Page 1

SERIES

Discount-Equipment.com

BULLETIN No.

SUPERSEDES

DATE

MM ~ Mech.

200078-R04

200078-R03

May 2004

MORTAR MIXER MODELS:

4S, S4S, 5S, 6S, 6SR, S6SR, 6PR,

8S, S8S, 8P, 10S, S10S, 12S & S12S

OPERATOR'S MANUAL

www.discount-equipment.com

Page 2

Discount-Equipment.com is your online resource for commercial and industrial

Discount-Equipment.com

quality parts and equipment sales.

Locations:

Florida (West Palm Beach): 561-964-4949

Outside Florida TOLL FREE: 877-690-3101

Need parts? Check out our website at www.discount-equipment.com

Can’t find what you need?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and fill out

the request form.

Please have the machine model and serial number available in order to help us get

you the correct parts. One of our experienced staff members will get back to you with

a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mayco, Toro/Stone,

Diamond Products, Magnum, Airman, Mustang, Power Blanket, Nifty Lift, Atlas Copco,

Chicago Pneumatic,

Tsurumi, Husquvarna/Target, Whiteman-Concrete/Mortar, Stow-Concrete/Mortar, Baldor,

Wacker, Sakai, Snorkel, Upright, Mi-T-M, Sullair, Neal, Basic, Dynapac, MBW, Weber,

Bartell, Bennar Newman, Haulotte, Ditch Runner, Blaw-Knox, Himoinsa, Best, Buddy,

Crown, Edco, Wyco, Bomag, Laymor, Terremite, Barreto, EZ Trench, Takeuchi, Basic, Bil-

Jax, Curtis, Gehl, Heli, Honda, ICS/PowerGrit, Puckett,

Clipper, MMD, Koshin, Rice, Gorman Rupp, CH&E, Cat Pumps, Comet, General Pump,

Giant,AMida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, Small Line, Wanco, Yanmar

Allmand Brothers, Essick, Miller Spreader, Skyjack, Lull, Skytrak,

Waldon, ASV, IHI, Partner, Imer,

Page 3

TABLE OF CONTENTS

Discount-Equipment.com

SECTION DESCRIPTION

Proposition 65 ................................................................................ i

1 Introduction .........................................................................................1

2 Safety ...............................................................................................2

2.1 General Safety ..............................................................................3

2.2 Operating Safety .........................................................................4

2.3 Maintenance Safety ...................................................................5

2.4 Transport Safety ..........................................................................5

2.5 Tire Safety ......................................................................................5

2.6 Storage Safety ..............................................................................5

2.7 Refueling Safety ..........................................................................6

2.8 Electrical Safety ...........................................................................6

2.9 Safety Signs ...................................................................................6

2.10 Sign-O Form ...............................................................................7

3 Safety Sign Locations ................................................................8

4 Operation .................................................................................... 13

4.1 To the New Operator or Owner .......................................... 13

4.2 How The Machine Works ....................................................... 14

4.3 Pre-Operation Checklist ........................................................15

4.4 Pre-Start Procedures ............................................................... 15

4.5 Machine Break-In ..................................................................... 16

4.6 Controls ....................................................................................... 17

4.7 Operating ................................................................................... 19

4.8 Transporting .............................................................................. 28

4.9 Storage ........................................................................................31

5 Service and Maintenance ..................................................... 32

5.1 Service ......................................................................................... 32

5.1.1 Fluids and Lubricants ...................................................................................32

5.1.2 Greasing ............................................................................................................32

5.1.3 Servicing Intervals ......................................................................................... 33

5.1.4 Service Record ................................................................................................38

5.2 Maintenance .............................................................................. 39

5.2.1 Engine Oil Changing ..................................................................................... 39

5.2.2 Engine Speed Setting ...................................................................................40

5.2.3 Air Cleaner Maintenance ............................................................................. 41

5.2.4 Belt Tension and Alignment ....................................................................... 42

5.2.5 Wiper Spacing and Replacement ............................................................. 43

5.2.6 Gearbox Oil Changing .................................................................................. 44

6 Trouble Shooting ..................................................................... 45

7 Specications ............................................................................ 46

7.1 Mechanical ................................................................................. 46

7.2 Bolt Torque ................................................................................. 47

8 Index ............................................................................................. 48

i

Page 4

WARNING

Discount-Equipment.com

CALIFORNIA - Proposition 65 Warning

Engine exhaust and some of its constituents and some dust created by power sanding, sawing,

grinding, drilling and other construction activities contains chemicals known to the State of California

to cause cancer, birth defects and other reproductive harm.

Some examples of these chemicals are:-

Lead from lead-based paints

Crystalline silica from bricks

Cement and other masonry products

Arsenic and chromium from chemically

treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals:

ALWAYS work in a well ventilated area, and work with approved safety equipment, such as dust

masks that are specially designed to lter out microscopic particles.

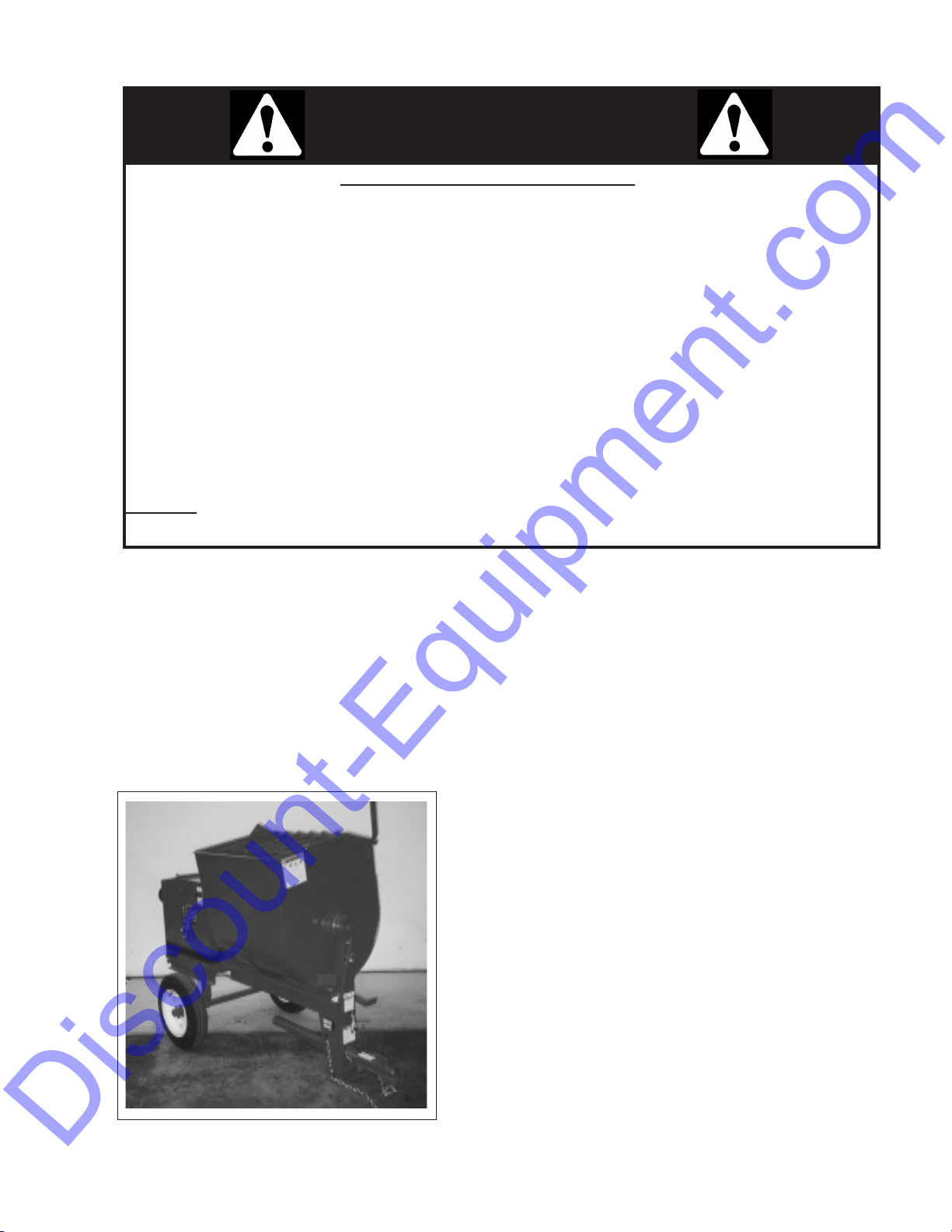

1 INTRODUCTION

Congratulations on your choice of a Crown Construction Equipment Mortar Mixer to complement your construction

operation. This equipment has been designed and manufactured to meet the needs of a discriminating buyer for the

ecient mixing of mortar or plaster.

Safe, ecient and trouble free operation of your Crown Mortar Mixer requires that you and anyone else who will be

operating or maintaining the Mixer, read and understand the Safety, Operation, Maintenance and Trouble Shooting

information contained in the Operator's Manual.

This manual is applicable to all the Model 4S, 5S, S5S, 6S, 6SR,

S6SR, 6PR, S8S, 8S, 8P, 10S, S10S,12S and S12S Mortar Mixers built

by Crown Construction Equipment. Use the Table of Contents or

Index as a guide when searching for specic information.

Keep this manual handy for frequent reference and to pass on to

new operators or owners. Call your Crown Construction Equipment distributor or dealer if you need assistance or information.

OPERATOR ORIENTATION - The directions left, right, front and rear,

as mentioned throughout this manual, are as seen from behind

the machine and facing in the direction of towing.

Page 5

2 SAFETY

Discount-Equipment.com

SAFETY ALERT SYMBOL

This Safety Alert symbol means

ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

3 Big Reasons

SIGNAL WORDS:

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety

messages. The appropriate signal word for

each message has been selected using the

following guide-lines:

Why is SAFETY important to you?

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

DANGER - Indicates an imminently hazardous situ-

ation that, if not avoided, will result in

death or serious injury. This signal word

is to be limited to the most extreme situations, typically for machine components

that, for functional purposes, cannot be

guarded.

WARNING -

Indicates a potentially hazardous situ-

ation that, if not avoided, could result

in death or serious injury, and includes

hazards that are exposed when guards

are removed. It may also be used to alert

against unsafe practices.

The Safety Alert symbol identies important safety messages on the Crown

Mortar Mixer and in the manual. When

you see this symbol, be alert to the

possibility of personal injury or death.

Follow the instructions in the safety

message.

Indicates a potentially hazardous situ-

CAUTION -

ation that, if not avoided, may result in

minor or moderate injury. It may also be

used to alert against unsafe practices.

SAFETY

YOU are responsible for the SAFE operation and maintenance of your Concrete Mixer. YOU must ensure that you

and anyone else who is going to operate, maintain or work

around the Concrete Mixer be familiar with the operating

and maintenance procedures and related SAFETY information contained in this manual. This manual will take you stepby-step through your working day and alerts you to all good

safety practices that should be adhered to while operating

the Mixer.

Remember, YOU are the key to safety. Good safety

practices not only protect you but also the people

around you. Make these practices a working part

of your safety program. Be certain that EVERYONE

operating this equipment is familiar with the recommended operating and maintenance procedures and

follows all the safety precautions. Most accidents can

be prevented. Do not risk injury or death by ignoring

good safety practices.

1

Page 6

• Mixerownersmustgiveoperatinginstructions

Discount-Equipment.com

to operators or employees before allowing them

to operate the machine, and at least annually

thereafter.

Stop engine, disconnect spark plug wire and

7.

wait for all moving parts to stop before servicing,

adjusting, repairing or cleaning.

• Themostimportantsafetydeviceonthisequipment is a SAFE operator. It is the operator’s

responsibility to read and understand ALL Safety

and Operating instructions in the manual and to

follow these. All accidents can be avoided.

• Apersonwhohasnotreadandunderstoodall

operating and safety instructions is not qualied

to operate the machine. An untrained operator

exposes himself and bystanders to possible serious injury or death.

• Donotmodifytheequipmentinanyway.

Unauthorized modication may impair the

function and/or safety and could aect the life

of the equipment.

2.1 GENERAL SAFETY

1. Read and understand the

Operator's manual and all

safety signs before

operating, maintaining,

adjusting, servicing or

cleaning the Mixer.

2.

Only trained competent persons shall operate the

Mixer. An untrained operator is not qualied to

operate the machine.

3.

Have a rst-aid kit available for use,

should the need arise and know how

to use it.

4.

Do not allow riders when towing.

5.

Have a re extinguisher available for use

should the need arise and know how to use

it.

Wear appropriate hearing protection when

8.

operating for long periods of time.

Dust Hazard ~ Wear appropriate dust

mask around this equipment.

9.

Ventilation ~ Never operate any

gas powered equipment in a poorly

10.

ventilated or enclose area. Avoid

prolonged breathing of exhaust

gases.

Hot Surface ~ Avoid contact with hot

exhaust system and engine.

11.

Allow to cool before performing

repairs or service.

2.1 GENERAL SAFETY

Electrocution Hazard ~ Always

12.

use proper size grounded

extension cord. Inspect all

extension cords for cuts, frayed

wire and broken connectors.

Do not use cords if not in good

condition.

13. Do not refuel the machine while

smoking or when

near open ame or sparks.

2.2 OPERATING SAFETY

1. Read and understand the Operator’s Manual and all

safety signs before operating, servicing, adjusting, or

cleaning the Mixer.

6.

Wear appropriate protective gear. This list

includes, but is not limited to:

- A hard hat

- Protective boots

with

slip resistant soles

- Protective goggles

- Heavy gloves

- Hearing protection

2. Do not allow riders on the machine during transport.

3. Install, close and secure all guards, shields and hoods

before starting or operating.

4. Stop engine or motor, disconnect spark plug wire or

unplug power cord, and wait for all moving parts to

stop before servicing, adjusting, repairing, or cleaning.

2

Page 7

5. Clear the area of all bystanders before starting.

Discount-Equipment.com

6. Keep hands, feet, hair and clothing away from

moving parts.

7. Keep working area clean and dry to prevent slipping and tripping.

8. Do not run the mixer in an explosive atmosphere

or in a poorly ventilated or enclosed area.

3. Follow good shop practices

- Keep service area

clean and dry.

- Be sure electrical

outlets and tools

are properly

grounded.

- Use adequate

light for the job

at

9. Wear appropriate hearing protection when operating for long periods of time.

10. Always attach safety chain when towing.

11. Do not exceed a safe travel speed when towing.

Slow down for corners and when going over

rough terrain.

12. Review safety instructions with all operators annually.

Gas engine powered units:

• Do not place hands in the drum unless the

engine is OFF and the spark plug wire is disconnected.

• Stay away from hot engine components during

operation.

• Do not smoke when refueling gas engine.

Electric motor powered units:

4. Keep hands, feet, clothing and hair away from all

moving and/or rotating parts.

5. Do not place hands in the drum unless the

engine is o and the spark plug wire is disconnected or the power cord is unplugged.

6. Do not attempt any adjustment or maintenance

to any system of the Mixer unless the power

source is disabled.

7. Make sure that all guards, shields and hoods are

properly installed and secured before operating

the Mixer.

8. Securely support the machine using blocks

or safety stands before working beneath it or

changing tires.

9. Store and transfer gasoline, solvents, cleaners

or any ammable liquids only in safety standard

approved containers.

2.4 TRANSPORT SAFETY

• Do not place hands in the drum unless the motor is

OFF and the power cord unplugged.

• Have a licensed electrician wire up and provide

power to the motor.

• Only use a power cord that is grounded.

• Always use an electrical cord with the required

power carrying capacity.

2.3 MAINTENANCE SAFETY

1. Review the Operator's Manual and all safety

items before working with, maintaining or operating the Mixer.

2. Stop engine or motor, disconnect spark plug wire

or unplug power cord, and wait for all moving

parts to stop before servicing, adjusting, repairing, or cleaning.

1. Read and understand ALL the information in the

Operator’s Manual regarding procedures and

SAFETY when operating the Mixer in the workplace and/or on the road.

2. Always travel at a safe speed. Use caution when

making corners or on a rough surface.

3. Make sure all the lights and reectors that are

required by the local highway and transport authorities are in place, are clean and can be seen

clearly by all overtaking and oncoming trac.

4. Do not allow riders on any part of the machine

during either road or highway travel.

5. Always use a safety chain between the Mixer and

the towing vehicle when transporting.

4

Page 8

6. Use a mechanical retainer through the ball hitch or

Discount-Equipment.com

clevis pin before transporting.

7. Ensure wheel nuts and axle hardware are tight.

2.5 TIRE SAFETY

1. Failure to follow proper procedures when mounting a tire on a wheel or rim can produce an explosion which may result in serious injury or death.

2. Do not attempt to mount a tire unless you have the

proper equipment and experience to do the job.

3. Have a qualied tire dealer or repair service perform required tire maintenance.

2.6 STORAGE SAFETY

1. Store unit in an area away from human activity.

2. Do not permit children to play on or around the

stored Mixer.

4. Turn motor o, unplug power cord or turn o

power at master panel and wait for all moving

parts to stop before servicing, maintaining, adjusting or cleaning.

5. Keep all electrical components in good condition.

2.9 SAFETY SIGNS

1. Keep safety signs clean and legible at all times.

2. Replace safety signs that are missing or have become

illegible.

3. Replaced parts that displayed a safety sign should

also display the current sign.

4. Safety signs are available from your Distributor or the

factory.

How to Install Safety Signs:

• Besurethattheinstallationareaiscleananddry.

2.7 REFUELING SAFETY

1. Handle fuel with care. It is highly ammable.

2. Allow engine to cool for 5 minutes before refueling. Clean up spilled fuel before restarting

engine.

3. Do not refuel the machine while smoking or

when near open ame or

sparks.

4. Always use an approved fuel

container.

5. Fill fuel tank outdoors.

6. Prevent res by keeping machine clean of accumulated trash, grease and debris.

2.8 ELECTRICAL SAFETY

1. Have a licensed electrician wire up and supply

power to the electric motor.

2. Always use a grounded power cord with the required capacity to carry the power to the motor.

3. Route the power cord out of the way or protect

from damage.

• Decideontheexactpositionbeforeyouremove

the backing paper.

• Removethesmallestportionofthesplitbacking

paper.

• Alignthesignoverthespeciedareaandcarefully

press the small portion with the exposed sticky

backing in place.

• Slowlypeelbacktheremainingpaperandcarefully

smooth the remaining portion of the sign in place.

• Smallairpocketscanbepiercedwithapinand

smoothed out using the piece of sign backing

paper.

2.10 SIGN-OFF FORM

Crown Construction Equipment follows the general

Safety Standards specied by the Society of Automotive Engineers (SAE) and the Occupational Safety

and Health Administration (OSHA). Anyone who will

be operating and/or maintaining the Crown Mortar

Mixer must read and clearly understand ALL Safety,

Operating and Maintenance information presented in

this manual.

Do not operate or allow anyone else to operate this

equipment until such information has been reviewed.

Annually review this information before the season

start-up.

5

Page 9

Make these periodic reviews of SAFETY and OPERATION a standard practice for all of your equipment. We feel

Discount-Equipment.com

that an untrained operator is unqualied to operate this machine.

A sign-o sheet is provided for your record keeping to show that all personnel who will be working with the

equipment have read and understand the information in the Operator’s Manual and have been instructed in the

operation of the equipment.

SIGN-OFF FORM

DATE

EMPLOYEES SIGNATURE

EMPLOYERS SIGNATURE

3 SAFETY SIGN LOCATIONS

The types of safety signs and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular function

related to that area, that requires your SAFETY AWARENESS.

•ThinkSAFETY!WorkSAFELY!

A

WARNING

B

A

ROTATING PART HAZARD

KEEP AWAY

201003

D

C

B

WARNING

MISSING GUARD HAZARD

Install, close and secure all

guards, shields and hoods before

201004

operating.

To prevent serious injury or death from rotating parts:

1. Install, close and secure all guards, shields and hoods

before operating.

2. Do not place hands in drum unless the motor or engine

is o and the power cord unplugged or the spark plug

wire is disconnected.

3. Keep hands, feet, hair and clothing away from moving

parts.

7

Page 10

REMEMBER - If Safety Signs

Discount-Equipment.com

have been damaged, removed,

become illegible or parts

replaced without safety signs,

new signs must be applied.

New safety signs are available

from your authorized dealer.

C

D

WARNING

201353

WARNING

Improper operation of this equipment can cause serious

injury or death.

Read Operator's Manual supplied with this machine before

operation or service.

Modication or alteration of this machine can cause serious

injury or death.

Do not alter or modify this machine without the express

written consent of the manufacturer.

201154

E

WARNING

ROTATING PART HAZARD

KEEP AWAY

To prevent serious injury or death from rotating parts:

1. Install, close and secure all guards, shields and hoods

before operating.

2. Do not place hands in drum unless the motor or engine

is o and the power cord unplugged or the spark plug

wire is disconnected.

3. Keep hands, feet, hair and clothing away from moving

parts.

201003

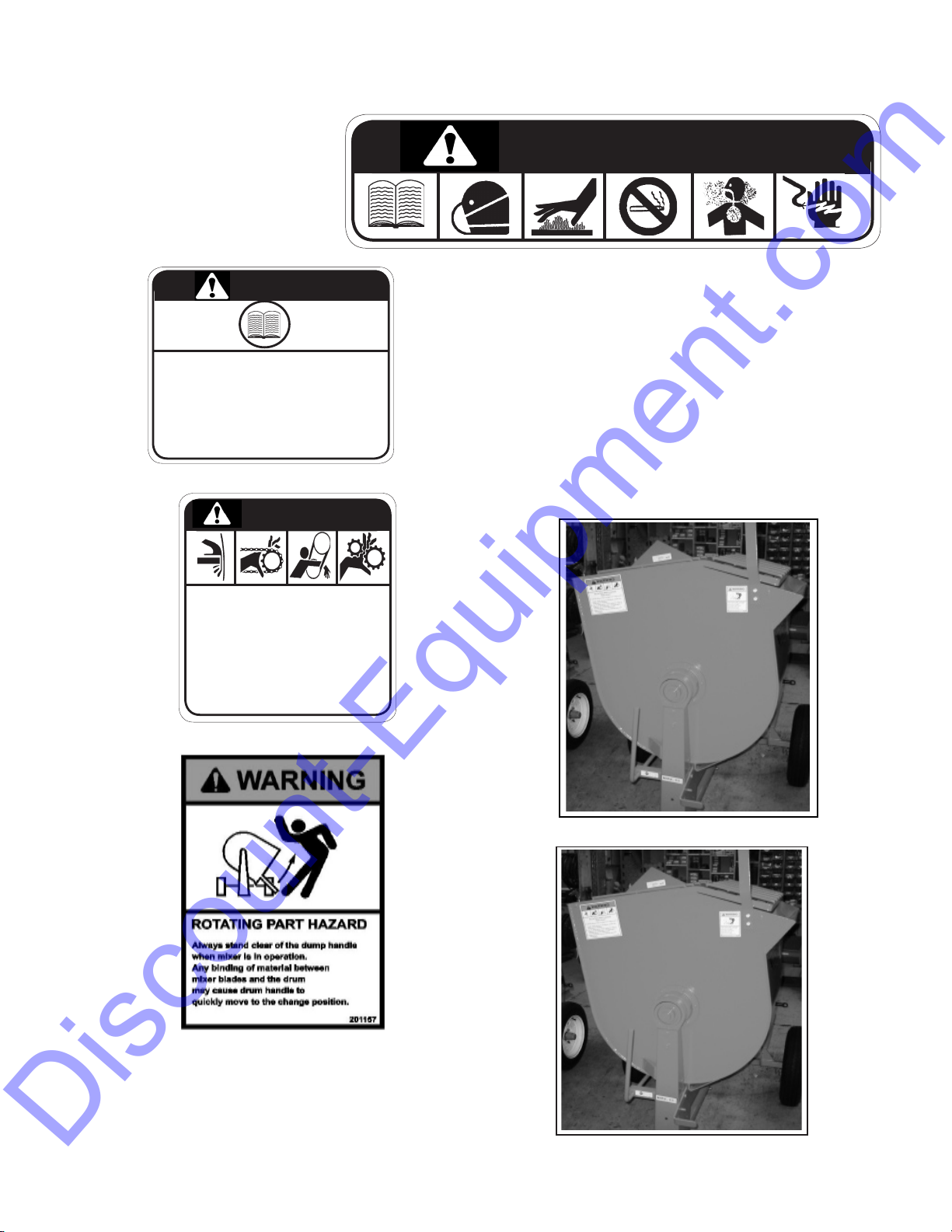

3 SAFETY SIGN LOCATIONS

The types of safety signs and locations on the equipment

are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Signs,

the type of warning and the area, or particular function

related to that area, that requires your SAFETY AWARENESS.

•ThinkSAFETY!WorkSAFELY!

E

F

E

REMEMBER - If Safety Signs have been damaged,

removed, become illegible or parts replaced without

safety signs, new signs must be applied. New safety

signs are available from your authorized dealer.

F

8

Page 11

3 SAFETY SIGN LOCATIONS

Discount-Equipment.com

GAS ENGINE POWER UNIT

The types of safety signs and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular function

related to that area, that requires your SAFETY AWARENESS.

•ThinkSAFETY!WorkSAFELY!

DECAL 'G' ~ ALSO LOCATED ON

OUTSIDE OF HOOD

G

G

1. Read and understand Operator's Manual and safety signs

before starting.

2. Stop engine, disconnect spark plug wire and wait for all

moving parts to stop before servicing, maintaining, adjusting or cleaning.

3. Keep hands, feet, hair and clothing away from moving parts.

4. Install, close and secure all guards, shields and hoods before

operating.

5. Do not place hands in the drum unless engine is OFF and

spark plug wire is disconnected.

6. Stay away from hot engine components during operation.

7. Do not smoke when refueling.

8. Follow good safety procedures when handling fuel.

9. Do not operate in an explosive atmosphere or a poorly

ventilated area without adequate ventilation.

10. Keep working area dry and clean to prevent slipping and

tripping.

11. Always attach safety chain when towing.

12. Comply with applicable transporting regulations when towing.

13. Do not allow riders during transporting.

14. Do not exceed a safe travel speed when transporting. Slow

down for corners and when going over rough terrain.

WARNING

H

201001

H

REMEMBER - If Safety Signs have been damaged,

removed, become illegible or parts replaced without

safety signs, new signs must be applied. New safety

signs are available from your authorized dealer.

J

10

USE

GASOLINE

FUEL ONLY

201152

DANGER

J

FIRE HAZARD

To prevent serious injury or death from re:

1. Do not smoke when refueling.

2. Keep sparks, ames and hot material away from ammable

substances.

NO SMOKING

201005

Page 12

3 SAFETY SIGN LOCATIONS

Discount-Equipment.com

ELECTRIC MOTOR POWER UNIT

The types of safety signs and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular function

related to that area, that requires your SAFETY AWARENESS.

•ThinkSAFETY!WorkSAFELY!

DECAL 'H' ~ ALSO LOCATED ON OUTSIDE OF

HOOD

K

K

1. Read and understand Operator's Manual and safety signs

before starting.

2. Turn motor o, unplug power cord or turn o power at

master panel and wait for all moving parts to stop before

servicing, maintaining, adjusting or cleaning.

3. Keep hands, feet, hair and clothing away from moving parts.

4. Install, close and secure all guards, shields and hoods before

operating.

5. Do not place hands in the drum unless engine is OFF and

power cord is unplugged.

6. Have a licensed electrician wire up and provide power to the

electric motor.

7. Use a power cord with the required capacity to carry the

power to the motor.

8. Route the power cord out of the way or protect it from damage.

9. Do not operate in an explosive atmosphere or a poorly

ventilated area without adequate ventilation.

10. Keep working area dry and clean to prevent slipping and

tripping.

11. Always attach safety chain when towing.

12. Comply with applicable transporting regulations when towing.

13. Do not allow riders during transporting.

14. Do not exceed a safe travel speed when transporting. Slow

down for corners and when going over rough terrain.

15. Review safety instructions annually.

CAUTION

201002

L

L

REMEMBER - If Safety Signs have been damaged,

removed, become illegible or parts replaced without

safety signs, new signs must be applied. New safety

signs are available from your authorized dealer.

11

DANGER

ELECTROCUTION HAZARD

1. Turn machine OFF, shut down and

lock out power source, unplug pow-

er cord and wait for all moving parts

to stop before servicing or repairing

machine or electrical components.

2. Keep electrical components in good

repair.

201006

Page 13

3 SAFETY SIGN LOCATIONS

Discount-Equipment.com

The types of safety signs and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular function

related to that area, that requires your SAFETY AWARENESS.

•ThinkSAFETY!WorkSAFELY!

M

WARNING

M

105

km/h

N

P

NOTICE

Ensure tow vehicle has towing capacity for the weight of this

machine.

Do not tow the machine unless the draw bar is bolted in

place and the safety bolt on the end of the draw bar is

securely fastened.

Close engine fuel cuto (where applicable) before towing

mixer to prevent leakage into the engine crankcase.

Use 2 people to lift and position hitch (pintle and ball) on

and o tow vehicle.

Securely attach hitch to towing vehicle - pintle or ball type

coupler (ball type shown).

Be certain ball clamp captures ball and lever or handwheel

is fully clamped. Ensure use of safety pin through latch or

handwheel (for ball type coupler).

Safety chain attachment (see illustration) chains must cross

under the draw bar and be positioned to prevent the draw

bar from dropping to the ground in the event of a hitch

failure.

Connect lighting plug/electric brake

plug (where applicable).

Make certain that the wheel lug nuts

and axle mounting hardware are tight.

Check pressure and overall

condition of tires.

Test brakes

(if applicable).

201001

201150

Excessive towing speed can cause serious

injury or death.

Do NOT exceed 65 mph (105 km/h)

1. Make certain that the wheel lug nuts and axle

mounting hardware are tight.

2. Check pressure and

overall condition of

tires.

N

P

CAUTION

Use 2 people to lift and position hitch on and o tow

vehicle.

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts

replaced without safety signs, new signs must

be applied. New safety signs are available from

your authorized dealer.

201151

201155

12

Page 14

4 OPERATION

Discount-Equipment.com

1. Read and understand the Operator’s Manual

and all safety signs before operating, servicing,

adjusting, or cleaning the Mixer.

2. Do not allow riders on the machine during transport.

3. Install, close and secure all guards, shields and

hoods before starting or operating.

4. Stop engine or motor, disconnect spark plug wire

or unplug power cord, and wait for all moving

parts to stop before servicing, adjusting, repairing, or cleaning.

5. Clear the area of all bystanders before starting.

6. Keep hands, feet, hair and clothing away from

moving parts.

7. Keep working area clean and dry to prevent slipping and tripping.

8. Do not run the mixer in an explosive atmosphere

or in a poorly ventilated or enclosed area.

OPERATING SAFETY

Slow down for corners and when going over

rough terrain.

12. Review safety instructions with all operators

annually.

Gas engine powered units:

• Do not place hands in the drum unless the en-

gine is OFF and the spark plug wire is disconnected.

• Stay away from hot engine components dur-

ing operation.

• Do not smoke when refueling gas engine.

Electric motor powered units:

• Do not place hands in the drum unless the mo-

tor is OFF and the power cord unplugged.

• Have a licensed electrician wire up and provide

power to the motor.

• Only use a power cord that is grounded.

9. Wear appropriate hearing protection when operating for long periods of time.

10. Always attach safety chain when towing.

11. Do not exceed a safe travel speed when towing.

4.1 TO THE NEW OPERATOR OR OWNER

The Crown Construction Equipment Mortar Mixer is

designed to eciently combine water, lime, aggregate and cement into a mixture for forming mortar. It

is the responsibility of the operator to be familiar with

the machine before starting.

It is the responsibility of the owner or operator to

read this manual before starting. Follow all safety

instructions exactly. Safety is everyone's business. By

following recommended procedures, a safe working

environment is provided for the operator, bystanders

and the environment.

• Always use an electrical cord with the required

power carrying capacity.

Many features incorporated into this machine are the

result of suggestions made by customers like you.

Read this manual carefully to learn how to operate the

machine safely and how to set it to provide maximum

mixing eciency. By following the operating instructions

in conjunction with a good maintenance program, your

Mixer will provide many years of trouble-free service.

13

Page 15

4.2 HOW THE MACHINE WORKS

Discount-Equipment.com

The Mortar Mixer consists of a large tilting drum with

internal rotating paddles or spiral blades for combining

cement, lime, aggregate and water into a mixture for

forming mortar. The enclosure on the back end houses

the electric motor or gas engine for turning the mixing elements. A set of pulleys and drive belt within the

enclosure transmits rotational power to a gearbox that

powers the mixing elements.

A lever on the front end of the drum assembly allows

the operator to tilt the drum to the required position

for mixing and emptying. A lever on the bottom of the

frame extends to the power compartment and moves

the gearbox to engage the drive belt for turning the mixing elements. An extendable hitch allows the hitch to

extend for towing and retracts during operation.

H

L

M

P

O

K

Fig. 1 MACHINE COMPONENTS

A Gas Engine

B Electric Motor

C Belt/Pulley Drive

D Gearbox

E Power Compartment

F Paddles

G Spiral Blades

H Grill

G

J Bag Splitter

K Drum

L Tilt Lever

M Drum Lock

N Engagement Clutch

O Hitch

P Safety Chain

Q Emergency Stop

14

J

H

Q

K

E

N

Page 16

4.3 PRE-OPERATION CHECKLIST

Discount-Equipment.com

Ecient and safe operation of the Mixer requires that

each operator reads and understands the operating

procedures and all related safety precautions outlined

in this section. A pre-operation checklist is provided

for the operator. It is important for both personal

safety and maintaining the good mechanical condition of the machine that this checklist is followed.

Before operating the Mixer and each time there-after,

the following areas should be checked o:

1. Gas Engine Units:

a. Check all uid levels: fuel, engine oil and

gearbox oil. Refuel or top up oil as required.

b. Check the tires and be sure that they are

inated to the specied pressure.

c. Check the tension and alignment of drive belt

when engaged. Tension or align as required.

d. Lubricate machine per Maintenance Section.

e. Close and secure all guards, shields and hoods.

4.4 PRE-START PROCEDURES

All machines are sent from the factory in a special shipping conguration to prevent spilling oil or gas. As a

result, the following items must be done prior to starting the machine:

1. Gas engine powered units:

a. Fill the engine crankcase with its specied oil

(SAE 30W or 10W30 oil).

IMPORTANT

Engine warranty is void if the

Refer to engine manual for oil specications if

engine is run without oil.

operating in unusual temperature conditions.

d. Check the engine speed at maximum. Be sure

it is set to give a paddle rotation speed of 3035 RPM and a spiral rotation of 40-45 RPM.

e. Use the emergency stop switch to stop the

engine to be sure that it works. Repair or

replace if it is not functioning.

f. Lubricate machine per Maintenance Section.

g. Close and secure all guards, shields and

hoods.

2. Electric motor units:

a. Check the tension and alignment of drive

belt when engaged. Tension and align as

required.

b. Check gearbox oil level. Top up as required.

c. Check the tires and be sure that they are

inated to the specied pressure.

b. Add SAE 80W90 oil to the gearbox.

c. Fill the fuel tank with regular unleaded gas. Do

not use an ethanol blend.

d. Start the engine and set the high idle speed

to give a mixing element rotation speed of 30

to 35 RPM for the paddles and 40 to 45 for the

spiral.

IMPORTANT

The engine is supplied from the engine

manufacturer with the high idle speed set at

approximately 3500 RPM and no gas or oil.

As a result, the engine is not run when it is

mounted to the Mixer. It is the responsibility

of the customer to add oil and gas, start the

engine and reset the high idle RPM to the operating range (Refer the Maintenance Section

for procedure).

e. The machine is shipped with the drum tilt

lever pointing down or fastened to the safety

grill. Remove lever and turn it around so it is

pointing up. Tighten mounting bolts to their

specied torque.

f. Be sure the emergency stop switch is function-

ing properly.

15

Page 17

4.4 PRE-START PROCEDURES

Discount-Equipment.com

(Cont'd)

2. Electric motor powered units:

4.6 CONTROLS

Before starting to work, all operators should familiarize themselves with the location and function of the

controls.

a. Have a licensed electrician provide power to the

motor. Use only a grounded cord with sucient

capacity to carry the required load.

b. Have a licensed electrician wire up the motor if it is

not a 110 volt unit.

c. The machine is shipped with the drum tilt lever

pointing down. Remove lever and turn it around

so it is pointing up. Tighten mounting bolts to their

specied torque.

4.5 MACHINE BREAK-IN

A special break-in procedure has been developed to insure the

integrity of the machine when rst starting. When using the

machine for the rst time, follow this procedure.

A. Before Starting:

1. Read the engine and Mixer Operator's Manuals.

2. Review and follow pre-start procedures before starting machine (Section 4.4).

B. At 1/2, 2, 5 and 10 hours:

1. Check all machine uid levels: Fuel, engine oil and

gearbox oil. Refuel or top up as required.

2. Retorque wheel bolts.

3. Check for loose hardware. Tighten to specied torque.

4. Check drive belt tension and alignment when engaged. Tension and align as required.

1. Gas engine powered units:

Always read the engine Operator's Manual supplied

with the machine for the detailed operating procedures for your engine.

a. Ignition switch:

This switch controls the electrical power to the

engine electrical system. Turn the switch clockwise to turn the electrical system ON and the

engine will run. Turn counterclockwise to stop

the engine.

b. Fuel shuto valves:

Each engine is equipped with a shut-o valve

between the fuel tank and the carburator. Slide

the fuel valve toward the block to turn ON and

away for OFF. Turn the fuel OFF when not in use

or before transporting.

c. Throttle:

This lever controls the engine RPM. Move the

lever laterally to increase or decrease the RPM.

Always run at maximum throttle operating.

d. Choke:

The choke controls the fuel/air mixture to the

engine. Close the choke when starting if the

engine is cold. Open the choke as the engine

warms. Always open the choke fully during

operation.

e. Starting rope:

This retracting rope and T bar is used to turn the

engine over for starting. Grasp the T bar rmly

and pull the rope sharply to start the engine.

Close the choke if the engine is cold.

5. Lubricate the points dened in the Maintenance section.

6. Then go to the service schedule as dened in the

Maintenance section.

C. At 10 hours:

1. Change the engine oil.

2. Change the gearbox oil.

3. Replace with their specied oil.

4. Then go to the oil replacement schedule as dened in

the Maintenance section and engine manual.

f. External Emergency Stop Switch:

This push-pull switch shorts out the power to

the gas engine ignition system and is located

on the outside of the hood. Push the switch

in to stop the engine and pull out to allow it

to run.

16

Page 18

c

Discount-Equipment.com

d

b

e

Honda

Fig. 2 GAS ENGINE CONTROLS

5. Drive Engagement Clutch:

This lever engages and disengages the mixing ele-

ments in the drum. Move to the left to disengage

the drive and ease to the right to engage. Always

disengage before starting the engine or motor and

a

Switch

Fig. 4 ELECTRIC MOTOR (TYPICAL)

Fig. 3 EXTERNAL EMERGENCY STOP

SWITCH (TYPICAL)

2. Electric Motor (Typical):

a. Master ON/OFF:

This switch controls the power to the electric

motor that turns the mixing elements in the

drum. Move the switch rearward to turn ON

and forward for OFF.

WARNING

Machine is shown with engine hood open

for illustrative purposes only. Never operate with hood open.

3. Drum Position:

This lever sets the position of the mixing drum.

Move the lever down to empty the drum and

up to mix.

4. Drum Position Lock:

This lever locks the mixing drum in its mixing

position. Pull up on lever to release the lock.

It will automatically engage when the drum is

moved into its mixing position.

3

5

4

Fig. 5 DRUM EMPTYING CONTROLS

17

Page 19

4.7 OPERATING

Discount-Equipment.com

1. Read and understand the Operator’s Manual

and all safety signs before operating, servicing,

adjusting, or cleaning the Mixer.

2. Do not allow riders on the machine during transport.

3. Install, close and secure all guards, shields and

hoods before starting or operating.

4. Stop engine or motor, disconnect spark plug wire

or unplug power cord, and wait for all moving

parts to stop before servicing, adjusting, repairing, or cleaning.

5. Clear the area of all bystanders before starting.

6. Keep hands, feet, hair and clothing away from

moving parts.

7. Keep working area clean and dry to prevent slipping and tripping.

8. Do not run the mixer in an explosive atmosphere

or in a poorly ventilated or enclosed area.

OPERATING SAFETY

Slow down for corners and when going over

rough terrain.

12. Review safety instructions with all operators

annually.

Gas engine powered units:

• Do not place hands in the drum unless the en-

gine is OFF and the spark plug wire is disconnected.

• Stay away from hot engine components dur-

ing operation.

• Do not smoke when refueling gas engine.

Electric motor powered units:

• Do not place hands in the drum unless the mo-

tor is OFF and the power cord unplugged.

• Have a licensed electrician wire up and provide

power to the motor.

• Only use a power cord that is grounded.

9. Wear appropriate hearing protection when operating for long periods of time.

10. Always attach safety chain when towing.

11. Do not exceed a safe travel speed when towing.

Each operator should review this section of the manual

when starting a project and as often as required to be

familiar with the machine. When operating, follow this

procedure:

1. Review and follow the Pre-Start and Pre-Operation

checklists.

2. Review the location and function of all controls.

3. Determine ratio of the cement, lime, water and aggregate required for your mixture. Always use the

same mixture ratio for each batch.

4. Be sure the mixing elements turn at 30 to 35 RPM

for the paddles and 40 to 45 RPM for the spiral to

insure proper mixing.

• Always use an electrical cord with the required

power carrying capacity.

Fig. 6 ELECTRICAL POWER SWITCH (TYPICAL)

19

Page 20

5. Starting machine:

Discount-Equipment.com

A. Electric motor powered units:

a. Check that everyone is clear of the ma-

chine.

b. Move power engagement clutch to the

left to disengage the mixing elements.

c. Unlatch and open the hood.

d. Turn the power switch ON.

e. Close and latch the hood.

f. Move power engagement clutch to the

right to engage the mixing elements.

B. Gas engine powered units:

a. Check that everyone is clear of the ma-

chine.

b. Pull the emergency stop switch out.

c. Move power engagement clutch to the

left to disengage the drive.

d. Unlatch and open the engine compart-

ment hood.

e. Move the throttle into its midrange posi-

tion.

f. Close the choke if starting when the

engine is cold.

g. Turn the ignition switch to its RUN posi-

tion.

h. Pull sharply on the T bar rope to start the

engine.

i. Allow the engine to run for a couple of

minutes to warm up.

j. Open the choke to its fully open position

when the engine is warm.

k. Move the throttle to its maximum RPM

position.

Fig. 7 EMERGENCY STOP SWITCH (TYPICAL)

IMPORTANT

Be sure the engine has been set

to give a mixing element speed

of 30 to 35 RPM for the paddles

l. Close and secure the engine compart-

m. Ease the power engagement clutch to

and 40 to 45 RPM for the spiral.

ment hood.

Fig. 8 POWER ENGAGEMENT CLUTCH

the right to engage the mixing elements.

WARNING

Machine is shown with engine hood

open for illustrative purposes only.

Never operate with hood open.

20

Page 21

6. Stopping machine:

Discount-Equipment.com

A. Electric motor powered units:

a. Move the power engagement clutch to

the left to disengage the mixing ele-

ments.

b. Empty the drum of the mortar mixture.

c. Unlatch and open the hood.

d. Turn the power switch OFF.

e. Close and latch the hood.

B. Gas engine powered units:

a. Move the power engagement clutch to

the left to disengage the mixing ele-

ments.

b. Empty the drum of the mortar mixture.

c. Unlatch and open the hood.

d. Move the throttle to its low idle position.

e. Stop the engine by turning the switch

OFF or depressing the kill switch or strap.

f. Close and secure the engine compart-

ment hood.

Power Switch

7. Emergency Stopping:

If an emergency arises, stop the machine by mov-

ing the power engagement clutch to the left to

disengage the mixing elements and then pushing

the kill switch in.

8. Machine placement:

Always place the Mixer in a location so the opera-

tor has easy access to the mixture ingredients

when adding to the mixing drum. Always position to

provide adequate clearance for the machine or

equipment removing the concrete mixture from the

mixing drum. On the electric motor models, route

the power cord out of the way to prevent damage.

Do not run the mixture in an explosive atmosphere

or in a poorly ventilated or enclosed area.

9. Filling:

When mixing mortar, follow this procedure:

a. Clear the working area of unauthorized person-

nel.

b. Start the motor or engine.

c. Engage the mixing elements.

d. Add half the required amount of water into the

mixing drum.

e. Add half the required amount of sand into the

drum.

f. Add the required mortar mix (cement, lime,

etc.).

g. Add the cement required for the batch.

h. Add the rest of the water.

i. Add the rest of the sand until the desired work-

ability is obtained.

21

External Emergency Stop Switch (Typical)

Fig. 9 STOPPING

WARNING

Machine is shown with engine

hood open for illustrative purposes

only. Never operate with hood

open.

NOTE

Add sand a little at a time until

the desired consistency is

obtained.

j. Mix until there is an even consistency

throughout the mixture. Look into the drum

and watch until the mixture is the same

color throughout. This means the mortar

mix is evenly distributed throughout the

mixture.

k. Disengage the mixing clutch.

l. Release the drum lock and slowly tilt the

drum down to discharge the mixture.

m. Raise the hinged grill out of the way when

discharging the mixture.

n. Move the drum back into its mixing position

and lock. Immediately engage the mixing

clutch and add half the water for the next

batch. This will help to keep the drum and

mixing elements clean and prevent lumps

from forming in the mortar.

Page 22

10. Mixing time:

Discount-Equipment.com

After all the ingredients have been added to the

drum, allow time for the material to reach a uniform

color and consistency. Watch the color and consistency of the mixture as the drum is turning. When

the entire mixture becomes a pale green color,

it means the mortar mix is uniformly distributed

throughout the mixture and can be discharged. If

the mixture is not uniform, the mortar will have

weak spots.

11. Emptying drum:

All Mixers are equipped with a lock for anchoring

the drum at the mixing angle. Move the wheelbarrow or other mortar receiver up to the side of the

Mixer. To empty the drum:

a. Disengage mixing clutch.

b. Release drum lock.

c. Move the wheelbarrow into position.

d. Slowly tilt the drum down.

e. Lift the hinged grill out of the way.

f. Fill the wheelbarrow.

g. Raise the drum back into its mixing position

and lock.

h. Engage mixing clutch.

i. Add half the water and sand for the next

batch. This will help to clean the mixing ele-

ments and inside of the drum.

NOTE

The Mixer is equipped with a solid grill

and bag splitter over the drum opening.

Place the bag of material on the grill/splitter and let the material fall into the drum.

Repeat with the next bag until the required

amount is added.

12. Mixing Elements:

A Mixer can be equipped with paddles or a spiral for

mixing the materials into a uniform mixture. Each

system has adjustable wipers to clean the sides and

ends of the drum. Maintain the wipers at 1/16 to

1/8 inch (1.5 to 3.0 mm) from the drum surface. A

large gap can result in a build-up on the surface.

This build-up will break loose and produce lumps or

chips in the mixture.

13. Preventing Build-up:

To maintain high quality mixing, consistent per-

formance and machine life, thoroughly clean the

mixer inside and out at the end of each day.

Under normal operating conditions, adding water

and sand and some aggregate to the drum immediately after emptying will wash and clean the mixing

elements and the inside of the drum and keep them

clean providing the wipers are set at 1/16 to 1/8

inch (1.5 to 3 mm) from the drum surface. If a slow

build-up is occurring, add water and coarse sand to

the drum at the end of the working day and let it

run for 15 minutes.

Fig. 10 FILLING

14. Removing Build-up:

Always disable the machine by unplugging the

power cord or disconnecting the spark plug wire.

Dried mix should be scraped out as necessary. DO

NOT strike the outside of the drum with a shovel,

hammer or other device to break up and loosen any

build-up, as this will dent and damage the drum.

At the end of the working day, thoroughly wash the

inside of the drum and the outside of the machine to

remove any residue build-up or clumps. Do not get

water on the electric motor or gas engine.

15. Drum speed:

The best mixing action occurs when the mixing ele-

ments are turning 30 to 35 RPM for the paddles and

40 to 45 for the spiral. Do not operate outside of this

speed range. Increasing the mixing element speed

does not signicantly change mixing characteristics.

Mixing time is much more important and the mixture must be thoroughly blended to obtain uniform

and consistent mortar.

22

Page 23

16. Capacities:

Discount-Equipment.com

Each model has its own specied capacity.

When that capacity is exceeded, the excess spills out

of the drum making a mess of the working area and

increases the required time for mixing. It is recommended to use an additional mixer if more mixing

capacity is required.

NOTE

On the larger models, a full drum

can ll more than one wheelbarrow. Change wheelbarrows until

the drum is empty.

Fig. 11 EMPTYING DRUM

G

1. Read and understand Operator's Manual and safety signs

before starting.

2. Stop engine, disconnect spark plug wire and wait for all

moving parts to stop before servicing, maintaining, adjusting or cleaning.

3. Keep hands, feet, hair and clothing away from moving parts.

4. Install, close and secure all guards, shields and hoods before

operating.

5. Do not place hands in the drum unless engine is OFF and

spark plug wire is disconnected.

6. Stay away from hot engine components during operation.

7. Do not smoke when refueling.

8. Follow good safety procedures when handling fuel.

9. Do not operate in an explosive atmosphere or a poorly

ventilated area without adequate ventilation.

10. Keep working area dry and clean to prevent slipping and

tripping.

11. Always attach safety chain when towing.

12. Comply with applicable transporting regulations when towing.

13. Do not allow riders during transporting.

14. Do not exceed a safe travel speed when transporting. Slow

down for corners and when going over rough terrain.

WARNING

Paddles

201001

Spiral

Table 1 Capacity Bags

4S

5S

S5S

6S

6SR

S6SR

6PR

S8S

8S

8P

10S

S10S

12S

S12S

1 - 1-1/2

2 - 2-1/2

3 - 3-1/2

3 - 4

23

Page 24

17. Power Engaging Clutch:

Discount-Equipment.com

The power engaging clutch lever is located

next to the drum tilting controls so it is

convenient for the operator to stop the

mixing elements when emptying the

drum. The linkage in the power compartment must be set so the drive belt does

not slip during operation and the operator must feel the lever go over-center as

it fully engages. Always disengage the

clutch when starting, stopped or emptying.

WARNING

Machine is shown with engine hood open

for illustrative purposes only. Never operate with hood open.

Linkage

18. Selection of Mortar type:

The performance of masonry is inuenced

by various mortar properties such as workability, bond strength, durability, extensibility and compression strength. Since

these properties vary with mortar type, it

is highly important that the mortar type

selected for a particular application is the

one that best meets the end-user requirements. Table 1 is a general guide for the

selection of for various masonry wall construction. Selection of mortar type should

also be based on the type of masonry units

to be used as well as the applicable building code and engineering practice standard requirements such as allowable design

stresses and lateral support.

Fig. 14 POWER ENGAGING CLUTCH SYSTEM

25

Lever - Engaged

Lever - Disengaged

Page 25

19. Guide for the selection of masonry Mortars

Discount-Equipment.com

TABLE 1 MORTAR TYPE:

Location Building Segment Recommended Alternative

Exterior, above grade Loadbearing wall N S or M

Non-loading wall, Parapet wall, N OB or S

chimney & veneer wall N S

Exterior, at or Foundation wall, retaining wall, M SC or N

below grade manholes, sewers pavements

walks and patios

Interior Loadbearing wall N S or M

Non loadbearing partitions. O N

A

This table does not provide for many specialized mortar used, such as reinforced masonry, acid resistant and re box mortars.

B

Type 0 mortar is recommended for use where the masonry is unlikely to be frozen when saturated or unlikely to be subject to high winds

or other signicant lateral loads. Type N or S mortar should be used in other cases.

C

Masonry exposed to weather in a nominally horizontal surface is extremely vulnerable to weathering. Mortar for such masonry should be

selected with due caution.

TABLE 2 MORTAR PROPORTIONS BY VOLUME

A

C

Parts by Parts by Aggregate ratio

volume of volume of (measured in

Mortar Portland hydrated damp, loose

type cement lime conditions)

M 1 1/4 Not less than 2 1/4

S 1 Over 1/4 to 1/2 and not more than 3

N 1 Over 1/2 to 1 1/4 times the sum of the

O 1 Over 1 1/4 to 2 1/2 volumes of cement

and lime used.

TABLE 3 PROPERTY SPECIFICATION REQUIREMENTS

Average compressive

strength at Water Air Aggregate ratio

Mortar 28 days, min psi retention content (measured in damp

type (MPa) min % max % loose conditions)

M 2500 (17.2) 75 12 Not less than 2 1/4 and

S 1800 (12.4) 75 12 not more than 3 1/2 times

N 750 (5.2) 75 14 the sum of the separate

O 350 (2.4) 75 14 volumes of cementitious

materials.

26

Page 26

20. Volumes and weights of materials:

Discount-Equipment.com

1 Bag of Cement 88 lb 1 Bag of Cement 40 Kg

1 Cu. ft. Sand/Gravel 85-100 lb 1 Cu. metre Sand/Gravel 1360-1600 Kg

1Cu. ft. Plain Concrete 140-150 lb 1Cu. metre Plain Concrete 2240-260 Kg

1 Cu. ft. Water 62-65 lb 1 litre Water 1 kg

1 Imperial Gallon of Water 10 lb 1 Cu. metre Water 1000 kg

1 Cu. Yard 27 cu. ft. = 7646 cu. metre

21. Operating hints:

a. Keep the working area as clean and dry as pos-

sible to prevent slipping and tripping.

b. Provide sucient space around the machine for

adding material to the drum and removing the

mixture.

c. Always add the materials in the same ratio to give

a uniform mixture for mortar.

d. Provide sucient time to thoroughly combine

the mixture to a uniform consistency before discharging from the drum.

e. The water requirements for the mixture can vary

depending on moisture content of the sand. Vary

the amount of water in the mixture to give the

consistency of the mortar desired.

Crown Construction Mixers are designed to be easily and

conveniently moved from place to place.

When moving the machine, follow this procedure:

1. On the larger Models, extend the pole to its full

length.

2. Secure with the lock pin and retainer.

4.8 TRANSPORTING

TRANSPORT SAFETY

1. Read and understand ALL the information in

the Operator’s Manual regarding procedures

and SAFETY when operating the Mixer in the

workplace and/or on the road.

2. Always travel at a safe speed. Use caution

when making corners or on a rough surface.

3. Make sure all the lights and reectors that are

required by the local highway and transport

authorities are in place, are clean and can be

seen clearly by all overtaking and oncoming

trac.

4. Do not allow riders on any part of the machine during either road or highway travel.

5. Always use a safety chain between the Mixer

and the towing vehicle when transporting.

6. Use a mechanical retainer through the ball

hitch or clevis pin before transporting.

7. Ensure wheel nuts and axle hardware are

tight.

3. Use 2 men to lift the hitch and pull the Mixer to the

new location.

4. Retract and lock the pole.

When transporting the machine, follow this procedure:

1. On the electric motor powered units, unplug the

power cord.

Fig. 15 MOVING

27

Page 27

2. On gas engine powered units, open the

Discount-Equipment.com

hood and close the fuel valve to prevent

ooding the carburetor.

3. Move the drum to its mixing position and

lock.

4. Attach the optional lighting bar and secure.

5. On the larger Models, extend the hitch

pole and secure with the lock pin and

retainer.

6. Securely attach the machine to the towing

vehicle.

7. Use a mechanical retainer through the

ball hitch or the clevis pin.

IMPORTANT

Be sure the ball on the truck is

the correct size for the hitch. Do

not use an undersized ball with

the hitch.

Fig. 16 FUEL SHUT OFF VALVE

WARNING

Machine is shown with engine hood open

for illustrative purposes only. Never operate with hood open.

8. Attach the safety chain to prevent unexpected separation. Cross the chains

under the hitch for support.

9. Plug the wiring harness into the truck.

Be sure all the lights are working.

10. Check that the wheel bolts are tightened to their specied torque.

11. Check that the tires are inated to

their required pressure.

12. Use special care when transporting

during times of limited visibility. Be

sure that you can be seen by oncoming and overtaking trac. Always use

the lighting bar.

13. Never exceed the speed appropriate

for the terrain and conditions. Slow

down for turns and when traveling

over rough terrain.

Ball Hitch

Clevis

Fig. 17 ATTACHMENT

29

Page 28

4.9 STORAGE

Discount-Equipment.com

STORAGE SAFETY

1. Store unit in an area away from human activity.

2. Do not permit children to play on or around

the stored Mixer.

At the end of the season or when the machine will not

be used for a period, inspect all major components of the

Mixer. Repair or replace any worn or damaged components to prevent any unnecessary down time at the start

of next project. When preparing for storage, follow this

procedure:

1. Drain the fuel from gas tank.

5 SERVICE AND MAINTENANCE

MAINTENANCE SAFETY

1. Review the Operator's Manual and all safety

items before working with, maintaining or

operating the Mixer.

2. Stop engine or motor, disconnect spark plug

wire or unplug power cord, and wait for all

moving parts to stop before servicing, adjusting, repairing, or cleaning.

3. Follow good shop practices:

Keep service area clean and dry. Be sure elec-

trical outlets and tools are properly grounded.

Use adequate light for the job at hand.

2. Turn the fuel supply valve OFF or unplug the power

cord.

3. Close and secure the hood.

4. Thoroughly wash the machine using a water hose or

pressure washer to remove all dirt, dust or residue.

IMPORTANT

Do not get water on the electric

motor or gas engine. Use an

air hose to clean the motor or

engine.

5. Inspect the inside of the drum. Chip out or break loose

any build-up.

6. Lubricate all the grease ttings.

7. Rotate the drum so it is pointing straight down or in its

emptying position.

8. Cover the machine with a tarpaulin and tie down if the

machine is not stored inside.

4. Keep hands, feet, clothing and hair away from

all moving and/or rotating parts.

5. Do not place hands in the drum unless the

engine is o and the spark plug wire is discon-

nected or the power cord is unplugged.

6. Do not attempt any adjustment or maintenance to any system of the Mixer unless the

power source is disabled.

7. Make sure that all guards, shields and hoods

are properly installed and secured before operating the Mixer.

8. Securely support the machine using blocks

or safety stands before working beneath it or

changing tires.

9. Store and transfer gasoline, solvents, cleaners

or any ammable liquids only in safety standard approved containers.

5.1 SERVICE

5.1.1 FLUIDS AND LUBRICANTS

1. Grease

Use an SAE multi-purpose high temperature grease

or a multi-purpose lithium base grease.

2. Gasoline

Use a standard unleaded gasoline for all operating

conditions. Do not use gasoline with an ethanol

blend.

Fig. 18 STORED

31

Page 29

Capacities:

Discount-Equipment.com

5.5 Honda: 0.95 US Gal (3.6 Lts, 0.79 Imp Gal)

9.0 Honda : 1.59 US Gal (6.0 Lts, 1.32 Imp Gal)

3. Engine oil:

Use an SAE 10W30 multi-viscosity oil meeting the

American Petroleum Institute (API) classication

of SF OR SG for normal operating temperatures.

Consult the engine manual for unusual operating

conditions. Do not mix oil types or viscosities.

Crankcase Capacity:

5.5 hp: 0.53 US Qts (0.5 Lts, 0.44 Imp Qts)

9.0 hp: 1.16 US Qts (1.1 Lts, 1.94 Imp Qts)

4. Storing Lubricants and Fluids

Your machine can operate at top eciency only if

clean lubricants are used. Use clean containers to

handle all uids. Store them in an area protected

from dust, moisture and other contaminants.

5.1.2 GREASING

Refer to section 5.1.1 for recommended grease. Use the

Maintenance Checklist provided to keep a record of all

scheduled maintenance.

5.1.3 SERVICING INTERVALS

Daily or 8 Hours

1. Check engine uid levels. Top as required.

a. Check engine oil level. Top up as required.

b. Check fuel level. Add as required.

Fig. 22 CLUTCH LINKAGE SHAFT (TYPICAL)

b

a

Fig. 19 ENGINE FLUID LEVELS

2. Check the drive belt tension with the clutch

engaged.

WARNING

Machine is shown with engine hood open

for illustrative purposes only. Never operate with hood open.

Machine

Clutch Linkage

Fig. 20 DRIVE BELT TENSION

Daily or 8 Hours (cont'd)

3. Grease the drum assembly bearings (2 locations).

Fig. 21 DRUM ASSEMBLY BEARINGS

4. Grease the clutch linkage shaft

in the power compartment (1

location).

32

Page 30

Daily or 8 Hours (cont'd)

Discount-Equipment.com

5. Use an air hose to blow out and clean

the engine, motor and compartment.

WARNING

Machine is shown with engine hood open

for illustrative purposes only. Never operate with hood open.

Weekly or 50 Hours

1. Change the engine oil.

IMPORTANT

Change more frequently if operating in high ambient temperatures or in very dusty or dirty

conditions.

a. Drain plug.

b. Fill plug.

2. Clean the engine air intake lter.

Gas Engine (Typical)

Electric Motor

Fig. 23 DRIVE COMPARTMENT

Weekly or 50 Hours (cont'd)

3. Check the gearbox oil level.

Fig. 24 ENGINE OIL

Fig. 26 GEARBOX LEVEL & DRAIN PLUGS

Fig. 25 ENGINE AIR INTAKE FILTER

35

Fig. 27 ELECTRIC MOTOR

Page 31

Annually or 400 Hours

Discount-Equipment.com

1. Grease the electric motor bearings with

1/2 shot of grease (2 locations).

2. Change gearbox oil

3. Repack wheel bearings. (2 locations).

4. Check wheel nut torque.

5. Check axle mounting hardware.

Fig. 29 WHEELS

5.1.4 SERVICE RECORD

See Lubrication and Maintenance sections for details of service. Copy this page to continue record.

ACTION CODE: š CHECK C CHANGE CL CLEAN

L LUBRICATE RE REMOVE R REPACK

HOURS

SERVICED

BY

MAINTENANCE

DAILY OR 8 HOURS

š Engine Fluid Levels

š Engine Oil Level & Fuel Level

š Drive Belt Tension

L Drum Assembly Bearings (2)

L Clutch Linkage Shaft (1)

CL Engine, Motor & Compartment

WEEKLY OR 50 HOURS

C Engine Oil, Drain Plug & Fill Plug

CL Engine Air Intake Filter

š Gearbox Oil Level

ANNUALLY OR 400 HOURS

L Electric Motor Bearings (2)

C Gearbox Oil

R Wheel Bearings (2)

š Wheel Nut Torque

š Check Axle Mounting Hardware

37

Page 32

5.2 MAINTENANCE

Discount-Equipment.com

By following a careful service and maintenance

program for your machine, you will enjoy many

years of trouble-free service.

5.2.1 ENGINE OIL CHANGING

1. Review the Operator’s Manual for the

engine.

2. Allow the engine to cool before changing

oil. Hot oil can cause burns if it contacts

exposed skin. Draining works best if the

oil is warm.

3. Be sure the ignition switch is o and fuel

valve is turned o.

4. Place a pan under the drain plug.

5. Remove the drain plug and allow oil to

drain for 10 minutes.

6. Install the engine drain plug and tighten.

7. Dispose of the oil in an approved container.

8. Add the specied type and amount of motor oil. Refer to Section 5.1.1 or the engine

manual.

WARNING

Machine is shown with engine hood open

for illustrative purposes only. Never operate with hood open.

Fig. 30 ENGINE OIL CHANGING (DRAIN PLUG)

5.2.2 ENGINE SPEED SETTING

Every engine is shipped from the engine factory without gas or oil because of re hazards

during shipping. They are all set with a high

idle of 3500 RPM. Since no uids are added at

the Mixer factory, the RPM is not reset. When

the Mixer is delivered, the uids must be

added and the RPM reset. To reset the RPM,

follow this procedure:

9. Run the engine for 1 minute and check for

leaks.

10. If leaks are found around the drain plug,

tighten slightly and repeat Step 12.

11. Check engine oil level. Top up as required.

Fig. 31 ENGINE SPEED SETTING

1. Read the engine manual supplied with

the machine.

2. Add fuel and the specied motor oil to

the crankcase and oil to the gearbox.

3. Start the engine and run at wide open

throttle.

4. Use a screwdriver to reset the high idle

stop screw.

5. Count the mixing element revolutions to

determine engine RPM. Set the engine

speed to give 30-35 RPM for the paddles

and 40-45 RPM for the spiral when mixing.

6. Load the drum and count the mixing element rotational speed again.

7. Reset if the speed changes as required.

39

Page 33

5.2.3 AIR CLEANER MAINTENANCE

Discount-Equipment.com

Each engine is equipped with lter to remove dust

and dirt from entering the air intake. To clean

the lter, follow this procedure:

1. Read the engine manual supplied with the

machine.

2. Unlatch and open the hood.

3. Remove the lter cover.

4. Remove lter and shake out.

5. Wash in a lter cleaning detergent if

heavily caked with dirt. Allow time to dry

before re-installing.

6. Replace lter after washing 5 times.

7. Install clean lter and secure cover.

WARNING

Fig. 32 AIR CLEANER

5.2.4 BELT TENSION AND ALIGNMENT

A drive belt and pulley system transmits power from the

motor or engine to the gearbox for rotating the

mixing elements. A clutch lever through an over

center linkage swings the gearbox and pulley over

to tighten and engage the drive. The belt tension

must be properly set when the clutch is engaged

to prevent slipping and the pulleys aligned to prevent belt wear. To set the tension and alignment,

follow this procedure:

Machine is shown with engine hood open

for illustrative purposes only. Never operate with hood open.

Clutch Engaged

1. Unlatch and open hood.

2. Disable power source by unplugging power

cord or disconnecting spark plug wire.

3. Remove the pins on each end of the linkage

arm.

4. Lengthen or shorten linkage arm length by

turning yokes on the threaded rod.

5. Repin linkage arm.

6. Engage clutch. There should be a denite

feeling when the clutch linkage goes over

center. If not readjust linkage.

7. The belt is properly tensioned when the midspan deects 1/4 inch (6 mm) when pushed

on with a 10 lb force.

8. Align the pulleys by loosening the motor or

engine mounting bolts.

9. Slide or tap the power unit into position to

align the pulleys.

10. Tighten power unit mounting bolts to their

specied torque.

Clutch Linkage (Typical)

Fig. 33 BELT TENSION AND ALIGNMENT

11. Close and secure the hood.

41

Page 34

5.2.5 WIPER SPACING AND REPLACEMENT

Discount-Equipment.com

5.2.6 GEARBOX OIL CHANGING

Each machine is equipped with wipers on the mixing

elements to scrape the build-up from the inside of the

drum. After extended use, they will wear. They need to be

adjusted so they clean the sides of the drum. To adjust or

repair, follow this procedure:

1. Thoroughly clean the inside of the drum to remove all

the build-up.

2. Open hood and disable power source by unplugging

power cord or removing spark plug wire.

3. To adjust wipers, loosen mounting bolts.

4. Tap or slide wipers to 1/16 inch (1.5 mm) from the

drum.

5. Tighten mounting bolts to their specied torque.

6. If there is no more adjustment available, remove old

wipers.

7. Replace wipers.

8. Set at 1/16 inch (1.5 mm) from the drum.

9. Tighten mounting bolts to their specied torque.

The gearbox transmits power from the belt/pulley drive to the

mixing elements in the drum. As the gearbox breathes during its warming and cooling cycle, contaminants can enter

through the breather. Change the oil annually to remove

these contaminants

To change the oil, follow this procedure:

1. Open the hood.

2. Disable the power source by unplugging the power cord

or removing the spark plug wire.

3. Place a pan under the drain plug.

4. Remove the drain, level and ll plugs and allow the oil to

drain for 10 minutes.

IMPORTANT

Allow the gearbox to cool before

changing oil. Hot oil can cause

burns if it contacts exposed skin.

Draining works best if the oil is

warm.

5. Clean the drain plug.

6. Install the drain plug and tighten.

Paddles

7. Add 1 quart of SAE 80W90 gear oil through the ll plug.

8. When the oil in the gearbox just lls the threads of the

level plug, the gearbox is at the proper level.

9. Install the level and ll plugs and tighten.

IMPORTANT

If the air passage

through the breather

is plugged, soak the

breather in solvent for

an hour and blow out

with an air hose.

NOTE

There is a hole in the top of the

shroud (with a rubber plug) for

lling the gearbox.

c

b

a

a Drain b Level c Fill

Fig. 35 GEARBOX PLUGS

Fig. 34 WIPERS

Spiral

43

Page 35

6 TROUBLE SHOOTING

Discount-Equipment.com

The Crown Construction Mortar Mixer uses a large heavy-duty drum with mixing elements for combining water,

cement, lime and sand into a mixture for forming mortar. It is a well engineered machine that requires minimum

maintenance.

In the following trouble shooting section, we have listed many of the problems, causes and solutions to the problems

which you may encounter.

If you encounter a problem that is dicult to solve, even after having read through this trouble shooting section,

please contact your authorized dealer, distributor or the factory. Before you call, please have this Operator’s Manual