Crystal Engineering XP2i Operating Manual

XP2i Operation Manual

for XP2i Digital Test Gauge (Standard and Dual-Display(DD))

Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Support . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

Introduction . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . |

. 1. . |

. . . . . Troubleshooting. . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Calibration .. .. .. .. .. |

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

37 |

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

Software . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

|

.3. . . . . . . . . . . . . . . . |

|

|

|||

Data Logging with DataLoggerXP |

|

9 |

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

|

. . . . . . . . . . . . . . . . . . . . . . . |

Accessories |

|

38 |

||

What is DataLoggerXP? |

|

9. |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

||

. . . . . . . . . . . . . . . . . . . . . . . . . |

Contact Us |

|

39 |

||

Installing the Software |

|

11 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

||

. . . . . . . . . . . . . . . . . . . . . . . . . |

Factory Service |

|

39 |

||

Authorizing a Gauge |

|

11 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

||

. . . . . . . . . . . . . . . . . . . . . . . . . |

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.39. . . . . . . |

|||

DataLoggerXP Software Operation |

|

12. |

|||

. . . . . . . . . . . . . . . . . . . . . . . . . |

Warranty |

|

39 |

||

XP2i DataLoggerXP Gauge Operation |

|

17 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

||

. . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

||

Excel Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21. . . . . . . . . . . . . |

|

|

|||

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

|

|

Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

|

|

|

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

|

|

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

|

|

Pressure Ranges, Display Scales, & Resolution . |

. . . . . . . . . . . . . . . . . . . . . . . |

27. . |

|

|

|

Part Numbering System . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

|

|

Safety & Certifications . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

28. |

|

|

|

Hazardous Locations . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

|

|

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

|

|

ATEX/IECEx Safety Instructions . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . |

31. . . . |

. |

|

|

Overview 1

Overview

INTRODUCTION

INTRODUCTION

Thank you for choosing the XP2i Digital Test Gauge from Crystal Engineering Corporation. Your XP2i is a combination of leading edge technology and rugged industrial design.

Accuracy is 0.1 percent of reading–so any XP2i can typically replace several gauges you may have been using. The XP2i is fully temperature compensated–so there is no change in accuracy throughout the entire operating temperature range!

The XP2i’s case is made from rugged aluminum alloy utilizing a gasket to seal the enclosure against dust and water intrusion. Even the RS-232 connector is fully sealed (with or without the red cover or rubber boot). Circuitry is mounted in shock absorbing elastomer supports and the batteries are easily accessible by removing four screws. But you won’t need to change the batteries often, since 3 AA batteries operate the XP2i for up to 1500 hours of continuous use. Other features include:

•Continuous capture of peak and valley pressure readings

•PSV mode

•Programming interface

•User-defined units

•Intrinsically Safe

•All welded 316 stainless steel sensor

We hope your XP2i meets your expectations, and we're interested in any comments or suggestions you may have. You can send us a note at: crystal@ametek.com. Many features in this and our other products are a direct result of your comments!

Crystal Engineering is the company that designs, manufactures, markets, and services the nVision reference pressure recorder, XP2i, and 30 series pressure calibrators, M1 Pressure Gauge, MultiCal multimeter pressure adapters, and a variety of industry specific pressure measuring equipment. Crystal Engineering pioneered features like full temperature compensation and “of reading” rated gauges and calibrators. Pressure measuring equipment is the only thing we do and that’s why we say:

™

™

Your XP2i can be customized, through the use of our free ConfigXP™ software. Your personal

computer can disable, enable, or modify a variety of features of your XP2i. Look for the  logo for programmable features, like:

logo for programmable features, like:

•A user defined pressure scale, and/or disable unused pressure units

•Password protection to prevent unauthorized changes

•Disable keypad recalibration, (peak) button, and/or (units) button

•Expand or decrease allowable Zero range

•Set the gauge to a different density of water factor (4° C, 60° F, or 68° F)

•Store a 12 digit ID or tag number in non-volatile memory

•Adjust calibration values

XP2i Operation Manual

Overview 2

OPERATING INSTRUCTIONS

The XP2i is shipped with batteries installed, so it’s ready to use. Press and hold the (on/off) button. The XP2i will first test all LCD segments. Release the (on/off) button when the XP2i indicates pressure.

The XP2i always resumes operation in the mode and the units of the pressure last used, and it does not automatically rezero when turned on.

Connect the XP2i to your system.

!!CAUTION:

!!CAUTION:

!!WARNING:

Use a wrench (¾" or 19mm) for installation and removal of XP2i! There is a limit to how much rotational force can be applied to the case, so don’t rely on, or use, the case to screw the XP2i into a fitting, and don’t use the case to remove the XP2i fitting, either.

Never insert any object into the pressure connection! The sensor diaphragm is very thin and can be damaged or destroyed by solid or sharp objects. Cleaning of the sensor must be done with appropriate solvents only.

Severe injury or damage can occur through improper use of pressure instruments! Do not exceed recommended pressure limits of tubing and fittings. Be certain all pressure connections are secured.

Most XP2i’s are intended for gauge pressure measurement. That is, they indicate the dif erence between applied pressure and ambient barometric pressure. However, the (zero) button can be used to force an XP2i to read zero pressure at any applied pressure, up to the full scale rating of the gauge. The factory default setting limits the maximum zero value to 20 psi, but this limit can be changed with .

.

Some XP2i’s are rated for absolute pressure. Absolute gauges indicate the difference between applied pressure and an internal vacuum reference. Absolute pressure is always positive. For instance barometric pressure at sea level is on average about 14.7 psi (approximately 100 kPa or 1 bar), so at sea level this is the lowest expected pressure indication. However, absolute gauges can be “zeroed” (unless prevented by ConfigXP). After zeroing an absolute gauge it is possible to indicate a negative or positive gauge pressure.

!!WARNING: This gauge can display zero pressure when connected to a source of pressure! Do not rely on the display indication before disconnecting— it may not be indicating true pressure. Never disconnect pressure instrumentation without first relieving system pressure!

XP2i Operation Manual

Functions 3

Functions

units Units Button

Pressing this button causes the XP2i to select the next available unit of pressure measurement.

See Pressure Ranges, Display Scales, & Resolution on page 28 or the list of pressure units available for your model.

Units that you don’t need or never use can be turned off. You can also define a special unit for your XP2i with ConfigXP. You can use the XP2i to display directly in a unit not otherwise available, such as feet of seawater, or foot-pounds of torque. When you select your custom unit from the keypad, the screen displays the USER icon.

Units that you don’t need or never use can be turned off. You can also define a special unit for your XP2i with ConfigXP. You can use the XP2i to display directly in a unit not otherwise available, such as feet of seawater, or foot-pounds of torque. When you select your custom unit from the keypad, the screen displays the USER icon.

Hi

peak Peak Button

Lo

On the XP2i, pressing the (peak) button causes the display to cycle through the following , depending on your setting in ConfigXP.

On the -DD, dual-line display XP2i, pressing the (peak) button causes the display to cycle through the following, depending on your setting in ConfigXP:

<No Icon> . . . . Live Pressure display

. . . . Maximum detected pressure

. . . . Maximum detected pressure

. . . . Minimum detected pressure

. . . . Minimum detected pressure

(blinking)  . . . . PSV Mode, maximum *

. . . . PSV Mode, maximum *

(blinking)  . . . . PSV Mode, minimum *

. . . . PSV Mode, minimum *

. . . . Average pressure

. . . . Average pressure

. . . . DataLoggerXP datalogging mode

. . . . DataLoggerXP datalogging mode

* From the factory this setting is disabled. Use ConfigXP to enable.

Peak High and Peak Low values are not saved when the gauge shuts off; they will reset to the current reading when the XP2i is turned on or reset.

In some cases the ability to display a peak value may not be needed, or may even be dangerous. ConfigXP allows you to disable this button.

In some cases the ability to display a peak value may not be needed, or may even be dangerous. ConfigXP allows you to disable this button.

XP2is can average 1 to 10 readings, recalculated every time pressure is measured (4 times per second). Enable and set the number of readings to be averaged with ConfigXP.

<No Icon> . . . . Live Pressure display

. . . . Maximum detected pressure

. . . . Maximum detected pressure

. . . . Minimum detected pressure

. . . . Minimum detected pressure

(blinking)  . . . . PSV Mode maximum *

. . . . PSV Mode maximum *

(blinking)  . . . . PSV Mode minimum *

. . . . PSV Mode minimum *

. . . . Average pressure

. . . . Average pressure

. . . . DataLoggerXP datalogging mode

(remaining points displayed on lower line)

. . . . Tare *

. . . . Tare *

. . . . Rate of change *

. . . . Rate of change *

. . . . Differential Mode *

. . . . Differential Mode *

+ |

. . . . Average Differential Mode * |

|

|

XP2i Operation Manual

Functions 4

zero

Resetting (Clearing) Recorded Peak Values

clear

Peak values can only be cleared when displaying either a Peak High or Peak Low recorded pressure. Press the (clear) button for at least ½ second. Dashed lines will briefly appear across the display indicating that both Peak values have been cleared. Both Peak High and Peak Low values will then display the current applied pressure. Pressing the (clear) button while either the Peak High ( HI

) or Peak Low ( LO ) icon is displayed will not affect the zero value. If you need to rezero the gauge, you must turn off both peak icons by pressing the (peak) button.

) or Peak Low ( LO ) icon is displayed will not affect the zero value. If you need to rezero the gauge, you must turn off both peak icons by pressing the (peak) button.

zero

Zero

clear

If you attempt to zero the gauge while applying a pressure which exceeds the Zero Limit (set in ConfigXP, defaults to 20 psi), the command will be ignored and “--HI-” will be displayed.

If you attempt to zero the gauge while applying a pressure which exceeds the Zero Limit (set in ConfigXP, defaults to 20 psi), the command will be ignored and “--HI-” will be displayed.

XXTo Zero the XP2i

Turn off peak indication by pressing the (peak) button repeatedly until the HI and LO icons are off, then press the (zero) button for at least ½ second when the gauge is vented to atmosphere.

The display will then briefly flash all dashed lines ( ), indicating that it has been re-zeroed. Absolute gauges will now indicate gauge pressure.

), indicating that it has been re-zeroed. Absolute gauges will now indicate gauge pressure.

!!WARNING: This gauge can display zero pressure when connected to a source of pressure! Do not rely on the display indication before disconnecting— it may not be indicating true pressure. Never disconnect pressure instrumentation without first relieving system pressure!

XXTo Clear the Zero Value on an XP2i

Turn off peak indication as described above, then press and hold the (zero) button until the display changes from ( ) to (

) to ( ).

).

This is especially useful for absolute gauges that have been zeroed to use for gauge pressure measurement.

XP2i Operation Manual

Functions 5

Tare (-DD, Dual-Line Display XP2i Only)

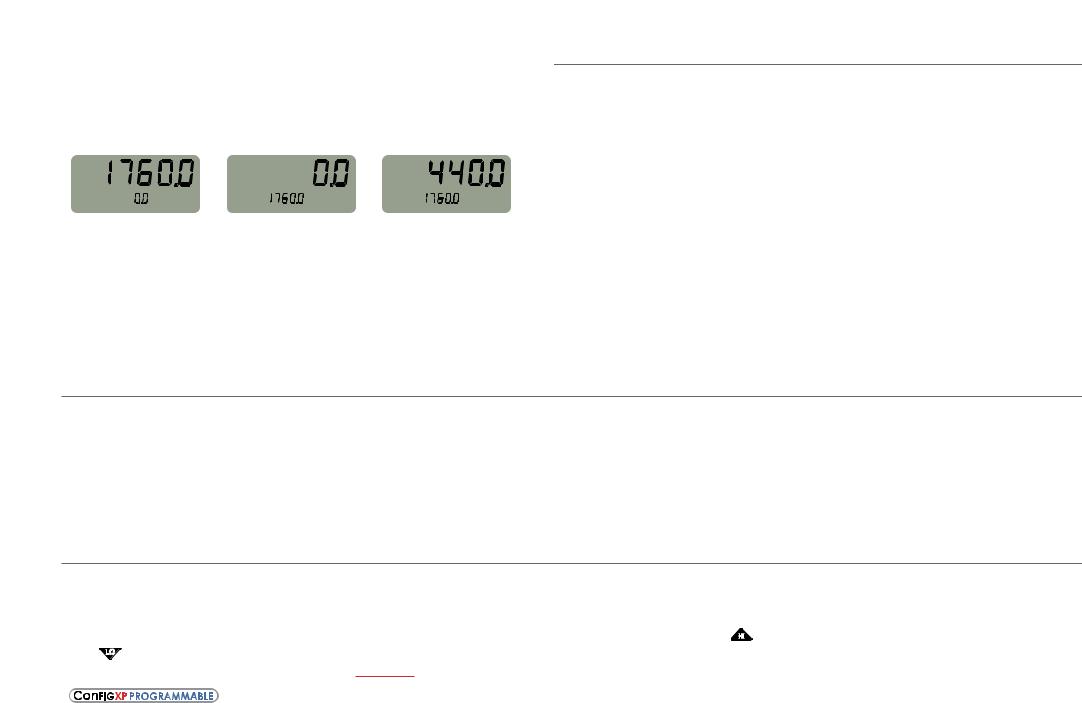

Tare is a constant value subtracted from the true pressure. For instance, if you were mixing gases by partial pressure, you might want to fill a tank to 1760 psi with air, then add another 440 psi of helium. To reduce the chance of error, you could tare the gauge at 1760 psi. Then you would add helium until the indication reached 440.

|

|

|

|

PSI |

|

|

PSI |

|

|

PSI |

TARE |

TARE |

TARE |

||||||||

Fill to pressure |

Press the Tare button |

Top-off with helium |

||||||||

In contrast to the Zero function discussed previously, Tare is not subject to the Zero Limit set in ConfigXP. Tare is available only when the TARE icon is on. To use the Tare feature, press the (peak) button repeatedly until the screen displays the TARE icon. The TARE icon will flash to remind you that live pressure may not be indicated on the screen. Apply pressure to the gauge until you reach the desired value. Press the (zero) button. The top line will change from true pressure to zero. The amount of the tare will be displayed on the second line.

To clear the tare, press and hold the (zero) button until the tare value changes from ( ) to (

) to ( ).

).  The Tare function is disabled by default, but can be enabled with ConfigXP.

The Tare function is disabled by default, but can be enabled with ConfigXP.

Rate (-DD, Dual-Line Display XP2i Only)

Rate is the measurement of pressure change per minute. When in Rate mode, the second line will display the rate, and the /min icon will display. Rate is calculated at every pressure measurement (4 times per second), and the displayed value is the average of the most recent 3 to 10 calculations. By increasing the number of calculations in the average, the XP2i will indicate a more stable rate. However, the XP2i will react more slowly to changes in rate.

To use the rate feature, press the (peak) button repeatedly until the /min icon displays. As pressure changes, the second line will indicate rate of change.

The rate function is disabled by default, but can be enabled and configured with ConfigXP. The number of calculations can also be set with the digital interface.

The rate function is disabled by default, but can be enabled and configured with ConfigXP. The number of calculations can also be set with the digital interface.

Differential Mode (-DD, Dual-Line Display XP2i Only)

Differential mode allows the XP2i-DD gauge (the master) to be connected to a second XP2i or XP2i-DD gauge (the slave) and display the pressure difference between the two gauges. A standard RS232 cable (p/n 2400) and null modem adapter (p/n 3456) or a null modem cable are required to directly connect the gauges. You must use ConfigXP to enable this feature, and once enabled, use the (peak) button on the master gauge until the Peak High ( HI

) and Peak Low ( LO ) icons are displayed simultaneously. An XP2i-DD gauge must be running firmware version R0114 or later, and an XP2i gauge must be running firmware version R0014 or later for this feature to work. Use XP2iUpdate to upgrade to the latest firmware.

) and Peak Low ( LO ) icons are displayed simultaneously. An XP2i-DD gauge must be running firmware version R0114 or later, and an XP2i gauge must be running firmware version R0014 or later for this feature to work. Use XP2iUpdate to upgrade to the latest firmware.

The differential mode is disabled by default, but can be enabled and configured with ConfigXP.

XP2i Operation Manual

Functions 6

Automatic Shut-off

The XP2i has a shutoff timer and will turn off automatically after 20 minutes of non-operation. Pressing any button or sending any command via the RS-232 connection resets the shutoff timer for another 20 minutes of operation. The XP2i will briefly display Auto Off 20 when turned on.

To disable the shutoff feature, turn on the XP2i by pressing the (on/off) and (zero) buttons simultaneously. The XP2i will briefly display the words No Auto Off to indicate that it will not turn off. The shutoff feature can be enabled again when turning the XP2i on, by pressing the same (on/off) and (zero) buttons. These settings are retained when the product is powered down.

Note: This key combination will not toggle the auto-shutoff feature if ConfigXP is set to require a password before changing settings.

Backlight

Pressing the (backlight) button instantly lights the display at maximum brightness. Hold down the button for 1 second to keep it on. The display will flash briefly, indicating that it will stay on for 1 minute. If you press the (backlight) button again, the backlight will go into a lower brightness setting to extend battery life, and remain on for 2 minutes after the last key is pressed. Press the (backlight) button once more and the light will go out.

If you start the XP2i in the No Auto Off mode, you may select the brightness level in the same way. The light will never time out and turn off. Turn off the XP2i, or press the (backlight) button repeatedly, to turn off the backlight.

Measuring Vacuum

All versions of the XP2i can be used to measure moderate vacuum, though only ranges of 300 psi (and 20 bar or 2000 kPa) and lower are actually tested and certified for vacuum operation.

When measuring pressure less than ambient barometric conditions, a minus (-) sign will appear.

Absolute gauges (models with a “B” in front of “XP2i” in the part number) will NOT indicate a negative sign when vacuum is applied, unless the (zero) button has been pressed while a pressure greater than full vacuum is applied to the gauge. If your absolute gauge does indicate a negative pressure, you can clear the zero value (“unzero”) by pressing the (zero) button until the display changes from ( ) to (

) to ( ).

).

!!CAUTION: XP2is are not recommended for continuous use below -14.5 psig.

For continuous use below -14.5 psig with high accuracy, choose our XP2i-DP Differential Pressure Gauge.

XP2i Operation Manual

Functions 7

Water Density (Inches of Water)

The following applies only to models where inches of water is a selectable pressure unit. As shipped from the factory, the XP2i is set to display inches of water corresponding to the density of water at 4° C (39.2° F). You may require a different water density for your application, so the XP2i can be set to use the density of water at 20° C (68° F) or 15.6° C (60° F) instead.

To check and/or change the water density setting from the keypad, turn on the XP2i by pressing the (on/off) button and the (peak) button simultaneously. The display will indicate either 4C, 60F, or 68F.

Press the (units) button until the display cycles to the desired water density, then press the (zero) button to store the selection (this will not zero the gauge).

Select and set the desired density of water.

Select and set the desired density of water.

Note: If the XP2i is password protected, or inches of water is disabled, you will not be able to view or change the water density from the keypad.

Overpressure Conditions

The XP2i will read pressure up to approximately 110% of the rated pressure range. Above 110% percent of the range the display will start flashing and the readings will not be reliable. The zero function does not affect the point at which the display starts flashing to indicate overpressure, so depending on the zero value it is possible that the display can start flashing without the maximum pressure being displayed.

For instance, if a 100PSIXP2i is zeroed when 30 psi is being applied, it will indicate that the overpressure condition has been reached at 80 psi (i.e., 110% x 100 psi – 30 psi = 80 psi).

Overpressure can affect accuracy, but the effect is only temporary unless the sensor has been destroyed. See Pressure Ranges, Display Scales, & Resolution on page 28 for maximum overpressure.

PSVtest Mode

PSVtest mode is designed for PSV and PRV (“Pressure Safety Valve” and “Pressure Relief Valve”, respectively) as well as for Rupture Disc (also known as “Burst Disc”) testing. It increases the measurement rate of the XP2i gauge to approximately eight times per second, to capture the peak pressure when the valve opened, and adds a method of automatically capturing the closing reseat pressure.

Use ConfigXP to activate PSVtest Mode. When the Peak High icon ( HI

) flashes, PSVtest mode is enabled. A special feature of PSVtest is that Peak Low is automatically reset to the Peak High value whenever a new Peak High value is detected. Once pressure stops increasing, as when a PSV opens (and the pressure drops below the maximum pressure) XP2i detects the new minimum pressure values (the Peak Low), capturing the closing pressure of a PSV.

) flashes, PSVtest mode is enabled. A special feature of PSVtest is that Peak Low is automatically reset to the Peak High value whenever a new Peak High value is detected. Once pressure stops increasing, as when a PSV opens (and the pressure drops below the maximum pressure) XP2i detects the new minimum pressure values (the Peak Low), capturing the closing pressure of a PSV.

Press the (peak) button once to view the captured reseat pressure. The Peak Low icon ( LO |

) will flash on the display. |

To clear the peaks, press the (clear) button while the display shows the High ( HI ) or Low ( |

LO ) icons. |

Application note AN-006–Pressure Safety Valve Testing detailing the operation of the PSVtest mode is available on xp2i.com, and includes examples on how to use the gauge in relief valve and burst disk testing.

XP2i Operation Manual

Functions 8

Low Battery Indication

The Battery icon ( ) uses three bars to display the battery level. When the icon displays all three bars, the batteries are full. The XP2i will continue to operate accurately while the icon is visible. When the batteries are exhausted, the letters batt will appear across the display. After batt appears, no pressure measurements will be possible until the batteries are replaced.

) uses three bars to display the battery level. When the icon displays all three bars, the batteries are full. The XP2i will continue to operate accurately while the icon is visible. When the batteries are exhausted, the letters batt will appear across the display. After batt appears, no pressure measurements will be possible until the batteries are replaced.

Battery Replacement

The XP2i uses 3 AA batteries. Loosen the four rear panel screws to gain access to the battery compartment. These four panel screws are captive inside the panel and are not removable. Pull the panel up to expose the battery compartment. After replacing the batteries, the XP2i will start operating immediately (without having to press the (on/off) button). This indicates that a complete reset has occurred, and is normal.

!!WARNING: Do not remove or change the batteries in hazardous locations.

!!WARNING: T4 or T3 Temperature Class is based on selection of approved battery. See the table below. !!CAUTION: Do not mix battery types or manufacturers.

ATEX/IECEx: The XP2i is Intrinsically Safe only if powered by one of the following battery types:

Approved Battery Type |

Ta= |

Marking |

|

|

|

|

|

Rayovac Max Plus 815 |

-20 to 50° C |

Ex ia IIC T4 Ga |

|

|

|||

Energizer E91* |

|||

|

|

||

Energizer EN91* |

-20 to 50° C |

Ex ia IIC T3 Ga |

|

Duracell MN1500 |

|||

|

|

||

|

|

|

*Energizer is manufactured by Energizer Holdings, Inc., and the Eveready Battery Company, Inc.

Many other battery types and models have been tested but failed to meet the requirements for Intrinsic Safety—do not assume other models are equivalent. The XP2i can be operated from an external power supply (AC adapter kit PN: 2984).

!!WARNING: Do not use AC adapter in hazardous locations.

CSA: The XP2i is Intrinsically Safe only if powered by one of the following battery types:

CSA: The XP2i est un système à sécurité Intrinsèque seulement s’il est alimenté par un des Piles de type suivant:

Approved Battery Type |

Ta= |

Marking |

|

(Approuvé Type de Batterie) |

(Marquage) |

||

|

|||

|

|

|

|

Rayovac Max Plus 815 |

-20 to 45° C |

Class I, Division 1, A, B, C, D T4 |

|

(Classse I, Division 1, A, B, C, D T4) |

|||

|

|

||

|

|

|

|

Energizer E91 |

|

Class I, Division 1, A, B, C, D T3C |

|

|

|

||

Energizer EN91 |

-20 to 50° C |

||

(Classse I, Division 1, A, B, C, D T3C) |

|||

|

|

||

Rayovac Max Plus 815 |

|

||

|

|

||

|

|

|

!!WARNING: Use of Duracell MN1500 batteries is not approved for CSA certification.

XP2i Operation Manual

Functions 9

Reset

If for some reason the XP2i needs to be reset, remove any battery for at least one minute, then reinstall the battery. If the reset is successful, the XP2i will start operating without pressing the (on/off) button. Reset will clear the zero, peak values will be reset to the current reading, and the XP2i will be set to the default engineering units.

!!WARNING: Do not remove or change the batteries in hazardous locations.

Communications/Programming

The XP2i responds to a query-based command language which allows remote control of the gauge. Please refer to the XP2i Programming Instructions for documentation of this feature.

XP2i Operation Manual

Data Logging with DataLoggerXP 10

Data Logging with DataLoggerXP

WHAT IS DATALOGGERXP?

WHAT IS DATALOGGERXP?

DataLoggerXP is an optional data logging mode available for the XP2i gauge. You may purchase the DataLoggerXP option with your original order or add it later.

With the XP2i’s long battery life, and Ultra Low Power (ULP) mode, you can log data over an entire year, without the need for external power supplies or battery replacements.

Download the DataLoggerXP software from the Crystal website and use it to save the data recorded on your XP2i.

Note: An evaluation mode allows you to record 100 data points before requiring purchase.

With an XP2i and DataLoggerXP you can:

•Record up to 32 000 pressure measurements (data points) into non-volatile flash memory.

•Save battery life and record over an entire year with Ultra Low Power (ULP) mode.

•Change data collection parameters, with or without a computer.

•Start and stop multiple collection runs from the keypad.

•Record pressure readings at intervals as fast as once per second or as slow as once every 18 hours.

•Record the averages, averages and peaks, or just the pressure indication.

•Store an indicated pressure by pushing one button.

•View the data on any Windows-equipped computer.

•Save the data files directly into Microsoft® Excel spreadsheets (requires Excel 2003, 2007, or 2010), or as comma separated text files.

XP2i Operation Manual

Data Logging with DataLoggerXP 11

DataLoggerXP Terminology

Clear Removes all stored data from the XP2i memory. Individual runs cannot be removed.

Download The act of copying stored data from the XP2i to a computer using DataLoggerXP software.

Events Non-data readings, optionally displayed as part of a run. These include tare values, low battery indications, or logging parameters.

Logging Interval The time, in seconds, between each data point.

Logging Type The type of data stored for each reading.

Logging Parameters The Logging Interval and Logging Type are referred to, in this document, as the Logging Parameters.

Run A set of one or more readings taken by the XP2i. The user can specify different logging parameters for each successive run.

Note: A maximum of 64 runs can be stored in memory.

Typical Usage

While there are a variety of ways in which the DataLoggerXP software and XP2i can be used, a typical way to use the DataloggerXP might be like this:

1Set the logging parameters–either with DataLoggerXP software or directly from the keypad.

2Enable data logging mode (the Record icon (  ) will illuminate).

) will illuminate).

3Take a recording.

4Use DataloggerXP software to download your data into an Excel worksheet or a text file.

XP2i Operation Manual

Loading...

Loading...