Page 1

Professional Shop Manual

Model 188 and CC 500 BAT Cordless Mower

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provid e su pp lem ental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and tr ained professional. Read, understand, a nd follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete a nd accura te as possib le at the time of publica tion. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2007 MTD Products Inc. All Rights Reserved

MTD Products Inc - Product Training and Education Department

FORM NUMBER - 769-03397

08/2007

Page 2

Page 3

Table of Contents

Chapter 1: Introduction ......................................................................................................1

Professional Shop Manual Intent..................................................................................... 1

About the text format .......................................................................................................1

Fasteners .......................................................................................................................... 2

Assembly .........................................................................................................................2

Understanding model and serial numbers........................................................................ 2

Chapter 2: ELECTRICAL System ....................................................................................3

The first electrical value to be discussed is Voltage. .......................................................3

The second electrical value is Current............................................................................. 3

The third and final value is Resistance............................................................................ 3

Ohm’s law ........................................................................................................................3

Kirchhoff’s current law ....................................................................................................4

Kirchhoff’s voltage law ................................................................................................... 4

How the system is wired together ....................................................................................4

Equipment needed to diagnosis an electrical system....................................................... 4

Equipment that may be useful ......................................................................................... 4

Digital volt ohm meter..................................................................................................... 5

Inductive amp meter ........................................................................................................5

Wiring or a schematic diagram........................................................................................ 5

Fused jumper wires ..........................................................................................................5

Types of circuits ...............................................................................................................5

Series ................................................................................................................................6

Parallel ............................................................................................................................. 6

Series/parallel ...................................................................................................................6

Types of failures ..............................................................................................................6

Shorts ............................................................................................................................... 6

Opens ...............................................................................................................................6

Increased resistance ......................................................................................................... 6

Switches ...........................................................................................................................7

Diodes ..............................................................................................................................7

Fuses ................................................................................................................................ 8

Initial trouble shooting .....................................................................................................9

Checking the motor ........................................................................................................10

Testing the switch box and harness ..............................................................................11

Batteries and charger .....................................................................................................15

Batteries .........................................................................................................................15

Charging the battery .......................................................................................................15

To test the battery pack.................................................................................................. 15

Battery charger ...............................................................................................................17

Battery indicator ............................................................................................................17

Returning to service .......................................................................................................19

System schematic drawing .............................................................................................20

Page 4

Chapter 3: Repair Procedures ..........................................................................................21

General safety warning ..................................................................................................21

Blades .............................................................................................................................21

Switch box assembly ..................................................................................................... 23

To replace the switch box.............................................................................................. 24

Motor .............................................................................................................................25

Motor mount ..................................................................................................................26

Page 5

CHAPTER 1: INTRODUCTION

INTRODUCTION

Professional Shop Manual Intent

This Manual is intended to provide service dealers with

an introduction to the electrical and mechanical

aspects of the new cordless electric mower for both

MTD and Cub Cadet.

Disclaimer: This manual was written using a pilot unit.

The information contained in this manual is correct at

the time of writing. Both the product and the information about the product are subject to change without

notice.

This manual covers the newly designed th ird generation of 19” DC powered (cordless) electric mowers. The

mower is to be designated 18A-188-xxx and is to be

introduced during the 2007-2008 season.

MTD Products has made two previous models of cordless mowers. The first model was produced from 1995

to 1997. it was designated 185-708-xxx, 186-708-xxx

and 18A-708-xxx. The second model was produced in

the same time period. The model numbers were 185798-xxx, 186-798-xxx and 18A-798-xxx.

The first model used a bail operated switch and the

second used a lever operated switch. Very few parts

are interchangeable between the mowers.

The electrical theory is the same for all three models of

cordless mower. However the test procedures will vary

between the different generations. The servic e procedures for the first two models of cordless mower can be

found in the 1996 Service Update Seminar Book (form

number 770-8877L).

About the text format

NOTE: is used to point-out information that is

relevant to the procedure, but does not fit as a

step in the procedure.

CAUTION: Indicates a potent ially hazardous situation that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER: Indicates an imminently hazardous

situation that, if not avoided, will result in death

or serious injury. This signal word is to be limited to the most extreme situations.

WARNING: Indicates a potentially hazardous

situation that, if not avoided, could result in

death of serious injury.

• Bullet points: indicate sub-steps or points.

Disclaimer: This Professional Shop Manual is

intended for use by trained, professional technicians.

• Common sense in operation and safety is

assumed.

• In no event shall MTD or Cub Cadet be liable for

poor text interpretation, or poor execution of the

procedures described in the text.

• If the person using this manual is uncomfortable

with any procedures they encounter, they should

seek the help of a qualified technician, MTD or

Cub Cadet Technical Support.

1

Page 6

INTRODUCTION

Fasteners

• Most of the fasteners used on the vehicle are

sized in fractional inches. Some are metric.

For this reason, wrench sizes are frequently

identified in the text, and measurements are

given in U.S. and metric scales.

• If a fastener has a locking feature that has

worn, replace the fastener or apply a small

amount of releasable thread locking compound

such as Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use

items that are not to be reused. Other fasteners

such as lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if

they do not show signs of wear or damage. This

manual leaves that decision to the judgement of

the technician.

Assembly

Torque specifications may be noted in the part of the

text that covers assembly or they may also be summarized in tables along with special instructions regarding

locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be

used so that the manual is handy as a quick-reference

guide as well as a step-by-step procedure guide that

does not require the user to hunt for information.

The level of assembly instructions provided will be

determined by the complexity and of reassembly, and

by the potential for unsafe conditions to arise from mistakes made in assembl y.

Some instructions may refer t o other parts of the manual for subsidiary procedures. This avoids repeating

the same procedure two or three times in the manual.

Understanding model and serial numbers

The model number is 18A-188-710. The break d own of

what the number mean is as follows:

• 18 - - - - - - - - - indicates that this is an electric

mower

• - - A - - - - - - - - indicates the sales level

• - - - - 18 - - - - - indicates the series and trim

• - - - - - - 8 - - - - indicates it is DC powered (cordless)

• - - - - - - - - 710 indicates that it is a Cub Cadet

The serial number is 1J056G10005. The serial number

reads as follows:

1...........................engineering level

..J.........................month of production (J = October)

.....05....................day of the month

.........6..................last digit of the year

...........G................plant it was built in

..............1.............assembly line number

.................0005.....number of unit built

Additional technical and service information may also

be available to our company authorized service center

personnel through our company corporate offices,

regional parts distributors and regional service center

field support personnel. Please contact the de signated

support office in your area or our corporate offices

directly should further service information be needed.

For Cub Cadet

Cub Cadet LLC

P.O. Box 368022

Cleveland, OH 44136

Telephone: (330) 273-8669

www.cubcadet.com

Or for MTD Brands

MTD Products LLC

P.O. Box 368022

Cleveland, OH 44136

Telephone: (800) 800-7310

www.mtdproducts.com

2

Page 7

CHAPTER 2: ELECTRICAL SYSTEM

ELECTRICAL SYSTEM

ELECTRICAL THEORY

In order to diagnosis any electrical system there are

few things the technician must know:

• Basic electrical values.

•Ohm’s law.

• Kirchhoff’s current law.

• Kirchhoff’s voltage law.

• How the system is wired together.

The first electrical value to be discussed is Voltage.

• Voltage is the “pressure” that electricity has. It is

the amount of force pushing electrons through a

circuit.

• This pressure is measured in volts.

• The capital letter “V” is used to represent volts.

The second electrical value is Current:

• Current is the “flow” of electricity. It is the amount

of electrons flowing in circuit.

• The flow of current is measured in Ampe res or

Amps for short.

• The capital letter “I” is used to represent Amps.

Ohm’s law

Ohm’s law state that voltage is the product of resistance times current. It is written as V=IxR. An example

of how ohm’s law works goes like this: It takes 1 volt to

push 1 amp through a resistance of 1 ohm (1=1x1).

Ohm’s law can be drawn in a triangle. When using the

triangle, cover the value to be found, and the two values left exposed signify how to obtain that value.

See Figure 2.1.

V

I

Figure 2.1

R

The third and final value is Resistance:

• Resistance is the opposition to current flow. It is

a restriction that slows down the flow of current.

• Resistance is measured in Ohm’s.

• The greek letter omega “

Ohm’s.

Ω” is used to represent

As an example if the “R” is covered, the “V” is over the

“I” which means V is divided by I. If the “V” is covered,

“I” and “R” is exposed, meaning IxR and so on.

3

Page 8

ELECTRICAL SYSTEM

Kirchhoff’s current law

Kirchhoff’s current law deals with nod es. No des a re th e

junction of two or more wires or the junction of a wire to

a component.

Kirchhoff’s current law states that what ever current

goes into a node must come out.

As an example: Three wires are connected with a wire

nut. one wire has 5 amps going into the wire nut. The

sum of the current coming out of the other two wires

must equal 5 amps. That could be 3 amps in one wire

and 2 amps in the other or it could be 2.5 amps in each

wire, but the total must be the same as the current

coming in. See Figure 2.2.

Node

5 Amps

3 Amps

2 Amps

How the system is wired together

All circuits have some basic rules that must be followed:

1. All circuits must have at least one voltage

source. It is could be a battery, an altenator or

both.

2. All circuits must have a load. To make a circuit

with out a load is the same as shorting out the

power source. A load could be:

• light

• motor

•resistor

•starter

• etc....

3. All circuits must have a complete path back to

the voltage source. This is also known as having

continuity.

NOTE: On outdoor power equipment, the frame

of the machine is used as the return path to the

battery. This is referred to as grounding the

machine. Any point on the frame should be the

same as the negative post of the battery (Electrically), unless there is a bad connection between

the battery and the frame.

Figure 2.2

Kirchhoff’s voltage law

Kirchhoff’s voltage law deals with voltage drops. A voltage drop is the amount of voltage used up or “dropped ”

by a resistance in the circuit. Ohm’s law stated that V =

IxR, every component in a circuit has resistance, even

the wires. T o push current through a resistance, it takes

voltage. Kirchhoff’s voltage law states that the sum of

all the voltage drops equals the source voltage.

An example: a circuit has a battery of 12V, a light bulb

that creates 3 ohms of resistance and there is 4 amps

of current in the circuit. The wires are assumed to have

0 ohms, if the proper size wire is used and there is no

corrosion in the wire, the resistance will be too small to

worry about. The light bulb uses 12 volts (4 amps x 3

ohms = 12 volts). the battery has 12 volts that equals

the 12 volts used by the light bulb.

4. Most circuits have additional components like

switches and fuses.

Equipment needed to diagnosis an electrical system:

• Digital volt ohm meter

• Wiring or a schematic diagram.

Equipment that may be useful:

• Fused jumper wires.

• Hand tools to gain access to components.

• Flash light.

CAUTION: A test light can not be used on this

mower. The system voltage is 48 volts. It will

destroy the test light and may result in injury to

the technician.

4

Page 9

ELECTRICAL SYSTEM

Digital volt ohm meter

Digital volt ohm meters or DVOMs are the most useful

tool to troubleshoot any electrical system. Depending

on the model of DVOM used, DVOMs can measure

Volts, Amps, Ohms and more. DVOMs are a must

when working on circuits with solid state components

(microchips). They have very high impedance, that

means they have very high resistance and pull very little current from the circuit. Use of analog equipment or

test lights will pull enough current to damage the microchips in the circuit. See Figure 2.3.

Inductive amp meter

An inductive amp meter, sometimes referred to as an

“amp clamp” or clamp meter, measures current following through a wire by the magnetic field created around

the wire. Clamp meters are very important when dealing with currents over 10 amps. A DVOM typically can

not measure current over 10 amps. Clamp meters are

also helpful because they can read current in a circuit

without opening it up to hook the meter into the circuit.

See Figure 2.4.

Figure 2.3

When measuring volts, always hook the meter in parallel with the circuit. That means do not disconnect the

component where measuring voltage.

When measuring current the meter must be connected

in series with the component to be measured. That

means opening the circuit and having the circuit go

through the meter.

NOTE: The only exception to this is when us ing

an inductive amp clamp.

When measuring resistance, the component must be

isolated from the circuit.

CAUTION: The meter has it’s own power source

to measure resistance. connecting the meter to

a component that has current going through it

will damage the meter (usually beyond repair).

NOTE: When measuring resistance and there is

no continuity, the meter will read infinity. This is

represented in a few different ways like: OL

(open line) or 1.0 displayed to the far left. Check

the operator’s manual for th e DVOM to see how

it is represented on your meter..

Figure 2.4

Wiring or a schematic diagram

A wiring or a schematic diagram is very important in

troubleshooting a circuit. The diagram shows how the

circuit was designed and what paths the electricity is

suppose to flow.

Fused jumper wires

Fused jumper wires are handy to he lp find b ad groun ds

or to jump across switches for testing purposes.

CAUTION: Only use fused jumper wires. If there

is a short in the circuit, using an unfused jump

could damage components in the circuit further.

Types of circuits

There are three ways a circuit can be wired. They are:

•Series

• Parallel

• Series/parallel

5

Page 10

ELECTRICAL SYSTEM

Series

• Series circuits are wired so that the current has

only one path to follow. See Figure 2.5.

Switch

Bulb

Battery

Figure 2.5

Parallel

Parallel circuits are wired so that current has multiple

paths to follow. See Figure 2.6.

Series/parallel

Series/parallel circuits have some sections wired in

series and some in parallel. See Figure 2.7.

Figure 2.7

Types of failures

There are three types of failures that can occur in an

electrical circuit:

Figure 2.6

1. Shorts

2. Opens

3. Increased resistance

Shorts

A short is when electricity takes a path that it was not

designed to take bypassing a component in the cir cuit.

An common example of a short is the wire that chafed

through. The bare copper will short the circuit when it

touches a ground source.

Opens

An open is when current can not complete its p ath back

to the power source.

A common example of this is a blown fuse.

Increased resistance

Increased resistance is as the name implies, an

increase in resistance.

Arguably the most common electrical failure, and the

hardest to find, it is when there is a loose connectio n or

corrosion. It is not an open because there is some current that can get through, but the increase in resistance

is enough to affect the circuit

6

Page 11

ELECTRICAL SYSTEM

Switches

To test a switch:

1. Remove the switch from the circuit.

2. Set the DVOM to the ohms scale (

3. With the switch in the off position touch one

probe to one of the tabs and the other probe to

the other tab.

4. For a NC switch there should be zero resist ance.

For a NO switch the meter should show an open

circuit.

5. With the probes still attached, turn the switch on.

The readings should reverse, NO should have

zero resistance and a NC switch should indicate

an open circuit.

6. Repeat for all the circuits in the switch

7. If the switch fails in any of the tests, replace the

switch.

Diodes

A diode acts like a one way valve. They allow current to

flow in only one direction. There will be a band on one

end of the diode. This indicates the negative side o f th e

diode. Most DVOMs have the ability to test a diode.

See Figure 2.8.

Silver band

Ω).

Testing a diode:

1. Isolate the diode in the circuit.

2. Set the DVOM to the diode scale.

See Figure 2.9.

Diode scale

Figure 2.9

NOTE: A diode requires and uses a small

amount of voltage before it allows current to follow through it. When testing a diode the Ohms

(Ω) scale can be used, but it will read resistance

in both directions. One side will be higher then

the other. the reading are hard to interpret without the datasheets of the diode, therefore the

diode scale is the preferred method of testing.

3. Attach the negative lead of the DVOM to the side

of the diode with a band on it.

(-)

electrons flow from the negative to the positive.

Figure 2.8

(+)

4. Place the positive lead on the other side of the

diode.

7

Page 12

ELECTRICAL SYSTEM

5. There should be continuity. See Figure 2.10.

Continuity

Silver band

(-)

Figure 2.10

6. Switch the leads.

7. The meter should indicate no continuity.

See Figure 2.11.

No continuity

(+)

Fuses

Fuses can be visually inspected to indicate they are

bad/blown (a dark spot or the element inside will be in

two pieces). Some times a fuse can be bad and not

show signs of this visually. Any time a fuse is removed

from a circuit, it should be tested for continuity with an

ohm meter before reinstalling. See Figure 2.12.

Figure 2.12

Silver band

(-)

Figure 2.11

8. If the results do not match the above, replace

the diode.

(+)

8

Page 13

ELECTRICAL SYSTEM

Initial trouble shooting

The first step in trouble shooting this mower is to make

sure the circuit breaker is set. To do this, first make

sure the mower is cold (has not been operated for at

least five minutes). Next push the breaker in.

See Figure 2.13.

Safety key

Breaker

Figure 2.13

After assuring the breaker is set and the safety key is in

place, remove the motor cover by following the steps

outlined in Chapter 3: Repair Procedures, and check

the fuse. If the fuse is ok, then troubleshoot the electrical system of this mower by looking at three components:

• The switch box assembly

• The batteries

• The motor

NOTE: Before attempting to trouble shoot this

mower, make sure the batteries are fully

charged.

Next, make sure the safety key is in place. The safet y

key acts as a fulcrum for the switch. With out it, the

switch can not operate. See Figure 2.14.

Safety key

Figure 2.14

9

Page 14

ELECTRICAL SYSTEM

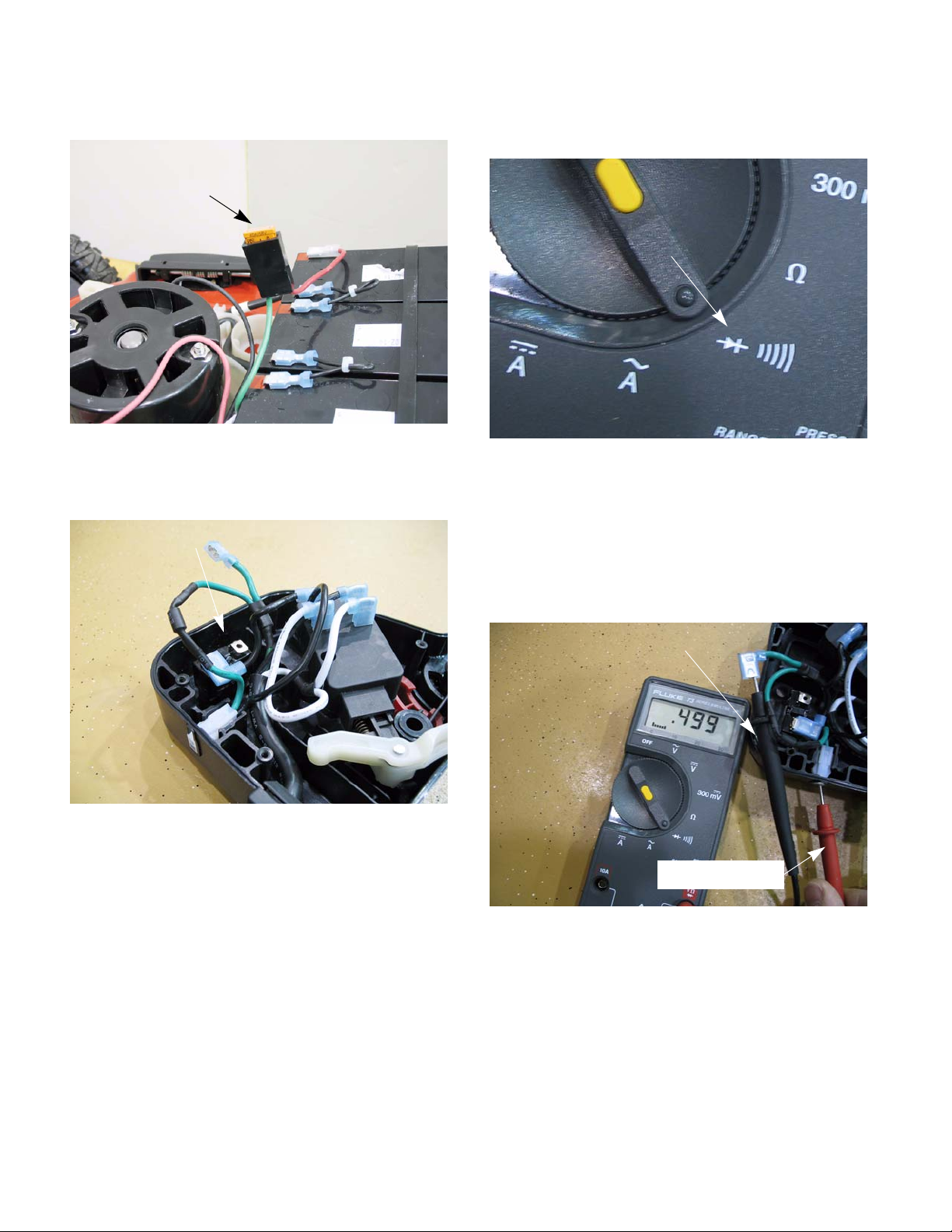

Checking the motor

To test the motor:

1. Remove the motor cover by follo wing the steps

described in Chapter 3: Repair Procedures.

2. Disconnect the motor from the harness.

See Figure 2.15.

Motor connector

Figure 2.15

5. The reading on the meter should be within .1

volts of the battery voltage. If it is, the switch box

is working properly and by process of elimination, the motor is the problem.

NOTE: The motor is not serviceable.

NOTE: If the reading is between .1 volt to 5 volts

look for lose or corroded connections.

NOTE: If there is no voltage reading, check the

fuse at the motor before testing further.

See Figure 2.17.

3. Engage the safety bail and hold it in place with a

spring clamp.

4. Connect a volt meter to the two spades in the

harness connector. See Figure 2.16.

Harness connector

Figure 2.16

Figure 2.17

10

Page 15

ELECTRICAL SYSTEM

Testing the switch box and harness

IMPORTANT: If the mower is within the warranty

period, Do Not open the switch box. Replace the

entire switch box for warranty. Outside of warranty, the switch box is serviceable.

1. To test the components inside the switch box,

remove and open the switch box by:

1a. Remove the two mounting screws with a T-

25 torx driver. See Figure 2.18.

Remove these screws

1c. Carefully separate the halves of the switch

box. Remove the side that fits against the

handle bar.. See Figure 2.20.

Figure 2.20

2. Test the switch.

NOTE: The switch is a double pole single throw

switch. That means that it controls two separate

circuits at the same time.

Figure 2.18

1b. Remove the five screws that hold the switch

assembly together. See Figure 2.19.

Remove these

screws

Figure 2.19

Handle bar

grove

2a. Mark and disconnect all four wires.

NOTE: Mark the wires to ensure they go back on

the proper spades. If the wires are put on wrong

the mower will not work properly, if at all.

2b. Test each circuit separately.

NOTE: Unlike most MTD switches, the terminals

that are in-line with each other, edge to edge,

are in the same circuit. See Figure 2.21.

Circuit 2

Circuit 1

11

Figure 2.21

Page 16

ELECTRICAL SYSTEM

2c. Circuit 1 is a normally closed circuit. That

means there should be continuity through

that circuit when the switch is at rest.

2d. To test that part of the switch, attach a

DVOM to the circuit. Set the meter to the

Ohms or “Ω

read zero ohms. See Figure 2.22.

2e. With the DVOM still attached, press in the

switch. The meter should read infinity.

See Figure 2.23.

” scale. The meter should

Figure 2.22

2f. Circuit 2 is a normally open circuit. That

means there should not be continuity

through that circuit when the switch is at

rest.

2g. To test that part of the switch, attach a

DVOM to the circuit. Set the meter to the

Ohms or “Ω” scale

read infinity. See Figure 2.24.

Figure 2.24

2h. With the DVOM still attached, press in the

switch. The meter should read zero or

near zero resistance. See Figure 2.25.

. The meter should

Figure 2.23

Figure 2.25

2i. If the switch has any reading different than

what is described above, replace the

switch.

2j. Reconnect the wires to the switch. Make

sure the wires are attached to the proper

terminals.

12

Page 17

ELECTRICAL SYSTEM

3. Test the circuit breaker.

NOTE: Make sure the circuit breaker is cool and

pressed in before testing it.

3a. Disconnect the two wires from the circuit

breaker. See Figure 2.26.

Figure 2.26

Circuit

breaker

4. Test the diode.

NOTE: There is a diode between the charger

jack and the circuit breaker. It has two jobs. First

it protects the batteries from a short in the

charger jack, like a child inserting something into

the charger jack. Secondly it helps to protect the

charger from a back-feed when the mower is

operated with the charger plugged in.

See Figure 2.28.

Diode

Charger

jack

3b. Attach a DVOM to the circuit breaker. Set

the meter to the Ohms or “Ω” scale

should read zero or near zero Ohms.

See Figure 2.27.

Figure 2.27

3c. If the meter reads anything over 0.1 Ohms,

replace the circuit breaker.

. It

Figure 2.28

CAUTION: Do not operate the mower with the

charger plugged in.

NOTE: An open diode will prevent the batteries

from charging. A shorted diode could allow the

batteries to short out or damage the charger.

4a. When testing the diode, make sure the

charger or any thing else is not plugged

into the charger jack.

13

Page 18

ELECTRICAL SYSTEM

4b. Remove the fuse. See Figure 2.29.

Fuse

Figure 2.29

4c. Disconnect the circuit breaker.

See Figure 2.30.

Unplug the circuit breaker

4d. Set the DVOM to the diode test scale.

See Figure 2.31.

Diode test scale

Figure 2.31

4e. Insert the positive probe of the DVOM into

the port of the charger jack that has the

green wire.

4f. Insert the negative probe into the connector

of the wire disconnected from the circuit

breaker. See Figure 2.32.

Figure 2.30

NOTE: By unplugging the fuse and circuit

breaker, the diode has been isolated. It is not

necessary to remove the heat shrink tubing from

the diode to test it.

NOTE: Diodes can be tested by using the Ohms

or “Ω” scale of a DVOM, but because of the way

diodes are constructed this is not an accurate

way to test them. When testing diode using the

“Ω” scale, it will read continuity in both directions. One direction will be high resistance and

the other direction will be a relatively low resistance. These readings will not tell you if the

diode is leaking.

Negative probe

Positive probe

Figure 2.32

14

Page 19

ELECTRICAL SYSTEM

4g. The DVOM should read less than 1 Ohm.

4h. Reverse the leads. See Figure 2.33.

Positive probe

Negative probe

Figure 2.33

4i. The DVOM should read open line or “OL”.

4j. If either reading varies from the values listed

above, replace the harness.

5. If all the components in the switch box are working properly and battery voltage still does not get

to the motor, replace the harness.

Batteries and charger

Batteries

Before an electrical system can be diagnosed, the bat-

tery must be fully charged and in good working order.

Charging the battery

NOTE: Batteries on most modern outdoor power

equipment are 12 volts. This mower uses a bank

of four, sealed 12 volt lead-acid batteries. The

four act as one and should be looked at and

treated as one big battery .

IMPORTANT: Do not replace individual batteries. Replace all four batteries with new batteries

that are the same age. This will prevent weaker

batteries overworking the strong batteries and

prolong the life of all of them.

IMPORTANT: The voltage of the battery bank is

over 48 volts for a fully charged battery bank. To

ensure that the batteries in the battery bank are

evenly charged, only use the charger that came

with the mower.

To test the battery pack:

CAUTION: The mower must run in order to test

the battery pack, move the mower to a safe location when operating it.

NOTE: The battery charger will charge the batteries to a voltage higher than then can maintain

on their own. Once the charger is unplugged, the

battery pack will start to bleed of excess voltage.

Allow 10 minutes for the batteries to normalize

after unplugging from a charger before measuring voltage.

1. Remove the motor cover by following the steps

described in Chapter 3: Repair Proc edures.

2. Attach a DVOM to the harness by back probing

where the connection at the battery pack and

place the DVOM in a secure location.

NOTE: Make a note of the battery voltage at this

point. A fully charged battery will read between

50.4 - 54.0 volts.

15

Page 20

ELECTRICAL SYSTEM

3. Attach a digital amp clamp to either one of the

motor leads (the current will be positive or negative depending on which LED is used).

Figure 2.34

4. Start the mower and run it for 10 seconds then

read both meters. See Figure 2.35.

NOTE: Do not operate the mow er in g r ass wh en

testing the battery pack. The measurements are

meant to be take with the blade as the only load

on the motor.

Interpreting the results

Table 1:

Voltage Current Possible reasons

>47.0 < 9.5 Normal readings

>47.0 >9.5 High load on

motor, a short in

the harness or

motor worn out.

Check for grass

build up underneath the deck.

44.0-47.0 < 9.5 Battery pack low

or one battery

going bad, charge

the battery pack

and retest.

< 44.0 < 9.5 Battery pack is

bad.

< 44.0 < 44.0 short in system

Figure 2.35

16

Page 21

ELECTRICAL SYSTEM

Battery charger

The batteries in the battery pack are wired in series

resulting in a 48 volt system. The battery charger for

this mower has an output of 54.5 volts so that the

whole battery pack is charged at one time.

To test the battery charger:

1. Disconnect the charger from the mower.

2. Plug the charger to an appropriate AC outlet.

3. Set a DVOM to the volts DC scale.

4. Attach the DVOM to the charger jack, the red (+)

lead to the pin next to the clip and the black(-)

lead on the other pin. See Figure 2.36.

Clip

Battery indicator

This mower is equipped with a battery level indicator.

The indicator has five LEDs, the n umber of LEDs that

are lit is an indication of the voltage level of the battery.

It will only light up when the mower is in operation.

To test the battery indicator, a cheap tester can be

made from parts around the shop or buying the parts

from an electronic supply store. The components

needed are:

•10K Ω variable resistor.

NOTE: A potentiometer, rheostat or a dash light

dimmer switch from a car can be used as a variable resistor. If using a rheostat or a potentiometer, multi-turn works best.

• A fuse holder with a small fuse.

NOTE: A 1 amp fuse is recommended.

• 1 alligator clips.

• 1 female spade connector.

• A jumper wire (to be used with the tester).

•Wire.

Figure 2.36

5. The meter should read 54.5 volts (+

the readings do not match this, replace the

charger.

NOTE: This charger is a two stage charger. The

initial stage will charge a battery pack at a voltage at a voltage of 57.6 volts (+

stage is used when the battery pack is fully discharged. When the battery pack is charged, the

charger will switch to a float charge mode,

charging the battery pack at a voltage of 54.5

volts (+

) .5 volts.

) .5 volts. this

To build the tester:

1. Solder a one lead of the fuse holder to the center

tap pin of the variable resistor. See Figure 2.37.

The package of the variable resistor will have

a schematic drawing. In the drawing this is

the center tap.

) .5 volts. If

Figure 2.37

2. Solder an additional length of wire to the other

lead of the of the fuse holder.

NOTE: The over all length of the additional wire

and the fuse holder should be at least 12”.

3. Crimp the female spade connector onto the end

of the new fuse holder lead.

17

Page 22

ELECTRICAL SYSTEM

4. Attach an alligator clip on to a piece of wire, at

least 12” in length.

5. Solder the piece of wire onto one of the other

two pins on the variable resistor. See Figure

2.38.

Alligator clip

Female spade

10K potentiometer

Fuse holder

Figure 2.38

Testing the battery indicator

NOTE: The battery pack should be fully charged

to test the battery indicator.

1. Disconnect the charger from the mower.

2. Remove the motor cover by following the steps

described in Chapter 3: Repair Procedures.

3. Unplug the wires from the battery indicator.

NOTE: The wire connectors are two different

sizes to help prevent getting them crossed when

plugging them in. See Figure 2.39.

Small tab is positive

Big tab is negative

Figure 2.39

4. Disconnect the battery pack.

5. Attach the spade end of the tester to the positive

tab of the indicator.

6. Attach the other end of the tester to the positive

post of the battery pack.

7. Attach one end of the jumper wire to the negative tab of the indicator and the other end to the

negative post of the battery pack.

18

Page 23

ELECTRICAL SYSTEM

8. Attach the positive lead of a DVOM to the positive (smaller) tab of the indicator. See Figure

2.40.

Positive lead of

DVOM

Tester leads

Figure 2.40

9. Attach the negative lead of the DVOM to the

negative post of the battery pack.

10. Set the DVOM to the DC volts scale and place it

close to the indicator so that both can be seen at

the same time.

12. Compare the results to Table 2.

Table 2:

LED

LED 1LED 2LED 3LED 4LED

operation

Voltage

green green green green red

52 - 47.9 ON ON ON ON OFF

47.9-

OFFONONONOFF

46.7

46.7-

OFF OFF ON ON OFF

45.2

45.2-

OFF OFF OFF ON OFF

40.4

40.4-28 OFF OFF OFF OFF ON

NOTE: If the results do not match the above

table, replace the indicator. If they do match the

above results, check the harness.

Returning to service

5

11. Slowly turn the variable resistor and note the

reading on the DVOM when the different LEDs

light up or go out. See Figure 2.41.

Monitor LEDs and DVOM

Figure 2.41

After diagnosing and repairing any fault in an electrical

circuit and any other repairs needed, the following

steps should be taken:

1. Test run the machine to verify that the condition

has been fix.

2. Cycle the circuit at least ten times.

3. Allow the machine to cool down for a couple of

hours.

4. Re-test the machine to verify the co ndition does

not re-appear.

5. If the condition does not re-appear, return the

machine back to service.

19

Page 24

ELECTRICAL SYSTEM

System schematic drawing

Circuit

Breaker

20

Page 25

CHAPTER 3: REPAIR PROCEDURES

REPAIR PROCEDURES

General safety warning

Whenever working on a cordless lawn mower, remove

the safety key. Only leave the key in if it is needed to

perform a test.

CAUTION: Use caution while working around

this lawn mower. A cordless lawn mower may

start unexpectedly.

Blades

The condition of the blades will greatly effect the quality

of the cut.

The blades should be sharpened and balanced after

every hour of cutting, depending on local conditions. A

dull blade tears the grass instead of cutting it. Torn

grass blades leaves a rough look and makes the grass

vulnerable to diseases.

Blades need to be examined for damage before sharpening. Blades must be balanced after sharpening to

reduce the vibrations felt from the deck.

Bent blades are a sign of a blade impact. When a bent

blade is found, the blades must be replaced and the

motor inspected for a bent shaft and cracked motor

mount.

To replace the blade:

WARNING: When removing the cutting blade for

sharpening or replacement, protect your hands

with a pair of heavy gloves or use a heavy rag to

hold the blade.

1. Disconnect the power supply to the mower and

turn the mower on its side.

2. Block the blade to prevent it from turning when

the bolt is removed. See Figure 3.1.

NOTE: The blade can be blocked using a piece

of wood between the blade and the mower deck

or use of a commercially available blade locking

device.

Blade holder

The cutting deck on this mower is mounted with a slight

rake, meaning that the front of the deck is a 1/4” - 3/8”

lower than the rear of the deck. T his is very important

to get the proper air flow in the deck so that the blades

can make the grass blades stand up to get cut.

The air flow in the cutting deck is generated by the

spinning blades. If the blades are mounted upside

down, the air flow will be reversed pushing the grass

down instead of standing up.

NOTE: Blades that are mounted upside down,

increase the risk of blade damage from struck

objects.

NOTE: The blade also act s as the cooling fan for

the motor. The motor will over heat if the blade is

mounted upside.

Figure 3.1

NOTE: The blade locking tool pictured above is

available through MTD parts. The part number is

BB-100.

21

Page 26

REPAIR PROCEDURES

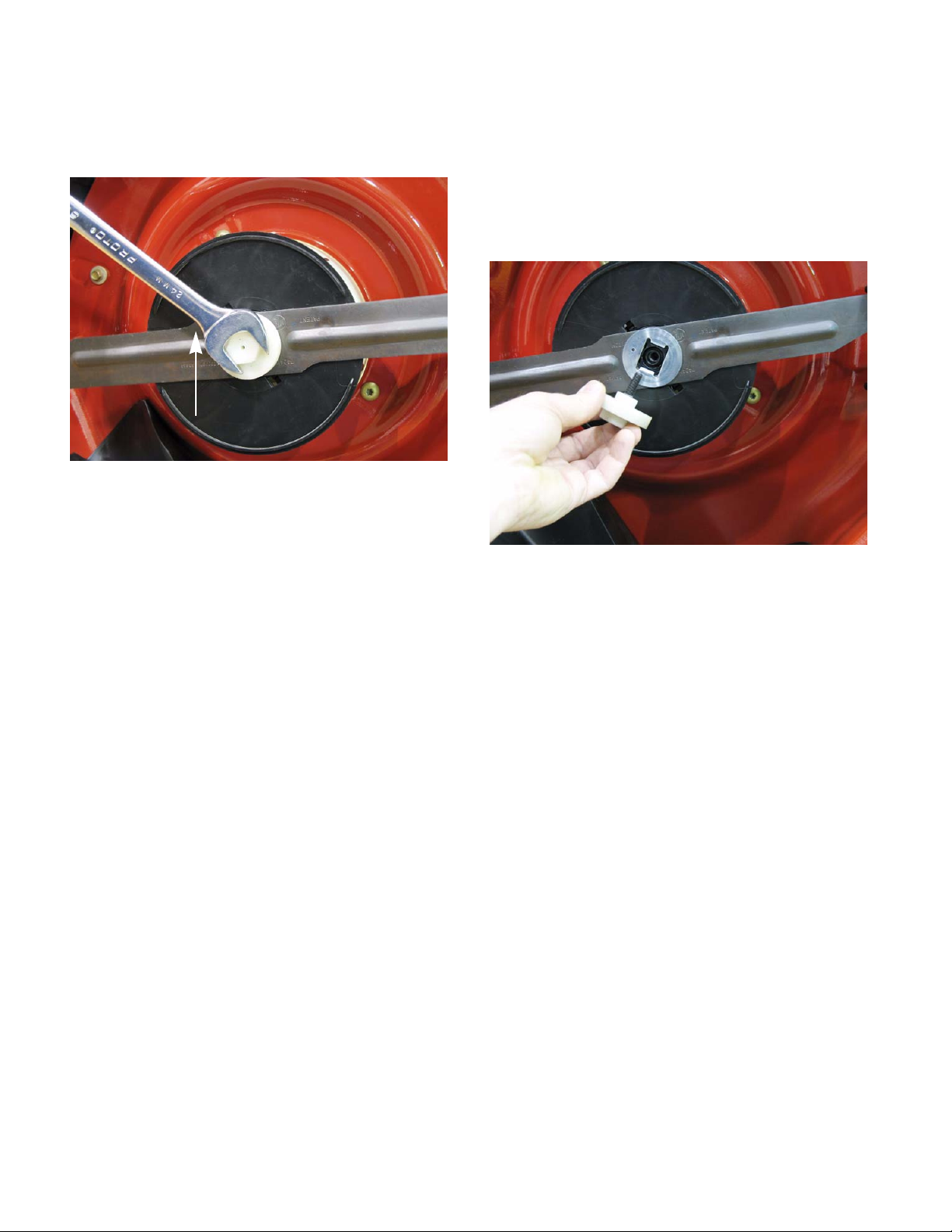

3. Loosen and remove the blade bolt, locking plate,

and blade using a 24 mm wrench. See Figure

3.2.

24 mm wrench

Figure 3.2

NOTE: Make certain to replace the parts in the

exact order in which they were removed. When

installing the cutting blade, be sure it is installed

with the curved ends pointing towards the

mower deck and not towards the ground. See

Figure 3.3.

4. The blade can be sharpened with a file or on a

grinding wheel.

NOTE: To properly sharpen the cutting blades,

remove equal amounts of metal from both ends

of the blades along the cutting edges, parallel to

the trailing edge, at a 25° to 30° angle.

WARNING: An unbalanced blade will cause

excessive vibration when rotating at high

speeds. It may cause damage to mower and

could break causing personal injury.

5. Place the cutting blade, locking plate, and blade

bolt on the motor shaft.

Figure 3.3

6. Tighten the blade bolt to a torque of 170-220 inlbs (19 - 25Nm).

WARNING: The blade hardware is not only used

to attach the blade assembly, but is also an insulated safety device and should never be altered

in any way. If replacement is necessary, use

original equipment parts.

7. Test run the mower before returning to service.

22

Page 27

REPAIR PROCEDURES

Switch box assembly

The switch box assembly is located on the upper handle bar. The switch and circuit breaker are housed

inside of it. To service the switch box assembly:

NOTE: Opening the switch box assembly will

void the warranty on this mower. For warranty

repairs, replace the switch box and harness as

an assembly.

1. Remove the safety key.

2. Slide the safety bail out of the switch box assembly.

3. Remove the two mounting screws usin g a T-27

Torx driver. See Figure 3.4.

Mounting screws

5. Remove the five screws holding the housing

together using a #2 phillips screwdriver. See Figure 3.5.

Remove screws

Figure 3.5

6. Separate the housing to reach the internal components.

NOTE: The test procedures for the components

of the switch box are in Chapter 2 Electrical system.

Figure 3.4

4. Unhook the harness from the clips on the handle

bar.

7. Install the switch box by following the above

steps in reverse order.

8. Test run the mower before returning it to service.

23

Page 28

REPAIR PROCEDURES

To replace the switch box:

1. Remove the safety key.

2. Slide the safety bail out of the switch box assembly.

3. Remove the motor cover by follo wing the steps

describe in the motor section of this chapter.

NOTE: For safety reasons it is a good idea to

remove the fuse whenever the motor cover is

removed.

4. Disconnect the battery pack and the motor.. See

Figure 3.7.

Motor connector

Battery

connection points

5. Remove the two mounting screws using a T-27

Torx driver. See Figure 3.8.

Mounting screws

Figure 3.8

6. Unhook the harness from the clips on the handle

bar.

7. Install the switch box assembly by following the

above steps in reverse order.

Figure 3.7

8. Test run the mower before returning to service.

24

Page 29

REPAIR PROCEDURES

Motor

The motor on this mower is a DC permanent magnet

motor. It is not serviceable. The test procedures for this

motor are covered in chapter 2 Electrical system.

To replace the motor:

1. Remove the safety key.

2. Remove the motor cover by:

2a. Place a flat head screwdriver into one of the

four slots in the cover. See Figure 3.9.

Push in tab

with a flat head screwdriver

3. Remove the blade by following the steps

described in the blade section of this chapter.

4. Remove the fan and blade hub from the motor

shaft. See Figure 3.11.

Blade hub

Figure 3.11

5. Unplug the motor. See Figure 3.12.

Figure 3.9

2b. Press in the tab while lifting on the cover.

Repeat steps 2a and 2b on the other slots.

NOTE: For safety reasons it is a good idea to

remove the fuse when ever the motor cover is

removed. See Figure 3.10.

Motor connector

Figure 3.12

Figure 3.10

25

Page 30

REPAIR PROCEDURES

6. Remove the four mounting screws. See Figure

3.13.

Mounting screws

Figure 3.13

7. Install the motor by following the above steps in

reverse order.

8. Test run the mower before returning it to service.

Motor mount

To replace th e mo to r mo u nt :

1. Remove the safety key.

2. Remove the motor by following the steps

described in the previous section of this manual.

3. Remove the three mounting screws using T-40

torx driver. See Figure 3.14.

Mounting screws

Figure 3.14

4. Remove the motor mount from the deck of the

mower.

5. Install the motor mount by following the above

steps in reverse order.

NOTE: tighten the motor mount screws to a

torque of 170-200 in-lbs (19 - 22.5 Nm).

6. Test run the mower before returning to service.

26

Loading...

Loading...