Page 1

Professional Shop Manual

I Series Riding Tractors

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outd oor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accura te as possible at the time of publication. However, du e to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2009 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-03231A

08/2009

Page 2

Page 3

Table of Contents

Chapter 1: Introduction .........................................................................................................1

Professional Shop Manual intent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description of the I-series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model and Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2: Engine related parts............................................................................................ 3

Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Exhaust pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fuel tank removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 3: Brakes ...................................................................................................................7

Brake system description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Brake adjustment - HydroGear transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Brake adjustment - IVT transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Brake puck/rotor replacement - HydroGear Transmissions . . . . . . . . . . . . . . . . . . . . . . . . 9

Brake shoes/drum - IVT transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Brake cross shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 4: Body/chassis .......................................................................................................17

The hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Remove the fender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 5A: Drive system - HydroGear Transmissions .................................................. 23

Drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Belt adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Drive pedal shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 5B: Drive system - IVT Transmission .................................................................. 29

Drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Belt adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Drop axle assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rebuilding the drop axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Drive pedal shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 6A: Steering - Hydrogear Transmissions........................................................... 49

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cam Slot Angle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Neutral and Transmission Links Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Wheel alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Steering gear box removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

I

Page 4

Rebuilding the steering gear box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Wear block adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Front wheels and axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Drag links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Tie rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Inboard steering gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Pivot bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Chapter 6B: Steering - IVT Transmission ......................................................................... 81

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Cam Slot Angle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Neutral and drive control links Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Wheel alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Steering gear box removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Rebuilding the steering gear box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Front wheels and axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Drag links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Tie rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Inboard steering gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Pivot bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Chapter 7: electrical system ...............................................................................................111

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Electrical environment: AC Vs. DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Types of circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Series/parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Shorts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Opens 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Increased resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

The Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Equipment that may be useful. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Digital Multi-meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Wiring diagram or schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Fused jumper wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Test lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Ammeters and specialized charging system testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Battery Testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Testing the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Voltage Drop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Cutting decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

II

Page 5

Chapter 8: Cutting Decks and lift shaft ............................................................................143

Cleaning the deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

To clean the deck while it is removed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

PTO belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Timing belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Spindles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

To replace a spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Leaving the deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Side to Side Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Front To Rear Leveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Deck Gauge Wheel Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Deck Rear Roller Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Deck lift shaft assembly bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Deck lift shaft assembly removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Deck lift links and cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Chapter 9: Maintenance intervals .................................................................................... 157

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Engine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

The spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Air filter and foam pre cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Servicing the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Clean the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

III

Page 6

IV

Page 7

CHAPTER 1: INTRODUCTION

INTRODUCTION

Professional Shop Manual intent

This Manual is intended to provide service dealers

with an introduction to the mechanical aspects of the Iseries tractor.

This Professional Shop Manual covers the I-series

tractor more specifically, and in greater depth than the

original Shop Handbook.

• The content in this manual supersedes any content in the handbook.

• Detailed service information about the engine

will be provided by the engine manufacturer, in

most cases.

Disclaimer: The information contained in this manual

is correct at the time of writing. Both the product and

the information about the product are subject to change

without notice.

About the text format:

NOTE: is used to point out information that is relevant to the procedure, but does not fit as a step

in the procedure.

• Bullet points: indicate sub-steps or points.

Caution is used to point out poten-

! CAUTION! CAUTION

property.

! WA RNING! WA RNING

injury.

! DANGER! DANGER

This signal word is to be limited to the most extreme

situations

tial danger to the technician, operator, bystanders, or surrounding

Warning indicates a pote ntially hazardous situation that, if not avoided,

could result in death of serious

Danger indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

Disclaimer: This manual is intended for use by trained,

professional technicians.

• Common sense in operation and safety is

assumed.

• In no event shall MTD or Cub Cadet be liable for

poor text interpretation or poor execution of the

procedures described in the text.

• If the person using this manual is uncomfort able

with any procedures they encounter , they shou ld

seek the help of a qualified technician or Cub

Cadet Technical Support.

Fasteners

• Most of the fasteners used on the vehicle are

sized in fractional inches. Some are metric. For

this reason, wrench sizes are frequently identified in the text, and measurements are given in

U.S. and metric scales.

• If a fastener has a locking feature that has worn,

replace the fastener or apply a small amount of

releasable threadlocking compound such as

Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use

items that are not to be reused. Other fasteners

such as lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if

the do not show signs of wear or damage. This

manual leaves that decision to the judgement of

the technician.

Assembly

Torque specifications may be noted in the part of

the text that covers assembly, they may also be summarized in tables along with special instructions

regarding locking or lubrication. Whichever method is

more appropriate will be used. In many cases, both will

be used so that the manual is handy as a quick-reference guide as well as a step-by-step proced ur e guid e

that does not require the user to hunt for information.

The level of assembly instructions provided will be

determined by the complexity and of reassembly, and

by the potential for unsafe conditions to arise from mistakes made in assembly.

Some instructions may refer to other parts of the

manual for subsidiary procedures. This avoids repeating the same procedure two or three times in the manual.

1

Page 8

INTRODUCTION

Description of the I-series

The I-series is a revolutionary new tractor platform

introduced in the 2007 season. This platform combines

a traditional lawn tractor with zero-turning capabilities.

This is accomplished by controlling the drive of the rear

wheels independently and the use of an innovative

steering system. See Figure 1.1.

Figure 1.1

The Steering gear box operates the control linkages for the transmissions while turning the front

wheels. This gives the I-series zero-turning capabilities

while using a traditional steering wheel.

The I-series comes with 42”, 46” and 50” deck

options. The I-series tractors also have the Cub Cadet

Rev-Tek system.

The I-series tractor can be equipped with two

HydroGear Transmissions or an IVT transmissio n. The

Infinitrak full-toroidal Infinitely Variable Transmission

(IVT) was first introduced in Europe for the 2009 model

year.

Model and Serial Numbers

The model and serial number tag can be found

under the seat. See Figure 1.2.

Serial number

Model number

Figure 1.2

The serial number is located to the right of the

model number as shown above. See Figure 1.2.

The model number is 17AF9BKH710. The break

down of what the number mean is as follows:

17.........................residential zero turn mower

...A.......................sales level

......F.....................engine code

........9...................frame

..........B................drive system

............K..............hood style

...............H...........deck (H = 46” K = 50”)

...................710....customer number

The serial number is 1J056G10005. The serial numbe r

reads as follows:

1...........................engineering level

..J.........................month of production (J = October)

.....05....................day of the month

.........6..................last digit of the year

...........G................plant it was built in

..............1.............assembly line number

.................0005.....number of unit built

2

Page 9

CHAPTER 2: ENGINE RELATED PARTS

ENGINE RELATED PARTS

This chapter will cover the engine accessories that

are manufactured by Cub Cadet.

IMPORTANT: The engine is manufactured by

Kohler. Refer to the Kohler manual for engine

specific service information.

Muffler

Remove the muffler by following these steps:

1. Remove the hood and bumper by following the

steps described in Chapter 4: Body/Chassis.

2. Remove the two screws on each side that hold

the muffler guard bracket. See Figure 2.1.

Remove these screws

3. Remove the hood pivot brackets by removing

the two screws that secure each one in place.

See Figure 2.2.

Remove these

screws

Figure 2.2

4. Pull the muffler cover and muffler out together.

See Figure 2.3.

Figure 2.1

Pull muffler foreword

Figure 2.3

NOTE: The muffler slides onto the exhaust

pipes. The heat of the exhaust makes the pipe s

expand and forms a seal with the muffler. Do not

weld or place a sealer between the muffler and

exhaust pipes.

3

Page 10

ENGINE RELATED PARTS

5. With the muffler on a work bench, remove the

four screws that fasten the muffler to the muffler

bracket. See Figure 2.4.

Remove these

screws

Figure 2.4

6. Remove the two screws that fasten the muffler

guard to the muffler bracket. See Figure 2.5.

Remove these screws

7. The muffler, muffler cover and the muffler

bracket can now be separated. See Figure 2.6.

Muffler brackets

Heat shield

Muffler

Figure 2.6

NOTE: The heat shield and muf fler bracket s can

be left together and handled as one part.

8. Install the muffler by following the above steps in

reverse order.

Figure 2.5

4

Page 11

ENGINE RELATED PARTS

Exhaust pipes

The exhaust pipes are manufactured by Cub

Cadet. To remove/replace the exhaust pipes:

1. Remove the muffler following the steps

described in the previous section.

2. Remove the mounting bolts using a 1/2” wrench.

See Figure 2.7.

Remove these bolts

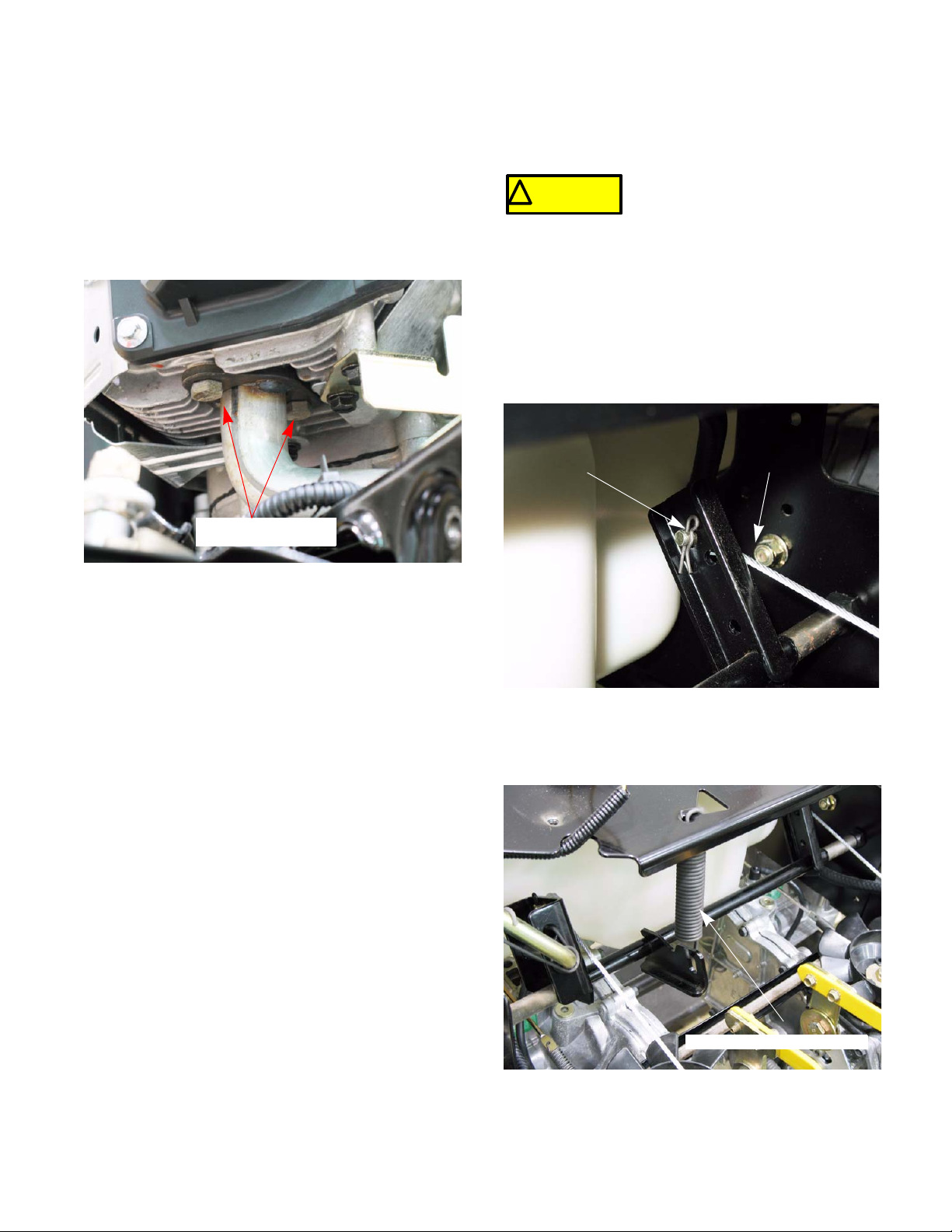

Fuel tank removal/replacement

Remove/replace the fuel tank by following these steps:

Gasoline and it vapors are

! CA UTION! CA UTION

system

1. Remove the deck.

2. Remove the fender by following the steps

described in Chapter 4: Body/Chassis.

3. Remove the hair pin clips retaining the deck lift

cables and disconnect the cables.

See Figure 2.8.

Hair pin clip

extremely flammable. Use common

sense when working around the fuel

Deck lift cable

Figure 2.7

3. DIscard the old exhaust gaskets. Clean all gasket material from the cylinder head (and exhaust

pipe if it is being reused.

4. Using new gaskets, install the exhaust pipes following the above steps in reverse order.

Figure 2.8

4. Unhook the deck lift assist spring.

See Figure 2.9.

Deck lift assist spring

Figure 2.9

5

Page 12

ENGINE RELATED PARTS

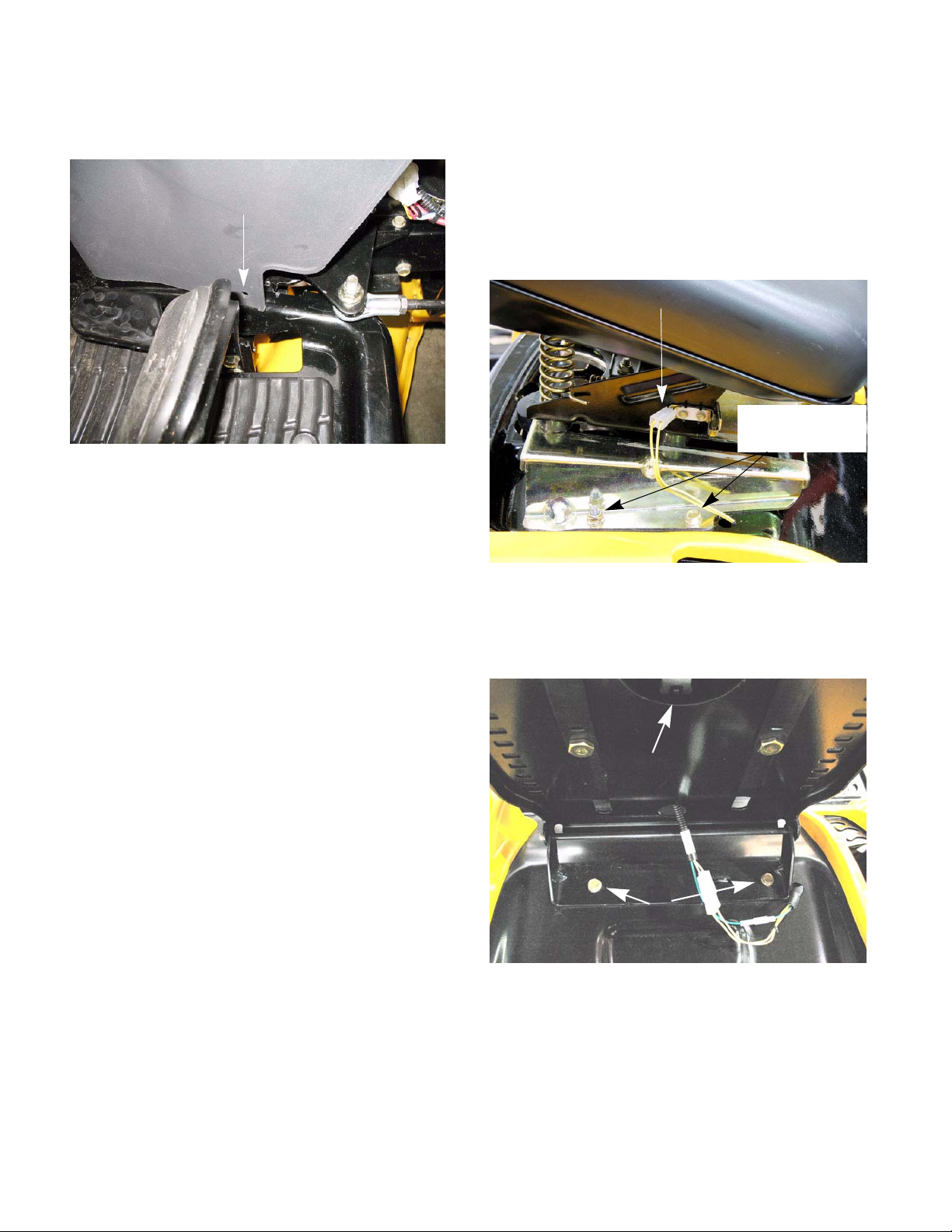

5. Remove the two screws and two nuts that fasten

the seat box cover. See Figure 2.10.

Remove these screws

Remove these screws

Seat box

Figure 2.10

6. Remove the seat box cover.

7. Clamp the fuel line. See Figure 2.11.

Fuel line clamp

Fuel line

Figure 2.11

8. Remove the fuel line clamp and slide the fuel

line off.

NOTE: The fuel tank has a barbed fitting. Anytime a fuel line is removed from a barbed fitting it

should be replaced because of the damag e

caused to the fuel line liner.

9. Lift the fuel tank out of the seat box.

10. Install the fuel tank by following the above steps

in reverse order.

11. Test run the tractor and check for leaks before

returning to service.

6

Page 13

CHAPTER 3: BRAKES

BRAKES

Brake system description

The I-series tractors have two braking systems

available based on which transmission is used.

HydroGear transmissions use a disc type brakes. The

IVT transmission uses an external drum brake system.

For HydroGear transmissions:

• The brakes are located on each transmission.

• They are activated by pressing on the brake

pedal.

• The brake pedal is attached to a brake cross

shaft assembly. This will pull on the two brake

rods.

• The brake rods are attached to the cam arms, in

the brake calipers, by over travel springs.

• When the cam arms are pulled forward they

push on the brake pins by a cam action applying

pressure to the brake pads.

• The brake cross shaft assembly also has a link

that is connected to the drive belt idler pulley

bracket. When the brakes are applied, the idler

pulley is pulled away from the drive belt. This detensions the belt, disengaging drive to the transmissions. See Figure 3.1.

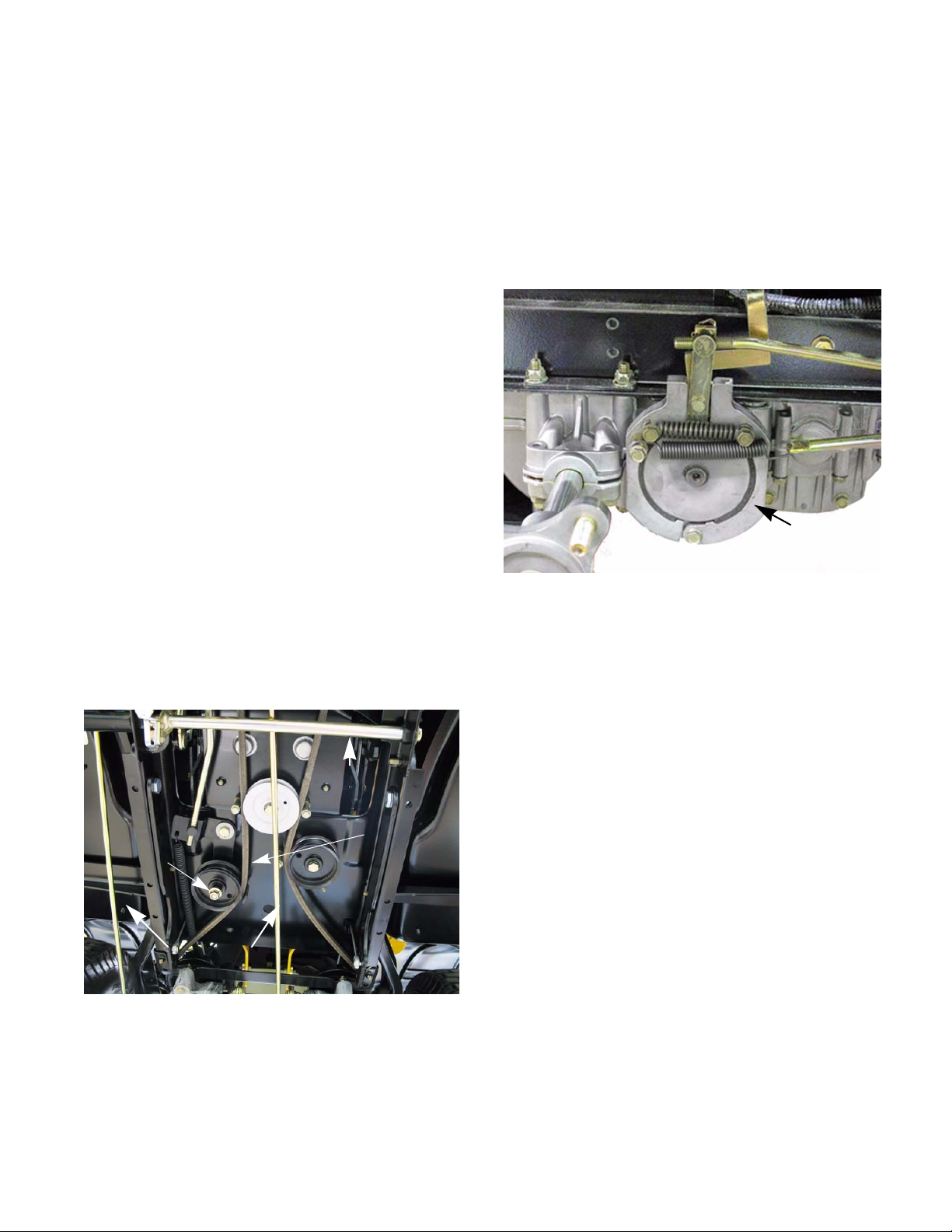

For the IVT transmission:

The IVT transmission has two drop axles. On each

drop axle there is an external drum brake.

See Figure 3.2.

Brake

Figure 3.2

• The brakes are applied whenever the drive

pedal is released.

• Depressing the brake pedal will disengage the

drive belt and apply extra force to the rear

shoes.

Idler pulley

Brake rods

Drive pedal shaft

Figure 3.1

• The idler pulley bracket has a gas charged

dampener attached to it. This dampener will

smooth out the engagement of the drive belt

when the brake pedal is released.

Belt

de-tensioned

7

Page 14

BRAKES

Brake adjustment - HydroGear transmissions

NOTE: Whenever performing a brake adjust-

ment, inspect the brake components for signs of

wear or damage.

1. Block the front wheels.

2. Lift and safely support the rear of the tractor.

See Figure 3.3.

Place jack stands here

Figure 3.3

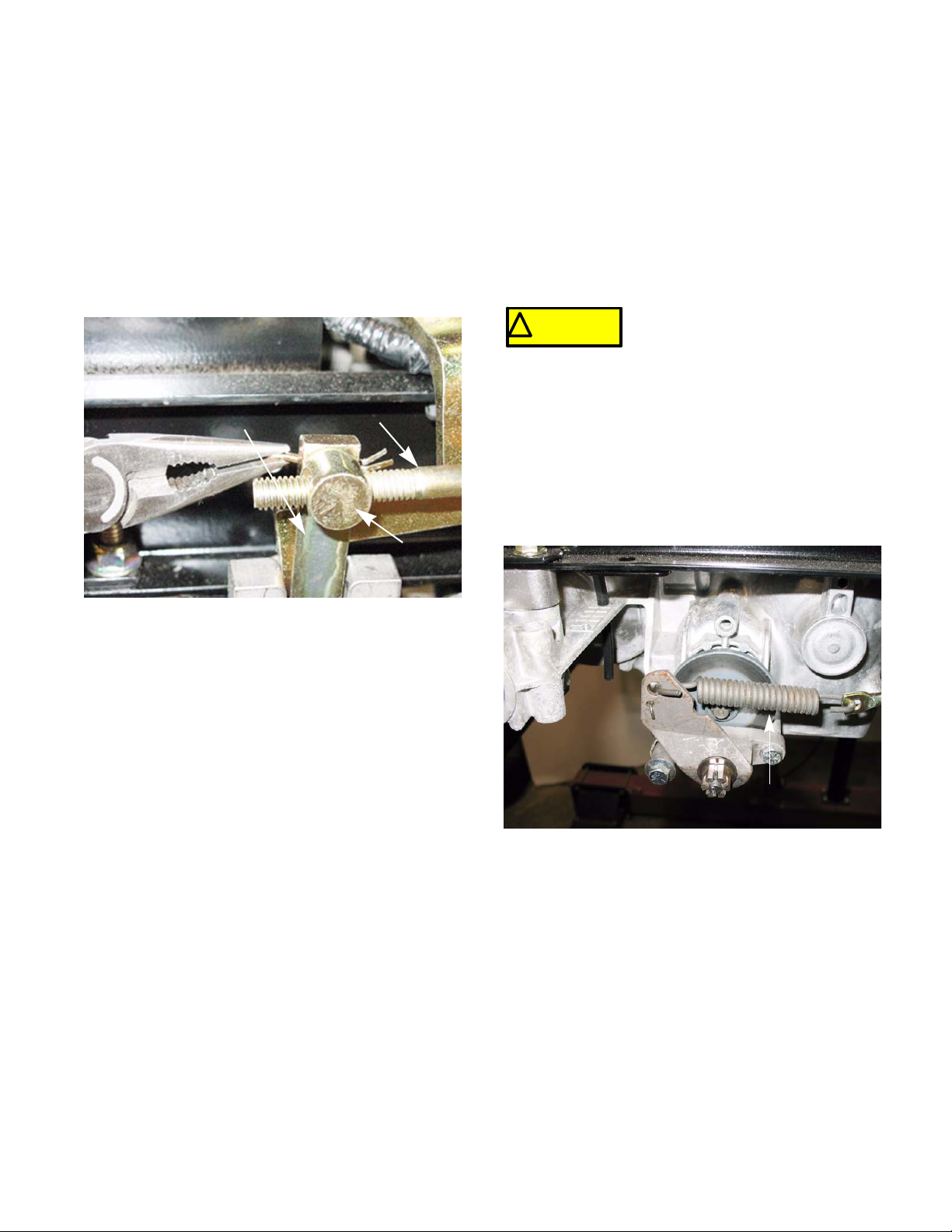

5. Back the castle nut off a few turns using a 9/16”

wrench.

NOTE: Even if the brakes are set to the correct

clearance, inserting a feeler gauge between the

rotor and the brake puck can be very difficult.

Loosen the castle nut first, then insert the feeler

gauge and tighten the nut to set the pro per clearances

6. Insert a .030” (0.8 mm) feeler gauge between

the brake rotor and the outboard brake puck.

See Figure 3.5.

0.030” feeler

gauge

NOTE: Make sure the brake and parking brake

are released.

3. Remove the rear wheels.

4. Remove the cotter pin locking the castle nut on

the brake caliper. See Figure 3.4.

Castellated nut

Figure 3.4

Cotter pin

Figure 3.5

NOTE: The tolerance for the brake clearance is

.020” - .040” (0.5 - 1.0mm). The .030 feeler

gauge will set the clearance at the midpoint.

7. Tighten the nut until there is a slight drag on the

feeler gauge when sliding it out.

NOTE: For even braking, both sides should be

set to the same clearance.

8. Install a new cotter pin.

9. Repeat same procedure on the other side.

10. Put the wheels back on. Tighten the lug nuts to a

torque of 53 - 60 ft lbs. (72 - 81 Nm).

11. Take the tractor off of the jack stands.

12. O pen the by-pass valves and check the parking

brake before returning the tractor to service.

• With the brakes released, the tractor should

have only hydraulic drag when it is pushed.

• With the brakes engaged, the wheels should

slide before they rotate when the tractor is

pushed.

8

Page 15

BRAKES

Brake adjustment - IVT transmissions

To adjust the brakes on IVT transmission:

1. Lift the rear of the tractor and safely support it

with a pair of jack stands.

2. Remove the rear wheels with a 3/4” wrench.

3. Release the parking brake.

4. Remove the cotter pin that retains the ferrule of

the drive control rod. See Figure 3.6.

brake disengagement block

Drive control rod

Ferrule

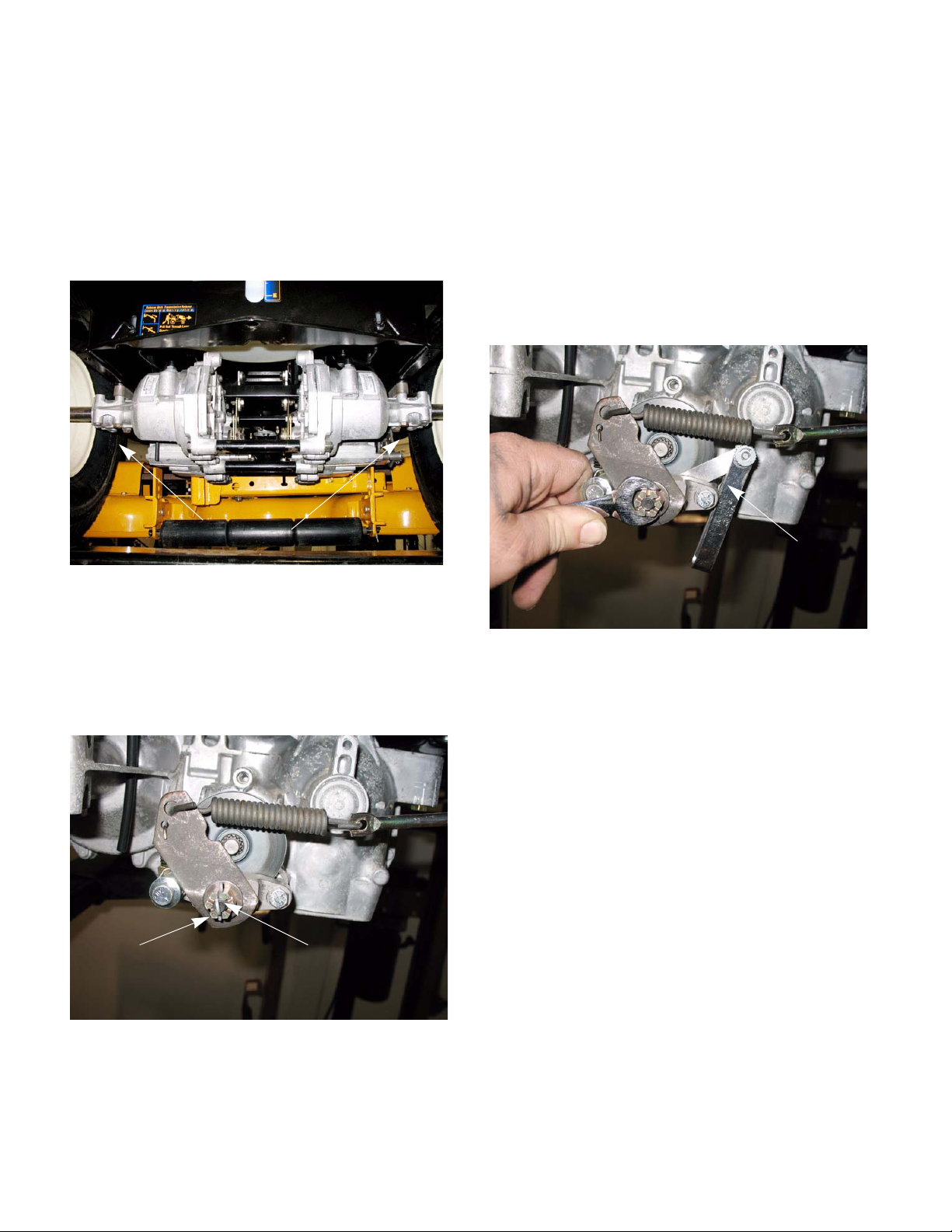

Brake puck/rotor replacement - HydroGear Trans-

missions

On HydroGear transmissions, the brake pucks are

a wearing part that will need to be serviced from time to

time. If a tractor is operated with the parking brake

dragging, the pucks will wear out rapidly and the brake

rotor will develop hot spots. If the tractor is operated

long enough, the rotor may have grinding marks on it

with excessively worn pucks.

If the rotor shows hot spots or any

! CA UTION! CA UTION

ure to do so can result in the failure of the brakes

The brake pucks and the rotors are serviced at the

same time. To service the brake pucks:

1. Jack up the tractor and remove the rear wheels

as described in the previous section.

2. Make sure the brakes are released.

3. Disconnect the brake rod spring. See Figure 3.7.

other signs of damage, including

warpage, it must be replaced. Fail-

Figure 3.6

5. Slide the ferrule of the drive control rod out of the

brake disengagement block.

NOTE: Once the control rod is disengaged, the

springs will clamp the brake shoes against the

drum. This will automatically center the disengagement block.

6. Adjust the ferrule until it slides into the hole in

the disengagement block with out applying pressure to it.

7. Install a new cotter pin into the ferrule to secure

it to the disengagement block.

8. Repeat the steps 4 - 6 on the other side of the

tractor.

9. Install the rear wheels. Tighten the lug nuts to a

torque of 53 - 60 ft lbs. (72 - 81 Nm).

10. Take the tractor off of the jack stands.

11. Test drive the tractor in a safe area before

returning it to service.

Disconnect this spring

Figure 3.7

9

Page 16

BRAKES

4. Loosen the rear mounting bolt. See Figure 3.8.

Remove this

bolt

Loosen this bolt

Figure 3.8

5. Remove the front mounting bolt, allowing the

caliper to swing down. See Figure 3.9.

7. Slide the brake rotor off to reach the inboard

brake puck. See Figure 3.10.

Inboard brake

puck

Figure 3.10

8. Remove the caliper for inspection when servicing the brake pucks. To do this, remove the rear

bolt loosened in step 4.

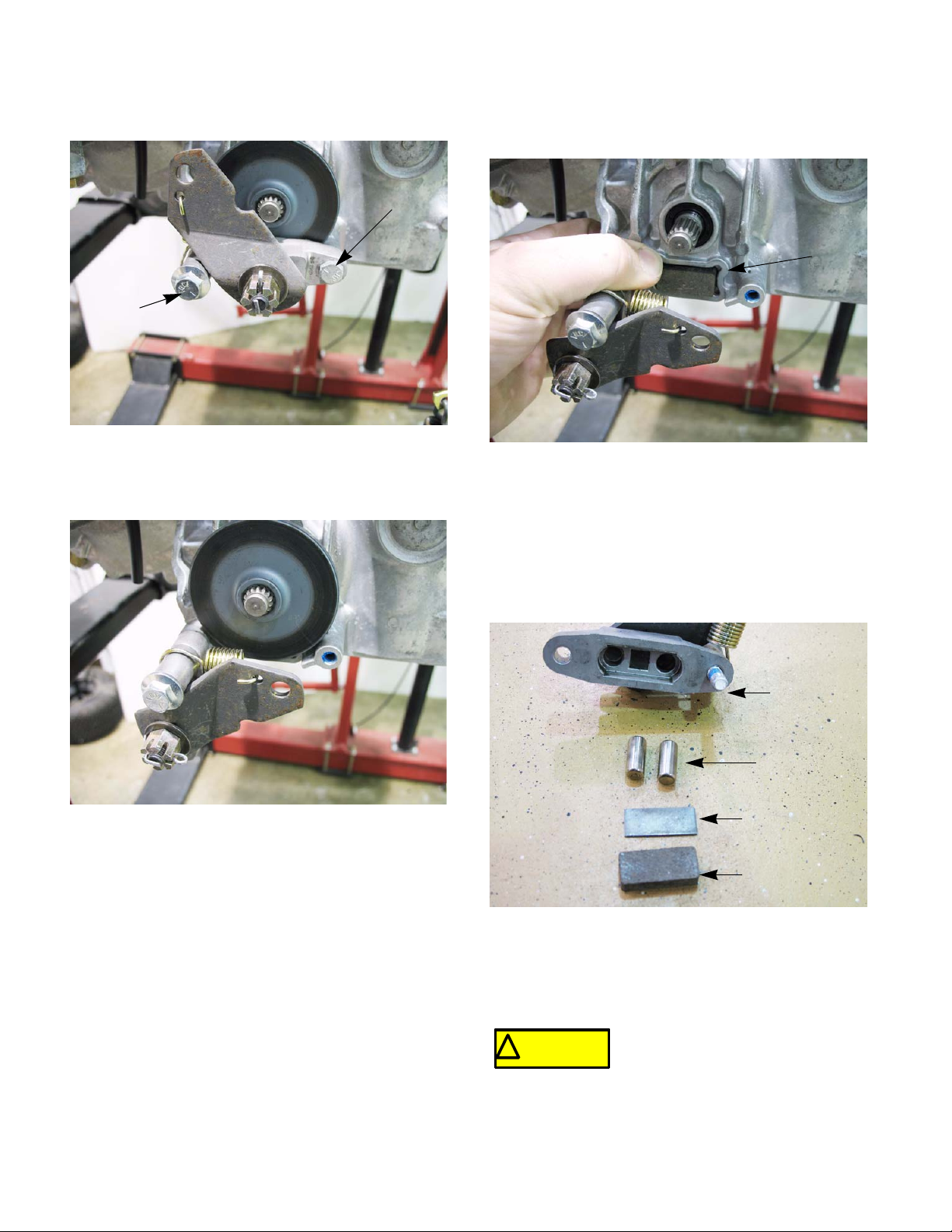

9. With the caliper on a work bench, remove the

brake puck, backing plate and the two brake

pins. See Figure 3.11.

Figure 3.9

6. The outboard brake puck should fall out when

the brake caliper swings down. If it did not, it can

be removed now.

Brake caliper

Brake pins

Backing plate

Brake puck

Figure 3.11

10. Check for free movement of the brake pins. A

dry lubricant can be used on the brake pins sparingly.

Never put grease or anti-seize on

! CA UTION! CA UTION

action of the pucks.

brake pins. It can migrate to the

brake pucks, preventing the braking

10

Page 17

BRAKES

11. Slide the brake pins into the caliper.

12. Place the backing plate in the caliper.

13. Place a new puck into the caliper.

See Figure 3.12.

Brake caliper re-assembled

Figure 3.12

NOTE: A piece of scotch tape may be used to

hold the new brake pucks in place for assembly.

The tape will grind away when the brakes are

applied.

16. Mount the brake caliper to the transmission.

Apply a small amount of releasable thread locking compound such as Loctite® 242 (blue) to the

mounting bolts and tighten to a torque of 80 120 in-lbs (9 - 13.5Nm).

17. Reconnect the brake rod spring.

18. Adjust the brakes as described in the previous

section.

19. Put the wheel on.

20. Repeat steps 4-19 on the other side.

21. When both sides are completed and both wheels

are back on, take the tractor off of the jack

stands.

22. O pen the by-pass valves and check the parking

brake before returning the tractor to service.

• With the brakes released, the tractor should

have only hydraulic drag when it is pushed.

• With the brakes engaged, the wheels should

slide before they rotate when the tractor is

pushed.

14. Place a new brake puck into the recess in the

transmission. Use a piece of scotch tape to hold

it in place.

15. Slide the brake rotor in place, shoulder out.

11

Page 18

BRAKES

Brake shoes/drum - IVT transmissions

On IVT transmissions, the brake shoes and drums

are the wearing parts that will need to be serviced from

time to time. If a tractor is operated with the parking

brake dragging, the shoes will wear out rapidly and the

brake drum will develop hot spots. If the tractor is operated long enough, the drum may have grinding marks

on it with excessively worn shoes.

If the drum shows hot spots or any

! CA UTION! CA UTION

ure to do so can result in the failure of the brakes

IMPORTANT: The brake shoes and the drums

must be replaced at the same time.

To service the brakes:

1. Jack up the tractor and remove the rear wheels

as described in the previous section.

2. Make sure the brakes are released .

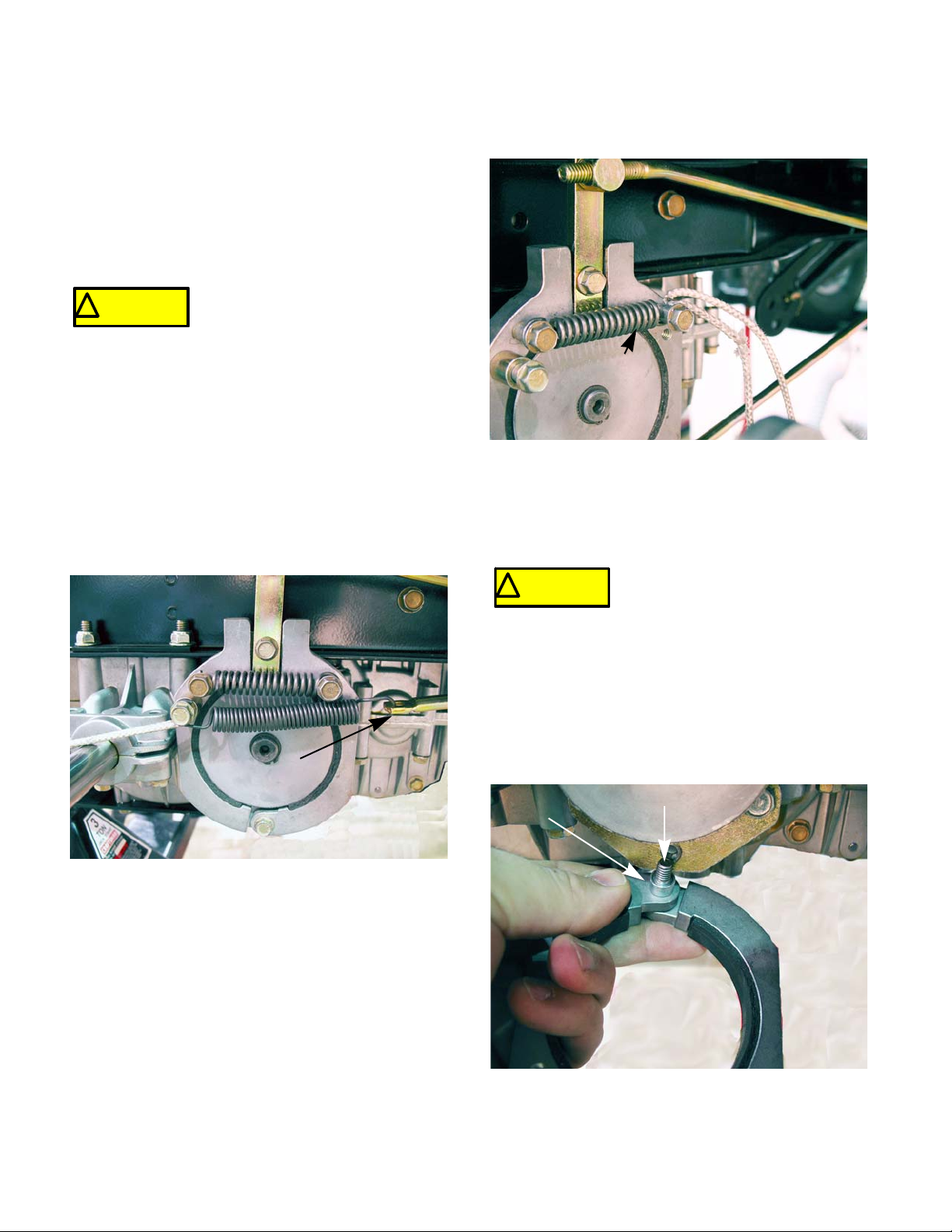

3. Disconnect the brake rod spring.

See Figure 3.13.

other signs of damage, including

warpage, it must be replaced. Fail-

4. Disconnect the brake shoe spring.

See Figure 3.14.

Brake shoe

spring

Figure 3.14

NOTE: There is a lot of tension in the brake

shoe springs. A piece of starter rope can be

used to remove the spring.

Do not remove the screws to dis-

! CA UTION! CA UTION

and can cause the screw to become a projectile as it is

being removed.

connect the brake shoe springs.

The springs are under high tension

Brake rod

Figure 3.13

5. Remove the pivot bolt at the bottom of the brake

shoes.

NOTE: There is a spacer behind the shoes that

will fall out as the pivot bolt is removed.

See Figure 3.15.

Spacer

Pivot bolt

Figure 3.15

12

Page 19

BRAKES

6. Remove the snap ring that secures the drum

with a pair of snap ring pliers. See Figure 3.16.

Remove the snap ring

Figure 3.16

7. Install the drum and shoes by following step s 1 7 in reverse order.

8. Repeat steps 1-8 on the other side of the tractor.

Brake cross shaft assembly

The brake cross shaft assembly for the HydroGear

transmissions and the IVT transmissions are not the

same. The procedure to service them are the same.

The brake cross shaft assembly is supported by

two bushings. Excessive movement in the brak e cro ss

shaft assembly may be an indication that the bushings

are worn out.

To replace the brake cross shaft bushings:

1. Remove the cotter pins that retain the three

brake rods. Slide the brake rods out of the brake

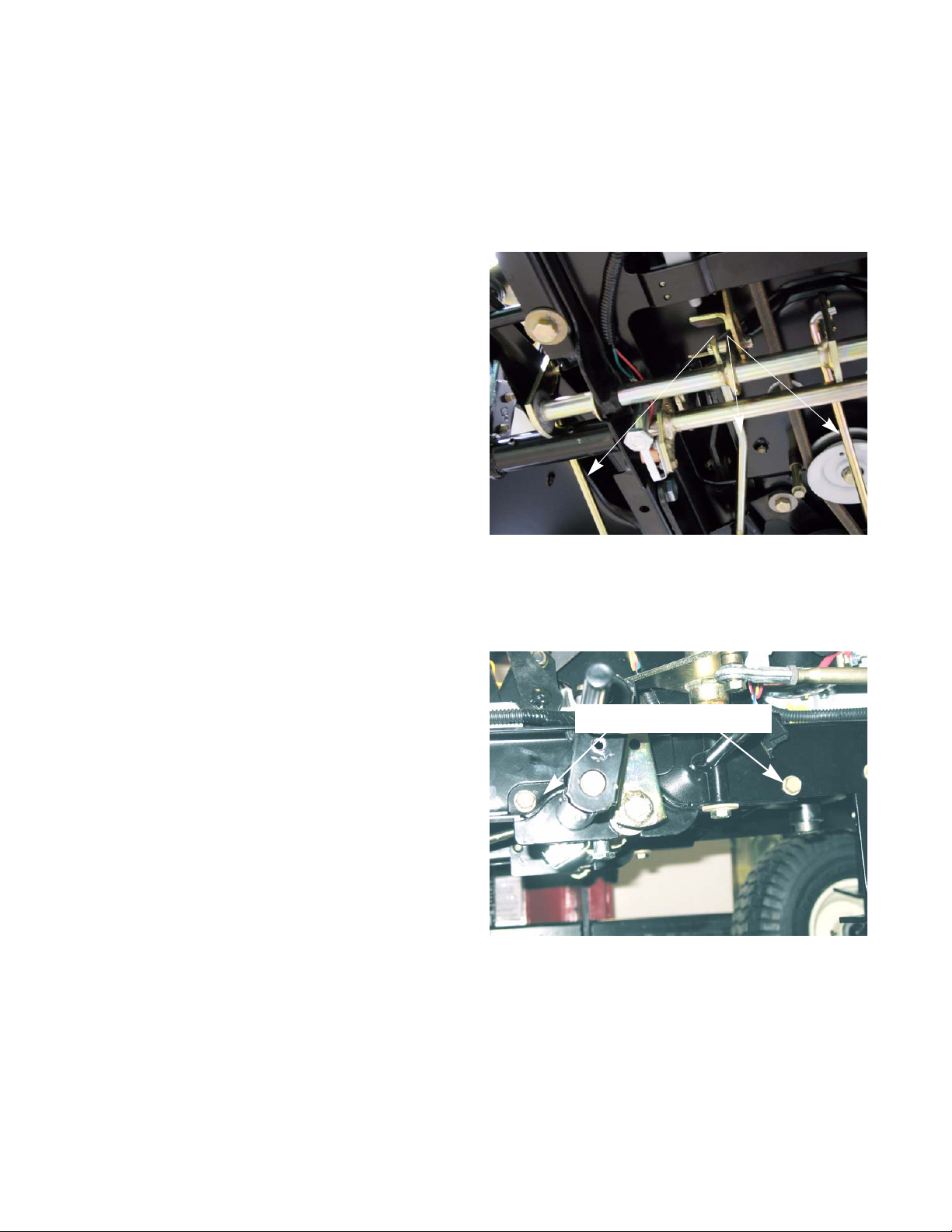

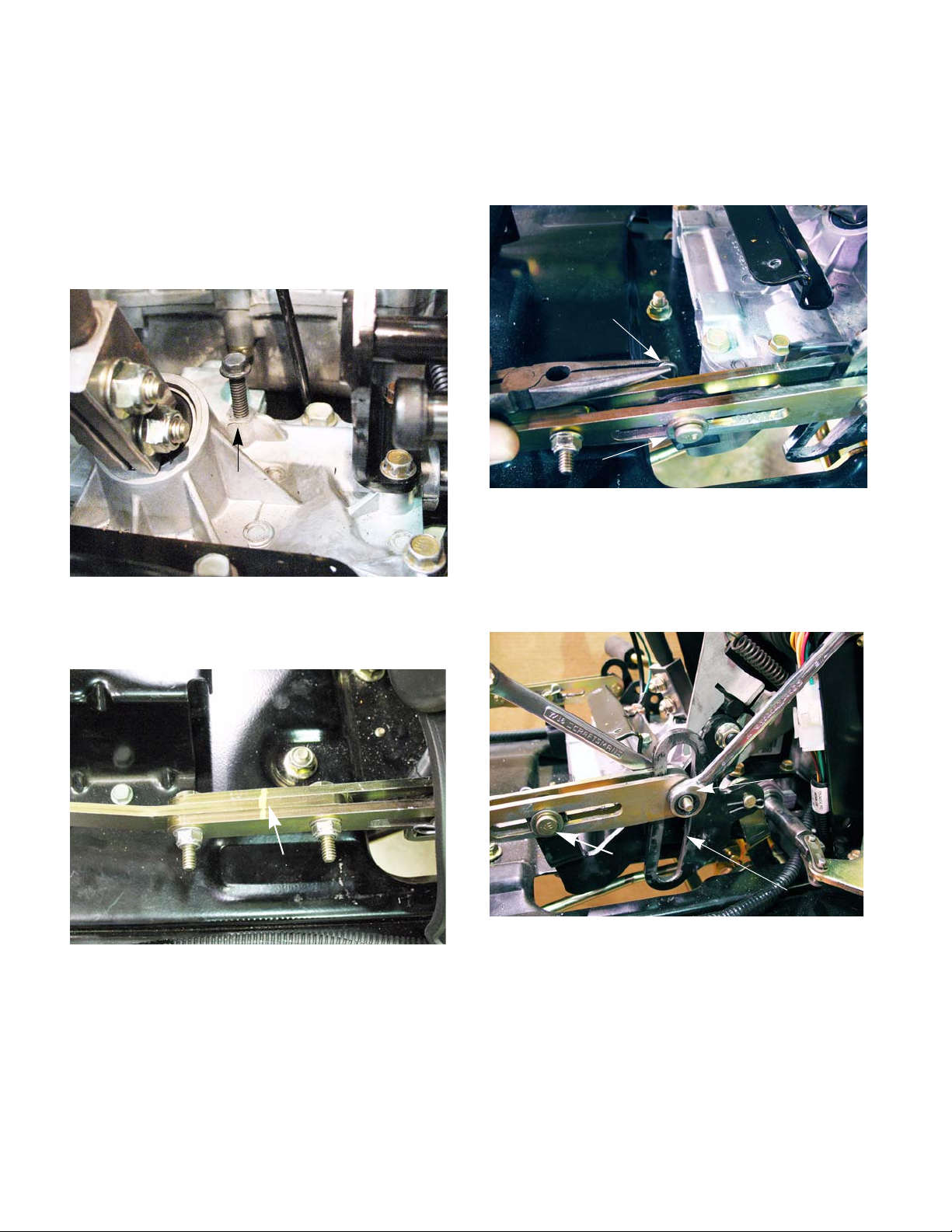

cross shaft assembly. See Figure 3.17.

Brake rods

Never put grease or anti-seize on

! CA UTION! CA UTION

braking surfaces, preventing the braking action of the

shoes.

9. Test drive the tractor in a safe area before

returning it to service.

the brake shoe pivot screw or the

drum splines. It can migrate to the

Figure 3.17

2. Remove the cotter pins on each end of the brake

cross shaft. See Figure 3.18.

Remove cotter pins

13

Figure 3.18

Page 20

BRAKES

3. Remove the right side bushing first. This will

allow the shaft to slide far enough to the lef t to let

the other bushing to come out.

4. Install new bushings by following the above

steps in reverse order.

NOTE: Do not put grease on the bushings.

Grease can trap dirt that will accelerate the wear

of the bushing.

5. Check the operation of linkage and test drive the

tractor in a safe area before returning to service.

To remove/replace the brake cross shaft assembly:

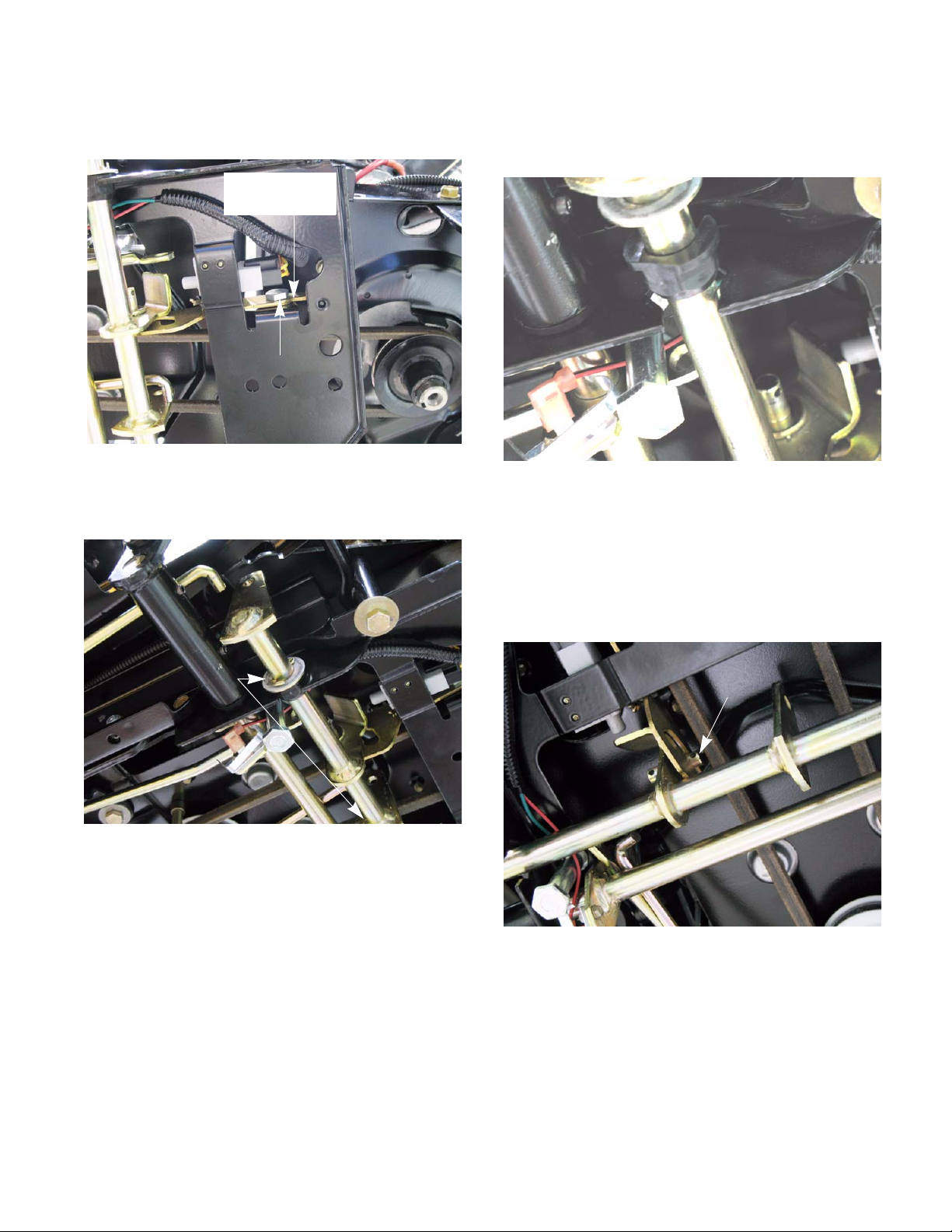

1. Remove the brake pedal by removing the two

screws using a 1/2” wrench.

2. Remove the cotter pins that retain the three

brake rods. Slide the brake rods out of the brake

cross shaft assembly. See Figure 3.19.

Brake rods

Figure 3.19

3. Remove the four screws (two on each side) that

hold the sub-frame in place and slide it down.

See Figure 3.20.

Remove these screws

Figure 3.20

14

Page 21

BRAKES

4. Loosen the shoulder bolt that the parking brake

plate pivots on. See Figure 3.21.

Parking brake

plate

Shoulder bolt

Figure 3.21

5. Remove the cotter pin from each end of the

brake cross shaft. See Figure 3.22.

6. Slide the split bushings out of their pockets in the

sub-frame, then pull them off of the brake cross

shaft assembly. See Figure 3.23.

Figure 3.23

7. Work the brake cross shaft ou t of the sub frame .

NOTE: Take care not to bend the parking brake

plate while working the brake cross shaft out.

Make sure the shoulder bolt is loose enough to

give the shaft clearance. The plate can be

removed if necessary. See Figure 3.24.

Remove cotter pins

Slide pin out of plate

Figure 3.22

Figure 3.24

8. Replace the brake cross shaft by following the

above steps in reverse order.

9. Test drive the tractor in a safe area before

returning to service.

15

Page 22

BRAKES

16

Page 23

CHAPTER 4: BODY/CHASSIS

BODY/CHASSIS

The hood

The I-series hood uses the same hood pivot sys-

tem as the 1000 series for easy removal.

To remove the hood:

1. The hood is front-hinged. See Figure 4.1.

Lift here

Figure 4.1

2. Open the hood by lifting the rear edge to tilt it forward.

3. Disconnect the headlight wires. See Figure 4.2.

4. Cut the wire tie that secures the headlight harness to the hood. See Figure 4.3.

Headlight harness

Wire tie

Figure 4.3

5. The hood hinges on a pair of shoulder bolts on

each side that fit into slots in the hood bracket.

6. The hinge travel is limited by the top shoulder

bolt that fits into a channel in the hood bracket.

7. Open the hood far enough to align the tabs with

the slots, then lift the hood off of the tractor.

See Figure 4.5.

Inset: headlight detail

Figure 4.2

NOTE: The ground terminals and powe r te rm i-

nals on the headlights are two different sizes.

The green wires (ground) fit the larger terminals.

The red wires (power) fit the smaller terminals.

17

Slots

Bracket

Shoulder bolts

Figure 4.4

Page 24

BODY/CHASSIS

Bumper

I-series tractors come equipped with a fast attach

bumper. To remove the bumper:

1. Remove the two screws, one on each side, that

secures the bumper bracket. See Figure 4.5.

Remove screw

Bumper

Figure 4.5

Dash Removal

The dash for the I-series is easy to remove. There

are a few repair procedures, such as the cam angle

adjustment or replacing the steering gearbox, that

require the dash to be removed. The step s to remove it

are as follows:

1. Remove the steering wheel:

1a. Remove the center cover. See Figure 4.7.

Center cover

2. Pull the bumper straight forward, sliding th e

bumper off of the shoulder bolts. See Figure 4.6.

Shoulder bolt

Figure 4.6

3. Install the bumper following the above steps in

reverse order.

Figure 4.7

1b. Remove the bolt with a 1/2” wrench.

See Figure 4.8.

Remove

this

bolt

Figure 4.8

NOTE: There is no puller needed for the steer-

ing wheel. Once the bolt is removed it will lift off

of the steering shaft.

18

NOTE: When replacing the steering wheel, lock

the steering gear box in neutral as described in

steering chapters (6A or 6B). This will make it

easier to center the steering wheel.

Page 25

BODY/CHASSIS

2. Remove the dash:

2a. Disconnect the key switch, module, PTO

switch and the hour meter.

See Figure 4.9.

Hour meter

PTO switch

Figure 4.9

2b. Disconnect the parking brake by removing

the hair pin clip and sliding the rod out of the

lever. See Figure 4.10.

2c. Remove the two screws attaching the dash

to the dash support. See Figure 4.11.

One on each side

Module and

key switch

Figure 4.11

2d. Remove the two screws in the cargo net

area, at the bottom of the dash.

See Figure 4.12.

Hair pin

clip

Rod

Figure 4.10

Remove these screws

Figure 4.12

NOTE: The cargo net was removed for a clearer

picture. Do not remove the net to remove the

dash.

NOTE: If removing the dash, disconnect the

throttle and choke cables at this point.

19

Page 26

BODY/CHASSIS

e

2e. Remove the screws at the bottom of the

dash, on each side. See Figure 4.13.

Screw removed

Figure 4.13

2f. The dash can now by lifted ov er the steering

shaft and placed to the side or on top of the

engine.

NOTE: If the throttle and choke cable are still

attached to the dash, care should be taken to

prevent damage to them when lifting the dash.

3. Install the dash by following the above steps in

reverse order.

Remove the fender

1. Remove the dash by following the steps

described in the previous section of this chapter.

2. Disconnect the wires to the seat switch.

NOTE: Tractors built prior to 2008 have two yel-

low wires that go to a switch on the side of the

seat bracket. See Figure 4.14.

Seat switch wires

Remove the nut

and bolt to remov

seat

Figure 4.14

NOTE: Tractor built from 2008 to present have

two yellow wires and a green wire that go to a

switch inside the seat.

Seat switch

Seat bracket

mounting screws

Figure 4.15

NOTE: When reconnecting the wires, the posi-

tion of the two yellow wires does not affect the

20

operation of the tractor.

3. Remove the seat bracket and seat as one piece.

4. Remove the grip from the deck lift handle.

Page 27

BODY/CHASSIS

5. Remove the nuts from the under side of the foot

rests. See Figure 4.16.

Remove these nuts

Figure 4.16

6. Remove the brake and drive pedals.

7. Remove the screw from the center of the fender.

See Figure 4.17.

10. Place the steering wheel on the steering shaft.

Turn the wheels to the left and right to allow the

fenders to clear the steering arm assembly.

See Figure 4.18.

Steering arm assembly

Place some tape

here to protect the paint

Figure 4.18

NOTE: When lifting the fender off of the tractor,

clear the left side first and rotate the fender to

clear the deck lift lever.

Remove this screw

Figure 4.17

8. Remove the fuel cap.

9. Standing behind the tractor , lif t the fender up till it

clears the studs for the seat.

1 1. Install the fender by following the previous steps

in reverse.

21

Page 28

BODY/CHASSIS

22

Page 29

DRIVE SYSTEM-HYDROGEAR

CHAPTER 5A: DRIVE SYSTEM - HYDROGEAR TRANSMISSIONS

There are two drive systems available for the Iseries tractor. One system uses two HydroGear transmissions. The other system uses an Infinitrak full-toroidal Infinitely Variable Transmission (IVT). Th is chap ter

will cover the HydroGear version of the tractor.

The HydroGear version of this tractor uses two

EZT transmissions. The transmission control linkages

work in unison with the steering linkage to create the

zero-turn feature. The neutral adjustments for the

transmissions and the transmission links are covered

in chapter 6A: Steering - HydroGear.

The Hydro-gear shop manual for the EZT transmissions is form number BLN-52622.

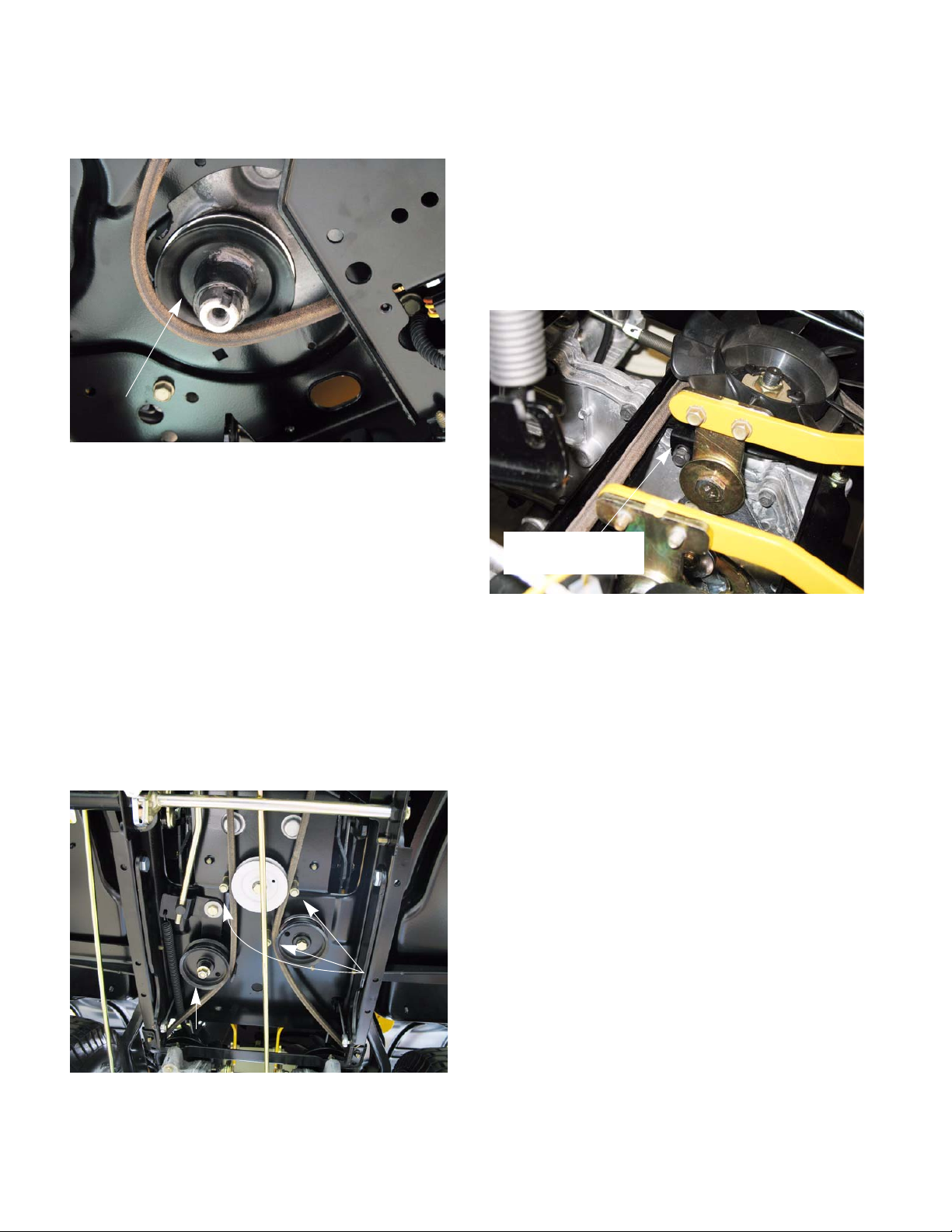

Drive belt

The drive belt is the most common drive system

component that will need attention. To remove/replace

the drive belt:

1. Remove the deck as described in chapter 8:

Cutting Decks and Lift Shaft.

2. Set the parking brake.

3. Unplug the electric PTO harness.

See Figure 5A.1.

4. Unbolt the electric PTO using an impact wrench

and a 5/8” socket. See Figure 5A.2.

PTO clutch

Remove bolt with an impact wrench

Figure 5A.2

NOTE: If the PTO clutch will not slide off of the

crankshaft, thread the bolt half way into the

crankshaft. Make sure the belt keeper is in place

to prevent the clutch from rotating. Start the

engine and turn the PTO on and off several

times to shake it loose.

Starter

PTO connector

Figure 5A.1

NOTE: If the PTO will not come off using the

steps above, remove the engine mounting bolts

and slide the engine back. This will give enough

clearance to slide the belt off of the engine pulley.

Cub Cadet belts are designed to fit

! CA UTION! CA UTION

prevent the de-clutching mechanism from working

properly when the brakes are applied.

our equipment and are not standard

lengths. Use of a non-OEM belt may

23

Page 30

DRIVE SYSTEM-HYDROGEAR

5. Slide the engine pulley down far enough to slip

the belt off of the pulley. See Figure 5A.3.

Engine pulley

Figure 5A.3

NOTE: Note the direction of the key in the

engine pulley. It should be facing down. If the

pulley is installed upside down, the belt alignment will be off.

NOTE: When installing the engine pulley and

electric PTO, coat the crank sh aft with anti-seize.

This will ease pulley and clutch removal in the

future.

NOTE: If the engine pulley is seized to the

crankshaft, the engine bolts can be removed to

slide the engine to the rear. This will provide

enough clearance to remove the belt.

7. Work belt off of the idler pulleys.

NOTE: It may be necessary to loosen the move-

able idler pulley to get the belt to clear the belt

guide on the idler bracket. See Figure 5A.4.

8. The transmission brace doubles as a belt

keeper. Remove the two screws that hold the

transmission brace to the transmission. Slide the

brace to the rear of the tractor to make enough

clearance to remove the belt. See Figure 5A.5.

Remove this

screw on each side

Figure 5A.5

9. Work belt around the transmission pulleys and

fans.

NOTE: Use care to prevent damage to the fans

when removing the belt.

6. Remove the three belt guides near the idler pulleys. See Figure 5A.4.

Belt guides

Moveable idler

Figure 5A.4

24

Page 31

DRIVE SYSTEM-HYDROGEAR

10. Remove the two screws that hold the transmission links to the shifter plate. See Figure 5A.6.

Transmission link

Remove these screws

Figure 5A.6

11. The belt can now be snaked out of the tractor.

12. Install the belt following the above steps in

reverse order.

Belt adjustment

The drive belt is tensioned by a spring loaded

moveable idler pulley. When the brakes are applied,

the drive belt is de-clutched. An adjustable linkage connects the tensioner pulley to the brake shaft. A brake

link that is out of adjustment will prevent the moveable

idler from correctly tensioning and de-tensioning the

belt.

As the belt wears and stretches, the moveable idler

needs to push the belt in further to keep proper belt

tension. To do this, the ferrule at the end of the brake

link needs to be at the middle of the slot in the idler pulley bracket. To adjust this brake link:

NOTE: The belt must be on when performing

this adjustment.

1. Release the parking brake.

2. Remove the deck as described in chapter 8 Cut-

ting Decks and Lift Shaft.

3. Remove the cotter pin and washer from the fer-

rule. See Figure 5A.7.

NOTE: Tighten the electric PTO clutch bolt to a

torque of 450 - 600 in-lbs (51 - 68 Nm).

13. Test drive the tractor before returning to service.

Cotter pin

Ferrule

Figure 5A.7

25

Page 32

DRIVE SYSTEM-HYDROGEAR

4. Slide the ferrule out of the idler bracket.

See Figure 5A.8.

Washer

Slot

Figure 5A.8

5. Adjust the ferrule so that it lines up with the rear

of the slot and slides in without pulling on the

spring. See Figure 5A.9.

Transmissions

The I-series tractor uses two EZT transmissions

from Hydro-gear. The transmissions can be removed

separately. To remove a transmission:

NOTE: The transmission model and serial number tags are located on the frame channel next

to the transmission that they refer to.

1. Remove the deck as described in chapter 8 Cut-

ting Decks and Lift Shaft.

2. Remove the drive belt as described previously in

this chapter.

NOTE: Leave the transmission links and the

transmission brace disconnected.

3. Lift and safely support the rear of the tractor.

4. Remove the rear wheels.

5. Unhook the by-pass rod. See Figure 5A.10.

Front of tractor

Figure 5A.9

6. Install the washer and a new cotter pin.

7. Test drive the tractor before returning to se rvic e.

8. Re-attach the deck.

Bad

spring

Unhook the spring

Figure 5A.10

6. Disconnect the brake rod by following the steps

described in Chapter 3: Brakes.

26

Page 33

DRIVE SYSTEM-HYDROGEAR

7. Remove the two bolts that thread into the cross

tubes. See Figure 5A.11.

Cross truss

Bolts

Figure 5A.11

8. Support the transmission to prevent it from fa lling while the mounting bolts are removed.

9. Remove the bolt holding the transmission to the

torque bracket. See Figure 5A.12.

10. Remove the two bolts that fasten the transmission to the frame. See Figure 5A.13.

Reinforcing strap

Spacer

Figure 5A.13

NOTE: The two transmission bolts pass through

a spacer and a reinforcing strap. When the bolt s

are removed, the spacer and strap can be

removed. See Figure 5A.13.

11. The transmission can now be removed from the

tractor.

Torque bracket

Bolt

Figure 5A.12

NOTE: There is a nut on the top side of the

torque bracket. Use a 7/16” wrench to hold it

while removing the bolt.

12. If replacing the transmission, remove the transmission pulley and fan assembly.

13. Remove the wheel hub assembly.

14. Install the hub on the new transmission and

tighten to a torque of 420 - 480 in-lbs (47.5 54Nm).

15. Install the transmission pulley and fan assembly

on the new transmission and tighten to a torque

of 300 - 460 in-lbs (34 - 52Nm).

16. Install the transmission by following steps 1 - 11

in reverse order.

17. Perform a neutral adjustment and wheel alignment by following the steps described in 6A:

Steering - HydroGear.

18. Test drive the tractor in a safe area before

returning to service.

27

Page 34

DRIVE SYSTEM-HYDROGEAR

Drive pedal shaft

To remove the drive pedal shaft:

1. Remove the deck as described in chapter 8 Cutting Decks and Lift Shaft.

2. Disconnect the link between the steering gear-

box and the bell crank on the drive pedal shaft.

See Figure 5A.14.

Steering gear box lever

Bell

crank

Link

Reverse switch

Figure 5A.14

6. Drive out the two roll pins that secure the drive

pedal bracket to the drive pedal shaft.

See Figure 5A.16.

Drive pedal bracket

Hex bushing

Figure 5A.16

7. Remove the hex bushing. See Figure 5A.16.

8. Slide the drive pedal shaft to the left to clear the

hole for the right side hex bushing.

See Figure 5A.17.

NOTE: It does not matter which side of the link is

disconnected.

3. Disconnect the reverse switch.

4. Remove and discard the cotter pin on the left

side of the drive pedal shaft. See Figure 5A.15.

Washer

cotter pin

Hex bushing

Figure 5A.15

Hole for hex bushing

Figure 5A.17

9. Install the drive pedal shaft by following the previous steps in reverse order.

10. Test drive the tractor before returning it to service.

5. Remove the washer and hex bushing.

See Figure 5A.15.

28

Page 35

CHAPTER 5B: DRIVE SYSTEM - IVT TRANSMISSION

DRIVE SYSTEM-IVT

There are two drive systems available for the Iseries tractor. One system uses two HydroGear transmissions. The other system uses an Infinitrak full-toroidal Infinitely Variable Transmission (IVT). This chapter

will cover the IVT version of the tractor.

The Infinitrak full-toroidal Infinitely Variable Transmission (IVT) removes the constraints of conventional

stepped ratio transmissions. Instead of using a system

of gears to determine the ratio range, the IVT uses a

variator that is made of a set of discs and rollers called

a “full toroidal” variator. In the IVT, the torque is controlled allowing optimization of the power train by allowing the engine to run at its most efficient RPM range

and stay there.

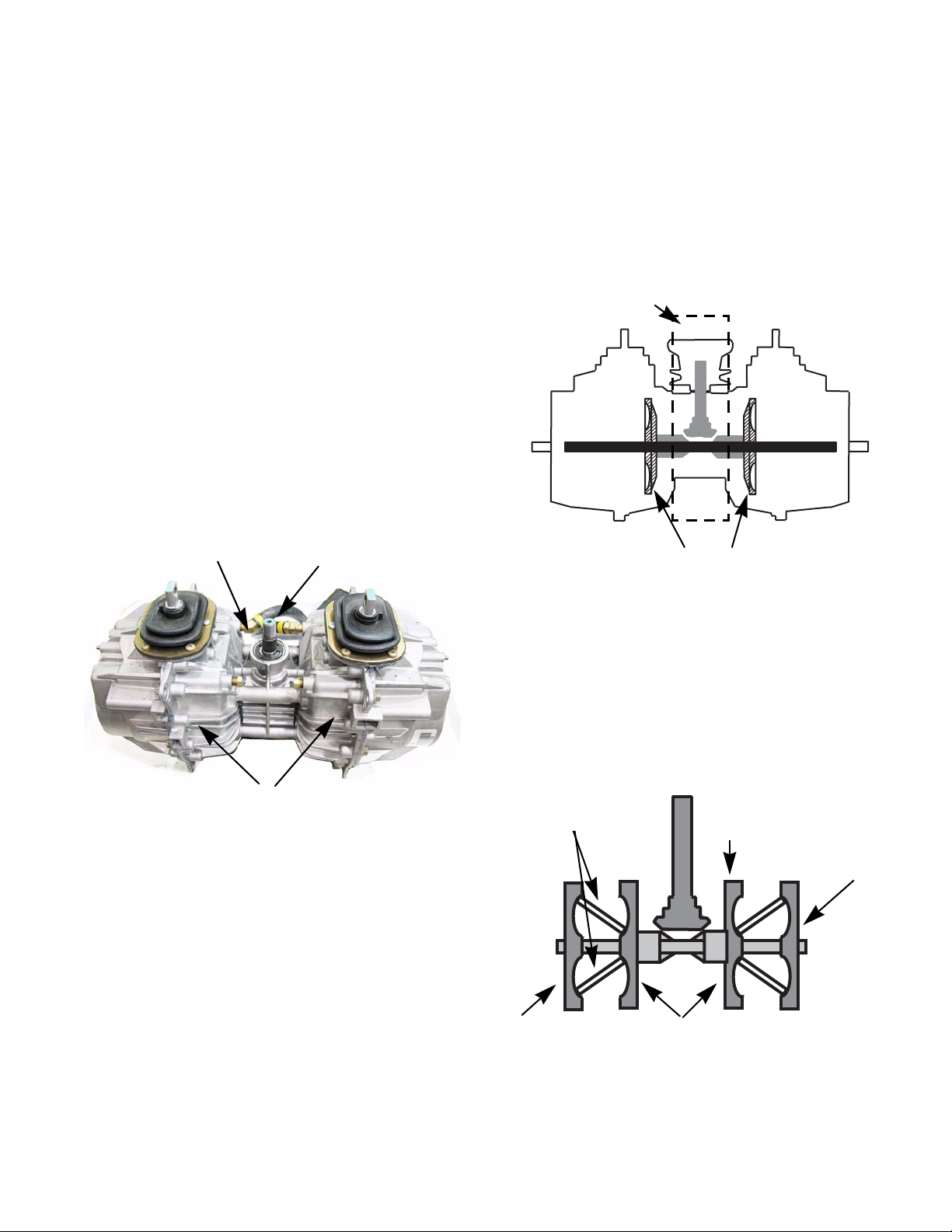

The IVT used on the I-series is a twin variator version. This means that there is one input and two outputs. See Figure 5B.1

“T” box

Input shaft

The power from the engine is transferred to the

transmission via a belt and pulleys. The power is

applied to a “T” box assembly. The “T” box output

drives the inner discs of the variator assemblies.

See Figure 5B.2

“T” box assembly

Inner disks

Figure 5B.2

Each inner disc drives a pair of rollers that drive the

output discs. The angle of the rollers determines the

speed of the output discs. When the rollers rides near

the center of the input discs, they are pressing against

the outer edge of the output discs. In this position, the

output disc will be turning at a much slower rate than

the input discs. See Figure 5B.3

Variators

Figure 5B.1

29

Rollers

Output disc

500 rpm

50 rpm

Input discs

Figure 5B.3

Page 36

DRIVE SYSTEM-IVT

NOTE: The RPM numbers used in figures 5B.2,

5B.3 and 5B.4 are not the actual measurements

of the disc speeds. They are just an example to

demonstrate the speed differences.

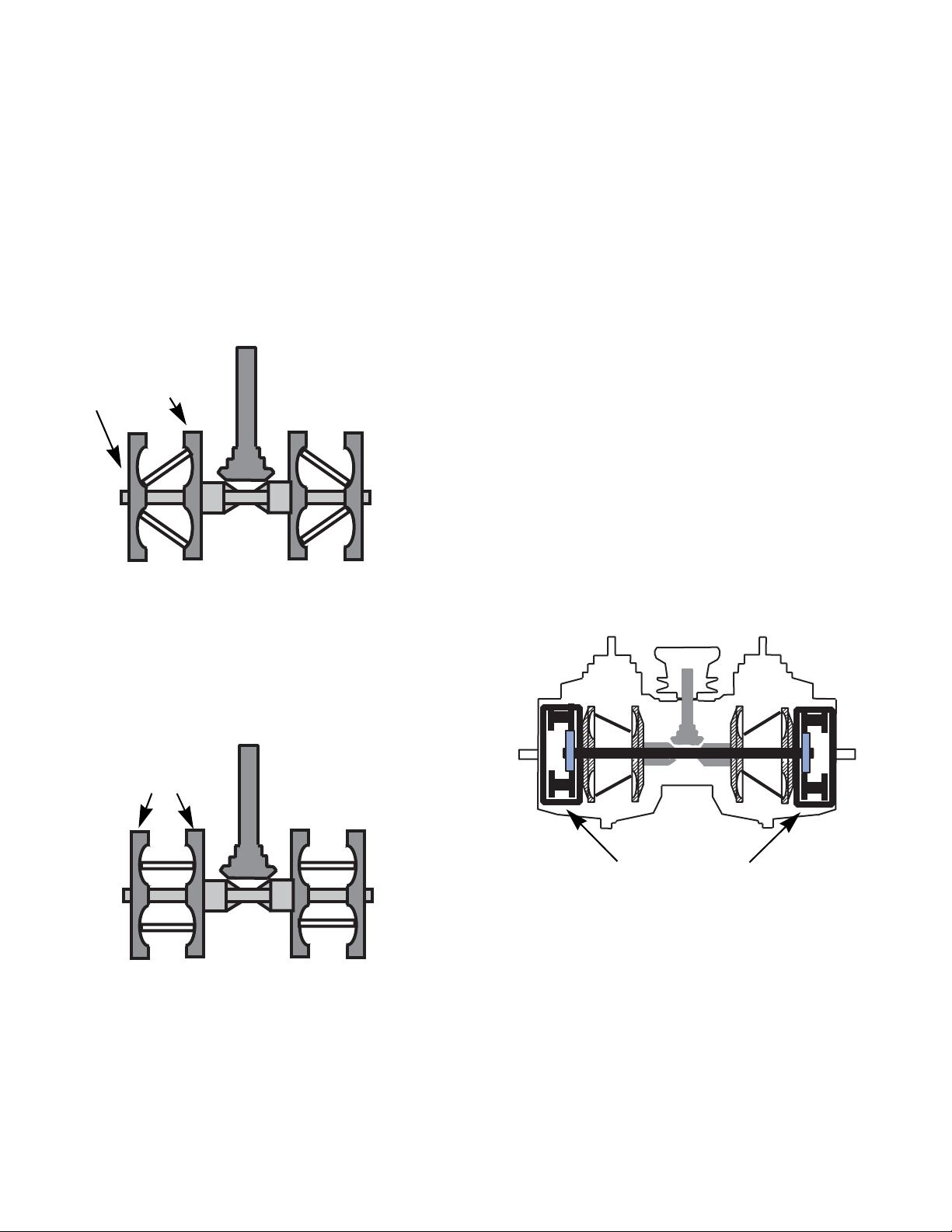

When the rollers rides near the outer edge of the

input discs, they are pressing against the center of the

output discs. In this position, the output disc will be

turning at a much faster rate than the input discs.

See Figure 5B.4

500 rpm

1,000 rpm

The key to making this work is a special traction

fluid that was developed for this transmission. A Traction fluid is a synthetic transmission fluid designed with

properties specifically for transmitting torque between

the discs and rollers.

Under normal load conditions this fluid acts like a

conventional lubricating fluid. When the fluid is subjected to extreme pressure, such as in the contact area

between the discs and rollers, the fluid changes to

exhibit its ElastoHydrodynamic Lubricant (EHL) properties. The EHL property of the traction fluid causes the

molecules in the fluid to become almost solid. This

increases the shear force transmitting properties of the

fluid.

The traction fluid in the contact area between the

rollers and discs turns into a semi-solid. This allows the

fluid to act like a gear tooth, transferring the torque

from the disc to the roller or vise versa. It also prevents

metal to metal contact extending the life of the moving

parts.

Figure 5B.4

When the rollers are in the neutral position o r in the

center of the disc valley, all of the discs are rotating at

the same speed. See Figure 5B.5

500 rpm

NOTE: Putting motor oil or hydraulic fluid in an

IVT transmission will destroy it.

Each of the variators are attached to a epicyclic,

also know as planetary, gear set. See Figure 5B.6

Epicyclic gear sets

Figure 5B.6

Figure 5B.5

30

Page 37

DRIVE SYSTEM-IVT

The output shaft of the T-box drives a sun gear in

the center of the planetary ge ars at the sa me sp eed a s

the input discs. The planetary gear carriers are

attached to the output discs. See Figure 5B.7

Output disk

Carrier

Planetary

gears

Epicyclic gear set

Figure 5B.7

The epicyclic gear set acts like an adding machine,

it subtracts the input (sun gear) speed from the output

(planetary gear carrier). See Figure 5B.8

Planetary gear

If the answer is positive, transmission drives in a

forward direction. If the answer is negative, the tra n s mission drives in reverse. If the answer is zero, the

transmission will have zero output and be in what is

known as a geared neutral state. See Figure 5B.9

Figure 5B.9

The answers from the epicyclic gear sets are collected by the transmission output shaf t s that a re dr iven

b the planetary gears. See Figure 5B.10

Carrier

Sun gear

Output shaft

Figure 5B.8

Figure 5B.10

31

Page 38

DRIVE SYSTEM-IVT

The transmission output shafts drive a pair of drop

axles assemblies.

The IVT transmissions are NOT serviceable.

The drop axles and brakes are serviceable and will be

covered in later sections of this chapter.

NOTE: Currently replacement traction fluid is n ot

available for purchase.

Drive belt

The drive belt is the most common drive system

component that will need attention. To remove/replace

the drive belt:

Cub Cadet belts are design to fit

! CAUTION! CAUTION

belt may prevent the de-clutching mechanism from

working properly when the brakes are applied.

1. Remove the deck as described in chapter 8:

Cutting Decks and Lift Shaft.

2. Lift and safely support the rear of the tractor.

3. Remove the three belt guides near the idler pul-

leys. See Figure 5B.11

our equipment and are not standard lengths. Use of a non-OEM

Belt Guides

32

Figure 5B.11

Page 39

DRIVE SYSTEM-IVT

4. Slide the retainer clip half way out of the dampener end using small flat head screw driver.

See Figure 5B.12

Moveable idler

Dampener end

Retainer clip

Figure 5B.12

5. Disconnect the dampener from the moveable

idler pulley bracket.

6. Disconnect the brake link from the moveable

idler pulley bracket.

9. Unplug the electric PTO harness.

See Figure 5B.14

Starter

PTO connector

Figure 5B.14

10. Unbolt the electric PTO using an impact wrench

and a 5/8” socket. See Figure 5B.15

7. Loosen the moveable idler pulley enough for the

belt to slip past the belt guide using a pair of

9/16” wrenches. See Figure 5B.13

Belt guide

Figure 5B.13

8. Slip the belt off of the idler pulleys.

PTO clutch

Remove bolt with an impact wrench

Figure 5B.15

NOTE: If the PTO clutch will not slide off of the

crankshaft, thread the bolt half way into the

crankshaft. Make sure the belt keeper is in place

to prevent the clutch from rotating. Plug in the

PTO clutch harness. Start the engine and turn

the PTO on and off several times to shake it

loose.

33

Page 40

DRIVE SYSTEM-IVT

11. Slide the engine pulley down far enough to slip

the belt off of the pulley. See Figure 5B.16

Engine pulley

Figure 5B.16

NOTE: If the engine pulley will not slide down

the crankshaft using the steps above, remove

the engine mounting bolts and slide the engine

back. This will give enough clearance to slide

the belt off of the engine pulley.

NOTE: Note the direction of the key in the

engine pulley. It should be facing down. If the

pulley is installed upside down, the belt alignment will be off.

NOTE: When installing the engine pulley and

electric PTO, coat the cran kshaft with anti-seize.

This will ease pulley and clutch removal in the

future.

NOTE: There is a spacer above the engine pulley. It is symmetrical and can not be put on

upside down. See Figure 5B.17

12. Remove the rear wheels.

13. Remove the transmission fan.

13a. Reach in through the wheel opening.

13b. Remove the three transmission fan screws

using a 5/16” wrench. See Figure 5B.18

Transmission

fan

Figure 5B.18

13c. Remove the transmission fan.

NOTE: Never use an impact wrench to remove

the transmission pulley. It will destroy the one

way bearing on the input shaft.

14. Remove the transmission belt guard.

14a. Remove the four screws using a 5/16”

wrench. See Figure 5B.19

Spacer

Belt guard

Engine

pulley

Figure 5B.19

14b. Remove the belt guard.

Figure 5B.17

34

Page 41

DRIVE SYSTEM-IVT

15. Slip the belt off of the transmission pulley.

16. Remove the belt from the tractor.

17. Install the belt following the previous steps in

reverse order.

Drive belt routing

Figure 5B.20

NOTE: Tighten the electric PTO clutch bolt to a

torque of 450 - 600 in-lbs (51 - 68 Nm).

18. Test drive the tractor before returning to service.

Belt adjustment

The drive belt is tensioned by a spring loaded

moveable idler pulley. When the brakes are applied,

the drive belt is de-clutched. An adjustable linkage connects the tensioner pulley to the brake shaft. A brake

link that is out of adjustment will prevent the moveable

idler from correctly tensioning and de-tensioning the

belt.

As the belt wears and stretches, the moveable idler

needs to push the belt in further to keep proper belt

tension. To do this, the ferrule at the end of the brake

link needs to be at the rear of the slot in the idler pulley

bracket.

NOTE: The moveable idler pulley has a dampener on it. The dampener allows a slow, smooth

engagement of the drive belt. See Figure 5B.21

Brake

link

Dampener

Moveable

idler

pulley

Figure 5B.21

The brake link is adjusted to the rear of the slot in

the moveable idler bracket. This allows the brake pedal

can return rapidly when the pedal is released, while the

dampener slows the engagement of the drive belt.

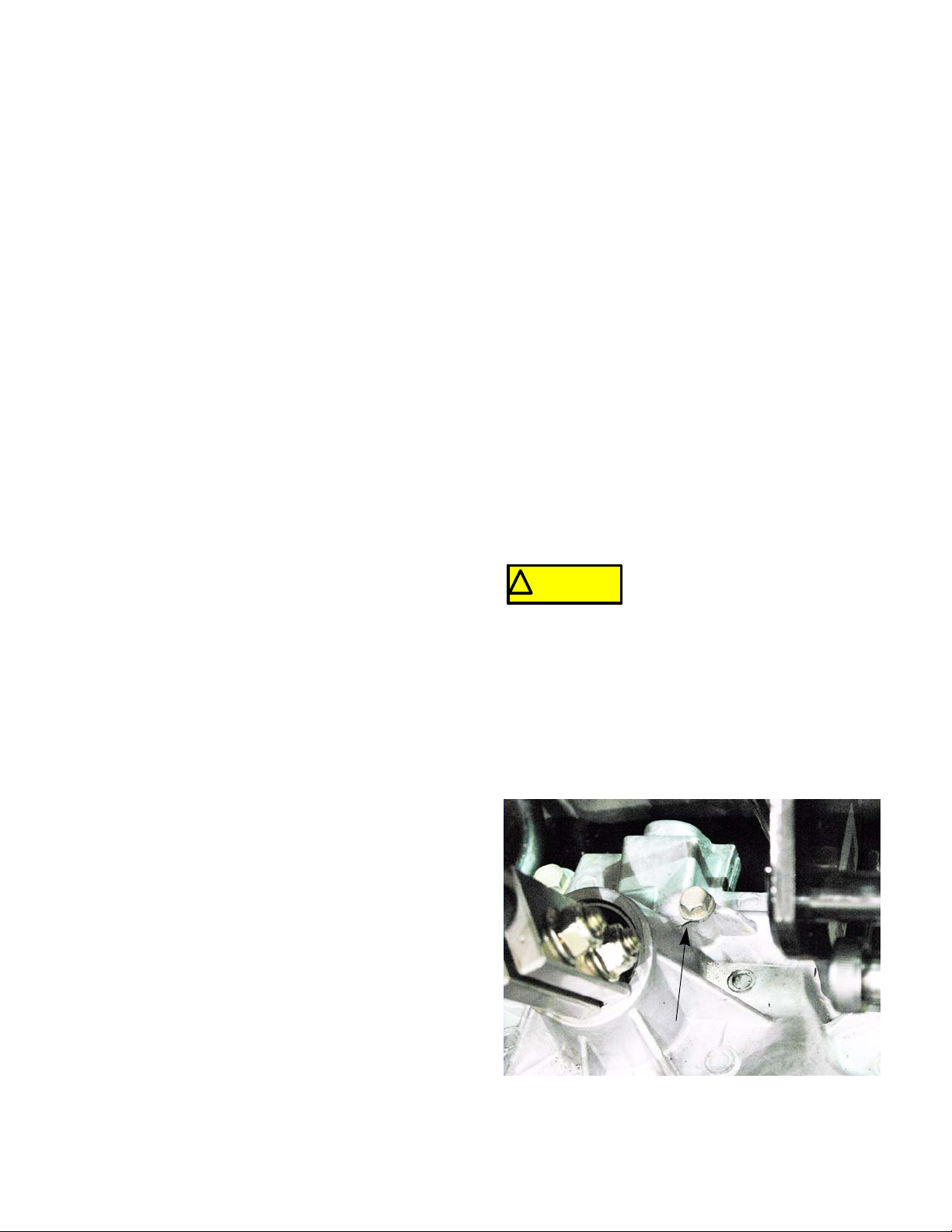

Operating the tractor with the idler

! CAUTION! CAUTION

the brake pedal is released.

To adjust this brake link:

NOTE: The belt must be on when performing

this adjustment.

1. Release the parking brake.

2. Remove the deck as described in chapter 8 Cut-

ting Decks and Lift Shaft.

35

pulley dampener removed will

result in the tractor lurching when

Page 42

DRIVE SYSTEM-IVT

3. Remove the cotter pin and washer from the ferrule. See Figure 5B.22

Cotter pin

Ferrule

Figure 5B.22

4. Slide the ferrule out of the idler bracket.

See Figure 5B.23

Transmissions

To remove the transmission:

1. Remove the deck as described in chapter 8 Cutting Decks and Lift Shaft.

2. Lift and safely support the rear of the tractor.

3. Remove the dash and fender by following the

steps described in Chapter 4: Body/Chassis.

4. Remove the rear wheels.

5. Remove the drive belt from the engine pulley

and the idler pulleys by following the procedures

described in the drive belt section of this chapter.

NOTE: The belt can stay on the transmission

pulley while the transmission is removed.

6. Unhook the by-pass rod spring on both sides of

the transmission. See Figure 5B.24

Washer

Slot

Figure 5B.23

5. Adjust the ferrule so that it lines up with the rear

of the slot and slides in without pulling on the

spring.

6. Install the washer and a new cotter pin.

7. Re-attach the deck.

8. Test drive the tractor before returning to se rvic e.

By-pass rod spring

Figure 5B.24

7. Disconnect the brake rods by following the steps

described in Chapter 3: Brakes.

8. Disconnect the drive control links:

36

Page 43

DRIVE SYSTEM-IVT

8a. Remove the hair and clevis pins.

See Figure 5B.25

drive control link

Hair pin clip

Clevis pin

Figure 5B.25

8b. Slide the drive control links off of the input

levers

9. Remove the two screws that fasten the expansion tank to the left side of the frame. See Figure

5B.26

10. Remove front mounting screw on each side of

the tractor using a 1/2” wrench.

See Figure 5B.27

Front mounting

screw

Figure 5B.27

NOTE: Support the transmission to prevent it

from falling while the mounting bolts are

removed.

11. Remove the two bolts that fasten the transmission to the frame and the support plate on each

side of the tractor. See Figure 5B.28

Expansion

tank

Figure 5B.26

NOTE: The seat frame plate was removed for a

clearer picture.

NOTE: Clamp off both of the lines going to the

expansion tank to help prevent loss of traction

fluid. Currently replacement traction fluid is not

available for purchase.

Support plate

Mounting bolts and nuts

Figure 5B.28

12. Lower the transmission out of the tractor.

NOTE: Avoid spilling traction fluid while moving

the transmission. Currently replacement traction

fluid is not available for purchase.

37

Page 44

DRIVE SYSTEM-IVT

13. If replacing the transmission assembly, remove

the transmission fan.

14. If only replacing the IVT (center section of the

transmission), remove the drop axles by following the procedures described in the drop axle

section of this manual.

15. Install the transmission by following the previous

steps in reverse order.

16. Perform a neutral adjustment and wheel alignment by following the steps described in 6B:

Steering - IVT.

17. Test drive the tractor in a safe area before

returning to service.

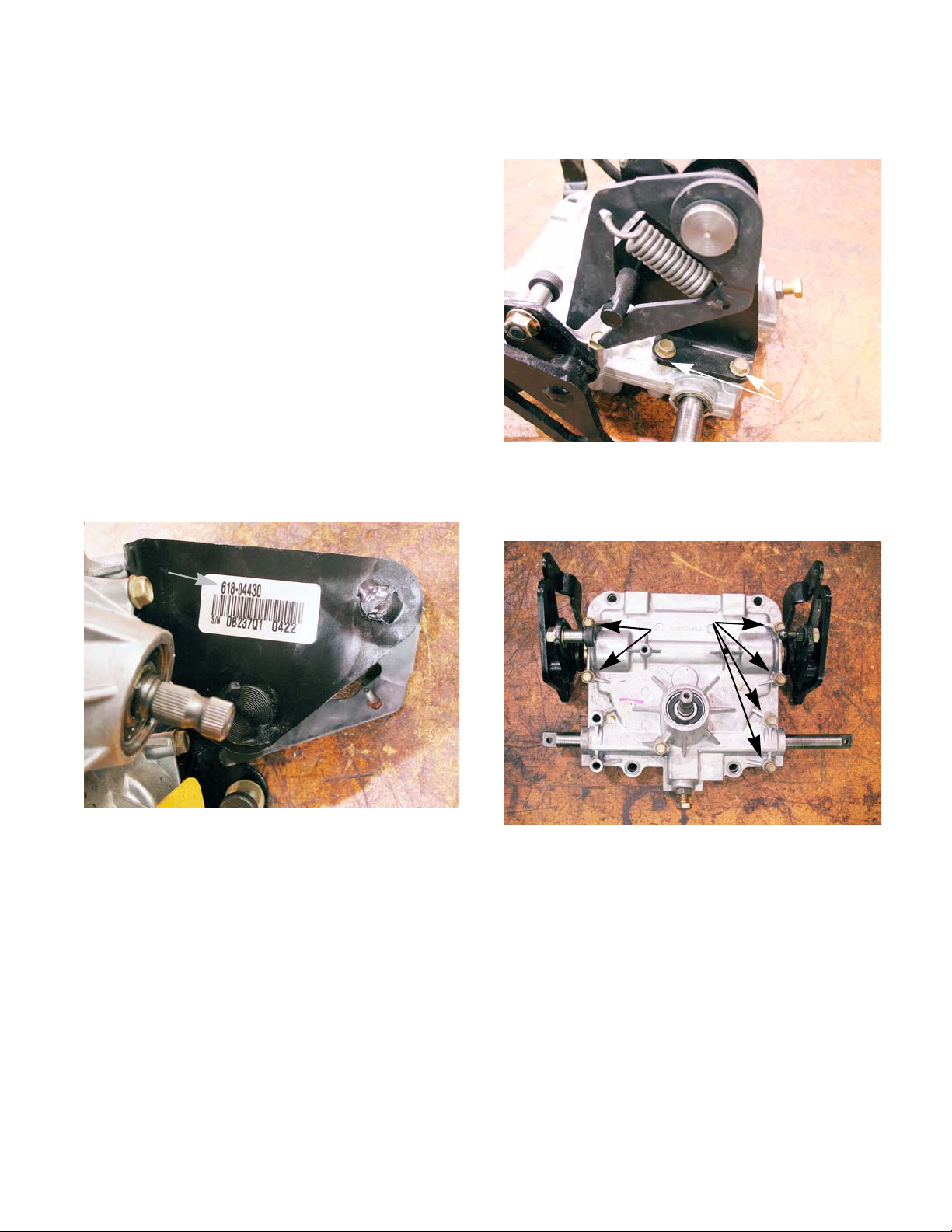

Drop axle assemblies

The drop axle assemblies on the IVT transmission

perform three functions:

• The drop axle assemblies are a gearbox that will

transmit the power of the IVT at a reduced speed

to the drive wheels.

• The drop axle contains a dog clutch assembly to

disconnect the transmission from the drive

wheel. This allowing the tractor to be pushed by

hand.

The drop axle assemblies are serviceable, sepa-

rately from the IVT.

To remove the drop axles:

1. Remove transmission assembly from the tractor

by following the procedures described in the previous section of this chapter.

2. Remove the eight screws the secure the transmission support bracket to the drop axles using

a 1/2” wrench. See Figure 5B.29

Transmission support bracket

38

Figure 5B.29

Page 45

DRIVE SYSTEM-IVT

3. Remove the four screws that secure the drop

axle assembly to the IVT, using a 1/2” wrench.

See Figure 5B.30

Remove these screws

Figure 5B.30

4. Tap the drop axle off of the alignment dowels

using a soft faced hammer. See Figure 5B.31

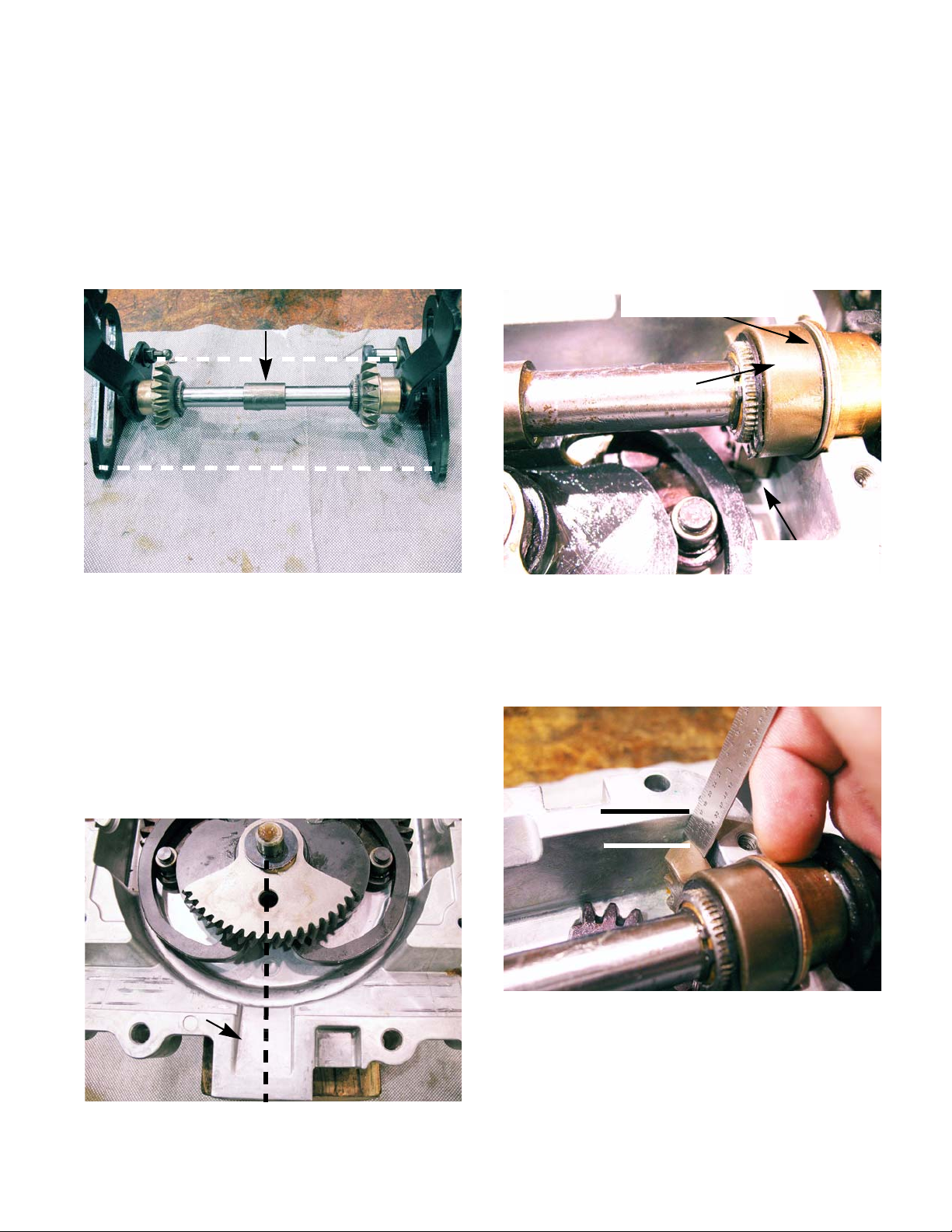

Rebuilding the drop axles

1. Remove the drop axle by following the procedures described in the previous section of this

chapter.

2. Remove the brake:

2a. Remove the snap ring that secures the

brake drum to the brake shaft.

See Figure 5B.32

Pivot Screw

Snap ring

Brake lever

Drop axle

Figure 5B.31

5. Install the drop axle by following the previous

steps in reverse order.

6. Test drive the tractor before returning it to service.

Figure 5B.32

2b. Remove the brake lever using a 3/8”

wrench. See Figure 5B.32

2c. Unthread the pivot bolt from the brake

mounting plate, but do not remove it.

2d. Slide the brake drum and shoes off of the

brake shaft as one assembly.

3. Remove the push nut that secures the by-pass

lever to the by-pass fork. See Figure 5B.33

By-pass lever

push nut

39

Figure 5B.33

NOTE: If the by-pass lever or fork are not being

replaced, the push nut can be left in place.

Page 46

DRIVE SYSTEM-IVT

4. Remove the by-pass lever.

NOTE: The by-pass lever has a very tight fit on

the by-pass fork. It will need to be persuaded off.

5. Remove the eleven housing screws using a 3/8”

wrench.

6. Lift the upper housing off of the gearbox.

7. Remove the drive axle assembly.

See Figure 5B.34

Drive axle

11. Remove the brake shaft assembly.

See Figure 5B.36

By-pass fork

Brake shaft assembly

Figure 5B.36

12. Slide the bushings off of the brake shaft.

13. Slide the washer and the spring off of the brake

shaft.

Figure 5B.34

8. Slide the bushing and the bearing off o f the drive

axle.

9. Remove the thrust bearing.

10. Remove the nut securing drive gear to the drive

axle. See Figure 5B.35

Drive axle

Drive gear

Thrust

bearing

Nut

Bushing

Bearing

14. Slide the dog clutch off of the brake shaft.

spur gear

Brake shaft

Washer

Bushing

NOTE: The dog clutch is spring loaded to

engage the spur gear . When the by-p ass lever is

operated, the dog clutch slides out of the spur

gear. This disconnects the Drive axle from the

IVT.

Dog

clutch

Figure 5B.37

Spring

Bushing

Figure 5B.35

NOTE: The nut is installed with Loctite #271

threadlocker.

40

Page 47

15. Separate the spur gear from the brake shaft by

$ [´

% [´

& [´

' [´

$

&

&

%

%

'

&

'

removing the retaining ring. See Figure 5B.38

DRIVE SYSTEM-IVT

NOTE: When seating the bushings of the brake

shaft in the drop axle housing, the tab on the

bushings must seat in the notch in the housing.

Retaining ring

Figure 5B.38

16. Remove the bearing. See Figure 5B.39

Input spur gear

Notch

Tab

Figure 5B.40

NOTE: Apply Loctite #271 or an equivalent

threadlocker to the threaded section of the drive

axle. Tighten the nut that secures the drive gear

to a torque of 42 - 50 ft lbs. ( 56 - 68 Nm).

NOTE: Fill the drop axle with 10.5 ounces of

737-0300A Durina

TM

grease.

NOTE: The drop axle has four different length

screws securing the housings together.Figure

5B.51 shows were the different screws go.

Bearing

Figure 5B.39

17. Remove the input spur gear. See Figure 5B.39

18. Clean and inspect all for the parts for damage

and signs of wear.

NOTE: Any parts that have damage or signs of

wear must be replaced.

19. Re-assemble the drop axle by following the previous steps in reverse order.

Figure 5B.41

NOTE: T ighten the screws to a torque of 90-120

in lbs. (10 - 14 Nm).

20. Test drive the tractor in a safe area before

returning it to service.

41

Page 48

DRIVE SYSTEM-IVT

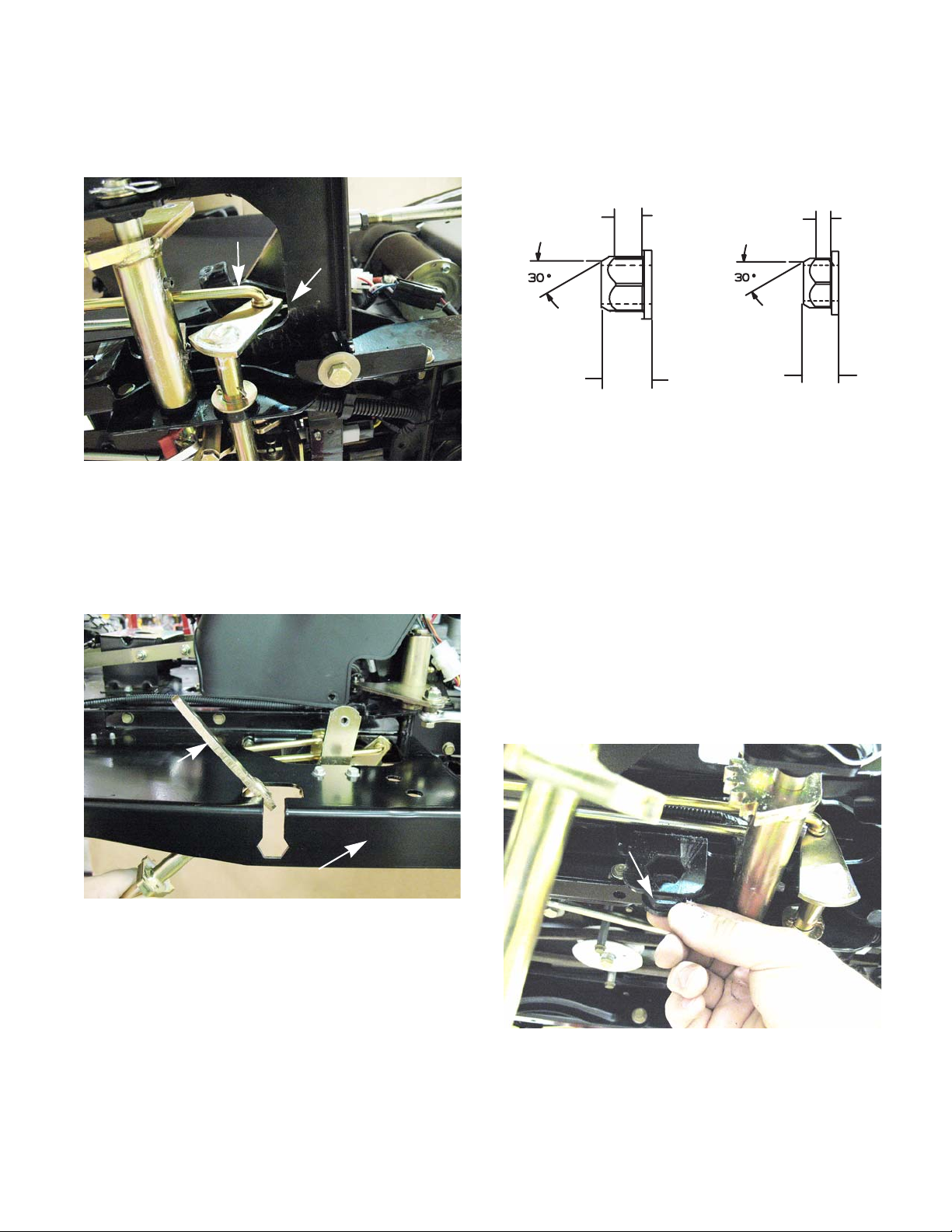

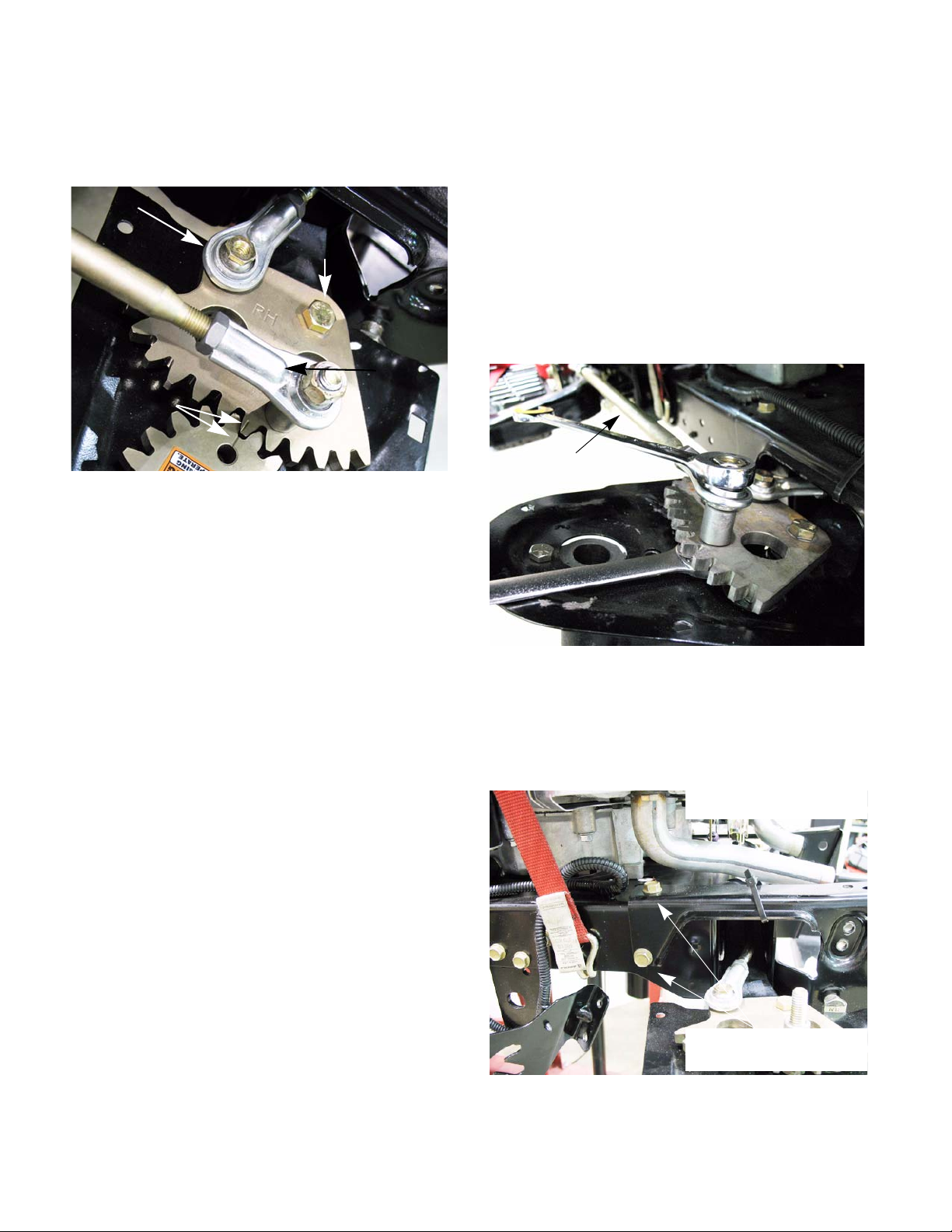

Drive pedal shafts

The I-series tractors equipped with the IVT transmission have two drive pedal assemblies. The main

drive pedal shaft is attached to the forward drive pedal.

It operates the brakes and pulls the drive control links

in the forward direction. The reverse drive pedal shaft

is geared to the main drive shaft. When the reverse

pedal is depressed, the reverse drive pedal shaft will

rotate the main drive pedal shaft in the reverse direction.

To remove the drive pedal shafts:

1. Remove the deck as described in chapter 8 Cut-

ting Decks and Lift Shaft.

2. Remove the fender by following the steps

described in Chapter 4: Body/Chassis.

3. Put a timing mark on the gears of the two shafts.

• One mark on the fourth tooth from the bottom of

the reverse gear.

• One mark on the fourth valley from the valley of

the main drive shaft gear. See Figure 5B.42

Timing marks

4. Remove the reverse drive pedal:

NOTE: If the main drive pedal shaft is the only

part that needs to be serviced, the reverse p edal

shaft can be left in place. However Cub Cadet

recommends removing the reverse pedal shaft

and replacing the bushings at the same time.

NOTE: Worn bushings on either drive pedal

shaft will cause some loss of wheel speed.

4a. Remove the hair pin clip and washer.

See Figure 5B.43

Washer

Reverse pedal

shaft

Hair pin clip

Figure 5B.42

NOTE: The timing marks will make re-assembly

easier.

Figure 5B.43

4b. Remove the split hex bushing.

See Figure 5B.44

Split hex bushing

Figure 5B.44

42

Page 49

DRIVE SYSTEM-IVT

4c. Rotate the reverse drive pedal shaft out of

the reverse pedal support.

See Figure 5B.45

reverse drive

pedal shaft

Reverse pedal support

Figure 5B.45

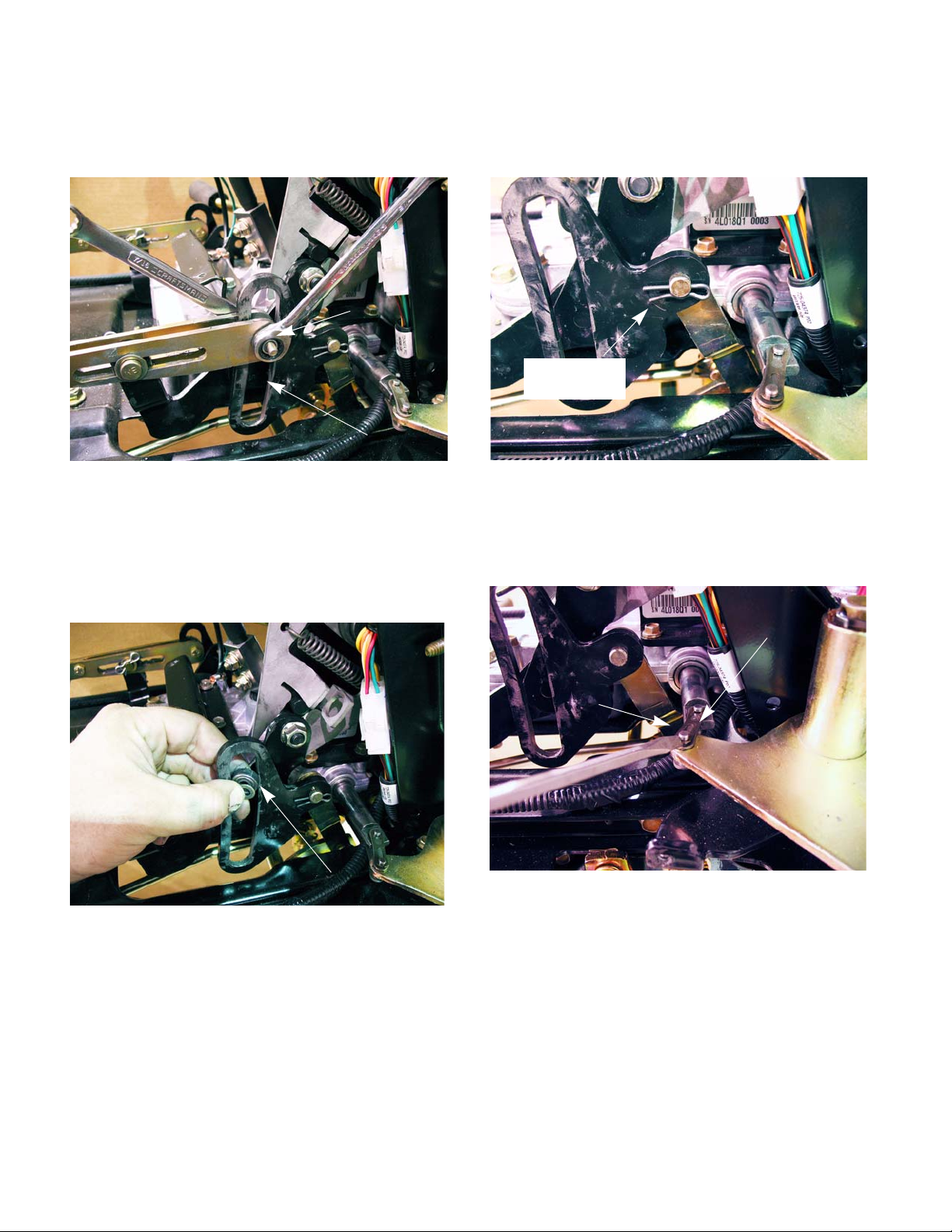

5. Disconnect the right side brake link from the

brake pedal shaft by removing the cotter pin.

See Figure 5B.46

6. Disconnect both brake release rods from the

main drive pedal shaft by removing the cotter

pins. See Figure 5B.47

Brake release rod

Cotter pin

Figure 5B.47

7. Remove the cotter pin and the split hex bushing

on the left side of the main drive pedal shaft.

See Figure 5B.48

Brake link

Figure 5B.46

Cotter

pin

Split hex bushing

Figure 5B.48

43

Page 50

DRIVE SYSTEM-IVT

8. Remove the hair pin clip, washer and hex bushing from the right side of the main drive pedal

shaft. See Figure 5B.49

Washer

Hex bushing

Figure 5B.49

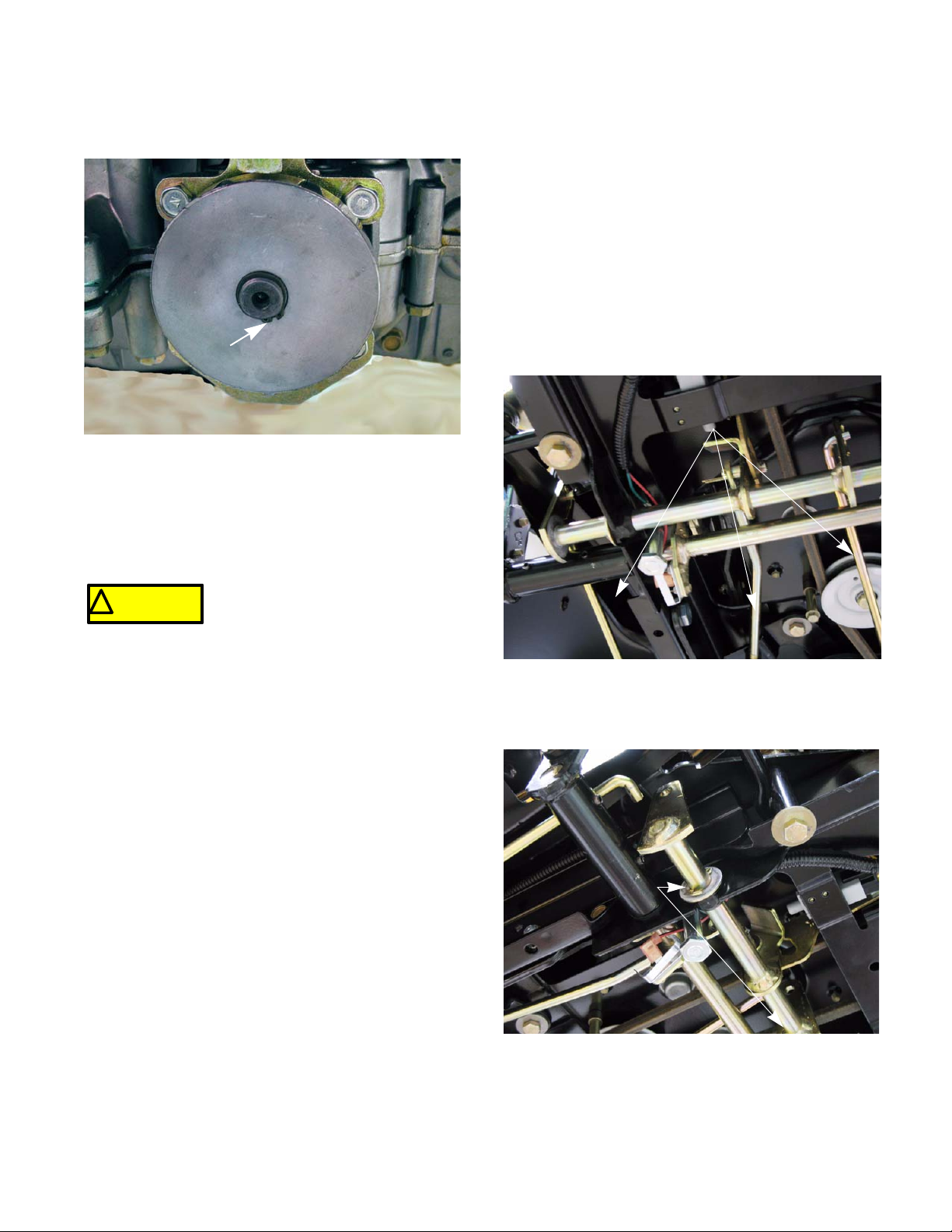

9. Drive out both of the roll pins securing the drive

pedal bracket to the main shaft using a 1/4” pin

punch. See Figure 5B.50

Hair pin clip

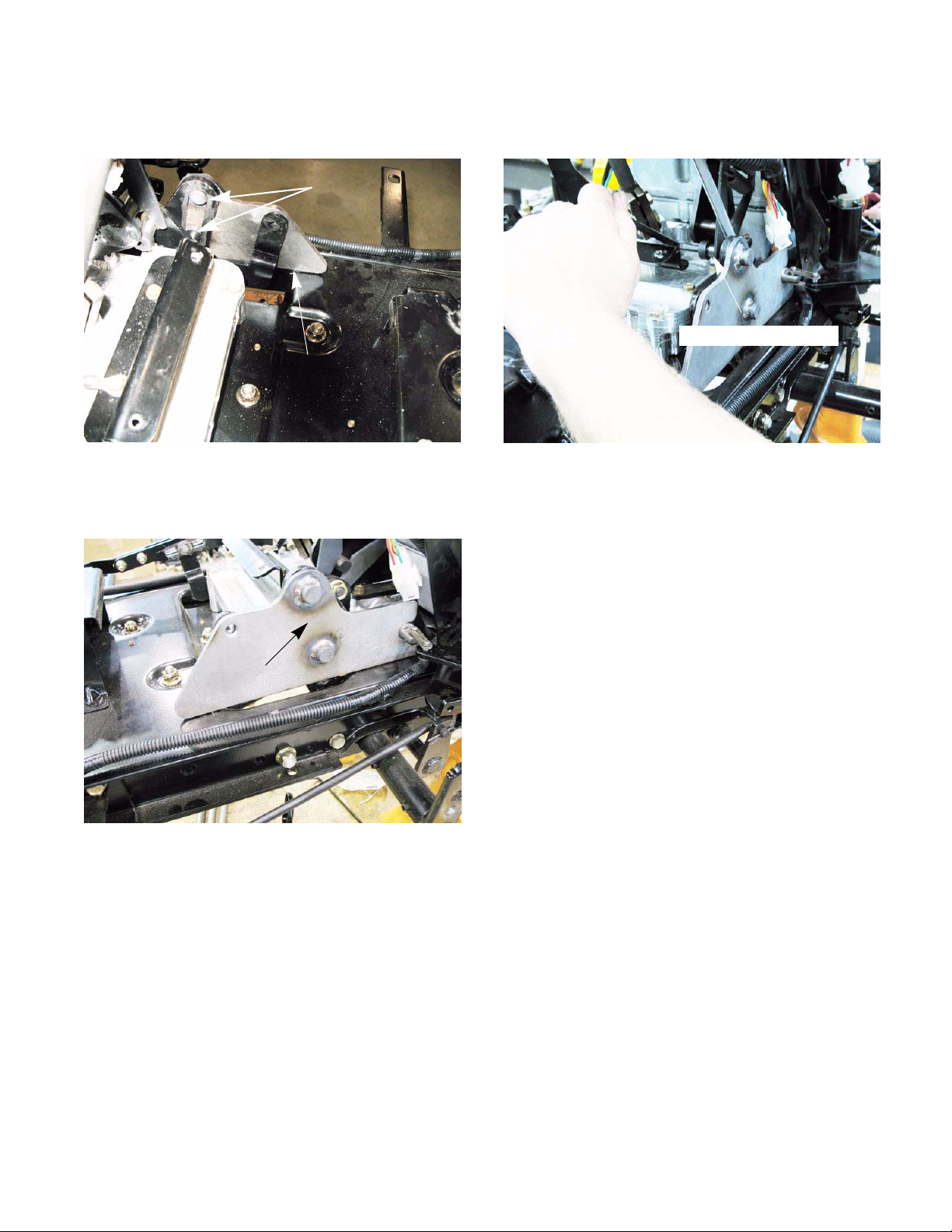

10. Remove the three screws that secure the

reverse pedal support using a 1/2” wrench.

See Figure 5B.51

Remove these screws

Figure 5B.51

11. Lift up on the outer edge of the reverse pedal

support while rotating it to the front to remove

the support.

Roll pins

Figure 5B.50

12. Slide the drive pedal bracket off of the main

shaft.

13. Remove the rear screw on both sides of the

drive pedal shaft support bracket.

See Figure 5B.52

Remove this screw

Middle hex

bushing

Figure 5B.52

14. Remove the middle hex bushing.

See Figure 5B.52

44

Page 51

DRIVE SYSTEM-IVT

15. Swing the rear of the drive pedal shaft support