Crown TC 3000 Series, TC 3000-3.0 Maintenance Manual

M

Revision: A • Printed in Germany

MAINTENANCE MANUAL

TC 3000 SERIES

Order Number: 812573-006

Thi

s master manual is subject to continual updates.

It is intended solely for companies authorised by CROWN.

The distribution of its content or copies thereof to third parties is prohibited.

CROWN Gabelstapler GmbH & Co. KG

– European Headquarters –

Moosacher Str. 52

80809 München

Germany

Tel +49 (0)89 93 00 2 – 0

Fax +49 (0)89 93 00 2 – 133

All rights reserved under international and Pan-American Copyright Agreement.

Copyright 2008

CROWN Equipment Corporation

I

TABLE OF CONTENTS

II

Notes:

TABLE OF CONTENTS

III

TC 3000

TABLE OF CONTENTS

SAFETY PAGE SERIAL NO. CUT REV.

Description of Symbols and Indicators . . . . . . . . . . . . . . . . . . 3

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Other indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . 4

Maintenance and Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Parking the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Working on the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Starting the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warning and Instruction Decals on the Truck . . . . . . . . . . . . . 5

INTRODUCTION PAGE SERIAL NO. CUT REV.

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Attachments and Modifications . . . . . . . . . . . . . . . . 9

Using the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Contact Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LUBRICATION & ADJUSTMENT PAGE SERIAL NO. CUT REV.

Lifting and Jacking up the Truck . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

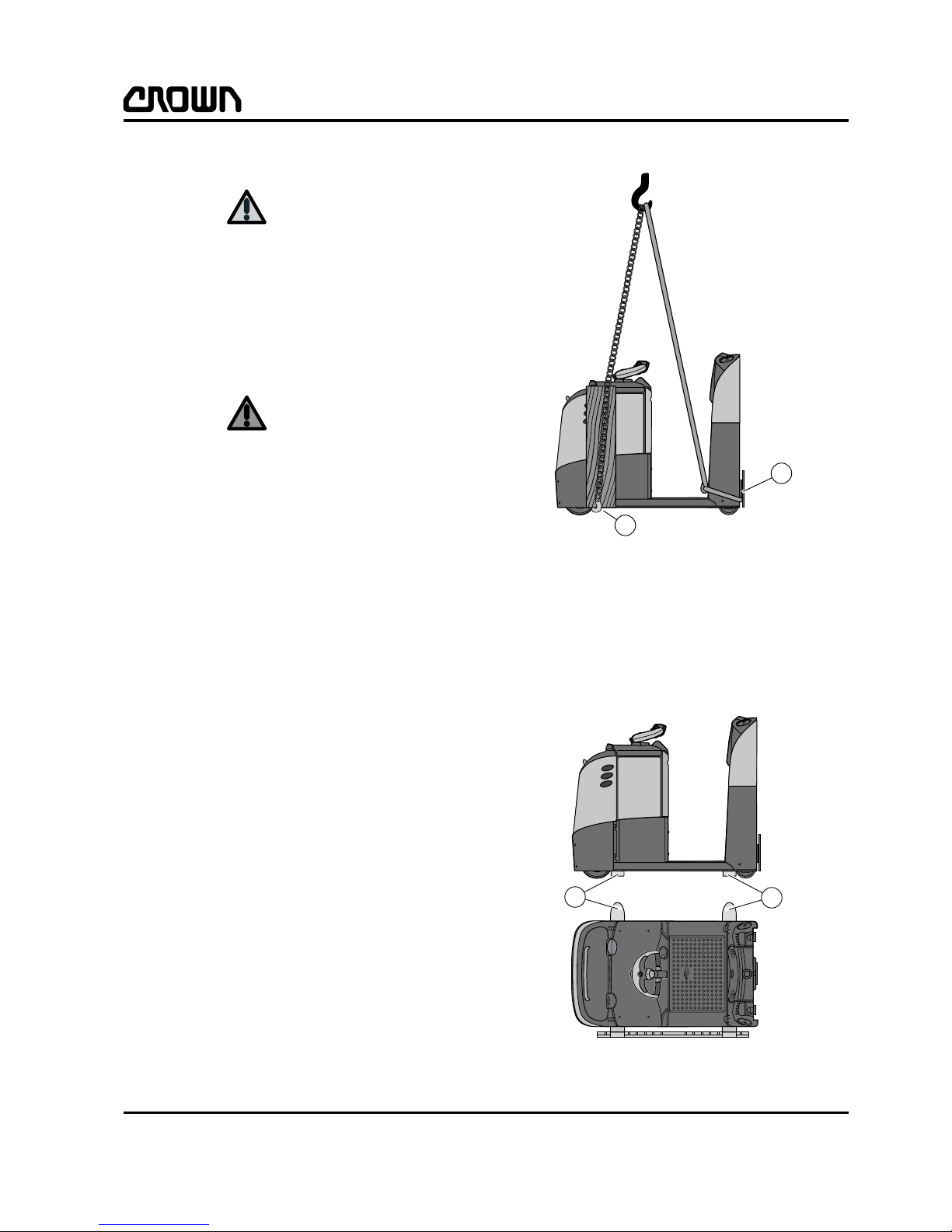

Lifting the truck with a crane . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting the truck with a forklift truck . . . . . . . . . . . . . . . . . . 13

Jacking up the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Towing the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Taking the Truck out of Service . . . . . . . . . . . . . . . . . . . . . . . . 16

Testing Re-Commissioned Trucks . . . . . . . . . . . . . . . . . . . . . 16

Restoring the Truck to Service . . . . . . . . . . . . . . . . . . . . . . . . 16

Recommended Lubricants and Accessories . . . . . . . . . . . . . 17

Cold Store Trucks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Planned Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inspection and Lubrication Points . . . . . . . . . . . . . . . . . . . . . 22

Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Castor Wheels and Skids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Adjusting the Castor Wheels and Skids . . . . . . . . . . . . . . . . . 26

DRIVE UNIT PAGE SERIAL NO. CUT REV.

Changing the Transmission Oil . . . . . . . . . . . . . . . . . . . . . . . . 29

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Replacing the Output Shaft Seal . . . . . . . . . . . . . . . . . . . . . . . 32

Special Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Shaft Seal Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Output shaft removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Output shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

TABLE OF CONTENTS

IV

TC 3000

Drive Wheel and Wheel Bolt Replacement . . . . . . . . . . . . . . .35

Drive Wheel Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Replacing the Wheel Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Drive Wheel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Replacing the Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Special Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Drive Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Drive Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Repairing the Drive Transmission Unit . . . . . . . . . . . . . . . . . .37

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Drive Transmission Unit Disassembly . . . . . . . . . . . . . . . . . . .38

Output shaft removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Bevel gear and bevel pinion removal . . . . . . . . . . . . . . . . .38

Drive Transmission Unit Assembly . . . . . . . . . . . . . . . . . . . . .39

Bevel pinion and drive pinion assembly . . . . . . . . . . . . . . .39

Bevel gear assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

ELECTRICAL SYSTEM PAGE SERIAL NO. CUT REV.

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Wire Colour Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Contact Symbol Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . .46

Electrical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Operator Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Operator Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Analyzer Menu - Status & Inputs . . . . . . . . . . . . . . . . . . . . . . .57

Analyzer Menu - Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Analyzer Menu - Access 2 Inputs . . . . . . . . . . . . . . . . . . . . . .60

Analyzer Menu - Access 3 Inputs . . . . . . . . . . . . . . . . . . . . . .61

Analyzer Menu - Access 3 Inputs . . . . . . . . . . . . . . . . . . . . . .62

Analyzer Menu - Access 5 Inputs . . . . . . . . . . . . . . . . . . . . . .63

Analyzer Menu - Test Outputs . . . . . . . . . . . . . . . . . . . . . . . . .64

Calibration - Rocker & Load Sensor . . . . . . . . . . . . . . . . . . . .65

Calibration - Steer System . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Selecting the CALIBRATION Menu . . . . . . . . . . . . . . . . . . . .82

Calibrating the Traction Potentiometer . . . . . . . . . . . . . . . . . .82

Steering Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

TABLE OF CONTENTS

V

TC 3000

Control Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Servicing and Replacing the Control Modules . . . . . . . . . . . 85

Discharging the Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Servicing the Control Modules . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing Control Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Event Codes - Access 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Event Codes - Access 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Drive Motor Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Drive Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Repairing the Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Dismantling the Rotor Assembly . . . . . . . . . . . . . . . . . . . 104

Assembling the Rotor Assembly . . . . . . . . . . . . . . . . . . . 104

Final task: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Steer Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Special Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Steer Motor Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Steer Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Repairing the Steer Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Steer Motor Disassembly . . . . . . . . . . . . . . . . . . . . . . . . 106

Steer Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Final tasks: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Contactors - Inspection and Repairs . . . . . . . . . . . . . . . . . . 108

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Control Module Safety Test . . . . . . . . . . . . . . . . . . . . . . . . . . 110

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Carrying out the PMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Testing Access 3 (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . 110

Testing Access 5 (SCM) . . . . . . . . . . . . . . . . . . . . . . . . . 110

BRAKE SYSTEM PAGE SERIAL NO. CUT REV.

Electromechanical Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Servicing the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Measuring the air gap . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Repairing the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Installing a wear part kit . . . . . . . . . . . . . . . . . . . . . . . . . 116

TABLE OF CONTENTS

VI

TC 3000

Replacing the brake in full . . . . . . . . . . . . . . . . . . . . . . . . 118

STEERING PAGE SERIAL NO. CUT REV.

Steering Assembly Installation and Removal . . . . . . . . . . . .123

Steering Assembly Components . . . . . . . . . . . . . . . . . . . . . .124

Steering Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . .124

Steering Assembly Installation . . . . . . . . . . . . . . . . . . . . . . .124

Final Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Steering Transmission Repair . . . . . . . . . . . . . . . . . . . . . . . .125

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Steering Transmission Disassembly . . . . . . . . . . . . . . . . . . . 125

Steering Transmission Assembly . . . . . . . . . . . . . . . . . . . . .125

Final tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Tiller Handle Components . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Tiller Handle Shell Removal and Assembly . . . . . . . . . . . . . .128

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Shell Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Shell Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Switch Unit Removal / Assembly . . . . . . . . . . . . . . . . . . . . . .130

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Switch Unit Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Switch Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

"Rabbit / Turtle" Toggle Module Removal and Assembly . .131

“Rabbit/Turtle” Toggle Module Disassembly . . . . . . . . . . . . .131

“Rabbit/Turtle” Toggle Module Assembly . . . . . . . . . . . . . . .131

Replacing the Tiller Handle PC Boards . . . . . . . . . . . . . . . . .132

Hydraulic PC Board Removal . . . . . . . . . . . . . . . . . . . . . . . .132

Hydraulic PC Board Assembly . . . . . . . . . . . . . . . . . . . . . . .132

Main PC Board Disassembly . . . . . . . . . . . . . . . . . . . . . . . .132

Main PC Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Traction Potentiometer Removal and Assembly

(POT Travel Switch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Traction Potentiometer Removal . . . . . . . . . . . . . . . . . . . . . . 133

Traction Potentiometer Assembly . . . . . . . . . . . . . . . . . . . . .134

Traction Potentiometer Calibration . . . . . . . . . . . . . . . . . . . .134

Safety Reverse Switch Removal and Assembly . . . . . . . . . . 135

Safety Reverse Switch Removal . . . . . . . . . . . . . . . . . . . . . .135

Safety Reverse Switch Assembly . . . . . . . . . . . . . . . . . . . . .136

Grip and Horn Switch Removal and Assembly . . . . . . . . . . .137

Control Handle Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Tiller Removal / Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Tiller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Tiller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Tiller Recuperating Spring Removal / Assembly . . . . . . . . .140

Recuperating Spring Removal . . . . . . . . . . . . . . . . . . . . . . . 140

Recuperating Spring Assembly . . . . . . . . . . . . . . . . . . . . . . .140

Steer Sensor Removal / Assembly . . . . . . . . . . . . . . . . . . . . . 141

Steer Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Steer Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Testing the Steer Sensor via the Analyzer Menu . . . . . . . . .142

Steering Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

TABLE OF CONTENTS

VII

TC 3000

PLATFORM PAGE SERIAL NO. CUT REV.

Platform Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Replacing the Platform Sensors . . . . . . . . . . . . . . . . . . . . . . 148

Platform Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Platform Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Platform Assembly and Testing the Platform Sensors . . . . . 14 8

Testing the Platform Sensors via the Analyzer Menu . . . 148

Possible error cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

SCHEMATIC DIAGRAMS PAGE SERIAL NO. CUT REV.

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

With Key Switch and Keypad . . . . . . . . . . . . . . . . . . . . . . . . . 154

Access™ 3/2 - Drive Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Access 2/3 - Logic Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Access 5 - Logic Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Access 8.1 - Tiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Access 8.2 - Backrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Switch Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Tiller Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Access 1 with Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

CAN connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Abbreviation List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Connectors and Sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Switches and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Wires and Wire Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . 169

Fuses and Fuse Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Wire Harness - Hitch Position Control Switch . . . . . . . . . . . 172

Assembly - Hitch Position Control Switch . . . . . . . . . . . . . . 174

Wire Harness - Hitch Position Control Switch F/C . . . . . . . 175

Horn Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Horn Switch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Assembly - SAS Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Main Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Spline Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

X10 Handle Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Display Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Programmer Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

CAN Handle Connection Wire Harness . . . . . . . . . . . . . . . . 190

Steer Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Straight Ahead Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Battery lock switch (BLS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Key Switch Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

DC / DC Converter Connector Cable . . . . . . . . . . . . . . . . . . . 195

DC / DC Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Power Supply Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Strobe Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Keypad Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

CAN Bus and Fuse Cable Extension . . . . . . . . . . . . . . . . . . . 200

CAN Bus cable extension . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Fuse Cable Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

TABLE OF CONTENTS

VIII

TC 3000

Main Contactor Cable Extension . . . . . . . . . . . . . . . . . . . . . . 201

Heating Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Alarm Connection Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Horn Filter Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Cable Pin 1 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Cable Pin 3 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Cable Pin 5 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Beacon Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Fan Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

1

SAFETY

2

Notes:

SAFETY

Description of Symbols and Indicators

3

TC 3000

Description of Symbols and

Indicators

Safety Notices

The following symbols will help you to assess the risk

to yourself, other people and materials should you fail

to comply with a safety notice:

DANGER

This symbol warns of immediate danger to the life and

health of personnel.

Severe injury or death will result.

Follow all instructions indicated by this symbol in order

to avoid injury or death.

WARNING

This symbol warns of potential danger to the life and

health of personnel.

Severe injury or death may result.

Follow all instructions indicated by this symbol in order

to avoid injury or death.

CAUTION

This symbol warns of possible danger to the health of

personnel.

Injury may result.

Follow all instructions indicated by this symbol in order

to avoid injury.

NOTE

This heading warns of material damage and indicates

additional information.

• This symbol denotes action to be taken to avoid

risks.

Other indicators

1., 2., 3. denote work steps to be taken.

(1), (2), (3) etc. indicate item numbers in illustrations.

• This symbol denotes a list.

SAFETY

General Safety Instructions

4

TC 3000

General Safety Instructions

Maintenance and Repair

Instructions

WARNING

Observe the safety notices contained in the maintenance manual, the operator manual and on the truck.

Failure to do so could result in serious or even fatal

injuries to maintenance and other person n el.

Powered trucks can become hazardous if maintenance

and service work are neglected. For this reason maintenance and inspections must be performed at sufficiently short intervals. There must be suitably trained

personnel and proper guidelines at your place of work.

Maintenance and Repairs

•

Work must be performed in accordance with these

service instructions and relevant service bulletins.

• Maintenance and repair work must only be per-

formed by qualified and authorized personnel.

• Keep fire protection equipment at ha nd and do not

use a naked flame to check fluid levels or to test for

leaks.

• Use groundwater neutral, non-flammable solvents

for cleaning. Always perform cleaning work over an

oil separator. Protect the electrical system against

damp.

• Keep the work place and battery charging station

clean, dry and well ventilated.

• Do not allow oils to penetrate the ground or the

drainage system. Used oil must be recycled correctly . Oil filters and dehumidifying inserts must be

treated as special waste. Observe the local authority regulations.

• Spilled battery fluid must be neutralized immedi-

ately and thoroughly rinsed.

• Keep the truck clean. This will facilitate tracing

loose or faulty components.

• Maintain the legibility of the data capacity plate and

data plate, warning and instruction decals.

• Truck modifications and additions may only be per-

formed with Crown’s prior written approval.

• The reliability , safety and suitability of Crown trucks

can only be ensured by using original Crown p arts.

Before Parking the Truck

•

Apply the brake until the truck comes to rest.

• Apply the parking brake.

• Switch off the truck and remove the key.

• When parking on a slope or incline always chock

all wheels.

Before Working on the Truck

•

Raise the truck so that the drive wheel can turn

freely.

• Apply the Emergency Disconnect and disconnect

the battery.

• Prevent the truck from rolling away and lowering.

• Allow sufficient room for manoeuvre when testing

the truck, to avoid endangering yourself and other

people.

Before Starting the Truck

•

Test the safety mechanisms.

• Get into the travel position.

• Test the travel direction switch, speed control,

steering, warning mechanisms and brakes.

SAFETY

General Safety Instructions

5

TC 3000

Warning and Instruction Decals on

the Truck

In the course of periodic maintenance work, check that

the warning and instruction decals on the truck are

complete and legible.

• Clean any dirty decals.

• Replace any faulty or missing decals.

The spare parts manual gives details of the labelling

and arrangement of the warning and instructio n decals

on the truck.

6

Notes:

7

INTRODUCTION

8

Notes:

INTRODUCTION

General

9

TC 3000

General

INFORMATION

This manual is intended only for trained, specialist

personnel who are authorised to carry out the

operations described.

Service Training

Crown offers appropriate truck-related training for

service personnel. For more information contact

Crown's service department.

Replacement Parts

This manual does not contain a spare parts list.

Replacement parts can be found in the spare parts

catalog.

Additional Attachments and

Modifications

WARNUNG

Untested modifications can lead to fata l ac cidents.

Any modification which alters the original condition of

the truck requires prior testing and approval in writing

by Crown (see contact address).

• The weight and position of attachments can have a

significant affect on the capacity and other features

of the truck.

• Modifications to the electrical system or the

subsequent installation of electric-powered

components can damage the truck.

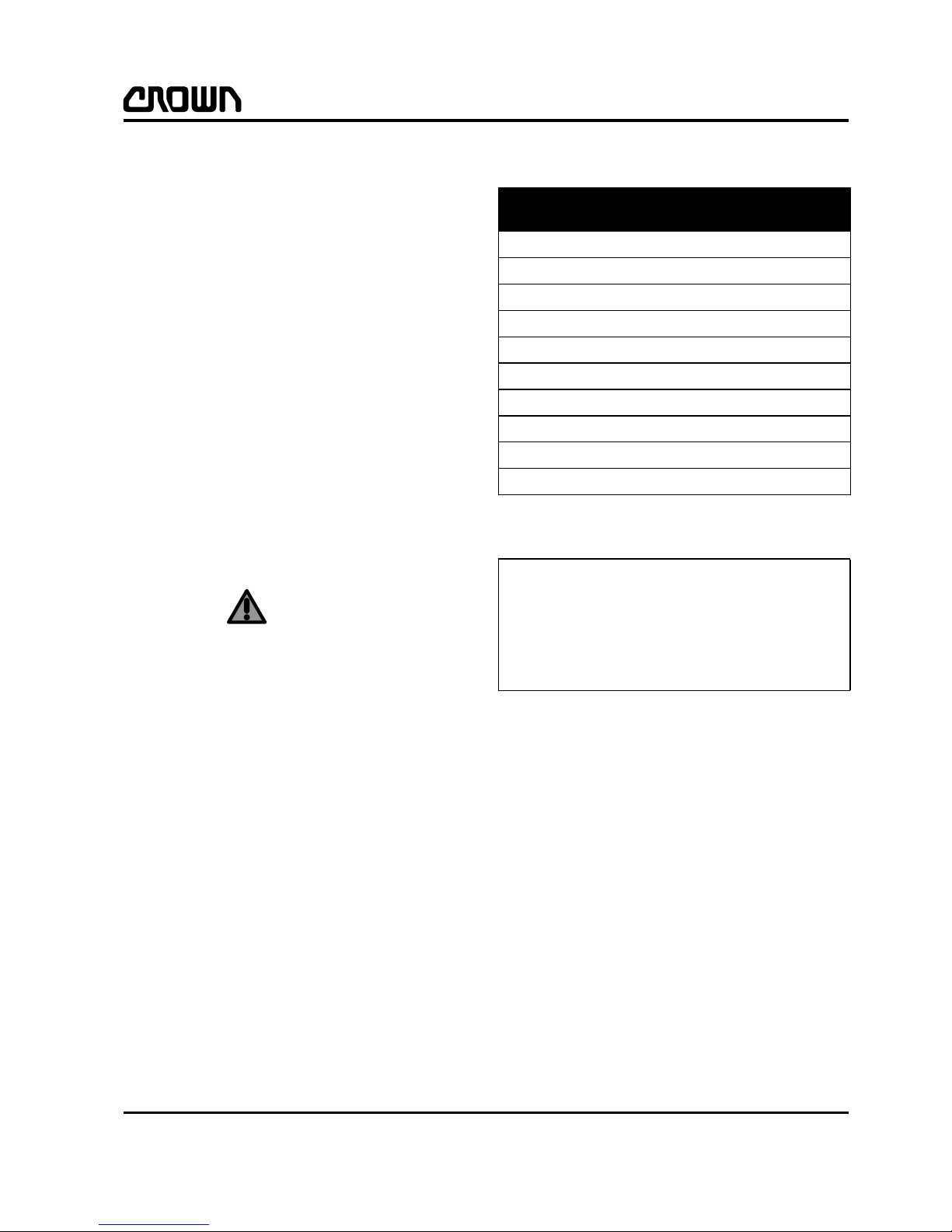

Using the Manual

Contact Address

:

Section

Table of Contents

Safety

Introduction

Lubrication & Adjustment

Drive Unit

Electrical System

Brake System

Steering

Platform

Schematic Diagrams

CROWN Gabelstapler GmbH & Co.KG

Moosacher Str. 52

80809 Munich

GERMANY

Tel.: +49 (0)89 / 93 002 -0

Fax: +49 (0)89 / 93 002 -175 or 133

INTRODUCTION

Models

10

TC 3000

Models

This manual covers maintenance and repair work for

the following model:

:

TC 3000-3.0

11

LUBRICATION & ADJUSTMENT

12

Notes:

LUBRICATION & ADJUSTMENT

Lifting and Jacking up the Truck

13

TC 3000

Lifting and Jacking up the Truck

CAUTION

Scalding risk from battery acid!

• You must remove the battery before transport-

ing the truck.

This will prevent possible battery acid leakage in the

truck and resulting material or personal damage.

Lifting the Truck

WARNING

Truck tipovers and falling loads can cause death!

• Make sure the lifting truck or crane as well as the

lifting gear have sufficient capacity.

Information on the capacity required can be found on

the truck data plate under “Truck Weight Less Battery”

and “Battery Weight”.

Lifting the truck with a crane

1. Remove the battery

2. Attach chains and hooks (2) to the cutouts in the

floorboard in front of the battery compartment (see

Fig.TC465).

3. Push a thin board on either side between the truck

and the chain.

4. Attach lifting slings around the tow hitch (1) (see

Fig.TC465).

Lifting the truck with a forklift truck

1. Remove the battery

2. Position the forks (1) of the truck that is doing the

lifting under the chassis of the lift truck (see

Fig. TC462).

TC465

TC462

2

1

1

1

LUBRICATION & ADJUSTMENT

Lifting and Jacking up the Truck

14

TC 3000

3. Attach the truck securely onto the forks (1) of the

truck doing the lifting (e.g. with a tensioning belt).

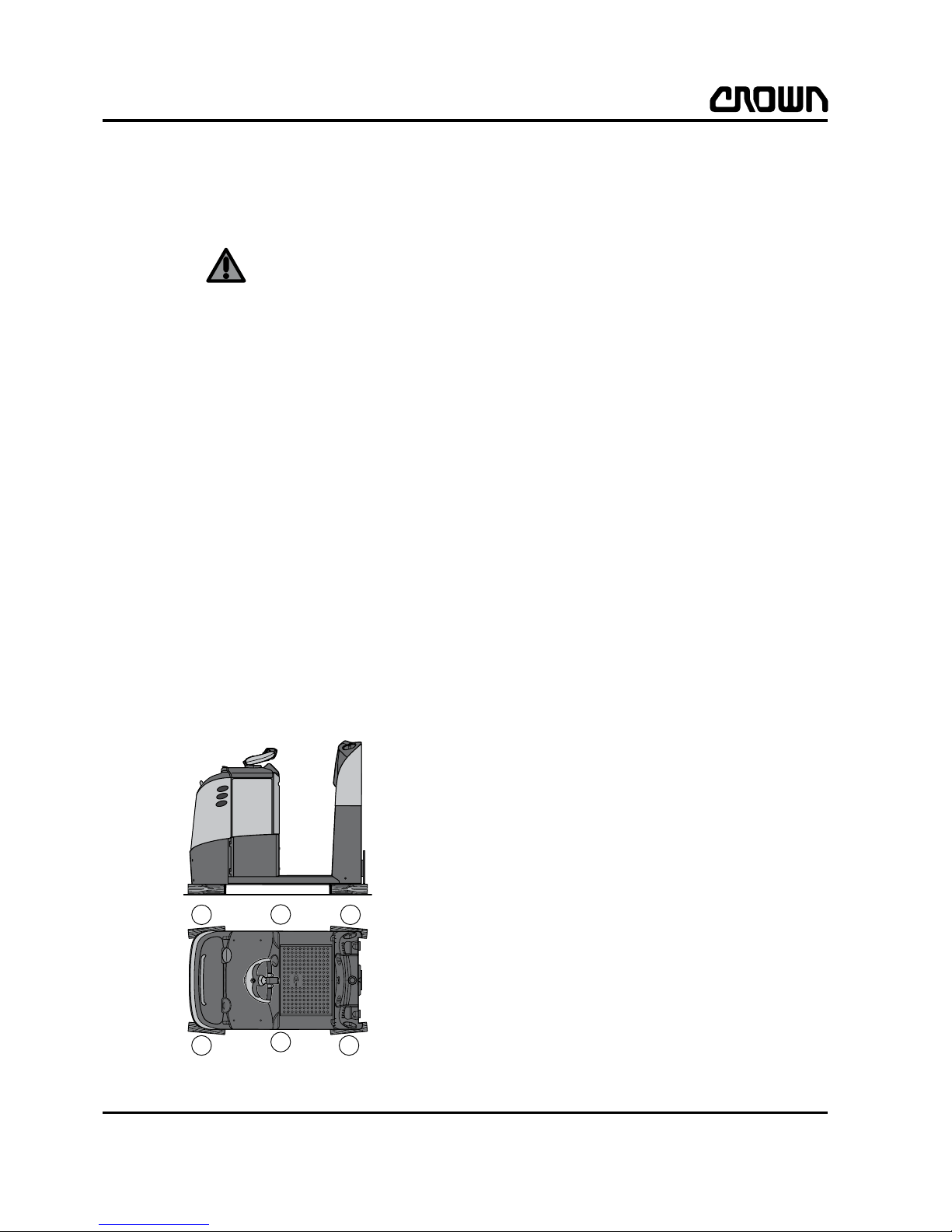

Jacking up the Truck

WARNING

Truck tipovers and incorrect handling of the

equipment can result in fatal injuries.

• Make sure the jack has sufficient capacity.

• Always support a raised truck with wooden blocks

or other suitable equipment to relieve the jack.

• Never place your hands or other parts of your body

under the truck before it has been supported.

Information on the capacity required can be found on

the truck data plate under “Truck Weight Less Battery”

and “Battery Weight”.

1. Place the jack in the centre of the left hand side of

the skirt (1, Fig. TC463) and raise the truck a

maximum of 20 mm.

2. Place hard wooden blocks (2) under the front and

rear ends of the chassis and lower the truck onto

them.

3. Place the jack in the centre of the right hand side

of the skirt (3) and raise the truck a maximum of

20 mm.

4. Place hard wooden blocks (4) underneath and

lower the truck.

TC463

1

3

4

4

2

2

LUBRICATION & ADJUSTMENT

Towing the Truck

15

TC 3000

Towing the Truck

WARNING

Truck tipovers and falling loads can cause death!

• Make sure the towing truck has sufficient capacity.

Information on the capacity required can be found on

the truck data plate under “Truck Weight Less Battery”

and “Battery Weight”.

NOTE

Risk of damage to the drive system!

As the drive wheel is braked on de-energised trucks,

the truck must be raised sufficiently when being towed

to prevent the drive wheel from contacting the ground.

1. Remove the battery.

2. Place the forks (1) of the towing tru ck un d er nea th

the lift truck (see Fig. TC464).

3. Raise the truck (approx. 20 mm) until the drive

wheel has been lifted off the ground.

4. Pull the truck slowly and only in a forward direc-

tion (as indicated by the arrow in Fig. TC464).

TC464

1

1

LUBRICATION & ADJUSTMENT

Taking the Truck out of Service

16

TC 3000

Taking the Truck out of Service

You must carry out the following tasks if you are withdrawing the truck from service for more than 3 months:

1. Disconnect the battery.

2. De-commission the battery in accordance with the

manufacturer‘s instructions.

3. Clean and then lubricate the truck.

NOTE

Note the following when cleaning the truck:

• Do not use pressure jets and/or solvents on the

truck.

• Do not use metal brushes.

• Do not wet-clean the electrical system.

• Do not use flammable cleaning agents.

• Take measures to protect the environment.

4. If possible store the truck in a dry room with as

constant a temperature and air humidity as

possible.

Do not park the truck outdoors or in a humid

environment.

5. If the truck has to be stored in hostile conditions

(e.g. saline atmosphere) treat the surface of the

truck with a suitable preservative to prevent

corrosion.

6. If the truck has to be stored in excessively dusty

conditions, cover it with a permeable material and

not plastic sheets as these can allow condensation

water to form.

7. Jack up the truck (see page 15), as otherwise the

constant pressure can cause the wheels to flatten.

Testing Re-Commissioned Trucks

Trucks that have been out of service for a long period

of time must be checked at regular intervals. T o do this,

proceed as follows:

1. Connect the battery and test the truck's functions.

2. Check the gear unit for leaks.

3. Check any anti-corrosion film that may have been

added and replace if necessary.

4. Disconnect the battery.

Restoring the Truck to Service

To restore the truck to service, proceed as follows:

1. Remove the anti-corrosion film.

2. Jack up the truck, remove the wooden blocks and

lower the truck.

3. Charge the battery or install a charged batt er y.

4. Connect the battery.

5. Carry out the daily safety inspection.

LUBRICATION & ADJUSTMENT

Recommended Lubricants and Accessories

17

TC 3000

Recommended Lubricants and

Accessories

The tables show typical lubricants used by Crown itself

in its facilities. However, you can use any lubricants

provided they meet the same technical criteria.

Cold Store Trucks

Special hydraulic oil, lubrication oil and grease must be

used for cold store trucks operating in low temperature

conditions (see table).

An anti-corrosion fluid (Crown no. 805236-004) must

be applied to all screws, washers, nuts, pins, retaining

rings etc. Carefully protect all electrical connections

and components against corrosion. For detailed information, refer to the Electrical System chapter.

Service intervals (see page 19) must be adapted to the

conditions of use.

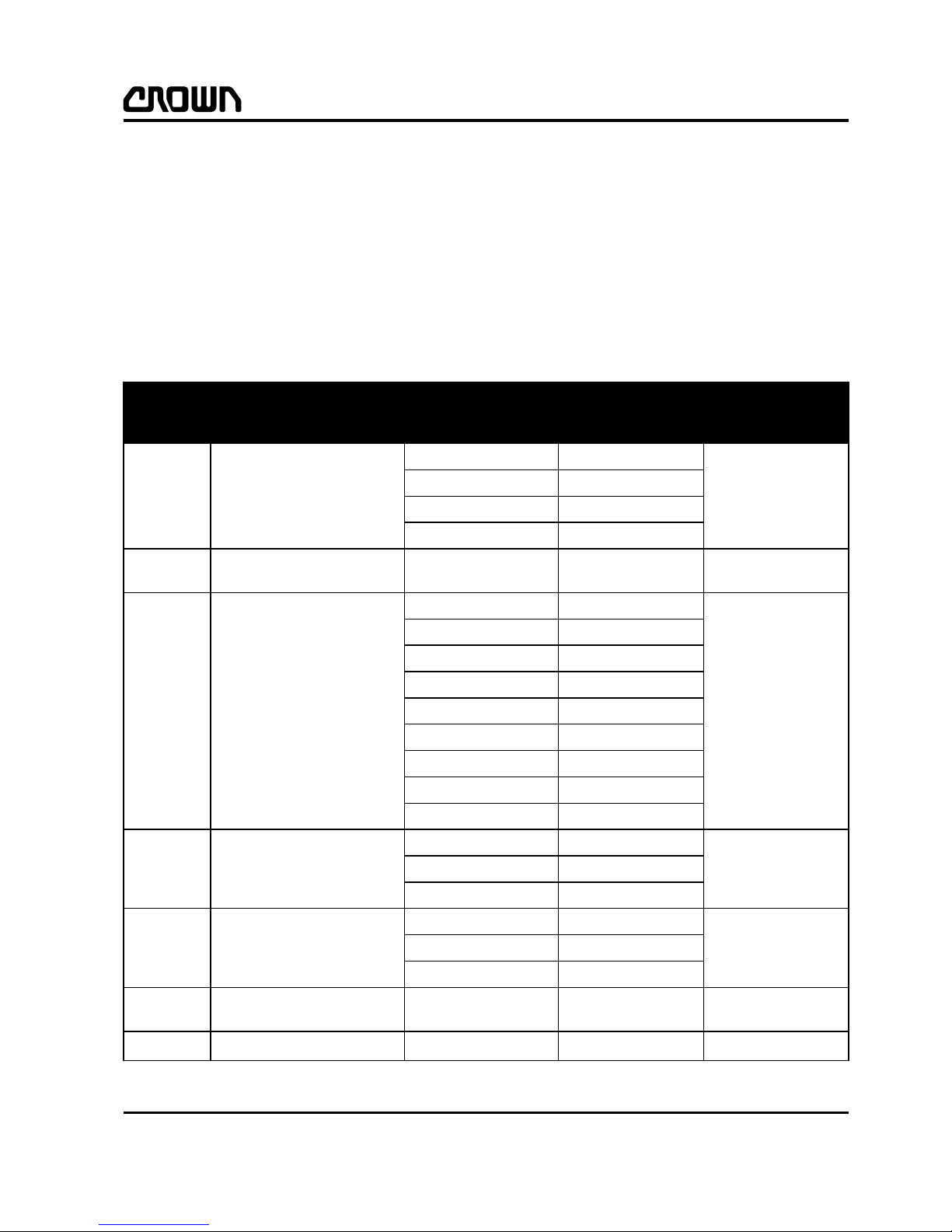

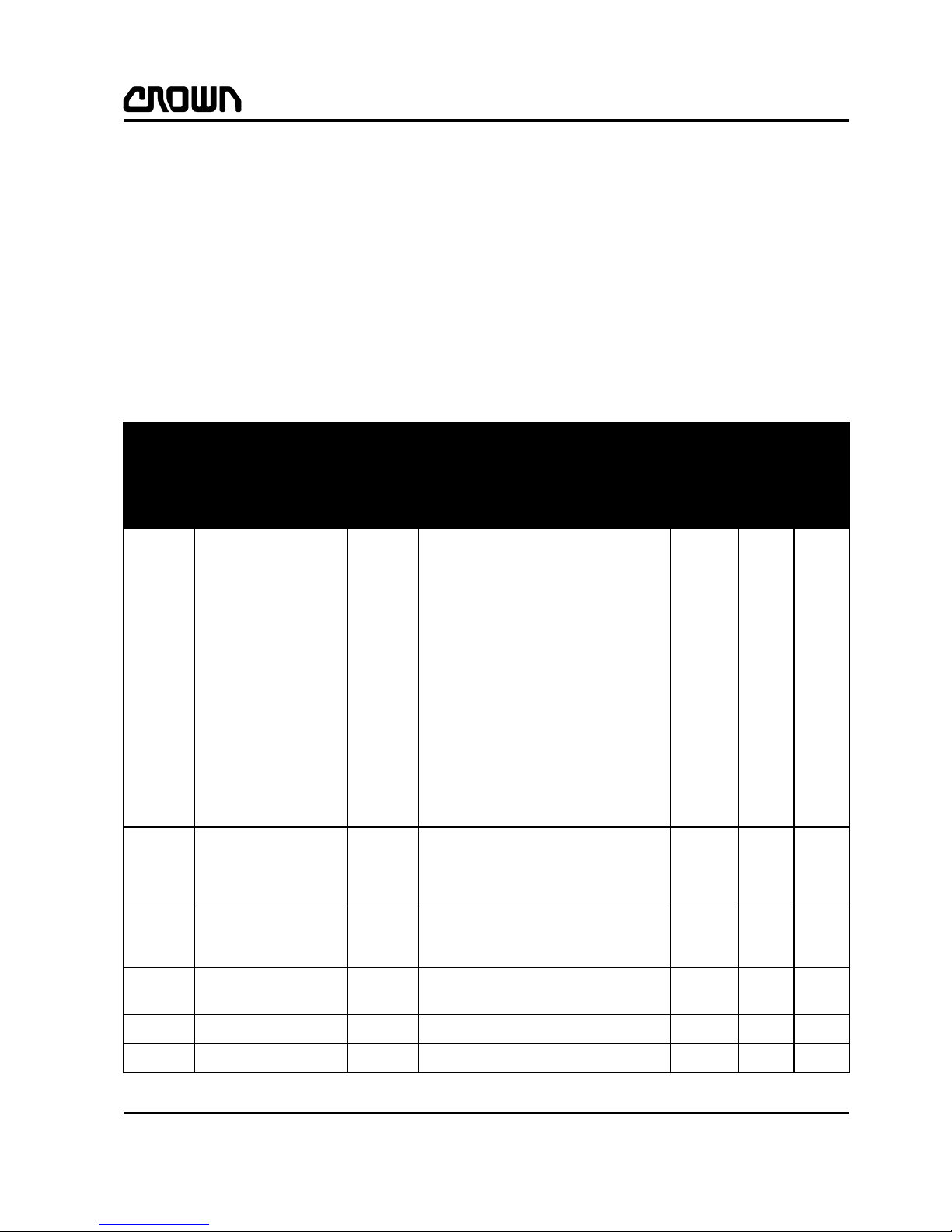

Type Lubricant Type Product Manufacturer Crown

Part Number

A

Transmission oil Hyp 85W90 Aral

053002-004

GX-D 85W90 Esso

Mobilube HD85W90 Mobil

Spirax MB90 Shell

AA

Low temperature transmission oil

Mobil SHC 624 Mobil

053002-009

B

Grease (Multi-Purpose) Aralube HLP2 Aral

053002-001

LM Grease Castrol

Regulus A2 Century

Beacon EP2 Esso

EP2 Maxol

Mobiluxe EP2 Mobil

Retinax LX Shell

ALGWMI SKF

Renolit MP Fuchs

BB

Low temperature grease Aralube SKL2 Aral

053002-005Unirex Lotemp EP Mobil

Duraplex EP2 Fuchs

G

Lubrication oil Essolube HDX+40 Esso

053002-007Kowal M 40 Aral

Delvac 1240 Mobil

GG

Low temperature lubrication

oil

Mobil SHC 626 Mobil

053002-008

M

Special grease

Molycote

®

BR-2 Plus

Dow Corning

-----------------

LUBRICATION & ADJUSTMENT

Recommended Lubricants and Accessories

18

TC 3000

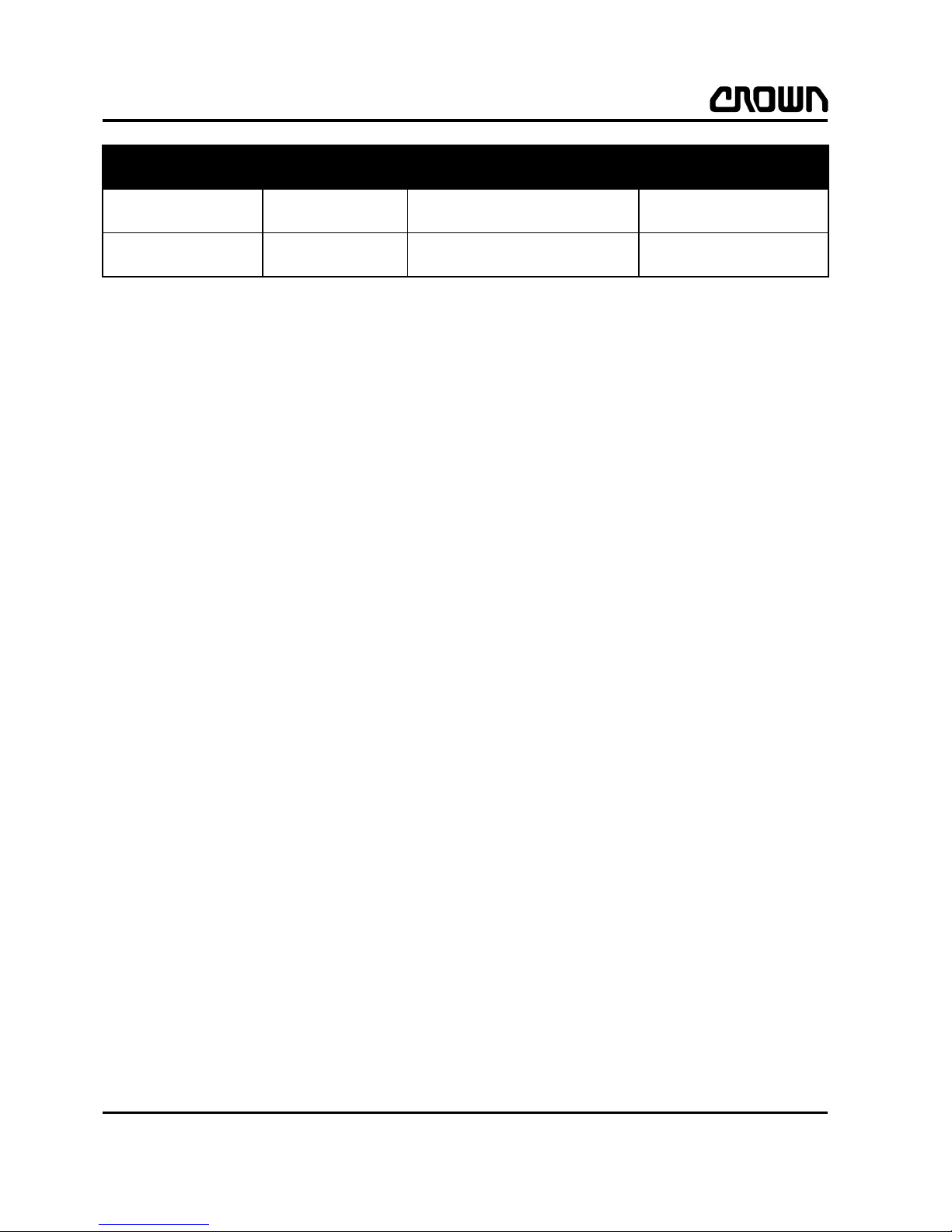

Lubricants Product Application Crown Part No.

Anti-corrosive agent Tectyl Corrosion inhibitor for cold store

trucks

805236-004

Rubber & Vinyl Dressing

Commercial Rubber Components, Plastic

Panels

-------------

LUBRICATION & ADJUSTMENT

Planned Maintenance

19

TC 3000

Planned Maintenance

The following inspection and maintenance schedule

assumes single-shift operation under normal conditions.

The maintenance intervals must however always be

adapted to the prevailing operating conditions. In dusty

or otherwise extreme operating conditions including

cold store application, the maintenance intervals specified must be reduced. Exact details should be discussed with a Crown service engineer.

Routinely check for wear, corrosion, damage, and test

component operation and safety when carrying out

maintenance work. If in doubt, replace components.

Planned maintenance must be performed either after a

certain number of service hours or a certain period of

time (whichever is reached first).

Guide to abbreviations:

M Months

h Service hours

X Perform on standard trucks

C Perform on cold store trucks

X/C Perform on standard and cold store trucks

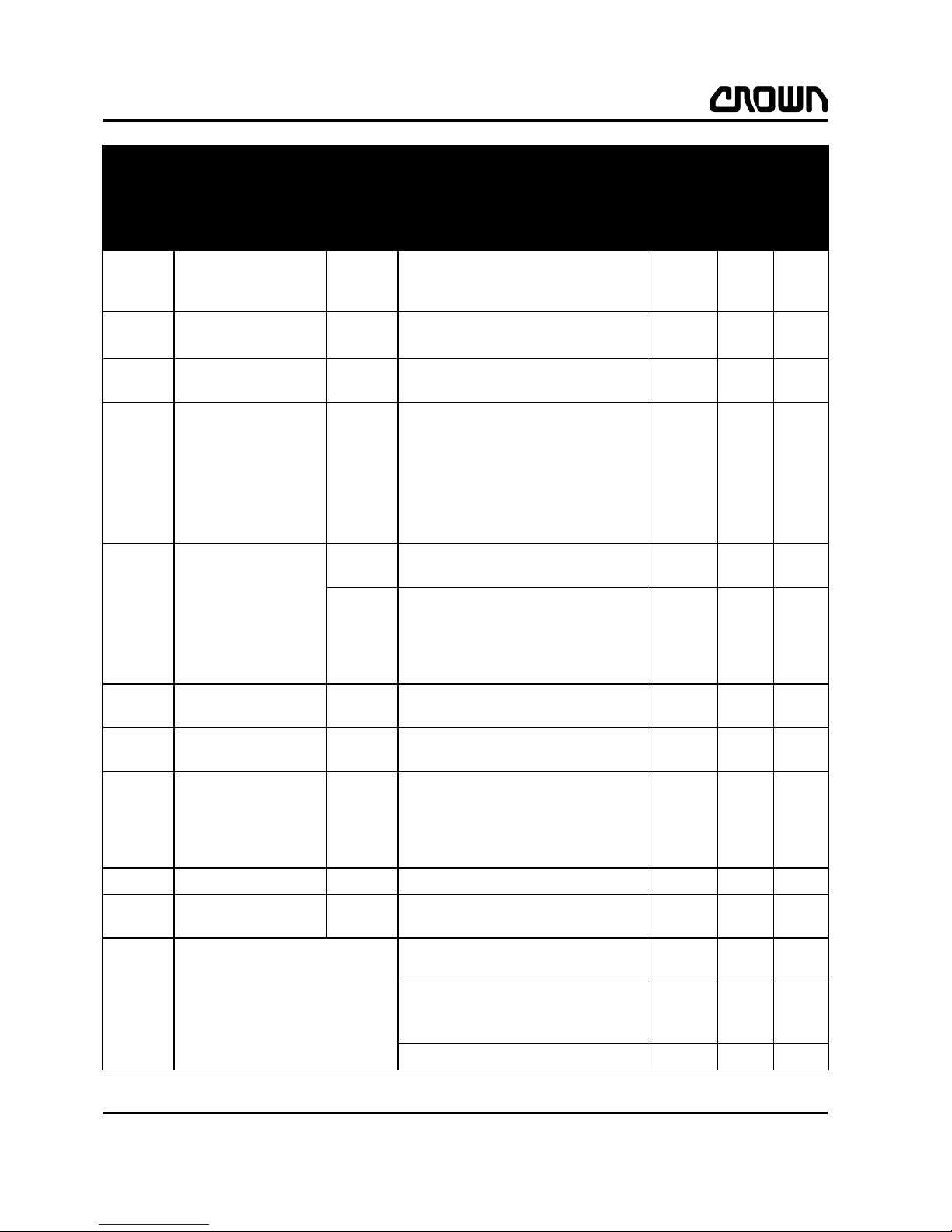

12 M 24 M 36 M

Position Component Lubri-

cant

Action 500 h 1000 h 5000 h

I-1 Truck, general Clean truck if necessary.

NOTE

Note the following when cleaning the

truck:

• Do not use pressure jets and/or

solvents on the truck.

• Do not use metal brushes.

• Do not wet-clean the electrical

system.

• Do not use flammable cleaning

agents.

• Note the environmental safety

guidelines.

X/C

I-2

Labels, decals

(a)

Check that labels and decals are legible.

Replace any illegible or severely damaged decals.

X/C X

I-3 Handles*

Backrest grab bar*

Work Assist ™*

Ensure it is fitted securely and check

for damage. X/C

I-4 Emergency

Disconnect

(b)

Test Emergency Disconnect power

switch.

X/C

I-5

Steering

(b)

Check operation.

X/C

I-6

Travel functions

(b)

Drive the truck in both directions.

X/C

LUBRICATION & ADJUSTMENT

Planned Maintenance

20

TC 3000

I-7

Brake

(b)

Test by changing the travel direction

with the travel switch.

Check brake switch.

X/C

I-8 Hitch Position

Control™

(b)

Test in both directions.

X/C

I-9 Load wheels and

castors

Check bearing play.

Check tyres for wear.

X/C

I-10 Drive wheel Check wheel nut torque (130 Nm).

NOTE

On new trucks or after removing/assembling the drive wheel, torque the

wheel nuts after 100 h to 130 Nm.

Check tyres for wear.

X/C

I-11 Drive motor Torque drive motor mounting screws

to 16 Nm.

X/C

Check that power cable connections

on the drive motor are secure.

Torques:

Torque the bottom nut to 7.5 Nm.

Torque the top nut to 2.5 Nm.

X/C

I-12 Drive transmission

unit

Torque drive transmission unit mounting screws to 70 - 75 Nm.

X/C

I-13 Battery connector Check connector housing, contact

springs and cables. Clean contacts.

X/C

I-14 Electrical system Check insulation of all accessible

wires for damage.

Make sure switches and connections

are fitted securely and check for damage.

X/C

L-15 Battery cover B/BB Lubricat e hin ge s an d lock. X/C

I-16 Main contactor Clean main contactor contacts and

check for wear.

X/C

I-17 Traction controller Torque the traction controller mount-

ing screws to 8 - 10 Nm.

X/C

Check the power cable connections

on the traction controller are secure.

Nut torque: 13 - 15 Nm

X/C

Check and analyse error log. X/C

12 M 24 M 36 M

Position Component Lubri-

cant

Action 500 h 1000 h 5000 h

Loading...

Loading...