Page 1

DE50 IDE Install Guide

Removable Ultra ATA 100 Drive Enclosure

NOTE: For Ultra ATA100 (100MByte/sec) operation, an Ultra ATA100 control-

ler and hard drive(s), and appropriate 40-pin, 80-conductor cable are required.

Rugged, Reliable, Mobile, Secure

TM

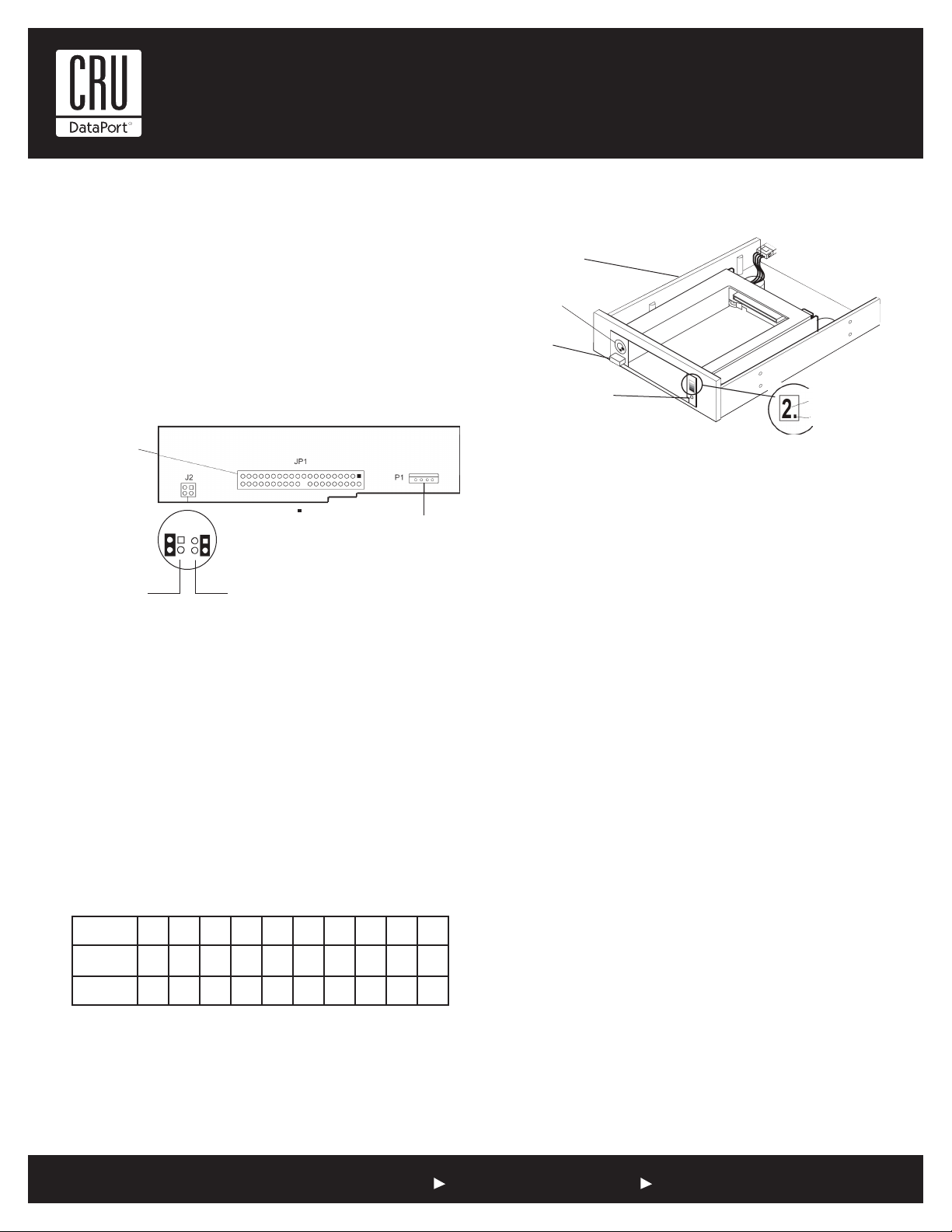

Drive Carrier Installation

Drive Carrier

Circuit Board

Top

Cover

Drive Mounting

Figure 1: Drive Carrier Disassembly

1. Loosen and remove the four (4) M3 Phillips Flat Hd. screws located on

the sides of the drive carrier unit. Save these screws for Step 6.

2. Since the drive carrier unit is shipped pre-assembled, disassemble the

drive carrier unit into its three (3) main components (Figure 1).

3. Install the Drive Carrier Circuit Board (cable-side down) onto the drive

by attaching the I/O cable on the board to the drive.

4. Set Master/Slave drive designation. There are two ways to set the

Master/Slave drive designation for the DE50 unit, as described below.

Bracket/Bottom

Plate Assembly

Drive Select Method

In most cases, this method forces the drive into either a Master or Slave

Drive configuration. This method will override any configuration of the Master/Slave Selection Jumper Option (J2) on the receiving frame motherboard.

The J2 jumper option is instead used to configure the unit ID display.

Master Drive

Remove the jumper from JMP1. Typically, no jumper installed on JMP1

forces the carrier into a Master Drive configuration (Figure 2).

Leave the J2 jumper option (on the receiving frame motherboard) as is for

Master Drive ID display purposes (factory-configured jumper is for Master

Drive designation).

Slave Drive

Install the jumper on JMP1 Pins C & D (Figure 2). Typically, a jumper

installed on Pins C & D forces the drive into a Slave Drive configuration

(refer to the drive manufacturer’s documentation for exact master/slave

jumper settings and reconfigure the jumper as necessary).

Configure the J2 jumper option for Slave Drive ID display purposes.

I/O Connector

NOTE: The information below is based on typical drive specifications.

Since specifications (specifically, pin assignments) between drive

manufacturers may vary, please refer to your drive manufacturer’s

documentation for information regarding Master/Slave configuration.

Cable Select Method (Recommended Method)

In most cases, there is no need to reconfigure the jumper on JMP1 located

on the rear of the drive carrier circuit board. A factory-installed jumper on

Pins B & D forces the drive into a Cable Select configuration (Figure 2).

With Cable Selection, the Master/Slave Drive designation is handled by

the Master/Slave Selection Jumper Option (J2) on the receiving frame

motherboard. If necessary, reconfigure jumper (factory-configured jumper

is for Master Drive designation). Skip section “Drive Select Method” and

continue with Step 5 of the Installation process.

Cable Select

Configuration

Jumper Installed

on Pins B & D

(Factory Default)

Figure 2: Drive Carrier Circuit Board

Recommended

Configuration

Typical Master Drive

Configuration

No Jumper

Installed

or

Typical Slave Drive

Configuration

Jumper Installed

on Pins C & D

5. Carefully turn the drive/circuit board assembly upside-down (drive is

bottom-mounted into bracket). Install the drive mounting bracket and

secure with four (4) M3 screws (provided).

NOTE: Make sure that the drive circuit board is properly seated in

the mounting bracket slot before tightening screws.

6. Carefully insert the drive/bracket assembly into the top cover and

secure with the four (4) M3 screws (saved from Step 1).

1-800-260-9800 www.CRU-DataPort.com

Page 2

Rugged, Reliable, Mobile, Secure

TM

Master/Slave J2 Jumper Option on the Receiving Frame Motherboard (Figure 3)

Master/Slave Selection Jumper (J2)

Master Drive configuration (Factory Default). Change jumper position to set

Slave Drive configuration.

Forces master/slave drive configuration on the receiving frame if JMP1

jumper option (located on the drive carrier circuit board) is configured to

Cable Select.

If using the Drive Select Method, this option is instead used to configure

the unit ID display (refer to Figure 4 for further information).

I/O

Connector

= Pin1

DC Power

Connector

Motherboard (rear view)

Figure 3: Receiving Frame

Slave Drive

Select (1)

J2

Master Drive Select (0)

(Factory Default)

For 5.25” peripheral slots, the 5.25” adapter bracket must be installed. The

receiving frame is side-mounted into the adapter bracket using four (4) M3

Phillips Pan Head screws (provided).

With the drive carrier locked in place inside the receiving frame, install the

DE50 into the 5.25” drive opening in the computer or expansion chassis.

Use the appropriate guides to position the DE50 unit, and fasten it into

place with four (4) self-tapping screws (included). Mounting holes are provided on each side and the bottom of the adapter bracket to accommodate

a variety of mounting configurations. Use the mounting holes which best

suit the computer or expansion chassis configuration.

Unit ID Select Switches Settings

The following table lists the unit ID select switch settings and the valid AT/

IDE unit numbers. Please note that all invalid switch settings have shaded

boxes and result in a blank display in the receiving frame window.

Unit ID Select

Position

Unit ID Select

Position

Unit ID Number

Display

NOTE: The unit ID number display is for ID display purposes only (when

using the Drive Select Method). The master/slave setting must still be set

on the DE50 unit itself (refer to Page 1 for further information).

0 1 2 3 4 5 6 7 8 9

Mas-

X

Blank 0 1 Blank Blank 2 4 Blank Blank Blank

Slave

ter

Figure 4: Unit ID Select Switch Settings

X X

Mas-

ter

Slave

X X X

Selecting the Unit ID Number

Use the alignment tool (provided) to select the ID number of the disk drive.

5.25” Adapter Bracket

(shown installed)

Key Lock &

Power Switch

Eject Button

Unit ID Select

Switch Location

Figure 5: Unit ID Select Switch Location

Unit ID Number

Indicator

Activity Indicator

NOTE: The lock on the Data Express receiving frame functions as a

lock and a DC power switch for the carrier unit. The lock MUST be

engaged (turned counterclockwise) in order to supply power to the

carrier and installed drive unit.

Limited Product Warranty

CRU-DataPort (CRU) warrants the Data Express DE50 to be free of significant defects in material and workmanship for a period of three years from

the original date of purchase. CRU’s warranty is nontransferable and is

limited to the original purchaser.

Limitation of Liability

The warranties set forth in this agreement replace all other warranties. CRU

expressly disclaims all other warranties, including but not limited to, the

implied warranties of merchantability and fitness for a particular purpose

and non-infringement of third-party rights with respect to the documentation and hardware. No CRU dealer, agent or employee is authorized to

make any modification, extension, or addition to this warranty. In no event

will CRU or its suppliers be liable for any costs of procurement of substitute products or services, lost profits, loss of information or data, computer

malfunction, or any other special, indirect, consequential, or incidental damages arising in any way out of the sale of, use of, or inability to use any CRU

product or service, even if CRU has been advised of the possibility of such

damages. In no case shall CRU’s liability exceed the actual money paid for

the products at issue. CRU reserves the right to make modifications and

additions to this product without notice or taking on additional liability.

Certification

EMI Standard: FCC Part 15 Class B, CE

EMC Standard: EN55022, EN55024

FCC Certification

This device has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received; including interference that may cause undesired operation.

Register your product at www.CRU-DataPort.com

A7-050-0001 Rev 2.1

1-800-260-9800 www.CRU-DataPort.com

Loading...

Loading...