Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

OPERATOR'S MANUAL

Zero Turn Riding Mower

CUB CADET LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PrintedIn USA

Time Saver Model

i1042

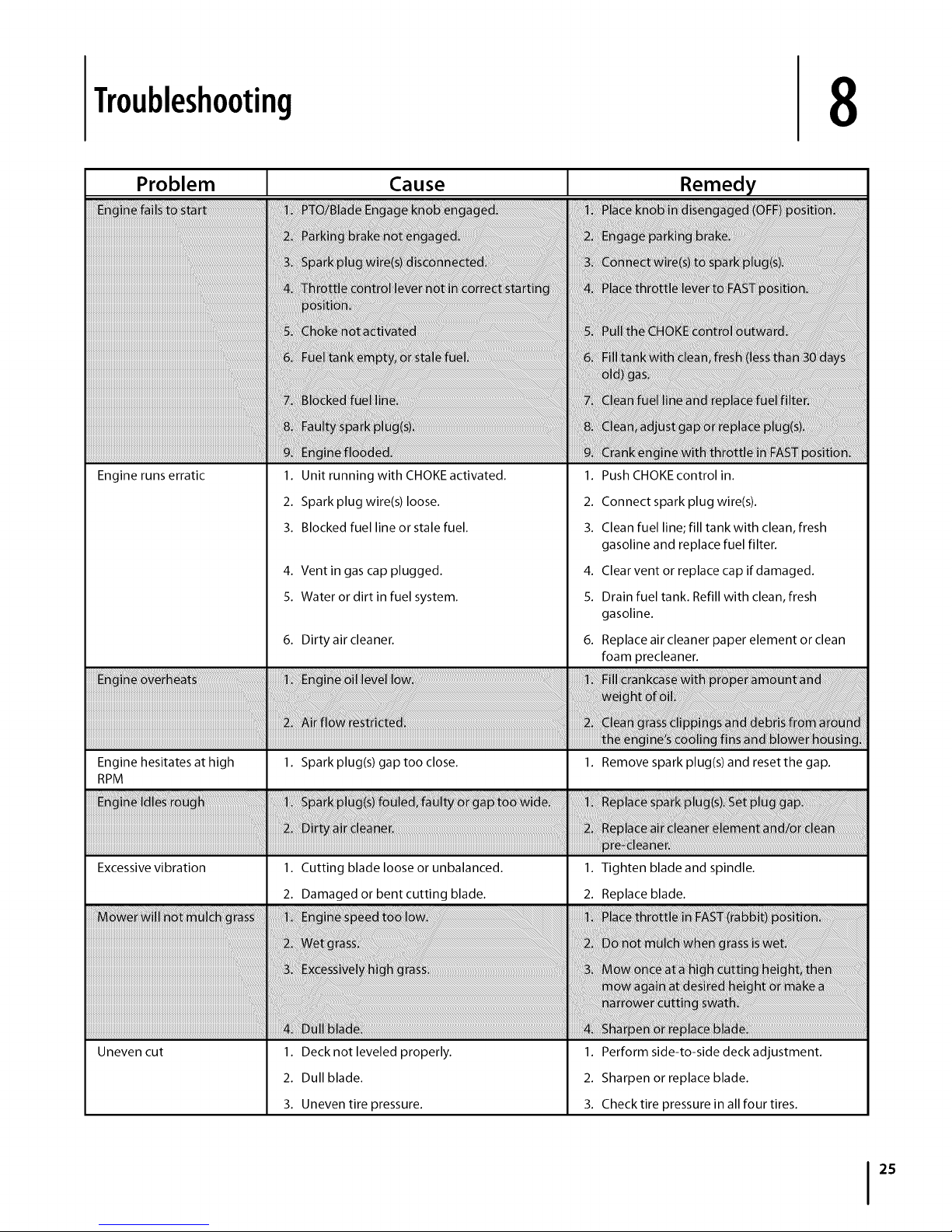

FORMNO.769-03654

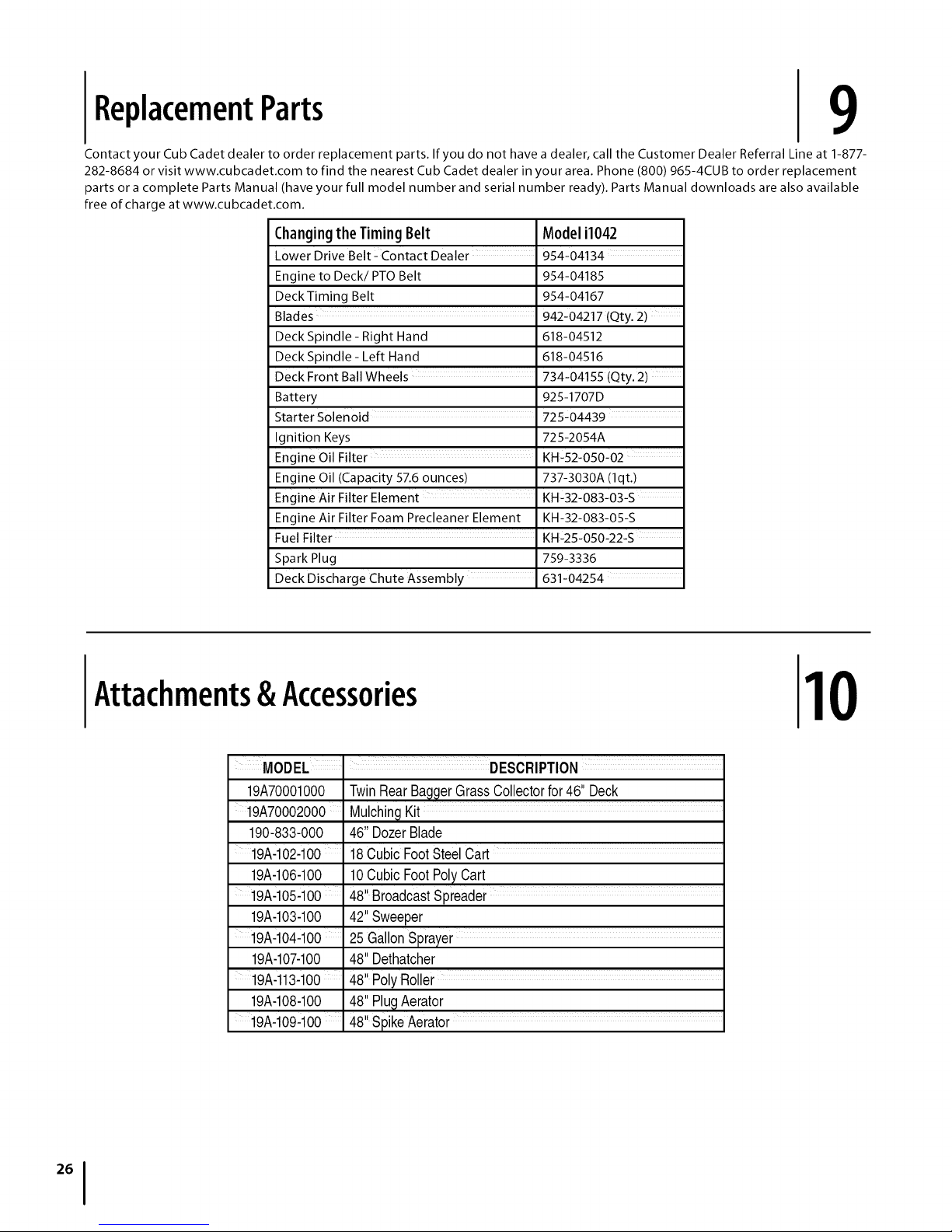

(Nov,2007)

Page 2

ToTheOwner

ThankYou

1

Thank you for purchasing a Lawn Tractor manufactured by Cub

Cadet LLC. It was carefully engineered to provide excellent

performance when properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the machine,

its features and operation. Please be aware that this Operator's

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. Cub Cadet

LLC reserves the right to change product specifications, designs

and equipment without notice and without incurring obligation.

Table of Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 8

Controls & Features ................................................ 9

Opera tion ................................................................ 12

Maintenance & Adjustment ................................. 15

This product has met the rigid safety standards of the Outdoor

Power Equipment Institute and an independent testing

laboratory. If you have any problems or questions concerning

the machine, phone your local Cub Cadet dealer or contact us

directly. Cub Cadet's Customer Support telephone numbers,

website address and mailing address can be found on this page.

We want to ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position.

Service .................................................................... 20

Troubleshooting .................................................... 25

Replacement Parts ............................................... 26

Attachments & Accessories .................................. 26

Warranty ................................................. Back Cover

RecordProductInformation

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate the

model plate by looking beneath the seat. This information will be

necessary, should you seek technical support via our web site or

with your local Cub Cadet dealer.

MODEL NUMBER

DDDDDDDDDDD

SERIAL NUMBER

DDDDDDDDDDD

CustomerSupport

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

0 Visit us on the web at www.cubcadetcom

0 Locate your nearest Cub Cadet Dealer at (877) 282-8684

0 Write us at Cub Cadet LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

Page 3

ImportantSafeOperationPractices

WARNING: This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

WARNING: Battery posts, terminals, and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause cancer and reproductive

harm. Wash hands after handling

DANGER: This machine was built to be operated according to the rules for safe operation

practices in this manual. As with any type of power equipment, carelessness or error on the

part of the operator can result in serious injury. This machine is capable of amputating hands

and feet and throwing objects. Failure to observe the following safety instructions could

result in serious injury or death.

2

Children

1.

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

machine and the mowing activity. They do not understand

the dangers. Never assume that children will remain where

you last saw them.

a. Keep children out of the mowing area and in

watchful care of a responsible adult other than the

operator.

b. Be alert and turn machine off if a child enters the

area.

c. Before and while backing, look behind and down for

small children.

d. Never carry children, even with the blade(s) shut off.

They may fall off and be seriously injured or interfere

with safe machine operation.

e. Use extreme care when approaching blind corners,

doorways, shrubs, trees or other objects that may

block your vision of a child who may run into the

machine.

To avoid back-over accidents, always disengage

the cutting blade(s) before shifting into Reverse.

If equipped, the "Reverse Caution Mode" should

not be used when children or others are around.

g. Keep children away from hot or running engines.

They can suffer burns from a hot muffler.

h. Remove key when machine is unattended to

prevent unauthorized operation.

2.

Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and should be trained and supervised

by an adult.

Operation

SafeHandlingofGasoline:

1. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

Page 4

c. Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefuelitontheground.

Ifthisisnotpossible,thenrefuelsuchequipmenton

atrailerwithaportablecontainer,ratherthanfroma

gasolinedispensernozzle.

d. Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfuelingis

complete.Donotuseanozzlelock-opendevice.

e. Extinguishallcigarettes,cigars,pipesandother

sourcesofignition.

f. Neverfuelmachineindoors.

g. Neverremovegascaporaddfuelwhiletheengine

ishotorrunning.Allowenginetocoolatleasttwo

minutesbeforerefueling.

h. Neveroverfillfueltank.Filltanktonomorethan1/2

inchbelowbottomoffillernecktoallowspacefor

fuelexpansion.

i. Replacegasolinecapandtightensecurely.

j. Ifgasolineisspilled,wipeitofftheengineand

equipment.Movemachinetoanotherarea.Wait5

minutesbeforestartingtheengine.

k. Toreducefirehazards,keepmachinefreeofgrass,

leaves,orotherdebrisbuild-up.Cleanupoilorfuel

spillageandremoveanyfuelsoakeddebris.

I. Neverstorethemachineorfuelcontainerinside

wherethereisanopenflame,sparkorpilotlight

asonawaterheater,spaceheater,furnace,clothes

dryerorothergasappliances.

m. Allowamachinetocoolatleastfiveminutesbefore

storing.

GeneralOperation:

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised bya

parent.

4. Never allow adults to operate this machine without proper

instruction.

5. To help avoid blade contact or a thrown object injury,

keep bystanders, helpers, children and pets at least 75 feet

from the machine while it is in operation. Stop machine if

anyone enters the area.

6. Thoroughly inspect the area where the equipment is to be

used. Remove all stones, sticks, wire, bones, toys, and other

foreign objects which could be picked up and thrown by

the blade(s). Thrown objects can cause serious personal

injury.

7. Plan your mowing pattern to avoid discharge of material

toward roads, sidewalks, bystanders and the like. Also,

avoid discharging material against a wall or obstruction

which may cause discharged material to ricochet back

toward the operator.

8. Always wear safety glasses or safety goggles during

operation and while performing an adjustment or repair

to protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

9. Wear sturdy, rough-soled work shoes and close-fitting

slacks and shirts. Loose fitting clothes and jewelry can be

caught in movable parts. Never operate this machine in

bare feet or sandals.

10. Be aware of the mower and attachment discharge direction

and do not point it at anyone. Do not operate the mower

without the discharge cover or entire grass catcher in its

proper place.

11. Do not put hands or feet near rotating parts or under the

cutting deck. Contact with the blade(s) can amputate

hands and feet.

12. A missing or damaged discharge cover can cause blade

contact or thrown object injuries.

13. Stop the blade(s) when crossing gravel drives, walks, or

roads and while not cutting grass.

14. Watch for traffic when operating near or crossing

roadways. This machine is not intended for use on any

public roadway.

15. Do not operate the machine while under the influence of

alcohol or drugs.

16. Mow only in daylight or good artificial light.

17. Never carry passengers.

18. Disengage blade(s) before shifting into reverse. Back up

slowly. Always look down and behind before and while

backing to avoid a back-over accident.

19. Slow down before turning. Operate the machine smoothly.

Avoid erratic operation and excessive speed.

20. Disengage blade(s), set parking brake, stop engine and

wait until the blade(s) come to a complete stop before

removing grass catcher, emptying grass, unclogging chute,

removing any grass or debris, or making any adjustments.

21. Never leave a running machine unattended. Always turn

off blade(s), place transmission in neutral, set parking

brake, stop engine and remove key before dismounting.

22. Use extra care when loading or unloading the machine into

a trailer or truck. This machine should not be driven up or

down ramp(s), because the machine could tip over, causing

serious personal injury. The machine must be pushed

manually on ramp(s) to load or unload properly.

23.

Muffler and engine become hot and can cause a burn. Do

not touch.

24.

Check overhead clearances carefully before driving under

low hanging tree branches, wires, door openings etc.,

where the operator may be struck or pulled from the

machine, which could result in serious injury.

4 I SECTION 2-- IMPORTANT SAFE OPERATION PRACTICES

Page 5

25.

Disengage all attachment clutches, depress the brake

pedal completely and shift into neutral before attempting

to start engine.

26.

Your machine is designed to cut normal residential grass of

a height no more than 10". Do not attempt to mow through

unusually tall, dry grass (e.g., pasture) or piles of dry leaves.

Dry grass or leaves may contact the engine exhaust and/or

build up on the mower deck presenting a potential fire

hazard.

27. Use only accessories and attachments approved for this

machine by the machine manufacturer. Read, understand

and follow all instructions provided with the approved

accessory or attachment.

28. Data indicates that operators, age 60 years and above, are

involved in a large percentage of riding mower-related

injuries. These operators should evaluate their ability

to operate the riding mower safely enough to protect

themselves and others from serious injury.

29. If situations occur which are not covered in this manual, use

care and good judgment. Contact your customer service

representative for assistance.

SlopeOperation:

Slopes are a major factor related to loss of control and tip-over

accidents which can result in severe injury or death. All slopes

require extra caution. If you cannot back up the slope or if you

feel uneasy on it, do not mow it.

For your safety, use the slope gauge included as part of this

manual to measure slopes before operating this machine on

a sloped or hilly area. If the slope is greater than 15 degrees as

shown on the slope gauge, do not operate this machine on that

area or serious injury could result.

Do:

1. Mow up and down slopes, not across. Exercise extreme

caution when changing direction on slopes.

2. Watch for holes, ruts, bumps, rocks, or other hidden

objects. Uneven terrain could overturn the machine. Tall

grass can hide obstacles.

3. Use slow speed. Choose a low enough speed setting so

that you will not have to stop or shift while on the slope.

Tires may lose traction on slopes even though the brakes

are functioning properly. Always keep machine in gear

when going down slopes to take advantage of engine

braking action.

4. Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

5. Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

6. Keep all movement on the slopes slow and gradual. Do

not make sudden changes in speed or direction. Rapid

engagement or braking could cause the front of the

machine to lift and rapidly flip over backwards which could

cause serious injury.

7. Avoid starting or stopping on a slope. If tires lose traction,

disengage the blade(s) and proceed slowly straight down

the slope.

DoNot:

1. Do not turn on slopes unless necessary; then, turn slowly

and gradually downhill, if possible.

2. Do not mow near drop-offs, ditches or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff, ditch, or if an edge caves in.

3. Do not try to stabilize the machine by putting your foot on

the ground.

4. Do not use a grass catcher on steep slopes.

5. Do not mow on wet grass. Reduced traction could cause

sliding.

6. Do not shift to neutral and coast downhill. Over-speeding

may cause the operator to lose control of the machine

resulting in serious injury or death.

7. Do not tow heavy pull behind attachments (e.g. loaded

dump cart, lawn roller, etc.) on slopes greater than 5

degrees. When going down hill, the extra weight tends

to push the tractor and may cause you to loose control.

(e.g. tractor may speed up, braking and steering ability are

reduced, attachment may jack-knife and cause tractor to

overturn).

Towing:

1. Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

2. Follow the manufacturers recommendation for weight

limits for towed equipment and towing on slopes.

3. Never allow children or others in or on towed equipment.

4. On slopes, the weight of the towed equipment may cause

loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Do not shift to neutral and coast downhill.

Service

1. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless,

and deadly gas.

2. Before cleaning, repairing, or inspecting, make certain the

blade(s) and all moving parts have stopped. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3. Periodically check to make sure the blades come to

complete stop within approximately (5) five seconds after

operating the blade disengagement control. If the blades

do not stop within the this time frame, your machine

should be serviced professionally by an authorized MTD

Service Dealer.

4.

Check brake operation frequently as it is subjected to wear

during normal operation. Adjust and service as required.

SECTION2 -- IMPORTANT SAFE OPERATION PRACTICES S

Page 6

5. Check the blade(s) and engine mounting bolts at frequent

intervals for proper tightness. Also, visually inspect blade(s)

for damage (e.g., excessive wear, bent, cracked). Replace

the blade(s) with the original equipment manufacturer's

(O.E.M.) blade(s) only, listed in this manual. "Use of parts

which do not meet the original equipment specifications

may lead to improper performance and compromise

safety!"

6. Mower blades are sharp. Wrap the blade or wear gloves,

and use extra caution when servicing them.

7. Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

8. Never tamper with the safety interlock system or other

safety devices. Check their proper operation regularly.

9. After striking a foreign object, stop the engine, disconnect

the spark plug wire(s) and ground against the engine.

Thoroughly inspect the machine for any damage. Repair

the damage before starting and operating.

10. Never attempt to make adjustments or repairs to the

machine while the engine is running.

11. Grass catcher components and the discharge cover are

subject to wear and damage which could expose moving

parts or allow objects to be thrown. For safety protection,

frequently check components and replace immediately

with original equipment manufacturer's (O.E.M.) parts only,

listed in this manual. "Use of parts which do not meet the

original equipment specifications may lead to improper

performance and compromise safety!"

12. Do not change the engine governor settings or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

13. Maintain or replace safety and instruction labels, as

necessary.

14. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM) and Three Way Catalyst (TWC) if so equipped.

SparkArrestor

internal combustion engine and should not be used

_ ARNING: This machine is equipped with an

any).

If a spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark arrester for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

Average Useful Life

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years, or 270

hours of operation. At the end of the Average Useful Life, buy

a new machine or have the machine inspected annually by an

authorized service dealer to ensure that all mechanical and

safety systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

on or near any unimproved forest-covered,

brushcovered or grass-covered land unless the

engine's exhaust system is equipped with a spark

arrester meeting applicable local or state laws (if

Donot modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

6 I SECTION 2-- IMPORTANT SAFE OPERATION PRACTICES

SAVETHESEINSTRUCTIONS!

Page 7

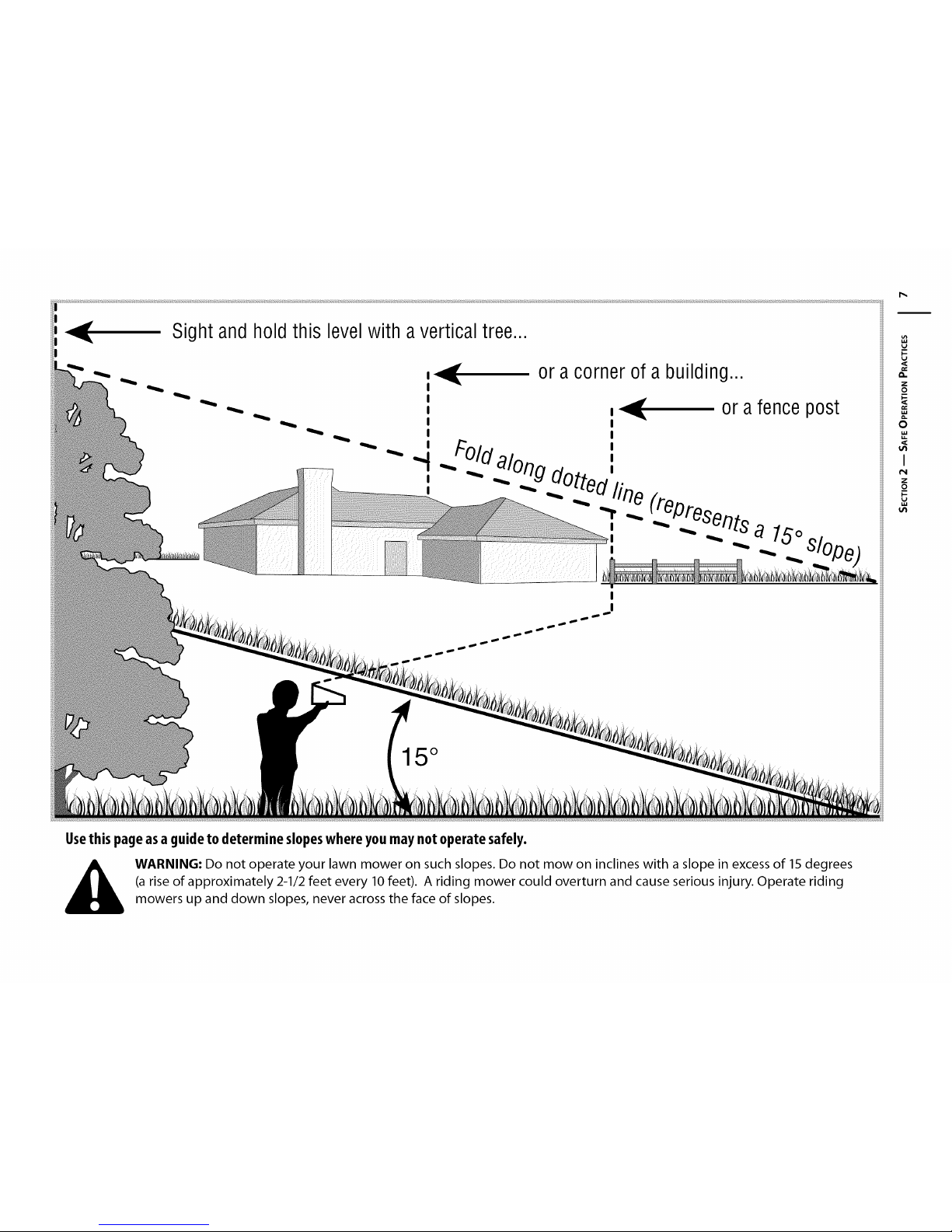

Sight and

hold this level with avertical tree...

or a corner of a building...

i -4 or a fence post

I I

I I

I I

' Foldo,_ ',

, _ _epresents_a 15°

I

15 °

I--

U

a.

Z

0

0

I

z

£

I--

Usethis pageasa guideto determineslopeswhereyou maynot operatesafely.

WARNING: Do not operate your lawn mower on such slopes. Do not mow on inclines with a slope in excess of 15 degrees

(a rise of approximately 2-1/2 feet every 10 feet). A riding mower could overturn and cause serious injury. Operate riding

mowers up and down slopes, never across the face of slopes.

Page 8

Assembly&Set-Up

3

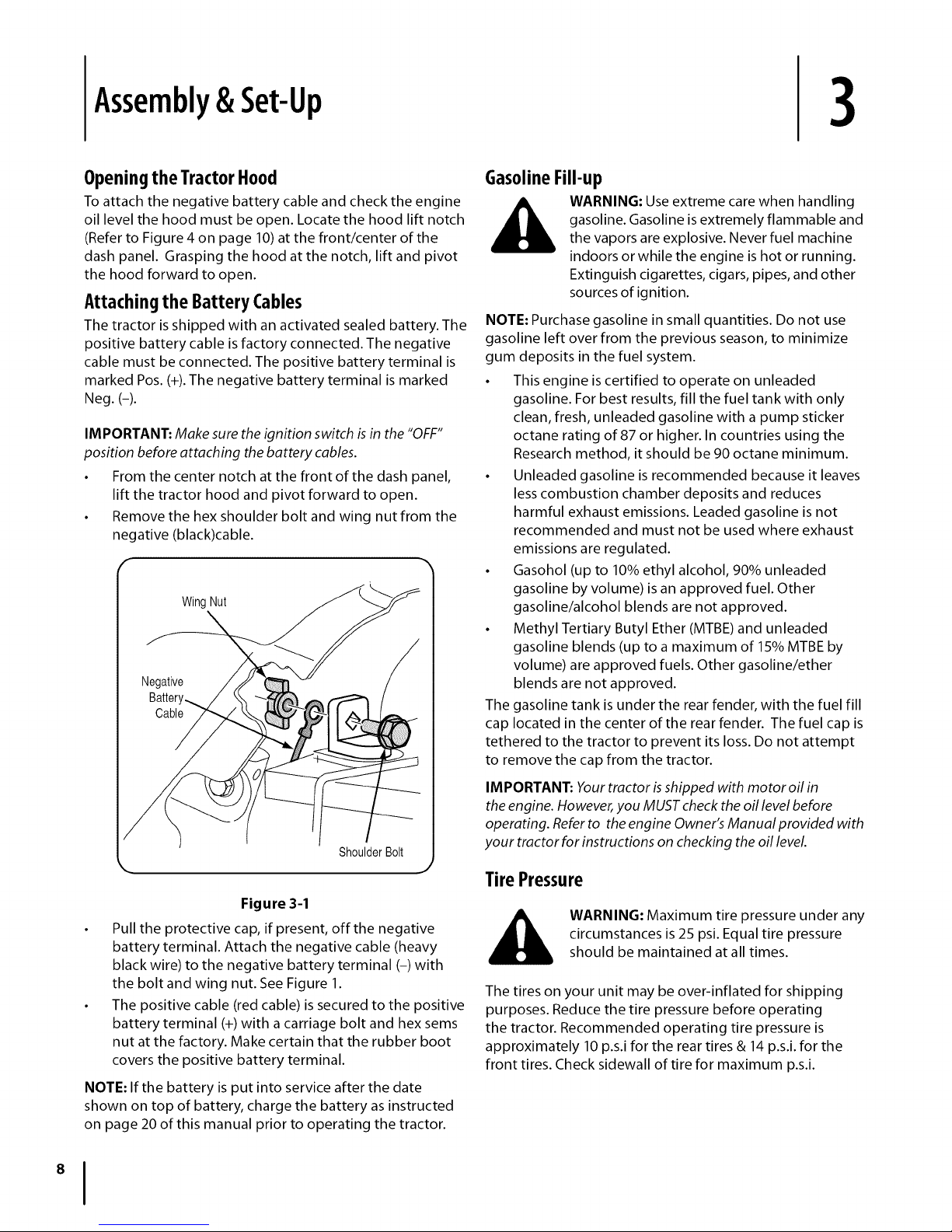

Opening the Tractor Hood

To attach the negative battery cable and check the engine

oil level the hood must be open. Locate the hood lift notch

(Refer to Figure 4 on page 10)at the front/center of the

dash panel. Grasping the hood at the notch, lift and pivot

the hood forward to open.

Attaching the Battery Cables

The tractor is shipped with an activated sealed battery. The

positive battery cable is factory connected. The negative

cable must be connected. The positive battery terminal is

marked Pos. (+). The negative battery terminal is marked

Neg. (-).

IMPORTANT: Make sure the ignition switch is in the "OFF"

position before attaching the battery cables.

• From the center notch at the front of the dash panel,

lift the tractor hood and pivot forward to open.

• Remove the hex shoulder bolt and wing nut from the

negative (black)cable.

Wing Nut

Negative

Cable

GasolineFill-up

__, ARNING: Use extreme care when handling

NOTE: Purchase gasoline in small quantities. Do not use

gasoline left over from the previous season, to minimize

gum deposits in the fuel system.

• This engine is certified to operate on unleaded

gasoline. For best results, fill the fuel tank with only

clean, fresh, unleaded gasoline with a pump sticker

octane rating of 87 or higher. In countries using the

Research method, it should be 90 octane minimum.

• Unleaded gasoline is recommended because it leaves

less combustion chamber deposits and reduces

harmful exhaust emissions. Leaded gasoline is not

recommended and must not be used where exhaust

emissions are regulated.

• Gasohol (up to 10% ethyl alcohol, 90% unleaded

gasoline by volume) is an approved fuel. Other

gasoline/alcohol blends are not approved.

• Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a maximum of 15% MTBE by

volume) are approved fuels. Other gasoline/ether

blends are not approved.

The gasoline tank is under the rear fender, with the fuel fill

cap located in the center of the rear fender. The fuel cap is

tethered to the tractor to prevent its loss. Do not attempt

to remove the cap from the tractor.

gasoline. Gasoline is extremely flammable and

the vapors are explosive. Never fuel machine

indoors or while the engine is hot or running.

Extinguish cigarettes, cigars, pipes, and other

sources of ignition.

I

Figure 3-1

Pull the protective cap, if present, off the negative

battery terminal. Attach the negative cable (heavy

black wire) to the negative battery terminal (-) with

the bolt and wing nut. See Figure 1.

The positive cable (red cable) is secured to the positive

battery terminal (+) with a carriage bolt and hex sems

nut at the factory. Make certain that the rubber boot

covers the positive battery terminal.

NOTE: If the battery is put into service after the date

shown on top of battery, charge the battery as instructed

on page 20 of this manual prior to operating the tractor.

ShoulderBolt

IMPORTANT: Yourtractor h shipped with motor oil in

theengine. However,you MUSTcheckthe oil levelbefore

operating. Referto theengine Owner'sManual provided with

your tractor for instructions on checking the oil level

TirePressure

circumstances is 25 psi. Equal tire pressure

WARNING: Maximum tire pressure under any

should be maintained atall times.

The tires on your unit may be over-inflated for shipping

purposes. Reduce the tire pressure before operating

the tractor. Recommended operating tire pressure is

approximately 10 p.s.i for the rear tires & 14 p.s.i, for the

front tires. Check sidewall of tire for maximum p.s.i.

Page 9

ControlsandFeatures

f

4

D

B

C

E

\

P

F

H

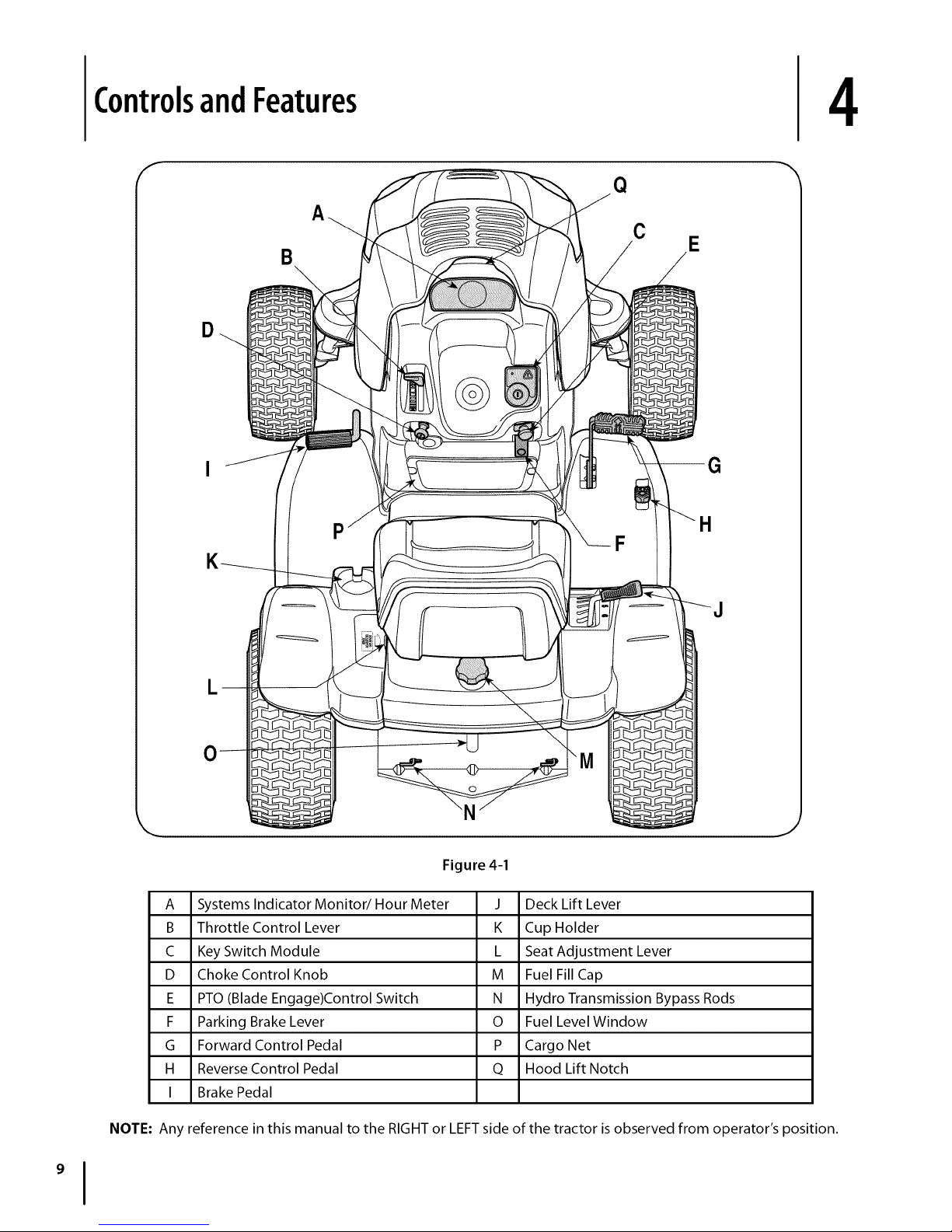

A Systems Indicator Monitor/Hour Meter

B Throttle Control Lever

C Key Switch Module

D Choke Control Knob

E PTO (Blade Engage)Control Switch

F Parking Brake Lever

G Forward Control Pedal

H Reverse Control Pedal

I Brake Pedal

NOTE: Any reference in this manual to the RIGHT or LEFT side of the tractor is observed from operator's position.

J

Figure 4-1

J Deck Lift Lever

K Cup Holder

L Seat Adjustment Lever

M Fuel Fill Cap

N Hydro Transmission Bypass Rods

O Fuel Level Window

P Cargo Net

Q Hood Lift Notch

Page 10

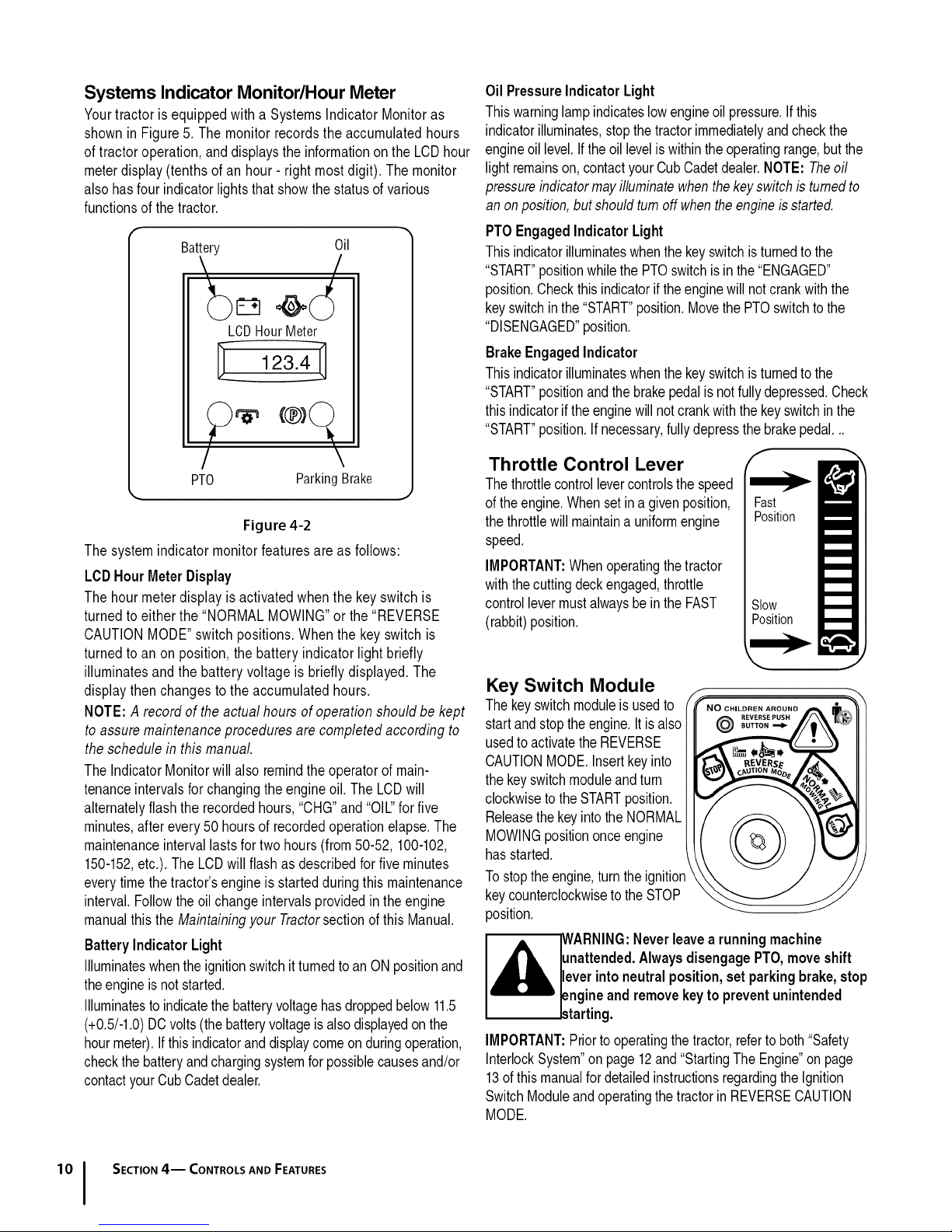

Systems Indicator Monitor/Hour Meter

Yourtractoris equippedwith a SystemsIndicator Monitoras

shownin Figure5. The monitorrecordsthe accumulatedhours

oftractor operation,anddisplaysthe informationontheLCDhour

meterdisplay(tenthsof an hour- right mostdigit). Themonitor

alsohas fourindicatorlights thatshowthe statusof various

functionsof the tractor.

Battery Oil

LCDHourMeter

123.4-

Oil PressureIndicatorLight

Thiswarninglampindicateslowengineoilpressure.Ifthis

indicatorilluminates,stopthetractorimmediatelyandcheckthe

engineoil level.If theoillevelis withintheoperatingrange,butthe

lightremainson,contactyourCubCadetdealer.NOTE:Theoil

pressureindicatormayilluminatewhenthekeyswitchis turnedto

an onposition,butshouldturn offwhentheengineisstarted.

PTOEngagedIndicator Light

Thisindicatorilluminateswhenthe keyswitchisturnedtothe

"START"positionwhilethe PTOswitchis inthe "ENGAGED"

position.Checkthisindicatorifthe enginewillnotcrankwiththe

keyswitchinthe"START"position.Movethe PTOswitchtothe

"DISENGAGED"position.

BrakeEngaged Indicator

Thisindicatorilluminateswhenthe keyswitchisturnedtothe

"START"positionandthebrakepedalis notfullydepressed.Check

thisindicatorifthe enginewillnotcrankwiththekeyswitchin the

"START"position.Ifnecessary,fullydepressthe brakepedal._

/

PTO ParkingBrake

Figure 4-2

Thesystem indicator monitorfeaturesareas follows:

LCDHourMeterDisplay

Thehour meterdisplay is activatedwhen the keyswitchis

turnedto either the "NORMALMOWING"orthe "REVERSE

CAUTIONMODE"switchpositions. Whenthe key switchis

turnedto an on position, the batteryindicator lightbriefly

illuminatesand the batteryvoltage is brieflydisplayed.The

displaythen changesto theaccumulatedhours.

NOTE:A record of theactual hours of operationshould be kept

to assuremaintenanceproceduresare completedaccordingto

the schedulein this manual.

TheIndicatorMonitorwill also remindtheoperatorof main-

tenanceintervalsfor changingthe engineoil. TheLCDwill

alternatelyflashthe recordedhours,"CHG"and"OIL"forfive

minutes,after every50 hoursof recordedoperationelapse.The

maintenanceintervallastsfor twohours (from50-52,100-102,

150-152,etc.). TheLCDwill flashas describedforfive minutes

everytimethetractor'sengineis startedduringthis maintenance

interval.Followthe oil changeintervalsprovidedintheengine

manualthis the Maintainingyour Tractorsection ofthis Manual.

Battery Indicator Light

Illuminateswhenthe ignitionswitchit turnedtoan ONpositionand

theengineis notstarted.

Illuminatesto indicatethe batteryvoltagehasdroppedbelow11.5

(+0.5/-1.0)DCvolts(the batteryvoltageis alsodisplayedon the

hourmeter).Ifthisindicatoranddisplaycomeon duringoperation,

checkthe batteryandchargingsystemforpossiblecausesand/or

contactyourCub Cadetdealer.

Throttle Control Lever

Thethrottlecontrollevercontrolsthe speed

ofthe engine.Whensetin a givenposition,

thethrottlewillmaintaina uniformengine

speed.

IMPORTANT:Whenoperatingthe tractor

withthecutting deckengaged,throttle

controllevermustalwaysbeinthe FAST

(rabbit)position.

f

Fast

Position

Slow

Position

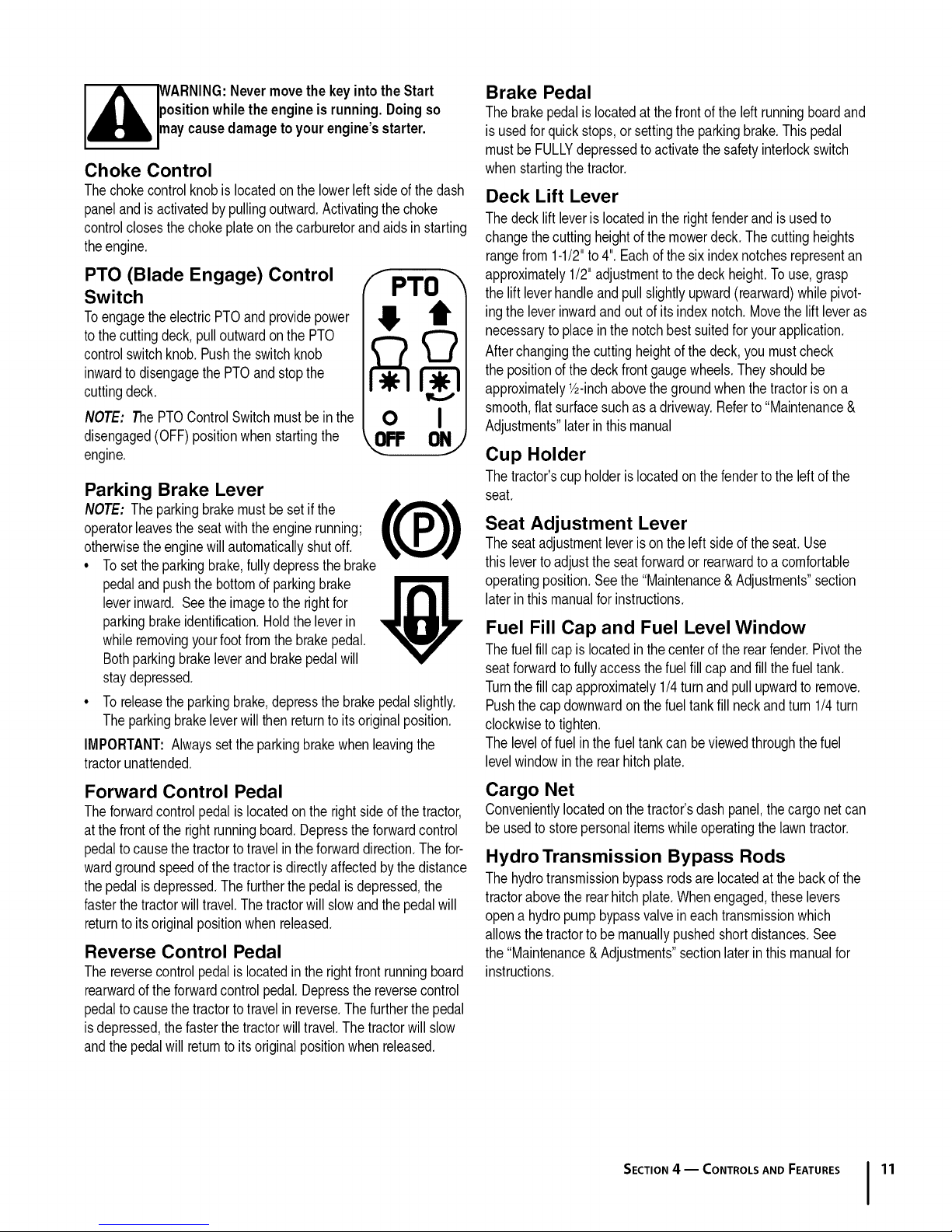

Key Switch Module

Thekeyswitchmoduleisusedto

startand stopthe engine.Itis also

usedto activatetheREVERSE

CAUTIONMODE.Insertkeyinto

thekeyswitchmoduleandturn

clockwisetotheSTARTposition.

Releasethe keyintothe NORMAL

MOWINGpositiononceengine

hasstarted.

Tostopthe engine,turntheignitior

keycounterclockwiseto theSTOP

position.

lunattended.AlwaysdisengagePTO,moveshift

I,_ ARNING:Neverleave a runningmachine

IMPORTANT:Priortooperatingthetractor,refertoboth"Safety

InterlockSystem"on page12and"StartingTheEngine"on page

13ofthismanualfordetailedinstructionsregardingthe Ignition

SwitchModuleandoperatingthetractorinREVERSECAUTION

MODE.

Ileverintoneutralposition,setparkingbrake,stop

lengineandremovekeyto preventunintended

_starting.

SECTION4-- CONTROLS AND FEATURES

Page 11

,_ IWARNING:NevermovethekeyintotheStart

positionwhilethe engineisrunning.Doingso

maycausedamageto yourengine'sstarter,

Choke Control

Thechokecontrolknobislocatedon the lowerleftsideofthedash

paneland isactivatedbypullingoutward.Activatingthechoke

controlclosesthechokeplateonthe carburetorandaids instarting

theengine.

PTO (Blade Engage) Control

Switch

Toengagethe electricPTOand providepower

tothe cuttingdeck,pulloutwardonthePTO

controlswitchknob.Pushthe switchknob

inwardtodisengagethePTOandstopthe

cuttingdeck.

NOTE: ThePTOControlSwitchmustbein the

disengaged(OFF)positionwhen startingthe

engine.

F PTO

! /

o I

Parking Brake Lever

NOTE: Theparkingbrakemustbeset ifthe

operatorleavestheseatwiththeenginerunning;

otherwisetheenginewillautomaticallyshutoff.

• Tosettheparkingbrake,fullydepressthebrake

pedaland pushthe bottomofparkingbrake

leverinward. Seethe imagetothe rightfor

parkingbrakeidentification.Holdthe leverin

whileremovingyourfootfromthebrakepedal.

Bothparkingbrakeleverand brakepedalwill

staydepressed.

• Toreleasetheparkingbrake,depressthebrakepedalslightly.

Theparkingbrakeleverwillthen returnto itsoriginalposition.

IMPORTANT:Alwayssetthe parkingbrakewhenleavingthe

tractorunattended.

Brake Pedal

Thebrakepedalislocatedat thefrontof theleftrunningboardand

isusedforquickstops,or settingthe parkingbrake.Thispedal

mustbe FULLYdepressedto activatethesafetyinterlockswitch

whenstartingthetractor.

Deck Lift Lever

Thedecklift leverislocatedin therightfenderandisusedto

changethecuttingheightofthe mowerdeck. Thecuttingheights

rangefrom 1-1/2"to4".Eachofthesixindexnotchesrepresentan

approximately1/2"adjustmenttothe deckheight.Touse,grasp

thelift leverhandleandpullslightlyupward(rearward)whilepivot-

ingtheleverinwardandout ofits indexnotch.Movetheliftleveras

necessaryto placeinthe notchbestsuitedforyourapplication.

Afterchangingthecuttingheightofthe deck,you mustcheck

thepositionof thedeckfrontgaugewheels.Theyshouldbe

approximately1/2-inchabovethegroundwhenthetractorisona

smooth,flat surfacesuchasa driveway.Referto "Maintenance&

Adjustments"laterinthis manual

Cup Holder

Thetractor'scupholderislocatedonthefendertothe leftofthe

seat.

Seat Adjustment Lever

Theseatadjustmentleverisonthe left sideoftheseat.Use

thisleverto adjusttheseatforwardor rearwardto a comfortable

operatingposition.Seethe "Maintenance&Adjustments"section

laterin thismanualforinstructions.

Fuel Fill Cap and Fuel Level Window

Thefuel fillcap islocatedin thecenterof therearfender.Pivotthe

seatforwardtofullyaccessthefuelfill capandfill thefueltank.

Turnthefillcap approximately1/4turnandpullupwardto remove.

Pushthe capdownwardonthe fueltankfillneckandturn 1/4turn

clockwisetotighten.

Theleveloffuel in thefueltankcan beviewedthroughthefuel

levelwindowinthe rearhitchplate.

Forward Control Pedal

Theforwardcontrolpedalis locatedonthe rightsideof thetractor,

atthe frontofthe rightrunningboard.Depresstheforwardcontrol

pedaltocausethe tractortotravelintheforwarddirection.Thefor-

wardgroundspeedofthe tractoris directlyaffectedbythedistance

thepedalis depressed.Thefurtherthepedalis depressed,the

fasterthetractorwill travel.Thetractorwill slowandthepedalwill

returnto itsoriginalpositionwhenreleased.

Reverse Control Pedal

Thereversecontrolpedalis locatedin therightfrontrunningboard

rearwardoftheforwardcontrolpedal.Depressthereversecontrol

pedaltocausethe tractortotravelin reverse.Thefurtherthepedal

isdepressed,the fasterthe tractorwilltravel.Thetractorwillslow

andthepedalwill returnto itsoriginalpositionwhenreleased.

Cargo Net

Convenientlylocatedonthetractor'sdashpanel,thecargonetcan

be usedto storepersonalitemswhileoperatingthelawntractor.

Hydro Transmission Bypass Rods

Thehydrotransmissionbypassrodsarelocatedatthebackofthe

tractorabovetherearhitchplate.Whenengaged,theselevers

opena hydropumpbypassvalveineach transmissionwhich

allowsthetractorto bemanuallypushedshortdistances.See

the"Maintenance& Adjustments"sectionlaterinthis manualfor

instructions.

SECTION4 -- CONTROLS AND FEATURES 11

Page 12

Operation

5

F

WARNING

AVOID SERIOUS INJURY OR DEATH

• GO UP AND DOWN SLOPES, NOTACROSS.

• AVOID SUDDEN TURNS.

• DONOTOPERATETHEUNITWHEREITCOULDSLIPORTIR

• IFMACHINESTOPSGOINGUPHILL, STOP BLADE(S) AND

BACKDOWNHILLSLOWLY.

• DONOTMOWWHENCHILDRENOROTHERSAREAROUND.

• NEVERCARRYCHILDREN,EVENWITHBLADESOFE

• LOOKDOWNANDBEHINDBEFOREANDWHILEBACKING.

• KEEPSAFETYDEVICES(GUARDS, SHIELDS, AND

SWITCHES)INPLACEANDWORKING.

• REMOVEOBJECTSTHATCOULDBETHROWNBYTHE

BLADE(S).

• KNOWLOCATIONANDFUNCTIONOFALLCONTROLS.

• BESUREBLADE(S) ANDENGINEARESTOPPEDBEFORE

PLACINGHANDSORFEETNEARBLADE(S).

• BEFORELEAVINGOPERATOR'SPOSITION, DISENGAGE

BLADE(S), PLACETHESHIFTLEVERINNEUTRAL, ENGAGE

BRAKELOCK,SHUTENGINEOFFANDREMOVEKEY.

READ OPERATOR'S MANUAL

ReverseCaution Mode

the tractor in the REVERSECAUTION MODE.

,_ WARNING: Use extreme caution while operating

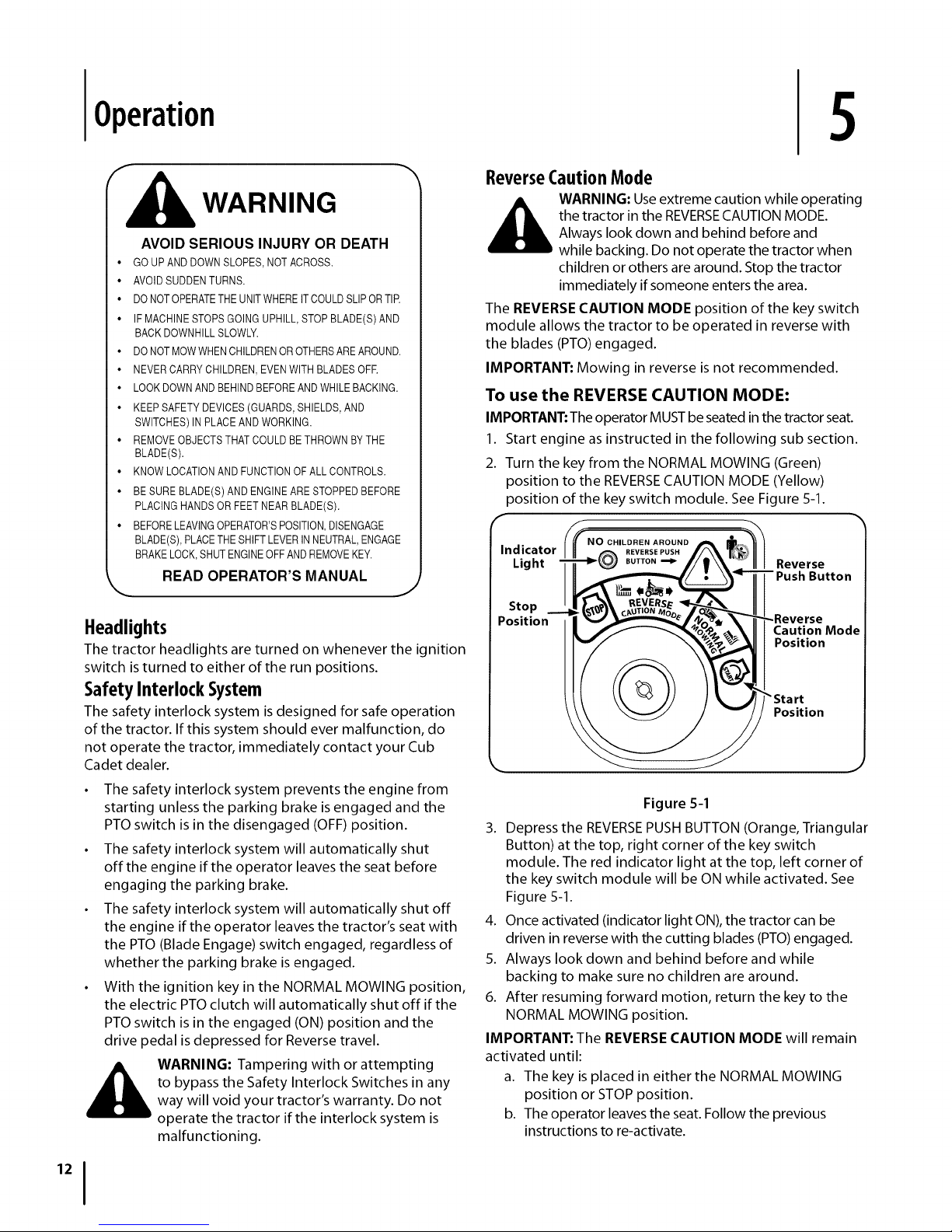

The REVERSE CAUTION MODE position of the key switch

module allows the tractor to be operated in reverse with

the blades (PTO) engaged.

IMPORTANT: Mowing in reverse is not recommended.

Always look down and behind before and

while backing. Do not operate the tractor when

children or others are around. Stop the tractor

immediately if someone enters the area.

To use the REVERSE CAUTION MODE:

IMPORTANT: The operator MUST be seated in the tractor seat.

1. Start engine as instructed in the following sub section.

2.

Turn the key from the NORMAL MOWING (Green)

position to the REVERSECAUTION MODE (Yellow)

position of the key switch module. See Figure 5-1.

. o,,.ooE.Aooo.oA

Indicator III _ ,_, BEVERSEPUSH//_ I1_111

Light __-_--I_ BUTTON_ J'/t\_ _y 111Reverse

_'_-_- PushButton

Headlights

The tractor headlights are turned on whenever the ignition

switch is turned to either of the run positions.

Safety Interlock System

The safety interlock system is designed for safe operation

of the tractor. If this system should ever malfunction, do

not operate the tractor, immediately contact your Cub

Cadet dealer.

• The safety interlock system prevents the engine from

starting unless the parking brake is engaged and the

PTO switch is in the disengaged (OFF) position.

• The safety interlock system will automatically shut

off the engine if the operator leaves the seat before

engaging the parking brake.

• The safety interlock system will automatically shut off

the engine if the operator leaves the tractor's seat with

the PTO (Blade Engage) switch engaged, regardless of

whether the parking brake is engaged.

• With the ignition key in the NORMAL MOWING position,

the electric PTO clutch will automatically shut off if the

PTO switch is in the engaged (ON) position and the

drive pedal is depressed for Reverse travel.

to bypass the Safety Interlock Switches in any

,_ WARNING: Tampering with or attempting

way will void your tractor's warranty. Do not

operate the tractor if the interlock system is

malfunctioning.

° t'tp° iiii

Figure 5-1

3. Depress the REVERSEPUSH BUTTON (Orange, Triangular

Button) at the top, right corner of the key switch

module. The red indicator light at the top, left corner of

the key switch module will be ON while activated. See

Figure 5-1.

4. Once activated (indicator light ON), the tractor can be

driven in reverse with the cutting blades (PTO)engaged.

5. Always look down and behind before and while

backing to make sure no children are around.

6. After resuming forward motion, return the key to the

NORMAL MOWING position.

IMPORTANT: The REVERSE CAUTION MODE will remain

activated until:

a. The key is placed in either the NORMAL MOWING

position or STOP position.

b. The operator leaves the seat. Follow the previous

instructions to re-activate.

Page 13

Startingthe Engine

,_ WARNING: Do not operate the tractor if the

NOTE: Refer to the engine Owner's Manual for gasoline

and oil fill-up instructions.

1. Insert the tractor key into the key switch module.

2. Disengage the PTO (Blade Engage) lever/knob.

3. Engage the tractor's parking brake.

4. Pull the choke control knob outward into the full choke

position (a warm engine may not require choking).

5. Move the throttle control lever to midway between the

SLOW and FAST positions.

6. Turn the ignition key clockwise to the START position.

After the engine starts, release the key. It will return to

the NORMAL MOWING position.

IMPORTANT: Do not hold the key in the START position

for longer than ten seconds at a time. Doing so may cause

damage to your engine's electric starter.

7. After the engine starts, gradually push the choke knob

fully inward as the engine warms up.

NOTE: Do not use the choke control to enrich the fuel

mixture, except as necessary to start and warm up the

engine.

interlock system is malfunctioning. This system

was designed for your safety and protection.

IMPORTANT

If leaving the tractor unattended, also turn the

ignition key offand remove the key.

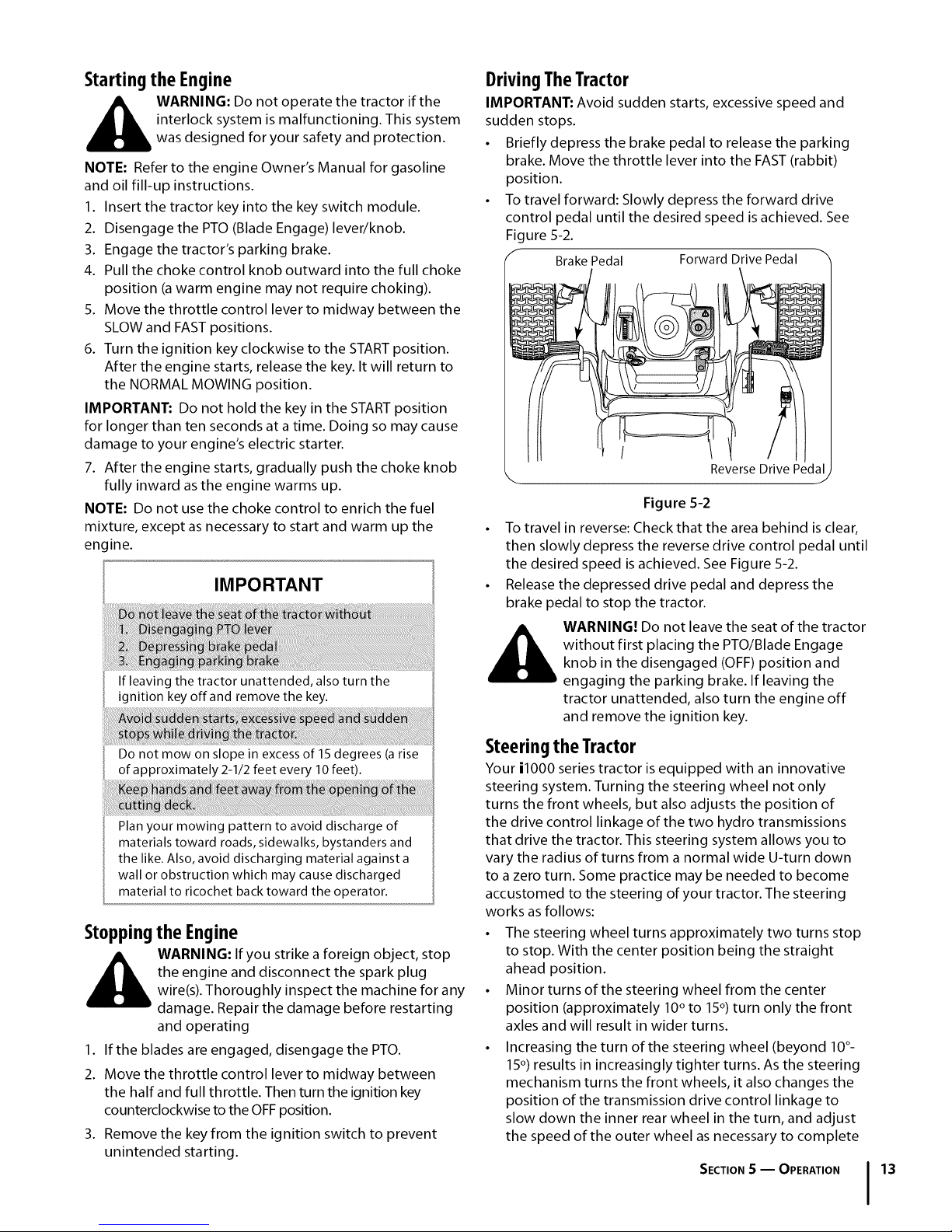

DrivingTheTractor

IMPORTANT: Avoid sudden starts, excessive speed and

sudden stops.

• Briefly depress the brake pedal to release the parking

brake. Move the throttle lever into the FAST (rabbit)

position.

• To travel forward: Slowly depress the forward drive

control pedal until the desired speed is achieved. See

Figure 5-2.

/r Brake Pedal Forward Drive Pedal "%

k, Reverse Drive Pedal/

Figure 5-2

To travel in reverse: Check that the area behind is clear,

then slowly depress the reverse drive control pedal until

the desired speed is achieved. See Figure 5-2.

Release the depressed drive pedal and depress the

brake pedal to stop the tractor.

WARNING! Do not leave the seat of the tractor

without first placing the PTO/Blade Engage

knob in the disengaged (OFF) position and

engaging the parking brake. If leaving the

tractor unattended, also turn the engine off

and remove the ignition key.

Do not mow on slope in excess of 15 degrees (a rise

of approximately 2-1/2 feet every 10 feet).

Plan your mowing pattern to avoid discharge of

materials toward roads, sidewalks, bystanders and

the like. Also, avoid discharging material against a

wall or obstruction which may cause discharged

material to ricochet back toward the operator.

Stoppingthe Engine

WARNING: If you strike a foreign object, stop

the engine and disconnect the spark plug

wire(s). Thoroughly inspect the machine for any

damage. Repair the damage before restarting

and operating

1. If the blades are engaged, disengage the PTO.

2. Move the throttle control lever to midway between

the half and full throttle. Then turn the ignition key

counterclockwise to the OFF position.

3. Remove the key from the ignition switch to prevent

unintended starting.

Steeringthe Tractor

Your i1000 series tractor is equipped with an innovative

steering system. Turning the steering wheel not only

turns the front wheels, but also adjusts the position of

the drive control linkage of the two hydro transmissions

that drive the tractor. This steering system allows you to

vary the radius of turns from a normal wide U-turn down

to a zero turn. Some practice may be needed to become

accustomed to the steering of your tractor. The steering

works as follows:

• The steering wheel turns approximately two turns stop

to stop. With the center position being the straight

ahead position.

• Minor turns of the steering wheel from the center

position (approximately 10° to 15°) turn only the front

axles and will result in wider turns.

• Increasing the turn of the steering wheel (beyond 10°-

15°) results in increasingly tighter turns. As the steering

mechanism turns the front wheels, it also changes the

position of the transmission drive control linkage to

slow down the inner rear wheel in the turn, and adjust

the speed of the outer wheel as necessary to complete

SECTION S -- OPERATION 13

Page 14

the desired turn. Turn the steering wheel back to the

center position as the turn is completed.

NOTE: It is not necessary to release the drive pedal when

making a turn. The change to the transmission linkage

occurs regardless of how far the drive pedal is depressed.

When the steering wheel is straightened, the tractor will

return to the speed set by the drive pedal.

• Turning the steering wheel fully to its stop in either

direction will fully turn the front wheels, reverse the

direction of the inner wheel and adjust the outer wheel

speed to execute a zero turn in the chosen direction.

Turn the steering wheel back to the center position as

the turn is completed.

NOTE: As the steering wheel is turned further toward

its stop, the effort needed to turn the steering wheel

increases.

IMPORTANT: Making tight or zero turns on grass will

greatly increase the potential for defacement of the turf.

Driving OnSlopes

IMPORTANT: Refer to the SLOPEGAUGE on page 7 to

help determine slopes where you may operate the tractor

safely.

• Mow up and down slopes, never across.

• Watch for holes, ruts, bumps, rocks, or other hidden

objects. Uneven terrain could overturn the machine.

Tall grass can hide obstacles.

• Avoid turns when driving on a slope. If a turn must

be made, turn downhill on the slope. Turning uphill

increases the possibility of a tractor rollover.

• Avoid stopping when driving up a slope. If it is

necessary to stop while driving up a slope, start up

smoothly and carefully to reduce the possibility of

flipping the tractor over backward.

Engaging the Parking Brake

NOTE: The parking brake must be set if the operator

leaves the seat with the engine running or the engine will

automatically shut off.

To set the parking brake:

1. Press the brake pedal completely down with you right

foot and hold it that position.

2. Push the parking brake lever downward and hold it in

that position.

3. Remove your foot from the brake pedal.

4. Release pressure from the parking brake lever.

After completing step 3, the brake pedal should remain

in the down position. If it doesn't, the parking brake is not

enaged. Repete steps 1-4 to engage the parking brake.

To disengage the parking brake, lightly press the brake

pedal.

unattended. Always disengage PTO, set parking

_ ARNING: Never leave a running machine

brake, stop engine and remove key to prevent

unintended starting

Engagingthe PTO

Engaging the PTO transfers power to the cutting deck or

other (separately available) attachments. To engage the

PTO:

1. Move the throttle control lever to the FAST (rabbit)

position.

2. Pull the PTO/Blade Engage knob outward into the

engaged (ON) position.

NOTE: Always operate the tractor with the throttle lever

in the FAST (rabbit) position for the most efficient use of

the cutting deck or other (separately available) PTO driven

attachments.

Mowing

thrown object injury, keep bystanders, helpers,

_ ARNING: To help avoid blade contact or a

This tractor is equipped with one of Cub Cadet's high

quality cutting decks. The following information will be

helpful when using the cutting deck with your tractor.

• Do not mow at high ground speed, especially if a mulch

kit or grass collector is installed.

• For best results it is recommended that the first two laps be

cut with the discharge thrown towards the center. After the

first two laps, reverse the direction to throw the discharge

to the outside for the balance of cutting. This will give a

better appearance to the lawn.

• Do not cut the grass too short. Short grass invites weed

growth and yellows quickly in dry weather.

• Mowing should always be done with the engine at full

throttle.

• Under heavier conditions it may be necessary to go back

over the cut area a second time to get a clean cut.

• Do not attempt to mow heavy brush and weeds and

extremely tall grass. Your tractor is designed to mow

lawns, not clear brush.

• Keep the blades sharp and replace the blades when

worn. Refer to the "SERVICE"section of this manual for

proper blade sharpening instructions.

IMPORTANT: When stopping the tractor for any reason

while on a grass surface, always

• Place the shift lever in neutral,

• Engage the parking brake,

• Shut engine off and remove the key

Doing so will minimize the possibility of having your lawn

"browned" by hot exhaust from your tractor's running

engine

children and pets at least 75 feet from the

machine while it is in operation. Stop machine

if anyone enters the area.

SECTION S-- OPERATION

Page 15

Maintenance&Adjustments

6

Maintenance

WARNING! Before performing any mainte-

nance or repairs, disengage the PTO, move the

drive control levers fully outward in the neutral

position, engage the parking brake, stop the

engine and remove the key to prevent unin-

tended starting.

Engine

Refer to the Kohler Owner's Manual for all engine main-

tenance intervals, procedures, specifications and instruc-

tions.

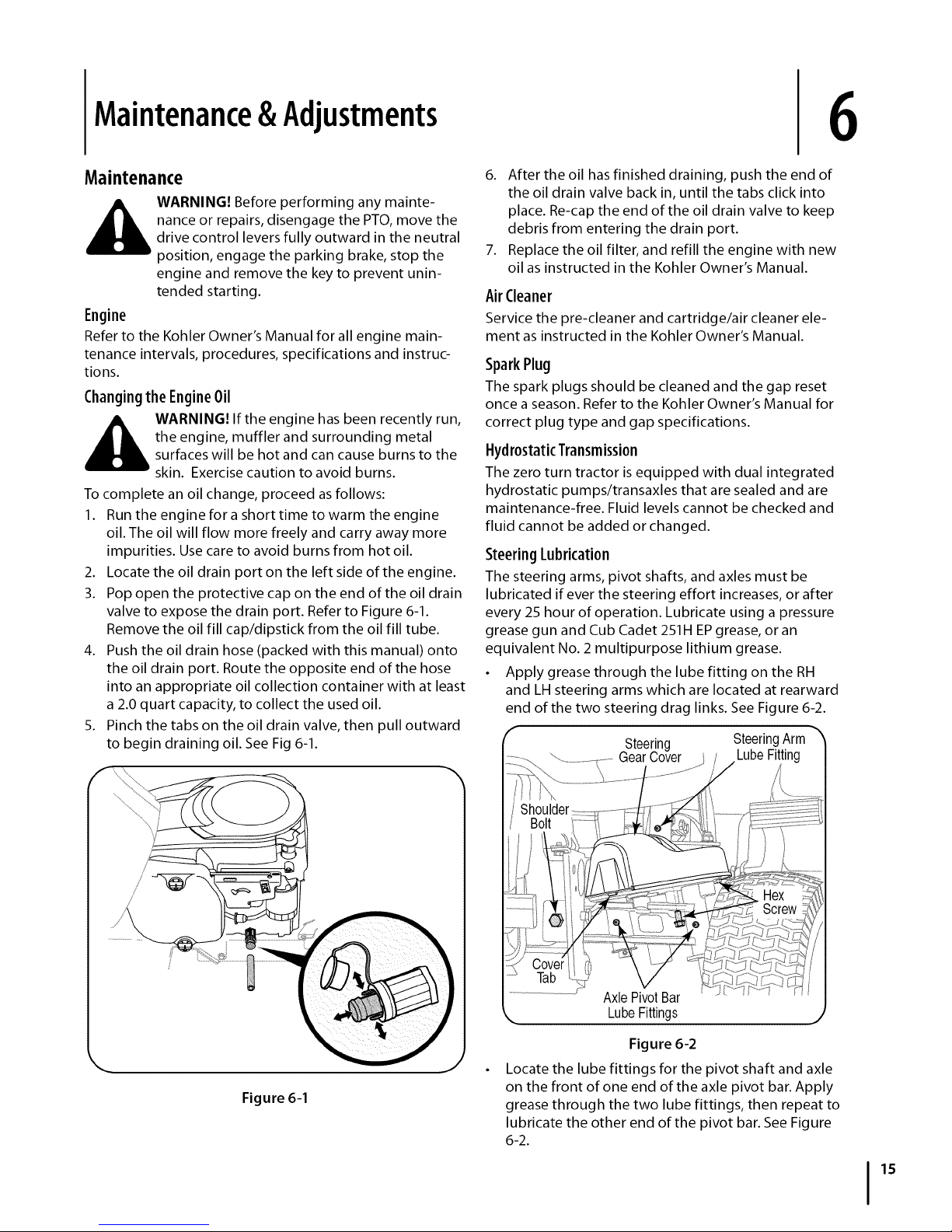

Changingthe EngineOil

the engine, muffler and surrounding metal

_ ARNING! If the engine has been recently run,

To complete an oil change, proceed as follows:

I. Run the engine fora short time towarm the engine

oil. The oil will flow more freely and carry away more

impurities. Use care to avoid burns from hot oil.

2. Locate the oil drain port on the left side of the engine.

3. Pop open the protective cap on the end of the oil drain

valve to expose the drain port. Refer to Figure 6-I.

Remove the oil fill cap/dipstick from the oil fill tube.

4. Push the oil drain hose (packed with this manual) onto

the oil drain port. Route the opposite end of the hose

into an appropriate oil collection container with at least

a 2.0 quart capacity, to collect the used oil.

5. Pinch the tabs on the oil drain valve, then pull outward

to begin draining oil. See Fig 6-I.

surfaces will be hot and can cause burns to the

skin. Exercise caution to avoid burns.

6. After the oil has finished draining, push the end of

the oil drain valve back in, until the tabs click into

place. Re-cap the end of the oil drain valve to keep

debris from entering the drain port.

7. Replace the oil filter, and refill the engine with new

oil as instructed in the Kohler Owner's Manual.

AirCleaner

Service the pre-cleaner and cartridge/air cleaner ele-

ment as instructed in the Kohler Owner's Manual.

SparkPlug

The spark plugs should be cleaned and the gap reset

once a season. Refer to the Kohler Owner's Manual for

correct plug type and gap specifications.

HydrostaticTransmission

The zero turn tractor is equipped with dual integrated

hydrostatic pumps/transaxles that are sealed and are

maintenance-free. Fluid levels cannot be checked and

fluid cannot be added or changed.

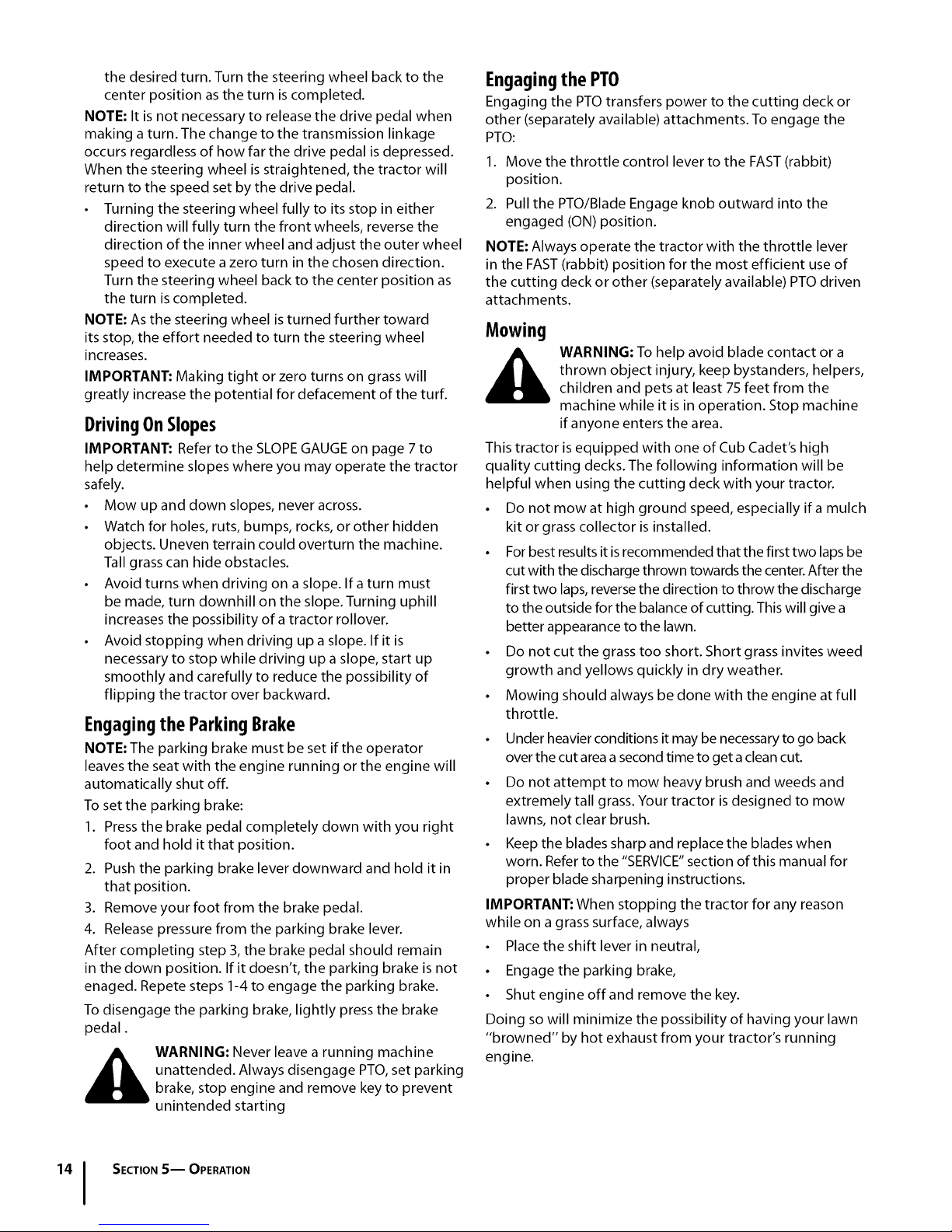

SteeringLubrication

The steering arms, pivot shafts, and axles must be

lubricated if ever the steering effort increases, or after

every 25 hour of operation. Lubricate using a pressure

grease gun and Cub Cadet 251H EP grease, or an

equivalent No. 2 multipurpose lithium grease.

• Apply grease through the lube fitting on the RH

and LH steering arms which are located at rearward

end of the two steering drag links. See Figure 6-2.

Steering SteeringArm

GearCover LubeFitting

//

Figure6-1

Lube _gs

Figure 6-2

Locate the lube fittings for the pivot shaft and axle

on the front of one end of the axle pivot bar. Apply

grease through the two lube fittings, then repeat to

lubricate the other end of the pivot bar. See Figure

6-2.

15

Page 16

CleaningSteeringGears

Once a year, or ira tight spot is experienced when turning

the steering wheel, remove the steering gear cover on

each end of the pivot bar and clean the two steering gears.

• From beneath the cover base plate on each end of the

pivot bar, remove the three hex screws securing the

steering gear coven Remove the covers and clean the

gears. It is not necessary to lubricate the gears. Refer to

Figure 6-2.

• Insert the tab of the LH steering gear cover into the

square hole in the LH base plate, position the cover, and

secure with the three hex screws. Do not over tighten.

Repeat to install the cover on the RH side.

LubricateFrontWheel Bearings

Lubricate the front wheel bearings with Cub Cadet 251H EP

grease after every 25 hours of operation. The lube fittings

are located in the rim hub inside each front wheel.

LubricateDeckSpindlesand Idler Bracket

Lubricate the deck spindles and idler bracket with Cub

Cadet 251H EPgrease after every 10 hours of operation.

The deck spindle lube fittings are in the spindle housings,

and can only be accessed from the underside of the deck.

Lubricate the idler bracket through the lube fitting in the

top of the shoulder bolt. Use a pressure grease gun to

lubricate the spindles and idler bracket.

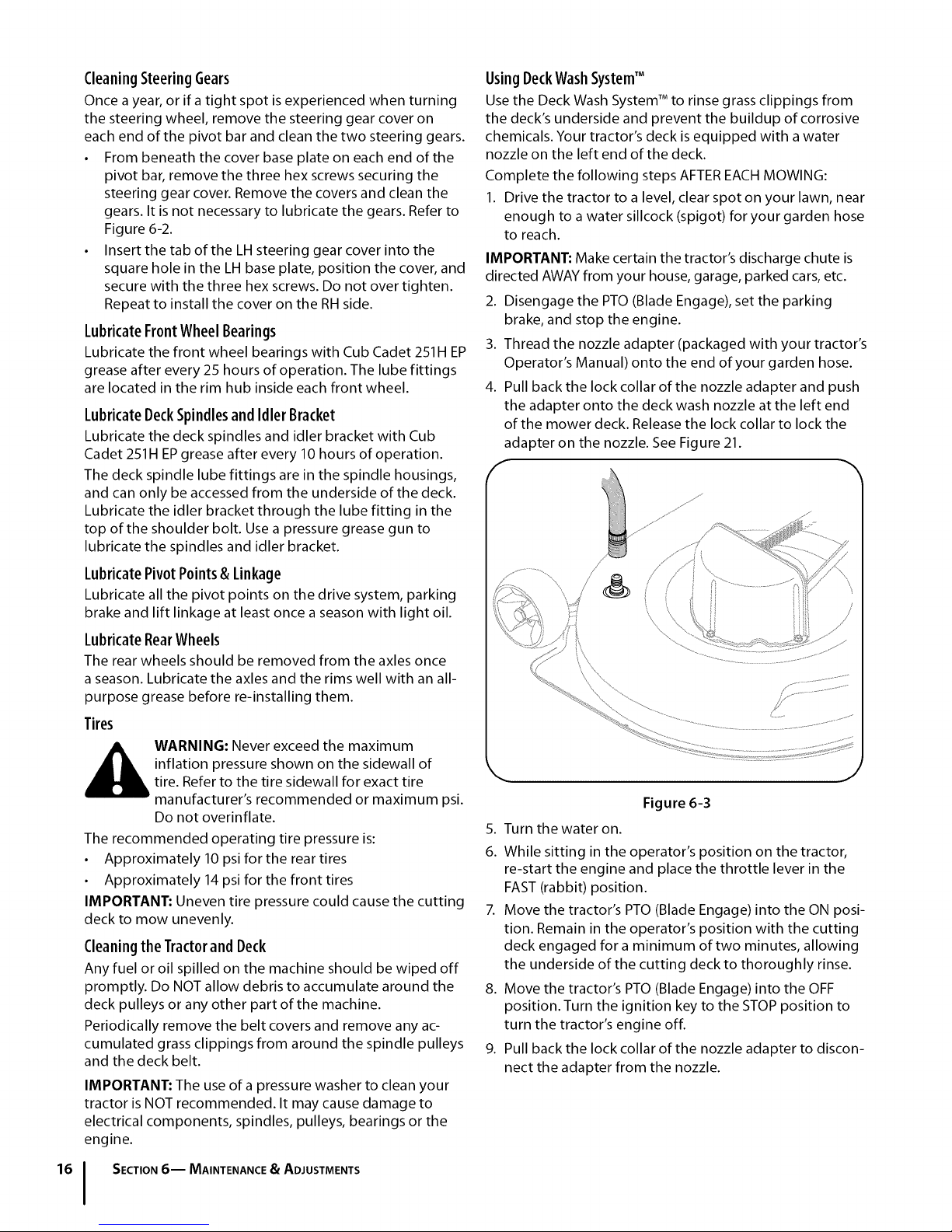

UsingDeckWashSystemTM

Use the Deck Wash System TM to rinse grass clippings from

the deck's underside and prevent the buildup of corrosive

chemicals. Your tractor's deck is equipped with a water

nozzle on the left end of the deck.

Complete the following steps AFTER EACH MOWING:

1. Drive the tractor to a level, clear spot on your lawn, near

enough to a water sillcock (spigot) for your garden hose

to reach.

IMPORTANT: Make certain the tractor's discharge chute is

directed AWAY from your house, garage, parked cars, etc.

2. Disengage the PTO (Blade Engage), set the parking

brake, and stop the engine.

3. Thread the nozzle adapter (packaged with your tractor's

Operator's Manual) onto the end of your garden hose.

4. Pull back the lock collar of the nozzle adapter and push

the adapter onto the deck wash nozzle at the left end

of the mower deck. Release the lock collar to lock the

adapter on the nozzle. See Figure 21.

LubricatePivotPoints& Linkage

Lubricate all the pivot points on the drive system, parking

brake and lift linkage at least once a season with light oil.

LubricateRearWheels

The rear wheels should be removed from the axles once

a season. Lubricate the axles and the rims well with an all-

purpose grease before re-installing them.

Tires

WARNING: Never exceed the maximum

inflation pressure shown on the sidewall of

tire. Refer to the tire sidewall for exact tire

manufacturer's recommended or maximum psi.

Do not overinflate.

The recommended operating tire pressure is:

• Approximately 10 psi for the rear tires

• Approximately 14 psi for the front tires

IMPORTANT: Uneven tire pressure could cause the cutting

deck to mow unevenly.

CleaningtheTractorandDeck

Any fuel or oil spilled on the machine should be wiped off

promptly. Do NOT allow debris to accumulate around the

deck pulleys or any other part of the machine.

Periodically remove the belt covers and remove any ac-

cumulated grass clippings from around the spindle pulleys

and the deck belt.

IMPORTANT: The use of a pressure washer to clean your

tractor is NOT recommended. It may cause damage to

electrical components, spindles, pulleys, bearings or the

engine.

SECTION6-- MAINTENANCE _ ADJUSTMENTS

Figure 6-3

5.

Turn the water on.

6.

While sitting in the operator's position on the tractor,

re-start the engine and place the throttle lever in the

FAST (rabbit) position.

7. Move the tractor's PTO (Blade Engage) into the ON posi-

tion. Remain in the operator's position with the cutting

deck engaged fora minimum of two minutes, allowing

the underside of the cutting deck to thoroughly rinse.

8. Move the tractor's PTO (Blade Engage) into the OFF

position. Turn the ignition key to the STOP position to

turn the tractor's engine off.

9. Pull back the lock collar of the nozzle adapter to discon-

nect the adapter from the nozzle.

Page 17

MovingtheTractorManually

If for any reason the tractor will not drive or you wish to

move the tractor, engage the two hydro transmission

bypass rods to manually move the tractor short distances.

IMPORTANT: Never tow or drag the tractor with the rear

wheels on the ground. Even with the bypass rods engaged.

Doing so will damage the transmissions.

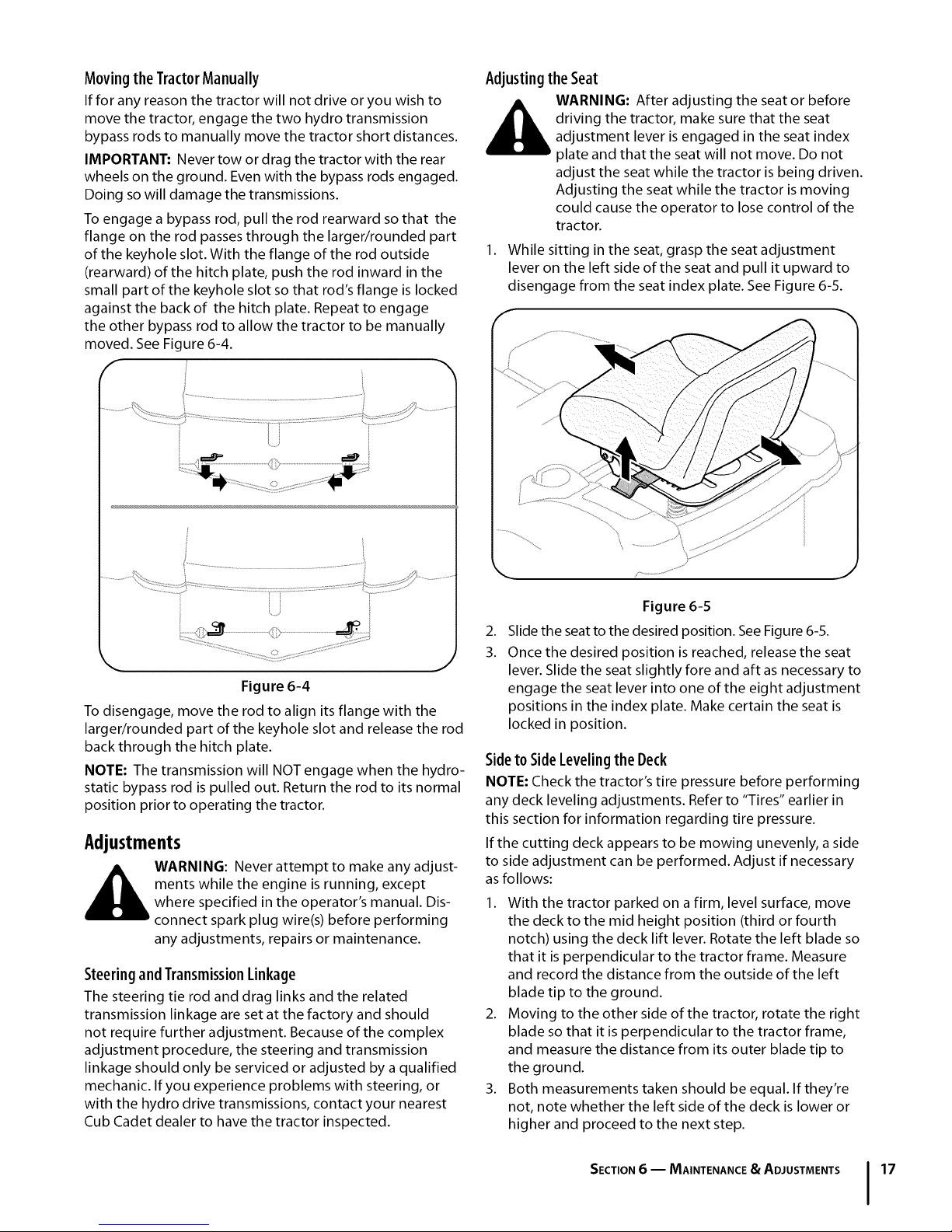

To engage a bypass rod, pull the rod rearward so that the

flange on the rod passes through the larger/rounded part

of the keyhole slot. With the flange of the rod outside

(rearward) of the hitch plate, push the rod inward in the

small part of the keyhole slot so that rod's flange is locked

against the back of the hitch plate. Repeat to engage

the other bypass rod to allow the tractor to be manually

moved. See Figure 6-4.

f

f

Adjusting the Seat

driving the tractor, make sure that the seat

_ ARNING: After adjusting the seat or before

adjustment lever is engaged in the seat index

plate and that the seat will not move. Do not

adjust the seat while the tractor is being driven.

Adjusting the seat while the tractor is moving

could cause the operator to lose control of the

tractor.

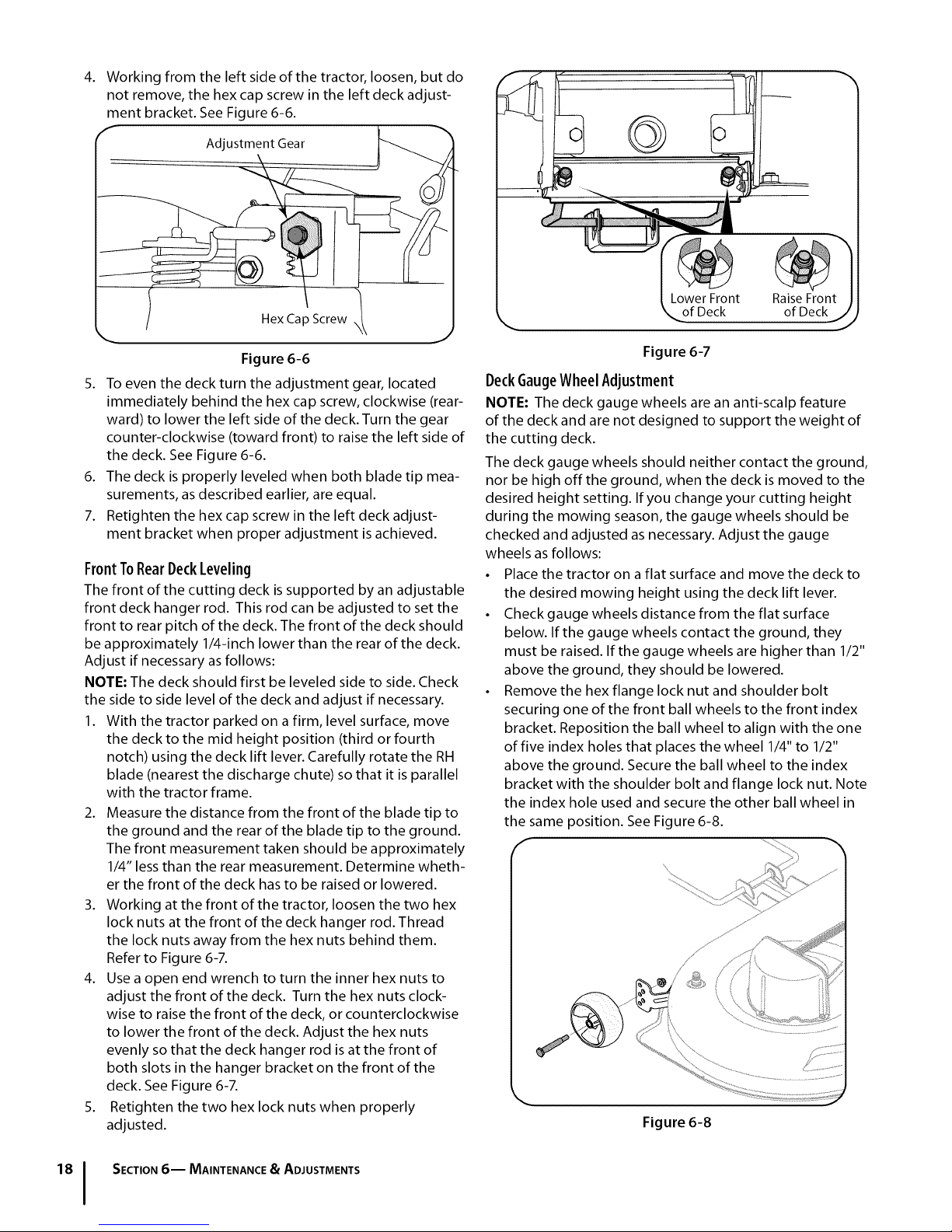

1. While sitting in the seat, grasp the seat adjustment

lever on the left side of the seat and pull it upward to

disengage from the seat index plate. See Figure 6-5.

_, ,J

Figure 6-4

To disengage, move the rod to align its flange with the

larger/rounded part of the keyhole slot and release the rod

back through the hitch plate.

NOTE: The transmission will NOT engage when the hydro-

static bypass rod is pulled out. Return the rod to its normal

position prior to operating the tractor.

Adjustments

ments while the engine is running, except

__ ARNING: Never attempt to make any adjust-

SteeringandTransmissionLinkage

The steering tie rod and drag links and the related

transmission linkage are set at the factory and should

not require further adjustment. Because of the complex

adjustment procedure, the steering and transmission

linkage should only be serviced or adjusted by a qualified

mechanic. If you experience problems with steering, or

with the hydro drive transmissions, contact your nearest

Cub Cadet dealer to have the tractor inspected.

where specified in the operator's manual. Dis-

connect spark plug wire(s) before performing

any adjustments, repairs or maintenance.

Figure 615

2.

Slide the seat to the desired position. See Figure 6-5.

3.

Once the desired position is reached, release the seat

lever. Slide the seat slightly fore and aft as necessary to

engage the seat lever into one of the eight adjustment

positions in the index plate. Make certain the seat is

locked in position.

Sideto SideLevelingthe Deck

NOTE: Check the tractor's tire pressure before performing

any deck leveling adjustments. Refer to "Tires" earlier in

this section for information regarding tire pressure,

If the cutting deck appears to be mowing unevenly, a side

to side adjustment can be performed. Adjust if necessary

as follows:

1. With the tractor parked on a firm, level surface, move

the deck to the mid height position (third or fourth

notch) using the deck lift lever. Rotate the left blade so

that it is perpendicular to the tractor frame. Measure

and record the distance from the outside of the left

blade tip to the ground.

2. Moving to the other side of the tractor, rotate the right

blade so that it is perpendicular to the tractor frame,

and measure the distance from its outer blade tip to

the ground.

3. Both measurements taken should be equal. If they're

not, note whether the left side of the deck is lower or

higher and proceed to the next step.

SECTION6 -- MAINTENANCE • ADJUSTMENTS 17

Page 18

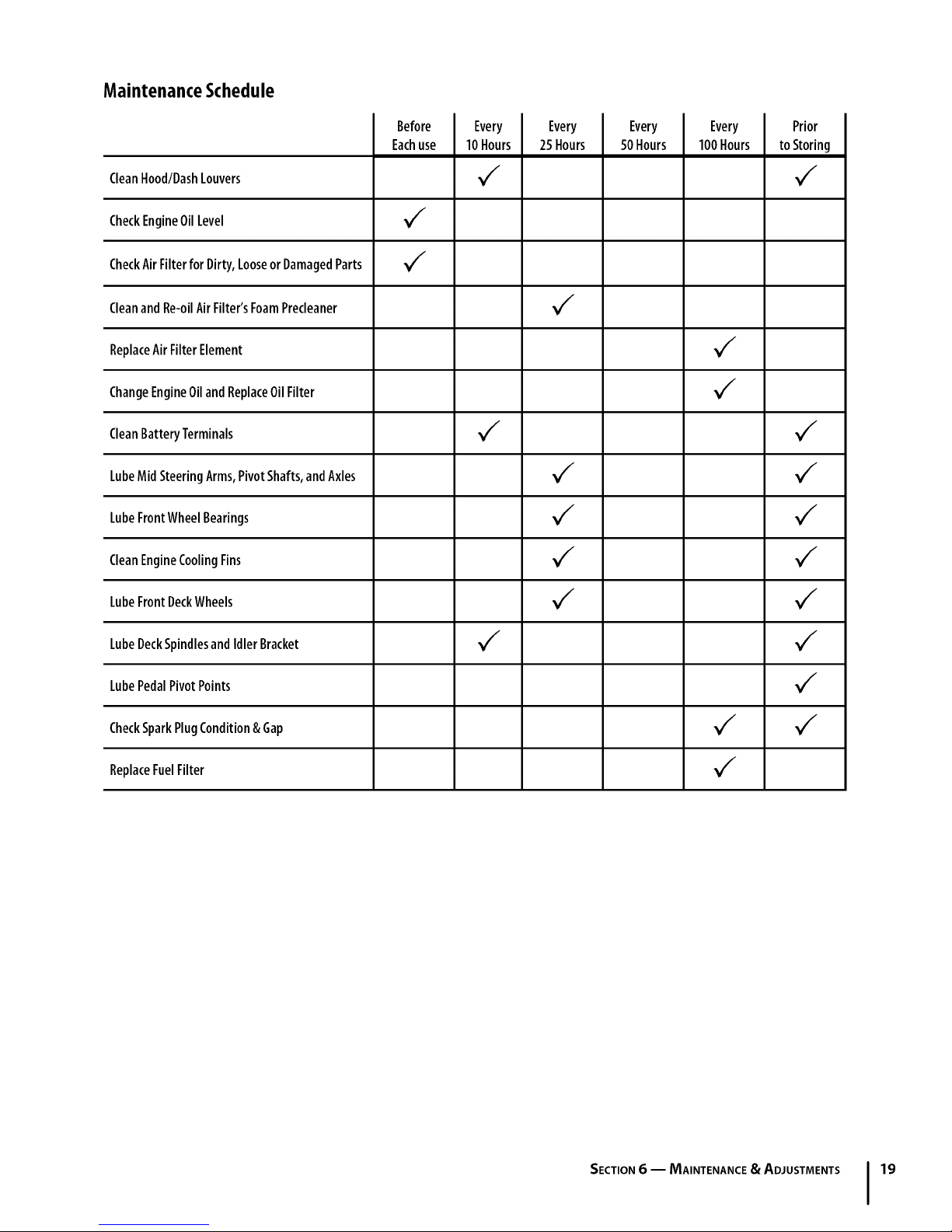

Working from the left side of the tractor, loosen, but do

not remove, the hex cap screw in the left deck adjust-

ment bracket. See Figure 6-6.

Adjustment Gear

Hex Cap Screw \

Raise Front

of Deckj

Figure 6-6

5. To even the deck turn the adjustment gear, located

immediately behind the hex cap screw, clockwise (rear-

ward) to lower the left side of the deck. Turn the gear

counter-clockwise (toward front) to raise the left side of

the deck. See Figure 6-6.

6. The deck is properly leveled when both blade tip mea-

surements, as described earlier, are equal.

7. Retighten the hex cap screw in the left deck adjust-

ment bracket when proper adjustment is achieved.

FrontToRearDeckLeveling

The front of the cutting deck is supported by an adjustable

front deck hanger rod. This rod can be adjusted to set the

front to rear pitch of the deck. The front of the deck should

be approximately 1/4-inch lower than the rear of the deck.

Adjust if necessary as follows:

NOTE: The deck should first be leveled side to side. Check

the side to side level of the deck and adjust if necessary.

1. With the tractor parked on a firm, level surface, move

the deck to the mid height position (third or fourth

notch) using the deck lift lever. Carefully rotate the RH

blade (nearest the discharge chute) so that it is parallel

with the tractor frame.

2. Measure the distance from the front of the blade tip to

the ground and the rear of the blade tip to the ground.

The front measurement taken should be approximately

1/4" less than the rear measurement. Determine wheth-

er the front of the deck has to be raised or lowered.

3. Working at the front of the tractor, loosen the two hex

lock nuts at the front of the deck hanger rod. Thread

the lock nuts away from the hex nuts behind them.

Refer to Figure 6-7.

4. Use a open end wrench to turn the inner hex nuts to

adjust the front of the deck. Turn the hex nuts clock-

wise to raise the front of the deck, or counterclockwise

to lower the front of the deck. Adjust the hex nuts

evenly so that the deck hanger rod is at the front of

both slots in the hanger bracket on the front of the

deck. See Figure 6-7.

5. Retighten the two hex lock nuts when properly

adjusted.

Figure 6-7

Deck GaugeWheel Adjustment

NOTE: The deck gauge wheels are an anti-scalp feature

of the deck and are not designed to support the weight of

the cutting deck.

The deck gauge wheels should neither contact the ground,

nor be high off the ground, when the deck is moved to the

desired height setting. If you change your cutting height

during the mowing season, the gauge wheels should be

checked and adjusted as necessary. Adjust the gauge

wheels as follows:

• Place the tractor on a flat surface and move the deck to

the desired mowing height using the deck lift lever.

• Check gauge wheels distance from the flat surface

below. If the gauge wheels contact the ground, they

must be raised. If the gauge wheels are higher than 1/2"

above the ground, they should be lowered.

• Remove the hex flange lock nut and shoulder bolt

securing one of the front ball wheels to the front index

bracket. Reposition the ball wheel to align with the one

of five index holes that places the wheel 1/4" to 1/2"

above the ground. Secure the ball wheel to the index

bracket with the shoulder bolt and flange lock nut. Note

the index hole used and secure the other ball wheel in

the same position. See Figure 6-8.

f

Figure 6-8

SECTION6-- MAINTENANCE _ ADJUSTMENTS

Page 19

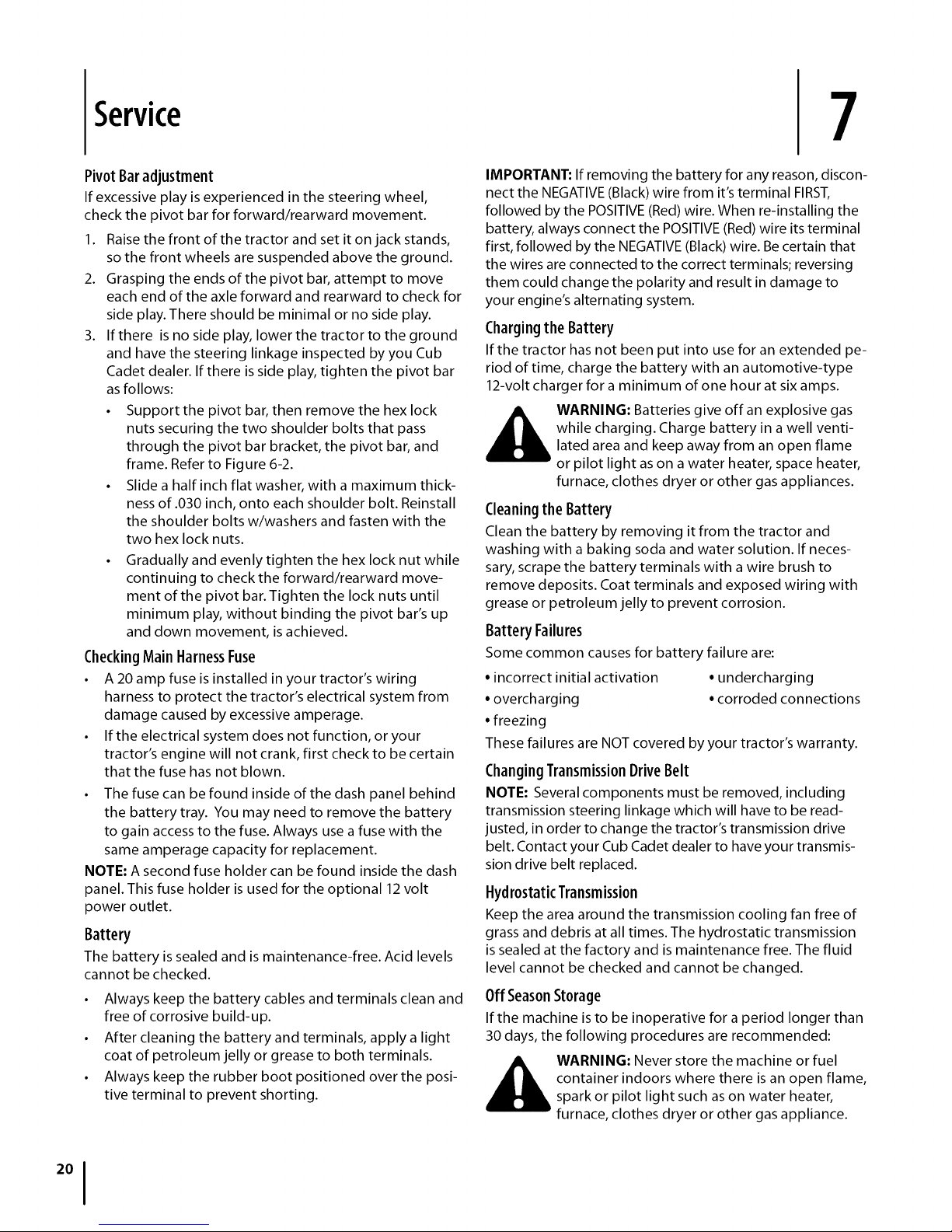

Maintenance Schedule

Before

Eachuse

CleanHood/DashLouvers

CheckEngineOilLevel

CheckAirFilterforDirty,LooseorDamagedParts

CleanandRe-oilAirFilter'sFoamPrecleaner

ReplaceAirFilterElement

ChangeEngineOilandReplaceOilFilter

CleanBatteryTerminals _

LubeMidSteeringArms,PivotShafts,andAxles Y'" Y'"

LubeFrontWheelBearings Y'" Y'"

CleanEngineCoolingFins Y'" Y'"

Every

10Hours

Every

25Hours

Every

SOHours

Every

100Hours

Prior

toStoring

LubeFrontDeckWheels Y'" Y'"

LubeDeckSpindlesandIdlerBracket Y'" Y'"

LubePedalPivotPoints

CheckSparkPlugCondition& Gap Y'" Y'"

ReplaceFuelFilter

SECTION6 -- MAINTENANCE • ADJUSTMENTS 19

Page 20

Service

7

Pivot Baradjustment

If excessive play is experienced in the steering wheel,

check the pivot bar for forward/rearward movement.

1. Raise the front of the tractor and set it on jack stands,

so the front wheels are suspended above the ground.

2. Grasping the ends of the pivot bar, attempt to move

each end of the axle forward and rearward to check for

side play. There should be minimal or no side play.

3. If there is no side play, lower the tractor to the ground

and have the steering linkage inspected by you Cub

Cadet dealer. If there is side play, tighten the pivot bar

as follows:

• Support the pivot bar, then remove the hex lock

nuts securing the two shoulder bolts that pass

through the pivot bar bracket, the pivot bar, and

frame. Refer to Figure 6-2.

• Slide a half inch flat washer, with a maximum thick-

ness of .030 inch, onto each shoulder bolt. Reinstall

the shoulder bolts w/washers and fasten with the

two hex lock nuts.

• Gradually and evenly tighten the hex lock nut while

continuing to check the forward/rearward move-

ment of the pivot bar. Tighten the lock nuts until

minimum play, without binding the pivot bar's up

and down movement, is achieved.

CheckingMain HarnessFuse

• A 20 amp fuse is installed in your tractor's wiring

harness to protect the tractor's electrical system from

damage caused by excessive amperage.

• If the electrical system does not function, or your

tractor's engine will not crank, first check to be certain

that the fuse has not blown.

• The fuse can be found inside of the dash panel behind

the battery tray. You may need to remove the battery

to gain access to the fuse. Always use a fuse with the

same amperage capacity for replacement.

NOTE: A second fuse holder can be found inside the dash

panel. This fuse holder is used for the optional 12 volt

power outlet.

Battery

The battery is sealed and is maintenance-free. Acid levels

cannot be checked.

• Always keep the battery cables and terminals clean and

free of corrosive build-up.

• After cleaning the battery and terminals, apply a light

coat of petroleum jelly or grease to both terminals.

• Always keep the rubber boot positioned over the posi-

tive terminal to prevent shorting.

IMPORTANT: If removing the battery for any reason, discon-

nect the NEGATIVE (Black) wire from it's terminal FIRST,

followed by the POSITIVE (Red) wire. When re-installing the

battery, always connect the POSITIVE (Red) wire its terminal

first, followed by the NEGATIVE (Black) wire. Be certain that

the wires are connected to the correct terminals; reversing

them could change the polarity and result in damage to

your engine's alternating system.

Chargingthe Battery

If the tractor has not been put into use for an extended pe-

riod of time, charge the battery with an automotive-type

12-volt charger for a minimum of one hour at six amps.

WARNING: Batteries give off an explosive gas

while charging. Charge battery in a well venti-

lated area and keep away from an open flame

or pilot light as on a water heater, space heater,

furnace, clothes dryer or other gas appliances.

Cleaningthe Battery

Clean the battery by removing it from the tractor and

washing with a baking soda and water solution. If neces-

sary, scrape the battery terminals with a wire brush to

remove deposits. Coat terminals and exposed wiring with

grease or petroleum jelly to prevent corrosion.

BatteryFailures

Some common causes for battery failure are:

• incorrect initial activation • undercharging

• overcharging • corroded connections

• freezing

These failures are NOT covered by your tractor's warranty.

ChangingTransmissionDriveBelt

NOTE: Several components must be removed, including

transmission steering linkage which will have to be read-

justed, in order to change the tractor's transmission drive

belt. Contact your Cub Cadet dealer to have your transmis-

sion drive belt replaced.

HydrostaticTransmission

Keep the area around the transmission cooling fan free of

grass and debris at all times. The hydrostatic transmission

is sealed at the factory and is maintenance free. The fluid

level cannot be checked and cannot be changed.

OffSeasonStorage

If the machine is to be inoperative for a period longer than

30 days, the following procedures are recommended:

WARNING: Never store the machine or fuel

container indoors where there is an open flame,

spark or pilot light such as on water heater,

furnace, clothes dryer or other gas appliance.

Page 21

IMPORTANT: Fuel left in the fuel tank during warm weath-

er deteriorates and will cause serious starting problems.

To prevent gum deposits from forming inside the engine's

carburetor and causing possible malfunction of the en-

gine, the fuel system must be either completely emptied,

or the gasoline must be treated with a stabilizer to prevent

deterioration.

1. If using a fuel stabilizer:

• Read the product manufacturer's instructions and

recommendations.

• Add to clean, fresh gasoline the correct amount of

stabilizer for the capacity of the fuel system.

• Fill the fuel tank with treated fuel and run the

engine for 2-3 minutes to get stabilized fuel into the

carburetor.

2. If emptying the fuel system:

• Do not drain fuel when the engine is hot. Allow the

engine adequate time to cool. Drain fuel into an ap-

proved container outdoors, away from open flame.

• Drain any large volume of fuel from the tank by

disconnecting the fuel line from the in-line fuel filter

near the engine.

• Reconnect the fuel line and run the engine until

it starts to falter, then use the choke to keep the

engine running until all fuel in the carburetor has

been exhausted.

• Again disconnect the fuel line and drain any remain-

ing gasoline from the system.

container outdoors, away from an open flame.

_ WARNING: Drain fuel only into an approved

Allow engine to cool. Extinguish cigarettes,

cigars, pipes, and other sources of ignition prior

to draining fuel.

Remove the spark plug and pour one (1)ounce of engine

oil through the spark plug hole into the cylinder. Crank the

engine several times to distribute the oil. Replace the spark

plug.

Before storing for an extended period, clean and lubricate

the tractor as instructed in "Maintenance and Adjustments."

CuttingDeckRemoval

To remove the cutting deck, proceed as follows:

1. Disengage the PTO (Blade Engage) and engage the

parking brake.

2. Place the deck gauge wheels in their highest setting

(lowest deck setting).

3. Lower the deck by moving the deck lift lever into the

bottom notch on the right fender.

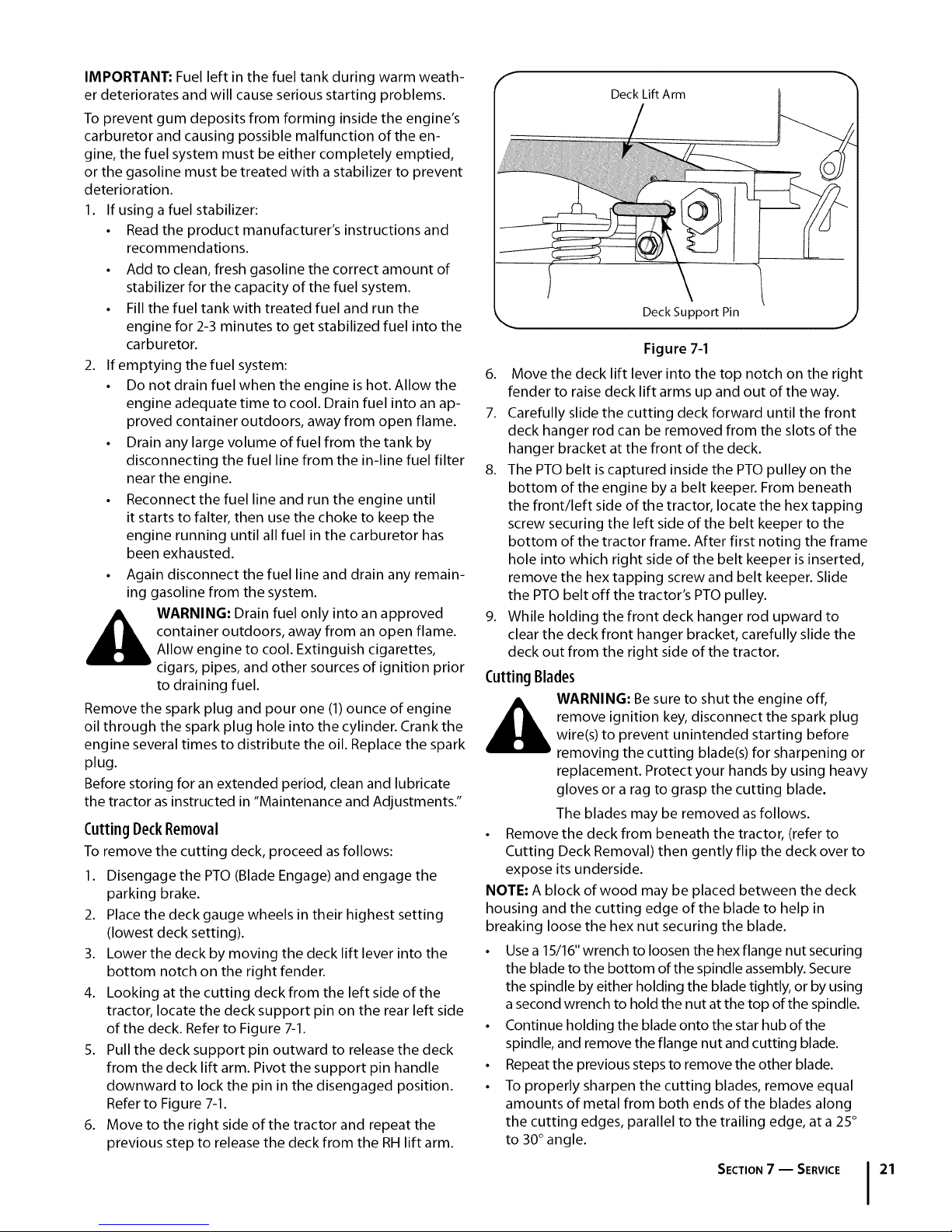

4. Looking at the cutting deck from the left side of the

tractor, locate the deck support pin on the rear left side

of the deck. Refer to Figure 7-1.

5. Pull the deck support pin outward to release the deck

from the deck lift arm. Pivot the support pin handle

downward to lock the pin in the disengaged position.

Refer to Figure 7-1.

6. Move to the right side of the tractor and repeat the

previous step to release the deck from the RH lift arm.

f

Deck Lift Arm

k Deck Support Pin

J

Figure 7-1

6. Move the deck lift lever into the top notch on the right

fender to raise deck lift arms up and out of the way.

7. Carefully slide the cutting deck forward until the front

deck hanger rod can be removed from the slots of the

hanger bracket at the front of the deck.

8. The PTO belt is captured inside the PTO pulley on the

bottom of the engine by a belt keeper. From beneath

the front/left side of the tractor, locate the hex tapping

screw securing the left side of the belt keeper to the

bottom of the tractor frame. After first noting the frame

hole into which right side of the belt keeper is inserted,

remove the hex tapping screw and belt keeper. Slide

the PTO belt off the tractor's PTO pulley.

9. While holding the front deck hanger rod upward to

clear the deck front hanger bracket, carefully slide the

deck out from the right side of the tractor.

Cutting Blades

remove ignition key, disconnect the spark plug

_ ARNING: Be sure to shut the engine off,

• Remove the deck from beneath the tractor, (refer to

Cutting Deck Removal) then gently flip the deck over to

expose its underside.

NOTE: A block of wood may be placed between the deck

housing and the cutting edge of the blade to help in

breaking loose the hex nut securing the blade.

• Use a 15/16" wrench to loosen the hex flange nut securing

the blade to the bottom of the spindle assembly. Secure

the spindle by either holding the blade tightly, or by using

asecond wrench to hold the nut at the top of the spindle.

• Continue holding the blade onto the star hub of the

spindle, and remove the flange nut and cutting blade.

• Repeat the previous steps to remove the other blade.

• To properly sharpen the cutting blades, remove equal

amounts of metal from both ends of the blades along

the cutting edges, parallel to the trailing edge, at a 25°

to 30° angle.

wire(s) to prevent unintended starting before

removing the cutting blade(s) for sharpening or

replacement. Protect your hands by using heavy

gloves or a rag to grasp the cutting blade.

The blades may be removed as follows.

SECTION7 -- SERVICE 21

Page 22

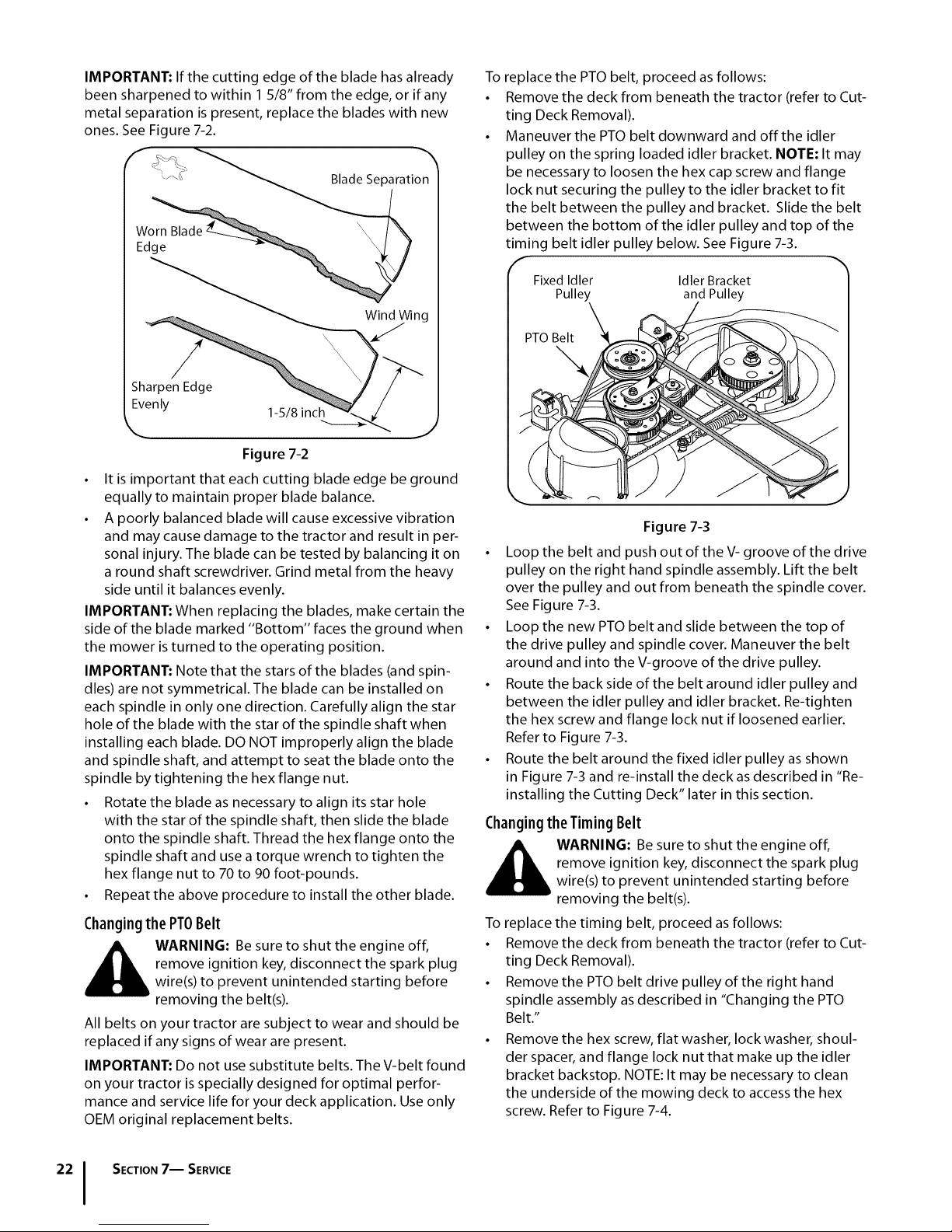

IMPORTANT:If the cutting edge of the blade has already

been sharpened to within 15/8" from the edge, or if any

metal separation is present, replace the blades with new

ones See Figure 7-2

BladeSeparation

Worn Blade

Edge

Wind Wing

Sharpen Edge

Evenly

_ J

• It is important that each cutting blade edge be ground

equally to maintain proper blade balance

• A poorly balanced blade will cause excessive vibration

and may cause damage to the tractor and result in per-

sonal injury The blade can be tested by balancing it on

a round shaft screwdriver Grind metal from the heavy

side until it balances evenly

IMPORTANT: When replacing the blades, make certain the

side of the blade marked "Bottom" faces the ground when

the mower is turned to the operating position

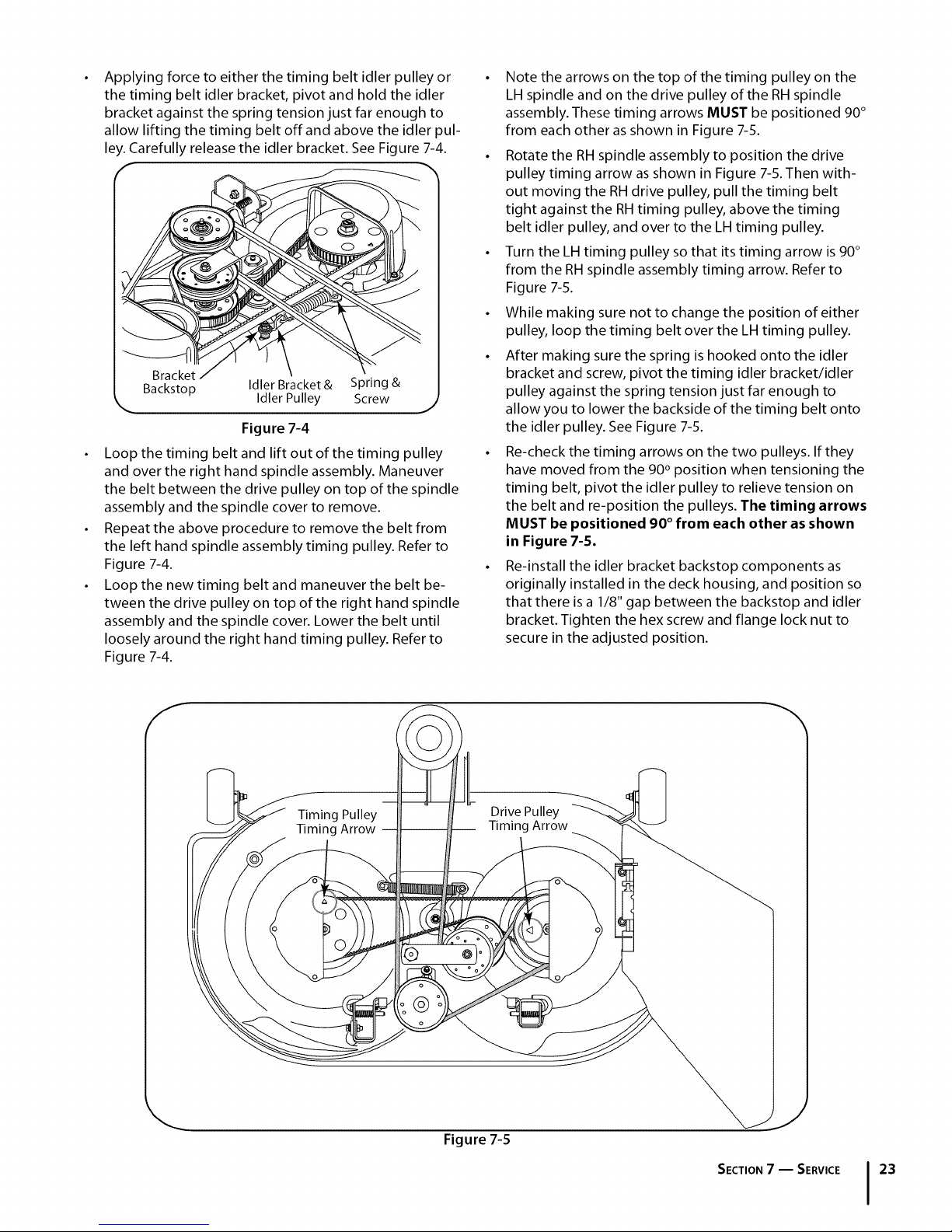

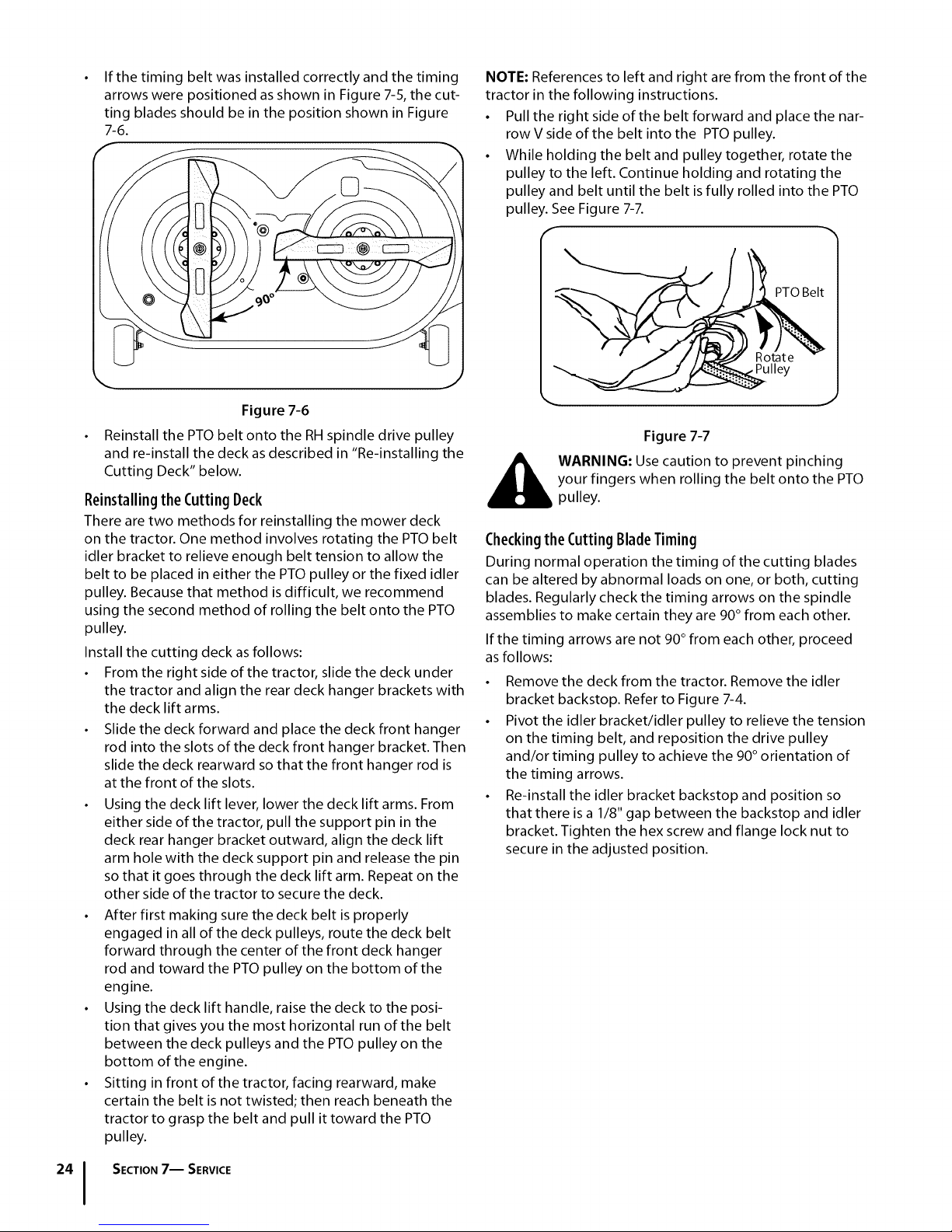

IMPORTANT: Note that the stars of the blades (and spin-