Page 1

www.mymowerparts.com

2004 Technical Update

Cub Cadet Big Country

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

This Service Manual is not a substitute for the Operator’s Manual. You must read, understand

and follow all of the directions in this manual as well as the Operator’s Manual before working

on this power equipment.

CUB CADET LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA

K&T Saw Shop 606-678-9623 or 606-561-4983

FORM NO.769-00971

(11/2003)

Page 2

www.mymowerparts.com

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 3

www.mymowerparts.com

TABLE OF CONTENTS

Battery Drain.....................................................................................................1

Bed Lift Switch ..................................................................................................3

New Wiring Harness..........................................................................................4

General Improvements......................................................................................6

Opening Price Point Unit................................................................................... 11

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 4

www.mymowerparts.com

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 5

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

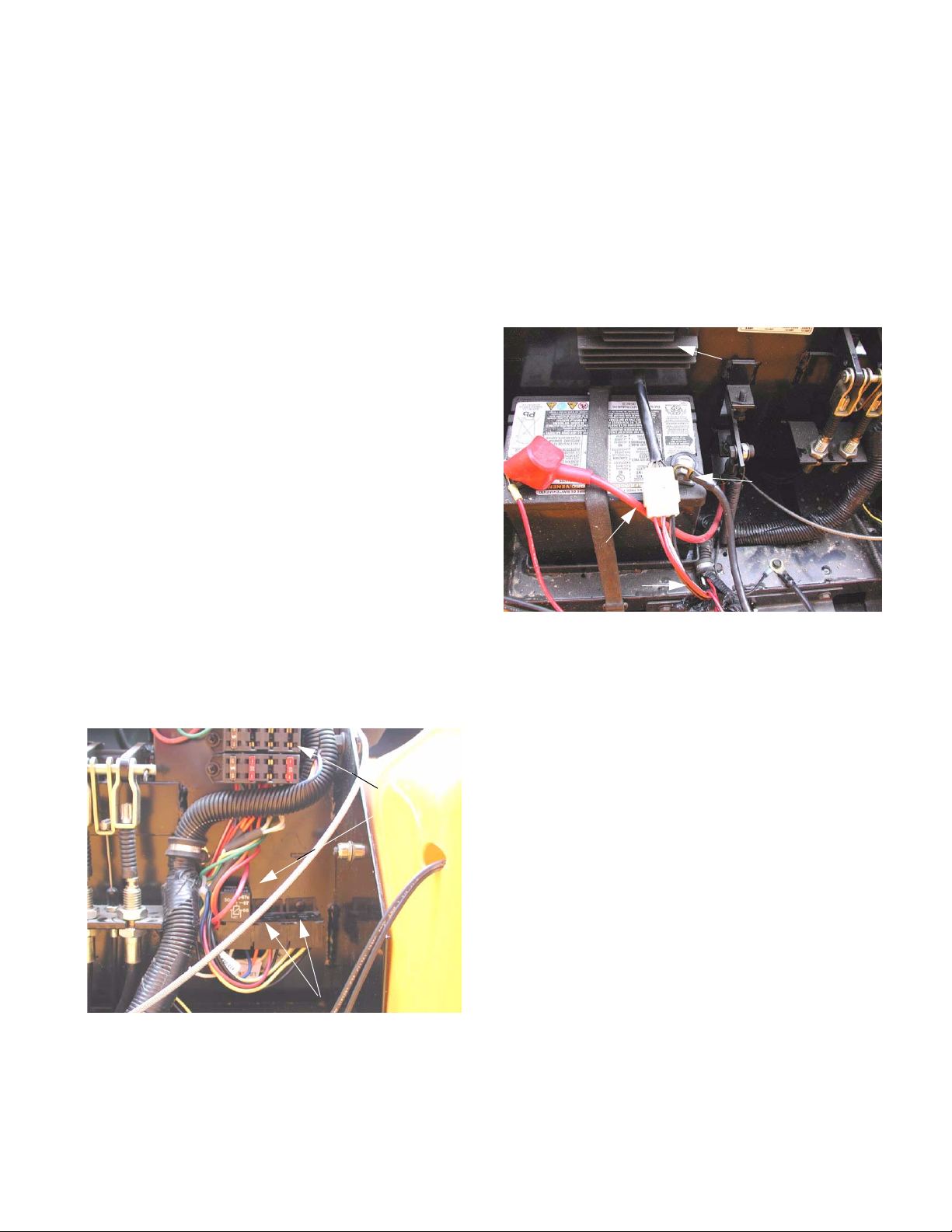

1. ISSUE: BATTERY DRAIN IN LONG TERM STORAGE (CC 431)

Some first-year production Big country Utility Vehicles

(prior to serial number 1A013B000001) may experience an electrical draw that drains the battery. The

problem will generally occur when the Big Country is

not in use for a month or more. If a customer has complained of this situation, the following change should be

made to the wiring harness.

1.1. Turn the engine off and remove the key from the

key switch. Tilt the driver’s seat forward and

check the serial number. If the serial number is

not legible, identify the wiring harness.

1.2. Remove the bolts, flat washers, and rubber

washers that secure the hood in the closed position using a 1/2” wrench. Open the hood.

1.3. Vehicles equipped with the wiring harness that is

subject to his occurrence are readily identifiable

by the location of the fuse box, relays and voltage regulator-rectifier. The fuse box is mounted

under the hood in a vertical position on driver’s

side of the firewall. Directly beneath it are

molded plugs for three relays. The regulatorrectifier is located under the hood on the passenger’s side firewall, directly above the battery. See Figure 1.3.

1.4. If not equipped with the effected harness further

diagnosis is necessary. If equipped with the

effected harness, disconnect the negative battery cable using a 7/16” wrench.

1.5. Unplug the harness connector from the pigtail on

the regulator-rectifier. See Figure 1.5.

Regulator rectifier

Negative

battery cable

Harness

plug

Cut here

Figure 1.5

1.6. Cut the two red wires that enter the harness

connector roughly 6” from the connector.

NOTE: It may be necessary to remove some of

the protective covering (conduit) from the harness.

Bed lift relay location

Figure 1.3

K&T Saw Shop 606-678-9623 or 606-561-4983

Fuses

Accessory

Relay

1.7. Strip 1/4” of insulation from the loose ends of the

red wires that are attached to the harness plug.

1.8. Twist the stripped ends together, and crimp them

securely into the yellow butt connector.

1.9. Strip 1/2” of insulation from the end of the red

wire provided in the kit.

1

Page 6

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

1.10. Fold the stripped end back on itself, and crimp it

securely into the other end of the yellow butt

connector. See Figure 1.10.

Harness

connector

2 Original

red wires

Yellow butt

connector

New red wire

Figure 1.10

1.11. Remove the accessory relay from the relay block

on the firewall. See Figure 1.11.

1.14. Strip 1/4” of insulation from the ends of the two

lengths of white wire and 1/2” of insulation from

the loose end of the red wire that was previously

added to the harness connector.

1.15. Twist the two stripped ends of the white wire

together and crimp them securely into the second yellow butt connector.

1.16. Fold the stripped end of the red wire back on

itself, and crimp it securely into the other end of

the yellow butt connector. See Figure 1.16.

White

wires

Yellow butt

connector

Red

wire

Accessory relay

Mounting

White wire

Figure 1.11

1.12. Remove the relay block from the firewall using a

phillips head screwdriver, and separate it from

the other two relay blocks.

NOTE: The relay blocks have interlocking channels on each side.

1.13. Cut the white wire that enters the accessory

relay block. Leave enough length accessible on

each side of the cut to strip the insulation from

the wire and install a butt connector.

crews

Figure 1.16

1.17. Install the relay block back on the firewall, and

plug-in the relay.

1.18. Plug the voltage regulator-rectifier connector

back into the harness connector.

1.19. Connect the negative battery cable to the negative battery terminal.

1.20. Close and secure the hood.

1.21. Test-run the Big Country 6 X 4 before returning it

to service.

NOTE: It may be necessary to remove some of

the protective covering (conduit) from the harness.

K&T Saw Shop 606-678-9623 or 606-561-4983

2

Page 7

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

2. ISSUE: REVERSED OPERATION OF ACCESSORY (BED LIFT) SWITCH (CC 438)

Some first-year production Big country Utility Vehicles

(after serial number 1A013B000001) may have been

made with mis-wired accessory connectors in the wiring harness. If this situation exists, rocking the bed lift

switch up will lower the bed, and rocking the bed lift

switch down will tilt the bed. If a customer has complained of this situation, the following change should be

made to the wiring harness:

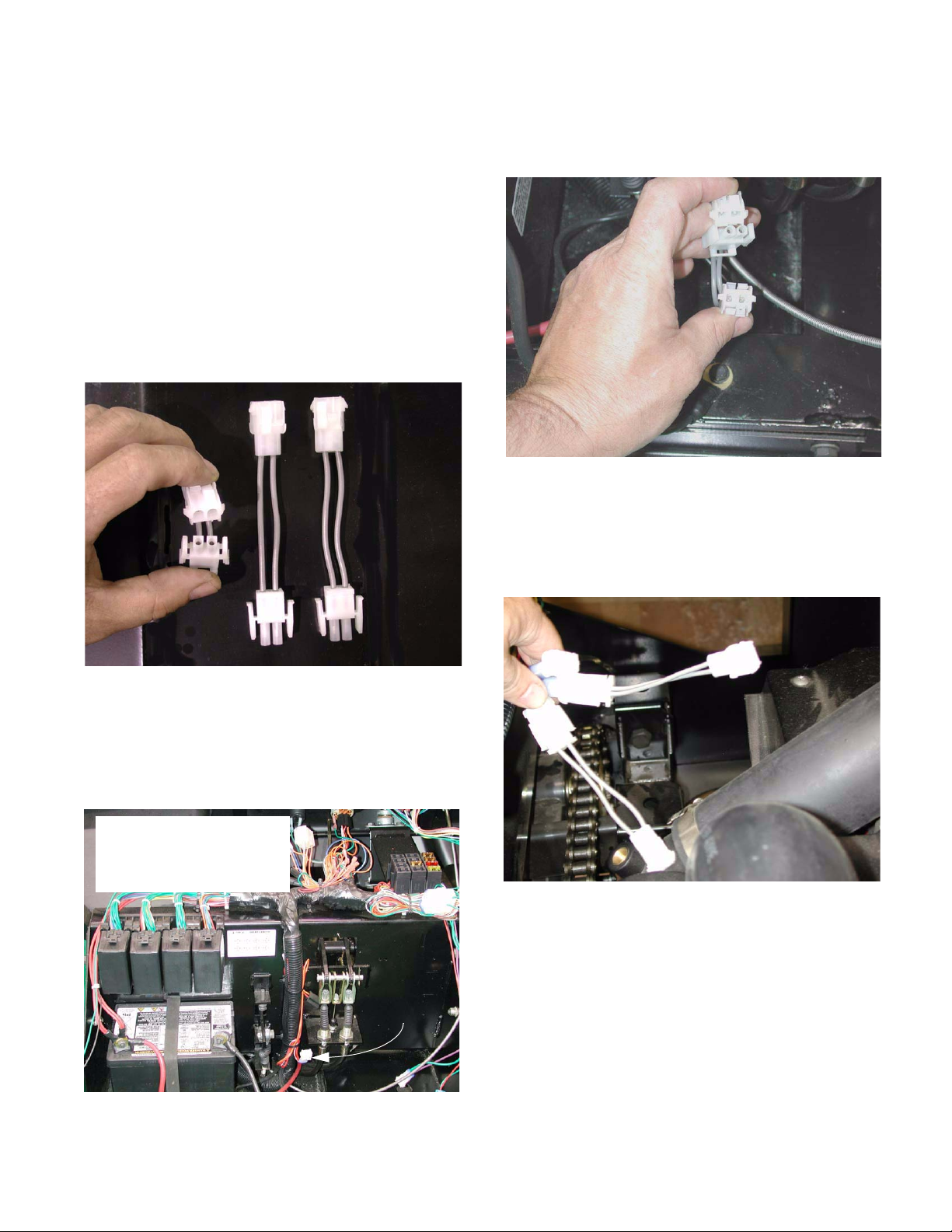

2.1. The service kit consists of three adaptors that

reverse the polarity of the connections.

See Figure 2.1.

Three adaptors

contained in

CC348 kit

2.4. Install one adaptor from the service kit as an

interface connector between the harness and

the accessory. See Figure 2.4.

Figure 2.4

2.5. Raise the bed. The final two connectors are

located among the bundle near the right rear

corner of the engine compartment, at the top of

the frame. See Figure 2.5.

Figure 2.1

2.2. Remove the two wing screws that secure the

hood, and open the hood.

2.3. Identify the front accessory relay connector.

See Figure 2.3.

The front accessory relay

connector has one red wire

and one red wire with a

white trace.

Front

accessory

relay

connector

Figure 2.3

Figure 2.5

2.6. Identify the connector that joins the lift motor to

the lift motor relays. It has one red wire and

one yellow wire. Install the second adaptor as

an interface connector between the lift motor

and the harness connection to the lift motor

relays.

2.7. Identify the rear accessory relay connector, and

install the third adaptor to it in similar fashion to

the first two adaptors. The rear accessory relay

connector has one purple wire and one black

wire.

3

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 8

y

_

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

2.8. The adaptors will reverse the polarity of the connections. If reveres action of accessories or bed

lift is not encountered, the adaptors are not necessary on that unit. See Figure 2.8.

Polarity reversed

Figure 2.8

2.9. Lower the bed. Close and secure the hood.

2.10. Test the operation of the bed lift and accessories

before returning the unit to service.

3. FEATURE: NEW WIRING HARNESS

3.1. The relays have been consolidated into a relay

center above the battery, in the place formerly

occupied by the voltage regulator-rectifier. The

fuse block has been moved from the vertical surface of the firewall. See Figure 3.1.

Fuse block

Relay

center

Figure 3.1

NOTE: The 4 X 2 and 6 X 4 use the same wiring

harness after serial number 1A013B000001. the

features listed apply to both models.

3.2. The relays and their sockets in the relay centered protected by plastic covers.

See Figure 3.2.

Accessory relay

sockets (covers

off)

Key to rela

center

Figure 3.2

4

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 9

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

3.3. One relay in this block is used by the original

equipment. The rest of the sockets accommodate pre-wired accessories. See Figure 3.3.

Detail of key to relay center

Figure 3.3

3.4. The relay covers go on in one direction only.

There is a notch in each cover that matches a

notch in the relay socket. See Figure 3.4.

3.5. The one relay that is not in this group is the

starter relay, which is located on the outside of

the harness, just below the center of the upper

cross-member at the front of the engine compartment. See Figure 3.5.

Figure 3.5

NOTE: The starter relay is different from the

other relays on the Big country 6 X 4, but is interchangeable with the relays used on the 2000

series, 3000 series, and the recent 1000 series.

Wrong

Figure 3.4

Right

3.6. The fuse block has been moved to the horizontal

surface at the top of the firewall on the driver’s

side of the vehicle. See Figure 3.6.

Fuse

block

Dashboard

Front of vehicle

Key to

fuse block

Figure 3.6

5

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 10

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

3.7. The fuse block also contains capacity for expansion, allowing the easy addition of accessories

See Figure 3.7.

Detail of key to fuse block

Figure 3.7

3.8. The voltage regulator-rectifier has been relocated to the right side of the cross-member at

the top front corner of the engine compartment.

See Figure 3.8.

3.10. The 4 X 2 and the 6 X 4 use the same wiring harness. The 6 X 4 has a mechanical gear selector

system while the 4 X 2 has an electrically controlled, vacuum actuated gear selector system.

The harness connections that join the push-button gear selector to the main harness in the 4 X

2 exist in the 6 x 4 as well. They are secured

behind the dashboard, but are not connected to

anything. See Figure 3.10.

Blanks for accessory

switches

4 X 2

gear

selector

button

holes

Controller and buttoner

connections for 4 x 2

gear selector

Figure 3.10

Instrument panel

Regulator / Rectifier

Figure 3.8

3.9. The instrument panel has been revised slightly,

and may be further revised for ‘04 production.

4. FEATURES: GENERAL IMPROVEMENTS

NOTE: Most of the features listed in this section

are present on the 4 X 2 and the 6 X 4. Lessons

learned in the first year of production have been

applied to all models.

4.1. Suspension travel has been increased.

See Figure 4.1.

Old front

suspension

travel

New front

suspension travel

Figure 4.1

6

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 11

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

4.2. The manually operated lift bed now features a

gas charged lift assist cylinder on the 6 X 4 as

well as the 4 X 2. See Figure 4.2.

Lift cylinder

Figure 4.2

4.3. The heat shield will move from the bed to the

muffler tor reduce vibration noise.

4.4. The dashboard and glove box are now a single

piece instead of two. See Figure 4.4.

Integrated

dashboard and

glove box

4.6. The two mounting systems are not interchangeable. The rear mounting points on the frame are

not drilled and cut to accept the rubber isolator

mounts. The front mounting points have

changed substantially. Inserting rubber isolator

mounts between the frame and the the engine

and transmission support bracket on a Big

Country 6 X 4 that was not meant to have them

will also create clearance issues between the

bed and the intake system. See Figure 4.6.

Solid rear mounting point

Figure 4.6

NOTE: The solid mounts may allow slightly

higher vibration at idle than the rubber mounts.

Figure 4.4

4.5. The engine and transmission support bracket (6

X 4) are solid mounted to the frame. Early versions (prior to serial number 1A013B000001)

used rubber isolated engine and transmission

support brackets. The solid mountings maintain

more consistent alignment between the transmission and the suspension. Mis-alignment

allows drive-shaft whip, causing vibration under

load, and accelerated wear.

4.7. All of this year’s production will have the smaller

headlights with better optics than last year. This

was a running change during ‘03 model year

production.

7

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 12

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

4.8. This year’s fenders will also be high-cut compared to last year’s fenders. This was a running

change during ‘03 model year production.

See Figure 4.8.

Figure 4.8

4.9. A seal has been added to the rear edge of the

hood.

4.12. Last year, if the optional brush guard was fitted,

it was necessary to remove it before opening the

hood. See Figure 4.12.

Figure 4.12

4.13. The new hood is mounted on a bracket that

slides into brackets on the frame, rather than a

piano hinge previously used. See Figure 4.13.

4.10. A more subtle change to the front fenders

involves the contour where the hood meets the

fender. The previous fender did not have the

extra ridge to help locate the edge of the hood.

See Figure 4.10.

Contour added for the edge of the

hood to seat in

Figure 4.10

4.11. Mossy Oak

flage will be an available finish for bodywork on

the Big country.

TM Dark Forrest Floor Pattern camou-

Frame bracket

Slide to remove

hood bracket

Figure 4.13

4.14. The pin is retained by a washer and hairpin clip.

Remove hairpin clip

and washer

8

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 13

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

4.15. The bed of the 4 X 2 is rated to carry 800 lbs, as

opposed to 1,000 lbs for the 6 X 4. The 4 X 2

bed is 39” long (internal) compared to 47” (internal) for the 6 X 4. See Figure 4.15.

Figure 4.15

4.16. The tailgate of the 4 X 2 bed differs from that of

the 6 X 4 in that of the 6 X 4 in that it is held in

place by 4 J-pins. See Figure 4.16.

4.17. It can be released at the top for loading or dumping. See Figure 4.17.

Tailgate bumpers

Tailgate lanyard

Figure 4.17

4.18. If the operator wishes to spread the contents of

the bed, the two bottom J-pins can be released.

This will allow the bottom of the tailgate to swing

away from the bed, while the top edge remains

fixed. See Figure 4.18.

J-pins

Figure 4.16

Figure 4.18

9

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 14

www.mymowerparts.com

Big Country 6 x 4 and 4 X 2 Update

4.19. Travel limiters are installed on the 4 X 2 bed

hinge point to keep the bed from tilting beyond

the intended range. Under no circumstances

should a Big Country 4 X 2 be placed in service

without those components in place.

See Figure 4.19.

Travel limiter

Figure 4.19

4.20. There have been some complaints of rattling tailgates. This issue will be addressed for ‘04 production.

4.23. For ‘04, the structure of the frame forward of the

engine bay will change. Instead of one hollow

channel beneath the floor, three separate channels will increase the rigidity of the structure.

Suspension pick-up points and mounting locations will remain unchanged. Some firewall

bracketry will be simplified. See Figure 4.23.

4.24. The pedal mounting brackets will also be simplified. See Figure 4.24.

Figure 4.23

4.21. For ‘04, the 4 X 2 Big Country will use a cable

operated shift mechanism instead of the electrically controlled, vacuum operated system currently in place.

4.22. The electrically controlled, vacuum operated differential lock will remain for the ‘04 season.

Figure 4.24

4.25. For ‘04, the front wheel mounting (lugs) and size

may be standardized to match the rear wheels.

4.26. For ‘04, the hood will be held down with a rubber

strap fastener. This will eliminate easy-to-lose

wing bolts, and it will hold the hood more firmly

in position.

10

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 15

www.mymowerparts.com

5. OPENING PRICE POINT

5.1. An OPP (opening price point) version of the 4 X

2 will be introduced for the 2004 model season.

5.2. It will use the same platform as the standard 4 X

2, with the possible exception of closed panels

on the side. See Figure 5.2.

Big Country 6 x 4 and 4 X 2 Update

Figure 5.2

5.3. The opening price point model may have a polymer bed.

5.4. The opening price point model may have four

four-bolt wheels. They will be smaller than those

found on the heavy duty 4 X 2.

5.5. Turf tread may be the only tire available for the

OPP model.

5.6. The opening price point model may feature a

translucent fuel tank.

5.7. The opening price point model will have a 9.5

H.P. single-cylinder Kawasaki engine and transaxle.

5.8. The engine and transmission cradle (OPP only)

will be changed to fit the Kawasaki drive train.

5.9. The rear spring rates of the OPP model will be

changed to reflect lighter usage.

5.10. The wiring harness will be pared-down for the

OPP model. Accessory harnesses must be

added for accessories.

11

K&T Saw Shop 606-678-9623 or 606-561-4983

Loading...

Loading...