Page 1

OPERATOR'S MANUAL

\ \

\

RZT SERIES

TRACTORS

Model Numbers

RZT 50 {w/_o"MowerDeck)

RZT 54 Iwi5_"MowerDeck)

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engfne's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). Ifa spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler isavailable through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com]

PRINTED IN U.S.A.

FORM NO. 769-02750

(10/06)

Page 2

TABLE OF CONTENTS

TRACTOR PREPARATION .................................................................................................... 2

IMPORTANT SAFE OPERATION PRACTICES .................................................................... 4

SAFETY DECALS AND LABELS ........................................................................................... 7

SLOPE GAUGE ...................................................................................................................... 8

TO THE OWNER .................................................................................................................... 9

CALLING SERVICE INFORMATION ...................................................................................... 9

RECORDING MODEL AND SERIAL NUMBER INFORMATION ........................................... 9

SECTION 1: CONTROLS AND FEATURES ......................................................................... 10

SECTION 2: OPERATION .................................................................................................... 13

SECTION 3: ADJUSTMENTS .............................................................................................. 20

SECTION 4: MAINTENANCE ............................................................................................... 21

SECTION 5: MOWER DECK ................................................................................................ 26

SECTION 6: ENGINE MANUAL ............................................................................................ 32

WARRANTIES ...................................................................................................................... 53

TRACTOR PREPARATION

Remove the upper crating material from the shipping

pallet, and cut any bands or tie straps securing the trac-

tor to the pallet.

Use the lift handle to raise the deck to its highest posi-

tion; engage the transmission bypass rods (Refer to

SECTION 1, CONTROLS AND FEATURES); and care-

fully roll the tractor off the shipping pallet. Disengage the

bypass rods.

Remove the deck wash system nozzle adapter and oil

drain tube from the manual bag and store for future use.

INSTALL OPERATOR'S SEAT

The operator's seat was partially inserted into the seat

pivot bracket for shipping purposes. To install the seat

proceed as follows:

1. Cut any straps securing the seat assembly and the

drive control levers to the tractor. Remove any

packing material.

NOTE: The seat is partially inserted into the slots of the

seat pivot bracket. If the seat does not become disen-

gaged from the pivot bracket when removing the pack-

aging material the pivot bracket may be pivoted upward

and the seat pushed into place as described in step 6. If

the seat does disengage the pivot bracket, instal the

seat as instructed in steps 2 through 6.

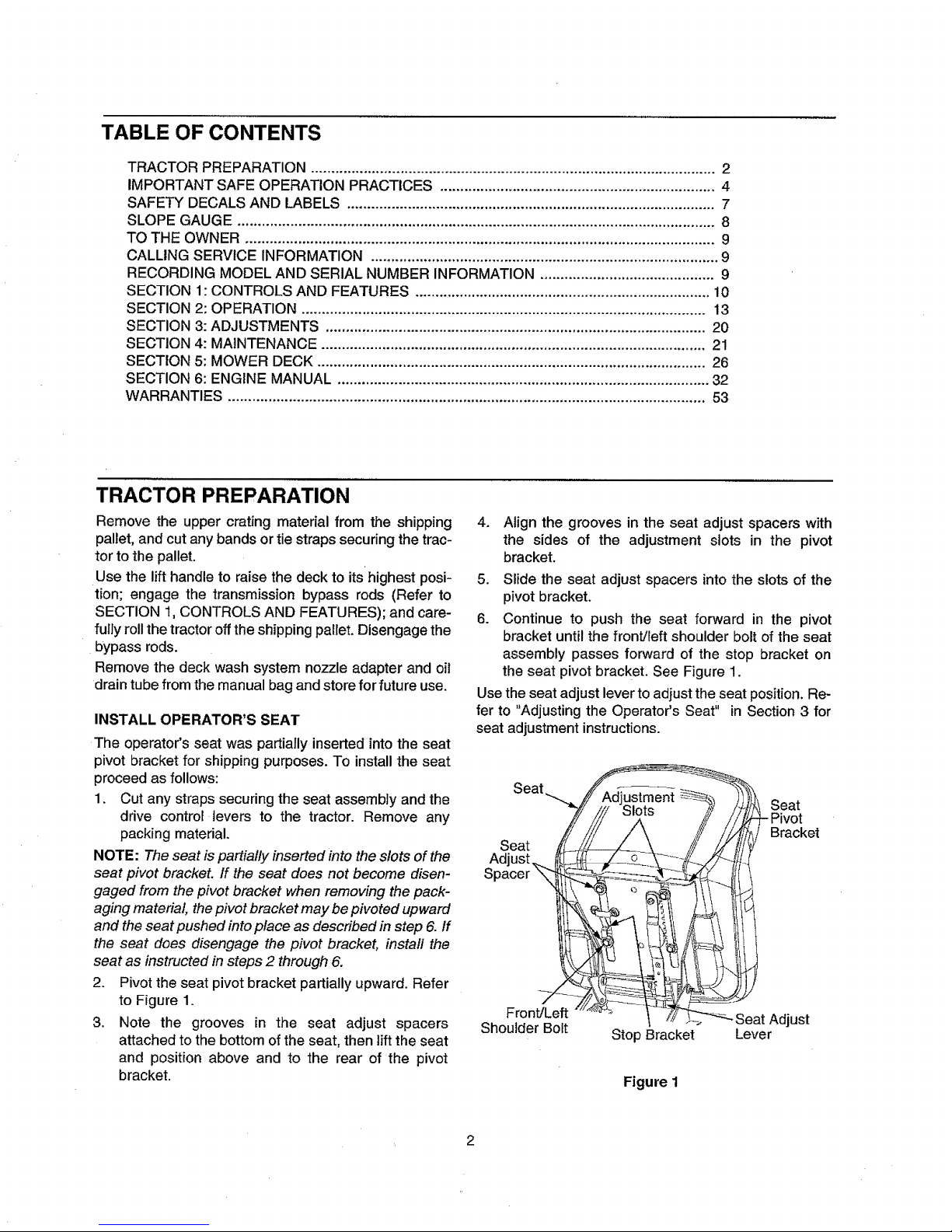

2. Pivot the seat pivot bracket partially upward. Refer

to Figure 1.

3. Note the grooves in the seat adjust spacers

attached to the bottom of the seat, then lift the seat

and position above and to the rear of the pivot

bracket.

4. Align the grooves in the seat adjust spacers with

the sides of the adjustment slots in the pivot

bracket.

5. Slide the seat adjust spacers into the slots of the

pivot bracket.

6. Continue to push the seat forward in the pivot

bracket until the front/left shoulder bolt of the seat

assembly passes forward of the stop bracket on

the seat pivot bracket. See Figure 1.

Use the seat adjust lever to adjust the seat position. Re-

fer to "Adjusting the Operator's Seat" in Section 3 for

seat adjustment instructions.

Seat

Seat

Adjust_

Spacer ",_

Seat

Bracket

Front/Left ust

Shoulder Bolt Stop Bracket Lever

Figure 1

Page 3

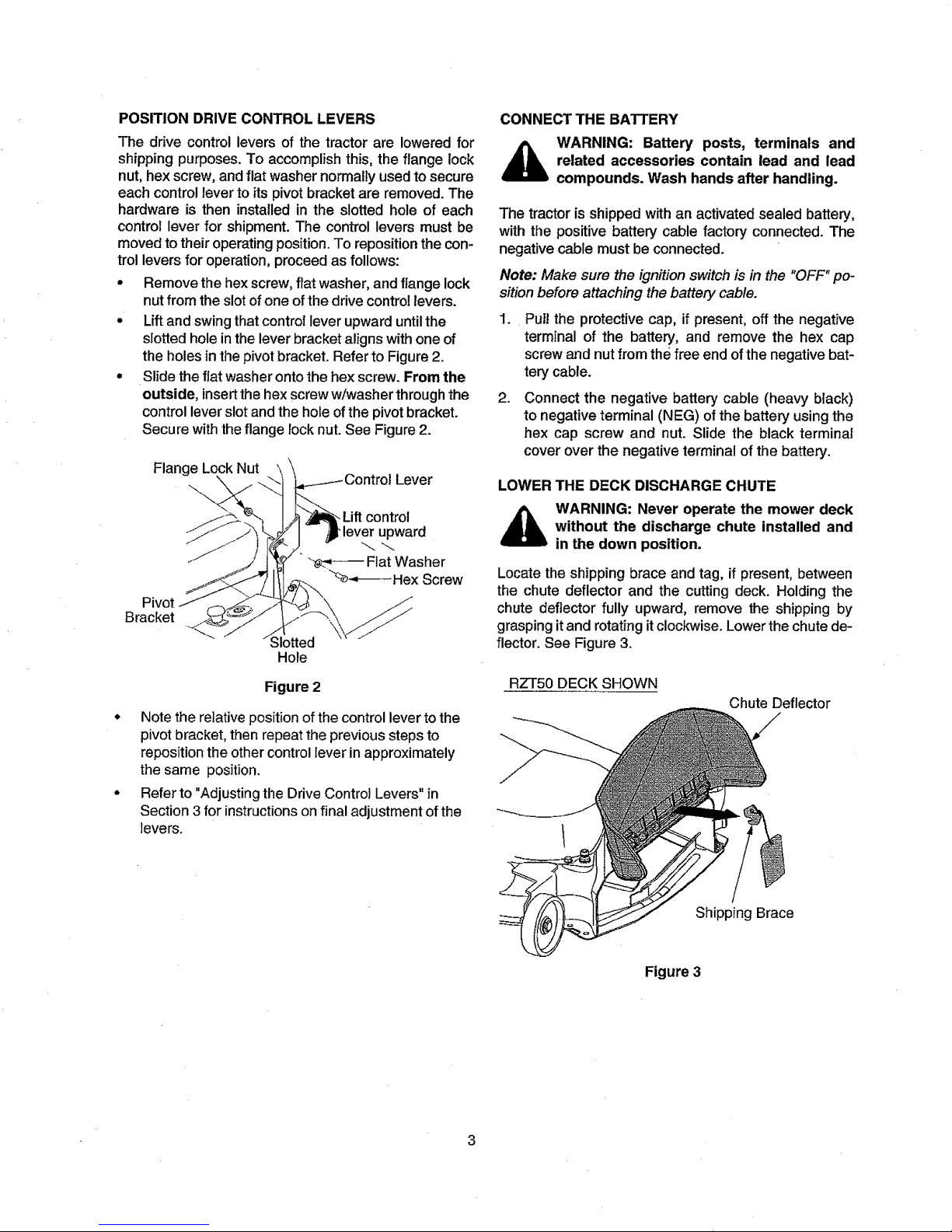

POSITION DRIVE CONTROL LEVERS

The ddve control levers of the tractor are lowered for

shipping purposes. To accomplish this, the flange lock

nut, hex screw, and flat washer normally usedto secure

each control lever to its pivot bracket are removed. The

hardware is then installedin the slotted hole of each

control lever for shipment. The control levers must be

moved to their operating position. To reposition the con-

trol levers for operation, proceed as follows:

- Remove the hex screw, flat washer, and flange lock

nutfrom the slot of one of the drive control levers.

- Lift and swing that controt lever upward until the

slotted hole in the lever bracket aligns with one of

the holes in the pivot bracket. Refer to Figure 2.

• Slide the fiat washer onto the hex screw. From the

outside, insertthe hex screw w/washer through the

control lever slot and the hole ofthe pivot bracket.

Secure with the flange rock nut. See Figure 2.

Flange Lock Nut

\ Lever

.Liftcontrol

upward

Fiat Washer

"x_*_--Hex Screw

Bracket

Slotted

Hole

Figure 2

° Note the relative position of the control lever to the

pivot bracket, then repeat the previous steps to

reposition the other control fever in approximately

the same position.

° Refer to "Adjusting the Drive Control Levers" in

Section 3 for instructions on final adjustment of the

levers.

CONNECT THE BATTERY

WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds. Wash hands after handling.

The tractor is shipped with an activated sealed battery,

with the positive battery cable factory connected. The

negative cable must be connected.

Note: Make sure the ignition switch is in the "OFF" po-

sition before attaching the battery cable.

.

,

Pull the protective cap, if present, off the negative

terminal of the battery, and remove the hex cap

screw and nut from the free end ofthe negative bat-

terycable.

Connect the negative battery cable (heavy black)

to negative terminal (NEG) of the battery using the

hex cap screw and nut. Slide the black terminal

cover over the negative terminal of the battery.

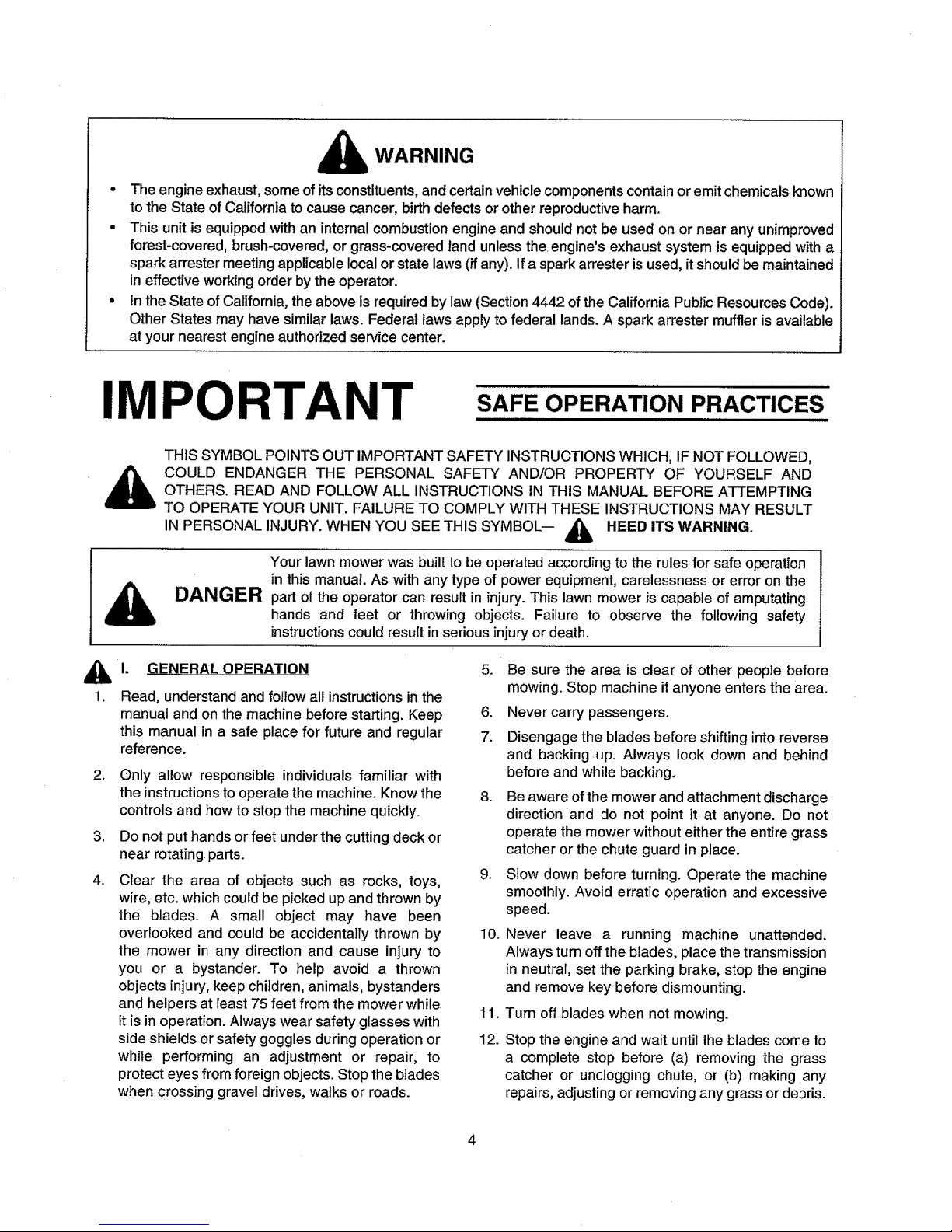

LOWER THE DECK DISCHARGE CHUTE

WARNING: Never operate the mower deck

without the discharge chute installed and

in the down position,

Locate the shipping brace and tag, if present, between

the chute deflector and the cutting deck. Holding the

chute deflector fully upward, remove the shipping by

grasping it and rotating it clockwise. Lower the chute de-

flector. See Figure 3.

RZT50 DECK SHOWN

Chute Deflector

Shipping Brace

Figure 3

3

Page 4

WARNING

• The engine exhaust, some of its constituents,andcertain vehicle components contain oremit chemicals known

to the State of California to cause cancer, birth defects or other reproductive harm.

° This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-covered, brush-covered, or grass-covered land unless the engine's exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

• in the State of California, the above is required by law (Section 4442 of the California Public Resources Code),

Other States may have similar laws, Federal laws apply to federal lands. A spark arrester muffler is available

at your nearest engine authorized service center.

IMPORTANT

SAFE OPERATION PRACTICES

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED,

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND

OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT

IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL-- A_. HEED ITS WARNING.

Your lawn mower was built to be operated according to the rules for safe operation

in this manual, As with any type of power equipment, carelessness or error on the

DANGER part of the operator can result in injury.This lawn mower is capable of amputating

hands and feet or throwing objects. Failure to observe the following safety

instructions could result in serious injury or death.

1. GENERAL OPERATION

1. Read, understand and follow all instructions in the

manual and on the machine before starting. Keep

this manual in a safe place for future and regular

reference.

2.

,

4.

Only allow responsible individuals familiar with

the instructionsto operate the machine. Know the

controls and how to stop the machine quickly.

Do not put hands or feet under the cutting deck or

near rotatingparts.

Clear the area of objects such as rocks, toys,

wire, etc. which could be picked up and thrown by

the blades. A small object may have been

overlooked and could be accidentally thrown by

the mower in any direction and cause injury to

you or a bystander. To help avoid a thrown

objects injury, keep children, animals, bystanders

and helpers at least 75 feet from the mower while

it is in operation. Always wear safety glasses with

side shields or safety goggles during operation or

while performing an adjustment or repair, to

protect eyes from foreign objects. Stop the blades

when crossing gravel drives, walks or roads.

5. Be sure the area is clear of other people before

mowing. Stop machine if anyone enters the area.

6. Never carry passengers.

7. Disengage the blades before shifting into reverse

and backing up. Always look down and behind

before and while backing.

8. Be aware of the mower and attachment discharge

direction and do not point it at anyone. Do not

operate the mower without either the entire grass

catcher or the chute guard in place.

9. Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and excessive

speed.

I0. Never leave a running machine unattended.

Always turn off the blades, place the transmission

in neutral, set the parking brake, stop the engine

and remove key before dismounting.

11.

12.

Turn off blades when not mowing.

Stop the engine and wait until the blades come to

a complete stop before (a) removing the grass

catcher or unclogging chute, or (b) making any

repairs, adjusting or removing any grass or debris.

4

Page 5

13. Mow only in daylight or good artificial light.

14. Do not operate the machine while under the

influence of alcohol or drugs.

15. Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the

machine into a trailer or truck. This unit should not

be driven up or down a ramp onto a trailer or truck

under power, because the unit could tip over

causing serious personal injury. The unit must be

pushed manually on a ramp to load or unload

properly.

17. Never make a cutting height adjustment while the

engine is running if the operator must dismount to

do so.

18.

Wear sturdy, rough-soled work shoes and close-

fitting slacks and shirts. Do not wear loose fitting

clothes or jewelry. They can be caught in moving

parts. Never operate a unit in bare feet, sandals

or sneakers.

!9. Check overhead clearance carefully before driving

under power lines, wires, bridges or low hanging

tree branches, before entering or leaving

buildings, or in any other situation where the

operator may be struck or putled from the unit,

which could result in serious injury.

20. Disengage all attachment clutches, set the

parking brake in the on position, and put the tap

bars to the neutral or out position before

attempting to start the engine.

21. Your mower is designed to cut normal residential

grass of a height no more than 10". Do not

attempt to mow through unusually tall, dry grass

(e.g. pasture) or piles of dry leaves. Debris may

build up on the mower deck or contact the engine

exhaust presenting a potential fire hazard.

22. Use only accessories approved for this machine

by Cub Cadet. Read, understand and follow all

instructions provided with the approved

accessory.

_11. SLOPE OPERATIQN

Slopes are a major factor related to loss of control and

tip-over accidents, which can result in severe injury or

death. All slopes require extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not

mow it.

For your safety, use the slope gauge included as part

of this manual to measure slopes before operating this

unit on a sloped or hilly area. If the slope is greater

than I5 ° as shown on the slope gauge, do not operate

this unit on that area or serious injury could result.

DO:

Mow across slopes, not up and down.

Keep all movement on the slopes slow and gradual.

Do not make sudden changes in speed or direction.

Rapid acceleration or deceleration could cause the

front of the machine to lift and rapidly flip over back-

wards, which could cause serious injury.

Avoid starting or stopping on a slope. If the tires are

unable to maintain traction, disengage the blades and

proceed slowly and carefully straight down the slope.

Do not mow the slope until able to maintain traction.

Use slow speed. Choose a low enough speed so that

you will not have to stop while on the slope.

Remove obstacles such as rocks, limbs, etc.

Watch for holes, ruts or bumps. Uneven terrain could

overturn the machine. Tall grass can hide obstacles.

Follow the manufacturer's recommendations for coun-

terweights with attachments to improve stability.

Use extra care with grass catchers or other attach-

ments. These can change the stability of the machine.

DO NOT:

Do not turn on slopes unless necessary; then turn

slowly and use extra care while turning.

Do not mow near drop-offs, ditches or embankments.

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

Do not mow on wet grass. Reduced traction could

cause sliding.

Do not try to stabilize the machine by putting your foot

on the ground.

Do not use the grass catcher on steep slopes.

III. CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them.

1. Keep children out of the mowing area and in

watchful care of an adult other than the operator.

2. Be alert and turn the machine off if children enter

the area.

3.

4.

Before and when backing up, took behind and

down for small children.

Never carry children, even with the blades off.

They may fall off and be seriously injured or may

interfere with safe machine operation.

Page 6

5. Never allow children under 14 years old to

operate the machine. Children 14 years and over

should only operate the machine under close

parental supervision and proper instruction.

6. Use extra care when approaching blind corners,

shrubs, trees or other objects that may obscure

your vision of a child or other hazard.

7. Remove the key when the machine is left

unattended to prevent unauthorized operation.

1.

3.

IV. SERVICE

Use extreme care in handlinggasoline and other

fuels. They are extremely flammable and the

vapors are explosive.

a. Use only an approved container.

b. Never remove fuel cap or add fuel with the en-

gine running. Allow the engine to cool at least

two minutes before refueling.

c. Replace the fuel cap securely and wipe off any

spilled fuel before starting the engine as it may

cause a fire or explosion.

d. Extinguish all cigarettes, cigars, pipes and oth-

er sources of ignition.

e. Never refuel the machine indoors because fuel

vapors will accumulate in the area.

f. Never store the fuel container or machine

inside where there is an open flame or spark,

such as a gas hot water heater, space heater

or furnace.

Never run a machine inside a closed area.

To reduce fire hazard, keep the machine free of

grass, leaves or other debris build-up. Clean up

oil or fuel spillage. Allow the machine to cool at

least 5 minutes before storing.

4. Before cleaning, repairing or inspecting, make

certain the blade and all moving parts have

stopped. Disconnect the spark plug wire, and

keep the wire away from the spark ptug to prevent

accidental starting.

5. Check the blade and engine mounting bolts at fre-

quent intervals for proper tightness. Also visually

inspect blades for damage (e.g., excessive wear,

bent, cracked). Replace with blades which meet

original equipment specifications.

6. Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

7. Never tamper with safety devices. Check their

proper operation regularly. Use all guards as

instructed in this manual.

8. After striking a foreign object, stop the engine,

remove the wire from the spark plug and

thoroughly inspect the mower for any damage.

Repair the damage before restarting and

operating the mower.

9. Grass catcher components are subject to wear,

damage and deterioration, which could expose

moving parts or altow objects to be thrown. For

your safety protection, frequently check the

components and replace with manufacturer's

recommended parts when necessary.

10. Mower blades are sharp and can cut. Wrap the

blades or wear gloves, and use extra caution

when servicing blades.

11. Check the park brake operation frequently. Adjust

and service as required.

12+Muffler, engine and belt guards become hot

during operation and can cause a burn. Allow to

cool down before touching.

13. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds

are dangerous.

14. Observe proper disposal laws and regulations.

Improper disposal of fluids and materials can

harm the environment and the ecology.

a. Prior to disposal, contact your local

Environmental Protection Agency to

determine the proper method for disposing of

the waste. Recycling centers are established

to properly dispose of materials in an

environmentally safe fashion.

b. Use proper containers when draining fluids.

Do not use food or beverage containers that

may mislead someone into drinking from

them. Properly dispose of the containers im-

mediately following the draining of fluids.

C.

DO NOT pour oil or other fluids into the

ground, down a drain or into a stream, pond,

lake, or other body of water. Observe Environ-

menta] Protection Agency regulations when

disposing of oil, fuel, coolant, brake fluid, fil-

ters, batteries, tires and other harmful waste.

15. With the exception of utilizing the deck wash

feature, we do not recommend the use of a

pressure washer or garden hose to clean your

tractor. Water may cause damage to electrical

components; pulleys; bearings; or the engine.

The use of water will result in shortened life and

reduce serviceability.

_lb WARNING - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

read, understand and follow the warnings and instructions in this manual and on the machine.

Page 7

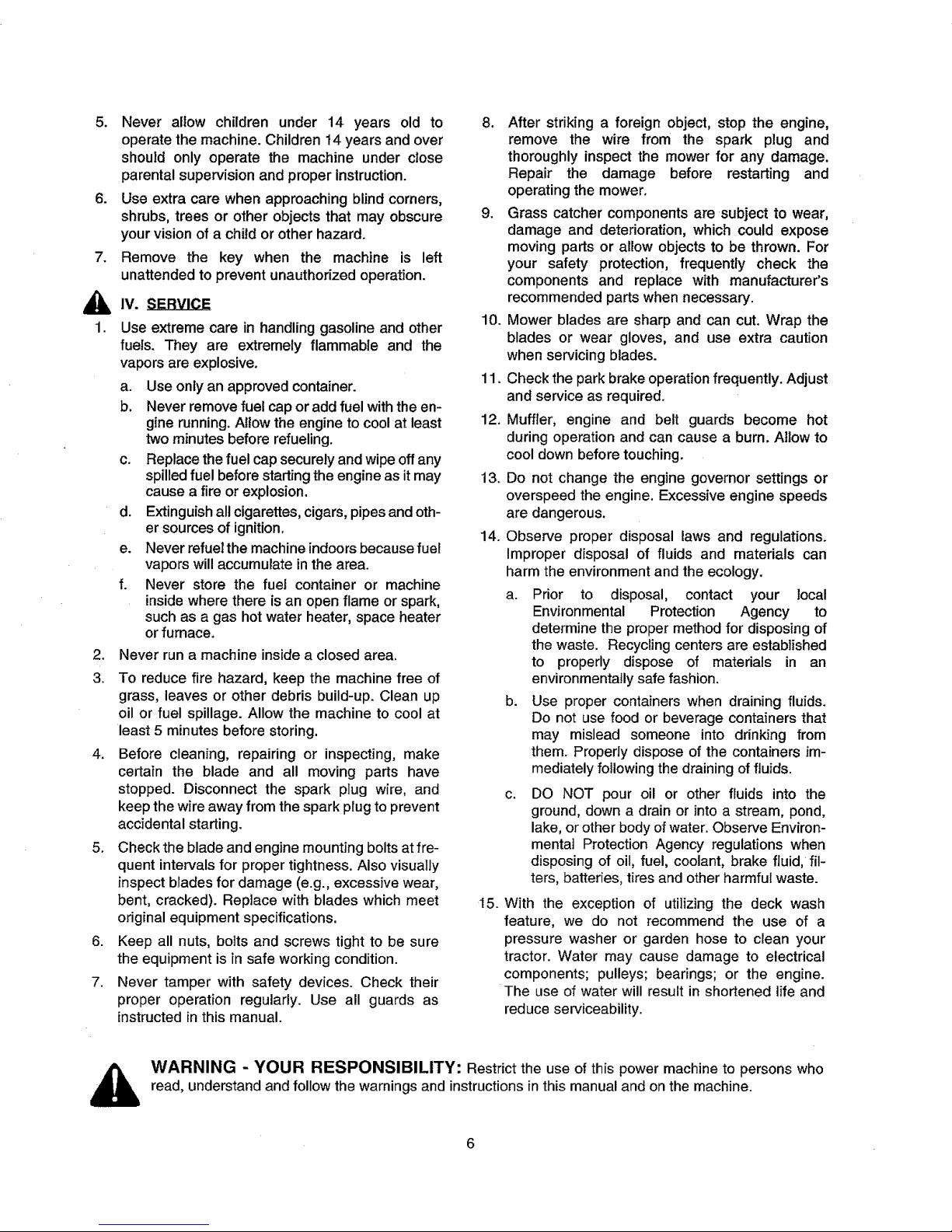

SAFETY DECALS AND LABELS

Keep product safety graphics (decals) clean. Replace any safety graphic that is damaged, destroyed, missing, paint-

ed over or can no longer be read. Replacement safety graphics are available through your dealer.

GENERAL SAFETY INSTRUCTIONS

- LOCATED ON LEFT CONSOLE

ASIDE OPERATOR'S SEAT

GENERAL OPERATING INSTRUCTIONS

- LOCATED ON RIGHT CONSOLE

ASIDE OPERATOR'S SEAT

DECK HEIGHT

INDICATOR

THROTTLE CONTROL

INDICATOR

PARK BRAKE

INDICATOR

i j

GENERAL SAFETY INSTRUCTIONS

WARNING - LOCATED IN CENTER

OF SEAT BOX FRAME

MOWER DECK

SAFETY GRAPHIC

HANDS AND FEET

SAFETY GRAPHIC

ASSEMBLE CHUTE DEFLECTOR TO THISIUNITI BEFORE OPERATING.

MOWER DECK

SAFETY GRAPHIC

MOWER DECK

INFORMATION GRAPHIC

Page 8

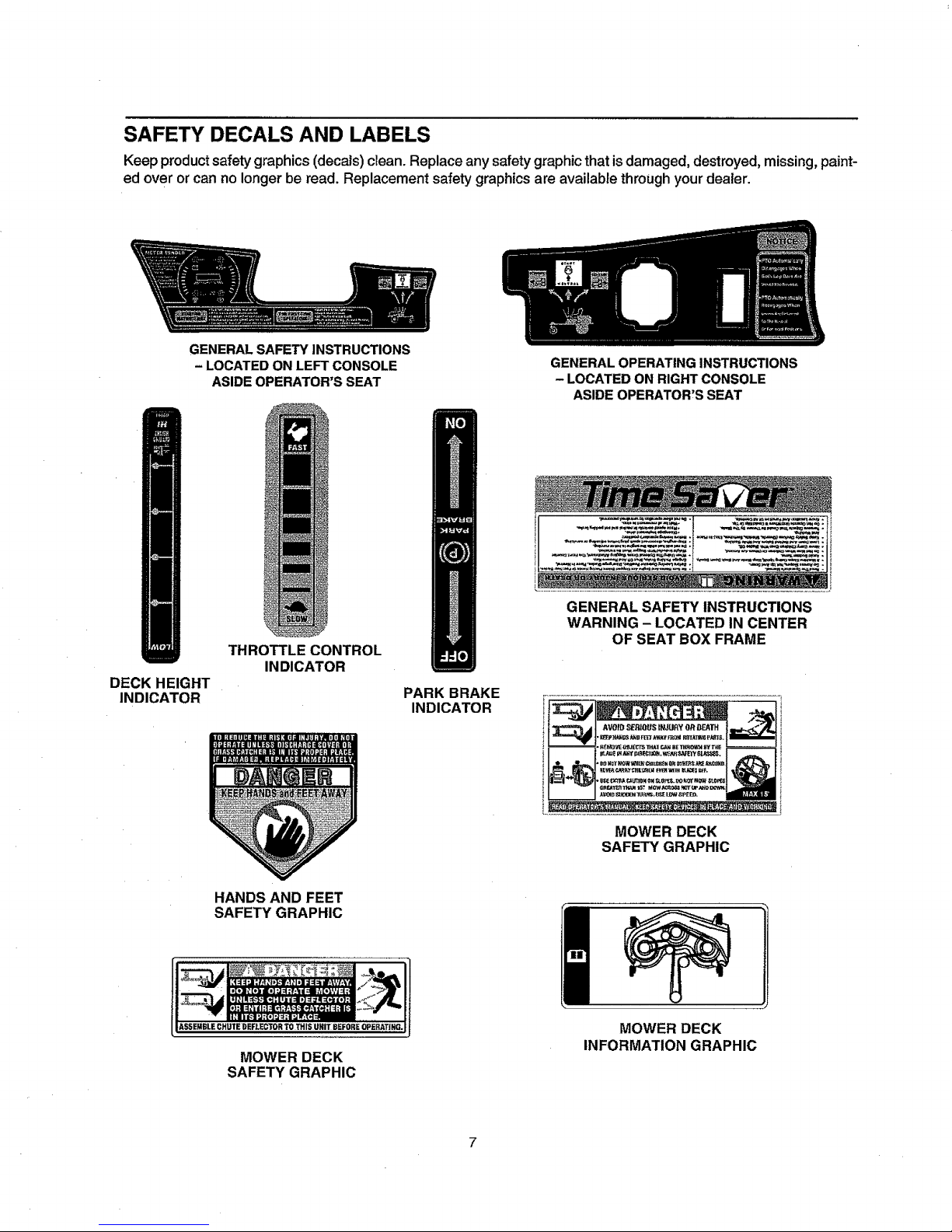

USE THIS PAGE AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

-.,d

I

Co

I

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

A POWER POLE

I _" A CORNER OF A BUILDING

| = .

| --... OR A FENCE POST

I

I _ ~ ~ u LIN,_ ,,,

..

I

I

15 °

WARNING

Do not mow on inclines with a slope in excess of 15 degrees (a rise of approximately 2-1/2 feet every 10 feet).

A riding mower could overturn and cause serious injury. ]f operating a walk-behind mower on such a slope, it is

extremely difficult to maintain your footing and you could slip, resulting in serious injury.

Operate RZT zero turn tractors across the face of slopes rather than up and down. Begin with the first pass

across the bottom of the slope and turn uphill at the end of each pass whenever possible.

=rrl

:3

P

v

Page 9

TO THE OWNER

This Operator's Manual is an importantpartof your newtractor.The informationcontained in thismanual has been

prepared in detail to help you better understand the features, correct operation, adjustments, and maintenance of

your tractor. The performance and dependability of this tractor rely greatly on the manner inwhich itis operated and

maintained. Therefore, it is recommended that all operators of the tractor carefully read this manual and fully under-

stand its operation. Also keep the manual available for reference to ensure proper operation, and that maintenance

procedures are performed as scheduled to assure the tractor's optimal mechanical condition.

NOTE: All references to LEFT, RIGHT, FRONT, and REAR, unless specifically stated otherwise, indicate that rela-

tive position on the tractor when facing forward while seated in the operator's seat.

CAUTION: DO NOT tow your RZT model tractor. Towing may damage the transmissions. Place the tractor on a

LEVEL SURFACE before pulling the transmission bypass rods to the engaged position (transmission disengaged).

Your localauthorized Cub Cadet dealer is interested in the performance you receive from your tractor, and with the

maintenance needed to ensure the satisfactory operation of your tractor. The dealer has trained service personnel

familiar with the latest servicing information, is equipped with the latest tools, and has a complete line of genuine

Cub Cadet service parts which assure properfit and high quality.

CALLING SERVICE INFORMATION

The engine manufacturer isresponsible for all engine-related issueswithregards to performance, power-rating, and

specifications.

Ifyou have difficulties with the tractor and/or equipment; have any questions regarding the operation or maintenance

of this equipment; or desire additional information not found in this manual, contact your nearest authorized Cub

Cadet dealer. If you need assistance in locating a dealer in your area, contact the Customer Dealer ReferralLine by

calling:

1-877-282-8684

Or you may contact Cub Cadet via the internet by logging on to our Web Site at:

www.cubcadet.com

To obtain top performance and assure economical operation, the tractor should be inspected by your authorized

dealer periodically or at least once a year, depending on its hours of use. Before calling your dealer, make sure that

you have your model number(s) and manufacturing date available for the dealer,

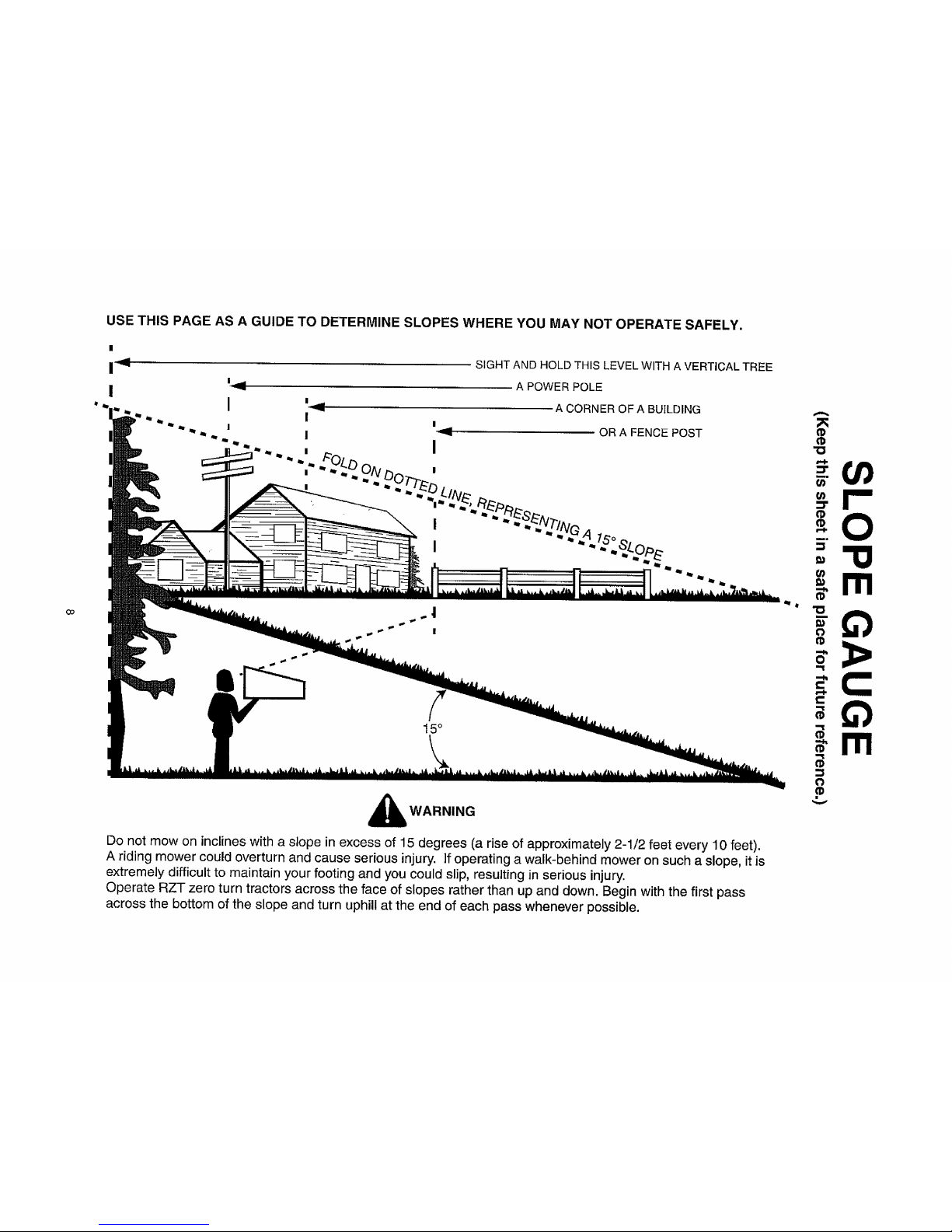

RECORDING MODEL AND SERIAL NUMBER INFORMATION

Product identification plates are provided for major components of yourtractor.The numbers on these plates are

important if your tractor should require dealer service, or ifyou need additional information on your tractor. Prior to

using your tractor for the first time, record the numbers from the identification plates in the appropriate spaces pro-

vided below.

The chassis model plate, showing the factory model number and Mfg. Date (See Figure 4) can be found either on

the underside of the seat mounting base or onthe right frame rail near the right front tire.

The engine information appears on a decal and label affixed to each side of the engine blower housing.

Model Factory Model No. Mfg. Date-S/N Delivery Date

Family I.D. Displacement Date of Mfg. Serial No.

i

XXXXXXXXXXX XXXXXXXXXX

Model Number Mfg. Date

P. O. BOX 31_1131

_Nw.cul_adst cm _, OH 4_1_

>gJ_LER LOC_70R PHON_ N UMS_J_: _77-2BZ_B_B4

i i

Figure 4

Page 10

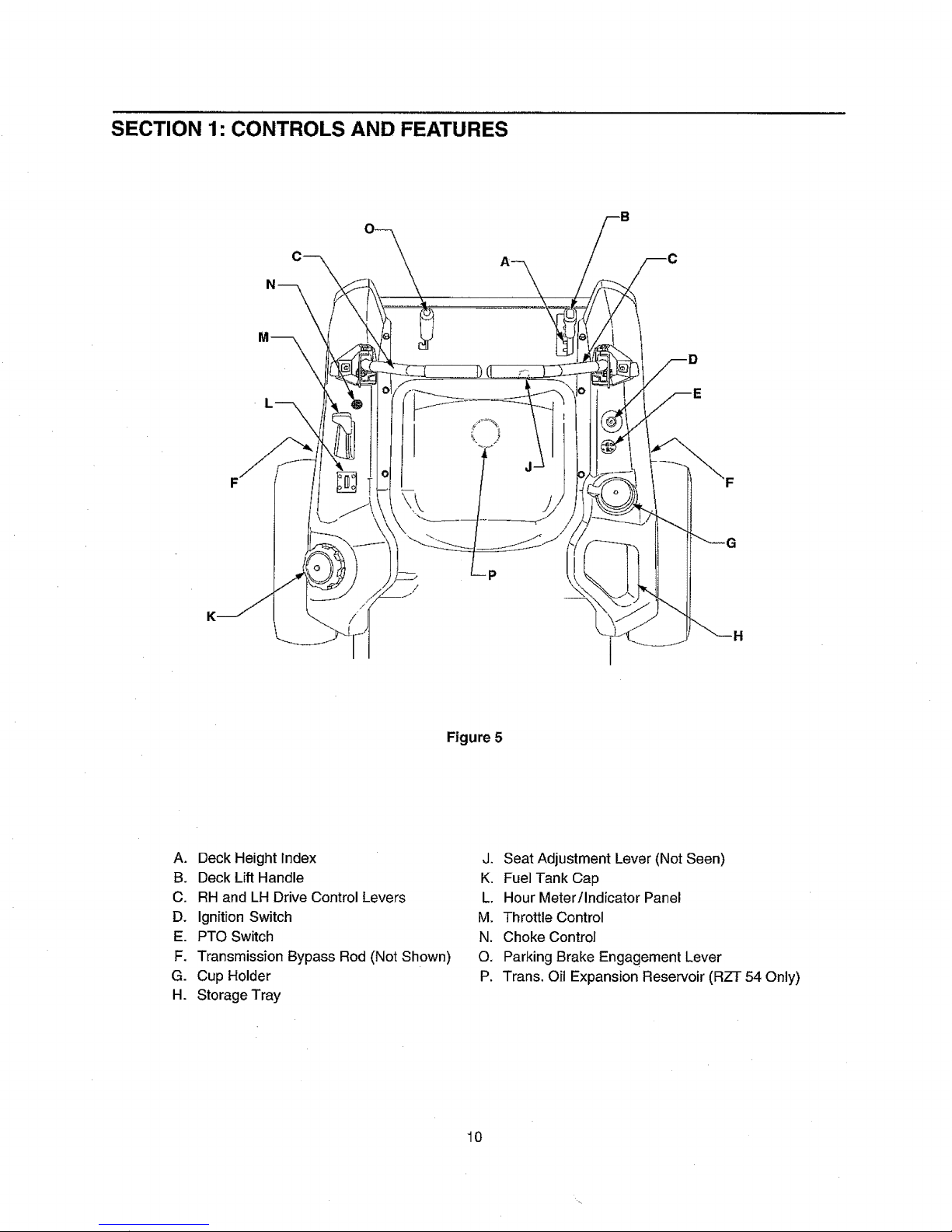

SECTION 1: CONTROLS AND FEATURES

P

/

Figure 5

A. Deck Height Index

B. Deck Lift Handle

C. RH and LH Drive Control Levers

D. Ignition Switch

E. PTO Switch

F. Transmission Bypass Rod (Not Shown)

G. Cup Holder

H. Storage Tray

J. Seat Adjustment Lever (Not Seen)

K. Fuel Tank Cap

L. Hour Meter/Indicator Panel

M. Throttle Control

N. Choke Control

O. Parking Brake Engagement Lever

P. Trans. Oil Expansion Reservoir (RZT 54 Only)

10

Page 11

NOTE: References to LEFT, RIGHT, FRONT, and

REAR indicate that position on the tractor when

facing forward while seated in the operators seat.

A. Deck Height Index

The deck height index consists of six index notches

located on the front/right of the seat box frame. Each

notch corresponds to a 1/2 inch change in the deck

height position ranging from 1-1/2 inches at the low-

est notch to 4 inches at the highest notch.

B. Deck Lift Handle

The deck lift handle is located on the front/right of the

seat box frame, and is used to raise and lower the

mower deck.

Pull the handle to the left out of the index notch and

push downward to lower the deck, or pull upward to

raise the deck. When the desired height is attained,

move the lift handle to the right until fully in the index

notch.

C. RH and LH Drive Control Levers

The RH and LH control levers are located on each

side of the operator'sseat. These hingedlevers pivot

outwardtoopenspace to permitthe operatorto either

sit in the tractor seat, or to dismountthe tractor. The

levers must be fully opened out and in the neutral

positionto start the tractorengine.

Each levercontrolsthe respective RH or LHtransmis-

sion. Consequently, these levers control all of the

movements of the tractor. Driving and steering utiliz-

ing these control levers is quite different from

conventionaltractors,and willtake some practice to

master. Refer to SECTION 2: OPERATION for

instructionson usingthe control levers.

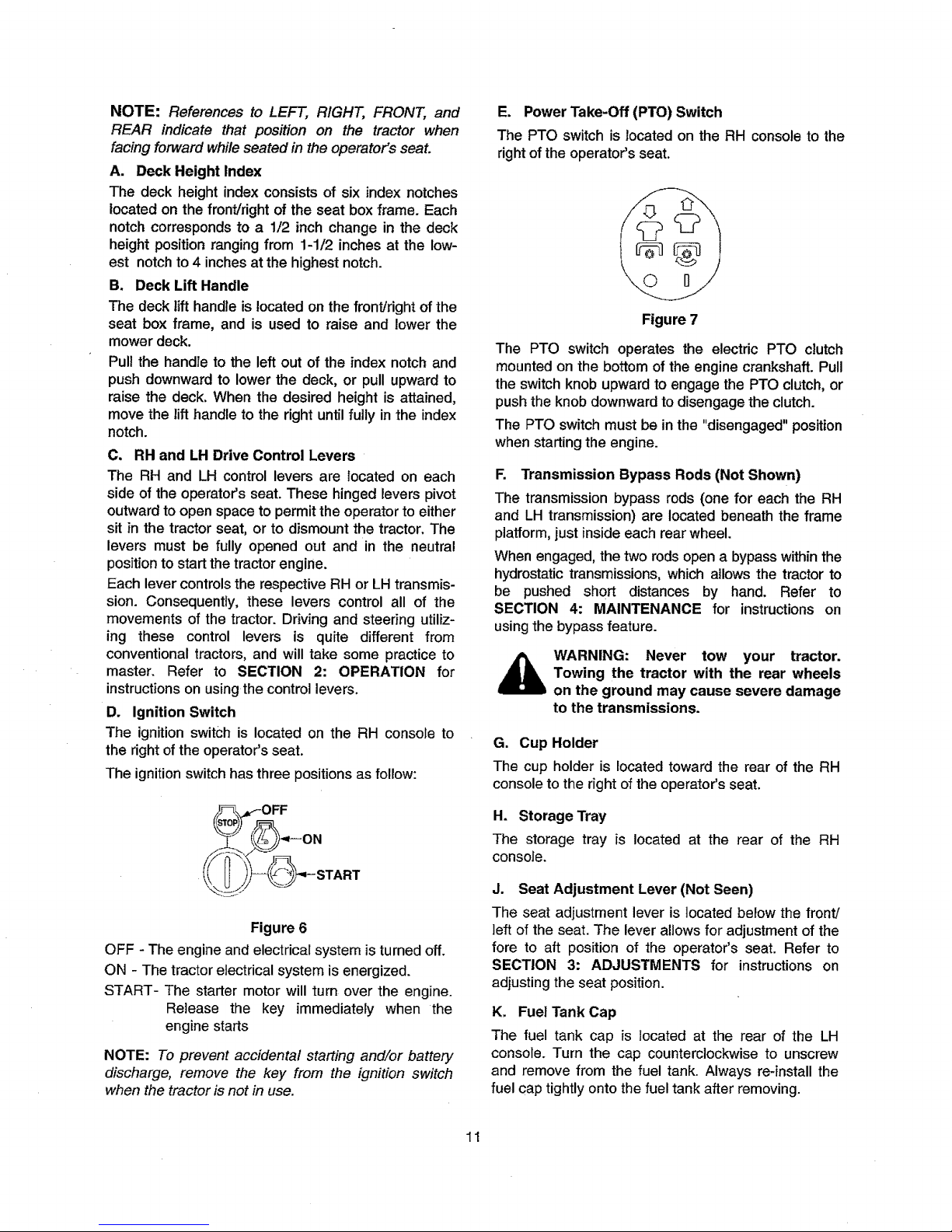

D. Ignition Switch

The ignitionswitch is located on the RH console to

the right ofthe operator'sseat.

The ignitionswitch has three positions as follow:

OFF

ON

START

Figure 6

OFF - The engine and electrical system is turned off.

ON - The tractor electrical system is energized.

START- The starter motor will turn over the engine.

Release the key immediately when the

engine starts

NOTE: To prevent accidental starting and/or battery

discharge, remove the key from the ignition switch

when the tractor is not in use.

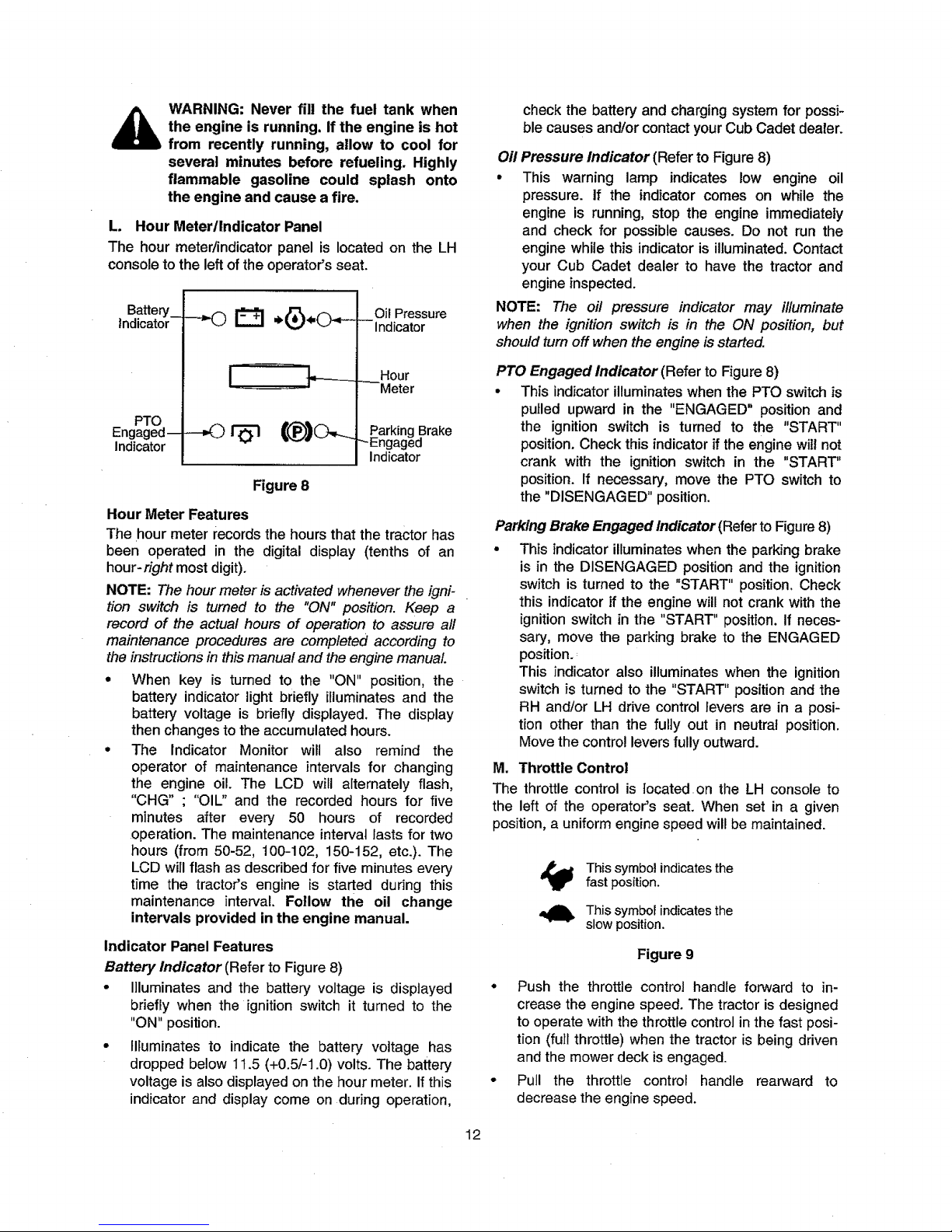

E. Power Take-Off (PTO) Switch

The PTO switch is located on the RH console to the

rightofthe operator'sseat.

Figure 7

The PTO switch operates the electric PTO clutch

mounted on the bottom of the engine crankshaft. Pull

the switch knob upward to engage the PTO clutch, or

push the knob downward to disengage the clutch.

The PTO switch must be in the "disengaged" position

when starting the engine.

R Transmission Bypass Rods (Not Shown)

The transmission bypass rods (one for each the RH

and LH transmission) are located beneath the frame

platform, just insideeach rear wheel.

When engaged, the two rods open a bypass within the

hydrostatic transmissions, which allows the tractor to

be pushed short distances by hand. Refer to

SECTION 4: MAINTENANCE for instructions on

using the bypass feature.

WARNING: Never tow your tractor.

Towing the tractor with the rear wheels

on the ground may cause severe damage

to the transmissions.

G. Cup Holder

The cup holder is located toward the rear of the RH

console to the right of the operator's seat.

H. Storage Tray

The storage tray is located at the rear of the RH

consoJe.

J. Seat Adjustment Lever (Not Seen)

The seat adjustment lever is located below the front/

left of the seat. The lever allows for adjustment of the

fore to aft position of the operator's seat. Refer to

SECTION 3: ADJUSTMENTS for instructions on

adjusting the seat position.

K. Fuel Tank Cap

The fuel tank cap is tocated at the rear of the LH

console. Turn the cap counterclockwise to unscrew

and remove from the fuel tank. Always re-install the

fuel cap tightly onto the fuel tank after removing.

11

Page 12

WARNING: Never fill the fuel tank when

the engine is running. If the engine is hot

from recently running, allow to cool for

several minutes before refueling. Highly

flammable gasoline could splash onto

the engine and cause a fire.

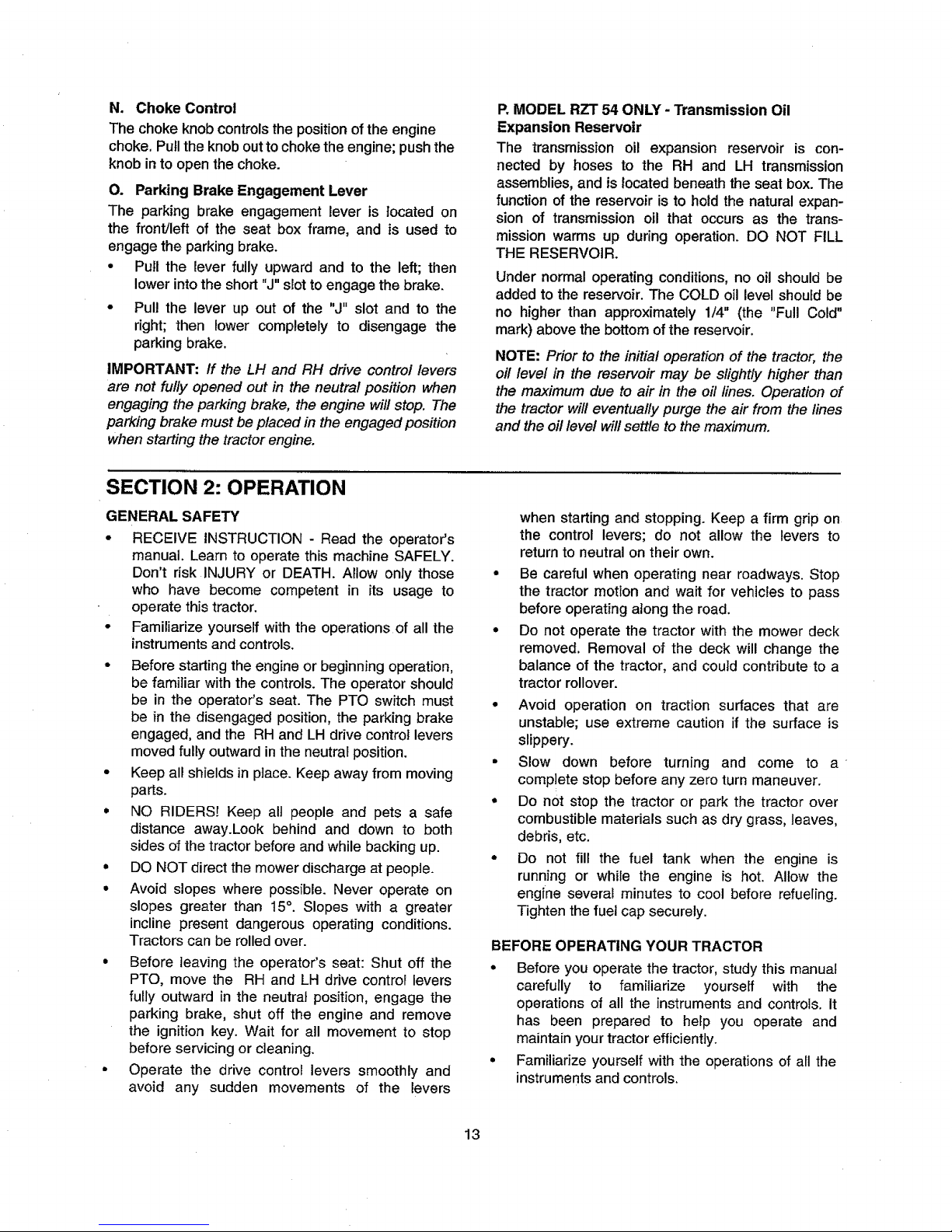

L. Hour Meter/Indicator Panel

The hour meter/indicator panel is located on the LH

consoleto the left of the operator'sseat.

Battery_

indicator

PTO

Engaged--

Indicator

Oil Pressure

Indicator

Hour

_Meter

Parking Brake

_Engaged

Indicator

Figure 8

Hour Meter Features

The hour meter records the hours that the tractor has

been operated in the digital display (tenths of an

hour-right most digit).

NOTE: The hour meter is activated whenever the igni-

tion switch is turned to the "ON" position. Keep a

record of the actual hours of operation to assure all

maintenance procedures are completed according to

the instructions in this manual and the engine manual

• When key is turned to the "ON" position, the

battery indicator light briefly illuminates and the

battery voltage is briefly displayed. The display

then changes to the accumulated hours.

• The Indicator Monitor will also remind the

operator of maintenance intervals for changing

the engine oil. The LCD will alternately flash,

"CHG" ; "OIL" and the recorded hours for five

minutes after every 50 hours of recorded

operation. The maintenance interval lasts for two

hours (from 50-52, 100-102, 150-152, etc.). The

LCD will flash as described for five minutes every

time the tractor's engine is started during this

maintenance interval. Follow the oil change

intervals provided in the engine manual.

Indicator Panel Features

Battery Indicator (Refer to Figure 8)

• Illuminatesand the battery voltage is displayed

briefly when the ignition switch it turned to the

"ON" position.

• Illuminates to indicate the battery voltage has

dropped below 11.5 (+0.5/-1.0) volts. The battery

voltageis also displayed on thehour meter. Ifthis

indicator and display come on during operation,

check the battery and charging system for possi-

ble causes and/orcontact your Cub Cadet dealer.

Oil Pressure Indicator (Refer to Figure 8)

° This warning lamp indicates low engine oil

pressure. If the indicator comes on while the

engine is running, stop the engine immediately

and check for possible causes. Do not run the

engine while this indicatoris illuminated.Contact

your Cub Cadet dealer to have the tractor and

engine inspected.

NOTE: The oil pressure indicator may illuminate

when the ignition switch is in the ON position, but

should turn off when the engine is started.

PTO Engaged Indicator (Refer to Figure 8)

• This indicatorilluminates when the PTO switch is

pulled upward in the "ENGAGED" positionand

the ignition switch is turned to the "START"

position. Check this indicator if the enginewillnot

crank with the ignition switch in the "START"

position.If necessary, move the PTO switch to

the "DISENGAGED" position.

Parking Brake Engaged Indicator (Refer to Figure 8)

• This indicatorilluminateswhen the parkingbrake

is in the DISENGAGED positionand the ignition

switch is turned to the "START" position, Check

this indicatorif the engine willnot crank withthe

ignition switch in the "START" position. If neces-

sary, move the parking brake to the ENGAGED

position._

This indicator also illuminateswhen the ignition

switch }s turned to the "START" position and the

RH and/or LH drive controllevers are in a posi-

tion other than the fully out in neutral position.

Movethe controlleversfullyoutward.

M. Throttle Control

The throttle control is located on the LH console to

the left of the operator's seat. When set in a given

position, a uniform engine speed will be maintained.

This symbol indicatesthe

fast position.

This symbol indicates the

slow position.

Figure 9

• Push the throttle control handle forward to in-

crease the engine speed. The tractor is designed

to operate with the throttle control in the fast posi-

tion (full throttle) when the tractor is being driven

and the mower deck is engaged.

• Pull the throttle controf handle rearward to

decrease the engine speed.

12

Page 13

N. Choke Control

The choke knobcontrolsthe positionof the engine

choke.Pulltheknobouttochoke the engine; pushthe

knobinto open the choke.

O. Parking Brake Engagement Lever

The parking brake engagement lever is located on

the front/left of the seat box frame, and is used to

engage the parkingbrake.

• Pull the lever fully upward and to the left; then

lowerintothe short "J" slot toengage the brake.

• Pul! the lever up out of the "J" slot and to the

right; then lower completely to disengage the

parkingbrake.

IMPORTANT: If the LH and RH drive control levers

are not fully opened out in the neutral position when

engaging the parking brake, the engine will stop. The

parking brake must be placed in the engaged position

when starting the tractor engine.

P.MODEL RZT 54 ONLY - Transmission Oil

Expansion Reservoir

The transmission oil expansion reservoir is con-

nected by hoses to the RH and LH transmission

assemblies, and is located beneath the seat box. The

function of the reservoir is to hold the natural expan-

sion of transmission oil that occurs as the trans-

mission warms up during operation. DO NOT FILL

THE RESERVOIR.

Under normal operating conditions, no oil should be

added to the reservoir. The COLD oil level shoufd be

no higher than approximately 1/4" (the "Full Cold"

mark) above the bottom of the reservoir.

NOTE: Prior to the initia! operationof the tractor, the

oil level in the reservoir may be slightly higher than

the maximum due to air in the oil lines. Operation of

the tractor will eventually purge the air fromthe fines

and the oil level will settle to themaximum.

SECTION 2: OPERATION

GENERAL SAFETY

• RECEIVE INSTRUCTION - Read the operator's

manual. Learn to operate this machine SAFELY.

Don't risk iNJURY or DEATH. Allow only those

who have become competent in its usage to

operate this tractor.

• Familiarize yourself with the operations of all the

instruments and controls.

• Before starting the engine or beginning operation,

be familiar with the controls. The operator should

be in the operator's seat. The PTO switch must

be in the disengaged position, the parking brake

engaged, and the RH and LH drive control levers

moved fully outward in the neutral position.

• Keep all shields in place. Keep away from moving

parts.

• NO RIDERS! Keep all people and pets a safe

distance away.Look behind and down to both

sides of the tractor before and while backing up.

• DO NOT direct the mower discharge at people.

• Avoid slopes where possible. Never operate on

slopes greater than 15°. Slopes with a greater

incline present dangerous operating conditions.

Tractors can be rolled over.

• Before leaving the operator's seat: Shut off the

PTO, move the RH and LH drive control levers

fully outward in the neutral position, engage the

parking brake, shut off the engine and remove

the ignition key. Wait for all movement to stop

before servicing or cleaning.

• Operate the drive control levers smoothly and

avoid any sudden movements of the levers

when starting and stopping. Keep a firm grip on

the control levers; do not allow the levers to

return to neutral on their own.

• Be careful when operating near roadways. Stop

the tractor motion and wait for vehicles to pass

before operating along the road.

• Do not operate the tractor with the mower deck

removed. Removal of the deck will change the

balance of the tractor, and could contribute to a

tractor rollover.

• Avoid operation on traction surfaces that are

unstable; use extreme caution if the surface is

slippery.

° Slow down before turning and come to a

complete stop before any zero turn maneuver.

• Do not stop the tractor or park the tractor over

combustible materials such as dry grass, leaves,

debris, etc.

• Do not fill the fuel tank when the engine is

running or while the engine is hot. Allow the

engine several minutes to cool before refueling.

Tighten the fuel cap securely.

BEFORE OPERATING YOUR TRACTOR

• Before you operate the tractor,study this manual

carefully to familiarize yourself with the

operationsof all the instruments and controls. It

has been prepared to help you operate and

maintain yourtractor efficiently.

• Familiarize yourself with the operationsof all the

instruments and controls.

13

Page 14

• This engine is certified to operate only on clean,

fresh, unleaded regular gasoline. For best results,

fill the fuel tank with only clean, fresh, unleaded

gasoline with a pump sticker octane rating of 87

or higher.

• Unleaded gasoline is recommended because it

leaves less combustion chamber deposits and

reduces harmful exhaust emissions. Leaded

gasoline is not recommended and must not be

used where exhaust emissions are regulated.

NOTE: Purchase gasoline in small quantities. Do not

use gasoline left over from the previous season, to

minimize gum deposits in the fuel system.

• Gasohol (up to 10% ethyl alcohol, 90% unleaded

gasoline by volume) is an approved fuel. Other

gasoline/alcohol blends are not approved.

• Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a maximum of 15% MTBE

by volume) are approved fuels. Other gasoline/

ether blends are not approved.

• Check the engine oil level.

• Clean the air cleaner element if necessary.

• Check the tire inflation pressures.

• Adjust the seat for operator's maximum comfort,

visibility and for maintaining complete control of

the tractor.

SAFETY INTERLOCK SYSTEM

This tractor is equipped with a safety interlock system

for the protection of the operator. If the interlock

system should ever malfunction, do not operate the

tractor. Contact your authorized Cub Cadet Dealer.

• The safety interlock system prevents the engine

from cranking or starting unless the RH and LH

drive control levers are moved fully outward in the

neutral position, the parking brake is engaged,

and the PTO is disengaged.

• To avoid sudden movement when disengaging

the parking brake, the safety interlock system will

shut off the engine if the RH and/or LH drive

control levers are moved to a position other than

the fully out in neutral position when the parking

brake is engaged

• The safety interlock system will shut off the

engine if the operator leaves the seat before

engaging the parking brake.

• The safety interlock system will shut off the

engine if the operator leaves the seat with the

PTO engaged, regardless of whether the parking

brake is engaged.

NOTE: The PTO switch must be moved to the

"OFF" position to restart the engine.

The safety interlocksystem will shut off the PTO

and the mower blades will stop if both drive con-

trol levers are moved into the reverse position.

The PTO will re-engage when one or both of the

levers are moved back to the neutral or forward

position.

STARTING THE ENGINE

WARNING: This unit is equipped with a

safety interlock system designed for the

protection of the operator. Do not oper-

ate the tractor if any part of the interlock

system is malfunctioning. Periodically

check the functions of the interlock sys-

tem for proper operation.

_1 WARNING: For personal safety, the

operator must be sitting in the tractor

seat when starting the engine.

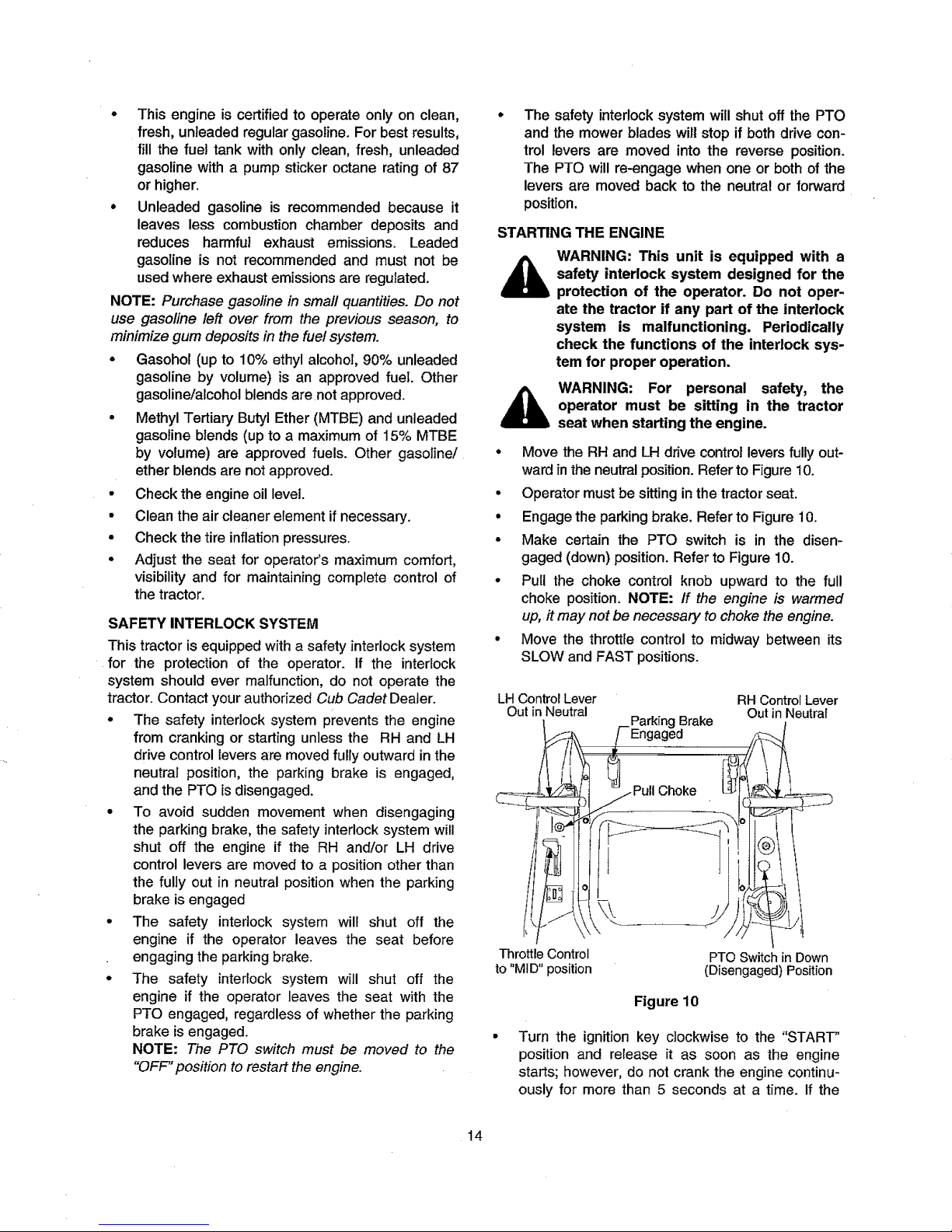

• Move the RH and LH drive control levers fully out-

ward in theneutral position. Refer to Figure10.

• Operator mustbe sittinginthe tractorseat.

• Engagethe parkingbrake. Refer to Figure 10.

• Make certain the PTO switch is in the disen-

gaged (down)position. Refer to Figure10.

• PuU the choke control knob upward to the full

choke position.NOTE: If the engine is warmed

up, it may not be necessary to choke the engine.

• Move the throttle controlto midway between its

SLOW and FAST positions.

LH Control Lever RH Control Lever

Out in Neutral Out in Neutrai

ParkingBrake

Engaged

oL

Throttle Control

to "MID" position

PTO Switch in Down

(Disengaged) Position

Figure 10

Turn the ignition key clockwise to the "START"

position and release it as soon as the engine

starts; however, do not crank the engine continu-

ously for more than 5 seconds at a time. If the

14

Page 15

engine does not start withinthis time, turn the key

to "OFF" and wait at least 15 seconds to allow the

engine's starter motor to cool. Try again after

waiting. If after a few attempts the engine fails to

start, do not keep trying to start it with the choke

dosed as this will cause flooding and make start-

ing more difficult.

As the engine warms up, gradually push the

choke knob downward to open the choke. Do not

use the choke to enrich the fuel mixture, except

as necessary to start the engine.

Allow the engine to run for a few minutes at mid

throttle before putting the engine under load.

Observe the hour meter/indicator panel. If the

battery indicator light or oil pressure light come

on, immediately stop the engine. Have the tractor

inspected by your Cub Cadet dealer.

COLD WEATHER STARTING

• When starting the engine at temperatures near or

below freezing, ensure the correct viscosity motor

oil is used in the engine and the battery is fully

charged. Start the engine as follows:

° Be sure the battery is in good condition. A warm

battery has much more starting capacity than a

cold battery.

• Use fresh winter grade fuel. Winter grade

gasoline has higher volatility to improve starting.

Do not use gasoline left over from summer.

• Follow the previous instruction for STARTING

THE ENGINE.

USING JUMPER CABLES TO START ENGINE

WARNING: Batteries contain sulfuric acid

and produce explosive gasses. Make

certain the area is well ventilated, wear

gloves and eye protection, and avoid

sparks or flames near the battery,

If the battery charge is not sufficient to crank the

engine, recharge the battery. If a battery charger is

unavailable and the tractor must be started, the aid of

a booster battery will be necessary. Connect the

booster battery as follows:

° Connect the end of one cable to the disabled

tractor battery's positive terminal; then connect

the other end of that cable to the booster

battery's positive terminal.

° Connect one end of the other cable to the booster

battery's negative terminal; then connect the

other end of that cable to the frame of the dis-

abled tractor, as far from the battery as possible.

• Start the disabled tractor following the normal

starting instructions previously provided; then

disconnect the jumper cables in the exact reverse

order of their connection.

Have the tractor's electrical system checked and

repaired as soon as possible to eliminate the

need for jump starting.

STOPPING THE ENGINE

" Place the PTO switch in the "OFF" position.

° Move the RH and LH drive control levers fully

outwardinthe neutralposition.

° Engagethe parkingbrake.

• Move the throttle control to the SLOW position

and allow the engine toidlefor aboutone minute.

° Turn the ignition key to the "OFF" position and

removethe key from the ignition switch.

NOTE: Always remove the key from the ignition

switch to prevent accidental starting or battery

discharge if the equipment is left unattended.

PRACTICE OPERATION (INITIAL USE)

Operating a zero-turn tractor is not like operating a

conventional type riding tractor. Although and be-

cause a zero turn tractor is more maneuverable,get-

ting used to operatingthe control levers takes some

practice.

We strongly recommend that you locate a reason-

ably large, leveland open "practice area" where there

are no obstructions, pedestrians, or animals. You

should practiceoperatingthe tractorfor a minimum_of

30 minutes.

Carefully move (or have moved) the tractor to the

practice area. When performing the practice session,

the PTO should not be engaged. While practicing,

operate the tractor at approximately 1/2-3/4 throttle

and at less than full speed in both forward and

reverse.

Carefully practice maneuvering the tractor using the

instructions in the following section "Driving the Trac-

tor." Practice until you are confident that you can

safely operate the tractor.

DRIVING THE TRACTOR

WARNING: Avoid sudden starts, exces-

sive speed and sudden stops.

WARNING: Do not leave the seat of the

tractor without disengaging the PTO,

moving drive control levers fully outward

in the neutral position, and engaging the

parking brake, if leaving the tractor

unattended, turn the ignition key off and

remove key.

15

Page 16

Adjust the operator's seat to the most

comfortable position that allows you to operate

the controls. See seat adjustment in the

ADJUSTMENTS section.

• Release the parking brake.

• Move the RH and LH drive control levers inward

in the neutral position. Refer to Figure 11.

Control Lever Moved

Inward and in Neutral

Figure 11

NOTE: If the control levers are not even in the neutral

position, refer to Section 3 and adjust the levers so

that they are even.

' Move the throttle control lever forward to the full

throttle position (3500-3600 RPM).

NOTE: The tractor and engine are designed to run at

full throttle. If performing a practice session, it is

preferable that the tractor is operated at less than full

throttle (approximately 2500-3000 RPM), but this only

applies to practice operation.

_L WARNING: Always maintain a firm grip

on the control levers. DO NOT release the

control levers to slow or stop the tractor;

move the levers to the neutral position

using your hands.

• To drive the tractor, firmly grasp the respective

drive control levers with your right and left hands

and proceed as follows -

Driving the Tractor Forward

,_ WARNING: Keep all movement of the

drive control levers slow and smooth.

Abrubt movement of the control levers

can affect the stability of the tractor and

could cause the tractor to flip over,

which may result in serious injury or

death to the operator.

• Slowly and evenly move both drive control levers

forward. The tractor will start to move forward.

See Figure 12.

As the control levers are pushed farther forward

the speed ofthe tractorwill increase.

DRIVING FORWARD

Faster

r

Figure 12

• To slow the tractor move the controls lever

rearward to attain the desired speed, or move the

levers to the neutral position to stop the tractor.

IMPORTANT; Always maintain your grasp on the

drive control levers. Do not release the levers to

slow the tractor or to return to neutral

Turning the Tractor While Driving Forward

WARNING: When reversing the direction

of travel, we recommend performing

gradual 'U' turns where possible.

Sharper turns increase the possibility of

turf defacement, and could affect control

of the tractor. ALWAYS slow the tractor

before making sharp turns.

To turn the tractor while driving forward, move the

control levers as necessary so that one lever is

rearward of the other. The tractor will turn in the

direction of the rearward control lever.

- To turn to the left, move the left drive control

lever rearward of the right lever. See Figure 13.

FORWARD LEFT TURN

16

Page 17

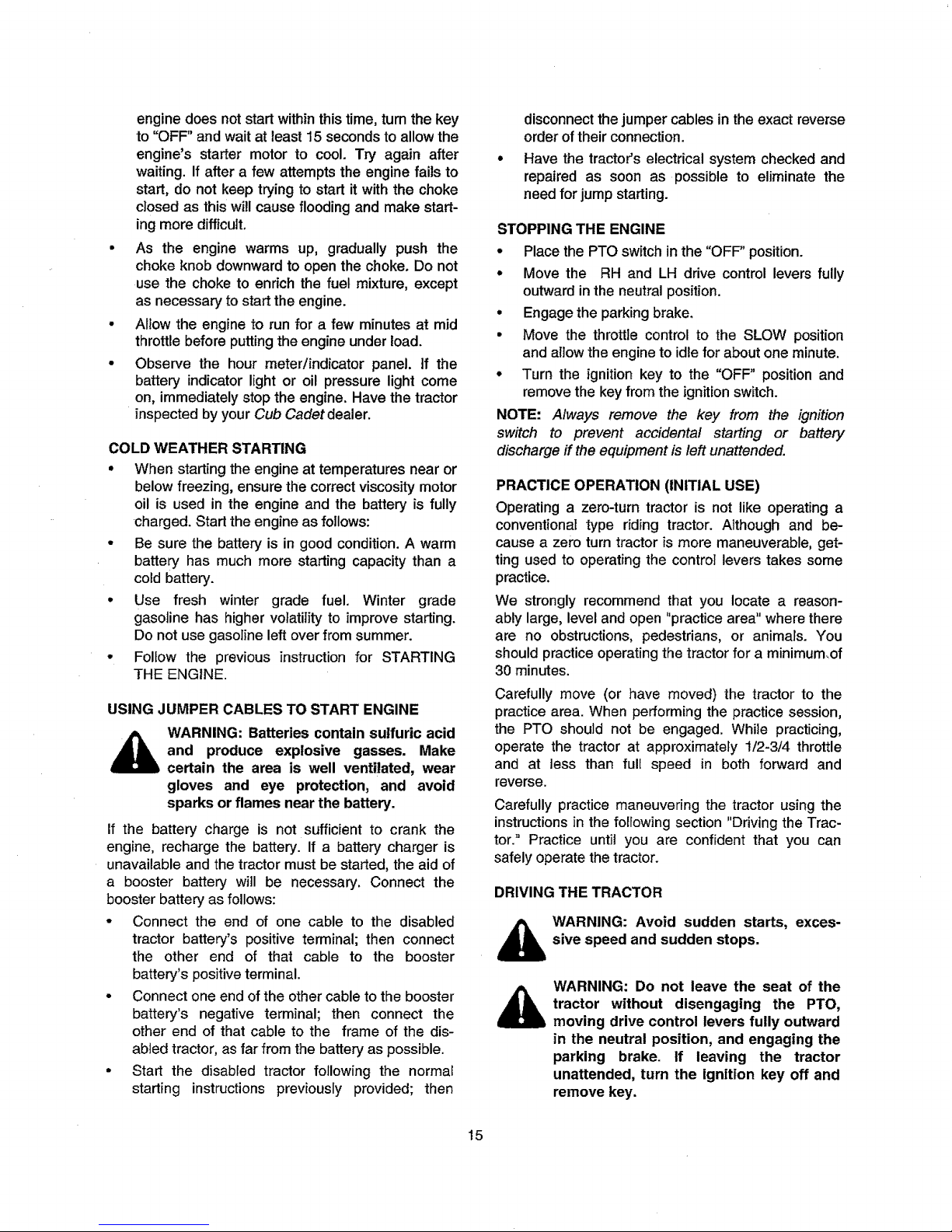

- Toturntotheright,movetherightdrivecontrol

leverrearwardoftheleftlever.SeeFigure14.

FORWARD RIGHT TURN

Figure 14

The greater the fore-to-aft distance between the

two levers, the sharper the tractor will turn.

To execute a "pivot turn," move the turn side

drive control lever to the neutral position, white

moving the other control lever forward.

IMPORTANT: Making a "pivot turn" on grass

will greatly increase the potential for

defacement of the turf.

IMPORTANT: Always maintain your grasp on the

drive control levers. Do not release the levers to

slow the tractor or to return to neutral

Turning While Driving Rearward

* To turn the tractor while driving rearward, move

the controlfevers as necessary so that one lever

is forward of the other.The tractorwillturn in the

direction of the forward controllever.

- To turn to the left while traveling in reverse,

move the leftdrive controllever forward of the

rightlever.See Figure16.

REARWARD LEFT TURN

Driving the Tractor In Reverse

WARNING: Always look behind and

down on both sides of the tractor before

backing up. Always look behind while

traveling in the reverse direction.

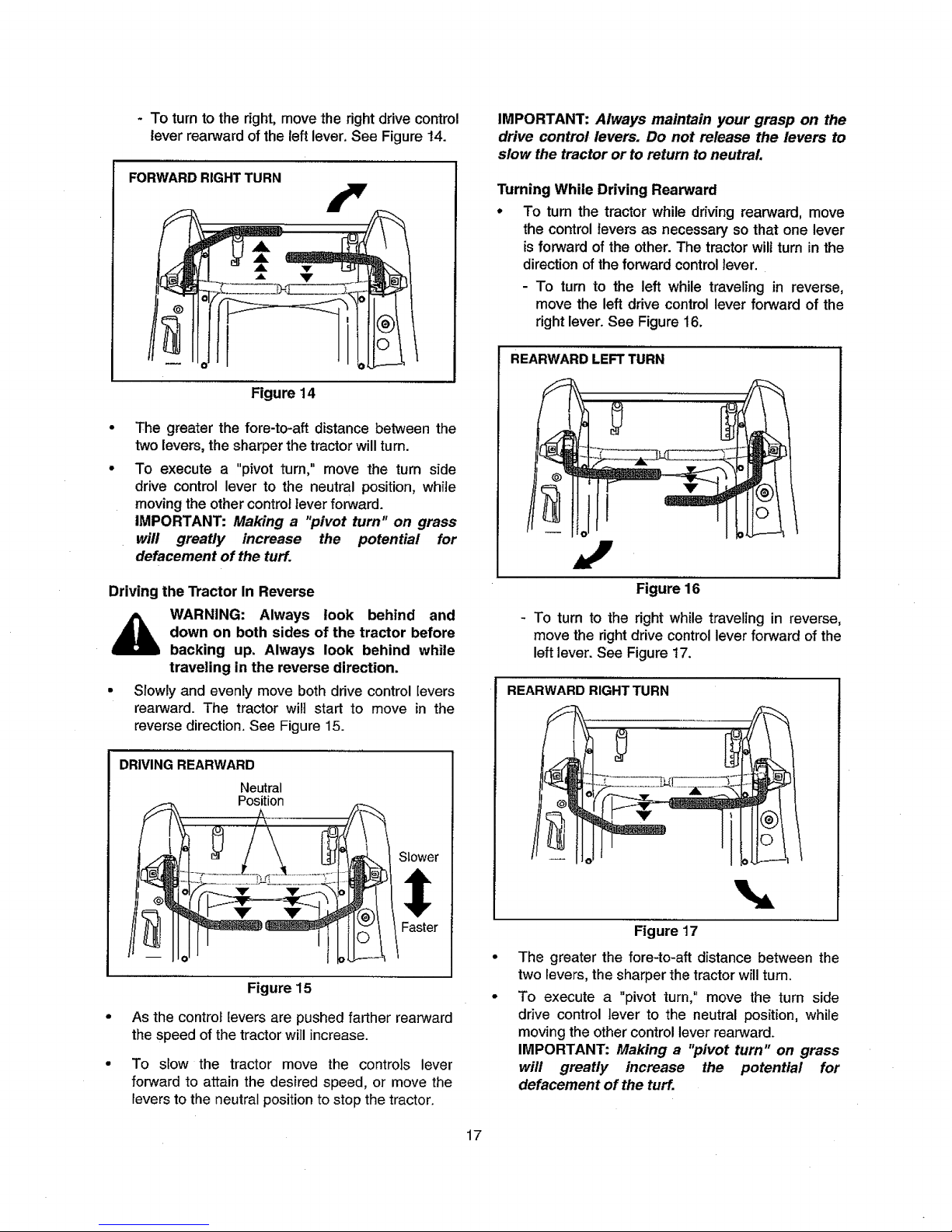

• Slowly and evenly move both drive control [evers

rearward. The tractor will start to move in the

reverse direction. See Figure 15.

DRIVING REARWARD

Neutral

Position

Figure 15

As the controf levers are pushed farther rearward

the speed of the tractor will increase.

To slow the tractor move the controls lever

forward to attain the desired speed, or move the

fevers to the neutral position to stop the tractor.

Figure 16

- To turn to the right while traveling in reverse,

move the right drive control lever forward of the

left lever. See Figure 17.

REARWARD RIGHT TURN

Figure 17

The greater the fore-to-aft distance between the

two levers, the sharper the tractor will turn.

To execute a "pivot turn," move the turn side

drive control lever to the neutral position, while

moving the other control lever rearward.

IMPORTANT: Making a "pivot turn" on grass

will greatly increase the potential for

defacement of the turf.

17

Page 18

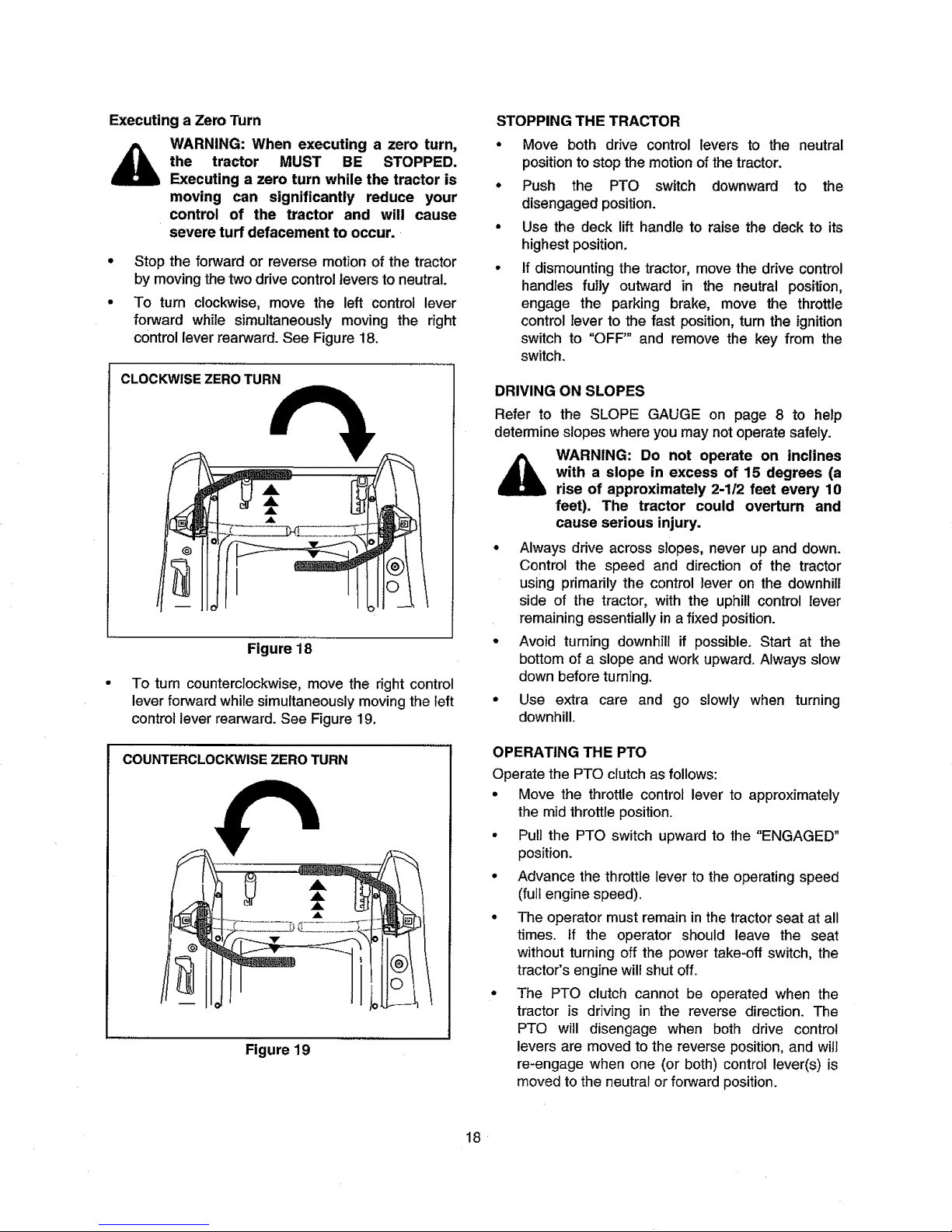

Executing a Zero Turn

_ WARNING: When executing a zero turn,

the tractor MUST BE STOPPED.

Executing a zero turn while the tractor is

moving can significantly reduce your

control of the tractor and will cause

severe turf defacement to occur.

• Stop the forward or reverse motion of the tractor

by moving the two drive control levers to neutral.

• To turn clockwise, move the left control lever

forward white simultaneously moving the right

control lever rearward. See Figure 18.

CLOCKWISE ZERO TURN

Figure 18

To turn counterclockwise, move the right control

lever forward while simultaneously moving the left

control lever rearward. See Figure 19.

COUNTERCLOCKWISE ZERO TURN

Figure 19

STOPPING THE TRACTOR

° Move both drive control levers to the neutral

position to stop the motion of thetractor.

° Push the PTO switch downward to the

disengaged position.

• Use the deck lift handle to raise the deck to its

highest position.

o If dismounting the tractor, move the drive control

handles fully outward in the neutral position,

engage the parking brake, move the throttle

control lever to the fast position, turn the ignition

switch to "OFF'" and remove the key from the

switch.

DRIVING ON SLOPES

Refer to the SLOPE GAUGE on page 8 to help

determine slopes where you may not operate safely.

_ WARNING: Do not operate on inclines

with a slope in excess of 15 degrees (a

rise of approximately 2-1/2 feet every 10

feet). The tractor could overturn and

cause serious injury.

° Always drive across slopes, never up and down.

Control the speed and direction of the tractor

using primarily the control lever on the downhill

side of the tractor, with the uphill control lever

remaining essentially in a fixed position.

• Avoid turning downhill if possible. Start at the

bottom of a slope and work upward. Always slow

down before turning.

• Use extra care and go slowly when turning

downhill.

OPERATING THE PTO

Operate the PTO clutch as follows:

• Move the throttle control lever to approximately

the mid throttle position.

• Pull the PTO switch upward to the "ENGAGED"

position.

• Advance the throttle lever to the operating speed

(full engine speed).

• The operator must remain in the tractor seat at all

times. If the operator should leave the seat

without turning off the power take-off switch, the

tractor's engine will shut off.

• The PTO clutch cannot be operated when the

tractor is driving in the reverse direction. The

PTO will disengage when both drive control

levers are moved to the reverse position, and will

re-engage when one (or both) control lever(s) is

moved to the neutral or forward position.

18

Page 19

USING THE MOWER DECK

WARNING: Make certain the area to be

mowed is free of debris, sticks, stones,

wire or other objects that can be thrown

by the rotating blades.

IMPORTANT: Do not engage the mower deck when

lowered in grass. Premature wear and possible failure

of the "V" belt and PTO clutch will result. Fully raise

the deck or move to a non grassy area before

engaging the mower deck.

• Mow across slopes, not up and down. If mowing

a slope, start at bottom and work upward to

ensure turns are made uphill.

• On the first pass pick a point on the opposite side

of the area to be mowed.

• Engage the PTO clutch using the PTO switch and

move the throttle control to the fast position.

• Lower the mower deck to the desired height

setting using the lift handle.

• Slowly and evenly push the RH and LH drive

control levers forward to move the tractor

forward, and keep the tractor headed directly

toward the alignment point.

NOTE: The speed of the tractor will affect the

quality of the mower cut. Mowing at full speed will

adversely affect the cut quality. Control the

ground speed with the control levers.

• When approaching the other end of the strip,

slow down or stop before turning. A U-turn is

recommended unless a pivot or zero turn is

required.

• Align the mower with an edge of the mowed strip

and overlap approximately 3 inches.

• Direct the tractor on each subsequent strip to

align with a previously cut strip.

• To prevent rutting or grooving of the tuff, if

possible, change the direction that the strips are

mowed by approximately 45 ° for the next and

each subsequent mowing.

_k WARNING: Be careful when crossing

gravel paths or driveways. Disengage

the PTO and raise the deck to the

highest position before crossing.

IMPORTANT: When stopping the tractor for any

reason while on a grass surface, always:

• Place the shift lever in neutral,

• Engage the parking brake,

• Shut engine off and remove the key.

Doing so will minimize the possibility of having your

lawn "browned" by hot exhaust from your tractor's

running engine.

CHECKING THE SAFETY INTERLOCK CIRCUITS

Periodically check the safety interlock circuits to

ensure they are workingproperly. If a safety circuitis

not working as designed, contact you Cub Cadet

dealer to have the tractorinspected. DO NOT operate

the tractor if any safety circuit is not functioning

properly. To check the safet_j circuits, proceed as

follows:

Sitting in the tractor seat with both drive control

levers opened fully outward, disengage the

parking brake and momentarily turn the ignition

switch to the start position. The engine should not

crank.

• Engage the parking brake and pull the PTO

switch upward to the engaged position.

Momentarily turn the ignition switch to the start

position; the engine should not crank.

• Push the PTO switch downward to the disen-

gaged position and engage the parking brake.

Start the engine and move one of the drive con-

trol levers from the fully outward neutral position.

The engine should stop running. Repeat the pro-

cedure with the opposite control lever.

• Move both control levers fully outward in the neu-

tral position and disengage the parking brake;

then lift upward from the operator's seat. The

engine should stop.

• With both control levers fully outward in the neu-

tral position and the parking brake engaged,

engage the PTO. Lift upward from the operator's

seat; the engine should stop.

• Start the tractor, disengage the parking brake,

and move the control levers inward to the neutral

operating position. Engage the PTO and move

both control lever slowly into the slow reverse

position; the PTO should disengage and the

mower deck should stop until one or both of the

control levers is moved to the neutral or forward

position.

19

Page 20

SECTION 3: ADJUSTMENTS

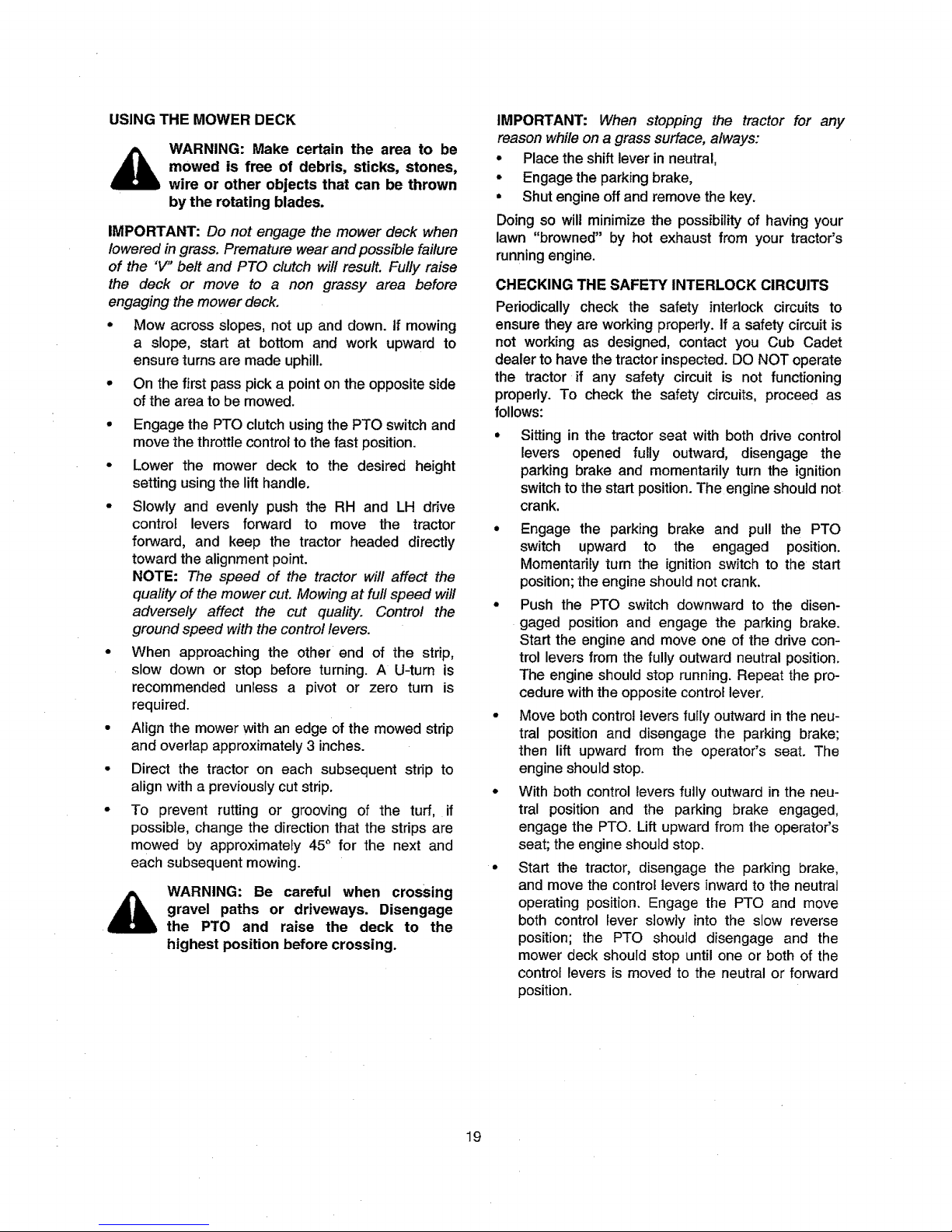

ADJUSTING THE OPERATORS SEAT

• To adjustthe positionof the seat, move and hold

the seat adjustment lever toward the left. Slide

the seat forward or rearward to the desired

position;then release the adjustmentlever. Make

sure seat is locked into positionbeforeoperating

thetractor.See Figure20,

Seat

Figure 20

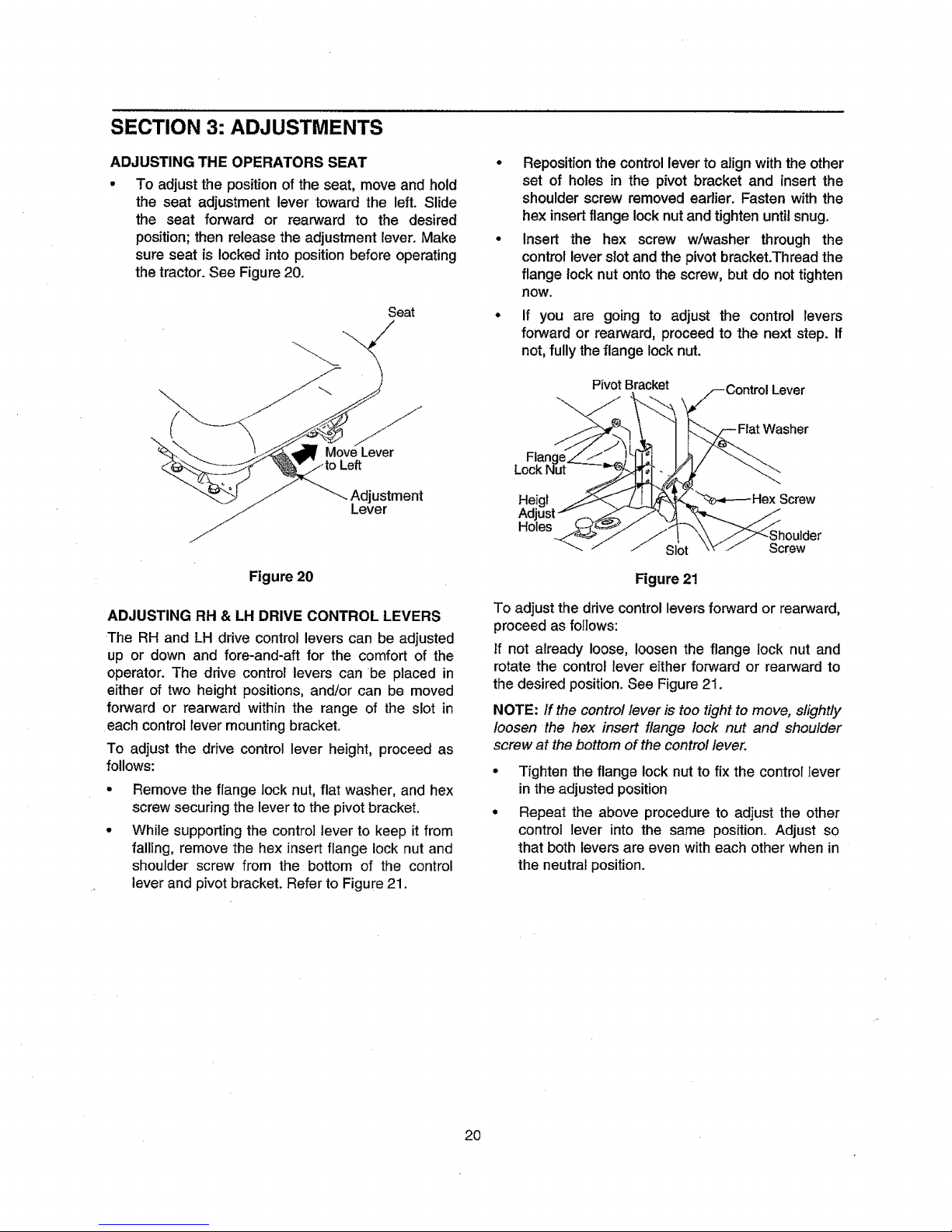

ADJUSTING RH & LH DRIVE CONTROL LEVERS

The RH and LH drive control levers can be adjusted

up or down and fore-and-aft for the comfort of the

operator. The drive control levers can be placed in

either of two height positions, and/or can be moved

forward or rearward within the range of the slot in

each control lever mounting bracket.

To adjust the drive control lever height, proceed as

follows:

Remove the flange lock nut, flat washer, and hex

screw securing the lever to the pivot bracket.

While supporting the control lever to keep it from

falling, remove the hex insert flange lock nut and

shoulder screw from the bottom of the control

lever and pivot bracket. Refer to Figure 21.

° Reposition the control lever to align with the other

set of holes in the pivot bracket and insert the

shoulder screw removed earlier. Fasten with the

hex insert flange lock nut and tighten until snug.

o Insert the hex screw w/washer through the

control lever slot and the pivot bracket.Thread the

flange lock nut onto the screw, but do not tighten

now.

If you are going to adjust the control levers

forward or rearward, proceed to the next step. If

not, fully the flange lock nut.

PivotBracket

Screw

Figure 21

To adjust the drive control levers forward or rearward,

proceed as follows:

If not already loose, loosen the flange lock nut and

rotate the control lever either forward or rearward to

the desired position. See Figure 21.

NOTE: If the control lever is too tight to move, slightly

loosen the hex insert flange lock nut and shoulder

screw at the bottom of the control lever.

Tighten the flange lock nut to fix the control lever

in the adjusted position

Repeat the above procedure to adjust the other

control lever into the same position. Adjust so

that both levers are even with each other when in

the neutrat position.

20

Page 21

SECTION 4: MAINTENANCE

ENGINE MAINTENANCE

Engine maintenance procedures and schedules can

be found in the copy of the engine manual found at

the end of this manual. Follow those schedules for

performingengine maintenance.

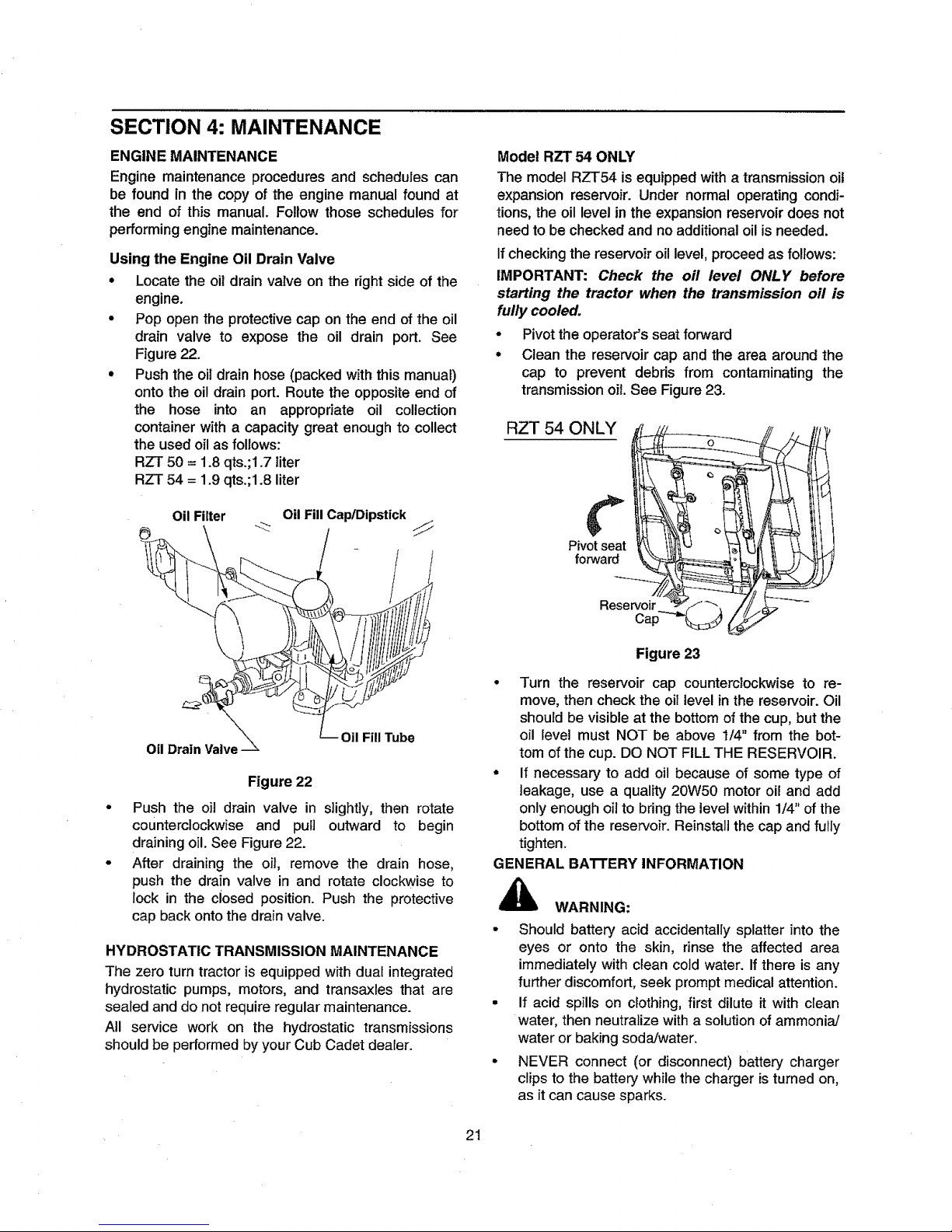

Using the Engine Oil Drain Valve

• Locate the oildrain vaXveon the rightside of the

engine.

• Pop open the protective cap on the end of the oil

drain valve to expose the oil drain port. See

Figure 22.

• Push the oil drain hose (packed with this manual)

onto the oil drain port. Route the opposite end of

the hose into an appropriate oil collection

container with a capacity great enough to collect

the used oilas follows:

RZT 50 = 1.8 qts.;1.7liter

RZT 54 = 1.9 qts.;1.8liter

Oil Filter OilFill Cap/Dipstick

Oil Drain Valve

Oil Fill Tube

Figure 22

Push the oil drain valve in slightly, then rotate

counterclockwise and pull outward to begin

draining oil. See Figure 22.

After draining the oil, remove the drain hose,

push the drain valve in and rotate clockwise to

lock in the dosed position. Push the protective

cap back onto the drain valve.

HYDROSTATIC TRANSMISSION MAINTENANCE

The zero turn tractor is equipped with dual integrated

hydrostatic pumps, motors, and transaxles that are

sealed and do not require regular maintenance.

All service work on the hydrostatic transmissions

should be performed by your Cub Cadet dealer.

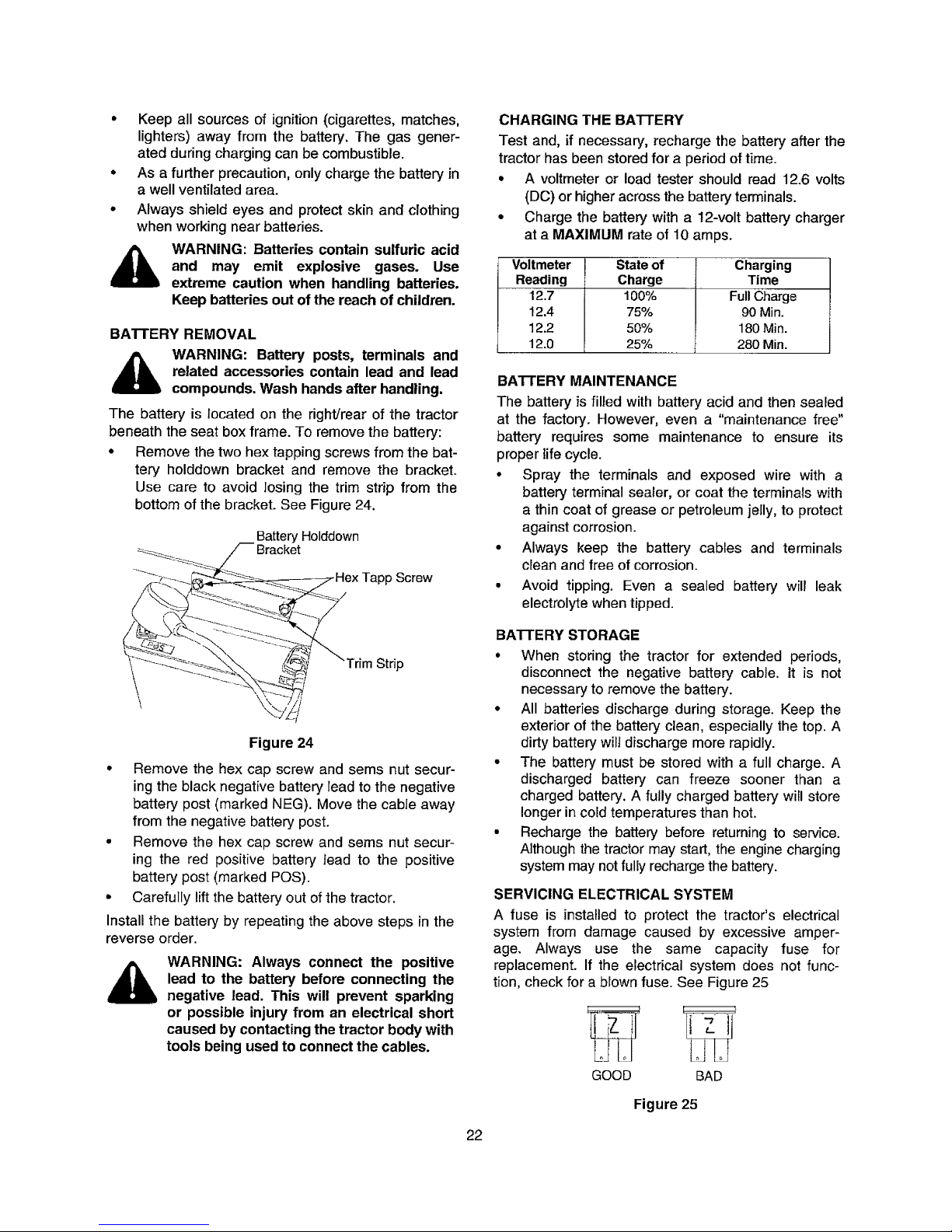

Model RZT 54 ONLY

The model RZT54 is equippedwith a transmissionoil

expansion reservoir. Under normal operating condi-

tions,the oil level in the expansion reservoir does not

need to be checked and no additional oil is needed.

if checking the reservoir oil level, proceed as follows:

IMPORTANT: Check the oil level ONLY before

starting the tractor when the transmission oil is

fully cooled,

• Pivotthe operator'sseat forward

• Clean the reservoircap and the area aroundthe

cap to prevent debris from contaminating the

transmissionoil. See Figure23.

RZT 54 ONLY

Pivotseat

forward

Figure 23

• Turn the reservoir cap counterclockwise to re-

move, then check the oil level in the reservoir. Oil

should be visible at the bottom of the cup, but the

oil level must NOT be above 1/4" from the bot-

tom of the cup. DO NOT FILL THE RESERVOIR.

= If necessary to add oil because of some type of

leakage, use a quality 20W50 motor oil and add

only enough oil to bring the level within 1/4" of the

bottom of the reservoir. Reinstall the cap and fully

tighten.

GENERAL BATFERY INFORMATION

i_ WARNING:

• Should battery acid accidentally splatter into the

eyes or onto the skin, rinse the affected area

immediately with clean cold water. If there is any

further discomfort, seek prompt medical attention.

• If acid spills on clothing, first dilute it with clean

water, then neutralize with a solution of ammonia/

water or baking soda/water.

• NEVER connect (or disconnect) battery charger

clips to the battery while the charger is turned on,

as it can cause sparks.

21

Page 22

• Keep all sources of ignition (cigarettes, matches,

lighters) away from the battery. The gas gener-

ated during charging can be combustible.

• As a further precaution, only charge the battery in

a well ventilated area.

• Always shield eyes and protect skin and clothing

when working near batteries.

WARNING: Batteries contain sulfuric acid

and may emit explosive gases. Use

extreme caution when handling batteries.

Keep batteries out of the reach of children.

BATTERY REMOVAL

WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds. Wash hands after handling.

The battery is located on the right!rearof the tractor

beneath the seat box frame. To remove the battery:

• Remove the two hex tapping screws from the bat-

tery holddown bracket and remove the bracket.

Use care to avoid losing the trim strip from the

bottom of the bracket. See Figure 24.

Battery Holddown

___ /'_ Bracket

\ \\ ;/

",_-_

Figure 24

• Remove the hex cap screw and sems nut secur-

ing the black negative battery lead to the negative

battery post (marked NEG). Move the cable away

from the negative battery post.

• Remove the hex cap screw and sems nut secur-

ing the red positive battery lead to the positive

battery post (marked POS).

• Carefully lift the battery out of the tractor.

Install the battery by repeating the above steps in the

reverse order.

WARNING: Always connect the positive

lead to the battery before connecting the

negative lead. This will prevent sparking

or possible injury from an electrical short

caused by contacting the tractor body with

tools being used to connect the cables.

CHARGING THE BA'n'ERY

Test and, if necessary, recharge the battery after the

tractor has been stored for a period of time.

• A voltmeter or load tester should read 12.6 volts

(DC) or higher across the battery terminals.

• Charge the battery with a 12-volt battery charger

at a MAXIMUM rate of 10 amps.

Voltmeter State of Charging

Reading Charge Time

12.7 100% Full Charge

12.4 75% 90 Min.

12.2 50% 180 Min.

12.0 25% 280 Min.

BATTERY MAINTENANCE

The battery is filled with battery acid and then sealed

at the factory. However, even a "maintenance free"

battery requires some maintenance to ensure its

proper life cycle.

• Spray the terminals and exposed wire with a

battery terminal sealer, or coat the terminals with

a thin coat of grease or petroleum jelly, to protect

against corrosion.

• Always keep the battery cables and terminals

clean and free of corrosion.

• Avoid tipping. Even a sealed battery will leak

electrolyte when tipped.

BATTERY STORAGE

° When storing the tractor for extended periods,

disconnect the negative battery cable, it is not

necessary to remove the battery.

• All batteries discharge during storage. Keep the

exterior of the battery clean, especially the top. A

dirty battery wilt discharge more rapidly.

• The battery must be stored with a full charge. A

discharged battery can freeze sooner than a

charged battery. A fully charged battery will store

longer in cold temperatures than hot.

• Recharge the battery before returning to service.

Although the tractor may start, the engine charging

system may not fully recharge the battery.

SERVICING ELECTRICAL SYSTEM

A fuse is installed to protect the tractor's electrical

system from damage caused by excessive amper-

age. Always use the same capacity fuse for

replacement. If the electrical system does not func-

tion, check for a blown fuse. See Figure 25

T

GOOD BAD

Figure 25

22

Page 23

If you have a recurring problem with blown fuses,

have the tractor's electrical system checked by your

Cub Cadet dealer.

Relays and Switches

There are several safety switches in the electrical

system. If a function of the safety interlock system

described earlier is not functioning properly, have the

electrical system checked by your Cub Cadet dealer.

LUBRICATION

• Using a pressure lubricating gun, lubricate the

front castor axles and pivot axle with Cub Cadet

251H EP grease after every 10 hours of service.

• Refer to the "MOWER DECK" section later in this

manual for deck lubrication procedures.

° Periodically lubricate all other pivot points with a

quality lubricating oil.

TIRE MAINTENANCE

Check the tire air pressure after every 50 hours of

operation or weekly. Keep the tires inflated to the rec-

ommended pressures. Improper inflation witl shorten

the tire service life. See the tire side wall for proper

inflation pressures. Observe the following guidelines:

• Do not inflate a tire above the maximum pressure

shown on the sidewall of the tire.

• Do not reinflate a tire that has been run flat or

seriously under inflated. Have a qualified tire

mechanic inspect and service the tire.

USING THE TRANSMISSION BYPASS RODS

If for any reason the tractor will not drive or you wish

to move the tractor, the two hydrostatic transmis-

sions are equipped with a bypass rod that will allow

youto manually movethe tractorshort distances.

_ WARNING: Do not tow the tractor, even

with the bypass rod engaged. Serious

transmission damage will result from

doing so.

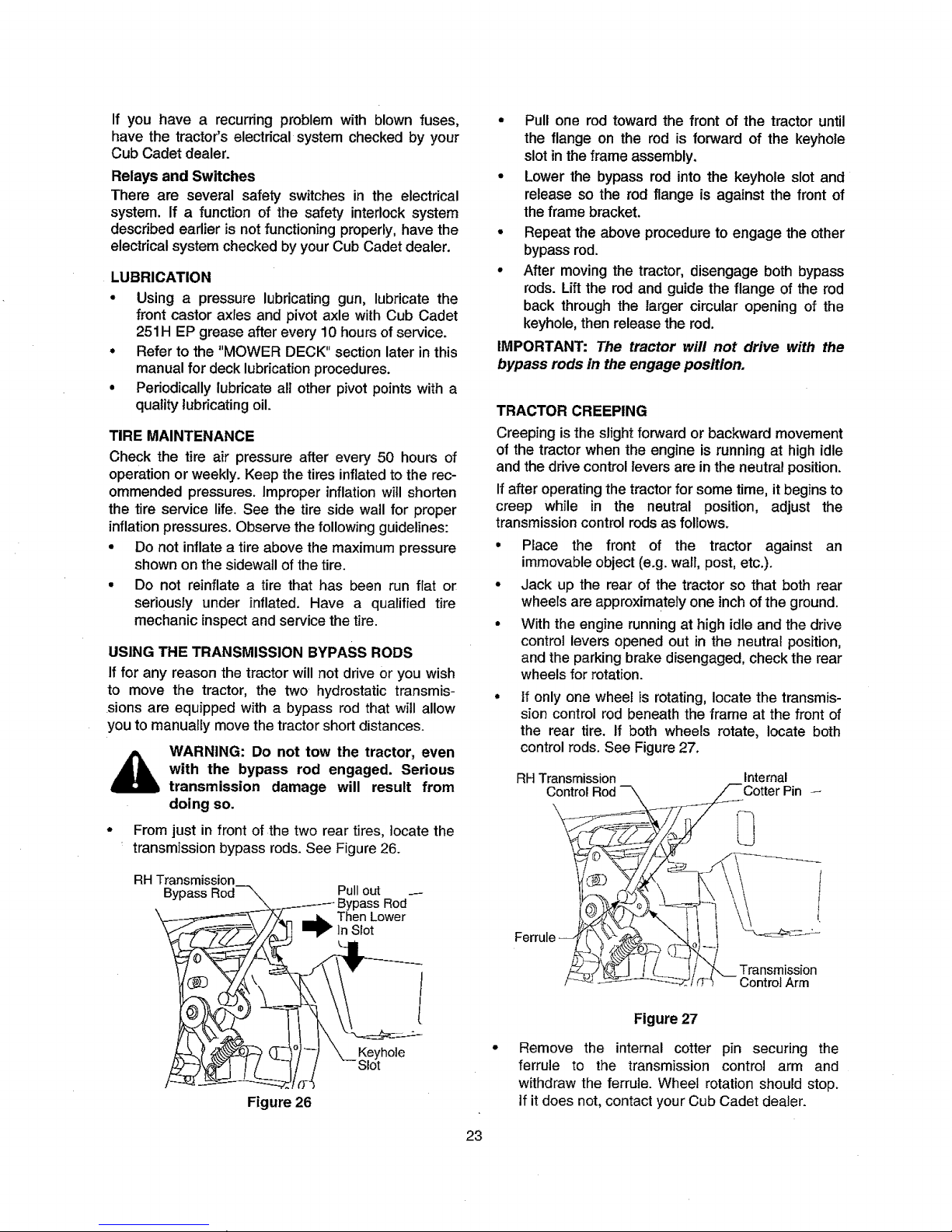

• From just in front of the two rear tires, locate the

transmission bypass rods. See Figure 26.

RH Transmission

Pullout

Bypass Rod

i_ Then Lower

In Slot

Figure 26

• Pull one rod toward the front of the tractor until

the flange on the rod is forward of the keyhole

slot in the frame assembly.

° Lower the bypass rod into the keyhole slot and

release so the rod flange is against the front of

the frame bracket.

° Repeat the above procedure to engage the other

bypass rod.

- After moving the tractor, disengage both bypass

rods. Lift the rod and guide the flange of the rod

back through the larger circular opening of the

keyhole, then release the rod.

IMPORTANT: The tractor will not drive with the

bypass rods in the engage position.

TRACTOR CREEPING

Creeping is the slight forward or backward movement

of the tractorwhen the engine is running at high idle

and the drive control levers are in the neutral position.

If after operating the tractor for some time, it begins to

creep while in the neutral position, adjust the

transmission control rods as follows.

• Place the front of the tractor against an

immovable object (e.g. wall, post, etc.).

• Jack up the rear of the tractor so that both rear

wheels are approximately one inch of the ground.

• With the engine running at high idle and the drive

control levers opened out in the neutral position,

and the parking brake disengaged, check the rear

wheels for rotation.

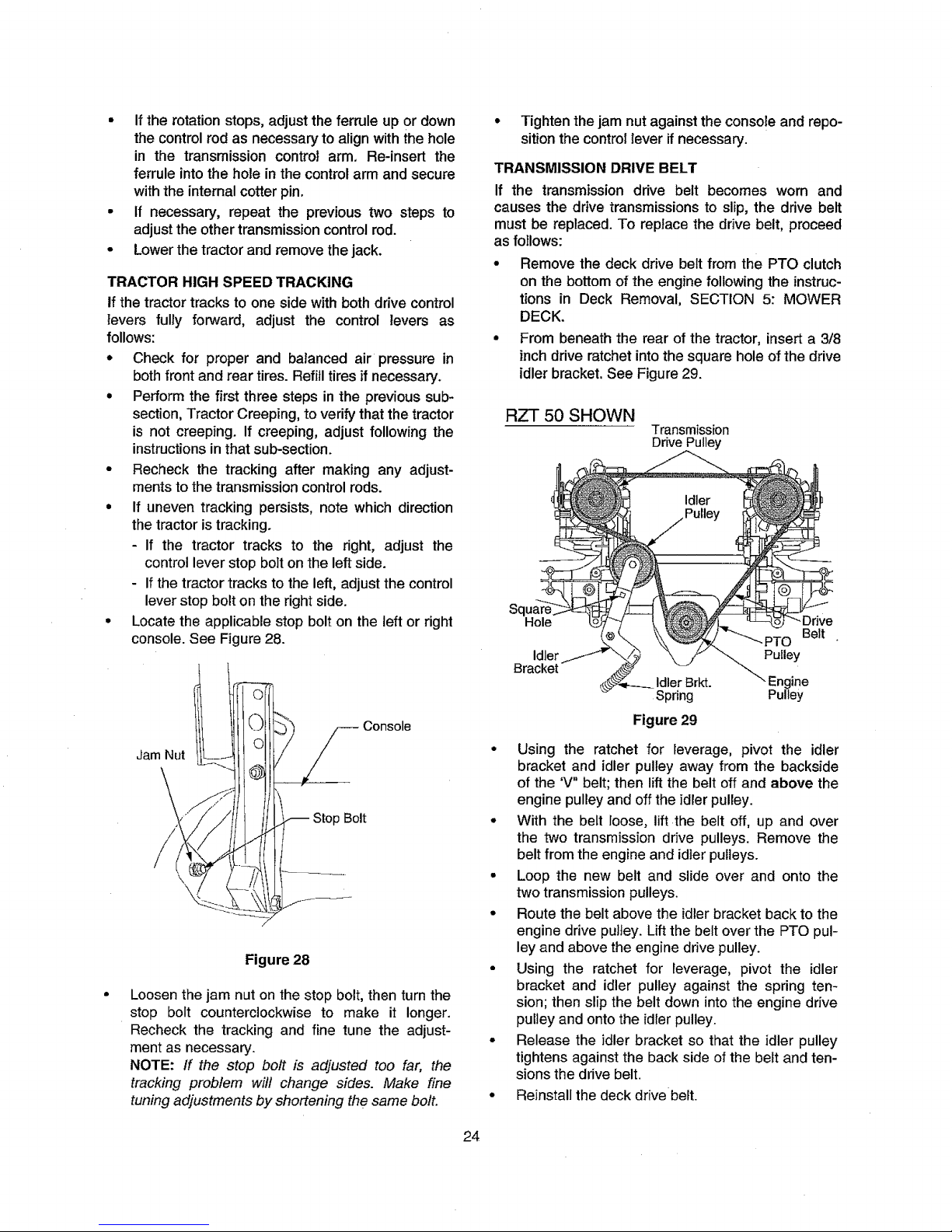

If only one wheel is rotating, locate the transmis-

sion controlrod beneath the frame at the front of

the rear tire. If both wheels rotate, locate both

control rods. See Figure27.

RH Transmission Internal

Control

Ferrule

Transmission

Control Arm

Figure 27

Remove the internal cotter pin securing the

ferrule to the transmission control arm and

withdraw the ferrule. Wheel rotation should stop.

If it does not, contact your Cub Cadet dealer.

23

Page 24

• Ifthe rotation stops, adjust the ferrule up or down

the control rod as necessary to align with the hole

in the transmission control arm, Re-insert the

ferrule into the hole in the control arm and secure

with the internal cotter pin.

• If necessary, repeat the previous two steps to

adjust the other transmission control rod.

• Lower the tractor and remove the jack.

TRACTOR HIGH SPEED TRACKING

If the tractor tracks to one side withboth drive control

levers fully forward, adjust the control levers as

follows:

• Check for proper and balanced air pressure in

both front and rear tires.Refilltiresif necessary.

• Perform the first three steps in the previous sub-

section,Tractor Creeping, to verifythat the tractor

is not creeping. If creeping, adjust following the

instructionsinthat sub-section.

• Recheck the tracking after making any adjust-

ments tothetransmissioncontrolrods.

• If uneven tracking persists,note which direction

the tractoris tracking.

- If the tractor tracks to the right, adjust the

controllever stop bolt onthe leftside.

- If thetractortracksto the left, adjust the control

leverstop bolton the right side.

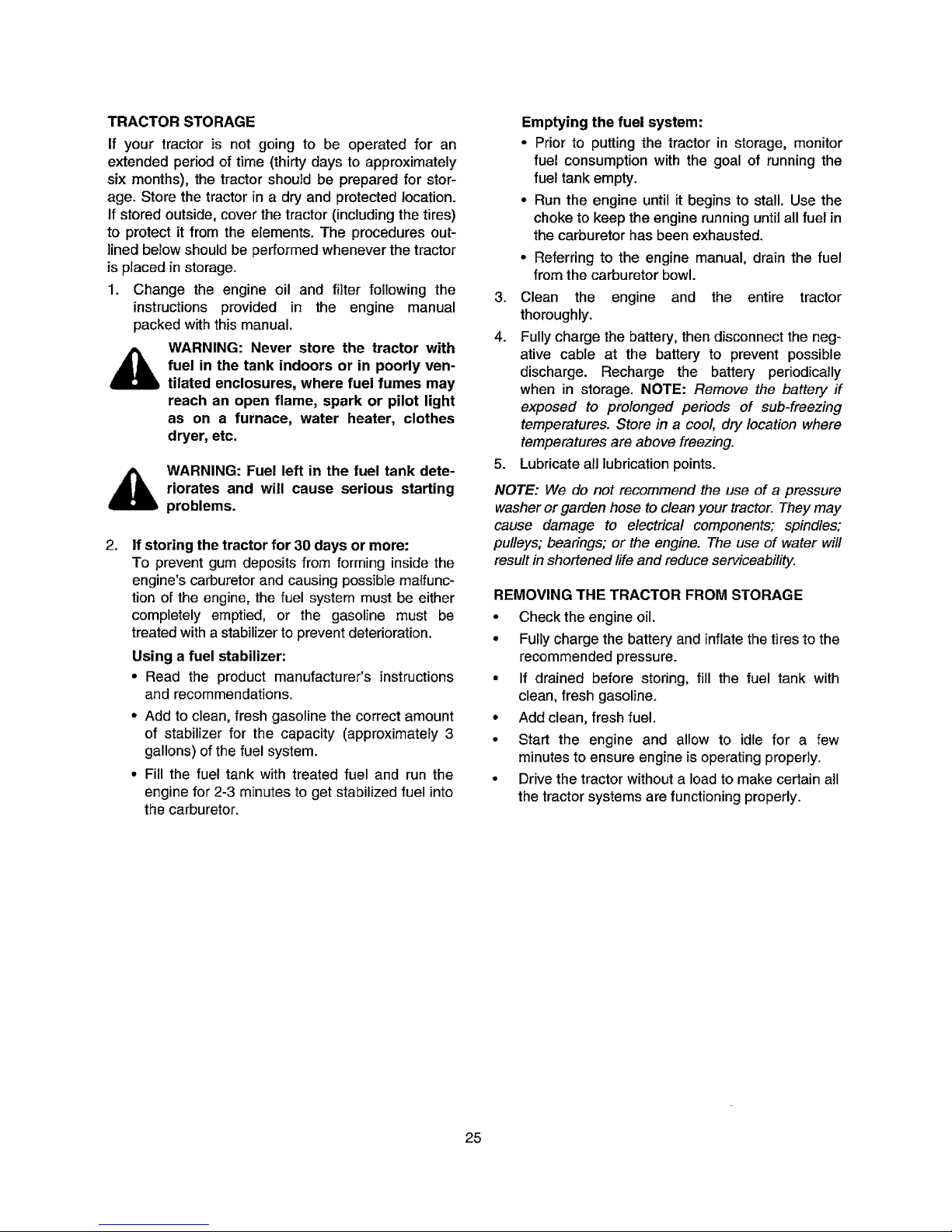

• Locatethe applicable stop bolt on the leftor right

console.See Figure 28.

Jam Nut

Stop Bolt

Figure 28

Loosen the jam nut on the stop bolt, then turn the

stop bolt counterclockwise to make it longer.

Recheck the tracking and fine tune the adjust-

ment as necessary.

NOTE: ff the stop bolt is adjusted too far, the

tracking problem will change sides. Make fine

tuning adjustments by shortening the same bolt.

• Tighten the jam nut against the console and repo-

sition the control lever if necessary.

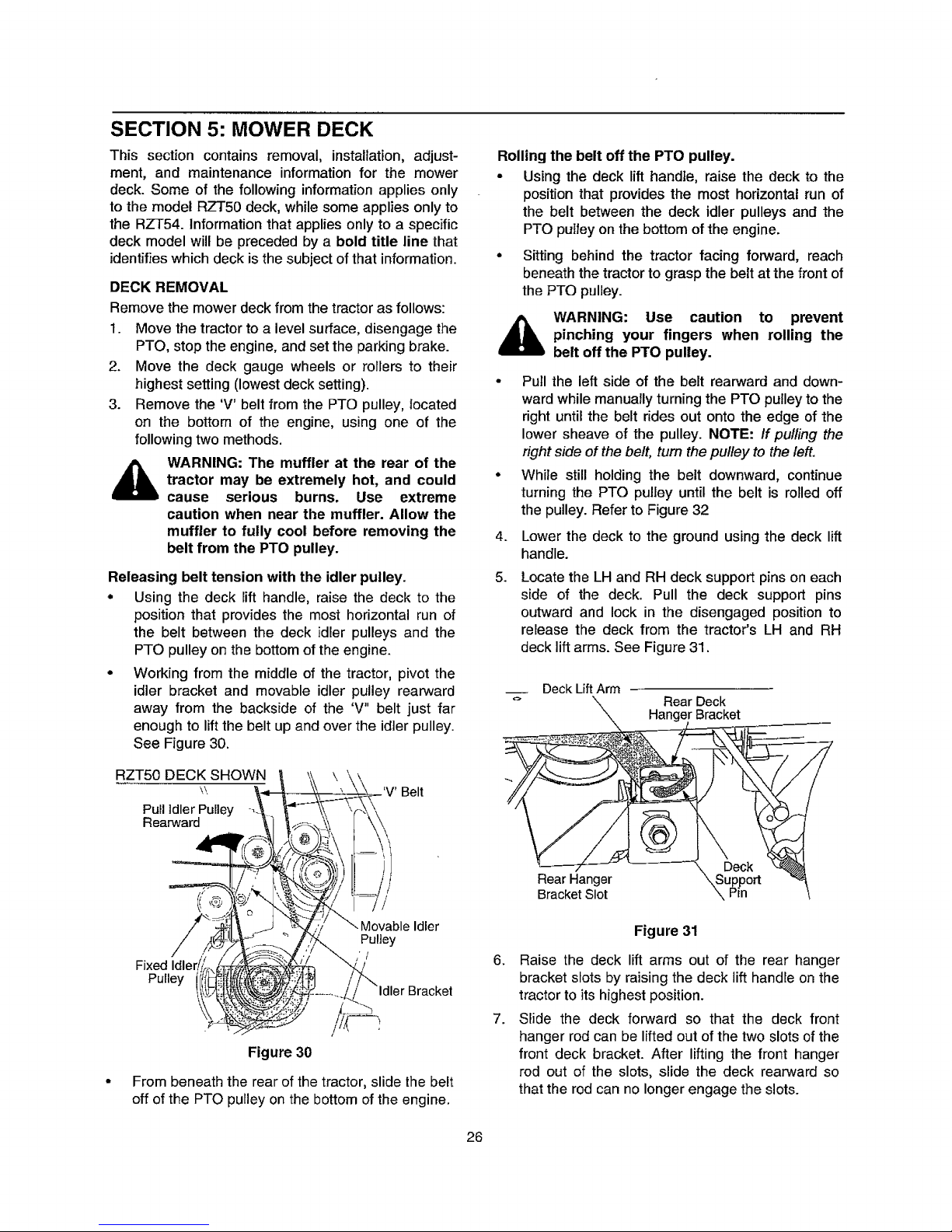

TRANSMISSION DRIVE BELT

If the transmission drive belt becomes worn and