Page 1

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

if the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY:

m Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WHAT TO DO iF YOU SMELL GAS:

• Do not try to light any appliance.

= Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• ALL RANGES

CAN TiP

• INJURYTO PERSONS

COULD RESULT

• iNSTALL ANTI=TIP

DEVICE PACKED WiTH

RANGE

• SEE iNSTALLATiON

iNSTRUCTiONS

• if you cannot reach your gas supplier, call the fire

department.

= Installation and service must be performed bya qualified

installer, service agency or the gas supplier.

Note: For appliances installed in the

State of Massachusetts see page 2.

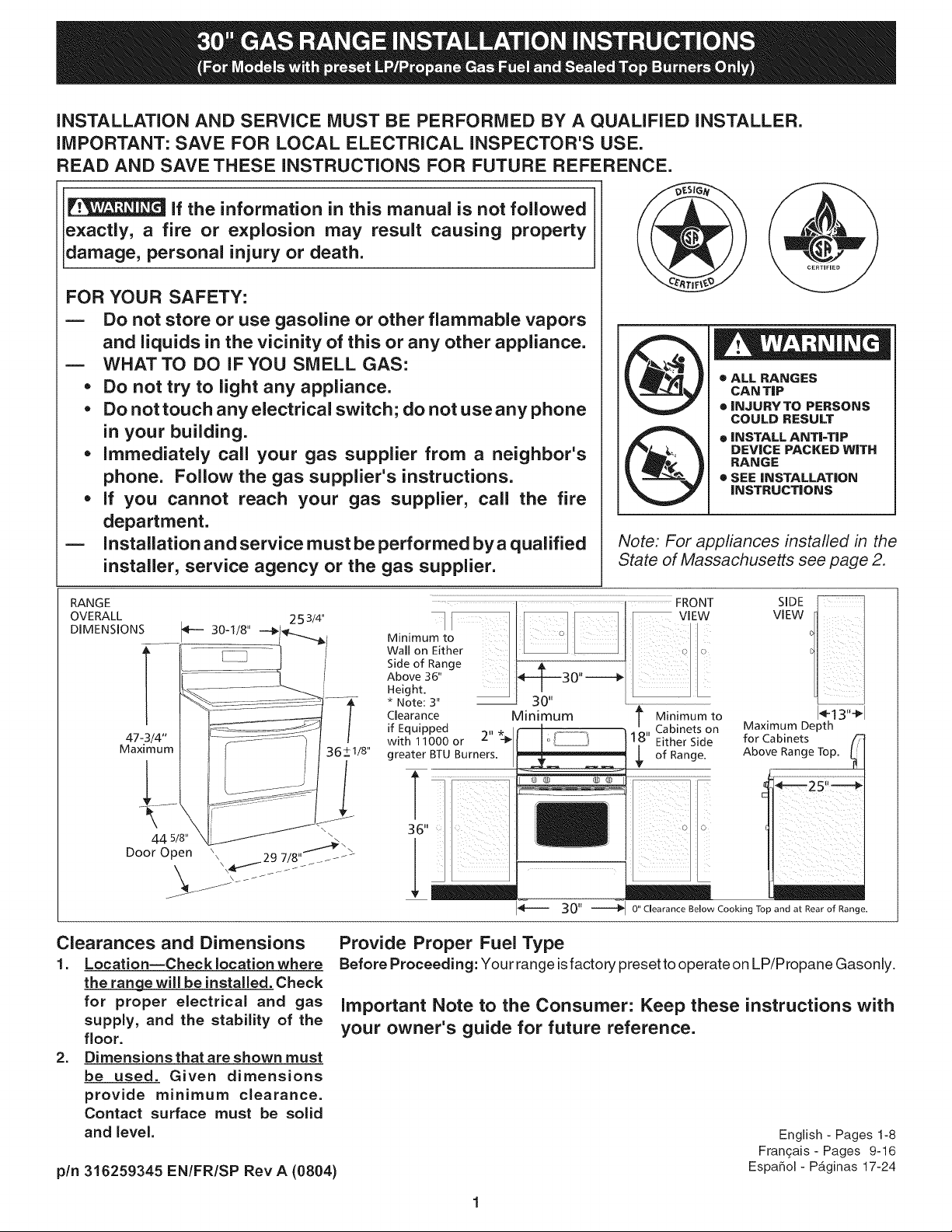

RANGE FRONT

OVERALLDIMENSIONS_ 30-1/8" 253/4" _ _ VIEW

47-3/4"

Maximum 36 + 1/8"

44 5/8" _\\\

Door Open \\ 29 7/8'''11_I_

Clearances and Dimensions

1. Location--Checklocationwhere

Provide Proper Fuel Type

Before Proceeding: Your range is factory preset to operate on LP/Propane Gasonly.

Minimum to

Wall on Either

Side of Range

Above 36"

Height.

* Note: 3" 30"

Clearance Minimum

with 11000 or "4_

if Equipped 2"

greater BTU Burners.

II

t Minimumto 14-13"-_1

18" Cabinets on Maximum Depth

Either Side for Cabinets

of Range. Above Range Top.

30" "'"-_10" Clearance aelow Cooking Top and at Rear of Range.

the range will be installed. Check

for proper electrical and gas

supply, and the stability of the

floor.

Important Note to the Consumer: Keep these instructions with

your owner's guide for future reference.

2. Dimensions that are shown must

be used. Given dimensions

provide minimum clearance.

Contact surface must be solid

and level.

pin 316259345 EN/FR/SP Rev A (0804)

SIDE

VIEW

_25,_

English - Pages 1-8

Fran£ais - Pages 9-16

Espa_ol- Pdtginas 17-24

Page 2

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing materialfrom the oven compartments

before connecting the gas and electrical supply to the

range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

1. Keep these instructions with your owner's guide for

future reference.

iMPORTANT SAFETY

iNSTRUCTiONS

Installation of this range must conform with local codes or, in

the absence of local codes, with the National Fuel Gas Code

ANSI Z223.1--1atest edition when installed in the United

States.

This range has been design certified by CSA International.

As with any appliance using gas and generating heat, there

are certain safety precautions you should follow. You will find

them in the Use & Care Manual, read it carefully.

= Be sureyour range is installed and grounded properly

by a qualified installer or service technician.

= This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No .70-

latest edition when installed in the United States.

See Grounding Instructions on page 5.

= Before installing the range in an area covered with

linoleum or any other synthetic floor covering, make

sure the floor covering can withstand heat at least

90°F above room temperature without shrinking,

warping or discoloring. Do not install the range over

carpeting unless you place an insulating pad or sheet of

1/4-inch thick plywood between the range and carpeting.

= Make sure the wall coverings around the range can

withstand the heat generated by the range.

= Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the lower

front panel of the range. Avoid touching the vent

openings or nearby surfaces as they may become hot

while the oven is in operation. This range requires fresh

air for proper burner combustion.

Stepping, leaning or sitting on the doors

or drawers of this range can result in serious injuries and

can also cause damage to the range.

= Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

. To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

= Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

= Do not use the over= as a storage space. This creates

a potentially hazardous situation.

= Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

= Do not store or use gasoline or other flammable

vapors and liquids near this or any other appliance.

Explosions or fires could result.

Reset all controls to the "off" position after using a

programmable timing operation.

FOR MODELS WiTH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils before

self-cleaning the oven. Wipe up excess spillage. Follow

the precleaning instructions in the Owner's Guide.

• Unlike the standard gas range, THIS COOKTOP iS

NOT REMOVABLE. Do not attempt to remove the

cooktop.

Special instructions for appliances installed in the State of

Massachusetts: This appliance can only be installed in the

State of Massachusetts by a Massachusetts licensed

plumber or gas fitter. When using a flexible gas connector,

it must not exceed 3 feet (36 inches) in length, A "T" handle

type manual gas valve must be installed in the gas supply

line to this appliance,

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING AN

ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes if the oven thermostat control

was left in the "ON" position.

Never leave children alone or unattended

in the area where an appliance is in use. As children grow,

teach them the proper, safe use of all appliances. Never

leave the oven door open when the range is unattended.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit with

a match. Hold a lighted match to the burner, then slowly turn

the knob to the LITE position. Use extreme caution when

lighting burners this way.

Page 3

Before Starting

Tools You Will Need

For leveling legs and Anti-Tip Bracket:

= Adjustable wrench or channel lock

tongue & groove pliers

o

5/16" Nutdriver or Flat Head Screw Driver

o

Electric Drill & 1/8" Diameter Drill Bit (3/16" masonry drill

bit if installing in concrete).

For gas supply connection:

* Pipe wrench -_

For burner flame adjustment:

Phillips head _ and

blade-type screwdrivers __-_

For gas conversion (LP/Propane or Natural):

= Open end wrench - 1/2"

Additional MaterialsYou Will Need

= Gas line shut-off valve. _,_

Pipe joint sealant that resists action of LP/Propane gas

A new flexible metal appliance conduit (1/2" NPTx 3/4"

or 1/2" I.D.)must be design certified by CSA International.

Because solid pipe restricts moving the range we

recommend using a new flexible conduit (4 to 5 foot

length) for each new installation and additional

reinstallations.

%

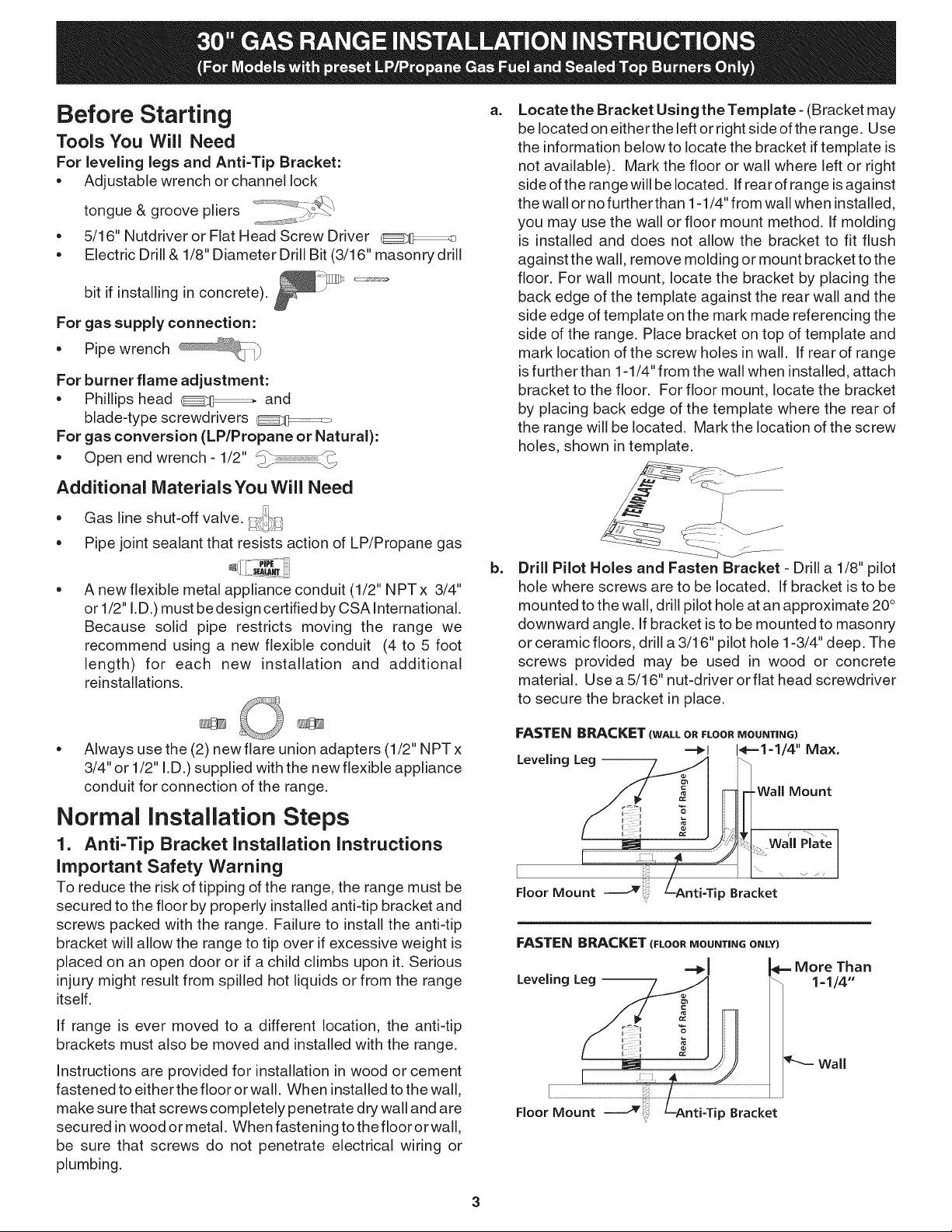

a. Locatethe Bracket Using the Template- (Bracket may

be located on either the left or right side ofthe range. Use

the information below to locate the bracket iftemplate is

not available). Mark the floor or wall where left or right

side ofthe range will be located. If rear of range isagainst

the wall or no further than 1-1/4" from wall when installed,

you may use the wall or floor mount method. If molding

is installed and does not allow the bracket to fit flush

against the wall, remove molding or mount bracket to the

floor. For wall mount, locate the bracket by placing the

back edge of the template against the rear wall and the

side edge of template on the mark made referencing the

side of the range. Place bracket on top of template and

mark location of the screw holes in wall. If rear of range

is further than 1-1/4" from the wall when installed, attach

bracket to the floor. For floor mount, locate the bracket

by placing back edge of the template where the rear of

the range will be located. Mark the location of the screw

holes, shown in template.

........... _:2 z-

b. Drill Pilot Holes and Fasten Bracket - Drill a 1/8" pilot

hole where screws are to be located. Ifbracket is to be

mounted to the wall, drill pilot hole at an approximate 20 °

downward angle. Ifbracket is to be mounted to masonry

or ceramic floors, drill a 3/16" pilot hole 1-3/4" deep. The

screws provided may be used in wood or concrete

material. Use a 5/16" nut-driver orfiat head screwdriver

to secure the bracket in place.

Always use the (2) new flare union adapters (1/2" NPTx

3/4" or 1/2" I.D.) supplied with the new flexible appliance

conduit for connection of the range.

Normal Installation Steps

1. Anti-Tip Bracket Installation Instructions

Important Safety Warning

To reduce the risk of tipping of the range, the range must be

secured to the floor by properly installed anti-tip bracket and

screws packed with the range. Failure to install the anti-tip

bracket will allow the range to tip over if excessive weight is

placed on an open door or if a child climbs upon it. Serious

injury might result from spilled hot liquids or from the range

itself.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the range.

Instructions are provided for installation in wood or cement

fastened to either the floor or wall. When installed tothe wall,

make sure that screws completely penetrate dry wall and are

secu red in wood or metal. When fastening to the floor or wall,

be sure that screws do not penetrate electrical wiring or

plumbing.

FASTEN BRACKET (FLOOR MOUNTING ONLY)

"=_1 I_= More Than

Leveling Leg _ _ 1=1/4 -

,_ Wall

Floor Mount i:: Anti-Tip Bracket

Page 4

C.

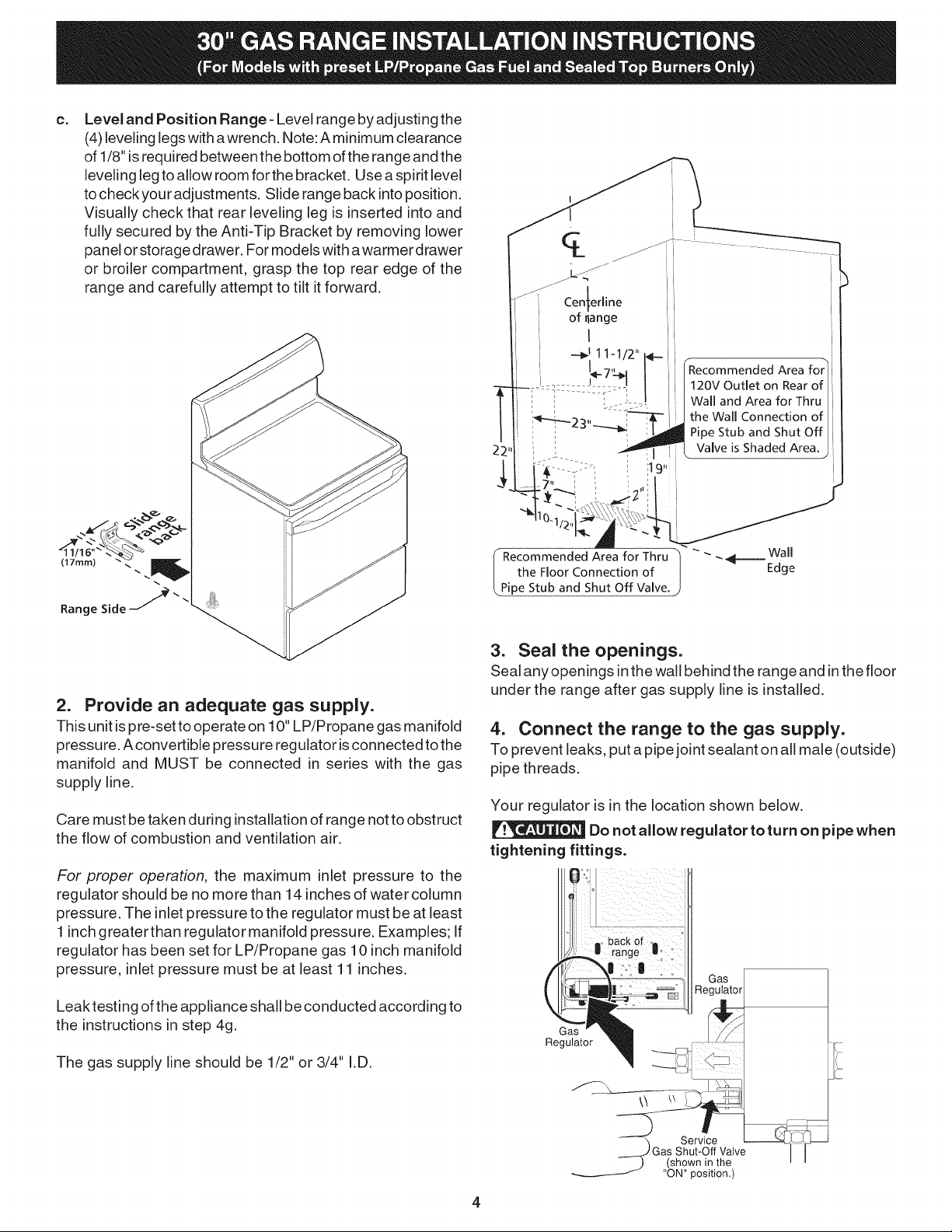

Level and Position Range- Level range byadjusting the

(4) leveling legswith awrench. Note: A minimum clearance

of 1/8" is required between the bottom ofthe range and the

leveling leg to allow room for the bracket. Use a spirit level

tocheck your adjustments. Slide range back into position.

Visually check that rear leveling leg is inserted into and

fully secured by the Anti-Tip Bracket by removing lower

panel or storage drawer. For models with awarmer drawer

or broiler compartment, grasp the top rear edge of the

range and carefully attempt to tilt itforward.

__ Cen_erline

of flange

I

--_ 11-1/2" _-

I,_7 I

o I "1

"_'_'-_ 23" _--i_-_ i the Wall Connection of _

! i ""_-_: ..d _ Pipe Stub and Shut Off| ]

22' i i _ I [ . Valve is Shaded Area. J

fRecommended Area for'_ i

i

120V Outlet on Rear of I

Wall and Area for Thru| l

-41_"-i_,_,_:__1 _"

(Recommended Area for Thru _ " " -_--_ a

| the Floor Connection of / Edge

[Pipe Stub and Shut Off Valve. )

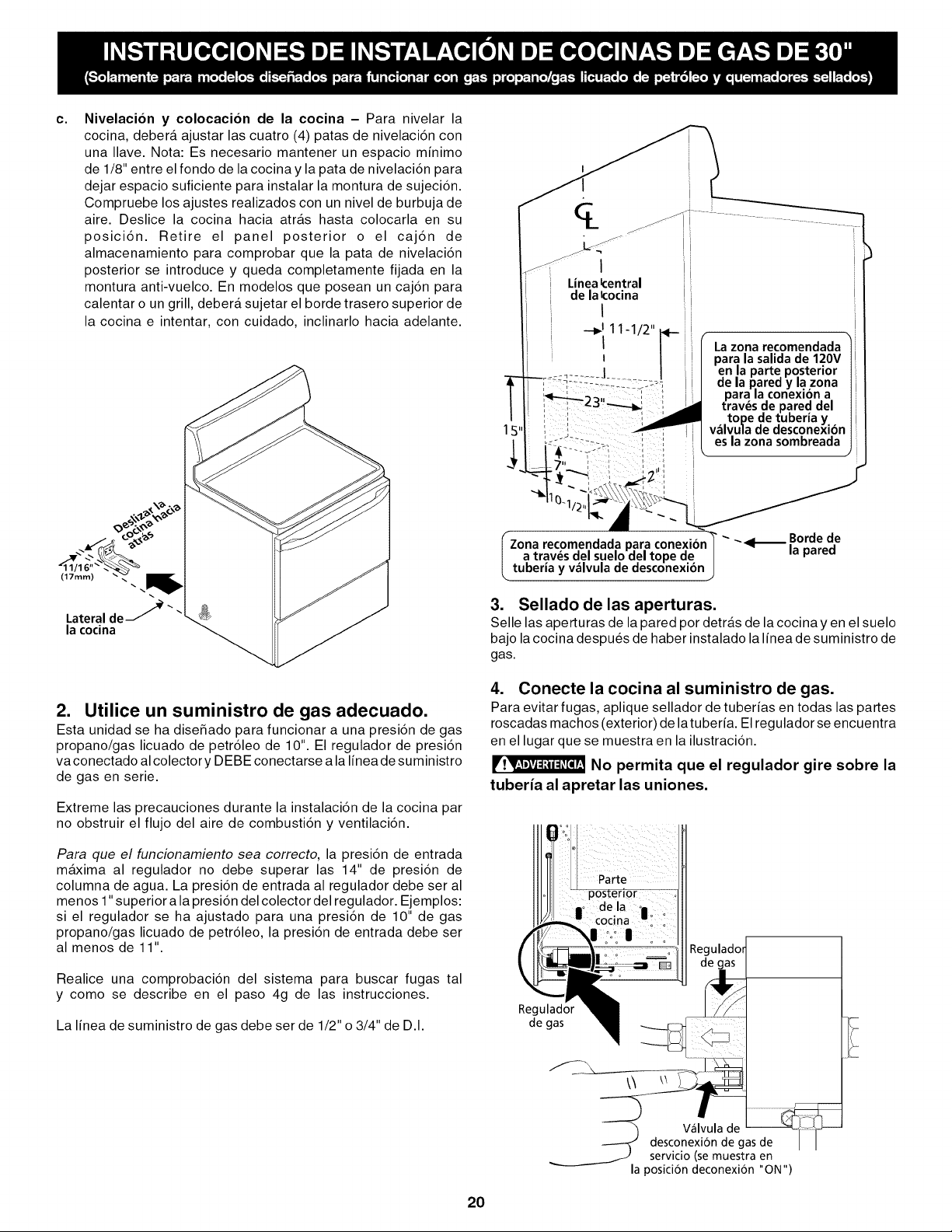

2. Provide an adequate gas supply.

This unit ispre-set to operate on 10" LP/Propane gas manifold

pressure. A convertible pressure regulator isconnected to the

manifold and MUST be connected in series with the gas

supply line.

Care must be taken during installation of range not to obstruct

the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to the

regulator should be no more than 14 inches of water column

pressure. The inlet pressure to the regulator must be at least

1 inch greaterthan regulator manifold pressure. Examples; If

regulator has been set for LP/Propane gas 10 inch manifold

pressure, inlet pressure must be at least 11 inches.

Leak testing of the appliance shall beconducted according to

the instructions in step 4g.

The gas supply line should be 1/2" or 3/4" I.D.

3. Seal the openings.

Seal any openings inthe wall behind the range and inthe floor

under the range after gas supply line is installed.

4. Connect the range to the gas supply.

To prevent leaks, put a pipe joint sealant on all male (outside)

pipe threads.

Your regulator is in the location shown below.

Do not allow regulator toturn on pipe when

tightening fittings.

Gas

Regulak

Gas

Regulator

-_ Service

_Gas Shut-Off Valve

) (shown in the

__ "ON" position.)

Page 5

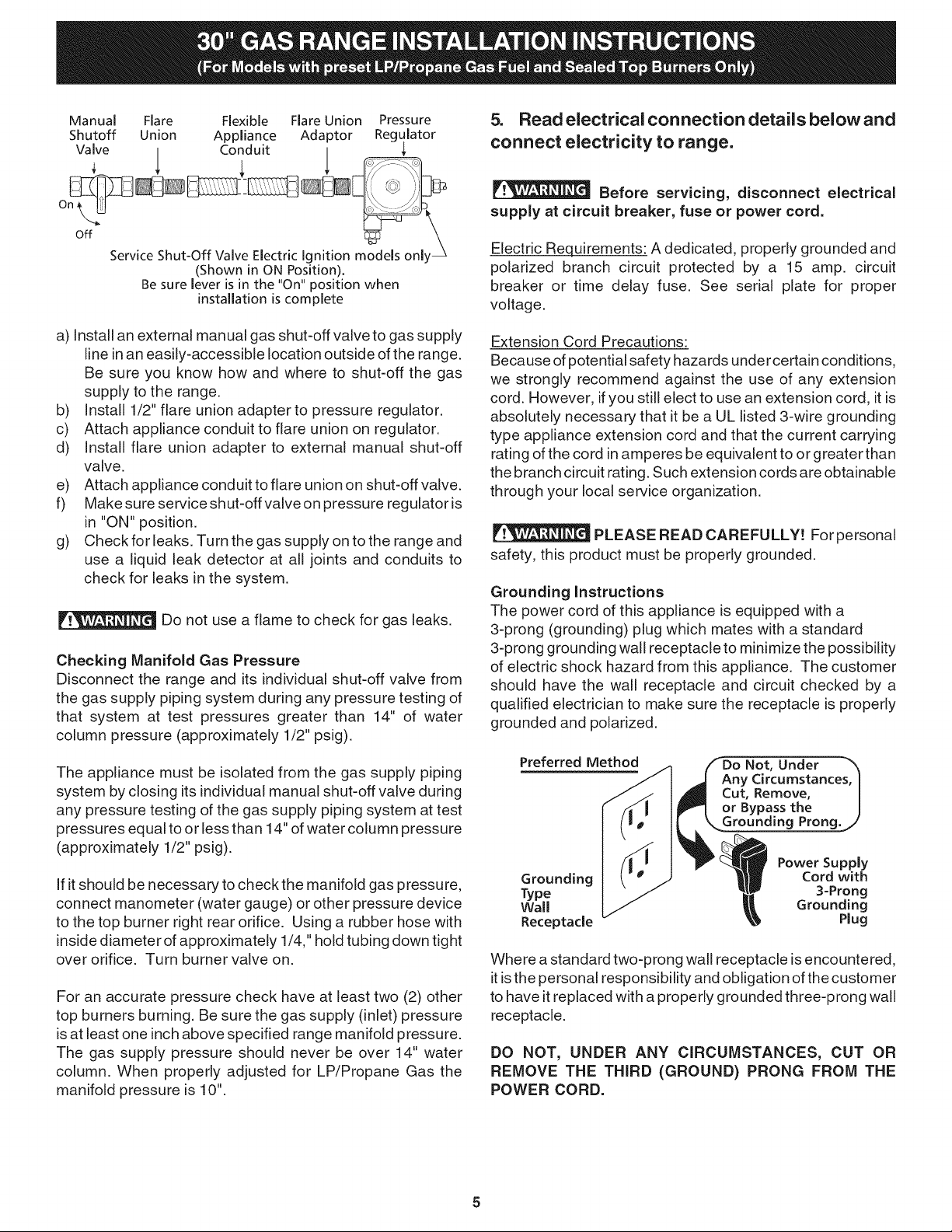

Manual Flare Flexible FlareUnion Pressure

Shutoff Union Appliance Adaptor Regulator

Valve / Conduit /

off

Service Shut=Off Valve Electdc ignition models only _

(Shown in ON Position).

Besure leveris in the "On" position when

installation is complete

5. Read electrical connection details belowand

connect electricity to range.

Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

Electric Requirements: A dedicated, properly grounded and

polarized branch circuit protected by a 15 amp. circuit

breaker or time delay fuse. See serial plate for proper

voltage.

a) Install an external manual gas shut-off valve to gas supply

line inan easily-accessible location outside of the range.

Be sure you know how and where to shut-off the gas

supply to the range.

b) Install 1/2" flare union adapterto pressure regulator.

c) Attach appliance conduit to flare union on regulator.

d) Install flare union adapter to external manual shut-off

valve.

e) Attach appliance conduit to flare union on shut-off valve.

f) Make sure service shut-off valve on pressure regulator is

in "ON" position.

g) Check for leaks. Turn the gas supply on to the range and

use a liquid leak detector at all joints and conduits to

check for leaks in the system.

Do not use a flame to check for gas leaks.

Checking Manifold Gas Pressure

Disconnect the range and its individual shut-off valve from

the gas supply piping system during any pressure testing of

that system at test pressures greater than 14" of water

column pressure (approximately 1/2" psig).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 14" of water column pressure

(approximately 1/2" psig).

If itshould be necessary to check the manifold gas pressure,

connect manometer (water gauge) or other pressure device

to the top burner right rear orifice. Using a rubber hose with

inside diameter of approximately 1/4," hold tubing down tight

over orifice. Turn burner valve on.

For an accurate pressure check have at least two (2) other

top burners burning. Be sure the gas supply (inlet) pressure

is at least one inch above specified range manifold pressure.

The gas supply pressure should never be over 14" water

column. When properly adjusted for LP/Propane Gas the

manifold pressure is 10".

Extension Cord Precautions:

Because of potential safety hazards under certain conditions,

we strongly recommend against the use of any extension

cord. However, if you still elect to use an extension cord, it is

absolutely necessary that it be a UL listed 3-wire grounding

type appliance extension cord and that the current carrying

rating of the cord in amperes be equivalent to or greater than

the branch circuit rating. Such extension cords are obtainable

through your local service organization.

PLEASE READ CAREFULLY! Forpersonal

safety, this product must be properly grounded.

Grounding Instructions

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle to minimize the possibility

of electric shock hazard from this appliance. The customer

should have the wall receptacle and circuit checked by a

qualified electrician to make sure the receptacle is properly

grounded and polarized.

Preferred

Grounding

Type

Wall

Receptacle

Not, Under

Any Circumstances, I

Cut, Remove, |

or Bypass the J

Grounding Prong.j

Power Supply

Cord with

3-Prong

Grounding

Plug

Where a standard two-prong wall receptacle is encountered,

it isthe personal responsibility and obligation of the customer

to have it replaced with a properly grounded three-prong wall

receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM THE

POWER CORD.

Page 6

Operation of Surface Burners

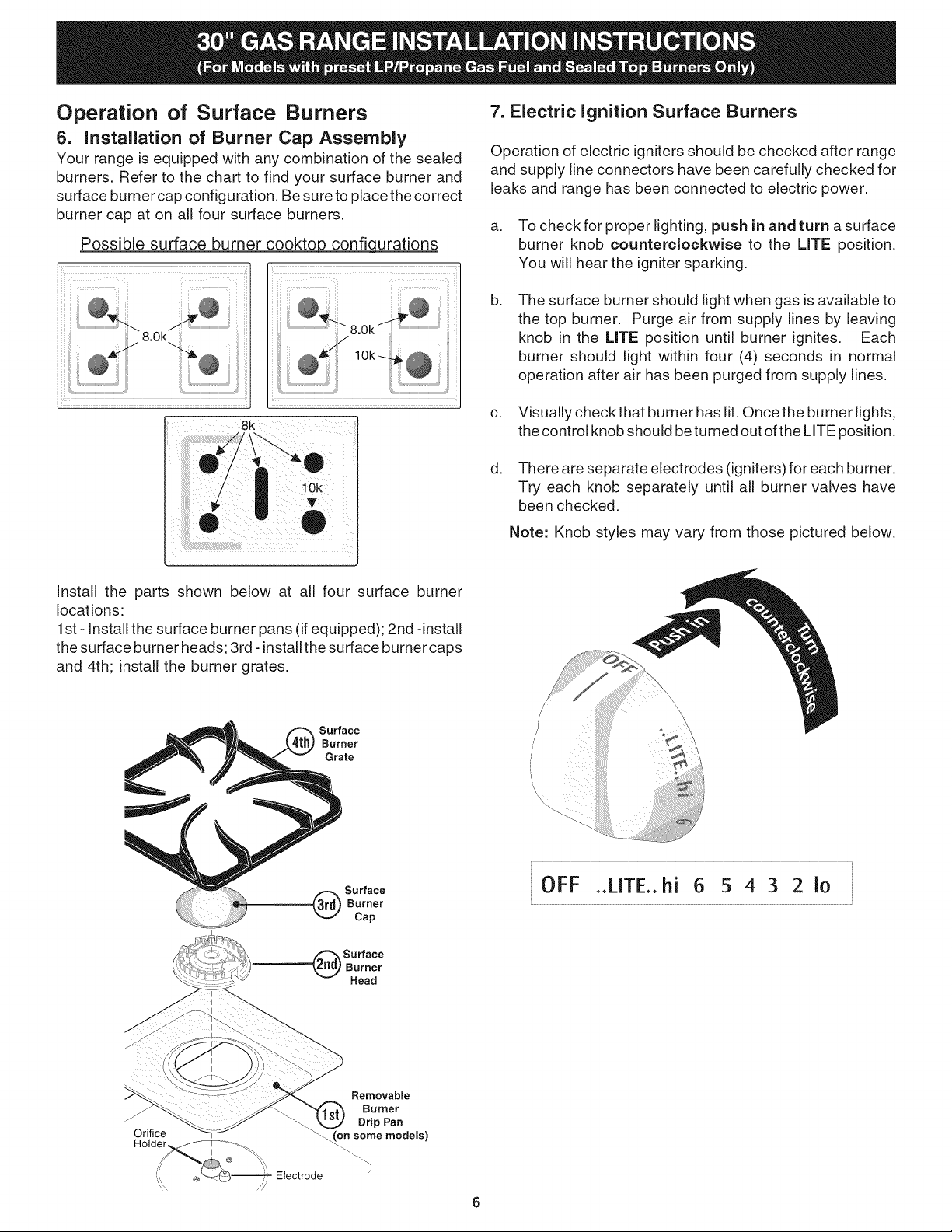

6. Installation of Burner Cap Assembly

Your range is equipped with any combination of the sealed

burners. Refer to the chart to find your surface burner and

surface burner cap configuration. Be sure to place the correct

burner cap at on all four surface burners.

Possible surface burner cooktop configurations

iiii :: ! ¸ iiiiii

@

i¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸i

8k

7. Electric ignition Surface Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

a. To check for proper lighting, push in and turn a surface

burner knob counterclockwise to the LITE position.

You will hear the igniter sparking.

b,

The surface burner should light when gas is available to

the top burner. Purge air from supply lines by leaving

knob in the LITE position until burner ignites. Each

burner should light within four (4) seconds in normal

operation after air has been purged from supply lines.

c. Visually check that burner has lit. Once the burner lights,

the control knob should be turned out of the LITE position.

d,

There are separate electrodes (igniters) for each burner.

Try each knob separately until all burner valves have

been checked.

Note: Knob styles may vary from those pictured below.

Install the parts shown below at all four surface burner

locations:

1st- Install the surface burner pans (if equipped); 2nd -install

the surface burner heads; 3rd -install the surface burner caps

and 4th; install the burner grates.

Surface

Burner

Grate

_ urface

Burner

Cap

iiiii

OFF ..LITE..hi 6 5 4 3 2 lo

Orifice

Removable

Burner

Drip Pan

(on some models)

Electrode

Page 7

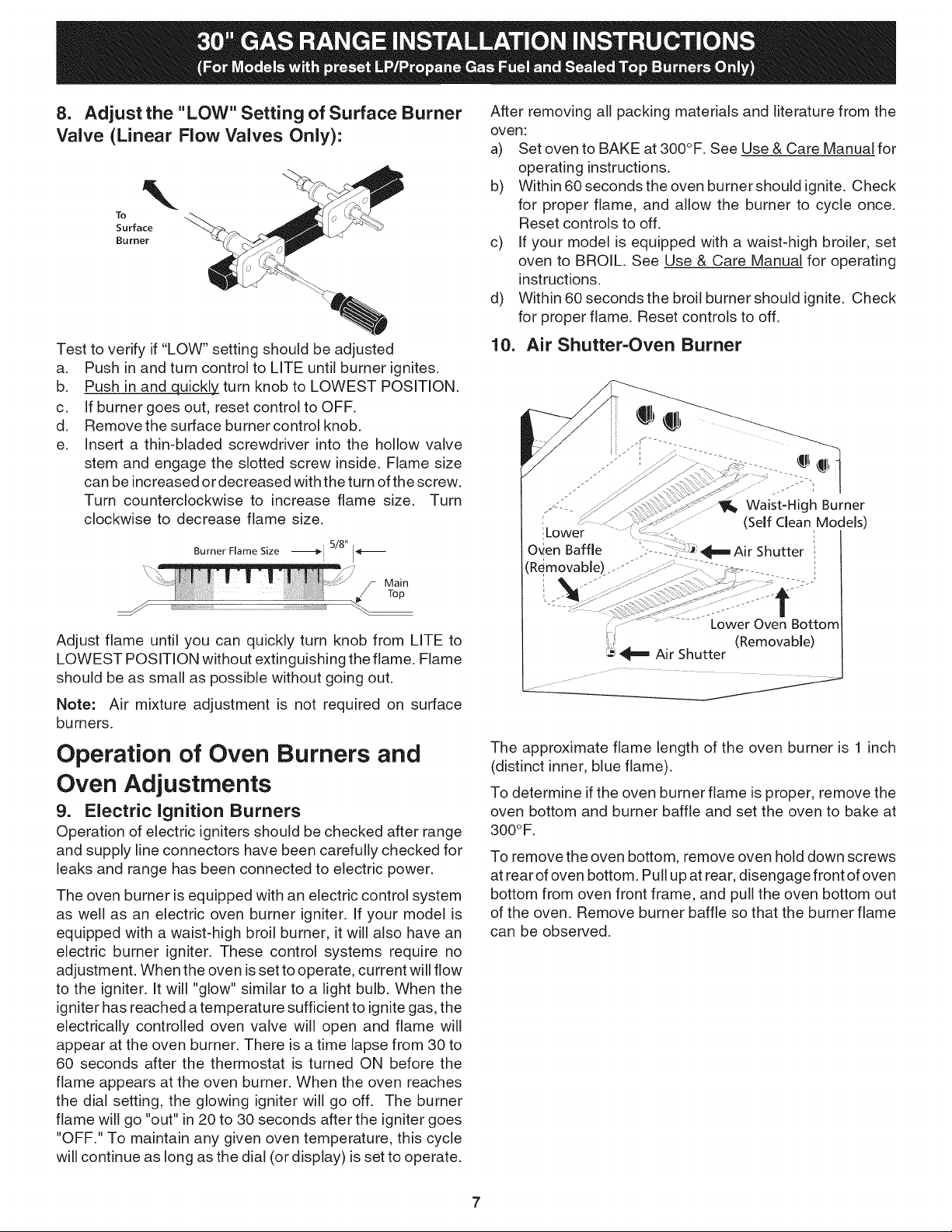

8. Adjust the "LOW" Setting of Surface Burner

Valve (Linear Flow Valves Only):

To

Surface

Burner

Test to verify if "LOW" setting should be adjusted

a. Push in and turn control to LITE until burner ignites.

b. Push in and quickly turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

e. Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame size

can be increased or decreased with the turn of the screw.

Turn counterclockwise to increase flame size. Turn

clockwise to decrease flame size.

Burner Flame Size _1 5/8" 14_

Main

Top

After removing all packing materials and literature from the

oven:

a) Set oven to BAKE at 300°F. See Use & Care Manual for

operating instructions.

b) Within 60 seconds the oven burner should ignite. Check

for proper flame, and allow the burner to cycle once.

Reset controls to off.

c) If your model is equipped with a waist-high broiler, set

oven to BROIL. See Use & Care Manual for operating

instructions.

d) Within 60 seconds the broil burner should ignite. Check

for proper flame. Reset controls to off.

10. Air Shutter-Oven Burner

St/-_ -_ _ _

s

r

i

Lower

O_en Baffle "-

Removable).... " "

P:i_Air Shutter !

Waist-High Burner

(SelfClean Models)

Adjust flame until you can quickly turn knob from LITE to

LOWEST POSITION without extinguishing the flame. Flame

should be as small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

Operation of Oven Burners and

Oven Adjustments

9. Electric Ignition Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

The oven burner is equipped with an electric control system

as well as an electric oven burner igniter. If your model is

equipped with a waist-high broil burner, it will also have an

electric burner igniter. These control systems require no

adjustment. When the oven is set to operate, current will flow

to the igniter. It will "glow" similar to a light bulb. When the

igniter has reached a temperature sufficient to ignite gas, the

electrically controlled oven valve will open and flame will

appear at the oven burner. There is a time lapse from 30 to

60 seconds after the thermostat is turned ON before the

flame appears at the oven burner. When the oven reaches

the dial setting, the glowing igniter will go off. The burner

flame will go "out" in 20 to 30 seconds after the igniter goes

"OFF." To maintain any given oven temperature, this cycle

will continue as long as the dial (or display) is set to operate.

Lower Oven Bottom

_ Air Shutter (Removable)

L_¸ •

The approximate flame length of the oven burner is 1 inch

(distinct inner, blue flame).

To determine if the oven burner flame is proper, remove the

oven bottom and burner baffle and set the oven to bake at

300°F.

To remove the oven bottom, remove oven hold down screws

at rear of oven bottom. Pull up at rear, disengage front of oven

bottom from oven front frame, and pull the oven bottom out

of the oven. Remove burner baffle so that the burner flame

can be observed.

Page 8

Iftheflameisyellowincolor,increaseairshutteropeningsize.

(See"2"inillustrationbelow.)Iftheflameisa distinctblue,

reducetheairshutteropeningsize.

Toadjustloosenlockscrew(see"3" illustrationbelow),

repositionairshutter,andtightenlockscrew.Replaceoven

bottom.

Oven

Burner

Tube

Care, Cleaning and Maintenance

Refer to the Use & Care Manual for cleaning instructions.

If removing the range is necessary for cleaning or

maintenance, shut off gas supply. Disconnect the gas and

electrical supply. Ifthe gas or electrical supply is inaccessible,

lift the unit slightly at the front and pull out away from the wall.

Pull only as far as necessary to disconnect the gas and

electrical supply. Finish removing the unit for servicing and

cleaning. Reinstall in reverse order making sure to level the

range and check gas connections for leaks. See page 3,

step 1 for proper anchoring instructions.

Lock Screw

Q Air Shutter I"l._ l_ Orifice............

Hood

11. Air Shutter-Broil Burner

The approximate flame length of the broil burner is 1 inch

(distinct inner, blue flame).

To determine if the broil burner flame is proper, set the oven

to broil.

If the flame is yellow in color, increase air shutter opening

size. (See "2" in illustration above.) If the flame is a distinct

blue, reduce the air shutter opening size.

To adjust, loosen lock screw (see "3" in illustration above),

reposition air shutter, and tighten lock screw.

12. Make Sure Range is Level.

Level the range by placing a level horizontally on an oven

rack. Check diagonally from front to back, then level the

range by either adjusting the leveling legs or by placing shims

under the corners of the range as needed.

Before You Call for Service

Read the "Before You Call" and operating instruction sections

in your Use & Care Manual. It may save you time and

expense. The list includes common occurrences that are not

the result of defective workmanship or materials in this

appliance.

Refer to the warranty in your Use & Care Manual for our toN-

free service number and address. Please call or write if you

have inquiries about your range product and/or need to order

parts.

_iii_iLil_iii _ i_!_/i_iii:i_!_i/ii__ _ii_ii_iiiii_i_I!II _i_ _i i

i i i i i i ii iiii i

13.After installation is complete, make sure all

controls are left in the OFF position.

Model and Serial Number Location

For sealed burner ovens, the serial plate is located on the

right-hand surface of the oven front frame at the storage or

warmer drawer; or the lower panel area.

When ordering parts for or making inquires about your range,

always be sure to include the model and serial numbers and

a lot number or letter from the serial plate on your range.

Your serial plate also tells you the rating of the burners, the

type of fuel and the pressure the range was adjusted for when

it left the factory.

Serial plate location

Open storage or warmer drawer,

or remove lower panel

(on some models)

Page 9

L'INSTALLATION ET L'ENTRETIEN DOlT f:TRE EFFECTUE_ PAR UN INSTALLATEUR QUALIFIE

iMPORTANT: _. CONSERVER POUR CONSULTATION PAR L'INSPECTEUR EN ELECTRICITE.

LISEZ ET CONSERVEZ CES iNSTRUCTiONS POUR CONSULTATION FUTURE.

Un feu ou une explosion peut survenir et 6tre la

cause de dommages a la propri6t6, de blessures ou entra_ner la

mort si les instructions de ce manuel ne sont pas suivies a la lettre.

POUR VOTRE SECURITI_ :

m N'entreposez pas ou n'utilisez pas de gazoline ou

d'autres liquides d6gageant des vapeurs inflammables

pres de cet appareil ou de tout autre appareil.

= QUE FAIRE SI VOUS SENTEZ L'ODEUR DE GAZ :

• N'allumez aucun appareil.

• Ne touchez a aucun interrupteur 61ectrique; n'utilisez aucun

t616phone clans votre 6difice.

• Appelez imm6diatement votre fournisseur de gaz d'un

t616phone d'un voisin. Suivez les instructions de votre

fournisseur de gaz.

• TOUTESLESCUISINIERES

PEUVENTETRERENVERSEES

• DESBLESSURESPEUVENT

ENRESULTER

• INSTALLEZLEDISPOSITIF

DECONTRE-RENVERSEMENT

EMBALL[=AVECLA CUISINIERE

• VOIR LESINSTRUCTIONS

D'INSTALLATION

• Si vous ne pouvez pas rejoindre votre fournisseur de gaz,

appelez les pompiers.

= L'installation et I'entretien dolt 6tre effectu6 par un installateur

qualifi& une firme de service ou le fournisseur de gaz.

DIMENSIONS

HORS TOUT

DE LA CUISINII_RE

47-3/4"

Maximum

_ 30-1/8"

25 314"

Dimensions et espaces libres

1. Localisation-V_rifiezl'endroito_la

cuisini_re sera install_e.

Assurezvous que les alimentations

de gaz et d'_lectricit6 sont

ad6quates et que le plancher est

solide.

2. Lesdistances indiqu_es doivent

_tre appliqu_es. Les distances

donn_es sont minimales. La

surface de support doit _tre solide

et au niveau.

pin 316259345 EN/FR/SP (0804)

..... ............. ........................ ......... VUE

°ErA

Espace min. aux

c6t6s de la _ _11°

cuisini6re, au I. 4_ ..... I I I

dessus de 914mm J4"-'_:_U"------_ I I I

J 3b" ....................................................

Espace de 76 mm Minimum Distance min.

t Note: t

(3") si munie de

36 -+1/8" de 11000 BTU.

brOleurs de plus "4_

2" des armoires,

30-1/8" _ Aucun espace requis sous la surface de cuisson et

Alimenter avec le bon type de gaz avant de proceder

Votre cuisini_re est r_gl_e pour fonctionner au gaz propane seulement.

9

18"de chaque

/ c6t_.dela

c_,s,n,e_e.

I'arri_re de la cuisiniOre.

PROFI_

Profondeur max.

des armoires au_

dessus,de la L'

culslnlere [!

Fran£ais- Pages 9-16

Espa_ol- PAginas 17-24

1÷13"_1

English - Pages 1-8

Page 10

Notes Importantes a I'installateur

1. Lisez toutes les instructions contenues dans cette notice

d'installation avant d'installer la cuisini@e.

2. Retirez tout mat@iau d'empaquetage des cavit6s du fourneau

avant d'alimenter en gazet en 61ectricit6.

3. Respectez tousles codes et ordonnances applicables.

4. Assurez-vous de laisser ces instructions.

Note importante au consommateur

1. Conservez ces instructions avec votre Guide d'utilisation

et d'entretien pour consultation future.

NOTICE DE SI CURITi IMPORTANTE

L'installation de cette cuisini@e dolt se respecter les codes

Iocaux ou dans leur absence, la derni@e 6dition du Code National

de Combustibles Gaziers (National Fuel Gas Code) ANSI

Z223.1(Iorsque install6e aux Etats-Unis).

Pour une installation dans une maison pr6fabriqu6e (mobile),

I'installation dolt respecter le paragraphe 24 CFR de la section

3280 de la norme de s6curit6 pour maisons pr6fabriqu6es

(Manufactured Home Construction and Safety Standard) -

pr6c6demment le paragraphe 24, HUD (section 280) de la norme

de s6curit6 f6d@ale pour fabrication de maisons mobiles (Federal

Sstandard for Mobile Home Construction and Safety); ou Iorsque

cette norme ne s'applique pas, la norme pour installations dans

des maisons pr6fabriqu6es (Standard for Manufactured Home

Installations), ANSI/NCSBCS A225.1, ou les codes Iocaux.

Cette cuisini@e a une conception homologu6e par ACNOR

International. Comme pour tous les appareils utilisant du gaz

et produisant de la chaleur, II y a certaines pr6cautions que

vous devez suivre. Vous les trouverez dans le Guide d'utilisation

et d'entretien, lisez les attentivement.

• Assurez vous que votre cuisini_re soit ad6quatement

instaii6e et raise a la terre par un technicien d'entretien.

• Cette cuisini_re dolt _tre _lectriquement raise a Ja terre

selon Jes normes IocaJes ou darts leur absence, selon Ja

pJusr6cente r_vJsion de la norme no..70 du code nationaJ

d'61ectricit6 (National ElectricaJ Code)- ANSJ/NFPA

(Iorsque instaJJ6e au× r2tats-Unis). Voir les directives de

mise b, la terre b,la page 6.

• Avant d'installer la cuisini_re sur un plancher recouvert de

linoi6um ou tout autre couvre plancher synth6tique,

assurez vous que le recouvrement peut r6sister & une

temp6rature d'au moins 32°C (90°F) au dessus de la

temperature de la piece sans r6tr6cir, gondoler ou se

d6colorer. N'installez pas la cuisini@e sur un tapis & moins

que vous ne placiez un panneau d'insolation ou une feuille

de contreplaqu6 de 6 mm (1/4") d'6paisseur entre la

cuisini_re et le tapis.

• Assurez vous que Ja tapJsserie ou autre recouvrement

mural autour de la cuisini_re puissetol6rer latemp6rature

d_gag6e par la cuisini_re.

• Ne bloquez pas la circuJation d'air de combustion de

I'a6rateur du fourneau ainsi qu'autour de Ja base ou

derriere Jepanneau frontaJ au bas de lacuisJni_re. Abstenez

vous de toucher les ouvertures d'a@ation ou les surfaces

adjacentes parce qu'elles peuvent devenir chaudes Iorsque

le fourneau chauffe. Cette cuisini@e a besoin d'un apport

d'air pour une combustion ad6quate aux br01eurs.

Ne laissez jamais un enfant sans supervision

darts un local o_ un appareil est en marche. Au fur et &mesure

que I'enfant grandit, enseignez lui I'utilisation s6curitaire de

tous les 61ectrom6nagers. Ne laissez jamais la porte du four

si la cuisini@e n'est pas sous surveillance.

Monter, s'asseoir, ou s'appuyer sur la porte ou

le tiroir de cette cuisinJ_re peut amener _ de s6rieuses

blessures et peut causer des dommages _ la cuisini_re.

• Ne remisez pas des articles pouvant attirer les enfants

darts Jes armoires au dessus de la cuisini_re. Les enfants

pourraient se br01er s6v_rement en grimpant sur la

cuisini_re pour atteindre ces articles.

• Les armoires de rangement au dessus des br_leurs

devraient _tre 6vJt6es pour 61iminer le besoin dese pencher

au dessus des br_leurs.

• Ajustez la flamme des br_ieurs de sorte qu'elles ne

d6passent pas le fond de I'ustensiie de cuisson.

Une flamme excessive est dangereuse.

• N'utiiisez pas le fourneau comme espace de rangement.

Ceci repr6sente une situation potentiellement

dangereuse.

• N'utilisez jamais votre cuisini_re pour r6chauffer ou

chauffer la piece. L'utilisation prolong6e de la cuisini@e

sans ventilation appropri6e peut 6tre dangereuse.

• N'entreposez pas ou n'utiiisez pas de gazoiine ou d'autres

liquides d6gageant des vapeurs inflammables pros de cet

appareil ou de tout autre appareil. Un feu ou une explosion

pourraient en r6sulter.

• Apr_s avoir utiliser une fonction programm6e, remettez la

sa position hors programme.

MODI_LES _, AUTO-NETTOYAGE :

• Enlevez la cuvette de r6tisserie, Janou rriture et les autres

ustensiJes avant de faire un cycle d'auto nettoyage du

fourneau. Essuyez les exc_s de d6versement. Suivez les

instructions du Guide d'utilisation et d'entretien.

• Contrairement aux cuisini_res _ gaz standard, LE DESSUS

DE CETTE CUJSlNIERE NE SE SOULEVE PAS. N'essayez

pas de le soulever.

DURANT UNE PANNE D'¢LECTRICITE_,

_PAS L'IGNJTION I_LECTRIQUE D'ALLUMAGE

DU FOUR. LORS D'UNE PANNE D'I_LECTRJCJTI_, METTEZ

TOUS LES BOUTONS DE COMMANDE DU FOUR .& "OFF"

POUR RI_ INJTIER SON FONCTIONNEMENT.

Au retour du courant, I'allumeur 61ectrique rallumera le brOleur

du four automatiquement si le bouton de commande du

thermostat du fourneau aura 6t6 laiss6 en position de marche

"ON".

Si une panne d'61ectricit6 survient durant le fonctionnement,

les brOleurs se maintiendront allum6s.

Durant une panne d'61ectricit6, les ronds des brOleurs peuvent

6tre allum6s avec une allumette. Tenez une allumette allum6e

pros du rond et tournez lentement son bouton vers "LITE".

Soyez extr6mement prudent Iors de cette op@ation.

10

Page 11

Avant de commencer

0utils dont vous aurez besoin

Pour les pattes de raise _ niveau et le support

de contre-renversement: _=---_:--_,__, _

• CI6 r6glable ou pince multiprise ordinaire _=:_-:=.-_s:_::':

• Toune-6crou de 5/16" ou tournevis droit (_

Perceuse 61ectrique et m_che de perceuse de 1/8" de

diam_tre. (m_che a maQonnerie de 3/16" si vous installez

dans le b6ton).

Pour le branehement du gaz :

• CI6 & tube -_

Pour le r_glage de la flamme du br_leur :

• Tournevis de type Phillips _ et

de type & lame (_Z_]_:_

Pour la conversion du type gaz (naturel ou propane):

• CI6 ouverte de 1/2"

Mat6riel additionnel que vous aurez besoin

• Soupape de fermeture du gaz _,<_

• SceNant pour tuyaux qui r6siste & I'attaque du gaz propane

Nouveau type de conduit m6tallique flexible pour appareils

(1/2" NPT x 3/4" ou 1/2" diam. int.) homologu6 par ACNOR

International. Nous recommandons une Iongueur de 1,2

& 1,5 m (4 & 5 pi.) de nouveau type de conduit m6tallique

flexible & toute nouvelle installation ou r6installation

pour permettre le d6placement de la cuisini_re.

Utilisez toujours les deux (2) joints d'adaptation (1/2"

NPT x 3/4" ou 1/2" diam. int.) fournis avec le nouveau type

de conduit flexible pour appareils, pour le raccordement

de la cuisini_re.

i tapes norrnales d'installation

1. instructions de montage du support de contre-

renversement - Avertissement de s6curit6 important

La cuisini_re dolt 6tre fix6e au plancher par I'installation ad6quate

de vis et de support de contre-renversement empaquet6s avec

la cuisini_re afin de r6duire le risque de renversement de celle-ci.

La cuisini_re peut s'incliner si un poids excessif est plac6 sur une

porte ouverte ou si un enfant monte sur la porte, si vous n6gligez

d'installer le support de contre-renversement. Des blessures

s6rieuses peuvent r6sulter de liquides brt]lants renvers6s ou par

la cuisini_re elle-m6me.

7

a. Situez le support en utlisant le gabarit- (Le support peut 6tre

Iocalis6 &gauche oub,droite de lacuisini_re. Utilisez I'information

donn6e ci-apr_s pour situer le support si le gabarit n'est pas

disponible). Marq uez leplancher ou letour a I'endroit o_ le c6t6

gauche ou droit de la cuisini_re sera situ6. Vous pouvez utiliser

la m6thode de montage au mur ou au plancher si I'arri_re de la

cuisini_re est appuy6 au mur ou pas plus 61oign6 du mur que 3

cm (1 1/4") apr_s installation. Enlevez la moulure ou fixez le

support au plancher si une moulure est install6e et ne permet

pas au support de s'appuyer fermement sur le mur. Pour un

montage contre lemur, situez le support en plaQant la partie

arri_re du gabarit contre lemur arri_re et le bord du gabarit sur

la marque faite qui identifie le c6t6 de la cuisini_re. Placez le

support par-dessus le gabarit et identifiez I'emplacement des

trous des vis dans le mur. Fixez le support au plancher si

I'arri_re de lacuisini_re est plus 61oign6 que 3cm (1-1/4") du tour

apr_s I'installation. Situez lesupport en plaQant la partie arri_re

du gabarit b,I'endroit o_ I'arri_re de la cuisini_re sera Iocalis6

pour un montage sur le plancher. Marquez I'emplacement des

trous des vis indiqu6s sur le gabarit.

/

b. Percez les trous d'aignement et fi×ez le support- Percez un

trou de 3 mm (1/8") aux endroits o_ les vis seront Iocalis6es.

Percez un trou d'alignement & un angle descendant

d'approximativement 20° si le support doit 6tre install6 sur le

mur. Percez un trou d'alignement de4 mm (3/16") par 44 mm

(1-3/4") de profondeur si le support dolt 6tre install6 dans la

maQonnerie ou des planchers de c6ramique. Les vis fournies

peuvent 6tre utilis6es dans le bois ou des mat6riaux en b6ton.

Utilisez un serre 6crou ou un tournevis plat afin de fixer le

support en place.

FIXEZ LE SUPPORT (MONTAGE AU MIlR Oil AL! PLANCHER)

Patte de

niveau

Montage au

plancher

FIXEZ LE SUPPORT (MONTAGE AL! PLANCHER $1EULEMENT)

Patte de

niveau

--_1 14-=-1=1/4"Max,

.Montage

au Mur

Plaque

IVlurale

- Support de

contre=renversement

Le support de contre-renversement doit aussi 6tre d6plac6 et

install6 avec la cuisini_re si celle-ci est re-localis6e.

Des instructions sont fournies pour une installation sur du

bois ou du ciment, fix6e soit au plancher ou au mur. Assurez-

vous que les vis p6n_trent compl_tement la cloison du mur et

qu'elles sont bien ancr6es dans le bois ou le m6tal Iorsque

I'installation est faite au mur. Assurez-vous que les vis ne

traversent pas la plomberie ou des ills 61ectriques durant la

fixation au plancher ou au mur.

I

Montage au _ _ort de

plancher contre-renversernent

11

Page 12

C.

Mise en place et a niveau de la cuisini_re= Mettez lacuisini@e

&niveau enajustant les pattes de mise & niveau (4) &I'aide d'une

cl6 & molette. Note: Un espacement minimum de3 mm (1/8") est

requis entre le bas de la cuisini@e et la patte d'ajustement afin

de permettre un espace pour le support. Utilisez un niveau &

bulle pour v6rifiervos ajustements. Glissez lacuisini@e vers sa

position. V6rifiez visuellement que la patte de mise & niveau

arri@e est compl@tement ins6r6e et fix6e darts le support de

contre-renversement en retirant le panneau inf6rieur ou letiroir

de rangement. Saisissez la partie sup6rieure arri@e de la

cuisini@e et essayez prudemment de la faire basculer vers

I'avant, pour les modules poss6dant un chauffe tiroir ou une

r6tisserie.

(17rnm)

i

L"aire en gris est Ja

[ocaJisation sugg6r6e

pour la prise & 120V

au tour artiste et J'aire

pour le branchement

travers Jernur, de la

jonction STUBB et de

Jasoupape de

fermeture, ,

Aire sugg6r6e pour la jonction -T_ _F------=Arr6te

]et la soupape de fermeture, I

au travers du piancher. J

C6t6 de -_

la cuisini_re

2. Fournissez une alimentation de gaz

adequate

Cet unit6 est pr6-r6gl6 pour fonctionner & une pression de gaz

propane de 10" CE au collecteur. Un r6gulateur convertible est

install6 sur le collecteur et DOlT 6tre reli6 en s6rie avec le tuyau

d'alimentation.

Lors de I'installation de la cuisini_re, des pr6cautions doivent

6tre prises pour pr6venir I'obstruction de la circulation d'air de

combustion et de ventilation.

Pour une op@ration ad@quate, la pression maximale & I'entr6e du

r6gulateur nedoit pas exc6der 14 pouces de colonne d'eau et la

pression a I'entr6e du r6gulateur doit 6tre au moins 1" CE sup6rieure

la pression au collecteur. Exemple : Si le r6gulateur est r6g16

10" CE de pression de gaz propane au collecteur, la pression &

I'entr6e doit 6tre au moins 11" CE.

La v6rification de fuites de L'appareil doit 6tre fait selon les

instructions en 4g.

Le diam_tre du tuyau d'amen6e de gaz doit 6tre de 1/2" ou de 3/

4 H"

4. Branchez la cuisiniere a I'alimentation de gaz.

Mettez du scellant sur tous les filets ext6rieurs (jonctions

m&les) pour pr6venir les fuites.

Le r6gulateur est & I'endroit indiqu6.

Ne faites pas pivoter le r_gulateur sur le

tuyau Iorsque vous serrez les raccords.

Regulate

a gaz

R6c

a gaz

3. Bouchez les ouvertures.

Apr_s I'installation de I'alimentation de gaz, bouchez toute

ouverture dans le mur en arri@e de la cuisini@e et dans le

plancher sous la cuisini@e.

_ fe(meo_n!_eP!u_e_,)tet'ne I I

12

Page 13

Soupape Joint Conduit Adaptateur R_gulateur

de _vas_ flexible de joint de pression

Fermeture pour _vas_

ManuelJe / appareiJ / ......

est en position ouverte ("ON.") Iorsque J'instalJation

est complete.

a) Installez une soupape manuelle de fermeture de gaz

& I'ext@ieur de la cuisini@e, dans un endroit facilement

accessible. Soyez certain de savoir oO la soupape de

fermeture de gaz de la cuisiniere est situee et de

savoir comment I'op@er.

b) Installez un adaptateur a joint evase de 1/2" sur le

r_gulateur.

c) Attachez le conduit pour appareil au joint sur le

regulateur.

d) Installez un adaptateur a joint evase a la soupape de

coupure ext@ieure.

e) Attachez le conduit au joint de la soupape de coupure.

f) Assurez vous que la soupape pour entretien du

r_gulateur est en position ouverte ("ON").

g) V@ifiez s'Jly a des fuites. Ouvrez I'alimentation de gaz

& la cuisinJere et & I'aide d'un liquJde pour detection de

fuJte & tousles joints du systeme et verJfJez les joints,

N'utilisez pas de flamme pour d_tecter les

fuites.

V_rification de la pression de gaz au collecteur

Pour tout essai du systeme d'alimentation _. une pression

sup@ieure & 14" de colonne d'eau (environ 1/2 Ib/po2)

debranchez la cuisiniere ainsi que sa soupape de coupure

individuelle du systeme.

Pour tout essai du systeme d'alimentation _. une pression

egale ou inf@ieure & 14" de colonne d'eau (environ 1/2 Ib/

po2), I'appareil doit 6tre isole du systeme en fermant sa

soupape individuelle d'alimentation.

S'il est necessaire de v@ifier la pression au collecteur, placez

un manometre de pression d'eau ou un autre instrument de

detection de pression &I'orifice du br01eurdroit arriere. Placez

un boyau de caoutchouc d'environ 1/4" de diametre sur

I'orifice, maintenez le fermement et ouvrez lavalve du br01eur.

Pour prendre une lecture precise, allumez au moins deux

(2) autres br01eurs. Assurez vous que la pression & I'entree

soit au moins de 1 po. de colonne d'eau sup@ieure & la

fourchette de pression specifi6e au collecteur. La pression

de I'alimentation ne doit jamais _tre au dessus de 14" de

colonne d'eau. Correctement ajustee, la pression au

collecteur est de4" de colonne d'eau pour le gaz naturel. Pour

le gaz propane, reglage adequat de la pression du collecteur

est 10" CE.

5. Lisez le d_tail du branchement electrique ci-

bas et branchez le courant _ la cuisiniere.

Avant d'effectuer de I'entretien, coupez le

courant au disjoncteur ou fusible ou d_branchez le cordon.

Besoins electriques: Une prise de courant dediee,

adequatement polarisee et mise & la terre protegee par un

disjoncteur ou un fusible & action diff@ee de 15 A. Voir la

plaque signaletique pour connaftre la bonne tension.

Precautions _.prendre pour I'utilisation d'une rallon%e_: Nous

deconseillons fortement I'utilisation de rallonge _.cause de

leurs risques potentiels sous certaines conditions. Cependant,

si vous choisissez quand m_me d'utiliser une rallonge, il est

absolument necessaire qu'elle soit de type pour appareils,

possede une branche de mise & la masse, soit de capacite

en courant egale ou sup@ieure a la capacite nominale du

circuit et soit homologuee par UL. De tels cordons de

rallonge sont disponibles par I'entremise de votre d@ositaire

de service local.

h, LIRE ATTENTIVEMENT! Pour votre

securite, cet appareil doit &tre adequatement mis & la terre.

Instructions de raise _ la terre.

Le cordon electrique de cet appareil est muni d'une prise

3 branches (avec mise _. la terre) qui se marie a un

receptacle standard pour minimiser la possibilite de

secousse electrique de cet appareil. Le client devrait faire

v@ifier le receptacle utilise pour s'assurer qu'il est

adequatement polarise et mis a la terre.

Branchement

R_ceptacle

mural

3 branches

/

O0 il y a des receptacles & deux branches, il est de la

responsabilite et obligation du client de faire remplacer

celui utilise par un circuit a trois ills avec receptacle qui est

adequatement mis a la terre.

SOUS AUCUN PRI_TEXTE VOUS NE DEVEZ COUPER OU

ENLEVER LA TROISII_IVIE BRANCH E(MISE h,LA TERRE)

DE LA PRISE DU CORDON D'AUMENTATION.

aucune consid_ration_

vous ne devez couper,|

enlever ou court-circuiter I

la branche de mise _ la/

terre de cette prise, j_

Cordon

d'alimentation

avec prise raise

la terre _ trois

branches

13

Page 14

Utilisation des br leurs

6. Installation des capuchons des br_leurs

Votre cuisiniere est munie d'une des combinaisons de

brQleurs scell6s suivante dont I'illustration renseigne sur la

configuration de votre cuisiniere pour installer les ca )uchons

correctement aux quatre ronds.

Configurations de brOleurs et capuchons possibles

8.0k

Installez les pieces montrees ci-bas sur les quatre brQleurs.

1° - Installez le cabaret amovible (si inclus);

2° - installez les t6tes des brQleurs;

3° - installez les capuchons des brQleurs, et

4° - installez les grilles des brQleurs.

iii! iii iiiiiiiiiii!iiii

10k

7. BrQleurs a allurnage 61ectrique

Le fonctionnement des allumeurs 61ectriques devrait 6tre

v6rifi6 apres que la cuisiniere et I"arriv6e de gaz aient et6

v6rifi6es minutieusement pour detecter les fuites et que

la cuisiniere ait 6re branchee au r6seau 61ectrique. Les

valves des brQleurs ont des positions de r6tention &

chacune des positions "OFF" et "LITE". Le bouton doit

6tre enfonce et tourne plus loin que ces positions de

r6tention.

a. Pour verifier si I'allumage s'effectue, poussez et tournez

le bouton d'un des ronds en sens anti-horaire, & la

position "LITE". Vous entendrez le craquement de

I'allumeur (voir I'illustration ci-bas).

b. Le rond devrait s'allumer Iorsque le gaz parvient au

brOleur. Purgez I'air de la tubulure d'alimentation en

laissant le bouton & la position "LITE" jusqu'& ce que le

brOleur s'allume. En operation normale, chaque brOleur

devrait s'allumer en moins de quatre (4) secondes

apres que I"air ait et6 purge de la tuyauterie

d'alimentation.

c. V6rifiez visuellement que le brOleur est allum& Une

fois allume, le bouton devrait 6tre pousse et tourne

hors de la position LITE".

d. d. II y a une electrode (allumeur) individuelle & chaque

brOleur. Essayez chaque bouton s@ar6ment jusqu"&

ce que chaque valve ait et6 v6rifi6e.

Note " Le style et la couleur du bouton peuvent diff6rer de

celui montr&

Grille de

surface

_brOleur

}ur certains

brQleur

T6te

du

Cabaret

amov ble

modeJes)

14

Page 15

8. Ajustez le r_glage minimum ("LO") des valves

des br_leurs.(Valves _ d_bit lin_aire seulement)

Vers les_

ronds de

la cuisini_re

Essai pour verifier si I'ajustement MiNiMUM doit &tre regle

a. Enfoncez et mettez le bouton & bas ("LFE") jusqu'& ce

que le brQleur s'allume.

b. Enfoncez le bouton et tournez le rapidement vers la

position minimum.

c. Si se brQleur s"eteint, replacez le bouton & arr&t ("OFF").

d. Enlevez le bouton de commande.

e. Inserez un tournevis & lame fine dans la tige creuse

poussez le & I'interieur. La dimension de la flamme peut

&tre augmentee ou diminuee en tournant la vis. Tournez

en sens contraire des aiguilles d'une montre pour

augmenter laflamme et dans I'autre sens pour la diminuer.

apparaisse au brQleurdu fourneau. Lorsque lefour atteindra la

temperature reglee au cadran, I'allumeur s"eteindra. Laflamme

du brQleur s"eteindra entre 20 et 30 secondes apres que

I'allumeur eut erecoupe. Ce cycle continuera pour maintenir

toute temperature reglee jusqu'& ce que I'indicateur/cadran

soit remis & "OFF".

Apres avoir enleve tout materiau d'emballage et la

documentation du four,

a) Reglez lefour pour cuire "BAKE" & 300°F. Voir le Guide

d'utilisation et d'entretien pour les directives d'operation.

b) Le brQleur du four devrait s'allumer en dedans de 60

secondes. Verifiez si la flamme est convenable et

r@etez la procedure une autre fois et remettez le

bouton de commande & "OFF")

c) Si votre modele est muni d'un brOleur de r6tisserie &

alimentation par prise unique, reglez le fourneau &

r6tisserie "BROIL". Voir le Guide d'utilisation et

d'entretien pour les directives d'operation.

d) Le brQleur de la r6tisserie devrait s'allumer en dedans

de 60 secondes. Verifiez si la flamme est convenable

et remettez le bouton de commande & "OFF".

10. Br_leur du fourneau a clapet d'air

Dimension de flamme__._ 5/8" 4-

de brOleur

Ajustez la flamme jusqu'& ce que vous puissiez passer

rapidement de la position "LITE" &"LO" sans que la flamme ne

s'eteigne. La flamme doit _tre aussi petite que possible sans

s'eteindre. Note : Le reglage d'air n'est pas requis pour les

brQleurs de des ronds de la cuisiniere.

Fonctionnernent et r glage des

br leurs du four.

9. Br_leurs a allumage 61ectrique

Le fonctionnement des allumeurs electriques devrait _tre

verifi6 apres que la cuisiniere et I'arrivee de gaz aient ete

verifiees minutieusement pour detecter les fuites et que

la cuisiniere ait ete branchee au reseau electrique.

Le brQleur du four est muni allumeur electrique ainsi que

d'un systeme de commande electrique. Si votre modele

est muni d'un brQleur de r6tisserie a alimentation par prise

unique, il aura egalement un allumeur electrique. Ces

systemes de commande ne n_cessitent aucun ajustement.

Lorsque le fourneau sera pr_t a fonctionner, le courant

parviendra & I'allumeur qui deviendra incandescent et

Iorsqu'il aura atteint la temperature d'ignition du gaz, la

valve de commande du four commandee electriquement

s'ouvrira et une flamme apparaftra au brQleur du fourneau.

II y a un delai de 30 a 60 secondes apres que le thermostat

soit mis en position "ON" et le moment que la fiamme

Br61eur de

rbtisserie (ModUles

D_flecteur du

;du fourneau ,-..

(D_montable).--'"

!__ Clapet & air ;I

auto=nettoyag a)

Fond du fourneau

(D_montable)

_=== Clapet _ air

La Iongueur approximative de la fiamme du brOleur du

fourneau est 25 mm (1") (centre de flamme bleu distinct)

Pour determiner si la flamme du brQleur dufour est adequate,

enlevez le fond du four et I"enceinte du brQleur et reglez le

fourneau &300°F

Enlevez les vis de maintien A I'arriere du fond du fourneau

pour pouvoir retirer le fond du fourneau. Soulevez &

I'arriere, degagez le fond avant du cadre du four et retirez

le fond du fourneau hors de celui-ci. Enlevez I'enceinte du

brOleur pour voir la flamme. Si la flamme est de couleur

jaune, augmentez I'ouverture du clapet d'air (voir "2" & la

figure ci-bas). Si la flamme est bleue, reduisez I'ouverture

du clapet d'air.

Pour faire le reglage, desserrez la vis de blocage ("3" ci-

bas), repositionnez le clapet d'air et serrez la vis de

blocage. Replacez le fond du fourneau.

15

Page 16

_1_ Tuybre de

brQieur du

fourneau

_ Capot

d'orifice

11. Br_leur de la r_tisserie a clapet d'air

La Iongueur approximative de la fiamme du brQleur du

fourneau est 25 mm (1") (centre de flamme bleu distinct)

Pour determiner si la flamme du brOleur de la r6tisserie est

adequate, reglez le fourneau _. "BROIL".

Si la flamme est de couleur jaune, augmentez I'ouverture

du clapet d'air (voir "2" _.la figure ci-dessus). Si la flamme

est bleue, reduisez I'ouverture du clapet d'air.

Soins, nettoyage et entretien

Pour les instruction de nettoyage, referez vous _. votre

Guide d'utilisation et d'entretien

Coupez I'alimentation de gaz si vous devez deplacer la

cu[sin[ere pour le nettoyage. Coupez le gaz et I'electr[cite.

Si le gaz ou I'electr[c[te n'est pas accessible, levez quelque

peu I'unite _.I'avant et tirez pour I'eloigner du mur. Avancez

la seulement aussi loin qu'il faut pour couper le gaz et

I'electricite. Completez le deplacement pour le nettoyage

et I'entretien. Remettez en position en [nversant la

procedure en vous assurant de qu'il n'y ait pas de fuite et

que la cu[sin[ere est au niveau. Voir I'etape 1 de la page 3

pour obtenir les instructions d'ancrage.

Avant que vous ne fassiez un

appel de service

Lisez "Avant d'appeler" et les sections de notices

d'operation de votre Guide d'utilisation et d'entretien, ils

peuvent vous sauver temps et argent. IIs comprennent

des occurrences qui ne parviennent pas de defaut de

materiau ou de main-d'oeuvre dans cet appareil.

Pour faire le reglage, desserrez la vis de blocage ("3" ci-

dessus), repositionnez le clapet d'air et serrez la vis de

blocage.

12. Assurez vous que la cuisiniere est au niveau.

Mettez la cuisiniere au niveau en plagant un niveau

horizontalement sur une grille du four. Verifiez diagonalement

de I'avant _. I'arriere, et ensuite ajustez le niveau soit en

ajustant les pattes de nivellement ou soit en plagant des

cales aux coins de la cuisiniere comme requis.

13. Apres que I'installation soit termin_e, assurez

vous que tous les boutons de commande soient

en position "OFF"

Localisation du no. de modele /

no. de s rie

Pour les fours _br_leurs scelles, laplaque d'ide ntification est

situee sur la surface _. droite du devant du cadre du

fourneau, _. la partie [nfer[eure du panneau derriere le

devant du tiroir rechaud ou de rangement.

Assurez vous de toujours fournir le no. de modele et de

serie ainsi que le no. de lot ou lettre sur la plaque

d'identification devotre cuisiniere Iorsque vous commandez

des pieces ou demandez de I'[nformation concernant votre

cuisiniere.

Pour conna_tre notre no. de telephone sans frais et notre

adresse, referez vous _. la garantie dans votre Guide

d'utilisation et d'entretien. Si vous avez des questions

concernant votre cu[siniere et/ou devez commander des

pieces de rechange n'hesitez pas _. nous telephoner ou _.

nous ecrire.

_i_ _i_i_iiI ii_iii_i_i_!_!iii _i_i_i_ _ ii ii

La plaque d'identification vous indique _galement la

capacite des brOleurs, letype de combustible et la pression

pour laquelle la cuisiniere etait reglee Iorsqu'elle a quitte la

manufacture.

16

Localisation de la plaque signal_tique

Ouvrez le tiroir rechaud ou de rangem_

elle est situee sur le c6te avant idroit

du cadre de la cuisiniere.

Page 17

LA INSTALACION Y CUALQUIER TIPO DE SERVICIO DEBERAN REALIZARLO UN

INSTLADOR CUALIFICADO.

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA USO DEL INSPECTOR LOCAL Y

PARA REFERENCIAS FUTURAS.

Si no se sigue con exactitud la informacion que se

proporciona en el presente manual, podria producirse fuego o

una explosion y causar graves dahos a la propiedad, personales

e incluso la muerte.

PARA SU SEGURIDAD:

--No almacene, ni utilice gasolina o cualquier otrotipo de liquidos

o gases inflamables cerca de esta o de cualquier otra aplicacibn

de este tipo.

EQUE DEBE HACER SI HUELE A GAS:

• No intente encender ninguna de las aplicaciones.

• No toque ning0n interruptor el6ctrico, ni utilice los tel6fonos

que pueda haber en el edificio.

• Aviseinmediatamentealaempresadesuministmdegasdesde untelefono

en el exterior del edificio. Siga las instrucciones que le proporcione la

empresadesuministrode gas.

• Sinopudieraponerseencontactoconlaempresadesuministrodegas,

avisede inmediatoalcuerpode bomberosdesu Iocalidad.

-- La instalacibn y cualquier tipo de servicio debera realizarlo un

instalador cualificado, una agencia de reparaciones certificada

o la empresa de suministro de gas.

@

@

Electrodomesticos instalados en el

estado de Massachusetts (vea la

p4gina 18).

• Todas las cocinas

pueden volcar

• Pueden producirse

da_os personales

• lnstale el dispositivo

antivuelco que se

surninistra con la cocina

• Consulte las instrucciones

de instalaci6n

DIMENSIONES

TOTALES DE

LA COCINA

47-3/4"

M,_ximo

Dimensiones y distancias

1. Ubicacibn -- Compruebe el lugar

de instalacibn de la cocina.

Compruebe que los suministros de

gasy electricidad sonlosadecuados

y la estabilidad del suelo.

2. Las dimensiones que se muestran

son las que deben utilizarse. Las

dimensiones que se proporcionan

dejar_n el espacio minimo. La

superficie de contacto debe ser

s61ida y estar nivelada.

p/n 316259326 EN/FR/SP (0804)

--- 30-1/8"

253/4" a;c, adma_in_ __ __fO: TAL L

i'2t e,acocina-, ,

poreoc mado o

........... *Nota: Distancia --J 30"

136 ! de3" (7,61 cms) Minimo t 1÷13"÷1

36"(91,43cms). • J .k,,

siseequipa con 2" * I ............

quemadores de ÷ I L_III_ 18 Profundidad maxima para /-

+/8 11000 BTU o .-_i ____ _ partesuperiordelacocina. L_

superlores.

_1_ 30-1/8" _ No de ar ningOn espacio por debajo de la parle superior

Utilice el tipo de combustible adecuado

Antes de conectarlo:

Su cocina se ha dise5ado para funcionar solamente con gas propano/gas

licuado de petr61eo

17

........... VISTA AVIS2

armarios por encima de la /

de a cocina y a parte trasera.

English - Pages 1-8

Frangais- Pages 9-16

EspaSol- P_.ginas 17-24

Page 18

Instrucciones importantes para el instalador

1. Lea todas las instrucciones que se proporcionan en este

manual de instalaci6n antes de comenzara instalar la cocina.

2. Retire todo el material de embalaje de los compartimentos

del horno antes de conectar el suministro de energia el6ctrica

y de gas a la cocina.

3. Siga siempre todos los c6digos y normativas locales

referentes a instalaci6n de cocinas.

4. Asegt]rese de que el comprador guarde estas instrucciones.

Instrucciones importantes para el comprador

1. Guarde estas instrucciones junto con la Guia de uso y

mantenimiento para referencias futuras.

INSTRUCCIONES DE SEGUIRDAD IMPORTANTES

La instalaci6n de esta cocina debera realizarse de acuerdo a la

normativa local o, en caso de que no existiera, de acuerdo a la

norma National Fuel Gas Code ANSI Z223.1JQltima edici6n, si

la instalaci6n se realiza en Estados Unidos.

Si la cocina se instala en una casa m6vil (caravana), la instalaci6n

debera realizarse de acuerdo a los estandar de seguridad

Manufactured Home Construction and Safety Standard

(Estandar de seguridad y construcci6n de casa prefabricadas),

Titulo 24 CFR, Secci6n 3280 [anteriormente denominada Federal

Standard for Mobile Home Construction and Safety (Estandar

federal para seguridad y construcci6n de casas prefabricadas),

Titulo 24, HUD (Secci6n 280)] o, en caso de que dicho estandar

no sea aplicable, debera seguirse la norma marcada por el

Standard for Manufactured Home Installations, ANSl/NCSBCS

A225.1, o bien, toda la normativa legal existente referente a

casas m6viles.

El diseSo de esta cocina posee la certificaci6n de CSA

International. Del mismo modo que sucede con otras aplicaciones

que utilizan gas y generan calor, existen ciertas recomendaciones

de seguridad que deberan seguirse siempre. Lea con detenimiento

la Guia de uso y mantenimiento.

• Aseg_rese de que un instalador cualificado o un t@cnico

del servicio de reparaciones certifica que su cocina se ha

instalado y posee una toma de tierra adecuada

• Esta cocina debera poseer unatoma de tierra adecuada de

acuerdo a la normativa local o bien, si no existiera, de

acuerdo a Io establecido en el codigo National Electrical

Code ANSI/NFPA N°70 - t]ltima edicion si se instala en los

Estados Unidos Consulte las instrucciones de instalacion

de la toma de tierra que se proporcionan en la pagina 5

• Antes de instalar la cocina en unazonacon recubrimiento

de linoleo o con cualquier otro tipo de suelo sint@tico,

debera asegurarse de que el recubrimiento del suelo

podra soportar temperaturas que superen 32°C la

temperatura ambiente sin que se deterioren, se

resquebrajen o pierdan color No instale la cocina sobre

suelos enmoquetados a no ser que se coloque un

recubrimiento de proteccion o una lamina de aislamiento

de 1/4"co ntrachapada para aislar la cocina de la moqueta

• Aseg_rese de que las cubiertas que se coloquen alrededor

de la cocina puedan soportar el calor que genere lacocina

• No obstruya el flujo de aire de combustion del orificio de

ventilacion, ni alrededor de la base oentre el panel frontal

inferior de la cocina Notoque lasaperturas de ventilacion,

ni las superficies adyacentes ya que es posible que se

calienten en exceso cuando el horno est@ en

funcionamiento Esta cocina requiere airefresco para que

la combustion del quemador sea la adecuada

Nodeje nunca ni_os solos o desatendidos en la

zonaen laquese utilice laaplicacion Conformevayan creciendo

los ni_os, debera explicarles el modo correcto de utilizar este

tipo de aplicaciones No deje nunca abierta la puerta del horno

si la cocina se va a quedar desatendida

No se suba, se apoye ose siente en las puertas

o en los cajones de esta cocina ya que podrian producirse

graves da_os personales yen la propia cocina

• Noalmacenearticulos que puedan Ilamar laatencibn de ni_os

en los armarios que haya encima de lacocina Cualquier ni_o

podria sufrir quemaduras de gravedad alsubirse en lacocina

para alcanzar dichos objetos

• Para evitar tener que alcanzar cualquier objeto que se

encuentre por encima de los quemadores de lacocina, evite

la instalacion de armarios encima de la misma

• Ajusteeltama_ode la Ilamadelquemador detal modoque no

rebase loslimitesde loscazos o utensilios que se utilicen para

cocinar Una llama excesiva puede ser peligrosa

• No utiliceel horno como lugar dealmacenamiento Si Io hace

pueden producirse situaciones depeligro reales

• No utilice nunca lacocina para calentar la habitacion Un uso

prolongado de lacocinaen espacios sinlaventilacion adecuada

es peligroso

• No almacene gasolina ni cualquier otrotipo decombustible o

gas inflamable cerca de lacocina o de cualquier otro tipo de

aplicacion Puede producirse fuego o una explosion

- Coloque todos los controles de la cocina en la posicion de

"apagado" despu_s de haber utilizado la funcion de

temporizacion programable

PARA MODELOS AUTOLIMPIABLES:

• Retire la parrilla, alimentos o cualquier otro utensilio antes

deactivarestafuncion Retirecon un pa_osi hay unexceso

de derrames Siga las instrucciones de limpieza que se

proporcionan en la Guia de uso y mantenimiento

• A diferencia que las cocinas de gas estandar, ESTA PLACA

NO SE PUEDE RETIRAR No intente levantar la placa

Electrodomesticos instalados en el estado de Massachusetts:

Este electrodomestico solo puede ser instalado en elestado de

Massachusetts por un professional de plomeria oinstalador de

equipos degas. Cuando se utilice un conector de gas flexible, este

no debe exceder los tres 3 pies (36 pulgadas) de Iongitud. Se debe

instalar una valvula de manejo de gas tipo "T" en la linea de

alimentacion de gas de este electrodomestico.

NO INTENTE ENCENDER EL HORNO DE

IGNICION ELI_CTRICA DURANTE UN APAGON DE LUZ

COLOQUE TODOS LOS CONTROLES EN LA POSICION DE

"APAGADO" CUANDO SE PRODUZCAN SITUACIONES DE

ESTE TIPO

El encendedor el6ctrico, volver& a encenderse automaticamente

al volver a conectarse el suministro de energia el6ctrica tras un

apag6n si se han dejado los controles en la posici6n de

"ENCENDIDO".

Si se produce un apag6n el6ctrico cuando est6 utilizando la

aplicaci6n, los quemadores de superficie continuaran en

funcionamiento y podra encenderlos con una cerilla.

Coloque una cerilla encendida al lado del quemador y, a

continuaci6n, gire lentamente el mando hasta colocarlo en

a posici6n LITE de encendido. Extreme las precauciones la

encender el quemador de este modo.

18

Page 19

Antes de comenzar

Herramientas que va a necesitar

Para patas de nivelaci6n y montura anti-vuelco:

• Llave ajustable o ahcates_-s_s_ ....

• Llave para apretar tuercas de 5/16" o un destornillador de

cabeza plana

• Taladro el_ctrico y una broca de 1/8" (broca de taladro de

hormigSn de 3/16" si se instala sobre hormigSn)

Para la conexi6n al suministro de gas:

• Llave grifa

Para el ajuste de la llama de los quemadores:

• Destornilladores de estrella _ _ y

de cabeza plana

Para la conversi6n a gas (PL/Propano o gas natural):

• Llave de boca de 1/2" _-#

Material adicional que va a necesitar

• Vfilvula de desconexidn de la linea de gas _

• Sellador para uniones de tuberias que resista la acciSn del

gas propano/PL

Un conducto de metal flexible (1/2" NPT x 3/4" o de 1/2" de

D.I.) con diseSo certificado por CSA International. Ya que

las tuberias rigidas restringen el movimiento de la cocina, se

recomienda el uso de tuberias flexibles nuevas (de entre

1,20 a 1,50 mts) durante la instalaci6n y cada vez que se vaya

a instalar de nuevo o se cambie de lugar posteriormente.

• Utilice siempre los dos (2) adaptadores de campana (1/

2" NPT x 3/4" o de 1/2" D.I.) que se suministran con el

conducto flexible nuevo para la conexi6n de la cocina.

Pasos para la instalacion

1. Advertencia de seguridad importante sobre las

instrucciones de instalacibn de la montura anti-vuelco

Para reducir el riesgo de que se vuelque la cocina, _sta debera

asegurarse al suelo mediante la montura especial anti-vuelco

que debera sujetarse al mismo del modo adecuado con los

tornillos que se suministran. Si no se instala del modo adecuado

esta montura, la cocina esta expuesta a volcarse si se coloca

un peso excesivo sobre una puerta abierta o en el caso de que

un niSo se agarre a la misma e intente subirse a ella. Estas

situaciones pueden provocar graves daSos personales por el

derramamiento de liquidos muy calientes o bien, por el peso de

la cocina en si.

Si en algQn momento se cambia de lugar la cocina, deberan

cambiarse de lugar tambi_n e instalarse de nuevo las monturas

anti-vuelco.

Estas instrucciones explican el modo de instalar la cocina

sobre madera o cemento y el modo de sujetarla a la pared o

al suelo. Si se instala sujeta a la pared, debera asegurarse de

que los tornillos se introducen completamente en la pared

seca y se aseguran en madera o metal. Cuando sujete la

cocina al suelo o a la pared, debera asegurarse de que los

tornillos no perforan ningQn cable el_ctrico o tuberias.

a.

Ubicacion de la montura con la ayuda de la plantilla- (la

montura puede ubicarse a la izquierda o a la derecha de la

cocina. A continuaci6n se proporciona la informaci6n

necesaria para ubicar la montura si no dispone de la plantilla).

Haga una marca en el suelo o en la pared a la izquierda o la

derecha. Si la parte posterior de la cocina va a quedar

apoyada contar la pared ova a quedar a menos de 1-1/4" de

la misma. Siga los pasos que se describen en el m_todo de

montaje en pared o suelo. Si se coloca una moldura que

impide que la montura se adapte completamente a la pared,

debera retira la moldura o bien, instalar la montura en el

suelo. En caso de que se monte en la pared, ubique la

montura colocando el borde trasero de la plantilla contra la

pared posterior y el borde lateral sobre la marca de referencia

realizada en el lateral de la cocina. Coloque la montura sobre

la plantilla y marque la ubicaci6n de los agujeros de los

tornillos en la pared. Si la parte posterior de la cocina se

encuentra a mas de 1-1/4" de la pared cuando la instale,

debera fijar la montura al suelo. Para montaje sobre suelo,

coloque el borde trasero de la plantilla en el lugar en el que se

vaya a instalar la cocina. Marque la ubicaci6n de los agujeros

de los tornillos que se muestra en la plantilla.

b.

Perforacion deagujeros piloto y monturadesujecion-Perfore

un agujero piloto de 1/8"en el lugaren elque sevayan a instalar los

tornillos. Si lamontura se va a instalar a en la pared, practique un

agujero piloto con una inclinaci6n aproximada de 20°hacia abajo.

Silamonturasevaainstalarsobre hormig6n parasuelosceramicos,

practique un agujero de 3/16" con una profundidad de 1-3/4".

Los tornillos que se suministran pueden utilizarse en hormig6n

omadera. Parafijar lamontura ensu sitio, utilice undestornillador

de cabeza plana o una Ilave para apretar tuercas de 5/16".

MONTURA DE SUJECI(_N (MONTAJE EN PARED 0 SUELO)

--_1 _--1-1/4" Max.

nivelacion

Montaje ----'_ - Montura

en suelo antivuelco

MONTURA DE SUJECI(_N (SOLO MONTAJE EN SUELO)

nivelacion 1-1/4"

Montaje J Montura

en suelo antivuelco

19

• Montaje

en pared

Placa

de pared

I*- Mas de

Page 20

Page 21

Vdlvula de Unibn de Conducto Adaptador Regulador

desconexion campana flexible de unibn de presion

manual / J de campana /

$61o modelos de igniddn el_ctrica con vfilvula de desconexidn de

servicio (se muestra en la posicion de conexibn "ON"). Asegt_rese

de que la palanca este en la posicibn de conexibn "ON" al finalizar

la instalacion.

a) Instale una v&lvula manual externa para cierre de gas

hacia la Iinea de suministro de gas que tenga una

ubicaciSn de f&cil acceso fuera de la cocina. Asegt3rese

de conocer dSnde y cSmo se cierra el suministro de gas

hacia la cocina.

b) Instale un adaptador para uniSnde campana de 1/2" hacia

el regulador de presiSn.

c) Conecte el conducto de la aplicaciSn a la uniSn de

campana en el regulador.

d) Instale el adaptador de la uni6n de campana hacia la

v&lvula manual extema de cierre.

e) Conecte el conducto de la aplicaciSn a la uniSn de

campana en la v&lvula de cierre.

f) Aseg_rese que lav_lvula de cierre de servicio sobre el

regulador de presi6n se encuentra en la posici6n de

encendido "ON".

g) Verifique si existen fugas. Encienda el suministro de gas

hacia la cocina y use el detector de derrames de Iiquidos

en todas las uniones y conductos para comprobar la

existencia de fugas en el sistema.

No use fuego para comprobar la existencia

de fugas de gas.

Revisi6n de la presi6n de gas en el colector

Desconecte la cocina y su vAIvula de cierre individual del

sistema de tuberia del suministro de gas durante cualquier

prueba de presi6n de ese sistema para presiones de prueba

superiores a 14" de presi6n de columna de agua

(aproximadamente 1/2" psig).

La aplicaci6n debe aislarse del sistema de la tuberia de

suministro de gas cerrando su vAIvula de cierre manual

individual durante cualquier prueba de presi6n del sistema de

tuberia de suministro de gas para presiones de prueba

iguales o mayores a 14" de presi6n de columna de agua

(aproximadamente 1/2" psig).

Si fuera necesario revisar la presi6n de gas en el colector,

conecte el man6metro (medidor de agua) u otro dispositivo

de presi6n al orificio posterior derecho del quemador superior.

Usando una manguera de caucho con undi&metro interior de

aproximadamente 1/4", sostenga fuerte la tuberia hacia abajo

sobre el orificio. Encienda la v&lvula del quemador.

Para una revisi6n exacta de la presi6n, tenga por Io menos

otros dos (2) quemadores superiores. Asegt3rese que la

presi6n del suministro de gas (entrada) se encuentra por Io

menos una pulgada por encima de la presi6n especificada en

el colector de la cocina. La presi6n del suministro de gas

nunca debe encontrarse por encima de 14" de la columna de

agua. Lapresi6ncorrectadelcolectordespuesdeajustarlopara

sufuncionamiento congas propano/gas licuado de petr61eodebe

ser de 10".

5. Lea los detalles sobre conexi6n electrica en

la parte inferior y conecte la electricidad segun