CTX DZ33II, DZ55II, DZ33, DZ55 Service Manual

Microprocessor Assembly

2.

Introduction

..............

........……………………………………………………………………….

1

Unpacking

.......................………………………………………………………………………

2

Materials/Tools Required

2

Dip

Switch Settings

5

Microprocessor Assembly Removal

8 Microprocessor Assembly Installation

11 Thermostat Wiring

12

Microprocessor Assembly Removal

13 Microprocessor Assemb

ly Installation

15

(Part Number 7610251)

INSTALLATION INSTRUCTIONS

Table of Contents

1. GENERAL ........................…………………………………………………………………………. 1

DESCRIPTION ......................……………………………………………………………………... 1

3. MICROPROCESSOR ASSEMBLY .............…………………………………………………….. 5

4. CTX GEMINI OVENS ...................………………………………………………………………. 8

5. CTX HEARTH BAKE And TRIPHASE OVENS .......………………………………………….. 13

Part Number 2402283

1/93

i

Microprocessor Assembly

CTX Gemini

Hearth Bake

Triohase

DZ55II

(Part Number 7610251)

INSTALLATION INSTRUCTIONS

1. GENERAL

1.01 The following provides instructions for the conversion from

Microprocessor Assembly (Part Number 7610007, 7610126, and all previous boards) to the new

Microprocessor Assembly (Part Number 7610251).

1.02 The CTX Microprocessor Assembly (Kit ACSKDZSTRAP) includes:

Part # 7610251 CTX Microprocessor Assembly

Part # 3006500 Wrist Grounding Strap (Disposable)

1.03 The Microprocessor Assembly, Part Number (PN 7610251), is

Part # 2402283 Installation Instructions

installed into the following CTX Gemini, Hearth Bake, or Triphase Ovens:

DZ33 HB4 Z30

DZ33II HB4 (Menu Select) Z40

DZ33II (Menu Select)

DZ55 HB6 (Menu Select)

DZ55II (Menu Select)

HB6 Z60

2. DESCRIPTION

Introduction

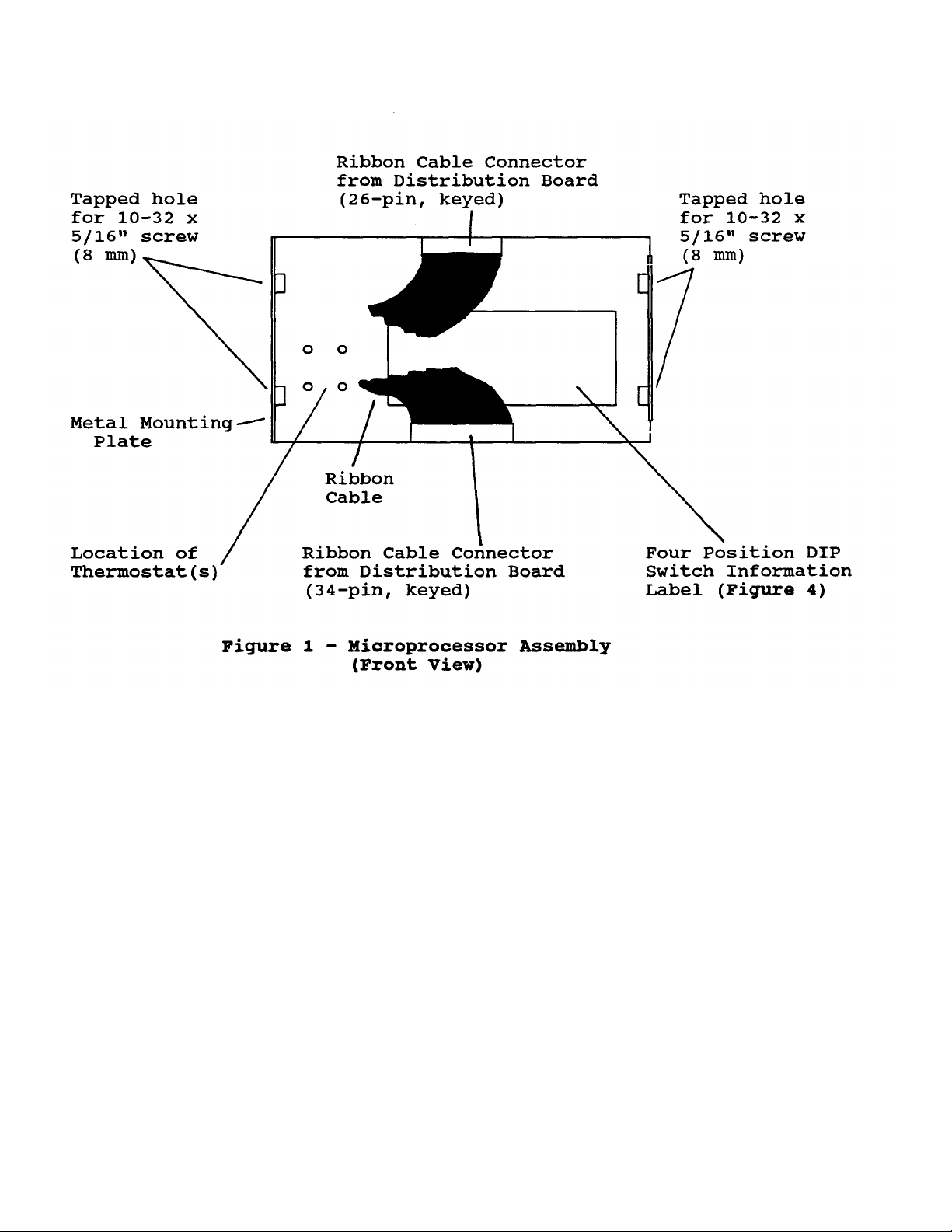

2.01 The Microprocessor Assembly consists of electrical connectors,

a 4-position DIP Switch, and related circuitry to provide control and interface

between the keypad assembly and various functional areas of an oven. The Microprocessor

Assembly is mounted to a metal plate which provides mounting facilities. A Label affixed to

the Metal Mounting Plate shows the related oven models and indicates DIP Switch toggle

positions. Refer to Figures 1 and 2.

Part Number 2402283

1/93

1

2.02 The conversion process consists of:

• Accessing the oven control compartment.

• Disconnecting associated wiring and removing the earlier version

Microprocessor Assembly.

• Setting the appropriate DIP-Switches on the new Microprocessor

Assembly.

• Installing The Microprocessor Assembly into the oven.

When the Microprocessor Assembly has been installed, the oven should be checked for

desired operation.

Unpacking

2.03 The Microprocessor Assembly was checked before leaving the

factory. Inspect the shipping container carefully for evidence of improper

handling during shipment. In case of damage, make an immediate claim to the dealer

or distributor from whom the unit was purchased. If the Microprocessor Assembly was

shipped to you, notify the carrier without delay and file a claim.

CAUTION

Before removing the Microprocessor Assembly from the

anti-static bag, attach the static strap to your wrist

and a good ground.

Materials/Tools Required

2.04 The following provides a list of Materials/Tools required for the installation of the

Microprocessor Assembly:

Disposable Ground Wrist Strap (Part Number 3006500)

(the disposable wrist strap is included in the Microprocessor

Assembly) Flat blade screwdriver 5/16" (8 mm) open-end wrench Appropriate

Installation/Technical documentation on the

particular oven requiring conversion.

2

3

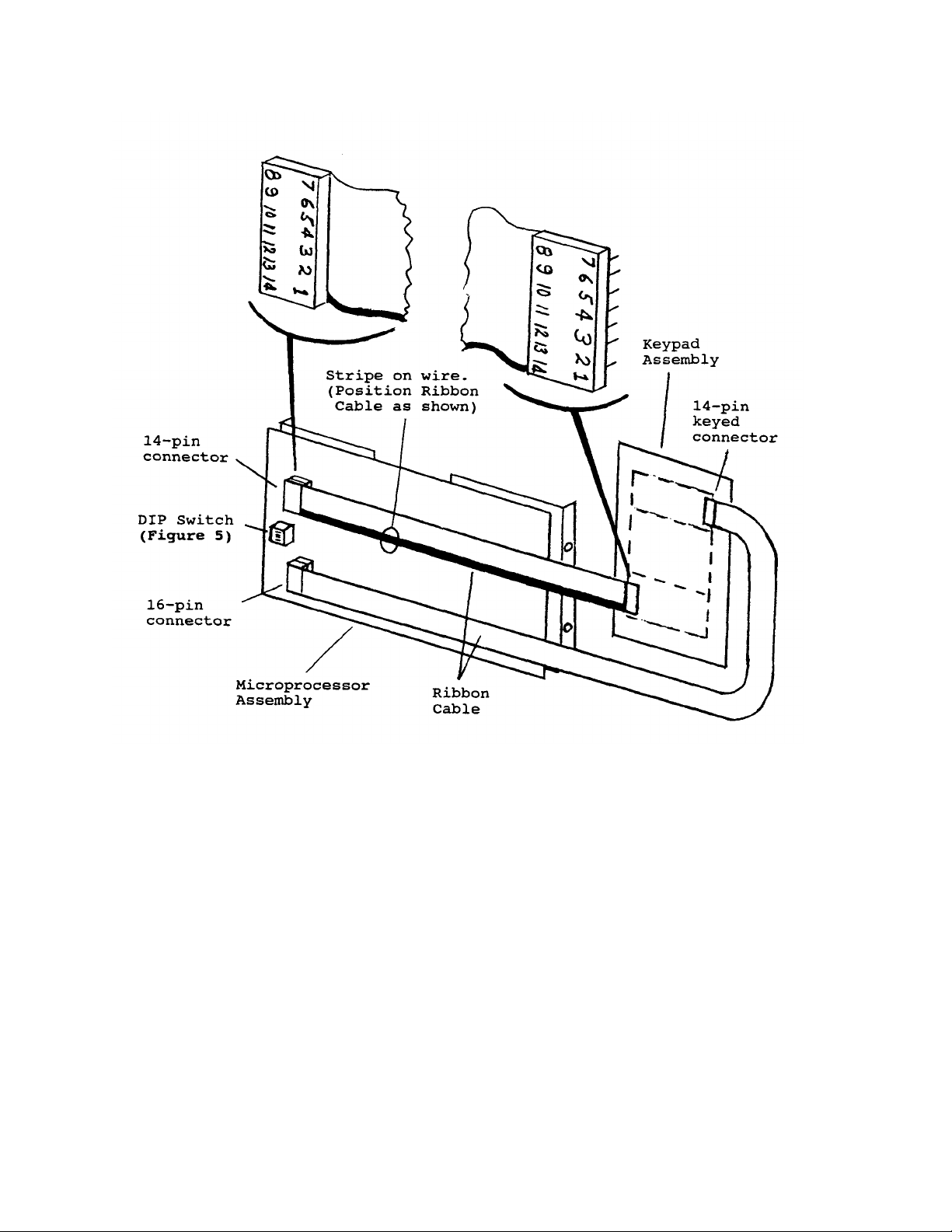

(Rear View)

Figure 2 - Ribbon Cable Connections Between Microprocessor Assembly And

Keypad Assembly (Rear View)

4

3. MICROPROCESSOR ASSEMBLY

5

Dip Switch Settings

3.01 The following provides instructions for keypad identification, oven identification, and DIP Switch settings:

Step

1.

2.

3.

4.

5.

6.

7.

8.

9.

Procedure

Open the shipping carton. Attach the supplied electrostatic

discharge wrist-strap to a good ground. This prevents

equipment damage caused by static discharge.

Remove the Microprocessor Assembly from the shipping carton

and anti-static bag. Use the open shipping carton or a

Static Mat as a clean reduced-static work area to place the

Microprocessor Assembly.

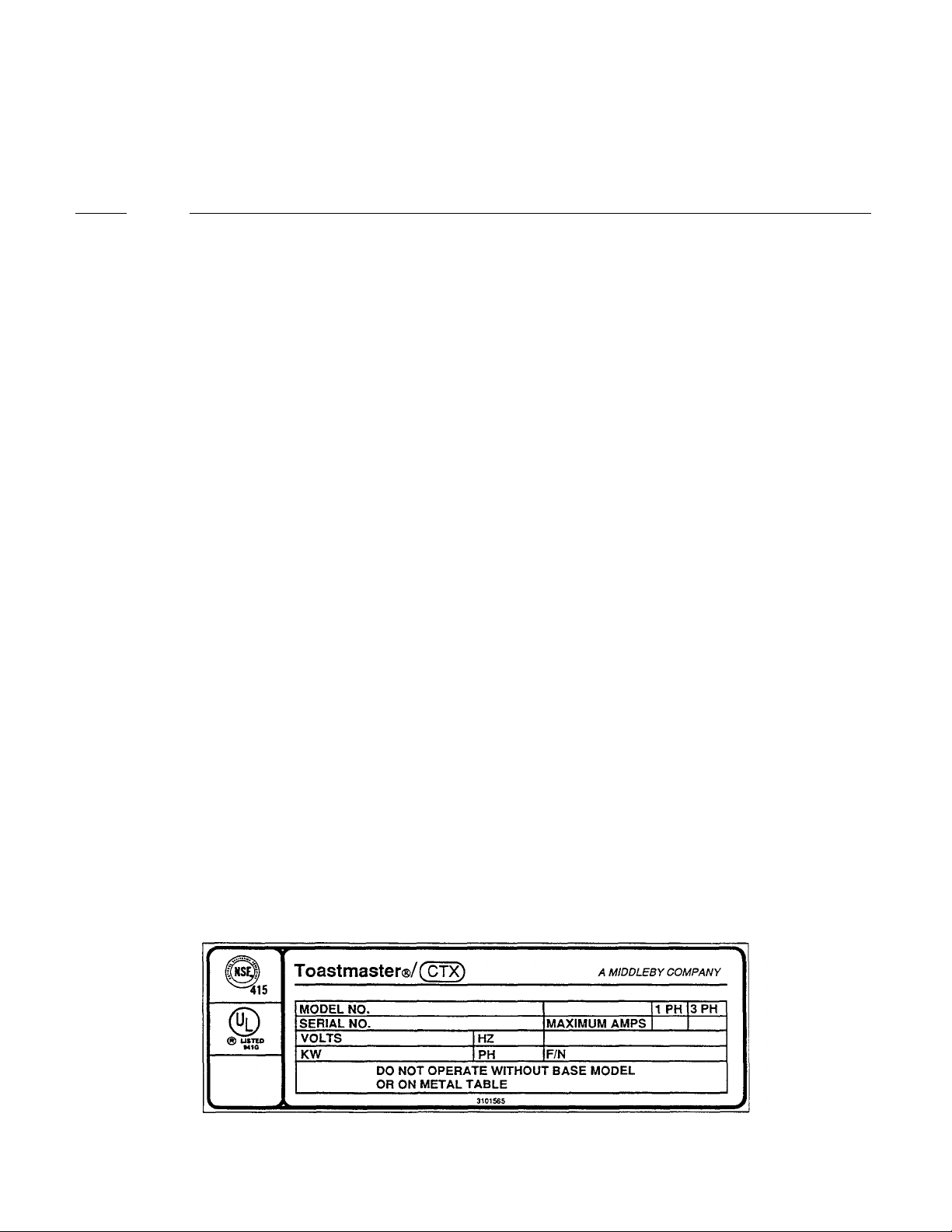

Refer to the Data Plate on the oven and note the Model

Number. Refer to Figure 3.

Refer to the keypad used on the oven. On the lower portion

of the keypad is printed Menu Select (late version) or it

is blank (non-Menu Select, early version). This indicates

the type of keypad used. Refer to Figure 4.

The keypad identification and oven model number are used to

identify the appropriate DIP Switch and related settings.

Refer to the DIP Switch Setting Information Label on the

Microprocessor Assembly and identify the specific oven Model

and associated DIP Switch setting. (Figure 5).

Place the Microprocessor Assembly with the component side

facing up. Locate the 4-position DIP Switch (Figure 5).

Set each switch to the correct position as shown on the

Switch Setting Information Label.

For Installation information into:

A. CTX Gemini (DZ) Ovens, refer to Paragraph 4.01.

B. CTX Hearth Bake (HB) and Triphase Ovens, refer

to Paragraph 5.01.

Figure 3 – Oven Data Plate

Loading...

Loading...