Page 1

Service Manual

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced

individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all instructions

and common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied

with the equipment. No liability can be accepted for any inaccuracies or omission in this publication, although care has been

taken to make it as complete and accurate as possible at the time of publication. However, due to the variety of outdoor power

equipment and continuing product changes that occur over time, updates will be made to these instructions from time to time.

Therefore, it may be necessary to obtain the latest materials before servicing or repairing a product. The company reserves the

right to make changes at any time to this publication without prior notice and without incurring an obligation to make such

changes to previously published versions. Instructions, photographs and illustrations used in this publication are for reference

use only and may not depict actual model and component parts. © Copyright 2005 MTD Products Inc. All Rights Reserved

MTD Products LLC - Product Training and Education Department

Cub Cadet Big Country 4x2

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

This Service Manual is not a substitute for the Operator’s Manual. You must read, understand

and follow all of the directions in this manual as well as the Operator’s Manual before working

on this power equipment.

PRINTED IN USA

CUB CADET LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

FORM NO.769-00965

(11/2003)

Page 2

Page 3

TABLE OF CONTENTS

Brakes...............................................................................................................1

Visual Inspection...............................................................................................1

Operational Tests..............................................................................................2

Complete Inspection..........................................................................................3

Brake Adjustment..............................................................................................7

Brake Linkage Adjustment ................................................................................9

4x2 Drive – Dana Transaxle.............................................................................. 13

Engine/Transmission Cradle............................................................................. 13

“Dogbone” Link Assembly................................................................................. 13

Transaxle Maintenance.....................................................................................13

Transaxle Removal ...........................................................................................14

4x2 Pushbutton Gear Selector..........................................................................15

Description........................................................................................................15

Self Diagnostics.................................................................................................18

Terms and Definitions ....................................................................................... 19

Gear Selector System Diagnostics.................................................................... 20

Explanation of Methodology..............................................................................20

Basic Checks ....................................................................................................20

Vacuum Tests ................................................................................................... 23

Differential Lock Actuator.................................................................................. 27

Gear Selector Electrical System........................................................................28

Differential Lock.................................................................................................31

Page 4

Page 5

Big Country 4 x 2

IMPORTANCE:

It is important that the brakes of the Big Country 4 X 2

Utility Vehicle be properly maintained in order for the

utility vehicle to operate safely and dependably. In

addition to the obvious safety concerns, there is an

electric interlock between the brakes and the gear

selector mechanism. If the brakes are out of adjustment, the gear selector mechanism will not work as it

was designed to. The condition and adjustment of the

brake system should be checked in accordance with

the two-tiered service interval described under the

“Service Intervals” heading in “Description of the Brake

System”.

DESCRIPTION OF THE BRAKE SYSTEM:

• The brake pedal arm lifts up on the pull bolt that

transfers the force through a stack of bellville

washers to an equalizer bracket. The equalizer

bracket distributes the brake pedal force

between the cores of two cables. The bellville

washers are stacked in opposite directions to

provide a spring action, softening the brake

pedal feel.

• Each cable housing is mounted to a bracket on

the firewall using two large jam nuts. Each cable

actuates a drum brake at the end of each rear

axle.

•A parking brake latches the brake pedal in the

applied position when engaged.

• There are two electrical switches in the system. A parking brake switch lights an indicator

bulb in the instrument panel to help prevent the

operator from trying to drive the Big Country 4 X

2 with the brakes engaged. A brake switch

works with the Electronic Shift Module to prevent

the operator from shifting gears without the

brake applied.

• Service intervals will vary with the type severity

of use. If the vehicle is operated on hills or with

heavy loads, it may be necessary to shorten the

maintenance intervals because of the increased

load on the brake system and the increased consequences of brake system failure. A visual

inspection and operational test should be performed every 50 hours. The brake drums

should be removed for a complete inspection

every 500 hours or 24 months, as the transaxle gear lube is being changed.

1. VISUAL INSPECTION AND OPERATIONAL TEST:

1.1. Open the hood of the Big country 4 X 2 and

examine the brake arm, parking brake latch, and

all of the associated hardware.

1.2. Check the condition of the brake cables and

their mounting hardware: See Figure 1.2.

Left brake

cable

Cable

clamp

Fuel tank

Figure 1.2

• Jam nuts at the front should be secure.

• Locating clamps at the front of the engine com-

partment should be secure.

• Mounting clips and clevis pins at the back end of

the cable housing should be secure and in good

condition.

• Cable cores should not be frayed or corroded.

Rubber boots should be intact.

• Cable housings should not be kinked, chafed,

burned, crushed or otherwise damaged.

1.3. Any significant wear, damage, or binding should

be addressed prior to making an operational

test.

1

Page 6

Big Country 4 x 2

1.4. If the operator of the vehicle has any specific

brake performance complaints, these complaints

should direct the visual examination and be confirmed during the operational test. If the operator describes an inherently unsafe condition, a

complete inspection should be performed in lieu

of the operational test.

2. OPERATIONAL TESTS

2.1. Operational be performed in a safe location that

is free of traffic, obstacles and hazards.

See Figure 2.1.

2.7. The parking brake should hold the vehicle

securely on a 22 degree incline with an operator

and a capacity load (800lbs.) in the bed. It

should take less than 100 pounds of pedal pressure to push the pedal down far enough to

engage the parking brake. See Figure 2.7.

Figure 2.7

Figure 2.1

2.2. Check the following points of performance:

2.3. The brakes should not drag when they are not

applied.

2.4. The gear selector buttons should operate when

there is enough pressure on the brake pedal to

prevent vehicle motion.

2.5. When the brakes are applied at speed, there

should be no unusual noises, and no pedal pulsation.

2.6. When the brakes are applied at speed on a lowcoefficient surface (such as a gravel parking lot)

the brakes should lock both rear wheels at the

same time.

2.8. There should be 7/8” of pedal travel as measured at the edge of the brake pedal pad before

pressure on the pedal begins to build.

See Figure 2.8.

.875” free-play

from here...........to here

Figure 2.8

2.9. If the Big Country 4 X 2 does not perform as

described, adjust the brakes as described in the

“Brake Adjustment” section of this manual.

2.10. If adjustment does not completely fix the problem, follow the procedures described in the

“Complete Inspection” section of this manual,

and repair any mechanical faults encountered.

2

Page 7

Big Country 4 x 2

3. COMPLETE INSPECTION (DRUM AND SHOE REMOVAL)

3.1. Perform operational tests if no unsafe conditions

have been described by the operator.

NOTE: All brake repair work should be done in

compliance with applicable OHSHA and EPA

regulations.

3.2. Loosen the five lug nuts on each rear wheel 1/2

turn each using a 3/4” socket.

3.3. Raise and safely support the rear of the Big

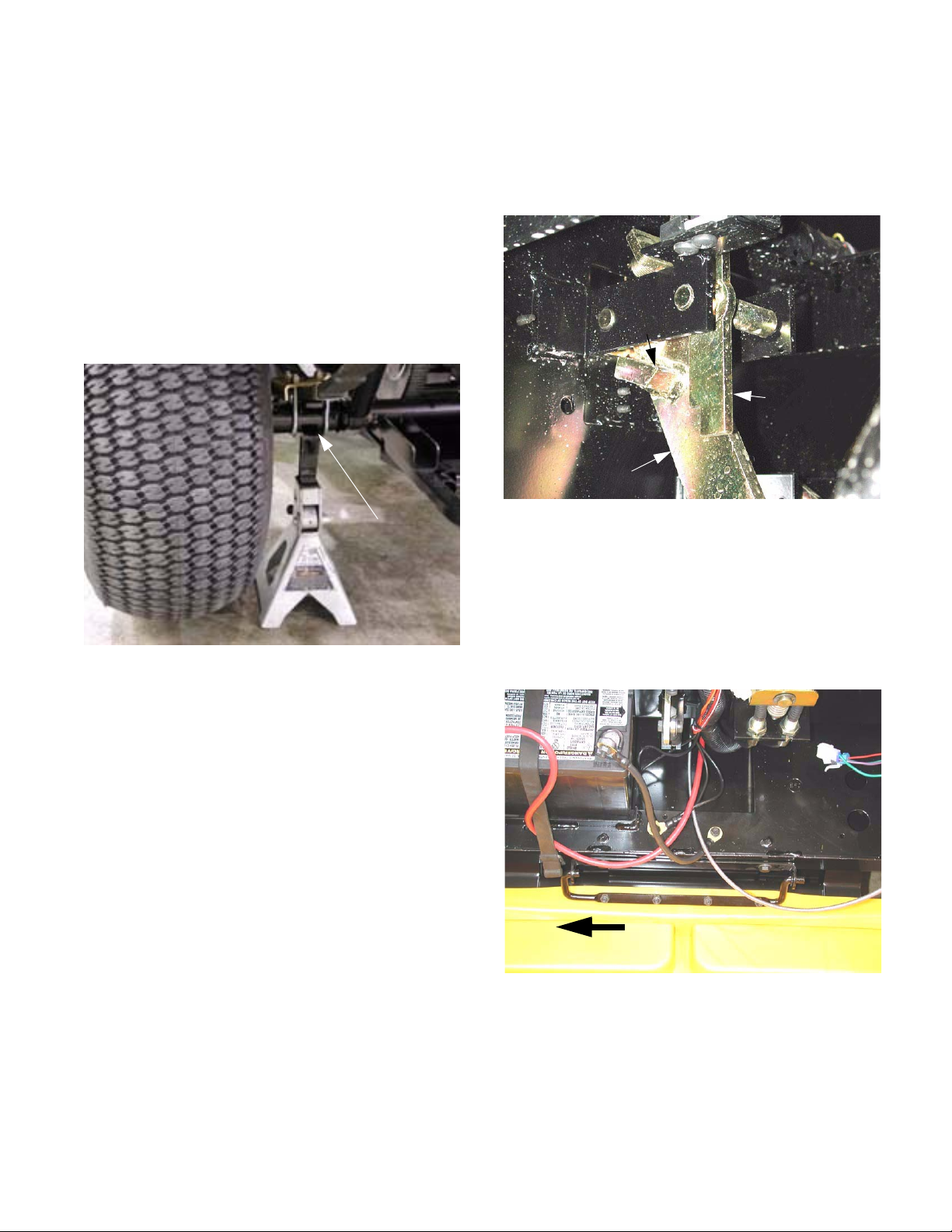

Country 4 X 2 with jack stands. See Figure 3.3.

Safe jack

location

3.5. Engage the parking brake. Insure the parking

brake assembly is engaging and disengaging

properly. The latch (parking brake lever) should

hook securely over the tab on the brake pedal

arm. See Figure 3.5.

Tab

Parking

brake lever

Brake

pedal arm

Figure 3.5

3.6. Attempt to rotate the rear wheels (drive wheels)

by hand. Neither wheel should rotate.

Figure 3.3

3.4. With the parking brake disengaged, attempt to

rotate the rear wheels. They should not drag. If

one or both rear wheels are difficult to rotate,

check the adjustment as described in the “Brake

Adjustment “ section of this manual.

3.7. If either wheel rotates: release the parking brake

and check the adjustment as described in the

“Brake Adjustment “ section of this manual.

3.8. Open or remove the hood. See Figure 3.8.

Slide to remove

Figure 3.8

NOTE: With some front mounted accessories in

place, it may be easier to open the hood far

enough to remove the hairpin clip from the hood

mounting pin, slide the hood assembly to the

right, and remove it completely

3

Page 8

Big Country 4 x 2

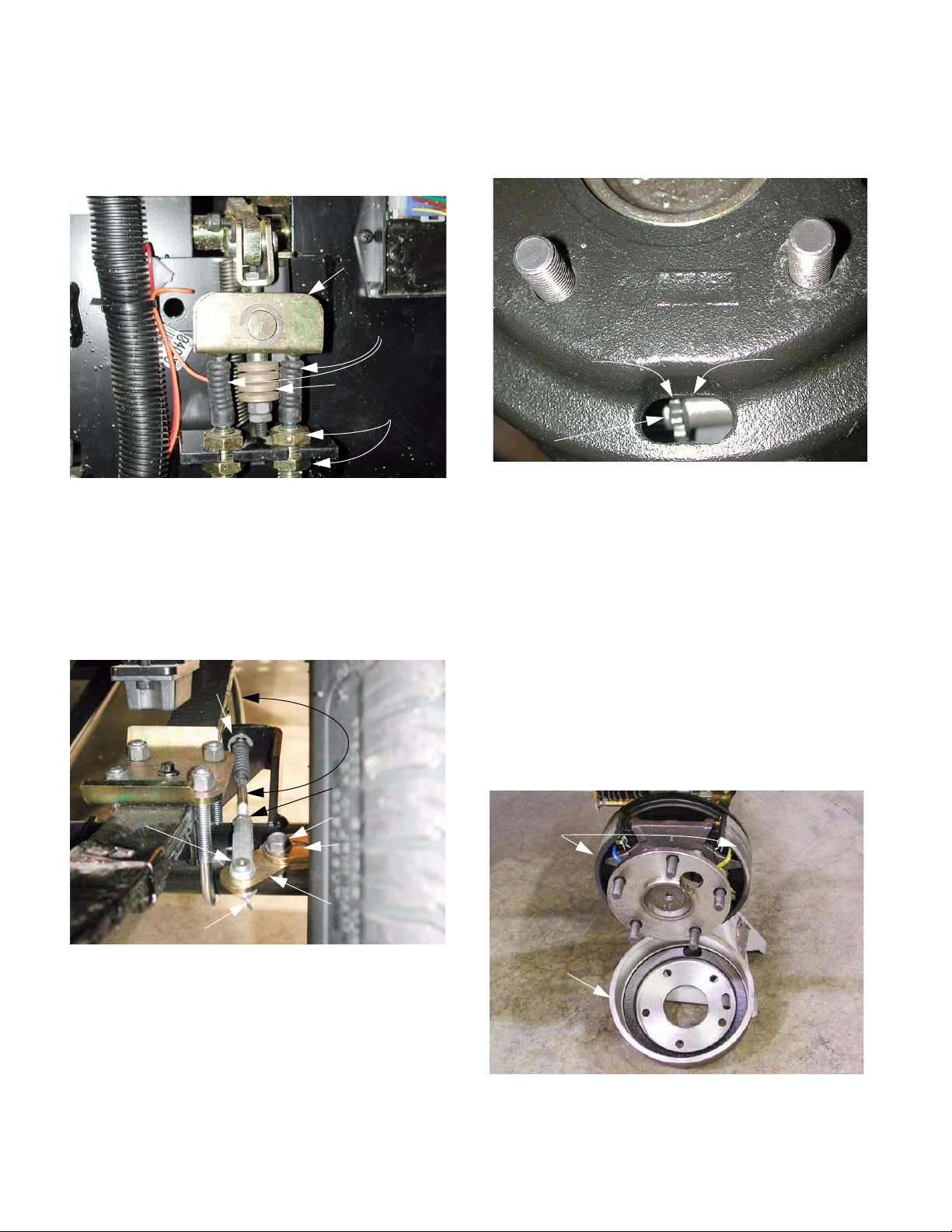

s

3.9. Inspect the brake cables for any damage or

wear. Inspect the hardware securing the cables

to the brake pedal assembly.

See Figure 3.9.

Equalizer bar

Brake cables

Bellville washer

Jam nuts

Figure 3.9

3.10. Release the parking brake.

3.11. Inspect the brake cables at the rear drive

wheels. Inspect the clevis pin, cotter pin, E-clip,

cotter pin, and washer securing the the brake

cables and the brake actuator hardware. See

3.11..

E-clip

Cable

Jam nut

Clevis pin

Mounting bolts

Brake actuator

3.15. Slacken the brake adjuster using a brake

adjuster spoon or flat blade screw driver.

See Figure 3.15.

Star

wheel

Brake

adjuster

Figure 3.15

NOTE: The brake adjuster is the same on both

sides of the Big Country, but is installed in opposite directions. The adjuster is installed with the

star wheel toward the front of the left side brake

assembly. The adjuster is installed with the star

wheel towards the rear of the right side brake

assembly. There is a conventional right hand

thread on the shaft attached to the star wheel.

Walk the teeth of either star wheel down in

order to loosen the brake shoe adjustment.

Walk the teeth up in order to tighten the

adjustment.

3.16. Inspect the brake shoes and drum for wear. The

shoes should be free of oil. See Figure 3.16.

Brake

shoes

Window in

brake drum

Brake actuator

extension arm

Cotter pin

Figure 3.11

3.12. Remove the rear wheels.

3.13. Remove the brake drums. If the brake drum will

not slide easily over the brake shoes, perform

the following two steps.

3.14. Rotate the brake drum until the access hole

(closest to the outer edge of the hub) is at the 6

O’clock position.

Brake

drum

Figure 3.16

4

Page 9

NOTE: If the friction material is contaminated

with oil, identify the source, repair the leak, and

replace the shoes.

NOTE: The friction material on the brake

shoes should not be worn to a thickness of less

than 3/32”. The friction material should not be

contaminated with oil. The friction material

should not show any signs of separating from

the steel portion of the brake shoe. If any of

these conditions exist, replace the brake shoes.

NOTE: If drums are reused at the time of reline,

they should be turned if the depth of scoring

exceeds .010"; if the inside diameter at the open

end of the drum exceeds the inside diameter at

the closed end by more than .010: (bellmouth

condition); if the drum rubbing surface is concave or convex by more than .005"; if they are

heat checked; and if they are out of round by

more than .010 total indicator reading or if pedal

pulsations or brake roughness is noticed. The

rebore limit is .060" over the original maximum

drum diameter of 7.005". If reboring to .060”

maximum does not correct any of these conditions, then the drum should be replaced. New

drums have a #50 grit blast applied to the rubbing surface. Drum surface finish is 40-125

micro-inches friction surface of the drum should

be smooth and true within .003 “.

3.17. Remove the cotter pins and clevis pins securing

the brake cables to the actuators on each brake.

The brake pedal may be carefully depressed

while the cable is disconnected from the actuator. This will confirm that the cable and linkage

move without binding. See Figure 3.17.

Big Country 4 x 2

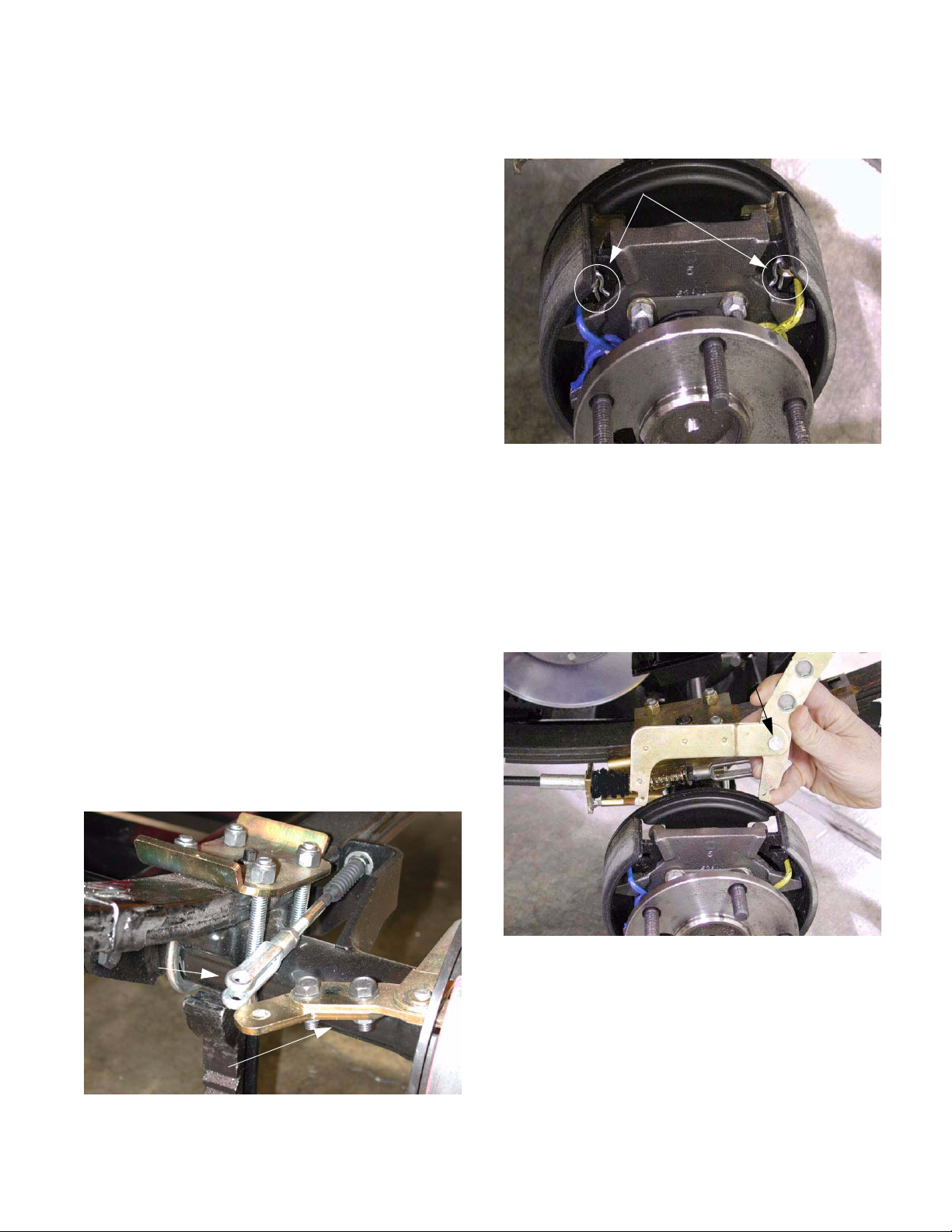

3.18. Remove the “R” shaped clips securing the brake

actuator to the brake shoes. See Figure 3.18.

“R” Shaped clips

Figure 3.18

3.19. Remove the brake actuator.

NOTE: The clevis pin is installed in the hole furthest from the pivot pin. The head of the pivot is

facing. The Pivot pin is secured to the actuator

by a C-clip and wave washer.

3.20. Inspect the actuator for any binding at the pivot

pin. See Figure 3.20.

Check for binding

and wear

Clevis

Brake Actuator

Figure 3.20

3.21. Rotate the star wheel on the adjuster to shorten

the adjuster to the end of its travel.

Figure 3.17

5

Page 10

Big Country 4 x 2

3.22. Pry out on the base of the brake shoes while

removing the adjuster. See Figure 3.22.

Blue

extension

spring

Brake adjuster

Figure 3.22

3.23. Remove the blue extension spring from the base

of each brake shoe. The extension spring keeps

the adjuster in contact with the base of the brake

shoe. See Figure 3.23.

Brake Shoe

3.24. Remove the torsion springs. See Figure 3.24.

Torsion

Spring

Release from bottom lip

using a screwdriver

or brake spoon

Figure 3.24

NOTE: Relieve the tension from the torsion

spring by prying up on the bottom of the spring

until it separates from the ledge on the brake

shoe.

NOTE: There is one blue and one yellow torsion

spring on each brake assembly. The blue

spring is installed towards the front on the

right side brake assembly and towards the

rear on the left side brake assembly.

Blue

extension

spring

3.25. Slide the brake shoes out from behind the cast

ears that hold them in place, and remove them.

See Figure 3.25.

Brake Shoe and

Spring Orientation

Cotter pin tool

Figure 3.23

Figure 3.25

3.26. Replace any damaged, worn, or corroded parts.

6

Page 11

Big Country 4 x 2

3.27. Assemble the brakes by reversing the shoe

removal process. See Figure 3.27.

Dust cover

Brake

mounting plate

Figure 3.27

NOTE: Apply a small amount of white lithium

grease to the metal-to-metal contact points as

the brake is assembled.

NOTE: Measure the bore of each drum, then set

the adjuster to bring the brake shoes for that

drum out to slightly less than the I.D. of the

drum. If a brake shoe and drum caliper is not

available, a tape measure will usually provide a

measurement that is close enough.

3.29. Adjust the brakes as described in the “Brake

Adjustment” section of this manual.

3.30. After brake adjustment is complete, perform the

operational test as described in the “Visual

Inspection and Operational Test” section of this

manual.

4. BRAKE ADJUSTMENT

4.1. If the brake adjustment is being performed after

other brake service, such as brake shoe

replacement or brake cable replacement, begin

with the “Brake Shoe Adjustment” step. Continue with the “Brake Linkage Adjustment”.

4.2. If brake adjustment is being performed as part of

scheduled maintenance or because of a performance complaint, begin by performing the

steps of the “Complete Inspection” section of this

manual up through the point of brake drum

removal, then proceed from the “Brake Shoe

Adjustment” step. Continue with “Brake Linkage

Adjustment”.

BRAKE SHOE ADJUSTMENT:

4.3. With the brake drums removed, make a visual

inspection of the brake shoes and the components that actuate them. See Figure 4.3.

3.28. Install the brake drum without the wheel using

two of the five lug nuts. Install the lug nuts

inside-out, so that the flat side is against the

brake drum. See Figure 3.28.

Lug nuts

Figure 3.28

NOTE: Rotate the brake drum as the lug nuts

are tightened to insure that it is centered.

Figure 4.3

7

Page 12

Big Country 4 x 2

4.4. Disconnect the clevis on the end of each brake

cable from the brake actuator extension arm by

removing the cotter pin and clevis pin.

See Figure 4.4.

Figure 4.4

NOTE: This step isolates the brake form the link-

age that actuates it, so that the two portions of

the system do not interfere with each other.

4.7. Set the adjuster so there is slight drag on the

brake drum when turned by hand. Then adjust

until no drag is present. At this point, play

should be absent from the actuator.

See Figure 4.7.

Loosen Tighten

Star Wheel

Figure 4.7

4.8. Repeat the process for the second brake, and

proceed with the brake linkage adjustment.

4.5. Install the brake drum using two of the five lug

nuts. Install the lug nuts inside-out, so that the

flat side of the nut faces the drum. Rotate the

drum during installation to center it.

See Figure 4.5.

Flat blade

screw driver

Figure 4.5

4.6. Position the access slot in the drum at the 6 oclock position, so that a brake adjuster spoon or

flat blade screwdriver can be inserted to reach

the star wheel on the brake adjuster.

8

Page 13

Big Country 4 x 2

BRAKE LINKAGE ADJUSTMENT:

4.9. Remove the fasteners that hold the hood closed,

and open or remove the hood if it is not already

open or removed.

4.10. Drop the clevis pins into place, securing each

brake cable clevis to the brake actuator extension arm.

NOTE: It is important that both clevis pins be in

place during adjustment because there is interplay between the left and right brake cables

through the equalizer bar.

4.11. Loosen each jam nut using a 1/2” wrench.

See Figure 4.11.

Clevis pin

(not secured by

cotter pin)

Make Fine

Adjustment Here

jam nut

4.15. Secure the clevis pins with new cotter pins when

adjustment is complete.

4.16. If more adjustment travel is needed, or if the

equalizer bracket is not level, the jam nuts at the

front of the brake cable can be adjusted to correct the situation using a pair of 7/8” wrenches.

See Figure 4.16.

Equalizer

bracket

Right

brake

cable

Left brake

cable

Jam Nuts

Figure 4.16

Figure 4.11

4.12. Adjust the brake cable by threading the clevis up

or down the threaded end of the brake cable to

lengthen or shorten the cable.

NOTE: The unthreaded part of the brake cable

end may be gripped with channel locks or a pair

of vice grips to prevent cable wind-up.

4.13. Adjustment is correct when there is 7/8” of free

play at the pedal before the stack of bellville

washers begins to compress, and the equalizer

brackets is horizontal.

NOTE: When adjustment is made, both brake

cables must be adjusted. This will prevent the

equalizer bar from being pulled down on one

side or the other.

4.14. Tighten the jam nut that locks the clevis on the

end of each brake cable using a 1/2” wrench.

NOTE: When adjusting the brake cables at the

firewall, the pedal travel will also be effected.

4.17. At rest, the pedal arm should stop against the

reinforcement plate that is welded to the firewall.

Brake pedal

arm

Reinforcement

Figure 4.17

NOTE: Confirm that there is at least 5/16” of

thread engagement between the clevis and the

cable end.

9

Page 14

Big Country 4 x 2

4.18. There should be 7/8” (.875”) of free-play in the

pedal before the pedal transmits movement to

the cables. Free-play is measured at the front

edge of the brake pedal pad. See Figure 4.18.

Figure 4.18

4.19. The parking brake should have sufficient holding

power to keep the vehicle from moving on a 22

degree grade with an operator in the seat and

800 lbs. in the load bed. See Figure 4.19.

4.20. When the parking brake is set, the brake switch

actuator should release the plunger on the brake

switch far enough to close the contacts within

the switch. use a 3/8” wrench to adjust the

brake switch actuator to achieve correct operation. See Figure 4.20.

Adjustment

slots

Brake

switch

actuator

Brake

switch

Brake Shown Released

Figure 4.20

NOTE: If the brake switch is not actuated, the

gear selector system will not function. If the

brake switch actuator is adjusted so that the

plunger is released before there is sufficient

pressure on the brake pedal to prevent vehicle

motion, an unsafe condition may occur.

Figure 4.19

8

0

0

L

B

4.21. Brake adjustments should be made using the

jam nuts on the cables, or the clevises at the

ends of the cables. The nut and jam nut on the

pull bolt are best left undisturbed.

See Figure 4.21.

Nut

Jam nut

Pull bolt

Figure 4.21

10

Page 15

4.22. Check to confirm that the parking brake indicator

in the instrument panel illuminates when the

parking brake is set. If it does not, it may be

necessary to adjust the parking brake switch.

See Figure 4.22.

Parking Brake Switch

Parking brake rod

Parking brake arm

Big Country 4 x 2

Figure 4.22

NOTE: The parking brake switch is separate

from the brake switch.

4.23. Perform an operational test as described in the

“Operational Test” section of this manual, in a

safe area that is free of traffic, hazards, and

obstacles. Correct any brake performance

issues before returning the Big Country 4 X 2 to

service.

11

Page 16

Big Country 4 x 2

12

Page 17

4 X 2 Drive Package: Dana Transaxle

1. ENGINE /TRANSMISSION CRADLE: DESCRIPTION

The engine and transaxle are supported by a single

structure that pivots on a “dogbone” link that connects

the front of the cradle to the frame. The cradle and

transaxle function as the Big County’s rear suspension.

The engine must be held in a stable position in relation

to the transaxle, in order to maintain tension on the

drive belt. The engine is mounted to the cradle, and

moves with the suspension.

2. “DOGBONE” LINK ASSEMBLY

2.1. Make a visual inspection of the link assembly at

each engine oil change interval (200 hrs), or if

any clunking noise is noticeable from the joint.

2.2. The joint consists of a metal body with two rubber bushings. The bushings allow the cradle to

swing up and down, and to pivot.

2.3. The life of the bushings will vary with temperature and severity of usage.

2.4. The joint can be replaced without removing the

cradle.

NOTE: The bolt and nut connecting the link to

the frame are SAE. The bolt and nut connecting

the cradle to the link are metric.

3. TRANSAXLE MAINTENANCE

3.1. Brake system maintenance is covered separately in the Brake System section of this manual.

3.2. The electrically controled, vacuum actuated gear

selector system is covered in the Gear Selector

section of this manual.

3.3. Lubrication intervals: Change the oil in the

transaxle after the first 50 hrs. of use. After this

break-in service is performed change the transaxle oil every 24 months or 500 hrs. of use.

3.4. If the oil in the transaxle becomes contaminated,

change it immediately

3.5. To drain the oil from the transaxle, remove the

hex-head plug that is located at the bottom of the

left side of the transaxle housing, directly below

the left axle tube.

NOTE: Clean the area surrounding the drain

plug before removal.

3.6. Check the oil level in the transaxle every 100

hrs. of use. If any leakage is evident, check the

level more frequently until the Big Country 4 X 2

can be taken to an authorized Cub Cadet dealer

for repair.

13

Page 18

4 X 2 Drive Package: Dana Transaxle

3.7. The amount of oil in the transaxle is 20 - 24

fl.oz. The level can be checked by removing the

black rubber cap visible on the top surface of the

transaxle housing, roughly in line with the axle

tubes. A clean steel rule, or improvised dipstick

should indicate the presence of oil 4 1/2“ (11.5

cm) down from the top surface of the transaxle

housing adjacent to the hole. The depth of the

oil in the housing should be 1 3/4” (4.5 cm).

See Figure 3.7.

The entire drive package and cradle can be removed

from the Big Country 4 X 2 as an assembly if the technician has reason to do so. If the transaxle is to be

repaired or replaced, the most direct method is to

remove it from the cradle without removing the cradle

from the frame.

NOTE: All of the shock absorber fasteners are

metric.

Figure 3.7

NOTE: Clean the area surrounding the rubber

plug prior to removal.

3.8. Lubrication type: For their transaxles, Dana

recommends SAE30 engine oil or 80W-90 gear

lube. This transaxle does not contain bronze

gears, so GL4 is a suitable grade if 80W-90 is

used. Cub Cadet Hydraulic Drive System Plus

(P/N 737-3121) is a suitable premium alternative.

3.9. Cleaning: The transaxle dissipates heat through

the housing. Accumulation of dirt will result in

higher operating temperatures and shortened

service life.

3.10. Corrosive substances such as salt spray and

chemicals found in some commercial detergents

and in fertilizers should be rinsed off immediately.

3.11. Do not direct a pressure washer at any seams,

joints, seals, vents, or plugs in the transaxle

housing.

3.12. There is a vent at the highest point in the housing. It must be kept free of blockage.

4. TRANSAXLE REMOVAL

14

Page 19

4 X 2 Gear Selector

1. DESCRIPTION OF THE GEAR SELECTOR SYSTEM:

1.1. The gear selector on the 4 X 2 Utility Vehicle is

electronically controlled and vacuum actuated.

The operator selects the desired gear by pushing one of three buttons on the dashboard.

The operator engages and disengages the differential lock using a yellow button to the left of

the steering wheel. See Figure 1.1.

Differential

lock button

Instrument panel

Figure 1.1

1.2. A corresponding light on the instrument panel

confirms the selection, or flashes a trouble code

in the event of a malfunction. See Figure 1.2.

Gear

selector

buttons

1.3. The brake switch is tied into the gear selector

circuitry. The vehicle will not shift gears if the

brake pedal is not depressed far enough to actuate the switch or if the switch actuator is out of

adjustment. See Figure 1.3.

Figure 1.3

1.4. The neutral switch, mounted on the transaxle,

above the Shift Wedge, confirms the position of

the shift wedge. A detent in the shift wedge

moves a contact roller in the neutral sensor

when the shift wedge moves, generating a signal

that goes to the electronic shift module (ESM).

See Figure 1.4.

Adjustable

brake

switch

actuator

Brake

switch

Detail of the instrument panel

Figure 1.2

Manual

over-ride

Vacuum actuator

15

Notch (neutral)

Shift wedge

Figure 1.4

Page 20

4 X 2 Gear Selector

1.5. The electronic shift module (ESM) processes

control inputs from the brake switch, neutral sensor, and the gear selector buttons on the dashboard. It figures out which way to move the

shifting wedge to engage the desired gear. If a

button is pushed, and the brake pedal is

depressed, the ESM energizes the solenoids

that control the vacuum to the servo that moves

the shifting wedge. The ESM is mounted on the

firewall, next to the brake pedal arm.

See Figure 1.5.

Brake

pedal

arm

Electronic

Shift

Module

1.7. The solenoids are covered by a protective rubber sheet. To reach them, remove the two wingnuts that secure the plenum to the upper crossmember, and carefully move the plenum aside.

The cover can be “unbuttoned” from the tow top

fasteners, and folded out of the way.

See Figure 1.7.

Protective cover

in place over vacuum solenoids

Figure 1.7

Figure 1.5

1.6. The solenoids are electrically operated valves

that direct vacuum to one side of the servo or the

other. The movement of the servo (vacuum actuator) is what moves the shift wedge. They are

mounted to the upper frame member at the forward corner of the engine compartment, to the

left hand side. See Figure 1.6.

Protective

cover

Plenum

(removed)

SOLENOIDS

Push-in fasteners

1.8. The vacuum line marked with a red dot car-

ries vacuum that moves the actuator in the

“forward” direction. This may be a movement

from neutral to forward, it may be a movement

from reverse to neutral, or it may be a movement

from reverse, past neutral to forward. The ESM

keeps track of which direction it is told to move

the actuator and whether or not the detent in the

shift wedge has passed the neutral sensor. The

vacuum line with the red dot should connect to

the solenoid nearest the outside of the vehi-

cle. That solenoid (forward) has one red wire

and one yellow wire with a black trace.

1.9. The vacuum line marked with the green dot

carries vacuum that moves the actuator in

the “reverse” direction. This may be a move-

ment form Neutral to Reverse, it may be a movement form Forward to Neutral, or it may be a

movement from Forward, past Neutral, to

Reverse. The vacuum line with the green dot

should connect to the middle solenoid. The

middle (reverse) solenoid has one red wire

and one orange wire.

Bed latch

Figure 1.6

16

Page 21

4 X 2 Gear Selector

1.10. The vacuum line marked with a blue dot pro-

vides vacuum to the actuator that controls

the differential lock. The differential lock is

engaged by a separate vacuum actuator. The

differential lock is disengaged by spring action

when two conditions are met: (1) The differential

lock solenoid is not activated and (2) If the differential lock was previously engaged, the speed of

the rear wheels is equal. The vacuum line with

the blue dot should connect to the inner solenoid. The inner (differential lock) solenoid has

one yellow wire with a white trace and one

green wire. See Figure 1.10.

Forward Reverse Differential

solenoid lock solenoid

Dots:

red

green

blue

Figure 1.10

• When the solenoid is de-energized, it provides a

vent to the atmosphere to release the pull on the

diaphragm.

NOTE: Because the differential lock actuator

only pulls in one direction, the vent from the

actuator is located in the plenum.

See Figure 1.11.

Plenum

Starter relay Vent tube for

differential

lock actuator

Figure 1.11

1.12. The vacuum reservoir (accumulator) holds a

reserve supply of vacuum to operate the actuator in low engine vacuum conditions. It is

mounted to the top of the transaxle.

See Figure 1.12.

1.11. Solenoid operation is as follows:

• A vacuum manifold connected to the vacuum

reservoir connects to the lower fitting on all three

solenoids.

• The color-marked elbows connect to the upper

fitting on each solenoid. The vacuum lines that

are connected to each solenoid by a colormarked elbow lead from the solenoid to an actuator.

• The orange and white wire provides power to the

forward and reverse solenoids. It should be

“hot” whenever the key switch is on. The solenoids are controlled by the presence or lack of

ground at the other wire that connects to each.

• The differential lock solenoid has a constant

ground, provided by the green wire. Presence of

current at the yellow and white wire triggers the

differential lock solenoid.

• When energized, each solenoid will connect

vacuum from the manifold (reservoir), through

the color marked elbow, to its actuator.

Vacuum (to solenoids)

Vacuum

reservoir

Vacuum

(from intake manifold)

Figure 1.12

NOTE: One vacuum line connects the intake

manifold to the vacuum reservoir. The other vacuum line connects the vacuum reservoir to the

solenoids.

17

Page 22

4 X 2 Gear Selector

1.13. The forward / reverse actuator is connected to

the shift wedge. Depending on which side of the

actuator vacuum is provided to, the actuator

moves the shift wedge in one direction or the

other. See Figure 1.13.

Vacuum

actuator

(servo)

Shift Wedge

Figure 1.13

1.14. The differential lock actuator is mounted lower

and farther back on the transaxle.

See Figure 1.14.

2. SELF DIAGNOSTICS

2.1. In the event of system malfunction, refer to the

fault code list.

2.2. If the Big Country does not shift properly, the

ESM will let the operator know there is a problem using the following table of fault codes.

Once the operator selects a gear, the instrument

panel will illuminate a gear light, or a combination of gear lights. DO NOT PRESS THE

ACCELERATOR UNTIL THE GEAR

SELECTED IS VERIFIED ON THE INSTRUMENT PANEL. These lights can be used to

determine if the vehicle shifted properly, or if

there is a shifting issue. The letter on the far left

represents the gear the vehicle was in prior to

shifting:

N

None

N

None

N

FN*

2

N

RN*

13

F

FRF*

None

R

R

RF*

None

Gear Selected

Light Code

R

Gear Selected

F

Fault Code

Light Code

Fault Code

3

Vent line to plenum

Figure 1.14

Vacuum from

solenoid

Gear Selected

N

Light Code

Fault Code

R

R RN*

None

1

F

None

F

FN*

2

* - Indicates the lights will flash for 5 seconds and an

audible tone will sound. During that time a shift will not

be allowed by the ESM. Once the lights stop flashing

the ESM will allow for shifting.

Example - The vehicle was in reverse (look at row

starting with "R"). The gear selected was forward (look

at "F" in "Gear Selected" row). The "Light Code"

flashed on the instrument panel is "RF", which corresponds with "Fault code 3". Looking up "code 3" in the

"Fault Codes Defined" section will list the potential

problems.

18

Page 23

4 X 2 Gear Selector

3. TERMS & DEFINITIONS -

• ESM - Electronic Shift Module

• Neutral Switch - in the neutral position the

switch is normally closed (NC).

• Shift Wedge - this is a wedge shaped mechanical part that actuates the Neutral Switch depending on the gear selected. The void portion of the

wedge is neutral.

• Closed Circuit Failure - the contacts in the

Neutral Switch will stay closed when the shift

wedge is in forward or reverse position. This will

occur if the shifting wedge is not contacting the

Neutral Sensor properly.

• Open Circuit Failure - the contacts in the Neutral Switch will stay in the open position even

when the contact roller passes the void in the

shifting wedge. This will occur if the contact

roller of the sensor is stuck inside the sensor

housing or if the wires leading to the sensor are

cut/disconnected.

NOTE: To determine the failure mode, it is necessary for the ESM to remember the original

state of the transmission gear, the gear that was

selected, and the state of the indicator lights.

NOTE: The ESM should automatically return the

shift wedge to the neutral position if the key

switch is turned off with the vehicle in gear.

Code 2: “FORWARD” and “NEUTRAL” lights flash

• Action C - Vehicle is in "REVERSE" and operator shifts to "NEUTRAL"

• This lets the operator know the vehicle was supposed to go to neutral, but probably ended up in

forward. The vacuum actuator probably shifted

the transmission into forward because the signal

to stop at neutral was not present. However, it

may not have shifted out of reverse if there was

mechanical binding, or loss of vacuum.

• Action D - Vehicle is in "NEUTRAL" and operator

attempts a shift to "FORWARD"

• This lets the operator know the vehicle was supposed to go to forward and it probably did, but it

was not verified because the Neutral Switch contacts never opened (due to mechanical binding

or a damaged switch).

Code 3: “FORWARD” and “REVERSE” lights flash

Action E - Vehicle is in “FORWARD” or “REVERSE”

and the operator shifts to the opposite direction

This lets the operator know the vehicle was supposed

to shift to the opposite direction and it probably did,

but the module was not able to verify. this may have

occurred because the neutral switch is damaged, or

there is mechanical binding, or loss of vacuum.

FAULT CODES DEFINED

Code 1: "REVERSE" and "NEUTRAL" lights flash

Action A - Vehicle is in "FORWARD" and operator

attempts a shift to "NEUTRAL"

• This lets the operator know the vehicle was supposed to go to neutral, but probably ended up in

reverse. The vacuum actuator probably shifted

the transmission into reverse because the signal

to stop at neutral was not present. However, it

may not have shifted out of forward if there was

mechanical binding, or loss of vacuum.

Action B - Vehicle is in "NEUTRAL" and operator

attempts a shift to "REVERSE"

• This lets the operator know the vehicle was supposed to go to reverse and it probably did, but it

was not verified because the contacts in the

Neutral Switch never opened (due to mechanical

binding or a damaged switch).

CAUTION: If the vehicle is shut off under a fault

condition it should return automatically to neutral. If the vacuum lines are defective, the unit

exhibits mechanical binding, or if the neutral

switch is damaged the unit will not return to neutral. When attempting to start the vehicle, either

all or none of the gear indicators will be illuminated. In those instances, before the vehicle will

start again, the contacts in the Neutral Switch

must be closed AND the vehicle will have to be

manually shifted into "NEUTRAL".

19

Page 24

4 X 2 Gear Selector

4. GEAR SELECTOR SYSTEM DIAGNOSIS

EXPLANATION OF METHODOLOGY:

• The gear selector system relies on two sub-systems (electrical and vacuum) to work properly. If

either sub-system fails, the entire system will not

operate correctly.

• A complete decision tree for diagnosis would be

unwieldy because of the number of variables

involved.

• The procedure as it is written here covers the

testing of each component in the system, and

should be a suitable guide for a competent technician who is not specifically familiar with the Big

Country gear selector system. The process:

1. Basic checks to identify obvious problems

and help define more in-depth problems.

2. Vacuum tests to see if the vacuum system

is responding to electrical inputs.

3. Electrical tests

• As technicians become familiar with this system,

they will be able to draw on their experience to

expedite the diagnostic process. The entire process may not be necklaces for every malfunction.

BASIC CHECKS:

4.1. Begin by test running Big Country vehicle to

confirm the problem. This may be done with the

vehicle on jack stands.

4.2. Safely lift and support the rear of the vehicle on

jackstands so that the rear wheels are clear of

the ground.

4.3. Raise the bed so that the transmission is visible

and accessible. Look at the position of the shift

wedge to confirm that the vehicle is in neutral.

NOTE: The bed may be removed entirely if the

technician finds it convenient.

4.4. Insure that no unsafe conditions will be created

by running the vehicle and operating the drive

system. See Figure 4.4.

Vehicle safely

supported

Exhaust

vented

Figure 4.4

4.5. Test run the vehicle, checking all modes of transmission operation.

NOTE: Perform tests at idle speed (1,250 to

1,400 RPM).

4.6. If the dash panel flashes “self diagnostic” signals, use the code descriptions in the “Fault

Codes Defined” section of this manual to help

identify the problem.

4.7. If the starter motor will not respond to the key

switch, check the neutral switch as described in

the “Gear Selector Electrical Diagnosis” section

of this manual.

4.8. If the transmission fails to shift in response to the

control button on the dashboard, turn the engine

off, and move the shift wedge by hand to check

for mechanical bind.

NOTE: It may be necessary to rotate the driven

clutch or the wheels slightly to engage forward

(F) or reverse (R) gear.

Clear work area

20

NOTE: A mechanical bind may indicate an internal transmission problem, not a gear selector

problem.

Page 25

4 X 2 Gear Selector

4.9. If the transmission fails to shift in response to the

control buttons on the dashboard, and the shift

wedge can be operated by hand with the engine

off, check the operation of the transmission.

• Manually place the shift wedge in neutral.

• Set the parking brake.

• Start the engine.

CAUTION: Keep well clear of any rotating components.

CAUTION: Do not reach over any rotating components or place yourself in a position that may

cause you to come into contact with rotating

components.

CAUTION: Do not wear loose fitting clothing that

may tangle in rotating components.

• Manually shift the transmission into each motion

gear (forward and reverse), and observe the

torque reaction of the transmission.

• Once a motion gear is engaged, it is possible to

return to the operator’s position and release the

parking brake to check wheel motion.

4.11. Remove the two wing nuts that secure the hood,

and open the hood.

4.12. Check to see if the arm on the brake pedal is

releasing the plunger far enough to close the

contacts within the switch when the pedal is

pressed.

4.13. If an audible click is not heard from the switch

when the brake pedal is pressed, adjust the

switch (and the brakes if necessary) as

described in the “Brake Adjustment” section of

this manual.

4.14. Check the brake switch connection for tightness,

and check the condition of the wires leading to

the switch. Power passes through the brake

switch to reach the buttons on the dashboard.

4.15. The back side of the buttons that control the

gear selector are visible with the hood open.

Check the connections for tightness and check

the condition of the wires leading to each button.

See Figure 4.15.

Forward button

• After wheel motion is checked, set the parking

brake, turn off the engine, and return the shift

wedge to neutral position.

• This procedure may be repeated for the other

motion gear.

NOTE: Unless the differential lock is engaged (if

the vehicle is equipped with one) or the parking

brake is set, with one of the wheel’s brakes disabled, the wheels may not rotate in the expected

direction because of normal differential action.

• With the parking brakes released, and the shift

wedge in neutral, spin the wheels. If there is

drag or unusual noises a problem may exist

within the transaxle or brakes.

4.10. Follow the functional test with a visual inspec-

tion of the gear selector system. After it is confirmed that the problem lies in the gear selector

system rather than the transaxle itself, the components of the gear selector system should be

examined.

NOTE: Refer to the “Description of the Gear

Selector System” section of this manual for pictures and descriptions of the components to be

inspected.

Neutral button

Reverse button

Figure 4.15

21

Page 26

4 X 2 Gear Selector

4.16. The ESM is visible on the firewall next to the

brake pedal arm. Check the harness connection

to the ESM for tightness, and check the condition of the wires leading to the ESM.

See Figure 4.16.

Electronic

Shift

Module

Figure 4.16

4.17. Check the condition of the fuse that provides

power to the gear selector system.

See Figure 4.17.

4.19. Check the operation of the neutral switch. The

switch is normally closed. The contact roller

should move freely, breaking continuity when

the roller is pressed upward by the shift wedge.

Adjust or replace if necessary. See Figure 4.19.

.566” to.610 (9/16” to 5/8”) from the

bottom of the hex to the top of the

shift wedge.

Figure 4.19

4.20. Check the tightness of the electrical connections

to the vacuum solenoids, and check the condition of the wires leadin g to the solenoid s.

Fuse that protects the ESM

Figure 4.17

4.18. The neutral switch is visible above the shift

wedge. Check the connection for tightness, and

check the condition of the wires leading to the

neutral sensor.

22

Page 27

4 X 2 Gear Selector

5. VACUUM TESTS

NOTE: The vacuum system is robust enough to

function reasonably well, even with substantial

leaks. The primary symptom of a leaky system

will be failure to return to neutral when the vehicle is turned-off in gear.

5.1. With the engine off and the choke closed,

release the clips that secure the air filter cover.

Remove the air filter cover and air filter.

5.2. Remove the air filter base and air horn baffle

using a socket wrench (10mm socket and 8mm

socket).

5.3. Trace the vacuum line from its source on the

intake manifold to the vacuum actuator. Look for

loose connections or damaged vacuum line.

See Figure 5.3.

Line to

reservoir

Intake manifold

5.7. After a visual check for obvious problems, check

for the presence of vacuum.

NOTE: A vacuum gauge that reads from 0 to 30

inches of mercury (HG) will be necessary to

complete this test. These instruments are commonly available at a reasonable price. They are

sometimes combined with low pressure pressure gauges. A U-tube manometer, as is sometimes used to check crankcase pressure is not

suitable. See Figure 5.7.

Vacuum gauge scale:

0 to 30 inches of

mercury (HG)

Vacuum port

Figure 5.3

5.4. The vacuum lines lead from the intake manifold

to the vacuum reservoir. From the reservoir, a

line goes up to both vacuum solenoids. From

the solenoids, a separate line leads to each side

of the vacuum actuator on the transaxle.

5.5. Correct any potential problems that are found

during the visual inspection.

5.6. Install the air filter and cover.

Figure 5.7

5.8. A quick check can be made by simply disconnecting the vacuum line from the engine at the

accumulator. Presence of vacuum can be felt

against a finger placed over the end of the line.

When the end of the line is open, the engine

note will become unsteady and the engine may

hunt for idle speed.

NOTE: All vacuum connections on the 4X2 are

secured with a light adhesive. After repairs are

completed, if a connection is not as secure as it

was previously, replace it or secure it with a

sparing amount of weather strip adhesive.

23

Page 28

4 X 2 Gear Selector

5.9. If a vacuum gauge is connected by T-fitting at

the reservoir (accumulator) end of the vacuum

line from the intake manifold, the following

readings should occur: See Figure

5.9.

• Idle speed: pulsing needle 7 - 18 in. HG.

• 2500 RPM: steady between 15 - 22 in. HG.

(usually 17 - 18 in. HG.)

• Over-run: highest reading > 30 in. HG.

• Engine Off: vacuum falls to 0.

Pulsing needle at idle

5.10. If a vacuum gauge is connected by T-fitting to

the line that leads from the accumulator to

the solenoid valves, the following readings

should occur: See Figure 5.10.

Steady needle at idle

Figure 5.10

• Idle speed: steady needle 15”-22” HG.

(usually 17”-18” HG.)

Figure 5.9

NOTE: If the vacuum level is low, it may be an

engine problem such as low compression or a

blocked exhaust system.

NOTE: If there are no engine problems and the

vacuum is low, the most common cause will be

leaky vacuum lines or fittings. To check for this,

dead-head the vacuum gauge to the line leading

to the manifold. If the vacuum level improves,

there are leaks in the system.

• 2500 RPM: steady needle 15”-22” HG.

(usually 17”-18” HG.)

• Over-run: steady needle 15”-22” HG.

(usually 17”-18” HG.)

Engine Off: vacuum will slowly bleed down to 0 over

the course of 10 - 15 minutes. In this time it will be possible to shift gear several times until the vacuum level

falls below about 7” HG. See Figure 5.10.

Maintains several shifts worth of

vacuum after the engine is stopped

Figure 5.10

24

Page 29

NOTE: The vacuum reaction is different from

one side of the reservoir to the other because

there is a check valve built into the reservoir.

The reservoir also acts as a damper, smoothing

out the vacuum levels variations and pulses.

NOTE: If the lines are reversed on the reservoir,

no vacuum will register on the gauge.

NOTE: If vacuum bleeds down quickly, there are

leaks in the system. Isolate different portions of

the system to identify leaks.

5.11. Dead-head the vacuum gauge to the outlet side

of the reservoir. If the vacuum level falls quickly,

the reservoir is leaking. See Figure 5.11.

Dead-head gauge

connection

4 X 2 Gear Selector

5.12. Disconnect and plug the fittings that lead to two

of the solenoid valves. If the vacuum bleeds

down quickly, the solenoid valve that is still connected is at fault. Reverse the test to confirm

the results. See Figure 5.12.

Forward Reverse Differential

solenoid solenoid lock solenoid

Gauge connection

Vacuum line to reservoir

Figure 5.12

Viscus from

intake manifold

Figure 5.11

5.13. If vacuum bleeds down with all of the solenoid

valves eliminated from the system, and the reservoir is not leaking: the leak lies in the line

between the valves and the accumulator.

5.14. If vacuum reaches the solenoid valves, but the

gear selector does not respond to the push button on the dashboard, check the action of the

solenoid valves.

5.15. Identify the vacuum line from the forward solenoid valve. Use a T-fitting to install the vacuum

gauge in-line between the solenoid and the shift

actuator (upper fitting). See Figure 5.15.

Vacuum gauge teed-into the vacuum

line from the forward solenoid to the

shift actuator

25

Figure 5.15

Page 30

4 X 2 Gear Selector

NOTE: The vacuum line from the forward sole-

noid will have a red dot on the elbow that connects it to the upper fitting on the valve. The

valve itself should be controlled by two wires: (1)

Orange with white trace wire and (1) yellow with

black trace wire.

5.16. Start the engine, operate the gear selector buttons on the dashboard, and observe the vacuum

reading on the gauge. The readings should be

as follows:

• Neutral to Reverse:

Brief ri se to r oughly 5” HG., followed by retu rn to 0 .

• Reverse to Forward:

5.17. Identify the vacuum line from the reverse solenoid valve. Use a T-fitting to install the vacuum

gauge in-line between the solenoid and the shift

actuator (upper fitting). See Figure 5.17.

Rise to 15”-22” HG. (usually 17”-18”) and hold

steady. May pause at roughly 5 HG.

• Forward to Neutral:

Pause at roughly 5” HG., drop to 0.

• Neutral to Forward:

Rise to 15”-22” HG. (usually 17”-18” HG.) and

hold.

• Forward to Reverse:

Pause at roughly 5” HG., drop to 0.

• Reverse to Neutral:

Brief rise to roughly 5” HG. followed by return to 0.

Tee connection

Figure 5.17

NOTE: The vacuum line from the reverse sole-

noid will have a green dot on the elbow that connects it to the upper fitting on the valve. The

valve itself should be controlled by two wires: (1)

orange with white trace wire and (1) orange wire.

5.18. Start the engine, operate the gear selector buttons on the dashboard, and observe the vacuum

reading on the gauge. The readings should be

as follows:

• Neutral to Reverse:

Rise to 15”-22” HG. (usually 17”-18”) and

hold steady.

• Reverse to Forward:

Brief rise to roughly 5” HG. followed by return to 0.

• Forward to Neutral:

Brief rise to roughly 5” HG. followed by return to 0.

• Neutral to Forward:

Brief rise to roughly 5” HG., followed by return to 0.

• Forward to Reverse:

Rise to 15”-22” HG. (usually 17”-18”) and

hold steady. May pause at roughly 5” HG.

• Reverse to Neutral:

Brief rise to roughly 5” HG. followed by return to 0.

26

Page 31

4 X 2 Gear Selector

5.19. If vacuum signals vary, check the electrical signal to the vacuum solenoid (see “Gear Selector

Electrical System Diagnosis” section of this

manual).

5.20. If the electrical system is functioning properly,

replace the suspect solenoid valve.

NOTE: The most common failure modes will be

for a solenoid valve to be stuck fully open or

stuck fully closed.

5.21. If the vacuum signals are correct to this point,

but the shift wedge does not operate correctly,

and the transmission does not have any internal

problems, there may be one of the following

issues:

• The vacuum actuator may be bad.

• There may be a vacuum leak between the vacuum solenoid and the vacuum actuator.

NOTE: A bad vacuum actuator will seldom work

in either direction.

5.22. To isolate a problem that lies down-stream of the

vacuum solenoids, dead-head the gauge into

the vacuum line that connects to the forward

side of the vacuum actuator. See Figure 5.22.

5.26. Repeat the test on the vacuum line that connects to the reverse side of the vacuum actuator.

The results should mirror the results of the first

test.

5.27. If both tests work as described, the vacuum

actuator is bad.

DIFFERENTIAL LOCK ACTUATOR

5.28. Testing the vacuum signal to the differential lock

actuator is a very similar procedure. All of the

tests upstream of the vacuum solenoids apply to

all three solenoids.

5.29. Because the differential lock actuator only needs

to move in one direction, there is only one vacuum line leading to the actuator. The second

line is only a vent.

5.30. Teeing-in the gauge between the solenoid and

the actuator should yield a vacuum reading that

rises to 17-18 inches, and holds when the

engine is turned off. See Figure 5.30.

Tee-in vacuum

gauge here

Differential lock

actuator

Vacuum here

pulls the shift

wedge toward

forward gear

Figure 5.22

5.23. Start the engine, and press the “F” button on the

dashboard.

5.24. The vacuum should rise to 15”-22” HG. (usually

17”-18” HG.).

NOTE: The “F” and “N” buttons will flash on the

control panel in the dashboard, and the shift

wedge will not move.

5.25. With any other gear selected, the vacuum level

should be 0.

Vent line

Vacuum line

Figure 5.30

27

Page 32

4 X 2 Gear Selector

5.31. The differential lock works independently of the

gear selector, and is not controlled by the ESM.

It responds directly to the yellow button to the left

of the steering wheel. See Figure 5.31.

Differential

lock button

Figure 5.31

NOTE: The differential lock button is a back-lit

momentary contact switch. When the differential

lock is engaged, the button will light-up. The differential lock will stay engaged, and the button

will stay lit until the button is pushed a second

time to disengage the differential lock.

6. GEAR SELECTOR ELECTRICAL SYSTEM DIAGNOSIS.

6.1. Any time a computer controlled circuit is being

checked, a high impedance circuit tester

should be used. A conventional circuit tester

simply places a light bulb in series with a ground

path from the circuit being tested. The draw

placed on the circuit by a conventional circuit

tester can damage computer circuitry such as

that used in the ESM. High impedance circuit

testers do not pass the full line current to ground,

but do pass a small portion of the line current to

ground, sense the presence of current, and light

a small LED indicator. High impedance circuit

testers are commonly available at a reasonable

price. See Figure 6.1.

High impedance

circuit tester

Figure 6.1

NOTE: Back-probing is the best technique for

finding power at molded connections. Clip the

end of the tester lead to a good ground, and

probe the connector with the end of the tester.

6.2. If there are no signs of life in the gear selector

electrical system, check the fuse as described in

the “BASIC CHECKS” section of this manual.

NOTE: If the fuse is blown, inspect the rest of

the gear selector wiring harness to find the

source of the short that caused the blown fuse.

28

Page 33

6.3. If the fuse is OK, check the relay.

See Figure 6.3.

Key to relay

center

Relay center

with covers

removed

4 X 2 Gear Selector

NOTE: Use this basic technique when checking

any in-puts or out-puts of the ESM. If power is

not found at the device that is connected to the

ESM, check for power where the wire in question reaches the ESM. If the two do not correspond, a the problem lies between them, in the

harness.

6.5. If it is established that the ESM has power, but

the gear selector does not respond to the buttons on the dashboard, check the brake switch.

See Figure 6.5.

Figure 6.3

TIP: The relay that controls power to the ESM also

controls power to the fuel shut-off solenoid. With the

relay uncovered, a technician should be able to hear

and feel the relay “click” when the key switch is turned

on. This click will confirm that the relay is getting

power. If the relay is successfully energizing the circuit

that contains the ESM, a report click should be heard

from the fuel shut-off solenoid. If the relay clicks but

the fuel shut-off solenoid does not, the relay may be

bad. Other possibilities include a fault in the wiring harness downstream of the relay, or a defective fuel shutoff solenoid.

6.4. If power is present coming from the relay, check

for power at the ESM. If there is no power to the

ESM, but there is power at the relay, a fault

exists in the wiring harness. See Figure 6.4.

Brake switch

(normally open)

Figure 6.5

NOTE: If the ESM does not know that the brake

pedal is pressed down, the gear selector system will not operate. The brake switch must be

properly adjusted as described in the “Brake

Adjustment” section of this manual.

NOTE: The red wires that feed power to the

gear selector buttons get their power from

the brake switch.

NOTE: There are two pair of male spade con-

nectors on the back of the brake switch. Two of

them lead to a set of contacts that are normally

open (plunger up). The other two lead to a set of

contacts that are normally closed (plunger up).

The wires should be connected to the terminals that lead to the normally closed contacts. they can be identified by “NC” stamped

on the male spade terminal.

Plunger

down:

contacts

closed

Back-probing the harness

at the ESM connection

Figure 6.4

NOTE: There are two red wires that connect to

the brake switch. One is “hot” whenever the key

switch is turned on. The second red wire is connected to the first (becoming hot) when the

brake pedal is depressed.

29

Page 34

4 X 2 Gear Selector

6.6. After power passes through the brake switch, it

reaches the gear selector button on the dashboard. If power reaches these buttons, the

brake switch contacts are closed.

See Figure 6.6.

Checking for power at

gear selector buttons

Figure 6.6

6.7. If the gear selector only works properly only

in one direction, the shift signal may not be

reaching the ESM from the gear selector button

on the dashboard.

6.10. The vacuum tests may identify a vacuum solenoid that is not working properly. Check the

power to the solenoids to confirm whether the

problem is in the solenoid itself or in the electrical signal to the solenoid.

NOTE: The orange with white trace wire that

leads to each vacuum solenoid is “hot”

whenever the key switch is in the on position.

The ESM energizes the vacuum solenoids by

creating a ground path through the second wire.

6.11. Check the orange with white trace wire for power

at each vacuum solenoid with the key switch in

the on position. See Figure 6.11.

Testing for power to

the solenoid

6.8. With the key switch on, check the red wire that

connects to the back of each gear selector button to insure that it is getting power.

6.9. Press each button and check for power at the

downstream spade terminal on the back of the

button to confirm that the contacts are closing,

and it is passing the shift signal back to the

ESM. See Figure 6.9.

Key switch “ON”

“Forward” button depressed

Voltage present

Figure 6.11

6.12. If there is no power, but the ESM has been confirmed to have power, check for power at the

ESM end of the wire. If power is present at the

ESM end of the wire, the problem lies in the harness between the ESM and the vacuum solenoid. If power is absent, the ESM may be at

fault.

6.13. Check the second wire on each vacuum solenoid (yellow with black trace for forward solenoid, orange for reverse solenoid) for power

when the corresponding gear is selected.

Figure 6.9

30

Page 35

4 X 2 Gear Selector

6.14. If power is present at the second wire, that

means that a ground path has successfully been

created, and the vacuum solenoid should be

open. See Figure 6.14.

Vacuum test at the

solenoid should

correspond with the

results of the

electrical test

Figure 6.14

6.15. If power and vacuum are present at the vacuum

solenoid, but vacuum is not being passed to the

port that leads to the vacuum actuator, replace

the vacuum solenoid.

NOTE: The solenoid can be double-checked by

substitution before replacement.

6.16. If the F-N-R lights on the instrument flash when

any of the gear selector buttons are pushed,

even after manually returning the shift wedge to

neutral, check the neutral switch.

See Figure 6.16.

Red wire with

white trace:

voltage present

in neutral

6.17. The red wire with white trace wire will show

power when the roller on the neutral switch is in

the detent in the shift wedge.

DIFFERENTIAL LOCK

6.18. With the hood open to gain access the back side

of the differential lock button, some tests can be

made at the button. See Figure 6.18.

Differential lock button

Power to lamp

in button and

to solenoid

Hot lead

(orange)

Figure 6.18

6.19. The green wire provides a ground for the

bulb in the button that lights when the differen-

tial lock is engaged. If the differential lock works

normally, but the button does not light-up when it

is engaged, check this connection for continuity

to ground.

6.20. The orange wire should be hot whenever the

key switch is turned on.

6.21. The yellow wire with white trace should be hot

with the key on and the differential lock

engaged. The small branch off of that wire provides current to light-up the button when the differential lock is engaged.

Ground

(green)

Figure 6.16

31

Page 36

4 X 2 Gear Selector

6.22. The yellow wire from the button activates the differential lock solenoid. The green wire from the

solenoid provides a constant ground. Check for

power and vacuum at the upper port when energized. See Figure 6.22.

Green

ground wire

Yellow wire with white

trace: hot to energize

Figure 6.22

6.23. If the differential lock fails to engage, and the

vacuum and electrical systems appear to be

functioning correctly, isolate the mechanical portion of the differential lock, and check it for freedom of movement and correct operation.

See Figure 6.23.

Vacuum actuator disconnected from

the differential lock actuator arm

Disengage

Engage

6.26. It will probably be necessary to rotate the input

shaft of the transmission in order to allow the differential lock to engage. This can be done by

grasping the driven clutch and rotating it.

6.27. If the unit shows signs of tampering or previous

repair, check for correct alignment and adjustment. See Figure 6.27.

Splined shaft

Clamp bolt on arm

Adjustable

length

Figure 6.27

6.28. The movement necessary to engage the differential lock should coincide with the action of the

vacuum actuator.

6.29. If the vacuum system, electrical system, and

adjustment are correct, there may be an internal

transmission problem.

6.30. If the gear selector fails to operate, and the vacuum and electrical systems appear to be functioning correctly, isolate the mechanical portion

of the transmission, and check it for freedom of

movement and correct operation.

6.31. With the engine turned off, and the parking brake

released, move the manual over-ride lever to

shift gears. It should firmly engage forward and

reverse.

Figure 6.23

6.24. With the engine turned off, and the parking brake

released, remove the cotter pin and clevis pin

that secure the differential lock actuator arm to

the clevis on the vacuum actuator.

6.25. Engage and disengage-engage the differential

lock manually to test its function.

32

Page 37

6.32. It will probably be necessary to rotate the input

shaft of the transmission in order to allow the

gears to mesh. This can be done by grasping

the driven clutch and rotating it. See Figure 6.32.

Figure 6.32

4 X 2 Gear Selector

6.33. If the manual over-ride does not work properly,

there may be an internal transmission problem.

33

Page 38

4 X 2 Gear Selector

34

Loading...

Loading...