Page 1

Operator’s Manual

2-Cycle Electric Start Capable

Handheld Blower / Vacuum

BV228

TABLE OF CONTENTS

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Oil and Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SAVE THESE INSTRUCTIONS

SERVICE

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

For assistance regarding the assembly, operation or maintenance of

the unit, please call 1-877-282-8684 (

668-1238 (in Canada). Additional information can be found at

www.cubcadet.com (in the United States) or www.cubcadet.ca (in

Canada).

Warranty service is available through an authorized service center.

To locate a service center in your area, please visit our website or

call the number listed above. Service on this unit, both within and

after the warranty period, should on

authorized and approved service center. When servicing, use only

identical replacement parts.

in the United States) or 1-800-

e performed by an

ly b

All information, illustrations, and specifications in this manual are based

on the latest product information available at the time of printing. We

reserve the right to make changes at any time without notice.

The product may vary slightly from the illustrations contained in this

manual.

Copyright© 2016 MTD SOU

IMPORTANT: Read this manual thoroughly before using this product. Follow all instructions.

769-11584 / 00 04/16

THWEST INC, All Rights Reserved.

Page 2

SAFETY

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper

accident prevention measures.

SYMBOL MEANING

DANGER:

Failure to obey a safety DANGER symbol WILL result in

serious injury or death to yourself or to others.

WARNING:

Failure to obey a safety WARNING symbol CAN result in

serious injury to yourself or to others.

Signals an EXTREME hazard.

Signals a SERIOUS hazard.

CAUTION:Signals a MODERATE hazard.

Failure to obey a safety CAUTION symbol MAY result in

property damage or injury to yourself or to others.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest Land

and the state of California (Public Resources Codes 4442 and

4443), Oregon and Washington require, by law that certain internal

combustion engines operated on forest brush and/or grass-covered

areas be equipped with a spark arrestor, maintained in effective

wor

ng order, or the engine be constructed, equipped and

ki

maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure

to follow these requirements could subject you to liability or a fine.

This unit is factory equipped with a spark arrestor. If it requires

replacement, contact your local service dealer to install the

appropriate

CALIFORNIA PROPOSITION 65

WARNING:

known to the state of California to cause cancer, birth defects

or other reproductive harm.

Read the operator’s manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

ler assembly.

muff

This product contains a chemical

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS BEFORE OPERATING

WARNING:

instructions must be followed. Please read these

instructions before operating the unit in order to ensure the

safety of the operator and any bystanders. Please keep

these instructions for later use.

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit.

• Do not operate this unit when tired, ill or under the influence of

alcohol, drugs or medication.

• Never allow children to operate the unit. Teens must be trained,

accompanied and supervised by an adult. Never allow adults to

operate the unit

• All guards and safety attachments must be installed properly

before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

• Be aware of risk of injury to the head, hands

• Carefully inspect the area before starting the unit. Remove

rocks, broken glass, nails, wire, string and other objects that

may be thrown or become entangled with the unit.

thout proper instruction.

wi

When using the unit, all safety

feet.

and

• Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they are

still at risk from thrown objects. Encourage bystanders to wear

eye protection. If you are approached, stop the unit immediately.

• Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments or

repairs before using the unit.

• Do

• This unit is intended for occasional, household use only.

t change the engine governor settings or overspeed the

no

engine.

2

Page 3

SAFETY WARNINGS FOR GAS UNITS

WARNING:Gasoline is highly flammable and

its vapors can explode if ignited. Take the following

precautions:

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the

tank. Never remove the fuel tank cap or add fuel when the

engine is hot. Always loosen the fuel tank cap slowly to relieve

any pressure in the tank before fueling.

• Always mix and add fuel in a clean, well-venti

where there are no sparks or flames. DO NOT smoke.

• Never operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any

spilled fuel from the unit immediately, before starting the unit.

Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine. DO NOT smoke.

• Never start or run the uni

Breathing exhaust fumes can kill. Operate this unit only in a well

ventilated outdoor area.

nside a closed room or building.

t i

WHILE OPERATING

• Wear safety glasses or goggles that meet current ANSI / ISEA

Z87.1 standards and are marked as such. Wear ear/hearing

protection when operating this unit. Wear a face mask or dust

mask if the operation is dusty.

• Wear heavy long pants, boots, gloves and a long sleeve shirt. Do

not wear loose clothing, jewelry, short pants, sandals o

barefoot. Secure hair above shoulder level.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a

stable position while starting. Refer to Starting and Stopping.

• Use the right tool. Only use this tool for its intended purpose.

• Always hold the unit with a firm grip when o

• Do not overreach. Always keep proper footing and balance. Take

extra care when working on stairs, steep slopes or inclines. To

avoid serious injury, do not operate the unit while on a ladder or

a roof.

• Keep hands, face, and feet away from all moving parts. Do not

touch or try to stop moving parts.

• Do not touch the engine or muffler. These parts get extremely

hot from operation, even after the

• Do not operate the unit faster than the speed needed to do the

job. Do not run the unit at high speed when not in use.

• Do not force the unit. It will do a better, safer job when used at

the intended rate.

• Always stop the unit when operation is delayed or when walking

from one location to another.

• Before setting the unit down, always make sure the engine is off

and all moving parts

• If you strike or become entangled with a foreign object, stop the

unit immediately and check for damage. Do not operate the unit

before repairing damage. Do not operate the unit with loose or

damaged parts.

• Turn the engine off and disconnect the spark plug for

maintenance or repair.

ve stopped.

ha

uni

pera

t is turned off.

lated o

ting.

utdoor area

o

r g

• Use only original equipment manufacturer (OEM) replacement

parts and accessories for this unit. These are

authorized service dealer. Use of any other parts or accessories

could lead to serious injury to the user, or damage to the unit,

and void the warranty.

• Keep the unit clean. Carefully remove vegetation and other

debris that could block moving parts.

• To reduce fire hazard, replace a faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

greas

• If the unit starts to vibrate abnormally, stop the unit immediately.

Inspect the unit for the cause of the vibration. Vibration is

generally an indicator of trouble.

r carbon build up.

e o

available f

rom your

BLOWER / VACUUM SAFETY

• Do not insert anything into the air openings, blower tubes or

nozzle. Do not operate the unit if any of the air openings or

tubes are blocked. Keep the air openings free from dust, lint,

hair and anything else that may reduce airflow.

• Do not operate the unit without the blower tubes, or vacuum

tubes and vacuum bag, securely attached. Make sure the

vacuum bag is completely zipped

not use the unit to spray liquids, especially flammable or

• Do

combustible liquids, such as gasoline. Do not use the unit in

areas where such liquids are present.

• Do not use the unit for spreading chemicals, fertilizer or any

other substance that may contain toxic materials.

• Do not set the unit down on any surface while the unit is

running. Debris can be picked up by the air intake and thrown

ou

he discharge opening, resulting in damage to the unit or

t t

property or causing serious injury to bystanders or the operator.

• During operation, never point the unit in the direction of people,

animals, windows or automobiles. Always direct blowing debris

away from people, animals, windows or automobiles.

• Use extra caution when blowing debris near solid objects, such

as trees, walls, fences, etc. When

such objects, not toward them.

• Take care when working near valuable plants. The force of the

blown air could damage tender plants.

• The unit is designed to pick up dry materials, such as leaves,

grass, small twigs or bits of paper. To avoid serious injury to the

operator and severe damage to the unit, do not vacuum wet

debris or water. To avoid severe damage to the unit, do not

vacuum ha

• Avoid situations that could cause the vacuum bag to catch fire.

Do not operate the unit near an open flame. Do not vacuum warm

ash from fire places, fire pits, etc. Do not vacuum discarded

cigars or cigarettes unless the cinders are completely cool.

• Never attempt to clear a clogged air intake opening while the

unit is running.

• Keep hair, fingers and a

parts and openings.

rd materials, such as metal, glass, etc.

ther body parts away from moving

ll o

closed.

possible, b

low away from

3

Page 4

OTHER SAFETY WARNINGS

• Maintain the unit with care.

• All service, other than the maintenance procedures described in

this manual, should be performed by an authorized service dealer.

• Never remove, modify or make inoperative any safety device

furnished with the unit.

• Before inspecting, servicing, cleaning, storing, transporting or

replacing any parts on the unit:

1. Stop the unit.

2. Make sure all moving p

3. Allow the unit to cool.

4. Disconnect the spark plug wire.

• Secure the unit while transporting.

• Never store the unit with fuel in the tank, inside a building where

fumes may reach an open flame (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

• Store the unit in a dry place, secured or at a height to prevent

unauthorized use or damage. Keep the unit out of the reach

children.

• Never douse or squirt the unit with water or any other liquid.

Keep handles dry and clean (free from debris, oil and grease).

Clean the unit after each use. Refer to Cleaning and Storage. Do

not use solvents or strong detergents.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

them these instructions.

s have stopped.

art

f

o

SAVE THESE INSTRUCTIONS

4

Page 5

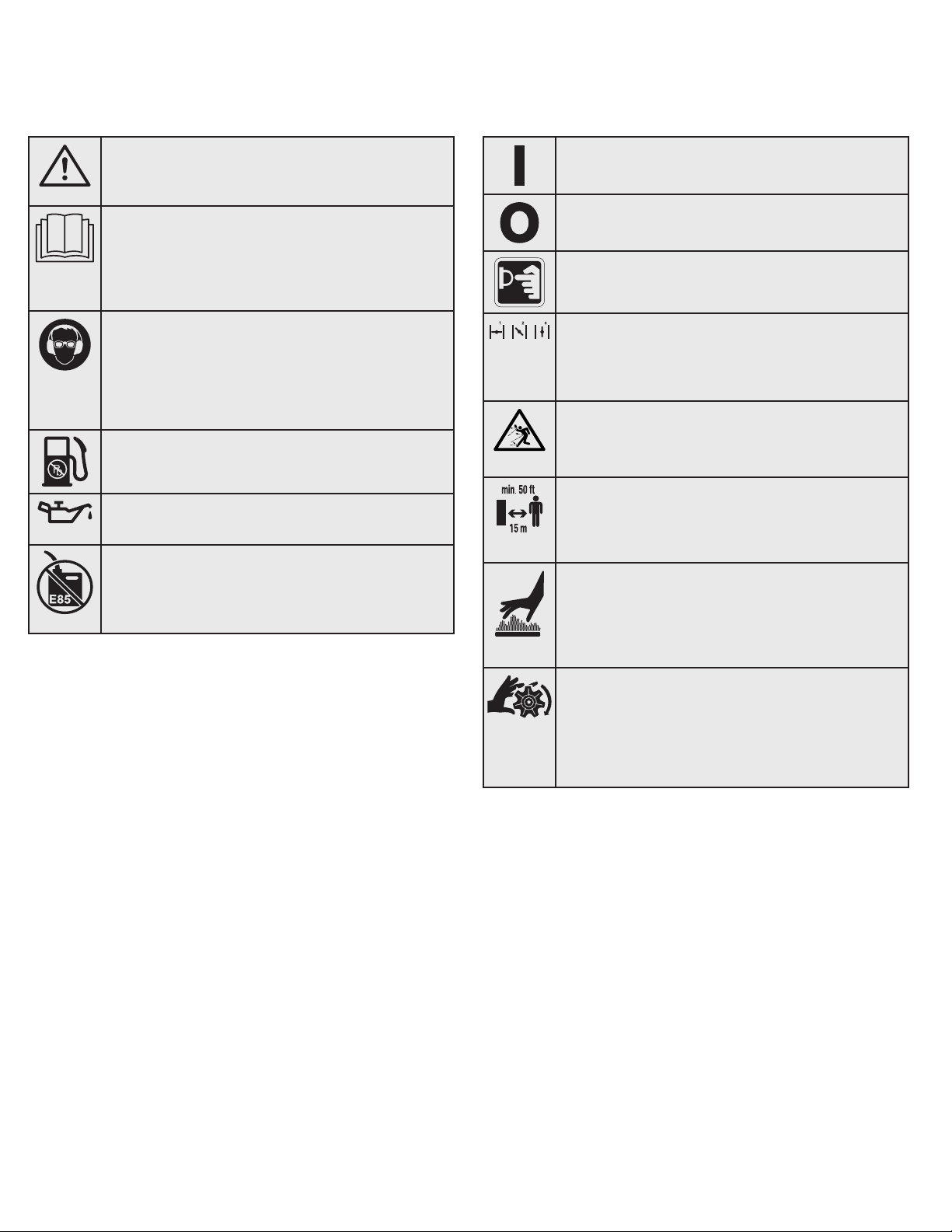

• SAFETY & INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

• READ OPERATOR'S MANUAL

WARNING:

manual(s) and follow all warnings and safety

instructions. Failure to do so can result in serious

injury to the operator and/or bystanders.

• WEAR EYE AND HEARING PROTECTION

WARNING:

noise can cause severe eye injury and hearing loss.

Wear eye protection meeting current ANSI / ISEA

Z87.1 standards and ear protection when operating

this unit. Use a full face shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel.

• OIL

Refer to operator’s manual for the proper type of oil.

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING:

containing greater than 10% ethanol will likely

damage this engine and void the warranty.

Read the operator’s

Thrown objects and loud

It has been proven that fuel

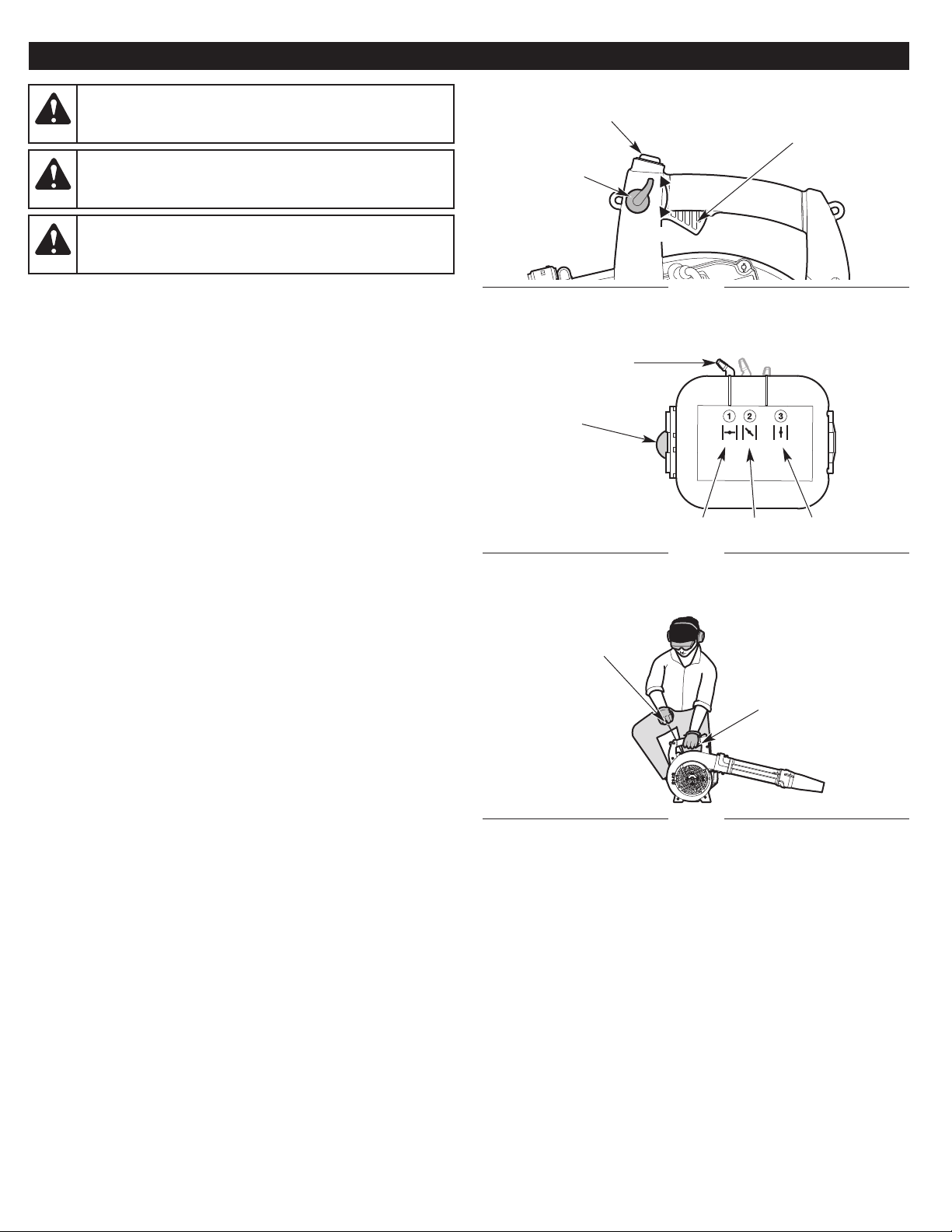

• ON/OFF STOP CONTROL

ON / START / RUN

• ON/OFF STOP CONTROL

OFF or STOP

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• CHOKE CONTROL

1. • FULL choke position

2. • PARTIAL choke position

3. • RUN choke position

• THROWN OBJECTS CAN CAUSE SEVERE INJURY

WARNING:

propelled at high speed, causing injury.

• KEEP BYSTANDERS AWAY

Small objects can be

WARNING:Keep all bystanders,

especially children and pets, at least 50 feet (15 m) from

the operating area.

• HOT SURFACE

WARNING:

or cylinder. You may get burned. These parts get

extremely hot from operation. When turned off, they

remain hot for a short time.

Do not touch a hot muffler

• BLOWERS – ROTATING IMPELLER BLADES CAN

CAUSE SEVERE INJURY

WARNING:

impeller to stop before changing tubes, cleaning or

performing any maintenance. Keep hands and feet

away from moving parts.

Stop the unit and allow the

5

Page 6

KNOW YOUR UNIT

APPLICATIONS

• Cleaning yards, garages, driveways, porches, patios, around

walls, fences and more

ASSEMBLY TOOLS REQUIRED

• Flat-head Screwdriver

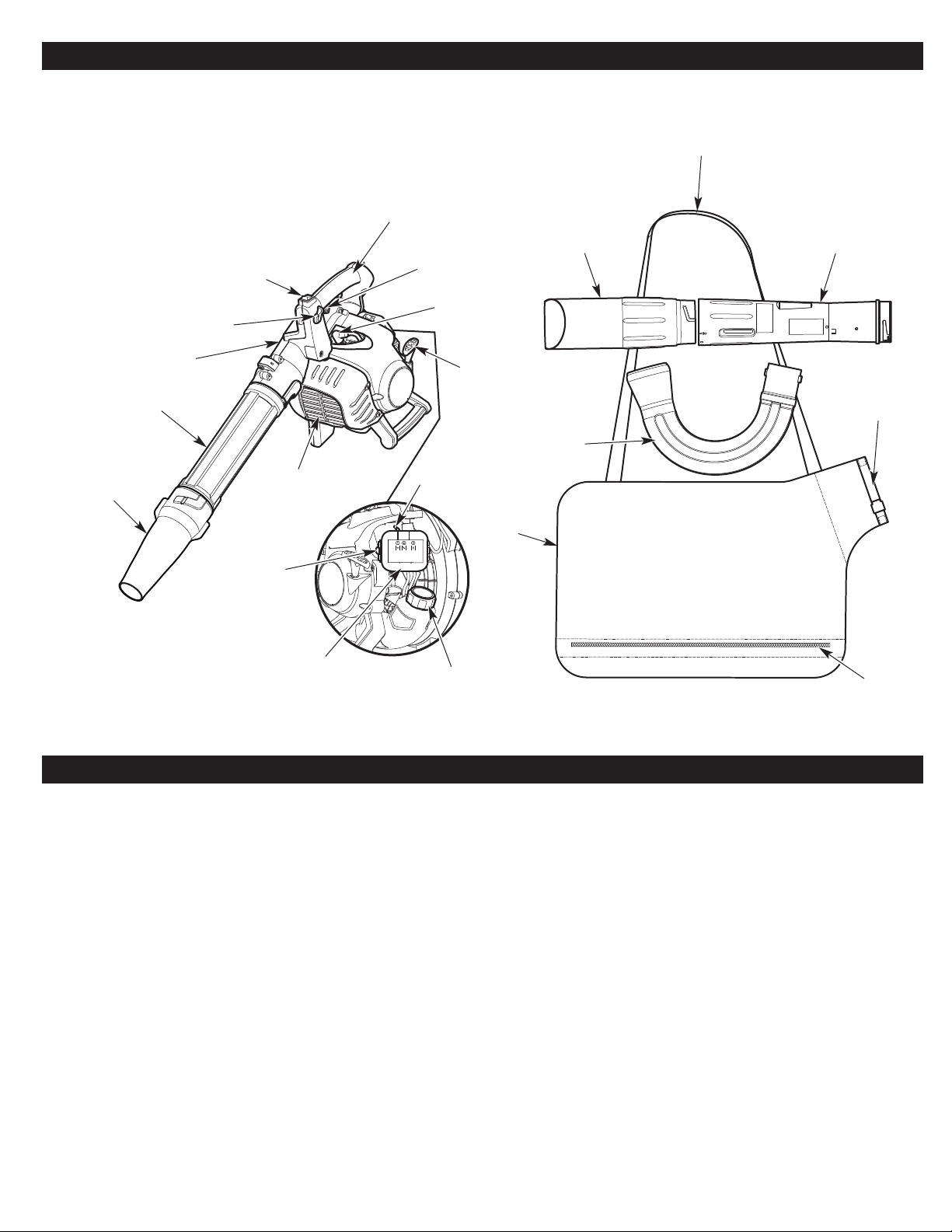

On/Off Switch

Cruise Control

Handle

Throttle

Control

Spark Plug

Lower

Vacuum Tube

Shoulder Strap

Upper

Vacuum Tube

Electric Start Port

Blower Tube

Nozzle

Muffler

Primer Bulb

Air Filter

Cover

Starter

Rope Grip

Choke Lever

Vacuum

Fuel Cap

Cinch Strap

Vacuum

Elbow Tube

Bag

Zipper

SPECIFICATIONS*

Engine Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 2-Cycle

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 cc (1.64 cu. in.)

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 in. (0.635 mm)

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion® RDJ7J or equivalent plug

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel/Oil Mixture

Fuel/Oil Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 oz. (414 ml

Approximate Unit Weight (No fuel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 12 lbs. (4.5 - 5.4 kg)

Air Volume** (measured at: outlet / blower tube / nozzle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450 / 425 / 310 cfm (12 / 12 / 8 m

Air Speed (Peak)** (measured at: outlet / blower tube / nozzle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 / 125 / 205 mph (193 / 201 / 330 km/h)

Air Speed (Average)** (measured at: outlet / blower tube / nozzle). . . . . . . . . . . . . . . . . . . . . . . . . . . 100 / 105 / 175 mph (161 / 169 / 282 km/h)

Mulching Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 16:1

Va

cuum Bag Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 Bushel (54.6 L)

3

/min)

)

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

** Measured per ANSI B175.2.

6

Page 7

ASSEMBLY

WARNING:

To avoid serious personal injury and

damage to the unit, shut the unit off before removing or

installing blower tubes, nozzles, vacuum tubes or the

vacuum bag.

WARNING:

To prevent serious personal injury, never

operate the unit without the blower tubes, or vacuum tubes

and vacuum bag, securely attached. Make sure the

vacuum bag is completely zipped closed.

ASSEMBLING THE UNIT AS A BLOWER

Always install the blower tube. The nozzle is optional.

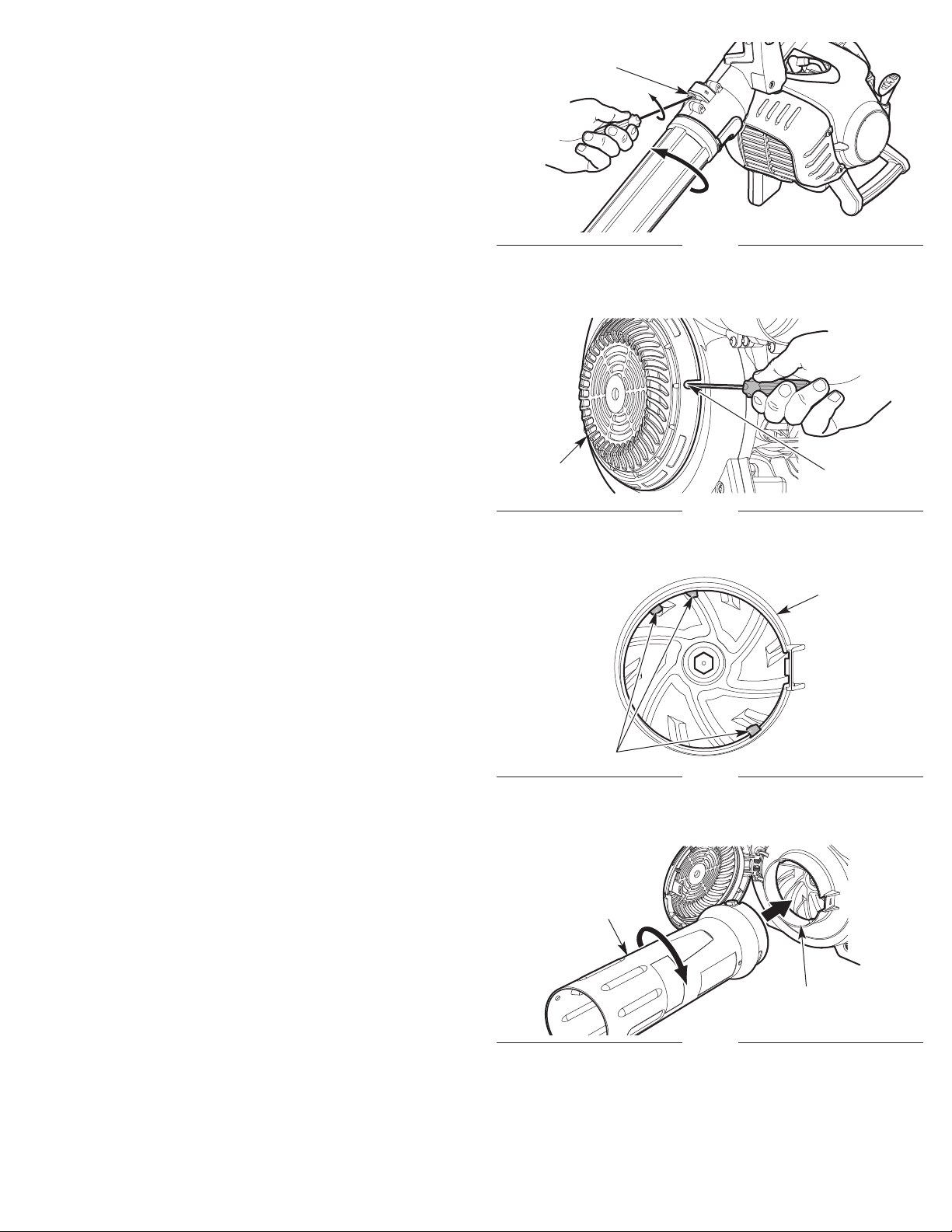

Installing the Blower Tube

1. Set the unit on a flat, level surface.

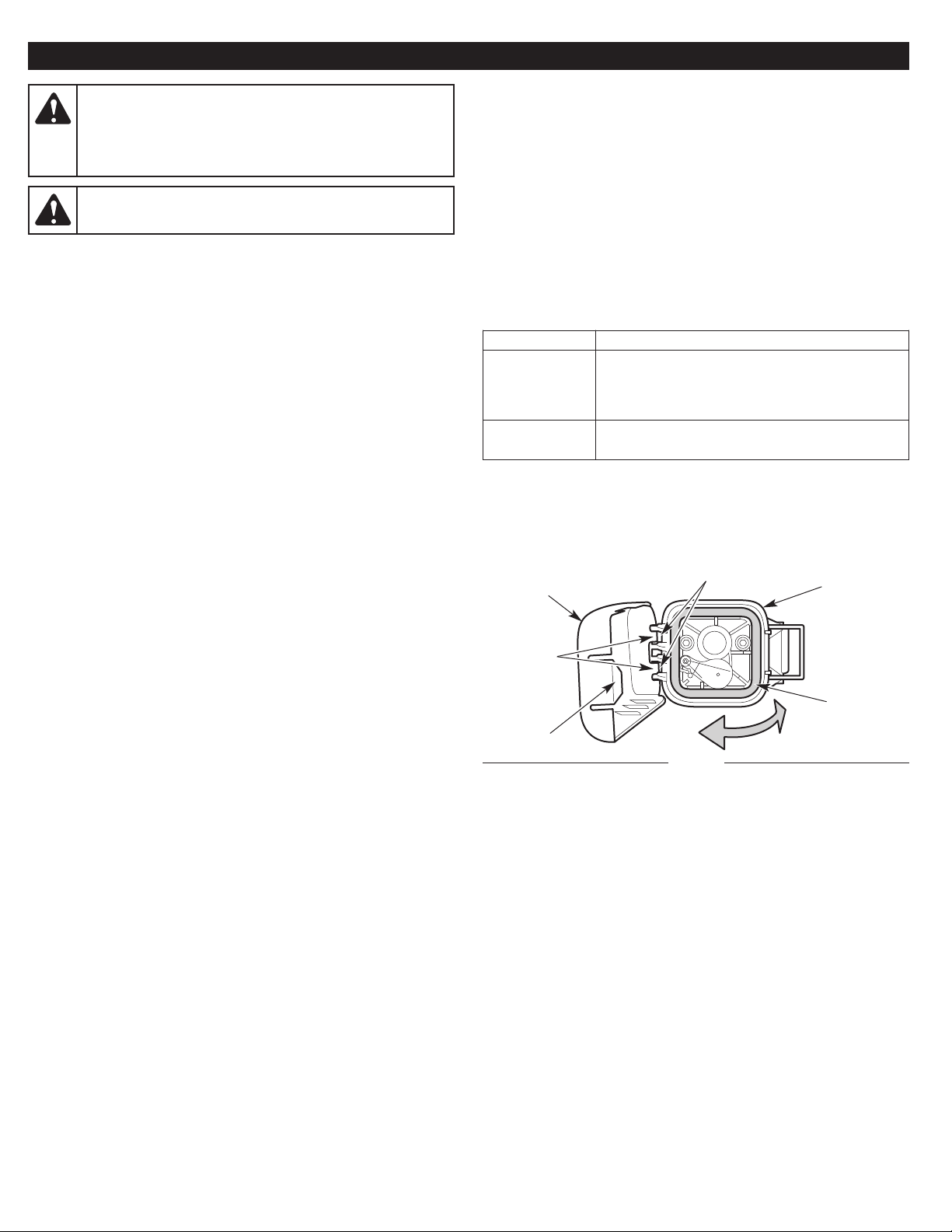

2. Align the bumps on the upper end of the blower tube with the

slots on the blower outlet (Fig. 1).

3. Insert the blower tube into the blower outlet (Fig. 1).

4. While holding the handle, twist the blower tube clockwise until it

locks into place (Fig. 1)

stalling the Nozzle

In

1. Set the unit on a flat, level surface.

2. Align the slots on the nozzle with the bumps on the lower end of

the blower tube (Fig. 2).

3. Install the nozzle onto the blower tube (Fig. 2).

4. While holding the blower tube, twist the nozzle clockwise until it

locks into place (Fig. 2). The tabs on the blower tube should

align with the tabs on the nozzle (Fig. 3).

.

Bumps

Slot

Bump

Slots

Fig. 1

Blower

Outlet

Blower Tube

Handle

Tabs

Blower Tube

Nozzle

Fig. 2

Tabs

Fig. 3

7

Page 8

ASSEMBLING THE UNIT AS A VACUUM

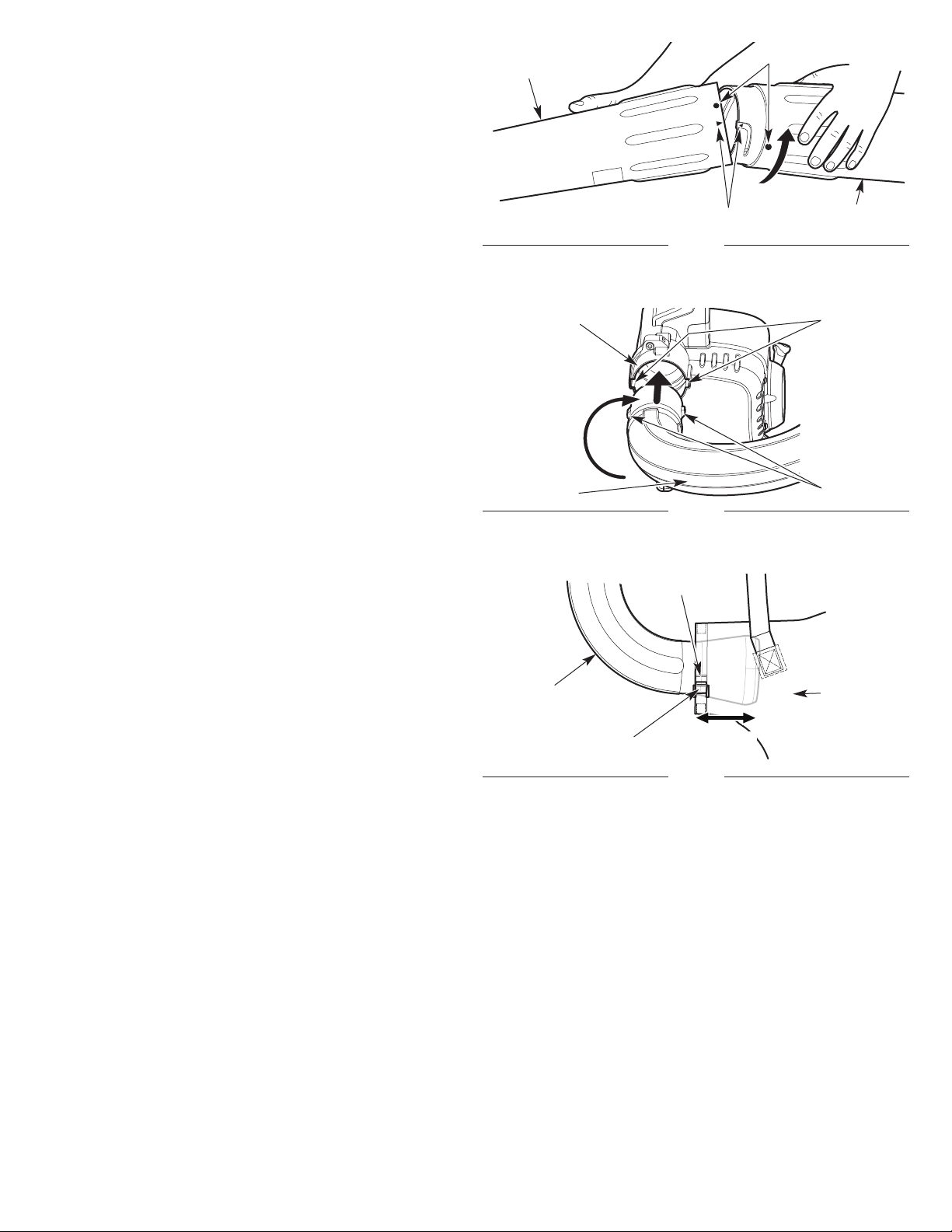

Removing the Blower Tube

1. Set the unit on a flat, level surface.

2. Insert a flat-head screwdriver into the tube lock. Turn the

screwdriver counterclockwise 1/4 turn and hold it in place (Fig. 4).

3. Twist the blower tube counterclockwise until it unlocks from the

blower outlet (Fig. 4).

4. Remove the blower tube from the blower outlet.

Removing the Nozzle

1. Set the unit on a

2. While holding the blower tube, twist the nozzle counterclockwise

until it unlocks from the blower tube.

3. Remove the nozzle from the blower tube.

Installing the Upper Vacuum Tube

1. Set the unit on a flat, level surface.

2. Insert a flat-head screwdriver into the hole in the impeller door

and press the impeller door lock tab inward (Fig. 5). Open the

impeller door.

3. While holding the

upper vacuum tube with the tabs in the impeller intake (Fig. 6).

4. Insert the upper vacuum tube into the impeller intake (Fig. 7).

5. Twist the upper vacuum tube clockwise with both hands until it

locks into place (Fig. 7).

Installing the Lower Vacuum Tube

1. Set the unit on a flat, level surface.

2. Align the arrow on the lower vacuum tube with the arrow on the

upp

acuum tube (Fig. 8).

er v

3. Insert the lower vacuum tube into the upper vacuum tube (Fig. 8).

4. Twist the lower vacuum tube clockwise with both hands until it

locks into place (Fig. 8).

NOTE: When properly assembled, the dot on the lower vacuum

tube should align with the dot on the upper vacuum tube (Fig. 8).

evel surface.

flat, l

imp

eller door open, align the slots on the

Impeller

Door

Tube Lock

Fig. 4

Impeller Door

Lock Tab

Fig. 5

Impeller Intake

Tabs

Fig. 6

Upper

Vacuum Tube

Impeller Intake

Fig. 7

8

Page 9

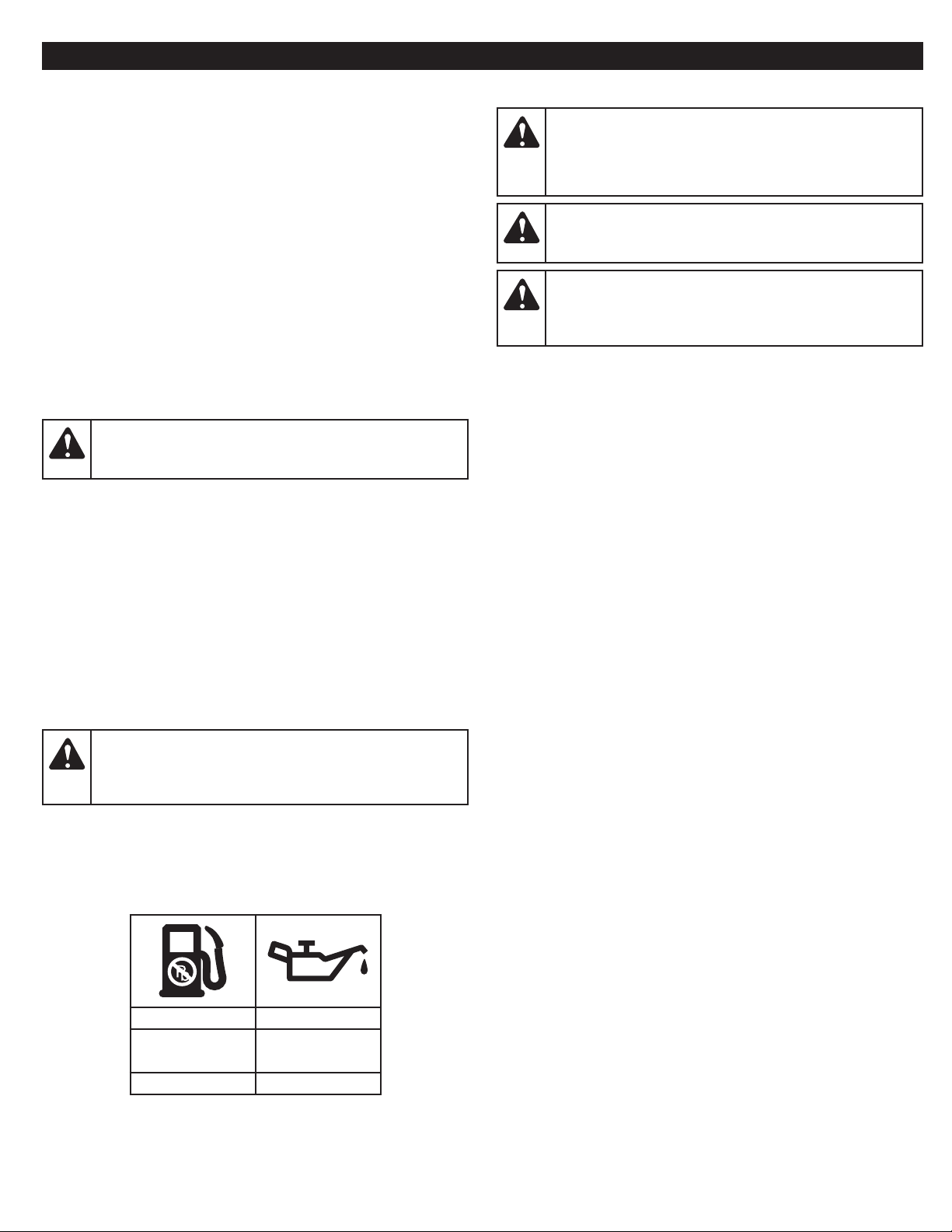

Installing the Vacuum Bag

1. Set the unit on a flat, level surface.

2. Align the bumps on the vacuum elbow tube with the slots on the

blower outlet (Fig. 9). The flared end of the vacuum elbow tube

should point to the right.

3. Insert the vacuum elbow tube into the blower outlet (Fig. 9).

4. Twist the vacuum elbow tube clockwise until it locks into place

(Fig. 9).

5. Insert the flared end of the vacuum elbow

e approximately 4

tub

inches (10 cm) into the vacuum bag (Fig. 10).

6. Pull the cinch strap to tighten the vacuum bag around the

vacuum elbow tube (Fig. 10).

NOTE: The cinch strap should be tight enough to prevent the

vacuum elbow tube from slipping out of the vacuum bag, but

loose enough for the vacuum bag to have limited movement

along the vacuum elbow tube.

Upper

Vacuum Tube

Blower Outlet

Fig. 8

Arrows

Dots

Lower

Vacuum Tube

Slots

Vacuum

Elbow Tube

Vacuum

Elbow Tube

Cinch Buckle

Bumps

Fig. 9

Cinch Strap

Vacuum Bag

4 inches

(10 cm)

Fig. 10

9

Page 10

OIL AND FUEL

OIL AND FUEL MIXING INSTRUCTIONS

The use of old and/or improperly mixed fuel is the most common cause

of performance problems. Use only fresh, clean unleaded gasoline.

Follow the instructions carefully for the proper gasoline/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs

water. As little a

separate, forming acids when stored. ALWAYS use fresh fuel (less

than 30 days old).

NOTE: Dispose of old fuel according to federal, state and local

regulations.

Using Blended Fuels

If using a blended fuel:

• Always use the fresh fuel mix explained in your operator's manual

• Use the fuel additive STA-BIL® or an equivalent

• Always agitate the fuel mix before fueling

WARNING:

has been proven that fuel containing greater than 10%

ethanol will likely damage this engine and void the warranty.

Using Fuel Additives

The container of 2-cycle oil provided with this unit includes a fuel

additive to help inhibit corrosion and minimize gum deposits.

Always use the brand of 2-cycle oil that came with this unit. If this is

unavailable, use a 2-cycle oil designed for air-cooled engines and

mix it with a fuel additive, such as STA-BIL Fuel Stabilizer or an

equivalent. Add 0.8 oz. (23 ml) of fuel a

according to the instructions on the container. NEVER add fuel

additives directly to the unit's fuel tank.

Mixing the Fuel

NOTE: This unit comes with a 3.2 oz. (95 ml) container of 2-cycle

oil. To obtain the correct fuel mixture described below, pour the

entire container into one gallon of unleaded gasoline.

water in the fuel can make fuel and oil

s 1%

t

he unit

DO NOT USE E85 FUEL IN THIS UNIT. It

dditive per gallon of fuel,

FUELING THE UNIT

WARNING:

vapors may explode. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the tank. Keep sparks and open flames at a distance

from the area.

WARNING:

from fuel spray. Never operate the unit without the fuel cap

securely in place.

WARNING:

area. Wipe up any spilled fuel immediately. Avoid creating

a source of ignition for spilled fuel. Do not start the engine

until fuel vapors dissipate.

1. Position the unit with the fuel cap facing up.

2. Slowly remove the fuel cap.

3. Place the fuel container spout into the fuel tank fill hole and fill

the tank.

NOTE: Do not overfill the tank.

4. Wipe up any fuel that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 30 ft. (9.1 m) from the fuel container and

the fueling site before starting the engine.

Gasoline is extremely flammable. Ignited

Remove the fuel cap slowly to avoid injury

Add fuel in a clean, well-ventilated outdoor

CAUTION:

reliability, pay strict attention to the gasoline and oil mixing

instructions on the 2-cycle oil container. Using improperly

mixed fuel can severely damage the engine.

Thoroughly mix the proper ratio of unleaded gasoline with 2-cycle

eng

oil. Do not mix them directly in the unit’s fuel tank. Use a

ine

separate fuel can. Use a 40:1 gasoline/oil ratio. See the table below

for specific gasoline and oil mixing ratios.

Unleaded gasoline 2-cycle oil

For proper engine operation and maximum

1 gallon U.S.

(3.8 liters)

1 liter 25 ml

MIXING RATIO - 40:1

3.2 fl. oz.

(95 ml)

10

Page 11

STARTING AND STOPPING

WARNING:

Operate this unit only in a well-ventilated

outdoor area. Carbon monoxide exhaust fumes can be

lethal in a confined area.

WARNING:

Avoid accidentally starting the unit. To avoid

serious injury, the operator and the unit must be in a stable

position when pulling the starter rope (Fig. 13).

WARNING:

When starting the unit, make sure it is not

directed toward people, animals, windows, automobiles or

loose debris.

STARTING INSTRUCTIONS

NOTE: This unit includes a cruise control, which allows the operator

to maintain the desired engine speed without having to squeeze

the throttle control.

1. Mix gasoline with oil. Refer to Oil and Fuel Mixing Instructions.

2. Fill the fuel tank. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off switch is in

the On ( I ) position at all times (Fig. 11).

3. Sl

4. Move the choke lever to Position 1 (Fig. 12).

5. Move the cruise control to the LO (slow) position (Fig. 11).

NOTE: Keep the cruise control in the LO (slow) position and DO

6. DO NOT squeeze the th

7. DO NOT squeeze the throttle control. Pull the starter rope with a

8. DO NOT squeeze the throttle control. Move the choke lever to

9. DO NOT squeeze the throttle control. Pull the starter rope with a

10. Squeeze and hold

11. Continue to squeeze the throttle control or keep the cruise

NOTE: The engine is properly warmed

NOTE: Once the engine is properly warmed, the cruise control may

y press and release the primer bulb 10 times (Fig. 12). If

owl

fuel cannot be seen in the primer bulb, press and release the

primer bulb until fuel is visible.

NOT squeeze the throttle control until step 10 (Fig. 11).

ttle control. Crouch in the starting

ro

position (Fig. 13).

controlled and steady motion 5 times (Fig. 13).

Position 2 (Fig. 12).

controlled and steady motion 3 to 5 times to start the engine.

throttle control or move the cruise control

the

to the HI (fast) position (Fig. 11). Allow the engine to warm up

for 30 to 60 seconds.

control in the HI (fast) position. Move the choke lever to

Position 3 (Fig. 12). Allow the engine to warm up for an

additional 60 seconds. The unit may be used during this time.

when it accelerates

up

without hesitation.

be adjusted and the throttle control can be used normally.

On/Off Switch

(I = On / O = Off)

Cruise Control

Choke Lever

Primer Bulb

Starter Rope Grip

HI (fast)

Position 1

Throttle Control

LO (slow)

Fig. 11

Position 3Position 2

Fig. 12

Starting

Position

Throttle Control

Fig. 13

IF... the engine hesitates, return the choke lever to Position 2 (Fig.

12) and continue the warm-up.

IF... the engine does not start, begin the starting procedure with

step 3.

IF... the engine fails to start after a few attempts: Move the choke

to Position 3. Sq

ueeze and hold the throttle control or move the

lever

cruise control to the HI (fast) position. Pull the starter rope with a

controlled and steady motion until the unit starts.

IF... the engine is already warm, begin the starting procedure with

step 8.

STOPPING INSTRUCTIONS

1. Release the throttle control, or move the cruise control to the LO

(slow) position, and allow the engine to idle.

2. Press and hold t

engine comes to a complete stop (Fig. 11).

11

he On/Off switch in the Off (O) position until the

Page 12

USING THE ELECTRIC START ACCESSORY

This unit can be started with an optional electri

(items sold separately). Refer to the electric start accessory

operator’s manual for the proper use of this feature.

Please contact your local retailer, call the Customer Support

Department or visit our website for more information.

tart accessory

c s

STARTING INSTRUCTIONS

NOTE: This unit includes a cruise control, which allows the operator

to maintain the desired engine speed without having to squeeze

the throttle control.

1. Mix gasoline with oil. Refer to Oil and Fuel Mixing Instructions.

2. Fill the fuel tank. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off switch is in

the On ( I ) position at all times (Fig. 11).

3. Sl

4. Move the choke lever to Position 1 (Fig. 12).

5. Move the cruise control to the LO (slow) position (Fig. 11).

NOTE: Keep the cruise control in the LO (slow) position and DO

6. DO NOT squeeze the th

7. DO NOT squeeze the throttle control. Insert the electric start

8. DO NOT squeeze the throttle control. Run the electric start

9. DO NOT squeeze the throttle control. Move the choke lever to

10. DO NOT squeeze the throttle control. Run the electric start

11. Remove the electric start accessory from the unit.

12. Squeeze and hold the throttle control or move the cruise control

13. Continue to squeeze the throttle control

NOTE: The engine is properly warmed up when it accelerates

NOTE: Once the engine is properly warmed, the cruise control may

y press and release the primer bulb 10 times (Fig. 12). If

owl

fuel cannot be seen in the primer bulb, press and release the

primer bulb until fuel is visible.

NOT squeeze the throttle control until step 12 (Fig. 11).

ttle control. Crouch in the starting

position (Fig. 13).

accessory into the electric start port (Fig. 14). Refer to the Operation

section of the electric start accessory operator’s manual.

accessory for 2 seconds.

Pos

ion 2 (Fig. 12).

it

accessory in intervals no longer than 2 seconds each until the

unit starts.

to the HI (fast) position (Fig. 11). Allow the engine to warm up

for 30 to 60 seconds.

control in the HI (fast) position. Move the choke lever to

Position 3 (Fig. 12). Allow the engine to warm up for an

additional 60 seconds. The unit may be used during this time.

without hesitation.

be adjusted and the throttle control can be used normally.

ro

r keep the cruise

o

ELECTRIC START ACCESSORIES

Item No. Description

49MASCBP912 . . . . . . . . . . . . . . . . . . . . . . . . . . . .Engine Starter Bit

49MRBESY912 . . . . . . . . . . . . . . . . . . . . . .Cordless Electric Starter

Electric Start Port

Fig. 14

STOPPING INSTRUCTIONS

1. Release the throttle control, or move the cruise control to the LO

(slow) position, and allow the engine to idle.

2. Press and hold the On/Off switch in the Off (O) position until the

engine comes to a complete stop (Fig. 11).

IF... the en

IF... t

IF... the engine fails to start after a few attempts: Move the choke

IF... the engine is already warm, begin the starting procedure with

gine hesitates, return the choke lever to Position 2 (Fig. 12)

and continue the warm-up.

he engine does not start, begin the starting procedure with

step 3.

lever to Position 3. Squeeze and hold the throttle control or

move the cruise control to the HI (fast) position. Run the electric

start accessory in intervals no longer than 2 se

the unit starts.

step 9.

cond

s each until

12

Page 13

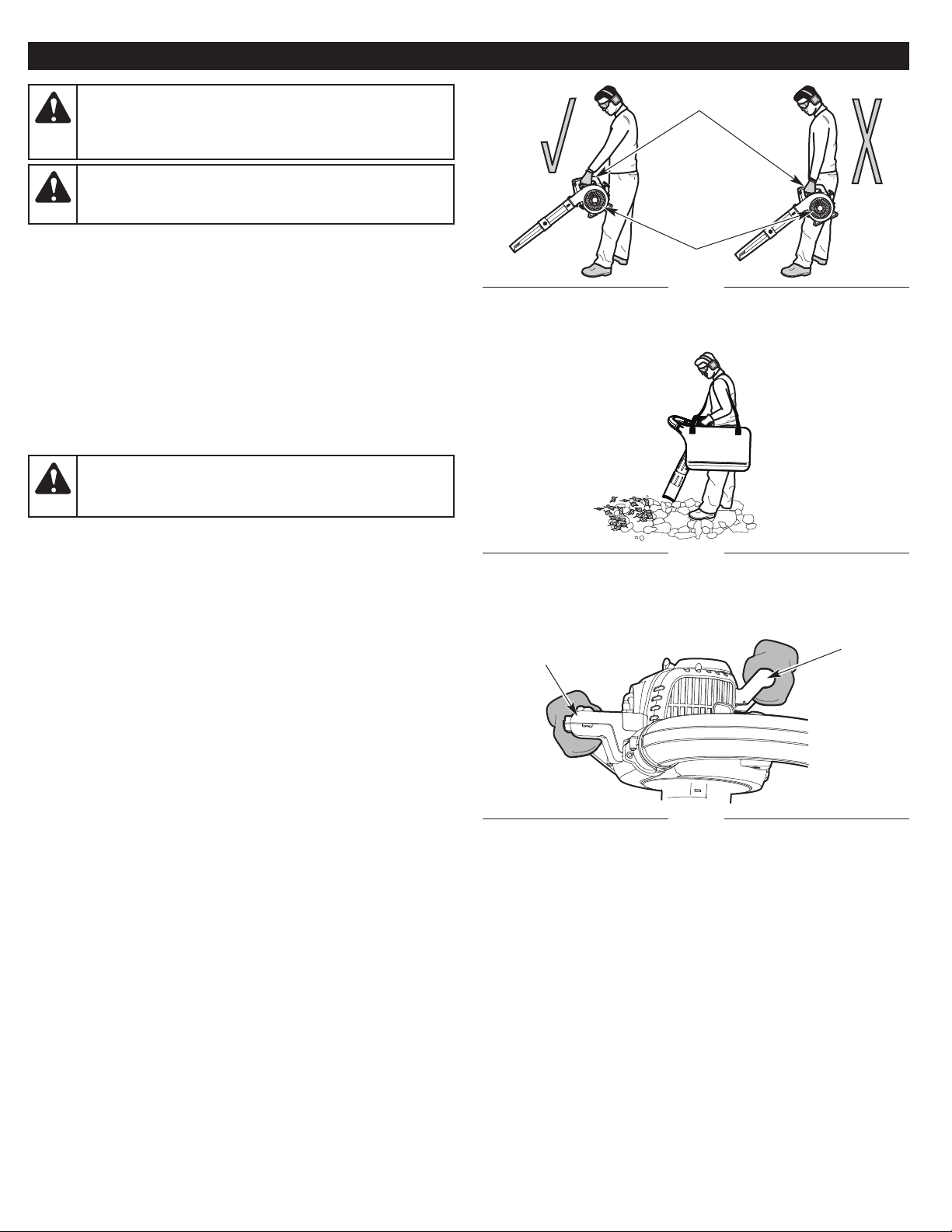

OPERATION

WARNING:

operate the unit without the blower tubes, or vacuum tubes

and vacuum bag, securely attached. Make sure the

vacuum bag is completely zipped closed.

WARNING:

protection to reduce the risk of injury when operating this unit.

Wear a face mask or dust mask if the operation is dusty.

To prevent serious personal injury, never

Always wear eye, hearing, hand, foot and body

HOLDING THE UNIT

As a Blower

• Stand in the operating position (Fig. 15). Stand up

not bend over.

• Keep feet apart and firmly planted.

• Hold the unit with a firm grip.

• Hold the unit in front of, and away from, your body (Fig. 15).

WARNING:

to the unit, DO NOT hold the unit at your side (Fig. 15). The

engine may be extremely hot. DO NOT block the air intake.

As a Vacuum

• Stand in the operating position (Fig. 16). Stand up straight. Do

not bend over.

• Keep feet apart and firmly planted.

• Place the shoulder strap over the left shoulder (Fig. 16).

• Hold the handle firmly with the right hand (Fig. 17)

secondary handle firmly with the left hand (Fig. 17).

To prevent serious personal injury or damage

straight. Do

old the

. H

Handle

Handle

Air Intake

Fig. 15

Fig. 16

Secondary

Handle

TIPS FOR BEST RESULTS

• Operate the unit only at reasonable hours, not early in the morning

or late at night when people might be disturbed. Comply with

times listed in local ordinances. Usual recommendations are 9:00

a.m. to 5:00 p.m., Monday through Saturday.

• To reduce noise levels, operate the unit at the lowest speed

needed to do the job. Limit the number of pieces of power

equipment used at any one

• Use rakes or brooms to loosen debris before operation.

• Use the cruise control to make continuous operation easier (Fig. 11).

• Clean up after operation. Dispose of debris appropriately.

As a Blower

• Conserve water by using the blower instead of a hose to

perform many outdoor cleaning actions.

• In dusty conditions, slightly dampen surfaces.

• Watch out for children, pets, open windows and freshly was

cars. Blow debris safely away. Never direct the unit toward

anyone while the unit is in operation.

• Sweep the unit from side to side with the blower tube several

inches above the ground. Slowly advance, keeping the

accumulated debris in front of the operator.

• Use the nozzle to concentrate the air stream closer to the ground.

time

.

d

he

Fig. 17

13

Page 14

As a Vacuum

WARNING:

materials, such as leaves, grass, small twigs or bits of

paper. To avoid serious injury to the operator and severe

damage to the unit, do not vacuum wet debris or water. To

avoid severe damage to the unit, do not vacuum hard

materials, such as metal, glass, etc.

WARNING:

vacuum bag to catch fire. Do not operate the unit near an

open flame. Do not vacuum warm ash from fire places, fire

pits, etc. Do not vacuum discarded cigars or cigarettes

unless the cinders are completely cool.

• Tilt the vacuum tube slightly.

• Sweep the unit from side to side with the vacuum tube a few

inches above the ground.

The unit is designed to pick up dry

Avoid situations that could cause the

EMPTYING THE VACUUM BAG

WARNING:

the engine and allow the impeller to come to a complete stop

before opening the vacuum bag.

Vacuumed debris is mulched as it passes through the impeller. This

allows the vacuum bag to hold more debris.

Empty the vacuum bag whenever it becomes full. When the vacuum

bag is full, suction will decrease noticeably. Also empty the vacuum

bag after each operation to prevent the deterioration of the vacuum

bag and the obstruction of air flow.

1. Wear eye protection and a dust ma

ft the buckle to loosen the cinch strap (Fig. 10).

2. Li

3. Remove the vacuum elbow tube from the vacuum bag (Fig. 10).

4. Unzip the vacuum bag and empty the contents into a garbage

bag or an appropriate container.

5. Turn the vacuum bag inside-out and vigorously shake out any

remaining dust and debris. Turn the vacuum bag right-side-out.

6. Re-install the vacuum bag. Refer to Installing the Vacuum Bag in

th

ssembly section.

e A

To avoid serious personal injury, always stop

sk.

14

Page 15

MAINTENANCE

WARNING:

the engine and allow it to cool before cleaning or maintaining

the unit. Never perform cleaning or maintenance while the

unit is running. Disconnect the spark plug wire to prevent

the unit from starting accidentally.

WARNING:

safety instructions to prevent serious personal injury.

To avoid serious personal injury, always stop

Wear protective clothing and observe all

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or

skills. If you are unsure about these procedures, take the unit to

an MTD authorized service dealer.

NOTE: Maintenance, replacement, or repair of the emission control

devices a

service dealer.

NOTE: Please read the California/EPA statement that came with the

unit for a complete listing of terms and coverage for the emissions

control devices, such as the spark arrestor, muffler, carburetor, etc.

FREQUENCY MAINTENANCE REQUIRED

Every 10 hours

(every 5 hours

in vacuum

mode)

Every 25 hours • Check the spark plug condition and gap.

system may be performed by an MTD authorized

nd

• Clean and re-oil the air filter. Refer to

Maintaining the Air Filter.

Refer to Maintaining the Spark Plug.

MAINTAINING THE AIR FILTER

Failure to maintain the air filter can result in poor performance or can

cause permanent damage to the engine. Engine failure due to

improper air filter maintenance is not covered by the product warranty.

Cleaning the Air Filter

1. Open the air filter cover: press in the lock tab and swing the air

filter cover to the left (Fig. 18).

2. Remove the air filter (Fig. 18).

3. Wash the a

thoroughly and allow it to dry.

4. Lightly coat the air filter with clean SAE 30 oil.

5. Squeeze the air filter to spread and remove excess oil.

6. Reinstall the air filter (Fig. 18).

NOTE: Operating the unit without the air filter and air filter cover will

VOID the warranty.

7. Close the air filter cover: insert the tabs on the air filter cover into

the

slots o

and press it closed until the lock tab snaps into place (Fig. 18).

ilter in detergent and water. Rinse the air filter

ir f

n the backplate. Swing the air filter cover to the right

Air Filter

Cover

Tabs

Lock Tab

Fig. 18

Slots

Backplate

Air Filter

15

Page 16

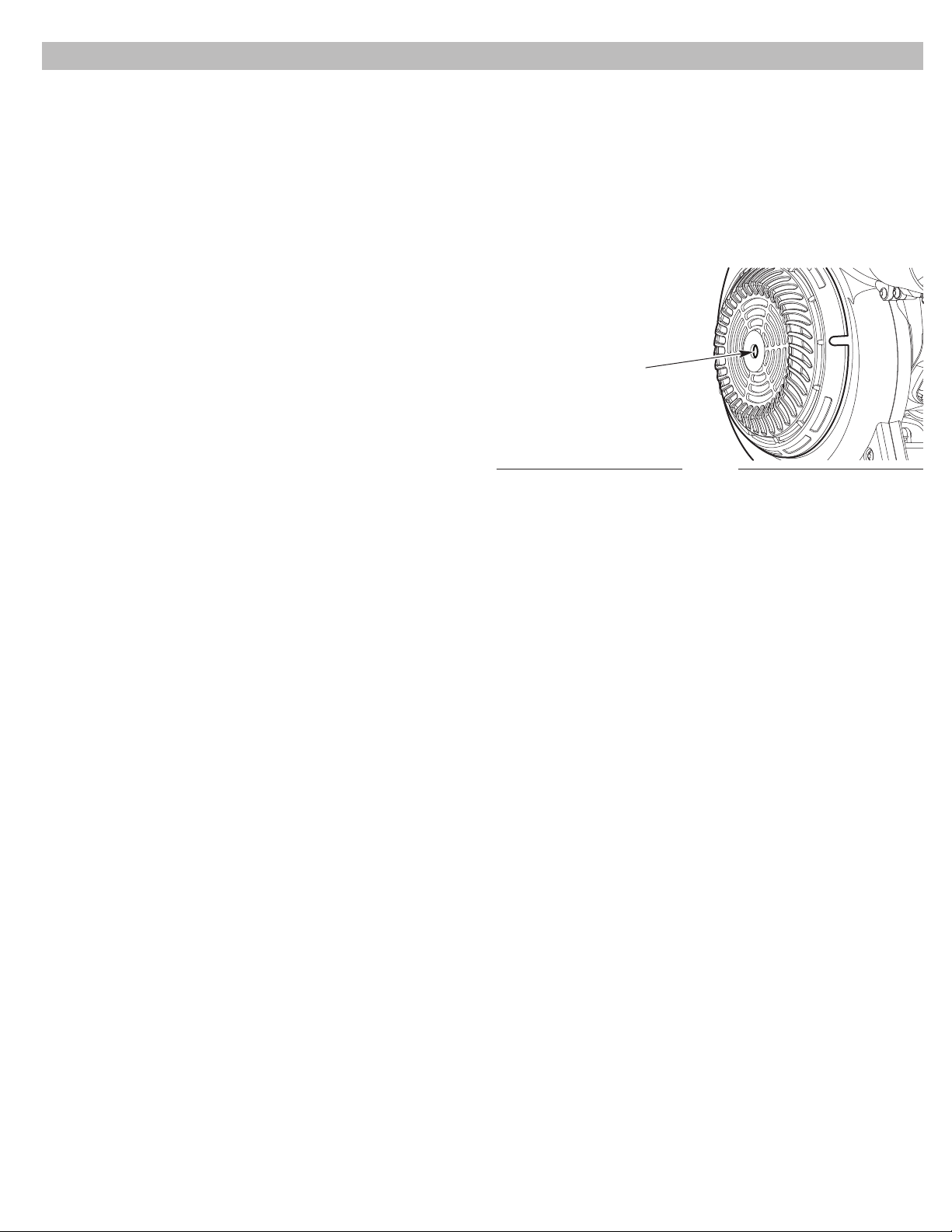

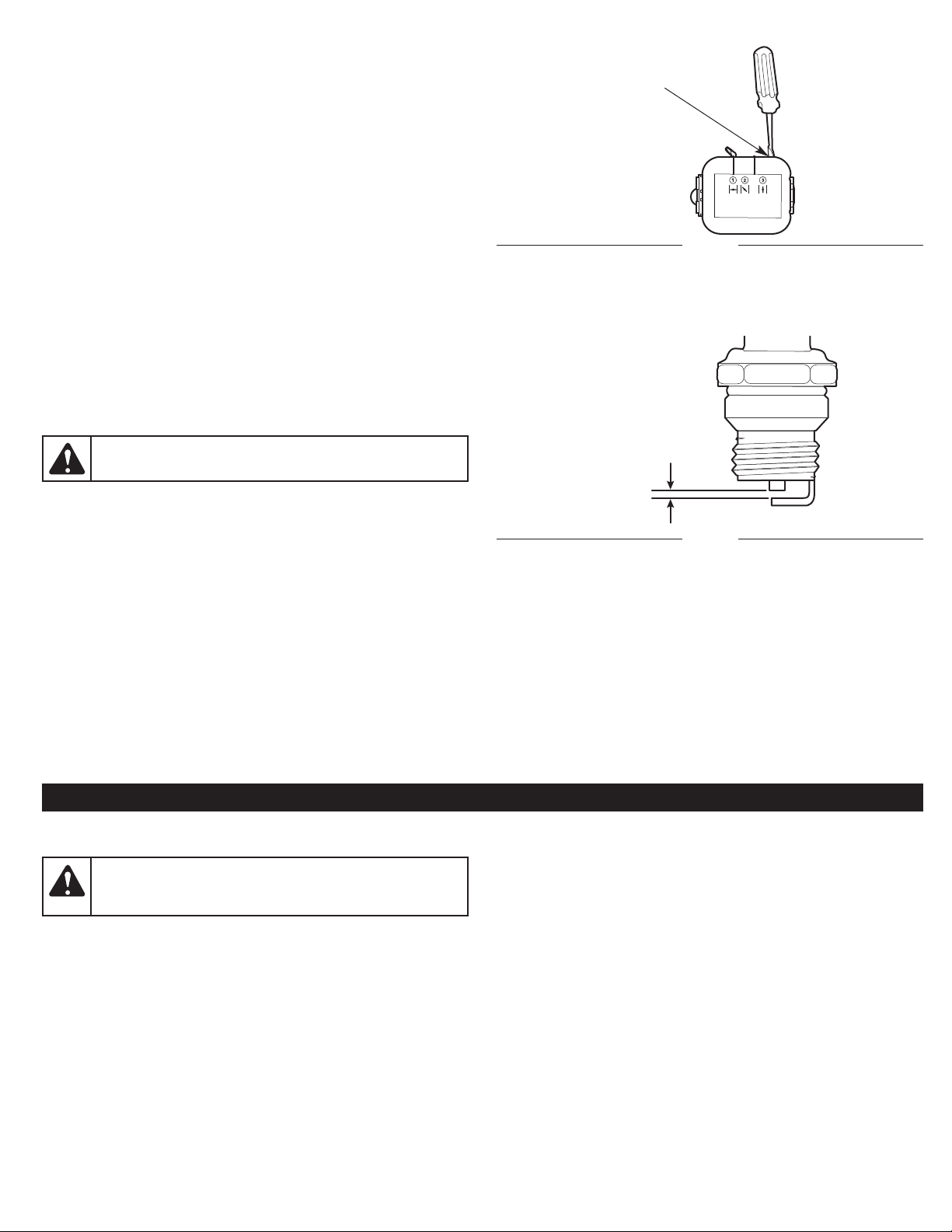

ADJUSTING THE IDLE SPEED

If the engine will not idle properly:

1. Start the engine. Refer to Starting and Stopping.

2. Move the cruise control to the LO (slow) position and let the

engine idle. If the engine stops, increase the idle speed. Use a

small Phillips screwdriver to turn the idle speed screw clockwise,

1/8 of a turn at a time, until the engine idles smoothly (Fig. 19).

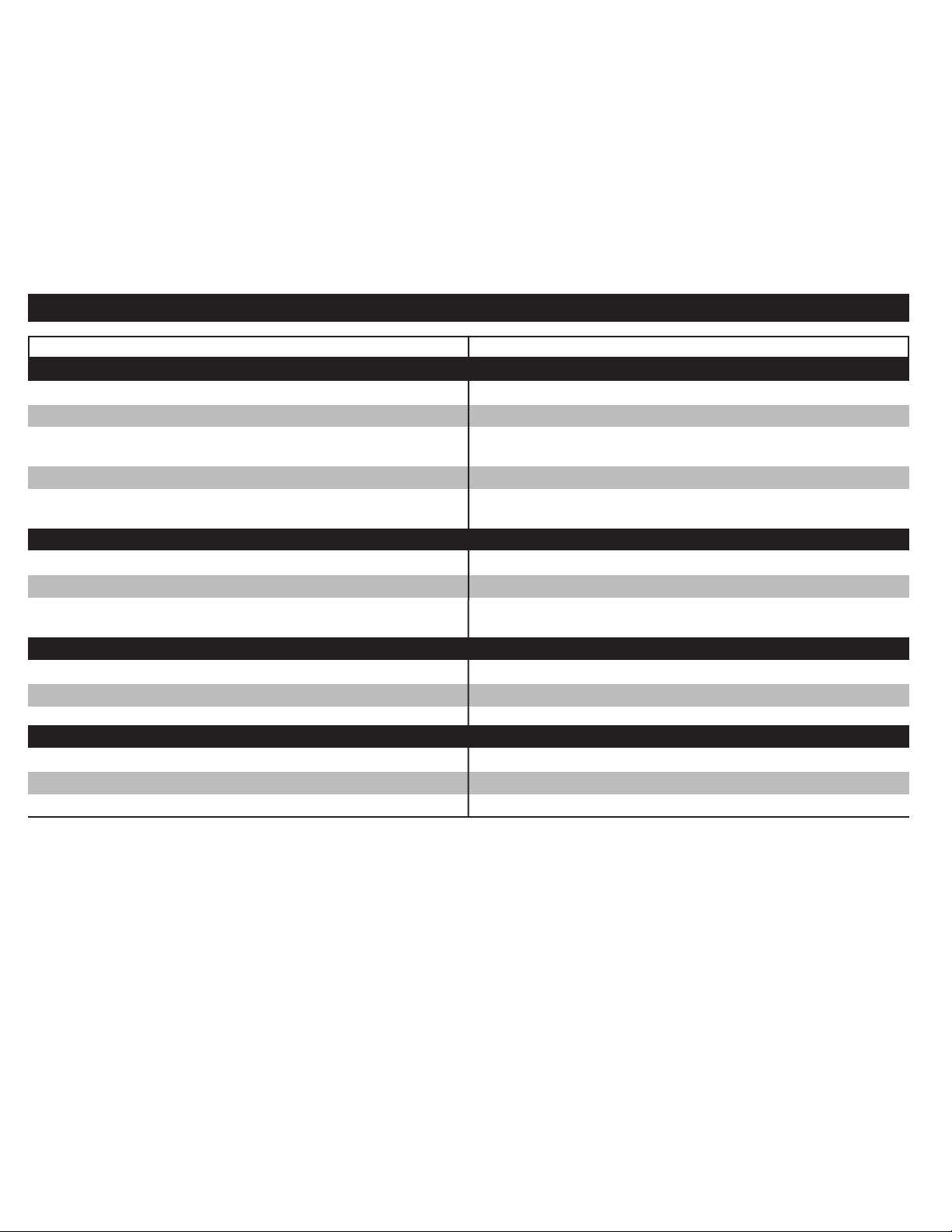

MAINTAINING THE SPARK PLUG

1. Stop the engine and allow it to cool. Grasp the spark plug boot

firmly and pull it from the spark plug.

2. Clean around the spark plug. Remove the spark plug from the

cylinder head with a 5/8-inch socket, turning counterclockwise.

Idle Speed Screw

Fig. 19

WARNING:

electrodes. Grit in the engine could damage the cylinder.

3. Inspect the spark plug. If the spark plug is cracked, fouled or

dirty, replace it with replacement part #753-06193, a Champion

RDJ7J o

4. Use a feeler gauge to set the air gap at 0.025 in. (0.635 mm)

(Fig. 20).

5. Install the spark plug in the cylinder head. Tighten the spark plug

with a 5/8-inch socket, turning it clockwise until snug.

NOTE: If using a torque wrench, torque to:

110-120 in.•lb. (12.3-13.5 N•m). Do not over tighten.

6. Reattach the spark plug boot.

r an equivalent spark plug.

Do not sand blast, scrape or clean spark plug

CLEANING AND STORAGE

CLEANING

WARNING:

the engine and allow it to cool before cleaning or maintaining

the unit.

Use a small brush to clean the outside of the unit. Do not use strong

detergents. Household cleaners that contain aromatic oils such as

pine and lemon, and solvents such as kerosene, can damage

plastic. Wipe off any moisture with a soft cloth.

To avoid serious personal injury, always stop

0.025 in.

(0.635 mm)

Fig. 20

STORAGE

• Never store a fueled unit where fumes may reach an open flame

or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

Long-term Storage

1. Remove the fuel cap, tip the unit and drain the fuel into an

approved container. Reinstall the fuel cap.

2. Start the

that all fuel has been drained from the carburetor.

3. Allow the engine to cool. Remove the spark plug and put 5

drops of any high-quality motor oil or 2-cycle oil into the

cylinder. Pull the starter rope slowly to distribute the oil. Reinstall

the spark plug.

4. Thoroughly clean the unit and inspect it for any loose or

damaged parts. Repair or repl

loose screws, nuts or bolts.

e

ngine and allow it to run until it stalls. This ensures

amaged parts and tighten

ace d

16

Page 17

Preparing the Unit for Use after Long-term Storage

1. Remove the spark plug. Tip the unit and drain all of the oil from

the cylinder into an approved container. Reinstall the spark plug.

NOTE: Do not use fuel that has been stored for more than 30 days.

Dispose of old fuel and oil according to federal, state and local

regulations.

TROUBLESHOOTING

PROBLEM SOLUTION

THE ENGINE WILL NOT START

The fuel tank is empty Fill the fuel tank with properly-mixed fuel

The primer bulb was not pressed enough Press the primer bulb 10 times or until fuel is visible

The engine is flooded

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly-mixed fuel

The spark plug is fouled Replace the spark plug

Move the choke lever to Position 3, squeeze the throttle control and

pull the starter rope

THE ENGINE WILL NOT IDLE

The air filter is dirty Clean or replace the air filter

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly-mixed fuel

The idle speed is incorrect Adjust the idle speed

THE ENGINE WILL NOT ACCELERATE

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly-mixed fuel

The air filter is dirty Clean or replace the air filter

THE ENGINE LACKS POWER OR STALLS

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly-mixed fuel

The air filter is dirty Clean or replace the air filter

The spark plug is fouled Replace the spark plug

If further assistance is required, contact an authorized service dealer.

17

Page 18

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by Cub Cadet LLC (Cub Cadet) with respect to new merchandise purchased and used in the

United States, its possessions and territories.

Cub Cadet warrants this product against defects in material and workmanship for a period of three (3) years commencing on the date of

original purchase and will, at its option, repair or replace, free of charge, any part f

limited warranty shall only apply if this product has been operated and maintained in accordance with the Operator’s Manual furnished with

the product, and has not been subject to misuse, abuse, commercial use, neglect, accident, improper maintenance, alteration, vandalism,

theft, fire, water or damage because of other peril or natural disaster. Da

attachment not approved by Cub Cadet for use with the product(s) covered by this manual will void your warranty as to any resulting

damage. This warranty is limited to ninety (90) days from the date of original retail purchase for any Cub Cadet product that is used for rental

or commercial purposes, or any other income-producing purpose.

HOW

TO OBTAIN SERVICE: Warranty service is available, WITH PROOF OF PURCHASE THROUGH YOUR LOCAL AUTHORIZED SERVICE

DEALER. To locate the dealer in your area, visit our website at www.cubcadet.com or www.cubcadet.ca, check for a listing in the Yellow

Pages, call 1-877-282-8684 or 1-800-668-1238 in Canada, or write to P.O. Box 361131, Cleveland, OH 44136-0019. No product returned

directly to the factory will be accepted unless prior written permission has been extended by the Customer Service Department of Cub Cadet.

Th

is limited warranty does not provide coverage in the following cases:

A. Tune-ups - Spark Plugs, Carburetor Adjustments, Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting Line, Inner Reels, Starter Pulley, Starter Ropes, Drive Belts, Saw Chains, Guide Bars,

Cultivator Tines, Blades.

C

. Cub Cadet does not extend any warranty for products sold or exported outside of the United States of America, its possessions and

territories, except those sold through Cub Cadet’s authorized channels of export distribution.

Cub Cadet reserves the right to change or improve the design of any Cub Cadet Product without assuming any obligation to modify any

product previously manufactured.

mage resulting from the installation or use of any accessory or

ound to be defective in material or workmanship. This

No impli

applicable period of express written warranty above as to the parts as identified. No other express warranty or guaranty, whether

written or oral, except as mentioned above, given by any person or entity, including a dealer or retailer, with respect to any product

shall bind Cub Cadet. Du

above. (Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the sole and exclusive remedy arising from the sales. Cub Cadet shall not be

liable for incidental or consequentia

lawn care services, for transportation or for related expenses, or for rental expenses to temporarily replace a warranted product.

(Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater t

of the product shall void this Warranty. You assume the risk and liability for loss, damage, or injury to you and your property and/or to others

and their property arising out of the use or misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the original purcha

as a gift.

How State Law Relates to this Warranty: This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

To locate your nearest service dealer, dial 1-877-282-8684 in the United States or 1-800-668-1238 in Canada.

rranty, including any implied warranty of merchantability or fitness for a particular purpose, applies after the

ed wa

ring the period of the Warranty, the exclusive remedy is repair or replacement of the product as set forth

l loss or damages including, without limitation, expenses incurred for substitute or replacement

han the amount of the purchase price of the product sold. Alteration of the safety features

ser, original lessee or the person for whom it was purchased

CUB CADET LLC

P.O. Box 361131

Cleveland, OH 44136-0019

18

Page 19

Manuel de l’utilisateur

Souffleur / aspirateur manuel à

démarrage électrique à 2 temps

BV228

TABLE DES MATIÈRES

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Familiarisez-vous avec votre appareil . . . . . . . . . . . . . . . . . . . . . .24

Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Assemblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Huile et carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Démarrage et arrêt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Nettoyage et entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Résolution des problèmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

CONSERVEZ CES

INSTRUCTIONS

SERVICE

NE RAMENEZ PAS CET APPAREIL CHEZ LE DÉTAILLANT.

UNE PREUVE D’ACHAT SERA EXIGÉE POUR TOUTE

PRISE EN CHARGE DANS LE CADRE DE LA GARANTIE.

Pour obtenir de l'aide sur l'assemblage, le fonctionnement ou la

maintenance de l'appareil, veuillez composer le 1-877-282-8684 (aux

États-Unis) ou le 1-800-668-1238 (au Canada). Des renseignements

supplémentaires peuvent être trouvés sur le site www.cubcadet.com

(aux États-Unis) ou www.cubcadet.ca (au Canada).

Le

service de garantie est disponible par l’intermédiaire d'un atelier

de réparations agréé. Pour trouver un atelier de réparations dans

votre région, veuillez consulter notre site Web ou composer le

numéro indiqué ci-dessus. La réparation de cet appareil, à la fois

pendant et après la période de garantie, ne doit être effectuée que

par un atelier de réparation agr

des pièces de rechange identiques.

pprouvé. Utilisez uniquement

éé a

Toutes les informations, illustrations et spécifications contenues

dans ce manuel tiennent compte des dernières informations

techniques disponibles au moment de mettre sous presse. Nous

nous réservons le droit d'y apporter des modifications à tout

moment, sans préavis.

Le produit peut varier légère

présent manuel.

Copyright © 2016 MTD SOUTHWEST INC., Tous droits réservés.

IMPORTANT : Lisez attentivement ce manuel avant d'utiliser ce produit. Respectez toutes les instructions.

769-11584 / 00 04/16

ment par rapport aux illustrations du

Page 20

SÉCURITÉ

Les symboles de sécurité visent à attirer votre attention sur les

dangers éventuels. Vous devez accorder une attention particulière

aux symboles de sécurité afin de bien les comprendre. Les

avertissements de sécurité n’éliminent pas les dangers en euxmêmes. Les instructions ou mises en garde ne remplacent en rien

les mesures de prévention appropriées contre les accidents.

SYMBOLE SIGNIFICATION

DANGER :

Le non-respect d'un symbole de DANGER sur le plan de la

sécurité ENTRAÎNERA des blessures graves, voire la mort

pour vous ou pour autrui.

AVERTISSEMENT :

danger GRAVE.

Le non-respect d'un symbole d'AVERTISSEMENT sur le

plan de la sécurité PEUT entraîner des blessures graves

pour vous ou pour autrui.

ATTENTION :

Le non-respect d'un symbole de ATTENTION sur le plan

de la sécurité PEUT entraîner des dommages matériels ou

des blessures pour vous ou pour autrui.

REMARQUE : vous donne des informations ou des consignes

essentielles pour l’utilisation ou l’entretien de l’équipement.

indique un danger EXTRÊME.

indique un

indique un danger MODÉRÉ.

NOTE SUR LE PARE-ÉTINCELLES

REMARQUE : à l’intention des utilisateurs sur les terrains

forestiers américains et dans les États de Californie, du Maine,

de l’Oregon et de Washington. Tous les services des forêts

américains et les États de Californie (codes des ressources

publiques 4442 et 4443), de l’Oregon et de Washington exigent, au

titre de la loi, que certains moteurs à combustion interne uti

ans les broussailles de forêt et/ou les zones recouvertes d’herbe

d

soient équipés d’un pare-étincelles, soient maintenus en bon état

de marche, ou soient construits, équipés et entretenus en vue

d’éviter tout risque d’incendie. Veuillez contacter les autorités

nationales ou locales pour connaître les réglementations à cet

égard. Le non-respect de ces exigences pourrait impliquer votre

responsabilit

en usine d’un pare-étincelles. Si un remplacement est nécessaire,

communiquez avec votre distributeur local pour l’installation du

silencieux approprié.

u entraîner une amende. Cet appareil est équipé

é o

PROPOSITION 65 DE L’ÉTAT DE CALIFORNIE

AVERTISSEMENT :

contient un composé chimique reconnu dans l'état de la

Californie comme produit pouvant provoquer des cancers

et des malformations congénitales et affecter l'appareil

reproducteur.

Veuillez lire le manuel de l’opérateur et respecter tous

les avertissements et consignes de sécurité. Dans le cas

contraire, l’opérateur et/ou les passants peuvent subir des

blessures graves.

lisés

Ce produit

• CONSIGNES DE SÉCURITÉ IMPORTANTES •

VEUILLEZ LIRE TOUTES LES INSTRUCTIONS AVANT

AVERTISSEMENT :

utilisez l'appareil, toutes les consignes de sécurité doivent

être respectées. Veuillez lire ces consignes avant d’utiliser

l’appareil pour assurer la sécurité de l’opérateur et de tous

les passants. Veuillez conserver ces instructions pour

référence ultérieure.

• Veuillez lire soigneusement ces instructions. Familiarisez-vous

avec les commandes et l’utilisation correcte de l’appareil.

• N’utilisez pas cet appareil quand vous êtes fatigué, malade ou sous

l’influence de boissons alcoolisées, de drogues ou de médicaments.

• Ne laissez jamais les enfants utiliser l’appareil. Les adolescent

doivent être formés, accompagnés et guidés par un adulte. Ne

permettez jamais aux adultes d’utiliser l’appareil sans avoir lu les

instructions appropriées.

• Tous les carters et dispositifs de sécurité doivent être

correctement installés avant l’utilisation de cet appareil.

• Inspectez l’appareil avant l’utilisation. Remplacez les pièces

endommagées. Détectez les fuites de carburant éventuelles.

Assu

z-vous que toutes les fixations sont en place et bien

re

serrées. Remplacez les pièces fissurées, ébréchées ou

endommagées d’une manière ou d’une autre. N’utilisez pas

l’appareil quand des pièces sont desserrées ou endommagées.

Lorsque vous

• Vous devez être conscient des risques de blessures à la tête,

aux mains et aux pieds.

• Inspectez attentivement la zone de travail avant de démarrer

l’appareil. Retirez les pierres, le verre cassé, les clous, les fils, les

ficelles et autres objets qui peuvent être projetés ou s’enrouler

dans l’appareil.

• Éloignez les enfants, les passants et les animaux domestiques ;

ils doivent rester dans un rayon d’

Même à cette distance, il existe néanmoins un risque de

projectiles pour les personnes à proximité. Encouragez-les à

porter des lunettes de sécurité. Si quelqu’un s’approche de

vous, arrêtez immédiatement l’appareil.

• Appuyez sur la manette des gaz et vérifiez qu’elle revient

automatiquement à la position de ralenti. Effectuez tous les

s

réglages ou réparations avant d’utilis

• Ne modifiez pas les réglages du régulateur et ne laissez pas le

moteur s’emballer.

• Cet appareil est uniquement destiné à un usage domestique

occasionnel.

ins 15 mètres (50 pieds).

au mo

’appareil.

er l

20

Page 21

AVERTISSEMENTS DE SÉCURITÉ POUR LES APPAREILS

À GAZ

AVERTISSEMENT :

extrêmement inflammable et ses vapeurs peuvent exploser

en présence d’une source d’inflammation. Prenez les

précautions suivantes :

• Stockez le carburant uniquement dans des récipients

spécifiquement conçus à cet usage et approuvés pour le

stockage de telles substances.

• Arrêtez toujours le moteur et laissez-le refroidir avant de remplir

le réservoir d’essence. N’enlevez jamais le bouchon du réservoir

de carburant ou ne remplissez jamais ce dernier quand le

moteur est chaud. Dévis

réservoir de carburant afin de relâcher toute pression présente

avant de le remplir.

• Mélangez et ajoutez toujours le carburant dans une zone

extérieure propre et bien aérée, en l’absence totale d’étincelles

ou de flammes. NE fumez PAS.

• N’utilisez jamais l’appareil quand le bouchon du réservoir de

carburant n’est pas correctement vissé.

• Évitez de créer une source

déversement de carburant. Essuyez immédiatement tout carburant

échappé du réservoir avant de démarrer l’appareil. Éloignez

l’appareil à 9,1 mètres (30 pieds) au moins de la source de

ravitaillement et du site avant de démarrer le moteur. NE fumez PAS.

• Ne démarrez jamais ou n’utilisez jamais l’appareil à l’intérieur

d’un espace ou d’un bâtiment clos. L’inhalation des fum

’échappement peut tuer. Utilisez cet appareil uniquement dans

d

une zone extérieure bien aérée.

oujours lentement le bouchon du

sez t

nflammation en présence d’un

d’i

l’essence est

ées

PENDANT L’UTILISATION

• Portez des lunettes de sécurité conformes aux normes ANSI / ISEA

Z87.1 en vigueur et marquées comme telles. Portez une protection

auditive pendant l’utilisation de cet appareil. Portez un écran facial

ou un masque antipoussières si la tâche est poussiéreuse.

• Po

rtez un pantalon long et épais, des bottes, des gants et une

chemise à manches longues. Ne portez pas des vêtements

amples, des bijoux, un pantalon court, des sandales et ne travaillez

pas pieds nus. Attachez vos cheveux au-dessus des épaules.

• Utilisez l’appareil uniquement en plein jour ou avec un bon

éclairage artificiel.

• Évitez tout démarrage accidentel.

démarrage dès que vous tirez sur le câble de démarreur. L’opérateur

t l’appareil doivent être dans une position stable pendant le

e

démarrage. Consultez les sections Mise en marche et Arrêt.

• Utilisez le bon outil. Utilisez uniquement cet outil pour l’usage prévu.

• Tenez toujours fermement l’appareil lors de l’utilisation.

• Ne vous penchez pas trop en avant. Conservez touj

position stable et un bon équilibre. Redoublez de prudence

lorsque vous travaillez dans des escaliers, des pentes ou des

rampes abruptes. Pour éviter les blessures graves, n'utilisez pas

l'appareil lorsque vous vous trouvez sur une échelle ou un toit.

• Éloignez vos mains, votre visage et vos pieds des pièces

mobiles. Ne touchez pas ou n’essayez pas d’arrêter des pièces

en mouvement.

• Ne touchez p

deviennent extrêmement chauds pendant l’utilisation, même

après l’arrêt de l’appareil.

• N’utilisez pas l’appareil à une vitesse supérieure à celle

nécessaire pour réaliser le travail. Ne faites pas fonctionner

l’appareil à haute vitesse quand vous ne l’utilisez pas.

e moteur ni le silencieux. Ces composants

as l

Placez-vous dans la position de

une

ours

• Ne forcez pas l’appareil. Il sera plus efficace et plus sûr si vous

l’utilisez à la vitesse pour l

• Arrêtez toujours l’appareil quand le travail est interrompu ou

quand vous vous déplacez d'un endroit à un autre.

• Avant de déposer l’outil, assurez-vous toujours que le moteur

est éteint et que toutes les pièces mobiles se sont immobilisées.

• Si vous heurtez ou enroulez un objet étranger dans l’appareil,

arrêtez immédiatement l’appareil et vérifiez les dommages

éventuels. Ne

N’utilisez pas l’appareil quand des pièces sont desserrées ou

endommagées.

• Arrêtez le moteur et débranchez la bougie pour les tâches

d’entretien ou les réparations.

• Utilisez uniquement des pièces et des accessoires de rechange

du fabricant d’origine pour cet appareil. Ils sont disponibles

auprès de votre centre de réparation agréé. L’utilisation d’aut

pièces ou accessoires pourrait entraîner de graves blessures de

l’utilisateur ou endommager l’appareil, et annuler la garantie.

• L’appareil doit rester propre. Retirez avec précaution la végétation

et autres débris qui pourraient bloquer les pièces mobiles.

• Pour réduire les risques d’incendie, remplacez un pot

d’échappement et un pare-étincelles défectueux. Nettoyez l’herbe,

les feuilles, les couche

carbone présents sur le moteur et le pot d’échappement.

• Si l’appareil commence à vibrer de façon anormale, arrêtez-le

immédiatement. Inspectez l’appareil pour découvrir l’origine des

vibrations. Les vibrations indiquent en général un problème.

démarrez pas l’appareil avant de l’avoir réparé.

re

aquelle il a été conçu.

e graisse excessives ou les dépôts de

s d

re

SÉCURITÉ RELATIVE À LA L'ASPIRATEUR/AU SOUFFLEUR

• N'insérez pas d'objet dans les ouvertures d'aération, les tubes

ou les buses du ventilateur. N'utilisez pas l'appareil si l'une des

ouvertures d'aération ou l'un des tubes sont bloqués. Gardez les

ouvertures d'aération exemptes de poussière, de peluches, de

cheveux et de tout ce qui peut réduire la circulation de l'air.

• N’utilisez pas l’appareil sans qu

l’aspirateur et qu’un sac d’aspirateur y soient solidement fixés.

Assurez-vous que la fermeture à glissière du sac de l'aspirateur

est entièrement fermée.

• N'utilisez pas l'appareil pour pulvériser des liquides,

particulièrement des liquides inflammables ou combustibles,

comme l'essence. N'utilisez pas l'appareil dans des zones où

ces liquides sont présents.

• N'utilisez pas

de l'engrais ou toute autre substance pouvant contenir des

matières toxiques.

• Ne déposez pas l'appareil pendant qu'il est en marche. Les

débris peuvent être captés par l'entrée d'air et être rejetés par

l'ouverture de décharge, entraînant des dégâts matériels ou

causant de graves blessures aux personnes présentes ou à

l'opérateur.

• Pendant le fonctionnement

personnes, des animaux, des fenêtres ou des automobiles.

Dirigez toujours les débris soufflés à l'écart des gens, des

animaux, des fenêtres ou des automobiles.

• Redoublez de prudence lors du nettoyage des débris se

trouvant à proximité d'objets solides, tels des arbres, des murs,

des clôtures, etc. Lorsque cela est possible, soufflez dans la

direction opposée à ces

• Faites attention lorsque vous travaillez à proximité de précieuses

plantes. La force de l'air soufflé peut endommager les plantes

délicates.

ppareil pour épandre des produits chimiques,

l'a

bjets, et non vers eux.

o

es tubes du souffleur ou de

e l

pointez jamais l'appareil vers des

, ne

s

21

Page 22

• L'appareil est conçu pour ramasser des matériaux secs, comme

des feuilles, de l'herbe, des brindilles ou des morceaux de papier.

Pour éviter les blessures graves de l'opérateur et de graves

dommages à l'appareil, n'aspirez pas des débris humides ou de

l'eau. Afin d'éviter de graves dommages à l'appareil, n'aspirez

pas de matériaux durs tels que le métal, le verre, etc.

• Évitez les situations qui pourraient provoquer l'incend

de l'aspirateur. N'utilisez pas cet appareil à proximité d'une

flamme. N'aspirez pas les cendres chaudes des cheminées, des

foyers, etc. N'aspirez pas de cigares ou cigarettes ayant été

jetés à moins que les cendres soient complètement refroidies.

• Ne tentez jamais de dégager une ouverture d'admission d'air

obstruée pendant que l'appareil est en marche.

• Gardez les cheveux, les doigts et toutes

corps à l'écart des pièces en mouvement et des ouvertures.

es autres parties du

l

ie d

u sac

AUTRES AVERTISSEMENTS DE SÉCURITÉ

• Entretenez soigneusement l'appareil.

• Toutes les réparations, autres que les procédures de

maintenance décrites dans ce manuel, doivent être effectuées

par un centre de réparations agréé.

• Ne retirez, modifiez ou rendez jamais inopérant tout dispositif de

sécurité fourni avec l'appareil.

• Avant une inspection, un entretien, un nettoyage, un entreposage,

un transport ou

tez l’appareil.

1. Arrê

2. Assurez-vous que toutes les pièces mobiles se sont arrêtées.

3. Laissez l’appareil refroidir.

4. Débranchez le fil de la bougie.

• Assurez-vous que l’appareil est sécurisé pour les transports.

• Quand le réservoir contient du carburant, ne rangez jamais

l’appareil à l’intérieur d’un bâtiment où des vapeurs d’essence

pourraient atteindre une

étincelles (interrupteurs, moteurs électriques, etc.).

• Rangez l’appareil dans un endroit sec et sûr ou en hauteur pour

éviter une utilisation non autorisée ou des dommages. Gardez

toujours l’appareil hors de portée des enfants.

• Ne mouillez pas ou n’éclaboussez pas l’appareil avec de l’eau ou

tout autre liquide. Gardez les poignées sèches et propres (sans

débris, hu

utilisation. Consultez la section Nettoyage et entreposage.

N'utilisez pas de solvants ou de puissants détergents.

• Conservez ces instructions. Consultez-les souvent et utilisez-les

pour former d’autres utilisateurs. Si vous prêtez cet appareil à

d’autres personnes, remettez-leur également ces instructions.

le remplacement d’une pièce de l’appareil :

lamme nue (veilleuses, etc.) ou des

f

t graisse). Nettoyez l’appareil après chaque

ile e

CONSERVEZ CES

INSTRUCTIONS

22

Page 23

• SYMBOLES DE SÉCURITÉ ET INTERNATIONAUX •

Le présent manuel de l’opérateur décrit les symboles et pictogrammes de sécurité et internationaux, susceptibles d’apparaître sur ce

produit. Veuillez lire le manuel de l’opérateur pour connaître les informations complètes sur la sécurité, l’assemblage, l’utilisation, l’entretien

et la réparation.

SYMBOLE SIGNIFICATION SYMBOLE SIGNIFICATION

• SYMBOLE D’ALERTE DE SÉCURITÉ

Indique un danger, un avertissement ou une mise en

garde. Peut être utilisé conjointement avec d’autres

symboles ou pictogrammes.

• LISEZ LE MANUEL DE L’OPÉRATEUR

AVERTISSEMENT :

lire le(s) manuel(s) de l’opérateur et respecter tous les

avertissements et consignes de sécurité. Dans le cas

contraire, l’opérateur et/ou les passants peuvent subir

des blessures graves.

• PORTEZ DES PROTECTIONS AUDITIVES ET

OCULAIRES

veuillez

AVERTISSEMENT :la

projection d’objets et les bruits forts peuvent

provoquer des blessures oculaires graves et une perte

auditive. Portez une protection oculaire conforme aux

normes ANSI / ISEA Z87.1 en vigueur, ainsi qu’une

protection auditive pendant l’utilisation de cet appareil.

Utilisez un écran facial complet dès que nécessaire.

• ESSENCE SANS PLOMB

Utilisez toujours de l’essence sans plomb, propre et

neuve.

• HUILE

Consultez le manuel de l’opérateur pour connaître le

type d’huile à utiliser.

• N’UTILISEZ PAS UN CARBURANT E85 DANS CET

APPAREIL

AVERTISSEMENT :

prouvé qu’un carburant contenant plus de 10 %

d’éthanol est susceptible d’endommager ce moteur et

d’annuler la garantie.

il a été

• COMMANDE DE MARCHE/ARRÊT

ALLUMAGE / DÉMARRAGE / MARCHE

• COMMANDE DE MARCHE/ARRÊT

ARRÊT

• POIRE D’AMORÇAGE

Poussez complètement et lentement la poire

d’amorçage à 10 reprises.

• COMMANDE DE L’ÉTRANGLEUR

1. • Position d’étranglement MAXIMUM

2. • Position d’étranglement PARTIELLE

3. • Position d’étranglement MARCHE

• LES OBJETS PROJETÉS PEUVENT CAUSER DES

BLESSURES GRAVES

AVERTISSEMENT :

objets peuvent être propulsés à des vitesses élevées,

provoquant des blessures.

• ÉLOIGNEZ LES PASSANTS

AVERTISSEMENT :

tous les passants, en particulier les enfants et les

animaux domestiques, à 15 m (50 pieds) au moins de

la zone de coupe.

• SURFACE CHAUDE

AVERTISSEMENT :

touchez pas un pot d’échappement ou un cylindre

chaud. Vous pourriez vous brûler. Ces éléments

chauffent énormément lorsque l’appareil est en

marche. Ils restent chauds pendant un court instant

après l’arrêt.

• SOUFFLEUSES – LES PALES EN ROTATION

PEUVENT CAUSER DES BLESSURES GRAVES

les petits

éloignez

ne

23

AVERTISSEMENT :

l'appareil et laissez la pale s'arrêter avant de changer

de tubes, de nettoyer ou d'effectuer un entretien

quelconque. Gardez les mains et les pieds éloignés

des pièces mobiles.

Arrêtez

Page 24

APPRENEZ À CONNAÎTRE VOTRE APPAREIL

APPLICATIONS

• Nettoyer les cours, les garages, les entrées, les porches, les

terrasses, autour des murs, des clôtures, etc.

OUTILS REQUIS POUR L’ASSEMBLAGE

• Tournevis à tête plate

Interrupteur Marche/Arrêt

Régulateur de vitesse

Port de démarrage

électrique

Tube souffleur

Poignée

Tube inférieur

de l'aspirateur

Manette des gaz

Bougie

Poignée du câble

de démarreur

Tube coudé

de l'aspirateur

Baudrier

Tube supérieur

de l'aspirateur

Sangle

Levier d’étrangleur

Sac de

l'aspirateur

Bouchon du réservoir

de carburant

Fermeture

à glissière

Buse

Pot

d’échappement

Poire

d’amorçage

Couvercle

du filtre à air

CARACTÉRISTIQUES*

Type de moteur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refroidi par air, 2 tempse

Cylindrée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 cc (1,64 po. cube)

Écartement des électrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,635 mm (0,025 po.)

Bougie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion® RDJ7J ou équivalent

Lubrification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rapport carburant/huile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Capacité du réservoir de carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414 ml (14 oz.)

Poids approximatif de l’appareil (sans carburant) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,5 - 5,4 kg (10 - 12 livres)