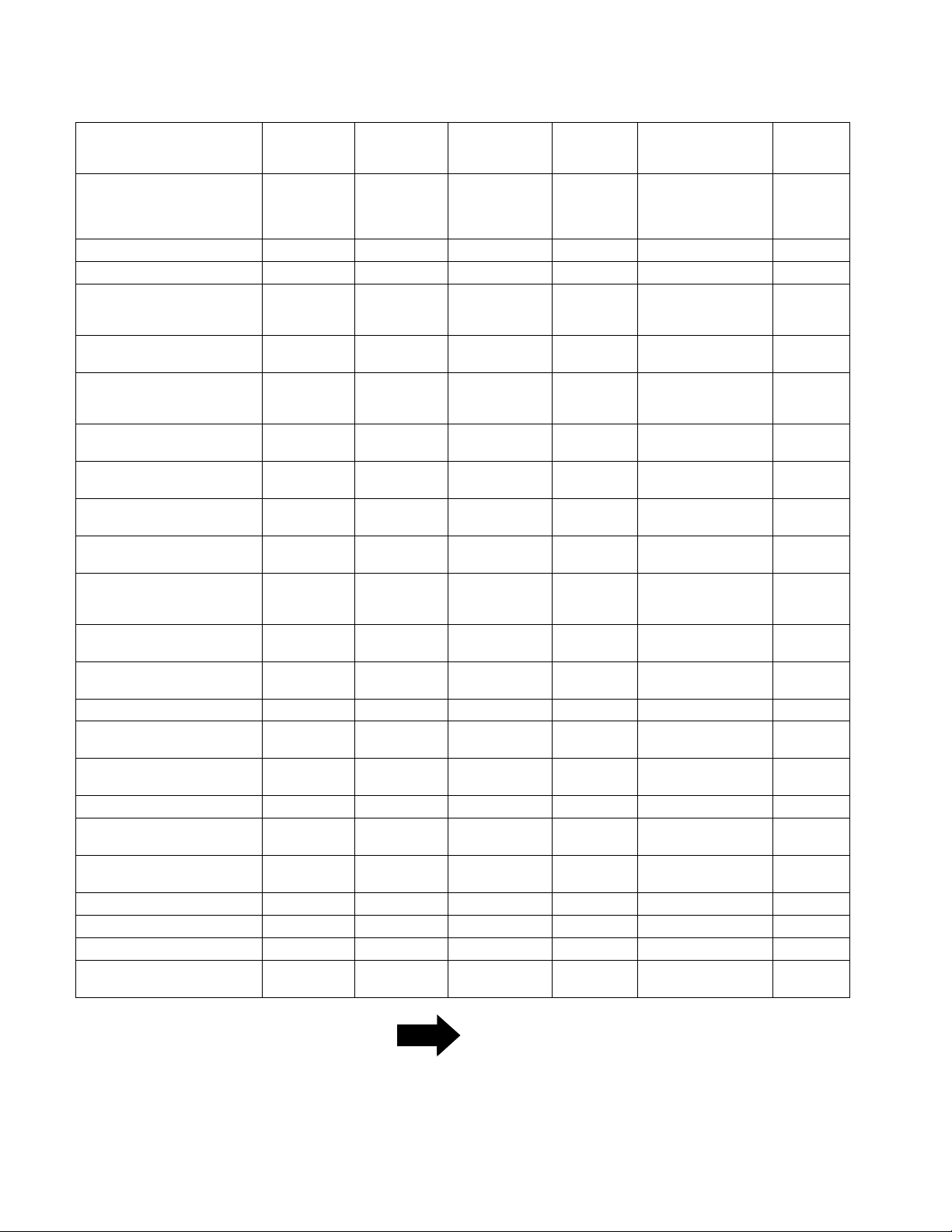

Page 1

O

PERATOR’S

M

ANUAL

2000

TRACTOR

Model Number

2186

w/48" Mower Deck

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com]

PRINTED IN U.S.A. FORM NO. 769-00622

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

(12/02)

Page 2

KOHLER CO.

FEDERAL AND CALIFORNIA EMISSION CONTROL SYSTEMS

LIMITED WARRANTY

SMALL OFF-ROAD EQUIPMENT ENGINES

The U. S. Environmental Protection Agency (EPA), the California Air Resources Board (CA RB), and Kohler Co. are pleased to explain the Federal and

California Emission Control Systems Warranty on your small off-road equipment engine. For California, engines produced in 1995 and later must be

designed, built and equipped to meet the state’s stringent anti-smog standards. In other states, 1997 and later model year engines must be designed,

built and equipped, to meet the U.S. EPA regulations for small non-road engines. The engine must be free from defects in materials and workmanship

which cause it to fail to conform with U.S. EPA standards for the first two years of engine use from the date of sale to the ultimate purchaser. Kohler Co.

must warrant the emission control system on the engine for the period of time listed above, provided there has been no abuse, neglect or imp r op er ma i ntenance.

The emission control system may include parts such as the carburetor or fuel injection system, the ignition system, and catalytic converter. Also included

are the hoses, belts and connectors and other emission related assemblies.

Where a warrantable condition exists, Kohler Co. will repair the engine at no cost, including diagnosis (if the diagnostic work is performed at an authorized dealer), parts and labor.

MANUFACTURER’S WARRANTY COVERAGE

Engines produced in 1995 or later are warranted for two years in California. In other states, 1997 and later model year engines are warranted for two

years. if any emission related part on the engine is defective, the part will be repaired or replaced by Kohler Co. free of charge.

OWNER’S WARRANTY RESPONSIBILITIES

(a) The engine owner is responsible for the performance of the required maintenance listed in the owner’s manual. Kohler Co. recommends that you

retain all receipts covering maintenance on the engine. But Kohler Co. cannot deny warranty solely for the lack of receipts or for your failure to

assure that all scheduled maintenance was performed.

(b) Be aware, however, that Kohler Co. may deny warranty coverage if the engine or a part has failed due to abuse, neglect, improper maintenance or

unapproved modifications.

(c) For warranty repairs, the engine must be presented to a Kohler Co. service center as soon as a problem exists. Call 1-800-544-2444, or access

our web site at: www.kohlerengines.com, for the names of the nearest service centers. The warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding warranty rights and responsibilities, you should contact Kohler Co. at 1-920-457-4441 and ask for an Engine Service

representative.

COVERAGE

Kohler Co. w arrants to the ultimate purchaser and each subsequent purchaser that the engine will be designed, built and equipped, at the time of sale, to

meet all applicable regulations. Kohler Co. also warrants to the initial purchaser and each subsequent purchaser, that the engine is free from defects in

material and workmanship which cause the engine to fail to conform with applicable regulations for a period of two years.

Engines produced in 1995 or later are warranted for to years in California. For 1997 and later model years, EPA requires manufacturers to warrant

engines for two years in all other states. These warranty periods will be begin on the date the engine is purchased by the initial purchaser. If any emission related part on the engine is defective, the part will be replaced by Kohler Co. at no cost to the owner. Kohler Co. is liable for damages to other

engine components caused by the failure of a warranted part still under warranty.

Kohler Co. shall remedy warranty defects at any authorized Kohler Co. engine dealer or warranty station. Warranty repair work done at an authorized

dealer or warranty station shall be free of charge to the owner if such work determines that a warranted part is defective.

Listed below are the parts covered by the Federal and California Emission Control Systems Warranty. Some parts listed below may require scheduled

maintenance and are warranted up to the first scheduled replacement point for that part. The warranted parts are:

• Oxygen sensor (if equipped) • Intake manifold (if equipped)

• Exhaust manifold (if equipped) • Catalytic muffler (if equipped)

• Fuel metering valve (if equipped) • Spark advance module (if equipped)

• Crankcase breather • Ignition module(s) with high tension lead

• Gaseous fuel regulator (if equipped) • Electronic control unit (if equipped)

• Carburetor or fuel injection system • Fuel lines (if equipped)

• Air filter, fuel filter, and spark plugs (only to first

scheduled replacement point )

LIMITATIONS

This Emission Control System Warranty shall not cover any of the following:

(a) repair or replacement required because of misuse or neglect, improper maintenance, repairs improperly performed or replacement not conformin g

to Kohler Co. specifications that adversely affect performance a nd/or durability and alterations or modifica tions not recommended or approved in

writing by Kohler Co.,

(b) replacement of parts and other services and adjustments necessary for required maintenance at and after the first scheduled replacement point,

(c) consequential damages such as loss of time, inconvenience, loss of use of the engine or equipment, etc.,

(d) diagnosis and inspection fees that do not result in eligible warranty service being performed, and

(e) any add-on or modified part, or malfunction of authorized parts due to the use of add-on or modified parts.

MAINTENANCE AND REPAIRS REQUIREMENTS

The owner is responsible for the proper use and maintenance of the engine. Kohler Co. recommends that all receipts and records covering the performance of regular maintenance be retained in case questions arise. If the engine is resold during the warranty period, the maintenance records should

be transferred to each subsequent owner. Kohler Co. reserves the right to deny warranty coverage if the engine has not been properly maintained; however, Kohler Co. may not deny warranty repairs solely because of the lack of repair maintenance or failure to keep maintenance records.

Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair establishment or individual; however, warranty repair must be performed by a Kohler authorized service center. Any replacement part or service that is equivalent in performance

and durability may be used in non-warranty maintenance or repairs, and shall not reduce the warranty obligations of the engine manufacturer.

2

Page 3

CONTENTS

Section Page

Section Page

Emission Control Systems Warranty... 2

Tractor and Deck Preparation.............. 3

Safe Operation Practices..................... 4

Product Graphics ................................. 7

To The Owner .................................... 8

Calling Service Information.................. 8

Recording Model & Serial Number ...... 8

I Controls and Indicators........................ 9

II Operation............................................. 14

III Adjustments......................................... 18

IV Maintenance ........................................ 23

V Mower Deck......................................... 33

TRACTOR AND DECK PREPARATION

After removing the top of the shippi ng crate, cut the tie

strap securing the m ower deck to the s ide panel o f the

crate. Using a hoist, or with the help of an assistant,

carefully lift the mower deck out of the shipping crate.

Cut the tie strap securing the PTO belt and remo ve the

belt from the deck

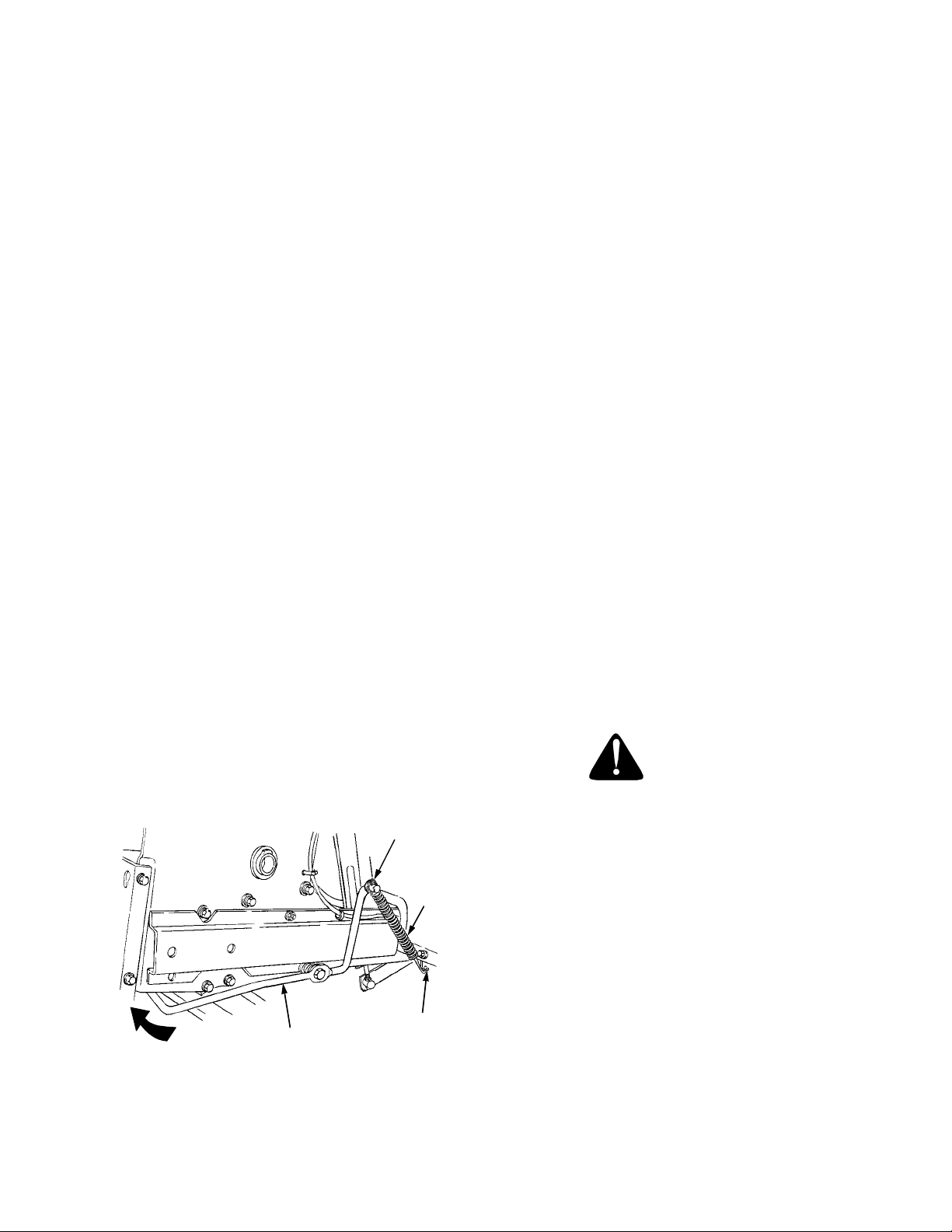

A. INSTALL LIFT ASSIST SPRINGS

The RH and LH lift assist rods are installed on the tractor

and suspended with rubber bands during shipment.

Remove the rubber bands and install the lift assist

springs as follows:

1. Raise the rearward end of the RH lift assist rod

located under the fender on the right/rear side of the

tractor frame, and remove the internal cotter pin

from the forward end of the rod.

2. Slide the larger hook of the lift assi st spring onto

the forward end of the lift assist rod.

VI Off-Season Storage ............................. 45

VII Mowing................................................. 46

Optional Equipment and Accessories. 47

Maintenance Chart............................... 48

Trouble Shooting.................................. 49

Lubrication Table ............................... 51

Lubrication Guides .............................. 52

Slope Gauge........................................ 55

Specifications....................................... 57

Warranty — Commercial Use.............. 58

Warranty — Residential Use................ 59

Maintenance Parts Chart .................... 60

3. Install the internal cotter pin to capture the spring

hook between the flange of the rod and the pin.

4. While lowering the rear end of the lift assist rod,

guide the other spring hook into the pigtail hook at

the lower front of the fender.

5. Tension the spring by pushing downward and then

inward on the rear of the lift as sist rod so that the

flange at rearward end of the rod is inside the

tractor frame.

6. Repeat steps 1 thru 5 to install the lift assist spring

onto the LH lift assist rod on the left side of the

tractor frame.

NOTE: Store the l ift a ssist spring s in th is po sit ion whe never the mower deck is removed from the tractor.

B. CONNECT THE BATTERY

WARNING

INTERNAL

COTTER PIN

LIFT

ASSIST

SPRING

LIFT ASSIST

ROD

Installing Lift Assist Springs in Storage Position.

PIGTAIL

HOOK

Battery posts, term ina ls an d r ela ted ac ce ss or ie s

contain lead and lead compounds. Wash hands

after handling.

The tractor is shipped with an activat ed sealed battery,

with the positive batte ry cable factory connected. The

negative cable must be connected.

Note: Make sure the ignition s witch is in the "OFF" po sition before attaching the battery cable.

1. Pull the protective c ap off the negative terminal of

the battery, and remove the hex cap s cre w and nut

from the free end of the negative battery cable.

2. Connect the negative battery cable (heavy black )

and ground wire (green) to negative terminal (—)

of the battery using the hex cap screw and nut.

Slide the black terminal cover over the negative

terminal of the battery.

3

Page 4

WARNING

• The engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known

to the State of California to cause cancer, birth defects or other reproductive harm.

• This uni t is equip ped with an inter nal comb ustion engin e and sh ould not be used on or near any unimprove d

forest-covered, br ush-cove red, or grass -covered land unles s the engine’ s exhaust s ystem is eq uipped with a

spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

• In the State of California, the above is required by law (Section 4442 of the California Public Resources Code).

Other States m ay ha ve simi lar laws. Fede ral laws appl y to f edera l lands. A spark arre ster mu ffle r is av aila ble

at your nearest engine authorized service center.

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FO LLOWED,

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND

OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT

IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL— HEED ITS WARNING.

Your lawn mower was built to be operated accor ding to the r ules for safe ope ration

in this manual. As with any type of po wer equipmen t, careless ness or error on the

DANGER

I. GENERAL OPERATION

1. Read, understand and follow all instructions in the

manual and on the machi ne befor e sta rting. Ke ep

this manual in a safe plac e for future and regular

reference and for ordering replacement parts

2. Only allow responsible individuals familiar with

the instructions to operate the machine. Know the

controls and how to stop the machine quickly .

3. Do not put hands or feet under the cutting deck or

near rotating parts.

4. Clear the area of objects such as rocks, toys,

wire, etc. which could be picked up and thrown by

the blades. A small object may have been

overlooked and could be acci dentally thrown by

the mower in any direction and cause injury to

you or a bystander. To help avoid a thrown

objects injury, keep children, animals, bystanders

and helpers at least 75 feet from the mower while

it is in operation. Always wear safety glasses with

side shields or safety goggles during operation or

while performing an adjustment or repair, to

protect eyes from foreign objects. Stop the blades

when crossing gravel drives, walks or roads.

part of the operator can result in injur y. This lawn mower is capabl e of amputating

hands and feet or throwing objects. Failure to observe the following safety

instructions could result in serious injury or death.

SAFE OPERATION PRACTICES

5. Be sure the area is cl ear of other people before

mowing. Stop machine if anyone enters the area.

6. Never carry passengers.

7. Disengage the blades before shifting into reverse

and backing up. Always look down and behind

before and while backing.

8. Be aware of the mower and attachment discharge

direction and do not point it at anyone. Do not

operate the mower without either the entire grass

catcher or the chute guard in place.

9. Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and exc essive

speed.

10. Never leave a running machine unattended.

Always turn off the blades, place the transmission

in neutral, set the parking brake, stop the engine

and remove key before dismounting.

11. Turn off blades when not mowing.

12. Stop the engin e and wai t unti l the bl ades co me t o

a complete stop before (a) removing the grass

catcher or unclogging chute, or (b) making any

repairs, adjusting or removing any grass or debris.

4

Page 5

13. Mow only in daylight or good artificial light.

DO:

14. Do not operate the machine while under the

influence of alcohol or drugs.

15. Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the

machine into a trailer or truck. This unit should not

be driven up or down a ramp onto a trailer or truck

under power, because the unit could tip over

causing serious personal injury. The unit must be

pushed manually on a ramp to load or unload

properly.

17. Never make a cutting height adjustment while the

engine is running if the operator must dismount to

do so.

18. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Do not wear lo ose fitting

clothes or jewelry. They can be caught in moving

parts. Never operate a unit in bare feet, sandals

or sneakers.

19. Check overhead clearance carefully before

driving under power lines, wires, bridg es or low

hanging tree branches, before entering or leaving

buildings, or in any other situation where the

operator may be struck or pulled from the unit,

which could result in serious injur y.

20. Disengage all attachment clutches, thoroughly

depress the brake pedal and shift into neutral

before attempting to start the engine.

21. Your mower is designed to cut normal residential

grass of a height no more than 10”. Do not

attempt to mow through unusually tall, dry grass

(e.g. pasture) or piles of dry leaves. Debris may

build up on the mower deck or contact the engine

exhaust presenting a potential fire haz ard.

Mow up and down slopes, not across.

Remove obstacles such as rocks, limbs, etc.

Watch for holes, ruts or bumps. Uneven terrain c ould

overturn t he mach ine. Tall grass can hide obstacles.

Use slow speed. Cho ose a low enough gear so tha t

you will not ha ve t o s t op or sh ift w hi le o n th e s lo pe . Al ways keep the machine in gear when going down

slopes to take advantage of engine braking action.

Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability.

Use extra care with grass catchers or other attachments. These can change the stability of the machine.

Keep all movement on the slopes slow and gradual.

Do not make sudden changes in speed or direction.

Rapid engagement or braking could cause the front of

the machine to lift and rapidly flip over backwards,

which could cause serious injur y.

Avoid starting or stopping on a slope. If the tires lose

traction, disengage the blades and proceed slowly

straight down the slope.

DO NOT:

Do not turn on slopes unless necessary; then, turn

slowly and gradually downhill, if possible.

Do not mow near drop-offs, dit ches or emb ank me nts .

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

Do not mow on wet grass. Reduced traction could

cause sliding.

Do not try to stabilize the machine by putting your foot

on the ground.

Do not use the grass catcher on steep slopes.

22. Use only accessories approved for this machine

by Cub Cadet. Read, understand and follow all

instructions provided with the approved

accessory.

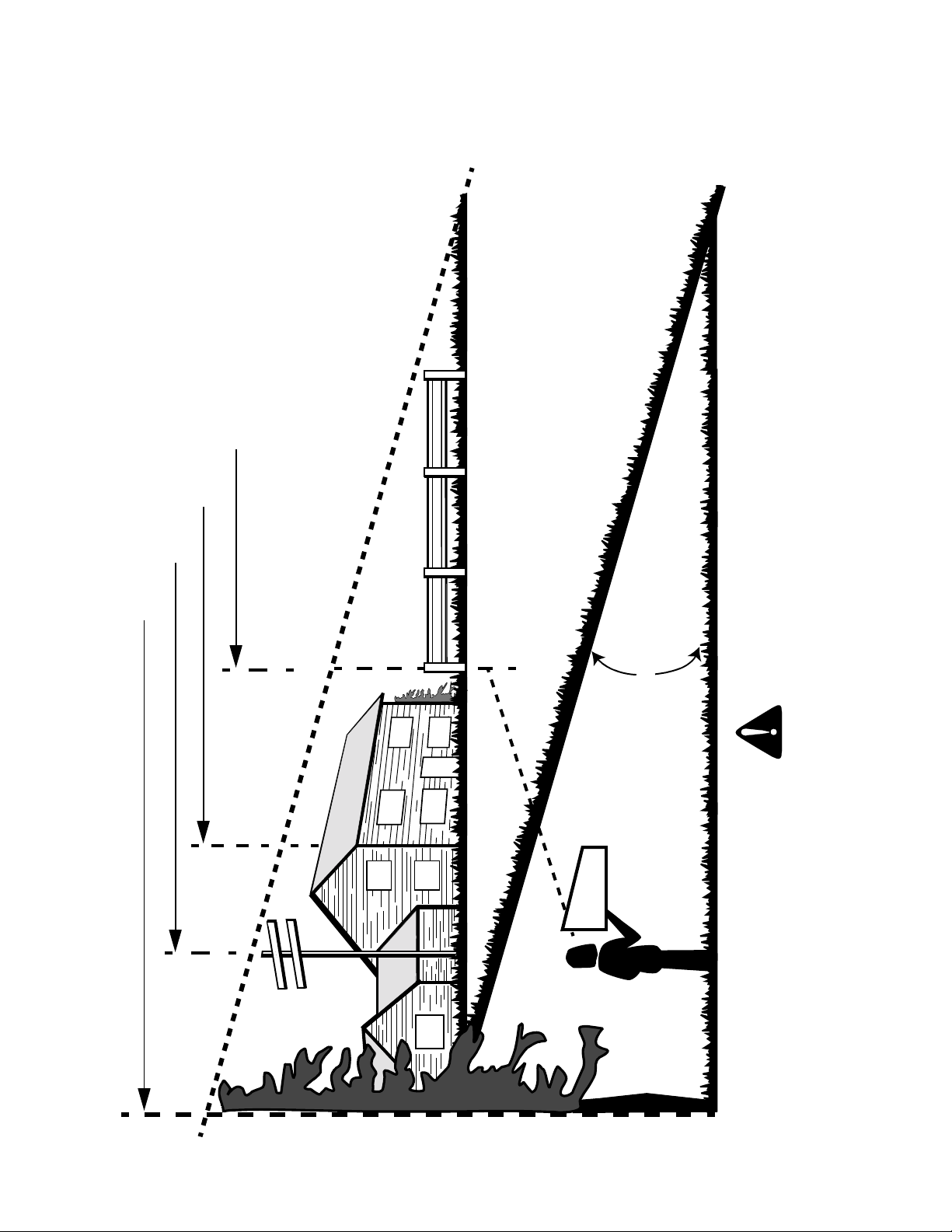

II. SLOPE OPERATION

Slopes are a m aj o r f a ctor related to loss of contr o l an d

tip-over accidents , which can re sult in sever e injur y or

death. All slopes require extra caution. If you c annot

back up the slope or if you feel uneasy on it, do not

mow it.

For your safety, use the slope gaug e include d as part

of this manual to measure slopes before operating this

unit on a sloped or hilly area. If the slope is greater

than 15° as shown on the slope gauge, do not operate

this unit on that area or serious injury could result.

III. CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them.

1. Keep children out of the mowing area and in

watchful care of an adult other than the operator.

2. Be alert and turn the machine off if children enter

the area.

3. Before and when backing up, look behind and

down for small children.

4. Never carry children, even with the blades off.

They may fall off and be seriously injured or may

interfere with safe machine operation.

5

Page 6

5. Never allow children under 14 years old to

operate the machine. Children 14 years and over

should only operate the machine under close

parental supervision and proper instruc tion .

6. Use extra care when approaching blin d corners,

shrubs, trees or other objects that may obscure

your vision of a child or other hazar d.

7. Remove the key when the machine is left

unattended to prevent unauthorized operation.

IV. SERVICE

1. Use extreme care in handling gasoline and othe r

fuels. They are extremely flammable and the

vapors are explosive.

a. Use only an approved container.

b. Never remove fuel cap or add fuel with the en-

gine running. Allow the engine to cool at least

two minutes before refueling.

c. Replace the fuel cap securely and wipe off any

spilled fuel before starting the engine as it may

cause a fire or explosion.

d. Extinguish all cigarettes, cigars, pipes and oth-

er sources of ignition.

e. Never refuel the machine indoors because fuel

vapors will accumulate in the area.

f. Never store the fuel container or machine

inside where there is an open flame or spa rk,

such as a gas hot water h eater, space h eater

or furnace.

2. Never run a machine inside a closed area.

3. To reduce fire hazard, keep the machine free of

grass, leaves or other debris build-up. Clean up

oil or fuel spillage. Allow the machine to cool at

least 5 minutes before storing.

4. Before cleaning, repairing or inspecting, make

certain the blade and all moving parts have

stopped. Disconnect the spark plug wire, and

keep the wire away from the spark plug to prevent

accidental starting.

5. Check the blade and engine mounting bolts at frequent intervals for proper tightness. Also visually

inspect blades for damage (e.g., excessive wear,

bent, cracked). Replace with blades which meet

original equipment specifications.

6. Keep all nuts, bolts and screws tigh t to be sure

the equipment is in safe working condition.

7. Never tamper with safety devices. Check their

proper operation regularly. Use all guards as

instructed in this manual.

8. After striking a foreign object, stop the engine,

remove the wire from the spark plug and

thoroughly inspect the mower for any damage.

Repair the damage before restarting and

operating the mower.

9. Grass catcher components are s ubject to wear,

damage and deterioration, which could expose

moving parts or allow objects to be thrown . For

your safety protection, frequently check the

components and replace with manufacturer’s

recommended parts when necessa ry.

10. Mower blades are sharp and can cut. Wrap the

blades or wear gloves, and use extra caution

when servicing blades.

11. Check brake operation frequently. Adjust and

service as required.

12. Muffler, engine and belt guards become hot

during operation and can ca use a burn. Allow to

cool down before touching.

13. Do not change the engine governor settings or

overspeed the engine. Ex cessive engine s peeds

are dangerous.

14. Observe proper disposal laws and regulations.

Improper disposal of fluids and materials can

harm the environment and the ecology.

a. Prior to disposal, contact your local

Environmental Protection Agency to

determine the p roper method for disposin g of

the waste. Recycling cen ters are establ ished

to properly dispose of materials in an

environmentally safe fashion.

b. Use proper containers when draining fluids.

Do not use food or b everage containers that

may mislead someone into drinking from

them. Properly dispo se of the containers immediately following the draining of fluids.

c. DO NOT pour oil or other fluids into the

ground, down a drai n or into a stream, pond,

lake, or other body of water. Observe Environmental Protection Agency regulations when

disposing of oil, f uel, coolant, brake fluid, filters, batteries, tires and other harmful waste.

15. We do not recommend the use of a pressure

washer or garden hose to clean your unit. They

may cause damage to electrical components;

spindles; pulleys; bearings; or the engine. The

use of water will result in shortened life and

reduce serviceability.

WARNING - YOUR RESPONSIBILITY:

read, understand and follow the warnings and instructions in this manual and on the machine.

Restrict the use of this power machine to pers ons who

6

Page 7

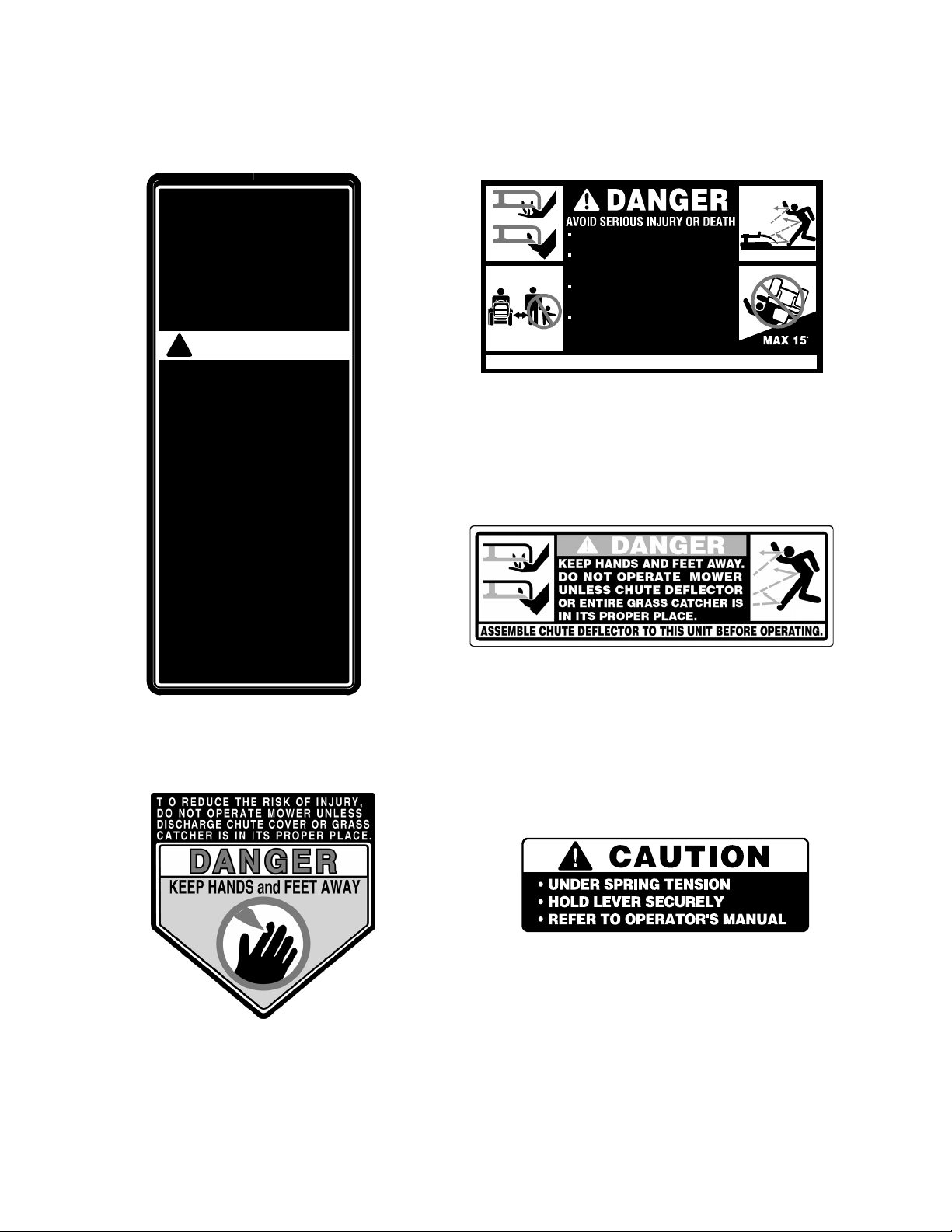

PRODUCT GRAPHICS

Keep product safety gr aphics (decals) clean. Replac e

any safety graphic that is damaged, destroyed, mis s-

STARTING INSTRUCTIONS

BE FAMILIAR WITH CONTROLS BEFORE

1.

STARTING ENGINE AND OPERATING.

SET CHOKE, MOVE THROTTLE TO MID

2.

POSITION AND DEPRESS BRAKE PEDAL.

TURN KEY TO THE START POSITION.

3.

AFTER ENGINE STARTS OPEN CHOKE.

4.

STOPPING INSTRUCTIONS

1.

DISENGAGE PTO AND SET PARKING BRAKE

MOVE THROTTLE CONTROL TO MID

2.

POSITION AND TURN KEY OFF.

WARNING

!

•

AVOID SERIOUS INJURY OR DEATH.

•

READ OPERATORS MANUAL AND ALL

WARNING LABELS BEFORE USING

MACHINE.

•

GO UP AND DOWN SLOPES, NOT ACROSS.

•

AVOID SUDDEN TURNS.

•

DO NOT OPERATE UNIT WHERE IT COULD

SLIP OR TIP.

•

IF MACHINE STOPS GOING UPHILL, STOP

PTO AND BACK DOWN HILL SLOWLY.

•

DO NOT MOW WHEN CHILDREN OR

OTHERS ARE AROUND.

•

NEVER CARRY CHILDREN.

•

LOOK DOWN AND BEHIND BEFORE AND

WHILE BACKING.

•

KEEP SAFETY DEVICES [GUARDS, SHIELDS,

AND SWITCHES] IN PLACE AND WORKING.

•

REMOVE OBJECTS THAT COULD BE

THROWN BY THE BLADES.

•

KNOW LOCA TION AND FUNCTION OF ALL

CONTROLS.

•

BE SURE THE BLADES AND THE ENGINE

ARE STOPPED BEFORE PLACING HANDS

OR FEET NEAR BLADES.

•

BEFORE LEAVING OPERATOR'S

POSITION, DISENGAGE PTO, ENGAGE

BRAKE LOCK, SHUT OFF ENGINE AND

REMOVE KEY.

.

ing, painted over or c an no longer be read. Replacement safety graphics are available through your

dealer.

KEEP HANDS AND FEET AWAY FROM

ROTATING PARTS

REMOVE OBJECTS THAT CAN BE

THROWN BY THE BLADE IN ANY

DIRECTION. WEAR SAFETY GLASSES.

DO NOT MOW WHEN CHILDREN OR

OTHERS ARE AOUND. NEVER CARRY

CHILDREN

USE EXTRA CAUTION ON SLOPES. DO

NOT MOW SLOPES GREATER THAN 15°.

MOW UP AND DOWN, NOT ACROSS

READ OPERATOR'S MANUAL. KEEP SAFETY DEVICES WORKING.

AVOID SUDDEN TURNS, USE LOW GEAR

.

.

.

.

SAFETY GRAPHIC – LOCATED ON

LEFT SIDE OF MOWER DECK

DEFLECTOR and SAFETY GRAPHIC –

LOCATED ON RIGHT SIDE OF DECK

GENERAL SAFETY INSTRUCTIONS

WARNING – LOCATED ON RIGHT

SIDE OF RUNNING BOARD

HANDS AND FEET SAFETY GRAPHIC–

LOCATED ON DEFLECTOR CHUTE

SAFETY GRAPHIC – LOCATED

ON LEFT SIDE OF DECK

7

Page 8

TO THE OWNER

This Operator’s Manual is an important part of your new tractor. The information contained in this manual has been

prepared in detail to he lp you bet ter underst and the featu res, corr ect operati on, adjust ments, and m aintenanc e of

your tractor. The performance and dependability of this tractor rely greatly on the manner in which it is operated and

maintained. Therefore, it is recommended that all operators of the tractor carefully read this manual and fully understand its operation. Also keep the manual available for reference to ensure proper operation, and that maintenance

procedures are performed as scheduled to assure the tractor’s optimal mechanical condition.

NOTE: All references to LEFT, RIGHT, FRONT, and REAR, unless specifically stated otherwise, indicate that rela-

tive position on the tractor when facing forward while seated in the operator’s seat.

CAUTION: DO NOT tow your Model 2186 tractor . Towing will damage the transmission. Place the tractor on a

LEVEL SURFACE before pulling the transmission release lever to the disengaged position.

Your local authorized Cub Cadet dealer is interested in the performance you receive from your tractor, and with the

maintenance needed to ensur e the sa tis fac to ry opera t ion of you r tractor . The dealer has trained service personnel

familiar with the latest s ervicing in formation, is e quipped with the l atest tools, a nd has a comple te line of genu ine

Cub Cadet service parts which assure proper fit and high quality.

CALLING SERVICE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, and

specifications.

If you have difficulties with the tractor and/or equipment; have any questions regarding the operation or maintenance

of this equipment; or desire additi onal information not found in th is manual, c ontact your near est authorized Cub

Cadet dealer. If you need assistance in locating a dealer in your area, contact the Customer Dealer Referral Line by

calling:

1-877-282-8684

To obtain top performance and assu re economical operation , the tractor should be inspected by your authorized

dealer periodically or at least once a year, depending on its hours of use. Before calling your dealer, make sure that

you have your model number(s) and manufacturing date available for the dealer.

RECORDING MODEL AND SERIAL NUMBER INFORMATION

Product identificati on plates are prov ided for major c omponents of your tractor. The num bers on these plate s are

important if your tract or shou ld requi re deal er se rv ice, or i f yo u nee d add iti ona l in for ma tion on y our tr ac tor. Pr io r to

using your tractor for the first time, record the numbers from the identification plates in the appropriate spaces provided below.

The chassis model plate , showing the factory model number and Mfg. Date (See Figure 1) can be found on the

underside of the seat mounting base. Pivot the seat foward to locate the decal.

The engine serial number decal (See Figure 2) is located on the engine blower housing.

Hood Model Factory Model No. Mfg. Date

Delivery Date Engine Model/Spec. No. Engine Serial No.

XXXXXXXXXXX XXXXXXX XXX

Model Number Mfg. Date

CUB CADET LLC

P. O. BOX

www.cubcadet.com

DEALER LOCATOR PHONE NUMBER:

361131

CLEVELAND, OH 44136

877-282-8684

Figure 1 Figure 2

8

Page 9

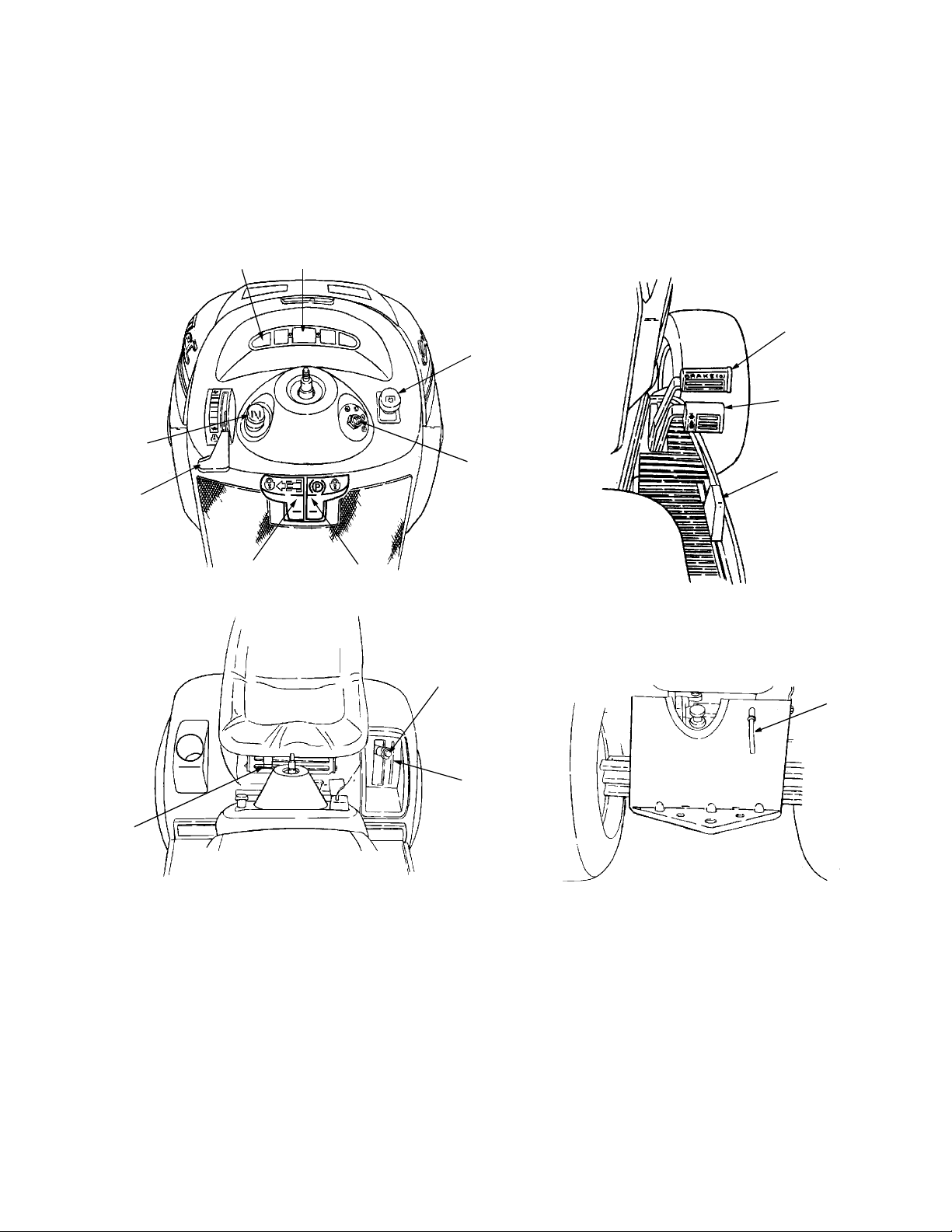

SECTION I. CONTROLS AND INDICATORS

Your Cub Cadet Tracto r has been s afety engineered.

This section gives a brief description of the function

and location of the various controls and indicators.

AB

F

E

H

G

Thoroughly acqua int your self w ith all th e control s and

indicators before attempting to start or operate the

tractor.

I

C

J

D

K

N

A. Low Oil Indicator

B. Hour Meter

C. Power Take-Off (PTO) Control Switch

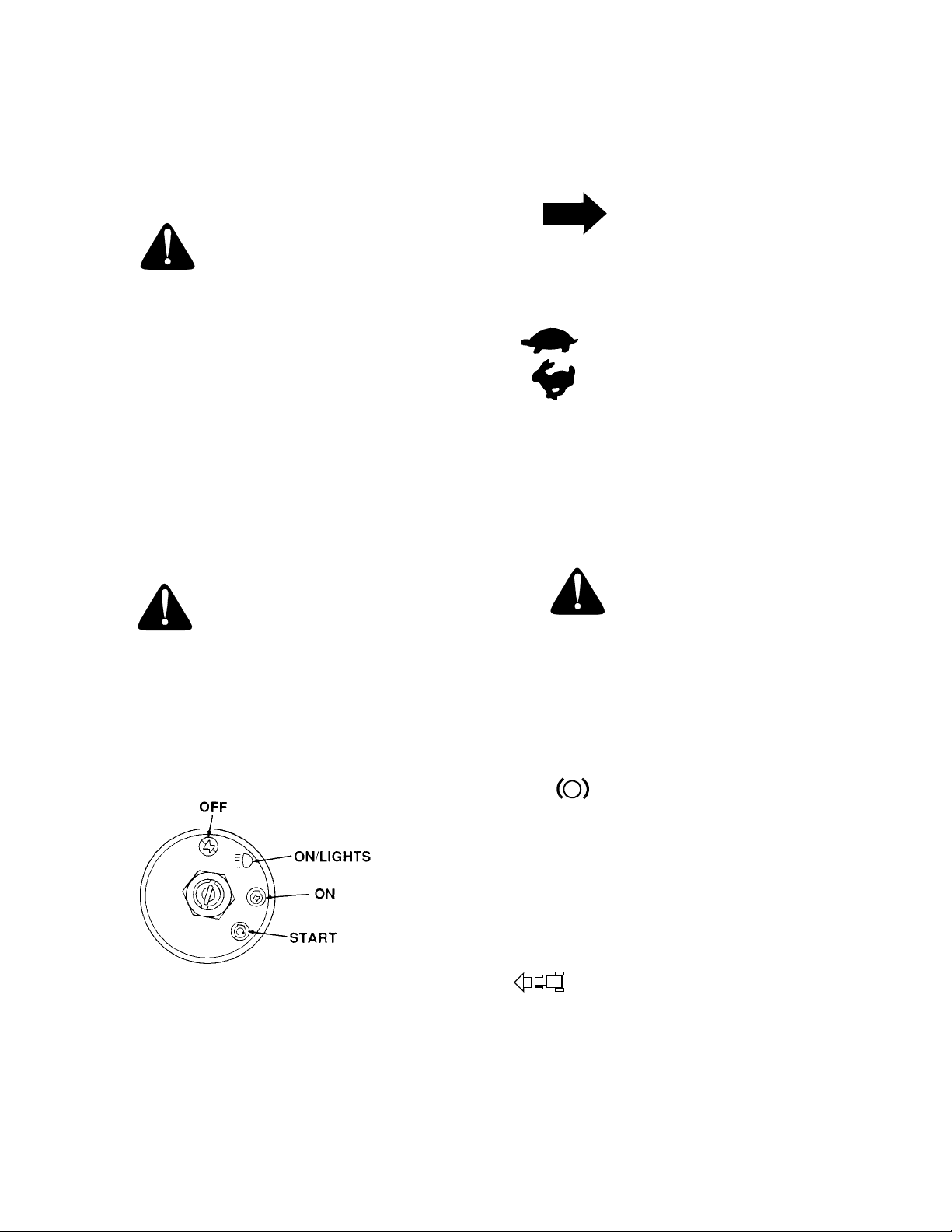

D. Ignition/Light Switch

E. Throttle Control Lever

F. Choke Control

G. Brake Pedal Lock

H. Cruise Control Lever

L

O

M

I. Brake Pedal

J. Forward Control Pedal

K. Reverse Control Pedal

L. Lift Handle

M. Lift Height Indicator

N. Seat Adjustment Lever

O. Transmission Release Lever

P. Fuses (Not Shown)

Q. Safety Interlock Switches (Not Shown)

Figure 3

9

Page 10

A. LOW OIL INDICATOR

This indicator will illuminate when the engine oil level is

low. If this indica tor il lum in ates , s top the tr a ctor i mm ediately and check the engi ne oil lev el. If the oil lev el is

within the operating range, but the light remains on,

contact your Cub Cadet dealer.

E. THROTTLE CONTROL LEVER

This lever controls the speed of the engine. When

set in a given position, the control cable will maintain

a uniform engine speed.

NOTE

CAUTION

Operating the tractor with low oil level or pressure could result in severe engine damage.

B. HOUR METER

The hour meter operates wheneve r the ignition key is

in the “ON” position. Record the actual hours of tractor

operation to ensure all maintenance procedures are

completed according to the schedule in this manual.

C. POWER TAKE–OFF (PTO) CONTROL SWITCH

The power take-off control switch operates the front

electric PTO clutch. Pull the switch knob to engage

(“RUN”), or push the knob to disengage (“OFF”) the

PTO clutch.

D. IGNITION/LIGHT SWITCH

WARNING

To prevent accidental starting and/or battery

discharge, remove the key from the ignition

switch when the tractor is not in use.

The combination lights and ignition switch is a four

position switch. (See Figure 4)

When using power take-off operated equipment, best performance is achieved with the

throttle lever in the “FAST” position.

This symbol shows slow position.

This symbol shows fast position.

F. CHOKE CONTROL

The choke control is operated manually. Pull the

knob out to ckoke the engine; push the knob in to

open the choke.

G. BRAKE PEDAL LOCK

WARNING

The hydrostatic tran smission will not h old the

tractor on a hill. Normal internal leakage in the

transmission will allow the tractor to roll downhill. To avoid an accident and/or possible injury, engage the brake pedal lock.

The brake lock lever, located in the center of the

dash panel below the steering wheel, is identified

with the symbol. Always engage the brake

pedal lock when dismounting the tractor. To engage

the brake pedal lock, depress the brake pedal and

push down on the brake pedal lock lever. Hold the

lever down while releasing the brake pedal. The lever should lock in the down position.

P

Figure 4

H. CRUISE CONTROL LEVER

The cruise control lever, located in the center of the

dash panel below the steering wheel, is identified with

the symbol. This lever can be used to maintain a desired “foot free” forward speed in areas

where constant speed changes are not required. Refer to Section II- OPERATION for instructions on how

to use this feature.

10

Page 11

I. BRAKE PEDAL

The brake pedal is located at the front of the right running board above the forward control pedal. Press

down to stop the tractor and disengage the cruise control. The brake pedal must be fully depress ed to activate the safety interlock switch when starting the

tractor.

J. FORWARD CONTROL PEDAL

The forward contr ol pe dal is l oc ated a t the fron t o f the

right running board below the brake pedal. Slowly

press down on the pedal to start moving for ward. The

forward ground speed of the tractor is directly affected

by the distance the pedal is depressed.

K. REVERSE CONTROL PEDAL

WARNING

Check behind the tractor to be sure the area is

clear of people, pets or obstacles. Use a slower

speed to maintain con trol of the tractor when

traveling in reverse.

The reverse control peda l is located in the right front

running board rearward of the the brake and forw ard

control pedals. P ress the peda l downward to move in

reverse.

L. LIFT HANDLE

The lift handle is loc ated in the lef t fender and is us ed

to raise and lower equipment used with the tractor. The

equipment can be set in any of six positions by depressing the top button on the handle, moving the handle to the desired position, then releasing the button. It

may be necessary to push or pull slightly on the handle

to depress the button. There is a lift assist spring which

reduces the effort needed to lift attachments. To adjust

spring tension refer to ADJUSTMENTS in Section III.

Figure 5

O. TRANSMISSION RELEASE LEVER

The transmission release lever is located at the back of

the tractor in the rear draw bar. This leve r disconnec ts

the hydro transmiss ion pump from the rea r axle to allow the unit to be pushed a short distance by hand.

To disengage the trans mission, pu ll back on the lever

until its lockin g flange is visible outside the drawbar,

then lift the lever up into the slot and release. To re-engage the transmission, pull back on the lever, drop out

of the slot and release.

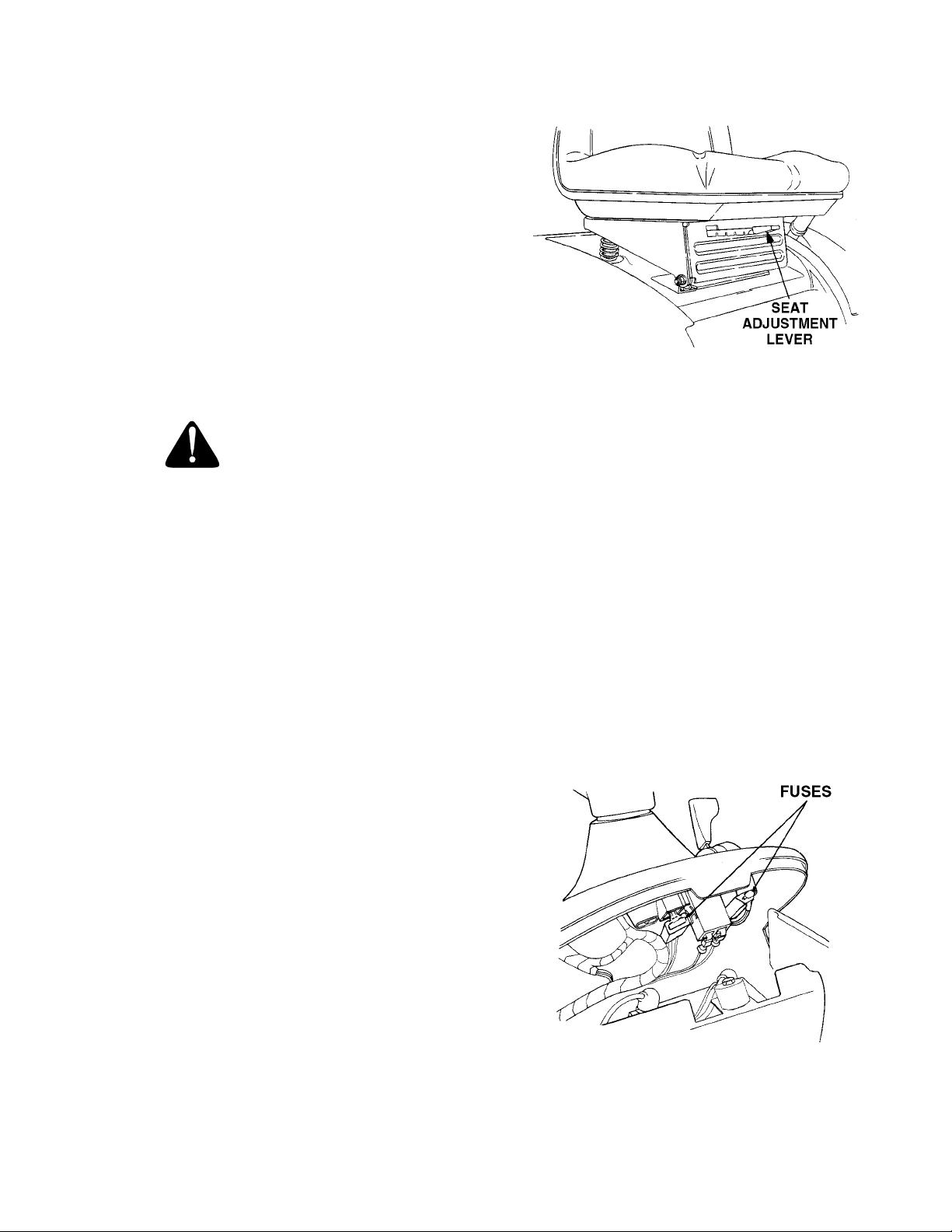

P. FUSES

The fuses are l ocate d under the hood between the i ndicator lamps and the hour meter (see Figure 6). Fuses

are installed to protect the tractor’s electrical circuitry

and components f rom damage caused by excessive

amperage.

M. LIFT HEIGHT INDICATOR

The lift height indicator is located in the left fender and

indicates the height of the deck attachment when installed.

N. SEAT ADJUSTMENT LEVER

The seat adjustment lever (see Figure 5) is used to

move the seat forward or rearward into one of five positions. See ADJUSTING THE SEAT in Section III.

Figure 6

11

Page 12

Q. SAFETY INTERLOCK SWITCHES

HOOD AND SIDE PANELS

This tractor is equ ipped w ith a s afety i nterloc k sy stem

for the protection of the operator. If the interlock system should ever malfunctio n, do not operate the tractor. Contact your authorized Cub Cadet Dealer. The

safety interlock system prevents the engine from

cranking or starti ng unl ess the brak e ped al is fully depressed, and the PTO switch is in the “OFF” position.

The safety interlock system will automatically shut off

the engine if the operator leaves the sea t before engaging the brake lock.

The safety interlock system will automatically shut off

the engine if the operator leaves the seat with the PTO

in the “RUN” position, regardless of whether the brake

lock is engaged. The PTO switch must be moved to the

“OFF” position to restart the engine.

The safety interlock system will automatically shut off

the PTO if the reverse control pedal is depr es sed wi th

the PTO in the “RUN” position. To re-engage the PTO,

release the reverse control pedal, move the PTO

switch to the “OFF” position, then again pull the switch

to the “RUN” position.

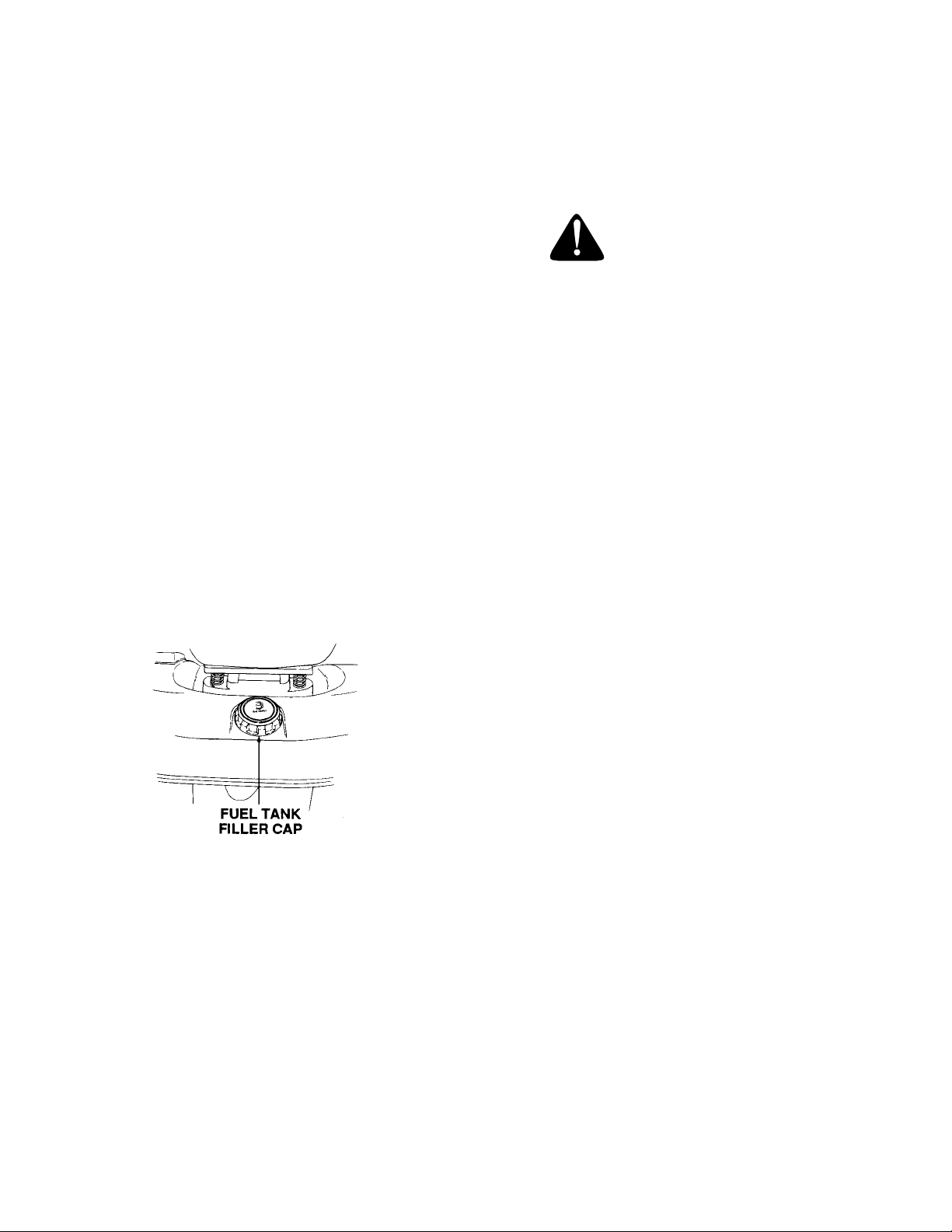

FUEL TANK

The fuel tank is located under the rear fender. The filler

cap is in the center/rear of the fender (see Figure 7).

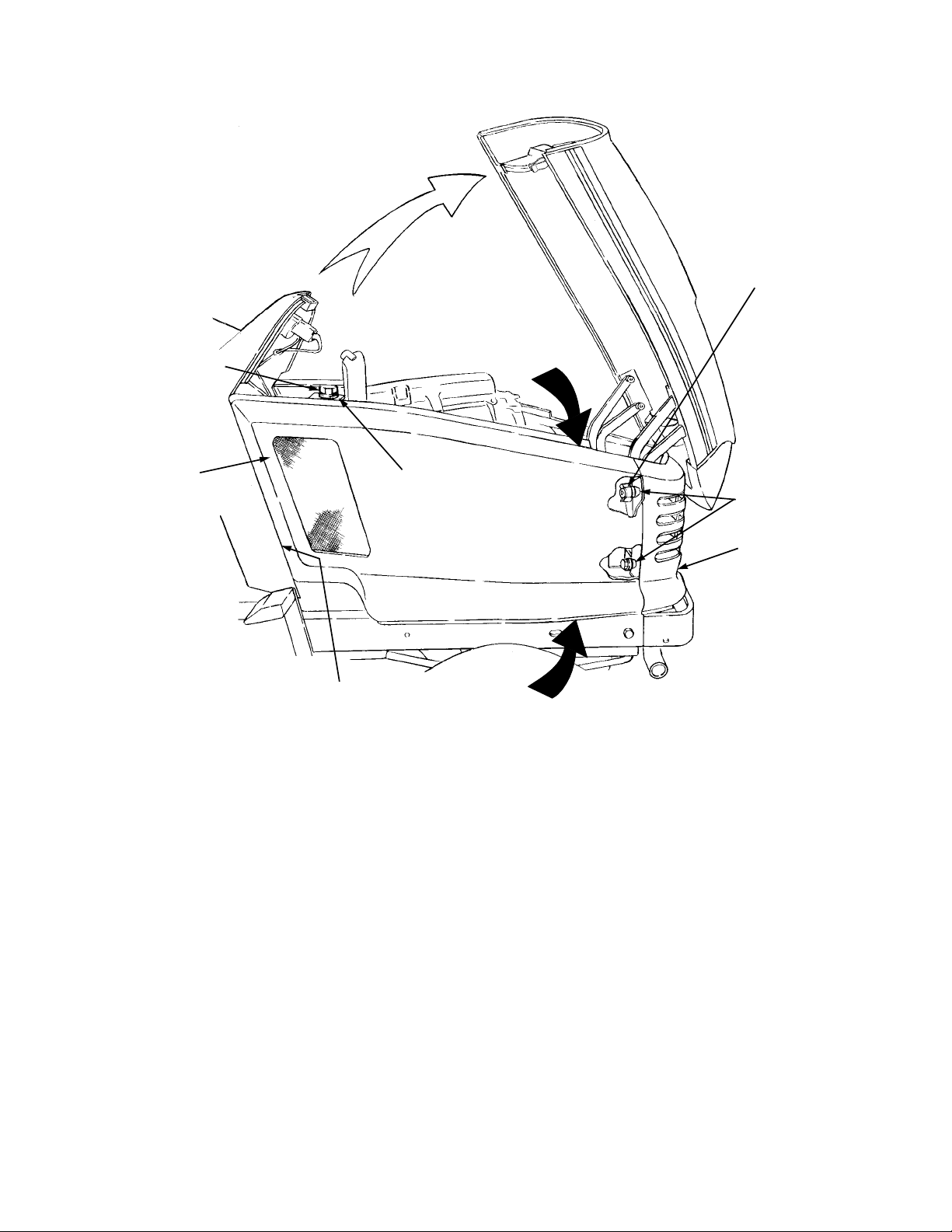

The tractor hood is arranged to swing up an d forward

for easy acce ss to the eng ine compartm ent (see Figure 8). Whenever engine maintenance is required, the

side panels can be removed.

WARNING

If the engine has been recently run, the engine,

muffler and sur rounding metal surfaces wil l be

hot and can cause bur ns to the sk in. Allow the

tractor to cool and u se cauti on when remo ving

the side panels.

To remove either the righ t or left side panel, refer to

Figure 8 and proceed as follows:

1. Engage the brake lock and raise the hood.

2. Loosen, but do not remove, the rear wing nut and

upper front wing nut.

3. Grasp the side panel just behind the grille and pull

outward to release the side panel from the

tapered bushings on the grille.

4. Slide the side panel forward and out of the groove

in the dash panel.

Figure 7

To install either the right or left side panel, refer to Figure 8 and proceed as follows:

1. Slide the rea r of pan el into the groov e in the d ash

panel.

2. Position the notch of the rear side panel tab on

the threads of the bulkhead rod, between the

bulkhead and wing nut.

3. Press the slots of the front side panel flange onto

the tapered retainers, between the reta iners and

the grille.

4. Tighten the rear and upper front wing nuts and

close the hood.

12

Page 13

UPPER FRONT

WING NUT

REAR WING NUT

SIDE PANEL

GROOVE IN

DASH PANEL

REAR TAB

ON PANEL

GRASP

RETAINER WITH

TAPERE D GU I D E

GRILLE

GRASP

Figure 8

13

Page 14

WARNING

SECTION II. OPERATION

Gasohol (up to 10% ethyl alcohol, 9 0% unleaded

gasoline by volume) is an approved fuel. Other

gasoline/alcohol blends are not approved.

RECEIVE INSTRUCTION - Read the

operator’s manual. Learn to operate this

machine SAFELY. Don’t risk INJURY or

DEATH.

1. Before starting the engine or beginning

operation, be familiar with the controls. The

operator must be seated, the PTO switch in

the “OFF” position and the brake pedal fully

depressed.

2. Keep all shie lds in place. K eep away from

moving parts.

3. NO RIDERS! Keep all peop le and pets a

safe distance away. Look behind to both

sides before backing up.

4. DO NOT direct the mower discharge at

people.

5. Avoid slopes. Tractors can be rolled over.

6. Before leaving the operator’s seat: Shut off

the PTO, engage the brake pedal lock, shut

off the engine and remove the ignition key.

Wait for all movement to stop before

servicing or cleaning.

Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends ( up to a maximum o f 15% MTBE

by volume) are approved fuels. Other gasoline/

ether blends are not approved.

4. Check the engine and transmission oil levels.

5. Clean the air cleaner element if necessary.

6. Check the tire inflation pressures.

7. Adjust the sea t for operator’s maximum comfort,

visibility and for maintaining complete control of

the tractor.

8. Remove the side panels and clean any

accumulated gras s an d debris from the engine a ir

inlet screen. Also clean the dash air intake screen,

grille and side panels to ensure adequate cooling.

9. Refer to the various sections of the Owner’s

Manual for additional inf ormati on .

STARTING THE ENGINE

7. Do not fill the fuel tank when the engin e is

running or while the engine i s hot. Ti ghten

the fuel cap securely.

BEFORE OPERATING YOUR TRACTOR

1. Before you o perate the tracto r, study this m anual

carefully. It has been prepared to help you operate

and maintain your tractor with utmost efficiency.

2. Familiarize your self with the operations of all the

instruments and controls.

3. This engine is certified to operate on unleaded

gasoline. For best results, fill the fuel tank with only

clean, fresh, unleaded gasoline with a pump

sticker octane rating of 87 or higher. In c ountries

using the Research method, it should be 90 octane

minimum.

Unleaded gasoline is recommended because it

leaves less combustion chamber deposits.

Leaded gasoline may be used in areas where

unleaded is not available and exhaust emissions

are not regulated. Be aware however, that the

cylinder head may require more frequent service.

WARNING

For personal safety, the operator must be sitting

in the tractor seat when starting the engine.

WARNING

This unit is equipped with a safety inerlock

system designed for the protection of the

operator. Do not operate the tractor if any part

of the interlock system is malfunctioning.

Periodically check the functions of the interlock

system for proper operation as described

below:

• The safety interlock system prevents the engine from cranking or starting unless the

brake pedal is fu lly dep ressed and the PTO

clutch engagement switch is in the “OFF” position.

14

Page 15

• The safety interlock system will automatically shut off the engine if the oper ator leaves

the seat before engaging the brake pedal

lock.

• The safety interlock system will automatically disengage the PT O if the reverse c ontrol

pedal is pressed down with the PT O in the

“RUN” position. To re-engage the PTO, release the reverse control pedal, move the

PTO switch into the “OFF” position and then

engage the PTO while seated.

• The safety interlock system will automatically shut off the tracto r engine if the operator

leaves the seat with the P TO in the “RUN”

position.

1. Operator must be sitting in the tractor seat.

2. Pull choke control knob to full choke position. Less

choking may be necessary due to variations in

temperature, grade of fuel, etc. Little or no choking

will be needed when the engine is warm.

3. Place the throttle midway between the “SLOW”

and “FAST” position.

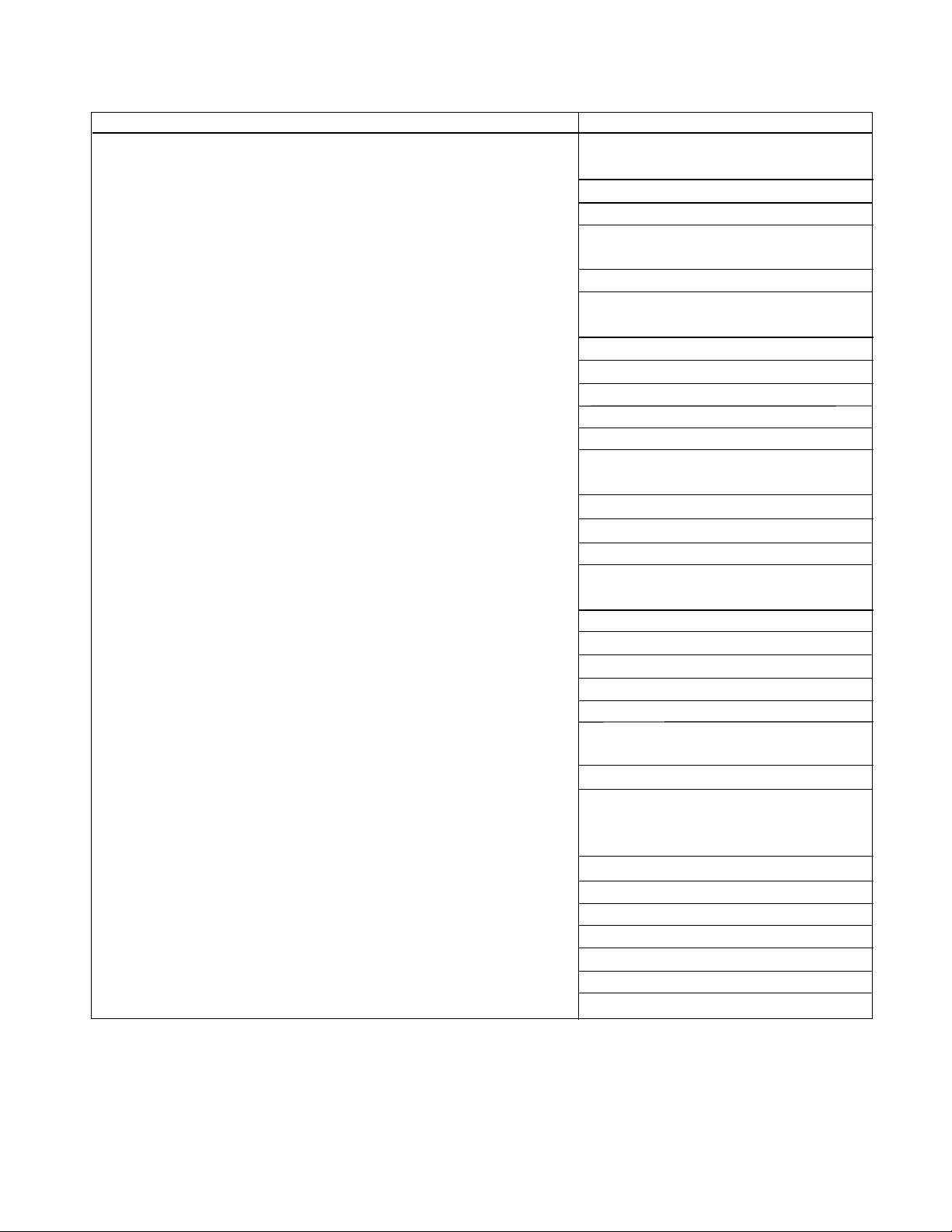

TRACTOR BREAK-IN PROCEDURE

CAUTION

Never operate a new engine immediately

under full load. Break it in carefully as shown

in the table below.

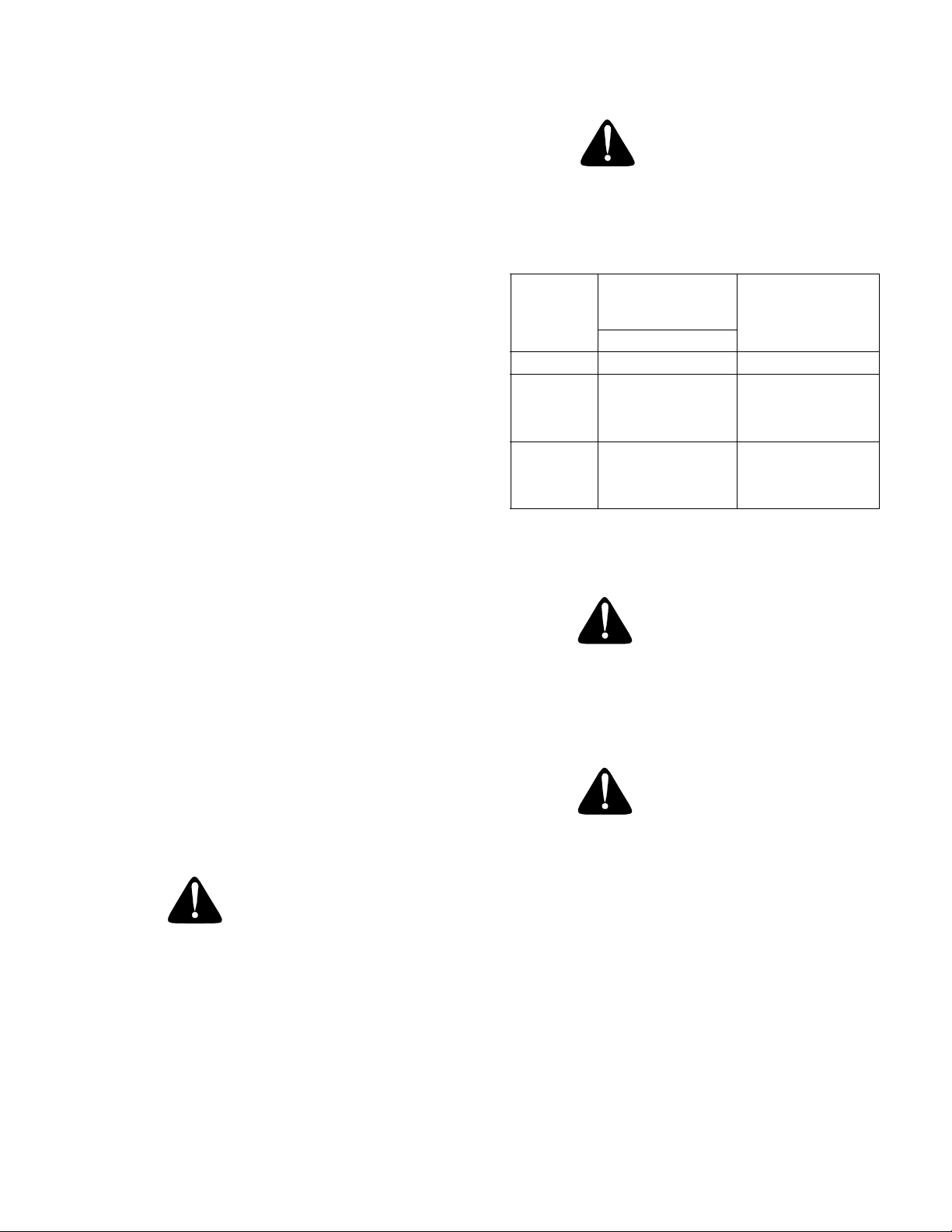

Engine Throttle

Period

1st hour X None

2nd hour

3rd through

12th hour

Control Lever

Position Load

1/2 3/4 Full

X

X

X

X

Light drawbar load

Mowing with tractor

at slow groundspeed

Medium drawbar

load

Normal mowing

or

or

4. Place the PTO switch in the “OFF” position.

5. Fully depress the brake pedal.

6. Turn the ignition key clockwise to the “START”

position and release it as soon as the engine

starts; however, do not crank the engine

continuously for more than 10 seconds at a time. If

the engine does n ot sta rt withi n thi s time , turn the

key “OFF” and wait a min u te to a llow th e en gi ne’ s

starter motor to cool, then try again.

7. After the engine sta rts, slowly release the brake

pedal. As the engine warms up, gradually push the

choke control knob al l the way in. Do not use the

choke to enrich the fuel mixture, except as

necessary to start the engine.

STOPPING THE ENGINE

CAUTION

Remove the key from the ignition switch to

prevent accidental starting or battery discharge

if the equipment is left unattended.

COLD WEATHER STARTING

WARNING

Engine exhaust ga ses are dangerous. Do not

run the engine in a confined area such as a

storage building any longer than is necess ary.

Immediately move the tractor outdoors.

WARNING

For personal safety, the operator must be sitting

in the tractor seat before starting the tractor.

When starting the engine at temperatures near or below

freezing, ensure the correct viscosity motor oil is used in

the engine and the battery is fully charged. Start the

engine as follows:

1. Pull the choke all the way out to full choke position.

Place the PTO switc h in the “O FF” pos ition. P lace the

throttle control lever between the “MID” and “FAST”

positions. Wait a moment to allow the engine speed to

stabilize, then turn the ignition key to the “OFF”

position. Remove the key from the ignition switch.

2. Move the throttle co ntr ol lev er to mi dwa y be twee n

the “SLOW” and “FAST” position.

3. Place the PTO switch in the “OFF” position.

4. Fully depress the brake pedal.

15

Page 16

5. Turn the ingnition key to the “START” position and

hold until the engine starts; however, do n ot crank

the engine continuously for more than 10

seconds at a time. Once t he e ngi ne s ta rt s, gr ad ua ll y

adjust the choke as needed to keep the engine

running until warmed up , then push the choke control

all the way in.

CAUTION

Do not use the forward or reverse control

pedals to change the direction of travel when

the tractor is in motion. Use the brak e pedal t o

bring the tractor to a stop before depressing

either the forward or reverse control pedal.

NOTE

If the engine fails to start after several attempts,

the engine may become flooded. If this

happens, wait a minute to allow the starter

motor to cool. Move the th rottle control to the

“SLOW” position, push the ch ok e in all the way

and momentarily crank the engine to help clear

the cylinders. With the throttle control in the

“SLOW” position and the choke all the wa y in,

turn the ignition key to the “START” position

while slowly pulling the choke out to a position

that will allow the engine to start. Gradually

adjust the choke as needed to keep the engine

running until warmed up, then push the choke

control all the way in.

DRIVING THE TRACTOR

CAUTION

Avoid sudden starts, excessive speed and

sudden stops.

CAUTION

Do not leave the seat of the tractor without

disengaging the PTO, depressing the brake

pedal and engaging the brake pedal lock. If

leaving the tractor unattended, also turn the

ignition key off and remove the key.

a. To move forwar d, slowly depre ss the forward

control pedal until the desired speed is

achieved.

b. To move in reverse, check that the area

behind is clear t hen fully depres s the reverse

control pedal.

3. Using the cruise control lever.

NOTE

The cruise control feature can only be operated

in the forward direction.

a. Slowly depr ess the forw ard con trol p edal un til

the desired speed is achieved.

b. Lightly push the cruise control lever downward

as far as possible and hold in this position.

c. While continuing to hold the cruise lever down,

lift your foot from the forward control pedal

(you should feel the cruise latch engage).

d. If properly engaged, the cruise lever and

forward contro l pedal s hould lo ck in the down

position, and the tractor will maintain the same

forward speed.

e. Disengage the cruis e co ntrol u sing one o f the

following methods:

• Depress the brake pedal to disengage the

cruise control and stop the tractor.

• Lightly depress the forward control pedal.

• Lift the cruise control lever upward.

NOTE

When using power take-off operated

equipment, best perform ance is achieved with

the throttle lever in the “FAST” position.

1. Depress the brake pedal to release the brake pedal

lock and let th e pedal up. Move the thr ottle lev er to

the position where the engine operates best for the

load to be handled.

2. Driving with forward or reverse pedals.

NOTE

Although not recommended, depressing the

reverse pedal will also disengage the cruise

control.

f. To change to the reverse direction when

operating with cruise control, depress the

brake pedal to disengage the cruise control

and stop the tractor; then depres s the rever s e

control pedal.

16

Page 17

DRIVING ON SLOPES

Refer to the SLOPE GAUGE on page 55 to help

determine slopes where you may not operate safely.

WARNING

Do not mow on inclines with a slope in excess

of 15 degrees (a rise of approximately 2-1/2 feet

every 10 feet). The tractor could overturn and

cause serious injury.

WARNING

Operate the tractor u p and down slop es, ne ver

across slopes. Always drive up or down the face

of a slope. Do not drive so that the tracto r may

tip over sideways .

Before operating the tractor on any slope, walk the

slope to look for possible hazards such as rocks.

mounds, ruts, stumps or other surface irregularities

which could cause the tractor to be upset.

Back the tractor with implement up the steepest portion

of each slope you intend t o work. If the tr actor cannot

negotiate the slope in reverse, the slope is too steep to

be worked.

Avoid turns when d riving on a slop e. If a turn mu st be

made, turn down the slope. Turning up a slope greatly

increases the chance of a roll over.

Avoid stopping when driving up a slope. If it is

necessary to stop while driving up a slope, start up

smoothly and carefully to reduce the possibility of

flipping the tractor over backward.

STOPPING THE TRACTOR

1. Start and run the engine a few minutes to warm up.

2. With the mowing deck, snow thrower, etc. installed

and the engine running at approximately 50%

throttle, engage and disengage the clutch at ten

second intervals (ten seconds ON-ten seconds

OFF) five times. The engine choke may have to be

pulled out slightly to accomplish this.

3. Increase the engine speed to 75% throttle and

again engage and disengage the PTO clutch at ten

second intervals five times.

4. Make certai n t he PTO i s dis eng age d a nd s to p th e

engine.

Operate the PTO clutch as follows:

1. Move the throttle control lever to approximately the

mid throttle position.

2. Pull the PTO switch to the “RUN” position.

3. Advance t he throttle lever to the operating speed

(full engine speed).

4. The operator must remai n in the tr actor seat at all

times. If the operator should leave the seat without

turning off the powe r take-off switch, the tr actor’s

engine will shut off.

5. The PTO clutch cannot be operated when the

tractor is driving in the reverse direction. The PTO

switch must in the “OFF” position when the reverse

control pedal i s depressed , or the PTO clutch will

automatically disengage. To re-engage the PTO

clutch, release the reverse control pedal, move the

PTO switch to the “OFF” po sition, then again pull

the switch to the “RUN” position.

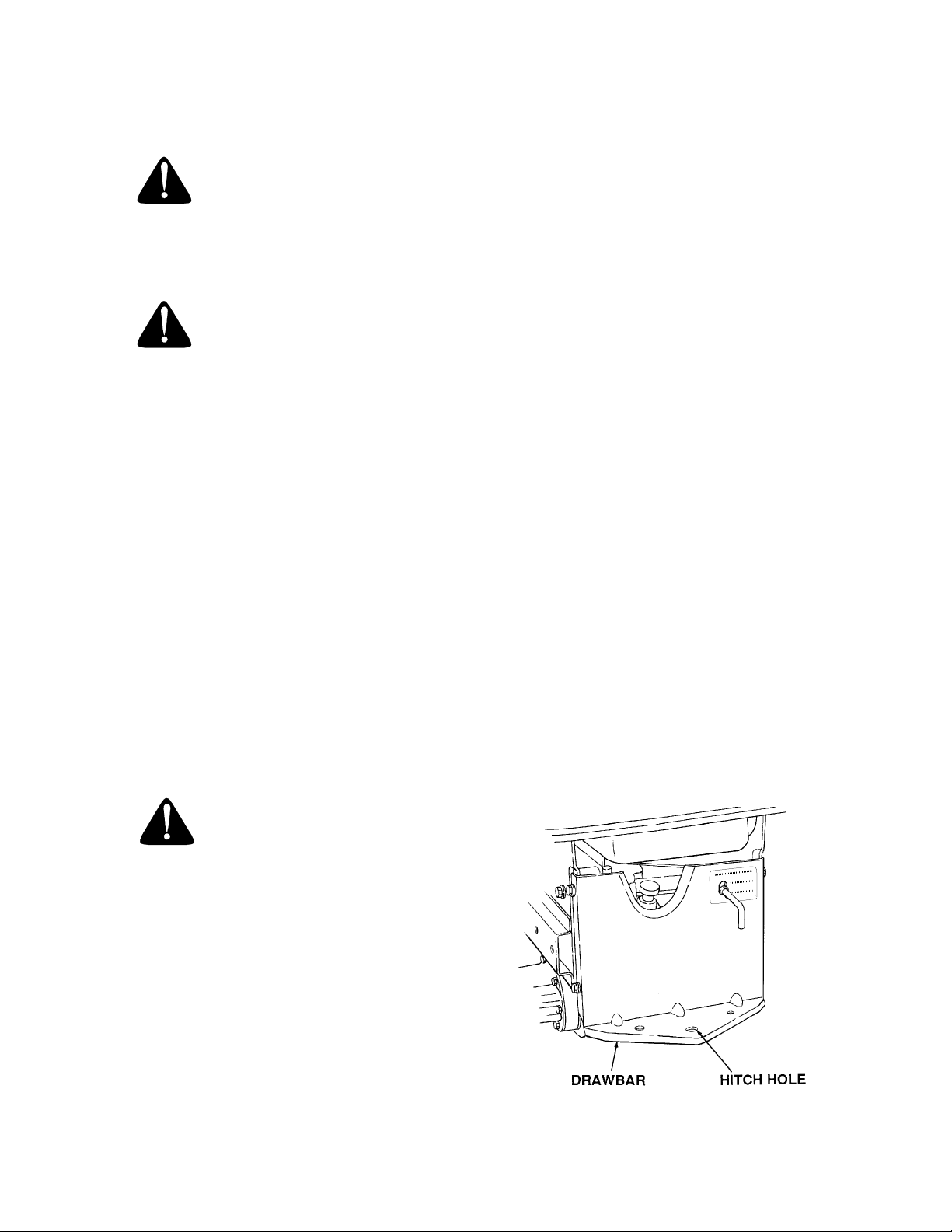

DRAWBAR

Drawbar type equipment must be hitched to the tractor

only at the hitch hole in the drawbar (See Figure 9).

CAUTION

Always engage the brake p edal lock, push the

PTO switch to the “OFF” position, lower the

equipment and shut off the engine before

dismounting. Never try to start the engine while

standing on the ground.

Fully depress the brake pedal to bring the tractor to a

complete stop (and disengage the cruise control),

engage the brake pedal lock, disengage the PTO, turn

the ignition swi tch to “ OFF’” an d remov e the ke y from

the switch before dismounting.

OPERATING THE POWER TA KE-OFF (PT O) CLUTCH

Before operating the new clutch under load (mowing

grass, etc.), perform the following break-in procedure:

Figure 9

17

Page 18

SECTION III. ADJUSTMENTS

This section contains adjustment information for the

Model 2186 tractor. Adjustment information for the 44inch deck is located in Section V – Mower Deck

beginning on page 33.

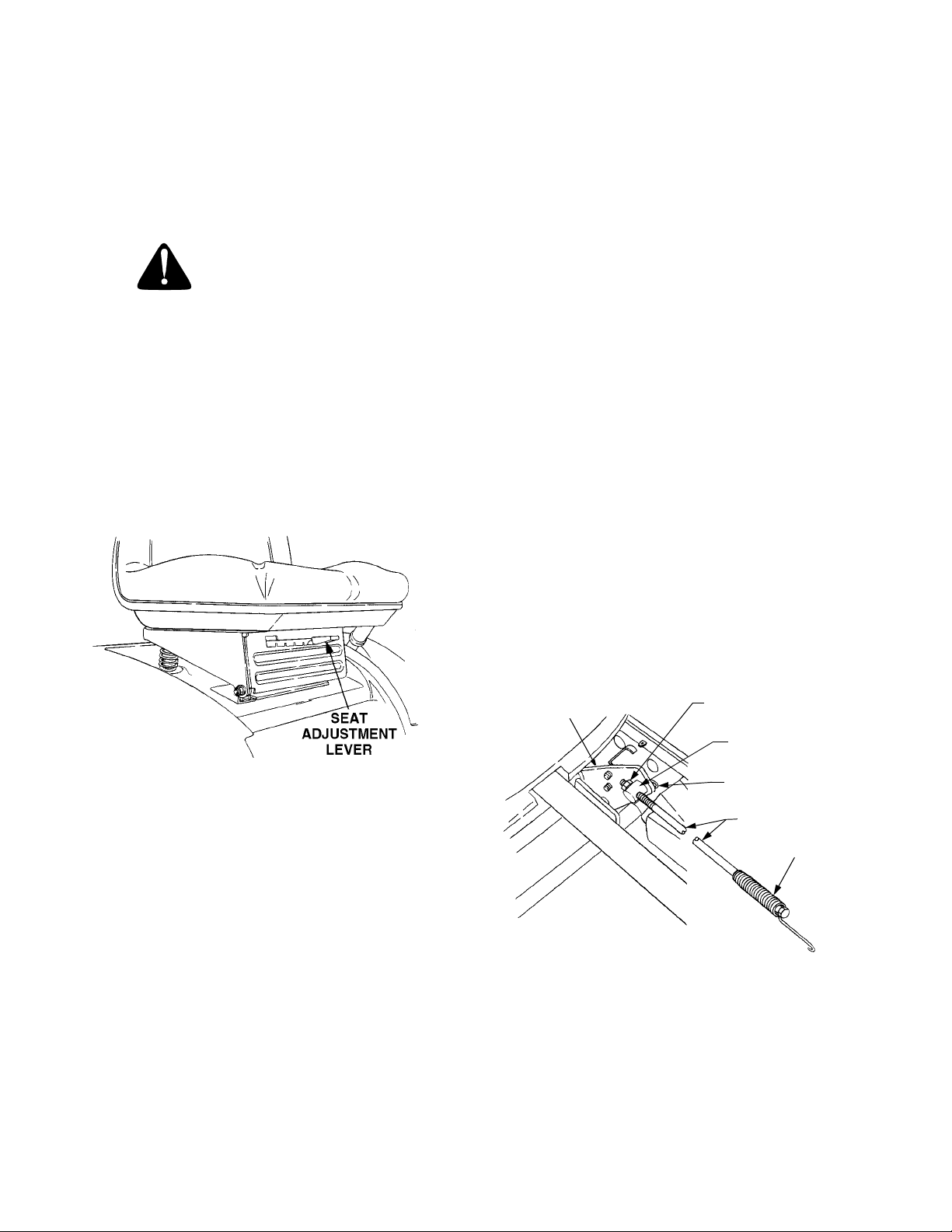

ADJUSTING THE SEAT

WARNING

Do not adjust the seat when the tractor is

moving. Adjusting the seat while the tractor is

moving could cause the operator to lose control

of the tractor.

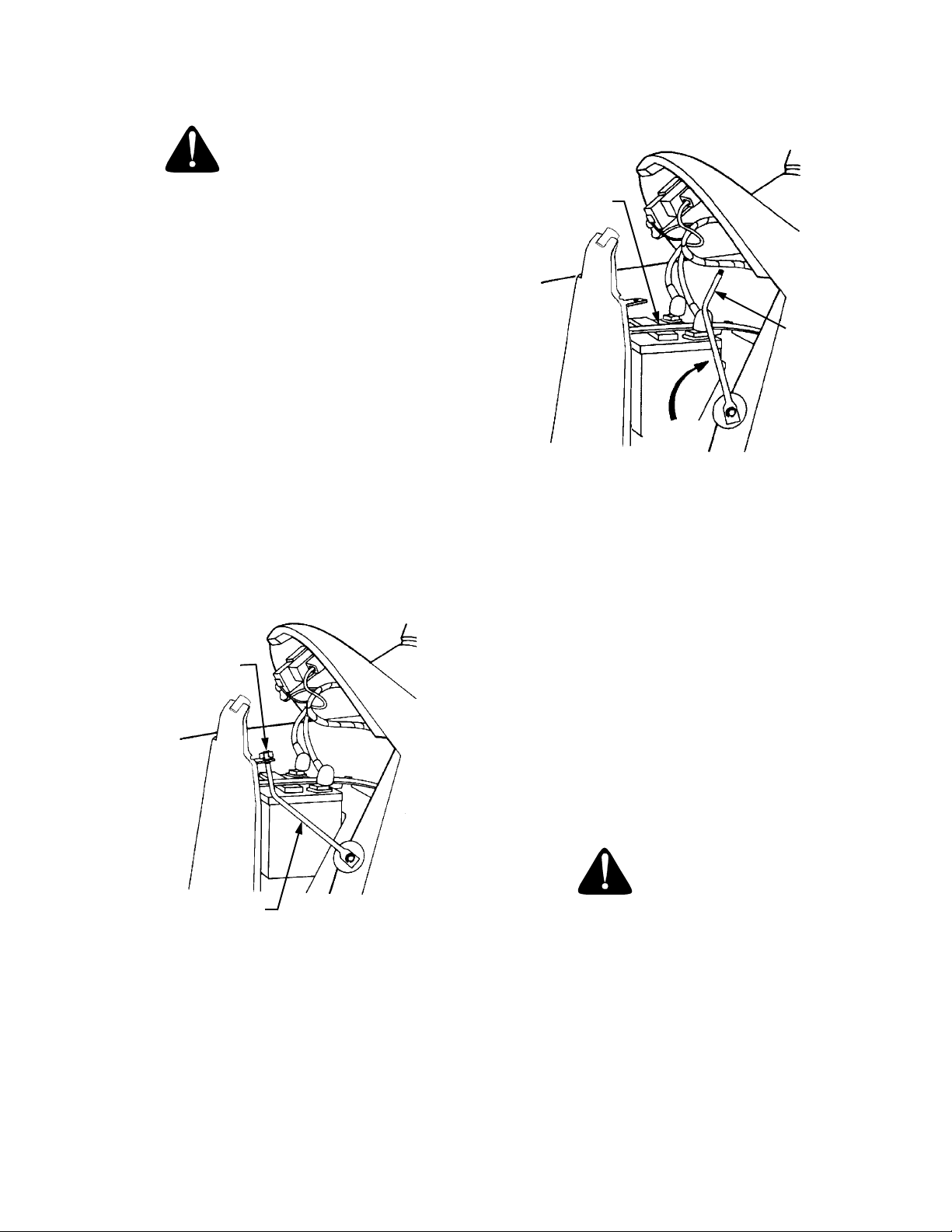

Before starting the tract or, adjust the seat forward or

rearward to the most comfortable driving position. To

reposition the seat, move the seat adjustment lever

(see Figure 10) upward and s lide the seat forward or

rearward. Release the adjustment lever when the seat

is comfortably positioned. Gently rock the seat forward

or rearward to be sure the seat is locked in place.

To adjust the braking force, refer to Figure 11 and

proceed as follows:

1. Place the tractor on a level surface with the brake

pedal lock disengaged. Stop the tractor engine

and remove the ignition key.

2. While working from the underside of the tractor,

facing the threaded end of the rod:

• Remove the internal cotter pin from the brake

rod adjustment ferrule and di sconnect the ferrule from the brake cam.

• Loosen the hex jam nut from against the ferrule.

To increase the braking force—

Turn the ferrule clockwis e (inwar d) one ful l turn at

a time until the ferrule can be inserted into the

brake cam w hile applying a minimal tension on

the spring.

To decrease the braking force—

Turn the ferrule counterclockwise (outward) one

full turn at a time until the ferrule can be inserte d

into the brake cam while applying a minimal

tension on the spring.

3. Turn the ferrule counterclockwise (outward) one

full turn to release the slight spring tension.

Tighten the jam nut against the ferrule, then insert

the ferrule into the brak e cam and secure with the

intenal cotter pin.

Figure 10

ADJUSTING THE BRAKES

During normal ope ra tio n o f t his t racto r , th e brak es ar e

subject to wear and will need periodic examination and

adjustment.

To check the brake adjustment, position the tractor on

a firm and level surface. Stop the trac tor engine and

remove the ignition key. Pull and lock the transmission

release lever in the “TRANSMISSION RELEASED”

position. Perform the following checks:

1. Engage the brake p edal l ock. If the trac tor can be

pushed forward or rearward, the braking force

must be increased.

2. Release the brake pedal lock. If the tractor cannot

be pushed forward or rearw ard, the braking force

must be decreased.

BRAKE

CAM

HEX JAM NUT

ADJUSTMENT

FERRULE

INTERNAL

COTTER PIN

BRAKE ROD

SPRING

Figure 11. Viewed from top (fender off).

Recheck the brake adjustment to ensure proper brake

operation before operating the tractor. If brake rod

adjustment does not correct the problem, see your

authorized Cub Cadet dealer.

18

Page 19

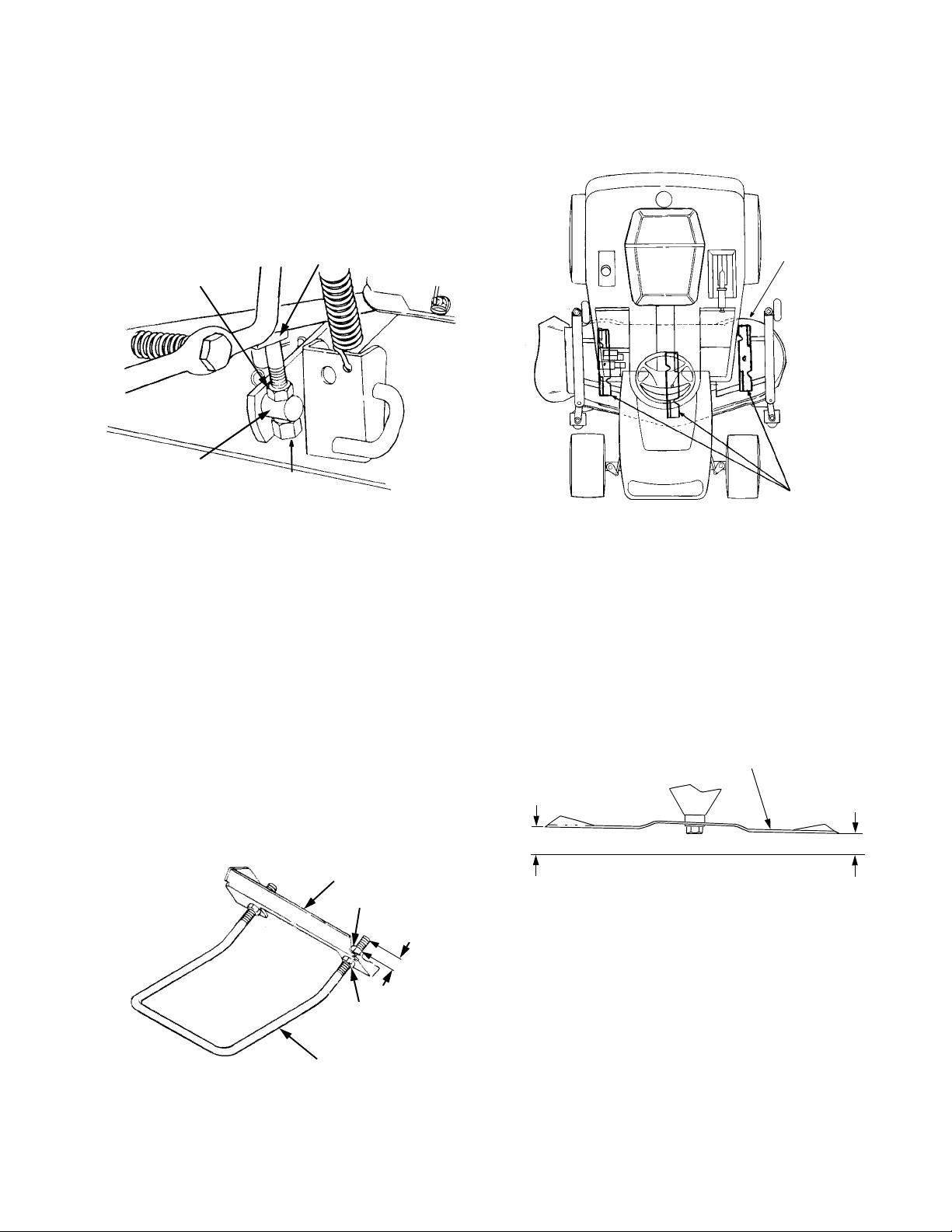

WHEEL ALIGNMENT

The front wheels should toe-in approximately 1/8 to

1/4 inch, as measured across dimensions A and B

shown in Figure 12.

PERPENDICULAR

TO FRAME

LOWER

STEERING

ARM

Figure 12. Viewed from beneath the tractor.

FRONT WHEEL ADJUSTMENT

5. Disconnect the front ball joints from the steering

arms by removing the hex lock nuts (Refer to

Figure 13). Manually move ea ch wheel to achieve

the required toe-in and equal D measurements.

6. Loosen the jam nuts from the ball joints (See

Figure 13).

BALL JOINT

JAM NUT

TIE ROD

HEX

LOCK

NUT

STEERING

ARM

Figure 13

7. Making sure not to move the lower steering arm or

either wheel, turn the ball joint in or out on each tie

rod as necessary to align with the hole in each

steering arm.

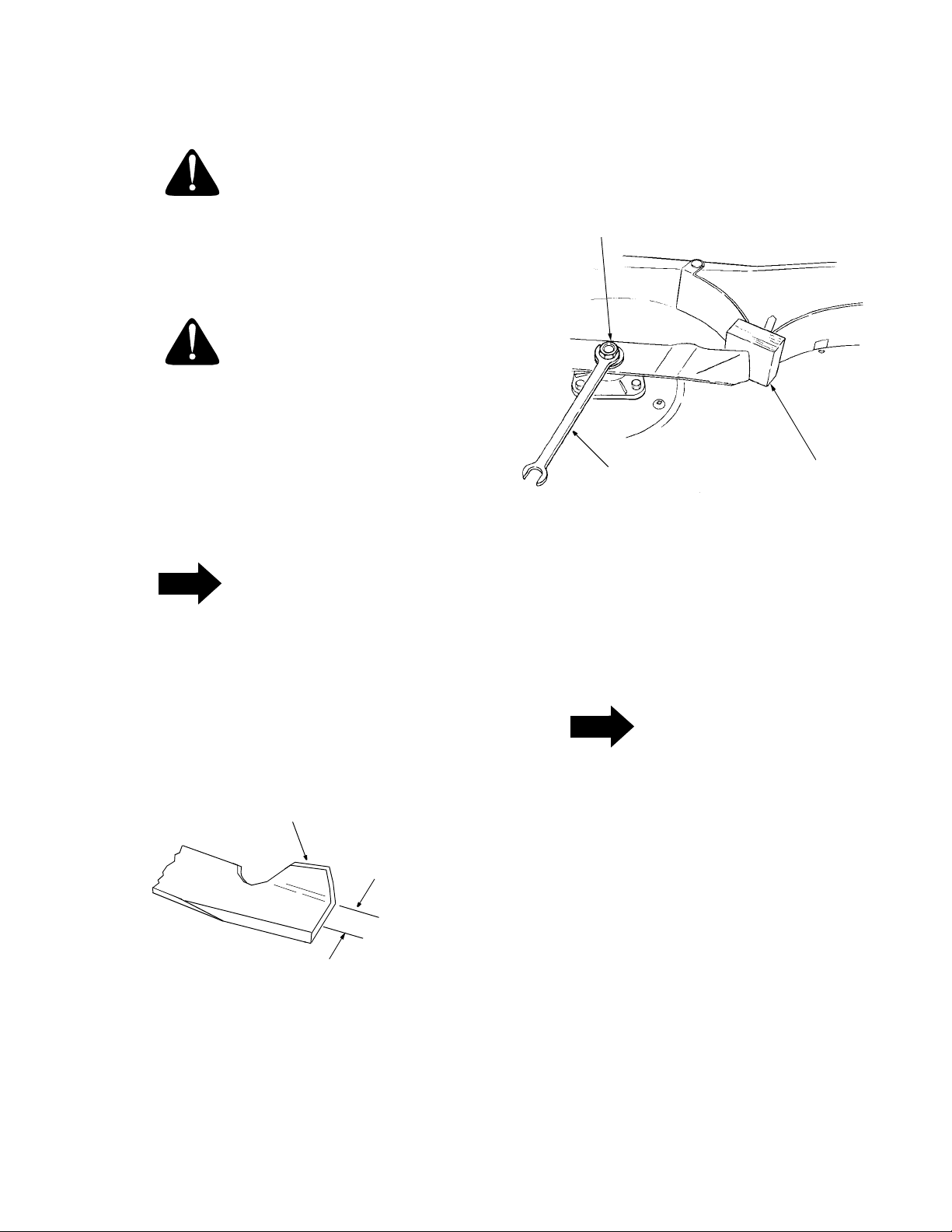

WARNING

Place the tractor on a firm and level surface.

To adjust the toe-in, proceed as follows:

1. Check the lower steering arm to ensure it is

perpendicular to the tractor frame (See Figure 12).

2. Place a mark at the same spot on both front

wheels; preferably the inner bead flange of the

wheel rims.

3. Rotate the wheels to position the marks at the front

horizontal diameter of the wheels, then measure

the distance between the marks and the bottom

edges of the tractor frame channels (See

measurement D in Figure 12). These two

measurements should be equal.

4. While holding the steering arms to prevent the

steering knuckles from moving, rotate the marks to

the rear horizontal diameter. Measure the distance

between the marks and the frame (See

measurement C in Figure 12). Measurement D

should be approximately 1/16 to 1/8 inch less than

measurement C on each side of the tractor.

8. Reinstall the ball joints in the stee ring arms and

secure with the hex lock nuts. Tighten the jam nuts

against the ball joints.

PIVOT BAR ADJUSTMENT

CAUTION

The tractor shou ld be checked every 50 hou rs

of operation for play between the frame axle

channel and the pivot axle.

Check and adjust the pivot axle as follows:

1. Raise the front ot the tractor and set it on jack

stands, so the front wheels a re suspen ded abov e

the ground.

CAUTION

For safety, block the rear wheels to prevent the

tractor from rolling and tipping or sliding the jack

stands.

19

Page 20

2. Pivot the ends of the axle up and down to check for

binding. If the axle is bindin g, lo os en the lock nu ts

(See Figure 14) until binding is eliminated.

PIVOT AXLE

ADJUSTMENT BOLTS

LOCK

NUT

FRAME AXLE

CHANNEL

A

A

LOCK

NUTS

PIVOT

AXLE

SECTION A-A

Figure 14

3. Grasping the ends of the pivot axle, attempt to

move each end of the axle forward an d rearward

to check for side play between th e axl e an d fram e

channel. If play is present, gradually tighten the

lock nuts until play is minimized.

4. Repeat steps 2 and 3 until minimum play with out

binding is achieved.

5. Raise the front of the tractor, remove the jack

stands, and lower the tractor to the ground.

Remove the blocks from the rear wheels.

HYDROSTATIC NEUTRAL ADJUSTMENT

The following adjustments will be necessary if the

tractor creeps forward or rearward when neither the

forward nor reverse pedals are depressed.

Checking the Transmission Neutral Setting

To check and adj ust the transmis sion neutral setti ng,

proceed as follows:

1. Drive the tractor for approximately 5-10 minutes to

warm up the transmission, then stop the engine

and engage the parking brake.

WARNING

Place the tractor on a firm and level surface and

chock the front wheels be fore raising the rear

wheels from the ground. Use jack stands to

support the rear of the tractor when raised.

2. Raise the rear of the tractor, so that the rear tires are

at least one inch above the surf ace, and set it on

jack stands. Make certain the jack stands are positioned to balance the tractor and prevent tipping.

WARNING

The operator presence safety circuit will stop

the engine if the seat i s empty when the brake

pedal is released. If an assistant is seated when

adjusting the neutral setting, use extreme

caution to prevent the tractor from tipping or

rolling. Similar precautions should be taken with

any other method of over-riding the safety

circuit, such as placing a weight in the seat.

Never operate the tractor with the sa fety circui t

disabled.

3. Carefully star t the tractor engine and release th e

parking brake. Observe both rear wheels for

rotation in either direction.

4. If wheel rotation is observed, adjust the neutral

setting as follows:

a. Disconnect the rear control rod from the

control arm by removing the hairpin cotter from

the pivot sleeve (Refer to Figure 15).

b. If wheel rotation stops when the rod is

disconnected, che ck and readjust the control

rod per the instructions below.

c. If wheel rotation continues , lo osen the loc knut

securing the hex cap screw and centering

spacer to the neutral bracket (See Figure 15).

d. If the rotati on is in the forward direc tion, sl ide

the centering spacer rearward until the wheels

just begin to rotate in the reverse direction.

Then slowly slide the space r slightly forward

until wheel rotation stops.

e. If the rotation is in the reverse direction, slowly

slide the cente ring sp acer sl ightly forwar d unti l

rotation stops.

f. Carefully tighten the hex cap screw and

locknut, making certa in the centering spacer

does not move.

g. Stop the engine and engage the parking

brake.

20

Page 21

3

2

1. Fron t C o nt r ol Rod

2. Rear Control Rod

3. Hex Tap Screw

4. Pivot Sleeve

5. Neutral Arm

CONTROL

CAM

6. Control Arm

7. Hex Cap Screw

8. Centering Spacer

9. Neutral Bracket

10. Hairpin Cotter

(Not Shown)

Figure 15.

Adjusting the Control Rod

After completing the previous steps (1 thru 4) for

checking neutral setting, ad just the control rod ( See

Figure 15) as follows:

NOTE

The brake pedal lock MUST be engaged to

properly adjust the control rod.

1

5

10

6

8

4

5

7

9

ADJUSTING LIFT ASSIST SPRING TENSION

The effort required to operate the implement lift handle

can be varied by loose ning or tighteni ng the lift assist

spring adjusting bolt (See Figur e 16). The bo lt can be

accessed from the rear of the tractor, inside the left

rear wheel. Turning the adjusting bolt clockwise will

decrease the manual effort required for lifting

attachments; turning counterclockwise will increase

the effort needed to lift the attachment.

1. Loosen, but do not remove, the hex tap screws

that fasten the front and rear control rods together.

2. While making certai n to not m ov e the fr on t contr ol

rod, control cam or co ntrol arm (See Figure 15),

slide the rear control rod in the direction necessary

to directly align the pin of the pivot sl eev e with the

lower hole of the control arm.

3. Insert the pivot sleeve pin into the control arm and

secure with the hairpin cotter, then tighten the hex

tap screws. Make sure to maintain the adjusted

position of the control rods when tightening the

screws.

4. Raise the rear of the tractor, remove the jack

stands and lower the tractor.

LIFT ASSIST

SPRING

ADJUSTING

BOLT

Figure 16

21

Page 22

CARBURETOR ADJUSTMENTS

WARNING

When making adjustments to the carburetor

while the engine is running, disengage the PTO

clutch and engage the brake pedal lock. Keep

clear of all moving parts and be careful of all hot

surfaces.

WARNING

Carbon monoxide fu mes can be fatal! Do not

make any adjustments to the carburetor in a

confined area such as a storage building. Move

the tractor outside into the air.

The carburetor is adjusted at the factory and under

normal operating conditions it will not require

readjusting. The high idle is set at the factory and

cannot be adjusted. If the engine does not operate

properly and the problem a ppears to be fuel system

related, check the following areas before adjusting the

carburetor: Refer to MAINTENANCE se cti on.

• Check for fuel in fuel tank

• Check fuel cap vent for blockage

• Check fuel line for pinched or obstructed areas

• Check for fuel filter blockage

• Check for a clogged air filter

If, however, the engine is hard-starting or runs roughly

or stalls at low idle speed, it may be necessary to

adjust or service the carburetor. Minor carburetor

adjustment may also be needed to compensate for

differences in fuel, temperature or altitude.

2. Idle Speed Se tti ng: Place the throttle control into

the “idle” or “slow” position. Set the low idle speed

to 1200 rpm (± 75 rpm) by turning the low idle

speed adjusting s crew i n or out. C heck the spee d

using a tachometer (See Figure 17).

NOTE: AIR CLEANER COVER MUST

BE REMOVED TO ADJUST

CARBURETOR IDLE SPEED

IDLE SPEED

ADJUSTING SCREW

AND SPRING

IDLE FUEL ADJUSTING

NEEDLE AND SPRING

Figure 17

NOTE

The recommended low idle speed for the engine is 1200 rpm. To ensu re best resul ts when

setting the low idle fuel needle, the low idle

speed must not exceed 1200 rpm (± 75 rpm).

The air filter element and element cover must be

assembled to the carburetor when running the engine.

Adjust the carburetor idle fuel mixture in the order

stated as follows (Refer to Figure 17):

NOTE

Carburetor adjustments should be made only

after the engine has warmed up.

1. Start the engine and run at half thr ottle for 5 to 10

minutes to warm up. The engine must be warm

before making the final settings. Check that the

throttle and choke plates can fully open.

CAUTION

The tip of the low idle fuel adjust ing needle is

tapered to critica l dimensions. Damage to the

needle and the seat in th e carburetor bo dy will

result if the needle is forced.

3. Low Idle Fuel Needle Setting: Place the thr ottle

into the “idl e” or “slow” positio n. Turn the low idle

fuel adjusting needle in slowly until the engine

speed decreases, and then back out approximately

3/4 turn to obta in the be st low sp ee d p erf or man c e.

4. Recheck the idle speed using a tachometer.

Readjust the speed as nece ssary.

22

Page 23

SECTION IV. MAINTENANCE

ENGINE MAINTENANCE

Maintenance, repa ir, or replacement of the emission

control devices an d syst ems , whi ch are being done at

the customer’s expense, may be performed by any

engine repair establishment or individual. Warranty

repairs must be performed by an authorized Kohler

service outlet.

ENGINE OIL

The engine-crankca se is fi lled wi th shi p- awa y o il. Thi s

oil may be used for the first 5 hours of engine operation

at temperatures between 0° and 90°F. If temperatures

are not within this rang e, d ra in the o il from the oil fi lte r

and crankcase and replace with new oil as specified in

the LUBRICATION TABLE.

To aid starting, the sel ection of crankcase lu bricating

oils should be based on the lowest anticipated

temperatures until the next scheduled oil change.

For oil change intervals of 100 hours, the following oils

are recommended.

Ambient Temperature Viscosity (Grade SG/SH)

+32°F and Above — Cub Cadet Engine Oil S.A.E.

10W30 or S.A.E. 10W40

• Never operate the engine with t he oil level below

the “L” mark or above the “F” mark on the dipstick.

NOTE

Check the oil level only while the engine is

stopped and the tractor is level.

CAUTION

The oil level should be checked every hour

during the first 5 hours of operation and prior to

every use thereafter.

OIL LEVEL

DIPSTICK

OPERATING

RANGE

Below +32°F — Cub Cadet Engine Oil S.A.E.

5W20 or S.A.E. 5W30*

*Synthetic Engi ne Oil S.A .E. 5W 20 or S.A.E . 5W30 is

acceptable, up to 40°F.

CHECKING THE OIL LEVEL

Regularly checking and maintaining the engine oil level

in the crankcase cannot be overemphasized. Close

monitoring of the oil leve l during the first 10 hours of

operation is especia lly important. Referring to Figure

18, check the oil level BEFORE EACH USE as follows:

• The engine must be cool so the oil has had time to

drain into the sump of the crankcase.

• Clean the area around the oil level di ps tick to pre vent debris from entering the crankc ase.

• Remove the dipstick and wipe it clean. Insert the

dipstick into the tube and press all the way down.

• Remove the dipstick and check the oil level.

• Always keep the oil level at or near the “F” mark on

the dipstick. If the oil is low, add oil of the proper

type up to the “F” mark. Always ch ec k the oil l ev el

with the dipstick before adding more oil.

OIL FILLER

CAP

Figure 18

23

Page 24

ADDING OIL

CAUTION

Never overfill the engine crankcase. The engine

may overheat and/or damag e may result if the

crankcase is below the “LOW” mark or over the

“FULL” mark on the dipstick.

WARNING

If the tractor has recently been operated, the

engine and surrounding areas may be hot. Use

caution not to burn yourself when removing the

side panels, draining the oil from the crankcase,

and changing the oil filter.

NOTE

For best results, fill to the “FULL” mark on the

dipstick as opposed to adding a given quanti ty

of oil. Always check the level on the dipstick

before adding more oil.

Refer to the LUBRICATION TABLE for information

regarding the proper type of oil to add to the

crankcase.

1. Place the tractor on a level surface and engage the

brake pedal lock. Stop the tractor engine and

remove the ignition key.

2. Clean the area around the oil level dipstick,

dipstick tube, and the oil filler cap to prevent debris

from entering the crankcase.

3. Remove the oil fill er cap from the left val ve cover

and SLOWLY pour in oil. Fill the cran kcase until

the oil level reaches the “FULL” mark on the

dipstick (Refer to Figure 18).

4. Reinstall the oil fi ller cap by screwing it securel y

into the valve cover.

NOTE

The oil filter should be changed at every oil

change interval. The filters can be obtained

through your Cub Cadet dealer under part

number KH-12-050-08.

Refer to the MAINTENANCE CHART and the

LUBRICATION TABLE for information regarding the

frequency of required oil changes and the quantity and

type of oil needed.

The oil filter is located behind the left side panel and is

mounted on the engine (See Figure 19).

OIL

FILTER

CAUTION

The oil filler cap MUST BE TIGHTENED

SECURELY INTO THE VALVE COVER AT

ALL TIMES WHEN THE ENGINE IS

OPERATING. Severe engine damage could

result from failure to do so.

DRAINING OIL AND REPLACING OIL FILTER

NOTE

The engine oil should be changed after the first

5 hours of operation. Then oil should be

changed after every 100 hours of operation.

PLASTIC

CAP

FLEXIBLE

TUBING

OIL DRAIN

VALVE

Figure 19

Run the engine for a few minutes to allow the oil in the

crankcase to w arm up. Warm o il will flow mo re freely

and carry away more of the engine sediment which

may have settled at the bottom of the cran kcase. Use

care to avoid burns from hot oil.

24

Page 25

While the engine oil is warm, proceed as follows:

NOTE

A 12 inch length of flexibl e tub in g is su ppl ied in

the owner’s manual package and should be

used to drain the engine oil.

1. Place the tractor on a level surface and engage the

brake pedal lock. Stop the tractor engine and

remove the ignition key.

FILLING THE CRANKCASE

CAUTION

Never overfill the engine crankcase. The engine

may overheat and/or dam age may result if th e

crankcase is below the “LOW” mark or over the

“FULL” mark on the dipstick.

2. Clean around the base of the oil filter, oil level

dipstick, dipstick tube, and the oil filler cap to

prevent debris from entering the crankcase.

3. Unseat the plastic dust cap from the engine oil

drain valve. To prevent loss of the cap, do not

remove the cap’s retaining ring from the drain

valve (Refer to Figure 19). Remove the dipstick

and oil fill cap.

4. Attach the flexible tubing (supplied in owner’s

manual package) to the drain valve. Place an

appropriate container below the open end of the

tubing to collect the old oil.

5. To open the drain valve, push it slightly inward and

turn it counterclockwis e until it stops, then pull it

outward.

6. Remove the filter by turning it counterclockwise

using an automotive type filter wrench to loosen.

7. Allow the old oil to completely drain from the

engine crankcase into the container below. To

close the drain valve, push it inward, turn

clockwise until it stops and then release it.

8. Remove the flex ible tubing from the drain valv e.

Clean the tubing and store in a safe place for future

use.

NOTE

For best results, fill to the “FULL” mark on the

dipstick as oppo sed to addin g a given q uantity

of oil. Always check the level on the dipstick

before adding more oil.

Refer to the LUBRICATION TABLE for information