Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

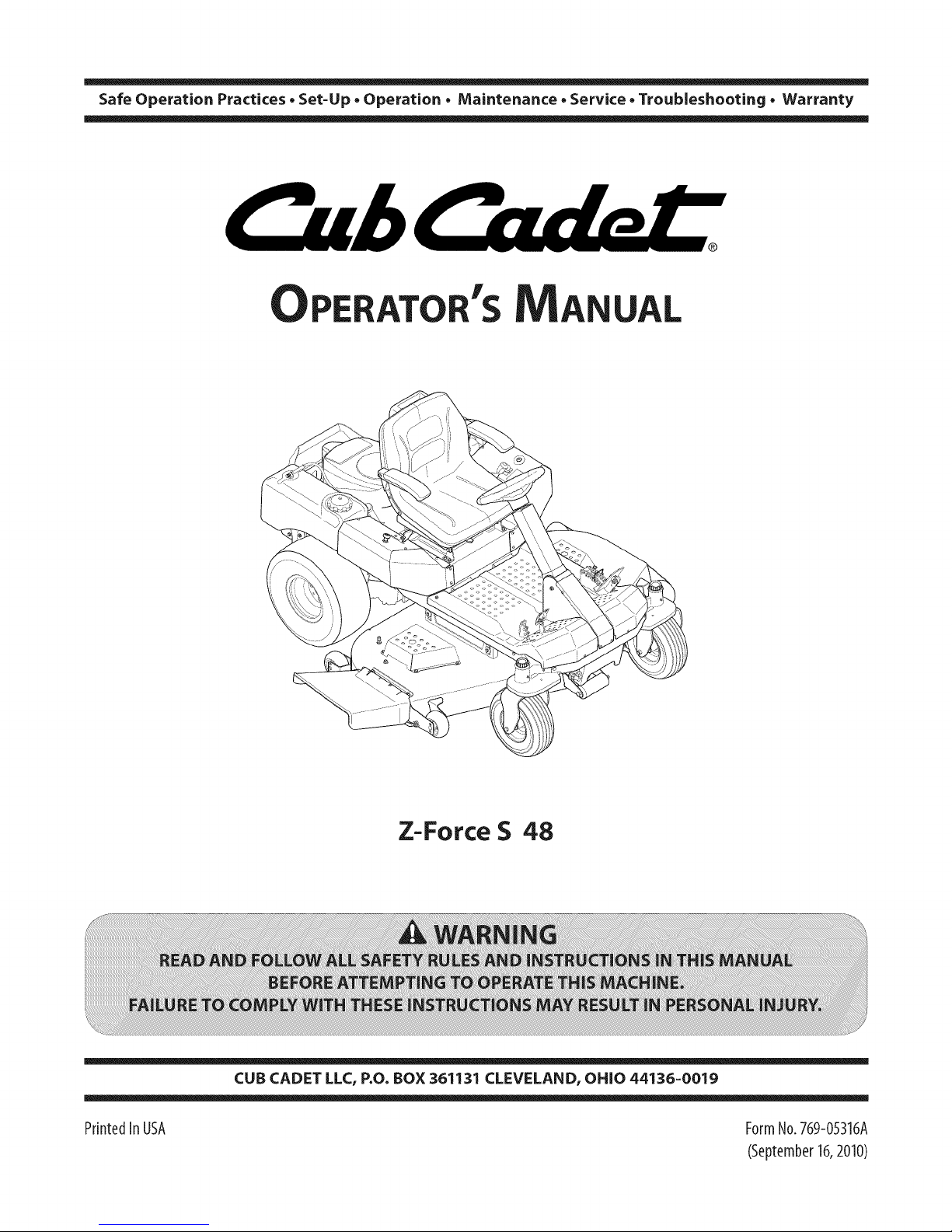

ATOR S

ANUAL

CUB CADET LLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019

PrintedIn USA FormNo.769-05316A

Z-Force S 48

(September16,2010)

Page 2

ToTheOwner

ThankYou

1

Thank you for purchasing a Cub Cadet Zero-Turn Tractor. It was

carefully engineered to provide excellent performance when

properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the machine,

its features and operation. Please be aware that this Operator's

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. We reserve

the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Table of Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 9

Controls & Features ................................................ 11

Operation ................................................................ 14

Maintenance & Adjustment. ................................. 18

If you have any problems or questions concerning the machine,

phone your local Cub Cadet dealer or contact us directly. Cub

Cadet's Customer Support telephone numbers, website address

and mailing address can be found on this page. We want to

ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position.

Service .................................................................... 24

Troubleshooting .................................................... 29

Replacement Parts ................................................ 30

Attachments & Accessories .................................. 32

Warranties ............................................................. 34

RecordProductinformation

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate the

model plate by standing at the left side of the tractor, pivoting

the seat forward and looking down at the seat frame. This

information will be necessary, should you seek technical support

via our web site or with your local Cub Cadet dealer.

MODEL NUMBER

DFI[3FI[3FI[3FI[3F1D

SERIALNUMBER

[3FI[3FI[3FI[3FI[3F1D

CustomerSupport

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

0 Visit us on the web at www.cubcadetcom

0 Locate your nearest Cub Cadet Dealer at (877) 282-8684

0 Write us at Cub Cadet LLC • EO. Box 361131 • Cleveland, OH • 44136-0019

Page 3

ImportantSafeOperationPractices

WARNING! This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING! Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

WARNING! Battery posts, terminals, and related accessories contain lead and lead

,A

compounds, chemicals known to the State of California to cause cancer and reproductive

harm. Wash hands after handling

DANGER! This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating hands and feet

and throwing objects. Failure to observe the following safety instructions could result in

serious injury or death.

2

GeneralOperation

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and should be trained and supervised

by an adult.

4. Never allow adults to operate this machine without proper

instruction.

5_

To help avoid blade contact or a thrown object injury,

keep bystanders, helpers, children and pets at least 75 feet

from the machine while it is in operation. Stop machine if

anyone enters the area.

6. Thoroughly inspect the area where the equipment is to be

used. Remove all stones, sticks, wire, bones, toys, and other

foreign objects which could be picked up and thrown by

the blade(s). Thrown objects can cause serious personal

injury.

7. Plan your mowing pattern to avoid discharge of material

toward roads, sidewalks, bystanders and the like. Also,

avoid discharging material against a wall or obstruction

which may cause discharged material to ricochet back

toward the operator.

8. Always wear safety glasses or safety goggles during

operation and while performing an adjustment or repair

to protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

9. Wear sturdy, rough-soled work shoes and close-fitting

slacks and shirts. Loose fitting clothes and jewelry can be

caught in movable parts. Never operate this machine in

bare feet or sandals.

10. Be aware of the mower and attachment discharge direction

and do not point it at anyone. Do not operate the mower

without the discharge cover or entire grass catcher in its

proper place.

11. Do not put hands or feet near rotating parts or under the

cutting deck. Contact with the blade(s) can amputate

hands and feet.

Page 4

12. Amissingordamageddischargecovercancauseblade

contactorthrownobjectinjuries.

13. Stoptheblade(s)whencrossinggraveldrives,walks,or

roadsandwhilenotcuttinggrass.

14. Watchfortrafficwhenoperatingnearorcrossing

roadways.Thismachineisnotintendedforuseonany

publicroadway.

15. Donotoperatethemachinewhileundertheinfluenceof

alcoholordrugs.

16. Mowonlyindaylightorgoodartificiallight.

17. Nevercarrypassengers.

18. Backupslowly.Alwayslookdownandbehindbeforeand

whilebackingtoavoidaback-overaccident.Beaware

andpayattentiontothesafetysystemfunctionthat

stopspowertothebladeswhendrivinginreverse.Ifnot

fuctioningproperly,contactanauthorizeddealerforsafety

systeminspectionandrepair.

19. Slowdownbeforeturning.Operatethemachinesmoothly.

Avoiderraticoperationandexcessivespeed.

20. Disengageblade(s),setparkingbrake,stopengineandwait

untiltheblade(s)cometoacompletestopbeforeremoving

grasscatcher,emptyinggrass,uncloggingchute,removing

anygrassordebris,ormakinganyadjustments.

21. Neverleavearunningmachineunattended.Alwaysturnoff

blade(s),placedrivecontrolleversinneutral,setparking

brake,stopengineandremovekeybeforedismounting.

22. Useextracarewhenloadingorunloadingthemachineinto

atrailerortruck.Thismachineshouldnotbedrivenupor

downramp(s),becausethemachinecouldtipover,causing

seriouspersonalinjury.Themachinemustbepushed

manuallyonramp(s)toloadorunloadproperly.

23.

Mufflerandenginebecomehotandcancauseaburn.Do

nottouch.

24.

Checkoverheadclearancescarefullybeforedrivingunder

lowhangingtreebranches,wires,dooropeningsetc.,

wheretheoperatormaybestruckorpulledfromthe

machine,whichcouldresultinseriousinjury.

25.

Disengageallattachmentclutches,settheparkingbraketo

the'ON'position.

26.

Yourmachineisdesignedtocutnormalresidentialgrassof

aheightnomorethan10".Donotattempttomowthrough

unusuallytall,drygrass(e.g.,pasture)orpilesofdryleaves.

Drygrassorleavesmaycontacttheengineexhaustand/

orbuilduponthemowerdeckpresentingapotentialfire

hazard.

27. Useonlyaccessoriesandattachmentsapprovedforthis

machinebythemachinemanufacturer.Read,understand

andfollowallinstructionsprovidedwiththeapproved

accessoryorattachment.

28. Dataindicatesthatoperators,age60yearsandabove,are

involvedinalargepercentageofridingmower-related

injuries.Theseoperatorsshouldevaluatetheirability

tooperatetheridingmowersafelyenoughtoprotect

themselvesandothersfromseriousinjury.

29. Ifsituationsoccurwhicharenotcoveredinthismanual,use

careandgoodjudgment.Contactyourcustomerservice

representativeforassistance.

SlopeOperation

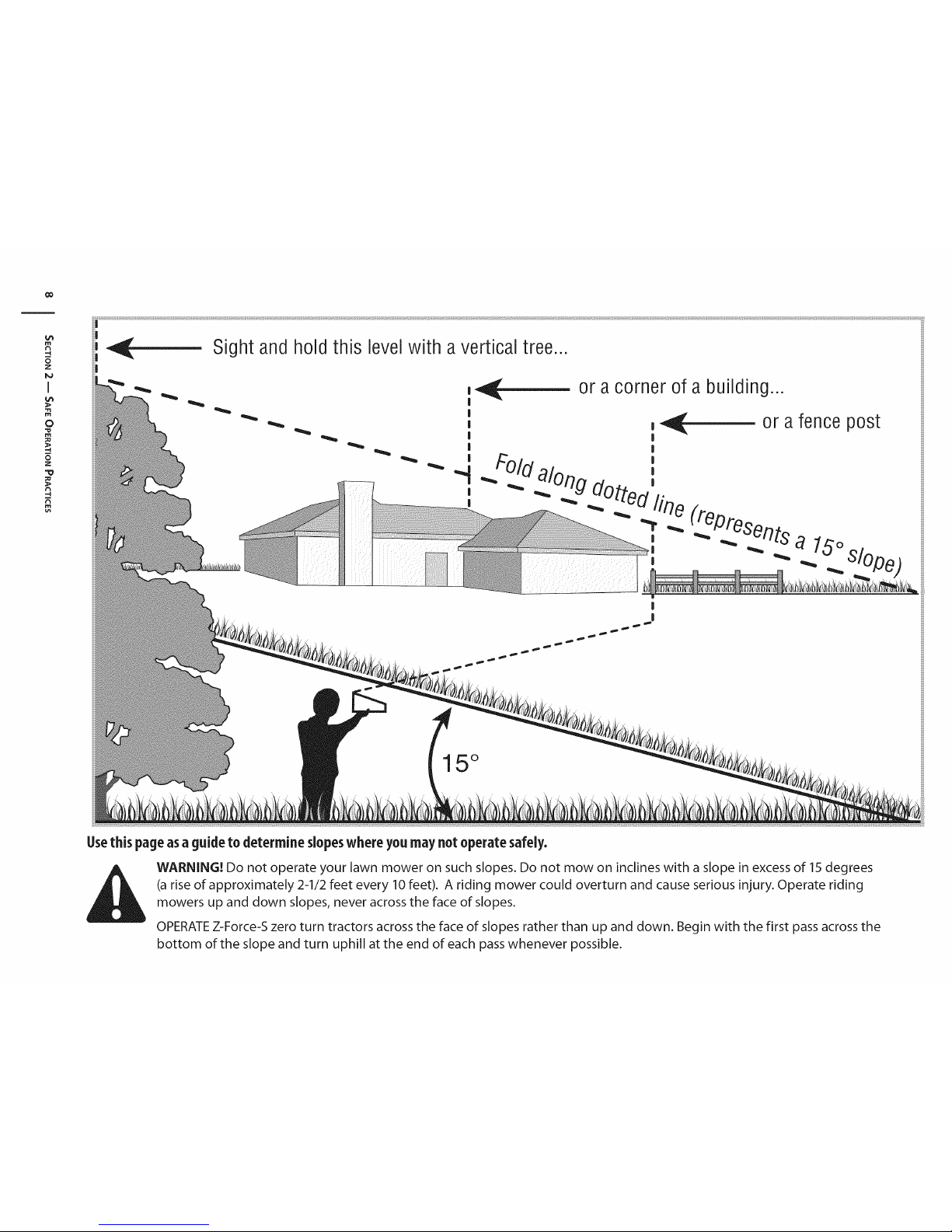

Slopes are a major factor related to loss of control and tip-over

accidents which can result in severe injury or death. All slopes

require extra caution. If you cannot back up the slope or if you

feel uneasy on it, do not mow it.

For your safety, use the slope gauge included as part of this

manual to measure slopes before operating this machine on

a sloped or hilly area. If the slope is greater than 15 degrees as

shown on the slope gauge, do not operate this machine on that

area or serious injury could result.

Do:

I.

Mow across slopes, not up and down. Exercise extreme

caution when changing direction on slopes.

2. Watch for holes, ruts, bumps, rocks, or other hidden

objects. Uneven terrain could overturn the machine. Tall

grass can hide obstacles.

3. Use slow speed. Choose a low enough speed so that you

will not have to stop while on the slope. Avoid starting

or stopping on a slope. If the tires are unable to maintain

traction, disengage the blades and proceed slowly and

carefully straight down the slope.

4. Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

5. Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

6. Keep all movement on the slopes slow and gradual. Do

not make sudden changes in speed or direction. Rapid

acceleration or deceleration could cause the front of the

machine to lift and rapidly flip over backwards, which

could cause serious injury.

DoNot:

I. Do not turn on slopes unless necessary; then turn slowly

uphill and use extra care while turning.

2. Do not mow near drop-offs, ditches or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff, ditch, or if an edge caves in.

3. Do not try to stabilize the machine by putting your foot on

the ground.

4. Do not use a grass catcher on steep slopes.

5. Do not mow on wet grass. Reduced traction could cause

sliding.

6. Do not tow heavy pull behind attachments (e.g. loaded

dump cart, lawn roller, etc.) on slopes greater than 5

degrees. When going down hill, the extra weight tends to

push the tractor and may cause you to lose control (e.g.

tractor may speed up, braking and steering ability are

reduced, attachment may jack-knife and cause tractor to

overturn).

4 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

Page 5

Children

1. Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

machine and the mowing activity. They do not understand

the dangers. Never assume that children will remain where

you last saw them.

a. Keep children out of the mowing area and in

watchful care of a responsible adult other than the

operator.

b. Be alert and turn machine off if a child enters the

area.

c. To avoid back-over accidents, always look behind

and down for small children.

d. Never carry children, even with the blade(s) shut off.

They may fall offand be seriously injured or interfere

with safe machine operation.

e. Use extreme care when approaching blind corners,

doorways, shrubs, trees or other objects that may

blockyour vision of a child who may run into the

path of the machine.

f. Keep children away from hot or running engines.

They can suffer burns from a hot muffler.

g. Remove key when machine is unattended to

prevent unauthorized operation.

2. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and should be trained and supervised

by an adult.

Towing

1. Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

2. Follow the manufacturers recommendation for weight

limits for towed equipment and towing on slopes.

3. Never allow children or others in or on towed equipment.

4. On slopes, the weight of the towed equipment may cause

loss of traction and loss of control.

5. The maximum weight on the hitch is 50 Ibs and the

maximum towed load is 500 Ibs.

6. Never allow passengers on the towed equipment.

7. Loss of traction can occur on slopes, 5° (9 %) maximum

grade.

8. Travel slowly and allow extra distance to stop.

9. Use caution during turns to avoid jack-knifing.

10. Use extra caution when operating in reverse.

11. Do not modify or repair the hitch, replace the hitch if

damaged.

12. Travel slowly and allow extra distance to stop.

13. Do not shift to neutral and coast downhill.

Service

SafeHandling of 6as01ine:

1. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

c. When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment on

a trailer with a portable container, rather than from a

gasoline dispenser nozzle.

d. Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

e. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel while the engine

is hot or running. Allow engine to cool at least two

minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more than 1/2"

below bottom of filler neck to allow space for fuel

expansion.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

k. To reduce fire hazards, keep machine free of grass,

leaves, or other debris build-up. Clean up oil or fuel

spillage and remove any fuel soaked debris.

I. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

m. Allow a machine to cool at least five minutes before

storing.

6eneral Service

1. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless,

and deadly gas.

2. Before cleaning, repairing, or inspecting, make certain the

blade(s) and all moving parts have stopped. Disconnect

the spark plug wire(s) and ground against the engine to

prevent unintended starting.

SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES S

Page 6

3. Periodically check to make sure the blades come to

complete stop within approximately (5) five seconds after

operating the blade disengagement control. If the blades

do not stop within the this time frame, your machine

should be serviced professionally by an authorized dealer.

4. Regularly check the safety interlock system for proper

function, as described later in this manual. If the safety

interlock system does not function properly, have your

machine serviced professionally by an authorized dealer.

5. Check the blade(s) and engine mounting bolts at frequent

intervals for proper tightness. Also, visually inspect blade(s)

for damage (e.g., excessive wear, bent, cracked). Replace

the blade(s) with the original equipment manufacturer's

(O.E.M.) blade(s) only, listed in this manual. "Use of parts

which do not meet the original equipment specifications

may lead to improper performance and compromise

safety!"

6. Mower blades are sharp. Wrap the blade or wear gloves,

and use extra caution when servicing them.

7. Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

8. Never tamper with the safety interlock system or other

safety devices. Check their proper operation regularly.

9. After striking a foreign object, stop the engine, disconnect

the spark plug wire(s) and ground against the engine.

Thoroughly inspect the machine for any damage. Repair

the damage before starting and operating.

10. Never attempt to make adjustments or repairs to the

machine while the engine is running.

11. Grass catcher components and the discharge cover are

subject to wear and damage which could expose moving

parts or allow objects to be thrown. For safety protection,

frequently check components and replace immediately

with original equipment manufacturer's (O.E.M.) parts only,

listed in this manual. "Use of parts which do not meet the

original equipment specifications may lead to improper

performance and compromise safety!"

12. Do not change the engine governor settings or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

13. Maintain or replace safety and instruction labels, as

necessary.

14. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

15. According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years,

or 270 hours of operation. At the end of the Average Useful

Life have the machine inspected annually by an authorized

service dealer to ensure that all mechanical and safety

systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

Donot modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

NoticeRegardingEmissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM) and Three Way Catalyst (TWC) if so equipped.

SparkArrestor

internal combustion engine and should not be used

i_lh WARNING! This machine is equipped with an

effective working order by the operator. In the State of California

the above is required by law (Section 4442 of the California

Public Resources Code). Other states may have similar laws.

Federal laws apply on federal lands.

A spark arrestor for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, RO. Box 361131 Cleveland, Ohio 44136-0019.

on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's

exhaust system is equipped with a spark arrestor

meeting applicable local or state laws (if any).

If a spark arrestor is used, it should be maintained in

6 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

Page 7

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate

M

®

!!l"

N

WARNING-- ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the

blade(s) can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in

operation.

WARNING-- SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees.

DANGER -- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover

or grass catcher is in its proper place. If damaged, replace immediately.

WARNING! Your Responsibility-- Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVETHESEINSTRUCTIONS!

SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES 7

Page 8

co

R

-4

6

Z

I

o

6

Z

-4

!

|

|

|

or a corner of a building...

|

15°

Usethis page as a guide to determine slopeswhere you may not operate safely.

WARNING! Do not operate your lawn mower on such slopes. Do not mow on inclines with a slope in excess of 15 degrees

(a rise of approximately 2-1/2 feet every 10 feet). A riding mower could overturn and cause serious injury. Operate riding

mowers up and down slopes, never across the face of slopes.

OPERATE Z-Force-S zero turn tractors across the face of slopes rather than up and down. Begin with the first pass across the

bottom of the slope and turn uphill at the end of each pass whenever possible.

Page 9

Assembly& Set-Up

Contents of Crate

3

One Lawn Tractor

One Z-Force-S Tractor Operator's

Manual

One Oil Drain Hose

One Engine Operator's Manual

TractorPreparation

1. Remove the upper crating material from the shipping pallet,

and cut any bands or tie straps securing the tractor to the

pallet.

2. If the deck is not in the highest mowing position (pushed all

the way forward), use the deck lift pedal to raise the deck to

its highest position. Refer to the Controls & Features section

for instructions on raising and lowering the deck.

3. Disengage the parking brake.

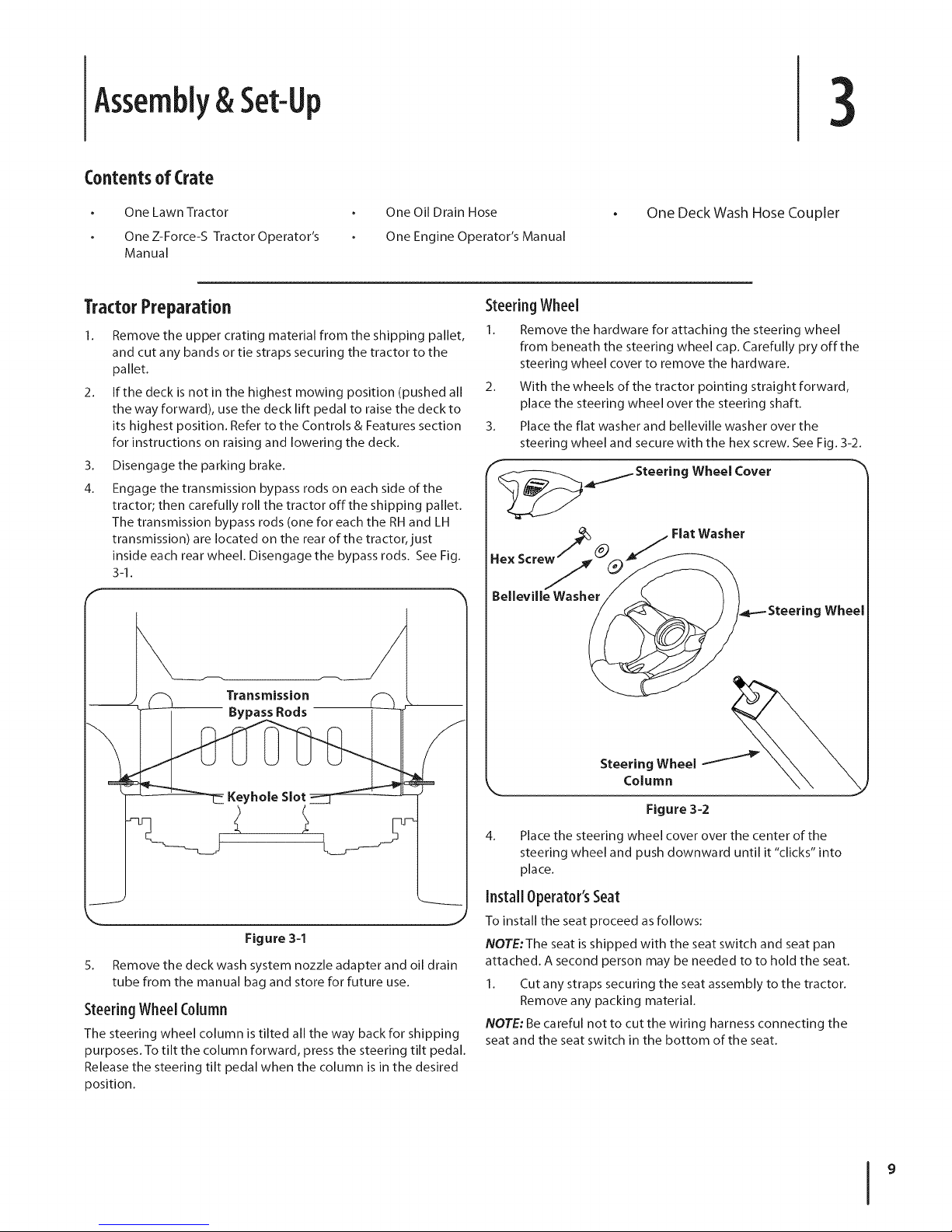

4. Engage the transmission bypass rods on each side of the

tractor; then carefully roll the tractor offthe shipping pallet.

The transmission bypass rods (one for each the RH and LH

transmission) are located on the rear of the tractor, just

inside each rear wheel. Disengage the bypass rods. See Fig.

3-1.

One Deck Wash Hose Coupler

SteeringWheel

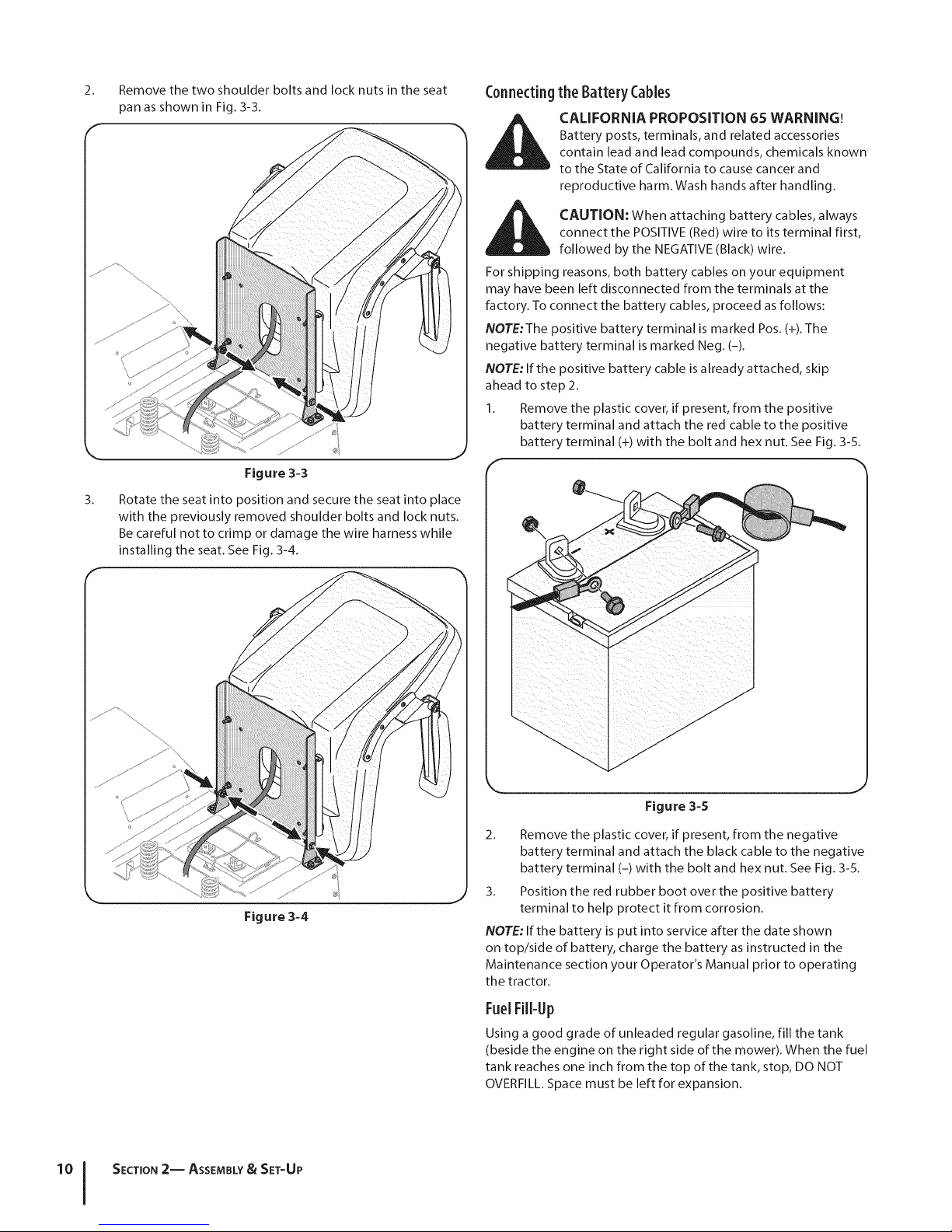

Remove the hardware for attaching the steering wheel

from beneath the steering wheel cap. Carefully pry off the

steering wheel cover to remove the hardware.

2.

With the wheels of the tractor pointing straight forward,

place the steering wheel over the steering shaft.

3. Place the flat washer and belleville washer over the

steering wheel and secure with the hex screw. See Fig. 3-2.

_ Steering Wheel Cover "_

Flat Washer

Belleville Wash_ Steering Wheel

Figure 3=1

5. Remove the deck wash system nozzle adapter and oil drain

tube from the manual bag and store for future use.

SteeringWheel Column

The steering wheel column is tilted all the way back for shipping

purposes. To tilt the column forward, press the steering tilt pedal.

Release the steering tilt pedal when the column is in the desired

position.

Steering Wheel /

Figure 3-2

4.

Place the steering wheel cover over the center of the

steering wheel and push downward until it "clicks" into

place.

Install Operator'sSeat

To install the seat proceed as follows:

NOTE:The seat is shipped with the seat switch and seat pan

attached. A second person may be needed to to hold the seat.

I. Cut any straps securing the seat assembly to the tractor.

Remove any packing material.

NOTE: Be careful not to cut the wiring harness connecting the

seat and the seat switch in the bottom of the seat.

Page 10

2. Removethetwoshoulderboltsandlocknutsintheseat

panasshowninFig.3-3.

Figure 3-3

3.

Rotate the seat into position and secure the seat into place

with the previously removed shoulder bolts and lock nuts.

Be careful not to crimp or damage the wire harness while

installing the seat. See Fig. 3-4.

Connectingthe Battery Cables

Battery posts, terminals, and related accessories

CALIFORNIA PROPOSITION 65 WARNING!

contain lead and lead compounds, chemicals known

to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

connect the POSITIVE (Red) wire to its terminal first,

CAUTION: When attaching battery cables, always

followed by the NEGATIVE (Black) wire.

For shipping reasons, both battery cables on your equipment

may have been left disconnected from the terminals at the

factory. To connect the battery cables, proceed as follows:

NOTE:The positive battery terminal is marked Pos. (+). The

negative battery terminal is marked Neg. (-).

NOTE: If the positive battery cable is already attached, skip

ahead to step 2.

1. Remove the plastic cover, if present, from the positive

battery terminal and attach the red cable to the positive

battery terminal (+) with the bolt and hex nut. See Fig. 3-5.

F

Figure 3-4

SECTION 2-- ASSEMBLY& SET-UP

Figure 3-5

2. Remove the plastic cover, if present, from the negative

battery terminal and attach the black cable to the negative

battery terminal (-) with the bolt and hex nut. See Fig. 3-5.

3. Position the red rubber boot over the positive battery

terminal to help protect it from corrosion.

NOTE: If the battery is put into service after the date shown

on top/side of battery, charge the battery as instructed in the

Maintenance section your Operator's Manual prior to operating

the tractor.

FuelFill-Up

Using a good grade of unleaded regular gasoline, fill the tank

(beside the engine on the right side of the mower). When the fuel

tank reaches one inch from the top of the tank, stop, DO NOT

OVERFILL. Space must be left for expansion.

Page 11

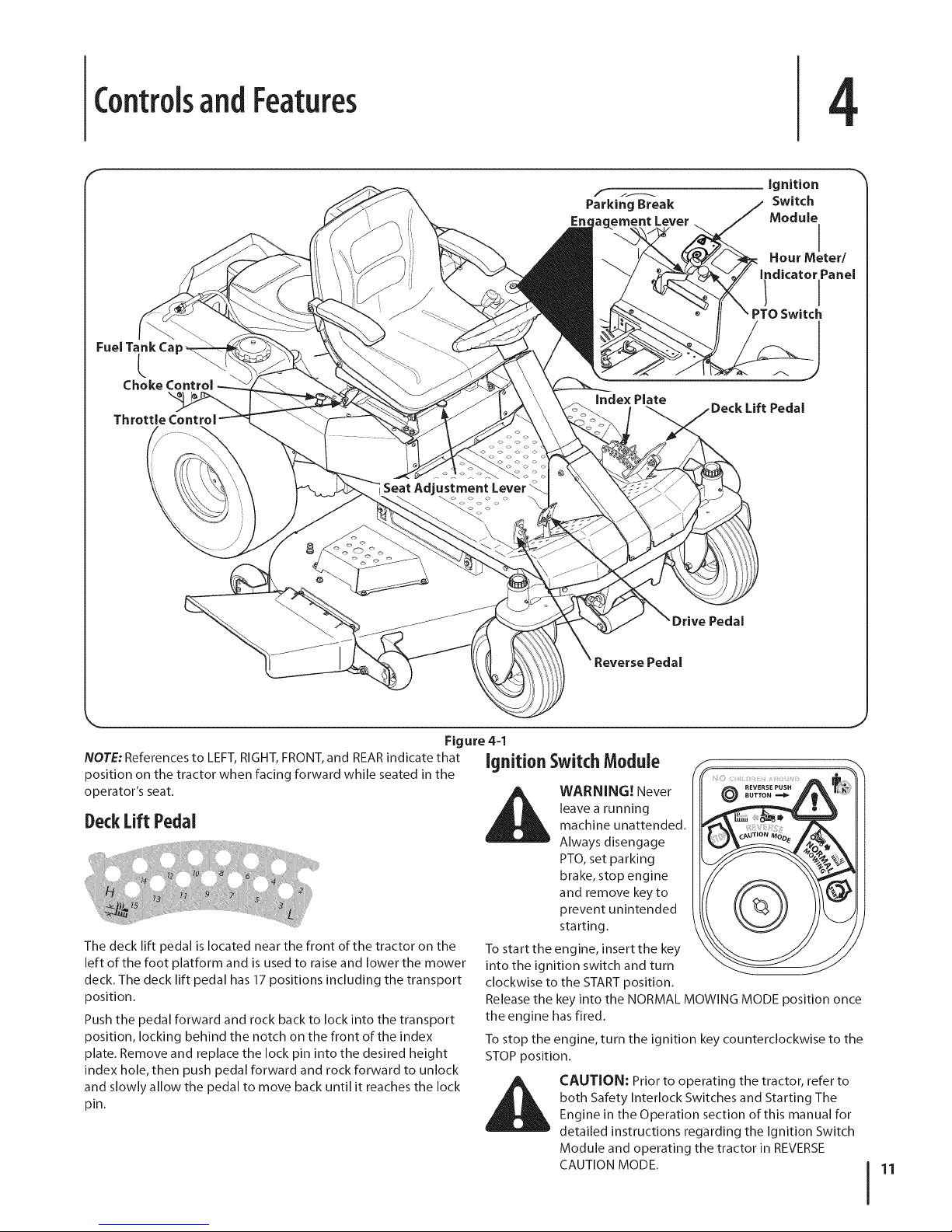

ControlsandFeatures

4

Fuel Tank Ca

f J_

Parking Break

Eric ement Lever

Ignition

Switch

Module

I

Hour Meter/

indicator Panel

NOTE: References to LEFT, RIGHT, FRONT, and REAR indicate that

position on the tractor when facing forward while seated in the

operator's seat.

DeckLift Pedal

The deck lift pedal is located near the front of the tractor on the

left of the foot platform and is used to raise and lower the mower

deck. The deck lift pedal has 17 positions including the transport

position.

Push the pedal forward and rock back to lock into the transport

position, locking behind the notch on the front of the index

plate. Remove and replace the lock pin into the desired height

index hole, then push pedal forward and rock forward to unlock

and slowly allow the pedal to move back until it reaches the lock

pin.

Reverse Pedal

Figure 4=1

Ignition SwitchModule

WARNING! Never

leave a running

machine unattended.

Always disengage

PTO, set parking

brake, stop engine

and remove key to

prevent unintended

starting.

To start the engine, insert the key

into the ignition switch and turn

clockwise to the START position.

Release the key into the NORMAL MOWING MODE position once

the engine has fired.

To stop the engine, turn the ignition key counterclockwise to the

STOP position.

CAUTION: Prior to operating the tractor, refer to

both Safety Interlock Switches and Starting The

Engine in the Operation section of this manual for

detailed instructions regarding the Ignition Switch

Module and operating the tractor in REVERSE

CAUTION MODE.

©

11

Page 12

PTO(PowerTake-Off)Switch

The PTO switch is located on the LH console to

the left of the operator's seat.

The PTO switch operates the electric PTO

clutch mounted on the bottom of the engine

crankshaft. Pull the switch knob upward to

engage the PTO clutch, or push the knob

downward to disengage the clutch.

The PTO switch must be in the "disengaged"

position when starting the engine.

PTO

• t

0 -I

Transmission BypassRods(Not Visible)

The transmission bypass rods (one for each the RH and LH

transmission) are located on the rear of the tractor, just inside

each rear wheel, below the fuel tank and the storage tray.

When engaged, the two rods open a bypass within the

hydrostatic transmissions, which allows the tractor to be pushed

short distances by hand.

tractor with the rear wheels on the ground may

CAUTION: Never tow your tractor. Towing the

cause severe damage to the transmissions.

CupHolder

The cup holder is located on the LH console to the left of the

operator's seat.

StorageTray

The storage tray is located at the rear of the LH console.

SeatAdjustment Lever

The seat adjustment lever is located below the front/left of the

seat. The lever a Ilows for adjustment of the fore to aft position

of the operator's seat. Refer to the Maintenance & Adjustments

section for instructions on adjusting the seat position.

FuelTankCap

The fuel tank cap is located on the LH console. Turn the fill cap to

remove. Always re-install the fuel cap tightly onto the fuel tank

after removing.

is running. If the engine is hot from recently running,

_ ARNING! Never fill the fuel tank when the engine

allow to cool for several minutes before refueling.

Highly flammable gasoline could splash onto the

engine and cause a fire.

HourMeter/IndicatorPanel

The hour meter/indicator panel is

located on the LH console to the left of

the operator's seat.

HourMeter Features

The hour meter records the hours that

the tractor has been operated in the

digital display (tenths of an hour- right

most digit).

NOTE:The hour meter is activated whenever the ignition switch

is turned to the "ON" position. Keep a record of the actual hours

of operation to assure all maintenance procedures are completed

according to the instructions in this manual and the engine

manual.

When key is turned to the "ON" position, the battery indicator

light briefly illuminates and the battery voltage is briefly

displayed. The display then changes to the accumulated hours.

The Indicator Monitor will also remind the operator of

maintenance intervals for changing the engine oil. The LCD

will alternately flash, "CHG" ; "OIL" and the recorded hours for

five minutes after every 50 hours of recorded operation. The

maintenance interval lasts for two hours (from 50-52,100-102,

150-152, etc.). The LCD will flash as described for five minutes

every time the tractor's engine is started during this maintenance

interval. Follow the oil change intervals provided in the engine

manual.

12 I SECTION 4-- CONTROLS AND FEATURES

Page 13

Indicator Panel Features

Battery Indicator

Illuminates and the battery voltage is displayed briefly when the

ignition switch it turned to the "ON" position.

Illuminates to indicate the battery voltage has dropped below

11.5 (+0.5/-1.0) volts. The battery voltage is aIso displayed on

the hour meter. If this indicator and display come on during

operation, check the battery and charging system for possible

causes and/or contact your Cub Cadet dealer.

Oil Pressure Indicator (If Engine So Equipped)

This warning lamp indicates low engine oil pressure. If the

indicator comes on while the engine is running, stop the engine

immediately and check for possible causes. Do not run the

engine while this indicator is illuminated. Contact your Cub

Cadet dealer to have the tractor and engine inspected.

NOTE:The oil pressure indicator may illuminate when the

ignition switch is in the ON position, but should turn offwhen

the engine is started.

PTO Engaged Indicator

This indicator illuminates when the PTO switch is pulled upward

in the "ENGAGED" position and the ignition switch is turned

to the "START" position. Check this indicator if the engine will

not crank with the ignition switch in the "START" position. If

necessary, move the PTO switch to the "DISENGAGED" position.

Parking Brake Engaged Indicator

This indicator illuminates when the parking brake is in the

DISENGAGED position and the ignition switch is turned to the

"START" position. Check this indicator if the engine will not crank

with the ignition switch in the "START" position. If necessary,

move the parking brake to the ENGAGED position.

This indicator also illuminates when the ignition switch is turned

to the "START" position and the RH and/or LH drive control levers

are in a position other than the fully out in neutral position. Move

the control levers fully outward.

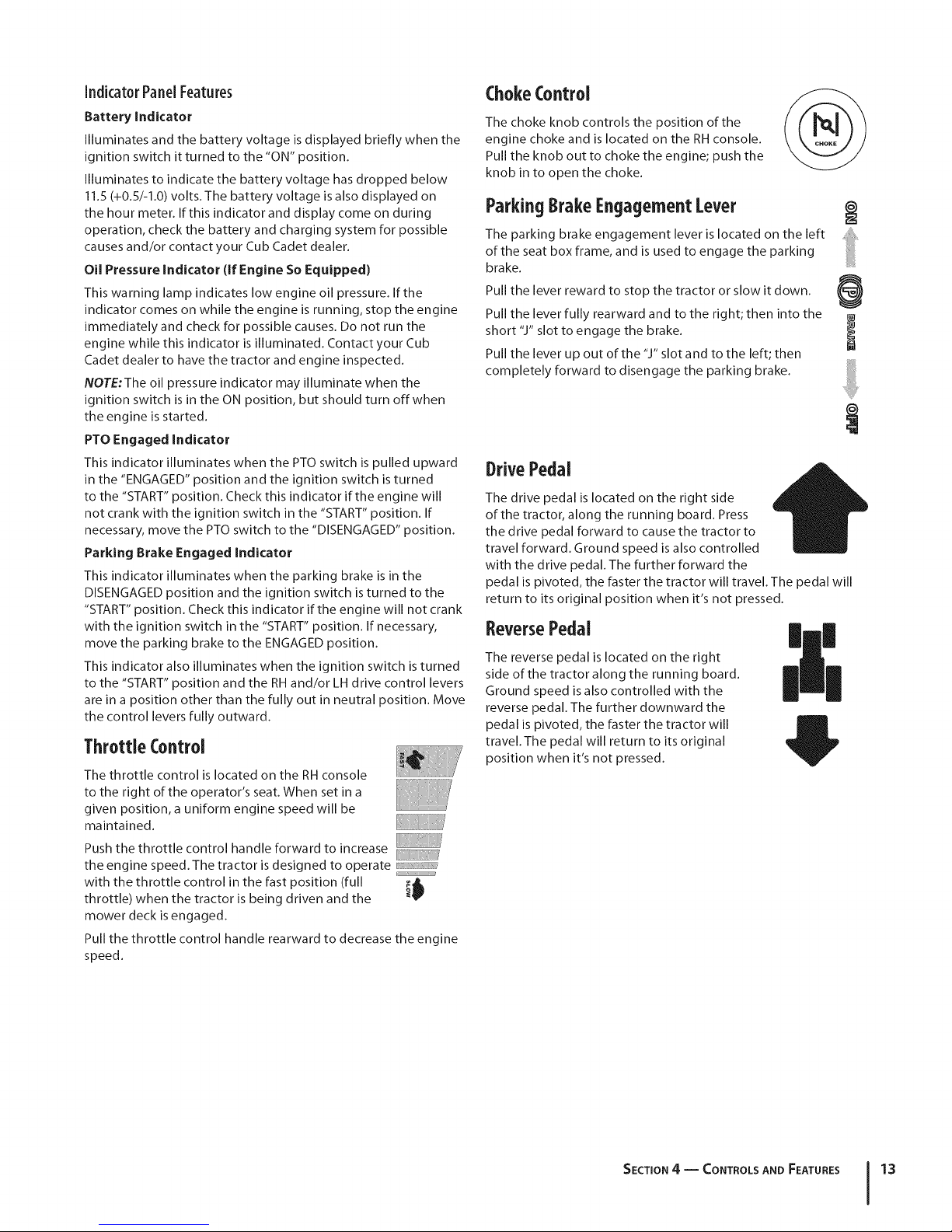

ThrottleControl

The throttle control is located on the RH console

to the right of the operator's seat. When set in a

given position, a uniform engine speed will be

maintained.

Push the throttle control handle forward to increase

the engine speed. The tractor is designed to operate

with the throttle control in the fast position (full _lh

throttle) when the tractor is being driven and the

mower deck is engaged.

Pull the throttle control handle rearward to decrease the engine

speed.

ChokeControl

The choke knob controls the position of the

engine choke and is located on the RH console.

Pull the knob out to choke the engine; push the

knob in to open the choke.

ParkingBrakeEngagementLever

The parking brake engagement lever is located on the left

of the seat box frame, and is used to engage the parking

brake.

Pull the lever reward to stop the tractor or slow it down.

Pull the lever fully rearward and to the right; then into the

short "J" slot to engage the brake.

Pull the lever up out of the "J" slot and to the left; then

completely forward to disengage the parking brake.

DrivePedal

The drive pedal is located on the right side

of the tractor, along the running board. Press

the drive pedal forward to cause the tractor to

travel forward. Ground speed is also controlled

with the drive pedal. The further forward the

pedal is pivoted, the faster the tractor will travel. The pedal will

return to its original position when it's not pressed.

ReversePedal

The reverse pedal is located on the right

side of the tractor along the running board.

Ground speed is also controlled with the

reverse pedal. The further downward the

pedal is pivoted, the faster the tractor will

travel. The pedal will return to its original

position when it's not pressed.

|

SECTION4 -- CONTROLS AND FEATURES 13

Page 14

Operation

5

GeneralSafety

RECEIVE INSTRUCTION -- Entirely read this operator's

manual. Learn to operate this machine SAFELY. Do not risk

INJURY or DEATH. Allow only those who have become

competent in its usage to operate this tractor.

Before starting the engine or beginning operation, be

familiar with the controls. The operator should be in the

operator's seat. The PTO switch must be in the disengaged

position and the parking brake engaged.

Keep all shields in place. Keep away from moving parts.

NO RIDERS! Keep all people and pets a safe distance away.

Look behind and down to both sides of the tractor before

and while backing up.

DO NOT direct the mower discharge at people.

Avoid slopes where possible. Never operate on slopes

greater than 15°. Slopes with a greater incline present

dangerous operating conditions. Tractors can be rolled

over.

Before leaving the operator's seat: Shut off the PTO and

engage the parking brake, shut off the engine and remove

the ignition key. Wait for all movement to stop before

servicing or cleaning.

Avoid any sudden movements of the steering wheel when

starting and stopping. Keep a firm grip on the steering

wheel.

Be careful when operating near roadways. Stop the tractor

motion and wait for vehicles to pass before operating

along the road.

Do not operate the tractor with the mower deck removed.

Removal of the deck will change the balance of the tractor,

and could contribute to a tractor rollover.

Avoid operation on traction surfaces that are unstable; use

extreme caution if the surface is slippery.

Slow down before turning and come to a complete stop

before any zero turn maneuver.

Do not stop the tractor or park the tractor over

combustible materials such as dry grass, leaves, debris, etc.

Do not fill the fuel tank when the engine is running or

while the engine is hot. Allow the engine several minutes

to cool before refueling. Tighten the fuel cap securely.

BeforeOperatingYourTractor

Before you operate the tractor, study this manual carefully

to familiarize yourself with the operation of all the

instruments and controls. It has been prepared to help you

operate and maintain your tractor efficiently.

This engine is certified to operate only on clean, fresh,

unleaded regular gasoline. For best results, fill the fuel

tank with only clean, fresh, unleaded gasoline with a pump

sticker octane rating of 87 or higher.

Unleaded gasoline is recommended because it leaves

less combustion chamber deposits and reduces harmful

exhaust emissions. Leaded gasoline is not recommended

and must not be used where exhaust emissions are

regulated.

NOTE: Purchase gasoline in small quantities. Do not use

gasoline left over from the previous season, to minimize

gum deposits in the fuel system.

Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline

by volume) is an approved fuel. Other gasoline/alcohol

blends are not approved.

Methyl Tertiary Butyl Ether (MTBE) and unleaded gasoline

blends (up to a maximum of 15% MTBE by volume) are

approved fuels. Other gasoline/ether blends are not

approved.

Check the engine oil level.

Clean the air cleaner element if necessary.

Check the tire inflation pressures.

Adjust the seat for operator's maximum comfort, visibility

and for maintaining complete control of the tractor.

SafetyInterlock Switches

This tractor is equipped with a safety interlock system for the

protection of the operator. If the interlock system should ever

malfunction, do not operate the tractor. Contact your Cub Cadet

dealer.

The safety interlock system prevents the engine from

cranking or starting unless the parking brake is engaged,

and the PTO (Blade Engage) knob is in the disengaged

(OFF) position.

The engine will automatically shut off if the operator leaves

the seat before engaging the parking brake.

interlock system is malfunctioning. This system was

WARNING! Do not operate the tractor if the

designed for your safety and protection.

Page 15

Startingthe Engine

WARNING! This tractor is equipped with a safety

interlock system designed for the protection of the

operator. Do not operate the tractor if any part of

the interlock system is malfunctioning. Periodically

check the functions of the interlock system for

proper operation.

WARNING! For personal safety, the operator must

be sitting in the tractor seat when starting the

engine.

NOTE: Refer to the Engine Operator's Manual for oil fill-up

instructions and refer to the Assembly & Set-Up section for

gasoline fill-up instructions.

1. Operator must be sitting in the tractor seat.

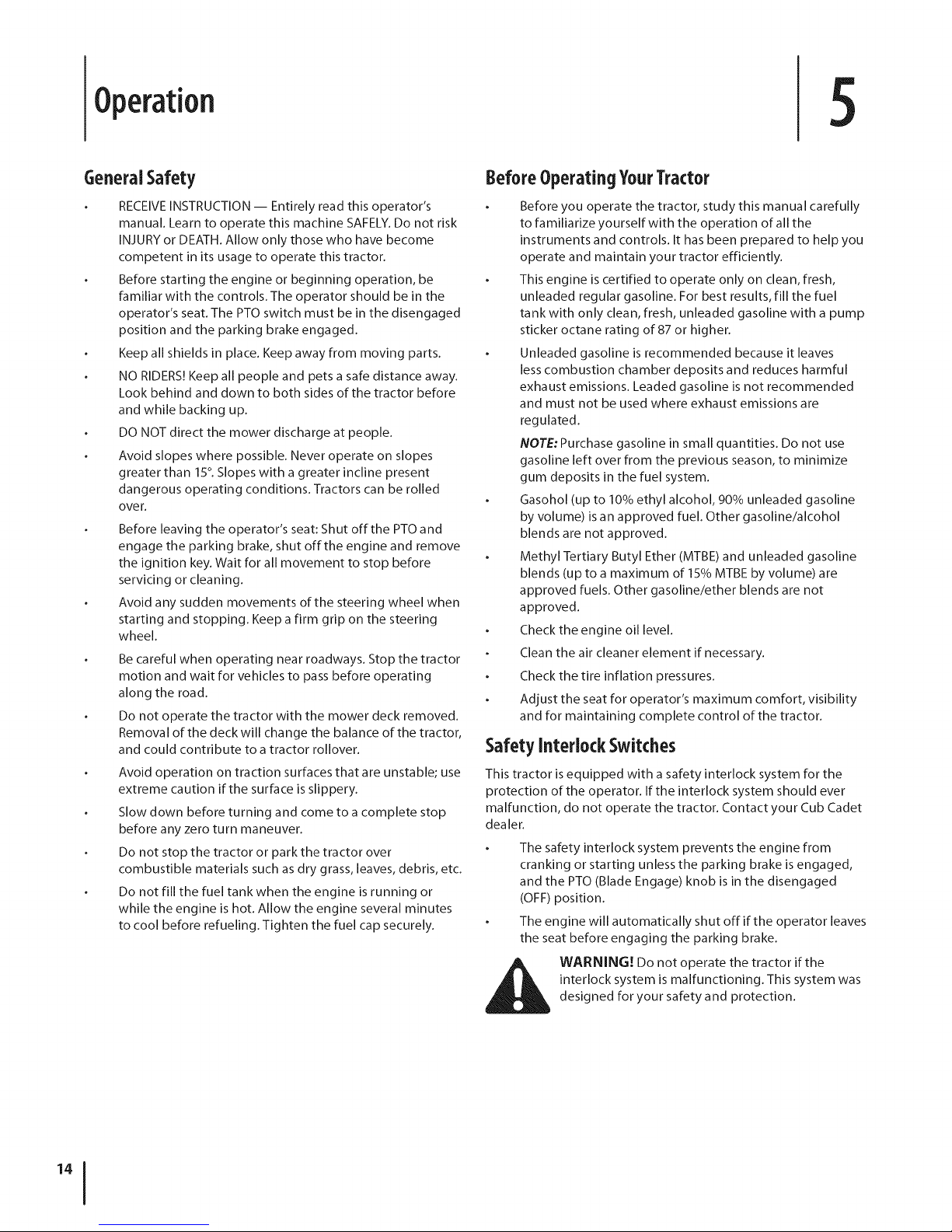

2. Engage the parking brake. Refer to Fig. 5-1.

Figure 5-1

3. Make certain the PTO switch is in the disengaged (down)

position. Refer to Fig. 5-1.

4. Pull the choke control upward into the full choke position

NOTE: If the engine is warmed up, it may not be necessary

to place the throttle control in the choke position.

5. Move the throttle control to midway between its SLOW and

FAST positions.

6. Turn the ignition key clockwise to the START position.

After the engine starts, release the key. It will return to the

NORMAL MOWING position.

CAUTION: Do NOT hold the key in the START

position for longer than ten seconds at a time. Doing

so may cause damage to your engine's electric

starter.

After the engine starts, deactivate the choke control.

NOTE: Do NOT leave the choke control on while operating

the tractor. Doing so will result in a "rich" fuel mixture and

cause the engine to run poorly.

8.

Allow the engine to run for a few minutes at mid throttle

before putting the engine under load.

9.

Observe the hour meter/indicator panel. If the battery

indicator light or oil pressure light come on, immediately

stop the engine. Have the tractor inspected by your Cub

Cadet dealen

C01dWeatherStarting

When starting the engine at temperatures near or below

freezing, ensure the correct viscosity motor oil is used in the

engine and the battery is fully charged. Start the engine as

follows:

1. Be sure the battery is in good condition. A warm battery

has much more starting capacity than a cold battery.

2. Use fresh winter grade fuel. Winter grade gasoline has

higher volatility to improve starting. Do not use gasoline

left over from summer.

3. Follow the previous instruction for Starting the Engine.

UsingJumperCablesToStart Engine

produce explosive gasses. Make certain the area is

WARNING! Batteries contain sulfuric acid and

well ventilated, wear gloves and eye protection, and

avoid sparks or flames near the battery.

If the battery charge is not sufficient to crank the engine,

recharge the battery. Ira battery charger is unavailable and

the tractor must be started, the aid of a booster battery will be

necessary. Connect the booster battery as follows:

I. Connect the end of one cable to the disabled tractor

battery's positive terminal; then connect the other end of

that cable to the booster battery's positive terminal.

2. Connect one end of the other cable to the booster

battery's negative terminal; then connect the other end of

that cable to the frame of the disabled tractor, as far from

the battery as possible.

3. Start the disabled tractor following the normal starting

instructions previously provided; then disconnect

the jumper cables in the exact reverse order of their

connection.

4.

Have the tractor's electrical system checked and repaired

as soon as possible to eliminate the need for jump starting.

Stoppingthe Engine

I. Place the PTO switch in the "OFF" position.

2. Engage the parking brake.

3. Move the throttle control to the SLOW position and allow

the engine to idle for about one minute.

4. Turn the ignition key to the "OFF" position and remove the

key from the ignition switch.

NOTE: Always remove the key from the ignition switch to prevent

accidental starting or battery discharge if the equipment is left

unattended.

SECTION S -- OPERATION 15

Page 16

DrivingTheTractor

i_lk WARNING! Avoid sudden starts, excessive speed

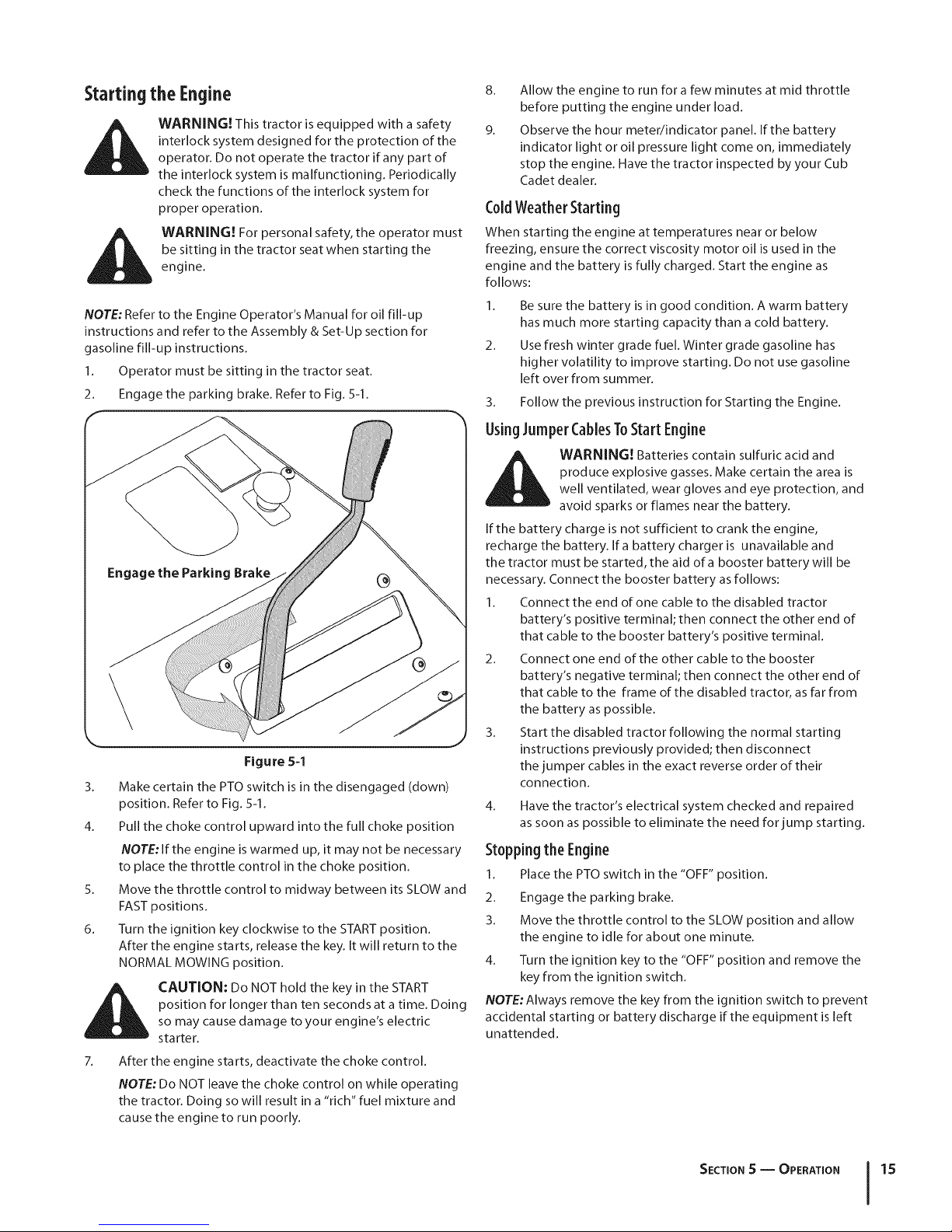

1. Release the parking brake. Move the throttle lever into the

2. To travel FORWARD, slowly press the drive pedal forward

Travel in Reverse _

and sudden stops.

FAST (rabbit) position.

until the desired speed is achieved. See Fig. 5-2.

<>

_ Travel Forward'

ReverseCautionMode

The REVERSE CAUTION MODE position of the key switch module

allows the tractor to be operated in reverse with the blades (PTO)

engaged.

NOTE: Mowing in reverse is not recommended.

the tractor in the REVERSECAUTION MODE. Always

WARNING! Use extreme caution while operating

look down and behind before and while backing. Do

not operate the tractor when children or others are

around. Stop the tractor immediately if someone

enters the area.

To use the REVERSECAUTION MODE:

NOTE:The operator MUST be seated in the tractor seat.

1. Start the engine as previously instructed on the previous

page.

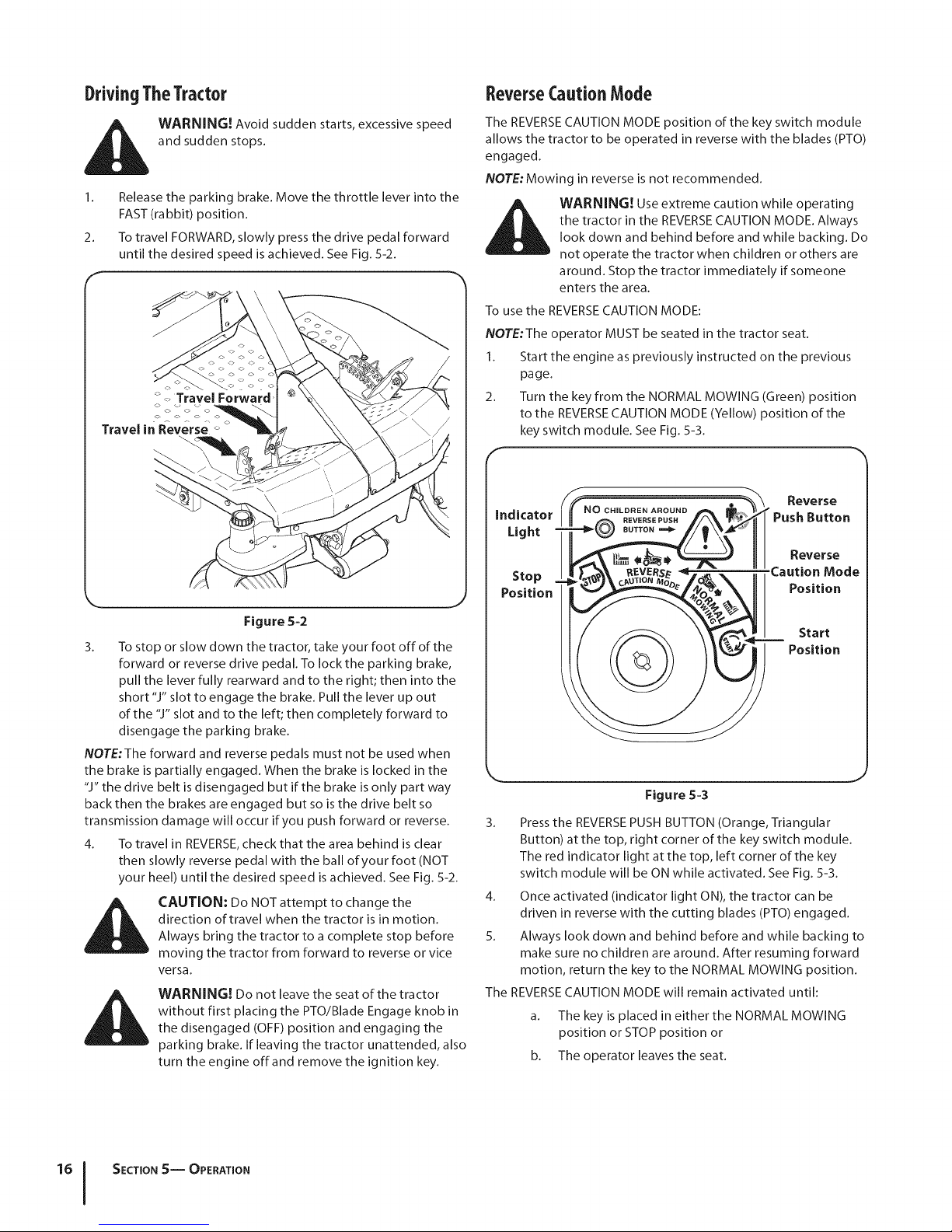

2. Turn the key from the NORMAL MOWING (Green) position

to the REVERSECAUTION MODE (Yellow) position of the

key switch module. See Fig. 5-3.

F

Figure 5-2

3. To stop or slow down the tractor, take your foot off of the

forward or reverse drive pedal. To lock the parking brake,

pull the lever fully rearward and to the right; then into the

short"J" slot to engage the brake. Pull the lever up out

of the "J" slot and to the left; then completely forward to

disengage the parking brake.

NOTE:The forward and reverse pedals must not be used when

the brake is partially engaged. When the brake is locked in the

"J" the drive belt is disengaged but if the brake is only part way

back then the brakes are engaged but so is the drive belt so

transmission damage will occur if you push forward or reverse.

4. To travel in REVERSE, check that the area behind is clear

then slowly reverse pedal with the ball of your foot (NOT

your heel) until the desired speed is achieved. See Fig. 5-2.

direction of travel when the tractor is in motion.

i_ CAUTION: Do NOT attempt to change the

Always bring the tractor to a complete stop before

moving the tractor from forward to reverse or vice

versa.

WARNING! Do not leave the seat of the tractor

without first placing the PTO/Blade Engage knob in

the disengaged (OFF) position and engaging the

parking brake. If leaving the tractor unattended, also

turn the engine offand remove the ignition key.

Indicator CHILDREN AROUND

Light BUTTON===_

Stop

Position

REVERSEPUSH

e

Reverse

PushButton

Reverse

Caution Mode

Position

Position

Start

k. j

Figure 5-3

3. Press the REVERSE PUSH BUTTON (Orange, Triangular

Button) at the top, right corner of the key switch module.

The red indicator light at the top, left corner of the key

switch module will be ON while activated. See Fig. 5-3.

4. Once activated (indicator light ON), the tractor can be

driven in reverse with the cutting blades (PTO) engaged.

5. Always look down and behind before and while backing to

make sure no children are around. After resuming forward

motion, return the key to the NORMAL MOWING position.

The REVERSE CAUTION MODE will remain activated until:

a. The key is placed in either the NORMAL MOWING

position or STOP position or

b. The operator leaves the seat.

SECTION S-- OPERATION

Page 17

DrivingOnSlopes

Refer to the SLOPE GAUGE on page 8 to help determine slopes

where you may operate the tractor safely.

i_ WARNING! Do not mow on inclines with a slope in

excess of 15 degrees (a rise of approximately 2-1/2

feet every 10 feet). The tractor could overturn and

cause serious injury.

Mow across slopes, not up and down.

Exercise extreme caution when changing direction on

slopes.

Watch for holes, ruts, bumps, rocks, or other hidden

objects. Uneven terrain could overturn the machine. Tall

grass can hide obstacles.

Do not turn on slopes unless necessary; then turn slowly

uphill and use extra care while turning. Turning up a slope

greatly increases the chance ofa rollover.

Avoid stopping when driving up a slope. If it is necessary

to stop while driving up a slope, start up smoothly and

carefully to reduce the possibility of flipping the tractor

over backward.

Mowing

WARNING! To help avoid blade contact or a

thrown object injury, keep bystanders, helpers,

children and pets at least 75 feet from the machine

while it is in operation. Stop machine if anyone

enters the area.

The following information will be helpful when using the cutting

deck with your tractor.

discharge of materials toward roads, sidewalks,

WARNING! Plan your mowing pattern to avoid

bystanders and the like. Also, avoid discharging

material against a wall or obstruction which may

cause discharged material to ricochet back toward

the operator.

Do not mowat high ground speed, especially ira mulch kit

or grass collector is installed.

Do not cut the grass too short. Short grass is prone to weed

growth and yellows quickly in dry weather.

Always operate the tractor with the throttle lever in the

FAST (rabbit) position while mowing.

For best results it is recommended that the first two laps be

cut with the discharge thrown towards the center. After the

first two laps, reverse the direction to throw the discharge

to the outside for the balance of cutting. This will give a

better appearance to the lawn.

Do NOT attempt to mow heavy brush and weeds or

extremely tall grass. Your tractor is designed to mow lawns,

NOT clear brush.

Keep the blades sharp and replace the blades when worn.

Usingthe DeckLiftPedal

Push the pedal forward until it locks into the transport position,

locking behind the notch on the front of the index plate. Remove

and replace the lock pin into the desired height index hole, then

press down on the lift pedal and slowly allow the pedal to move

back until it reaches the lock pin.

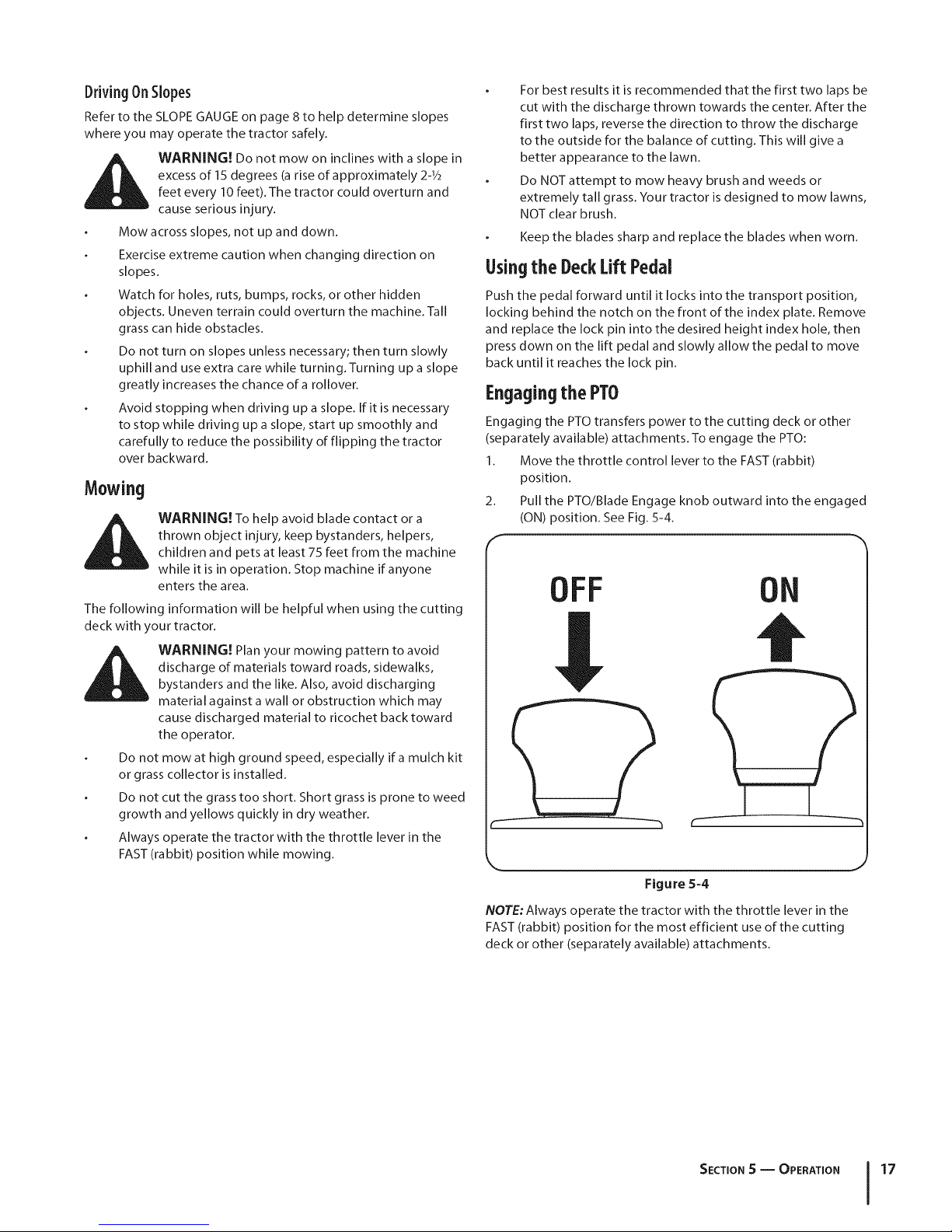

Engagingthe PTO

Engaging the PTO transfers power to the cutting deck or other

(separately available) attachments. To engage the PTO:

1. Move the throttle control lever to the FAST (rabbit)

position.

2. Pull the PTO/Blade Engage knob outward into the engaged

(ON) position. See Fig. 5-4.

OFF

ON

t

Figure 5-4

NOTE: Always operate the tractor with the throttle lever in the

FAST (rabbit) position for the most efficient use of the cutting

deck or other (separately available) attachments.

J

SECTION S -- OPERATION 17

Page 18

Maintenance&Adjustments

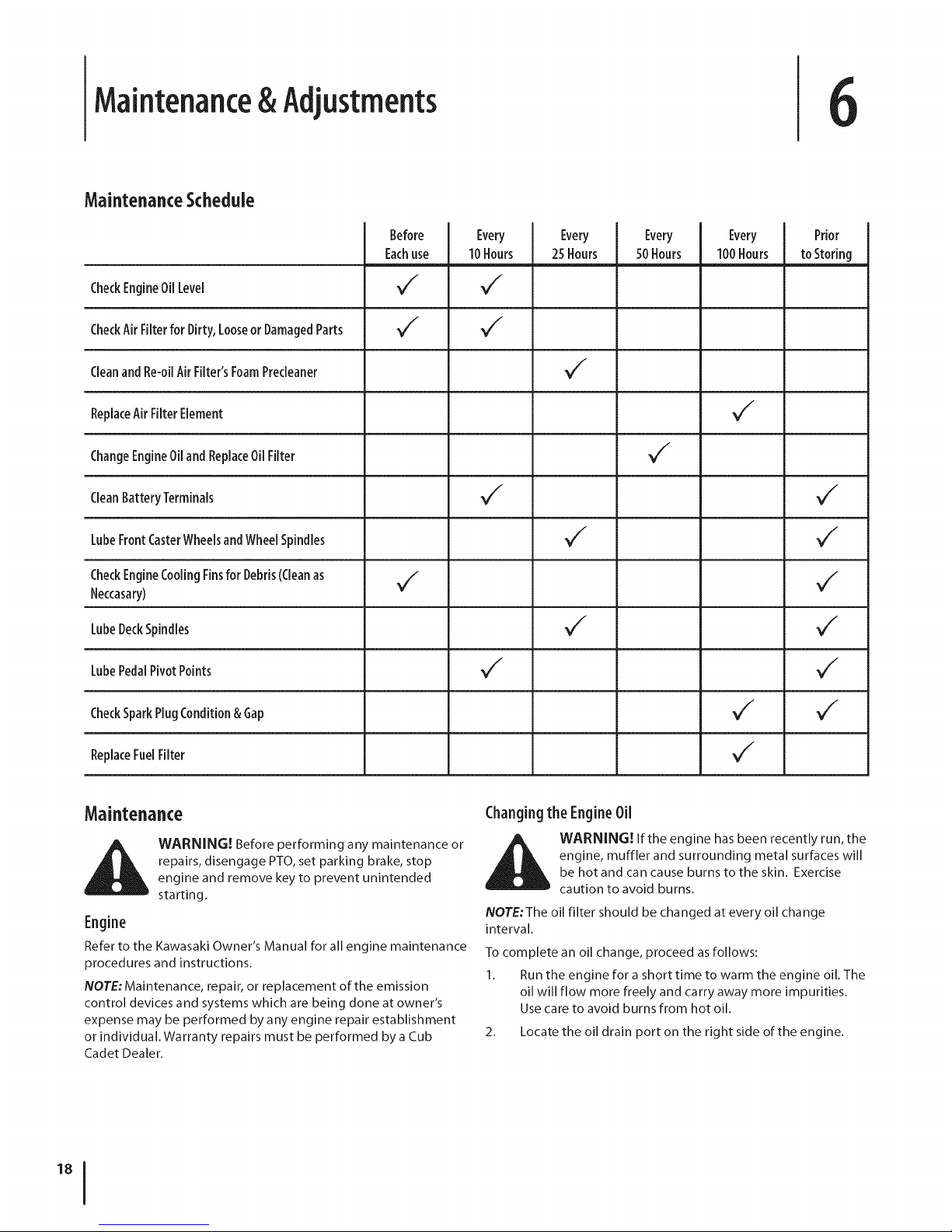

MaintenanceSchedule

6

Before

Eachuse

CheckEngineOilLevel y / y /

CheckAirFilterfor Dirty, LooseorDamagedParts _

CleanandRe-oilAirFilter'sFoamPredeaner _/

ReplaceAirFilterElement V /

ChangeEngineOiland ReplaceOilFilter _/

CleanBattery Terminals _" _"

LubeFrontCasterWheelsandWheelSpindles y / y /

CheckEngineCoolingFinsfor Debris(Cleanas V/ V/

Neccasary)

LubeDeckSpindles _

LubePedalPivotPoints _

Every

10Hours

Every

25Hours

Every

SOHours

Every

100Hours

Prior

toStoring

CheckSparkPlugCondition&Gap _

ReplaceFuelFilter

Maintenance

WARNING! Before performing any maintenance or

repairs, disengage PTO, set parking brake, stop

engine and remove key to prevent unintended

starting.

Refer to the Kawasaki Owner's Manual for all engine maintenance

procedures and instructions.

NOTE: Maintenance, repair, or replacement of the emission

control devices and systems which are being done at owner's

expense may be performed by any engine repair establishment

or individual. Warranty repairs must be performed by a Cub

Cadet Dealer.

Changingthe EngineOil

engine, muffler and surrounding metal surfaces will

_ ARNING! If the engine has been recently run, the

NOTE:The oil filter should be changed at every oil change

interval.

To complete an oil change, proceed as follows:

1. Run the engine for a short time to warm the engine oil. The

2. Locate the oil drain port on the right side of the engine.

be hot and can cause burns to the skin. Exercise

caution to avoid burns.

oil will flow more freely and carry away more impurities.

Use care to avoid burns from hot oil.

Page 19

3.

Pop open the protective cap on the end of the oil drain

valve to expose the drain port. Refer to Figure 6-1. Remove

the oil fill cap/dipstick from the oil fill tube.

Figure 6-1

4. Push the oil drain hose (packed with this manual) onto the

oil drain port. Route the opposite end of the hose into an

appropriate oil collection container with at least a 2.0 quart

capacity, to collect the used oil.

5. Turn the oil drain valve 1/4-turn, then pull outward to begin

draining oil. After the oil has finished draining, push the

end of the oil drain valve back in and turn 1/4-turn to secure

it back in place. Re-cap the end of the oil drain valve to

keep debris from entering the drain port.

6. After the oil has finished draining, push the end of the oil

drain valve back in, until the tabs click into place. Re-cap

the end of the oil drain valve to keep debris from entering

the drain port.

7. Replace the oil filter, and refill the engine with new oil as

instructed in the Kawasaki Owner's Manual.

Air (:leaner

Service the pre-cleaner and cartridge/air cleaner element as

instructed in the Kawasaki Owner's Manual.

SparkPlug(s)

The spark plug should be cleaned and the gap reset once a

season. Refer to the Kawasaki Owner's Manual for correct plug

type and gap specifications.

Hydrostatic Transmission

The hydrostatic transmission is sealed at the factory and is

maintenance-free. The fluid level cannot be checked and the

fluid cannot be changed.

Battery

Battery posts, terminals, and related accessories

CALIFORNIA PROPOSITION 65 WARNING!

contain lead and lead compounds, chemicals known

to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

The battery is sealed and is maintenance-free. Acid levels cannot

be checked and fluid can not be added.

Always keep the battery cables and terminals clean and

free of corrosive build-up.

After cleaning the battery and terminals, apply a light coat

of petroleum jelly or grease to both terminals.

disconnect the NEGATIVE (Black) wire from its

CAUTION: If removing the battery for cleaning,

terminal first, followed by the POSITIVE (Red) wire.

When re-installing the battery, always connect the

POSITIVE (Red) wire its terminal first, followed by the

NEGATIVE (Black) wire. Be certain that the wires are

connected to the correct terminals; reversing them

could result in serious damage to your engine's

alternating system.

Battery Storage

1. When storing the tractor for extended periods, disconnect

the negative battery cable. It is not necessary to remove

the battery.

2. All batteries discharge during storage. Keep the exterior

of the battery clean, especially the top. A dirty battery will

discharge more rapidly.

3. The battery must be stored with a full charge. A discharged

battery can freeze sooner than a charged battery. A fully

charged battery will store longer in cold temperatures than

hot.

4.

Recharge the battery before returning to service. Although

the tractor may start, the engine charging system may not

fully recharge the battery.

SECTION 6 -- MAINTENANCE & ADJUSTMENTS 19

Page 20

TractorStorage

If your tractor is not going to be operated for an extended period

of time (thirty days to approximately six months), the tractor

should be prepared for storage. Store the tractor in a dry and

protected location. If stored outside, cover the tractor (including

the tires) to protect it from the elements. The procedures

outlined below should be performed whenever the tractor is

placed in storage.

1. Change the engine oil and filter following the instructions

provided in the engine manual packed with this manual.

WARNING! Never store the tractor with fuel in the

tank indoors or in poorly ventilated enclosures,

where fuel fumes may reach an open flame, spark or

pilot light as on a furnace, water heater, clothes

dryer, etc.

2_

If storing the tractor for 30 days or more:

a. To prevent gum deposits from forming inside

the engine's carburetor and causing possible

malfunction of the engine, the fuel system must be

either completely emptied, or the gasoline must be

treated with a stabilizer to prevent deterioration.

WARNING! Fuel left in the fuel tank deteriorates

and will cause serious starting problems.

b. Using a fuel stabilizer:

Read the product manufacturer's instructions

and recommendations.

Add to clean, fresh gasoline the correct

amount of stabilizer for the ca pacity

(approximately 3 gallons) of the fuel system.

Fill the fuel tank with treated fuel and run the

engine for 2-3 minutes to get stabilized fuel

into the carburetor.

Emptying the fuel system:

Prior to putting the tractor in storage, monitor

fuel consumption with the goal of running

the fuel tank empty.

Run the engine until it begins to stall. Use the

choke to keep the engine running until all fuel

in the carburetor has been exhausted.

Referring to the engine manual, drain the fuel

from the carburetor bowl.

3. Clean the engine and the entire tractor thoroughly.

4. Fully charge the battery, then disconnect the negative

cable at the battery to prevent possible discharge.

Recharge the battery periodically when in storage.

NOTE: Remove the battery if exposed to prolonged periods

of sub-freezing temperatures. Store in a cool, dry location

where temperatures are above freezing.

5. Lubricate all lubrication points.

NOTE: Use a pressure washer or garden hose is not

recommended to clean your tractor. They may cause

damage to electrical components, spindles, pulleys,

bearings or the engine. The use of water will result in

shortened life and reduce serviceability.

RemovingTheTractorFromStorage

1. Check the engine oil.

2. Fully charge the battery and inflate the tires to the

recommended pressure.

3. If drained before storing, fill the fuel tank with clean, fresh

gasoline.

4. Add clean, fresh fuel.

5. Start the engine and allow to idle for a few minutes to

ensure engine is operating properly.

6. Drive the tractor without a load to make certain all the

tractor systems are functioning properly.

Cleaningthe Tractor

Any fuel or oil spilled on the machine should be wiped off

promptly. Do NOT allow debris to accumulate around the cooling

fins of the engine, the transmission's cooling fan or on any other

part of the machine, especially the belts and pulleys.

Smart JetTM

Your tractor's deck is equipped with a water port on its surface as

part of its deck wash system.

Use the Smart Jet TM to rinse grass clippings from the deck's

underside and prevent the buildup of corrosive chemicals.

Complete the following steps AFTER EACH MOWING:

1. Drive the tractor to a level, clear spot on your lawn, near

enough for your garden hose to reach.

chute is directed AWAY from your house, garage,

CAUTION: Make certain the tractor's discharge

parked cars, etc.

1. Disengage the PTO (Blade Engage), set the parking brake

and stop the engine.

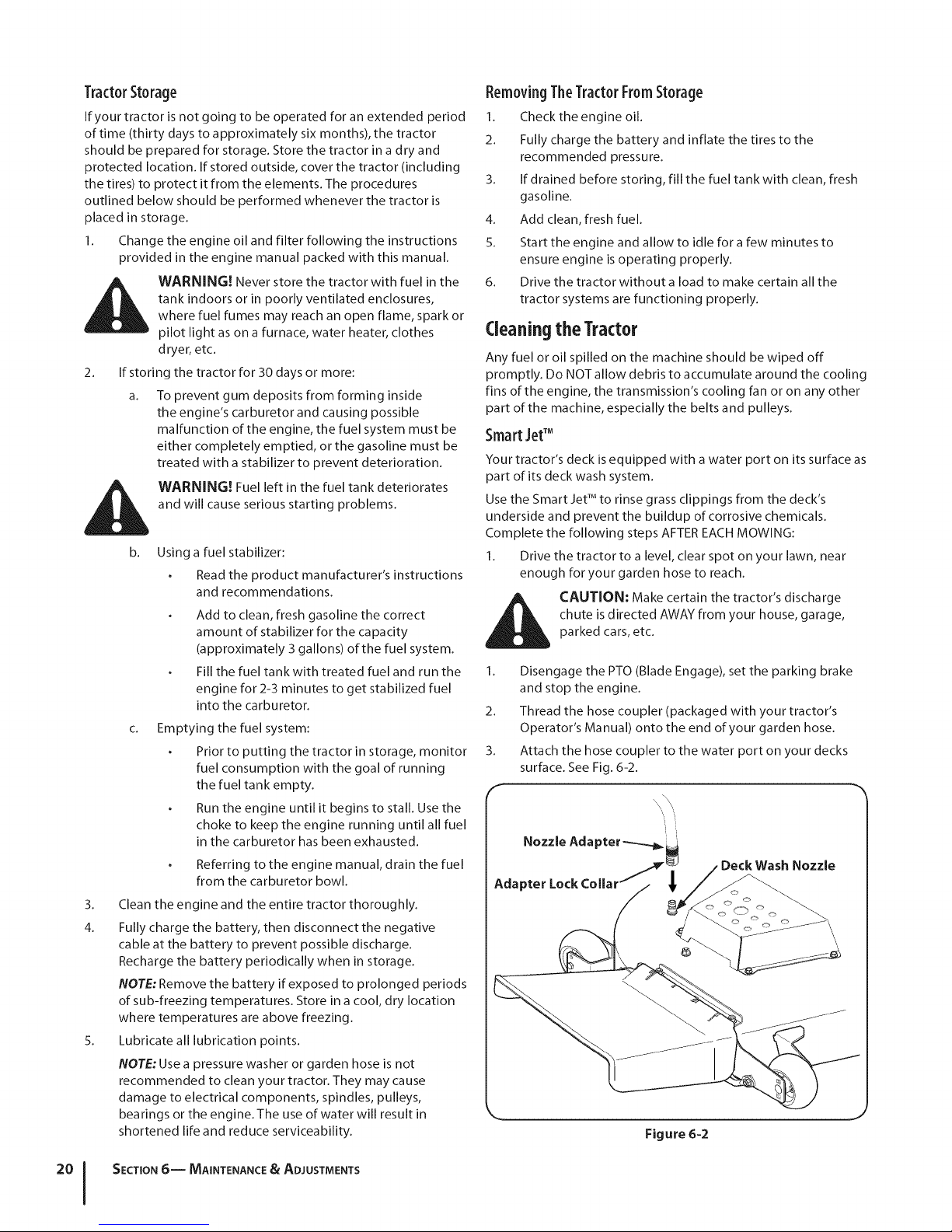

2. Thread the hose coupler (packaged with your tractor's

Operator's Manual) onto the end of your garden hose.

3. Attach the hose coupler to the water port on your decks

surface. See Fig. 6-2.

f

Nozzle Ada

Adapter

J

Figure 6-2

SECTION 6-- MAINTENANCE & ADJUSTMENTS

Page 21

4.

Turn the water on.

5.

While sitting in the operator's position on the tractor, start

the engine and place the throttle lever in the FAST (rabbit)

position.

6. Move the tractor's PTO (Blade Engage) into the ON position.

7. Remain in the operator's position with the cutting deck

engaged for a minimum of two minutes, allowing the

underside of the cutting deck to thoroughly rinse.

8. Move the tractor's PTO (Blade Engage) into the OFF

position.

9. Turn the ignition key to the STOP position to turn the

tractor's engine off.

10. Turn the water off and detach the hose coupler from the

water port on your deck's surface.

11. Repeat step 4-10 on the opposite side of the cutting deck.

After cleaning your deck with the Smart JetTM system, return to

the operator's position and engage the PTO. Keep the cutting

deck running for a minimum of two minutes, allowing the

underside of the cutting deck to thoroughly dry.

Lubrication

WARNING! Before lubricating, repairing, or

inspecting, always disengage PTO, set parking

brake, stop engine and remove key to prevent

unintended starting.

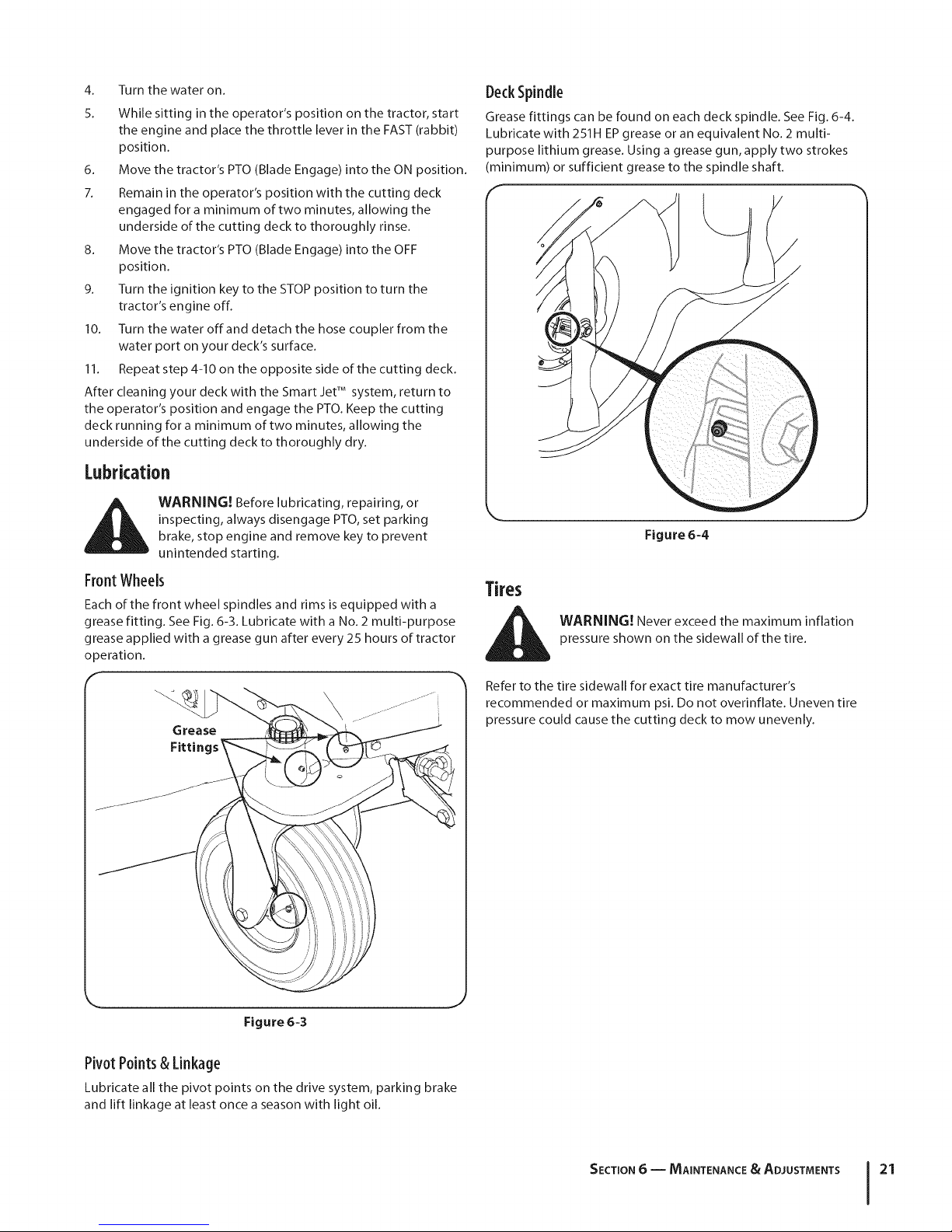

Front Wheels

Each of the front wheel spindles and rims is equipped with a

grease fitting. See Fig. 6-3. Lubricate with a No. 2 multi-purpose

grease applied with a grease gun after every 25 hours of tractor

operation.

f

_._ \_ ............i

Grease

Fittings _

DeckSpindle

Grease fittings can be found on each deck spindle. See Fig. 6-4.

Lubricate with 251H EP grease or an equivalent No. 2 multi-

purpose lithium grease. Using a grease gun, apply two strokes

(minimum) or sufficient grease to the spindle shaft.

f

Figure 6-4

WARNING! Never exceed the maximum inflation

pressure shown on the sidewall of the tire.

Refer to the tire sidewall for exact tire manufacturer's

recommended or maximum psi. Do not overinflate. Uneven tire

pressure could cause the cutting deck to mow unevenly.

k_ j

Figure 6-3

Pivot Points& Linkage

Lubricate all the pivot points on the drive system, parking brake

and lift linkage at least once a season with light oil.

SECTION 6 -- MAINTENANCE & ADJUSTMENTS 21

Page 22

Adjustments

NOTE: Check the tractor's tire pressure before performing

any deck leveling adjustments. Refer to Tires on page 21 for

information regarding tire pressure.

WARNING! Shut the engine off, remove the

ignition key and engage the parking brake before

making adjustments. Protect your hands by using

heavy gloves when handling the blades.

Levelingthe Deck(Sideto Side)

NOTE: Check the tractor's tire pressure before performing

any deck leveling adjustments. Refer to Tires on page 21 for

information regarding tire pressure. Always level the deck side to

side before front to rear.

NOTE:When leveling the deck side-to-side, make sure the two

rear adjustment gears are set in the middle of the adjustment

range.

If the cutting deck appears to be mowing unevenly, a side to side

adjustment can be performed. Adjust if necessary as follows:

1. With the tractor parked on a firm, level surface, place the

deck lift pedal in a middle mowing )osition and rotate

both outside blades so that they are perpendicular with the

tractor.

2. Measure the distance from the outside of the left blade

tip to the ground and the distance from the outside of the

right blade tip to the ground. Both measurements taken

should be equal. If they're not, proceed to the next step.

3. Loosen, but do NOT remove, the hex bolt on the front left

deck hanger link. See Fig. 6-5.

Levelingthe Deck(FrontToRear)

NOTE: Check the tractor's tire pressure before performing

any deck leveling adjustments. Refer to Tires on page 21 for

information regarding tire pressure. Always level the deck side to

side before front to rear.

The front of the deck should be between V4"and %" lower than

the rear of the deck. Adjust if necessary as follows:

1. Park the tractor on a firm, level surface and place the deck

lift pedal in a middle position.

2. Rotate the blade nearest the discharge chute so that it is

parallel with the tractor.

3. Measure the distance from the front of the blade tip to the

ground and the rear of the blade tip to the ground. The

first measurement taken should be between 1/4"and %" less

than the second measurement.

Determine the approximate distance necessary for proper

adjustment and proceed, if necessary.

4. Loosen, but do NOT remove, the hex bolt on the left and

right rear deck hanger brackets. See Fig. 6-5.

5. Using a wrench, raise or lower the left and right side of the

deck by turning the adjustment gears. See Fig. 6-5.

6. The deck is properly leveled when the front tip of the

blade is 1/4"lower tham the rear tip. Retighten the hex bolt

on the left and right rear deck hanger links when proper

adjustment is achieved.

Adjusting the Belt Tension

To tighten or loosen the tension on the belt, tighten or loosen

the jam nuts on the U-rod, see Fig. 6-6, until a ten-pound pull

with a spring scale deflects the belt about I/2".

f

\

Adj // ,

Gear / '

.......(

\ \_ \X

He× Bolt

Figure 6-5

NOTE:The front right deck hanger link is not adjustable

and is used to help adjust the other hanger links.

4. Using a wrench, raise or lower the left side of the deck by

turning the adjustment gears. See Fig. 6-5.

The deck is properly leveled when both blade tip measurements

are equal. Retighten the hex bolt on the front left deck hanger

bracket when proper adjustment is achieved.

SECTION 6-- MAINTENANCE & ADJUSTMENTS

Figure 6-6

Page 23

Setting the DeckWheels

Move the tractor on a firm and level surface, preferably

pavement, and proceed as follows

1. Select the height position of the cutting deck by placing

the deck lift pedal in the normally desired mowing height

setting.

2. Check the deck wheels for contact or excessive clearance

with the surface below. The deck wheels should have

between 1/4-1/2"clearance above the ground.

3. If the deck wheels have excessive clearance or contact with

the surface, adjust as follows:

a. Raise the deck lift pedal to its highest setting.

b. Remove the front and rear deck wheels by removing

the lock nuts and shoulder bolts which secure them

to the deck. See Fig. 6-7.

f

Deck Wheel

Parking BrakeAdjustment

If the tractor does not come to a complete stop when the brake

lever is completely engaged, or if the tractor's rea r wheels can

roll with the parking brake applied (and the hydrostatic relief

valve open), the brake is in need of adjustment. See your Cub

Cadet dealer to have the brake properly adjusted.

Adjusting the Seat

To adjust the position of the seat, push the seat adjustment lever

to the left. Slide the seat forward or rearward to the desired

position; then release the adjustment lever. Make sure seat is

locked into position before operating the tractor. See Fig. 6-8.

f

,%

Figure 6-7

C.

Place the deck lift pedal in the desired mowing

height setting.

d.

Reinsert the shoulder bolts (with each gauge wheel)

into the index hole that leaves approximately

1/2-inch between the bottom of the wheel and the

pavement.

Figure 6-8

SECTION 6 -- MAINTENANCE & ADJUSTMENTS 23

Page 24

Service

7

WARNING! Before performing any service, place

the PTO switch in the "OFF" position, engage the

parking brake lever, turn the ignition key to the

"OFF" position and remove the key from the switch.

Battery Removal

accessories contain lead and lead compounds. Wash

WARNING! Battery posts, terminals and related

hands after handling.

The battery is located beneath the seat box frame. To remove the

battery:

1. Push down and back on the battery hold-down bracket as

shown in Fig. 7-1 to free it from the seat mount frame.

Chargingthe Battery

Test and, if necessary, recharge the battery after the tractor has

been stored for a period of time.

A voltmeter or load tester should read 12.6 volts (DC) or

higher across the battery terminals. See Fig. 7-2.

Voltmeter Stateof Charging

Reading Charge Time

12.7 100% Full Charge

12.4 75% 90 Min.

12.2 50% 180 Min.

12.0 25% 280 Min.

Figure 7-2

Charge the battery with a 12-volt battery charger at a

MAXIMUM rate of 10 amps.

ServicingElectrical System

A fuse is installed to protect the tractor's electrical system from

damage caused by excessive amperage. Always use the same

capacity fuse for replacement. If the electrical system does not

function, check for a blown fuse.

If you have a recurring problem with blown fuses, have the

tractor's electrical system checked by your Cub Cadet Service

Dealer.

Figure 7=1

2. Remove the hex cap screw and sems nut securing the black

negative battery lead to the negative battery post (marked

NEG). Move the cable away from the negative battery post.

3. Remove the hex cap screw and seres nut securing the red

positive battery lead to the positive battery post (marked

POS).

4. Carefully lift the battery out of the tractor.

5. Install the battery by repeating the above steps in the

reverse order.

WARNING! Always connect the positive lead to the

battery before connecting the negative lead. This

will prevent sparking or possible injury from an

electrical short caused by contacting the tractor

body with tools being used to connect the cables.

RelaysandSwitches

There are several safety switches in the electrical system. Ira

function of the safety interlock system described earlier is not

functioning properly, have the electrical system checked by your

Cub Cadet Service Dealer.

Page 25

DeckRemoval

Remove the mower deck from the tractor as follows:

1. Move the tractor to a level surface, disengage the PTO, stop

the engine, and set the parking brake.

2. Place the deck lift pedal in the lowest mowing position and

replace the lock pin in front of pedal in the deck height

bracket and secure by locking the lock pin. See Fig. 7-3.

5.

Pull the cotter pins out of the four deck lift adjustment

brackets. See Fig. 7-5.

f.

Figure 7-5

/

/ /

/

i

Lowest

Mowing

/ Position

Highest

Mowing

Position

Figure 7-3

3.

Using a 1/2"drive in the idler pulley bracket, turn the wrench

towards the back of the tractor and slide the belt off the

PTO pulley. See Fig. 7-4.

Idler

Bracket

_ AUTION: The deck lift helper springs will cause

the click pin is not in front of the pedal.

6. Slide the links off the pins and then slide the deck out from

underneath the tractor to the right side.

NOTE: It may be easier to place the deck lift pedal in the

transport position when sliding the deck out from underneath

the tractor.

the deck lift pedal to slam to the highest position if

Figure 7-4

4. Once the belt is off the PTO pulley, slide the deck forward

and unhookthe U-Rod atthe nose of the deck.

SECTION7 -- SERVICE 2S

Page 26

DeckInstallation

Install the deck on the tractor as follows:

1. Place the deck lift pedal in the highest mowing position

and secure it by placing the click pin behind the pedal.

Refer to Fig. 7-3.

2. Slide the deck under the tractor on the right side of the

tractor lining up the deck lift adjustment brackets and the

deck lift brackets on the deck. See Fig. 7-6.

Deck Lift Adjustment Brackets

Deck Lift Brackets

5.

After all four cotter pins are secure, slide the deck forward

and hook the deck to the U-rod.

6.

Route the belt as shown in Fig. 7-8. After routing the belt

around the PTO pulley, use a 1/2"drive in the idler pulley

bracket and turn towards the back of the tractor to finish

routing the belt around the idler pulley.

Figure 7-8

J

Figure 7-6

3.

Once the deck is under the tractor, move the deck lift pedal

to the lowest mowing position.

NOTE:To make the brackets line up properly it may be

necessary to place a small block of wood under each side

of the deck.

4.

Once the brackets are properly aligned, slide the pin on the

deck lift adjustment bracket into the lift bracket and secure

with cotter pins. See Fig. 7-7.

f

/

Bracket Pin

................................. ,

/ /

o / /

/

/

/

/ j

\ \

\

7. Place the deck in the highest mowing position by removing

J

/

\

the click pin and push the pedal forward and rock back to

lock into the transport position, locking behind the notch

on the front of the index plate.

8. Refer to the Maintenance & Adjustments section to level

the deck if required.