Page 1

afe Operation Practices Set-Up Operation Maintenance Service Troubleshooting

S

PERATOR’S

O

M

ANUAL

Hedge Trimmer CC924HT

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

FORM NO. 769-13611 00

DATE:01/25/2018

Page 2

Thank You

Thank you for purchasing a Hedge Trimmer manufactured

by MTD Asia. It was carefully engineered to provide

excellent performance when properly operated and

maintained.

Please read this entire manual prior to operating the

equipment. It instructs you how to safely and easily set up,

operate and maintain your machine. Please be sure that

you, and any other persons who will operate the machine,

carefully follow the recommended safety practices at all

times. Failure to do so could result in personal injury or

property damage.

All information in this manual is relative to the most

recent product information available at the time of

printing. Review this manual frequently to familiarize

yourself with the machine, its features and operation.

Table of Contents

Safety instructions.................................................3

Warning labels and Symbols................................5

Get to know your Hedge Trimmer......................6

Fuel and Oil instructions.......................................7

Operating Instructions..........................................8

Record Product Information

Before setting up and operating your new equipment,

please locate the model plate on the equipment and

record the information in the provided area to the right.

You can locate the model plate on the engine of the

hedge trimmer.

This information will be necessary, should you seek

technical support via our web site, Customer Support

Department,or with a local authorized service dealer.

Please be aware that this Operator’s Manual may cover

a range of product specications for various models.

Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. MTD

Asia reserves the right to change product specications,

designs and equipment without notice and without

incurring obligation. If you have any problems or

questions concerning the machine, phone an authorized

MTD service dealer or contact us directly.MTD’s Customer

Support telephone numbers, website address and mailing

address can be found on this page. We want to ensure

your complete satisfaction at all times.

Throughout this manual, all references to and

of the machine are observed from the operating

positon.

Maintenace and Repair.......................................10

Cleaning and Storage..........................................13

Trouble-shooting..................................................14

Specification..........................................................15

Contents.................................................................15

MODEL NUMBR

SERIAL NUMBER

Customer Support

Please do NOT return the machine to the retailer or dealer without first contacting our Customer

Support Department.

If you have diculty in assembling this product or have any questions regarding the controls, operation,

or maintenance of this machine, you can seek help from the experts. Choose from the options below:

Visit us on the web at www.mtdproducts.com

Contact MTD AU • P.O. Box 376 Dandenong.Vic.3175

Email Address:mtdservice@mtd.com.au Customer Service Phone:1300 951 594

-2-

Page 3

SAFETY INSTRUCTIONS

WARNING

THIS HEDGE TRIMMER CAN CAUSE SERIOUS INJURIES. Read the instructions carefully for the

correct handling, preparation, maintenance, starting and stopping of the hedge trimmer.

become familiar with all controls and the proper use of the hedge trimmer.

Clothing and Equipment

Always wear proper eye glasses to prevent eyes from the risk of thrown objects.

Always wear suitable ear protectors in order to protect your ears from noise.

Please wear sturdy gloves, helmet, wear non-skid boots or safety shoes and dress in long pants.

Do not be barefoot, barelegged or wear open-toed shoes.

Do not wear loose or dangling clothes, neckties, scarf, or jewelry which could be caught in the

blades.

Secure the hair so it is above shoulder length.

Working conditions

Never allow children to use the machine.

Keep the area clear of all persons, particularly small children and pets.

Operate only where rm footing is assured. Do not operate from a slippery ground.

Do not operate when under the inuence of alcohol, drugs or medications. You must be in good

physical and mental health in order to operate safely.

Do not operate in the closed building. Exhaust gases contain poisonous carbon monoxide.

Do not operate when your vision is limited or when the weather conditions do not permit to use the

product safely.

Please have enough breaks during cutting.

Beware of overhead power lines.

Fuel handling

WARNING

Use extra care when handling fuels. They are ammable and the vapors are explosive.

Always shut o the engine before refueling.

Store fuel in containers specially designed for this purpose.

Refuel outdoors only and do not smoke while refueling or operating the machine.

Ensure correct fuel or fuel/oil mixture is used. Add fuel before starting work.

Never operate the machine without the fuel cap securely in place.

Never remove the cap of the fuel tank or add fuel when the engine is hot.

Always replace and securely tighten the fuel cap after refueling.

If petrol is spilled, do not attempt to start the engine but move the machine away from the area of

spill and avoid creating any source of ignition before petrol vapors have dissipated.

If the fuel tank is drained, this should be done outdoors.

3-

-

Page 4

Before operation

Before operating the hedge trimmer, always ensure that the operating position is safe and secure.

Do not operate the hedge trimmer with a damaged or excessively worn blade.

Always ensure that all handles and guards are tted when using the hedge trimmer. Never attempt

to use an incomplete hedge trimmer or one tted with an unauthorized modication.

Check the machine for loose fasteners and fuel leakage. Make sure that the cutting device is properly

installed and securely fastened.

Inspect the hedge and work area to avoid damaging the cutting blades.

Make sure that the blades stop moving when the throttle lever is released and the engine runs at idle

speed.

Operation

Always use two hands to operate a hedge trimmer tted with two handles.

Always be aware of your surroundings and stay alert for possible hazards of which you may not be

aware due to the noise of the hedge trimmer.

Do not put hands or feet near or under the moving blades while engine is running.

Keep any parts of your body away from the muer when the engine is running.

Keep the cutting device below the waist level.

Do not cut too close to the ground in order to avoid hitting small stones.

Never touch the muer spark plug, or other metallic parts while the engine is running or

immediately after shutting down the engine. It could cause serious burns or electrical shock.

To reduce re hazards, keep the engine and silencer free of debris, leaves and excessive lubricant.

Ensure that the hedge trimmer is correctly located in a designated working position before starting

the engine.

If the blades strike any foreign object or the hedge trimmer starts making any unusual noise or

vibration, immediately shut o the unit and allow it to stop. Check the unit for any damage and

repair the damage.

Stop the engine before

a. cleaning or when clearing a blockage

b. checking, carrying out maintenance or working on the hedge trimmer,

c. adjusting the working position of the cutting device,

d. leaving the hedge trimmer unattended.

Maintenance Storage and Transportation

When the hedge trimmer is stopped for servicing, inspection or storage, shut o the engine,

disconnect the spark plug wire and make sure all moving parts have come to a stop. Allow the hedge

trimmer to cool down before making any inspections, adjustments and etc.

Do not change the engine governor settings or overspeed the engine.

Replace faulty silencers and spark arrestors, if tted.

Use only recommended, genuine replacement parts to avoid creating a hazard or voiding your

warranty.

Store the hedge trimmer where the fuel vapor will not reach an open ame or spark. Always allow

the hedge trimmer to cool down before storing.

When transporting or storing the hedge trimmer, always t the cutting device transport guard.

-4-

Page 5

WARNING LABELS AND SYMBOLS

Read warning labels on the unit and understand them. If any label is missing, damaged, or

worn get a replacement from your dealer and install it in the correct position.

SAFETY AND WARNING SYMBOL

Indicates danger,warning or a reason

to be cautious.Can be used together

with other symbols or pictograms

READ OPERATING MANUAL

Non-compliance with the operating

instructions and precautions may

result in serious injuries.Read the

operating manual before starting or

operating the unit.

WEAR HEAD, EYE AND EAR

PROTECTION

CAUTION: Ejected objects may

cause serious head,eye injuries

and excess noise may cause

loss of hearing.When operating

the unit,wear head ,eye and ear

protection.

KEEP BYSTANDERS AWAY

CAUTION: All bystanders,especially

children and pets,must be kept at

least 15m from the working area.

PETROL

Always use clean and fresh lead-free

petrol for mixing petrol.

OIL

Use only authorised oil according

to the operating manual for mixing

petrol.

EJECTED OBJECTS AND ROTATING

PARTS MAY CAUSE SERIOUS

INJURIES

CAUTION: Do not use the unit if the

protective housing has not been

correctly positioned for cutting.Keep

away from the rotating line coil.

ON/

OFF/

CHOKE SETTINGS

1.CHOKE CLOSE starting position

2.CHOKE OPEN running position

IGNITION SWITCH

RUN

IGNITION SWITCH

OFF/STOP

BEWARE OF HOT SURFACES

DO not touch hot muer cover,gear

box or cylinder

SHARP BLADE

CAUTION: The blades are very sharp

and can easily cause cuts.

EXHAUST GAS

Exhaust gas contains carbon

monoxide, an odorless and deadly

poison. Do not run engine in an

enclosed area.

REAR HANDLE

The rear handle can be swiveled to

ve positions.

5-

-

Page 6

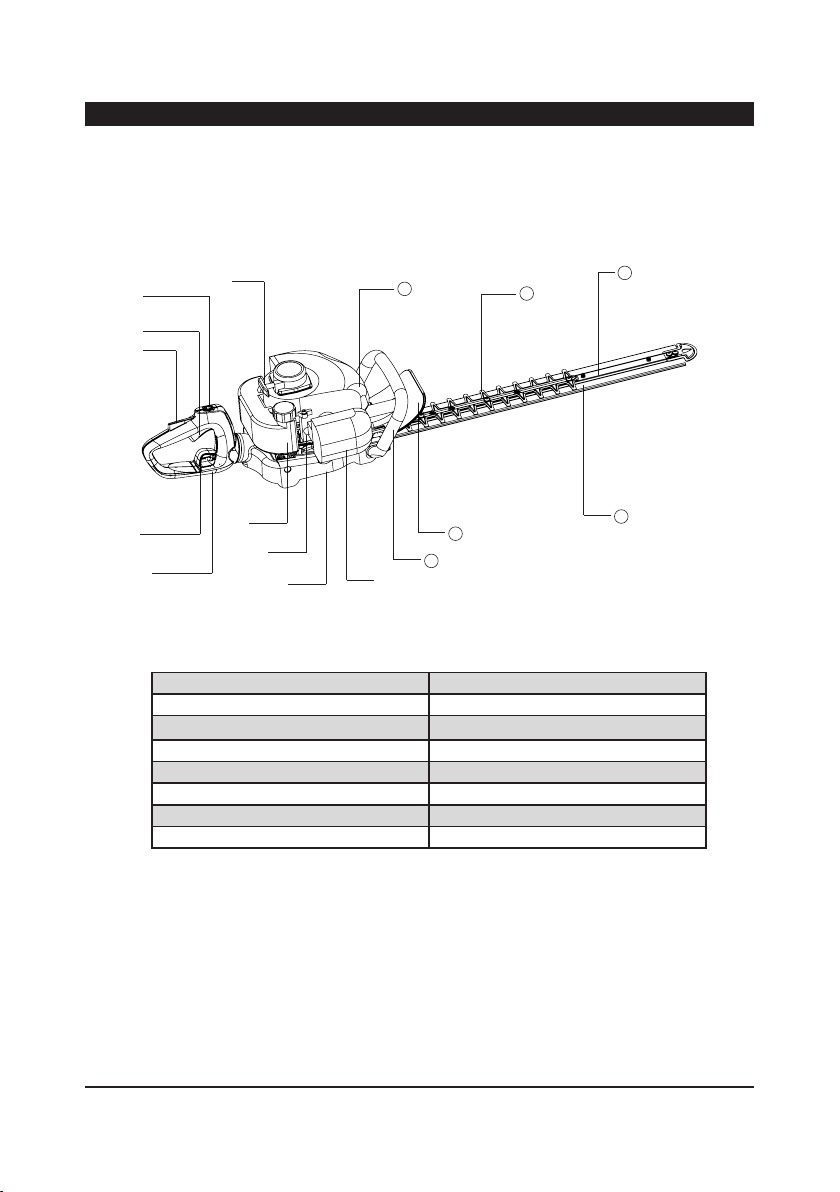

GET TO KNOW YOUR HEDGE TRIMMER

DOUBLE BLADE HEDGE TRIMMER

②

⑥

12

15

③

①

④

⑧

⑦

⑤

⑨

⑩

14

13

1.Throttle Lockout 9.Gear Case

2.Ignition Switch 10.Air Filter Cover

3.Throttle Trigger 11.Blade

4.Handle Lock Button 12.Spark Plug Cap

5.Rear Handle 13.Front Handle

6.Recoil Starter Grip 14.Front Guard

7.Primmer Bulb 15.Blade Protection

8.Fuel Tank 16.Blade Protective Sleeve

11

16

-6-

Page 7

FUEL AND OIL INSTRUCTIONS

WARNING

OIL

1. Only use high quality special oil for air cooled 2-stroke engine,JASO FC or FD, or ISO-L-EGC

or EGD oil. Never use water cooled engine oil or any oil for 4-stroke engine.

Fuel

1. Always use fresh, clean lead-free fuel. Minimum octane number: 90#.

Mixing Ratio

1. Recommended mixing ratio of fuel and oil is 50:1.

Warnings

1. Keep sparks and open ames at a distance from the area where you mixing the fuel or

lling the fuel tank with the mixture.

2. Do not mix the fuel and oil directly in the fuel tank; always use the mixing tank to do this

job.

3. Do not ll the fuel tank with too much mixture.Wipe up any spilled fuel from the unit

immediately.

4. Move the unit 5 meters away from the fueling source and site before starting the engine.

5. Never use fuel which has been stored for longer than 30 days. That may bring damage to

the unit, especially for the carburetor or the engine.

7-

-

Page 8

Run

Ignition Switch

Stop

Throttle Trigger

Throttle Lockout

Primmer Bulb

Choke Lever

Idle screw

Carburetor

Run Position

Start Position

OPERATING INSTRUCTIONS

STARTING

WARNING

Before starting the engine, keep the cutting

attachment clear of everything around it.

WARNING

Exhaust gases contain carbon monoxide, a

colorless, odorless,poisonous gas. Do not

operate the engine in enclosed areas. Provide

adequate ventilation at all time.

1. Use the mixing tank to mix the fuel and oil.

Fill fuel tank with the mixture. See “Fuel and Oil

Instructions”.

2. Push the ignition switch to the “Run” positon.

3. Make sure throttle lockout and throttle trigger at

the released position.

starter handle in right hand. Gently pull the

starter rope out until you feel that the pawls

hook onto the ywheel, and then pull the

starter quickly.

8. Repeat several times until the engine starts.

9. After starting the engine, run the engine at

the idling speed for a few minutes.

10.After the engine is warmed up appropriately

press throttle lockout and throttle trigger, then

choke lever will be back to the run position

automatically.

4. Fully press and release the primmer bulb for 10

times. Some amount of fuel should be visible

in the primer bulb and fuel lines.

5. Move choke lever to the position.

6. When the engine is already warm or on hot

days, set the choke lever to the position.

7. Put the machine on at ground,make sure the

cutting attachment is clear of everything

around it.Hold the unit with your left hand and

press it against the ground.While holding the

WARNING

Releasing the starting rope suddenly may allow

the rope to whip around and cause injury and/or

damage to the recoil starting mechanism. When

starting engine,rmly grasp the recoil starter

grip; do not grasp the starter rope itself. Always

control the rope as it rewinds into the housing.

1.If the engine fails to start, do not try to

pull the recoil starter too many times with

the choke lever to the position. Just

press down the throttle lockout and

squeeze the throttle trigger to switch the

choke lever to the position, and then

release the throttle triggle back. Repeat to

pull the recoil starter grip until the engine

starts.

2.After starting the engine, run the engine at

the idling speed for a few minutes.

-8-

Page 9

45° 90°

45° 90°

0-15

3.The engine should be run at idle speed for a

few minutes to allow sucient warm-up time

to prevent engine damage before applying a

load. This will allow oil to reach engine parts,

and allow piston

specication.

clearance to reach design

STOP

1.Release the throttle trigger back and run the

engine at the idling speed.

2. Turn the switch to the “OFF/STOP” position.

3. Suddenly stopping engine from high

speed operation can cause engine damage.

Reduce engine speed to idle speed for one

minute.

WARNING

Move the choke lever to the position or

unplug the spark plug if the engine can not be

shut down by the two upper steps,then adjust

the carburetor after the machine becomes

cold or contact the authorized dealer for help.

HANDLE ROTATION

The rear handle of the unit can be swiveled

to 5 dierent positions to suit the job

requirement.Including center position, 45°

position to the left and right,And 90°to the

left and right.This feature is particularly

useful for vertical and angled cutting.

1. Pull out the handle lock button;

2. Swivel the rear handle to the desired

position;

3. Release the button to lock the rear

handle securely in position.

WARNING

1.Do not swivel the rear handle when the

throttle lever is triggered.

2.When swiveling the rear handle, do not

trigger the throttle lever until the rear

handle is securely locked in position.Hedge

Trimmer must be stopped before adjusting

the swivel handle.

OPERATING

1.When cutting the hedges horizontally,

the unit should be held so that the blades

form 0-15° with the cutting direction.

2. At the vertical cutting, swing the blades up

and down on the hedges

WARNING

1. Always hold the unit rmly with both

hands.

2. When the throttle trigger is released, it

will take a little while before the blades

completely stop.

3. Use special caution when cutting hedges,

which are along with a wire fence.

The blades should not contact the fence,

otherwise the blades will be damaged.

4. The hedge trimmer is determined to cut

the hedges or small bushes.Do not use the

unit to cut thick branches, trees or grass,

which may damage the blades and

other parts.

5. If the blades are clogged by the leaves or

branches, immediately stop the

unit,and remove the stu out of the blades.

9-

-

Page 10

Choke Lever

Idle screw

Carburetor

Run Position

Start Position

Fuel Filter

Air Filter

Air Filter Cover

MAINTENANCE AND REPAIR

CARBURETOR

1. Idling speed can be adjusted by idle

screw.

2. Adjusting the idle-speed screw clockwise

will increase the idling speed and adjusting

it counterclockwise will decrease the idling

speed. You should use a tachometer

to measure the speed while adjusting.

Make sure the idling speed within the

recommended range 2700~3300 rpm.

3. Every unit had been run and tested at the

factory to ensure that the carburetor works

at its best condition. But after a period of

use, if trimmer head or cutting blade

continues to rotate at idling or the engine

stops when you fully release the throttle

trigger, make adjustment to idle screw.

WARNING

Improper adjustment may cause damage to

the unit. If engine does not run well after

carburetor adjustment, please contact the

authorized dealer where you bought the

product.

FUEL FILTER

1. Empty the fuel tank.Make sure there is no

reserved fuel.

2. Pull the fuel lter out of the tank with a hook

or wire and disconnect the lter from the fuel

hose.

3. Wash the lter with clean kerosene(or replace

the old lter if it is heavily fouled,and clean the

fuel tank),then put the lter back to the

hose,and put the fuel hose back to the fuel tank.

WARNING

Many solvents are highly ammable and may

cause serious burns.Improper use of solvents

can result in re or an explosion.Do not use

gasoline or low ash-point solvents to clean the

fuel lter. Clean only in a well-ventilated area

away from sources of sparks or ame, including

any appliances with a pilot light.

AIR FILTER

CLean and lubricate air lter at every 25 hours of

use. It is important to service these components

properly.If the air lter is not cleaned and serviced,

any warranty will be deemed null and void.

1. Disassemble the lter cover, and pull the lter

out of the air lter housing.

2. check the lter,replace a new one if necessary.

3.Wash the element in kerosene,put it in engine oil

and squeeze it by one hand.leave it to drip and

dry completely.

4.Assemble the lter,lter cover and use screw

to tight the parts together.

-10-

Page 11

Washing

Drying

Engine Oil

Squeezing

Spark Plug Wrench

0.6-0.7MM

Spark Arrester

WARNING

Improper element cleaning can result in

engine damage.Do not use compressed air

to clean or dry element. Never use gasoline.

Do not operate engine with air lter parts

removed.

SPARK PLUG

After every 50 operating hours, take out the

spark plug and check its condition.

1. Switch o the engine and allow it to cool

down.

2. Grasp the plug wire rmly and pull the plug

cap from the spark plug.

3. Wipe o dust or dirt around spark plug.

4. Unscrew spark plug in counterclockwise

direction with the attached spark plug

wrench.

5. Brush o carbon deposits.

6. Check and adjust spark plug gap to 0.6-0.7mm.

7. Screw in the spark plug and tighten to a torque

of 14-17 N M. Do not over tighten.

8. Re-attach the spark plug cap.

9. If spark plug is damaged or the unit still

cannot work well after cleaning, replace with a

new one.

10. To ensure the machine work well Please use

the specied plug.

MUFFLER

Spark Arrester Service

Every 50 hours of operation

1. Remove the spark arrester from the exhaust

hole of muer.

2. Clean deposits from the spark arrester screen

by brushing it.

3. Install the spark arrester.

Carbon Removal of Engine Internal Parts

Every 50 hours of operation or found strikingly

low engine high-speed and rule out other causes

you need to clean up the engine internal carbon

deposition.

These items must be performed with proper

tools. please do it with the assistance of

professionals or authorized dealer.

GEAR CASE

1. Rell the grease into the gearbox every 25

hours operation;

2. Use the grease pump and inject the grease

30g until it comes out of the gearbox.

3. Inject through grease nipple or grease screw.

-

11-

Page 12

Oil inlet

10°

10°

45°

45°

ANTI-VIBRATION SYSTEM

WARNING

The damaged anti-vibration system may

cause the vibration or breakage of any parts.

1. Check periodically if the springs are deformed

or out of place.

BlADES

1. Please replace the blades if damaged or

worn seriously.

2. Please use the sharpener or le to grind

the cutting edges, referring to the angle in

the below picture.

3. Clean the blades after grinding and apply

the grease on the edges.

2. Please use an authorized service dealer to

repair any damages.

REGULAR CHECK LIST

INTERVAL

ITEM

Check the bolt and nut,tighten up if necessary

Check for gas leak

Check and clean air cleaner

Check the cooling air intake port,cooling

ns,around muer

Check and clean spark plug

Check and clean fuel lter

Remove carbon deposits on muer and cylinder

Clean spark arrester

Replace spark plug

Replace fuel piping (fuel pipe,grommet)

Items with must be performed with proper tools,please do it with assistance of professionals

or authorized dealer.

BEFORE OPERATION

DAILY INSPECT

-12-

EVERY

50 HRS

EVERY

100 HRS

EVERY

2 YRS

Page 13

CLEANING AND STORAGE

CLEANING

1.Brush o dust and grass cuttings from the unit and wipe up water and oil stain with dry cloth.

STORAGE

1. Keep the unit away from ames or sparks when it contains fuel.

2. Allow the unit to cool before storage.

3. Store the unit in a dry, well-ventilated and secure location or at an adequate height to prevent any

inadvertent use or damage. Keep out of the reach of children.

LONG-TERM STORAGE

1. Drain all the fuel out of the tank into a container with an identity symbol for 2-stroke engines. Do

not use fuel which has been stored for longer than 30 days.

2. Start the engine and leave running until it stops. This ensures that all the fuel has been drained out

of the carburetor and used up.

3. Stop the engine and allow it to cool down. Remove the spark plug and pour 30ml high quality

2-cycle engine oil into the cylinder. Gently pull the starter rope to disperse the oil. Set the plug

back.

WARNING

Before using the unit after the s torage period, remove the spark plug and pour out all the

engine oil from the cylinder.

4. Complete clean every part and carefully inspect for damaged or loose parts. Repair or replace the

damaged parts and, if necessary, tighten all loose screw, nuts and bolts. Apply anti-rust oil to the

metal parts such as throttle cable. The unit is now ready for storage.

5. Store the unit in a dry, well-ventilated and secure location or at an adequate height to prevent any

inadvertent use or damage. Keep out of the reach of children.

TRANSPORTATION

1. Before transporting the unit, allow it to cool down.

2. Empty the fuel tank before transit. Make sure the fuel cap is securely tightened.

3. It is better to take o the cutting attachments and protect them with a proper cover to avoid

unexpected damage.

4. Secure the unit with rope to prevent it from shifting during transportation. Do not try to

transport it by a bicycle or motorcycle.

13-

-

Page 14

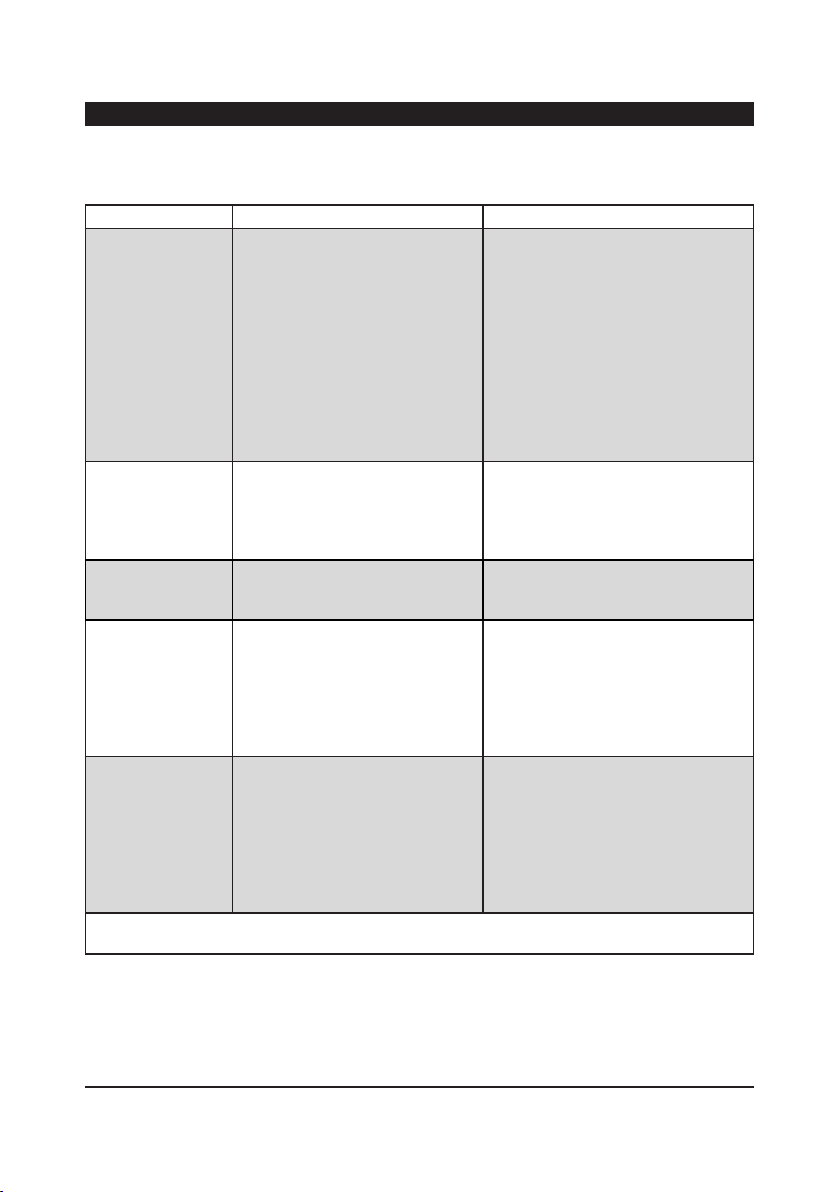

TROUBLESHOOTING

Problem Cause Remedy

1. Spark plug wire disconnected.

2. Ignition switch set to OFF.

3. Fuel tank empty.

4. Stale or improperly mixed fuel

Engine does not start

Engine does not run

constantly at no load

Engine does not idle 1.Improper carburetor adjustment.

Engine does not

accelerate

Engine has no power

or stops during

cutting

If further assistance is required, please contact your authorized service dealer.

mixture.

5. Dirty air lter/oil lter.

6. Incorrectly gapped or dirty spark

plug.

7. Primer bulb not depressed

adequately.

8. Flooded engine.

1. Dirty air/oil lter.

2. Stale or improperly mixed fuel

mixture.

3. Incorrectly gapped or dirty spark

plug.

1. Dirty air/oil lter.

2. Throttle wire disconnected.

3. Defective throttle control lever.

4. Incorrectly gapped or dirty spark

plug.

5. Improper carburetor adjustment.

1. Spool head or blade entangled

with grass.

2. Dirty air/oil lter.

3. Stale or improperly mixed fuel

mixture.

4. Improper carburetor adjustment.

1. Reconnect wire.

2. Set switch to ON.

3. Add fuel.

4. Empty the tank and ll with fresh fuel

mixture.

5. Clean or replace lter.

6. Clean or adjust the gap.

7. Slowly and fully depress the primer

bulb 10 times.

8. Squeeze the throttle and pull the

starter rope with the choke lever in

the operating position.

1. Clean or replace lter.

2. Empty the tank and ll with fresh fuel

mixture.

3. Clean or adjust the gap.

1.Adjust according to the manual or

turn to an authorized service dealer

for help.

1. Clean or replace lter.

2. Reconnect throttle wire.

3. Replace the throttle control lever.

4. Clean or adjust the gap.

5. Adjust according to the manual or

turn to an authorized service dealer

for help.

1. Stop the engine and clean the cutting

attachment.

2. Clean or replace the lter.

3. Empty the tank and ll with fresh fuel

mixture.

4. Adjust according to the manual or

turn to an authorized service dealer

for help.

-14-

Page 15

SPECIFICATION

Model CC924HT

Engine Mitsubishi Air Cooled 2-Stroke Engine

Carburetor Diaphragm

Clutch Type Centrifugal

Starter Recoil

Displacement 22.5cc

Max Power 0.7KW

Mixing Ratio(Gasoline/OIl): 50:1

Idle Speed 2700-3300 rpm

Speed at Max,Torque: 6000 rpm

Speed at Max,Power: 7000 rpm

Gear Box Reduction Ratio: 4.5

Fuel Tank Capacity : 0.5L

Cutting Length 600

Blade Pitch 35

Net Wt. 6.0 KG

Package dimension 1213x290x280mm

CONTENTS

Item Description Quantity

1 Main Part 1

2 Mixing Tank 1

3 Operator's Manual 1

4 Warranty 1

5 Tool bag 1

5.1 Spark Plug Wrench(with Screwdriver) 1

5.2 Inner Hexagon Wrech S4 1

5.3 Inner Hexagon Wrech S5 1

5.4 8/10mm Open End Wrenches 1

15-

-

Page 16

NOTE

Loading...

Loading...