Page 1

Operator’s Manual

SERIES 5000

TRACTOR

MODEL 5252

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning

forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark

arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the

muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box

361131 Cleveland, Ohio 44136-0019.

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com]

PRINTED IN U.S.A. FORM NO. 769-00867I

: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

(7/06)

Page 2

TABLE OF CONTENTS

TO THE OWNER .................................................................................................................... 2

CALLING SERVICE INFORMATION ...................................................................................... 2

RECORDING MODEL AND SERIAL NUMBER INFORMATION ........................................... 3

IMPORTANT SAFE OPERATION PRACTICES ..................................................................... 4

SAFETY LABELS ................................................................................................................... 8

SECTION 1: CONTROLS AND FEATURES .......................................................................... 9

SECTION 2: OPERATION .................................................................................................... 14

SECTION 3: ADJUSTMENTS .............................................................................................. 23

SECTION 4: TRACTOR MAINTENANCE ............................................................................ 26

SECTION 5: ENGINE INFORMATION AND MAINTENANCE ............................................. 38

SECTION 6: MOWER DECK ................................................................................................ 43

SECTION 7: SPECIFICATIONS ........................................................................................... 52

SECTION 8: OPTIONAL EQUIPMENT AND ACCESSORIES ............................................. 54

WARRANTY STATEMENTS ................................................................................................ 55

TO THE OWNER

This Operator’s Manual is an important part of your new tractor. The information contained in this

manual has been prepared in detail to help you better understand the features, correct operation,

adjustments, and maintenance of your tractor. The performance and dependability of this tractor rely

greatly on the manner in which it is operated and maintained. Therefore, it is recommended that all

operators of the tractor carefully read this manual and fully understand its operation. Also keep the

manual available for reference to ensure proper operation, and that maintenance procedures are

performed as scheduled to assure the tractor’s optimal mechanical condition.

NOTE: All references to LEFT, RIGHT, FRONT, and REAR, unless specifically stated otherwise,

indicate that relative position on the tractor when facing forward while seated in the operator’s seat.

Your authorized Cub Cadet dealer is interested in the performance you receive from your tractor, and

with the maintenance needed to ensure the satisfactory operation of your tractor. The dealer has

trained service personnel familiar with the latest servicing information, is equipped with the latest

tools, and has a complete line of genuine Cub Cadet service parts which assure proper fit and high

quality.

CALLING SERVICE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance,

power-rating, and specifications.

If you have difficulties with the tractor and/or equipment; have any questions regarding the operation

or maintenance of this equipment; or desire additional information not found in this manual, contact

your dealer. If you need assistance in locating a dealer in your area, contact the Customer Dealer

Referral Line by calling:

1-877-282-8684

Or you may contact Cub Cadet via the internet by logging on to our Wed Site at:

www.cubcadet.com

Before contacting your dealer or Cub Cadet, make sure that you have your model number(s) and

manufacturing date(s) available.

2

Page 3

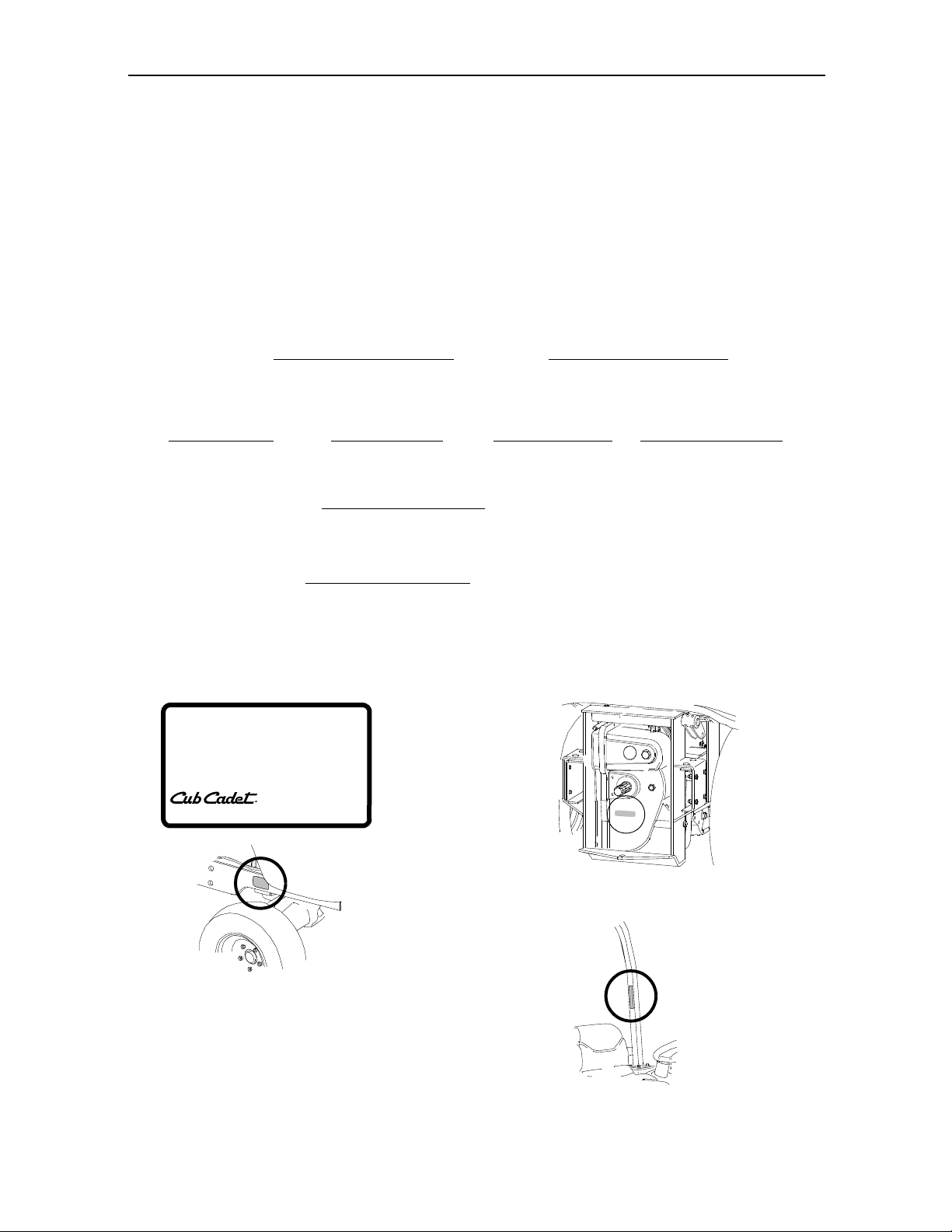

RECORDING MODEL AND SERIAL NUMBER INFORMATION

Product identification plates are provided for major components of your tractor. The numbers on these

plates are important if your tractor should require dealer service, or if you need additional information

on your tractor. Prior to using your tractor for the first time, record the numbers from the identification

plates in the appropriate spaces provided below.

• The tractor model plate is located on the right frame rail behind the right front tire.

• The engine information plate is located on the side of the blower housing at the front of the

engine.

• The transmission serial plate is located on the rear of the transmission, below the PTO shaft.

• The ROPS information plate is located on a vertical leg of the ROPS.

Tractor Model Plate:

Model Number Mfg. Date (Serial No.)

Engine Information:

Model No. Displacement Spec. No. Serial No.

Transmission Serial Plate:

Serial Number

ROPS Information Plate:

ROPS Serial No.

TRACTOR MODEL PLATE

XXXXXXXXXXX XXXXXXXXXX

Model Number Mfg. Date

CUB CADET LLC

P. O. BOX

www.cubcadet.com

DEALER LOCATOR PHONE NUMBER:

361131

CLEVELAND, OH 44136

877-282-8684

TRANSMISSION SERIAL PLATE

ROPS INFORMATION PLATE

3

Page 4

IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL,

HEED ITS WARNING.

WARNING: The engine exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer, birth defects or other

reproductive harm.

DANGER: Your tractor was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. To help prevent accidents, read and take the following precautions before

operating this tractor. Failure to observe the following safety instructions could result in serious

injury or death.

1. GENERAL OPERATION

• Read, understand, and follow all instructions in

the operator’s manual and on the machine

before starting. Keep this manual in a safe

place for future and regular reference.

• Only allow responsible individuals familiar with

the instructions to operate the machine. All

operators should evaluate their ability to operate the tractor safely enough to protect

themselves and others from serious injury.

Know controls and how to stop the machine

quickly.

• Do not put hands or feet under the cutting deck

or near rotating parts.

• Clear the area of objects such as rocks, toys,

wire, etc. which could be picked up and thrown

by the blades. A small object may have been

overlooked and could be accidentally thrown by

the mower in any direction and cause injury to

you or a bystander. To help avoid a thrown

objects injury, keep children, animals,

bystanders and helpers at least 75 feet from

the mower while it is in operation. Always wear

safety glasses with side shields or safety

goggles during operation or while performing

an adjustment or repair, to protect eyes from

foreign objects. Stop the blades when crossing

gravel drives, walks or roads.

• Be sure the area is clear of other people before

mowing. Stop machine if anyone enters the

area.

• Never carry passengers.

• Use extreme caution when shifting into reverse

and backing up. Always look down and behind

before and while backing.

• Be aware of the mower and attachment

discharge direction and do not point it at

anyone. Do not operate the mower without

either the entire grass catcher or the chute

guard in place.

• Slow down before turning. Operate the

machine smoothly. Avoid erratic operation and

excessive speed.

• Never leave a running machine unattended.

Always turn off the blades, place the

transmission in neutral, set the parking brake,

stop the engine and remove key before

dismounting.

• Turn off blades when not mowing.

• Stop the engine and wait until the blades come

to a complete stop before (a) removing the

grass catcher or unclogging chute, or (b)

making any repairs, adjusting or removing any

grass or debris.

• Mow only in daylight or good artificial light.

• Do not operate the machine while under the

influence of alcohol or drugs.

• Use extra care when loading or unloading the

machine into a trailer or truck because the unit

could tip over causing serious personal injury.

• Never make a cutting height adjustment while

the engine is running if the operator must

dismount to do so.

• Wear sturdy, rough-soled work shoes and

close-fitting slacks and shirts. Do not wear

loose fitting clothes or jewelry. They can be

caught in moving parts. Never operate a unit in

bare feet, sandals or sneakers.

4

Page 5

• Disengage all attachment clutches, thoroughly

depress the brake pedal and shift into neutral

before attempting to start the engine.

• Your mower is designed to cut normal

residential grass of a height no more than 10”.

Do not attempt to mow through unusually tall,

dry grass (e.g. pasture) or piles of dry leaves.

Debris may build up on the mower deck or

contact the engine exhaust presenting a

potential fire hazard.

• Use only accessories approved for this

machine by Cub Cadet. Read, understand and

follow all instructions provided with the

approved accessory.

• Use the roll bar and seat belt for safe operation.

Overturning the tractor without a roll bar, or with

a roll bar and the seat belt unfastened, can

result in death or injury.

• Always use the seat belt, except when the roll

bar is in the folded position, or if the roll bar has

been removed.

• Use the handholds and running boards when

getting on and off the tractor to help prevent

accidental falls. Keep the running boards clear

of mud and debris.

• Keep all safety decals clean and readable.

Replace any missing, illegible, or damaged

safety decals.

• Always sit in the tractor seat when starting the

engine or operating controls. Do not start the

engine or operate controls while standing

beside the tractor.

• Never tamper with safety devices. Check their

proper operation regularly. Contact your Cub

Cadet dealer if safety devices malfunction.

• Avoid accidental contact with control pedals

while the engine is running, as this can cause

unexpected movement of the tractor.

• Pull only from a drawbar or the lower hitch links

in the down position. Make certain the drawbar

pin is locked in place. Pulling from the rear axle

of the tractor or any point above the axle could

cause the tractor to overturn.

• Maintain the weight balance of the tractor.

Install front end weights to counterbalance

heavy implements attached to the three point

hitch. Do not operate the tractor with a light

front end.

• Do not leave equipment in the raised position.

• Watch for traffic when operating near or

crossing roadways. If local laws permit road

travel, use the flashing hazard lights and SMV

signs when traveling on public roadways.

• Make certain all tractor lights are illuminated

when operating at night.

• Check overhead clearance carefully before

driving under power lines, wires, bridges or low

hanging tree branches, before entering or

leaving buildings, or in any other situation

where the operator and/or roll bar may be

struck, which could result in serious injury.

• If the tractor becomes stuck, use reverse to

free the tractor to prevent tractor upset.

2. SLOPE OPERATION

Slopes are a major factor related to loss of control

and tip-over accidents which can result in severe

injury or death. All slopes require extra caution. If

you cannot back up the slope or if you feel uneasy

on it, do not operate this unit on that area or serious

injury could result.

Do not operate on inclines with a slope in excess of

15 degrees (a rise of approximately 2-1/2 feet every

10 feet). The tractor could overturn and cause

serious injury

DO:

• Operate up and down slopes, not across.

• Remove obstacles such as rocks, limbs, etc.

• Watch for holes, ruts or bumps. Uneven terrain

could overturn the machine. Tall grass can hide

such obstacles.

• Place the transmission in the low range. when

climbing or descending slopes. Always keep

machine in gear when going down slopes to

take advantage of engine braking action.

• Follow the manufacturers recommendations for

counterweights to improve stability.

• Keep all movement on the slopes slow and

gradual. Do not make sudden changes in

speed or direction. Rapid engagement or

braking could cause the front of the machine to

lift and rapidly flip over backwards which could

cause serious injury.

• Avoid starting or stopping on a slope. If tires

lose traction, disengage the PTO and proceed

slowly straight down the slope.

DO NOT:

• Do not turn on slopes unless necessary; then,

turn slowly and gradually downhill, if possible.

• Do not mow near drop-offs, ditches or

embankments. The mower could suddenly turn

over if a wheel goes over the edge of a cliff or

ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction

could cause sliding.

• Do not try to stabilize the machine by putting

your foot on the ground.

5

Page 6

3. CHILDREN

• Tragic accidents can occur if the operator is not

alert to the presence of children. Children are

often attracted to the machine. Never assume

children will remain where you last saw them.

• Keep children out of the mowing area and in

watchful care of an adult other than the

operator.

• To avoid back-over accidents, always disengage the cutting blades before shifting in

reverse. The "PTO Reverse Override Switch"

should not be used when children or others

are around.

• Be alert and turn machine off if children enter

the area.

• Before and when backing, look behind and

down for small children.

• Never carry children, even with the blades off.

They may fall off and be seriously injured or

interfere with safe machine operation.

• Never allow children under 14 years old to

operate the machine. Children 14 years and

over should only operate machine under close

parental supervision and proper instruction.

• Use extra care when approaching blind

corners, shrubs, trees or other objects that may

obscure your vision of a child or other hazard.

• Remove key when machine is unattended to

prevent unauthorized operation.

4. OPERATING THE PTO

• When operating PTO driven equipment,

disengage the PTO, stop the engine, and wait

until the PTO stops before dismounting the

tractor and disconnecting the equipment.

• Do not wear loose fitting clothing when

operating the PTO or when near rotating

equipment.

• To prevent injury, do not adjust, unclog, clean,

or service PTO driven equipment while the

tractor engine is running.

• Make certain all PTO shields are always installed.

5. SAFETY FRAME (ROPS)

Your tractor is equipped with a rollover protective

structure (ROPS) which must be maintained in a

fully functional condition. Use care when driving

through doorways or spaces with a low overhead.

• Never modify the ROPS in any way.

• Never attempt to straighten or reweld any part

of the main frame or retaining brackets that

have been damaged. Doing so may weaken

the structure and endanger your safety.

• Never secure any parts on the main frame or

attach the safety frame with anything other than

the special fasteners specified.

• Never attach ropes, chains, or cables to the

ROPS for pulling purposes.

• Although the ROPS provides you the maximum

protection possible, never take unnecessary risks.

6. SERVICE

• Use extreme care in handling gasoline and

other fuels. They are extremely flammable and

the vapors are explosive. Use only an approved

container.

a. Use only an approved container.

b. Never remove fuel cap or add fuel with the

engine running. Allow the engine to cool at

least two minutes before refueling.

c. Replace the fuel cap securely and wipe off

any spilled fuel before starting the engine as

it may cause a fire or explosion.

d. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

e. Never refuel the machine indoors because

fuel vapors will accumulate in the area.

f. Never store the fuel container or machine in-

side where there is an open flame or spark,

such as a gas hot water heater, space heater or furnace.

• Escaping hydraulic fluid under pressure can

penetrate the skin. If fluid is injected into the

skin, seek immediate medical attention. Do not

use your hand to check for leaks. Use a piece

of cardboard or paper.

• Never run a machine inside a closed area.

• To reduce fire hazard, keep the tractor free of

any debris build-up. Clean up oil or fuel spillage.

• Before cleaning, repairing or inspecting, make

certain the blades and all moving parts have

stopped.

• Check the blade fasteners at frequent intervals

for proper tightness. Also visually inspect

blades for damage (e.g., excessive wear, bent,

cracked). Replace with blades which meet

original equipment specifications.

6

Page 7

• Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

• Never tamper with safety devices. Check their

proper operation regularly.

• After striking a foreign object, stop the engine,

and thoroughly inspect the mower for any

damage. Repair the damage before restarting

and operating the mower.

• Mower blades are sharp and can cut. Wrap the

blades or wear gloves, and use extra caution

when servicing blades.

• Check brake operation frequently. Adjust and

service as required.

• Engine components become hot during

operation and can cause a burn. Allow to cool

down before touching.

• Do not change the engine governor settings or

overspeed the engine. Excessive engine

speeds are dangerous.

• Observe proper disposal laws and regulations.

Improper disposal of fluids and materials can

harm the environment and the ecology.

• Prior to disposal, determine the proper method

to dispose of waste from your local

Environmental Protection Agency. Recycling

centers are established to properly dispose of

materials in an environmentally safe fashion.

• Use proper containers when draining fluids. Do

not use food or beverage containers that may

mislead someone into drinking from them.

Properly dispose of the containers immediately

following the draining of fluids.

• DO NOT pour oil or other fluids into the ground,

down a drain or into a stream, pond, lake or

other body of water. Observe Environmental

Protection Agency regulations when disposing

of oil, fuel, coolant, brake fluid, filters, batteries,

tires and other harmful waste.

• We do not recommend the use of a pressure

washer or garden hose to clean your unit. They

may cause damage to electrical components;

spindles; pulleys; bearings; or the engine. The

use of water will result in shortened life and

reduce serviceability.

WARNING:

read, understand and follow the warnings and instructions in this manual and on the machine.

- YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

7

Page 8

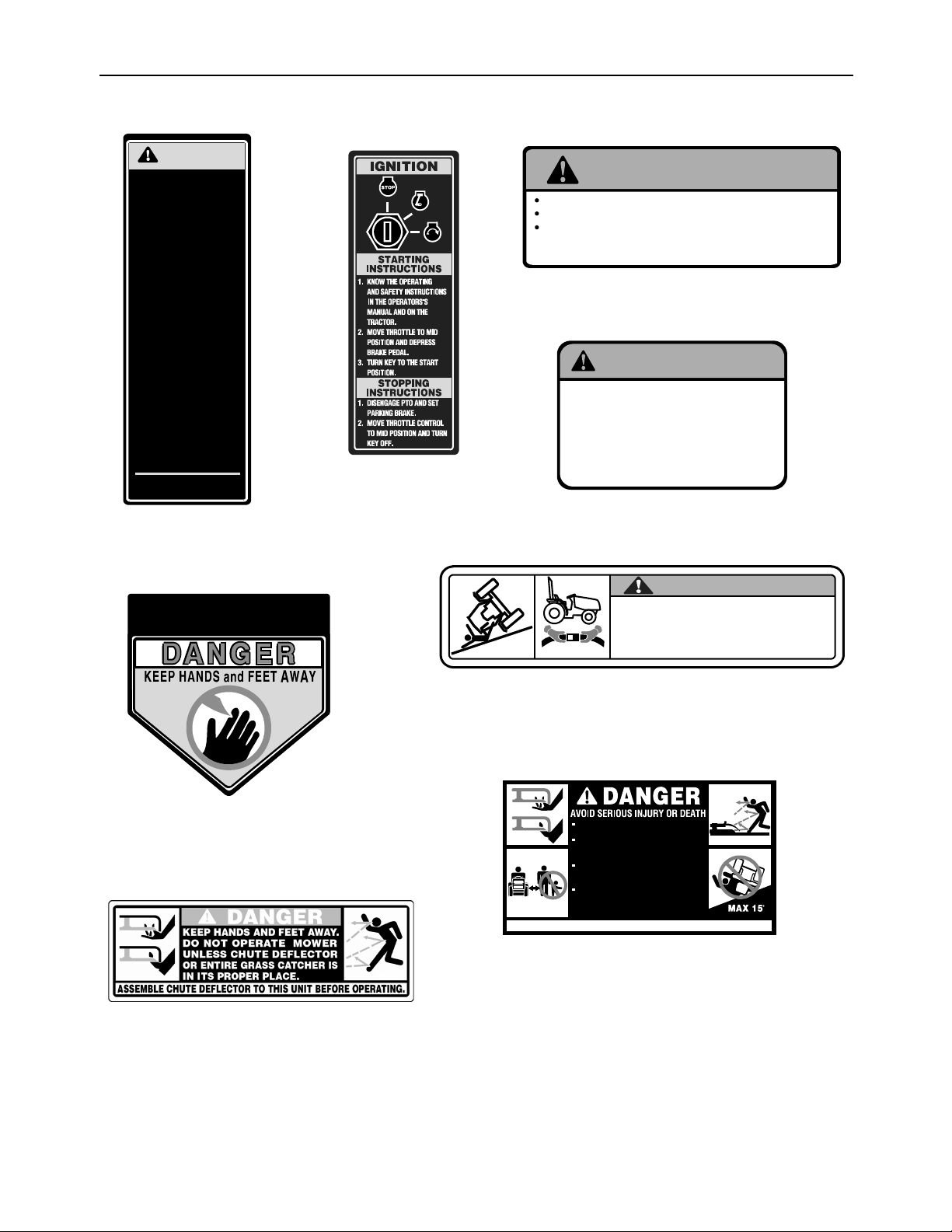

SAFETY LABELS

WARNING

AVO ID SERIOUS

INJURY OR DEATH

1.

GO UP AND DOWN SLOPES,

NOT ACROSS.

2.

AVOID SUDDEN TURNS.

3.

DO NOT OPERATE UNIT WHERE

IT COULD SLIP OR TIP.

IF MACHINE STOPS GOING

4.

UPHILL, STOP PTO AND BACK

DOWN HILL SLOWLY.

DO NOT MOW WHEN CHILDREN

5.

OR OTHERS ARE AROUND.

DO NOT ALLOW PASSENGERS

6.

ON THE TRACTOR AT ANY TIME.

LOOK DOWN AND BEHIND

7.

BEFORE AND WHILE BACKING.

KEEP SAFETY DEVICES

8.

[GUARDS, SHIELDS, AND

SWITCHES] IN PLACE AND

WORKING.

9.

REMOVE OBJECTS THAT

COULD BE THROWN BY

THE BLADES.

10.

KNOW LOCATION AND

FUNCTION OF ALL CONTROLS.

BE SURE THE BLADES AND THE

11.

ENGINE ARE STOPPED BEFORE

PLACING HANDS OR FEET NEAR

BLADES.

BEFORE LEAVING OPERATOR'S

12.

POSITION, DISENGAGE PTO,

ENGAGE BRAKE LOCK, SHUT

OFF ENGINE AND REMOVE KEY.

SLOW DOWN FOR TURNS,

13.

ROUGH GROUND AND SLOPES

TO AVOID UPSET.

14. ON PUBLI C ROADS USE SMV

EMBLEM AND HAZARD LIGHTS.

READ OPERATOR'S

MANUAL

INSTRUCTION-WARNING

LEFT RUNNING BOARD

DIE OUTLINE DOES NOT PRINT

INSTRUCTION LABEL

RIGHT RUNNING BOARD

WARNING

To avoid personal injury, keep PTO shield in place.

Pull only from draw bar. pulling from any other point can cause rear overturn.

Disengage PTO and stop engine before servicing tractor, or implements,

or attaching or detaching implements.

FAILURE TO FOLLOW ANY OF THE INSTRUCTIONS ABOVE CAN CAUSE

SERIOUS INJURY TO THE OPERATOR, OR OTHER PERSONS.

PTO WARNING LABEL

REAR PTO SHIELD

WARNING

BATTERIES CONTAIN ACID AND EXP LO SIV E GAS.

EXPLOSION CAN R ESULT FR OM SPAR KS, FLAM ES,

OR W R ONG CABL E CON NECTIO NS. TO CON NECT

JUM PER CABLES OR CHAR GER SEE M ANU AL FOR

CORRECT PROCEDURE. FAILURE TO FOLLOW THE

ABOVE IN STR UCT IONS CAN CAU SE SER IOUS

PERSONAL INJU RY OR DEATH .

BATTERY WARNING LABEL

LOCATED UNDER HOOD

TO REDUCE THE RISK OF INJU RY, DO NOT

OPERATE

UNLESS DISCHARGE COVER OR

GRASS CATCHER IS IN ITS PROPER PLACE.

DAMAGED, REPLACE IMMEDIATELY.

IF

HANDS/FEET SAFETY GRAPHIC

ON DEFLECTOR CHUTE

DEFLECTOR and SAFETY GRAPHIC –

LOCATED ON RIGHT SIDE OF DECK

WARNING

When improperly operated this tractor can

roll over or upset. Use of the ROPS and

seat belt minimize the possibility of injury

or death if roll over or upset occurs.

ROLL OVER WARNING LABEL

ON RIGHT/REAR FENDER

KEEP HANDS AND FEET AWAY FROM

ROTATING PA RTS

REMOVE OBJECTS THAT CAN BE

THROWN BY THE BLADE IN ANY

DIRECTION. WEAR SAFETY GLASSES.

DO NOT MOW WHEN CHILDREN OR

OTHERS ARE AOUND. NEVER CARRY

CHILDREN

USE EXTRA CAUTION ON SLOPES. DO

NOT MOW SLOPES GREATER THAN 15°.

MOW UP AND DOWN, NOT ACROSS

READ OPERATOR'S MANUAL. KEEP SAFETY DEVICES WORKING.

AVOID SUDDEN TURNS, USE LOW GEAR

SAFETY GRAPHIC – LOCATED ON

LEFT SIDE OF MOWER DECK

.

.

.

.

8

Page 9

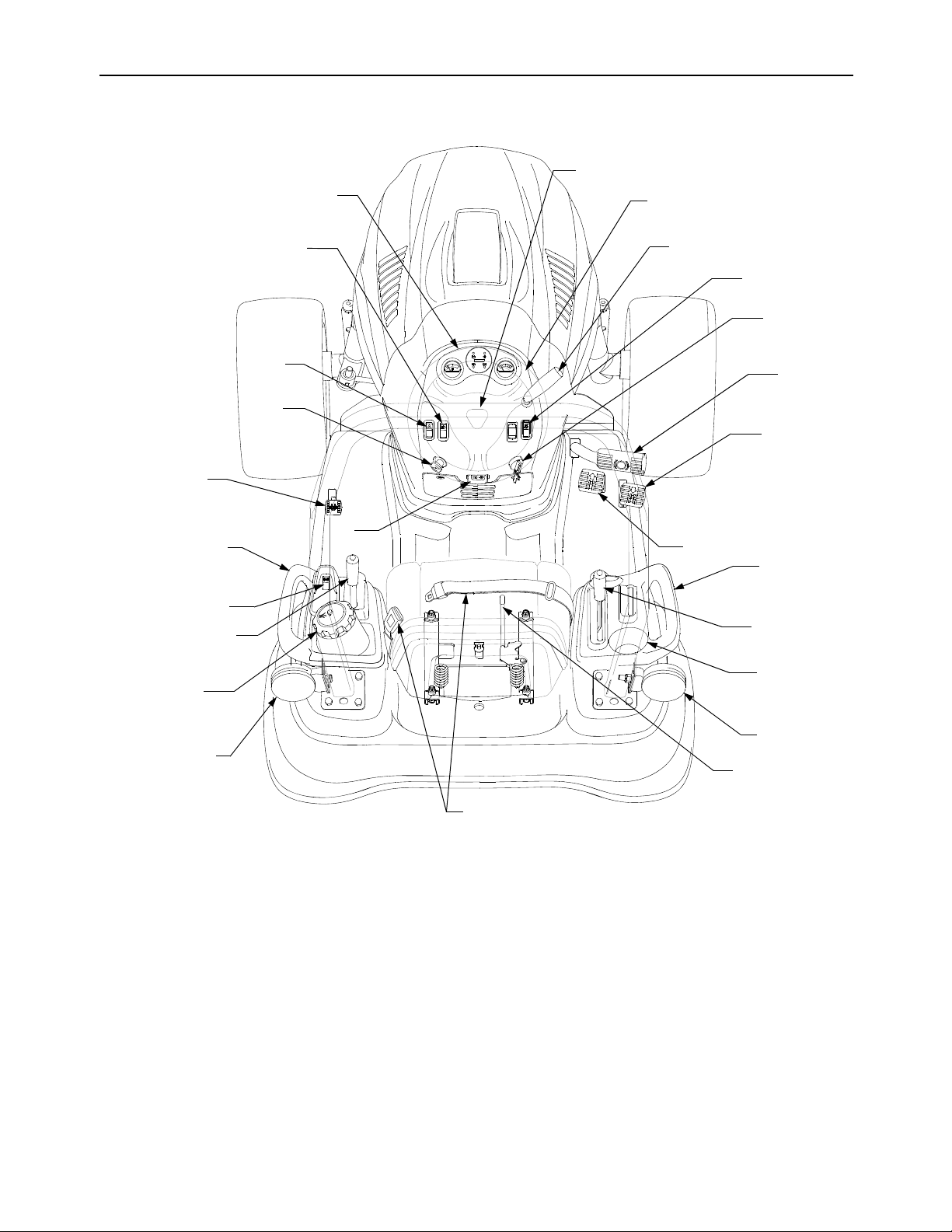

SECTION 1: CONTROLS AND FEATURES

X

W

A

V

B

C

D

HOURS 1/10

U

FUEL

EF

RPM

x10000

4

E

T

F

S

R

H

G

H

Q

P

J

K

O

L

A.

Throttle Handle

B.

PTO Switch

C.

Ignition Switch

D.

Brake Pedal

E.

Reverse Pedal

F.

G. Forward Pedal

* Steering Wheel, Seat, and ROPS Transparent for Clarity

N

Figure 1

H.Steering Wheel

Hand Holds

Hydraulic Lift Lever

J.

Cup Holder

K.

Amber Hazzard Light

L.

Seat Adjustment Lever

M.

Seat Belt

N.

O. Fuel Fill Cap

P. Trans. Hi/Lo Shift Lever

9

M

PTO Reverse Override Switch

Q.

Parking Brake Lever

R.

Differential Lock Pedal

S.

Choke Control Knob

T.

Hazzard Light Switch-If Equipped

U.

Headlight Switch

V.

ROPS (Fixed or Foldable)W.

Instrument Panel

X.

L

Page 10

NOTE: References to LEFT and RIGHT indicate

that side of the tractor when facing forward while

seated in the drivers seat. Reference to FRONT

indicates the grille end of the tractor; to REAR, the

tow plate end.

A. Steering Wheel

The steering wheel is centered on the dash panel,

and used to change the direction (left or right) of

the tractor while driving.

NOTE: This tractor is equipped with hydraulic

power steering. With this feature, the cap and

spokes of the steering wheel may change position.

B. Throttle Handle

This symbol indicates the

fast position.

This symbol indicates the

slow position.

The throttle handle is located to the right of the

steering wheel on the dash panel. When set in a

given position, a uniform engine speed will be

maintained. Rotate the handle rearward to increase

the engine speed.

C. PTO Switch

OFF

STOP

ON

START

Figure 3

OFF - The engine and electrical system is turned

off.

ON - The tractor electrical system is energized.

START- The starter motor will turn over the engine.

Release the key immediately when the

engine starts

E. Brake Pedal

Brake Pedal

Symbol

Figure 4

The brake pedal is located at the front of the right

running board above the forward and reverse

pedals. Depress to engage the tractor brakes and

neutralize the hydrostatic transmission. Fully

depress the brake pedal to activate the safety

interlock switch when starting the tractor.

PTO

Switch

Symbol

Figure 2

The PTO switch is a rocker type switch located to

the right of the steering wheel on the dash panel.

Push the top of the PTO switch downward to

engage the PTO. Push the bottom of the switch

downward to disengage.

D. Ignition Switch

NOTE: To prevent accidental starting and/or battery

discharge, remove the key from the ignition switch

when the tractor is not in use.

The ignition switch has three positions as follows:

F. Reverse Pedal

Reverse

Pedal

Symbol

Figure 5

The reverse control pedal is located on the right

running board below the brake pedal. Press the

pedal down to move in reverse.

WARNING: Check behind the tractor to

be sure the area is clear of people or

obstacles. Use a slower speed to

maintain control of the tractor when

traveling in reverse.

10

Page 11

G. Forward Pedal

Forward

Pedal

Symbol

Figure 6

The forward control pedal is located on the right

running board below the brake pedal. Slowly press

down on the pedal to start moving forward. The

forward ground speed of the tractor is directly

affected by the distance the pedal is depressed.

H. Hand Holds

Hand holds are built into both the left and right hand

fender covers. The handles can be used to assist in

mounting and dismounting the tractor.

J. Hydraulic Lift Lever

The hydraulic lift lever is located on the right fender.

This lever is used to raise and lower the three point

hitch lift arms.

• Move the lift lever fully rearward to raise the lift

arms.

• Move the lift lever forward to lower the lift arms.

• Move the lift lever fully forward and to the right

ahead of the float lock bracket to lock the lift in

the float position.

K. Cup Holder

The cup holder is located on the right fender.

L. Amber Hazard Lights

The hazard lights are located on each side of the

ROPS. The lights illuminate in a flashing mode

when the hazard light switch is turned on. Always

use the hazard lights when it is necessary to warn

others that the tractor is being operated in the area.

M. Seat Adjustment Lever

The seat adjustment lever is located at the right/

front of the seat. This lever is used to adjust the

seat forward or backward.

O. Fuel Fill Cap

The fuel fill cap is located on the left fender beside

the operator’s seat.

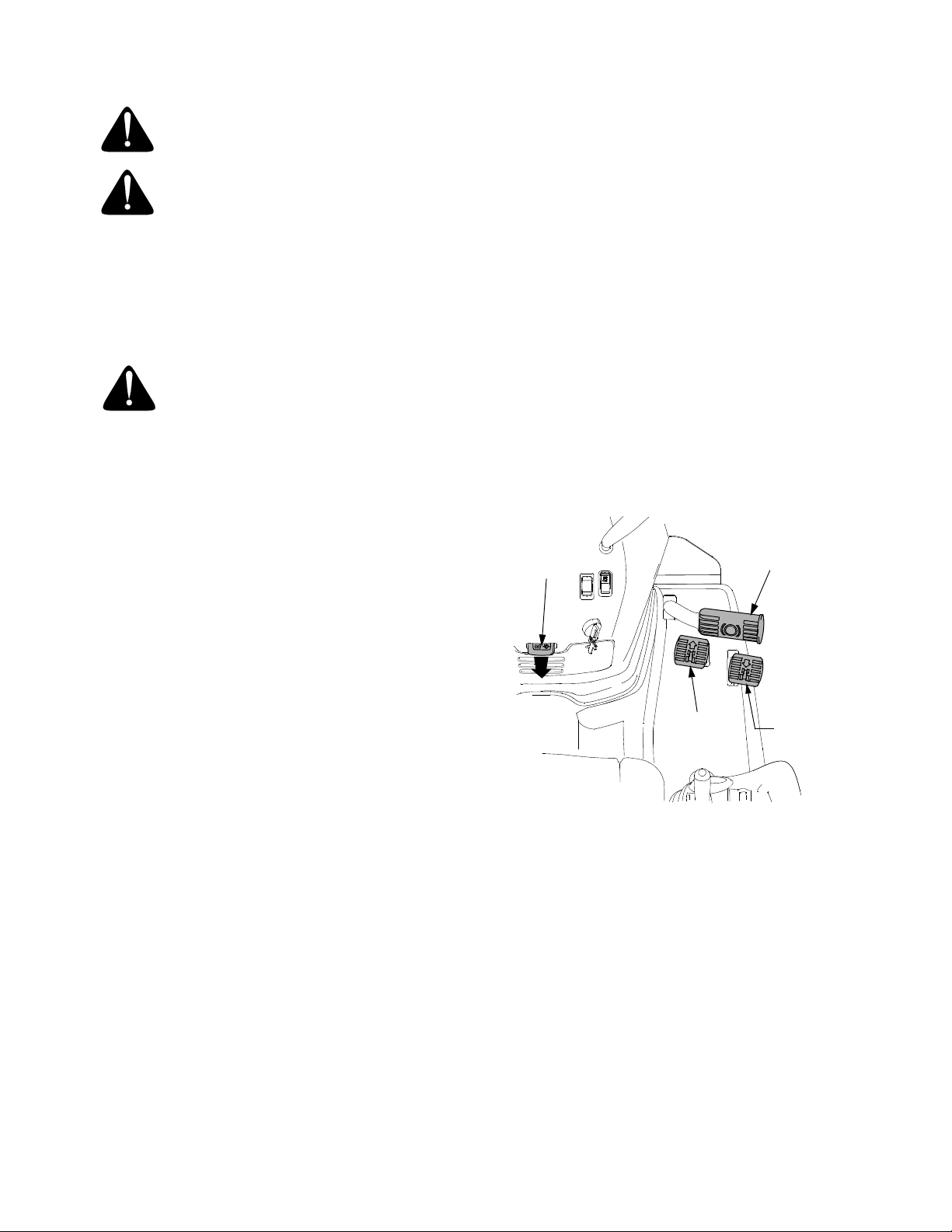

P. Transmission Hi/Lo Range Shift Lever

The Hi/Lo range shift lever is located on the left

fender. The lever has two speed range settings and

a neutral position. The lever must be shifted into

either the high or low range prior to depressing the

forward or reverse pedal to drive the tractor.

• Push the lever fully forward to shift into the high

range.

• Pull the lever fully rearward to shift into the low

range.

• Move the lever to the center position to shift

into the neutral position.

WARNING: Never attempt to shift the

Hi/Lo range lever when the tractor is in

motion.

Q. PTO Reverse Override Switch

The PTO reverse override switch is located on the

left fender. Depress the front of the switch to

engage the override which allows the PTO to

operate while the tractor is traveling in the reverse

direction. The indicator light in the override switch

will illuminate when the switch is depressed to the

"ENGAGED" position.

IMPORTANT: Once activated, this function remains

activated until the ignition switch is turned to the

OFF position for a duration of at least 20 seconds.

WARNING: Use EXTREME caution

when operating PTO driven attachments while traveling in the reverse

direction.

R. Parking Brake Lever

Parking

Brake

Symbol

N. Seat Belt

The seat belt, when properly adjusted and used in

conjunction with the Rollover Protective Structure

(ROPS), can greatly reduce the risk of serious

injury or death to the operator if an accidental

tractor overturn occurs.

WARNING: DO NOT use the seat belt if

the ROPS structure has been removed

from the tractor.

Figure 7

The parking brake lever is located below the

steering wheel in the dash panel. With the brake

pedal fully depressed, push the parking brake lever

downward and release the brake pedal to lock the

parking brake.

11

Page 12

S. Differential Lock Pedal

Diff. Lock

Pedal

Symbol

Figure 8

Located at the front of the left running board, the

differential lock pedal engages the transmission

differential lock.

The differential lock is used to gain additional traction when operating the tractor on wet or loose soil.

When the pedal is depressed the rear wheels of the

tractor are prevented from rotating independently of

one another.

WARNING: When operating with the

differential lock engaged, the tractor

will be difficult to steer. Do not drive

the tractor on roadways or at high

speeds with the differential lock

engaged.

U. Hazard Light Switch—If Equipped

Figure 10

The hazard light switch is a rocker type switch

located to the left of the steering wheel on the dash

panel. Push the top of the hazard light switch

downward to activate the flashing amber lights.

WARNING: Always activate the flashing hazard lights when operating the

tractor on, or near, roadways.

V. Headlight Switch

Headlight

Switch

Symbol

NOTE: Disengagement of the differential lock is

recommended prior to turning the tractor on grass

or other maintained surfaces — tire damage to the

turf could occur.

T. Choke Control Knob

The choke knob controls the position of the engine

choke. Pull the knob out to choke the engine; push

the knob in to open the choke.

Choke

Knob

Figure 9

Figure 11

The headlight switch is a rocker type switch located

to the left of the steering wheel on the dash panel.

Push the top of the headlight switch downward to

turn on the headlights and instrument panel gauge

lights.

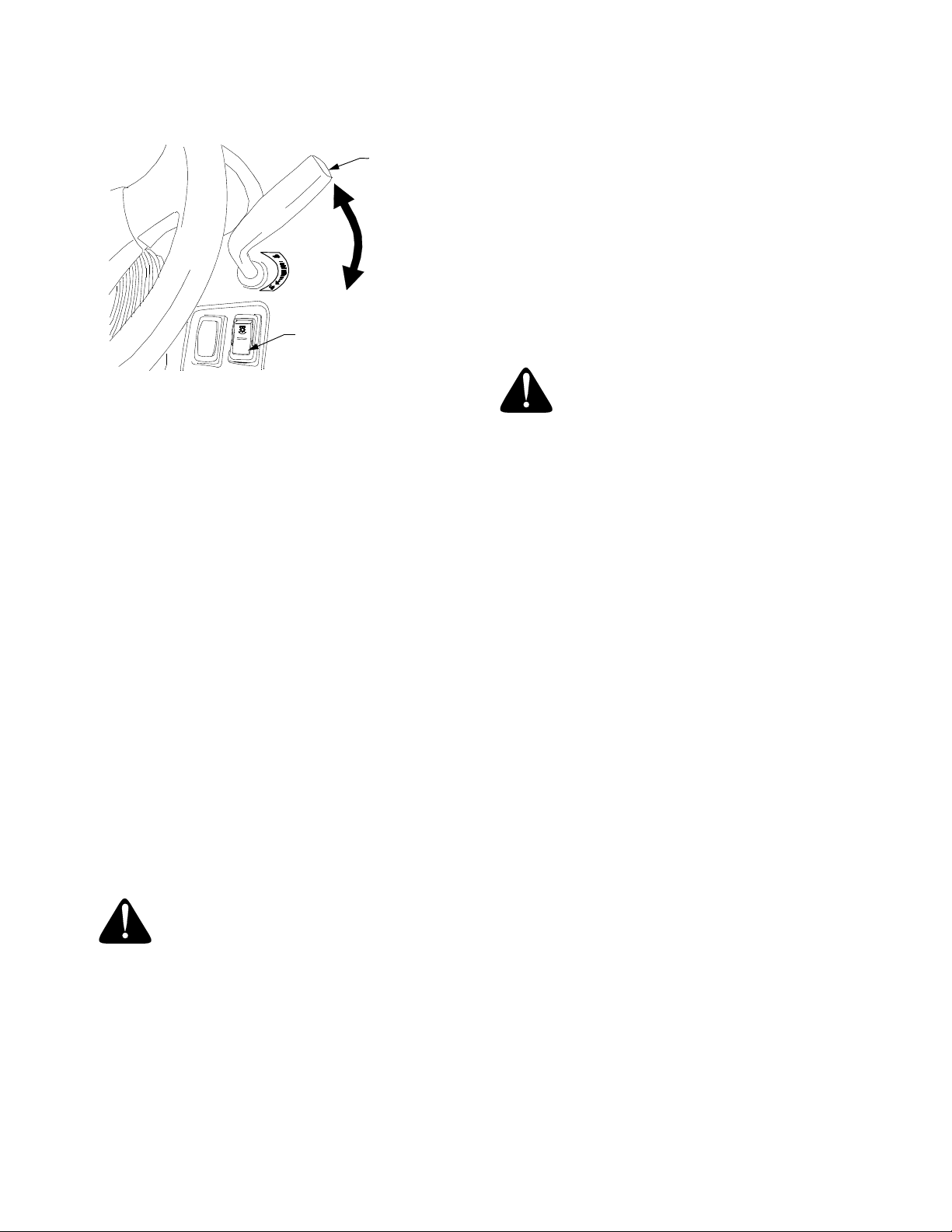

W. ROPS (Rollover Protective Structure)

The ROPS is installed to prevent or reduce injuries

to the operator should the tractor accidentally

overturn. The protection provided by the ROPS is

minimized if the seat belt is not used. For those

models equipped with a foldable ROPS - this

feature allows the ROPS to be lowered when

operating in areas with low overhead clearance.

12

Page 13

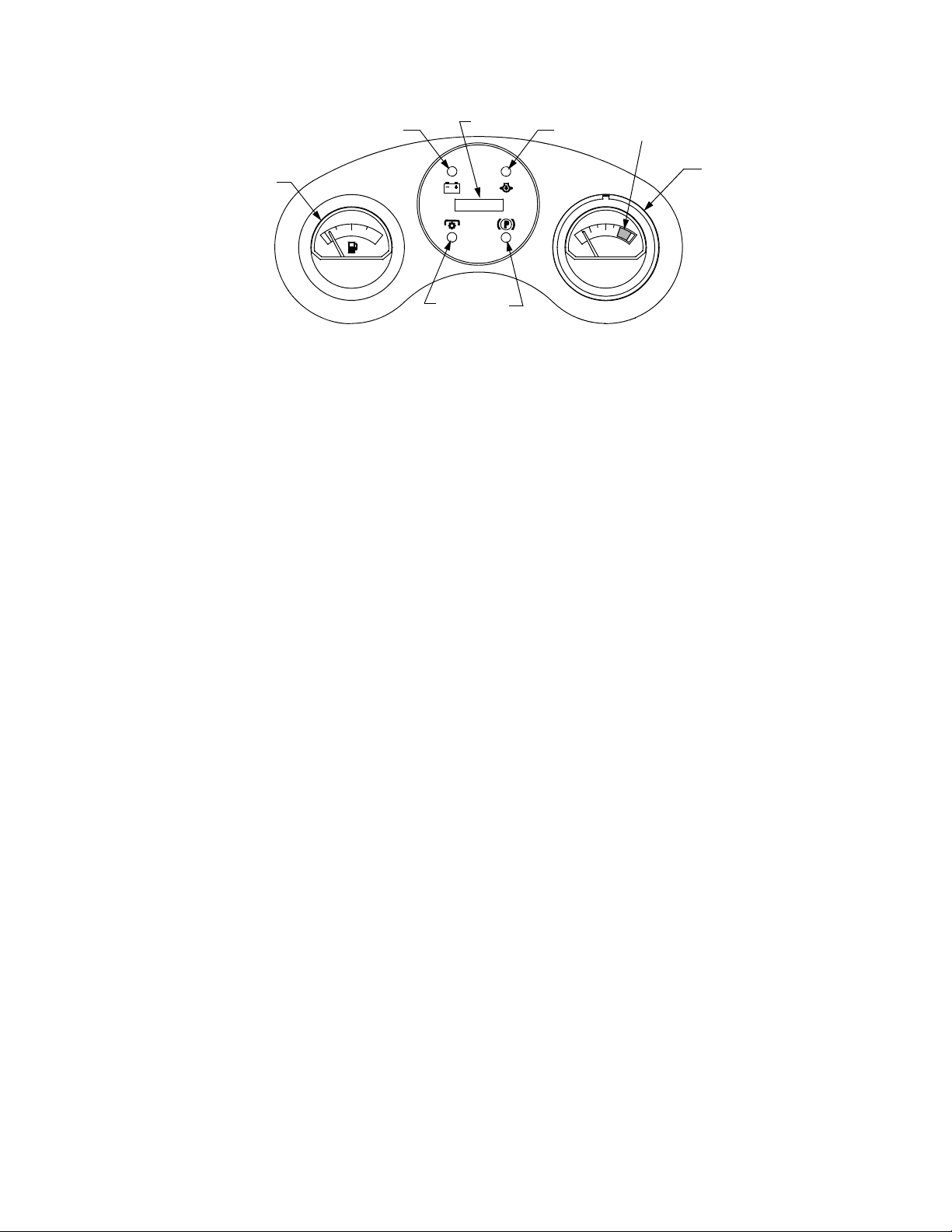

X. Instrument Panel

3

1

FUEL

EF

5

Figure 12

1. Fuel Gauge

The fuel gauge monitors the fuel level in the fuel

tank. The needle pointing to the right indicates a full

tank. The ignition switch must be in the ON position

to activate the fuel gauge.

2. Tachometer

The tachometer shows the engine speed in revolutions per minute (RPM). Optimal engine operating

speed is approximately 3400-3600 RPM. When

operating PTO driven attachments the RPM indicator needle must be within the green range on the

tachometer dial.

3. Battery Indicator Light

• Bulb illuminates and battery voltage is displayed

briefly when the ignition switch it turned to the

"ON" position.

• Illuminates to indicate the battery voltage has

dropped below 11.5 (+0.5/-1.0) DC volts. The

battery voltage is also displayed on the hour

meter. If this indicator and display come on

during operation, check the battery and charging

system for possible causes and/or contact your

Cub Cadet dealer.

4. Oil Pressure Indicator

This warning lamp indicates low engine oil pressure.

If this indicator illuminates, stop the tractor

immediately and check the engine oil level. If the oil

level is within the operating range, but the light

remains on, contact your Cub Cadet dealer. NOTE:

The oil pressure indicator may illuminate when the

key switch is turned to the on position, but should

turn off when the engine is started.

7

HOURS 1/10

4

04

6

Green

Range

2

RPM

x1000

5. PTO Engaged Indicator

This indicator illuminates whenever the PTO switch

is pulled upward in the "ENGAGED" position while

the key switch is turned to the "ON" position. Check

this indicator if the engine will not crank with the key

switch in the "START" position— the indicator should

not be illuminated. If necessary, move the PTO

switch to the "DISENGAGED" position.

6. Brake Engaged Indicator

This indicator illuminates whenever the brake pedal

is fully depressed or the parking brake is engaged

and the key switch is turned to the "ON" position.

Check this indicator if the engine will not crank when

the key switch is turned to the "START" position —

the indicator should be illuminated. If necessary,

fully depress the brake pedal.

7. Hour Meter/Battery Display

The hour meter records the hours and tenths of an

hour (right most digit) that the tractor has been

operated.

• The hour meter is activated when the key switch

is turned to the “ON” switch position. Because

the key switch may be accidentally left in the

"ON" position, a record of the actual hours of

operation should be kept to assure maintenance procedures are completed according to

the schedule in this manual.

• When the key switch is turned to the "ON" position, the battery indicator light briefly illuminates

and the battery voltage is briefly displayed. The

display then changes to the accumulated hours.

13

Page 14

SECTION 2: OPERATION

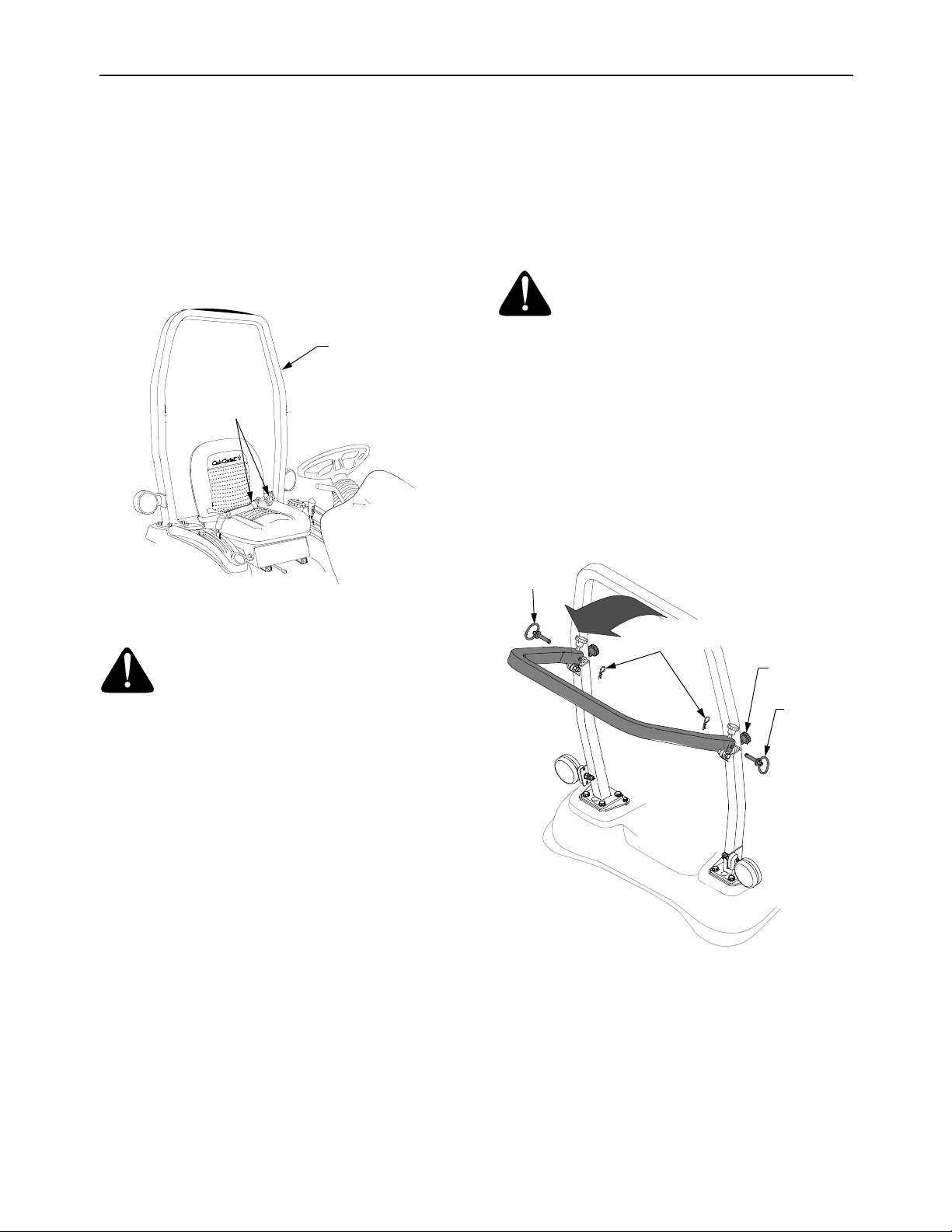

ROLLOVER PROTECTIVE STRUCTURE (ROPS)

This tractor is equipped with a Rollover Protection

Structure (ROPS) and seat belts. When used

together they are effective in reducing injuries to the

operator in the event of an accidental tractor

rollover. The safety provided by the ROPS is

minimized if the seat belt is not properly adjusted

AND buckled. Refer to ADJUSTMENTS for seat

belt adjustment.

ROPS

SEAT

BELT

MODELS EQUIPPED WITH A FOLDING ROPS

The foldable ROPS feature allows the operator to

quickly lower the ROPS to operate in areas where

there is low overhead clearance. However, the

ROPS should be used in the lowered position only

when absolutely necessary. Operate with the

ROPS in the ‘up’ position whenever possible.

WARNING: A folded ROPS does not

provide rollover protection. When the

ROPS is in the folded position, the seat

belt must NOT be used.

Reposition the ROPS as follows:

• Loosen the two clamp knobs on the front of the

ROPS to relieve their pressure on the ROPS.

See Figure 14.

• Remove the two internal cotter pins, and, while

supporting the ROPS, withdraw the hitch pins.

See Figure 14. Carefully lower the ROPS.

• Reinstall the hitch pins and internal cotter pins

for storage.

HITCH

PIN

Figure 13

WARNING: Always wear the seat belt

when operating the tractor equipped

with a ROPS. However, if the ROPS is in

the folded position or has been removed, the seat belt must not be used.

Use the following guidelines when using a tractor

equipped with a ROPS:

• Be aware of overhead clearances in the area of

operation. Check for clearance of door (or gate)

openings and other overhead objects such as

utility lines and tree branches. Overhead

objects could catch the ROPS and upset the

tractor.

• Do not modify the ROPS by drilling holes for, or

welding accessories to the structure.

• Do not use the ROPS to pull objects with the

tractor. Use ONLY the tractor rear tow plate for

pulling.

• In the event of an accident, have the ROPS

carefully inspected and, if necessary, replaced

by your Cub Cadet dealer. Do not attempt to

repair the ROPS.

INTERNAL

COTTER PIN

CLAMP

KNOB

HITCH

PIN

Figure 14

To raise the ROPS:

• Remove internal cotter pins and hitch pins and

lift the ROPS into position.

• Insert the hitch pins and secure with the

internal cotter pins.

• Tighten the clamp knobs against the ROPS.

14

Page 15

SAFETY INTERLOCK SYSTEM

This tractor is equipped with a safety interlock system for the protection of the operator. If the interlock

system should ever malfunction, do not operate the

tractor. Contact your authorized Cub Cadet Dealer.

The safety interlock system prevents the engine

from cranking or starting unless the brake pedal is

fully depressed, and the PTO is “OFF”.

• The safety interlock system will shut off the

engine if the operator leaves the seat before

engaging the parking brake.

• The safety interlock system will shut off the

engine if the operator leaves the seat with the

PTO “ON”, regardless of whether the brake

lock is engaged.

NOTE: The PTO switch must be moved to the

“OFF” position to restart the engine.

• The safety interlock system will shut off the

PTO if the reverse control pedal is depressed,

unless the reverse override function is

activated.

NOTE: If the reverse override function has

been activated, it will remain activated until the

ignition switch is turned to the "OFF" position

for a 20 second duration.

FUELING THE TRACTOR

Fill the fuel tank with only clean, fresh, unleaded

regular grade gasoline with a minimum octane

rating of 87. If engine knocking or pinging occurs,

use a different source of gasoline or a higher

octane rating.

Oxygenated Fuels.

or reformulated gasoline, are gasoline blended with

alcohols or ethers. Gasoline blended with either

ethyl alcohol (maximum 10% by volume) or methyl

tertiary butyl ether (MTBE, maximum 15%) are

approved as fuels for the engine, provided they

meet the minimum octane rating requirement. Other

gasoline/alcohol or gasoline/ether blends are not

approved for use in the tractor’s engine. If any

undesirable operating symptoms occur, use

gasoline with a lower percentage of alcohol or ether.

Purchase fuel in a quantity that can be used within

30 days to assure fuel freshness. Do not use

gasoline left over from the previous season to

minimize gum deposits in the fuel system.

WARNING: Gasoline is extremely

flammable and can be explosive in

certain conditions. Do not fill the fuel

tank when the engine is running or

while the engine is hot. Tighten the

fuel cap securely.

Some fuels, called oxygenated

The fuel fill cap is located on the fender to the left of

the seat. Unscrew the fuel cap and fill tank from an

approved gasoline container. Immediately wipe up

any spilled fuel.

WARNING: Never fill the fuel tank to

the top of the filler neck. Expansion

could result in overflow through the

vents in the cap, allowing highly

flammable fuel to come in contact with

the operator.

NEW TRACTOR BREAK-IN PROCEDURES

Proper care during the first hours of operation will

help to assure optimal performance from your new

tractor.

• Never operate a new engine immediately under

full load. Allow the engine to warm up.

• Avoid operating the engine for prolonged periods

at either high or low speed with no load.

• Use the transmission’s low speed range for

heavy loads to avoid lugging down or stalling

the engine due to overload.

• Closely monitor the engine oil and keep filled to

the recommended level.

• After the first ten hours of operation, check the

front wheel lug bolts and rear wheel lug nuts. If

necessary, retorque to 60-70 ft. lbs.

• Perform all break-in maintenance procedures

found in the MAINTENANCE section.

STARTING THE ENGINE

WARNING: Always sit in the operator’s

seat when starting the tractor. Never

start the tractor from any other

position.

• Operator must be sitting in the tractor seat.

• Pull the choke control knob out to the full choke

position. Less choking may be necessary due

to variations in temperature, grade of fuel, etc.

Little or no choking will be needed when the

engine is warm.

• Make sure the PTO switch is in the “OFF”

position. NOTE: The PTO light on instrument

panel will be lit if the switch is in the "ON"

position.

15

Page 16

• Move the throttle handle to midway between

the “SLOW” and “FAST” position. Refer to

Figure 15.

THROTTLE

HANDLE

SLOW

FAST

PTO SWITCH

IN ‘OFF’

POSITION

Figure 15

• Either fully depress and hold the brake pedal or

engage the parking brake. NOTE: The parking

brake indicator on instrument panel will light

when the pedal is properly depressed.

• Turn the ignition key clockwise to the “START”

position and release it as soon as the engine

starts; however, do not crank the engine

continuously for more than 10 seconds at a

time. If the engine does not start within this

time, turn the key to “OFF” and wait a minute to

allow the engine’s starter motor to cool. Try

again after waiting. If after a few attempts the

engine fails to start, do not keep trying to start it

with the choke closed as this will cause flooding

and make starting more difficult. Instead, fully

open the choke and start the engine.

NOTE: Upon start-up, a metallic ticking noise may

occur. This is caused by hydraulic lifter leakdown

during storage. The noise will normally cease within

the first minutes of engine warm up. If the noise

continues, increase the engine speed to mid-throttle

and allow the engine to run for several minutes. If

the noise persists, contact your Cub Cadet dealer.

WARNING: If the starter disengages the

engine flywheel, but the engine does

not continue to run, allow the engine to

come to a complete stop before

attempting to restart the engine. Damage to the starter may result from

failure to do so.

• After the engine starts, slowly release the brake

pedal. As the engine warms up, gradually push

the choke control knob all the way in. Do not

use the choke to enrich the fuel mixture, except

as necessary to start the engine.

• Allow the engine to run for a few minutes at mid

throttle before putting the engine under load.

• Observe the instrument panel. If the battery

indicator light or oil pressure light come on,

immediately stop the engine. Have the tractor

inspected by your Cub Cadet dealer.

COLD WEATHER STARTING

Be sure to use the proper oil for the expected

temperatures and use winter grade fuel. Follow the

normal engine starting instructions above.

However, allow the engine ample time to warm up

before putting the tractor under load.

USING JUMPER CABLES TO START ENGINE

WARNING: Batteries contain sulfuric

acid and produce explosive gasses.

Make certain the area is well ventilated,

wear gloves and eye protection, and

avoid sparks or flames near the battery.

If the battery charge is not sufficient to crank the

engine, recharge the battery. If a battery charger is

unavailable and the tractor must be started, the aid

of a booster battery will be necessary. Connect the

booster battery as follows:

• Connect the end of one cable to the disabled

tractor battery’s positive terminal; then connect

the other end of that cable to the booster

battery’s positive terminal.

• Connect one end of the other cable to the

booster battery’s negative terminal.

• Connect the other end of that cable to the

frame of the disabled tractor, as far from the

battery as possible.

• Start the disabled tractor following the normal

starting instructions previously provided; then

disconnect the jumper cables in the exact

reverse order of their connection.

• Have the tractor’s electrical system checked

and repaired as soon as possible to eliminate

the need for jump starting.

STOPPING THE ENGINE

• Place the PTO switch in the “OFF” position.

• Place the throttle control lever somewhere

between the mid and full throttle position.

• Turn the ignition key to the “OFF” position and

remove the key from the ignition switch.

NOTE:

Always remove the key from the ignition

switch to prevent accidental starting or battery

discharge if the equipment is left unattended.

16

Page 17

DRIVING THE TRACTOR

WARNING: Avoid sudden starts, excessive speed and sudden stops.

• Turn the ignition switch to “OFF’” and remove

the key from the switch before dismounting.

• Depress the button in the center of the seat belt

buckle to release the seat belt.

WARNING: Do not leave the seat of the

tractor without disengaging the PTO

and engaging the parking brake. If

leaving the tractor unattended, turn the

ignition key off and remove key.

• Adjust the operator’s seat to the most comfortable position that allows you to operate all

controls and pedals. See seat adjustment in the

ADJUSTMENTS section.

WARNING: DO NOT use the seat belt if

the ROPS has been lowered or

structure has been removed from the

tractor.

• Adjust the seat belt to fit snugly but comfortably

around your lap, then buckle the seat belt.

Refer to ADJUSTMENTS section.

• Shift the transmission Hi/Lo range shift lever on

the left fender to the desired speed setting.

Refer to USING THE HI/LO RANGE SHIFT

LEVER sub-section below.

• Use the tractor and/or auxiliary hydraulic lift

lever(s) to raise all tractor attachments from the

ground if transporting the tractor to a work site.

• Depress the brake pedal to release the parking

brake, then slowly release the brake pedal.

• Move the throttle handle to the position where

the engine operates best for the load to be

handled (normally 3500-3600 RPM).

• Slowly depress either the forward or reverse

pedal to move the tractor in the desired

direction. Refer to USING THE FORWARD

and REVERSE PEDALS in paragraphs below.

USING THE FORWARD AND REVERSE PEDALS

The hydrostatic transmission provides constantly

variable ground speeds within the speed rating of

each (HI/LO) transmission range. The tractor speed

is controlled by the forward and reverse pedals on

the front of the right running board.

The forward and reverse pedals are self neutralizing. The transmission and pedals return to neutral

when the pedals are released and the tractor will

slow to a stop. NOTE: Use the brake pedal to stop

the tractor.

• To move forward, slowly depress the forward

control pedal (See Figure 16) until the desired

speed is achieved. The speed of the tractor is

directly related to the distance the pedal is

depressed.

PARKING

BRAKE

LEVER

Depress

to go

Forward

BRAKE

PEDAL

Depress

to go in

Reverse

Figure 16

STOPPING THE TRACTOR

• Fully depress the brake pedal to bring the

tractor to a complete stop. Push downward on

the parking brake lever and release the pedal

to engage the parking brake. See Figure 16.

• Depress the rear of the PTO switch to

disengage the PTO.

• Place the throttle control lever somewhere

between the mid and full throttle position.

• To move in reverse, check that the area behind

is clear then slowly depress the reverse control

pedal. Refer to Figure 16.

NOTE: Do not use the forward or reverse control ped-

als to change the direction of travel when the tractor is

in motion. The abrupt direction change may unseat

the operator and will cause premature wear in the

transmission. Allow the tractor to stop before changing directions.

17

Page 18

USING THE HI/LO RANGE SHIFT LEVER

WARNING: The tractor must be

stopped before engaging or disengaging the transmission Hi/Lo range shift

lever. Shifting while the tractor is in

motion will cause damage to the

transmission.

WARNING: Always maintain a tractor

speed that allows for complete control

and stability of the machine. Be aware

of dangerous areas or conditions.

Referring to Figure 17, pull the lever to the right

side of the slot to clear the shift gate, then shift the

lever as follows :

PTO REVERSE

OVERRIDE

SWITCH

LOW

SHIFT GATE

Figure 17

N

HI

HI/LO RANGE

SHIFT LEVER

DRIVING ON SLOPES

WARNING: Do not operate on inclines

with a slope in excess of 15 degrees (a

rise of approximately 2-1/2 feet every

10 feet). The tractor could overturn and

cause serious injury.

IMPORTANT: Always shift the transmission

into the LOW speed range BEFORE beginning

the climb or descent of any slope.

Operate the tractor up and down slopes, never

across slopes. Do not drive so that the tractor may

tip over sideways

Before operating the tractor on a slope, walk the

slope to look for possible hazards such as rocks,

mounds, stumps, or surface irregularities which

could cause the tractor to be upset.

Back the tractor with attachment up the steepest

portion of each slope you intend to work. If the

tractor cannot negotiate the slope in reverse, the

slope is too steep to be worked.

Avoid turns when driving on a slope. If a turn must

be made, turn down the slope. Turning up a slope

greatly increases the chance of a roll over.

Avoid stopping when driving up a slope. If it is

necessary to stop while driving up a slope, start up

smoothly and carefully to reduce the possibility of

flipping the tractor over backward.

HI range — Shift the lever fully forward in slot.

Forward speed 0 to 8.0 mph.

Reverse speed 0 to 4.0 mph.

Hi range is normally used for transport and can be

used with some tractor attachments

LOW range — Shift the lever fully rearward in slot.

Forward speed 0 to 4.0 mph.

Reverse speed 0 to 2.0 mph.

Low range is recommended for use with most PTO

driven tractor attachments. Low range must be

used when climbing or descending slopes.

NEUTRAL — Shift the lever to the center of slot.

Disengages the transmission drive.

Use ONLY for towing or moving the tractor when

not under power.

USING THE DIFFERENTIAL LOCK PEDAL

Depressing the differential lock pedal engages a

mechanism in the transmission that locks the

differential. This prevents the rear wheels from

rotating independently of each other and provides

constant power to both rear wheels when additional

traction is needed.

IMPORTANT: Do not engage the differential

lock when one of the rear wheels is rotating.

Stop the wheel rotation and then engage the

differential lock.

WARNING: When operating with the

differential lock engaged, the tractor

will be difficult to steer. Do not drive

the tractor on roadways or at high

speeds with the differential lock

engaged.

18

Page 19

• Fully depress and hold the differential lock

pedal to engage the transmission differential

lock. Release the pedal to disengage the

differential lock. See Figure 18.

DIFFERENTIAL

LOCK PEDAL

(Depress and

Hold to Engage)

Figure 18

NOTE: Because of the drive load on the internal

engagement mechanism, releasing the differential

lock pedal may not always disengage the

differential lock. It may be necessary to slow the

tractor, or reverse the direction of travel, to

disengage the differential lock.

• Move the lift lever rearward in the slot to raise

the equipment.

• Move the lift lever fully forward and to the right

ahead of the float lock gate to lock the lift in the

float position.

ENGAGING THE PTO

WARNING: The operator must be in the

seat at all times when the PTO is

engaged. If the operator should leave

the seat without turning off the PTO

switch, the tractor’s engine will shut off.

• Move the throttle handle to the mid throttle

position. See Figure 20.

• Push the top of the PTO switch downward to

engage the PTO (See Figure 20). The PTO

light on the instrument panel will come on.

• Observing the tachometer on the instrument

panel, use the throttle handle to increase the

engine speed to the PTO operating range

(3400-3600 rpm).

THROTTLE HANDLE

USING THE HYDRAULIC LIFT LEVER

The hydraulic lift system provides power for raising

and positioning three point hitch and belly mounted

equipment. To raise an attachment using the

hydraulic lift system, the engine must be running.

Generally, an attachment can be lowered with the

engine running or off.

• Move the lift lever forward in the slot to lower

the equipment to the desired height setting.

Refer to Figure 19.

Raise

Lower

Float

HYDRAULIC

LIFT LEVER

FLOAT LOCK

GATE

Mid Throttle

to Engage

3500 RPM

to Run

PTO SWITCH

Figure 20

• Push the bottom of the switch downward to

disengage the PTO.

IMPORTANT: Normally the PTO will not

operate when the tractor is driven in the reverse

direction. The PTO reverse override switch

must be activated to operate the PTO while

traveling in reverse.

Figure 19

19

Page 20

USING THE PTO REVERSE OVERRIDE SWITCH

The PTO reverse override switch, located on the

left fender, allows the PTO to operate while the

tractor is traveling in the reverse direction. See

Figure 21.

PTO REVERSE

OVERRIDE

SWITCH

Use of the headlights, along with a SMV (Slow

Moving Vehicle) emblem, is also recommended

when operating the tractor on or near roadways to

increase visibility to traffic.

HAZARD LIGHTS

Always use the flashing amber hazard lights along

with the SMV (Slow Moving Vehicle) emblem when

operating the tractor on, or near, roadways. Also

activate the hazard lights when necessary to warn

others that the tractor is being operated in the area.

• To turn on the flashing hazard lights, depress

the top end of the hazard light switch located to

the left of the headlight switch.

• To turn off the hazard lights, depress the

bottom of the light switch.

Figure 21

• The PTO should first be engaged using the

PTO switch on the dash panel.

• Depress the front of the override switch to

activate the reverse override system. The light

in the override switch will come on.

IMPORTANT: Once activated, the reverse

override will remain activated until the ignition

switch is turned to the OFF position. If the override switch is illuminated, the system is

activated.

WARNING: Use EXTREME CAUTION

when operating PTO driven attachments while traveling in the reverse

direction.

HEADLIGHTS

Always use the headlights for after dusk and predawn operation of the tractor. The lights not only

illuminate the work area, but also increase the

visibility of the tractor for anyone who might enter

the area of operation.

• To turn on the headlights, depress the top end

of the headlight switch located to the left of the

steering wheel.

• To turn off the headlights, depress the bottom

of the light switch.

USING THE TOP LINK RETAINER HOOK

The top link hook is provided to retain the top link of

the three point hitch when not in use.

To utilize the top link hook, proceed as follows:

• Manually lift the 3-pt. hitch top link fully upward.

• Pivot the link hook from its storage position to

the center and lower the top link into the hook

of the rod. See Figure 22.

IMPORTANT: When using the three point

hitch, the retainer hook must be pivoted fully

rearward to avoid interference with the top link.

TOP LINK

HOOK

Figure 22

TOP

LINK

20

Page 21

REMOVING THE REAR PTO COVER

The rear PTO cover is a safety feature designed to

prevent items from accidentally being caught by the

rotating shaft. The cover should be removed only

when the rear PTO is being utilized.

To remove and reinstall the cover, proceed as

follows:

• Loosen the two screws on the left side of the

cover. Refer to Figure 23.

• Slide the cover to the right until the slots of the

cover are free of the screws and pull the cover

off. See Figure 23.

REAR PTO

SHAFT

PTO

COVER

SLOTS

IMPORTANT: When transporting pull-behind

equipment on public roadways, always use a

safety chain to supplement the connection

between the tractor and towed equipment. The

safety chain must have a strength rating equal

to or greater than the gross weight of the equipment being towed.

USING THE THREE POINT HITCH

WARNING: Always disengage the PTO,

stop the engine, and set the parking

brake before dismounting the tractor

to connect, disconnect, or adjust three

point hitch mounted implements.

Use the rear three point hitch system to attach

three point mounted implements, which are

normally driven by the rear PTO. Use the tractor’s

hydraulic lift system to raise and lower the three

point hitch and set the height position of the

implement.

Slide to Right

and Pull Off

HEX SCREW

Figure 23

• When finished using the rear PTO, slide the

cover fully onto the shaft; then slide the cover

to the left until the slots are underneath the

screw heads. Tighten the screws to secure the

cover. Refer to Figure 23.

USING THE HITCH PLATE

Use only the hitch plate (Refer to Figure 24), for

towing pull-behind equipment (carts, trailers, etc.)

or dragging loads.

Raise the lower links of the three point hitch to their

highest position to prevent interference with the

towed equipment.

Refer to the ADJUSTMENTS section for instructions on adjusting the RH adjustable lift link, top

hitch link, and hitch chains. See Figure 24.

FIXED

LIFT

LINK

HITCH

PLATE

LOWER HITCH LINK

TOP

HITCH LINK

HITCH

CHAIN

ADJUSTABLE

LIFT LINK

Figure 24

21

Page 22

TRACTOR WEIGHTING

When implements are installed on either the front or

rear of the tractor, the normal balance of the tractor

is altered.

• As a rear mounted implement is raised to the

transport position, the balance point of the

tractor shifts rearward, which may result in a

loss of steering control and tractor stability.

• When a front mounted implement is raised, the

balance point shifts forward and may result in a

loss of traction and stability.

To counterbalance these weight shifts, weight

should be added to the tractor in the form of either

front cast iron weights, a rear weight box, and/or

liquid tire ballast. Only enough weight should be

added to obtain good traction, control, and stability.

Excessive weight will unnecessarily load down the

tractor’s engine and transmission.

Front Weights

To counterbalance three point hitch mounted

equipment, a weight bracket/bumper kit and cast

iron weights are available from your Cub Cadet

dealer. Refer to the Weighting Table for the proper

ballast to be added to the front of the tractor.

Weighting the Rear of the Tractor

To counterbalance front mounted equipment, use a

rear weight box, and/or liquid ballast in the rear

tires. Refer to the Weighting Table for the proper

ballast to be added to the rear of the tractor.

NOTE: Consult with your Cub Cadet dealer about

having liquid ballast added to your tires, and for any

special maintenance after the procedure is

performed. Because special equipment and a

familiarity with the practice is required, only a

qualified tire technician should perform this

procedure.

INSTALL ONLY EQUIPMENT APPROVED FOR

USE ON THE 5000 SERIES TRACTOR.

TRACTOR WEIGHTING TABLE

Equipment Installed

on Tractor

Rear Mounted Finish

Mower

Rear Mounted Tiller Front Weight Bracket and

Rear Mounted Blade,

Box Blade, Rake

Rear Mounted Post Hole

Digger

Front Snow Thrower None Required None Required

Front Blade None Required None Required

Method of Weighting Weight Required

Front Weight Bracket and

Suitcase Weights

Suitcase Weights

Front Weight Bracket and

Suitcase Weights

Front Weight Bracket and

Suitcase Weights

A minimum of four suitcase weights (168 pounds)

A minimum of two suitcase weights (84 pounds)

A minimum of two suitcase weights (84 pounds)

A minimum of four suitcase weights (168 pounds)

** If the center of gravity of the additional weight is positioned closer to the rear axle and higher above the

ground, more weight must be added. If the additional weight is carried farther from the axle and lower, less

weight may be used.

22

Page 23

SECTION 3: ADJUSTMENTS

ADJUSTING THE SEAT

For the comfort of the operator, a single lever

adjustable seat is provided to set the fore to aft

position of the seat. Adjust the seat to the most

comfortable position that allows you to operate all

controls and pedals.

WARNING: Do not adjust the seat when

the tractor is moving, as this could

cause the operator to lose momentary

control of the tractor and result in an

accident.

• To adjust the seat, pivot the seat adjustment

lever to the left and hold while repositioning the

seat to the desired position.

• After repositioning the seat, release the lever to

lock the seat in position. Slide the seat either

slightly forward or rearward to assure it is

locked, or until engagement of the lock is felt.

See Figure 25.

SEAT

ADJUSTMENT

LEVER

Adjust the final length of the seat belt using the

adjuster clip, buckle link, and upper belt webbing on

the right half of the belt.

• To lengthen the belt, hold the ends of the

adjuster clip and tip upward the side of the clip

toward the buckle link. See Figure 26.

• While holding the clip, pull the upper webbing

of the belt through the clip toward the buckle

link. See Figure 26.

• Hold the belt and pull the buckle link to the left

to remove the slack in the upper webbing of the

belt between the adjuster clip and the link.

RELEASE

BUTTON

BUCKLE

LINK

BUCKLE

UPPER

WEBBING

Tip Sides of Clip

Pull Belt to

Lengthen

Pull Belt to

Shorten

ADJUSTER

CLIP

LOWER

WEBBING

Figure 26

• To shorten the belt, tip the other side of the clip

upward, pull the free end of the belt webbing to

the right, and pull the buckle link to the left to

remove the slack.

Pivot Lever

to Left

Figure 25

ADJUSTING THE SEAT BELT

WARNING: Always wear the seat belt

when operating the tractor equipped

with a ROPS. If the ROPS has been

removed, the seat belt should not be

used.

NOTE: If the belt is too long or too short to be prop-

erly adjusted using the upper belt webbing, the

adjustment clip should be repositioned. To do so,

firmly grasp the adjustment clip and pull the lower

webbing though the clip. Move the clip toward the

anchor point at the seat to shorten the belt, or

toward the buckle link the lengthen the belt.

THREE POINT HITCH ADJUSTMENTS

• Adjust the RH adjustable lift link to level the

lower hitch links. Loosen the jam nut and turn

the adjustment tube as shown in Figure 27 to

shorten or lengthen the lift link. Tighten the jam

nut against the adjustment tube after adjusting.

JAM

Loosen

Jam Nut

Shorten

NUT

ADJUSTMENT

TUBE

Lengthen

Figure 27

23

Page 24

• The length of the upper hitch link is normally

determined by the design of each implement.

To adjust the upper hitch link, loosen the locking lever and turn the adjustment tube as

shown in Figure 28. After the appropriate length

is attained, tighten the locking lever. If correctly

adjusted, the upper hitch link will be parallel or

nearly parallel to the lower hitch links.

• Distance ‘A’ should be 1/8"-1/4" less than

distance ‘B’ if the toe-in is correct. If it is not,

readjust the toe-in.

A

ADJUSTMENT

TUBE

Shorten

Lengthen

LOCKING

LEVER

Loosen

Lock Lever

Figure 28

• The length of the hitch chains limit the side-toside movement of the hitch lower links. To

adjust the length of the hitch chains, loosen the

jam nut and turn the hex collar on the adjustment rod as shown in Figure 29. Tighten the

jam nut after adjusting.

HEX COLLAR

ON ROD

Turn Hex Collar

to Shorten

HEX JAM NUT

Turn Hex Collar

to Lengthen

ADJUSTMENT

ROD

Figure 29

B

Figure 30

READJUST THE TOE-IN AS FOLLOWS:

NOTE: The left ball joint and jam nut are left hand

threaded.

• Loosen the jam nuts at both the LH and RH ball

joints. See Figure 31.

• Slide an open-end wrench onto the flat area at

either end of the tie rod and turn the tie rod as

follows:

Rearward to shorten the tie rod and increase

the toe-in. See Figure 31.

Forward to lengthen the tie rod and decrease

the toe-in. See Figure 31.

ADJUSTING FRONT WHEEL TOE-IN

The front wheel toe-in is set at the factory and

should maintain the proper setting. However, the

toe-in should be checked periodically and

readjusted if necessary.

CHECK THE TOE-IN AS FOLLOWS:

• Place the tractor on a level surface with the

wheels in the straight ahead position.

• Place an easily visible mark on the center lines

of both front tires at the horizontal center line of

the wheel.

• Measure and record the distance ‘A’ between

the two marks. See Figure 30.

• Roll the tractor forward or rearward until the

marks are at the horizontal center line at the

rear of the wheels. Measure and record the

distance ‘B’ between the marks. See Figure 30.

Front of

Tractor

Increase

Toe-in

Decrease

Toe-in

TIE ROD

JAM NUT

RH BALL JOINT

Figure 31

• Readjust the tie rod as necessary to obtain the

correct toe-in, then tighten the jam nuts against

the ball joints.

24

Page 25

ADJUSTING THE BRAKES

The tractor brakes are adjusted at the factory and

should experience minimal wear if the tractor is

operated normally. However, all brake pads are

subject to wear and at some point the brake linkage

may have to be adjusted.

Check the brakes as follows:

• Place the tractor on a level surface. Stop the

tractor engine.

• From beneath the RH running board, remove

the internal cotter pin to disengage the brake

rod ferrule from the brake pedal. Position the

brake rod to make certain there is no pull on

the brake actuator arm. See Figure 32.

• From the rear of the tractor, use a feeler gauge

to measure the gap between the outer brake

puck and the brake disc. The gap should measure between .012 and .015". See Figure 32.

• If the gap is greater than .015", tighten the hex

nut on the brake assembly until the gap is

within the tolerance.

• Position the ferrule to align with the hole in the

brake pedal. If the ferrule does not align with

the hole, loosen the jam nut by turning it away

from the ferrule

• Adjust the ferrule on the brake rod to align with

the brake pedal hole, then tighten the jam nut

against the ferrule.

• Insert the ferrule in the brake pedal and secure

with the internal cotter pin.

• Repeat the previous steps to check and, if

necessary, adjust the LH brake assembly.

INTERNAL

COTTER PIN

JAM NUT

GAUGE

.012 - .015"

BRAKE DISC

FERRULE

RH BRAKE ROD

BRAKE

ACTUATOR

ARM

BRAKE PEDAL

HEX NUT

Figure 32

25

Page 26

SECTION 4: TRACTOR MAINTENANCE

The service life and reliability of any machine

depends upon the care it is given. Proper lubrication and maintenance is a vital part of that care.

Using the Lubrication and Maintenance Chart as a

guide, monitor the hourmeter on the instrument

panel to ensure the required maintenance procedures are performed. The maintenance schedule

reflects the minimal requirements to maintain the

equipment. More frequent inspections and maintenance is preferable.

Make certain that all lubrication fittings are installed

and functioning. Wipe away all old grease and dirt

from the lube fittings to prevent foreign materials

from entering as the new grease is applied. Use a

pressure lubricating gun to force in new grease.

LUBRICATION TABLE

Application

Engine

Type of

Lubricant

Engine

Oil

Capacity

Approx.

2.1 Qts.

w/Filter

API

Classifi-

cation

SG,

SH,

or

SJ

Apply pressure until clean grease emerges from the

lubrication point.

Miscellaneous working parts not provided with

lubrication fittings should be oiled regularly with a

good grade of lubricating oil.

Lubricate the tractor thoroughly before taking it to a

remote location for a prolonged period of time.

Lubricant is cheap. Use plenty of it. Worn parts can

be expensive to replace.

Store your supply of lubricating grease and oil in

clean, covered containers to protect them from dust

and dirt. Keep the lubricating gun nozzle clean.

General Information

Anticipated

Ambient

Temp.

Below 32°F

0°F to 100°F 10W-30 †

SAE

Viscosity

5W-20 †

5W-30 †

Description

Use High

Quality Engine Oil

Cub Cadet

737-3030A (1Qt.)

Hydrostatic

Transmission

and

Hydraulic

System

Lube

Fittings

Cub Cadet

Drive System

Fluid Plus

Grease

Approx.

20 Qts.

(5.0 Gal.)

As

Needed

Use Cub Cadet

Drive System Fluid Plus

737-3120 (1 Qt.)

737-3121 (1 Gal.)

Use Cub Cadet

251H EP Grease

737-3034 (14.5 Oz. Cartridge)

† Using multi grade oils (5W-20, 5W-30, and 10W-30) will increase oil consumption. Check the engine

oil level frequently when using them.

26

Page 27

LUBRICATION AND MAINTENANCE CHART (ILLUSTRATION)

18

9

7

5

9

6

11

4

8

17

4

4

1

3

2

15

10

16

12

13

12

13

5

14

27

Page 28

LUBRICATION AND MAINTENANCE CHART

Service Intervals

Ref.

No.

1 Check Engine Oil Level

2 Check Air Cleaner

3 Clean Air Cleaner Foam

Precleaner Element

4 Change Engine Oil and Replace

Oil Filter

5 Retorque Front Wheel Lug Bolts

and Rear Wheel Lug Nuts

6 Check Transmission Oil Level

7 Replace Hydrostatic

Transmission Oil Filter

8 Replace Hydraulic System Filter first

9 Replace Hydraulic/Hydrostatic

Oil

10 Replace Air Cleaner Paper

Element

Operation to

be Performed

10

Every

Before

each use

Hours

•

•

first

10

hours

•

25

Every

†

first

25

hours

25

hours

50

Every

Hours

100