Page 1

Page 2

Page 3

products

®

Signature Series amplifi er is the

®

1

Macro-Tech Series

Celebrating the Crown

our Macro-Tech

culmination of a long heritage of Crown

and design ideas that began in the early 1970s.

Y

In these pages you can explore how the Macro-Tech Series

came to be, understand its advanced features, and enjoy

stories and sales literature from its colorful past.

Page 4

the most accurate reproduction of an audio signal you’ve ever

heard. And because we put the quality of sound above all else,

Crown amplifi ers are the most coveted in the business.

When it comes to manufacturing amps, our work is based on

one simple fact: there are no shortcuts to quality. And our Macro-

Techs have proven this time and time again in some of the most

demanding applications in the world.

For this special, limited Macro-Tech release, we wanted to bring

you more than just the typical operation manual. This brochure

goes much further, delving into the Macro-Tech’s development,

design philosophy, and advanced technical features. We’ve also

included some brochures from the past, a bio of Crown’s chief R&D

engineer Gerald Stanley, customer statistics, anecdotes and more.

, sparked

®

Macro-Tech Series of power amplifi ers.

®

Enjoy!

ometimes a product fi ts an application so well, it

is deemed a classic. The term is synonymous with

the Crown

S

Crown Macro-Tech Series

That product line, and its predecessor Micro-Tech

innovative technologies that provided lower distortion, less

thermal stress, higher output power, greater reliability, more

power density and superior audio quality.

No compromises, no gimmicks. Just brilliant engineering

backed by superior manufacturing, support and an

unsurpassed commitment to quality.

Like all Crown amps, the defi ning characteristic of the Macro-

Tech Series is sonic accuracy. A tight, rock-solid low end, with

smooth, detailed highs and a well-defi ned midrange. In short,

Since 1984, Crown has shipped

approximately 272,625 MT and MA

amplifi ers to date. That’s approximately

54 million watts into 4 ohms or 65

million watts into 2 ohms!

2

Page 5

3

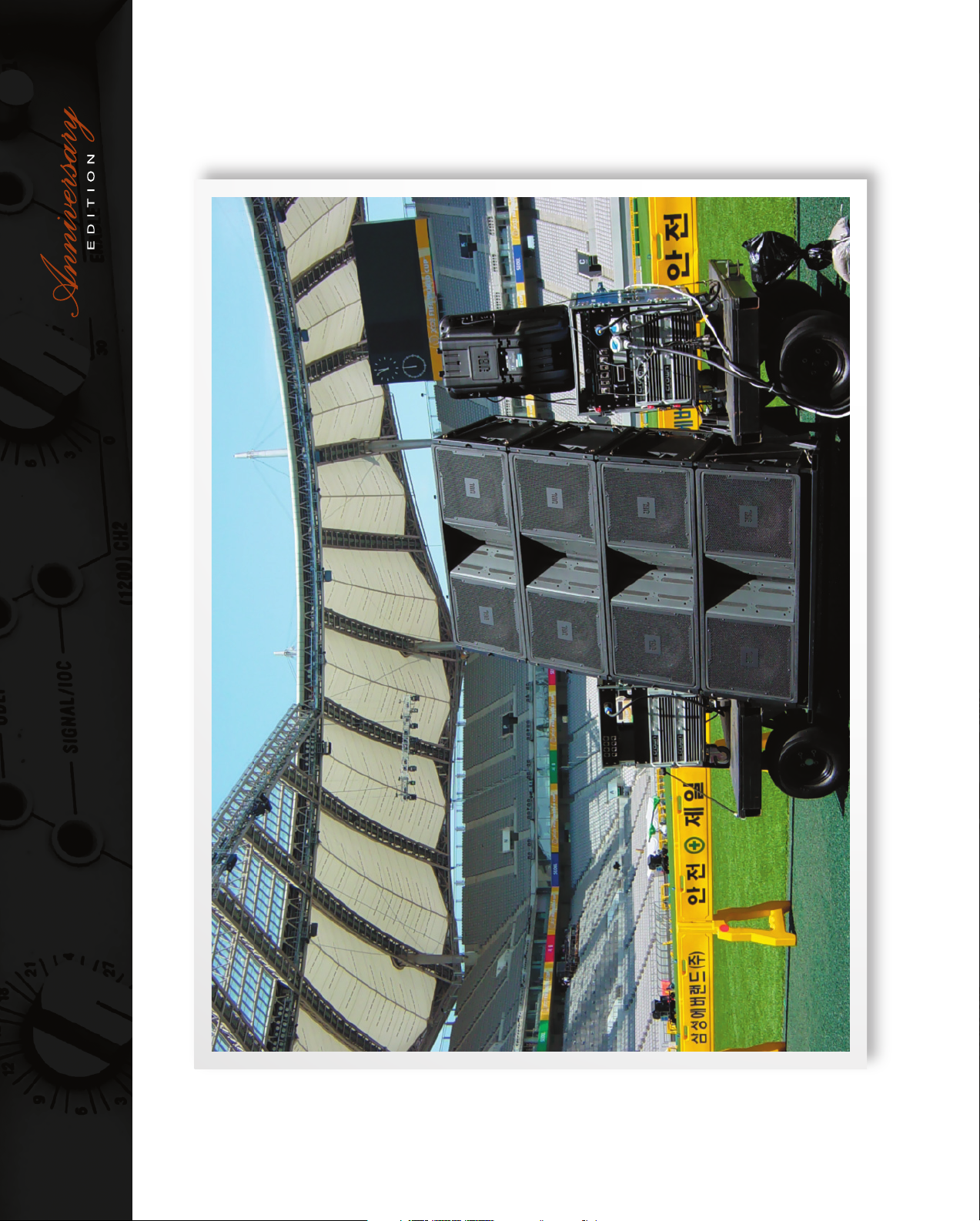

Crown Macro-Tech amplifi ers were used at the 64,640-seat Sangam Stadium in Seoul, South Korea, during the 2002 World Cup.

Page 6

TOUR

Neil Diamond tour

Pro Show, SPL Sound, XFL

Seoul Word Cup 2002

THEME PARK

Universal Studios

Everland (Korea)

Six Flags of America

Audio Analysts

Morgan Sound

Clair Brothers

Disturbed (band)

FIXED INSTALL

Club Capitale

Sydney 2000 Olympics

Crystal Cathedral

Art Garfunkel Tour

Maryland Sound

Gemini Sound

On Stage Audio

Offi cial All Star Cafe

Hard Rock Live

Experience Music Project

Spirit, Roxy

Enterprise Live

Deep night clubs

A Sampling of Crown Macro-Tech Users

STADIUM / ARENA

American Airlines Arena

American Airlines Center

Ralph Engelstad Arena

Key Arena

Xcel Energy Arena

Conseco Field House

Coors Field

Volkswagen Stadium

Hong Kong Stadium

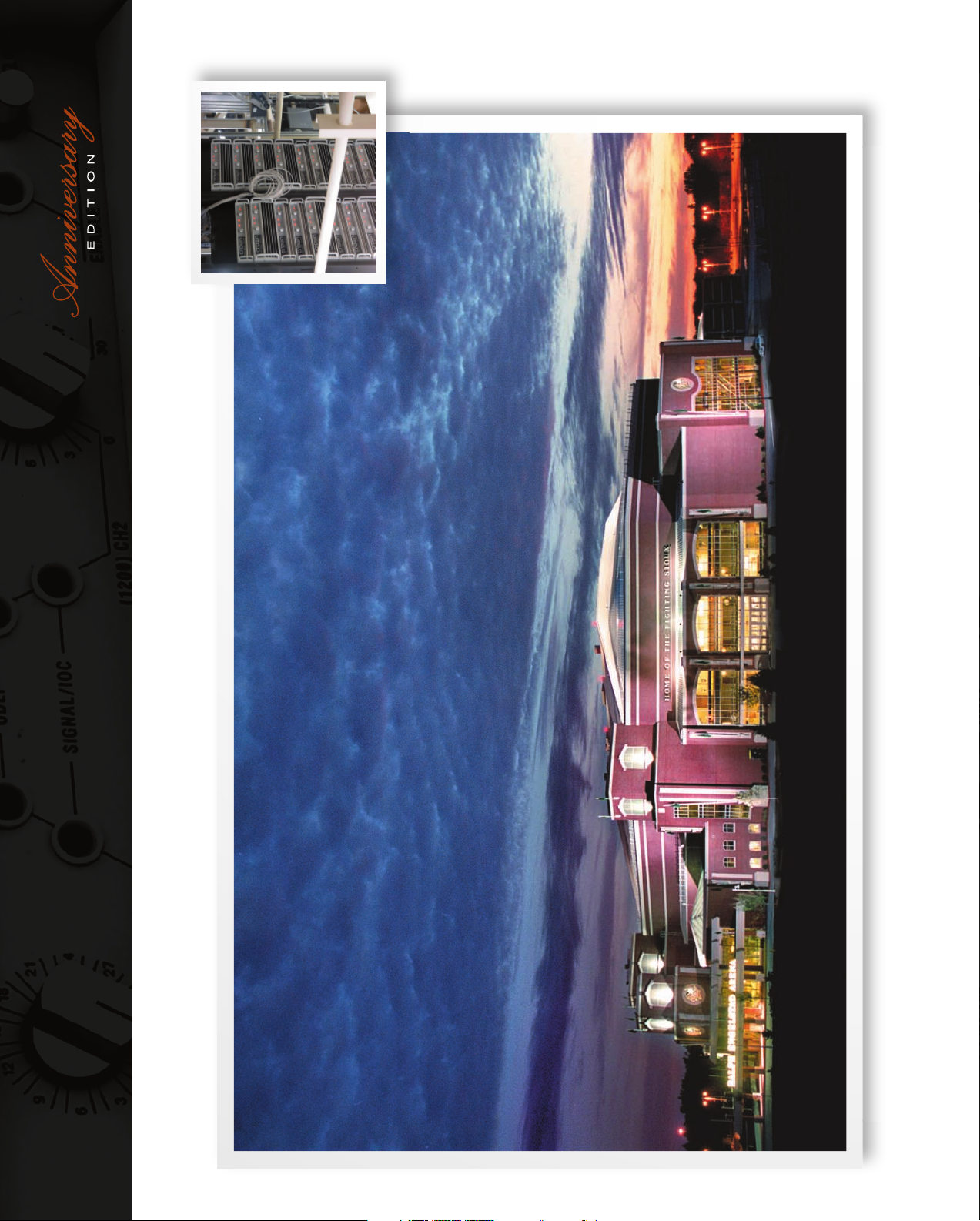

Racks of Crown Macro-Tech amplifi ers power this 2001 extravaganza staged in Salt Lake City’s Salt Palace for the Annual

Gala held by Utah Governor Mike Leavitt. Rocky Mountain Audio Visual chose Crown Macro-Tech along with JBL Vertec

speakers to provide concert-quality sound for the event. (Find out more at http://www.jblpro.com/pressroom/rmav_utah.htm.)

4

Page 7

5

Crown Macro-Tech amplifi ers power the premium sound system employing JBL PD Series speakers in the 400,000 sq. ft. Ralph Engelstad Arena in Grand Forks, North Dakota.

Page 8

How It All Began...

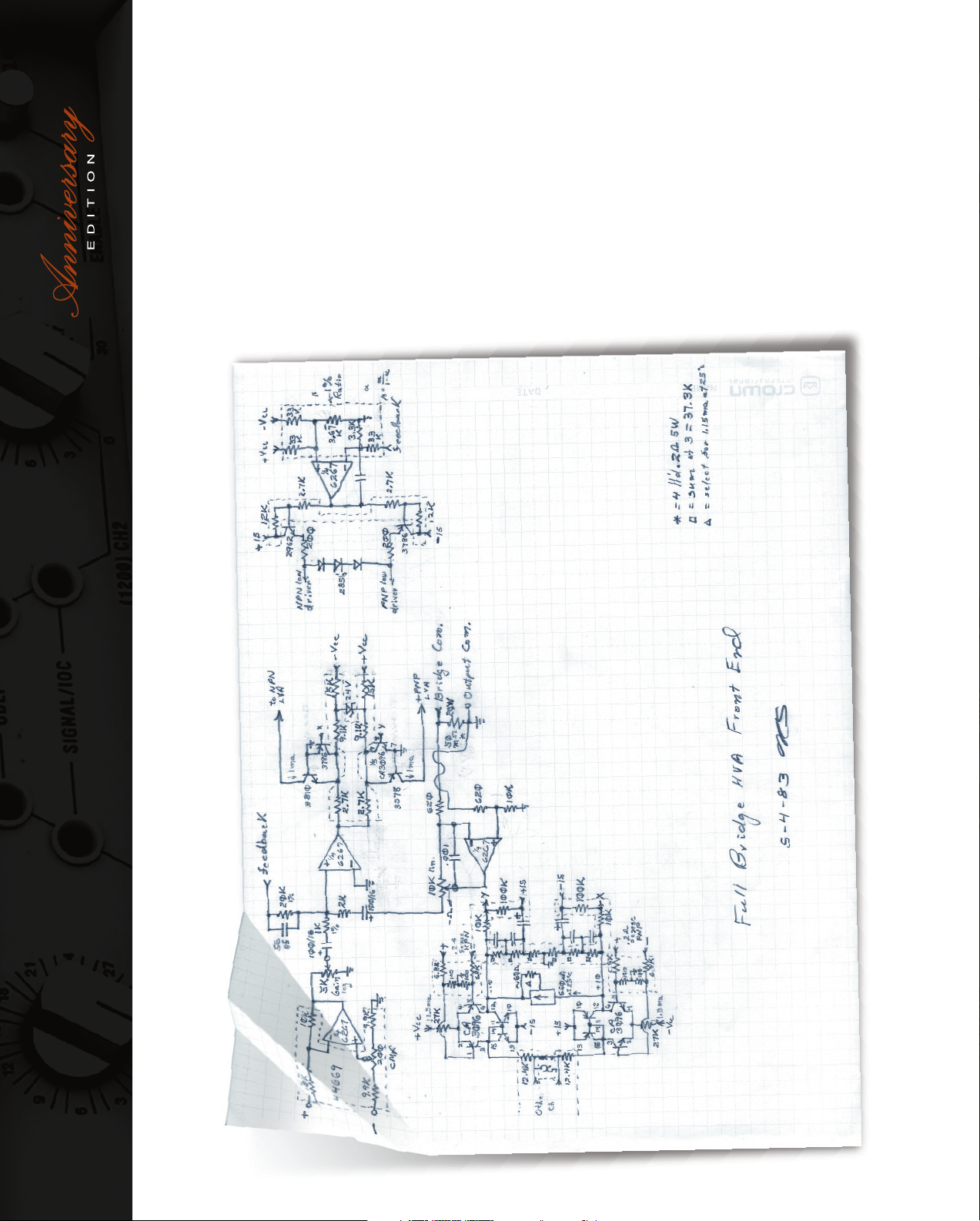

The brainstorming for this whole family began with

collaboration between engineers Gerald Stanley and Jim

Wordinger. In considering the drawbacks of current power

amplifi ers, they were looking for ways to:

• pack more power into a smaller rack space

• improve reliability by preventing overheating

• lower the cost per watt.

Gerald’s Grounded-Bridge design and Junction Temperature

Simulation were already in his toolkit. In 1975, JTS was

employed in the SA-2 and PSA-2 amplifi ers, while Grounded

Bridge was used in the M-600.

Gerald and Jim thought, “How about taking our two best

technologies and putting them in the same product?” The

Micro-Tech Series was born. The original name of this series

was to be HVA for High Value Amplifi er.

), protected

®

power supply, also called bi-level

®

, awed the audio industry with new

®

™ topology provided 4 times the power of

technologies that reduced distortion and thermal

he Macro-Tech product line, and its precursor

Micro-Tech

existing power transistors without sacrifi cing reliability.

stress — while increasing reliability, audio quality, power density

and power output.

Three patented technologies invented by Crown’s Gerald Stanley

led to those benefi ts:

The Macro-Tech Design Philosophy

T

• Grounded Bridge

• Junction Temperature Simulation (JTS), otherwise known

two best

taking our

How about

and putting

technologies

as Output Device Emulator Protection (ODEP

the power transistors from overheating and maximized their

potential power output by keeping them at the optimum

temperature.

them in the

same product?”

power-supply switching, was used in the MA-3600VZ and MA-

5000VZ Series. The supply changes its impedance to adapt to

the signal voltage and current. This technology permits large

amounts of power in a compact package while achieving ultra-

low distortion and without generating excess heat.

• Variable Impedance or VZ

6

Page 9

In those days, Crown was

recognized as a manufacturer

of home hi-fi products. But the

HVA Series was intended for

pro audio Touring and MI, not

for the living room. It was a new

direction for Crown.

Crown’s president at that time,

Max Scholfi eld, recognized that

Crown’s marketing needed to

be shaken up, so he hired Dr.

Clay Barclay to drive change

in Crown’s marketing and sales

divisions. Clay realized that

the MI and Touring industries

needed a product like this, and

he sold the idea to Crown and

to potential customers.

7

A 1983 schematic by Gerald Stanley of the Grounded Bridge circuit.

Page 10

An early sketch by Jim Wordinger

showing a proposed chassis layout

of a pre-Micro-Tech power amplifi er.

The MT-700 (never released) was the fi rst Micro-Tech amp. Then

came the MT-1000 which provided 1000 watts into 2 ohms. Next

was the MT-1200 which produced 1200 watts, thanks to bigger

power transformers.

The technology in Micro-Tech products helped Crown develop

amps for Magnetic Resonance Imaging (MRI). General Electric

asked Crown to make amplifi ers with more voltage and current

than what was available. We created bigger amps for GE, such as

the 7780, using JTS and Grounded Bridge.

Micro-Tech

Jim and Clay used to share ideas over lunch, where Jim told Clay

about the concept. Clay came up with the name “Micro-Tech”

because the goal was to put high technology into a micro-sized

amp. It was a new packaging paradigm as well as a new market.

In the early 1980s, Jim Wordinger went to Showco, one of the

major touring sound companies. At that time they were doing

sound for David Bowie using PSA power amps. According to

Jim, “We asked them what they would like to see in an amplifi er.”

“They said, ‘We’d like them smaller and lower-cost.’ I couldn’t

say anything about what we were working on, but their comment

certainly vindicated our design goals. Showco was one of

our fi rst customers; they used a lot of Micro-Techs. We had a

relationship with them. They would fi nd any problems fi rst and

then we’d fi x them.”

Eventually Clair Brothers bought Showco. Now they are using

over 2000 MA-3600VZs.

8

Page 11

Crown Macro-Tech 10,000.

9

two-thirds of the midrange drivers because

they weren’t used to seeing that kind

of power. Crown shipped in 24 drivers,

installed them, and wired them differently.

Problem solved. That’s the kind of support

Crown would do.”

...they weren’t

used to seeing

that kind of power.”

™ cards) and offered a better appearance.

“We supplied the fi rst Macro-Tech

prototypes to John McBride of MD

Systems, doing a tour for Garth Brooks.

At one gig, the FOH engineer noted that

he had to keep pushing the level up in

the midrange. The problem wasn’t with

the amps. Actually, MD had burned up

It was developed for John Royer and

Tom Allebrandi who did sound for the

Indianapolis 500. Three of these amps

were modifi ed to drive the race track’s

240V distributed-speaker system —

replacing two huge war-surplus amplifi ers

from a battleship.

Macro-Tech

Building on our experience with the MT series, Gerald and

Jim developed the Macro-Tech Series in 1987. It added Plug-

In-Processors (PIP

Jim Wordinger remembers, “In the early days we’d compare

MA amplifi ers side-by-side with competitive amps. Ours had

more punch and deeper bass, which I attributed to more output

voltage and current.”

The huge Macro-Tech 10,000 amplifi er was basically an MRI amp

modifi ed for audio use with a new audio interface and front panel.

Page 12

amp Crown ever made. Around 1992, Crown introduced the

MA-24x6 and MA-36x12 amps with a different power rating

in each channel for bi-amping woofers and horn drivers.

VZ technology (with bi-level power supply switching) was fi rst

prototyped in an MA-1200. It was feared that the switching

would affect the audio, but that did not happen. The fi rst

bi-level amps were MRI units custom-made for Picker

International, a medical imaging company.

Jim Stembel, Crown’s International Business Development

Manager, recalls: “At the trade show in which we introduced

the MA-3600VZ, it was the fi rst amp with that much power in

two rack spaces. One of our biggest competitors asked, ‘Why

put all that power in two rack units?’ We replied, ‘Because

we could.’ That power density was unheard of at the time. It

was quite a signifi cant landmark.”

“When we introduced the MA-5000, one of our major

customers asked, ‘Why does anybody need that much

power?’ Again it was an amplifi er ahead of its time — it

was so large compared to anything else on the market. At

the time, nobody appreciated the power of the MA-5000.

Of course, the MA-5000 has gone on to become a wildly

successful amp in touring sound — a standard. They really

were trend-setting amplifi ers.”

10 years ago in Pro Sound News, a poll reported that 9 out

10 of the major tours used Crown, mostly MA amps. We still

have die-hard customers who refuse to use anything else.

So, starting with Grounded Bridge, invented in 1971, and

JTS, invented in 1974, those two key pieces of technology

enabled the Micro-Tech and Macro-Tech family. After a long

lifetime, most of those products are still running. That’s what

we think they should do.

MA-5000s are used on

™, used the same main board as the

destroyers and aircraft carriers.”

In 1992, Crown engineer Andy Archias worked on

the MA-5000. Crown’s upper management was

delighted that the amp had such a positive impact

on the company, the music industry, and the audio

world. MA-5000s were even used on destroyers

and aircraft carriers (and still are today).

A major supporter of MA amps was Sam

Helms, manager of Sigmet, a premier pro audio

representative in New Jersey. Sam put Crown

amps through all sorts of torture tests. As he

says, “We put low-frequency square waves into

the amp and drove a subwoofer with that signal.

This was to show how the MA’s damping factor

controlled speaker-cone motion compared to the

competition. It was no contest.”

“Using a signal generator, we put 60 Hz in the

front end of the amp, ran the level controls up, got

high-power out of the amp and welded pieces

of metal with it! Or we’d take an AC cord, cut off

the end of it, put on a banana jack, plug it in the

back of the amplifi er, and run a drill off it. The

competition would shut off and the Crown amp

would just keep going. You could drill through a

4x4 with no problem at all.”

Crown’s elite studio amplifi er, the Macro-

Reference

MA-3600VZ, but with remote load sensing for

higher damping factor. It was the best-measuring

10

Page 13

11

Crown’s Vice President of Research and Development, Gerald Stanley.

In an era of

cookbook

designs and buggy

software, it would

seem that the most

basic lessons of

history have been

forgotten. Crown’s

recipe is simple:

design, build and

service each product

as if you were the

customer. This

approach not only

drives the product to

excellence, it drives

the people to be the

Gerald comments on Crown’s

success over the years:

he mastermind behind the Macro-Tech Series, and

all Crown solid-state electronics for over 40 years,

is our senior vice president of R&D Gerald Stanley.

best that they can be.”

Gerald recalls, “When I was a kid I used to go around to

neighbors to get old radios. I liked to get parts out of them, and

I liked to soup them up.” This early interest in electronics led to

an amazing career.

This brilliant engineer joined Crown part-time in 1964, fi rst

working as a tape-recorder tech, draftsperson and engineer,

About Gerald Stanley

T

when he designed the SA-20-20 and SA-60-60 — the fi rst

solid-state Crown amplifi ers. In 1965 he received a BSE from

Michigan State (Honors College) and MSE from the University

of Michigan in 1966 (State College Fellowship).

Gerald has this to say about the SA-60-60: “It was a dual 60W

8-ohm amplifi er. Only a few were made. They were unreliable,

using only high-speed fuses for protection. The SA-20-20 was

a 1-rack-space amp that soon became the SA-30-30. The SA-

20-20 used smaller versions of the SA-60-60 output devices.

The 60-60 was DC coupled throughout and the 20-20 was AC

coupled at the input. The DC-300 was not the fi rst DC audio

amp, but it was the fi rst that was reliable.”

Gerald went on to invent the technology behind all of Crown’s

power amp series. He holds a huge number of patents: 31 in

the U.S. alone, and many more in other countries.

Page 14

circuitry to simulate the instantaneous operating conditions of

those output transistors. Its name describes what it does: Output

Device Emulation Protection or ODEP. It not only simulates the

operation of the output transistors but it also compares their

operation to their known SOA. If more power is about to be asked

of the output devices than they are capable of delivering under

the present conditions, ODEP immediately limits the drive level

until it falls within the SOA. Limiting is proportional and kept to

an absolute minimum — only what is required to prevent output

transistor damage.

When ODEP limiting begins, the IOC circuitry will see that the

input waveform does not match the output waveform, and an error

(Input Output Comparator)

®

Macro-Tech Advanced Features

The Macro-Tech Series employs a number of innovative, patented

technologies. Let’s look at them in detail.

IOC

The IOC circuit compares the output signal of the amplifi er with

the input signal. If there is any difference other than gain, then it

is considered distortion and the IOC indicator fl ashes. This LED

lights whenever there is distortion of 0.05% or more. (Note that

amplifi er clipping is typically close to 3% THD.) An IOC condition

also is sensed by an IQ-PIP module installed in PIP-compatible

amplifi ers.

IOC is designed to report any form of distortion. IOC not only

signal is generated. If the compressors are on, they will see the

error signal and compress the input signal to correct the problem.

When this happens, there is no audible signal degradation.

Compression is subtle, and not noticeable unless the system is

driven to extremely high levels.

How does ODEP limiting increase the effi ciency of the output

transistors? It keeps them at the optimum temperature.

The transistors are neither overheated, nor overprotected.

Overprotecting results in transistors not being driven to their full

output level.

Gerald invented ODEP to solve two long-standing problems with

amplifi er designs:

checks the waveform for distortion, but also reports input

overload and even a protective action that mutes or shuts down

an amplifi er. With all of these features, IOC monitors the entire

amplifi er. When the IOC indicator is off, the amplifi er is defi nitely

operational and undistorted. IOC provides a real-time proof of

Output Device Emulation Protection (ODEP)

performance.

In short, ODEP enables the amplifi er to use the output transistors

more effi ciently while greatly increasing their reliability.

Finally, the status of ODEP is monitored in two ways. First, the front

panel ODEP indicators show whether the amplifi er is functioning

correctly or if ODEP is limiting the drive level. Second, ODEP data

is fed to the PIP connector at the back of the amplifi er so advanced

• Preventing amplifi er shutdown during demanding operation, and

• Increasing the effi ciency of the output transistors.

ODEP limits the signal when necessary to prevent overheating

and failure of the amplifi er output transistors. Crown engineers

established a rigorous program to measure the safe operating

area (SOA) — related to temperature — of each output transistor

before installing it in an amplifi er. Gerald also designed intelligent

One of Gerald Stanley’s many patents.

12

Page 15

13

Grounded Bridge theory

for electronics-savvy readers

The power-supply bridge rectifi er is not ground

referenced, and the transformer secondary is not center-

tapped. This allows the power supply to deliver +VCC

and -VCC from the same bridge rectifi er and fi lter as a

total difference in potential regardless of their voltages

with respect to ground.

Composite output devices are arranged to function as

gigantic NPN and PNP devices. Each output stage has

two composite NPN and two composite PNP devices.

The devices connected to the load are referred to as

“high-side NPN and PNP” and the devices connected

to ground are referred to as “low-side NPN and PNP.”

Positive current is delivered to the load by increasing

conductance simultaneously in the high-side NPN and

low-side PNP stage, while decreasing conductance of

the high-side PNP and low-side NPN in synchrony.

Imagine a graph of current versus voltage (I versus V) in

an output stage of a power amplifi er. This graph has four

quadrants: +V and +I, -V and +I, –V and –I, +V and –I.

Grounded Bridge is a four-quadrant amplifi er topology.

Resistive loads only use the fi rst and third quadrants (+V,

+I and -V, –I). Reactive loads also use the second and

fourth quadrants (–V, +I and +V, –I).

amplifi er designs, averaging

only 20%. Because of this,

Class A amplifi ers are large,

heavy and run very hot.

That is because the amp

runs constantly at full power.

On the other hand, Class A

Crown’s Grounded Bridge topology makes the amplifi er deliver

PIP modules like the IQ-PIP-USP3 can use it to make decisions and

control the amplifi er. With ODEP you get the maximum power with

the maximum protection — the show goes on!

peak-to-peak voltages to the load that are twice the voltage seen

Grounded Bridge

designs have the least amount

of distortion.

Class B operation is the

opposite of Class A. Both

output devices are never

allowed to be on at the same

time. The bias is set so that

current fl ow in a specifi c

output device is zero when

not stimulated with an input

signal. Each output device

is on for exactly one half of

a complete sinusoidal signal

cycle. Due to this operation,

Class B designs show high

effi ciency, but poor linearity

around the crossover region.

by the output devices and twice the voltage generated by the

power supplies. In other words, the amplifi er can produce louder

sound without stressing the output transistors. The results are

higher effi ciency, lower distortion and superior reliability.

Class AB+B

Crown invented the Class AB+B amplifi er design, which provides

both high effi ciency and low distortion. AB+B circuitry draws

less AC power and wastes less heat than Class A, and has less

distortion than Class B or Class AB. To explain how AB+B works,

fi rst we need to explore other amplifi er classes.

Audio power amplifi ers are classifi ed primarily by the design of

the output stage (the transistors and related circuitry that send

signals to the loudspeakers). Classifi cation is based on the

amount of time the output devices (power transistors) are made

to operate during each cycle of the signal. Amplifi er classes are

also defi ned in terms of output bias current (the amount of current

This is because it takes time

to turn one device off and the

other device on, causing extreme crossover distortion. All of

this restricts Class B designs to applications with low power

consumption, such as battery operated two-way radios and

other communications equipment.

fl owing in the output devices with no signal present).

In Class A operation, both output transistors conduct continuously

for the entire cycle of signal swing, so the bias current fl ows

in the output devices at all times. Both devices are always on.

Class A amplifi ers are single-ended designs with either PNP or

NPN output devices. Class A is the most ineffi cient of all power

Page 16

An amplifi er power supply must be large enough

to handle both the maximum voltage and

maximum current the amplifi er needs to drive

its rated power into a specifi ed load. In order

to meet this requirement, most conventional

supplies are heavy, large, and produce lots

of heat. In contrast, the VZ supply gets more

current AND voltage out of a smaller, lighter, and

more effi cient package by dynamically adapting

to both signal and load requirements in real-

time. This provides the best power match to the

Class AB operation allows both devices to be on at the same

time (as in Class A), but just barely. The output bias is set so

that current fl ows in a specifi c output device appreciably more

than a half cycle, but less than the entire cycle. That is, only a

little current is allowed to fl ow through both devices — unlike the

complete load current of Class A designs — but enough current

to keep each device operating so they respond instantly to

input voltage demands. Thus the inherent non-linearity of Class

B designs is eliminated, without the gross ineffi ciencies of the

Class A design. It is this combination of good effi ciency (around

50%) with excellent linearity that makes Class AB the most

widest range of loads.

The VZ power supply is divided into two

segments. When the output stage requires high

voltage, the segments are arranged in series to

deliver twice the voltage of a single segment.

When the output stage requires high current,

the segments are arranged in parallel to deliver

twice the current of a single segment.

Sensing circuitry “watches” the voltage of the

popular audio amplifi er design.

Class AB+B design involves two pairs of output devices. One

pair operates Class AB, while the other (slave) pair operates

Class B. Class AB+B designs are just as effi cient as Class AB,

but have even less distortion.

To summarize, AB+B circuitry draws less AC power and wastes

less heat than Class A, and has less distortion than Class B or

Class AB.

signal to determine when to switch VZ modes.

The power supply continuously adapts to the

output signal: high voltage or high current.

The switching circuitry is designed to prevent

audible switching distortion to yield the highest

possible dynamic transfer function.

Variable Impedance (VZ)

VZ is the name of Crown’s patented bi-level power supply

technology. It allows Crown to pack large amounts of power into a

compact package while achieving ultra-low distortion and without

generating excessive heat.

package...”

to pack large

It allows Crown

into a compact

amounts of power

A Circuit Diagram from the VZ Patent.

14

Page 17

15

Normally, the power supplies operate in the high-current (low-impedance)

mode for maximum thermal effi ciency. When the voltage demand spikes, the

supplies quickly shift into high-voltage (high-impedance) mode. Because

voltage and current requirements vary with the output level and frequency

content of the source signals, the power supplies are designed to be able to

continually switch between the two modes as needed with no degradation

to the audio signal. With VZ, you get not only maximum power, but also the

best power matching to your load.

ILoad/ILimit (MA-5000)

This LED indicates the maximum real-world load that you can put on your

amplifi er. The ILoad/ILimit feature is designed to help you get the maximum

power out of your amplifi er. In the real world, loudspeaker impedance varies

with frequency, and loudspeaker impedance ratings are only approximations.

Without ILoad/ILimit, you have to do some lengthy calculations to

approximate the maximum number of loudspeakers you can drive with

the amplifi er — and this does not allow for a 4-ohm loudspeaker whose

impedance drops below 2 ohms at 80 Hz.

This is why your amplifi er has ILoad/ILimit. The ILoad function turns a

channel’s ILoad/ILimit indicator green when it senses that current is fl owing to

the load. The ILimit function turns the indicator red when it reaches maximum

current output. This makes it possible to connect real loudspeakers and

conduct realistic tests to fi nd the maximum number of loudspeakers that

should be connected. To do a test like this, you can operate under worst-

case conditions and continue to connect additional loudspeakers in parallel

with each output until the ILoad/ILimit indicator turns red. The optimum load

is achieved before the ILoad/ILimit indicator turns red, so disconnecting the

last added loudspeaker gives you an optimized load.

Page 18

Reference articles on

Macro-Tech amplifi er

technology

Go to the Crown website’s

Amplifi er Technical Information

page at this address:

http://www.crownaudio.com/amp_

htm/ampinfo.htm.

Under the heading “Other Crown

Amplifi er Technologies” check out

these articles:

• IOC Distortion Detector

• Understanding Damping Factor

Protection).

• Grounded Bridge Topology

• ODEP (Output Device Emulator

Loudspeaker Offset Integration

Loudspeaker Offset Integration (LOI) protects speakers

from damaging asymmetrical waveforms, DC and ultrasonic

signals. LOI circuits use double integrating fi lters in the

amplifi er’s feedback circuitry to protect loudspeakers in

several different ways. First, they center asymmetrical audio

waveforms that cause off-center woofer cone movement. Off-

center cone movement increases loudspeaker heating and

distortion while reducing the loudspeaker’s power handling

ability. Second, LOI fi lters unwanted DC and subsonic

frequencies using a third-order Butterworth fi lter with a 35-

Hz corner frequency. Third, LOI fi lters unwanted ultrasonic

frequencies (RF) that can cause tweeter burnout using a

second-order Bessel fi lter with a 50-kHz corner frequency.

LOI does NOT protect loudspeakers from large transient

voltages or excessive power levels for prolonged periods of

at www.crownaudio.com.

time. For information on techniques to protect loudspeakers,

refer to the Crown Amplifi er Application Guide, available online

PIP™ Modules

PIP (Programmable Input Processor) modules provide features

that can be added to customize the amplifi er. PIP modules

plug into the connector inside the back panel of the amplifi er.

Features range from error-driven compressor/limiters to remote

control and monitoring via System Architect or IQwic™.

Your amplifi er is a PIP2 amplifi er, which means it can take

advantage of the many advanced features found in PIP2

modules, as well as all standard PIP modules. Visit the Crown

website at www.crownaudio.com, or contact Crown Customer

Service, for descriptions of available PIP and PIP2 modules.

In the 1990s, nearly 9 out of 10 major touring companies chose

Macro-Tech amplifi ers to power their sound systems.

16

Page 19

Amp room at SooYoung Ro Church in Pusan, South Korea.

VZ theory for electronics-savvy readers

VZ offers a simple way to apply Class-H operation to a

Grounded Bridge circuit. Class H changes the power

supply voltage from a lower level to a higher level

when larger output swings are required. Class H also

modulates the higher power-supply voltage by the input

signal. This allows the power supply to track the audio

input and provide just enough voltage for optimum

operation of the output devices.

The Grounded Bridge has a particularly simple supply

needed for Class H in that only one supply needs to be

rail switched, whereas a common half-bridge (totem-

pole) output stage needs two such switched supplies

per channel. The bi-level (VZ) supply is further elegant

17

in that the power supply is always fully utilized in both

high- and low-voltage confi gurations. No segments of

the power supply are wasted.

• 1971: Gerald Stanley invents Grounded Bridge topology.

Crown Amplif iers Time Line

and PSA-2 fi rst used JTS.

• 1974: Gerald invents Junction Temperature Simulation (JTS).

• 1975: M-600 was the fi rst amp to use Grounded Bridge. SA-2

• 1984: MT-1000 was the fi rst combination of Grounded Bridge

and JTS, and Crown’s fi rst amp intended for the MI and

Touring Sound markets.

• 1985: MT-1200 was a higher power version of MT-1000. MT-

600 also was released. MT-1200LX and MT-600LX had a fancy

extruded front panel and more displays.

10K application is to power 465 speakers at the Indianapolis

• 1986: MA-10K provides 10,000 watts of power. The fi rst MA-

500 Motor Speedway.

• 1987: MA-1200 and MA-600 (with PIP panels).

power supply switching. VZ technology was fi rst prototyped

in an MA-1200. The fi rst bi-level amps were MRI units custom-

made for Picker.

• 1991: MA-3600VZ featuring Variable Impedance (VZ) bi-level

MA-3600VZ and MA-5000VZ quickly become the touring

standards. MA-24x6 and MA-36x12 for bi-amping are

introduced.

• 1992: MA-5000VZ also features Variable Impedance.

• 1999: MA-602, 1202, 2402 and MA-5002VZ.

Page 20

An early sketch of a Micro-Tech schematic by Jim Wordinger.

A page from Audio Engineering Society Preprint 959 (N-1),

“What Watt in Amplifi er Testing” by Gerald Stanley and

Robert McLaughlin.

18

Page 21

19

Right: Prototype test data

from 1984 and 1986.

A mid-1960s shot of Gerald Stanley.

Harman Pro Group President Blake Augsburger (left) and

Crown President Mark Graham (right) display Gerald’s latest

patent plaques in a recent Crown assembly meeting.

Page 22

Versatile, Earth-Shaking Power

No other amplifi er can give you as much

versatility in delivering earth-shaking power as

Macro-Tech. Through the patented Grounded-

Bridge circuitry and Multi-Mode (A, AB + B)

circuitry, each Macro-Tech can drive high output

Crown’s commitment to excellence in design,

manufacturing and service, is what makes

Macro-Tech the choice for professional sound

reinforcement.

he Macro-Tech Series continues

to build on Crown’s legendary

reputation as the industry reference

levels into massive loads while achieving the

lowest distortion and greatest reliability.

The Grounded Bridge utilizes output transistors

in a very effi cient four-quadrant bridge which

is immune to dynamic crossover distortion.

With this bridge design, the transistors share

the same voltage, current and load so only one

power supply is required per channel. This

results in an effi cient use of both power supply

circuitry and chassis space. Rapid, uniform

heat dissipation is promoted by our transistor

mounting and heat diffuser designs. Smaller,

more compact chassis can be used which

provide a very high output power to size and

weight ratio.

Macro-Tech Sonic Purity

Macro-Technology — a combination of technological advances that enhance

the quality of live and recorded sound, and Crown’s commitment to product

excellence in reaching innovative levels of performance and reliability.

Shown on the next three pages is a reproduction

of the original Macro-Tech brochure.

T

for sonic purity, power and durability. Unmatched

in the marketplace, Macro-Tech provides

the excellence and reliability that industry

professionals stake their reputations on time after

time. And with good reason. Crown amplifi ers are

designed to take the heavy use of professional

sound reinforcement day in and day out without

failure — or coloring the sound. When it comes

to delivering the purest signal transfer possible,

nothing else beats a Macro-Tech.

Superior Engineering For Superior

Performance

Our amplifi ers are engineered with the

philosophy of producing the very best sound

possible under both normal and extreme

operation conditions. To achieve this, our

engineers examined all the factors in amplifi er

design and operation. The result is a number of

patented Crown circuit designs that allow the

Macro-Tech Series to achieve sonic purity and

reliability that Crown is known for around the

world. This design philosophy, combined with

20

Page 23

21

(Programmable Input

®

Processor) compatible. These circuit card modules

plug into a P.I.P. connector on the rear panel of the

P.I.P. Compatibility

All Macro-Techs are P.I.P

amplifi er. Crown’s P.I.P. modules enable you to tailor

each amplifi er to specifi c applications as well as plug

into future technology as it’s developed. Installation

of an IQ-P.I.P. permits each Macro-Tech to interface

with our innovative IQ System™ for complete amplifi er

monitoring and control. Some current P.I.P. modules

include a sophisticated programmable crossover

and equalizer, remotable mic/line priority mixers and

calibrated sensing modules.

Amplifi er Status At A Glance

The Macro-Tech Series front panel gives you vital

operating information with a minimum of effort. Two

dual-function IOC/Signal Presence indicators monitor

the transfer function of each channel. Green indicator

lights illuminate to show signal presence and fl ash

brightly if distortion equals or exceeds 0.05 percent.

An amber Enable indicator, powered by a small,

separate power supply, verifi es operation of the

amplifi er’s low signal circuits, DC protection and

onboard digital computer.

A pair of amber ODEP indicators show the reserve

energy status and indicate when unfavorable

operating conditions are sensed and limiting is

beginning to take place.

ODEP™ (Output Device Emulator Protection)

ODEP, Crown’s sophisticated protection circuitry, is a radical

departure from other amplifi er protection methods.

Crown developed ODEP to solve two long-standing problems in

amplifi er design: to prevent amplifi er shutdown during demanding

operation, and to increase the effi ciency of output circuitry. To do

this, Crown initiated a program which tests every output transistor

to determine its SOA (safe operating area). ODEP circuitry inside

the amplifi er then simulates the operation of the output transistors

and compares it to their SOA. In the unlikely event that more

power is required than the transistors are capable of delivering

under current conditions, ODEP immediately limits their drive

level until it falls within their SOA. This limiting is proportional and

is kept to an absolute minimum. This level of protection enables

Crown to increase output effi ciency while at the same time greatly

increasing amplifi er reliability. You get maximum power with

maximum protection.

Unlike other amplifi er protection schemes that shut down the

amplifi er, Crown’s ODEP makes certain the show goes on.

(Input Output Comparator)

®

IOC

The IOC is a sophisticated built-in distortion meter that

compares the wave-form of the input signal to the waveform of

the output signal. In the rare instance that it detects a variation

of 0.05 percent or more, it fl ashes the IOC indicator of the

offending channel.

The IOC indicators help you troubleshoot the source of distortion

by showing you where it’s not — your Crown amplifi er.

Page 24

Legendary

While many manufacturers have come and gone,

Crown has continued to prosper. For over 40 years,

the ownership of our company has remained

unchanged — a claim we alone can make. And

through these many years, our commitment to

the industry and customers has stayed true. Our

tradition for unequaled excellence has been

refl ected time and again in accolades from our

peers, including the recent ranking by Pro Sound

News as number one in touring sound. Further,

of the top ten touring groups at any given time, a

majority are using Crown equipment.

Our technical support staff is unequaled for

friendly, knowledgeable service and are within a

phone call’s reach. They’re well versed with all

aspects of Crown amplifi ers and offer a level of

support unsurpassed in the industry.

To ensure we achieve our standard for providing

the very best product possible, we manufacture

our own circuit boards, form our own sheet

metal, and machine and paint our own parts. It’s

a constant striving for excellence that refl ects

the high level of pride our employees hold. Our

assemblers are skilled craftsmen who have

worked for us for many years, and we say without

reservation or doubt that our engineers are the

best. It’s no wonder that our amplifi ers are, too.

22

Page 25

23

Top left to right: Macro Reference,

Micro-Tech, and Macro-Tech

brochures.

We hope you’ve enjoyed this

journey into the exciting past

of the Crown Micro-Tech and

Macro-Tech Series — amplifi ers

that are world renowned for their

technical innovations, reliability

and superb sound.

Right: Macro-Tech brochure and a

Crown newsletter article about the

Macro-Tech 5000VZ.

Page 26

01/08

140623-1

, Inc., 1718 W. Mishawaka Rd., Elkhart, Indiana 46517-9439 U.S.A. Telephone: 574-294-8000

®

©2008 by Crown Audio

TRADEMARKS NOTICE: Crown, Crown Audio, IQ, IOC, IQ System, Macro-Tech, ODEP, P.I.P., and VZ are registered trademarks; Grounded Bridge, PIP, and PIP2 are

trademarks of Crown International.

System Architect and JBL are used for information only and are the property of their respective companies.

Crown Audio, Inc. reserves the right to make changes in specifications, software, or products without prior notice. Crown Audio, Inc. also assumes no responsibility

for any error in type or print reproduction of the features or specifications in this literature. The information provided here was deemed accurate as of the publication

date. However, updates to this information may have occurred. For the latest in product information, please visit the Crown website at www.crownaudio.com.

Some models may be exported under the name Amcron.

Page 27

Page 28

Loading...

Loading...