Page 1

Operator’s Manual

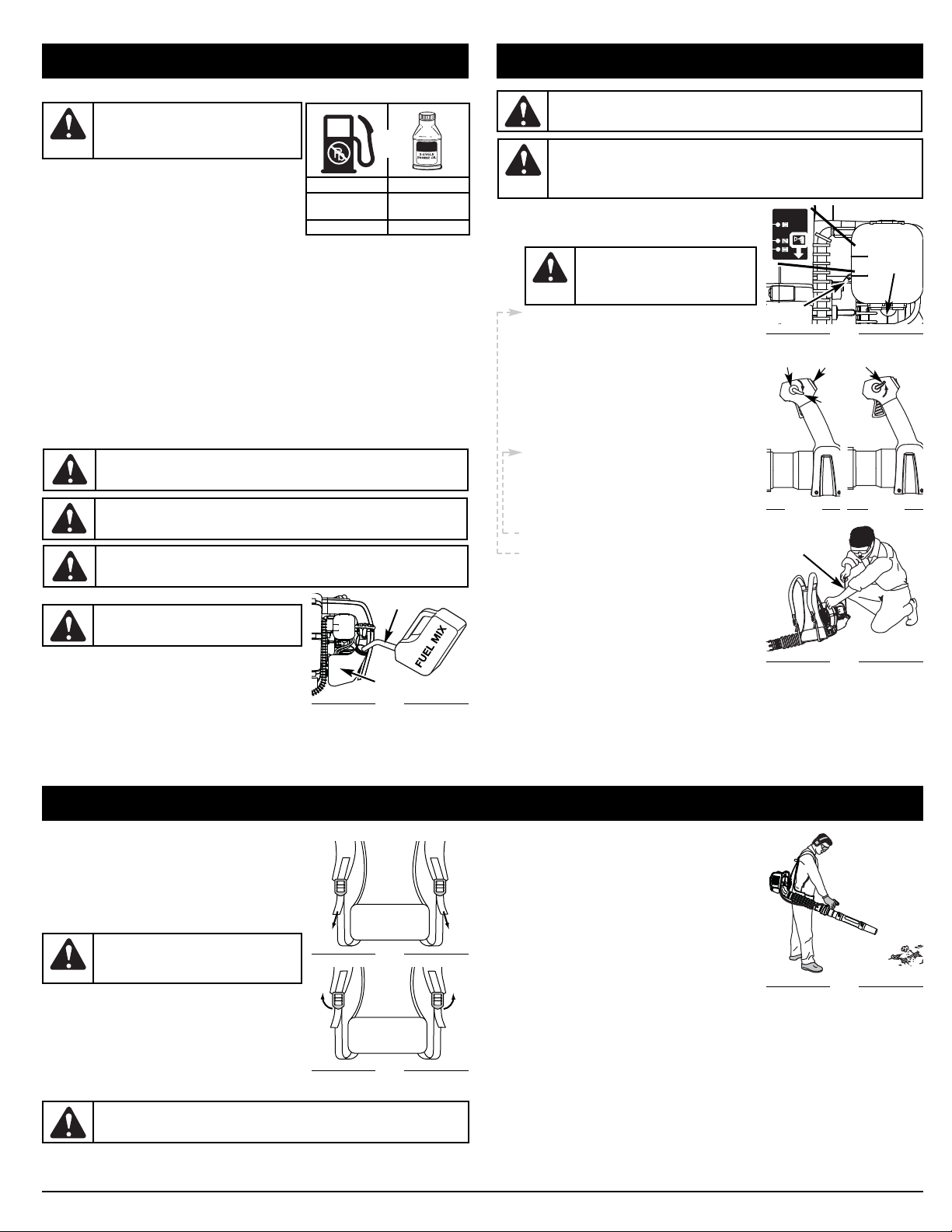

2-Cycle Backpack Blower

BP226

P/N 769-04595 P00 (01/09)

For service call 1-877-282-8684, or 1-800-668-1238 in Canada to

obtain a list of authorized service dealers near you. For more details

about your unit, visit our website at www.cubcadet.com or

www.cubcadet.ca.

DO NOT RETURN THE UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S. PATENTS.

OTHER PATENTS PENDING.

Service on this unit both within and after the warranty period should be

performed only by an authorized and approved service dealer.

Copy the serial number here:

Copy the model and parent part number here:

All information, illustrations, and specifications in this manual are based on

the latest product information available at the time of printing. We reserve

the right to make changes at any time without notice.

Copyright© 2009 MTD SOUTHWEST INC, All Rights Reserved.

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Oil and Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Starting/Stopping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . . . .7

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E12

SAVE THESE INSTRUCTIONS

Before beginning, locate the unit’s model plate. It lists the model and

serial numbers of your unit. Refer to the sample plate below and

copy the information for future reference.

In an effort to reduce the impact on the forests,

and reduce carbon and greenhouse gas

emissions, MTD is using less paper by reducing

the text size of this manual.

DO NOT RETURN

THIS PRODUCT

For Assistance please call 1-877-282-8684 (U.S.) or

1-800-668-1238 (Canada)

or visit www.cubcadet.com / www.cubcadet.ca

MODEL :

S/N :

ITEM :

Page 2

2

• Add fuel in a clean, well-ventilated area outdoors where there are

no sparks or flames. Slowly remove the fuel cap only after

stopping engine. Do not smoke while fueling. Wipe up any spilled

fuel from the unit immediately.

• Avoid creating a source of ignition for spilled fuel. Do not start

the engine until fuel vapors dissipate.

• Move the unit at least 30 feet (9.1 m) from the fueling source and site

before starting the engine. Do not smoke. Keep sparks and open

flames away from the area while adding fuel or operating the unit.

WHILE OPERATING

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Operate this unit only in a wellventilated outdoor area.

• Wear safety glasses or goggles that are marked as meeting ANSI

Z87.1–1989 standards and are marked as such. Wear ear/hearing

protection when operating this unit.

• Never run the unit without the the proper equipment attached.

• To reduce the risk of hearing loss associated with sound level(s),

always wear ear/hearing protection when operating this unit.

• Wear heavy long pants, boots, gloves, and a long sleeve shirt. Do

not wear loose clothing, jewelery, short pants, sandals or go

barefoot. Secure hair above shoulder level.

• To avoid static electricity shock, do not wear rubber gloves or

any other insulated gloves while operating this unit.

• Use the unit only in daylight or good artificial light.

• Keep outside surfaces free from oil and fuel.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a stable

position while starting. Refer to Starting/Stopping Instructions.

READ ALL INSTRUCTIONS BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit.

• Read this operating instruction manual carefully. Be thoroughly

familiar with the controls and the proper use of the equipment.

Know how to stop the unit and disengage the controls quickly.

• Do not operate this unit when tired, ill, or under the influence of

alcohol, drugs, or medication.

• Never allow children to operate the equipment. Never allow

adults unfamiliar with the instructions to use the unit. Never allow

adults to operate the equipment without proper instruction.

• All blower tubes must be installed properly before operating the

unit.

SPECIAL SAFETY WARNINGS FOR GAS ENGINES

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the fuel tank.

Never remove the cap of the fuel tank, or add fuel, when the engine

is hot. Never operate the unit without the fuel cap securely in place.

Loosen the fuel tank cap slowly to relieve any pressure in the tank.

• IMPORTANT SAFETY INSTRUCTIONS •

Read the Operator’s Manual and follow all warnings and safety instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

FOR QUESTIONS, CALL 1-877-282-8684 IN U.S. OR 1-800-668-1238 in CANADA

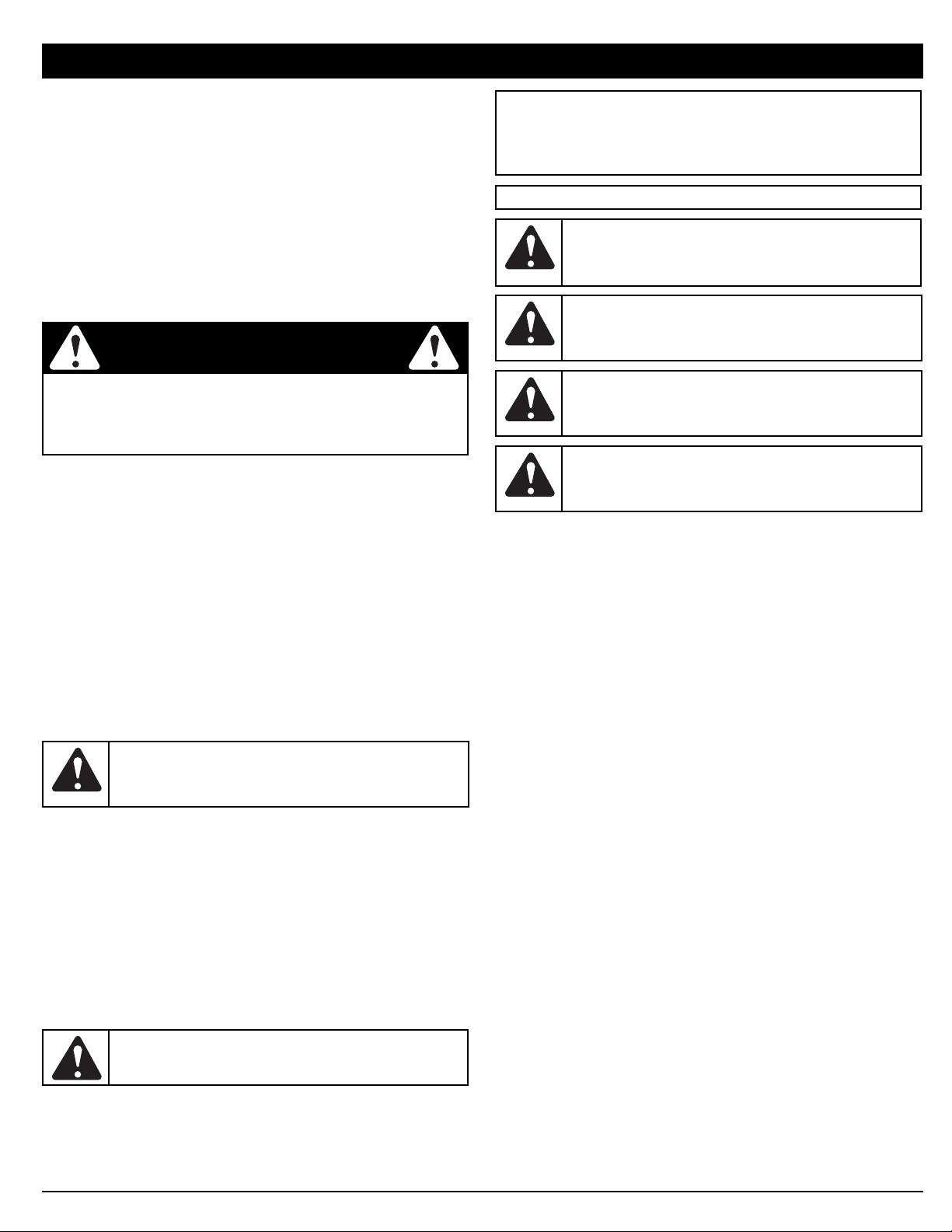

The purpose of safety symbols is to attract your attention to possible

dangers. The safety symbols, and their explanations, deserve your

careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they

give are not substitutes for proper accident prevention measures.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

SAFETY ALERT:

Indicates danger, warning or

caution. Attention is required in order to avoid serious

personal injury. May be used in conjunction with other

symbols or pictographs.

DANGER:

Failure to obey a safety warning will result

in serious injury to yourself or to others. Always follow

the safety precautions to reduce the risk of fire, electric

shock and personal injury.

WARNING:

Failure to obey a safety warning can

result in injury to yourself and others. Always follow the

safety precautions to reduce the risk of fire, electric

shock and personal injury.

CAUTION:

Failure to obey a safety warning may

result in property damage or personal injury to yourself

or to others. Always follow the safety precautions to

reduce the risk of fire, electric shock and personal injury.

RULES FOR SAFE OPERATION

SYMBOL MEANING

WARNING:

When using the unit, you must follow the

safety rules. Please read these instructions before operating

the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

WARNING:

Gasoline is highly flammable, and its

vapors can explode if ignited. Take the following

precautions:

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest Land

and the state of California (Public Resources Codes 4442 and

4443), Oregon and Washington require, by law that certain internal

combustion engines operated on forest brush and/or grass-covered

areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped and

maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure

to follow these requirements could subject you to liability or a fine.

This unit is factory equipped with a spark arrestor. If it requires

replacement, ask your LOCAL SERVICE DEALER to install the

Accessory Part #753-05945 Muffler Assembly.

CALIFORNIA PROPOSITION 65 WARNING

WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT CONTAINS

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO

CAUSE CANCER, BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM.

Page 3

3

RULES FOR SAFE OPERATION

• Do not set unit on any surface except a clean, hard area while

engine is running. Debris such as gravel, sand, dust, grass, etc.

could be picked up by the air intake and thrown out by the

discharge opening, damaging unit, property, or causing serious

injury to bystanders or operator.

• Use the right tool. Only use this tool for its intended purpose.

• Do not force unit. It will do the job better and with less likelihood

of injury at a rate for which it was designed.

• Do not overreach or use from unstable surfaces such as ladders,

trees, steep slopes, rooftops, etc. Always keep proper footing

and balance.

• Always hold the unit with a firm grip when operating.

• Keep hands, face, and feet away from all moving parts. Do not

touch or try to stop the impeller when it is rotating. Do not

operate without guards in place.

• Do not put any object into openings. Do not use with any

opening blocked; keep free of dirt, debris, and anything that may

reduce the air flow.

• Do not touch the engine or muffler. These parts get extremely

hot from operation, even after the unit is turned off.

• Do not operate the engine faster than the speed needed to do

the job. Do not run the engine at high speed when not in use.

• Always stop the engine when operation is delayed or when

walking from one location to another.

• Stop the engine for maintenance, repair, to install or remove the

blower tubes. The unit must be stopped and the impeller no

longer turning to avoid contact with the rotating blades.

• If you strike or come into contact with a foreign object, stop the

engine immediately and check for damage. Do not operate

before repairing damage. Do not operate the unit with loose or

damaged parts.

• Use only replacement parts recommended for this tool that are

sold by a Cub Cadet outlet. Use of any replacement parts

purchased elsewhere may be hazardous, and will also void your

warranty.

• Never use this unit for spreading chemicals, fertilizers or other

substances which may contain toxic materials.

• To reduce fire hazard, replace faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

grease or carbon build up.

• Turn the engine off and disconnect the spark plug for

maintenance or repair.

• Never point the blower or blowing debris in the direction of

people, animals, or in the direction of windows. Always direct the

blowing debris away from people, animals, and windows. Use

extra caution when blowing debris near solid objects such as

trees, automobiles, walls, etc.

OTHER SAFETY WARNINGS

• Always disconnect the spark plug before performing

maintenance or accessing movable parts. See Replacing the

Spark Plug.

• Never store the unit, with fuel in the tank, inside a building where

fumes may reach an open flame (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

• Allow the engine to cool before storing or transporting. Be sure

to secure the unit while transporting.

• Store the unit in a dry place, secured, or at a height to prevent

unauthorized use or damage. Keep out of the reach of children.

• Never douse or squirt the unit with water or any other liquid.

Keep handles dry, clean, and free from debris. Clean after each

use, see Cleaning and Storage instructions.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

these instructions to them.

SPECIAL NOTE: Exposure to vibrations through prolonged use of

gasoline powered hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of people prone to

circulation disorders or abnormal swelling. Prolonged use in cold

weather has been linked to blood vessel damage in otherwise

healthy people. If symptoms occur such as numbness, pain, loss

of strength, change in skin color or texture, or loss of feeling in the

fingers, hands or joints, discontinue use of this tool and seek

medical attention. A reduced vibration system does not guarantee

avoidance of these problems. Users who operate power tools on a

regular basis must closely monitor their physical condition and the

condition of this tool.

SAVE THESE INSTRUCTIONS

Page 4

4

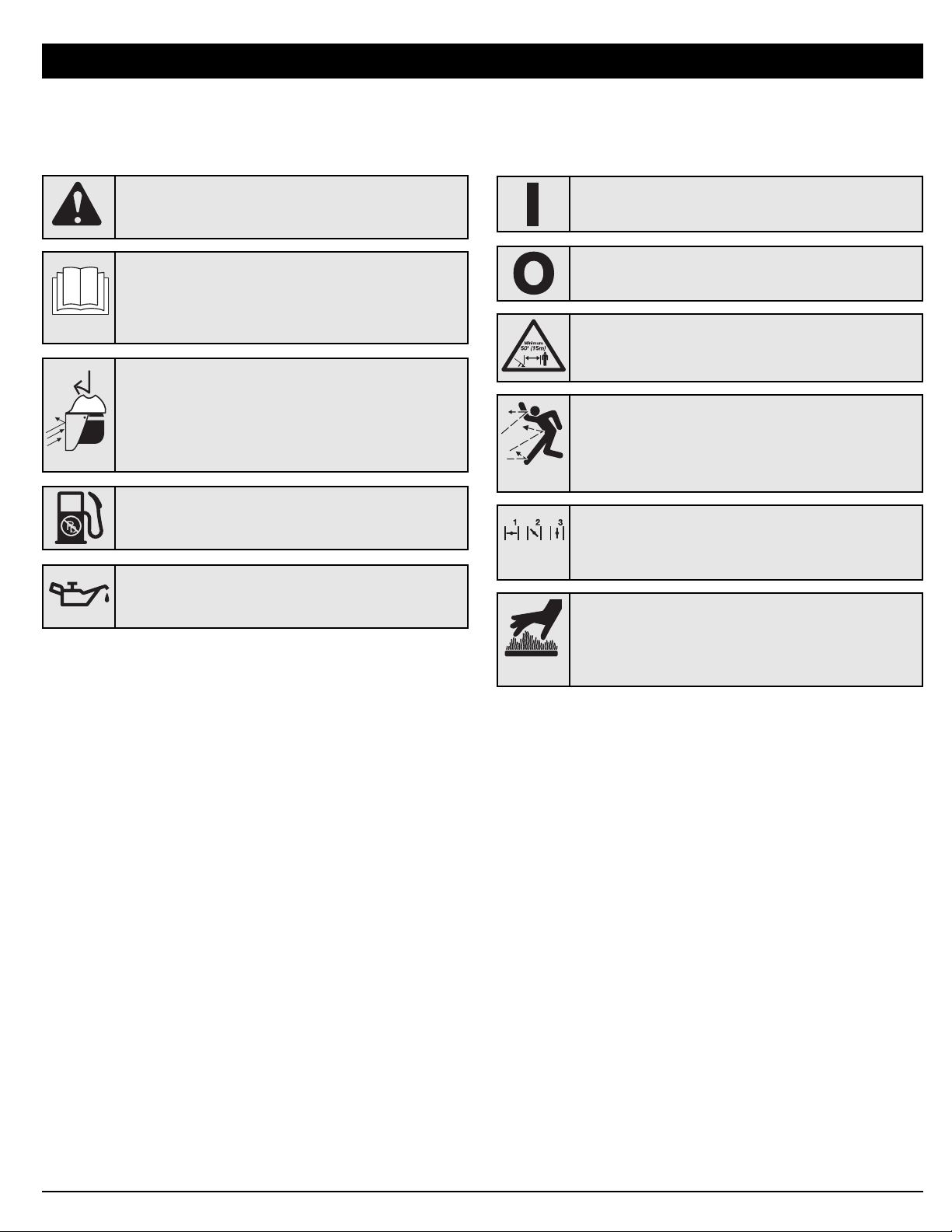

• SAFETY AND INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating, maintenance,` and repair information.

RULES FOR SAFE OPERATION

• READ OPERATOR'S MANUAL

WARNING: Read the operator’s manual(s) and

follow all warnings and safety instructions. Failure to

do so can result in serious injury to the operator

and/or bystanders.

• KEEP BYSTANDERS AWAY

WARNING:

Keep all bystanders, especially children

and pets, at least 50 feet (15 m.) from the operating area.

SYMBOL MEANING

• THROWN OBJECTS CAN CAUSE SEVERE INJURY

WARNING: Keep clear of blower outlet. Never

point the blower at yourself or others. Objects can

be thrown from blower. Do not operate unit without

proper attachments and guards in place.

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

SYMBOL MEANING

• WEAR EYE AND HEARING PROTECTION

WARNING: Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear eye

protection meeting ANSI Z87.1–1989 standards and

ear protection when operating this unit. Use a full

face shield when needed.

•OIL

Refer to operator’s manual for the proper type of oil.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel.

• ON/OFF STOP CONTROL

OFF or STOP

• ON/OFF STOP CONTROL

ON / START / RUN

• HOT SURFACE

WARNING: Do not touch a hot surface. You may

get burned. These parts get extremely hot from

operation. They remain hot for a short time after the

unit is turned off.

• CHOKE CONTROL

1. • FULL choke position

2. • PARTIAL choke position

3. • RUN choke position

Page 5

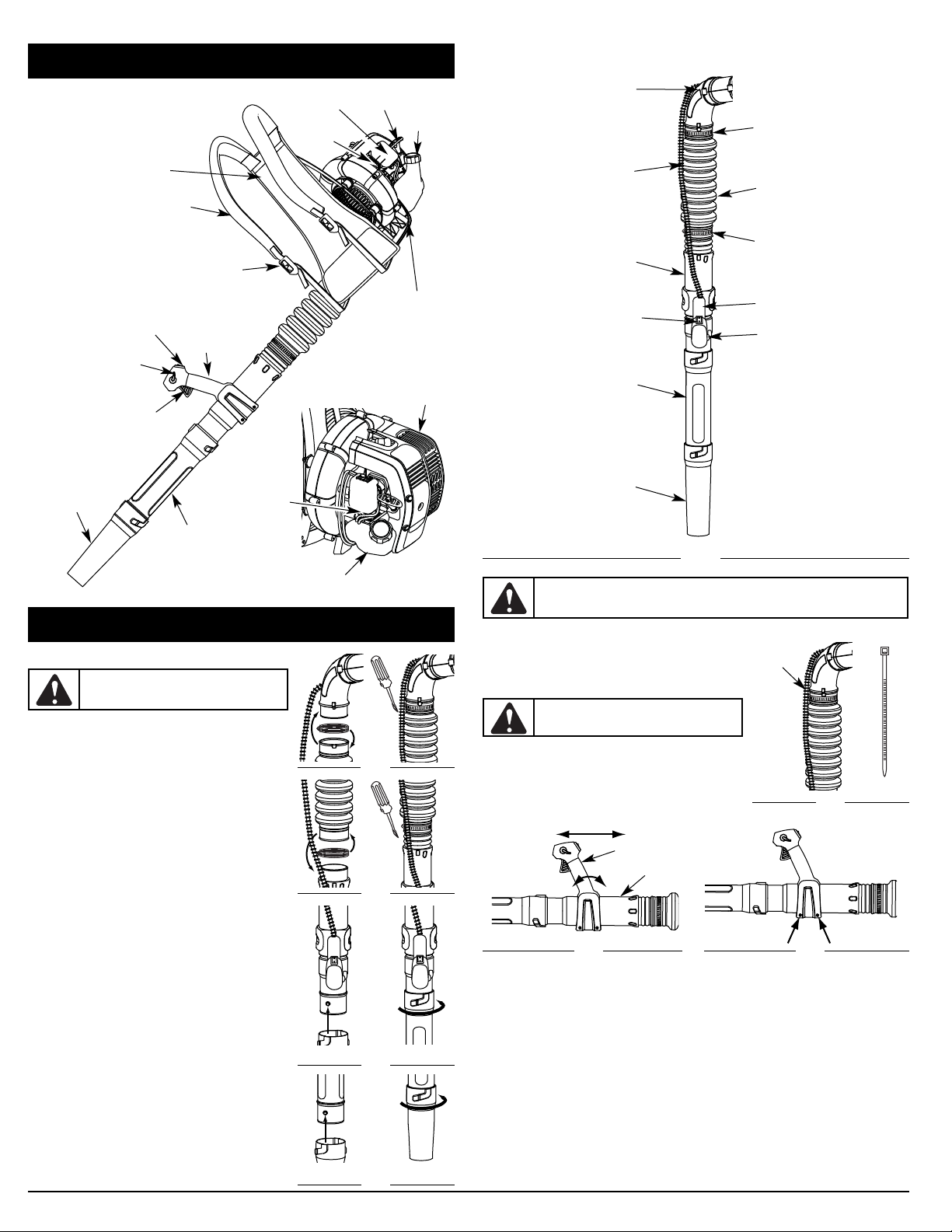

5

Stand

On/Off Switch

Starter Rope

Handle

Muffler

Air Filter Cover

KNOW YOUR UNIT

Primer Bulb

Suspension System

Fuel Tank

Choke Lever

Fuel

Cap

Trigger

Blower Tube

Shoulder Support Buckle

Cruise Control

Nozzle

ASSEMBLY INSTRUCTIONS

ASSEMBLING THE BLOWER TUBE

Installing the Flex Tube

1. Place a hose clamp over the end of the Flex Tube (Fig. 1, A).

2. Slide the end of the Flex Tube with the clamp on it over the

elbow tube (Fig. 1, B).

3. Tighten the screw on the hose clamp to secure the Flex Tube

to the elbow tube (Fig. 1, C).

Installing the Upper Blower Tube

1. Place a hose clamp over the other end of the Flex Tube (Fig.

2, A).

2. Slide the end of the hose with the clamp on it over the top

end of the upper blower tube (Fig. 2, B).

3. Tighten the screw on the hose clamp to secure the Flex Tube

to the upper blower tube (Fig. 2, C).

Installing the Lower Blower Tubes and Nozzle

1. Align the bump slot on the end of the first lower blower tube

with the bump on the bottom end of the upper blower tube

(Fig. 3, A).

2. Insert the bump on the upper blower tube into the bump slot

on the tube extension (Fig. 3, A).

3. Twist the extension tube clockwise around the upper blower

tube until the handle tube bump locks into place (Fig. 3, B).

4. Align the bump slot on the top end of the nozzle with the

bump on the bottom end of the second lower blower tube

(Fig. 4, A).

5. Insert the bump on the second lower blower tube into the

bump slot on the nozzle (Fig. 4, A).

6. Twist the nozzle clockwise around the second lower blower

tube until the nozzle bump locks into place (Fig. 4, B).

Fig. 1

B

A

C

Fig. 2

B

A

C

WARNING:

To avoid serious personal injury

and damage to the unit, shut the unit off before

removing or installing the blower tubes.

A

B

Fig. 3

Shoulder Support

Fig. 5

Adjusting the Throttle Grip

1. Move the throttle grip to a location on the upper blower

tube that is comfortable for you (Fig. 7).

2. Using a Torx T-20 Torx screwdriver, tighten the two screws

at the bottom of the throttle grip (Fig. 8).

Flex Tube

Hose Clamp

Elbow Tube

Upper Blower Tube

Lower Blower Tube

Nozzle

Throttle Cables

Hose Clamp

Cruise Control

Throttle Grip

Fig. 7

A

Fig. 8

Throttle Grip

Fig. 4

B

A

Secure the Throttle Cables

Place a zip tie around the elbow tube and the throttle cables

(Fig. 6) as shown, making sure not to crimp the cables.

The completed blower tube should look like Figure 5.

Fig. 6

Zip Tie

Zip Tie

WARNING:

Do not rotate the handle clockwise

to adjust. This may cause the throttle cables to

disconnect from the throttle grip or the engine.

WARNING:

To avoid serious personal injury, make sure that all four parts of the

blower tube are locked in place or firmly installed.

Throttle Grip

Upper Blower Tube

On/Off Switch

Page 6

Using the Cruise Control

1. Once the engine has started and warmed up, squeeze the trigger

to accelerate the unit as needed (Fig. 11A).

2. For longer periods of operation and to eliminate possible finger fatique, move the cruise control

toward the fast position to incrementally increase or maintain the unit’s engine speed (Fig. 11A).

When the cruise control is pressed, the trigger will recede into the handle.

3. To decrease engine speed, move the cruise control to the idle position and the trigger will return to

idle position (Fig. 11B).

6

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons for the unit

not running properly. Be sure to use fresh, clean unleaded fuel.

Follow the instructions carefully for the proper fuel/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such

as ethanol, methanol, or MTBE (ether). Alcohol-blended fuel

absorbs water. As little as 1% water in the fuel can make fuel

and oil separate. It forms acids when stored. When using

alcohol-blended fuel, use fresh fuel (less than 60 days old).

Using Blended Fuels

If you choose to use a blended fuel, or its use is unavoidable, follow recommended precautions:

• Always use the fresh fuel mix explained in your operator's manual

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

The bottle of 2-cycle oil that came with your unit contains a fuel additive which will help inhibit corrosion

and minimize the formation of gum deposits. It is recommended that you use our 2-cycle oil with this

unit. If unavailable, use a good 2-cycle oil designed for air-cooled engines along with a fuel additive,

such as STA-BIL® Gas Stabilizer or an equivalent. Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel

according to the instructions on the container. NEVER add fuel additives directly to the unit's fuel tank.

Thoroughly mix the proper ratio of 2-cycle engine oil with unleaded gasoline in a separate fuel can. Use a

40:1 fuel/oil ratio. Do not mix them directly in the engine fuel tank. See the table below for specific gas

and oil mixing ratios.

NOTE: One gallon (3.8 liters) of unleaded gasoline mixed with one 3.2 oz. (95 ml.) bottle of 2-cycle oil

makes a 40:1 fuel/oil ratio.

NOTE: Dispose of the old fuel/oil mix in accordance to Federal, State and Local regulations.

FUELING THE UNIT

1. Remove the fuel cap.

2. Place the gas container’s spout into the fill hole on the fuel

tank (Fig. 9) and fill the tank.

NOTE: Do not overfill the tank.

3. Wipe up any fuel that may have spilled.

4. Reinstall the fuel cap.

5. Move the unit at least 30 ft. (9.1 m) from the fueling source and site before starting the engine.

NOTE: Dispose of the old fuel mixture in accordance to Federal, State and Local regulations.

OIL AND FUEL INFORMATION

Fig. 9

WARNING:

Remove fuel cap slowly to avoid

injury from fuel spray. Never operate the unit

without the fuel cap securely in place.

STARTING INSTRUCTIONS

STARTING/STOPPING INSTRUCTIONS

1. Mix gas with oil. Fill fuel tank with fuel/oil mixture.

See Oil and Fuel Mixing Instructions.

2. Fully press and release the primer bulb 10 times,

slowly. Some amount of fuel should be visible in the

primer bulb and fuel lines (Fig. 10). If you can’t see

fuel in the bulb, press and release the bulb as many

times as it takes until you can see fuel in it.

3. Place the red choke lever in Position 1 (Fig. 10).

4. Press down the cruise control to lock the trigger in

the run position (Fig. 11A).

5. Crouch in the starting position (Fig. 12) and pull the

starter rope 5 times in a smooth and rapid motion.

6. Place the red choke lever in Position 2 (Fig. 10).

7. Pull the starter rope in a smooth and rapid motion

until the engine starts.

8. Allow the engine to warm up for 30 to 60 seconds.

NOTE: Engine may take longer to warm up and reach

maximum operating speed at colder temperatures.

NOTE: Unit is properly warmed up when engine

accelerates without hesitation.

9. Once the engine is warmed up, place the red choke

lever in Position 3 (Fig. 10).

10. Raise the cruise control to return the trigger to the

idle position (Fig. 11B). The unit is ready for use.

IF... the engine hesitates, return the red choke lever to

Position 2 (Fig. 11) and continue warm-up.

IF... the engine does not start, go back to step 2.

IF... the engine fails to start after a few attempts, place

the red choke lever in Position 3 (Fig. 10) and press

down the cruise control. Pull the starter rope briskly 3

to 8 times. The engine should start. If not, repeat.

IF WARM... If the engine is already warm, start the unit

with the red choke lever in Position 2 (Fig. 10). After

the unit starts, move the red choke lever to Position

3 (Fig. 10) and raise the cruise control.

WARNING:

Avoid accidental starting. Make sure you are in the starting position when

pulling the starter rope (Fig. 12). To avoid serious injury, the operator and unit must be

in a stable position while starting.

To avoid serious personal injury, make sure that the blower tube is locked in place or

firmly installed.

WARNING:

Operate this unit only in a well-ventilated outdoor area. Carbon monoxide

exhaust fumes can be lethal in a confined area.

Fig. 10

Primer

Bulb

Choke

Lever

Fig. 12

Starter Rope

OPERATING INSTRUCTIONS

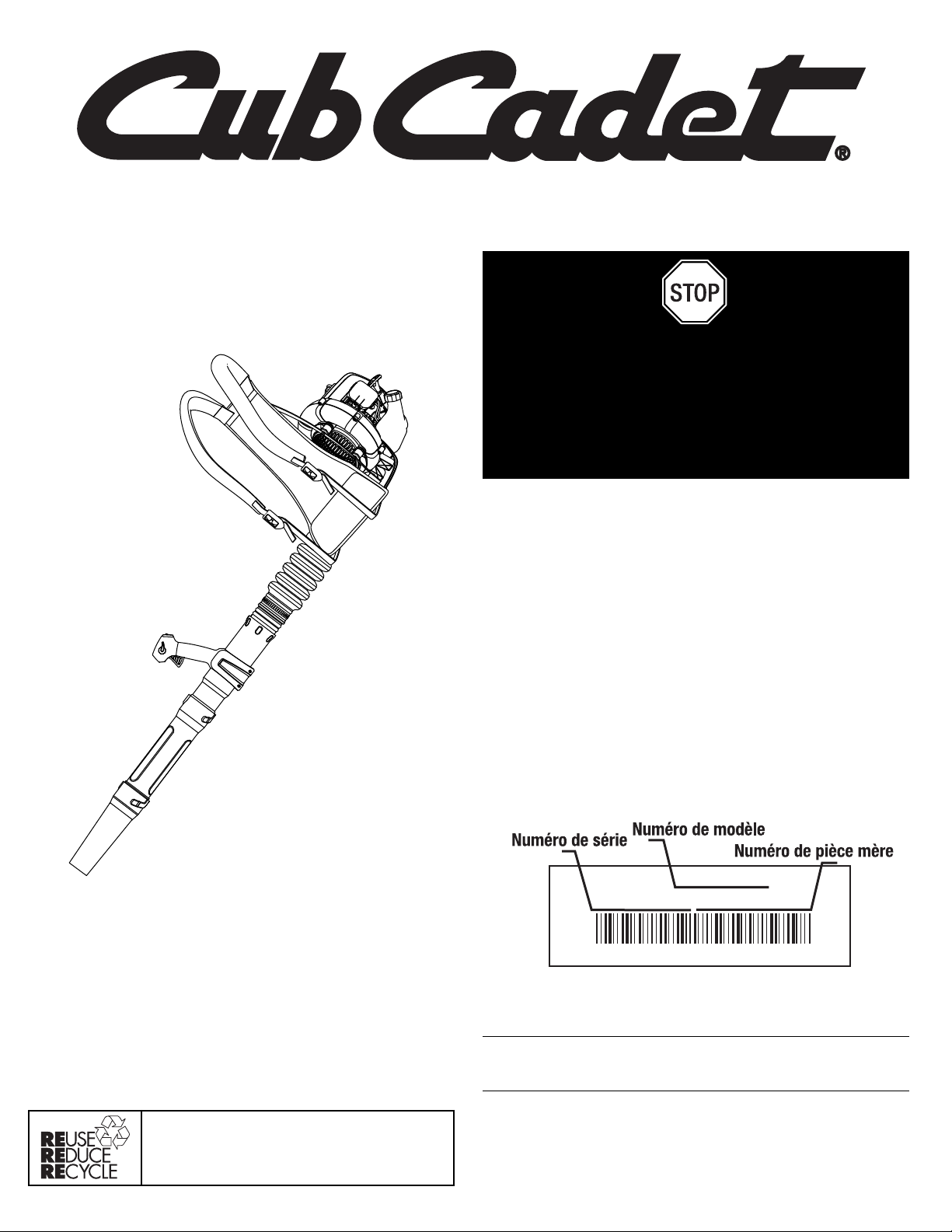

ADJUSTING THE SUSPENSION SYSTEM

1. Place the unit’s shoulder supports over the shoulders while

the unit is behind you.

2. Pull the shoulder support handles to tighten the shoulder

supports (Fig. 13).

Releasing the Suspension System

1. To release the shoulder supports, pull up on bottom tab of

the shoulder support buckles (Fig. 14).

HOLDING THE BLOWER

Before operating the unit, stand in the operating position (Fig. 15).

Check for the following:

• Operator is wearing proper clothing, such as boots, safety

glasses or goggles, ear/hearing protection, gloves, long pants

and long sleeve shirt.

• If the conditions are dusty, the operator is wearing a dust

mask or face mask.

• The unit is in good working condition.

• The tubes are in place and secure.

OPERATING TIPS

• Assure the unit is not directed at anybody or any loose debris before starting the unit.

• Verify that the unit is in good working condition. Make sure the tubes are in place and secure.

• Always hold the unit securely when operating.

WARNING:

To avoid serious personal injury,

wear goggles or safety glasses at all times when

operating this unit. Wear a face mask or dust

mask in dusty locations.

Fuel Can Spout

Fuel Tank

• To reduce the risk of hearing loss associated with sound

level(s), hearing protection is required.

• Operate power equipment only at reasonable hours— not

early in the morning or late at night when people might be

disturbed. Comply with times listed in local ordinances. Usual

recommendations are 9:00 am to 5:00 pm, Monday through

Saturday.

• To reduce noise levels, limit the number of pieces of

equipment used at any one time.

• To reduce noise levels, operate power blowers at the lowest

possible speed to do the job.

• Check your equipment before operation, especially the

muffler, air intakes and air filters.

• Use rakes and brooms to loosen debris before blowing.

• In dusty conditions, slightly dampen surfaces or use a mister

attachment when water is available.

• Conserve water by using power blowers instead of hoses for many lawn and garden applications,

including areas such as screens, patios, grills, porches, and gardens.

• Watch out for children, pets, open windows or freshly washed cars, and blow debris safely away.

• Use the full blower nozzle extension so the air stream can work close to the ground.

• Clean up after using blowers and other equipment. Dispose of debris appropriately.

• Use the cruise control (Fig. 11, A) to keep the trigger depressed while operating to make continuous

operation easier.

APPLICATIONS

1 Use the blower for trees, shrubs, flower beds and hard-to-clean areas.

2. Use the unit around buildings and for other normal cleaning procedures.

3. Use the blower around walls, overhangs, fences and screens.

WARNING:

To prevent serious personal injury or damage to the unit, make sure

blower tubes are in place before you operate the unit.

Fig. 15

CAUTION:

For proper engine operation and

maximum reliability, pay strict attention to the oil

and fuel mixing instructions on the 2-cycle oil

container. Using improperly mixed fuel can

severely damage the engine.

Fig. 13

Fig. 14

Trigger

in Run

Position

Fig. 11A

On/Off

Switch

Fig. 11B

Cruise

Control

Trigger

in Idle

Position

SLOW

FAST

STOPPING INSTRUCTIONS

1. Release your hand from the trigger or raise the cruise control. Allow the engine to cool down by idling.

2. Press the On/Off Switch in the OFF (O) position and hold until the engine comes to a complete stop

(Fig. 11A).

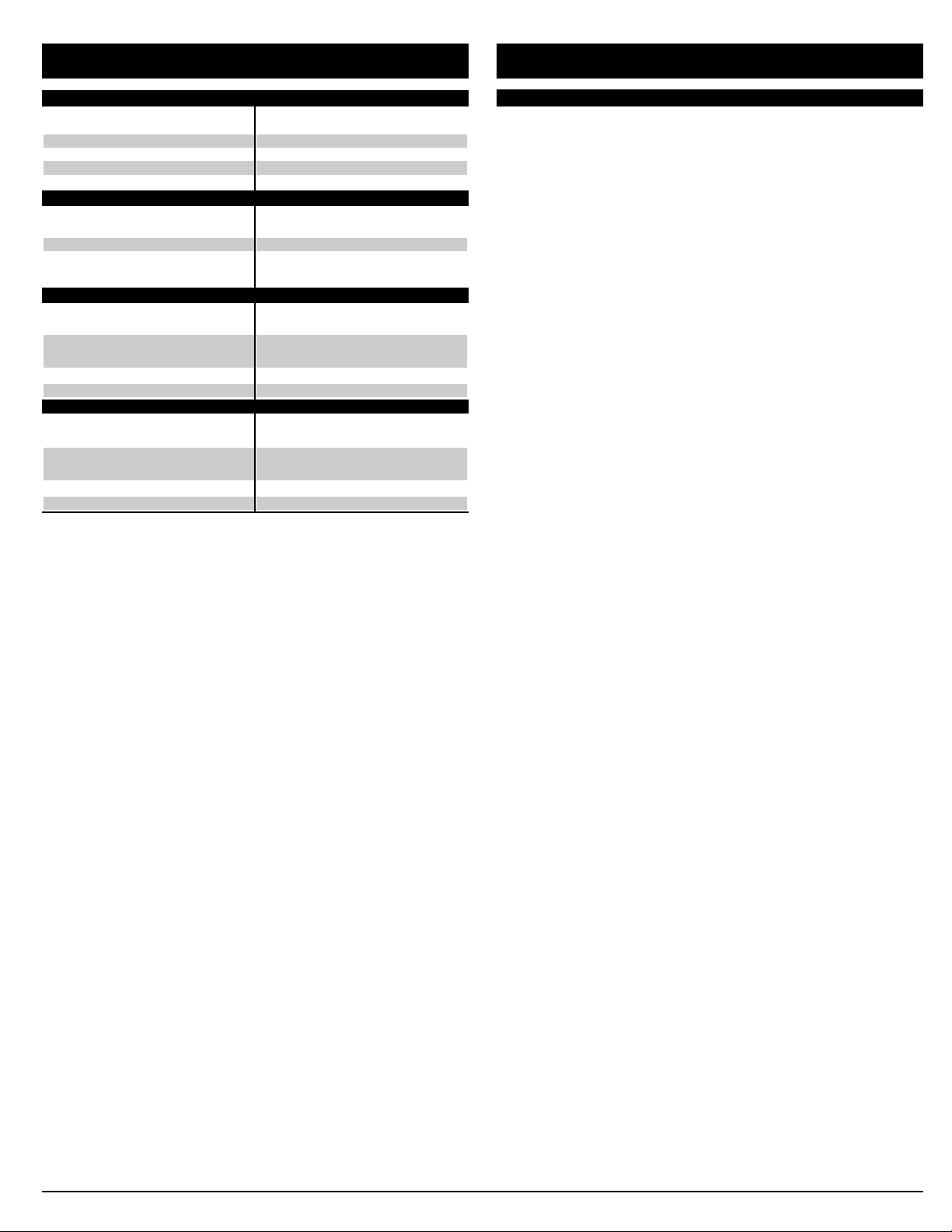

MIXING RATIO - 40:1

UNLEADED GAS* 2 CYCLE OIL

1 GALLON U.S.

(3.8 LITERS)

3.2 FL. OZ.

(95 ml)

1 LITER 25 ml

+

WARNING:

Gasoline is extremely flammable. Ignited vapors may explode. Always

stop the engine and allow it to cool before filling the fuel tank. Do not smoke while filling

the tank. Keep sparks and open flames at a distance from the area.

WARNING:

Add fuel in a clean, well ventilated outdoor area. Wipe up any spilled fuel

immediately. Avoid creating a source of ignition for spilt fuel. Do not start the engine

until fuel vapors dissipate.

*

WARNING: DO NOT USE E85 FUEL IN THIS UNIT. It has been proven that fuel

containing greater than 15% ethanol will likely damage this engine and void the warranty.

WARNING:

DO NOT USE E85 FUEL

IN THIS UNIT. It has been proven that

fuel containing greater than 15% ethanol

will likely damage this engine and void

the warranty.

3

2

1

Page 7

7

MAINTENANCE AND REPAIR INSTRUCTIONS

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Clean and re-oil the air filter every 25 hours of operation. It is an important item to maintain. Failure to maintain

your air filter properly can result in poor performance or can cause permanent damage to your engine.

1. Open the air filter cover. Push the locking tab on the top of the cover inward, then pull the air filter

cover out and down. (Fig. 16).

2. Remove the air filter (Fig. 17).

3. Wash the filter in detergent and water (Fig. 18). Rinse the filter thoroughly and allow it to dry.

4. Apply enough clean SAE 30 motor oil to lightly coat the filter (Fig. 19).

5. Squeeze the filter to spread and remove excess oil (Fig. 20).

6. Replace the filter (Fig. 17).

NOTE: If the unit is operated without the air filter, you will VOID the warranty.

7. Reinstall the air filter cover. Position the slots on the bottom of the air filter cover onto the tabs at

the bottom of the back plate (Figs. 17).

8. Swing the cover up until the tab on the air filter backplate snaps into place in the slot on the air filter

cover (Fig. 21).

CARBURETOR ADJUSTMENT

The idle speed of the engine is adjustable. An idle adjustment

screw is between the air filter cover and the engine starter

housing (Fig. 22).

NOTE: Careless adjustments can seriously damage your unit. An

authorized service dealer should make carburetor

adjustments.

Check Fuel

Old and/or improperly mixed fuel is usually the reason for improper

unit performance. Drain and refill the tank with fresh, properly-mixed

fuel prior to making any adjustments. Refer to Oil and Fuel Information.

Clean Air Filter

The condition of the air filter is important to the operation of the unit.

A dirty air filter will restrict air flow. This is often mistaken for an out of adjustment carburetor. Check the

condition of the air filter before adjusting the idle speed screw. Refer to Air Filter Maintenance.

FREQUENCY MAINTENANCE REQUIRED SEE

Before using Fill fuel tank with fresh fuel* p 6

Every 25 hrs

Clean and re-oil air filter

Check spark plug condition and gap

p 7

p 7

Every 125 hrs Clean spark arrestor p 7

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These procedures

should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. If you are unsure about these

procedures take your unit to a Cub Cadet or other qualified service dealer.

NOTE: Maintenance, replacement, or repair of the emission control devices and system may be

performed by a Cub Cadet or other qualified service dealer.

In order to assure peak performance of your engine, inspection of the engine exhaust port may be

necessary after 125 hours of operation. If you notice lost RPM, poor performance or general lack of

acceleration, this service may be required. If you feel your engine is in need of this inspection, refer service

to a Cub Cadet or other qualified service dealer for repair. DO NOT attempt to perform this process

yourself as engine damage may result from contaminants involved in the cleaning process for the port.

WARNING:

To prevent serious injury, never perform maintenance or repairs with unit

running. Always service and repair a cool unit. Disconnect the spark plug wire to ensure

that the unit cannot start. See Replacing the Spark Plug.

Fig. 17

Air Filter

Back

Plate

Tab s

Locking Tab

Fig. 16

Locking Tab

Air Filter

Cover

Fig. 18

Fig. 19

Fig. 21

Locking Tab

Air Filter

Cover

Fig. 20

Fig. 22

Idle Adjustment

Screw

Adjust Idle Speed Screw

If, after checking the fuel and cleaning the air filter, the engine still will not idle, adjust the idle speed

screw as follows:

1. Start the engine and let it run at a high idle for a minute to warm up. Refer to Starting/Stopping

Instructions.

2. Release the throttle trigger and let the engine idle. If the engine stops, insert a small phillips in

between the Air Filter Cover and the Engine Cover (Fig. 22). Turn the idle speed screw in, clockwise,

1/8 of a turn at a time (as needed) until the engine idles smoothly.

Checking the fuel mixture, cleaning the air filter, and adjusting the idle speed should solve most engine

problems. If not and all of the following are true:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

Have the carburetor adjusted by an authorized service dealer.

REPLACING THE SPARK PLUG

Use a Champion #RDZ4H or a replacement part number 75305784 spark plug. The correct air gap is 0.025 in. (0.635 mm).

Remove the plug after every 25 hours of operation and check its

condition.

1. Stop the engine and allow it to cool.

2. Grasp the plug wire firmly and pull the cap from the spark plug.

3. Clean dirt from around the spark plug. Remove the spark

plug from the cylinder head by turning a 5/8 in. socket

counterclockwise.

4. Replace cracked, fouled or dirty spark plug. Set the air gap at

0.025 in. (0.635 mm) using a feeler gauge (Fig. 23).

5. Install a correctly-gapped spark plug in the cylinder head.

Turn the 5/8 in. socket clockwise until snug.

If using a torque wrench torque to:

110-120 in.•lb. (12.3-13.5 N•m)

Do not over tighten.

SPARK ARRESTOR MAINTENANCE

Inspect the spark arrestor after every 125 hours of operation.

1. Stop the engine and allow it to cool. Remove the four (4)

screws on the back of the engine cover with a flat-head

screwdriver or T-25 Torx bit (Fig. 24).

2. With a

Phillips

screwdriver, remove the screws attaching the

spark arrestor cover to the muffler (Fig. 25).

3. Remove the spark arrestor cover.

4. Remove the spark arrestor screen from the spark arrestor

cover (Fig. 25).

5. Clean the spark arrestor screen with a wire brush or replace it.

6. Reinstall the spark arrestor screen, spark arrestor cover and screws.

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong detergents. Household cleaners

that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can damage plastic

housing or handle. Wipe off any moisture with a soft cloth.

STORAGE

• Never store the unit with fuel in the tank where fumes may reach an open flame or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

LONG TERM STORAGE

If you plan on storing the unit for an extended time, use the following storage procedure:

1. Drain all fuel from the fuel tank into a container with the same 2-cycle fuel mixture. Do not use fuel

that has been stored for more than 60 days. Dispose of the old fuel/oil mix in accordance to Federal,

State and Local regulations.

2. Start the engine and allow it to run until it stalls. This ensures that all fuel has been drained from the

carburetor.

3. Allow the engine to cool. Remove the spark plug and put 1 oz. (30 ml) of any high quality motor oil

or 2-cycle oil into the cylinder. Pull the starter rope slowly to distribute the oil. Reinstall the spark

plug.

NOTE: Remove the spark plug and drain all of the oil from the cylinder before attempting to start the

trimmer after storage.

4. Thoroughly clean the unit and inspect it for any loose or damaged parts. Repair or replace damaged

parts and tighten loose screws, nuts or bolts. The unit is ready for storage.

TRANSPORTING

• Allow the engine to cool before transporting

• Drain fuel from unit

• Tighten fuel cap before transporting

• Secure the unit while transporting

Fig. 24

T- 25

Screws

T- 25

Screws

Fig. 23

0.025 in.

(0.635 mm)

WARNING:

Do not sand blast, scrape or

clean electrodes. Grit in the engine could

damage the cylinder.

*

DO NOT use E85 fuel in this unit. It has been proven that fuel containing greater than

15% ethanol will likely damage this engine and void the warranty.

Fig. 25

Muffler

Spark Arrestor

Screen

Spark Arrestor

Cover

Philips Head

Screws

WARNING:

To avoid serious personal injury,

always turn your unit off and allow it to cool

before you clean or service it.

Page 8

8

TROUBLESHOOTING

If further assistance is required, contact your authorized service dealer.

CAUSE ACTION

Air filter is plugged Replace or clean the air filter

Old or improperly mixed fuel Drain fuel tank and add fresh fuel mixture

Improper carburetor adjustment Adjust according to the Carburetor Adjustments

section or take to an authorized service dealer

for an adjustment

CAUSE ACTION

Empty fuel tank Fill fuel tank with properly mixed fuel

Primer bulb wasn't pressed enough Press primer bulb fully and slowly 10 times

Old or improperly mixed fuel Drain fuel tank and add fresh fuel mixture

Fouled spark plug Replace or clean the spark plug

Plugged spark arrestor Clean or replace spark arrestor

CAUSE ACTION

Old or improperly mixed fuel Drain fuel tank and add fresh fuel mixture

Improper carburetor adjustment Adjust according to the Carburetor Adjustments

section or take to an authorized service dealer

for an adjustment

Fouled spark plug Replace or clean the spark plug

Plugged spark arrestor Clean or replace spark arrestor

CAUSE ACTION

Old or improperly mixed fuel Drain fuel tank and add fresh fuel mixture

Improper carburetor adjustment Adjust according to the Carburetor Adjustments

section or take to an authorized service dealer

for an adjustment

Dirty air filter Clean or replace the air filter

Plugged spark arrestor Clean or replace spark arrestor

ENGINE WILL NOT START

ENGINE WILL NOT IDLE

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STALLS

SPECIFICATIONS

* All specifications are based on the latest product information available at the time of printing. We

reserve the right to make changes at any time without notice.

ENGINE*

Engine Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 2-Cycle

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 cc

Idle Speed RPM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,800–4,200 rpm

Operating RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,800–8,200 rpm

MPH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150–175

CFM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450–500

Ignition Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rocker Switch

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 in. (0.635 mm)

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel/Oil Mixture

Fuel/Oil Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diaphragm, All-Position

Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Spring Assist Starting™ Auto Rewind

Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Baffled with Guard

Throttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Manual Spring Return

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 oz. (591 ml)

Page 9

Manuel de L'utilisateur

Souffleur à dos à 2-temps

BP226

P/N 769-04595 P00 (01/09)

Copiez le numéro de série ici :

Copiez le numéro de modèle / pièce mère ici :

Toutes les informations, illustrations et spécifications contenues dans

ce manuel tiennent compte des dernières informations techniques

disponibles au moment de mettre sous presse. Nous nous réservons

le droit d'y apporter des modifications à tout moment, sans préavis.

Copyright© 2009 MTD SOUTHWEST INC., Tous droits réservés.

Obtenez la liste des concessionnaires agréés appelez le 1-877-282-8684

aux États-Unis ou le 1-800-668-1238 au Canada. Pour de plus amples

informations à propos de votre appareil, visitez www.cubcadet.com

ou www.cubcadet.ca.

NE RETOURNEZ PAS L'APPAREIL AU DÉTAILLANT CHEZ QUI

VOUS L'AVEZ ACHETÉ. TOUT SERVICE SOUS GARANTIE

NÉCESSITE UNE PREUVE D'ACHAT.

CE PRODUIT EST COUVERT PAR UN OU PLUSIEURS BREVETS

AMÉRICAINS, ET D’AUTRES SONT EN INSTANCE.

Tout entretien effectué sur cet appareil pendant et après la période

de garantie doit être fait par un concessionnaire agréé uniquement.

Avant d'assembler votre nouvel équipement, repérez la plaque

signalétique de l'appareil et copiez ses informations dans l'espace cidessous. Ces informations sont essentielles si vous désirez obtenir de

l'aide auprès de notre service technique ou d'un distributeur agréé. Un

exemple de plaque signalétique est présenté ci-dessous.

CONSERVER CES INSTRUCTIONS

TABLE DES MATIÈRES

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F1

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F2

Familiarisez-vous avec l’appareil . . . . . . . . . . . . . . . . . . . . . . . . .F5

Instructions de montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F5

Informations sur l’huile et le carburant . . . . . . . . . . . . . . . . . . . .F6

Instructions de démarrage et d’arrêt . . . . . . . . . . . . . . . . . . . . . .F6

Mode d’emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F6

Entretien et réparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F7

Nottoyage et entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F7

Tableau de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F8

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F8

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E12

Dans un effort de réduire l’impact sur les forets et

réduire les émissions de gaz carbonique ainsi

que les émissions de gaz à effet de serre, MTD

utilise moins de papier en réduisant la taille du

texte de ce manuel.

NE RETOURNEZ

PAS CE PRODUIT

Pour une assistance, veuillez appeler le 1-877-282-8684

(E.U.) ou le 1-800-668-1238 (Canada)

ou visitez : www.cubcadet.com / www.cubcadet.ca

MODEL :

S/N :

ITEM :

Page 10

F2

• IMPORTANTES CONSIGNES DE SÉCURITÉ •

• Toujours arrêter le moteur et le laisser refroidir avant faire l’appoint de

carburant. Ne jamais retirer le bouchon du réservoir de carburant ou

faire l’appoint pendant que le moteur est chaud. Ne jamais utiliser

l’outil sans que le bouchon du réservoir soit bien en place. Desserrer

le bouchon lentement afin de relâcher la pression du réservoir.

• Ajoutez le carburant dans un endroit bien aéré et propre, en plein

air, à l’abri des sources d’étincelles ou flammes vives. Ne retirer

(lentement) le bouchon du réservoir d’essence qu’après avoir

arrêté le moteur. Ne pas fumer pendant l’approvisionnement de

carburant. Essuyer immédiatement le carburant répandu sur l’outil.

• Éviter de créer une source d’allumage pour le carburant répandu.

Ne pas lancer le moteur avant que toutes les vapeurs se soient

dissipées, afin d’éviter de créer une source d’allumage pour le

carburant répandu.

• Éloigner l’outil d’au moins 9 m (30 pi) du point d’approvisionnement

en carburant avant de démarrer le moteur. Ne pas fumer et éloigner

toute source d’étincelles ou de flammes vives du point

d’approvisionnement ou d’utilisation de l’outil.

PENDANT L’UTILISATION

• Ne jamais démarrer ou utiliser l’outil dans un local clos.

L’inhalation des vapeurs d’échappement peut être mortelle.

N’utiliser l’outil qu’à l’extérieur, dans un endroit bien aéré.

• Pour réduire les risques de blessures par des objets projetés, porter

des lunettes de sécurité conformes à la norme ANSI Z87.1–1989.

• Ne jamais utiliser l’outil s’il n’est pas équipé des accessoires

nécessaires.

• Pour réduire les risques de perte de l’ouïe causée par le niveau de

bruit, toujours porter une protection auditive lors de l’utilisation.

• Portez des pantalons épais et longs, des bottes, des gants et une

chemise à manches longues. Ne marchez pas pieds nus et évitez

LISEZ TOUTES LES INSTRUCTIONS AVANT L'UTILISATION

• Veuillez lire les instructions avec soin. Familiarisez-vous avec les

commandes et l'utilisation correcte de cet appareil.

• Veuillez lire le manuel de l'utilisateur attentivement. Familiarisez-vous avec

les commandes et l'utilisation correcte de l’appareil. Sachez comment

arrêter l’appareil et désactiver les commandes rapidement.

• N'utilisez pas l'appareil si vous êtes fatigué, malade ou sous

l'effet de l'alcool, de drogues ou de médicaments.

• Ne laissez pas les enfants faire fonctionner l’appareil. Ne laissez jamais

des adultes qui ne se sont pas familiarisés avec les instructions utiliser

l’appareil. Ne laissez jamais des adultes n'ayant jamais reçu les

instructions nécessaires faire fonctionner l’appareil.

• Tous les tubes du soffleur doivent être correctement installés

avant d'utiliser cet appareil.

AVERTISSEMENTS DE SÉCURITÉ SPÉCIAUX POUR TÊTES

D’ENTRAÎNEMENT À ESSENCE

• Ne conserver le carburant que dans des récipients spécialement

conçus et homologués pour le stockage de ce type de produit.

Lisez le(s) manuel(s) de l'utilisateur et suivez tous les avertissements et consignes de sécurité. Vous pourriez à défaut entraîner des

blessures graves pour vous ou d'autres personnes.

SI VOUS AVEZ DES QUESTIONS, APPELEZ LE

1-877-282-8684

AUX ÉTATS-UNIS, OU LE 1-800-668-1238 AU CANADA

Les symboles de sécurité attirent votre attention sur des dangers

potentiels. Ces symboles et leurs détails explicatifs méritent que

vous les lisiez et compreniez bien. Les avertissements de

sécurité ne peuvent éviter les dangers de par eux-mêmes. Les

consignes ou mises en garde qu'ils donnent ne remplacent pas

des mesures préventives appropriées contre les accidents.

REMARQUE: donne des informations ou des instructions vitales

pour le fonctionnement ou l'entretien de l'équipement.

ALERTE DE SÉCURITÉ :

Indique un danger, un

avertissement ou une mise en garde. Soyez vigilant afin

d'éviter toute blessure grave. Ce symbole peut être

combiné à d'autres symboles ou pictogrammes.

DANGER :

l e non-respect d’un avertissement peut

causer dommages matériels ou blessures graves pour

tous. Respectez les consignes de sécurité afin de réduire

les risques d'incendie, d'électrocution et de blessures.

AVERTISSEMENT :

le non-respect d’un avertissement

peut causer dommages matériels ou blessures graves pour

tous. Respectez les consignes de sécurité afin de réduire les

risques d'incendie, d'électrocution et de blessures.

MISE EN GARDE :

le non-respect d’un avertissement

peut causer dommages matériels ou blessures graves pour

tous. Respectez toujours les consignes de sécurité afin de

réduire les risques d'incendie, d'électrocution et de

blessures.

CONSIGNES DE SÉCURITÉ

SYMBOLE SIGNIFICATION

AVERTISSEMENT :

Suivez soigneusement les

consignes de sécurité lorsque vous utilisez cet appareil.

Dans l'intérêt de votre sécurité et de celle des personnes

à proximité, prenez soin de lire ces instructions avant de

faire fonctionner la machine. Veuillez garder les

instructions en lieu sûr pour usage ultérieur.

AVERTISSEMENT :

L'essence est extrêmement

inflammable et ses vapeurs peuvent exploser si on y

met le feu. Veuillez prendre les précautions suivantes.

PARE-ÉTINCELLES

REMARQUE : à l'intention des utilisateurs opérant dans les

terres forestières des États-Unis et dans les états de Californie,

du Maine, de l'Orégon et de Washington. Toutes les terres

forestières des États-Unis et de l'état de Californie (Codes sur les

ressources publiques 4442 et 4443), de l'Orégon et de Washington

exigent de par la loi que certains moteurs à combustion interne

utilisés dans des zones couvertes de taillis ou d'herbe soient

équipés d'un pare-étincelles en parfait état de fonctionnement, ou

qu'ils soient conçus, équipés et entretenus pour la prévention des

incendies. Renseignez-vous auprès des autorités de votre province

ou de votre municipalité concernant la réglementation en vigueur.

Vous pourriez être passible d'une amende ou être tenu responsable

si vous ne respectez pas cette réglementation. Cet appareil est

équipé d'un pare-étincelles en usine. Si silencieux, réf. 753-05945,

doit être remplacé, communiquez avec le service technique.

AVERTISSEMENT DE LA PROPOSITION 65 DE CALIFORNIE

AVERTISSEMENT

LES GAZ D'ÉCHAPPEMENT DU MOTEUR DE CET

APPAREIL CONTIENNENT DES PRODUITS CHIMIQUES

CONSIDÉRÉS PAR L'ÉTAT DE CALIFORNIE COMME

POUVANT CAUSER LE CANCER, DES MALFORMATIONS

CONGÉNITALES OU D'AUTRES EFFETS NOCIFS SUR

L'APPAREIL DE REPRODUCTION.

Page 11

F3

CONSIGNES DE SÉCURITÉ

les vêtements lâches, bijoux, pantalons courts et sandales. Relevez

les cheveux au-dessus des épaules.

• Ne pas porter de gants en caoutchouc ou isolés pour éviter les

décharges d’électricité statique lors de l’utilisation.

• N’utiliser l’outil qu’en plein jour ou sous bon éclairage artificiel.

• Garder l’extérieur de l’outil exempt d’huile et de carburant.

• Éviter tout démarrage accidentel. Toujours se tenir en position

de démarrage avant de tirer la corde de démarrage. L’opérateur

et l’outil doivent tous deux être en position d’équilibre lors du

démarrage. Voir les instructions de Démarrage et arrêt.

• L’outil doit toujours être posé sur une surface propre et ferme.

Les matériaux tels que le gravier, le sable, la poussière, l’herbe,

etc. peuvent être aspirés par l’admission d’air et projetés par la

sortie de l’outil, ce qui peut endommager l’outil, causer des

dégâts matériels et des blessures graves à l’utilisateur ou aux

personnes se trouvant à proximité.

• Toujours utiliser un outil adéquat pour l’application. Ne pas

utiliser cet outil pour un usage pour lequel il n’est pas conçu.

• Ne pas forcer l’outil. Il fonctionnera plus efficacement et sera

moins dangereux si sa capacité nominale n’est pas dépassée.

• Ne pas essayer de travailler hors de portée ou en se tenant sur

une surface instable, telle qu’une échelle, un arbre, un toit, une

pente abrupte, un toit, etc. Toujours se tenir bien campé, en

position d’équilibre.

• Toujours tenir l’outil fermement pendant l’utilisation.

• Garder les mains, le visage et les pieds à l’écart des pièces en

mouvement. Ne pas essayer de toucher ou d’arrêter l’hélice en

rotation. Ne pas utiliser l’outil si les dispositifs de protection ne

son pas en place.

• Ne jamais introduire quoi que ce soit dans les ouvertures. Garder

les ouvertures dégagées, exemptes de poussières et de débris

ou autres risquant de réduire la circulation d’air.

• Ne toucher ni le moteur, ni le silencieux. Ces pièces deviennent

très chaudes pendant le fonctionnement. Elles restent brûlantes

pendant quelques temps après l’arrêt.

• Ne pas faire fonctionner le moteur à un régime plus qu’il n’est

nécessaire pour s’acquitter de la tâche. Ne pas faire tourner le

moteur à haut régime à vide.

• Toujours arrêter le moteur si le travail est interrompu ou avant de

se déplacer d’un endroit à un autre.

• Arrêter le moteur et débrancher avant toute opération d’entretien

ou réparation et avant d’installer ou retirer les tubes de

souffleuse. Le moteur et les pales de l’hélice doivent être

parvenus à l’arrêt complet pour éviter tout danger de blessure

par les pièces en rotation.

• Si l’appareil heurte ou se prend dans un objet, arrêtez le moteur

immédiatement et vérifiez que l’appareil n’a pas été

endommagé. Ne pas utiliser avant d’avoir réparé les dommages.

Ne pas utiliser l’appareil avec des pièces ayant du jeu ou qui

sont endommagées.

• N'utilisez que des pièces de équipement original rechange du

fabricant pour cet appareil. Elles sont disponibles auprès de votre

concessionnaire agréé. L'utilisation de pièces ou accessoires

autres que ceux de éqiupement original peut causer des

blessures graves, endommager l’appareil et annuler sa garantie.

• Ne jamais utiliser cet outil pour répandre des produits chimiques,

engrais ou matériaux pouvant contenir des substances toxiques.

• Afin de réduire les risques d’incendie, remplacer tout silencieux

ou pare-étincelles défectueux et garder le moteur et le silencieux

exempts d’herbe, de feuilles et d’accumulation excessive de

graisse ou de calamine.

• Éteignez le moteur et débranchez la bougie pour effectuer son

entretien ou sa réparation.

• Ne jamais diriger le tube de la souffleuse vers des personnes,

animaux domestiques ou fenêtres. Toujours souffler les débris en

direction opposée des personnes, animaux domestiques et

fenêtres. Redoubler de prudence lors du travail à proximité

d’objets massifs tels que des arbres, véhicules, murs, etc.

AUTRES AVERTISSEMENTS DE SÉCURITÉ

• Toujours débrancher la bougie avant de travailler sur les pièces

mobiles.

• N’entreposez jamais l’appareil avec de l’essence dans le

réservoir à l’intérieur d’un bâtiment où les vapeurs peuvent

entrer en contact avec toute source de flammes (lampes témoin,

etc.) ou d’étincelles (interrupteurs, moteurs électriques, etc.).

• Laisser le moteur refroidir avant de remiser ou transporter l’outil.

Bien arrimer l’outil pour le transport.

• Remiser l’outil dans un endroit sec pouvant être verrouillé ou en

hauteur afin d’empêcher des dommages ou un usage non

autorisé. Garder l’outils hors de portée des enfants.

• Ne jamais immerger l’outil et ne jamais l’arroser avec de l’eau ou

tout autre liquide. Garder les poignées sèches, propres et

exemptes de débris. Nettoyer après chaque usage. Voir les

sections Nettoyage et Remisage.

• Conserver ces instructions. Les consulter fréquemment et les

utiliser pour instruire d’autres utilisateurs. Si l’outil est prêté, il

doit être accompagné de ces instructions.

REMARQUE SPÉCIALE: L’exposition à des vibrations due à un

usage prolongé d’outils à essence peut entraîner une lésion des

vaisseaux sanguins ou des nerfs au niveau des doigts, mains et

articulations des personnes prédisposées aux troubles de la

circulation et aux tuméfactions anormales. L’utilisation prolongée

en eau froide a été reliée aux lésions des vaisseaux sanguins chez

des personnes normalement en santé. En cas de symptômes tel

qu’engourdissement, douleur, perte de force, changement de

couleur ou de texture de la peau, perte de sensation dans les

doigts, les mains ou les articulations, cessez l’utilisation de

l’appareil et consultez un médecin. Un système anti-vibration ne

garantit pas que ce genre de problème puisse être évité. Les

individus utilisant des outils mécaniques de manière régulière

doivent surveiller attentivement leur état physique et celui de

l’appareil.

CONSERVER CES INSTRUCTIONS

Page 12

F4

• SYMBOLES DE SÉCURITÉ ET INTERNATIONAUX •

Ce manuel de l'utilisateur décrit les symboles et pictogrammes de sécurité et internationaux pouvant apparaître sur ce produit. Consultez le

manuel de l'utilisateur pour les informations concernant la sécurité, le montage, le fonctionnement, l'entretien et les réparations.

CONSIGNES DE SÉCURITÉ

• LISEZ LE MANUEL DE L'UTILISATEUR

AVERTISSEMENT : Lisez le manuel de

l'utilisateur et suivez tous les avertissements et

consignes de sécurité. Vous pourriez à défaut

entraîner des blessures graves pour vous ou d'autres

personnes.

SYMBOLE SIGNIFICATION

• SYMBOLE ALERTE DE SÉCURITÉ

Indique un danger, un avertissement ou une mise en

garde. Ce symbole peut être combiné à d'autres

symboles ou pictogrammes.

SYMBOLE SIGNIFICATION

• COMMANDE MARCHE/ARRÊT

ARRÊT

• COMMANDE MARCHE/ARRÊT

ALLUMAGE / DÉMARRAGE / MARCHE

• NIVEAU D'HUILE

Voir le manuel de l'utilisateur pour le type d'huile

approprié.

• CARBURANT SANS PLOMB

Utilisez toujours du carburant sans plomb frais et

propre.

• ÉLOIGNEZ LES SPECTATEURS

AVERTISSEMENT : Éloignez tout spectateur,

les enfants et les animaux domestiques en

particulier, d'au moins 15 m (50 pieds) de la zone de

coupe.

•

LES OBJETS PROJETÉS

PEUVENT CAUSER DES

BLESSURES GRAVES

AVERTISSEMENT : Tenez-vous à l'écart de la

sortie de souffleuse. Ne dirigez jamais la souffleuse vers

vous ou vers les autres. La souffleuse peut projeter des

objets. Ne faites pas fonctionner l'appareil sans les

accessoires et protections nécessaires.

• CONTRÔLE DE L'ÉTRANGLEUR

1. • Position d’ÉTRANGLEMENT MAXIMUM

2. • Position d’ÉTRANGLEMENT PARTIEL

3. • Position MARCHE

• SURFACE CHAUDE

AVERTISSEMENT : Ne pas toucher aux

surfaces chaudes. Vous pourriez vous brûler. Ces

pièces deviennent très chaudes à l'utilisation. Elles

restes chaudes brièvement après l'arrêt.

• PORTEZ DES PROTECTIONS (TÊTE, YEUX ET

OREILLES)

AVERTISSEMENT : Les objets projetés et les

bruits forts peuvent endommager la vue et l’ouïe.

Portez une visière de norme ANSI Z87.1–1989 et des

protège-oreilles pendant l'utilisation. la chute d’objets

peut causer des blessures graves à la tête. Protégezvous la tête pendant l'utilisation de l'appareil.

Page 13

F5

SAVOIR VOTRE UNITÉ

Pied

Commande

Marche/Arrêt

Poignée du

cordon du

démarreur

Silencieux

Couvercle du filtre

à air/silencieux

Poire

d'amorçage

Système de support

Réservoir

Levier

d’étranglement

Bouchon

du

carburant

Gâchette

Tube de soufflage

Boucle de la support d’épaule

Régulateur de

vitesse

Poignée de la

manette des gaz

Buse

ASSEMBLAGE DU TUBE DU SOUFFLEUR

Installer le Flex Tube

1. Placer un collier de serrage à l’extrémité du tube flexible (Fig. 1, A).

2. Glisser l’extrémité du tube flexible avec le collier de serrage en

place sur la sortie de la buse du logement de l’hélice (Fig. 1, B).

3. Aligner la bosse sur le tube flexible avec la bosse de la buse

du moteur (Fig. 1, C).

4. Serrer la visse du collier de serrage pour fixer le tube flexible

à buse de sortie de l’hélice (Fig. 1, C).

Installer le tube de soufflage supérieur

1. Placer un collier de serrage à l’autre extrémité du tube flexible

(Fig. 2, A).

2. Glisser cette extrémité du tube avec le collier de serrage en

place sur l’extrémité supérieure du tube de soufflage

supérieur (Fig. 2, B).

3. Serrer la visse du collier de serrage pour fixer le tube flexible

au tube de soufflage supérieur (Fig. 2, C).

Installer les tubes de soufflage inférieurs et la buse

1. Aligner l’encoche sur l’extrémité du premier tube de soufflage

inférieur avec la bosse sur l’extrémité inférieure du tube de

soufflage supérieur (Fig. 3, A).

2. Insérer la bosse sur le tube de soufflage supérieur dans

l’encoche sur le tube d’extension (Fig. 3, A).

3. Pivoter le tube d’extension dans le sens des aiguilles d’une

montre autour du tube de soufflage supérieur jusqu’à ce que

la bosse du tube se verrouille en place (Fig. 3, B).

4. Aligner l’encoche sur la partie supérieure de la buse avec la

bosse sur l’extrémité inférieure du second tube de soufflage

inférieur (Fig. 4, A).

5. Insérer la bosse sur le tube de soufflage supérieur dans

l’encoche de la buse (Fig. 4, A).

6. Pivoter la buse dans le sens des aiguilles d’une montre autour

du tube de soufflage inférieur jusqu’à ce que la bosse de la

buse se verrouille en place (Fig. 4, B).

Fig. 1

B

A

C

Fig. 2

B

A

C

AVERTISSEMENT :

Afin d’éviter de graves

blessures et éviter d’endommager l’appareil,

coupez le moteur avant de retirer ou d’installer

les tubes du souffleur.

A

B

Fig. 3

Supports d’épaules

Fig. 5

Ajuster la prise de la manette des gaz

1. Bougez la prise de la manette des gaz vers un endroit sur le

tube de soufflage supérieur qui vous est confortable (Fig. 7).

2. A l’aide d’un tournevis Torx T-20, serrez les deux vis au bas

de la prise de la manette des gaz (Fig. 8).

Tube flexible

Collier de serrage

Tube en coude

Tube de soufflage

supérieur

Tube de soufflage

inférieur

Buse

Câbles des gaz

Collier de serrage

Régulateur de vitesse

Poignée de la manette

des gaz

AVERTISSEMENT :

Afin d’éviter de graves blessures assurez-vous que les parties

du tube du souffleur sont bien verrouillées et serrées en place.

Fig. 4

B

A

INSTRUCTIONS DE MONTAGE

Attachez bien les câbles de la manette des gaz

1. Placez une attache autobloquante autour du tube coudé

et des câbles de la manette des gaz (Fig. 6), tel qu’indiqué,

en vous assurant de ne pas pincer la gaine des câbles.

Fig. 6

Attache

autobloquante

Attache

autobloquante

Le souffleur assemblé devrait ressembler à la Figure 5.

AVERTISSEMENT :

Ne pas tourner la

manette dans le sens des aiguilles d’une montre

pour l’ajuster. Ceci pourrait déconnecter les

câbles de la manette des gaz ou du moteur.

Fig. 7

A

Fig. 8

Poignée de la

manette des gaz

Tube de soufflage

supérieur

Commande

Marche/Arrêt

Page 14

F6

INFORMATIONS SUR L’HUILE ET LE CARBURANT

INSTRUCTIONS DE DÉMARRAGE ET ARRÊT

MÉLANGE D'HUILE ET DE CARBURANT

En général, si l'appareil ne fonctionne pas correctement, c'est que

le carburant est vieux ou mal mélangé. Prenez soin d'utiliser de

l’essence sans plomb fraîche et propre. Suivez à la lettre les

instructions de mélange de carburant et d'huile.

Définition des carburants mélangés

Les carburants d'aujourd'hui sont souvent un mélange d'essence

et d'oxygénés comme l'éthanol, le méthanol ou l'éther MTBE. Un

carburant mélangé à l'alcool absorbe l'eau. Il suffit de 1 % d'eau

pour séparer le carburant et l'huile. Cela forme de l’acide pendant

le stockage. Si vous devez utiliser ce type de carburant, servezvous de carburant frais (moins de 60 jours).

Usage de carburants mélangés

Si vous choisissez d'utiliser ou ne pouvez éviter d'utiliser un carburant mélangé, suivez les conseils suivants :

• Utilisez toujours un mélange de carburant frais selon le manuel de l'utilisateur.

• Agitez toujours le mélange de carburant avant d'alimenter l'appareil.

• Videz le réservoir et faites marcher le moteur jusqu'à l’assécher avant d'entreposer l'appareil.

Utilisation d'additifs de carburant

La bouteille d'huile 2-temps livrée avec l’appareil contient un additif permettant d'empêcher la corrosion et de minimiser

la formation de résidus de gomme. Nous vous recommandons d’utiliser ce type d’huile uniquement. Si cela n’est pas

disponible, utilisez une bonne huile 2-temps conçue pour les moteurs à 2-temps refroidis par air en y ajoutant un additif,

tel que le stabilisant de gaz STA-BIL ou un produit équivalent Ajoutez 23 ml (0,8 oz) d'additif par 4 litres (1 gallon) de

carburant selon les instructions du récipient. N'ajoutez JAMAIS d'additifs directement dans le réservoir de l'appareil.

Mélangez soigneusement l'huile moteur 2-temps avec de l'essence sans plomb dans un bidon séparé.

Utilisez un rapport 40:1 d'essence/huile. Ne les mélangez pas directement dans le réservoir de carburant.

Voir le tableau ci-dessous pour les rapports de mélange d’essence et d’huile.

REMARQUE : 3,8 litres (1 gallon) d'essence sans plomb mélangés avec une bouteille de 95 ml (3.2 oz) d'huile

2-temps donnent un rapport d’essence/huile de 40:1.

REMARQUE : Éliminez le vieux mélange de carburant conformément aux règlements fédéral, provincial

et municipal en vigueur.

AJOUR DE CARBURANT

1. Déposez le bouchon à essence.

2. Placez le bec du récipient d’essence dans l’orifice du

réservoir et remplissez celui-ci (Fig. 9).

REMARQUE : Ne remplissez pas trop le réservoir.

3. Essuyez tout déversement d’essence.

4. Remettez le bouchon du réservoir.

5. Éloignez l'appareil d'au moins 9,1 m (30 pi) de la source et du site de ravitaillement en essence avant

de démarrer le moteur.

REMARQUE : Éliminez le vieux mélange de carburant conformément aux règlements fédéral, provincial

et municipal en vigueur.

Fig. 9

AVERTISSEMENT :

Enlevez le bouchon du

réservoir lentement pour ne pas être blessé par

les jets d'essence. Ne faites pas marcher

l'appareil sans que le bouchon soit bien mis.

1. Mélangez l’essence avec l’huile. Remplissez le

réservoir d’essence avec le mélange essence/huile.

Consultez les Instructions de mélange huile/essence.

2. Appuyez lentement et dix fois de suite sur la poire

d’amorce. Une certaine quantité de carburant devrait

être visible dans la poire d'amorce et les tuyaux

d’essence (Fig. 10). Si le carburant n’est pas visible

dans la poire d’amorce, appuyez dessus autant de

fois que nécessaire jusqu’à ce l’essence arrive.

3. Placez le levier d’étranglement rouge en position 1 (Fig. 10).

4. Poussez sur le régulateur de vitesse pour verrouiller la

manette dans la position Marche (Fig. 11A).

5. Accroupissez-vous dans la position de démarrage

(Fig. 12) et tirez le cordon du démarreur 5 fois dans

un mouvement rapide et régulier.

6. Placez le levier d’étranglement rouge en position 2 (Fig. 10).

7. Tirez le cordon du démarreur dans un mouvement

rapide et régulier jusqu’à ce que le moteur démarre.

8. Laisser le moteur chauffer pendant 30 à 60 secondes.

REMARQUE : Il se peut que par temps froid le moteur

prenne plus de temps à chauffer jusqu’à sa

température d'utilisation.

REMARQUE : L’appareil est suffisamment chaud lorsque

le moteur accélère sans accrocs.

9. Dès que le moteur est chaud, placez le levier

d’étranglement rouge dans la position 3 (Fig. 10).

10. Relâchez le régulateur de vitesse pour remettre la

manette en position de ralenti (Fig. 11B). L’appareil

est prêt pour l’utilisation.

SI...si le moteur fait des accros, remettez le levier de

l’étranglement rouge dans la position 2 (Fig. 10) et

continuez à chauffer le moteur.

SI... le moteur ne démarre pas, retourner à l’étape 2.

SI... le moteur ne démarre pas après plusieurs tentatives,

remettrez le levier d’étranglement en position 3 (Fig.

10) et poussez sur le régulateur de vitesse. Tirez sur

le cordon du démarreur d’un coup sec de 3 à 8 fois

de suite. Le moteur devrait démarrer. Sinon, répétez

SI CHAUD... Si le moteur est déjà chaud, démarrez le moteur avec le levier d’étranglement

rouge dans la position 2 (Fig. 10). Après le démarrage du moteur, poussez le levier de

l’étrangleur en position 3 (Fig. 10) et relâchez le régulateur de vitesse.

AVERTISSEMENT :

éviter le démarrage accidentel. Se tenir en position de

démarrage pour lancer le moteur (Fig. 12). Lors du démarrage, l’opérateur et l’outil

doivent être en position d’équilibre afin d’éviter le risque de blessures graves. Afin

d’éviter de graves blessures et éviter d’endommager l’appareil, s’assurer que les tubes

de soufflage sont bien en place avant d’utiliser l’appareil.

AVERTISSEMENT :

n’utiliser l’outil qu’à l’extérieur, dans un endroit bien aéré. Les

émanations d’oxyde de carbone dans un endroit confiné peuvent être mortelles.

Bec du récipient d’essence

Reservoir d’essence

INSTRUCTIONS D’UTILISATION

AJUSTER LE SYSTEME DE SUPPORT

1. Placer les supports d’épaules de l’appareil sur les épaules

et l'appareil sur le dos.

2. Tirez sur les poignées du support d’épaules pour les resserrer

(Fig. 13).

Enlever le système de support

1. Pour libérer les supports d’épaules, tirez sur la languette

inférieure des boucles des supports d’épaules (Fig. 14).

TENUE DE LA SOUFFLEUSE/ASPIRATEUR

Avant d’utiliser l’outil, se tenir en position de travail et effectuer

les vérifications suivantes (Fig. 15) :

• L’utilisateur doit porter une tenue appropriée, c’est-à-dire des

chaussures de travail, des lunettes de sécurité, une protection

auditive, des gants, des pantalons longs et une chemise à

manches longues.

• Si l’endroit est poussiéreux, porter un masque anti-poussière.

• S’assurer que l’outil est en bon état de marche.

• Vérifier que les tubes sont en place et bien assujettis.

CONSEILS PRATIQUES

• Lors du démarrage, veiller à ne pas diriger l’outil vers des personnes ou des débris.

Fig. 13

Fig. 14

• S’assurer que l’outil est en bon état de marche. Vérifier que

les tubes et protection sont en place et bien assujettis.

• Lorsque la souffleuse est utilisée à hauteur des hanches ou dans une

position inhabituelle, il est recommandé de la tenir à deux mains.

• Utiliser une protection auditive pour éviter les risques de perte

de l’ouïe causée par un niveau de bruit élevé.

• N’utiliser l’outil qu’à des heures raisonnables, c’est-à-dire pas

trop tôt le matin ou tard le soir lorsque cela peut déranger les

personnes vivant aux environs. Se conformer aux

réglementations locales qui sont habituellement de 9 à 17

heures, du lundi au samedi.

• Pour réduire le niveau sonore, utiliser le moins possible

d’outils motorisés en même temps.

• Pour réduire le niveau sonore utiliser la souffleuse au régime

minimum permettant de s’acquitter de la tâche.

• Vérifier l’équipement avant de commencer le travail, en particulier le

silencieux, l’admission d’air et les filtres à air.

• Utiliser un râteau ou un balai pour séparer les débris avant de les souffler.

• Dans les endroits poussiéreux, humecter légèrement l’aire de travail ou utiliser un accessoire de

pulvérisation si une source d’eau est disponible.

• Conserver l’eau en utilisant la souffleuse au lieu d’un tuyau d’arrosage pour le nettoyage des endroits

tels que les gouttières, moustiquaires, patios, grills, porches et jardins.

• Prendre garde aux enfants, animaux domestiques, fenêtres ouvertes et véhicules fraîchement lavés,

et souffler les débris à l’opposé de tels obstacles.

• Utiliser la tubulure complète afin que l’embout reste près du sol.

• Après utilisation d’une souffleuse ou d’autres outils motorisés, Nettoyer la zone de travail. Jeter les

débris dans des poubelles.

• Utilisez le régulateur de vitesse (Fig. 11A) pour maintenir cette dernière enfoncée pour en faciliter

l'opération continue.

UTILISATION DE LA SOUFFLEUSE

1 Utiliser la souffleuse pour le déblayage des arbres, buissons, massifs de fleurs et autres endroits difficiles à nettoyer.

2. Utiliser l’outil pour le nettoyage des bâtiments et autres applications normales.

3. Utiliser la souffleuse pour le nettoyage des murs, surplombs, palissades et moustiquaires.

AVERTISSEMENT :

Afin d’éviter de graves blessures et éviter d’endommager

l’appareil, s’assurer que les tubes de soufflage sont bien en place avant d’utiliser

l’appareil.

Fig. 15

MISE EN GARDE :

Pour assurer un bon

fonctionnement et une fiabilité maximale du moteur,

suivez à la lettre les instructions de mélange d'huile et

de carburant du récipient d'huile 2-temps. L'emploi de

carburant mal mélangé peut endommager le moteur

sérieusement.

Fig. 10

Poire

d'amorçage

Levier

d’étrangleur

Gâchette

en position

rapide

Fig. 11A

Commande

Marche

Fig. 11B

Régulateur

de vitesse

Gâchette

en position

lente

LENTE

RAPIDE

CONSIGNES POUR LE DEMARRAGE

Utiliser le régulateur de vitesse

1. Dès que le moteur a démarré et qu’il est chaud, actionnez la manette des gaz pour accélérer

l’appareil (Fig. 11A).

2. Pour des périodes d’utilisation plus longues et pour éviter la fatigue des doigts, poussez le régulateur de vitesse

vers la position RAPIDE pour agmenter systématiquement ou maintenir la vitesse du moteur de l'appareil (Fig.

11A). Lorsque le régulateur de vitesse est poussé, la manette des gaz s’enfoncera dans la poignée.

3. Pour diminuer la vitesse du moteur, déplacez le régulateur de vitesse vers la position LENT et la

manette des gaz retournera le moteur au ralenti (Fig. 11B).

AVERTISSEMENT :

Pour éviter les risques

de blessures, toujours porter des lunettes de

sécurité lors de l’utilisation de cet outil. Porter un

masque respiratoire dans les endroits poussiéreux.

CONSIGNES POUR ARRETER L’APPAREIL

1. Relâcher la gâchette ou régulateur de vitesse et laisser le moteur refroidir en le faisant tourner au ralenti.