CTLST CAT24WC17PI-1.8TE13, CAT24WC17PA-TE13, CAT24WC17PA-1.8TE13, CAT24WC17P-TE13, CAT24WC17P-1.8TE13 Datasheet

...

Preliminary

D

OUT

ACK

SENSE AMPS

SHIFT REGISTERS

CONTROL

LOGIC

WORD ADDRESS

BUFFERS

START/STOP

LOGIC

STATE COUNTERS

SLAVE

ADDRESS

COMPARATORS

E2PROM

V

CC

EXTERNAL LOAD

COLUMN

DECODERS

XDEC

DATA IN STORAGE

HIGH VOL TAGE/

TIMING CONTROL

V

SS

WP

SCL

A

0

A1

A2

SDA

CAT24WC03/05/09/17

2K/4K/8K/16K-Bit Serial E2PROM

FEATURES

■ 400 KHZ I

2

C Bus Compatible*

■ 1.8 to 6.0Volt Operation

■ Low Power CMOS Technology

■ Write Protect Feature

–Top 1/2 Array Protected When WP at V

IH

■ 16-Byte Page Write Buffer

DESCRIPTION

The CAT24WC03/05/09/17 is a 2K/4K/8K/16K-bit Serial

CMOS E2PROM internally organized as 256/512/1024/

2048 words of 8 bits each. Catalyst’s advanced CMOS

technology substantially reduces device power require-

PIN CONFIGURATION

DIP Package (P)

1

A

0

2

A

1

3

A

2

SS

4

V

8

V

CC

7

WP

6

SCL

5

SDA

SOIC Package (J)

A

A

A

V

SS

1

0

2

1

3

2

4

8

V

CC

7

WP

6

SCL

5

SDA

■ Self-Timed Write Cycle with Auto-Clear

■ 1,000,000 Program/Erase Cycles

■ 100 Year Data Retention

■ 8-pin DIP, 8-pin SOIC and 8-pin TSSOP Package

■ Commercial, Industrial and Automotive

Temperature Ranges

ments. The CAT24WC03/05/09/17 features a 16-byte

page write buffer. The device operates via the I2C bus

serial interface, has a special write protection feature,

and is available in 8-pin DIP or 8-pin SOIC

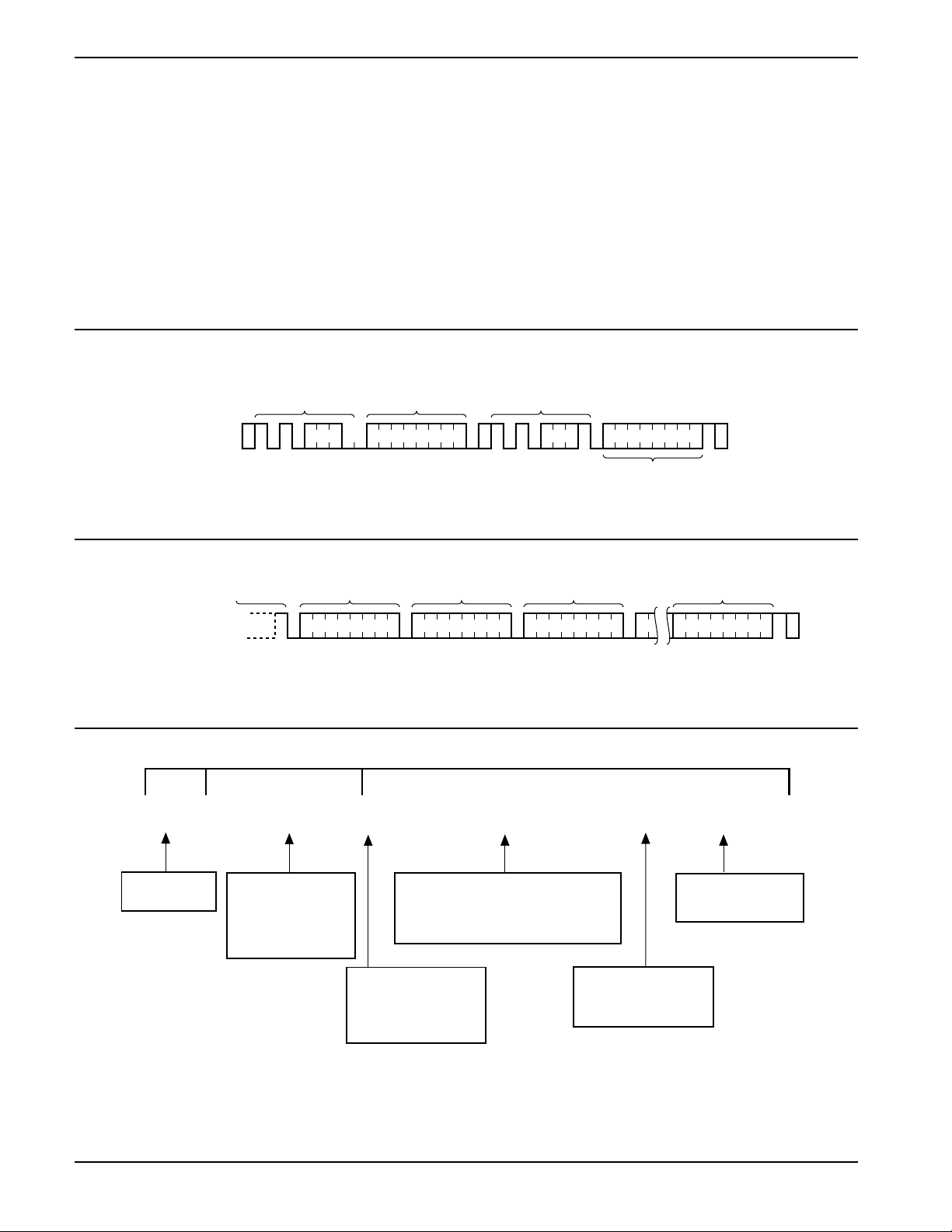

BLOCK DIAGRAM

TSSOP Package (U)

A

A

A

V

SS

PIN FUNCTIONS

(** Available for 24WC03 only)

1

0

2

1

3

2

4

SS

8

7

6

5

V

CC

WP

SCL

SDA

Pin Name Function

A0, A1, A2 Device Address Inputs

SDA Serial Data/Address

SCL Serial Clock

WP Write Protect

V

CC

V

SS

* Catalyst Semiconductor is licensed by Philips Corporation to carry the I2C Bus Protocol.

© 1999 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

+1.8V to +6.0V Power Supply

Ground

1

24WCXX F03

Doc. No. 25063-00 2/98 S-1

CAT24WC03/05/09/17

Preliminary

ABSOLUTE MAXIMUM RATINGS*

Temperature Under Bias ................. –55°C to +125°C

Storage Temperature....................... –65°C to +150°C

Voltage on Any Pin with

Respect to Ground

VCC with Respect to Ground ............... –2.0V to +7.0V

Package Power Dissipation

Capability (Ta = 25°C) .................................. 1.0W

(1)

........... –2.0V to +V

CC

+ 2.0V

*COMMENT

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

These are stress ratings only, and functional operation of

the device at these or any other conditions outside of those

listed in the operational sections of this specification is not

implied. Exposure to any absolute maximum rating for

extended periods may affect device performance and

reliability.

Lead Soldering Temperature (10 secs) ............ 300°C

Output Short Circuit Current

(2)

........................ 100mA

RELIABILITY CHARACTERISTICS

Symbol Parameter Min. Max. Units Reference Test Method

(3)

N

T

V

I

LTH

END

DR

ZAP

(3)

(3)

(3)(4)

Endurance 1,000,000 Cycles/Byte MIL-STD-883, Test Method 1033

Data Retention 100 Years MIL-STD-883, Test Method 1008

ESD Susceptibility 2000 Volts MIL-STD-883, Test Method 3015

Latch-up 100 mA JEDEC Standard 17

D.C. OPERATING CHARACTERISTICS

VCC = +1.8V to +6.0V, unless otherwise specified.

Limits

Symbol Parameter Min. Typ. Max. Units Test Conditions

I

CC

(5)

I

S

I

LI

I

LO

V

IL

V

IH

V

OL1

V

OL2

Power Supply Current 3 mA f

= 100 KHz

SCL

Standby Current (VCC = 5.0V) 0 µAVIN = GND or V

Input Leakage Current 10 µAVIN = GND to V

Output Leakage Current 10 µAV

= GND to V

OUT

Input Low Voltage –1 VCC x 0.3 V

Input High Voltage VCC x 0.7 VCC + 0.5 V

Output Low Voltage (VCC = 3.0V) 0.4 V IOL = 3 mA

Output Low Voltage (VCC = 1.8V) 0.5 V IOL = 1.5 mA

CC

CC

CAPACITANCE TA = 25°C, f = 1.0 MHz, VCC = 5V

Symbol Test Max. Units Conditions

(3)

C

I/O

C

IN

Note:

(1) The minimum DC input voltage is –0.5V. During transitions, inputs may undershoot to –2.0V for periods of less than 20 ns. Maximum DC

voltage on output pins is VCC +0.5V, which may overshoot to VCC + 2.0V for periods of less than 20ns.

(2) Output shorted for no more than one second. No more than one output shorted at a time.

(3) This parameter is tested initially and after a design or process change that affects the parameter.

(4) Latch-up protection is provided for stresses up to 100 mA on address and data pins from –1V to VCC +1V.

(5) Standby Current (ISB) = 0µA (<900nA).

Input/Output Capacitance (SDA) 8 pF V

(3)

Input Capacitance (A0, A1, A2, SCL, WP) 6 pF V

I/O

IN

= 0V

= 0V

CC

Doc. No. 25063-00 2/98 S-1

2

Preliminary

A.C. CHARACTERISTICS

VCC = +1.8V to +6.0V, unless otherwise specified.

Read & Write Cycle Limits

Symbol Parameter 1.8V, 2.5V 4.5V-5.5V

Min. Max. Min. Max. Units

CAT24WC03/05/09/17

F

SCL

(1)

T

I

t

AA

t

BUF

t

HD:STA

t

LOW

t

HIGH

t

SU:STA

t

HD:DAT

t

SU:DAT

(1)

t

R

(1)

t

F

t

SU:STO

t

DH

(1)

Clock Frequency 100 400 kHz

Noise Suppression Time 200 200 ns

Constant at SCL, SDA Inputs

SCL Low to SDA Data Out 3.5 1 µs

and ACK Out

Time the Bus Must be Free Before 4.7 1.2 µs

a New Transmission Can Start

Start Condition Hold Time 4 0.6 µs

Clock Low Period 4.7 1.2 µs

Clock High Period 4 0.6 µs

Start Condition Setup Time 4.7 0.6 µs

(for a Repeated Start Condition)

Data In Hold Time 0 0 ns

Data In Setup Time 50 50 ns

SDA and SCL Rise Time 1 0.3 µs

SDA and SCL Fall Time 300 300 ns

Stop Condition Setup Time 4 0.6 µs

Data Out Hold Time 100 100 ns

Power-Up Timing

(1)(2)

Symbol Parameter Max. Units

t

PUR

t

PUW

Power-up to Read Operation 1 ms

Power-up to Write Operation 1 ms

Write Cycle Limits

Symbol Parameter Min. Typ. Max Units

t

WR

The write cycle time is the time from a valid stop

condition of a write sequence to the end of the internal

program/erase cycle. During the write cycle, the bus

Note:

(1) This parameter is tested initially and after a design or process change that affects the parameter.

(2) t

PUR

and t

are the delays required from the time VCC is stable until the specified operation can be initiated.

PUW

Write Cycle Time 10 ms

interface circuits are disabled, SDA is allowed to remain

high, and the device does not respond to its slave

address.

3

Doc. No. 25063-00 2/98 S-1

CAT24WC03/05/09/17

Preliminary

FUNCTIONAL DESCRIPTION

The CAT24WC03/05/09/17 supports the I2C Bus data

transmission protocol. This Inter-Integrated Circuit Bus

protocol defines any device that sends data to the bus to

be a transmitter and any device receiving data to be a

receiver. Data transfer is controlled by the Master device

which generates the serial clock and all START and

STOP conditions for bus access. The CAT24WC03/05/

09/17 operates as a Slave device. Both the Master and

Slave devices can operate as either transmitter or receiver, but the Master device controls which mode is

activated. A maximum of 8 devices (24WC03), 4 devices

(24WC05), 2 devices (24WC09) and 1 device (24WC17)

may be connected to the bus as determined by the

device address inputs A0, A1, and A2.

Figure 1. Bus Timing

SCL

t

SU:STA

t

F

t

LOW

t

HD:STA

t

HIGH

t

HD:DAT

PIN DESCRIPTIONS

SCL: Serial Clock

The CAT24WC03/05/09/17 serial clock input pin is used

to clock all data transfers into or out of the device. This

is an input pin.

SDA: Serial Data/Address

The CAT24WC03/05/09/17 bidirectional serial data/address pin is used to transfer data into and out of the

device. The SDA pin is an open drain output and can be

wire-ORed with other open drain or open collector

outputs.

A0, A1, A2: Device Address Inputs

These inputs set device address when cascading multiple devices. When these pins are left floating the

default values are zeros.

A maximum of eight devices can be cascaded when

using 24WC03 device. All three address pins are used

t

R

t

LOW

t

SU:DAT

t

SU:STO

SDA IN

SDA OUT

Figure 2. Write Cycle Timing

SCL

SDA

BYTE n

Figure 3. Start/Stop Timing

SDA

t

t

AA

ACK8TH BIT

STOP

CONDITION

t

DH

t

WR

START

CONDITION

BUF

5020 FHD F03

ADDRESS

5020 FHD F04

Doc. No. 25063-00 2/98 S-1

SCL

START BIT

STOP BIT

5020 FHD F05

4

Preliminary

CAT24WC03/05/09/17

for 24WC03. If only one 24WC03 is addressed on the

bus, all three address pins (A0, A1, and A2) can be left

floating or connected to V

SS

A total of four devices can be addressed on a single bus

when using 24WC05 device. Only A1 and A2 address

pins are used with this device. The A0 address pin is a

no connect pin and can be tied to VSS or left floating. If

only one 24WC05 is being addressed on the bus, the

address pins (A1 and A2) can be left floating or connected to VSS.

Only two devices can be cascaded when using 24WC09.

The only address pin used with this device is A2. The A0

and A1address pins are no connect pins and can be tied

to V

or left floating. If only one 24WC09 is being

SS

addressed on the bus, the address pin (A2) can be left

floating or connected to VSS.

The 24WC17 is a stand alone device. In this case, all

address pins (A0, A1and A2) are no connect pins and

can be tied to V

or left floating.

SS

WP: Write Protect

If the WP pin is tied to VCC the upper half of memory array

becomes Write Protected (READ only)(locations 80H to

FFH for 24WC03, locations 100H to 1FFH for 24WC05,

locations 200H to 3FFH for 24WC09, locations 400H to

7FFH for 24WC17). When the WP pin is tied to V

SS

or

left floating normal read/write operations are allowed to

the device.

I2C BUS PROTOCOL

The following defines the features of the I2C bus protocol:

(1) Data transfer may be initiated only when the bus is

not busy.

(2) During a data transfer, the data line must remain

stable whenever the clock line is high. Any changes

in the data line while the clock line is high will be

interpreted as a START or STOP condition.

START Condition

The START Condition precedes all commands to the

device, and is defined as a HIGH to LOW transition of

SDA when SCL is HIGH. The CAT24WC03/05/09/17

monitor the SDA and SCL lines and will not respond until

this condition is met.

STOP Condition

A LOW to HIGH transition of SDA when SCL is HIGH

determines the STOP condition. All operations must end

with a STOP condition.

DEVICE ADDRESSING

The bus Master begins a transmission by sending a

START condition. The Master then sends the address

of the particular slave device it is requesting. The four

Figure 4. Acknowledge Timing

SCL FROM

MASTER

DATA OUTPUT

FROM TRANSMITTER

DATA OUTPUT

FROM RECEIVER

START

1

Figure 5. Slave Address Bits

24WC03

24WC05

24WC09

24WC17

* A0, A1 and A2 correspond to pin 1, pin 2 and pin 3 of the device.

** a8, a9 and a10 correspond to the address of the memory array address word.

***A0, A1 and A2 must compare to its corresponding hard wired input pins (pins 1, 2 and 3).

1 0 1 0 A2 A1 A0 R/W

1 0 1 0 A2 A1 a8 R/W

1 0 1 0 A2 a9 a8 R/W

1 0 1 0 a10 a9 a8 R/W

89

ACKNOWLEDGE

5020 FHD F06

5

Doc. No. 25063-00 2/98 S-1

CAT24WC03/05/09/17

Preliminary

most significant bits of the 8-bit slave address are fixed

as 1010 for the CAT24WC03/05/09/17 (see Fig. 5). The

next three significant bits (A2, A1, A0) are the device

address bits and define which device or which part of the

device the Master is accessing. Up to eight CAT24WC03,

four CAT24WC05, two CAT24WC09, and one

CAT24WC17 may be individually addressed by the

system. The last bit of the slave address specifies

whether a Read or Write operation is to be performed.

When this bit is set to 1, a Read operation is selected,

and when set to 0, a Write operation is selected.

After the Master sends a START condition and the slave

address byte, the CAT24WC03/05/09/17 monitors the

bus and responds with an acknowledge (on the SDA

line) when its address matches the transmitted slave

address. The CAT24WC03/05/09/17 then performs a

Read or Write operation depending on the state of the

R/W bit.

Acknowledge

After a successful data transfer, each receiving device is

required to generate an acknowledge. The Acknowledging device pulls down the SDA line during the ninth clock

cycle, signaling that it received the 8 bits of data.

The CAT24WC03/05/09/17 responds with an acknowledge after receiving a START condition and its slave

address. If the device has been selected along with a

write operation, it responds with an acknowledge after

receiving each 8-bit byte.

When the CAT24WC03/05/09/17 is in a READ mode it

transmits 8 bits of data, releases the SDA line, and

monitors the line for an acknowledge. Once it receives

this acknowledge, the CAT24WC03/05/09/17 will continue to transmit data. If no acknowledge is sent by the

Master, the device terminates data transmission and

waits for a STOP condition.

WRITE OPERATIONS

Byte Write

In the Byte Write mode, the Master device sends the

START condition and the slave address information

(with the R/W bit set to zero) to the Slave device. After

the Slave generates an acknowledge, the Master sends

the byte address that is to be written into the address

pointer of the CAT24WC03/05/09/17. After receiving

another acknowledge from the Slave, the Master device

transmits the data byte to be written into the addressed

memory location. The CAT24WC03/05/09/17 acknowledge once more and the Master generates the STOP

condition, at which time the device begins its internal

programming cycle to nonvolatile memory. While this

internal cycle is in progress, the device will not respond

to any request from the Master device.

Page Write

The CAT24WC03/05/09/17 writes up to 16 bytes of data

in a single write cycle, using the Page Write operation.

The Page Write operation is initiated in the same manner

as the Byte Write operation, however instead of terminating after the initial word is transmitted, the Master is

allowed to send up to 15 additional bytes. After each byte

has been transmitted the CAT24WC03/05/09/17 will

respond with an acknowledge, and internally increment

Figure 6. Byte Write Timing

BUS ACTIVITY:

MASTER

SDA LINE

Figure 7. Page Write Timing

S

T

BUS ACTIVITY :

MASTER

SDA LINE

Doc. No. 25063-00 2/98 S-1

A

R

T

S

SLAVE

ADDRESS

S

T

A

SLAVE

R

ADDRESS

T

S

BYTE

ADDRESS (n)

A

C

K

NOTE: IN THIS EXAMPLE n = XXXX 0000(B); X = 1 or 0

A

C

K

A

C

K

BYTE

ADDRESS

DATA n

A

C

K

A

C

K

DATA n+1

6

DATA

S

T

O

P

P

A

C

K

DATA n+P

A

C

K

24WCXX FO9

5020 FHD F08

S

T

O

P

P

A

C

K

24WCXX F09

Preliminary

CAT24WC03/05/09/17

the low order address bits by one. The high order bits

remain unchanged.

If the Master transmits more than 16 bytes prior to

sending the STOP condition, the address counter ‘wraps

around’, and previously transmitted data will be overwritten.

Once all 16 bytes are received and the STOP condition

has been sent by the Master, the internal programming

cycle begins. At this point all received data is written to

the CAT24WC03/05/09/17 in a single write cycle.

Acknowledge Polling

The disabling of the inputs can be used to take advantage of the typical write cycle time. Once the stop

condition is issued to indicate the end of the host’s write

operation, the CAT24WC03/05/09/17 initiates the internal write cycle. ACK polling can be initiated immediately.

This involves issuing the start condition followed by the

slave address for a write operation. If the CAT24WC03/

05/09/17 is still busy with the write operation, no ACK will

be returned. If the CAT24WC03/05/09/17 has completed the write operation, an ACK will be returned and

the host can then proceed with the next read or write

operation.

device’s failure to send an acknowledge after the first

byte of data is received.

READ OPERATIONS

The READ operation for the CAT24WC03/05/09/17 is

initiated in the same manner as the write operation with

the one exception that the R/W bit is set to a one. Three

different READ operations are possible: Immediate Address READ, Selective READ and Sequential READ.

Immediate Address Read

The CAT24WC03/05/09/17’s address counter contains

the address of the last byte accessed, incremented by

one. In other words, if the last READ or WRITE access

was to address N, the READ immediately following

would access data from address N+1. If N=E (where E

= 255 for 24WC03, 511 for 24WC05, 1023 for 24WC09,

and 2047 for 24WC17), then the counter will ‘wrap

around’ to address 0 and continue to clock out data.

After the CAT24WC03/05/09/17 receives its slave address information (with the R/W bit set to one), it issues

an acknowledge, then transmits the 8-bit byte requested.

The master device does not send an acknowledge but

will generate a STOP condition.

WRITE PROTECTION

The Write Protection feature allows the user to protect

against inadvertent programming of the memory array.

If the WP pin is tied to VCC, the upper half (locations 80H

to FFH for 24WC03, locations 100H to 1FFH for 24WC05,

locations 200H to 3FFH for 24WC09, locations 400H to

7FFH for 24WC17) of the memory array is protected and

becomes read only. The CAT24WC03/05/09/17 will

accept both slave and byte addresses, but the memory

location accessed is protected from programming by the

Figure 8. Immediate Address Read Timing

BUS ACTIVITY:

MASTER

SDA LINE

S

T

A

R

T

S

ADDRESS

Selective Read

Selective READ operations allow the Master device to

select at random any memory location for a READ

operation. The Master device first performs a ‘dummy’

write operation by sending the START condition, slave

address and byte address of the location it wishes to

read. After the CAT24WC03/05/09/17 acknowledge the

word address, the Master device resends the START

condition and the slave address, this time with the R/W

bit set to one. The CAT24WC03/05/09/17 then responds

with its acknowledge and sends the 8-bit byte requested.

S

SLAVE

A

DATA

C

K

T

O

P

P

N

O

A

C

K

SCL

SDA 8TH BIT

89

STOPNO ACKDATA OUT

7

Doc. No. 25063-00 2/98 S-1

5020 FHD F10

CAT24WC03/05/09/17

Preliminary

The master device does not send an acknowledge but

will generate a STOP condition.

Sequential Read

The Sequential READ operation can be initiated by

either the Immediate Address READ or Selective READ

operations. After the CAT24WC03/05/09/17 sends the

initial 8-bit byte requested, the Master will respond with

an acknowledge which tells the device it requires more

data. The CAT24WC03/05/09/17 will continue to output

an 8-bit byte for each acknowledge sent by the Master.

The operation is terminated when the Master fails to

Figure 9. Selective Read Timing

S

T

A

BUS ACTIVITY :

MASTER

SDA LINE

R

T

S

SLAVE

ADDRESS

BYTE

ADDRESS (n)

A

C

K

respond with an acknowledge, thus sending the STOP

condition.

The data being transmitted from the CAT24WC03/05/

09/17 is outputted sequentially with data from address N

followed by data from address N+1. The READ operation address counter increments all of the CAT24WC03/

05/09/17 address bits so that the entire memory array

can be read during one operation. If more than the E

(where E = 255 for 24WC03, 511 for 24WC05, 1023 for

24WC09, and 2047 for 24WC17) bytes are read out, the

counter will “wrap around” and continue to clock out data

bytes.

A

C

K

S

T

A

R

T

S

SLAVE

ADDRESS

A

DATA n

C

K

S

T

O

P

P

N

O

A

C

K

24WCXX F11

Figure 10. Sequential Read Timing

BUS ACTIVITY:

MASTER

SDA LINE

SLAVE

ADDRESS

A

C

K

ORDERING INFORMATION

Prefix Device # Suffix

CAT

Optional

Company ID

24WC03

Product Number

24WC03: 2K

24WC05: 4K

24WC09: 8K

24WC17: 16K

DATA n+1

A

C

K

J

Temperature Range

Blank = Commercial (0˚ - 70˚C)

I = Industrial (-40˚ - 85˚C)

A = Automotive (-40˚ - 105˚C)*

Package

P: PDIP

J: SOIC (JEDEC)

U: TSSOP **

I

A

C

K

DATA n+2

Operating V oltage

Blank: 2.5V - 6.0V

1.8: 1.8V - 6.0V

A

C

K

-1.8

DATA n+xDATA n

N

O

A

C

K

TE13

Tape & Reel

TE13: 2000/Reel

S

T

O

P

P

5020 FHD F12

* -40˚ to +125˚C is available upon request

Notes:

(1) The device used in the above example is a 24WC03JI-1.8TE13 (SOIC, Industrial Temperature, 1.8 Volt to 6 Volt Operating

Voltage, Tape & Reel)

Doc. No. 25063-00 2/98 S-1

** Available for 24WC03

8

Loading...

Loading...