Page 1

Safe Operation Practices Set-Up Operation Maintenance Service Troubleshooting

·

· · · ·

PERATOR’S

O

ANUAL

M

Brushcutter

CC924/CC927D/CC927U

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

FORM NO. 769-11081 02

01/25/2018

Page 2

Safety Instructions..........................................3

Symbols...........................................................5

Get to know yur brush cutter.........................7

Maintenace and repair................................. 14

Cleaning and Storage..................................17

Tro

ubleshooting...........................................18

Assembly Instructions....................................9

Fuel and Oil Instructions..............................11

Contents ....................................................... 20

Operating Instructions.................................12

Before setting up and operating your new equipment,

please locate the model plate on the equipment and record

the information in the provided area to the right. You can

locate the model plate on the engine of the brushcutter

This information will be necessary, should you seek technical

support via our web site, Customer Support Department,

or with a local authorized service dealer.

Visit us on the web at www.mtdproducts.com

Contact MTD AU • P.O. Box 376 Dandenong.Vic.3175

Email Address: mtdservice@mtd.com.au Customer Service Phone:1300 951 594

19

2

Page 3

Page 4

18. The rotary spool head and/or the cutting blade may keep running for a short time just after

your shutting it down. Always be aware of the rotating parts; they are dangerous. If the

cutting attachments cannot stop at idling, you should adjust the carburetor.

19. Never use parts, accessories or attachments which are not authorized for this unit. Otherwise,

the user may be seriously injured and/or the unit damaged and the warranty may be deemed

null and void.

20. If situations occur which are not covered in this manual, please contact MTD customer service

department or your nearest local dealer.

4

Page 5

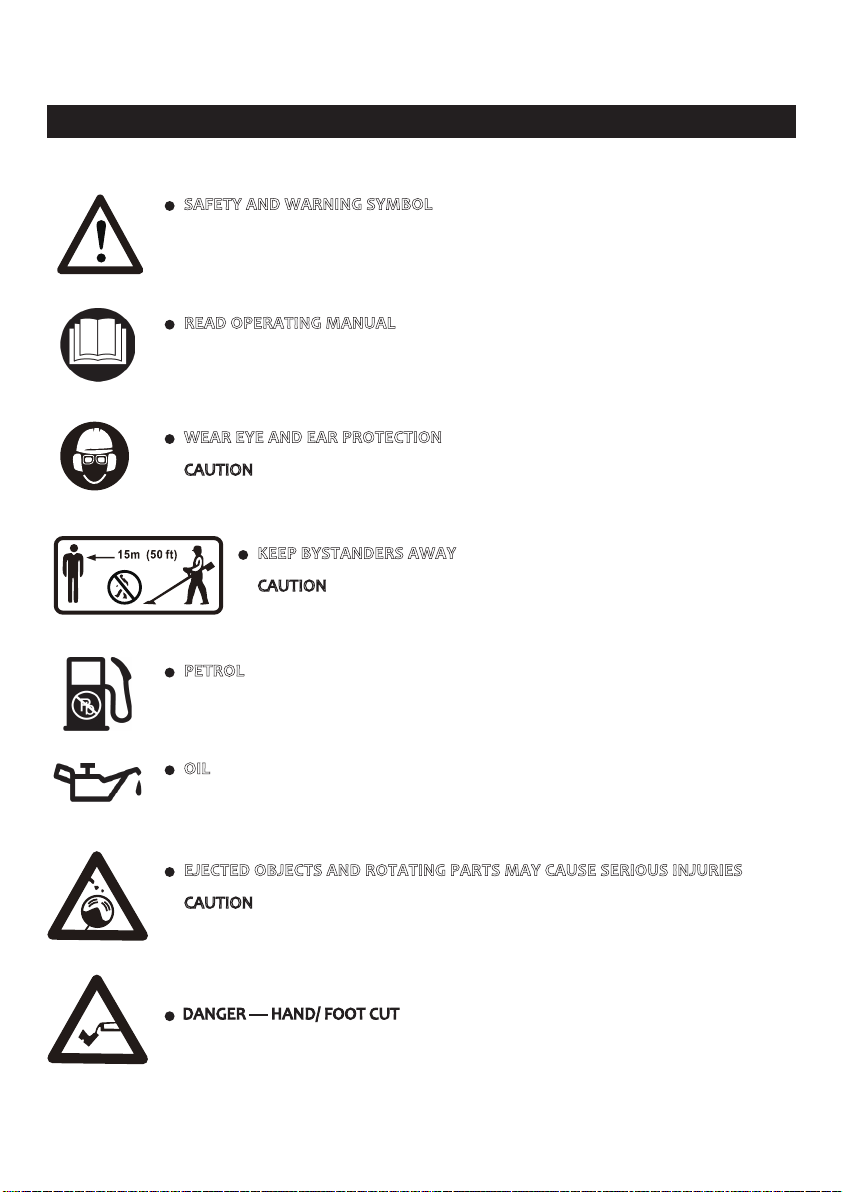

SYMBOLS

SAFETY AND WARNING SYMBOL

Indicates danger,warning or a reason to be cautious.Can be used together with

other symbols or pictograms.

READ OPERATING MANUAL

Non-compliance with the operating instructions and precautions may result in

serious injuries.Read the operating manual before starting or operating the unit.

WEAR EYE AND EAR PROTECTION

CAUTION: Ejected objects may cause serious eye injuries and excess noise may

cause loss of hearing.When operating the unit,wear eye and ear protection.

KEEP BYSTANDERS AW AY

CAUTION: All bystanders,especially children and pets,must be kept at

least 15m from the working area.

PETROL

Always use clean and fresh lead-free petrol for mixing petrol.

OIL

Use only authorised oil according to the operating manual for mixing petrol.

EJECTED OBJECTS AND ROTATI NG PARTS M AY CAUSE SERIOUS INJURIES

CAUTION: Do not use the unit if the protective housing has not been correctly

positioned for cutting.Keep away from the rotating line coil.

Keep hands and feet away from rotating parts.

5

Page 6

IGNITION SWITCH

RUN

IGNITION SWITCH

OFF/STOP

BEWARE OF HOT SURFACES

SHARP BLADE

CAUTION

9000

MAXIMUM RPM

GLOVES

Please wear sturdy gloves.

SHOES

Please wear afety shoes.

Page 7

GET TO KNOW YOUR BRUSHCUTTER

Brushcutter with “D” Handle

Throttle Lockout

Ignition Switch

Harness Bracket

D-Handle

Muffler Cover

Spark Plug Cap

Air Filter Cover

Fuel Tank

Throttle Cable

Throttle Trigger

Shaft Tube

Clamping Bracker For

Cutting Attachment Shield

Gear Case

Trimmer Head

Cutting Attachment Shield

7

Page 8

GET TO KNOW YOUR BRUSHCUTTER

Brushcutter with “Bull” Handle

Throttle Cable

Throttle Lockout

Ignition Switch

Throttle Trigger

Muffler Cover

Spark Plug Cap

Air Filter Cover

Harness Bracket

Fuel Tank

Throttle Cable Collector

U-Handle

Clamping Bracket For U-Handle

Shaft Tube

Clamping Bracket For

Cutting Attachment Shield

Gear Case

Trimmer Head

Cutting Attachment Shield

8

Page 9

ASSEMBLY INSTRUCTIONS

INSTALL AND ADJUST HANDLE

“D” Handle

1. Push the handle down onto the tube,and

set the lower handle into the right place,

so that the parts matched right.

2. Insert the bolt into the bolt hole and push

it through.and put the nut into the nut hole

on the lower handle back.tighten the bolt,

but do not tighten the bolt completely.

3. While holding the unit in the operation,

move the handle to the location that

provides the best grip. Place it a minimum

of 6 inches(152mm) from the end of the grip.

make sure the handle base between arrows.

4. Tighten the bolt until the handle is secure.

D-Handle

Locking Knob

Washer

U-Handle

.

Middle Clamp

Top Clamp

Bottom Clamp

INSTALL THE CUTTING ATTACHMENT SHIELD

Align the two holes on the cutting attachment

shield with the other two holes in the clamping

bracket, then tighten them up with screws.

Lower Handle

152mm

“Bull” Handle

1. Put the “Bull” Handle between the top and

middle clamps, and then connect the top,

middle and bottom clamps by tightening

the handle locking knob.

2. You can adjust the operating angles of the

handle by loosening the handle locking knob.

Screw

Clamping

Bracket

Cutting

Attachment

Shield

INSTALL THE CUTOFF KNIFE

1. Align the knife hole with the hole on shield,

9

then tighten them up with screws.

Cutoff Knife

Cutting Attachment

Shield

Screw

Page 10

INSTALL THE TRIMMER HEAD

1. Align the shaft bushing hole with the locking

rod slot in the protective cover and the

notch in the gear case, and then insert the

locking rod into these three holes/slots.

Holding the locking rod to ensure the output

shaft in place.

2. Ensure the threads of the trimmer head and

the center of the output shaft are in line

with each other, and then rotate the trimmer

head clockwise (observed by operator) until

it is securely tightened.

Locking Rod

Protective Cover

INSTALL THE CUTTING BLADE(if attached)

1. Align the shaft bushing hole with the locking

rod slot in the protective cover and the notch

in the gear case, and then insert the locking

rod into these three holes/slots. Holding the

loc

king rod to en

sure the output shaft in

place.

2. Install the blade to the output shaft and

make sure it contacts closely with the shaft

busing.

3. Install the blade holder and blade holder

cover one by one.

4. Finally, install the locking nut and tighten

it by the hex wrench.

Shaft Bushing

Gear case

Output Shaft

Clockwise

Gear case

Blade Holder Cover

10

Blade Holder

Blade Holder Cover

Locking Nut

Locking Rod

Wrench

Clockwise

Page 11

FUEL AND OIL INSTRUCTIONS

FUEL AND OIL INSTRUCTIONS

OIL

1. Only use high quality special oil for air cooled 2-stroke engine,JASO FC or FD, or ISO-L-EGC or EGD

oil. Never use water cooled engine oil or any oil for 4-stroke engine.

Fuel

1. Always use fresh, clean lead-free fuel. Minimum octane number: 90.

Mixing Ratio

1. Recommended mixing ratio of fuel and oil is 50:1.

Warnings

the fuel tank with the mixture.

2. Do not mix the fuel and oil directly in the fuel tank; always use the mixing tank to do this job.

immediately.

4. Move the unit 5 meters away from the fueling source and site before starting the engine.

5. Never use fuel which has been stored for longer than 30 days. That may bring damage to the

unit, especially for the carburetor or the engine.

11

Page 12

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

STARTING COLD ENGINE

WARNING : Before starting the

engine, keep the cutting attachment

clear of everything around it.

1. Use the mixing tank to mix the fuel and oil.

Fill fuel tank with the mixture. See “Fuel and

Oil Instructions”.

2. Push the ignition switch to the “Run” positon.

3

. Press throttle lockout and throttle trigger and

then release them one by one.

Stop

Ignition Switch

Run

Throttle

Lockout

7. While holding the starter handle in right

hand. Gently pull the starter rope out until

you feel that the pawls hook onto the

8. Repeat several times until the engine starts.

9. Move choke lever to “HALF OPEN” position.

Allow the engine to run for 2

temperatures.

minutes to

-3

Throttle Trigger

Ignition Switch

Stop

4. Fully press and release the primmer bulb for

10 times. Some amount of fuel should be

visible in the primer bulb and fuel lines.

5. Move choke lever to the “CLOSE” position.

6. Hold the unit with your left hand and press

it against the ground.

Run

Throttle Trigger

“D”HANDLE

“BULL”HANDLE

Throttle Lockout

Primmer

Bulb

: Unit is properly warmed up when engine

Note

accelerates without hesitation.

Once the engine is warmed up, place the choke

lever to the “Full Open” position.

12

Page 13

Close

SHOULDER HARNESS

1. Wear the harness on the shoulder then

Full open

Choke

Lever

STARTING WARM ENGINE

1. Push the ignition switch to the “Run”

position

2. Move the choke lever to the“HALF OPEN”

position.

3. Hold the unit in left hand and press it against

the ground.

4. While holding the starter handle in right

hand. Gently pull the starter rope out until

you feel that the pawls hook onto the

5. Repeat several times until the engine starts.

6. Move the choke level to the“Full Open”

position.

your stature until you feel comfortable with

it on.

2. Attach harness hook to the suspension

loop on the shaft. Make sure the unit

gets a good balance before operating.

Quick-release mechanism

WARNING

mechanism on the harness to free

of emergency.

:

the idling engine to cool down.

2. Move the ignition switch to the “Stop”

WARNING

to the “CLOSE” position if the engine

can not be shut down by the two

after the machine becomes cold or

contact the authorized dealer for help.

: Move the choke lever

1. The trimmer head releases the line without

tap the trimmer head on the ground while

operating the unit at high speed

2. The cutting line should always have the max.

which automatically removes any excess

line that is released.

13

Page 14

MAINTENANCE AND REPAIR

MAINTENANCE AND REPAIR

FUEL FILTER

1. Empty the fuel tank.

fuel tank.

Filter

Filter Cover

CARBURETOR

Fuel Filter

AIR FILTER

Disassemble the filter cover, and pull the filter

from the air filter housing

2. Check the filter for deterioration,replace it if

necessary

3. Wash the filter with kerosene,put it in the engine

oil and squeeze it by one hand.

4. Replace it in the case,and assemble the air cleaner

cover.

2. Adjusting the idle-speed screw clockwise

will increase the idling speed and adjusting

it counterclockwise will decrease the idling

speed. You should use a tachometer to

measure the speed while adjusting. Make

sure the idling speed within the

recommended range 2700~3300 rpm.

3. Every unit had been run and tested at the

factory to ensure that the carburetor works

at its best condition. But after a period of

use, if trimmer head or cutting blade

continues to rotate at idling or the engine

stops when you fully release the throttle

trigger, make adjustment to idle-speed screw.

Page 15

Improper adjustment

WARNING

may cause damage to the unit. If

engine does not run well after

carburetor adjustment, please

contact the authorized dealer where

you bought the product.

idle-speed screw

:

7. Screw in the spark plug and tighten to a

8. Re-attach the spark plug cap.

9. If spark plug is damaged or the unit still

cannot work well after cleaning, replace

with a new one.

10. To ensure the machine work well Please use

SPARK PLUG

After every 50 operating hours take out the

spark plug and check its condition.

down.

the spark plug.

4. Unscrew spark plug in counterclockwise

direction with the attached spark plug

wrench.

6. Check and adjust spark plug gap to 0.6-0.7

mm.

Spark Plug Wrench

0.6 -0.7 mm

MUFFLER

Spark Arrester Service

Every 50 hours of operation

1. Remove the spark arrester from the exhaust

hole of muffler.

2. Clean deposits from the spark arrester screen

by brushing it.

3. Install the spark arrester.

Spark Arrester

15

Page 16

Carbon Removal of Engine Internal Parts

Every 50 hours of operation or found strikingly

low engine high-speed and rule out other causes

you need to clean up the engine internal carbon

deposition.

These items must be performed with proper tools.

please do it with the assistance of professionals or

authorized dealer.

GEAR CASE

1. Stop the engine to check if there is enough

lubricating grease in the gear case after

every 25 hours of use.

2. Remove the oiling bolt on the gear case.

3. Replenish good quality lithium grease as

TUBE/CLUTCH HOUSING

Remove the two screws at the joint of clutch and

tube ,disassemble the parts. then assemble the

parts In the reverse order after repair.

Clutch housing

Tube

4. Screw and tighten the bolt.

Clutch housing

Oiling Bolt

Transmission Shaft

Regular Check List

INTERVAL

ITEM

Check the bolt and nut,tighten up if necessary

Check for gas leak

Check the cooling air intake port,cooling fin,around muffler

Check and clean air cleaner

Check and clean spark plug

Check and clean fuel filter

Remove carbon deposits on muffler and cylinder

Clean spark arrester

Replace spark plug

Replace fuel piping (fuel pipe,grommet)

Items with must be performed with proper tools,please do it with assistance of professionals

or authorized dealer.

BEFORE

DAILY INSPECT

OPERATION

EVERY

50 HRS

EVERY

100 HRS

Tube

EVERY 2 YRS

16

Page 17

CLEANING

STORAGE

LONG-TERM STORAGE

:

4.

5.

TRANSPORTATION

17

Page 18

TROUBLE-SHOOTING

TROUBLE-SHOOTING

Problem Cause Remedy

1. Spark plug wire disconnected.

2. Ignition switch set to OFF.

3. Fuel tank empty.

4. Stale or improperly mixed fuel

mixture.

Engine does not start

Engine does not run

constantly at no load

Engine does not idle 1.Improper carburetor adjustment

Engine does not

accelerate

Engine has no power

or stops during

cutting

5. Dirty air lter/oil lter.

6. Incorrectly gapped or dirty spark

plug.

7. Primer bulb not depressed

adequately.

8. Flooded engine.

1. Dirty air/oil

. Stale or improperly mixed fuel

2

mixture.

3. Incorrectly gapped or dirty spark

plug.

1. Dirty air/oil

2. Throttle wire disconnected..

3. Defective throttle control lever.

4. Incorrectly gapped or dirty spark

plug.

5. Improper carburetor adjustment

1. Spool head or blade entangled with

grass.

2. Dirty air/oil filter.

3. Stale or improperly mixed fuel

mixture.

4. Improper carburetor adjustment

lter.

lter.

1. Reconnect wire.

2. Set switch to ON.

3. Add fuel.

4. Empty the tank and ll with fresh fuel

mixture.

5. Clean or replace filter.

6. Clean or adjust the gap.

7. Slowly and fully depress the primer

bulb 10 times.

8. Squeeze the throttle and pull the

starter rope with the choke lever in the

operating position.

1. Clean or replace

2. Empty the tank and

mixture.

3. Clean or adjust the gap.

1.Adjust according to the manualor turn to

an authorized service dealer for help.

1. Clean or replace

2. Reconnect throttle wire.

3. Replace the throttle control lever.

4. Clean or adjust the gap.

5. Adjust according to the manual or

turn to an authorized service dealer for

help.

1. Stop the engine and clean the cutting

attachment.

2. Clean or replace the filter.

3. Empty the

mixture.

4. Adjust according to the manual or turn

to an authorized service dealer for help.

.

lter.

lter.

tank and fill with fresh fuel

If further assistance is required, please contact your authorized service dealer.

ll with fresh fuel

18

Page 19

SPECIFICATION

Model Number: CC927D CC924 CC927U

Engine:

Displacement: 25.6cc 22.5cc 25.6cc

Carburator:

Clutch Type:

Starter:

Max.Power: 0.8KW 0.7KW 0.8KW

Mixing Ration(Fuel/Oil)

Idle Speed:

Speed at Max,Torque: 6000rpm 6000rpm 6000rpm

Speed at Max,Power: 7500rpm 7000rpm 7500rpm

WOT Speed: 8800+/-500rpm 8800+/-500rpm8500+/-500rpm

Trimmer Head Diameter:

Blade Head Diameter(if attached): 255mm 255mm 255mm

Shaft Tube Diameter

Gear Box Reduction Ratio:

Fuel Tank Capacity: 0.6L 0.45L

Net Weight: 5.1Kg

e Size:

Packag

MHI Air Cooled 2-Stroke Engine

Diaphragm

Centrifugal

Recoil

50:1

3000+/-300rpm

410mm

φ24mm

3

4:

0.6L

5.5Kg5.0Kg

185x 30.5/13 x28cm

19

Page 20

CONTENTS

Item

1

2

3

4

5

6

7

8

9

10

Model Number: CC927D

Main Unit(including D handle)

Main Unit(including BULL handle)

Back Pack Harness

Cutting Attachment Shield

Trimmer Head

Manual

Warranty

Mixing Tank

Clamping Bracket for U handle

Tool Bag

Spark Plug Wrench

10.1

Screwdriver

10.2

Inner Hexagon Wrench(S4,S5)

10.3

Open End Wrenches

10.4

CC924 CC927U

1

N/A

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

N/A

1

1

1

1

1

N/A

N/A

1 1

1 1

1 1

1 1

1 1

N/A1

1

1

20

Loading...

Loading...