Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

ATOR S

ANUAL

RZT Series Tractor m Moclel RZT54

CUB CADET LLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019

PrintedIn USA FormNo.769-06543

(October14,2010)

Page 2

ToTheOwner

ThankYou

Thank you for purchasing a Cub Cadet Zero-Turn Tractor. it was

carefully engineered to provide excellent performance when

properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review this

manual frequently to familiarize yourself with the machine, its

features and operation.

Tableof Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 9

Controls & Features ................................................ 12

Operation ................................................................ 15

Maintenance & Adjustment. ................................. 21

1

Please be aware that this Operator's Manual may cover a range

of product specifications for various models. Characteristics and

features discussed and/or illustrated in this manual may not be

applicable to all models. We reserve the right to change product

specifications, designs and equipment without notice and

without incurring obligation.

If you have any problems or questions concerning the machine,

phone your local Cub Cadet dealer or contact us directly. Cub

Cadet's Customer Support telephone numbers, website address

and mailing address can be found on this page. We want to

ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position.

Service .................................................................... 26

Troubleshooting ..................................................... 31

Replacement Parts ............................................... 32

Attachments & Accessories .................................. 34

Warranties ............................................................. 38

RecordProductinformation

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. This information

will be necessary, should you seek technical support via our web

site or with your local Cub Cadet dealer. Pivot the seat assembly

forward to locate the model plate on the underside of the seat

pivot bracket.

MODEL NUMBER

FllqFllqFllqFllqFllqD

SERIAL NUMBER

F1FIF1FIF1FIF1FIF1FID

CustomerSupport

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

0 Visit us on the web at www.cubcadet.com

0 Locate your nearest Cub Cadet Dealer at (877) 282-8684

0 Write us at Cub Cadet LLC • EO. Box 361131 • Cleveland, OH • 44136-0019

Page 3

ImportantSafeOperationPractices

WARNING! This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING! Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

WARNING! Battery posts, terminals, and related accessories contain lead and lead

,A

compounds, chemicals known to the State of California to cause cancer and reproductive

harm. Wash hands after handling

DANGER! This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating hands and feet

and throwing objects. Failure to observe the following safety instructions could result in

serious injury or death.

2

GeneralOperation

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and should be trained and supervised

by an adult.

4. Never allow adults to operate this machine without proper

instruction.

5_

To help avoid blade contact or a thrown object injury,

keep bystanders, helpers, children and pets at least 75 feet

from the machine while it is in operation. Stop machine if

anyone enters the area.

6. Thoroughly inspect the area where the equipment is to be

used. Remove all stones, sticks, wire, bones, toys, and other

foreign objects which could be picked up and thrown by

the blade(s). Thrown objects can cause serious personal

injury.

7. Plan your mowing pattern to avoid discharge of material

toward roads, sidewalks, bystanders and the like. Also,

avoid discharging material against a wall or obstruction

which may cause discharged material to ricochet back

toward the operator.

8. Always wear safety glasses or safety goggles during

operation and while performing an adjustment or repair

to protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

9. Wear sturdy, rough-soled work shoes and close-fitting

slacks and shirts. Loose fitting clothes and jewelry can be

caught in movable parts. Never operate this machine in

bare feet or sandals.

10. Be aware of the mower and attachment discharge direction

and do not point it at anyone. Do not operate the mower

without the discharge cover or entire grass catcher in its

proper place.

11. Do not put hands or feet near rotating parts or under the

cutting deck. Contact with the blade(s) can amputate

hands and feet.

Page 4

12. Amissingordamageddischargecovercancauseblade

contactorthrownobjectinjuries.

13. Stoptheblade(s)whencrossinggraveldrives,walks,or

roadsandwhilenotcuttinggrass.

14. Watchfortrafficwhenoperatingnearorcrossing

roadways.Thismachineisnotintendedforuseonany

publicroadway.

15. Donotoperatethemachinewhileundertheinfluenceof

alcoholordrugs.

16. Mowonlyindaylightorgoodartificiallight.

17. Nevercarrypassengers.

18. Backupslowly.Alwayslookdownandbehindbeforeand

whilebackingtoavoidaback-overaccident.Beaware

andpayattentiontothesafetysystemfunctionthat

stopspowertothebladeswhendrivinginreverse.Ifnot

fuctioningproperly,contactanauthorizeddealerforsafety

systeminspectionandrepair.

19. Slowdownbeforeturning.Operatethemachinesmoothly.

Avoiderraticoperationandexcessivespeed.

20. Disengageblade(s),setparkingbrake,stopengineandwait

untiltheblade(s)cometoacompletestopbeforeremoving

grasscatcher,emptyinggrass,uncloggingchute,removing

anygrassordebris,ormakinganyadjustments.

21. Neverleavearunningmachineunattended.Alwaysturnoff

blade(s),placedrivecontrolleversinneutral,setparking

brake,stopengineandremovekeybeforedismounting.

22. Useextracarewhenloadingorunloadingthemachineinto

atrailerortruck.Thismachineshouldnotbedrivenupor

downramp(s),becausethemachinecouldtipover,causing

seriouspersonalinjury.Themachinemustbepushed

manuallyonramp(s)toloadorunloadproperly.

23.

Mufflerandenginebecomehotandcancauseaburn.Do

nottouch.

24.

Checkoverheadclearancescarefullybeforedrivingunder

lowhangingtreebranches,wires,dooropeningsetc.,

wheretheoperatormaybestruckorpulledfromthe

machine,whichcouldresultinseriousinjury.

25.

Disengageallattachmentclutches,settheparkingbrake

tothe'ON'positionandmovetheRHandLHdrivecontrol

leverstotheneutralpositionbeforeattemptingtostartthe

engine.

26.

Yourmachineisdesignedtocutnormalresidentialgrassof

aheightnomorethan10".Donotattempttomowthrough

unusuallytall,drygrass(e.g.,pasture)orpilesofdryleaves.

Drygrassorleavesmaycontacttheengineexhaustand/

orbuilduponthemowerdeckpresentingapotentialfire

hazard.

27. Useonlyaccessoriesandattachmentsapprovedforthis

machinebythemachinemanufacturer.Read,understand

andfollowallinstructionsprovidedwiththeapproved

accessoryorattachment.

28. Dataindicatesthatoperators,age60yearsandabove,are

involvedinalargepercentageofridingmower-related

injuries.Theseoperatorsshouldevaluatetheirability

tooperatetheridingmowersafelyenoughtoprotect

themselvesandothersfromseriousinjury.

29. Ifsituationsoccurwhicharenotcoveredinthismanual,use

careandgoodjudgment.Contactyourcustomerservice

representativeforassistance.

SlopeOperation

Slopes are a major factor related to loss of control and tip-over

accidents which can result in severe injury or death. All slopes

require extra caution. If you cannot back up the slope or if you

feel uneasy on it, do not mow it.

For your safety, use the slope gauge included as part of this

manual to measure slopes before operating this machine on

a sloped or hilly area. If the slope is greater than 15 degrees as

shown on the slope gauge, do not operate this machine on that

area or serious injury could result.

Do:

I.

Mow across slopes, not up and down. Exercise extreme

caution when changing direction on slopes.

2. Watch for holes, ruts, bumps, rocks, or other hidden

objects. Uneven terrain could overturn the machine. Tall

grass can hide obstacles.

3. Use slow speed. Choose a low enough speed so that you

will not have to stop while on the slope. Avoid starting

or stopping on a slope. If the tires are unable to maintain

traction, disengage the blades and proceed slowly and

carefully straight down the slope.

4. Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

5. Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

6. Keep all movement on the slopes slow and gradual. Do

not make sudden changes in speed or direction. Rapid

acceleration or deceleration could cause the front of the

machine to lift and rapidly roll over backwards, which

could cause serious injury.

DoNot:

I. Do not turn on slopes unless necessary; then turn slowly

uphill and use extra care while turning.

2. Do not mow near drop-offs, ditches or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff, ditch, or if an edge caves in.

3. Do not try to stabilize the machine by putting your foot on

the ground.

4. Do not use a grass catcher on steep slopes.

5. Do not mow on wet grass. Reduced traction could cause

sliding.

6. Do not tow heavy pull behind attachments (e.g. loaded

dump cart, lawn roller, etc.) on slopes greater than 5

degrees. When going down hill, the extra weight tends

to push the tractor and may cause you to loose control

(e.g. tractor may speed up, braking and steering ability are

reduced, attachment may jack-knife and cause tractor to

overturn).

4 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

Page 5

Children

1. Tragic accidents ca n occur if the operator is not alert to the

presence of children. Children are often attracted to the

machine and the mowing activity. They do not understand

the dangers. Never assume that children will remain where

you last saw them.

a. Keep children out of the mowing area and in

watchful care of a responsible adult other than the

operator.

b. Be alert and turn machine off if a child enters the

area.

c. To avoid back-over accidents, always look behind

and down for small children.

d. Never carry children, even with the blade(s) shut off.

They may fall offand be seriously injured or interfere

with safe machine operation.

e. Use extreme care when approaching blind corners,

doorways, shrubs, trees or other objects that may

blockyour vision of a child who may run into the

path of the machine.

f. Keep children away from hot or running engines.

They can suffer burns from a hot muffler.

g. Remove key when machine is unattended to

prevent unauthorized operation.

2. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and should be trained and supervised

by an adult.

Towing

1. Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

2. Follow the manufacturers recommendation for weight

limits for towed equipment and towing on slopes.

3. Never allow children or others in or on towed equipment.

4. On slopes, the weight of the towed equipment may cause

loss of traction and loss of control.

5.

Travel slowly and allow extra distance to stop.

6.

Do not shift to neutral and coast downhill.

7.

Do not tow heavy pull behind attachments (e.g. loaded

dump cart, lawn roller, etc.) on slopes greater than 5

degrees. When going down hill, the extra weight tends

to push the tractor and may cause you to loose control

(e.g. tractor may speed up, braking and steering ability are

reduced, attachment may jack-knife and cause tractor to

overturn).

Service

SafeHandling of 6as01ine:

1. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

c. When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment on

a trailer with a portable container, rather than from a

gasoline dispenser nozzle.

d. Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

e. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel while the engine

is hot or running. Allow engine to cool at least two

minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more than 1/2"

below bottom of filler neck to allow space for fuel

expansion.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

k. To reduce fire hazards, keep machine free of grass,

leaves, or other debris build-up. Clean up oil or fuel

spillage and remove any fuel soaked debris.

I. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

m. Allow a machine to cool at least five minutes before

storing.

6eneral Service

1. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless,

and deadly gas.

2. Before cleaning, repairing, or inspecting, make certain the

blade(s) and all moving parts have stopped. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3. Periodically check to make sure the blades come to

complete stop within approximately (5) five seconds after

operating the blade disengagement control. If the blades

do not stop within the this time frame, your machine

should be serviced professionally by an authorized dealer.

4. Regularly check the safety interlock system for proper

function, as described later in this manual. If the safety

interlock system does not function properly, have your

machine serviced professionally by an authorized dealer.

SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES S

Page 6

5. Check the blade(s) and engine mounting bolts at frequent

intervals for proper tightness. Also, visually inspect blade(s)

for damage (e.g., excessivewear, bent, cracked). Replace

the blade(s) with the original equipment manufacturer's

(O.E.M.)blade(s) only, listed in this manual. "Use of parts

which do not meet the original equipment specifications

may lead to improper performance and compromise

safety!"

6. Mower blades are sharp. Wrap the blade or wear gloves,

and useextra caution when servicing them.

7. Keep all nuts, bolts, and screws tight to be sure the

equipment isin safeworking condition.

8. Never tamper with the safety interlock system or other

safety devices. Check their proper operation regularly.

9. After striking a foreign object, stop the engine, disconnect

the spark plug wire(s) and ground against the engine.

Thoroughly inspect the machine for any damage. Repair

the damage before starting and operating.

10. Never attempt to make adjustments or repairs to the

machine while the engine is running.

11. Grasscatcher components and the discharge cover are

subject to wear and damage which could expose moving

parts or allow objects to be thrown. For safety protection,

frequently check components and replace immediately

with original equipment manufacturer's (O.E.M.)parts only,

listed in this manual. "Useof parts which do not meet the

original equipment specifications may lead to improper

performance and compromise safety!"

12. Do not change the engine governor settings or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

13. Maintain or replace safety and instruction labels, as

necessary.

14. Observe proper disposal laws and regulations for gas,oil,

etc. to protect the environment.

15. According to the Consumer Products Safety Commission

(CPSC)and the U.S.Environmental Protection Agency (EPA),

this product hasan Average Useful Life of seven (7)years,

or 270 hours of operation. At the end of the Average Useful

Life have the machine inspected annually by an authorized

service dealer to ensure that all mechanical and safety

systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

Donot modifyengine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

NoticeRegardingEmissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM) and Three Way Catalyst (TWC) if so equipped.

SparkArrestor

internal combustion engine and should not be used

i_lh WARNING! This machine is equipped with an

effective working order by the operator. In the State of California

the above is required by law (Section 4442 of the California

Public Resources Code). Other states may have similar laws.

Federal laws apply on federal lands.

A spark arrestor for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, RO. Box 361131 Cleveland, Ohio 44136-0019.

on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's

exhaust system is equipped with a spark arrestor

meeting applicable local or state laws (if any).

If a spark arrestor is used, it should be maintained in

6 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

Page 7

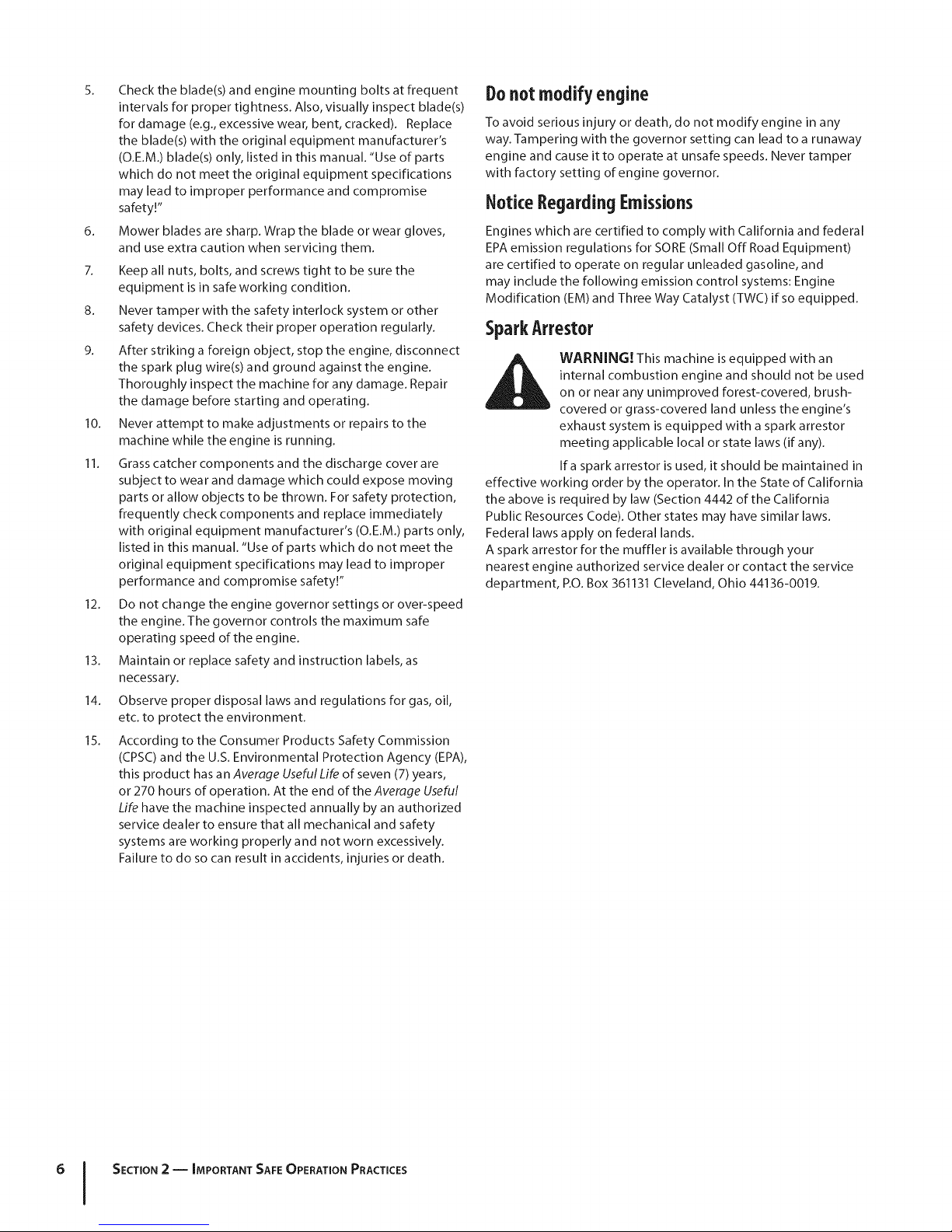

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate

M

®

!!l"

N

WARNING-- ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the

blade(s) can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in

operation.

WARNING-- SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees.

DANGER -- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover

or grass catcher is in its proper place. If damaged, replace immediately.

WARNING! Your Responsibility-- Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVETHESEINSTRUCTIONS!

SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES 7

Page 8

co

R

-4

6

Z

I

o

6

Z

-4

!

|

|

|

or a corner of a building...

|

15°

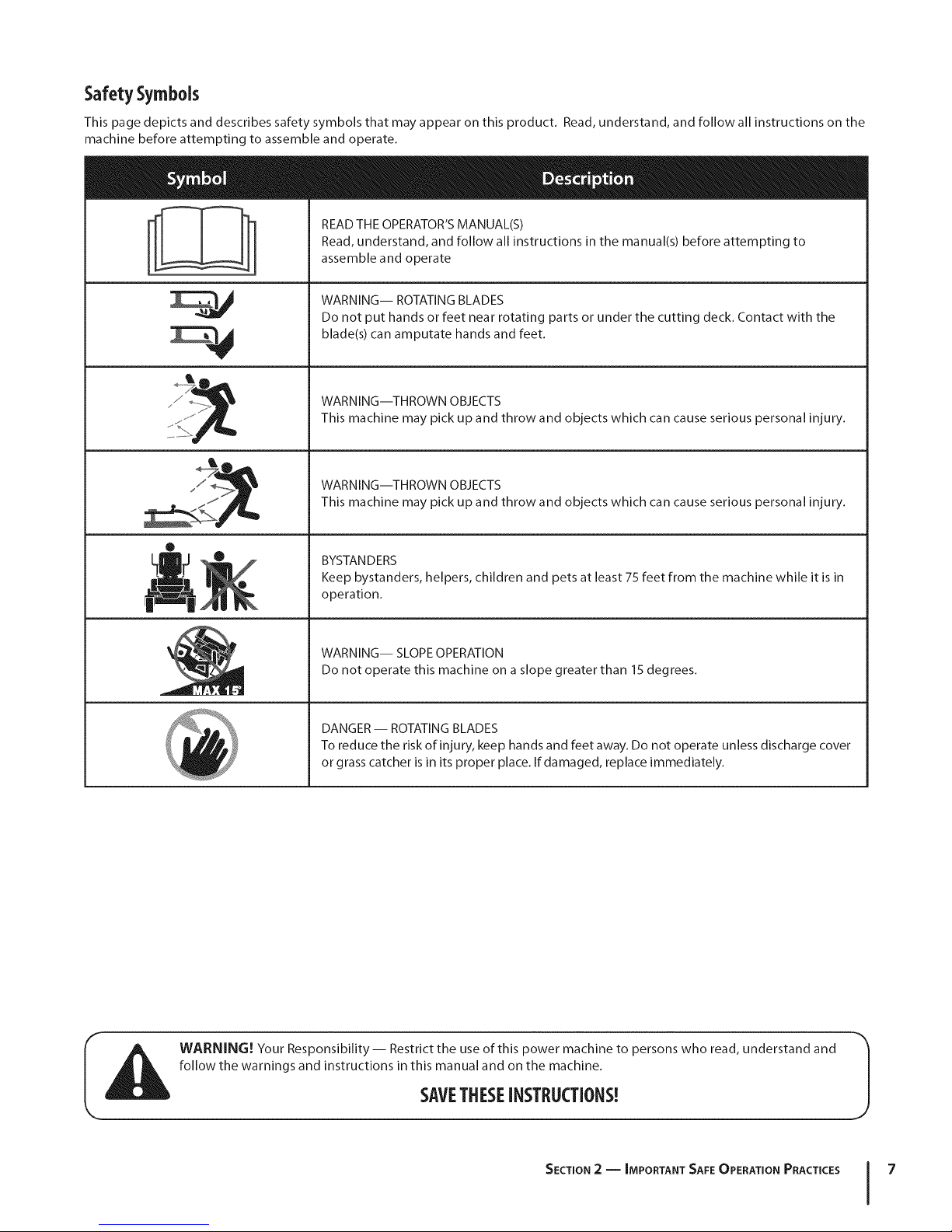

Use this page as a guide to determine slopes where you may not operate safely.

WARNING! Do not operate your lawn mower on such slopes. Do not mow on inclines with a slope in excess of 15 degrees (a

rise of approximately 2-1/2 feet every 10 feet).

OPERATE zero turn tractors across the face of slopes rather than up and down. Begin with the first pass across the bottom of

the slope and turn uphill at the end of each pass whenever possible.

Page 9

Assembly&Set-Up

Contents of Crate

3

One RZT Tractor

One RZT Tractor Operator's

Manual

NOTE:This Operator's Manual covers several models. Tractor

features may vary by model. Not all features in this manual are

applicable to all tractor models and the tractor depicted may

differ from yours.

One Oil Drain Tube

One Engine Operator's Manual

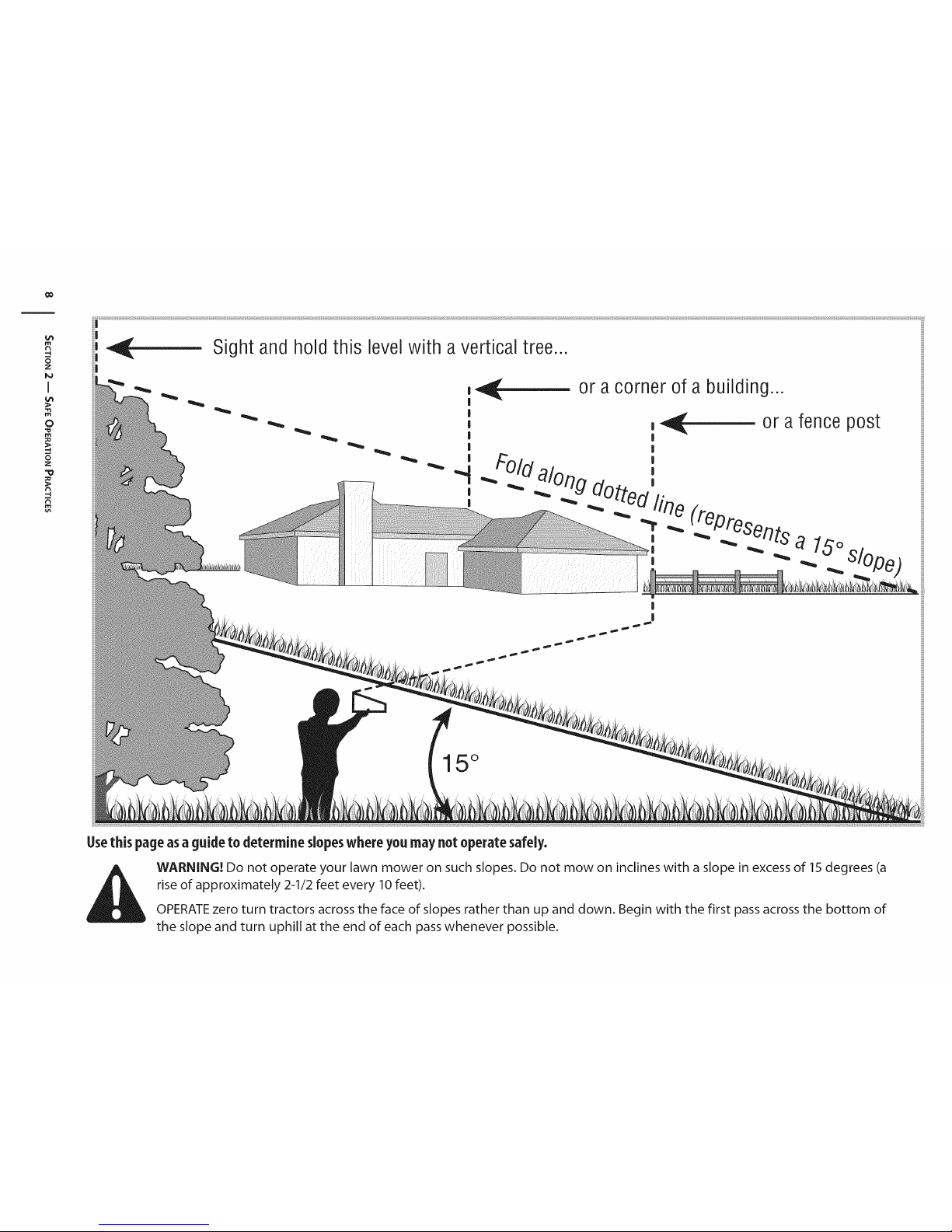

TractorPreparation

Remove the upper crating material from the shipping pallet, and

cut any bands or tie straps securing the tractor to the pallet.

Use the lift handle to raise the deck to its highest position.

Engage the transmission bypass rods on each side of the

tractor; then carefully roll the tractor off the shipping pallet.

The transmission bypass rods (one for each the RH and LH

transmission) are located beneath the frame platform, just inside

each rear wheel. Disengage the bypass rods. See Fig. 3-1.

RH Transmission

Bypass Rod

Pull Out Bypass

Rod Then Lower i

Into Slot

One Deck Wash Hose Coupler

2. Remove the two shoulder bolts and lock nuts in the seat

pan as shown in Fig. 3-2.

Seat Pan

Shoulder

Bolt

Bolt

Figure 3-2

3.

Rotate the seat into position and secure the seat into place

with the previously removed shoulder bolts and lock nuts.

Be careful not to crimp or damage the wire harness while

installing the seat. See Fig. 3-3.

J

Figure 3-1

Remove the deck wash system nozzle adapter and oil drain tube

from the manual bag and store for future use.

Install Operator'sSeat

To install the seat proceed as follows:

NOTE:The seat is shipped with the seat switch and seat pan

attached.

1. Cut any straps securing the seat assembly and the drive

control levers to the tractor. Remove any packing material.

NOTE: Be careful not to cut the wiring harness connecting the

seat and the seat switch.

J

Harness

Seat Bracket _

Shoulder

\

Bolts

J

Figure 3-3

Page 10

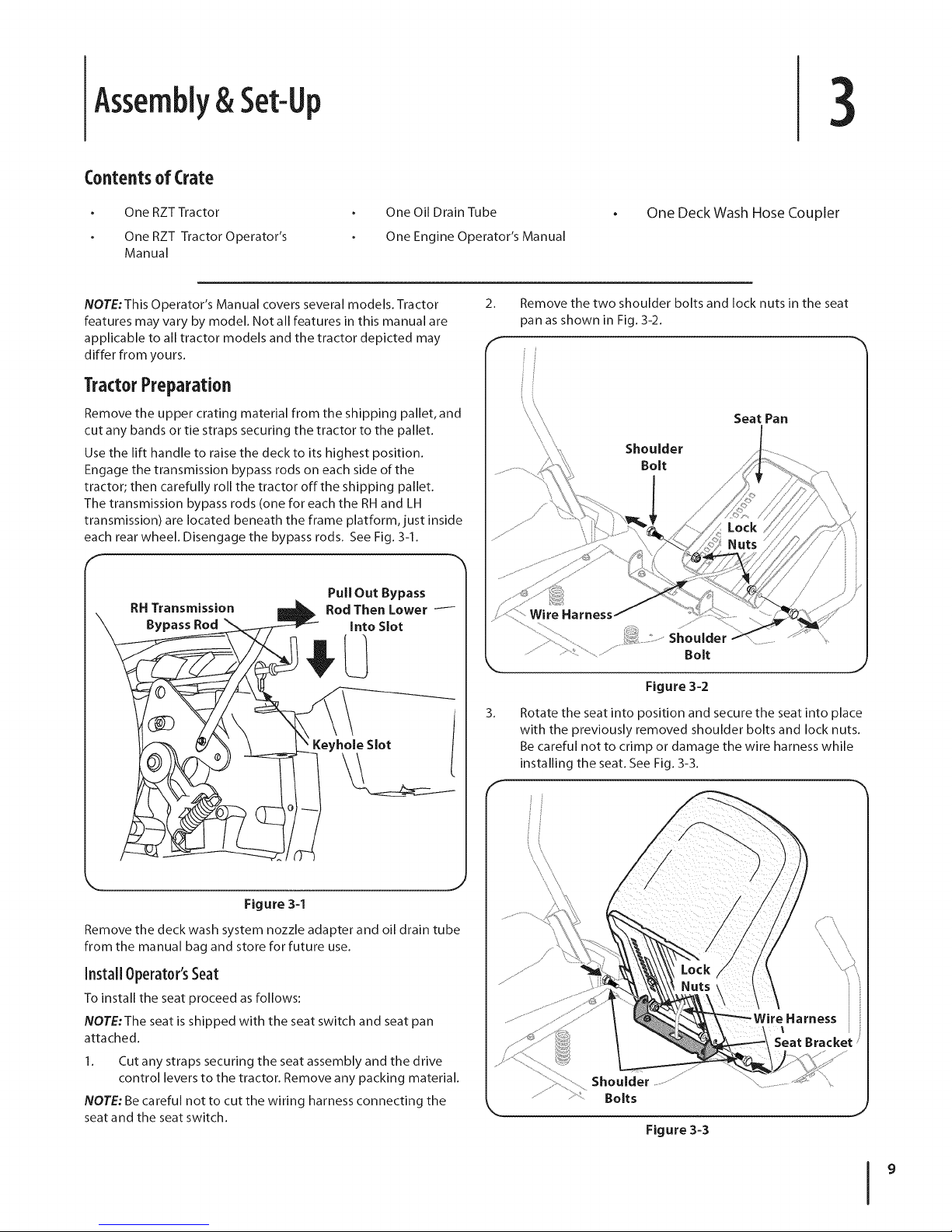

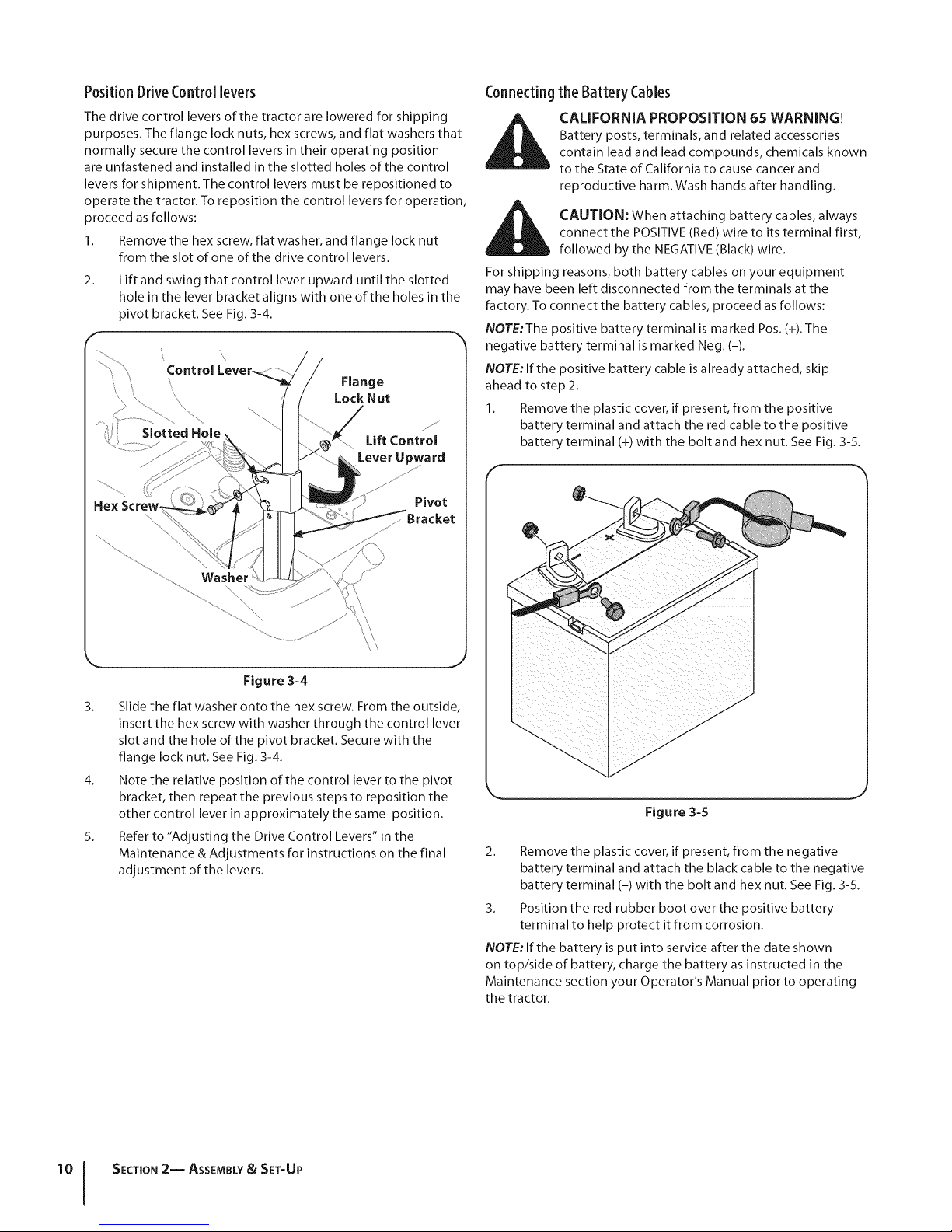

Position DriveControllevers

The drive control levers of the tractor are lowered for shipping

purposes. The flange lock nuts, hex screws, and flat washers that

normally secure the control levers in their operating position

are unfastened and installed in the slotted holes of the control

levers for shipment. The control levers must be repositioned to

operate the tractor. To reposition the control levers for operation,

proceed as follows:

1. Remove the hex screw, flat washer, and flange lock nut

from the slot of one of the drive control levers.

2.

Lift and swing that control lever upward until the slotted

hole in the lever bracket aligns with one of the holes in the

pivot bracket. See Fig. 3-4.

Lift Control

Lever Upwa rd

_s f_

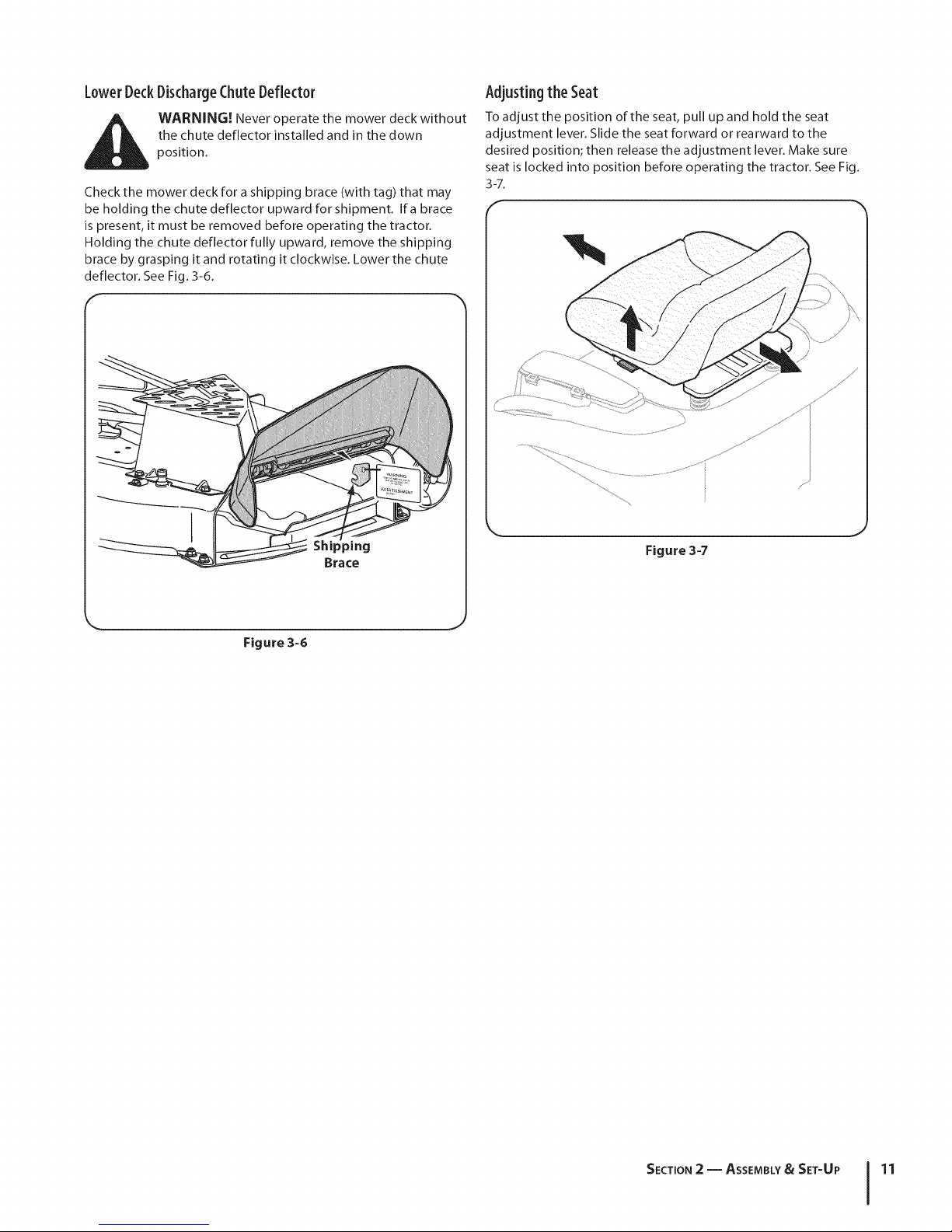

Connectingthe Battery Cables

Battery posts, terminals, and related accessories

CALIFORNIA PROPOSITION 65 WARNING!

contain lead and lead compounds, chemicals known

to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

connect the POSITIVE (Red) wire to its terminal first,

CAUTION: When attaching battery cables, always

followed by the NEGATIVE (Black) wire.

For shipping reasons, both battery cables on your equipment

may have been left disconnected from the terminals at the

factory. To connect the battery cables, proceed as follows:

NOTE:The positive battery terminal is marked Pos. (+). The

negative battery terminal is marked Neg. (-).

NOTE: If the positive battery cable is already attached, skip

ahead to step 2.

1. Remove the plastic cover, if present, from the positive

battery terminal and attach the red cable to the positive

battery terminal (+) with the bolt and hex nut. See Fig. 3-5.

F

Hex Screw.

Figure 3-4

3.

Slide the flat washer onto the hex screw. From the outside,

insert the hex screw with washer through the control lever

slot and the hole of the pivot bracket. Secure with the

flange lock nut. See Fig. 3-4.

4.

Note the relative position of the control lever to the pivot

bracket, then repeat the previous steps to reposition the

other control lever in approximately the same position.

5.

Refer to "Adjusting the Drive Control Levers" in the

Maintenance & Adjustments for instructions on the final

adjustment of the levers.

Pivot

Figure 3-5

2. Remove the plastic cover, if present, from the negative

battery terminal and attach the black cable to the negative

battery terminal (-) with the bolt and hex nut. See Fig. 3-5.

3. Position the red rubber boot over the positive battery

terminal to help protect it from corrosion.

NOTE: If the battery is put into service after the date shown

on top/side of battery, charge the battery as instructed in the

Maintenance section your Operator's Manual prior to operating

the tractor.

SECTION 2-- ASSEMBLY& SET-UP

Page 11

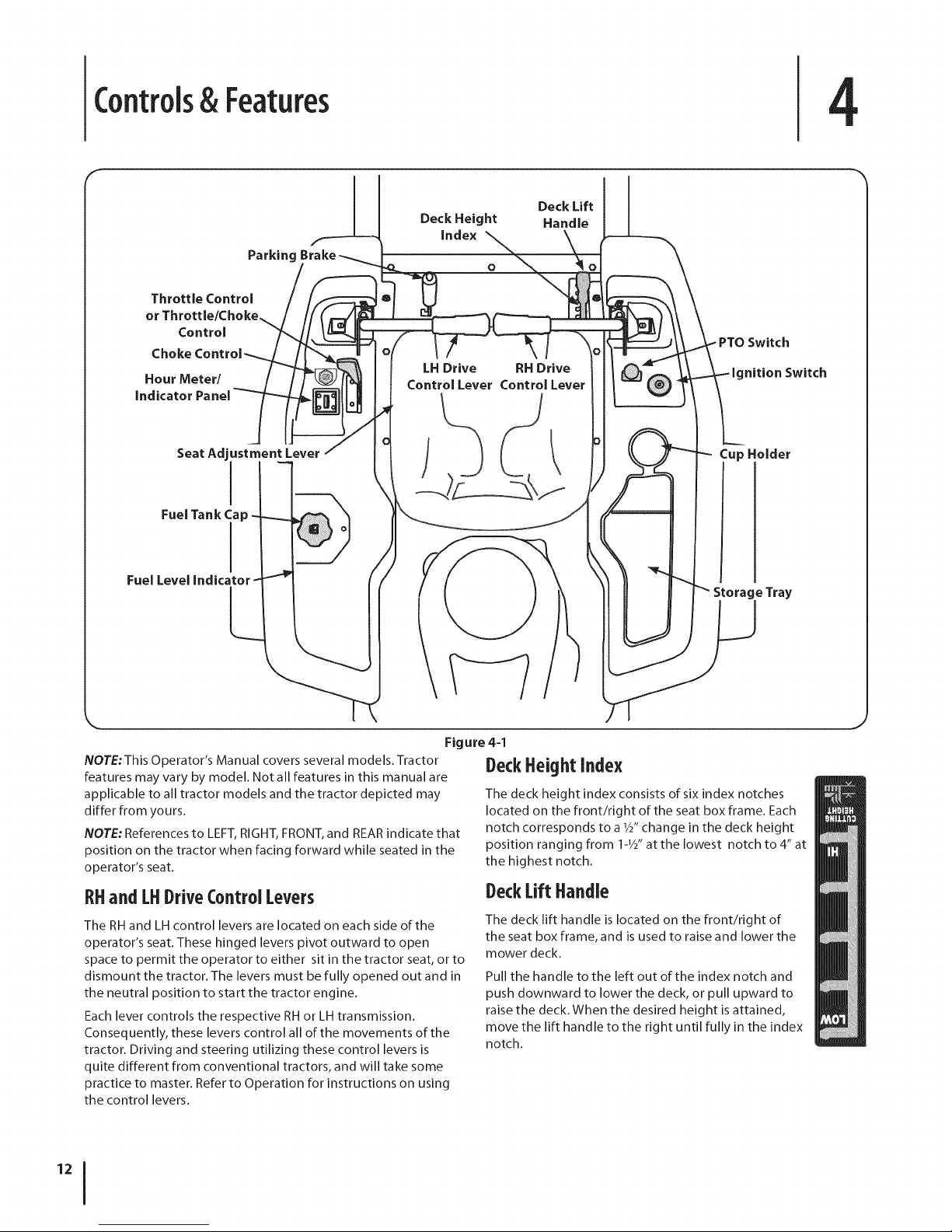

LowerDeckDischargeChuteDeflector

the chute deflector installed and in the down

_[_ ARNING! Never operate the mower deck without

Check the mower deck for a shipping brace (with tag) that may

be holding the chute deflector upward for shipment. Ifa brace

is present, it must be removed before operating the tractor.

Holding the chute deflector fully upward, remove the shipping

brace by grasping it and rotating it clockwise. Lower the chute

deflector. See Fig.3-6.

position.

Adjusting the Seat

Toadjust the position of the seat, pull up and hold the seat

adjustment lever.Slide the seatforward or rearward to the

desired position; then release the adjustment lever. Make sure

seat is locked into position before operating the tractor. SeeFig.

3-7.

f

Figure 3-6

Figure 3-7

SECTION 2 -- ASSEMBLY& SET-UP 11

Page 12

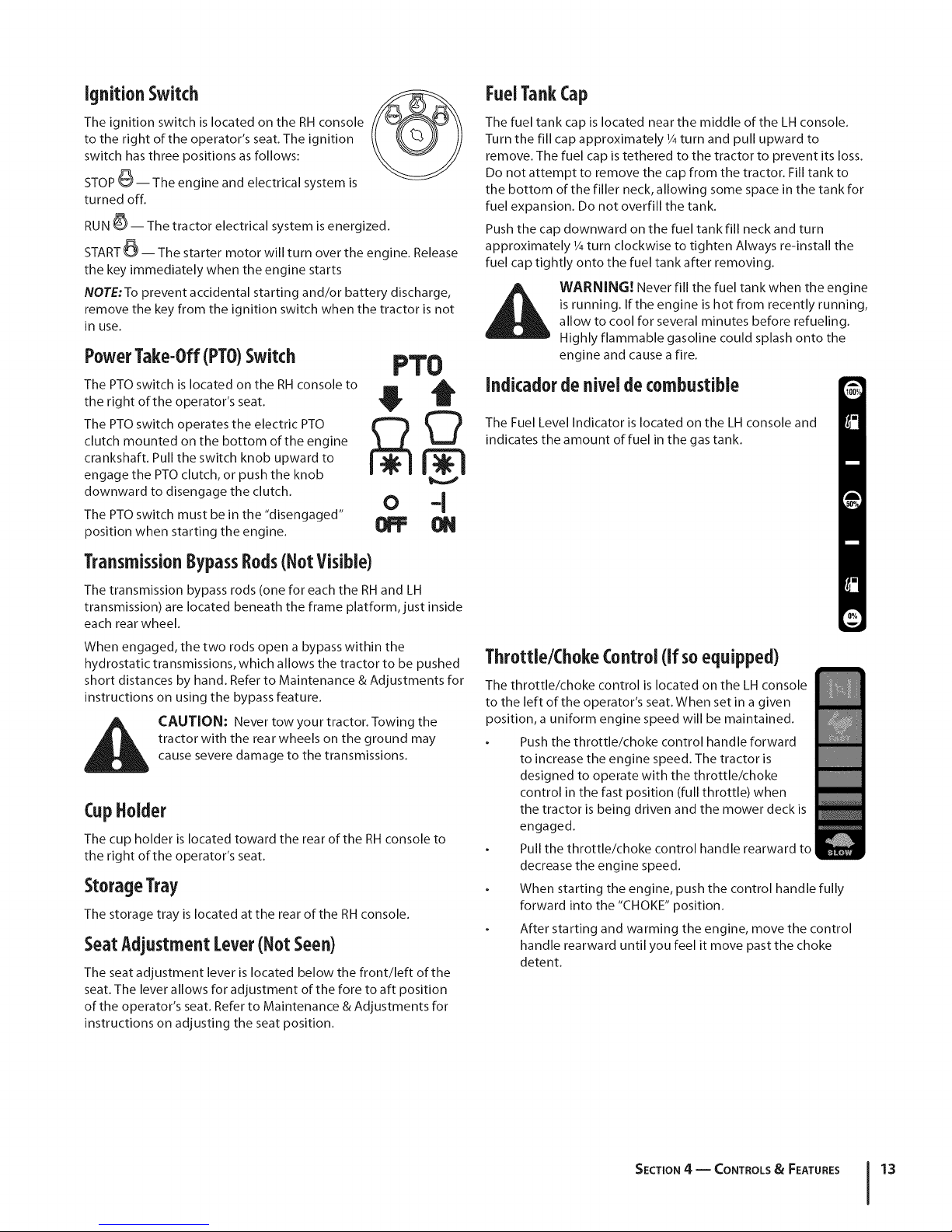

Controls& Features

F

4

Throttle Control

or Throttle/Choke

Control

Choke

Hour Meter/

indicator Panel

Seat Adjustment Lever

Fuel Tank Cap

I

I

Parking

Deck Height

index

LHDrive RH Drive

Control Lever Control Lever

Deck Lift

Handle

nition Switch

Cup Holder

Storage Tray

Figure 4=1

NOTE:This Operator's Manual covers several models. Tractor

features may vary by model. Not all features in this manual are

applicable to all tractor models and the tractor depicted may

differ from yours.

NOTE: References to LEFT, RIGHT, FRONT, and REAR indicate that

position on the tractor when facing forward while seated in the

operator's seat.

RHand[HDriveControl Levers

The RH and LH control levers are located on each side of the

operator's seat. These hinged levers pivot outward to open

space to permit the operator to either sit in the tractor seat, or to

dismount the tractor. The levers must be fully opened out and in

the neutral position to start the tractor engine.

Each lever controls the respective RH or LH transmission.

Consequently, these levers control all of the movements of the

tractor. Driving and steering utilizing these control levers is

quite different from conventional tractors, and will take some

practice to master. Refer to Operation for instructions on using

the control levers.

DeckHeightIndex

The deck height index consists of six index notches

located on the front/right of the seat box frame. Each

notch corresponds to a 1/S'change in the deck height

position ranging from 1-1/2"at the lowest notch to 4" at

the highest notch.

DeckLift Handle

The deck lift handle is located on the front/right of

the seat box frame, and is used to raise and lower the

mower deck.

Pull the handle to the left out of the index notch and

push downward to lower the deck, or pull upward to

raise the deck. When the desired height is attained,

move the lift handle to the right until fully in the index

notch.

Page 13

ignition Switch

The ignition switch is located on the RH console

to the right of the operator's seat. The ignition

switch has three positions as follows:

STOP _-- The engine and electrical system is

turned off.

RUN _-- The tractor electrical system is energized.

START _-- The starter motor will turn over the engine. Release

the key immediately when the engine starts

NOTE:To prevent accidental starting and/or battery discharge,

remove the key from the ignition switch when the tractor is not

in use.

PowerTake-Off(PTO)Switch

The PTO switch is located on the RH console to

the right of the operator's seat.

The PTO switch operates the electric PTO

clutch mounted on the bottom of the engine

crankshaft. Pull the switch knob upward to

engage the PTO clutch, or push the knob

downward to disengage the clutch.

The PTO switch must be in the "disengaged"

position when starting the engine.

PTO

• Q

NI

0 -I

FuelTankCap

The fuel tank cap is located near the middle of the LH console.

Turn the fill cap approximately 1/4turn and pull upward to

remove. The fuel cap is tethered to the tractor to prevent its loss.

Do not attempt to remove the cap from the tractor. Fill tank to

the bottom of the filler neck, allowing some space in the tank for

fuel expansion. Do not overfill the tank.

Push the cap downward on the fuel tank fill neck and turn

approximately 1/4turn clockwise to tighten Always re-install the

fuel cap tightly onto the fuel tank after removing.

is running. If the engine is hot from recently running,

i_li WARNING! Never fill the fuel tank when the engine

allow to cool for several minutes before refueling.

Highly flammable gasoline could splash onto the

engine and cause a fire.

Indicador de nivei decombustible

The Fuel Level Indicator is located on the LH console and

indicates the amount of fuel in the gas tank.

Transmission BypassRods(Not Visible)

The transmission bypass rods (one for each the RH and LH

transmission) are located beneath the frame platform, just inside

each rear wheel.

When engaged, the two rods open a bypass within the

hydrostatic transmissions, which allows the tractor to be pushed

short distances by hand. Refer to Maintenance & Adjustments for

instructions on using the bypass feature.

tractor with the rear wheels on the ground may

CAUTION: Never tow your tractor. Towing the

causeseveredamage to the transmissions.

CupHolder

The cup holder is located toward the rear of the RH console to

the right of the operator's seat.

StorageTray

The storage tray is located at the rear of the RH console.

SeatAdjustmentLever(NotSeen)

The seat adjustment lever is located below the front/left of the

seat. The lever aIlows for adjustment of the fore to aft position

of the operator's seat. Refer to Maintenance & Adjustments for

instructions on adjusting the seat position.

Throttle/ChokeControl (if soequipped)

The throttle/choke control is located on the LH console

to the left of the operator's seat. When set in a given

position, a uniform engine speed will be maintained.

Push the throttle/choke control handle forward

to increase the engine speed. The tractor is

designed to operate with the throttle/choke

control in the fast position (full throttle) when

the tractor is being driven and the mower deck is

engaged.

Pull the throttle/choke control handle rearward to

decrease the engine speed.

When starting the engine, push the control handle fully

forward into the "CHOKE" position.

After starting and warming the engine, move the control

handle rearward until you feel it move past the choke

detent.

SECTION 4 -- CONTROLS & FEATURES 13

Page 14

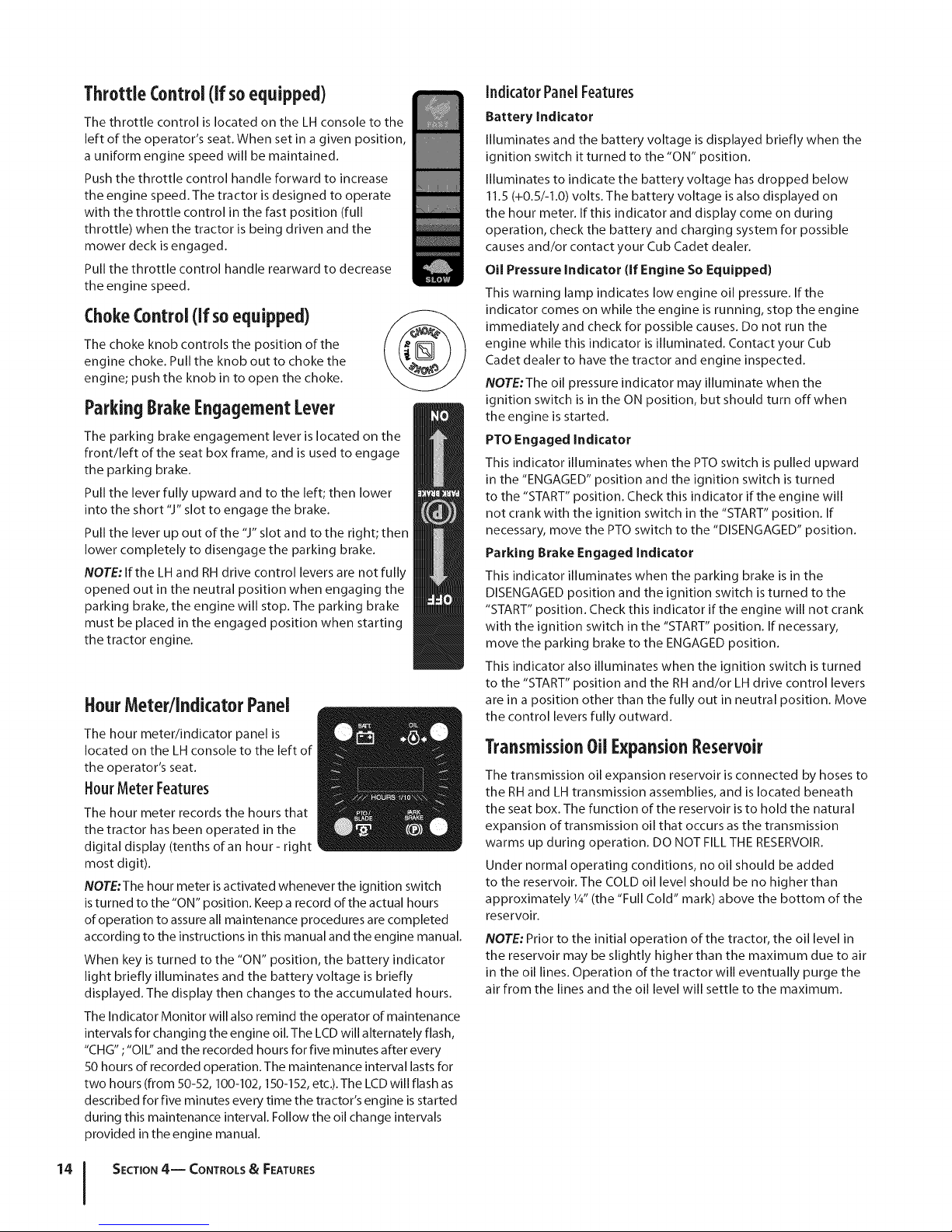

ThrottleControl (if soequipped)

The throttle control is located on the LH console to the

left of the operator's seat. When set in a given position,

a uniform engine speed will be maintained.

Push the throttle control handle forward to increase

the engine speed. The tractor is designed to operate

with the throttle control in the fast position (full

throttle) when the tractor is being driven and the

mower deck is engaged.

Pull the throttle control handle rearward to decrease

the engine speed.

ChokeControl(if soequipped)

The choke knob controls the position of the

engine choke. Pull the knob out to choke the

engine; push the knob in to open the choke.

ParkingBrakeEngagementLever

The parking brake engagement lever is located on the

front/left of the seat box frame, and is used to engage

the parking brake.

Pull the lever fully upward and to the left; then lower

into the short "J" slot to engage the brake.

Pull the lever up out of the "J" slot and to the right; then

lower completely to disengage the parking brake.

NOTE: If the LH and RH drive control levers are not fully

opened out in the neutral position when engaging the

parking brake, the engine will stop. The parking brake

must be placed in the engaged position when starting

the tractor engine.

HourMeter/IndicatorPanel

The hour meter/indicator panel is

located on the LH console to the left of

the operator's seat.

HourMeter Features

The hour meter records the hours that

the tractor has been operated in the

digital display (tenths of an hour- right

most digit).

NOTE:The hour meter is activated whenever the ignition switch

is turned to the "ON" position. Keep a record of the actual hours

of operation to assure all maintenance procedures are completed

according to the instructions in this manual and the engine manual.

When key is turned to the "ON" position, the battery indicator

light briefly illuminates and the battery voltage is briefly

displayed. The display then changes to the accumulated hours.

The Indicator Monitor will also remind the operator of maintenance

intervals for changing the engine oil. The LCD will alternately flash,

"CHG" ;"Oli:' and the recorded hours for five minutes after every

50 hours of recorded operation. The maintenance interval lasts for

two hours (from 50-52, 100-102, 150-152, etc.). The LCD will flash as

described for five minutes every time the tractor's engine is started

during this maintenance interval. Follow the oil change intervals

provided in the engine manual.

Indicator PanelFeatures

Battery Indicator

Illuminates and the battery voltage is displayed briefly when the

ignition switch it turned to the "ON" position.

Illuminates to indicate the battery voltage has dropped below

11.5 (+0.5/-1.0) volts. The battery voltage is a Iso displayed on

the hour meter. If this indicator and display come on during

operation, check the battery and charging system for possible

causes and/or contact your Cub Cadet dealer.

Oil Pressure Indicator (If Engine So Equipped)

This warning lamp indicates low engine oil pressure. If the

indicator comes on while the engine is running, stop the engine

immediately and check for possible causes. Do not run the

engine while this indicator is illuminated. Contact your Cub

Cadet dealer to have the tractor and engine inspected.

NOTE:The oil pressure indicator may illuminate when the

ignition switch is in the ON position, but should turn offwhen

the engine is started.

PTO Engaged Indicator

This indicator illuminates when the PTO switch is pulled upward

in the "ENGAGED" position and the ignition switch is turned

to the "START" position. Check this indicator if the engine will

not crank with the ignition switch in the "START" position. If

necessary, move the PTO switch to the "DISENGAGED" position.

Parking Brake Engaged Indicator

This indicator illuminates when the parking brake is in the

DISENGAGED position and the ignition switch is turned to the

"START" position. Check this indicator if the engine will not crank

with the ignition switch in the "START" position. If necessary,

move the parking brake to the ENGAGED position.

This indicator also illuminates when the ignition switch is turned

to the "START" position and the RH and/or LH drive control levers

are in a position other than the fully out in neutral position. Move

the control levers fully outward.

TransmissionOilExpansionReservoir

The transmission oil expansion reservoir is connected by hoses to

the RH and LH transmission assemblies, and is located beneath

the seat box. The function of the reservoir is to hold the natural

expansion of transmission oil that occurs as the transmission

warms up during operation. DO NOT FILL THE RESERVOIR.

Under normal operating conditions, no oil should be added

to the reservoir. The COLD oil level should be no higher than

approximately 1/4"(the "Full Cold" mark) above the bottom of the

reservoir.

NOTE: Prior to the initial operation of the tractor, the oil level in

the reservoir may be slightly higher than the maximum due to air

in the oil lines. Operation of the tractor will eventually purge the

air from the lines and the oil level will settle to the maximum.

SECTION 4-- CONTROLS & FEATURES

Page 15

Operation

5

GeneralSafety

RECEIVE INSTRUCTION -- Entirely read this operator's

manual. Learn to operate this machine SAFELY.Do not risk

INJURY or DEATH. Allow only those who have become

competent in its usage to operate this tractor.

Before starting the engine or beginning operation, be familiar

with the controls. The operator should be in the operator's

seat. The PTO switch must be in the disengaged position,

the parking brake engaged, and the RH and LH drive control

levers moved fully outward in the neutral position.

Keep all shields in place. Keep away from moving parts.

NO RIDERS! Keep all people and pets a safe distance away.

Look behind and down to both sides of the tractor before

and while backing up.

DO NOT direct the mower discharge at people.

Avoid slopes where possible. Never operate on slopes

greater than 15°. Slopes with a greater incline present

dangerous operating conditions. Tractors can be rolled over.

Before leaving the operator's seat: Shut off the PTO, move

the RH and LH drive control levers fully outward in the

neutral position, engage the parking brake, shut offthe

engine and remove the ignition key. Wait for all movement

to stop before servicing or cleaning.

Operate the drive control levers smoothly and avoid

any sudden movements of the levers when starting and

stopping. Keep a firm grip on the control levers.

Be careful when operating near roadways. Stop the tractor

motion and wait for vehicles to pass before operating

along the road.

Do not operate the tractor with the mower deck removed.

Removal of the deck will change the balance of the tractor,

and could contribute to a tractor rollover.

Avoid operation on traction surfaces that are unstable; use

extreme caution if the surface is slippery.

Slow down before turning and come to a complete stop

before any zero turn maneuver.

Do not stop the tractor or park the tractor over

combustible materials such as dry grass, leaves, debris, etc.

Do not fill the fuel tank when the engine is running or

while the engine is hot. Allow the engine several minutes

to cool before refueling. Tighten the fuel cap securely.

BeforeOperatingYourTractor

Before you operate the tractor, study this manual carefully

to familiarize yourself with the operation of all the

instruments and controls. It has been prepared to help you

operate and maintain your tractor efficiently.

This engine is certified to operate only on clean, fresh,

unleaded regular gasoline. For best results, fill the fuel

tank with only clean, fresh, unleaded gasoline with a pump

sticker octane rating of 87 or higher.

Unleaded gasoline is recommended because it leaves less

combustion chamber deposits and reduces harmful exhaust

emissions. Leaded gasoline is not recommended and must

not be used where exhaust emissions are regulated.

NOTE: Purchase gasoline in small quantities. Do not use

gasoline left over from the previous season, to minimize

gum deposits in the fuel system.

Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline

by volume) isan approved fuel. Other gasoline/alcohol

blends are not approved.

Methyl Tertiary Butyl Ether (MTBE) and unleaded gasoline

blends (up to a maximum of 15% MTBE by volume) are

approved fuels. Other gasoline/ether blends are not approved.

Check the engine oil level.

Clean the air cleaner element if necessary.

Check the tire inflation pressures.

Adjust the seat for operator's maximum comfort, visibility

and for maintaining complete control of the tractor.

SafetyinterlockSystem

This tractor is equipped with a safety interlock system for the

protection of the operator. If the interlock system should ever

malfunction, do not operate the tractor. Contact your authorized

Cub Cadet Dealer.

The safety interlock system prevents the engine from

cranking or starting unless the RHand LH drive control

levers are moved fully outward in the neutral position, the

parking brake is engaged, and the PTO is disengaged.

To avoid sudden movement when disengaging the parking

brake, the safety interlock system will shut offthe engine

if the RH and/or LH drive control levers are moved to a

position other than the fully out in the neutral position

when the parking brake is engaged.

The safety interlock system will shut off the engine if the

operator leaves the seat before engaging the parking brake.

The safety interlock system will shut off the engine if the

operator leaves the seat with the PTO engaged, regardless

of whether the parking brake is engaged.

NOTE:The PTO switch must be moved to the "STOP"

position to restart the engine.

The safety interlock system will shut off the PTO and the

mower blades will stop if both drive control levers are

moved into the reverse position. The PTO will re-engage

when one or both of the levers are moved back to the

neutral or forward position.

15

Page 16

Startingthe Engine

WARNING! This tractor is equipped with a safety

interlock system designed for the protection of the

operator. Do not operate the tractor if any part of

the interlock system is malfunctioning. Periodically

check the functions of the interlock system for

proper operation.

WARNING! For personal safety, the operator must

be sitting in the tractor seat when starting the

engine.

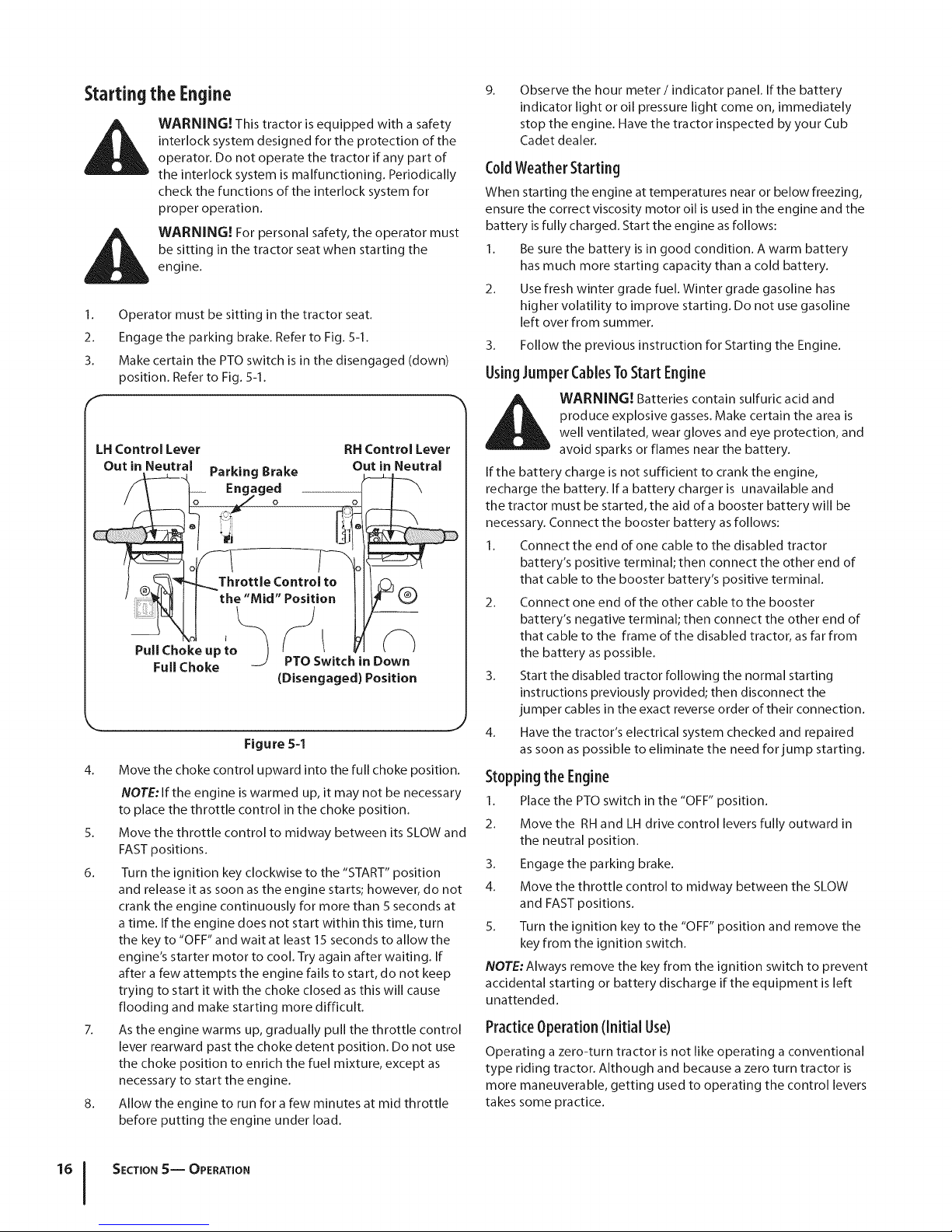

1. Operator must be sitting in the tractor seat.

2. Engage the parking brake. Refer to Fig. 5-1.

3. Make certain the PTO switch is in the disengaged (down)

position. Refer to Fig. 5-1.

LH Control Lever

Out in Neutral .....

j_______ l-arKing BraKe

_\ o_ Engaged

_ _----_L Throttle Control to

(_ . 11

Pull Choke up to 1 _ ,

FulIChoke -J PTO Switch

(Disengagedl Position

k_ j

Figure 5-1

4. Move the choke control upward into the full choke position.

NOTE: If the engine is warmed up, it may not be necessary

to place the throttle control in the choke position.

5. Move the throttle control to midway between its SLOW and

FAST positions.

6. Turn the ignition key clockwise to the "START" position

and release it as soon as the engine starts; however, do not

crank the engine continuously for more than 5 seconds at

a time. If the engine does not start within this time, turn

the key to "OFF" and wait at least 15 seconds to allow the

engine's starter motor to cool. Try again after waiting. If

after a few attempts the engine fails to start, do not keep

trying to start it with the choke closed as this will cause

flooding and make starting more difficult.

7. As the engine warms up, gradually pull the throttle control

lever rearward past the choke detent position. Do not use

the choke position to enrich the fuel mixture, except as

necessary to start the engine.

8. Allow the engine to run for a few minutes at mid throttle

before putting the engine under load.

RH Control Lever

Out in Neutral

in Down

9.

Observe the hour meter/indicator panel. If the battery

indicator light or oil pressure light come on, immediately

stop the engine. Have the tractor inspected by your Cub

Cadet dealer.

C01dWeatherStarting

When starting the engine at temperatures near or below freezing,

ensure the correct viscosity motor oil is used in the engine and the

battery is fully charged. Start the engine as follows:

I. Be sure the battery is in good condition. A warm battery

has much more starting capacity than a cold battery.

2. Use fresh winter grade fuel. Winter grade gasoline has

higher volatility to improve starting. Do not use gasoline

left over from summer.

3. Follow the previous instruction for Starting the Engine.

UsingJumperCablesToStart Engine

produce explosive gasses. Make certain the area is

WARNING! Batteries contain sulfuric acid and

well ventilated, wear gloves and eye protection, and

avoid sparks or flames near the battery.

If the battery charge is not sufficient to crank the engine,

recharge the battery. Ira battery charger is unavailable and

the tractor must be started, the aid of a booster battery will be

necessary. Connect the booster battery as follows:

I. Connect the end of one cable to the disabled tractor

battery's positive terminal; then connect the other end of

that cable to the booster battery's positive terminal.

2. Connect one end of the other cable to the booster

battery's negative terminal; then connect the other end of

that cable to the frame of the disabled tractor, as far from

the battery as possible.

3. Start the disabled tractor following the normal starting

instructions previously provided; then disconnect the

jumper cables in the exact reverse order of their connection.

4. Have the tractor's electrical system checked and repaired

as soon as possible to eliminate the need for jump starting.

Stoppingthe Engine

I. Place the PTO switch in the "OFF" position.

2. Move the RH and LH drive control levers fully outward in

the neutral position.

3. Engage the parking brake.

4. Move the throttle control to midway between the SLOW

and FAST positions.

5. Turn the ignition key to the "OFF" position and remove the

key from the ignition switch.

NOTE; Always remove the key from the ignition switch to prevent

accidental starting or battery discharge if the equipment is left

unattended.

PracticeOperation(Initial Use)

Operating a zero-turn tractor isnot like operating a conventional

type riding tractor. Although and because a zero turn tractor is

more maneuverable, getting used to operating the control levers

takes some practice.

SECTION S-- OPERATION

Page 17

It is strongly recommended that you locate a reasonably large,

level and open "practice area" where there are no obstructions,

pedestrians, or animals. You should practice operating the

tractor for a minimum of 30 minutes.

Carefully move (or have moved) the tractor to the practice area.

When performing the practice session, the PTO should not be

engaged. While practicing, operate the tractor at approximately

1/2-3Athrottle and at less than full speed in both forward and

reverse.

Carefully practice maneuvering the tractor using the instructions

in the following section "Driving the Tractor." Practice until you

are confident that you can safely operate the tractor.

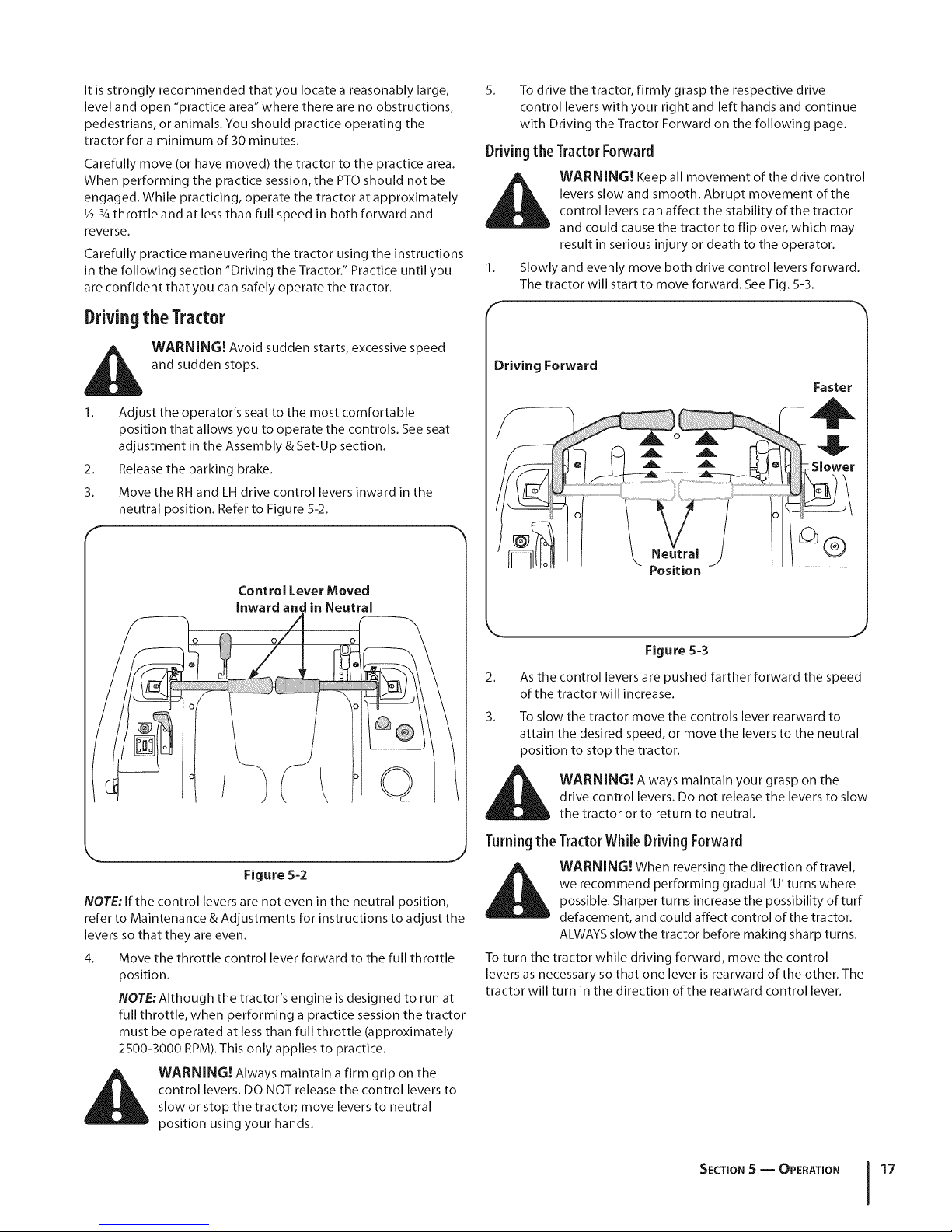

Drivin9 the Tractor

WARNING! Avoid sudden starts, excessive speed

and sudden stops.

1. Adjust the operator's seat to the most comfortable

position that allows you to operate the controls. See seat

adjustment in the Assembly & Set-Up section.

2. Release the parking brake.

3. Move the RH and LH drive control levers inward in the

neutral position. Refer to Figure 5-2.

5.

To drive the tractor, firmly grasp the respective drive

control levers with your right and left hands and continue

with Driving the Tractor Forward on the following page.

Drivingthe TractorForward

levers slow and smooth. Abrupt movement of the

_ ARNING! Keep all movement of the drive control

control levers can affect the stability of the tractor

and could cause the tractor to flip over, which may

result in serious injury or death to the operator.

Slowly and evenly move both drive control levers forward.

The tractor will start to move forward. See Fig. 5-3.

F

Driving Forward

Faster

Control Lever Moved

Inward and in Neutral

/ Q

Figure 5-2

NOTE: If the control levers are not even in the neutral position,

refer to Maintenance & Adjustments for instructions to adjust the

levers so that they are even.

4. Move the throttle control lever forward to the full throttle

position.

NOTE:Although the tractor's engine is designed to run at

full throttle, when performing a practice session the tractor

must be operated at less than full throttle (approximately

2500-3000 RPM). This only applies to practice.

_] o Position

Figure 5-3

2. As the control levers are pushed farther forward the speed

of the tractor will increase.

3. To slow the tractor move the controls lever rearward to

attain the desired speed, or move the levers to the neutral

position to stop the tractor.

WARNING! Always maintain your grasp on the

drive control levers. Do not release the levers to slow

the tractor or to return to neutral.

Turningthe TractorWhile DrivingForward

WARNING! When reversing the direction of travel,

we recommend performing gradual 'U' turns where

possible. Sharper turns increase the possibility of turf

defacement, and could affect control of the tractor.

ALWAYS slow the tractor before making sharp turns.

To turn the tractor while driving forward, move the control

levers as necessary so that one lever is rearward of the other. The

tractor will turn in the direction of the rearward control lever.

control levers. DO NOT release the control levers to

_ WARNING! Always maintain a firm grip on the

slow or stop the tractor; move levers to neutral

position using your hands.

SECTION S -- OPERATION 17

Page 18

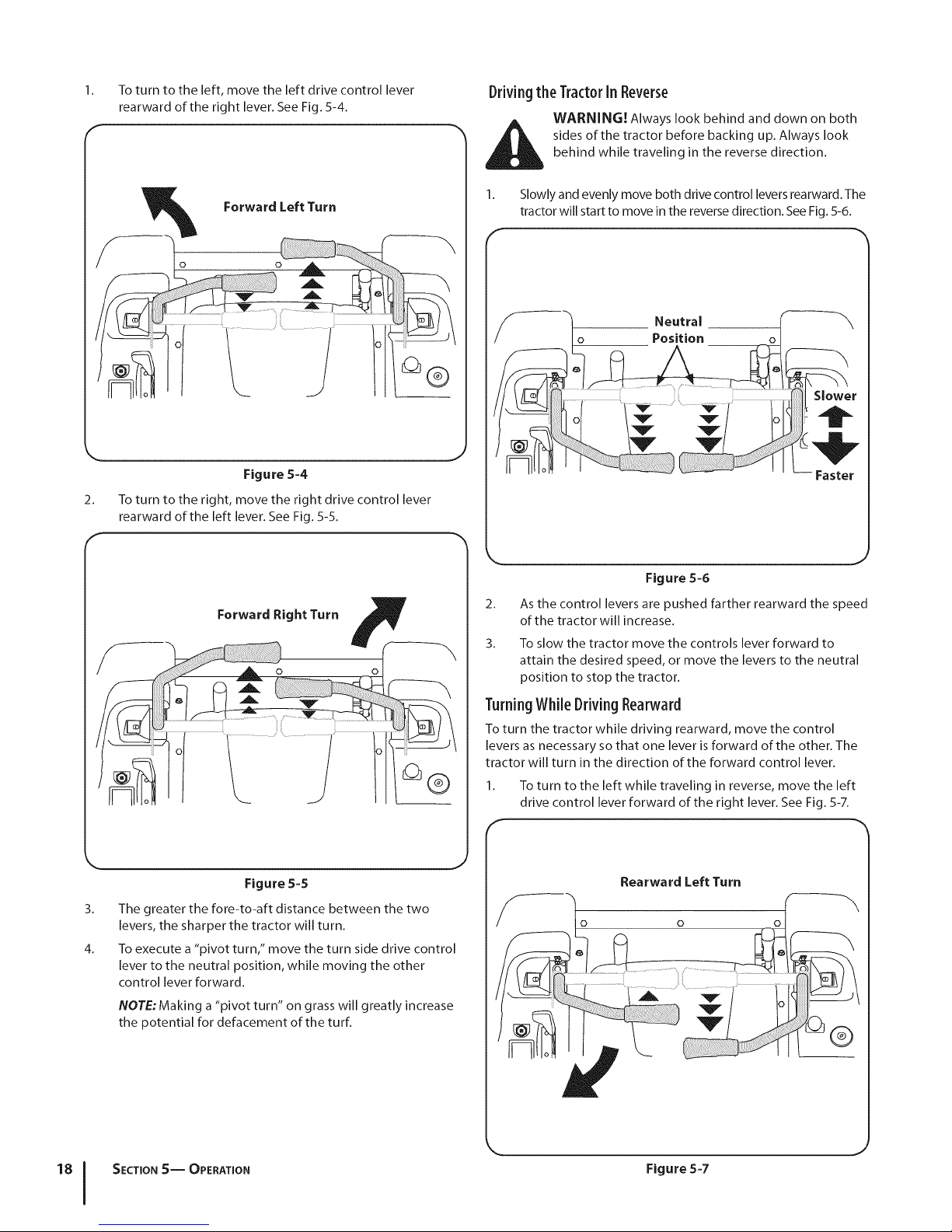

1. To turn to the left, move the left drive control lever

rearward of the right lever. See Fig. 5-4.

Forward Left Turn

Figure 5-4

2. To turn to the right, move the right drive control lever

rearward of the left lever. See Fig. 5-5.

Drivingthe Tract0rIn Reverse

WARNING! Always look behind and down on both

behind while traveling in the reverse direction.

sides of the tractor before backing up. Always look

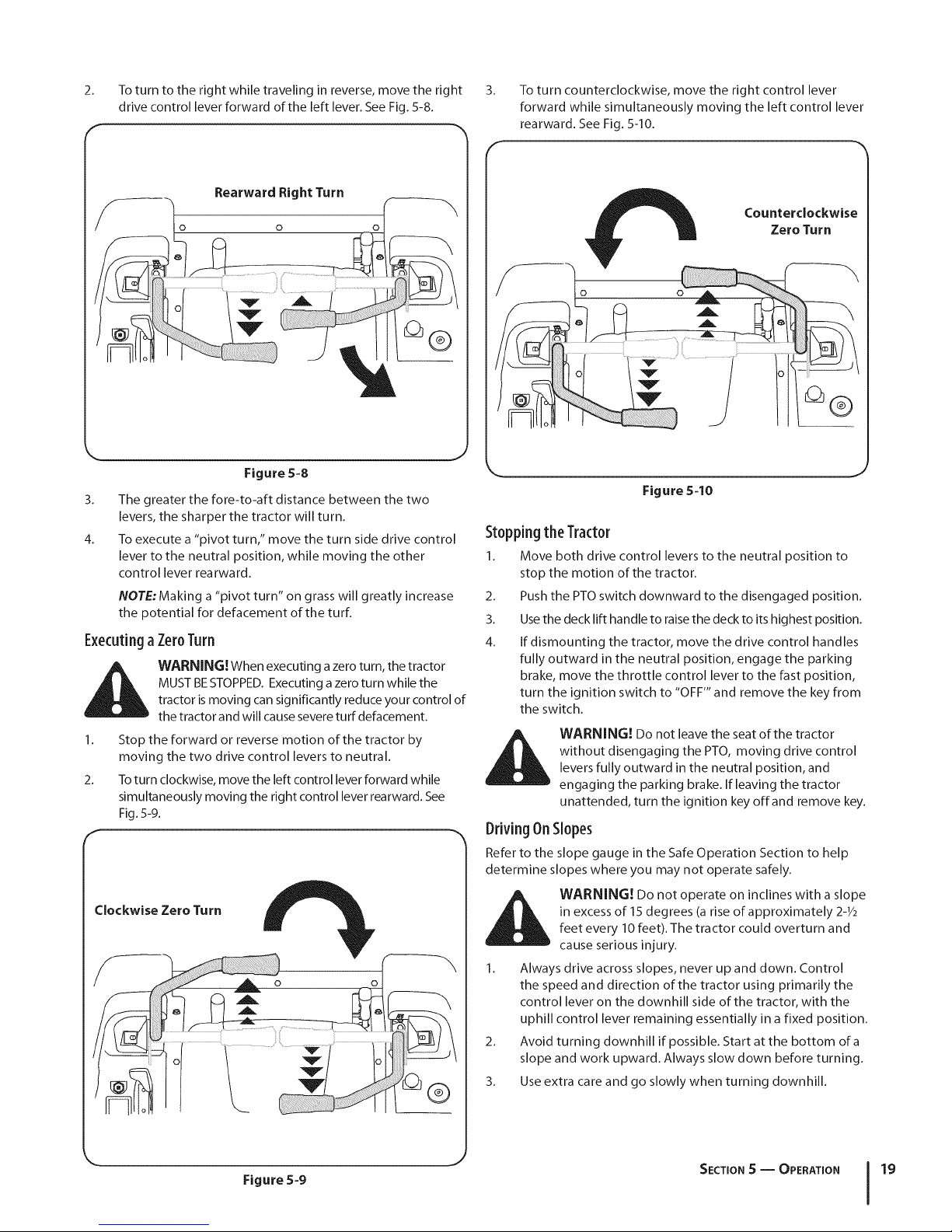

1. Slowly and evenly move both drive control levers rearward. The

tractor will start to move in the reverse direction. See Fig. 5-6.

F

/f--h .eu,ra,

__//----- tlll_ Position o l

t li<_f If k........ ; ..... f 11 Slower

Hot \'_ "_l iol'/ I_-

Forward Right Turn

........] 1°

Figure 5-5

3. The greater the fore-to-aft distance between the two

levers, the sharper the tractor will turn.

4. To execute a "pivot turn," move the turn side drive control

lever to the neutral position, while moving the other

control lever forward.

NOTE: Making a "pivot turn" on grass will greatly increase

the potential for defacement of the turf.

Figure 5-5

2.

As the control levers are pushed farther rearward the speed

of the tractor will increase.

3. To slow the tractor move the controls lever forward to

attain the desired speed, or move the levers to the neutral

position to stop the tractor.

TurningWhile DrivingRearward

To turn the tractor while driving rearward, move the control

levers as necessary so that one lever is forward of the other. The

tractor will turn in the direction of the forward control lever.

1. To turn to the left while traveling in reverse, move the left

drive control lever forward of the right lever. See Fig. 5-7.

F

Rea rwa rd Left Turn

o o

SECTION 5-- OPERATION

\

Figure 5-7

Page 19

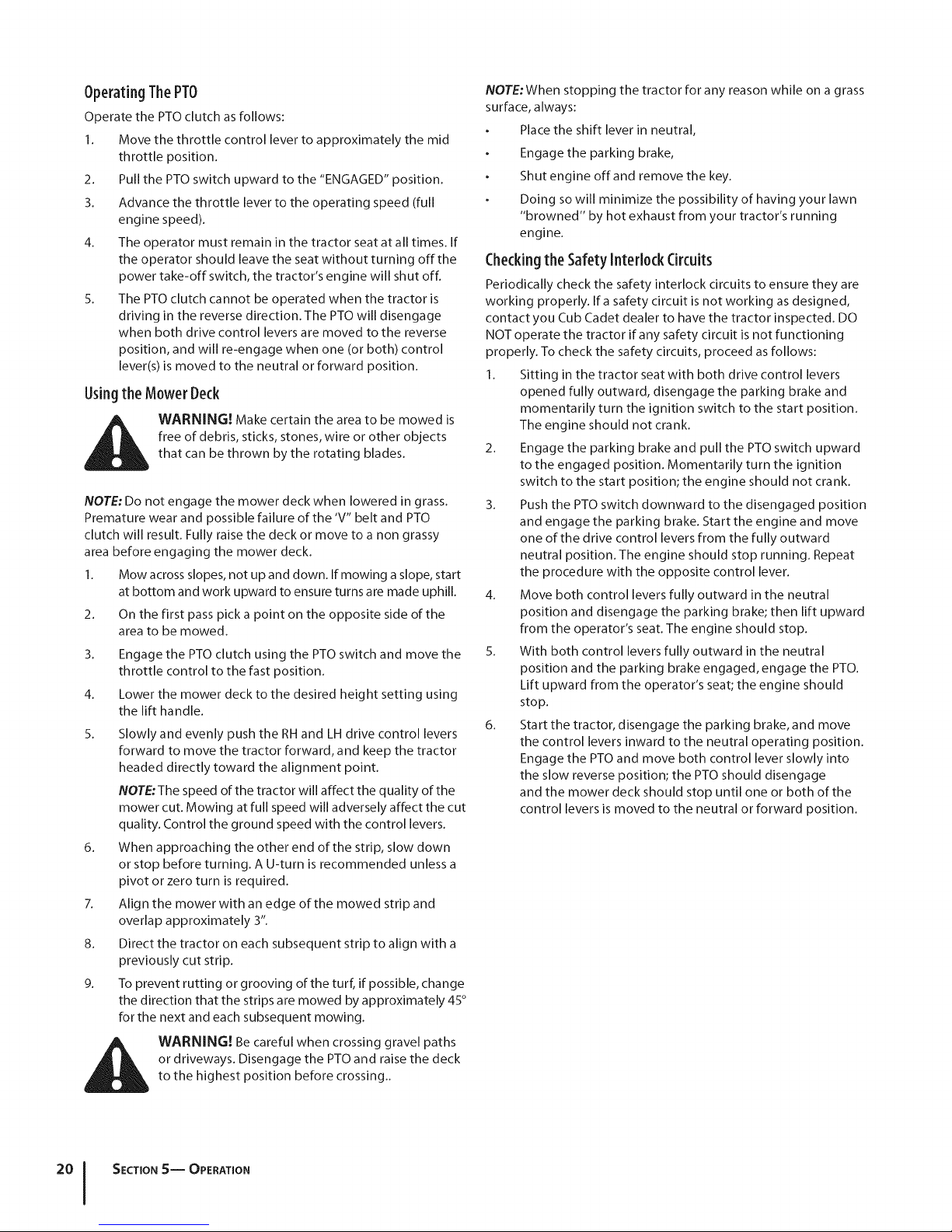

2. To turn to the right while traveling in reverse, move the right

drive control lever forward of the left lever. See Fig. 5-8.

Rearward Right Turn

k. _ j

Figure 5-8

3. The greater the fore-to-aft distance between the two

levers, the sharper the tractor will turn.

4. To execute a "pivot turn," move the turn side drive control

lever to the neutral position, while moving the other

control lever rearward.

NOTE: Making a "pivot turn" on grass will greatly increase

the potential for defacement of the turf.

Executinga Zer0Turn

MUST BESTOPPED. Executing a zero turn while the

_ ARNING! When executing azero turn, the tractor

1. Stop the forward or reverse motion of the tractor by

2. To turn clockwise, move the left control lever forward while

tractor is moving can significantly reduce your control of

the tractor and will cause severe turf defacement.

moving the two drive control levers to neutral.

simultaneously moving the right control lever rearward. See

Fig. 5-9.

3.

To turn counterclockwise, move the right control lever

forward while simultaneously moving the left control lever

rearward. See Fig. 5-10.

f

Counterclockwise

Zero Turn

Figure 5=10

Stoppingthe Tractor

1. Move both drive control levers to the neutral position to

stop the motion of the tractor.

2. Push the PTO switch downward to the disengaged position.

3. Use the deck lift handle to raise the deck to its highest position.

4. If dismounting the tractor, move the drive control handles

fully outward in the neutral position, engage the parking

brake, move the throttle control lever to the fast position,

turn the ignition switch to "OFF'" and remove the key from

the switch.

without disengaging the PTO, moving drive control

WARNING! Do not leave the seat of the tractor

levers fully outward in the neutral position, and

engaging the parking brake. If leaving the tractor

unattended, turn the ignition key offand remove key.

DrivingOnSlopes

Refer to the slope gauge in the Safe Operation Section to help

determine slopes where you may not operate safely.

Clockwise Zero Turn

Figure 5-9

in excess of 15 degrees (a rise of approximately 2-_/2

WARNING! Do not operate on inclines with a slope

feet every 10 feet). The tractor could overturn and

cause serious injury.

1. Always drive across slopes, never up and down. Control

the speed and direction of the tractor using primarily the

control lever on the downhill side of the tractor, with the

uphill control lever remaining essentially in a fixed position.

2. Avoid turning downhill if possible. Start at the bottom of a

slope and work upward. Always slow down before turning.

3. Use extra care and go slowly when turning downhill.

J

SECTION S -- OPERATION 19

Page 20

OperatingThePTO

Operate the PTO clutch as follows:

1. Move the throttle control lever to approximately the mid

throttle position.

2. Pull the PTO switch upward to the "ENGAGED" position.

3. Advance the throttle lever to the operating speed (full

engine speed).

4. The operator must remain in the tractor seat at all times. If

the operator should leave the seat without turning off the

power take-off switch, the tractor's engine will shut off.

5. The PTO clutch cannot be operated when the tractor is

driving in the reverse direction. The PTO will disengage

when both drive control levers are moved to the reverse

position, and will re-engage when one (or both) control

lever(s) is moved to the neutral or forward position.

Usingthe Mower Deck

i_ WARNING! Make certain the area to be mowed is

NOTE: Do not engage the mower deck when lowered in grass.

Premature wear and possible failure of the 'V" belt and PTO

clutch will result. Fully raise the deck or move to a non grassy

area before engaging the mower deck.

1. Mow across slopes, not up and down. If mowing a slope, start

2. On the first pass pick a point on the opposite side of the

3. Engage the PTO clutch using the PTO switch and move the

4. Lower the mower deck to the desired height setting using

5. Slowly and evenly push the RH and LH drive control levers

6. When approaching the other end of the strip, slow down

7. Align the mower with an edge of the mowed strip and

8. Direct the tractor on each subsequent strip to align with a

9. To prevent rutting or grooving of the turf, if possible, change

free of debris, sticks, stones, wire or other objects

that can be thrown by the rotating blades.

at bottom and work upward to ensure turns are made uphill.

area to be mowed.

throttle control to the fast position.

the lift handle.

forward to move the tractor forward, and keep the tractor

headed directly toward the alignment point.

NOTE:The speed of the tractor will affect the quality of the

mower cut. Mowing at full speed will adversely affect the cut

quality. Control the ground speed with the control levers.

or stop before turning. A U-turn is recommended unless a

pivot or zero turn is required.

overlap approximately 3".

previously cut strip.

the direction that the strips are mowed by approximately 45°

for the next and each subsequent mowing.

NOTE: When stopping the tractor for any reason while on a grass

surface, always:

Place the shift lever in neutral,

Engage the parking brake,

Shut engine off and remove the key.

Doing so will minimize the possibility of having your lawn

"browned" by hot exhaust from your tractor's running

engine.

Checkingthe SafetyInterlock Circuits

Periodically check the safety interlock circuits to ensure they are

working properly. Ira safety circuit is not working as designed,

contact you Cub Cadet dealer to have the tractor inspected. DO

NOT operate the tractor if any safety circuit is not functioning

properly. To check the safety circuits, proceed asfollows:

1. Sitting in the tractor seat with both drive control levers

opened fully outward, disengage the parking brake and

momentarily turn the ignition switch to the start position.

The engine should not crank.

2. Engage the parking brake and pull the PTO switch upward

to the engaged position. Momentarily turn the ignition

switch to the start position; the engine should not crank.

3. Push the PTO switch downward to the disengaged position

and engage the parking brake. Start the engine and move

one of the drive control levers from the fully outward

neutral position. The engine should stop running. Repeat

the procedure with the opposite control lever.

4. Move both control levers fully outward in the neutral

position and disengage the parking brake; then lift upward

from the operator's seat. The engine should stop.

5. With both control levers fully outward in the neutral

position and the parking brake engaged, engage the PTO.

Lift upward from the operator's seat; the engine should

stop.

6. Start the tractor, disengage the parking brake, and move

the control levers inward to the neutral operating position.

Engage the PTO and move both control lever slowly into

the slow reverse position; the PTO should disengage

and the mower deck should stop until one or both of the

control levers is moved to the neutral or forward position.

i_ WARNING! Be careful when crossing gravel paths

or driveways. Disengage the PTO and raise the deck

to the highest position before crossing..

SECTION S-- OPERATION

Page 21

Maintenance&Adjustments

MaintenanceSchedule

6

Before

Eachuse

CheckEngineintakeScreen/Cover

CleanHood/DashLouvers _

CleanBattery Terminals _

LubeFrontPivot AxleandCasterAxles _

CleanEngineCoolingFins V/" V/"

LubeFrontDeckWheels V / V/

NOTE:This Operator's Manual covers several models. Tractor 2.

features may vary by model. Not all features in this manual are

applicable to all tractor models and the tractor depicted may

differ from yours. 3.

,/

Maintenance

WARNING! Before performing any maintenance or

repairs, disengage the PTO, move the drive control

levers fully outward in the neutral position, engage

the parking brake, stop the engine and remove the

key to prevent unintended starting.

Every

lOHours

f

Every

25 Hours

Move the tractor to an area within reach of the hose where the

dispersal of wet grass clippings is acceptable to you. Disengage

the PTO,engage the parking brake and stop the engine.

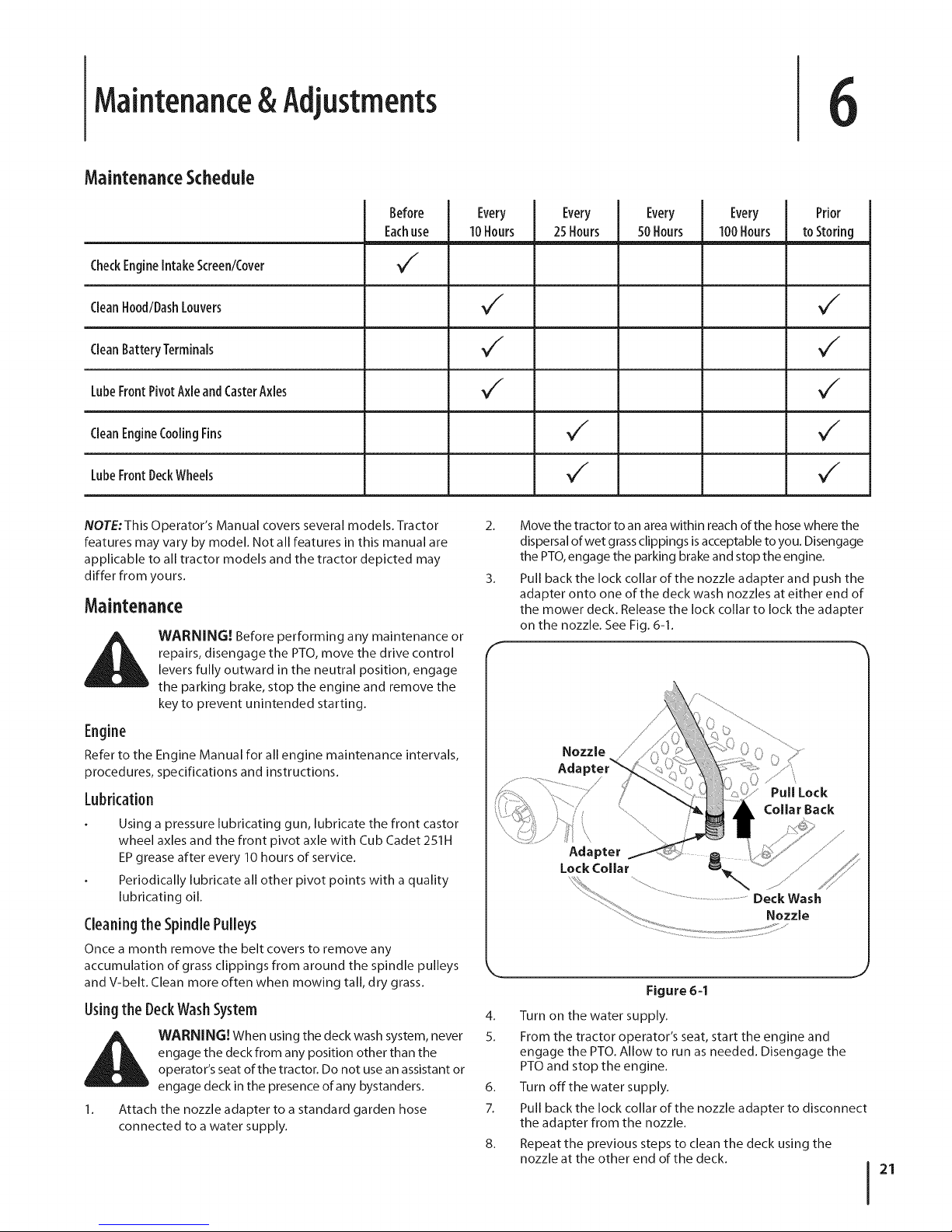

Pull back the lock collar of the nozzle adapter and push the

adapter onto one of the deck wash nozzles at either end of

the mower deck. Release the lock collar to lock the adapter

on the nozzle. See Fig. 6-1.

Every

50 Hours

Every

I00 Hours

toStoring

Prior

Engine

Refer to the Engine Manual for all engine maintenance intervals,

procedures, specifications and instructions.

Lubrication

Using a pressure lubricating gun, lubricate the front castor

wheel axles and the front pivot axle with Cub Cadet 251H

EP grease after every 10 hours of service.

Periodically lubricate all other pivot points with a quality

lubricating oil.

Cleaningthe SpindlePulleys

Once a month remove the belt covers to remove any

accumulation of grass clippings from around the spindle pulleys

and V-belt. Clean more often when mowing tall, dry grass.

Usingthe DeckWashSystem

WARNING! When using the deck wash system, never

engage the deck from any position other than the

operator's seat of the tractor. Do not use an assistant or

engage deck in the presence of any bystanders.

1. Attach the nozzle adapter to a standard garden hose

connected to a water supply.

Nozzle

Aria

Pull Lock

Collar Back

Adapter

L j

Figure 6=1

4. Turn on the water supply.

5. From the tractor operator's seat, start the engine and

engage the PTO. Allow to run as needed. Disengage the

PTO and stop the engine.

6. Turn off the water supply.

7. Pull back the lock collar of the nozzle adapter to disconnect

the adapter from the nozzle.

8. Repeat the previous steps to clean the deck using the

nozzle at the other end of the deck.

21

Page 22

TireMaintenance

Check the tire air pressure after every 50 hours of operation or

weekly. Keep the tires inflated to the recommended pressures.

Improper inflation will shorten the tire service life. See the tire side

wall for proper inflation pressures. Observe the following guidelines:

Do not inflate a tire above the maximum pressure shown

on the sidewall of the tire.

Do not reinflate a tire that has been run flat or seriously under

inflated. Have it inspected and serviced bya qualified tire

mechanic.

GeneralBattery Information

_lh WARNING!

, Should battery acid accidentally splatter into

the eyes or onto the skin, rinse the affected area

immediately with clean cold water. If there is any

further discomfort, seek prompt medical attention.

If acid spills on clothing, first dilute it with clean

water, then neutralize with a solution of ammonia/

water or baking soda/water.

NEVER connect (or disconnect) battery charger

clips to the battery while the charger is turned on, as

it can cause sparks.

Keep all sources of ignition (cigarettes, matches,

lighters) away from the battery. The gas generated

during charging can be combustible.

As a further precaution, only charge the battery

in a well ventilated area.

Always shield eyes and protect skin and clothing

when working near batteries.

Batteries contain sulfuric acid and may emit

explosive gases. Use extreme caution when handling

batteries. Keep batteries out of the reach of children.

4.

Recharge the battery before returning to service. Although

the tractor may start, the engine charging system may not

fully recharge the battery.

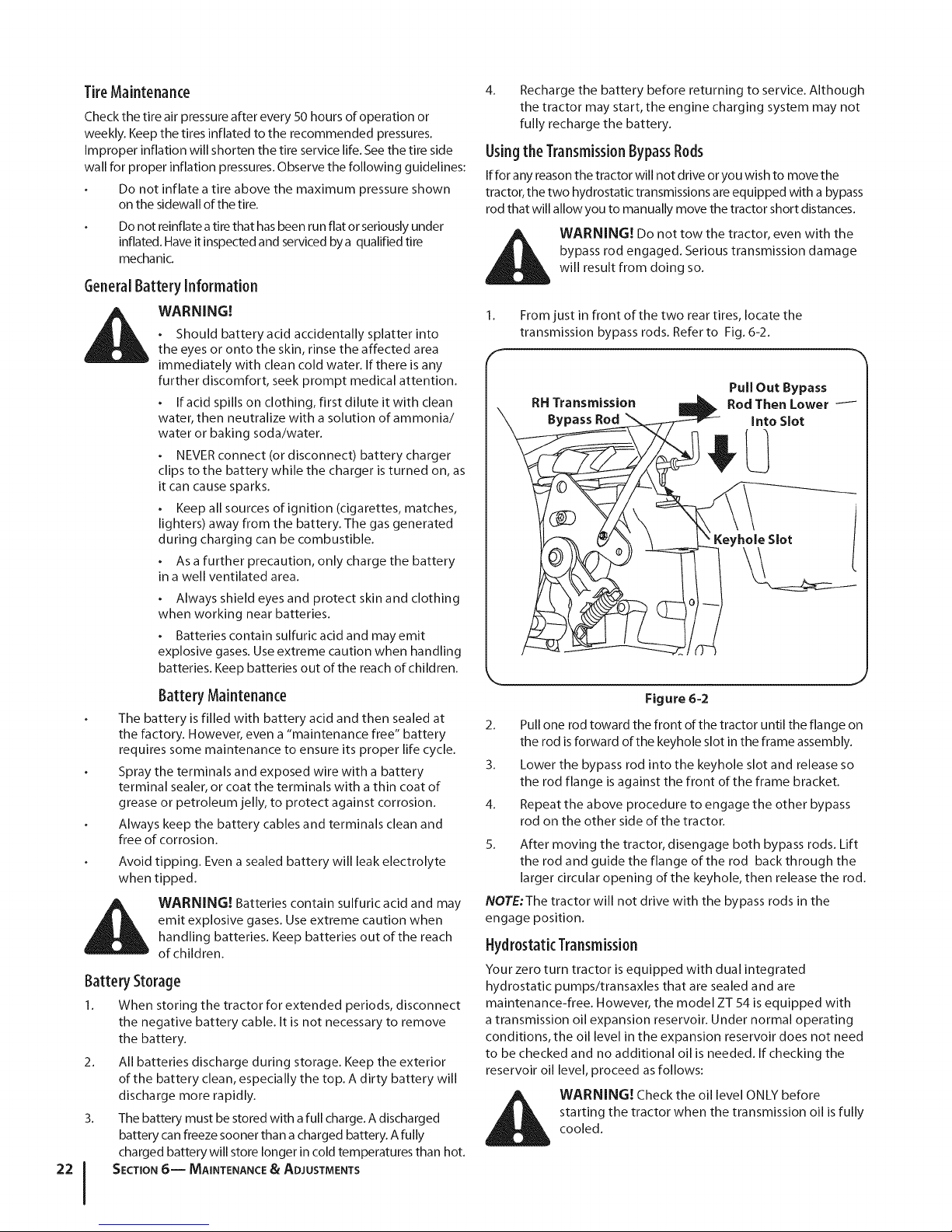

Usingthe TransmissionBypassRods

If for any reason the tractor will not drive or you wish to move the

tractor, the two hydrostatic transmissions are equipped with a bypass

rod that will allow you to manually move the tractor short distances.

bypass rod engaged. Serious transmission damage

WARNING! Do not tow the tractor, even with the

will result from doing so.

1. From just in front of the two rear tires, locate the

transmission bypass rods. Refer to Fig. 6-2.

RH Transmission

Bypass Rod

Pull Out Bypass

Rod Then Lower i

Into Slot

Keyhole Slot

Battery Maintenance

The battery is filled with battery acid and then sealed at

the factory. However, even a "maintenance free" battery

requires some maintenance to ensure its proper life cycle.

Spray the terminals and exposed wire with a battery

terminal sealer, or coat the terminals with a thin coat of

grease or petroleum jelly, to protect against corrosion.

Always keep the battery cables and terminals clean and

free of corrosion.

Avoid tipping. Even a sealed battery will leak electrolyte

when tipped.

WARNING! Batteries contain sulfuric acid and may

emit explosive gases. Use extreme caution when

handling batteries. Keep batteries out of the reach

of children.

Battery Storage

1. When storing the tractor for extended periods, disconnect

the negative battery cable. It is not necessary to remove

the battery.

2. All batteries discharge during storage. Keep the exterior

of the battery clean, especially the top. A dirty battery will

discharge more rapidly.

3. The battery must be stored with a full charge. A discharged

battery can freeze sooner than a charged battery. A fully

charged battery will store longer in cold temperatures than hot.

SECTION6-- MAINTENANCE& ADJUSTMENTS

Figure 6-2

2. Pull one rod toward the front of the tractor until the flange on

the rod is forward of the keyhole slot in the frame assembly.

3. Lower the bypass rod into the keyhole slot and release so

the rod flange is against the front of the frame bracket.

4. Repeat the above procedure to engage the other bypass

rod on the other side of the tractor.

5. After moving the tractor, disengage both bypass rods. Lift

the rod and guide the flange of the rod back through the

larger circular opening of the keyhole, then release the rod.

NOTE:The tractor will not drive with the bypass rods in the

engage position.

Hydrostatic Transmission

Your zero turn tractor is equipped with dual integrated

hydrostatic pumps/transaxles that are sealed and are

maintenance-flee. However, the model ZT 54 is equipped with

a transmission oil expansion reservoir. Under normal operating

conditions, the oil level in the expansion reservoir does not need

to be checked and no additional oil is needed. If checking the

reservoir oil level, proceed as follows:

_ WARNING! Check the oil level ONLY before

starting the tractor when the transmission oil is fully

cooled.

Page 23

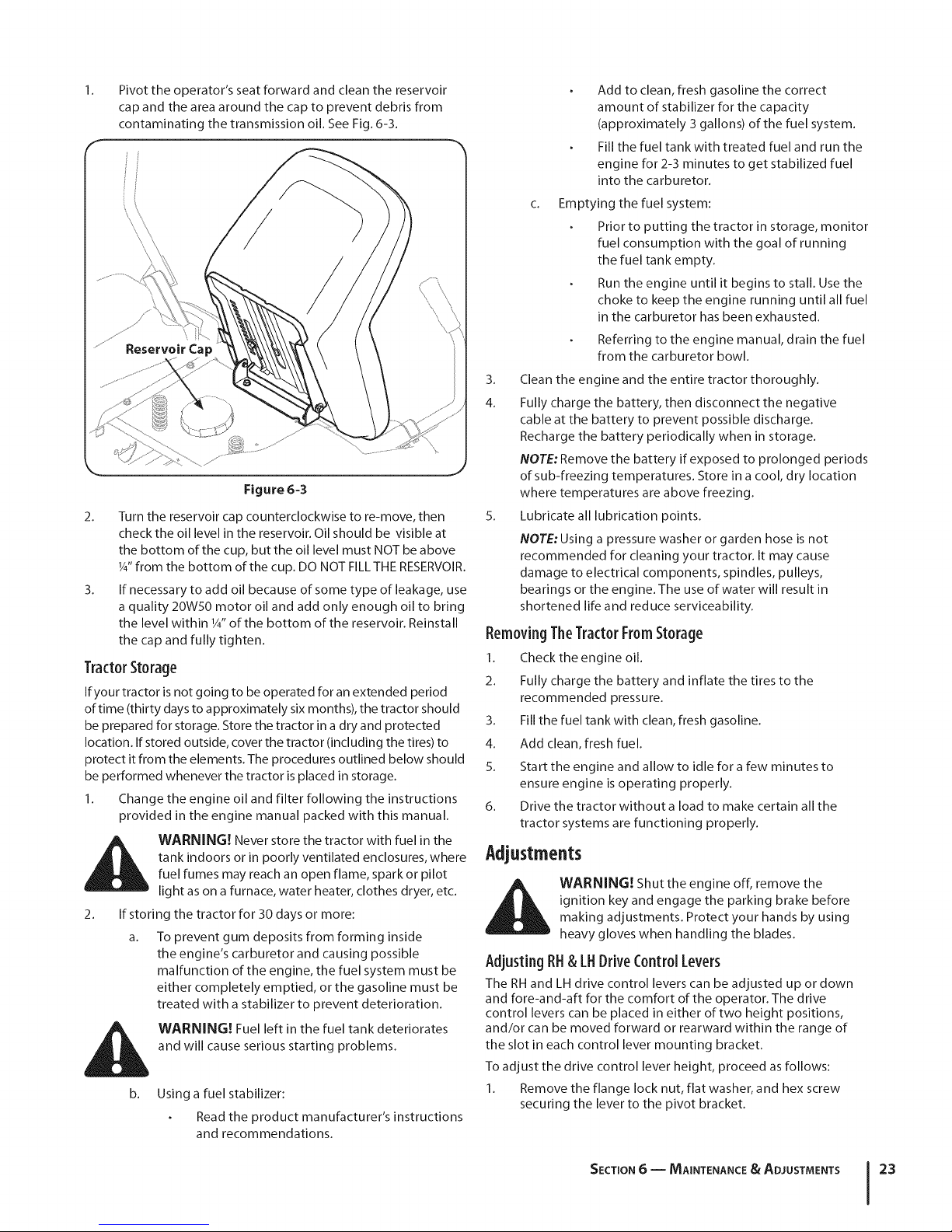

Pivottheoperator'sseatforwardandcleanthereservoir

capandtheareaaroundthecaptopreventdebrisfrom

contaminatingthetransmissionoil.SeeFig.6-3.

Figure 6-3

2. Turn the reservoir cap counterclockwise to re-move, then

check the oil level in the reservoir. Oil should be visible at

the bottom of the cup, but the oil level must NOT be above

1A"from the bottom of the cup. DO NOT FILL THE RESERVOIR.

3. If necessary to add oil because of some type of leakage, use

a quality 20W50 motor oil and add only enough oil to bring

the level within 1/4"of the bottom of the reservoir. Reinstall

the cap and fully tighten.

TractorStorage

If your tractor is not going to be operated for an extended period

of time (thirty days to approximately six months), the tractor should

be prepared for storage. Store the tractor in a dry and protected

location. If stored outside, cover the tractor (including the tires) to

protect it from the elements. The procedures outlined below should

be performed whenever the tractor is placed in storage.

1. Change the engine oil and filter following the instructions

provided in the engine manual packed with this manual.

WARNING! Never store the tractor with fuel in the

tank indoors or in poorly ventilated enclosures, where

fuel fumes may reach an open flame, spark or pilot

light as on a furnace, water heater, clothes dryer, etc.

If storing the tractor for 30 days or more:

a. To prevent gum deposits from forming inside

the engine's carburetor and causing possible

malfunction of the engine, the fuel system must be

either completely emptied, or the gasoline must be

treated with a stabilizer to prevent deterioration.

WARNING! Fuel left in the fuel tank deteriorates

and will cause serious starting problems.

b. Using a fuel stabilizer:

Read the product manufacturer's instructions

and recommendations.

Add to clean, fresh gasoline the correct

amount of stabilizer for the capacity

(approximately 3 gallons) of the fuel system.

Fill the fuel tank with treated fuel and run the

engine for 2-3 minutes to get stabilized fuel

into the carburetor.

C_

Emptying the fuel system:

Prior to putting the tractor in storage, monitor

fuel consumption with the goal of running

the fuel tank empty.

Run the engine until it begins to stall. Use the

choke to keep the engine running until all fuel

in the carburetor has been exhausted.

Referring to the engine manual, drain the fuel

from the carburetor bowl.

3. Clean the engine and the entire tractor thoroughly.

4. Fully charge the battery, then disconnect the negative

cable at the battery to prevent possible discharge.

Recharge the battery periodically when in storage.

NOTE: Remove the battery if exposed to prolonged periods

of sub-freezing temperatures. Store in a cool, dry location

where temperatures are above freezing.

5. Lubricate all lubrication points.

NOTE: Using a pressure washer or garden hose is not

recommended for cleaning your tractor. It may cause

damage to electrical components, spindles, pulleys,

bearings or the engine. The use of water will result in

shortened life and reduce serviceability.

RemovingTheTractorFromStorage

1. Check the engine oil.

2. Fully charge the battery and inflate the tires to the

recommended pressure.

3. Fill the fuel tank with clean, fresh gasoline.

4. Add clean, fresh fuel.

5. Start the engine and allow to idle for a few minutes to