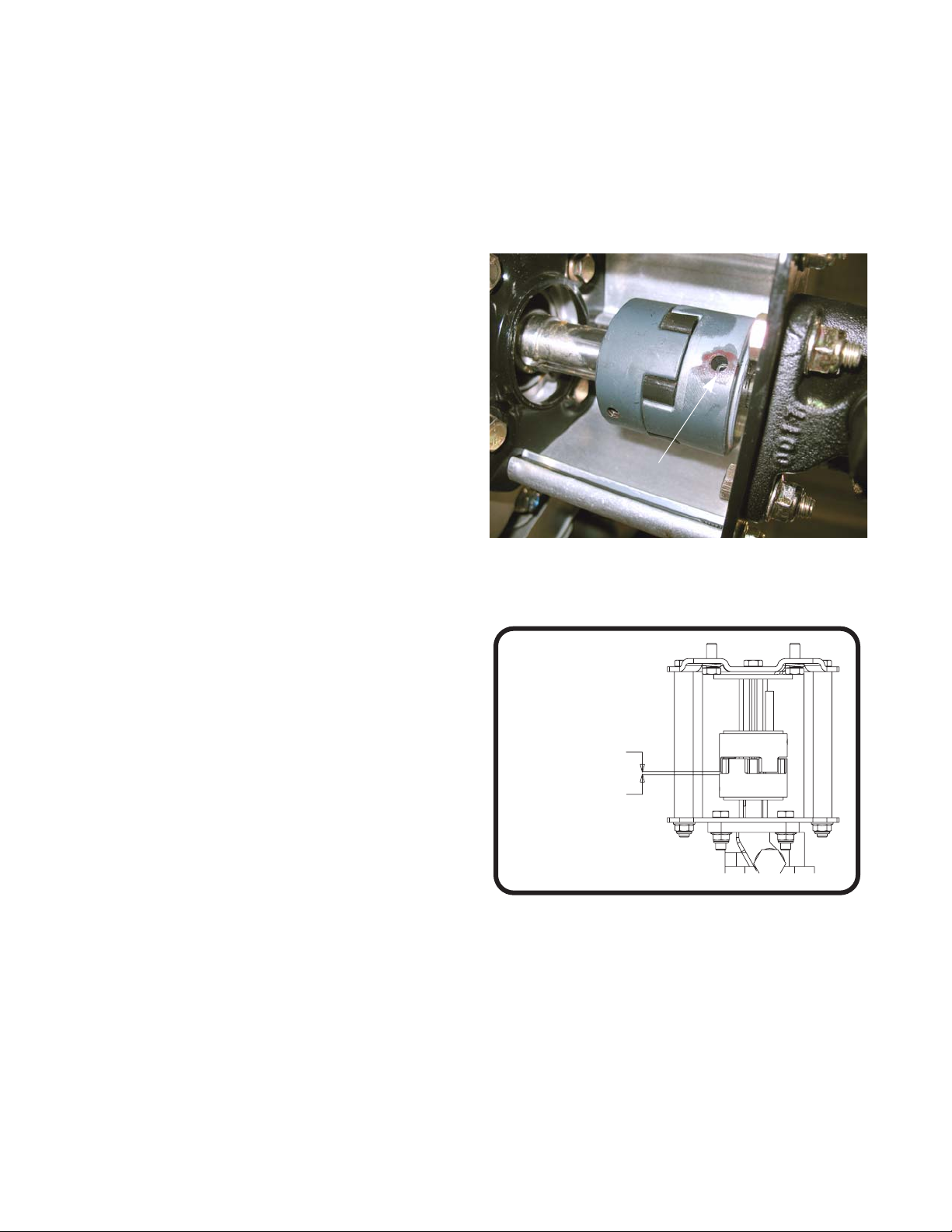

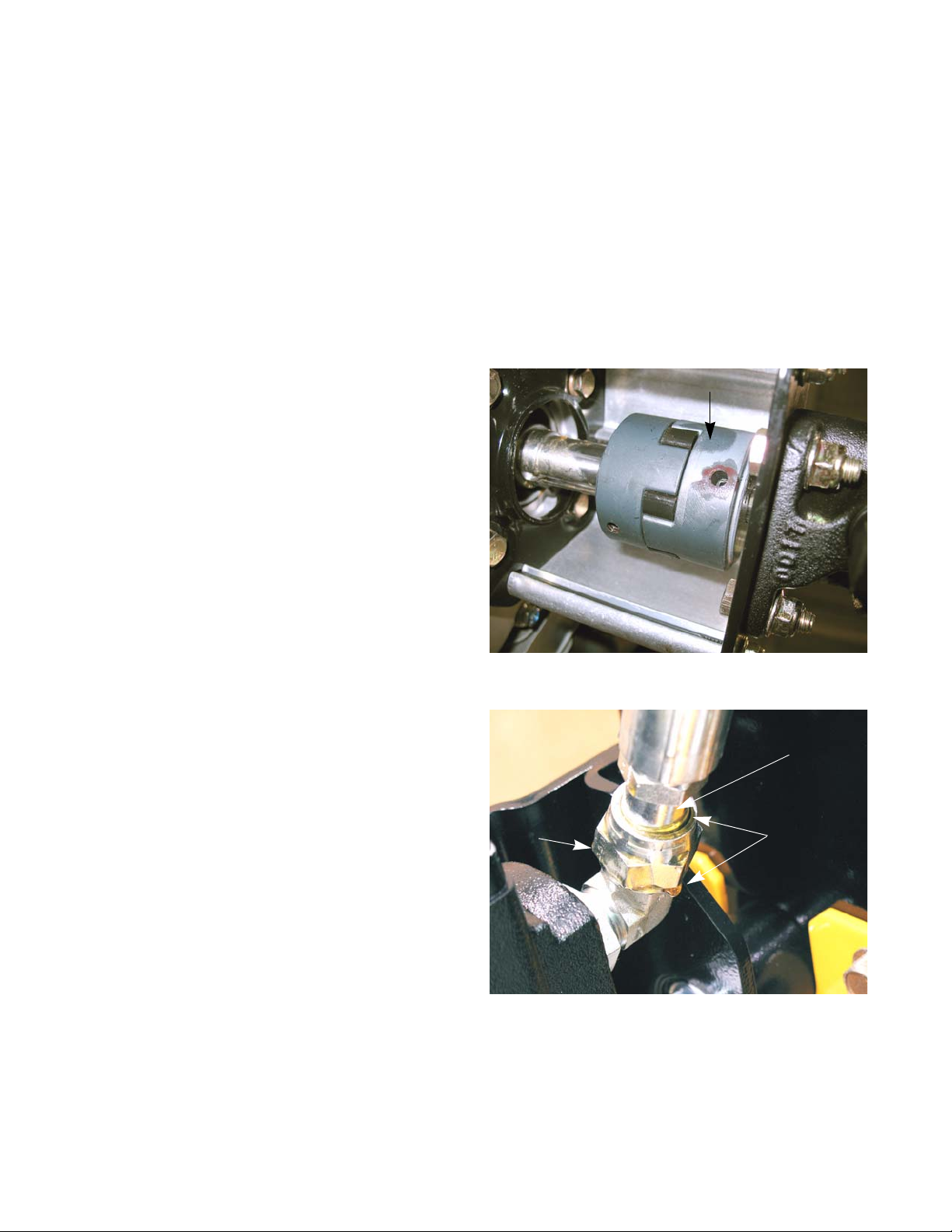

6SLGHUFRXSOLQJ

&OHDUDQFH

´

Engine coupler gap

MTD uses jaw type couplers to connect the engine to the pump. Jaw type cou plers are made of three parts; two

metallic coupler halves and a polymer spacer referred to as a spider. This type of coupling will isolate the engine

vibration from the pump. It also compensates for minor pump mis-alignments.

The coupler must have a gap of 0.010” to 0.06 0” (0.25 - 1.5 mm) between th e two metal halves in orde r to isolate

the pump from the engine vibrations. To set the gap:

1. Inspect the spider for signs of damage or wear.

NOTE: If the spider has signs of wear or damage

the pump must be removed to replace the

spider.

2. Remove the set screw from the pump coupler half.

See Figure 2.8.

Set screw

1. Insert a 0.010” to 0.060” (0.25 - 1.5 mm) feeler

gauge between the coupler halves.

2. Adjust the pump coupler halve until there is a slight

drag on the feeler gauge.

3. Apply a small amount of releasable thread locking

compound such as Loctite® 242 (blue) to the set

screw.

4. Install the set screw and tighten it to a torque of 78

in lbs (9 Nm).

5. Test run the log splitter in a safe area be fo re ret ur n-

ing it to service.

See Figure 2.9.

Figure 2.8

Figure 2.9

8

Page 13

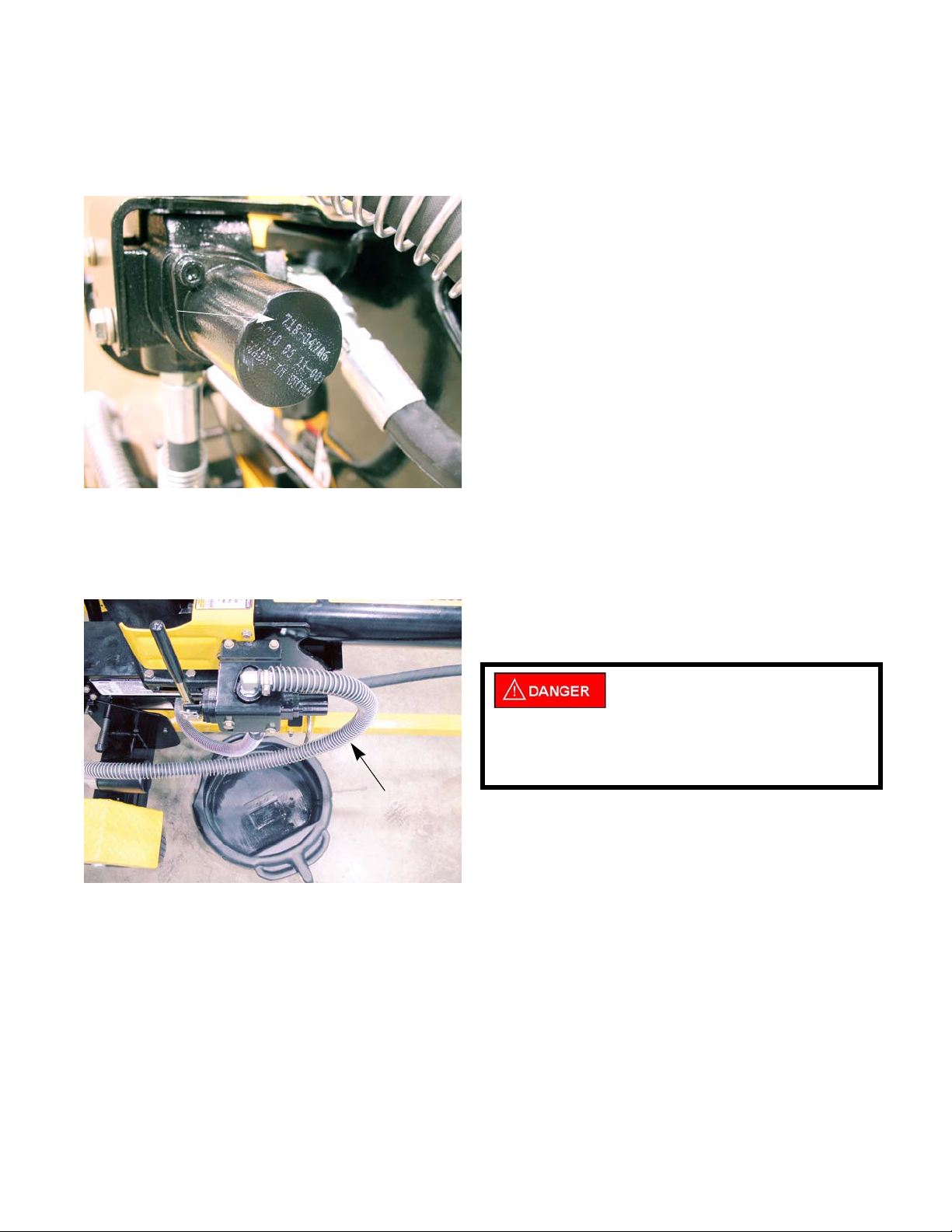

Pump removal/replacement

Figure 2.10

O-ring boss

O-ring face

3/4” wrench

Hose clamp

15/16” wrench

Engine and pump

To remove the pump:

1. Place a suitable container, large enough to hold all of

the fluid in the reservoir under the pump.

NOTE: On models with a vertical shaft engine, remove the

engine by following the procedures described in

the vertical shaft engine section of this chapter.

2. Loosen the hose clamp that secures the suction hose

to the pump.

3. Remove the suction hose and drain the fluid into the

container that was placed under the pump.

NOTE: The suction hose is steel reinforced. Trying to

clamp off the hose can result in damage to the

hose.

4. Remove the high pressure hose from the pump using

a 3/4” wrench and a 15/16” wrench.

See Figure 2.11.

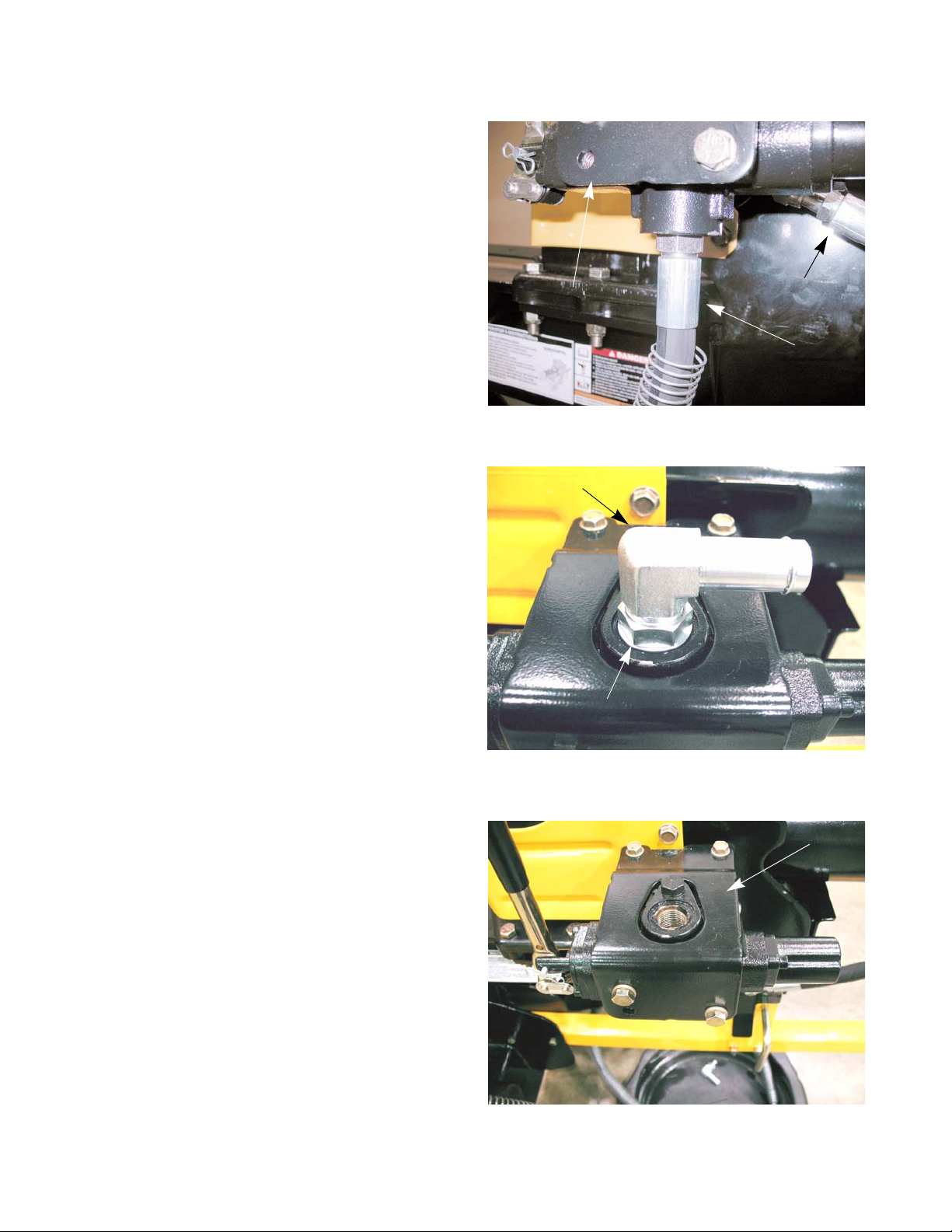

NOTE: The elbow fitting on th e discharge side of the pump

has an O-ring boss on the side that goes into the

pump. When installing the fitting, loosely thread it

in until it is in the correct alignment. Then tighten

the jam nut to compress the O-ring, providing the

seal.

See Figure 2.10.

See Figure 2.11. Inset.

Figure 2.11

Figure 2.12

NOTE: The side of the elbow fitting that the high pressure

hose connects to has an O-ring face. Inspect the

O-ring, part number #721-04411, before installing

the hose on re-assembly. A damaged O-ring can

cause fluid to leak out and/or air to be sucked into

the system.

5. Remove the three coupling support bracket nuts

using a 1/2” wrench.

6. Slide the pump and the coupling support bracket off

as one assembly.

See Figure 2.12.

9

Page 14

2010 Log Splitters

7. Remove the set screw that secures the pump coupling half using a 1/8” hex key. See Figure 2.13.

8. Remove the coupling and the key.

9. Remove the four nuts and bolts that attach the coupling support bracket to the pump using a pair of

1/2” wrenches.

10. Install the pump by following the previous steps in

reverse order.

NOTE: DO NOT use teflon tape on any fitting on an

MTD log splitter. Pieces of the tape can get

into the system and damage the valve or the

pump.

See Figure 2.13.

Coupling support bracket

Set screw

NOTE: Apply a light coat of oil to the O-rings be fore

re-assembly.

NOTE: When tightening hoses with O-ring face fittings, hold the hose so that the center part of it does not

rotate against the O-ring while the swivel section is tightened. If the center part rotates, the O-ring can

be damaged and it will leak under pressure.

11. Set the engine coupling gap by following the steps described in the engine coupling gap section of this chapter.

12. Fill the reservoir with oil.

13. Disconnect and ground the spark plug wire.

14. Pull over the engine 12 times to prime the pump.

15. Connect the spark plug wire and start the engine.

16. Cycle the log splitter through its full travel 12 times to bleed the system.

17. Test run the log splitter before returning it to service.

Figure 2.13

10

Page 15

Hydrualic Diagnosis

CHAPTER 3: HYDRAULIC DIAGNOSIS

OVERVIEW

The main components of the log splitter are all fairly expensive. Hip-shot diagnosis will result in wasted time and

money for the dealer. Throwing wrong parts at a log splitter gets expensive fast.

Troubleshooting is a process of developing and testing theorie s ab ou t th e pr ob lem tha t ca us ed the custo m er to

bring the log splitter in for repair.

To properly diagnose a problem with the hydraulic system of a log splitter;

1. Get complete information from the customer;

1a. Make sure the customer understands how to operate the log splitt er.

1b. Make sure the customer knows what the log splitter is supposed to be able to do.

1c. Get a thorough description of the problem the customer is having with the equipment

1d. Get as much maintenance history of the log splitter as possible.

2. Understand the equipment;

2a. Know how each component works in the system.

2b. Know what symptoms each component might produce if it fails.

2c. Test the components against their specifications to identify the problem.

3. Use your understanding of the equipment to work in a logical sequence; See Figure 3.1.

3a. Check the simple stuff first.

3b. Use symptoms to focus your attention.

3c. Test and eliminate theories.

Pump performance;

Wrong oil / low oil

Poor engine or drive performance

Slipping engine coupler

Blocked vent

Low flow rate (bad pump)

Low pressure / flow droop (bad pump)

Missing pump or engine key

Cold oil (below 20

Clogged inlet screen

o

)

Pump O.K.

Control valve;

Pressure relief too low

Pressure relief too high

Will not stay in return position

Pump O.K.

Control valve O.K.

Cylinder;

External leaks;

(nipple, shaft seal, or bore-end seal)

Internal leaks (blow-by)

Mechanical bind (shaft)

Mechanical bind (beam)

Figure 3.1

11

Page 16

2010 Log Splitters

Understanding the hydraulic flow

It starts at the reservoir (tank). See Figure 3.2.

• The tank acts as the axle of the log splitter.

• Check the level of the hydraulic fluid, and add

hydraulic fluid through the oil fill port.

• The tank is vented by a passage drilled through

the pipe plug. See Figure 3.2.

• The outlet on the engine side of the tank feeds

hydraulic fluid directly to the pump.

See Figure 3.3.

• The filter housing mounted on the tank provides

a return path to the tank.

Figure 3.2

Tank outlet

12

Figure 3.3

Page 17

Hydrualic Diagnosis

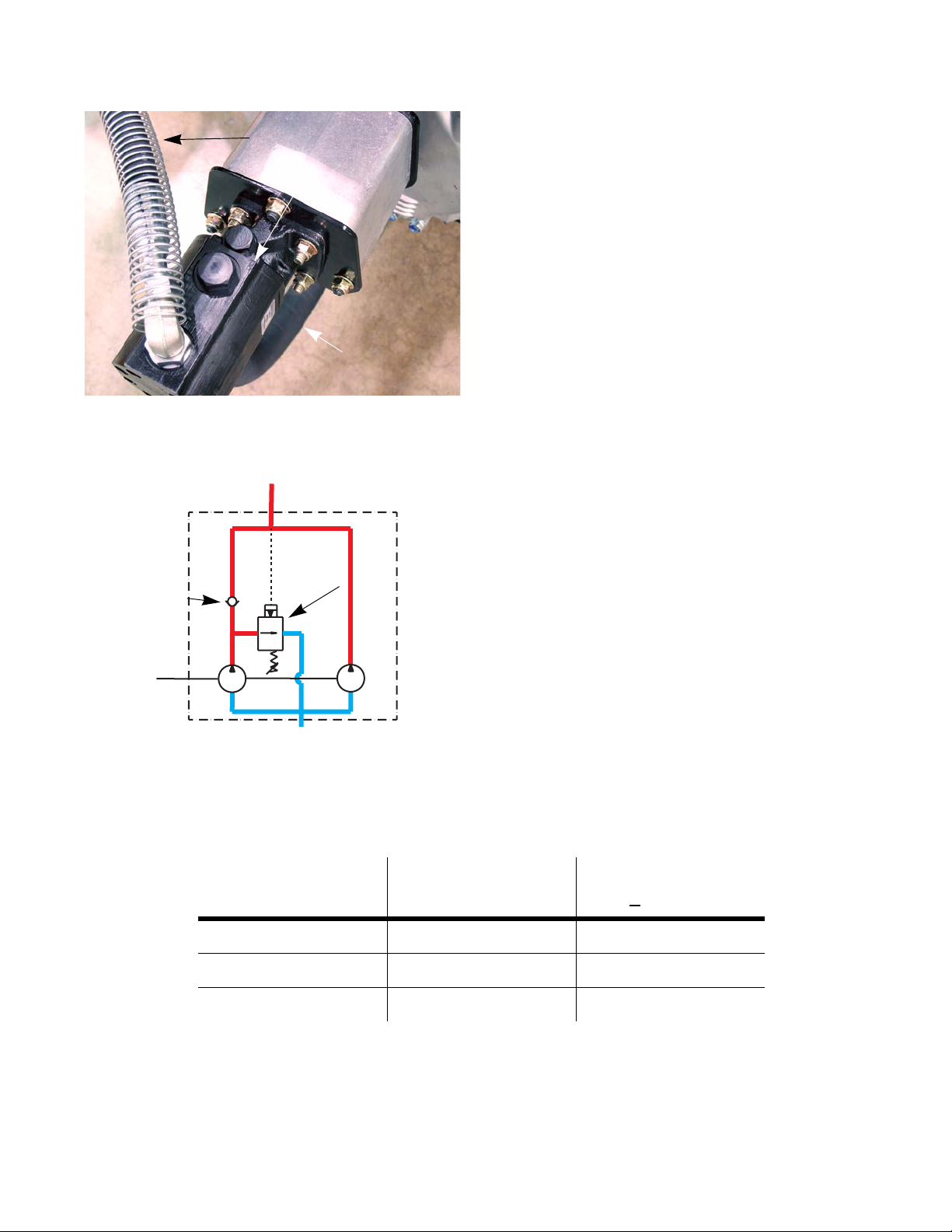

Check valve

3RZHUIURP

HQJLQH

Pressurized line to

the control valve

Pump

Suction hose

Figure 3.4

+LJKSUHVVXUHOLQH

WRWKHFRQWUROYDOYH

By-pass valve

93

6XFWLRQOLQHWRWDQN

Figure 3.5

The pump draws fluid from the tank, and forces it under

pressure to the control valve.

• The pump is capable of producing 3,400 PSI (234

bar) at a pump speed of 3,500 RPM.

• The pump is a two-stage pump.

• There is no relief valve in the pump.

• There is unloading or by-pass valve in the volume

circuit.

• The pump is direct-driven from the engine.

• The pump delivers pressurized hydraulic fluid to

the control valve.

Two-stage pumps operate in a volume and a pressure

mode.

In the volume mode both stages are pumping fluid to

the control valve. The volume mode is used to rapidly

move the wedge down the beam.

NOTE: The pressure stage flow is at a much lower GPM

rating than the volume stage, but the pressure is

much higher.

In the pressure mode, the pressure of the fluid from the

pressure stage closes the check valve. The fluid coming

out of the volume stage can not open the check valve and

is diverted to the by-pass valve which will dump the fluid to

the intake side of the pump.

The pressure mode is used to drive the wedge through

the wood that is being split.

See Figure 3.4.

Pump By-pass Settings

Pump Tonnage

By-pass Pressure

+

100 PSI

718-04127 21,25 and 27 500 (34 bar)

718-04729 27 ton HP pump 1000 (69 bar)

718-04128 33 700 (48 bar)

13

Page 18

2010 Log Splitters

The open-center control valve does four things: See Figure 3.6.

1. Regulate:

It regulates fluid pressure.

• If the pressure exceeds a pre-set limit, the relief valve opens, returning fluid directly to the tank.

• In any no-load condition, pressure should not exceed 300 PSI (20 BAR).

2. Forward:

It drives the ram toward the base plate.

• In the forward position, the control valve directs pressurized fluid th rough the hose to the port at the rear of

the cylinder.

• This drives the piston up the bore, displacing fluid from the shaft side of the cylinder.

• The control valve allows displaced fluid to leave the shaft end of the cylinder through the trunnion, returning to the control valve.

• The control valve dumps displaced fluid back into the tank through the low pressure hose.

3. Retract:

It draws the ram away from the base plate.

• In the retract position, the control valve sends fluid through the trunnion it is mounted to, to the shaft side

of the cylinder.

• This drives the piston down the bore, displacing fluid from the base side of the cylinder.

• The control valve allows displaced fluid to leave the base end of the cylinder through the high pressure

hose, returning to the control valve.

• The control valve dumps displaced fluid back into the tan k through the low pressure hose.

• The control lever is held in the retract position by a detent. When the piston bottoms-out, the build-up of

pressure of between 500 and 2,000 PSI forces the valve out of detent, returning it to neutral.

4. Neutral:

In the neutral position, fluid from the pump is dumped directly back into the tank through the low pressure hose.

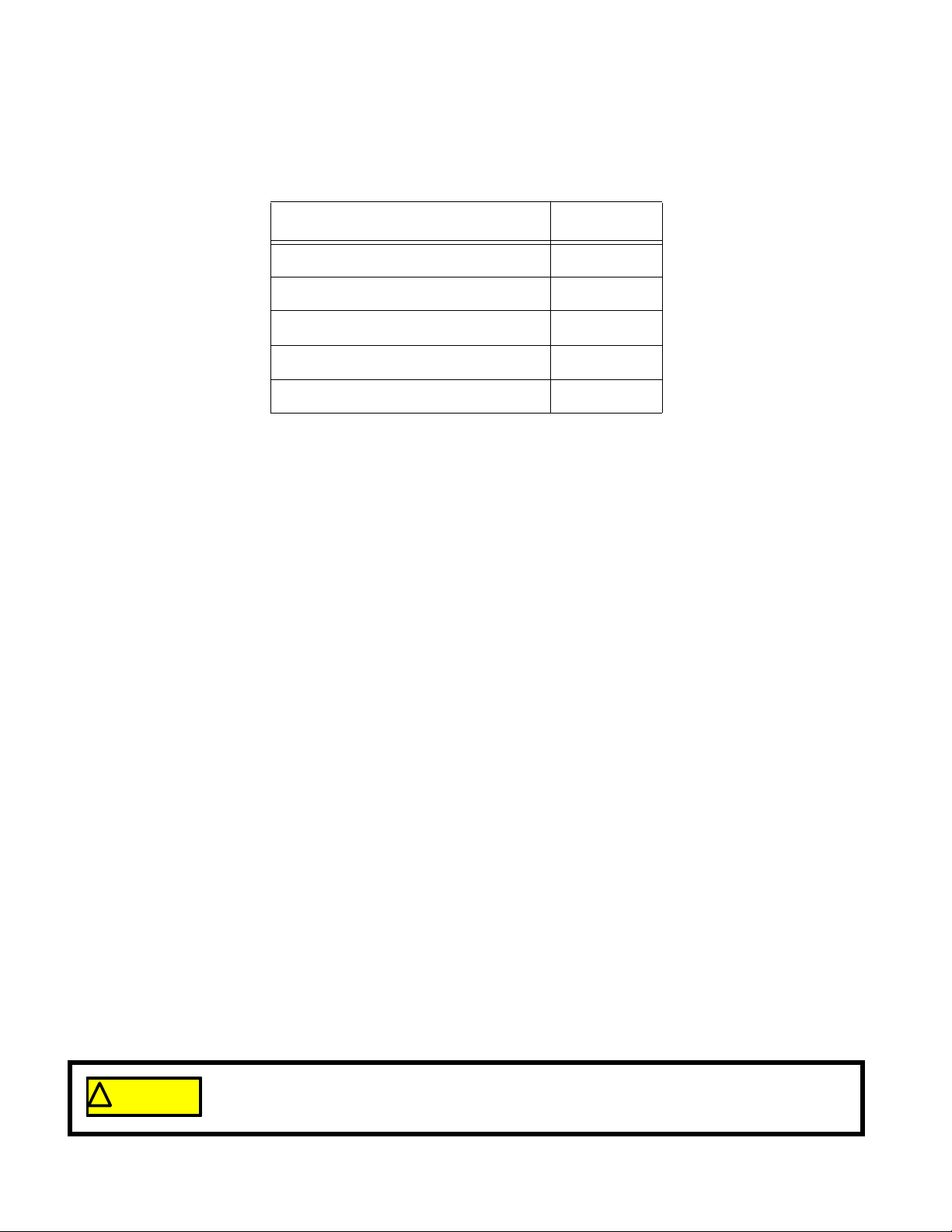

Relief Valve Settings

Valve part

number

Tonnage

Relief valve

setting

+ 100

Control valve

718-04706 27 and 33 3400 PSI

(234 bar)

718-04739 21 2700 PSI

(186 bar)

718-04740 25 3200 PSI

(221 bar)

14

Figure 3.6

Page 19

Hydrualic Diagnosis

Cylinder

Figure 3.7

High pressure hose

The Cylinder See Figure 3.7.

• Both ports of the cylinder are connected to the

control valve.

• When pressure is applied to the port at the base of

the cylinder (through the flexible high-pressure

hose), the ram extends.

• When pressure is applied to the shaft end of the

cylinder (through the trunnion), the ram retracts .

• When pressure is applied to one port, fluid from

the other port is forced back to the control valve by

the movement of the piston in the cylinder bore.

The Hoses:

The high pressure hoses:

• High-pressure hoses connect the pump to the

control valve and the control valve to the base of

the cylinder.

• High pressure means 3,400 PSI (+ 100) working

pressure.

Low pressure

hose

Figure 3.8

NOTE: The low pressure hose that supplies the pump carries fluid under vacuum. If it leaks, it will draw-in air,

but may leak very little fluid out. This entrapped air will create cavitation in the pump. Poor pump perfor

mance accompanied by whining or growling noises can indicate a leaky suction-side hose.

NOTE: The pressure of the fluid in the low pressure hose that runs from the control valve to the tank can be

approximately 300 PSI.

The low pressure hoses:

• Low pressure hoses connect the tank to the pump

and the control valve to the tank.

• Hoses must not collapse under the suction pressure to the pump.

• Low pressure hoses are fastened with hose

clamps.

-

15

Page 20

2010 Log Splitters

Log splitter test procedures

1. Preparation

Troubleshooting and diagnosing a hydraulic system is a process that should be performed in a specific order.

This chapter is laid out in the order the tests should be performed to get the best results.

NOTE: There is a hydraulic system testing work sheet a t the end of this chapter. The work sheet is designed to

assist in troubleshooting the hydraulic system. When performing war ranty repair s, the work sheet must

be turned in with the failed part(s). Before starting any testing of the log splitter, record the model num

ber, serial number, pum p model number and the valve model number on the worksheet. This information will be needed during the testing.

Just because a hydraulic pump is not p umping well does not mean the pump is ba d. Before condemning part s or

getting into deeper diagnosis, check the basics.

External factors that will effect pump performance include:

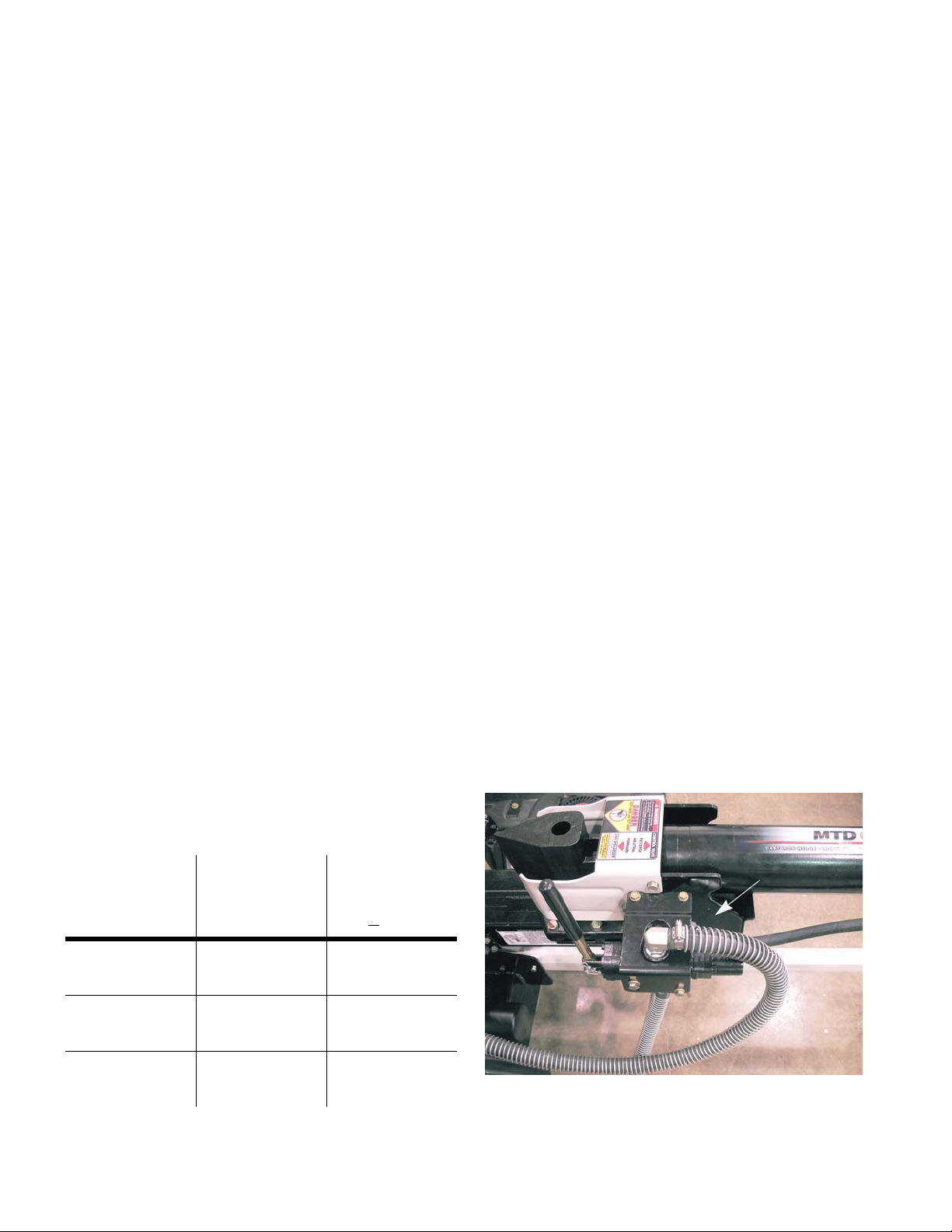

Engine coupler

A. Engine coupler: See Figure 3.9.

• Check for a worn spider.

• Check for a sheared or missing key.

• Check for a loose set screw that will allow the

coupler to spin on the crankshaft or the pump

shaft.

-

B. Leaking fitting: See Figure 3.10.

• Damaged O-ring

• Mis-aligned O-ring

• Missing O-ring

NOTE: The fitting may not be leaking fluid, but suck-

ing in air. This can cause sluggish operation.

NOTE: When tightening hoses with O-ring face fit-

tings, hold the hose so that the center part of

it does not rotate against the O-ring while the

swivel section is tightened. If the center part

rotates, the O-ring can be damaged and it

will leak under pressure.

Swivel section

Figure 3.9

Center section

Oil leak

Figure 3.10

16

Page 21

Hydrualic Diagnosis

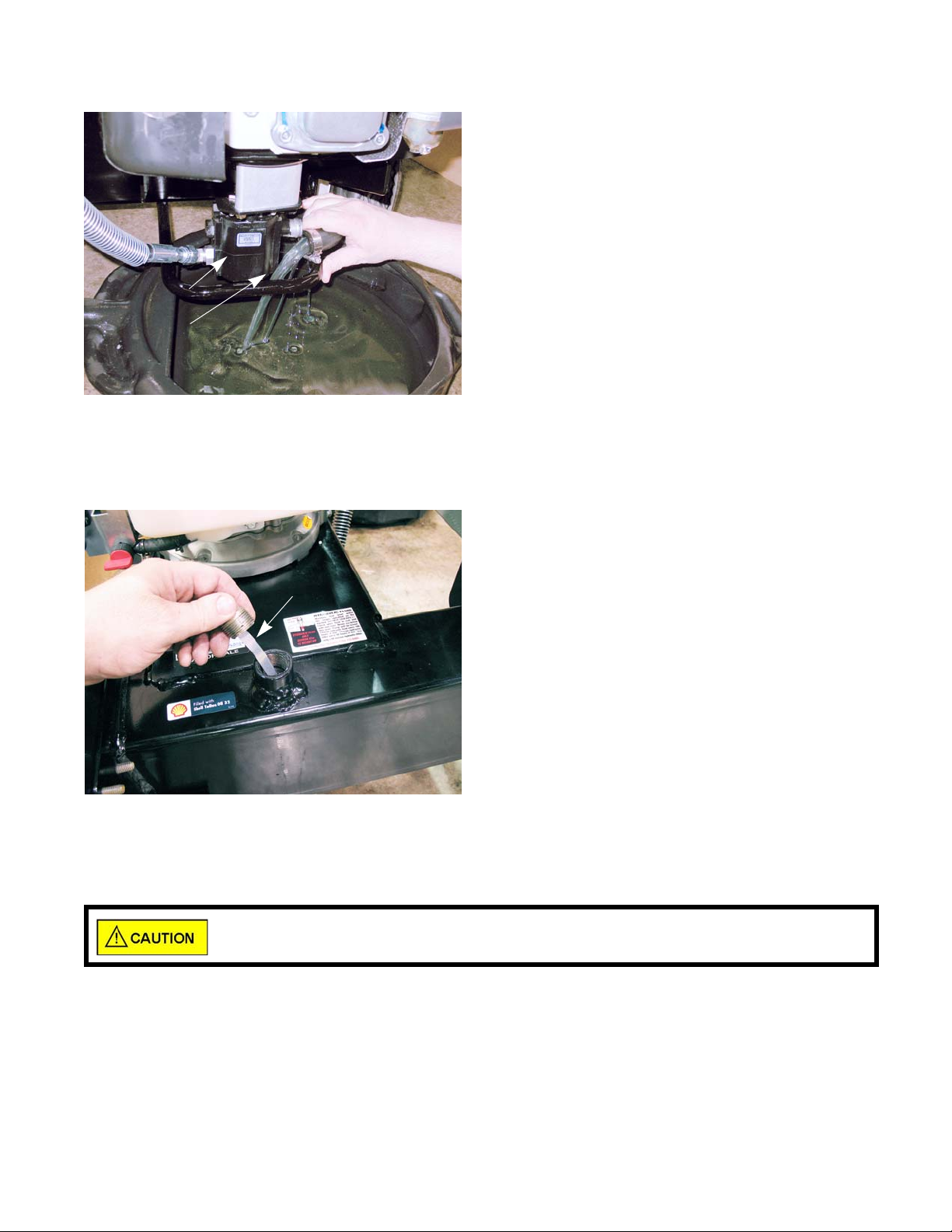

C. Fluid not getting to the pump See Figure 3.11.

• If fluid is not reaching the pump, the log splitter will

not work

• Continued running with a dry pump will destroy the

pump. This is not warrantable damage.

• To check the fluid supply to th e pu m p:

Pump

Oil free flowing

Figure 3.11

Dip stick

a. Place a drain pan under the pump.

b. Disconnect the suction hose from the pump.

c. Fluid should flow freely from it.

• Watch the hose that feeds the pump while the ram

is in motion. If the hose is collapsing, it will blockoff the supply of fluid to the pump.

• Entrained air from a suction hose leak will cause a

loss of splitting force and a noisy pump.

D. Low fluid / wrong fluid: See Figure 3.12.

• With the log splitter on level ground, remove the

dipstick from the tank to check the fluid.

• Check fluid cold. It expands when it gets hot.

• Read the fluid level on the dipstick.

• The reservoir will hold 3 or 5 gallons depending on

the model.

• Use either Dexron III ATF or SAE 10WAW (ISO 32

viscosity grade) hydraulic fluid. Do not mix the two.

NOTE: Models that are produced pre-filled, are filled with

10WAW (ISO 32).

• If in doubt, drain it out; replace the fluid with known

Figure 3.12

Hot hydraulic fluid can cause burns. Do not check the fluid until the hydraulic system has

cooled to ambient temperature after use.

E. Cold temperatures

• Hydraulic fluid gets thick at low temperatures; the splitter should not be used with hydraulic fluid temperature below 20

• Hydraulic tests should be performed with the fluid warmed-up to 120

• When the fluid is too cold, pressure will be high and flow will be low.

• When the fluid is too cold, log splitter operation will be sluggish.

° F. (-6.66° C.)

correct hydraulic fluid.

• Too little fluid will starve the pump.

• T oo much fluid will slow performance and spill from

the vent.

° F. (49°C.) to get accurate results.

17

Page 22

2010 Log Splitters

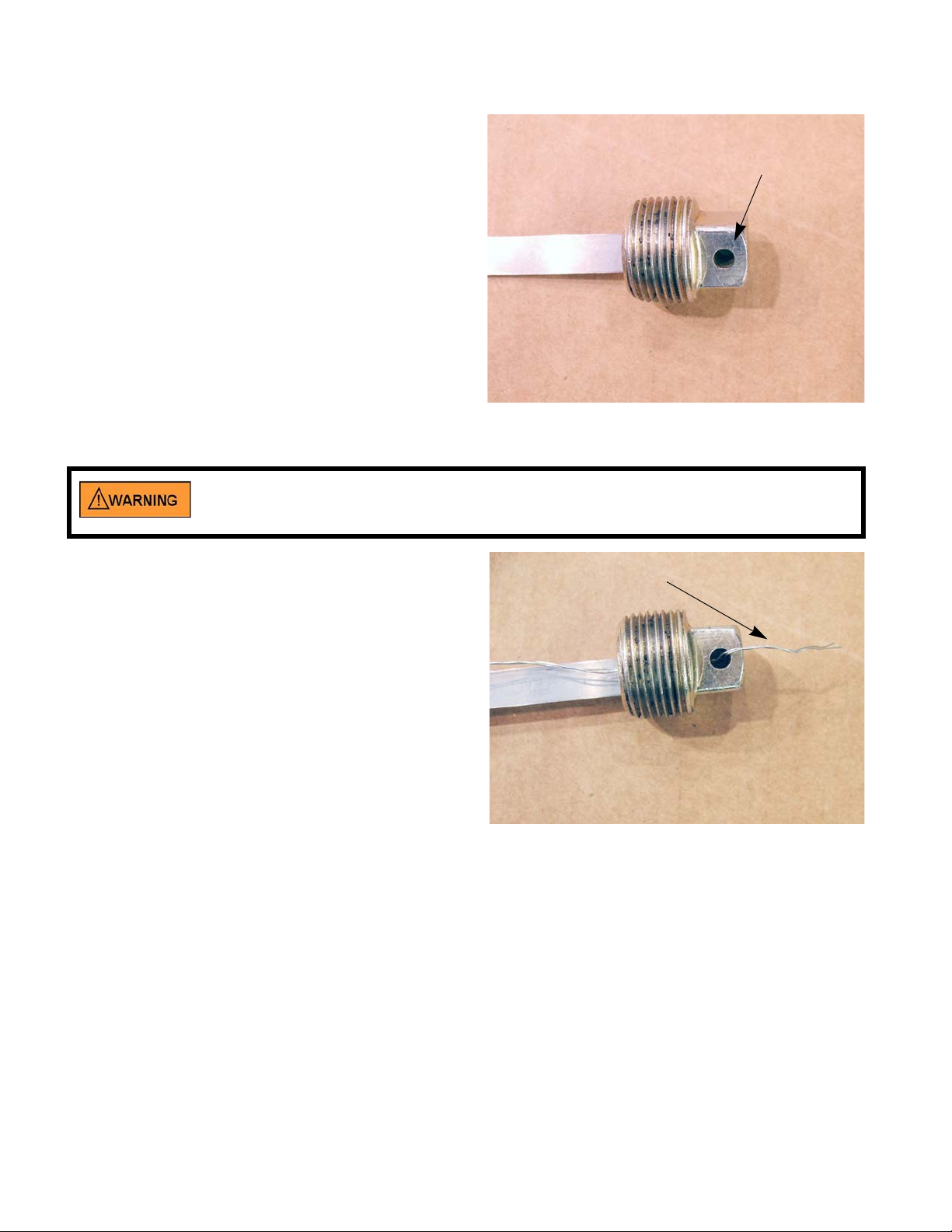

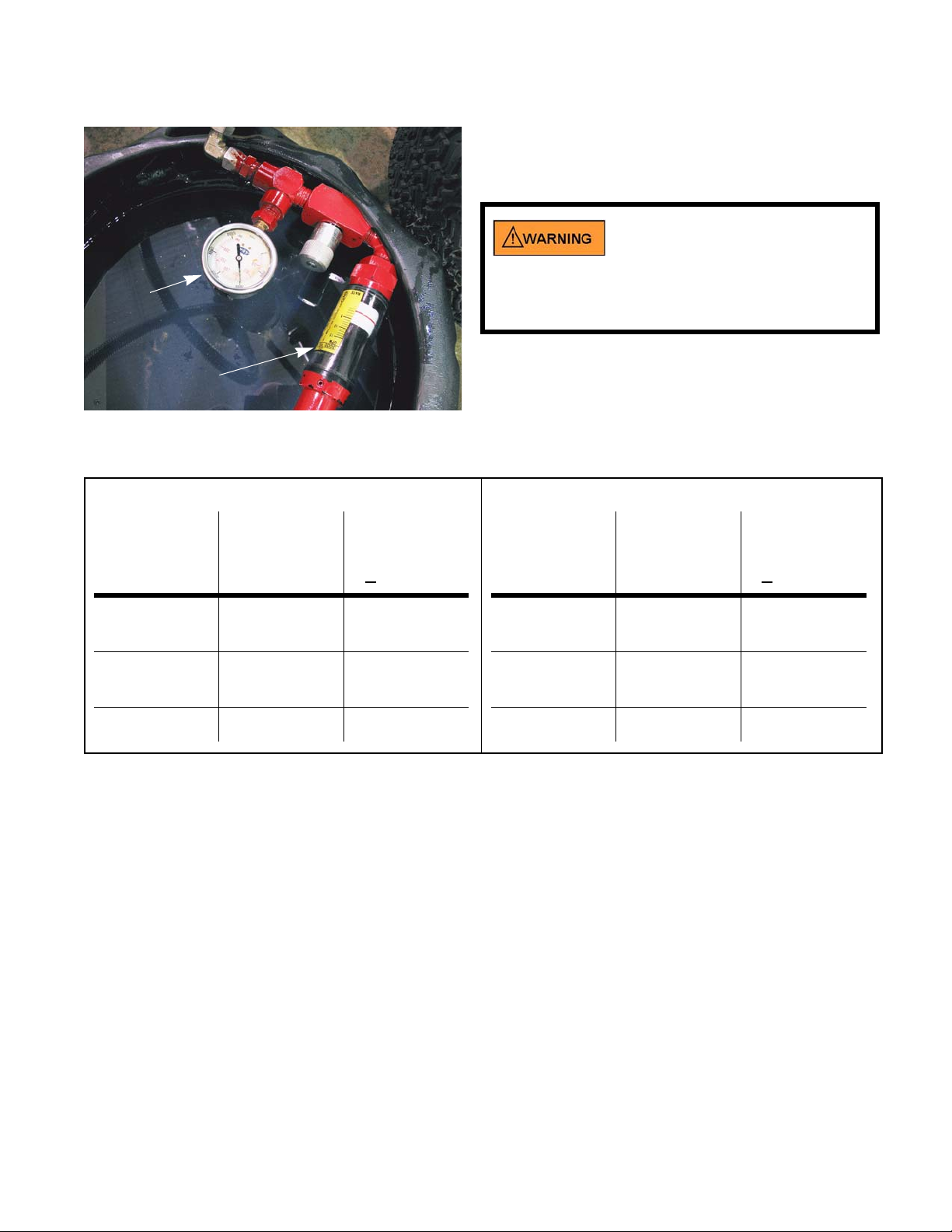

F. Inspect the tank vent: See Figure 3.13.

• The tank vent is drilled through the pipe plug.

• As the fluid moves from the tank to the cylinder,

it draws air in. As fluid moves from the cylinder

back to the tank, air is forced out of the tank.

• If the tank cannot “breathe” through the vent,

extending the ram will form a vacuum in the

tank.

• If the tank cannot “breathe” through the vent,

retracting the ram will pressurize the tank.

• The ram will move through part of its’ stroke,

then stop as the vacuum or pressure builds.

• The vent also allows for the thermal expansion

of the hydraulic fluid.

If the tank is pressurized by a blocked vent, relieve the pressure by extendin g the r am before

attempting to remove the plug. Removing the plug from a pressurized tank can launch a dangerous projectile.

Vent

Figure 3.13

To check the tank vent:

• Remove the dip stick.

• Insert a piece of wire into the vent hole until it

comes out of the rivet that attaches the dip stick

to the plug. See Figure 3.14.

G. Replace the hydraulic oil filter:

• Turn the oil filter counter-clockwise to remove it.

• Coat the O-ring of the new oil filter with a light coat of oil.

• Thread the oil filter onto the oil filter housing hand tight

Checking the vent

Figure 3.14

18

Page 23

3,500 RPM

Hydrualic Diagnosis

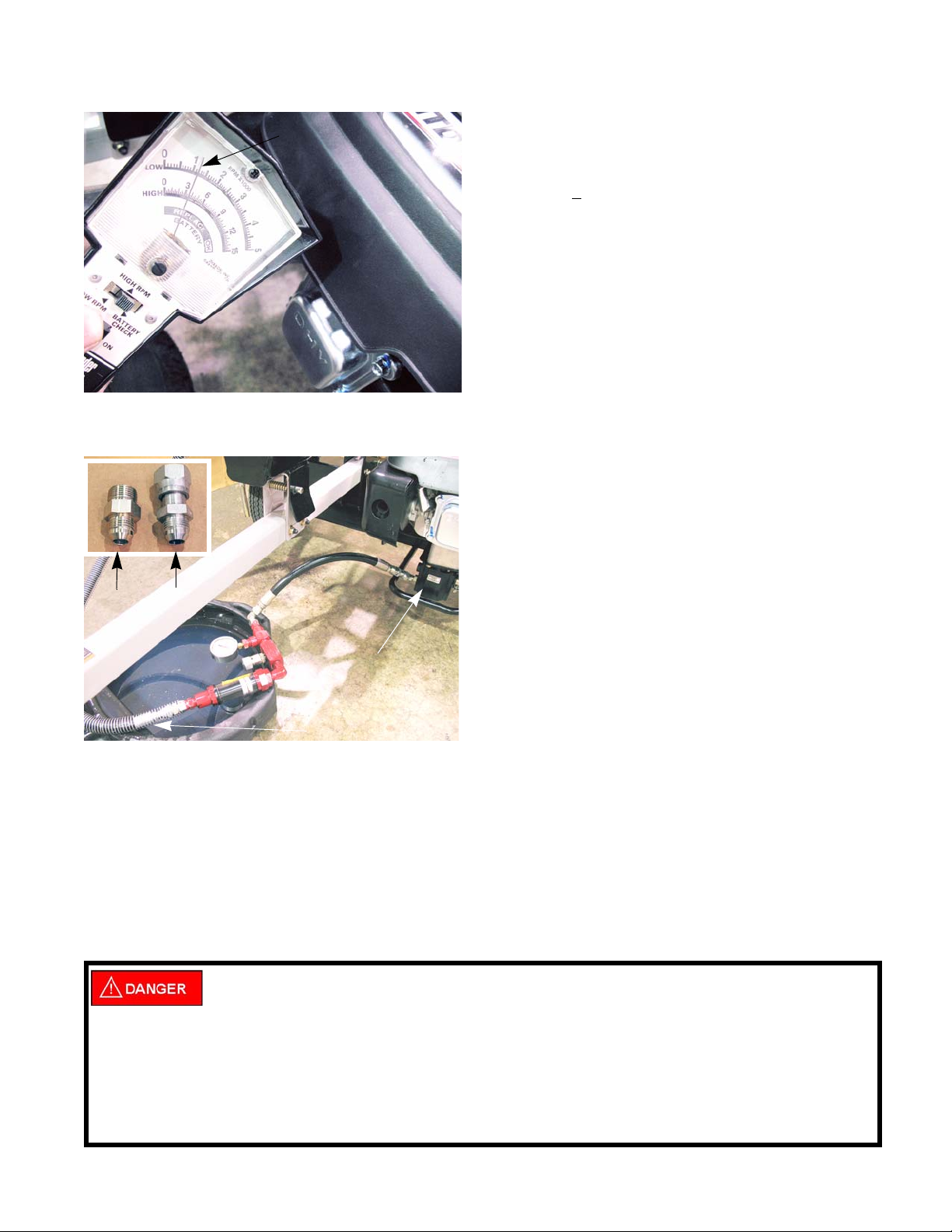

H. Engine performance: See Figure 3.15.

• The engine should be adjusted to run at 3,500

RPM

+ 100. Check it with a tachometer.

• The engine must be in good state of tune: good

spark plug, clean air filter, fresh fuel, clean carbu

retor, correct valve lash.

• The engine must be in good mechanical condition:

good compression.

• If the engine speed is set correctly, but it slowsdown excessively under load, there is an engine

performance issue.

-

Figure 3.15

8XHL68XHLO

Pump

Line to control valve

Figure 3.16

NOTE: DO NOT use teflon tape on any fitting on a MTD log splitter. Pieces of the tape can get into the system

and damage the valve or the pump.

• The engine performance issue must be fixed

before valid pump tests can be made.

I. With the engine turned-off, relie ve hydraulic pressure

from the system by moving the lever on the control

valve through its full range of travel.

J. Connect the flow and pressure test gauge set

(P/N 759-3742) between the pump and the control

valve.

• The pressure gauge should be on the pump side.

• The flow meter should be on the control valve side.

NOTE: A 1/2” male JIC to 1/2” male O-ring face (OFS)

adapter (Parker Hannifin number 8XHLO) and a

1/2” male JIC to a 1/2” female OFS (Parker Hanni

fin number 8XHL6) will be needed to connect the

test kit to the log splitter.

K. Confirm that the needle valve on the test gauge set is

fully open and all connections are tight.

See Figure 3.16. Inset.

-

NOTE: When tightening hoses with O-ring face fittings, hold the hose so that the center part of it does not

rotate against the O-ring while the swivel section is tightened. If the center part rotates, the O-ring can

be damaged and it will leak under pressure.

L. Start and run the log splitter to warm-up the fluid and check the test set connections for leaks. Cycle the

ram 12 times to purge air from the hydraulic system.

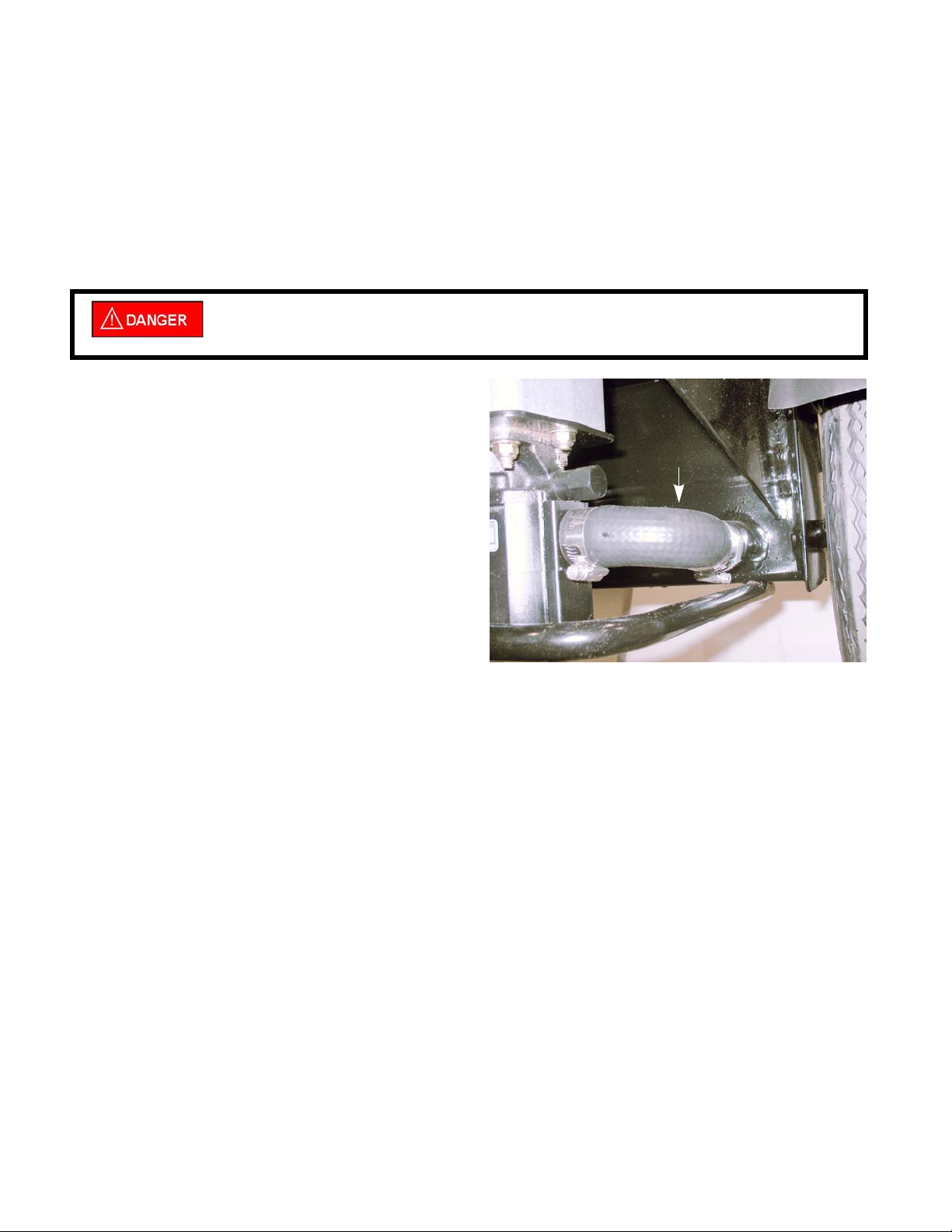

Hydraulic fluid under high pressure can be dangerous. A high-pressure hyd raulic fluid leak o r

spray can penetrate the skin. If this happens, seek immediate medical attention to reduce the

risk of blood poisoning leading to death or limb amputation.

If a hydraulic fluid leak develops at any time during testing or operation of the log splitter, turn it off and

repair the leak before any further work is done.

Exhaust fumes from running engines contain carbon monoxide (CO). Carbon monoxide is a colorless

odorless gas that is fatal if inhaled in sufficient quantity. Only run engines in well ventilated areas. If running

engines indoors, use an exhaust evacuation system with adequate make-up air ventilated into the shop.

19

Page 24

2010 Log Splitters

2. Pump base-line test (ram stationary)

A. Perform all of the procedures described in the

preparation section of this chapter.

B. With the engine running, record the engine

RPMs on the worksheet at the end of this

chapter.

NOTE: Copies of the worksheet can be do wnloaded

from the dealer service site or photo copied

out of this book.

C. Record the flow meter reading on the work-

sheet. See Figure 3.17.

D. Record the pressure reading on the work-

sheet.

E. Record the rated pump capacity from the

pump capacities chart on to the worksheet.

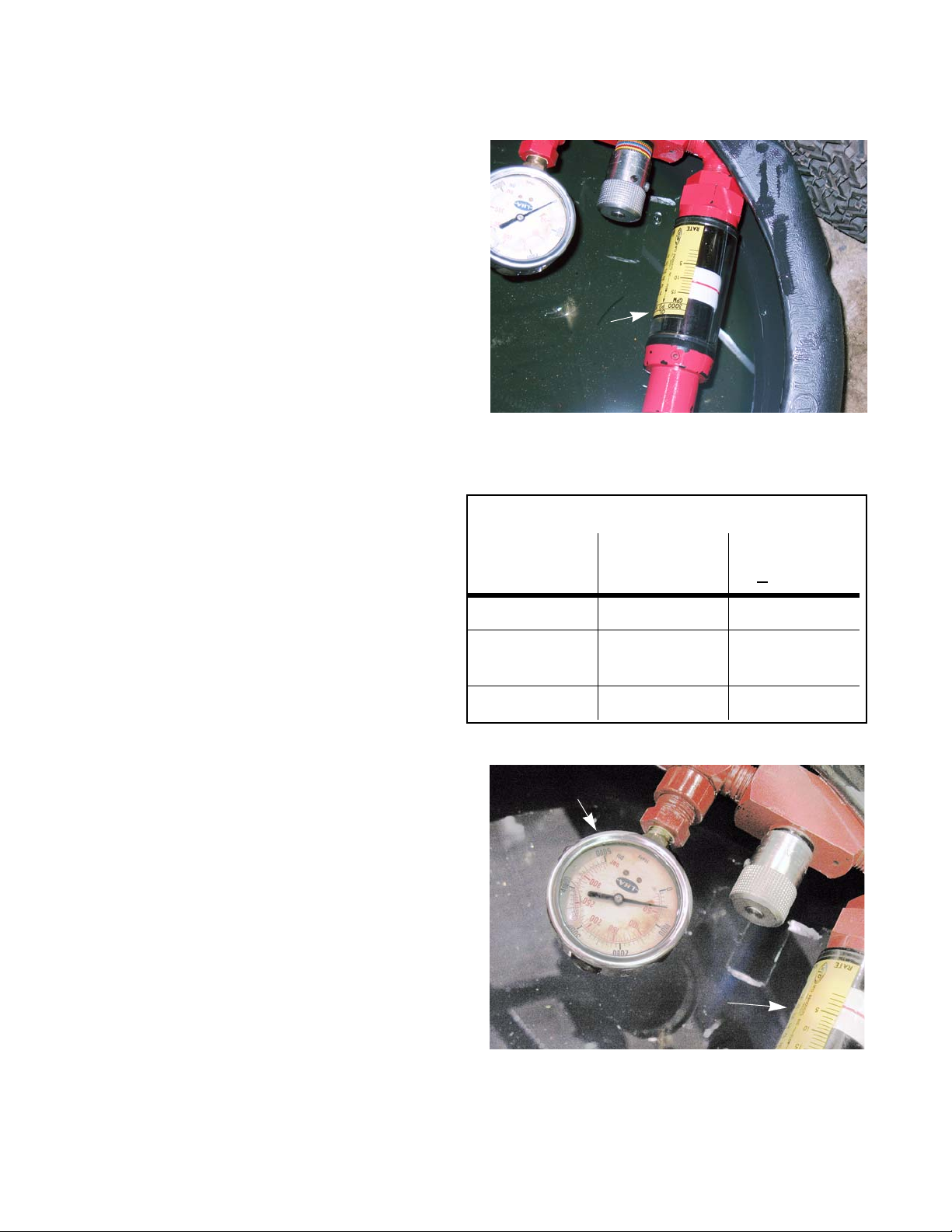

3. Pump load testing (ram stationary)

A. Slowly close the needle valve just far enough

to identify the by-pass point.

Flow meter

Figure 3.17

Pump Capacities

Pump Tonnage

GPM/LPM

+ 1 GPM

718-04127 21,25 and 27 9.5 (36 lpm)

718-04729 27 ton HP

13 (46 lpm)

pump

718-04128 33 15 (57 lpm)

500 PSI

NOTE: The by-pass point is the point were the

pump switches from volume mode to pres

sure mode. There will be a noticeable drop

in the flow reading.

B. Record the engine RPMs on the worksheet.

C. Record the flow meter reading on the work-

sheet.

D. Record the pressure reading on the work-

sheet. See Figure 3.18.

E. Record the rated pump by-pass setting from

the pump by-pass settings chart on to the

worksheet.

20

-

3 lpm

Figure 3.18

Page 25

2,000 PSI

1.5 lpm

Figure 3.19

Hydrualic Diagnosis

F. Slowly close the needle valve to build 2,000 PSI (220

Bars).

See Figure 3.19.

Do NOT exceed 3,200 PSI (220

Bars). This test is performed up-

stream of the relief valve in the log

splitter hydraulic system, rendering the relief

valve ineffective during the test. Over-loading the system will damage the pump.

G. Record the engine RPMs on the worksheet.

H. Record the flow meter reading on the worksheet.

I. Record the pressure reading on the worksheet.

J. IMMEDIATELY open the needle valve, then turn-off

the engine.

Pump By-pass Settings

Pressure Mode Flow Capacities

By-pass

Pump Tonnage

718-04127 21,25 and

27

718-04729 27 ton HP

pump

718-04128 33 700 (48 bar)

K. Record the rated flow rate from the pressure mode flow capacities chart on to the worksheet.

Interpreting the test results:

NOTE: The engine governor should ho ld engine RPMs constant during the test.

• If the pump fails to produce the base-line flow rate, but engine RPM is 3,500, there is problem with the

drive system (engine coupler) or the pump.

• The flow should be within 1 GPM (3.8 LPM) of the rated capacity.

Pre s sur e

+

100 PSI

500 (34 bar)

1,000 (69

bar)

Pump T onnage GPM/LPM

718-04127 21,25 and

1.5 (5.5 lpm)

27

718-04729 27 ton HP

3 (11 lpm)

pump

718-04128 33 3 (11 lpm)

+

0.5 gpm

• If flow droops more than 1 GPM (3.8 LPM), and the engine RPM falls, there is an engine problem

• If pressure fails to build, there is a problem with the drive system (engine coupler, keys or the pump).

• If flow drops more than 1 GPM (3.8 LPM), the eng ine RPM does not cha nge, and the engine exhaust note

does not change, there is a problem with the drive system (engine coupler and spider) or the pump.

• If base-line flow is within 1 GPM (3.8 LPM), pressure builds to 2,000 PSI (138 Bars) when the needle

valve is closed; the pump, engine, and drive are working properly.

• To identify drive problems examine the engine coupler and spider.

• If the pump fails to switch from volume mode to pressure mode within 100 PSI of the rate by-pass setting,

the pump is bad.

21

Page 26

2010 Log Splitters

4. Control valve test

A. Turn off the engine.

B. Relieve hydraulic pressure from the system by moving the lever on the control valve through it’s full

range of travel.

C. Remove the test gauges from between the pump and the control valve.

D. Reinstall the original hydraulic hose that connected the pump to the control valve.

E. Install the test gauges between the log splitter

control valve and the extend port on the

hydraulic cylinder.

e1. Disconnect the hydraulic hose that runs

from the log splitter control valve to the

extend port on the hydraulic cylinder.

NOTE: The control valve is mounted to one of the

trunnions of the cylinder. This makes it diffi

cult to connect the test gauge set to the side

of the hydraulic system that retracts the ram.

e2. Install the test gauge set with the pressure

gauge nearest on the control valve side and

the flow meter on the cylinder side.

See Figure 3.20.

Extend port

Control valve

-

e3. Start the engine.

e4. Check for leaks.

e5. Cycle the ram 12 times to warm-up the fluid and purge air from the hydraulic system.

F. While extending the ram, gently release the control lever several time.

NOTE: The control lever must return to the neutral position as soon as it is released. If it fails to do so, even

once, the valve must be replaced.

G. Move the control lever to the retract position.

NOTE: The control lever should stay in the retract position until the ram is fully retracted. After the ram is

retracted, the system will build pressure and return the control lever to the neutral position.

Figure 3.20

22

Page 27

Hydrualic Diagnosis

H. Extend the cylinder fully using the log splitter control

valve.

• As the ram reaches the end of its travel, pressure

will build until the relief valve opens.

• Record the maximum pressure reached on the

worksheet.

Valve part

number

Relief Valve Settings

Relief valve

Tonnage

setting

+ 100 PSI

718-04706 27 and 33 3400 PSI

(234 bar)

718-04739 21 2700 PSI

(186 bar)

718-04740 25 3200 PSI

(221 bar)

NOTE: The relief valve is not adjustable. If the reading is more than 100 PSI of what is listed in the chart,

replace the valve. If the reading is more than 100 PSI lower than what is listed in the chart, it could be

a bad valve or a cylinder leaking internally.

5. Cylinder blow-by test:

A. Hold the control valve in the extend position until the ram stops moving.

NOTE: If the needle on the pressure gauge moved too

fast to get a good reading on the extension stroke,

adjust the needle valve while retracting the cylin

der to slow down the rate that the pressure builds.

Repeat step H.

I. Record the rated relief valve pressure from the relief

valve settings chart on to the worksheet.

-

B. Record the flow reading after the ram stops moving.

NOTE: Pressure decay when the ram is fully extended indi cates that the cylind er/piston sea ls ar e no t wor king.

NOTE: Seal kits are available to repair leaking cylinders. If the cylin der has mechanical damage, it must be

replaced.

What to do about failures

1. If a pump is bad:

• Replace the pump. The pump is not serviceable.

• If the pump failed because of an external cause, identify and eliminate the cause.

NOTE: Any disassembly of the pump WILL VOID THE W ARRANTY. Do no t take the pump ap art if the rep air is

warrantable.

2. If the control valve is bad:

• If the repair is warrantable, replace the control valve.

NOTE: Any disassembly of the control valve WILL VOID THE WARRANTY . Do not take the control valve apart

if the repair is warrantable.

3. If the cylinder is bad:

• If the cylinder is leaking at a seal, it may be repaired using a cylinder rebuild kit.

• If the cylinder is leaking at a welded seam, or has mechanical damage such as a bent shaft, replace the

cylinder.

23

Page 28

2010 Log Splitters

System drawings

Control valve in Neutral

+LJKSUHVVXUH

/RZSUHVVXUH

1RPRYHPHQW

&RQWUROYDOYH

&\OLQGHU

3XPS

Figure 3.21

• The pump drives hydraulic fluid to the control valve.

• Fluid is shunted directly back to the reservoir

• No cylinder movement results

)LOWHU

5HVHUYRLU

24

Page 29

Control valve in Extend (splitting)

+LJKSUHVVXUH

/RZSUHVVXUH

1RPRYHPHQW

3XPS

Hydrualic Diagnosis

&RQWUROYDOYH

)LOWHU

&\OLQGHU

5HVHUYRLU

Figure 3.22

• The pump drives hydraulic fluid to the control valve.

• The spool in the control valve directs pressurized fluid to the base end of the cylinder.

• The pressurized fluid forces the piston up the bore of the cylinder.

• As the piston moves up the bore, it displaces fluid that is on the ram side of the piston.

• The spool in the control valve also connects ports joining the ram end of the cylinder to the reservoir.

• This allows displaced fluid to return to the reservoir.

25

Page 30

2010 Log Splitters

Control valve in Retract

+LJKSUHVVXUH

/RZSUHVVXUH

1RPRYHPHQW

3XPS

&RQWUROYDOYH

)LOWHU

&\OLQGHU

5HVHUYRLU

Figure 3.23

• The pump drives hydraulic fluid to the control valve.

• The spool in the control valve directs pressurized fluid to the ram end of the cylinder.

• The pressurized fluid forces the piston down the bore of the cylinder.

• As the piston moves down the bore, it displaces fluid that is on the base side of the piston.

• The spool in the control valve also connects port s joining the base end of the cylinder to the reservoir.

• This allows displaced fluid to return to the reservoir.

26

Page 31

Relief in Neutral

+LJKSUHVVXUH

/RZSUHVVXUH

1RPRYHPHQW

Hydrualic Diagnosis

&RQWUROYDOYH

&\OLQGHU

)LOWHU

3XPS

5HVHUYRLU

Figure 3.24

• This drawing shows the relief valve in action with the control valve in neutral.

• The relief action is the same no matter what position the control valve is in.

• If pressure builds beyond the pre-set limit, the relie f valv e opens, spill ing fluid thr ough a port that returns it

to the reservoir.

27

Page 32

2010 Log Splitters

28

Page 33

LOG SPLITTER HYDRAULIC SYSTEM WORK SHEET

For use with test kit part number 759-374 2

NOTE: This worksheet must be completed and submitted

with the failed component for a warranty claim to

be paid

NOTE: Detailed hydraulic system testing instructions can

be found in the 2010 and Newer Log Splitters man

ual, form number 769-06184.

Model number

Serial number

Pump number

1. Preparation

Inspect the engine coupler, keys and the spider

Check fluid flow from tank to pump (inlet screen)

Check the hydraulic fluid level

Inspect the tank vent

Replace the oil filter

Check engine speed

Install the test gauges between the pump and the

selector valve.

Start and run the log splitter to warm-up the fluid

and check the test set connections for leaks. Cycle

the ram 12 times to purge air from the hydraulic

system.

2. Pump base-line test (ram stationary), record the following:

Engine RPM

Flow meter reading

Pressure reading

Flow rating from the pump capacities chart.

RPM (set to 3,500)

718-04127 21,25 and 27 9.5 (36 lpm)

718-04729 27 ton HP

718-04128 33 15 (57 lpm)

Valve number

Pump Capacities

Pump Tonnage

GPM/LPM

+ 0.5 GPM

13 (46 lpm)

pump

NOTE: The engine must be at 3,500 RPM for all

testing. If the engine RPMs fall under load, repair

the engine before testing the hydraulics.

Do NOT exceed 3,200 PSI (220

Bars). This test is performed up-stream

of the relief valve, rendering the relief

valve ineffective during the test. Overloading the system will damage the

pump.

3. Pump load test (ram stationary), record the following:

3a. Slowly close the needle valve just far

enough to identify the by-pass point.

Engine RPM

Flow meter reading

Pressure reading

Pressure rating from the by-pass settings

chart.

Pump By-pass Settings

By-pass

Pump Tonnage

Pressure

+ 100 PSI

718-04127 21,25 and 27 500 (34 bar)

718-04729 27 ton HP

pump

1,000 (69

bar)

718-04128 33 700 (48 bar)

Form Number 769-06191

Page 34

3b. Continue closing the needle valve until the

pressure gauge reads 2,000 PSI.

the following:

Engine RPM

Record

Pressure Mode Flow Capacities

Pump Tonnage

GPM/LPM

+ 0.5 GPM

Interpreting the results:

4. Control valve test

Relieve the hydraulic pressure from the system.

Flow meter reading

Pressure reading

Flow from the pressure mode flow capacities

chart.

• Open the needle valve to relieve the pressure and turn off the engine

• A significant difference between the specified and observed pump performance indicates a bad pump.

718-04127 21,25 and 27 1.5 (5.6 lpm)

718-04729 27 ton HP

3 (11 lpm)

pump

718-04128 33 3 (11 lpm)

NOTE: If the readings are low, inspect the engine coupler, the keys, set screws and the spider before condemning the pump.

Relief Valve Settings

Install the test gauges between the control valve

and the cylinder.

Warm-up the fluid an d purge air fr om the hydraulic

system.

Control returns to the stop position when released

from the extend position.

Valve part

number

Tonnage

718-04706 27 and 33 3400 PSI

718-04739 21 2700 PSI

Control stays in the retract position until the piston

is fully retracted.

4a. Extend the cylinder fully using the log split-

ter control valve.

718-04740 25 3200 PSI

Relief valve

setting

+100 PSI

(234 bar)

(186 bar)

(221 bar)

• As the ram reaches the end of its travel,

pressure will build until the relief valve

opens. Record the following:

5. Cylinder blow-by test

Record the flow reading.

Maximum pressure reached.

Relief valve setting from the relief valve settings chart.

NOTE: The relief valve is not adjustable. If the reading does not match what is listed in the chart, replace the

valve. A high reading is a bad control valve. A low reading could be a bad valve or a cylinder leaking

internally.

5a. Hold the control valve until the ram stops moving.

NOTE: Fluid movement when the ram is fully extended indicates that the piston seals are not working.

NOTE: Seal kits are available to repair leaking cylinders. If the cylinder has mechanical damage it must be

replaced.

Page 35

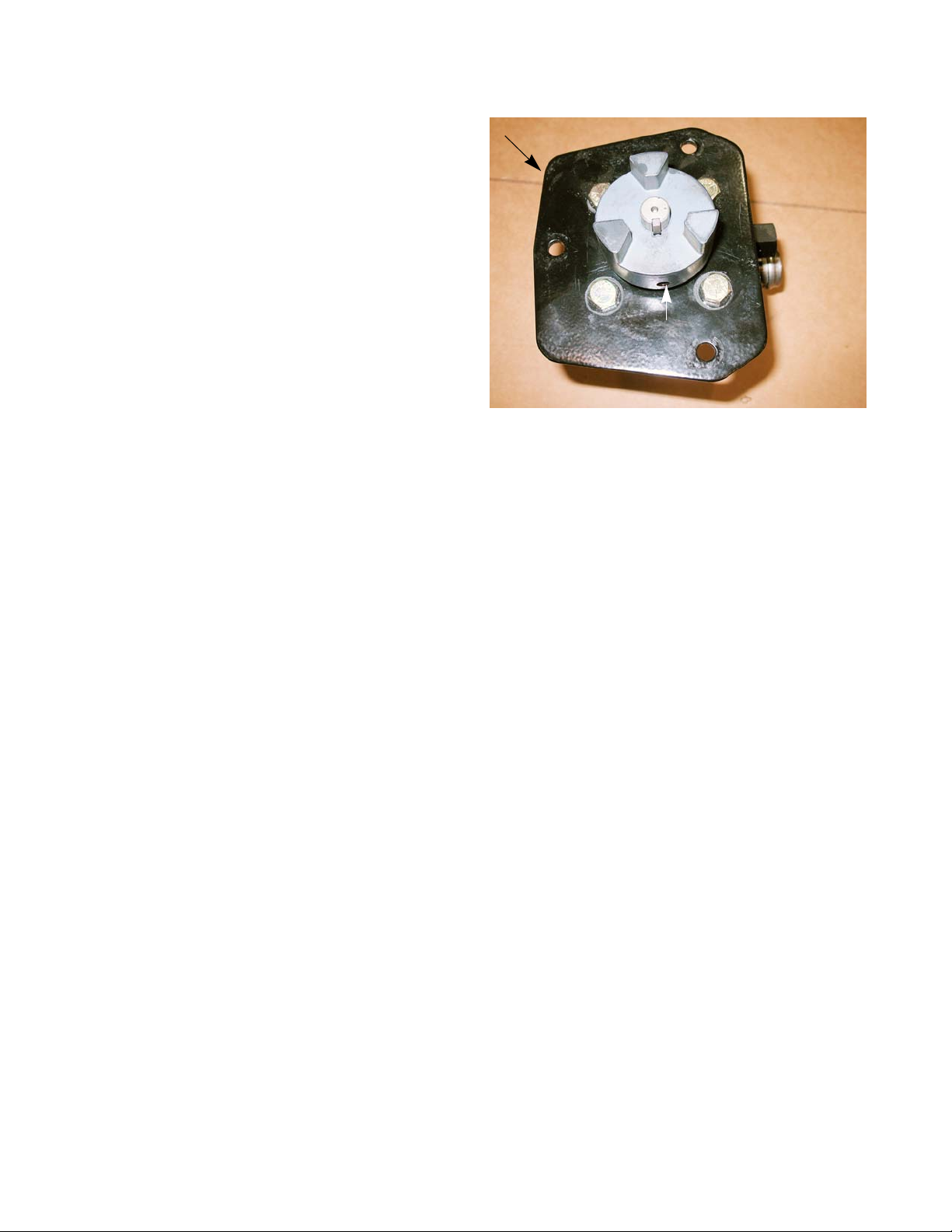

Valve number

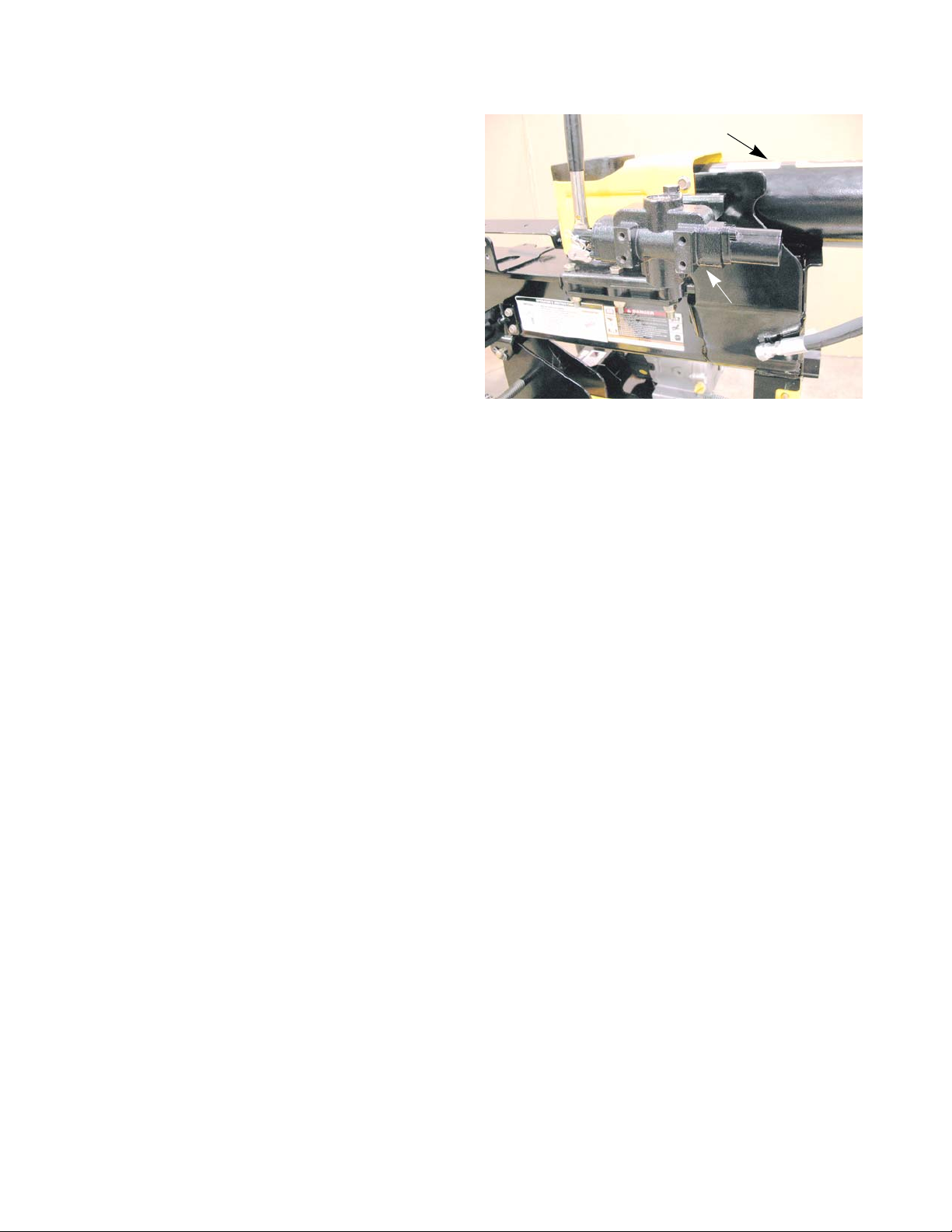

Figure 4.1

CHAPTER 4: CONTROL VALVE

MTD uses three different control valves on log splitters.

The size of the log splitter determines which valve is used.

The three different valves are identical on the outside.

Whenever testing or replacing a control valve, verify the

part number of the valve on the splitter is the one listed in

the parts drawing for that specific splitter. The valve part

number is stamped into the end cap of the valve.

See Figure 4.1.

NOTE: The numbers were filled with white paint to

improve visibility for the picture.

NOTE: The only parts of the control valve that are service-

able are the spring cover , lever , master link and the

lever bracket.

NOTE: DO NOT use teflon tape on any fitting on a MTD

log splitter. Pieces of the tape can get into the sys

tem and damage the valve or the pump.

Control valve

-

Control valve removal/replacement

To remove a control valve:

1. With the engine turned-off, relieve hydraulic pressure

from the system by moving the lever on the control

valve through its full range of travel.

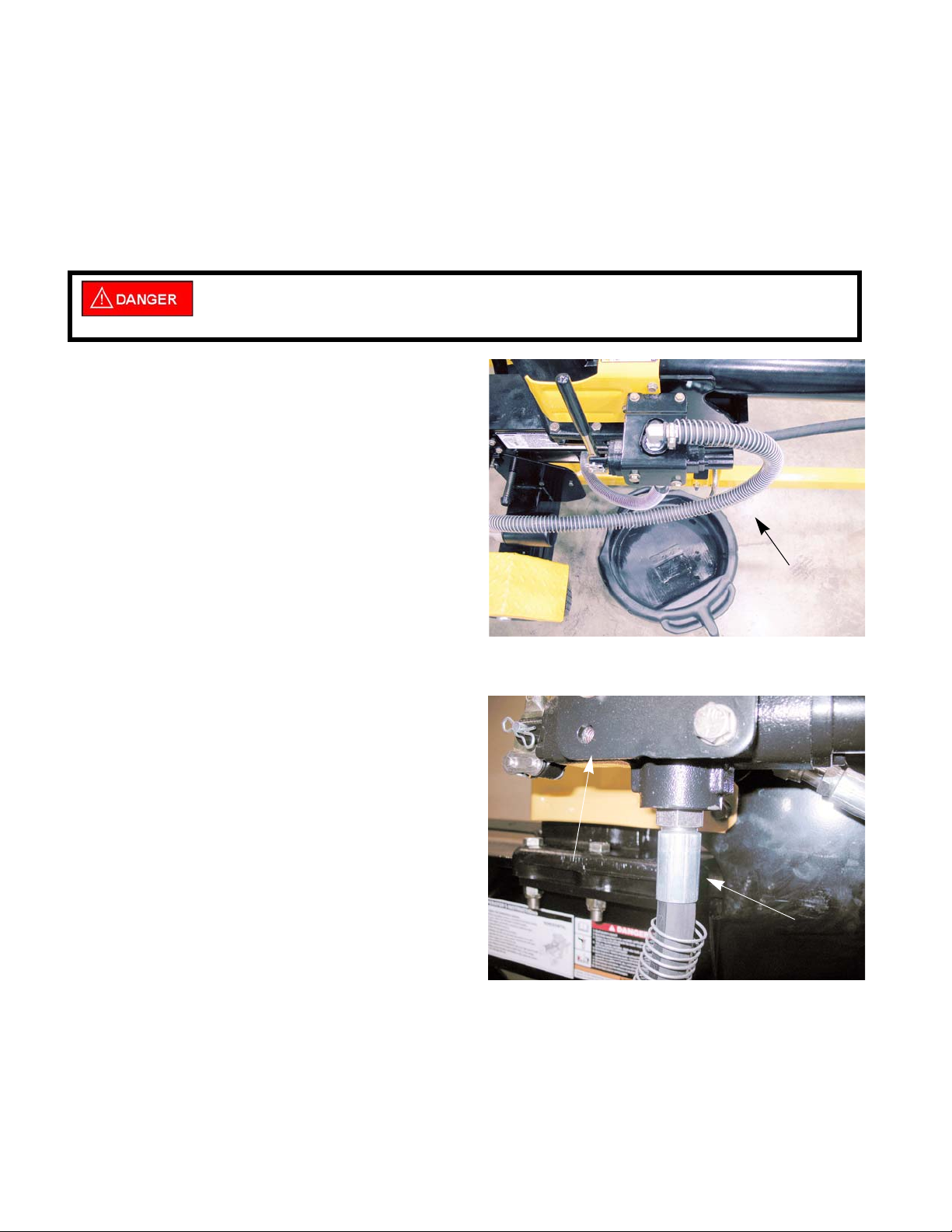

Hydraulic fluid under high pressure

can be dangerous. A high-pressure

hydraulic fluid leak or spray can penetrate the skin. If this happens, seek immediate

medical attention to reduce the risk of blood poisoning leading to death or limb amputation.

low pressure

return line

Figure 4.2

4. Loosen the hose clamp on the low pressure return line using a 5/16” wrench.

2. Thoroughly clean all dirt and debris from around the

valve.

NOTE: Any dirt or debris that gets inside the valve can

destroy it.

3. Place a suitable container under the valve to catch

the fluid that will leak out as the hydraulic lines are

removed.

See Figure 4.2.

5. Disconnect the low pressure return line.

31

Page 36

2010 Log Splitters

6. Disconnect the high pressure hose from the pump.

7. Disconnect the high pressure supply hose from the

valve using a 15/16” wrench.

8. Disconnect the high pressure hose that connects

the valve to the base of the cylinder.

See Figure 4.3.

9. Remove the return hose fitting:

9a. Hold the fitting with a 1” wrench.

See Figure 4.4.

9b. Back off the jam nut with a 1” wrench.

9c. Remove the fitting.

Control valve

Return hose fitting

Jam nut

Hose to the

cylinder

high pressure

supply hose

Figure 4.3

10. Remove the two screws that hold the valve to the

mounting bracket using a 9/16” wrench.

See Figure 4.5.

11. Remove the two screws that hold the mounting

bracket to the cylinder using a 1/2” wrench.

See Figure 4.5.

32

Figure 4.4

Mounting bracket

Figure 4.5

Page 37

Jam nut

Straight fitting

Elbow fitting

Control valve

12. Hold the straight fitting with a 1” wrench.

See Figure 4.6.

13. Back off the jam nut using a 7/8” wrench.

See Figure 4.6.

14. Unthread the straight fitting and valve from the cylinder.

Figure 4.6

15. Place the control valve in a vise with the straight fitting facing up. See Figure 4.7.

Figure 4.7

16. Remove the straight fitting.

17. Mark the orientation of the elbow to the valve.

18. Loosen the jam nut on the elbow fitting using a 15/16”

wrench.

33

Page 38

2010 Log Splitters

To install the valve:

19. Transfer the elbows orientation mark to the new

valve.

20. Check or replace the O-rings on the fittings.

21. Thread the elbow into the valve, hand tight, until it is

aligned with the orientation mark.

22. Tighten the jam nut until the O-ring is compressed.

23. Thread the end of the straight fitting without the jam

nut into the control valve. Tighten the fitting until it

compresses the O-ring.

24. Thread the straight fitting and control valve into the

cylinder hand tight.

25. Align the valve so that it is parallel to the cylinder.

See Figure 4.8.

26. Finish installing the control valve by following steps 1 - 12 in reverse order.

NOTE: The threads of the straight fitting ar e seale d by the jam nut compressing the O-ring, not by bottoming

out the threads.

NOTE: When tightening hoses with O-ring face fittings, hold the hose so that the center part of it does not

rotate against the O-ring while the swivel section is tightened. If the center part rotates, the O-ring can

be damaged and it will leak under pressure.

Cylinder

Valve

Figure 4.8

27. Replace the filter by following the procedures described in Chapter 8: Maintenance.

28. Check the hydraulic fluid level.

29. Start the engine.

30. Cycle the control valve through its full range of travel 12 times to bleed the air from the system.

31. Test run the splitter before returning it to service.

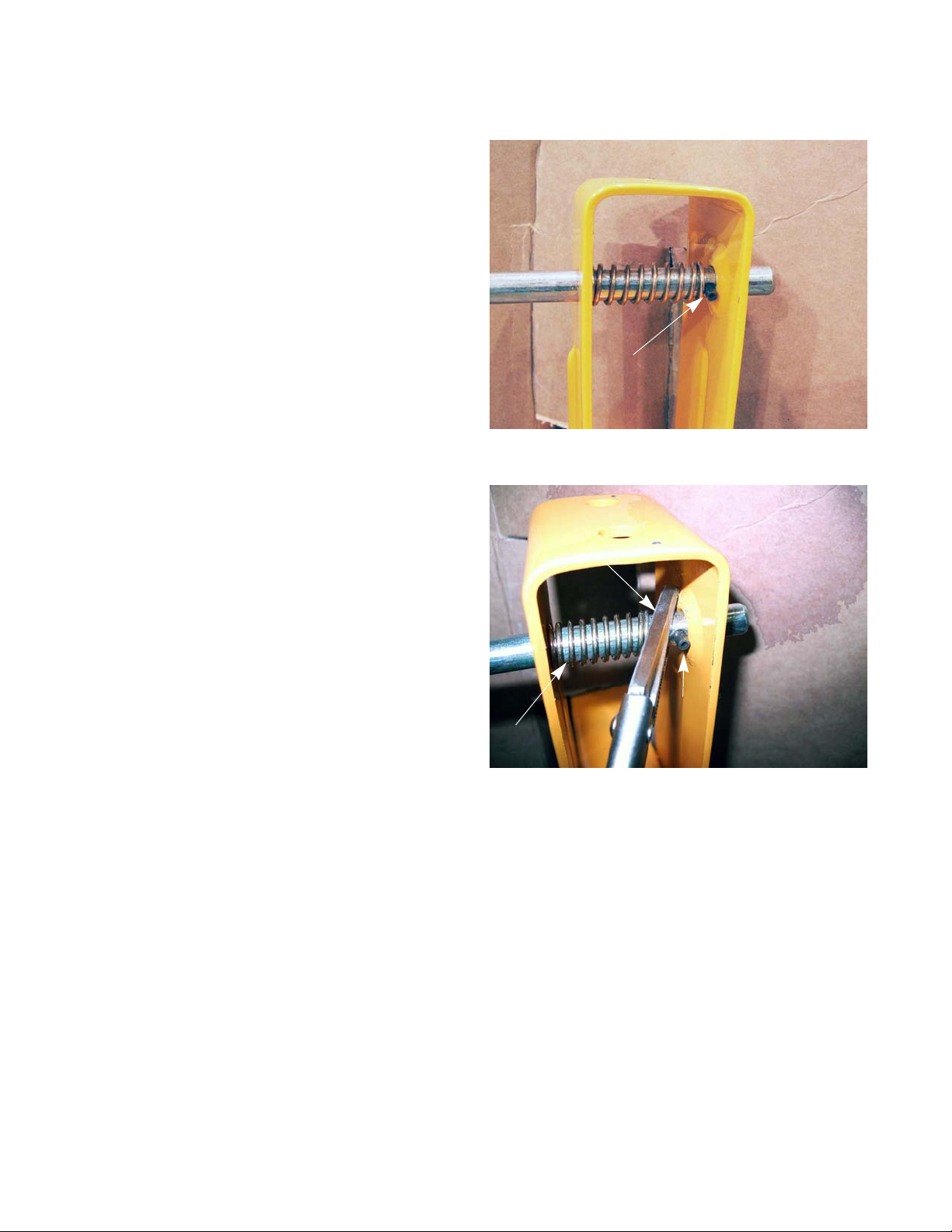

Control valve spring cover

34

Page 39

socket headed

Figure 4.9

cap screw

Control valve

To replace the valve sprin g co ver :

NOTE: The spring cover part number is 718-0522.

1. Thoroughly clean the valve and surrounding area.

NOTE: Any dirt or debris that gets inside the valve can

destroy it.

2. Remove both of the socket headed cap screws that

hold the spring cover to the valve using a 5 mm hex

key.

See Figure 4.9.

3. Remove the spring cover.

4. Carefully remove the old sealant from the valve.

Sealant

Figure 4.10

NOTE: Not all of the valves will have sealant under the

spring cover.

5. Thoroughly clean the exposed area of the valve.

To install the spring cover:

6. Apply a small bead of Loctite® 515 Flange Sealan t or

equivalent compound to the spring cover.

7. Apply a small amount of releasable thread locking

compound such as Loctite® 242 (blue) to the threads

of the socket headed cap screws.

8. Install the spring cover and tighten the screws to a

torque of 70 - 90 in lbs (8 - 10 Nm).

9. Test run the splitter in a safe area before returning it

to service.

35

Page 40

2010 Log Splitters

Control valve lever bracket

To replace the lever bracket:

NOTE: The lever bracket part number is 718-04765.

1. Thoroughly clean the valve and surroun din g ar e a.

NOTE: Any dirt or debris that gets inside the valve

can destroy it.

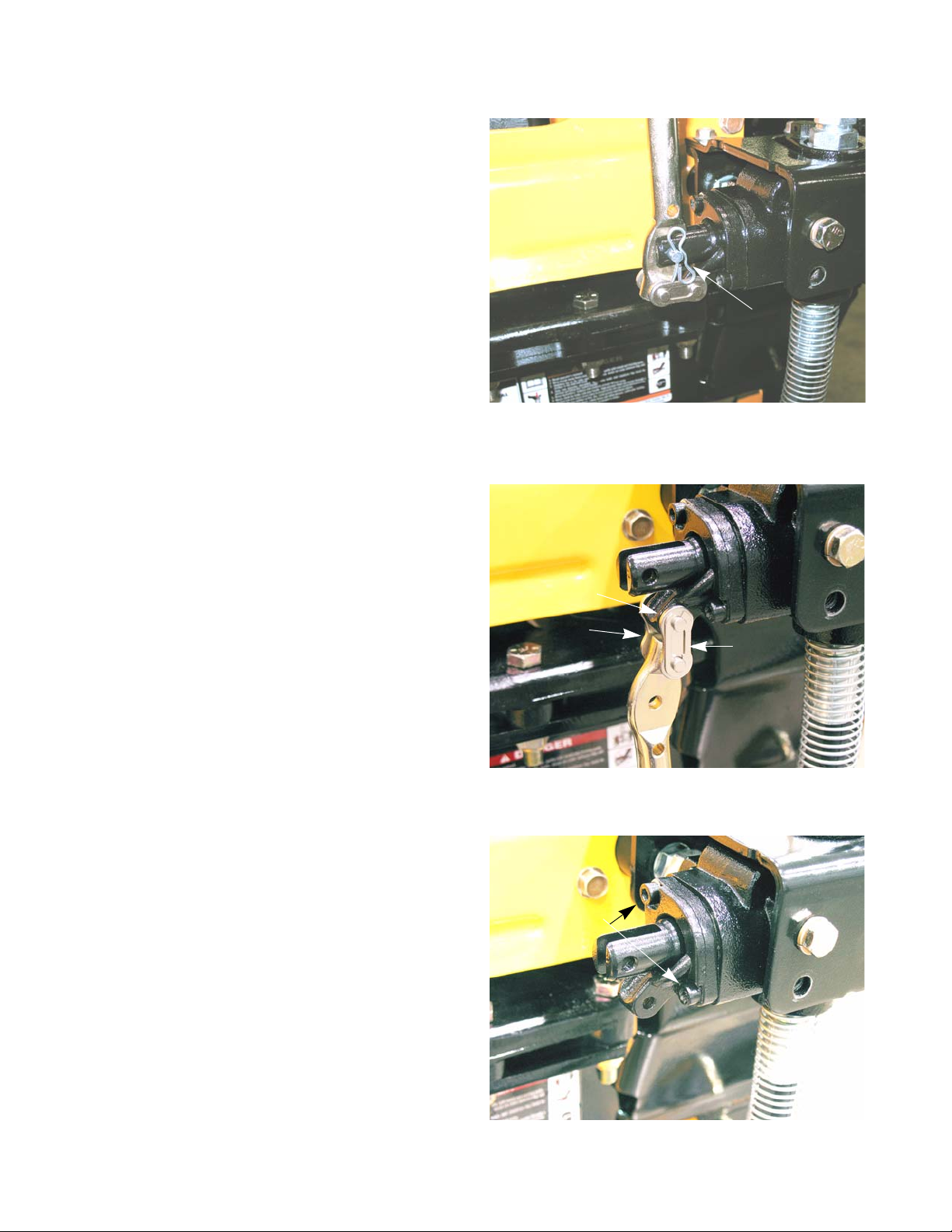

2. Remove the bowtie clip and the clevis pin.

See Figure 4.11.

3. Slide the control lever out of the end of the spool

and let it hang down.

Bowtie clip

Figure 4.11

4. Remove the master link locking clip.

See Figure 4.12.

5. Remove the master link top plate.

6. Remove the master link and the control lever.

7. Remove both of the socket head cap screws that

hold the lever bracket to the valve using a 5 mm hex

key.

See Figure 4.13.

8. Remove the lever bracket.

9. Install the lever bracket by following the previous

steps in reverse order.

Master link

top plate

Master link

Socket headed

cap screws

Locking clip

Figure 4.12

NOTE: Apply a small amount of releasable thread

locking compound such as Loctite® 242

(blue) to the threads of the socket headed

cap screws.and tighten the screws to a

torque of 70 - 90 in lbs (8 - 10 Nm).

10. Test run the splitter in a safe area before returning it

to service.

36

Figure 4.13

Page 41

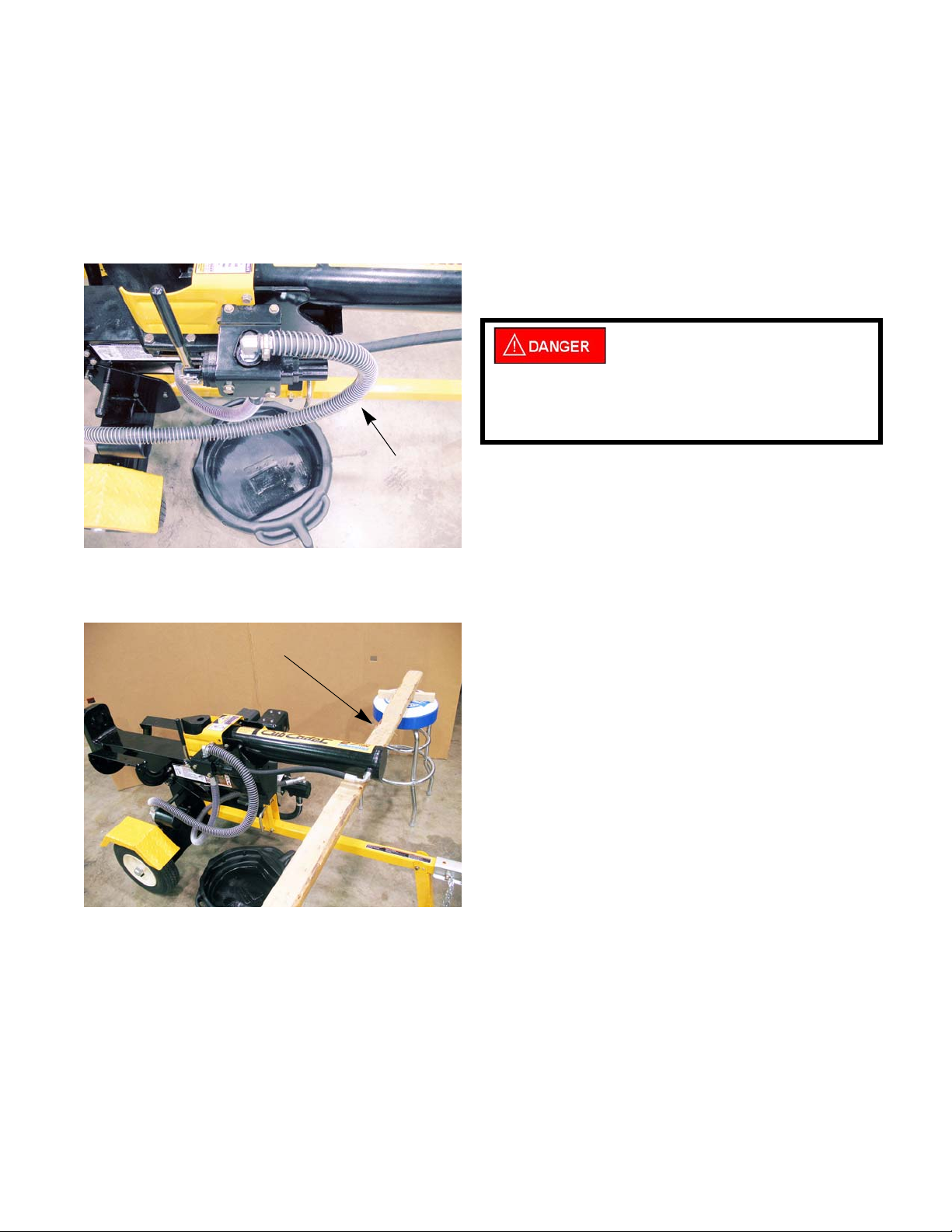

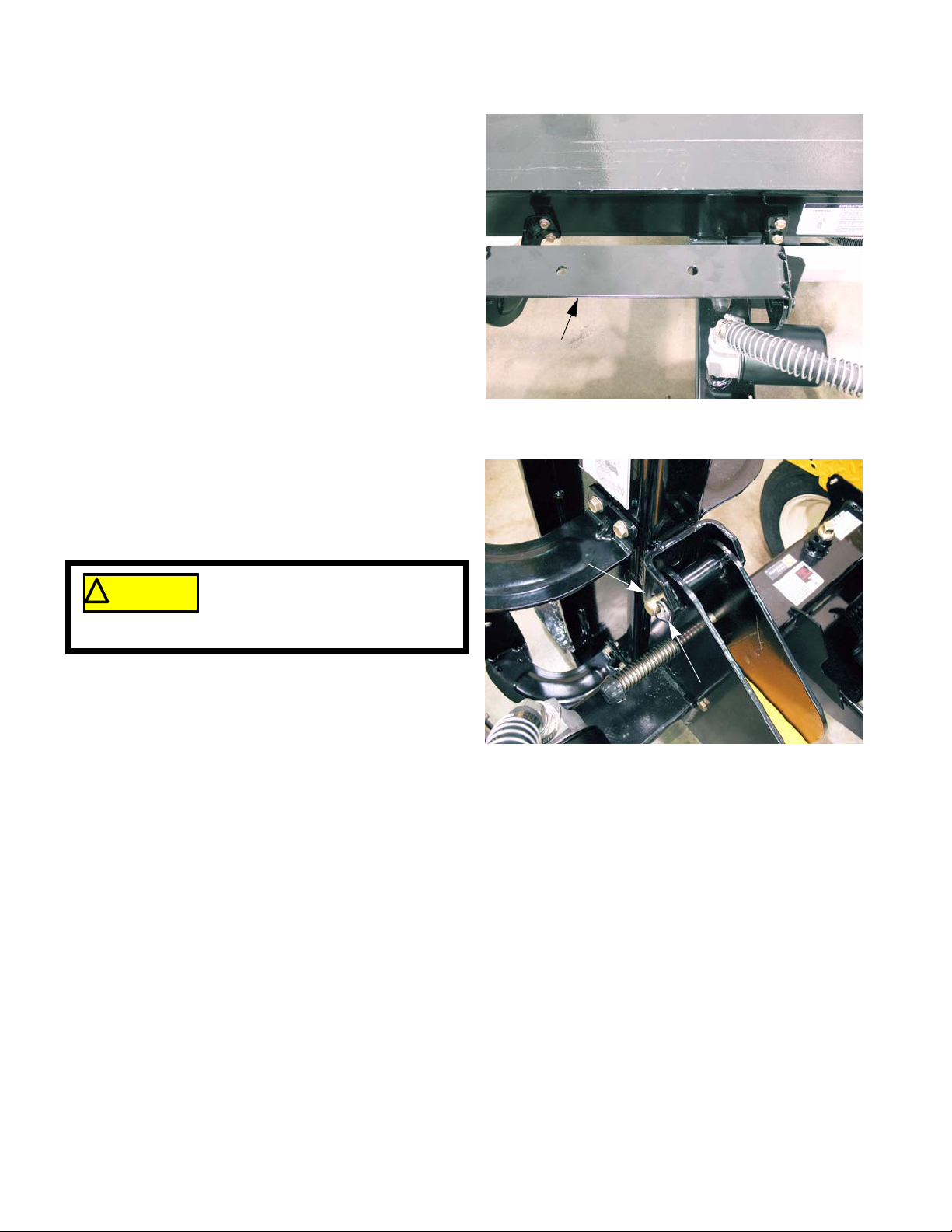

Cylinder removal

CYLINDER

CHAPTER 5: CYLINDER

To remove/replace the cylinder:

1. With the engine turned-off, relieve hydraulic pressure

from the system by moving the lever on the control

valve through it’s full range of travel.

Hydraulic fluid under high pressure

can be dangerous. A high-pressure

hydraulic fluid leak or spray can penetrate the skin. If this happens, seek immediate

medical attention to reduce the risk of blood poisoning leading to death or limb amputation.

low pressure

return line

Figure 5.1

2”x4” and stools used as a saw horse

2. Thoroughly clean all dirt and debris from around the

valve.

NOTE: Any dirt or debris that gets inside the valve can

destroy it.

3. Place a suitable container under the valve to catch

any fluid that will leak out as the hydraulic lines are

removed.

4. Place a saw horse or something similar under the

rear of the cylinder to support it.

5. Remove the control valve by following the procedures described in Chapter 4: Control Valve.

NOTE: The high pressure hose should be removed from

See Figure 5.1.

See Figure 5.2.

the base of the cylinder.

Figure 5.2

37

Page 42

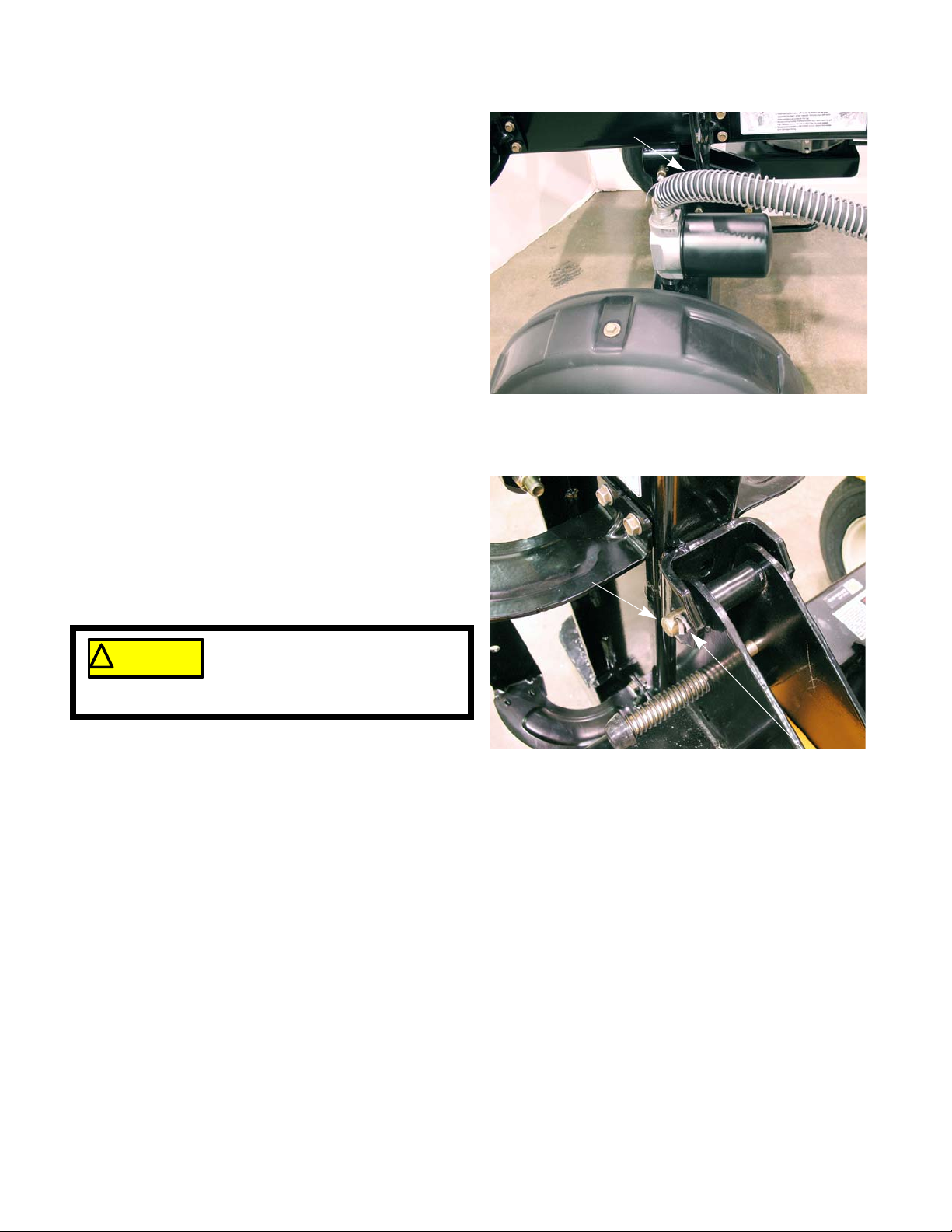

2010 Log Splitters

6. Remove the six screws that secure the log dislodger

to the beam using a 9/16” wrench.

7. Remove the nut and bolt that attach the wedge to

the cylinder ram using a pair of 3/4” wrenches.

8. Remove the cylinder from the log splitter.

9. Install the cylinder by following the previous steps in

reverse order.

NOTE: When tightening hoses with O-ring face fit-

tings, hold the hose so that the center part of

it does not rotate against the O-ring while the

swivel section is tightened. If the center part

rotates, the O-ring can be damaged and it

will leak under pressure.

See Figure 5.3.

Log dislodger

Figure 5.3

Wedge bolt

10. Fill the hydraulic reservoir.

11. Start the log splitter.

12. Cycle the ram 12 times to purge air from the hydraulic system.

13. Check hydraulic fluid level, fill as needed.

14. Test run the splitter in a safe area before returning it to service.

38

Figure 5.4

Page 43

CYLINDER

Cylinder rebuilding

The cylinder used on the MTD log splitter come from two different suppliers but have the same part number.

When replacing the whole cylinder, the two are interchangeable. However, when rebuilding the cylinder, the manu

facturer (type) of the cylinder must be identified so that the proper rebuild kit can be ordered. The cylinders are identified as E-type and X-type.

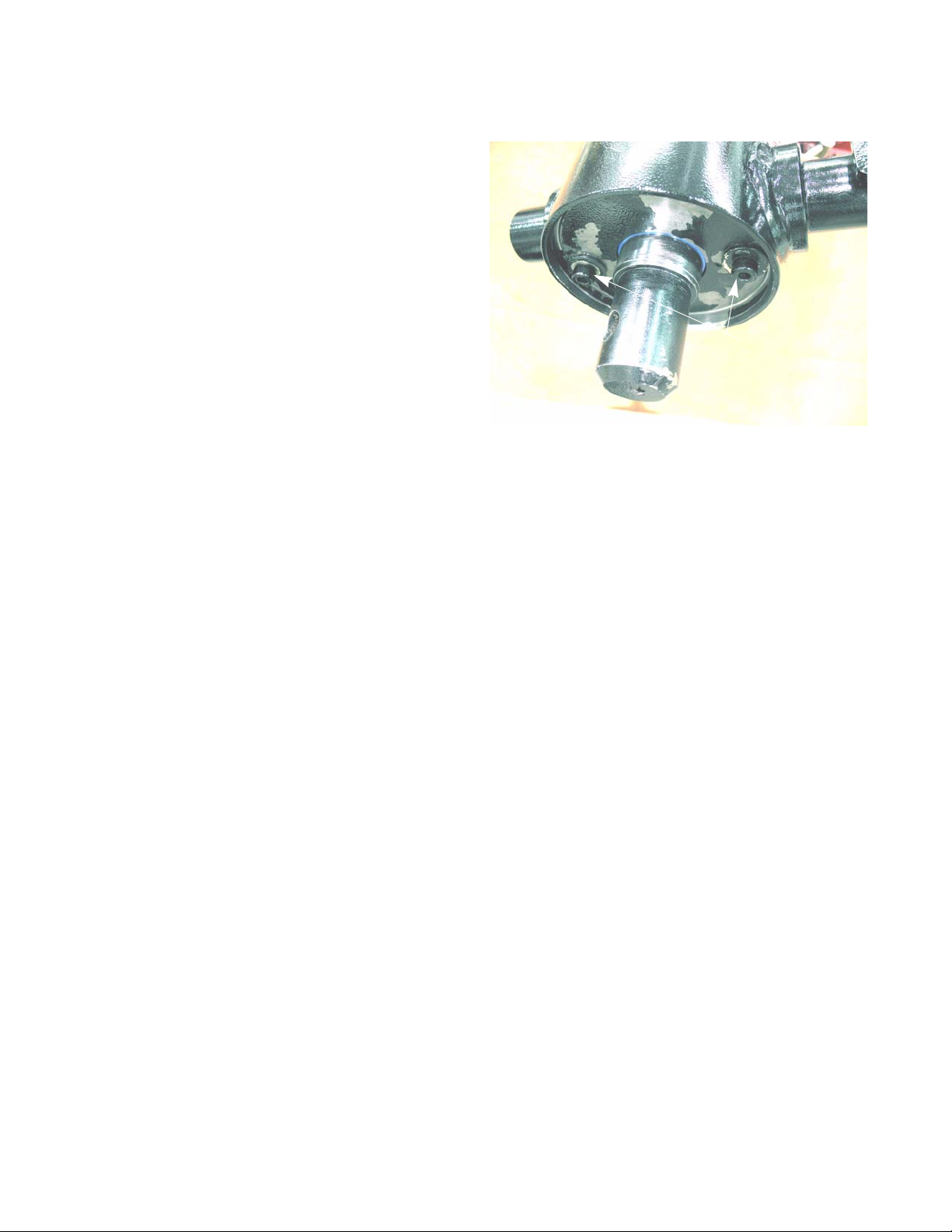

To identify the cylinder type:

The E-type cylinder:

• Uses socket headed screws with washers to hold

the rod guide against the retaining ring.

Socket headed screws

-

Figure 5.5

Hex headed screws

Figure 5.6

The X-type cylinder:

• Uses two hex headed screws with washers to hold

the rod guide against the retaining ring.

39

Page 44

2010 Log Splitters

To rebuild a cylinder:

The procedures to rebuild an “E-type” or an “X-type” cylinder are the same.

Hot hydraulic fluid can cause burns. Do not work on the cylinder until the hydraulic system has

cooled to ambient temperature after use.

Hydraulic fluid under high pressure can be dangerous. A high-pressure hydraulic fluid leak or

spray can penetrate the skin. If this happens, seek immediate medical attention to r educe the risk

of blood poisoning leading to death or limb amputation.

If a piece of hydraulic equipment develops a high pressure leak, turn it off immediately. Do not

operate it until the leak is repaired.

1. Clean the log splitter to prevent any dirt or debr is

from getting into the hydraulic system.

2. Block the wheels of the log splitter to prevent it from

moving.

NOTE: If there are hydraulic leaks or the possibility

3. St art the engine and cycle the control va lve until the

ram is fully extended.

4. Turn off the engine and allow the engine and the

hydraulic fluid to cool down.

5. Relieve hydraulic pressure from the system by moving the lever on the control valve through it’s full

range of travel.

6. Place a suitable 5 gallon bucket under the valve to

catch the hydraulic fluid from the cylinder and the

lines.

7. Disconnect the high pressure hose that goes to the

base of the cylinder from the control valve.

See Figure 5.7.

further damage to the cylinder, skip step 3.

See Figure 5.8.

Wheel chocks

Figure 5.7

NOTE: Route the hose into the bucket.

8. Disconnect the return hose from the oil filter housing.

NOTE: Route the hose into the bucket.

40

Return hose

High pressure

hose

Figure 5.8

Page 45

CYLINDER

Ratchet strap

Bungee cord

Figure 5.9

9. Wrap a ratchet strap around the wedge and the base

plate.

See Figure 5.9.

10. Hold the control valve in the extend position.

NOTE: A bungee cord can be used to hold the control

valve in the extend position.

11 . Tighten the ratchet strap until the ram is fully

extended.

12. Move the control valve to the retract position.

13. Wrap a heavy duty ratchet strap around the cylinder

and wedge.

14. Tighten the ratchet strap until the ram is fully

retracted.

See Figure 5.10.

See Figure 5.9.

Ratchet strap

Log dislodger

Figure 5.10

NOTE: Hydraulic fluid will be draining from the return hose

while the ram is retracting.

15. Remove the control valve by following the procedures described in Chapter 4: Control Valve.

16. Remove the six screws that secure the log dislodger

to the beam using a 9/16” wrench.

See Figure 5.11.

Figure 5.11

41

Page 46

2010 Log Splitters

17. Remove the nut and bolt that attached the wedge to

the cylinder ram using a pair of 3/4” wrenches.

See Figure 5.12.

18. Place the cylinder in a vise with padded jaws.

Wedge bolt

Figure 5.12

Rod guide

NOTE: DO NOT over tighten the vise. This can

deform the cylinder preventing the pist on

and rod removal.

19. Remove the two screws and washers that hold the

rod guide in place.

NOTE: There is thread locking compound on the

screws. It may be necessary to apply some

heat to the rod guide to release the screws.

20. Gently tap the rod guide into the cylinder using a

brass punch until it clears the retaining ring.

21. Remove the retaining ring. See Figur e 5.14.

NOTE: Be careful not to scratch any part of the cyl-

inder bore or the ram.

NOTE: A brass pick can be made out of a brazing

rod. It can be used to pry the retaining ring

out of the cylinder without damaging the cyl

inder or the ram.

See Figure 5.13.

Figure 5.13

Retaining ring

-

NOTE: There will be some residual fluid in the cylin-

der. Place some rags or paper towels under

the ram end of the cylinder to catch the fluid

that spills.

42

Figure 5.14

Page 47

Clean paint from the inside

edge of the cylinder

CYLINDER

22. Clean the paint from the inside edge of the cylinder.

See Figure 5.15.

NOTE: Paint on the inside edge of the cylinder can catch

the back-up ring, pulling it out of the grove and

wedging between the rod guide and the cylinder

wall.

23. Pull the ram out of the cylinder.

Do not use compressed air to force

the piston out of the log splitter bore.

Compressed air may eject the piston

with dangerous force.

NOTE: The piston will catch the rod guide and pull it out

with the ram.

Figure 5.15

Figure 5.16

Puller

NOTE: The piston and the rod guide may separate from

the cylinder quickly. Be prepared to support the

weight of the rod and the guide.

NOTE: Be careful not to mar the chromed surface of the

piston rod.

NOTE: If the rod guide will not come out of the cylinder:

• Push the ram all the way in.

• Attach a puller to the rod guide. See Figure 5.16.

• Gently pull the rod guide out.

NOTE: If a puller was needed to pull the rod guide out, the

outer O-ring and the back-up ring of the rod guide

are most likely destroyed.

24. Slide the rod guide to the end of the ram, opposite

the piston.

25. Support the ram in a vise with padded jaws.

26. Remove the rod guide.

NOTE: If there is paint on the end of the rod, it must be

removed before the rod guide can be removed.

NOTE: DO NOT remove the piston from the ram. The O-ring between the ram and the piston is not service-

able.

27. Inspect the cylinder and rod before proceeding:

27a. Inspect the shaft and piston to confirm that the cylinder is rebuildable.

NOTE: A bend or surface damage on the rod will make the cylinder unfeasible to rebuild.

27b. Inspect the cylinder bore for deformations and surface damage.

27c. Inspect the hydraulic fittings on the cylinder for damage.

27d. Inspect the cylinder for cracks around the fittings and welds. Magnaflux if in doubt.

43

Page 48

2010 Log Splitters

Int

l

28. Carefully pry the outer piston seal off of the piston.

See Figure 5.17.

29. Carefully pry the O-ring out of the groove in the piston.

30. Install a new O-ring and outer piston seal.

31. Carefully pry the back-up ring out of the groove in

the outside diameter of the rod guide.

32. Carefully pry the O-ring seal out of the groove in the

outside diameter of the rod guide.

See Figure 5.18.

Outer seal

O-ring

Figure 5.17

Back-up ring

33. Carefully pry the scraper out of the recess in the rod

guide.

34. Carefully pry the internal seal out of its recess in the

rod guide.

35. Compress the new seal and position it with the lip

facing away from the side of the rod guide that has

the screw holes, then let it expand into the groove

that it will ride in.

NOTE: Soaking the new scraper and seal in hot

36. Install the new scraper in the recess in the side of

the rod guide that has the screw holes.

NOTE: The scraper has an “L” shaped cross-sec-

44

See Figure 5.19.

water will make them more pliable.

tion. The leg of the L should face the screw

hole side of the rod guide.

O-ring

Figure 5.18

ernal sea

Scraper

Figure 5.19

Page 49

CYLINDER

Back-up ring

O-ring

Figure 5.20

39. Lubricate the piston with the same type of fluid that will be used in the hydraulic system of the log splitter: 10W

hydraulic fluid, or Dexron III automatic transmission fluid.

40. Insert the shaft and piston into the bore of the cylinder.

41. Lubricate the seals on the rod guide using the same type of fluid that will be used in the hydraulic system of the

log splitter.

42. Insert a protector sleeve through the seal and scraper to prevent damage during installation.

37. Install a new back-up ring in the g roove, positioned at

the edge of the groove that is closer to the side of the

rod guide that has the screw holes.

38. Install a new O-ring seal in the groove, next to the

back-up ring.

43. Slip the rod guide over the shaft and into the bore of the c ylin de r.

44. Use a length of 2” iron pipe (or similar driver) to drive the rod guide into the bore, p ast the gro ove that the wire

snap ring locks into.

45. Install the snap ring.

Pry points

Rod guide

Figure 5.21

46. Pull the shaft and piston up to the top of the bore, so

that the piston moves the rod guide back into place

against the snap ring.

47. Pull the shaft and piston up to the top of the bore, so

that the piston moves the rod guide back into place

against the snap ring.

NOTE: The bolts may be installed temporarily, for use as

pry-points.

See Figure 5.21.

45

Page 50

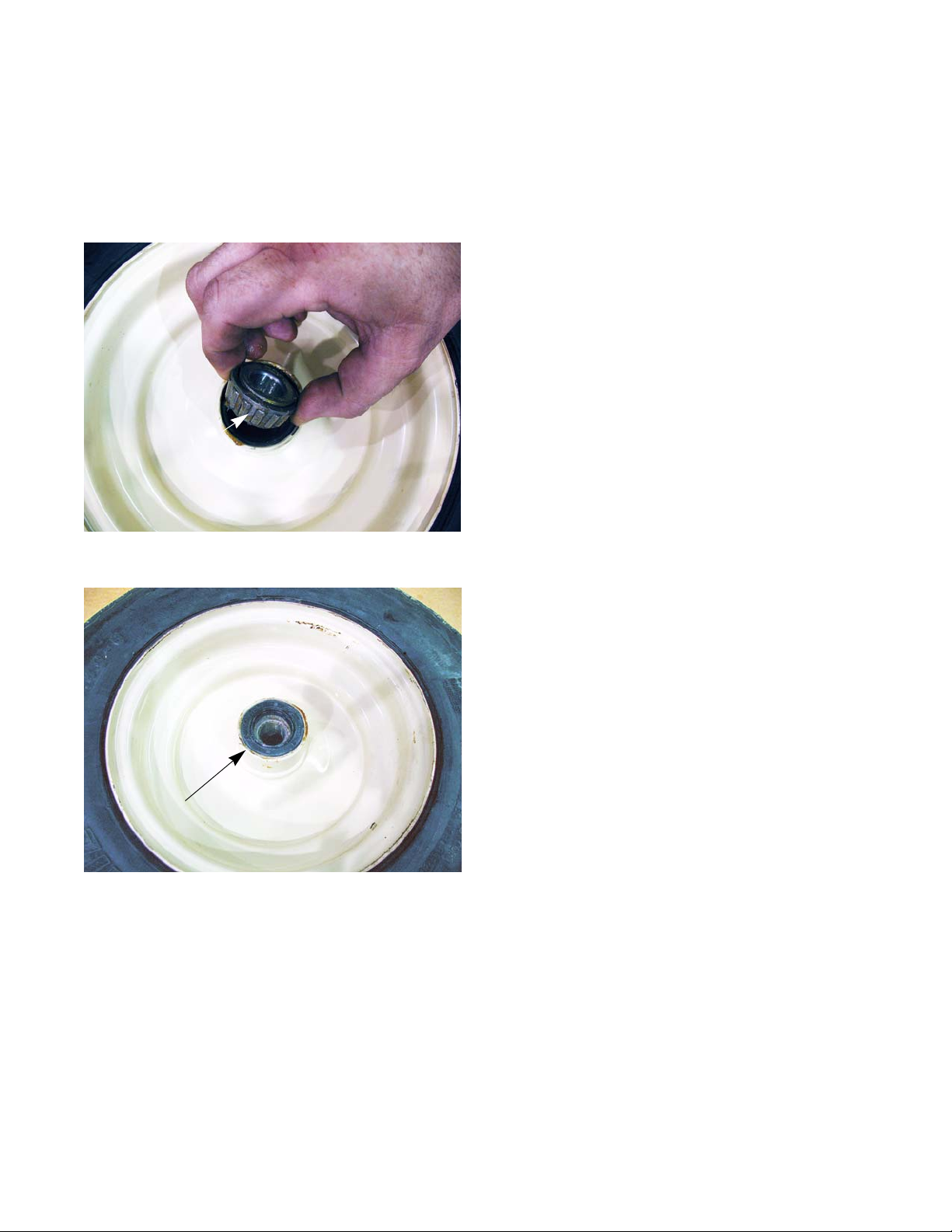

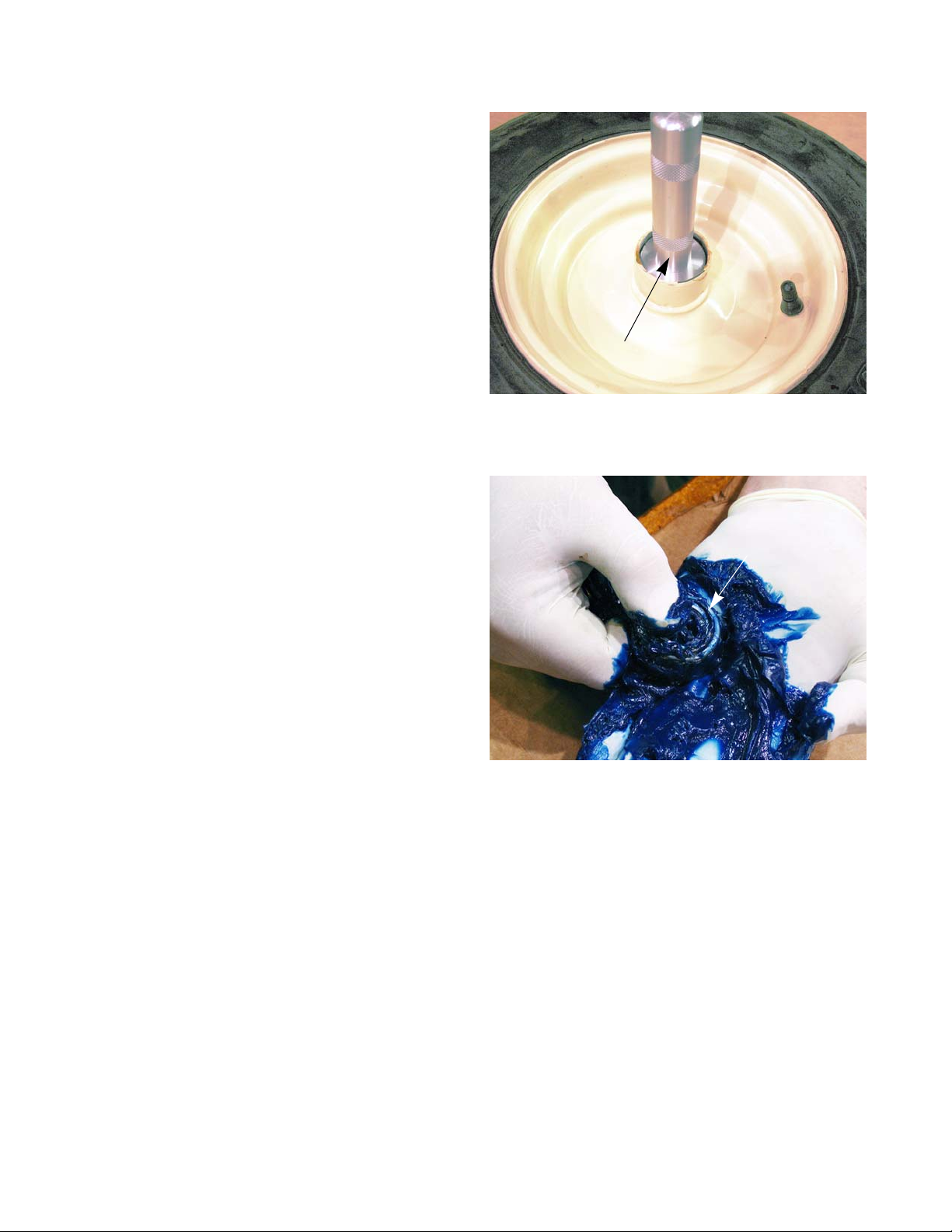

2010 Log Splitters