Page 1

BDU-10/21

Hydrostatic Transmissions

Service and Repair Manual

BLN-50327

January 2009

Page 2

BDU-10/21

Table of Contents

Table of Contents

Description Page

Introduction ......................................................................................................3

General Description.......................................................................................3-5

Fluids...............................................................................................................6

Safety Precautions ...........................................................................................6

Maintenance....................................................................................................6

Troubleshooting Diagram.................................................................................. 7

Troubleshooting Chart....................................................................................... 8

Minor Repairs ............................................................................................. 9-14

General Information......................................................................................9

Shaft Seals............................................................................................. 9-10

Charge Check V alves.............................................................................10-11

Bypass Valves ............................................................................................11

Easy Ride V alves ........................................................................................11

Charge Pumps ..................................................................................... 12-14

Major Repairs ........................................................................................... 14-21

General Information.................................................................................... 14

Disassembly Procedures....................................................................... 15-17

Reconditioning & Replacement of Components ............................................ 17

Assembly Procedures ........................................................................... 17-21

BDU-10S Parts Drawing & Parts List........................................................... 22-23

BDU-10L Parts Drawing & Parts List. .......................................................... 24-25

BDU-21L Parts Drawing & Parts List. .......................................................... 26-27

Page 2

BDU-10/21

Page 3

Introduction/General Description

Introduction

BDU-10/21

The purpose of this manual is to provide information useful

in servicing the BDU Hydrostatic Transmission product

line. This manual includes unit and component description, troubleshooting, maintenance, and repair procedures.

A transmission normally will not require servicing, other

than the vehicle manufacturer’s recommended fluid and

filter changes during the life of the vehicle in which it is

installed. Should other servicing be required, the unit must

be removed from its installed location and thoroughly

cleaned before beginning most procedures.

General Description

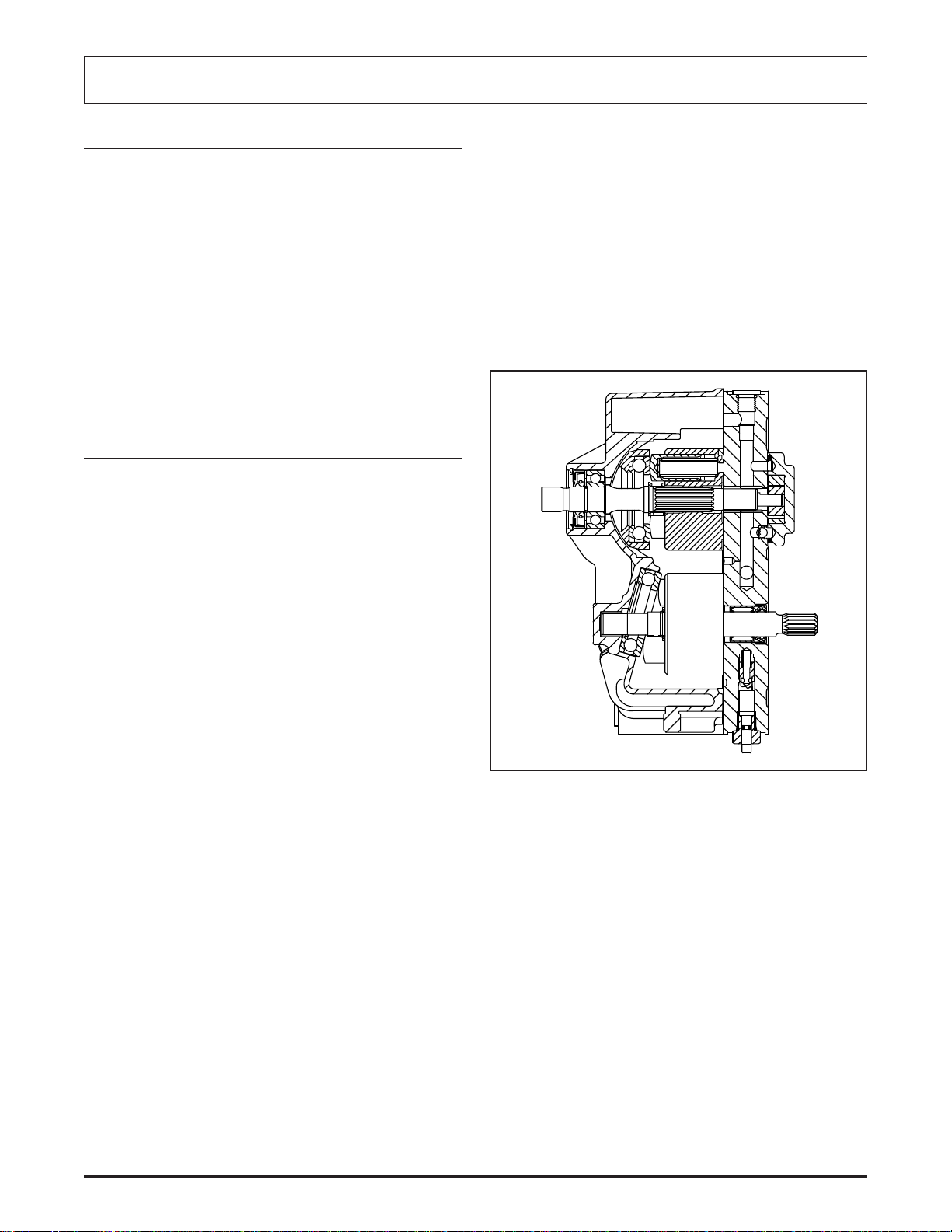

The BDU Hydrostatic Transmission is designed for the

transfer and control of power. It provides an infinitely

variable speed range between zero and maximum in both

forward and reverse modes of operation. The BDU transmission can be mounted to a variety of transaxles including

most HYDRO-GEAR models.

The BDU transmission is a “U” style transmission with a

variable displacement pump and a fixed displacement

motor. The variable displacement pump features a cradle

swashplate with a direct-proportional displacement control. Reversing the direction of tilt of the swashplate

reverses the flow of oil from the pump and thus reverses the

direction of the motor output rotation. The fixed displacement motor uses a fixed swashplate. The pump and motor

are of the axial- piston design and utilize spherical- nosed

pistons which are held against a thrust race by internal

compression springs.

The fluid supply for the BDU-10L/21L transmission is

contained in an external reservoir and passes through an

external filter prior to entering the transmission and feeding

the fixed displacement gerotor charge pump. Excess fluid

in the charge circuit is discharged over the charge relief

valve back to the charge pump inlet. Constant flow across

a small fixed orifice connecting the charge circuit to the

transmission housing supplements the cooling flow.

BDU-10L Transmission

The BDU-10S transmission has a self-contained fluid

supply and an integral filter. The fluid is forced through the

filter by positive “head” on the fluid in the housing/reservoir

with an assist by the negative pressure created in the pump

pistons as they operate.

BDU-10/21

Charge check valves in the center section are used to

control the makeup flow of fluid to the low pressure side of

the loop.

A spool type bypass valve is utilized in the transmission to

permit moving the vehicle for short distances at low speeds

(2mph) (3.2 km/hr) without starting the engine.

Page 3

Page 4

BDU-10/21

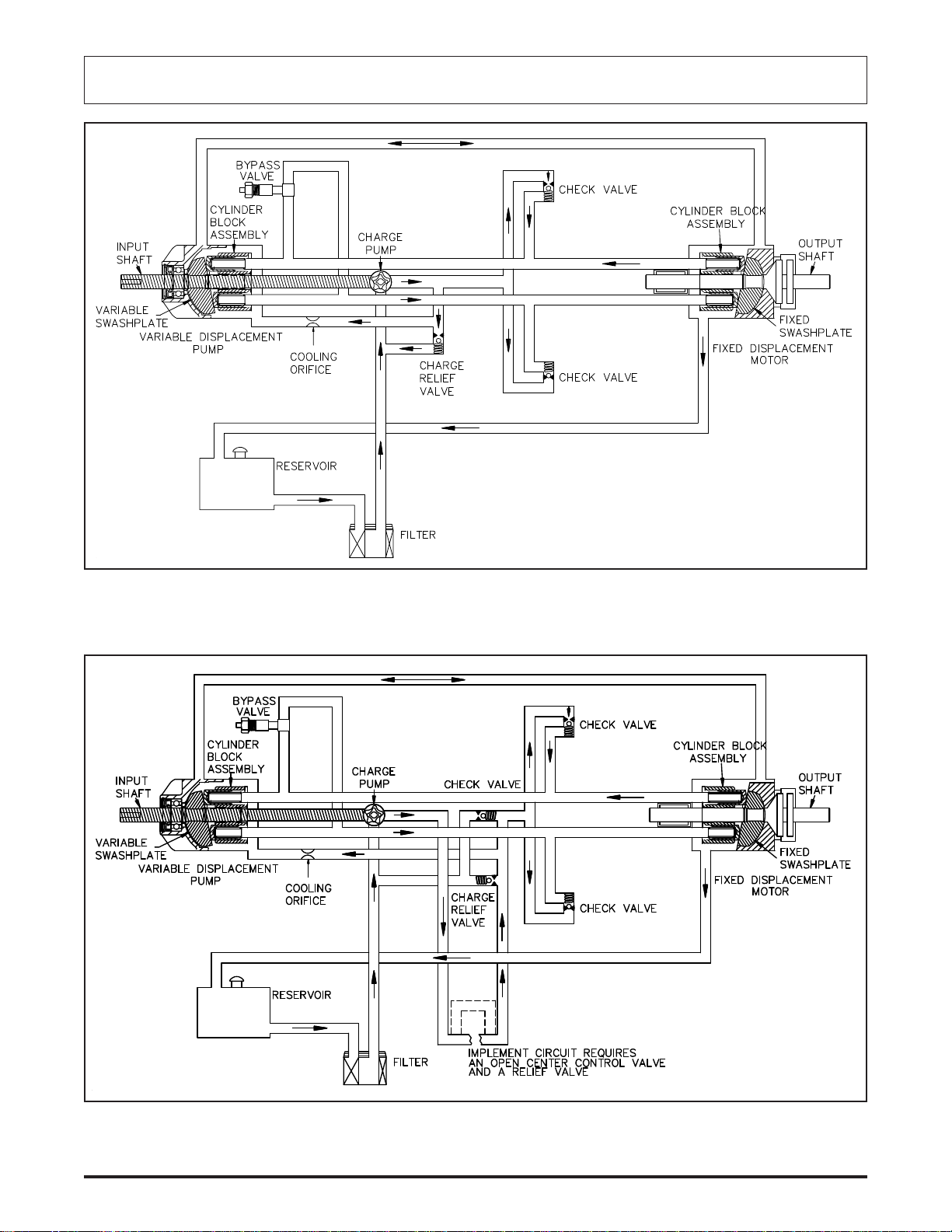

The BDU-21L transmission offers an optional Implement

(auxiliary) pump. The auxiliary circuit provides a rated flow

of 1.5 gpm (5.67 l/min) and 500 PSI (34.5 bar) operating

pressure at a 3200 RPM pump speed.

Fluid from the charge pump flows first to the implement

control valve, then to the charge relief valve and charge

check valves in the center section. This requires an “open

center” type control valve to allow fluid flow to return to the

transmission. A check valve is included to allow oil to be

drawn into the charge circuit should flow returning from the

implement circuit be insufficient to charge the closed loop.

A relief valve must be included in addition to the implement

control valve.

The BDU-21L offers an Easy Ride Valve option. The Easy

Ride Valve acts like a high pressure spike suppressor in

the system loop. The valve opens under high acceleration

loads. The result is a dampening of the aggressiveness,

without affecting the overall efficiency of the transmission.

General Description

BDU-21L Transmission with Easy Ride Valve

Option

BDU-10S Hydrostatic Flow Illustration

BDU-10/21Page 4

Page 5

General Description

BDU-10/21

BDU-10L/21L Hydrostatic Flow Illustration

BDU-21L/A Hydrostatic Flow Illustration

BDU-10/21

Page 5

Page 6

BDU-10/21

Maintenance

Fluids

The fluids used in HYDRO-GEAR products have been

carefully selected, and only equivalent, or better products

should be substituted.

Typically, an engine oil with a minimum rating of 9.0 cSt

(55 SUS) at 230°F (110°C) and an API classification of SJ/

CD is recommended. A 20W-50 engine oil has been

selected for use by the factory and is recommended for

normal operating temperatures. For colder climate operation (see chart), a change to a 10w-40 engine oil may be

necessary. Another alternative that will provide excellent

all climate performance and extended time between oil

changes is a 15W-50 synthetic engine oil.

SAE VISCOCITY GRADES

20W-50

10W-40

15W-50 Synthetic

-35

o -5o

AMBIENT AIR TEMPERATURE oF

15o 60

o

100

o

Maintenance

Check the transmission cooling fan for broken or distorted

blades, and check to see that the fan is securely fastened.

Replace the fan if damaged.

Keep the transmission clean. Grass clippings and dirt will

influence the cooling efficiency of the fins on the transmission housings. Avoid high pressure fluid washes, compressed air is the preferred method of removing loose

debris. Avoid the immediate area of the lip seals or damage

may occur.

Check to make sure the bypass valve and linkage is

operational. The bypass valve should be fully released

before operating the vehicle. It should extend approximately 0.22" (5.588mm) from the hex nut.

Inspect the transmission for leaks at the lip seals, damage

to fittings, hoses, the filter, or to the housings. Check the

oil level and add oil as necessary to bring it up to the proper

level. Refer to vehicle owners manual.

Safety Precautions

Certain procedures may require the vehicle to be disabled

(wheels raised off the ground, engine disconnected, etc.)

in order to prevent possible injury to the technician and

bystanders.

Some cleaning solvents are flammable. To avoid possible

fire, do not use cleaning solvents in an area where a source

of ignition may be present.

The loss of hydrostatic driveline power may result in the

loss of hydrostatic braking capacity. Proper brake maintenance becomes very important should this condition

develop.

BDU-10L

BDU-21L/A

BDU-10/21Page 6

Page 7

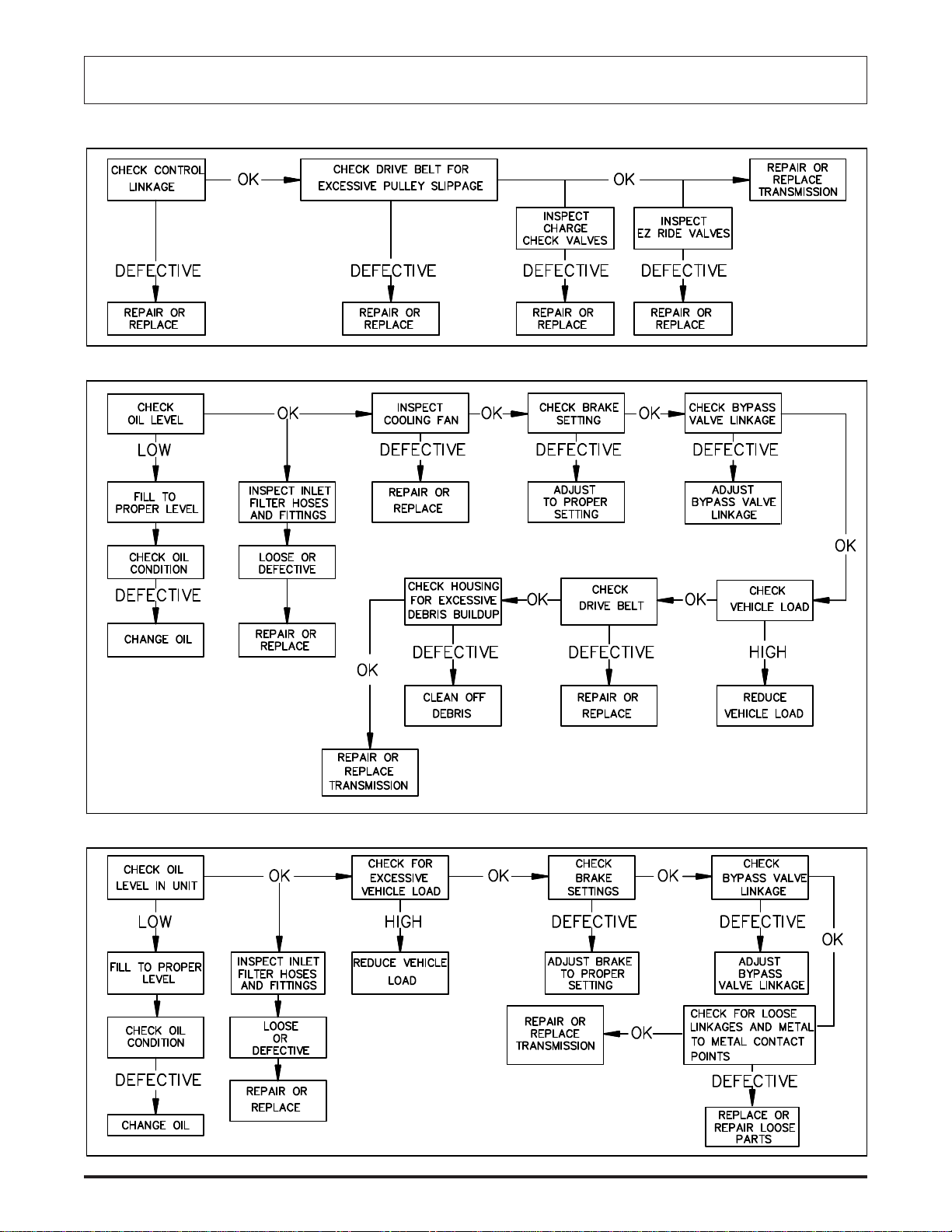

Troubleshooting Diagram

OPERATES IN ONE DIRECTION ONLY

OPERATING HOT/LOSING POWER

BDU-10/21

BDU-10/21

NOISY UNDER LOAD

Page 7

Page 8

BDU-10/21

Troubleshooting Chart

WARNING!!!

THE VEHICLE SHOULD BE ON LEVEL GROUND AND

THE ENGINE DISABLED BEFORE PERFORMING ANY ADJUSTMENTS

SYMPTOM - OPERATES IN ONE DIRECTION ONLY

POSSIBLE CAUSE CORRECTIVE ACTION

-Inspect control linkage -Repair or replace

-Inspect drive belt & pulleys -Repair or replace

-Inspect check valves -Repair or replace

-Inspect easy ride valves -Repair or replace

SYMPTOM - NOISY

POSSIBLE CAUSE CORRECTIVE ACTION

-Check oil level & condition -Fill to proper level or change oil

-Check for excessive loading -Reduce vehicle loading

-Check brake setting -Adjust brake to proper setting

-Check for loose parts -Repair or replace loose parts

-Check bypass valve operation -Repair or replace valve or linkage

-Check inlet flow conditions -Repair or remove obstruction or leaks

-Inspect check valves -Repair or replace

-Inspect easy ride valves -Repair or replace

-Inspect auxillary circuit -Repair or replace

SYMPTOM - LOW POWER

POSSIBLE CAUSE CORRECTIVE ACTION

-Check engine RPM -Adjust to correct setting

-Check drive belt & pulleys -Repair or replace

-Check oil level & condition -Fill to proper level or change oil

-Check for excessive loading -Reduce vehicle loading

-Check brake setting -Adjust brake to proper setting

-Check for loose parts -Repair or replace loose parts

-Check bypass valve operation -Repair or replace valve or linkage

-Check inlet flow conditions -Repair or remove obstruction or leaks

-Check operating temperature -Repair or replace unit

-Inspect check valves -Repair or replace

-Inspect easy ride valves -Repair or replace

-Inspect auxillary circuit -Repair or replace

SYMPTOM - OPERATING HOT

POSSIBLE CAUSE CORRECTIVE ACTION

-Check bypass valve operation -Repair or replace

-Check for debris buildup -Clean off debris

-Check oil level & condition -Fill to proper level or change oil

-Check for excessive loading -Reduce vehicle loading

-Check brake setting -Adjust brake to proper setting

-Check cooling fan for damage -Repair or replace

-Inspect check valves -Repair or replace

-Inspect easy ride valves -Repair or replace

-Inspect auxillary circuit -Repair or replace

Page 8

BDU-10/21

Page 9

Minor Repair

Minor Repair

BDU-10/21

General Information

Minor repairs may be performed, following the procedures

in this section, without voiding the unit warranty.

Cleanliness is a primary means of assuring satisfactory life

on either new or repaired units. Cleaning parts by using

solvent wash and air drying is usually adequate. As with

any precision equipment, all parts must be kept free of

foreign materials and chemicals.

Protect all exposed sealing surfaces and open cavities

from damage and foreign material. The outer surfaces must

be cleaned before beginning any repairs.

It is recommended that all O-rings and seals be replaced.

Lightly lubricate all O-rings and seals with a clean petroleum jelly prior to assembly.

Plug/Fitting Torques

If any plugs were removed during servicing, they should be

torqued as indicated in the accompanying table:

Shaft Seals

Lip type seals are used on the pump input shaft, pump

through shaft (not all models use the through shaft), motor

output shaft and displacement control shaft. These seals

can be replaced without major disassembly of the unit.

However, replacement of the seals generally requires

removal of the transmission from the machine.

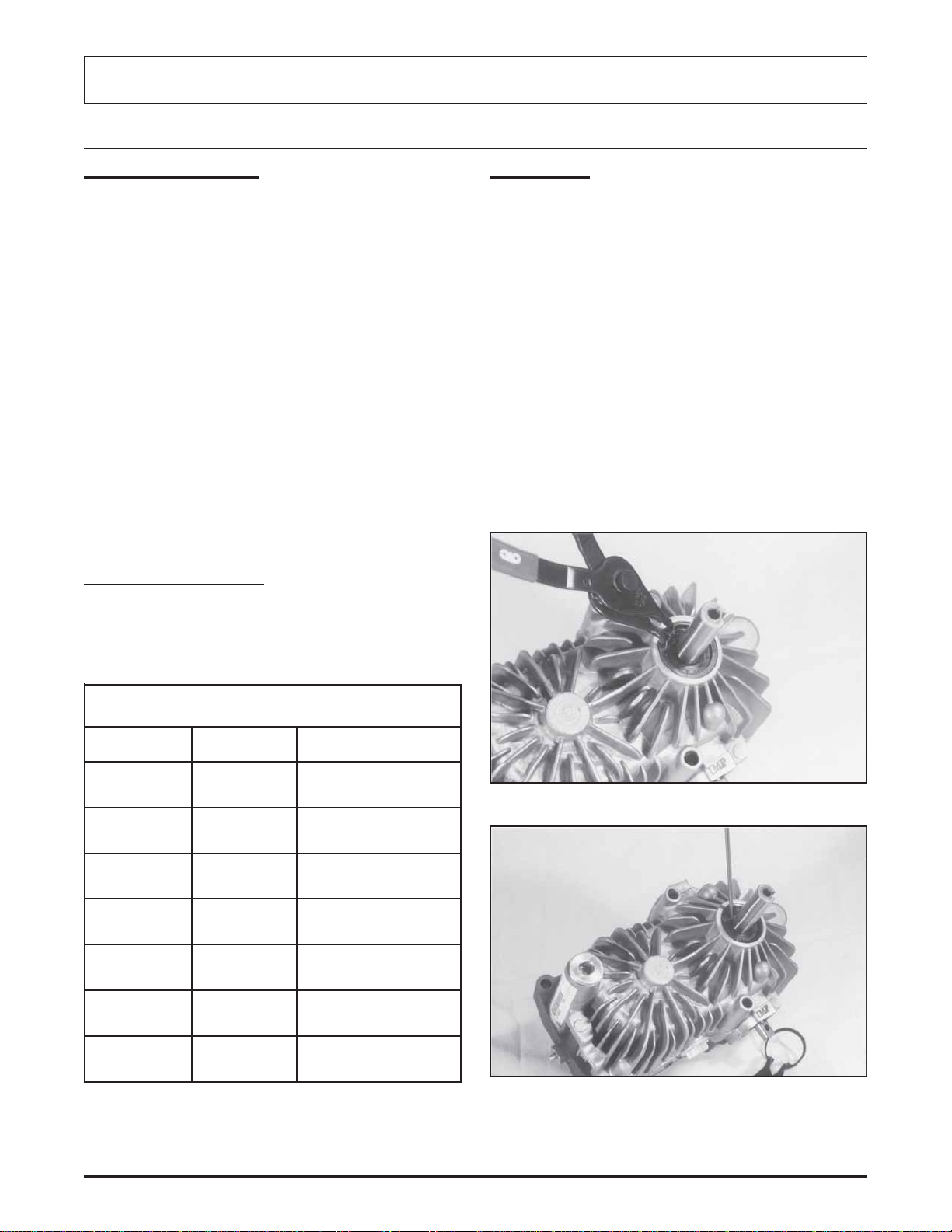

To replace the pump input shaft seal, first remove the

retaining ring from the housing.

Carefully pull the seal out of the housing bore. A “hook” type

tool may be used to grasp the seal and pull it out, or a slide

hammer type puller may be used to remove the seal. Care

must be taken so as not to damage the housing bore, shaft

sealing surface, or bearing. Once removed, the seal is not

reusable.

NOITAREPOEUQROTNOITPIRCSEDTRAP

gulPssapyB

)s(gulPkcehC

gulPedirysaE

gnittiF/gulPleetS

01(

gnittiF/gulPleetS

gnittiF/gulPleetS

gnittiF/gulPleetS

bl042-081

SNOITACIFICEPSEUQROT

nibl021-48

)mN5.31-5.9(

nibl042-081

)mN72-02(

nibl042-081

)mN72-02(

nibl021-69

)mN5.31-8.

nibl042-081

)mN72-02(

ni

)mN72-02(

nibl042-081

)mN72-02(

SEAS81-61/9

daerhTthgiartSEAS02-61/7

Retaining Ring Removal

daerhTthgiart

daerhTthgiartSEAS61/9

daerhTthgiartSEAS61/7

daerhTthgiartSEAS61/9

daerhTthgiartSEAS4/3

daerhTthgiartSEAS8/7

Lip Seal Removal

BDU-10/21

Page 9

Page 10

BDU-10/21

Minor Repair

Shaft Seals

Inspect the sealing area on the shaft for rust, wear, or

contamination. Polish the sealing area on the shaft if

necessary.

Wrap the spline or keyed end of the shaft with with a thin

plastic or cellophane to prevent damage to the seal lip

during installation.

Lubricate the new seal with petroleum jelly and slide the

seal over the shaft and press it into the housing bore. Be

careful not to damage the seal.

Install the retaining ring in the housing.

The pump through shaft, motor output shaft and displace-

ment control shaft may be replaced following a similar

procedure as outlined for the pump input shaft seal. These

seals are not held in position by a retaining ring.

Charge Check Valves

Remove the check valve plug with a 1/4" internal hex

wrench.

Remove the check valve spring and check ball (or poppet)

from the center section.

CAUTION: Do not allow the check ball to fall into the

closed loop passages in the center section. Removal

may be difficult but can be accomplished with a

magnet, or by removing the plug from the end of the

center section. Do not allow contaminants to be

introduced to the system.

Lip Seal Installation

Retaining Ring Installation Check Valve Options

Page 10

Check Valve Removal/ Installation

BDU-10/21

Page 11

BDU-10/21Minor Repair

Inspect the check balls (or poppets) and mating seats in

the center section for damage or foreign material.

Position the transmission so that the check valve port will

be in the upright position (as shown) and install the check

ball (or poppet), spring and plug (with o-ring) into the center

section. Make sure the plug stem is properly positioned

into the poppet or damage and failure will occur. Be certain

the check ball does not fall into the closed loop passage.

Torque the plug to 15-20 ft.lbs (20-27 Nm).

Turn the unit over and repeat the procedure for the other

side.

Bypass Valve

Remove the bypass valve plug with a 9/16" hex wrench.

Retain the valve spring to the valve spool with petroleum

jelly. Install the valve spool, spring and plug (with o-ring)

into the center section. Torque the plug to 7-10 ft.lbs.

(9.5-13.5 Nm).

Depress the bypass valve several times to insure that it

operates smoothly and fully closes. The bypass “button”

should extend from the hex plug approximately 0.22"

(5.588 mm) when fully released (closed).

Easy Ride Valves

Remove the Easy Ride valve plug with a 11/16" open end

wrench or socket.

Remove the spring, piston and sleeve from the center

section.

Inspect the piston nose for damage.

Inspect the piston sleeve and spring for damage. The

piston should slide freely in the sleeve, but should fit tight

enough to create a vacuum.

Remove the bypass valve plug, spool and spring from the

transmission center section.

Inspect the valve spool and mating bore in the center

section for damage or foreign material. The spool must

move freely. It is recommended that the o-rings be replaced.

Inspect the valve seat in the center section for damage. If

the valve seat is damaged the center section must be

replaced. Refer to the Major Repair section of this manual.

Install the piston, sleeve and valve spring.

Install the hex plug and torque to 15-20 ft.lbs. (20-27 Nm).

Bypass Valve Easy Ride Valve

BDU-10/21

Page 11

Page 12

BDU-10/21

Charge Pump

Minor Repair

The correct charge pump orientation is determined by the

rotation of the pump shaft (CW or CCW). Before removing

the charge pump, make note of, and/or mark its position to

simplify the reassembly process.

BDU-10L CCWBDU-10L CW

NOTE: Unlike the BDU-10L, some BDU-21L transmis-

sions have an implement circuit designed into the charge

pump cover. These covers are different and are

reversible. It is very important that they are reassembled in

the same orientation as they were removed.

BDU-10L With Through Shaft Charge Pump

not

BDU-21L CW

Page 12

BDU-21L Aux. CW

BDU-21L Aux. CCWBDU-21L CCW

BDU-10/21

Page 13

Minor Repair

BDU-10/21

Disassembly Procedures

Using a 5 or 6mm internal hex wrench, remove the two (2)

screws holding the charge pump cover to the center

section.

Remove the charge pump cover and o-ring. Avoid turning

or twisting the charge cover during removal, or damage

to the charge relief valve spring may occur.

Remove the charge pump gerotor assembly.

For BDU-21L with implement circuit: Remove the

charge pump shim, two aligning pins, two o-rings, the

gerotor assembly and the charge pump drive pin. Make

note of the top and/or bottom of the gerotor assembly.

For BDU-21L: Remove the charge pump drive pin.

For BDU-10L with a through shaft: Remove the charge

pump drive pin, spacer plate and o-ring. Make note of the

top and/or bottom of the spacer plate.

Remove the charge relief valve spring and ball.

For BDU-21L: Install the charge relief valve spring and ball.

Install the drive pin. Install the gerotor assembly. Install a

new o-ring and the charge pump cover. NOTE:The charge

relief spring must enter the recessed hole in the charge

pump cover. Torque the bolts evenly to 12-15 ft.lbs.

(16.3-20.3 Nm).

BDU-10L Charge Pump Components

NOTE: The BDU-21L with implement circuit has the charge

relief valve spring and ball in the charge pump cover.

Inspect the gerotor assembly, charge pump cover, and

center section (or spacer plate) for abnormal wear, damage

or foreign material. Inspect the charge relief valve ball and

spring. Inspect the charge relief valve seat in the center

section for damage or foreign material.

Assembly Procedures

Prior to reassembly of the charge pump, apply a small

quantity of petroleum jelly to the I.D., O.D., and faces of the

gerotor assembly.

NOTE: Improper assembly of the charge relief valve spring

and ball, or the incorrect orientation of the charge cover will

cause a priming failure. If assembled properly, the charge

pressure should be maintained at 25 to 70 PSI

(1.72-4.82 bar) at 3000 RPM pump speed.

For BDU-10L Install the charge relief valve spring and ball.

Install the gerotor assembly. Install a new o-ring and the

charge pump cover. NOTE:The charge relief spring must

enter the recessed hole in the charge pump cover. Torque

the bolts evenly to 7-10 ft.lbs. (9.5-13.5 Nm).

BDU-10L Through Shaft Charge Pump Components

For BDU-10L models with through shaft: Install the

charge relief valve spring and ball. Install a new o-ring and

the spacer plate onto the aligning pins paying attention to

the correct orientation. NOTE:The charge relief spring

must enter the recessed hole in the spacer plate. Install the

charge pump drive pin. Install the gerotor assembly. Install

a new o-ring and charge pump cover. Torque the bolts

evenly to 7-10 ft.lbs. (9.5-13.5 Nm).

BDU-10/21

Page 13

Page 14

BDU-10/21

Major Repair

Charge Pump

Assembly Procedures

For BDU-21L with implement circuit: Install the drive

pin. Install a new o-ring on each side of the gerotor

assembly and position the gerotor assembly onto the

aligning pins in the same orientation as it was removed.

Install the charge pump shim and the charge pump cover.

Torque the bolts evenly to 18-25 ft.lbs.(24.4-33.9 Nm).

Major Repair

General Information

Major repairs described in the following sections are for the

complete disassembly and reassembly (Major Repair) of

the transmission and will void all product warranty, unless

license to perform said major repairs was previously

obtained from an authorized representative of HYDROGEAR.

Cleanliness is a primary means of assuring satisfactory life

on repaired units. Cleaning parts by using solvent wash

and air drying is usually adequate. As with any precision

equipment, all parts must be kept free of foreign materials

and chemicals.

Protect all exposed sealing surfaces and open cavities

from damage and foreign material. The outer surfaces

should be cleaned before beginning any repairs.

It is recommended that all O-rings and seals be replaced.

Lightly lubricate all O-rings and seals with a clean petroleum jelly prior to assembly.

BDU-21L Charge Pump Components

BDU-21L/A CW Charge Pump Components

It is recommended that parts requiring replacement be

replaced with the complete assembly (kit) as shown in the

service parts drawings on pages 22-27.

Prior to performing major repairs on the BDU Hydrostatic

Transmission, remove the transmission from its installed

location and remove any external components such as a

cooling fan and input pulley or frame mounting hardware.

NOTE: Thoroughly clean all exposed surfaces prior to any

further disassembly.

Remove the oil lines (hoses and fittings) so that as much

oil as possible can be drained from the housing.

BDU-21L/A CCW Charge Pump Components

BDU-10/21Page 14

Page 15

Disassembly Procedures

Prior to performing major repairs on the BDU remove the

external components as described in the Minor Repairs

section of this manual. These include the following:

Bypass Valve

Charge Check Valves

Charge Pump Assembly

Using a 6 mm internal hex wrench, remove the eight

screws which retain the center section to the housing.

BDU-10S Center Section Removal

The internal springs of the pistons should separate the

center section from the housing. Remove the center

section from the housing.

BDU-10/21Major Repair

For BDU-10S remove the filter element, filter washer and

spring from the housing.

BDU-10S Filter Removal

Remove the pump cylinder block kit from the pump shaft.

Inspect the splines on the shaft and in the pump block for

damage or excessive wear. Check the pistons and block

bores for excessive wear. The pistons should fit with very

little side clearance in the block bores, but must slide

freely. NOTE:The correct bore diameter for 21cc blocks is

0.6776 to 0.6784 while the 10cc blocks should be 0.6295

to 0.6303. 21cc pistons should be 0.6770 to 0.6767 and the

10cc pistons should be 0.6291 to 0.6288.

Remove the pump cylinder block spring and thrust washer

from the pump shaft.

CAUTION: The cylinder blocks may stick to the surface of the center section. Exercise caution to prevent damage to the components.

Remove the gasket and two aligning pins from the housing.

The gasket will not be reusable.

BDU-10S Aligning Pins and Gasket

BDU-10/21

Remove the motor cylinder block kit and shaft assembly

from the housing. Check the pistons and block bores for

excessive wear. The pistons should fit with very little side

clearance in the block bores, but must slide freely. Inspect

the splines for damage or unusual wear. Replacement of

the complete assembly is recommended if damage or

excessive wear is found.

Remove Cylinder Blocks

Page 15

Page 16

BDU-10/21

Major Repair

Disassembly Procedures

10CC and 21CC Cylinder Block Kit Components

Remove the motor thrust bearing assembly from the

housing.

Remove the swashplate assembly and cradle bearings

(BDU-10 only) from the housing.

NOTE: The cradle bearings in newer BDU-21L transmissions are not removable from the housing. If damage is

present, a new housing kit is necessary.

Remove the input shaft lip seal retaining ring.

Pull the lip seal out of the housing bore. A hook type tool

may be used to pry the seal out. Care must be taken to

avoid damage to the housing bore, shaft sealing surface or

bearing. Once removed, the seal is not reusable.

Remove the bearing spacer washer.

Remove the pump shaft assembly from the housing.

Inspect the splines on the shaft for damage or unusual

wear.

Inspect the bearing. Replacement of the assembly is

recommended if any damage or excessive wear is found.

Inspect the cradle bearing’s low friction coating for wear.

Inspect the swashplate and thrust bearing for any unusual

wear or damage. If damage to the swashplate or cradle

bearings is found then inspect the housing for possible

damage. Replace complete assemblies as necessary.

Remove the slot guide block from the displacement control

shaft.

BDU-10 Pump Shaft Components

BDU-21 Pump Shaft Components

Remove the displacement control shaft from the housing.

Remove the displacement control shaft lip seal from the

housing. Care must be taken to avoid damage to the

housing bore.

Swashplate, Cradle Bearings, Block Spring and

Washer Removed

Page 16

Inspect the housing for damage.

BDU-10/21

Page 17

Major Repair

BDU-10/21

Disassembly Procedures Reconditioning and Replacement of Parts

After disassembly, all parts should be thoroughly cleaned

in a suitable solvent.

Inspect all parts for damage, nicks or unusual wear

patterns. Replace all parts having unusual, excessive wear

or discoloration.

Inspect the sealing surfaces, bearing surfaces, and shaft

splines. Polish the sealing areas on the shafts if necessary. Replace any worn or damaged parts.

The running surfaces of the cylinder blocks MUST be flat

and free from scratches. If scratches or wear are found on

the running surface of the cylinder block or center section,

replace the parts.

Housing, Control Arm and Lip Seal

Assembly Procedures

Inspect the control shaft journal bearing for excessive

wear. The BDU 10 control shaft journal bearing should be

0.4722 to 0.4733 while the BDU 21 control shaft journal

bearing should be 0.5904 to 0.5908.

Inspect the BDU-10 motor shaft journal bearing for excessive wear. The BDU 10 motor shaft journal bearing should

be 0.4961 to 0.4998.

Inspect the BDU-21 motor shaft needle bearing for damage.

If excessive wear or damage is found, replace the complete

housing assembly.

Inspect the center section for damage to the cylinder block

running surface.

Inspect the BDU-10 pump shaft journal bearing for excessive wear. The journal bearing should be 0.4998 to 0.4961.

Inspect the needle bearing for damage. If any damage or

excessive wear is found, replace the complete center

section assembly.

Clean and lightly oil parts prior to assembly of the BDU

transmission.

Be sure to torque all threaded parts to the recommended

torque levels.

Replace all o-rings, gaskets and shaft seals.

CAUTION: Most parts have critical high tolerance

surfaces. Care must be exercised to prevent damage

to these surfaces during assembly. Protect exposed

surfaces, openings, and ports from damage or foreign material.

Install the displacement control shaft.

BDU-10/21

Page 17

Page 18

BDU-10/21

Major Repair

Assembly Procedures

BDU-10 Control Arm Installation

Install the swashplate into the housing. The slot on the

swashplate must engage the slot guide block on the

displacement control shaft. Use a tool such as a screwdriver or scribe to hold the guide block in position while

installing the swashplate.

BDU-10 Pump Shaft Installation

Install the pump shaft assembly into the housing.

Install the bearing spacer washer.

Install the lip seal and retaining ring as described in the

minor repair section.

Install the cradle bearings. (BDU-10 only)

Install the slot guide block onto the displacement control

shaft.

BDU-10 Swashplate Components

BDU-10 Swashplate Installation

NOTE: As a product improvement, since July 1, 1993 the

BDU-21 thrust bearings for both the motor and pump are

now the same. They are not interchangeable with the old

versions. New housing kits, or new swashplate kits will be

necessary to accomodate new thrust bearings.

Page 18

BDU-10/21

Page 19

BDU-21 Swashplate Components

BDU-10/21Major Repair

BDU-21 with Swashplate Installed

Old Styles

BDU-21 Swashplate Changes

Hold the swashplate in position and measure the end play

of the displacement control shaft using a dial indicator or

a depth guage. Using a suitable sleeve, press the control

shaft bearing into the housing until the control shaft end

play is between 0.020" and 0.060" (.508-1.52 mm).

New Styles

Install the thrust washer and pump cylinder block spring

onto the pump shaft.

Install the springs piston washers and pistons into the

cylinder block. The pistons must move freely in their bores.

Measure Control Arm End Play BDU-10 Cylinder Block Kit

BDU-10/21

Page 19

Page 20

BDU-10/21

Major Repair

Assembly Procedure

NOTE: To simplify the installation of both the motor block

and the pump block kits, wrap a rubber band snuggly

around the pistons. This is intended to hold the pistons in

their bores as the block kits are handled during installation.

Install the motor thrust bearing into the housing.

NOTE: It will be necessary to have a DRY journal bearing

to prevent a hydraulic lock while installing the motor shaft.

Install the motor shaft/cylinder block kit. Use caution to

prevent damage to the journal bearing while guiding the

shaft into position. Once installed, it will be necessary to

hold the assembly in position until the center section has

been installed.

BDU-21 Cylinder Block Kit with Rubber Band

With the swashplate in the “neutral” (0 angle) position and

the transmission housing laying on its side, install the

pump cylinder block kit onto the pump shaft in the housing.

BDU-10 Motor Shaft Kit Installation

BDU-21 Motor Shaft Kit Installation

BDU-10 with Pump Block Installed

Page 20

BDU-10/21

Page 21

Major Repair

For BDU-10 Check to see that the piston springs are

centered in the cylinder block bores. If necessary, position

them with a small screwdriver. Use caution to avoid

damage to the cylinder block face.

For BDU-10S Install the filter spring, washer and new filter

element.

Install the two aligning pins, and install a new gasket onto

the housing.

BDU-10/21

BDU-10 Center Section Assembly

Install the eight bolts and torque evenly to 10-15 ft.lbs.

(13.56-20.34 Nm).

Rotate the shafts a minimum of two turns to assure correct

assembly. When properly assembled the shafts should

require minimal torque to turn, approximately 15 in. lbs.

(1.7 Nm) maximum.

BDU-10

Lubricate the running surfaces of the cylinder blocks and

the center section.

Position the housing with the housing opening UP, and

install the center section onto the housing while holding the

motor shaft in position in the housing journal bearing.

CAUTION: Make sure all parts are properly aligned.

Do not use excessive force.

Refer to the Minor Repairs section in this manual to

complete reassembly of the BDU transmission.

BDU-10/21

Page 21

Page 22

BDU-10/21

BDU-10S Parts Drawing & Parts List

Page 22

BDU-10/21

Page 23

PARTS LIST

.ONNOITPIRCSED.ONNOITPIRCSED

1TFAHSPMUP52ETALPHSAWSELBAIRAV

2GNIRGNINIATERERIW03LAESPIL

BDU-10/21BDU-10S Parts Drawing & Parts List

3GNIRAEBLLABTFAHS23YLBMESSAK

4RECAPS73SSELDAEHTHGIARTS-NIP

5LAESPIL83TEKSAGNOITCESRETNEC

6GNIRGNINIATER93RETLIF

8GNIRAEBELDARC04REHSAWTSURHT

2

1LAESPIL14GNIRPSRETLIF

31MRANOINNURT24TIKEVLAVKCEHC

41EDIUGTOLS74WERCSPACDAEHTEKCOS

51TIKGNISUOH15LARIPS-NIP

71YSSAGNI

91YLBMESSANOITCESRETNEC06GNIRPSKCOLB

12LAESPIL86RELEVEL

RAEBLLABTSURHT35TIKEVLAVSSAPYB

COLB

BDU-10/21

22TFAHSROTOM96

32REHSAWTSURHTKCOLB

CILEH

GNIRPS

NOISSERPMOCLA

Page 23

Page 24

BDU-10/21

BDU-10L Parts Drawing & Parts List

Page 24

BDU-10/21

Page 25

PARTS LIST

.ONNOITPIRCSED.ONNOITPIRCSED

1TFAHSPMUP73SLDHTSNIP

2GNIRGNINIATERERIW83TEKSAGNOITCESRETNEC

BDU-10/21BDU-10L Parts Drawing & Part s List

3GNIRAEBLLABTFAHS24TIKEVL

4RECAPS44TIKFEILEREGRAHC

5LAESPIL74WERCSPACDAEHTEKCOS

6GNIRGNINIATER35TIKEVLAVSSAPYB

21LAESPIL06GNIRPSKCOLB

31M

41EDIUGTOLS36TIKPMUPEGRAHC

51TIKGNISUOH46YLBMESSAROTOREG

71YSSAGNIRAEBLLABTSURHT76WERCSPAC

91YLBME

12LAESPIL96GNIRPSPMOCLACILEH

22TFAHSROTOM57ETALPRECAPS

32REHSAWTSURHTKCOLB77PIL-LAES

52ETAL

23YLBMESSAKCOLB

RANOINNURT26GNIR-O

SSANOITCESRETNEC86RELEVEL

PHSAWSELBAIRAV87NIPSSELDAEH

AVKCEHC

BDU-10/21

Page 25

Page 26

BDU-10/21

BDU-21L Parts Drawing & Parts List

Page 26

BDU-10/21

Page 27

PARTS LIST

.ONNOITPIRCSED.ONNOITPIRCSED

1TFAHSPMUP13ETALPHSAWSELBAIRAV

2GNIRGNINIATER93GNIR-O

3GNIRGNINIATER04TIKPMUPEGRAHC

BDU-10/21BDU-21L Parts Drawing & Part s List

4RECA

5GNIRAEBTFAHS24TIKEVLAVKCEHC

6LAESPILTFAHSPMUP44TIKEVLAVFEILEREGRAHC

21LAESPILNOINNURT54TIKEVLAVFEIL

31MRANOINNURT64NIP

41EDIUGTOLS94TIKKCEHC/SSAPYBXUA

51TIKGNISUOH05TIKEVLAVSSAPYB

71YSSAGNIRAEBLLABTSURHT25GULP

91R

02GNIRPSKCOLB75WERCSPACDAEHTEKCOS

12TIKKCOLBREDNILYCPMUP85WERCSPACDAEHTEKCOS

22TFA

PS14TIKROTOREG

ERXUA

EHSAWTSURHTKCOLB45TIKRETLIFXUA

HSROTOM66GULP

BDU-10/21

32LAESPIL76REVOCRETLIF

52TIKNOITCESRETNEC96NIP

62NIP57MIHSPMUPEGRAHC

72TEKSAGNOITCESRETNEC48TIKEVLAVEDIRY

83TIKKCOLBREDNILYCROTOM

SAE

Page 27

Page 28

© 2009 HYDRO-GEAR

Printed in U.S.A.

Rev. P5

Loading...

Loading...