Page 1

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

if the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY:

= Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

= WHAT TO DO iF YOU SMELL GAS:

• Do not try to light any appliance.

• Do nottouch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• if you cannot reach your gas supplier, call the fire

department.

= Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

OVERALL

DiMENSiONS

30" incl. door handle ViEW

25 3/4" .... FRONT

/

' *Minimum to --

48"

Maximum

Side Wall Minimum t

Side of l-

on Either "5"-_ / 1_8"

Range 5.... _ of Range.

O0 O O0

Refer to your serial plate for

applicable agency certification

o ALL RANGES

CAN TiP

• INJURYTO PERSONS

COULD RESULT

e iNSTALL ANTI=TIP

DEVICE PACKED WiTH

RANGE

• SEE INSTALLATION

iNSTRUCTiONS

Note: For appliances installed in the

State of Massachusetts see page 2.

Minimum to

Cabinets on

Either Side

Maximum Depth

for Cabinets

Above Range Top.

1_-13"-_1

36"

30" _ 0" Clearance Below Cooking Top and at Rear of Range.

Clearances and Dimensions

1. Location--Check location where the range will be

installed. Check for proper electrical and gas supply,

Provide Proper Fuel Type

Before Proceeding: Your range isfactory preset to operate

on LP/Propane gas only.

and the stability of the floor.

2. Dimensions that are shown must be used. Given

dimensions provide minimum clearance. Contact

surface must be solid and level.

Important Note to the Consumer:

Keep these instructions with your Owner's Guide

for future reference.

pin 316259360 En/Sp (0809) Espafiol- Paginas 9-16

Page 2

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven compartments

before connecting the gas and electrical supply to the

range.

3. Observe allgoverning codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

1. Keep these instructions with your Use & Care Guide for

future reference.

IMPORTANT SAFETY INSTRUCTIONS

Installation of this range must conform with local codes or, in

the absence of local codes, with the National Fuel Gas Code

ANSI Z223.1--1atest edition when installed in the United

States.

When installed in a manufactured (mobile) home, installation

must conform with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 [formerly the Federal

Standard for Mobile Home Construction and Safety, Title 24,

HUD (Part 280)] or, when such standard is not applicable, the

Standard for Manufactured Home Installations, ANSI/NCSBCS

A225.1, or with local codes.

This range has been design certified by CSA International. As

with any appliance using gas and generating heat, there are

certain safety precautions you should follow. You will find them

in the Use & Care Guide, read it carefully.

• Besureyour range is installed and grounded properly

by a qualified installer or service technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical CodeANSI/NFPA No .70-

latest edition when installed in the United States.

See Grounding Instructions on page 5.

• Before installing the range in an area covered with

linoleum orany other synthetic floor covering, make

sure the floor covering can withstand heat at least

90°F above room temperature without shrinking,

warping or discoloring. Do not install the range over

carpeting unless you place an insulating pad or sheet of

1/4-inch thick plywood between the range and carpeting.

• Make sure the wall coverings around the range can

withstand the heat generated by the range.

• Do not obstruct the flow of combustion airat the oven

vent nor around the base or beneath the lower front

panel of the range. Avoid touching the vent openings or

nearby surfaces as they may become hot while the oven

is in operation. This range requires fresh air for proper

burner combustion.

. Air curtain or other overhead range hoods, which operate

by blowing a downward airflow on to a range, shall not be

used in conjunction with gas ranges other than when the

hood and range have been designed, tested and listed by

an independent test laboratory for use in combination with

each other.

Never leave children alone or unattended

in the area where an appliance is in use. As children grow,

teach them the proper, safe use of all appliances. Never leave

the oven door open when the range is unattended.

Stepping, leaning or sitting on the doors

or drawers of this range can result inserious injuries and

can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as astorage space. This creates

a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other appliance.

Explosions or fires could result.

• Reset all controls to the "off" position after using a

programmable timing operation.

FOR MODELSWITH SELF=CLEAN FEATURE:

. Remove broiler pan, food and other utensils before

self=cleaning the oven. Wipe up excess spillage. Follow

the cleaning instructions in the Use & Care Guide.

. Unlike the standard gas range, THIS COOKTOP IS

NOT REMOVABLE. Do notattempt to removethe cooktop.

Special instructions for appfiances installed in the State of

Massachusetts: This appliance can only be installed in the

State of Massachusetts by a Massachusetts licensed

plumber or gas fitter. When using a flexible gas connector, it

must not exceed 3 feet (.36 inches) in length. A "T" handle

type manual gas valve must be installed in the gas supply

fine to this appliance.

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING AN

ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitorwill automatically re-ignite the oven burner

when power resu rues ifthe oven thermostat control was left

in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit with a

match. Hold a lighted match to the burner, then slowly turn

the knob to the LITE position. Use extreme caution when

lighting burners this way.

Page 3

Before Starting

Tools You Will Need

For leveling legs and Anti=Tip Bracket:

• Adjustable wrench or channel lock pliers

• 5/16" Nutdriver or Flat Head Screw Driver

• Electric Drill & 1/8" Diameter Drill Bit (5/32" Masonry Drill

Bit if installing in concrete)

For gas supply connection:

• Pipe wrench :-_

For burner flame adjustment:

• Phillips head and

blade-type screwdrivers __

For gas conversion (LP/Propane or Natural):

• Open end wrench - 1/2"

Additional Materials You Will Need

• Gas line shut-off valve _%t

• Pipe joint sealant that resists action of LP/Propane gas

A new flexible metal appliance conduit (1/2" NPTx 3/4"

or 1/2" I.D.)must bedesign certified byCSA International.

Because solid pipe restricts moving the range we

recommend using a new flexible conduit (4 to 5 foot

length) for each new installation and additional

reinstallations.

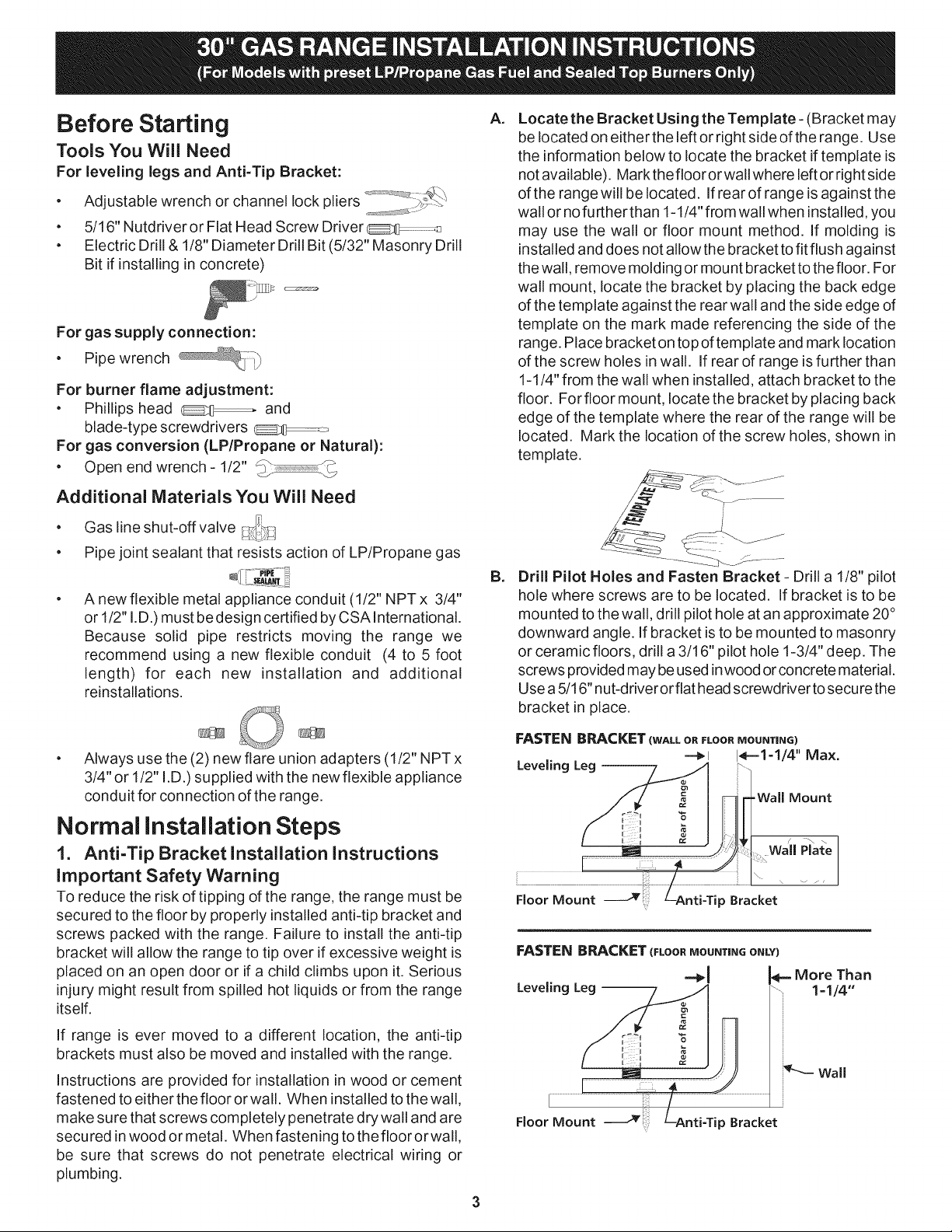

A. Locate the Bracket Using the Template- (Bracket may

be located on either the left or right side of the range. Use

the information below to locate the bracket if template is

not available). Mark the floor or wall where left or right side

of the range will be located. If rear of range is against the

wall or no fudher than 1-1/4" from wall when installed, you

may use the wall or floor mount method. If molding is

installed and does not allowthe bracket tofit flush against

the wall, remove molding or mount bracket to the floor. For

wall mount, locate the bracket by placing the back edge

of the template against the rear wall and the side edge of

template on the mark made referencing the side of the

range. Place bracket ontopof template and mark location

of the screw holes in wall. If rear of range isfurther than

1-1/4" from the wall when installed, attach bracket to the

floor. Forfloor mount, locate the bracket by placing back

edge of the template where the rear of the range will be

located. Mark the location of the screw holes, shown in

template.

B. Drill Pilot Holes and Fasten Bracket - Drill a 1/8" pilot

hole where screws are to be located. If bracket is to be

mounted to the wall, drill pilot hole at an approximate 20°

downward angle. If bracket is to be mounted to masonry

or ceramic floors, drill a 3/16" pilot hole 1-3/4" deep. The

screws provided may be used inwood or concrete material.

Use a5/16" nut-driver or flat head screwdriver to secure the

bracket in place.

• Always use the (2) new flare union adapters (1/2" NPT x

3/4" or 1/2" I.D.) supplied with the new flexible appliance

conduit for connection of the range.

Normal Installation Steps

1. Anti-Tip Bracket Installation Instructions

Important Safety Warning

To reduce the risk of tipping of the range, the range must be

secured to the floor by properly installed anti-tip bracket and

screws packed with the range. Failure to install the anti-tip

bracket will allow the range to tip over if excessive weight is

placed on an open door or if a child climbs upon it. Serious

injury might result from spilled hot liquids or from the range

itself.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the range.

Instructions are provided for installation in wood or cement

fastened to either the floor or wall. When installed to the wall,

make sure that screws completely penetrate dry wall and are

secured in wood or metal. When fastening to the floor or wall,

be sure that screws do not penetrate electrical wiring or

plumbing.

FASTEN BRACKET (FLOORMOUNTINGONLY)

Leveling Leg ..... ' 1-1/4"

Floor Mount LAnti=Tip Bracket

--_1 4-- More Than

o

-

Wall

Page 4

C=

Level and Position Range- Level range by adjusting the

(4) leveling legs with awrench. Note: A minimum clearance

of 1/8" is required between the bottom ofthe range and the

leveling leg to allow room for the bracket. Use a spirit level

to check your adjustments. Slide range back intoposition.

Visually check that rear leveling leg is inserted into and

fully secured by the Anti-Tip Bracket by removing lower

panel or storage drawer. For models with awarmer drawer

or broiler compartment, grasp the top rear edge of the

range and carefully attempt to tilt it forward.

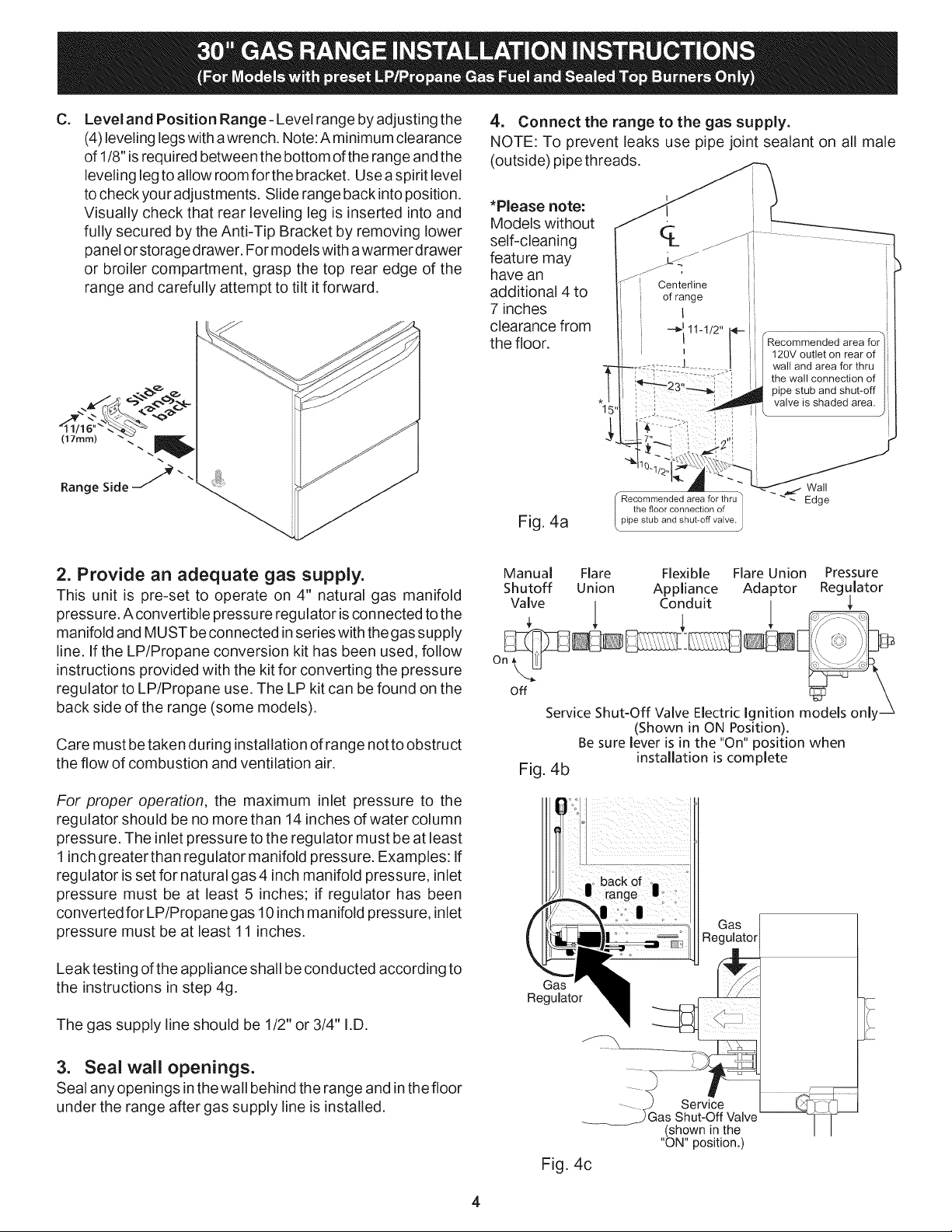

4. Connect the range to the gas supply.

NOTE: To prevent leaks use pipe joint sealant on all male

(outside) pipe threads.

*Please note:

Models without

self-cleaning

feature may

have an

additional 4to

7 inches

clearance from

the floor.

I _ va ves shaded area |

5" J , ; i

Centerline

of range I

I !

--_111-1/2" _,--i _

| Recommended area fe d

i I i i 120V outlet on rear of |

--,-....... J..... / wall and area for thru / i

_q__::- :- :;:1 Ii the wall connection of|

' , 23" ', i_ .

I I __ ptpe stub and shut'°ff /

2. Provide an adequate gas supply.

This unit is pre-set to operate on 4" natural gas manifold

pressure. A convertible pressu re regulator isconnected to the

manifold and MUST be connected in series with the gas supply

line. If the LP/Propane conversion kit has been used, follow

instructions provided with the kitfor converting the pressure

regulator to LP/Propane use. The LP kit can be found on the

back side of the range (some models).

Care must be taken during installation of range not to obstruct

the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to the

regulator should be no more than 14 inches of water column

pressure. The inlet pressure to the regulator must be at least

1inch greater than regulator manifold pressure. Examples: If

regulator is set for natural gas 4 inch manifold pressure, inlet

pressure must be at least 5 inches; if regulator has been

converted for LP/Propane gas 10 inch manifold pressure, inlet

pressure must be at least 11 inches.

for thru'_ _ _ Edge

Fig. 4a

I the floor connection of

pipe stub and shut-off valve.J

Manual Flare Flexible Flare Union Pressure

Shutoff Union Appliance Adaptor Regulator

Valve / Conduit /

off

Service Shut-Off Valve Electric Ignition models onl_''_'4'_m__,nly___x

(Shown in ON Position).

Besure lever isin the "On" position when

installation is complete

Fig. 4b

Leak testing of the appliance shall be conducted according to

the instructions in step 4g.

The gas supply line should be 1/2" or 3/4" I.D.

3. Seal wall openings.

Seal any openings inthewall behind the range and in thefloor

under the range after gas supply line is installed.

_..__J_Gas Shut-Off Valve

(shown in the

"ON" position,)

Fig. 4c

Page 5

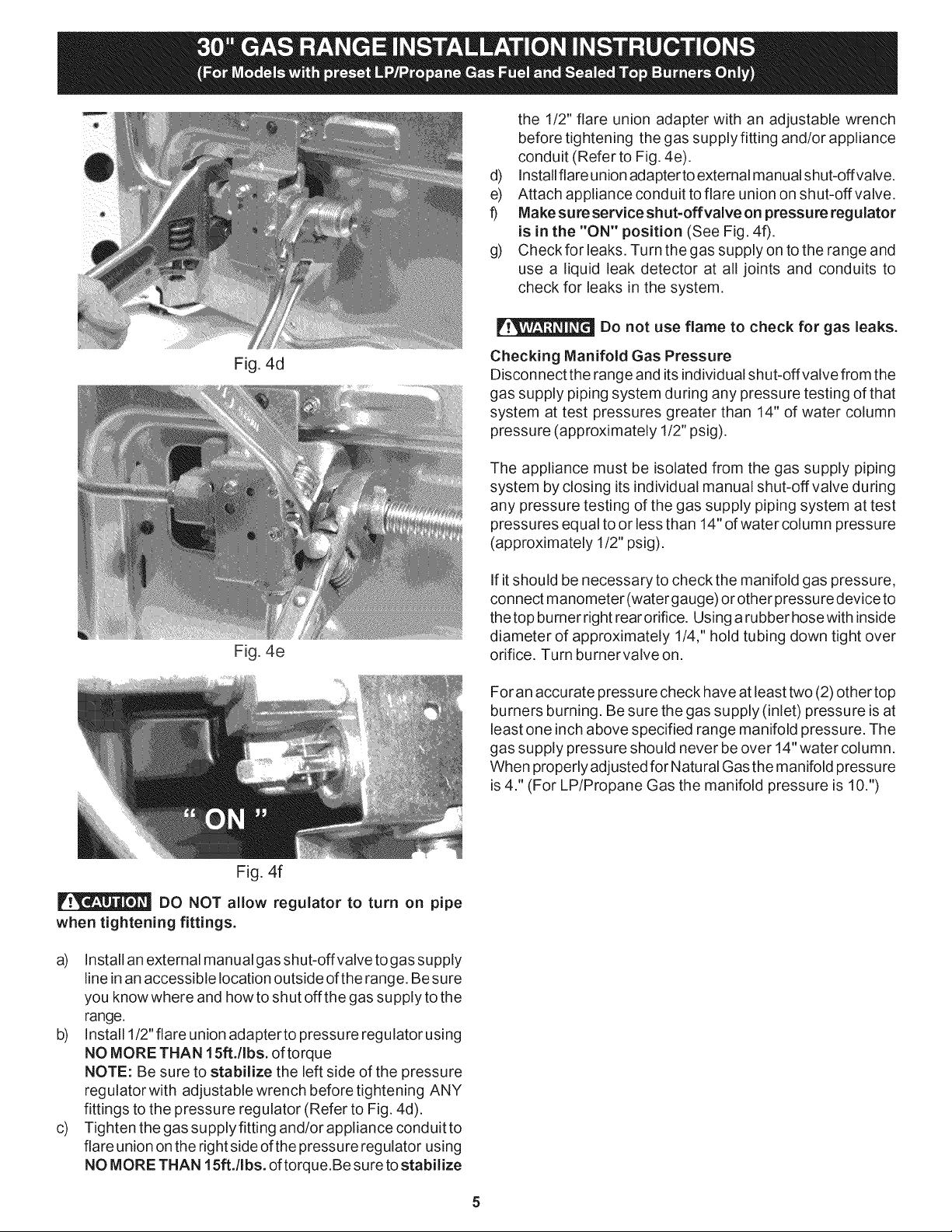

the 1/2" flare union adapter with an adjustable wrench

before tightening the gas supplyfitting and/or appliance

conduit (Refer to Fig. 4e).

d)

Install flare union adapter to external manual shut-offvalve.

e)

Attach appliance conduit toflare union on shut-off valve.

f)

Make sure service shut-offvalve on pressure regulator

is in the "ON" position (See Fig. 4f).

g)

Check for leaks. Turn the gas supply on to the range and

use a liquid leak detector at all joints and conduits to

check for leaks in the system.

Do not use flame to check for gas leaks.

Fig. 4d

Fig. 4e

Checking Manifold Gas Pressure

Disconnect the range and its individual shut-offvalve from the

gas supply piping system during any pressure testing of that

system at test pressures greater than 14" of water column

pressure (approximately 1/2" psig).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 14" of water column pressure

(approximately 1/2" psig).

If itshould be necessary to check the manifold gas pressure,

connect manometer (water gauge) or other pressure device to

the top burner right rear orifice. Using a rubber hose with inside

diameter of approximately 1/4," hold tubing down tight over

orifice. Turn burnervalve on.

For an accurate pressure check have at least two (2) other top

burners burning. Be sure the gas supply (inlet) pressure is at

least one inch above specified range manifold pressure. The

gas supply pressure should never be over 14" water column.

When properly adjusted for Natural Gas the manifold pressure

is 4." (For LP/Propane Gas the manifold pressure is 10.")

Fig. 4f

DO NOT allow regulator to turn on pipe

when tightening fittings.

a) Install an external manualgas shut-offvalve togas supply

line inanaccessible location outside of the range. Besure

you know where and how to shut off the gas supply to the

range.

b) Install 1/2" flare union adapterto pressure regulator using

NO MORE THAN 15ft./Ibs. of torque

NOTE: Be sure to stabilize the left side of the pressure

regulator with adjustable wrench before tightening ANY

fittings to the pressure regulator (Refer to Fig. 4d).

c) Tighten the gas supply fitting and/or appliance conduit to

flare union on the right side of the pressure regulator using

NO MORE THAN 15ft./Ibs. oftorque.Be sure tostabilize

Page 6

5. Read these electrical connection details first Grounding instructions

then connect electricity to range.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with astandard

Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

3-prong grounding wall receptacle to minimize the possibility

of electric shock hazard from this appliance, The customer

should have the wall receptacle and circuit checked by a

Electric Requirements: A dedicated, properly grounded and

polarized branch circuit protected bya 15amp. circuit breaker

qualified electrician to make sure the receptacle is properly

grounded and polarized,

or time delay fuse. See serial plate for proper voltage.

Extension Cord Precautions:

Because of potential safety hazards under certain conditions,

we strongly recommend against the use of any extension

cord. However, if you still elect to use an extension cord, it is

absolutely necessary that it be a UL listed 3-wire grounding

type appliance extension cord and that the current carrying

rating of the cord inamperes be equivalent to or greater than

the branch circuit rating. Such extension cords are obtainable

through your local service organization.

PLEASE READ CAREFULLY! For personal

safety, this product must be properly grounded.

Preferred Method

DO Not, Under _'_

Any Circumstances, I

Cut, Remove, |

or Bypass the J

rounding Prong..,,/

Power Supply

Grounding

Type

Wall

Receptacle

_1_ Cord with

_ 3=Prong

_ Grounding

Plug

6. Assembly of the Burner Caps and Burner

Grates:

It isvery important to makes sure that all of the Surface Burner

Caps and Surface Burner Grates are installed correctly and in

the correct locations,

Please Note: The burner heads are secured to the

cooktop. THE COOKTOP IS NOT REMOVABLE. Do not

attempt to remove or lift the cooktop.

REMEMBER -- DO NOT ALLOW SPILLS, FOOD,

CLEANING AGENTS OR ANY OTHER MATERIAL TO

ENTER THE GAS ORIFICE HOLDER OPENING. Always

keep the Burner Caps and Burner Heads in place whenever

the surface burners are in use.

Where a standard two-prong wall receptacle is encountered,

it is the personal responsibility and obligation of the customer

to have it replaced with a properly grounded three-prong wall

receptacle.

DO NOT, UNDERANYCIRCUMSTANCES, CUTOR REMOVE

THE THIRD (GROUND) PRONG FROM THE POWER CORD.

Page 7

7. Electric ignition Surface Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

a. To check for proper lighting, push in and turn a surface

burner knob counterclockwise to the LITE position. You

will hear the igniter sparking (See Fig. 1).

b.

The surface burner should light when gas is available to

the top burner. Purge air from supply lines by leaving knob

in the LITE position until burner ignites. Each burner

should light within four (4) seconds in normal operation

after air has been purged from supply lines.

c. Visually check that burner has lit. Once the burner lights,

the control knob should be turned out of the LITE position.

d.

There are separate electrodes (igniters) for each burner.

Try each knob separately until all burner valves have been

checked.

Test to verify if "LOW" setting should be adjusted

a. Push in and turn control to LITE until burner ignites.

b. Push in and quickly turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

e. Insert a thin-bladed screwdriver into the hollowvalve stem

and engage the slotted screw inside. Flame size can be

increased or decreased with the turn of the screw. Turn

counterclockwise to increaseflame size. Turn clockwise

to decrease flame size.

Burner Flame Size

Main

Top

Adjust flame until you can quickly turn knob from LITE to

LOWEST POSITION without extinguishing the flame, Flame

should be as small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

Operation of Oven Burners and

/

\

Fig. 1

8. Adjust the "LOW" Setting of Surface Burner

Valve (Linear Flow Valves Only):

To

Surface

Burner

Oven Adjustments

9. Electric Ignition Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power,

The oven burner isequipped with an electric control system as

well as anelectric oven burner igniter. Ifyour model isequipped

with awaist-high broil burner, itwill also have an electric burner

igniter. These control systems require no adjustment. When

the oven is set to operate, current will flow to the igniter. Itwill

"glow" similar to a light bulb. When the igniter has reached a

temperature sufficient to ignite gas, the electrically controlled

oven valve will open and flame will appear atthe oven burner.

There is a time lapse from 30 to 60 seconds after the

thermostat isturned ON before the flame appears atthe oven

burner. When the oven reaches the dial setting, the glowing

igniter will go off. The burner flame will go "out" in 20 to 30

seconds after the igniter goes "OFF." To maintain any given

oven temperature, this cycle will continue as long as the dial

(or display) is set to operate.

After removing all packing materials and literature from the

oven:

a) Set oven to BAKE at 300°F. See Use & Care Guide for

operating instructions.

b) Within60secondstheovenburnershouldignite. Check

for properflame, and allowthe burner tocycle once. Reset

controls to off.

c) Ifyourmodel isequipped with awaist-high broiler, setoven

toBROIL. See Use &Care Guide foroperating instructions.

d) Within 60 seconds the broil burner should ignite. Check

for proper flame. Reset controls to off.

Page 8

10. Air Shutter-Oven Burner

12. Make Sure Range is Level.

Level the range by placing a level horizontally on anoven rack.

Check diagonally from front to back, then level the range by

either adjusting the leveling legs or by placing shims under the

corners of the range as needed.

Waist-High Burner

Lower

Oven Baffle

(Removable) .......

_ Air Shutter

(Self Clean Models)

_Air Shutter

o

-Lower Oven Bottom

(Removabme)

The approximate flame length of the oven burner is 1 inch

(distinct inner, blue flame).

To determine if the oven burner flame is proper, remove the

oven bottom and burner baffle and set the oven to bake at

300°F.

To remove the oven bottom, remove oven hold down screws

at rear of oven bottom. Pull upat rear, disengage front of oven

bottom from oven front frame, and pull the oven bottom out of

the oven. Remove burner baffle so that the burner flame can

be observed.

Ifthe flame is yellow incolor, increase air shutter opening size.

(See "2" in illustration below.) If the flame isa distinct blue,

reduce the air shutter opening size.

To adjust loosen lock screw (see "3" illustration below),

reposition air shutter, and tighten lock screw. Replace oven

bottom.

Oven

Burner

Tube

13.After installation is complete, make sure all

controls are left in the OFF position.

Care, Cleaning and Maintenance

Refer to the Use & Care Guide for cleaning instructions.

If removing the range isnecessary for cleaning or maintenance,

shut offgas supply. Disconnect the gas and electrical supply.

If the gas or electrical supply is inaccessible, lift the unit

slightly at the front and pull out away from the wall. Pull only

as far as necessary to disconnect the gas and electrical

supply. Finish removing the unit for servicing and cleaning.

Reinstall in reverse order making sure to level the range and

check gas connections for leaks. See page 3,

step 1for proper anchoring instructions.

Before You Call for Service

Read the "Before You Call" and operating instruction sections

in your Use & Care Guide. It may save you time and expense.

The list includes common occurrences that are not the result

of defective workmanship or materials in this appliance.

Refer tothe warranty inyour Use &Care Guide for our toll-free

service number and address. Please call or write ifyou have

inquiries about your range product and/or need to order parts.

Model and Serial Number Location

For sealed burner ovens, the identification plate is located on

the right-hand surface of the oven front frame at the storage or

warmer drawer; or the lower panel area.

Lock Screw

®

(_Air Shutter =_

11.Air Shutter-Broil Burner

The approximate flame length of the broil burner is 1 inch

(distinct inner, blue flame).

To determine if the broil burner flame is proper, set the oven

to broil.

Ifthe flame is yellow incolor, increase air shutter opening size.

(See "2" in illustration above.) Ifthe flame is a distinct blue,

reduce the air shutter opening size.

To adjust, loosen lock screw (see "3" in illustration above),

reposition air shutter, and tighten lock screw.

Orifice

Hood

When ordering parts for or making inquires about your range,

always be sure to include the model and serial numbers and

a lot number or letter from the identification plate onyour range.

Your identification plate also tells you the rating of the burners,

the type of fuel and the pressure the range was adjusted for

when it left the factory.

Open warmer drawer,

Serial plate location is here

Page 9

LA INSTALACION Y CUALQUIER TIPO DE SERVICIO DEBERAN REALIZARLO UN INSTLADOR

CUALIFICADO.

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA USO DEL iNSPECTOR LOCAL Y

PARA REFERENCIAS FUTURAS.

Si no se sigue con exactitud la informaci6n que se

proporciona en el presente manual, podria producirse fuego o

luna explosi6n y causar graves dahos a la propiedad, personales

[e incluso la muerte.

PARA SU SEGURIDAD:

mNo almacene, ni utilice gasolina o cualquier otto tipo de liquidos

o gases inflamables cerca de esta o de cualquier otra

aplicaci6n de este tipo.

tuQUE DEBE HACER SI HUELE A GAS:

• No intente encender ninguna de las aplicaciones.

• No toque ning_n interruptor el_ctrico, ni utilice los tel6fonos

que pueda haber en el edificio.

• Aviseinmediatamentea laempresa desuministrode gasdesde untel6fono

en ei exterior del edificio. Siga las instrucciones que le proporcione la

empresa desuministro de gas.

• Sino pudiera ponerse en contacto con laempresa de suministro de gas,

avise deinmediato alcuerpo de bornberos de su Iocalidad.

-- La instalaci6n y cualquier tipo de servicio deber& realizarlo un

instalador cualificado, una agencia de reparaciones certificada

o la empresa de suministro de gas.

DIMENSIONES

TOTALES DE 253/4"

LA COCINA 1/4" de la puerta

al manga

lateral Minimo

alaladesambOSestufa:de5" "5"-_ _r- .......

Refiera a su placa serial para la

certificaci6n aplicable de la agencia

gTodas las cocinas

pueden volcar

ePueden )roducirse

dahos personales

o lnstale el dispositivo

antivuelco que se

suministra con la cocina

• Consulte las instrucciones

de instalaci6n

Electrodomesticos instalados en el

estado de Massachusetts (vea la pagina

107

1_ 1_-13"_1

18" Profundidad m_xima para /-

M[nimo armarios por encima de la [

_, parte superior de la cocina. L_

" ..........................................

Dimensiones y distancias

1. Ubicaci6n -- Compruebe el lugar de instalaci6n de

la cocina. Compruebe que los suministros de gas y

electricidad son los adecuados y la estabilidad del

suelo.

2. Las dimensiones que se muestran son las que deben

utilizarse. Las dimensiones que se proporcionan

dejar_n el espacio minimo. La superficie de contacto

debe ser s61ida y estar nivelada.

pin 316259360 En/Sp (0809)

_ 30"----*

No de ar ningun espacio pot debajo de la parte superior

de a coc na y a parte trasera.

Utilice el tipo de combustible adecuado

Antes de conectarlo:

Su cocina se ha disehado para funcionar solamente con gas

propano/gas licuado de petr61eo

Instrucciones importantes para el comprador:

Guarde estas instrucciones junto con la Guia

de uso y mantenimiento para referencias

futuras.

English- Pages 1-8

Page 10

Instrucciones importantes para el instalador

1. Lea todas las instrucciones que se proporcionan en este manual

de instalaci6n antes de comenzara instalar la cocina.

2. Retire todo el material de embalaje de los compartimentos del

homo antes de conectar el suministro de energ iael6ctrica y degas

a la cocina.

3. Siga siempre todos los c6digos y normativas locales referentes a

instalaci6n de cocinas.

4. Asegt_rese de que el compradorguarde estas instrucciones.

Instrucciones importantes para el comprador

1. Guarde estas instrucciones junto con la Guia de uso V

mantenimiento para referencias futuras.

INSTRUCCIONES DE SEG UIRDAD IMPORTANTES

La instalaci6n de esta cocina deber_ realizarse de acuerdo a la

normativa local o, en caso de que no existiera, de acuerdo a la norma

National Fuel Gas Code ANSI Z223.1--Qltima edici6n, si la instalaci6n

se realiza en Estados Unidos.

Si la cocina se instala en una casa m6vil (caravana), la instalaci6n

debera realizarse de acuerdo a los est_ndarde seguridad Manufactured

Home Construction and Safety Standard (Est_ndar de seguridad y

construcci6n de casa prefabricadas), Titulo 24 CFR, Secci6n 3280

[anteriormente denominada Federal Standard for Mobile Home

Construction andSafety(Est_ndar federal paraseguridad yconstrucci6n

de casas prefabricadas), Titulo 24, HUD (Secci6n 280)] o, en caso de

quedichoestandar nosea aplicable, deber_ seguirse la norma marcada

por el Standard for Manufactured Home Installations, ANSI/NCSBCS

A225.1, o bien, toda la normativa legal existente referente a casas

m6viles.

Eldise_o deestacocina posee lacertificaci6n de CSAInte rnational. Del

mismo modo que sucede con otras aplicaciones que utilizan gas y

generan calor, existen ciertas recomendaciones de seguridad que

deberan seguirse siempre. Lea con detenimiento la Guia de uso V

mantenimiento.

-AsegQrese de que un instalador cualificado o un t6cnico del servicio

de reparaciones certifica que su cocina se ha instalado y posee una

toma de tierra adecuada.

- Esta cocina deber_ poseer una toma de tierra adecuada de acuerdo

a la normativa local o bien, si no existiera, de acuerdo a Io

establecido en el c6digo National Electrical Code ANSI/NFPA N°

70-- _ltima edici6n si se instala en los Estados Unidos. Consulte las

instrucciones de instalaci6n de la toma de tierra que se proporcionan

en la p_gina 5.

-Antes de instalar la cocina en una zona con recubrimiento de lin61eo

o con cualquier otro tipo de suelo sintetico, deber_ asegurarse de

que el recubrimiento del suelo podr_ soportar temperaturas que

superen 32°C la temperatura ambiente sin que se deterioren, se

resquebrajen o pierdan color. No instale la cocina sobre suelos

enmoquetados a no ser que se coloque un recubrimiento de

protecci6n o una I_mina de aislamiento de 1/4" contrachapada para

aislar la cocina de la moqueta.

- AsegQrese de que las cubiertas que se coloquen alrededor de la

cocina puedan soportar el calor que genere la cocina.

- No obstruya el flujo de aire de combusti6n del orificio de ventilaci6n,

ni alrededor de la base o entre el panel frontal inferior de la cocina.

No toque las aperturas de ventilaci6n, ni las superficies adyacentes

ya que es posible que se calienten en exceso cuando el homo est6

en funcionamiento. Esta cocina requiere aire fresco para que la

combusti6n del quemador sea la adecuada.

= No se deben usar las cortinas de aire o cualquier otra

campana de ventilaci6n superior que sople aire hacia

abajo sobre la estufa a gas a menos que la campana de

ventilaci6n y la estufa hayan sido dise_adas, probadas y

certificadas pot un laboratorio de pruebas independiente

para el uso combinado de la una con la otra.

No deje nunca nJSos solos o desatendJdos en

la zona en la que se utJlJce la aplJcacJ6n. Conforme vayan

creciendo los nJSos, deber_ explicarles el modo correcto de

utilizar este tJpo de aplicacJones. No deje nunea abJerta la

puerta del homo si la coeina se va a quedar desatendida.

No se suba, se apoye o se sJente en las puertas

o en los cajones de esta eoeJna ya que podrian producirse

graves daSos personales yen la propJa cocJna.

No almacene artJculos que puedan Ilamar la atenci6n de

nJ_os en los armarios que haya encima de lacocJna. CualquJer

nJSo podrJa sufrJr quernaduras de gravedad al subirse en la

cocJna para alcanzar dJchos objetos.

Para evJtar tenet que alcanzar cualquJer objeto que se

encuentre pot eneJma de los quemadores de la cocina, evite

la Jnstalaeibn de armarios encJma de lamJsma.

Ajusteel tamaSo de lallama del quemadorde tal modo que no

rebase los IJmJtes de los cazos o utensJlios que se utJlieen

para cocJnar. Una llama exeesiva puede set pelJgrosa.

No utJlJceel homo como lugar de almacenamiento. Si Io hace

pueden produeJrse situacJones de pelJgro reales.

No utJlJcenunea la coeina para calentar la habJtaci6n. Un uso

prolongado de la cocina en espaeios sin la ventJlaci6n

adeeuada es pelJgroso.

No almacene gasolJna nJcualquier otto tJpo de combustible

o gas Jnflamable cerca de la cocJna o de eualquJer otto tJpo de

aplJcaci6n. Puede producJrse fuego o una explosJ6n.

Coloque todos los controles de la coeina en la posJci6n de

"apagado" despu6s de haber utilizado la funci6n de

temporizaei6n programable.

PARA MODELOS AUTOLIMPIABLES:

Retire la parrilla, alimentos o eualquJer otto utensJlio antes

de actJvar esta funeJ6n. Retire con un paso sJ hay un

exeeso de derrames. SJga las JnstruccJones de IJmpJeza

que se proporcJonan en la GuJa de uso y mantenJmiento.

• A dJferencJa que las cocJnas de gas est_ndar, ESTA PLACA

NO SE PUEDE RETIRAR. No Jntente levantar la placa.

Electrodomesticos instalados en el estado de Massachusetts:

Este electrodomestico solo puede ser instalado en elestado de

Massachusetts por un professional de plomeria oinstalador de

equipos de gas. Cuando se utilice un conector de gas flexible, este

no debe exceder los tres 3pies (36 pulgadas) de Iongitud. Se debe

instalar una valvula de manejo degas tipo "T' en la linea de

alimentacion de gas de este electrodomestico.

NO INTENTE ENCENDER EL HORNO DE

IGNICION ELECTRICA DURANTE UN APAGON DE LUZ.

COLOQUE TODOS LOS CONTROLES EN LA POSIClON DE

"APAGADO" CUANDO SE PRODUZCAN SITUAClONES DE

ESTETIPO.

El encendedor el6ctrico, volvera aencenderse automaticamente

al volver a conectarse el suministro de energia el6ctrica tras un

apag6n si se han dejado los controles en la posici6n de

"ENCENDIDO".

Si se produce un apag6n el6ctrico cuando est6 utilizando la

aplicaci6n, los quemadores de superficie continuaran en

funcionamiento y podr_, encenderlos con una cerilla.

Coloque una cerilla encendida al lado del quemador y, a

continuaci6n, gire lentamente el mando hasta colocarlo en

a posici6n LITE de encendido. Extreme las precauciones la

encender el quemador de este modo.

10

Page 11

Antes de cornenzar

Herramientas que va a necesitar

Para patas de nivelaciOn y rnontura anti-vuelco:

• Llave ajustable o a =cates .......

• Llave para apretar tuercas de 5/16" o un destornillador de

cabeza plana

• Taladro elOctrico y una broca de 1/8" (broca de taladro de

hormigOn de 5/32" si se instala sobre hormigOn)

Para la conexidn al suministro de gas:

• Llave grifa -_

Para el ajuste de la llama de los quemadores:

• Destornilladores de estrella _ y

de cabeza plana _:_

Para la conversion a gas (PL/Propano o gas natural):

• Llave de boca de 1/2"

Material adicional que va a necesitar

• Vb,lvula de desconexiOn de la linea de gas _,_._,_

• Sellador para uniones de tuberias que resista la acciOn del

gas propano/PL

Un conducto de metal flexible (1/2" NPT x 3/4" o de 1/2" de

D.I.) con diseSo certificado por CSA International. Ya que

las tuberias rigidas restringen el movimiento de la cocina, se

recomienda el uso de tuberias flexibles nuevas (de entre

1,20 a 1,50 mts) durante la instalaciOn y cada vez que se vaya

a instalar de nuevo o se cambie de lugar posteriormente.

• Utilice siempre los dos (2) adaptadores de campana (1/

2" NPT x 3/4" o de 1/2" D.I.) que se suministran con el

conducto flexible nuevo para la conexiOn de la cocina.

Pasos para la instalacion

1. Advertencia de seguridad irnportante sobre las

instrucciones de instalaciOn de la rnontura anti-vuelco

Para reducir el riesgo de que se vuelque la cocina, 6sta debera

asegurarse al suelo mediante la montura especial anti-vuelco

que debera sujetarse al mismo del modo adecuado con los

tornillos que se suministran. Si no se instala del modo adecuado

esta montura, la cocina esta expuesta a volcarse si se coloca

un peso excesivo sobre una puerta abierta o en el caso de que

un niSo se agarre a la misma e intente subirse a ella. Estas

situaciones pueden provocar graves daSos personales pot el

derramamiento de liquidos muy calientes o bien, por el peso de

la cocina en sL

Si en algOn momento se cambia de lugar la cocina, deberan

cambiarse de lugar tambiOn e instalarse de nuevo las monturas

anti-vuelco.

Estas instrucciones explican el modo de instalar la cocina

sobre madera o cemento y el modo de sujetarla a la pared o

al suelo. Si se instala sujeta a la pared, debera asegurarse de

que los tornillos se introducen completamente en la pared

seca y se aseguran en madera o metal. Cuando sujete la

cocina al suelo o a la pared, deberb, asegurarse de que los

tornillos no perforan ningOn cable elOctrico o tuberias.

I

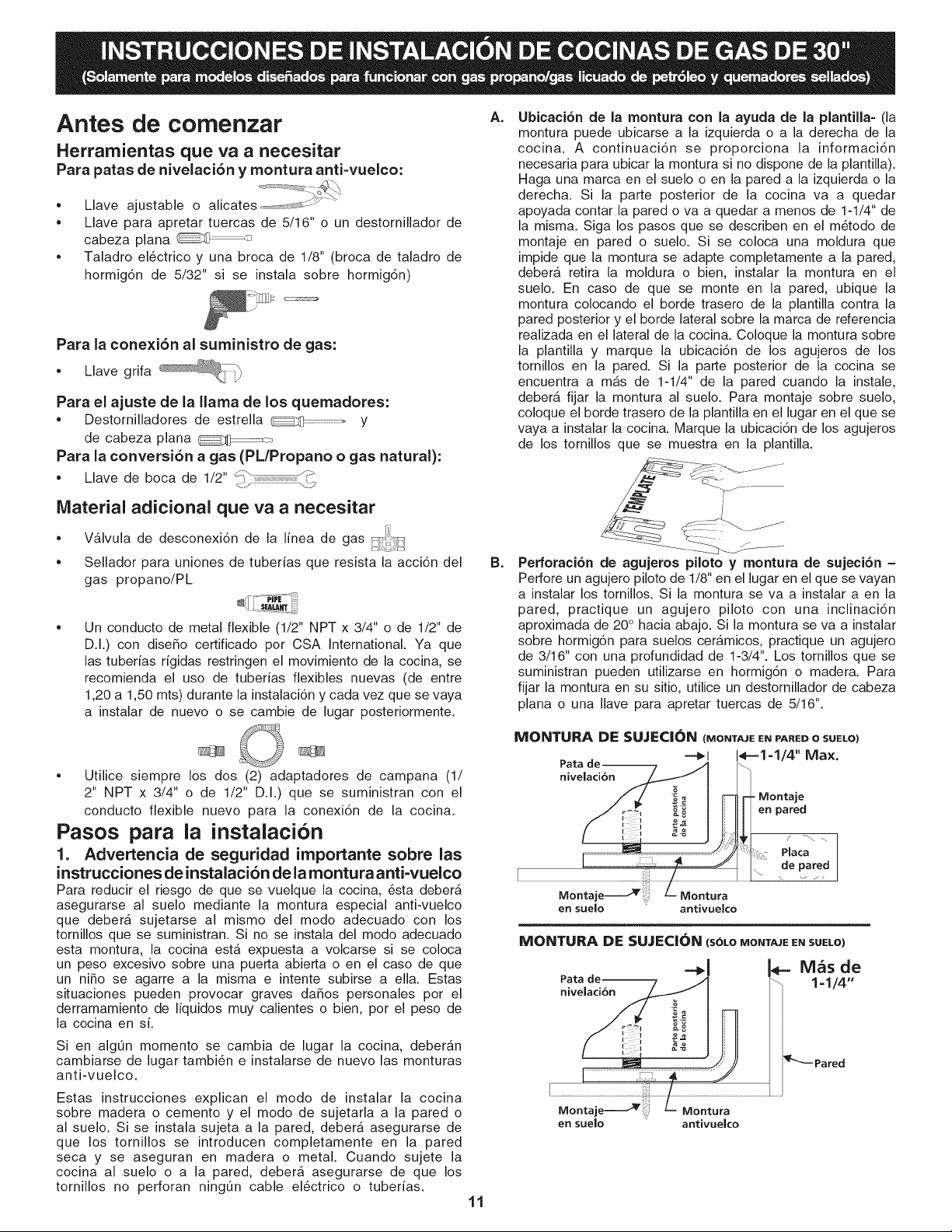

A. UbicaciOn de la montura con la ayuda de la plantilla= (la

montura puede ubicarse a la izquierda o a la derecha de la

cocina. A continuaciOn se proporciona la informaciOn

necesaria para ubicar la montura si no dispone de la plantilla).

Haga una marca en el suelo o en la pared a la izquierda o la

derecha. Si la parte posterior de la cocina va a quedar

apoyada contar la pared ova a quedar a menos de 1-1/4" de

la misma. Siga los pasos que se describen en el mOtodo de

montaje en pared o suelo. Si se coloca una moldura que

impide que la montura se adapte completamente a la pared,

deberb, retira la moldura o bien, instalar la montura en el

suelo. En caso de que se monte en la pared, ubique la

montura colocando el borde trasero de la plantilla contra la

pared posterior y el borde lateral sobre la marca de referencia

realizada en el lateral de la cocina. Coloque la montura sobre

la plantilla y marque la ubicaciOn de los agujeros de los

tornillos en la pared. Si la parte posterior de la cocina se

encuentra a mas de 1-1/4" de la pared cuando la instale,

debera fijar la montura al suelo. Para montaje sobre suelo,

coloque el borde trasero de la plantilla en el lugar en el que se

vaya a instalar la cocina. Marque la ubicaciOn de los agujeros

de los tornillos que se muestra en la plantilla.

.....

B. Pefforaeidn de agujeros piloto y montura de sujeeidn -

Perfore un agujero piloto de 1/8" en el lugar en el que se vayan

a instalar los tornillos. Si la montura se va a instalar a en la

pared, practique un agujero piloto con una inclinacidn

aproximada de 20 ° hacia abajo. Si la montura se va a instalar

sobre hormigdn para suelos cerfimicos, practique un agujero

de 3/16" con una profundidad de 1-3/4". Los tornillos que se

suministran pueden utilizarse en hormigOn o madera. Para

fijar la montura en su sitio, utilice un destornillador de cabeza

plana o una Ilave para apretar tuercas de 5/16".

MONTURA DE SIJ.IECI!I_N (MONTAJEENPARED0 SLIELO)

--_1 I'q'--1=1/4" Max.

nivelaciOn

- Montaje

en pared

Plata

de pared

MONTIJRA DE SLIJECIClN (SOLOMONTAJEENSUELO)

nivelad6n 1=1/4"

Montaje_ _ii Montura

en suelo antivueko

11

Page 12

C=

Nivelacion y colocacion de la cocina - Para nivelar la

cocina, debera ajustar las cuatro (4) patas de nivelaci6n

con una Ilave. Nota: Es necesario mantener un espacio

minimo de 1/8" entre el fondo de la cocina y la pata de

nivelaciOn para dejar espacio suficiente para instalar la

montura de sujeciOn. Compruebe los ajustes realizados

con un nivel de burbuja de aire. Deslice la cocina hacia

atras hasta colocarla en su posici6n. Retire el panel

posterior o el caj6n de almacenamiento para comprobar

que la pata de nivelaciOn posterior se introduce y queda

completamente fijada en la montura anti-vuelco. En

modelos que posean un caj6n para calentar o un grill,

debera sujetar el borde trasero superior de la cocina e

intentar, con cuidado, inclinarlo hacia adelante.

Lateral de -_

la cocina

2. Conexi6n a un suministro de gas adecuado.

Esta unidad se hadise_ado para funcionar con un colector de

gas natural de 4". El colector esta conectado a un regulador

de presi6n convertible y DEBE conectarse en serie con la linea

de suministro de gas. Sise ha utilizado eljuego de conversi6n

para PL/Propano, siga las instrucciones que se proporcionan

con el juego de conversi6n. Este juego podra encontrarlo en

la parte posterior de la cocina. Extreme las precauciones

durante la instalaci6n de la cocina par no obstruir el flujo del

aire de combusti6n y ventilaci6n (algunos modelos).

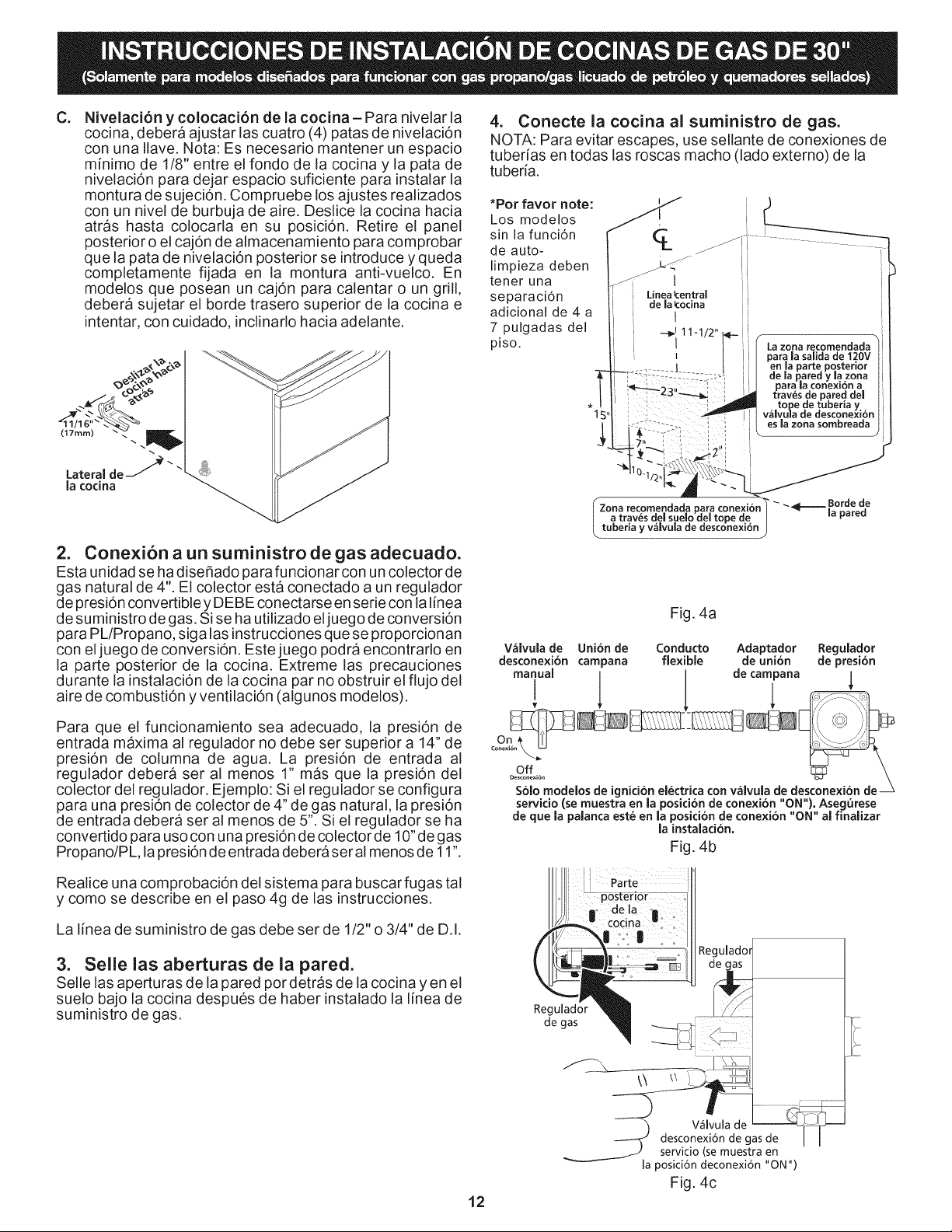

4. Conecte la cocina al suministro de gas.

NOTA: Para evitar escapes, use sellante de conexiones de

tubedas en todas las roscas macho (lado externo) de la

tubed&

*Pot favor note:

Los modelos

sin la funci6n

de auto-

limpieza deben

tener una

separaci6n

adicional de 4 a

7 pulgadas del

piso.

15"

%

t

Linea Icentral

de la k:ocina

I

:i

para la salida de 120V

en la parte posterior

de la pared y lazona

para la conexlon a

traves _Jepared del

tope de tubeda y

t La zona recomendada

v,_lvu|a de desconexibn

es _azona sombreada

4-- Borde de

la pared

Fig. 4a

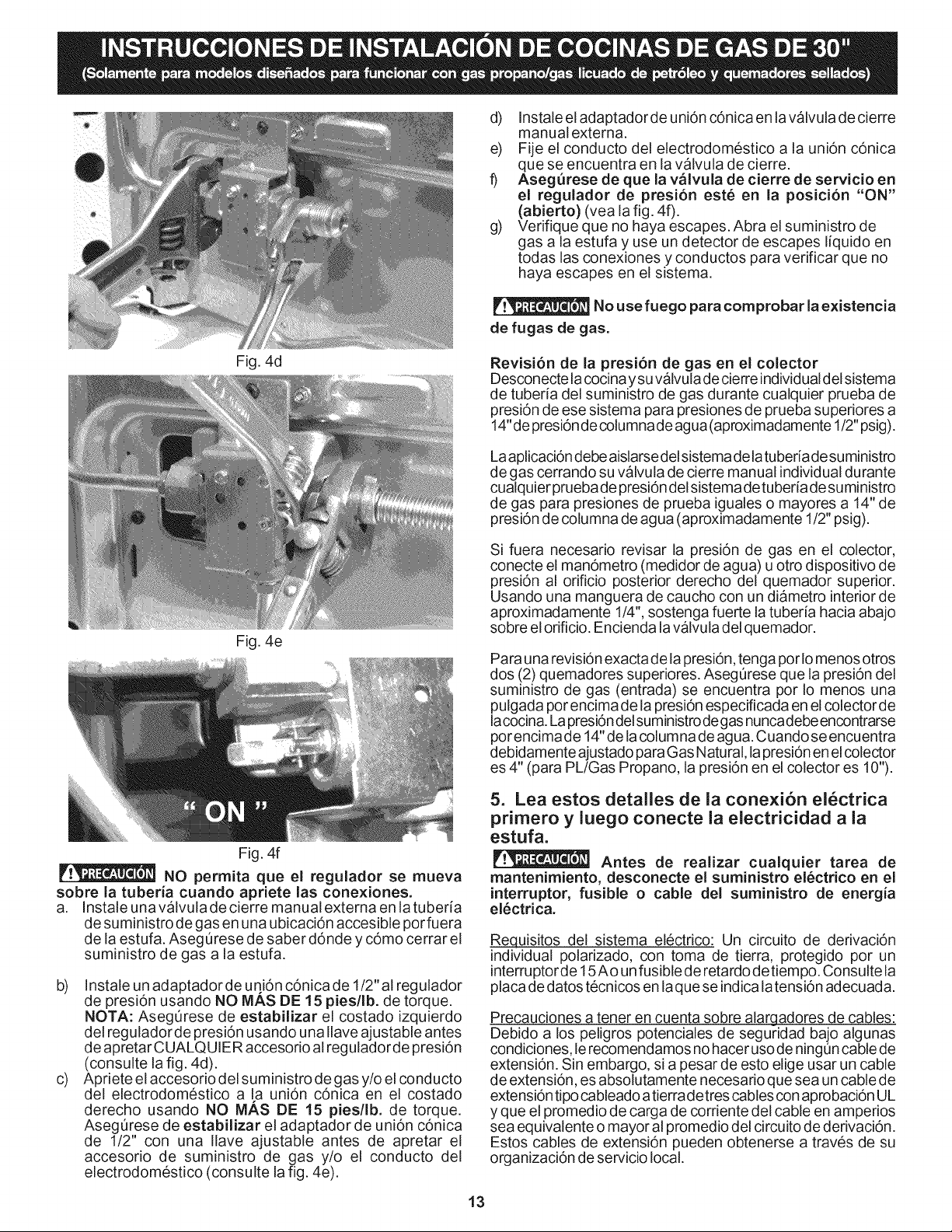

V_lvula de Uni6n de Conducto Adaptador Regulador

desconexi6n campana flexible de uni6n de presi6n

manual / I de campana /

Para que el funcionamiento sea adecuado, la presi6n de

entrada maxima al regulador no debe ser superior a 14" de

presi6n de columna de agua. La presi6n de entrada al

regulador debera ser al menos 1" mas que la presi6n del

colector del regulador. Ejemplo: Si el regulador se configura

para una presiOn de colector de 4" de gas natural, la presi6n

de entrada debera ser al menos de 5". Si el regulador se ha

convertido para uso con una presi6n de colector de 10"de gas

Propano/PL, la presi6n de entrada debera ser al menos de 11".

Realice una comprobaci6n del sistema para buscar fugas tal

y como se describe en el paso 4g de las instrucciones.

La linea de suministro de gas debe ser de 1/2" o 3/4" de D.I.

3. Selle ias aberturas de ia pared.

Selle las aperturas de la pared pot detras de la cocina yen el

suelo bajo la cocina despues de haber instalado la linea de

suministro de gas.

Solo modelos de ignici6n el_ctrica con valvula de desconexiOn de

servicio (se muestra en la posicion de conexi6n "ON"). Asegurese

de que la palanca este en la posicion de conexion "ON" al finalizar

la instalaci6n,

Fig. 4b

Regulado_

Regulador

de gas

desconexi6n de gas de I I

servicio (se muestra en

la posici6n deconexi6n "ON")

Fig. 4c

12

Page 13

d) Instaleeladaptadordeuni6nc6nicaenlavalvuladecierre

manualextema.

e) Fijeelconductodelelectrodomesticoalauni6nc6nica

queseencuentraenlavalvuladecierre.

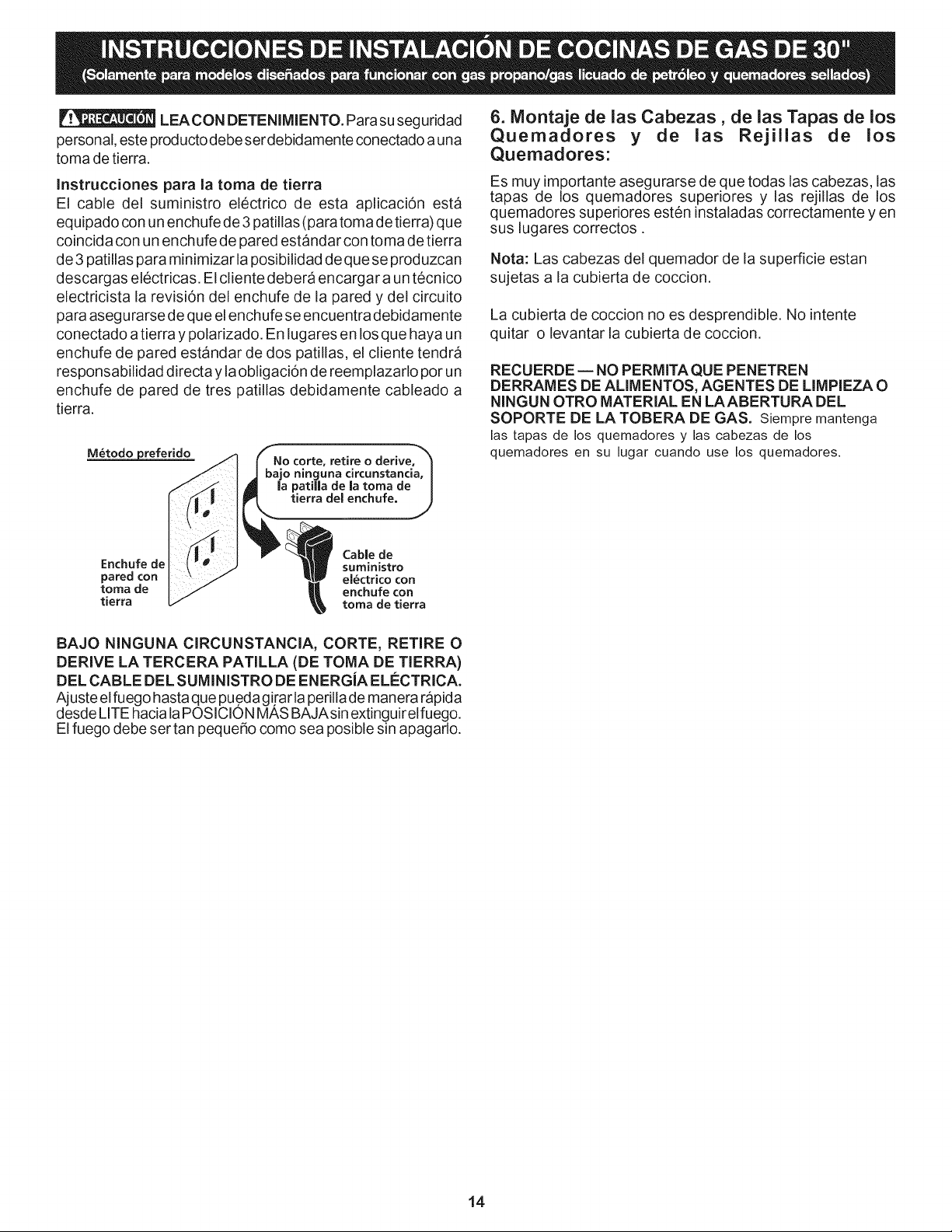

f) Aseg_rese de que la v_lvula de cierre de servicio en

el regulador de presi6n est6 en la posici6n "ON"

(abierto) (vea la fig. 4f).

g) Verifique que no haya escapes. Abra el suministro de

gas a la estufa y use un detector de escapes liquido en

todas las conexiones y conductos para verificar que no

haya escapes en el sistema.

No use fuego para comprobar laexistencia

de fugas de gas.

Fig.4d

Fig.4e

Fig.4f

NO permita que el regulador se mueva

sobre la tuberia cuando apriete las conexiones.

a. Instale una valvula de cierre manual externa en la tuberia

de suministro de gas en una ubicaci6n accesible por fuera

de la estufa. AsegOrese de saber d6nde y c6mo cerrar el

suministro de gas a la estufa.

b) Instale un adaptador de uni6n c6nica de 1/2" al regulador

de presi6n usando NO MAS DE 15 pies/lb, de torque.

NOTA: AsegOrese de estabilizar el costado izquierdo

del regulador depresi6n usando una Ilave ajustable antes

de apretar CUALQUIER accesorio al reguladorde presi6n

(consulte la fig. 4d).

c) Apriete el accesorio del suministro de gas y/o el conducto

del electrodomestico a la uni6n c6nica en el costado

derecho usando NO IVlAS DE 15 pies/lb, de torque.

AsegQrese de estabilizar el adaptador de uni6n c6nica

de 1/2" con una Ilave ajustable antes de apretar el

accesorio de suministro de gas y/o el conducto del

electrodomestico (consulte la fig. 4e).

Revisi6n de la presion de gas en el colector

Desconecte lacocinay suvalvuladecierre individual del sistema

de tubeda del suministro de gas durante cualquier prueba de

presi6n de ese sistema para presiones de prueba superiores a

14"de presi6ndecolumnadeagua (aproximadamente 1/2"psig).

Laaplicaci6ndebeaislarsedelsistemadelatubedadesuministro

de gas cerrando su valvula de cierre manual individual durante

cualquierpruebade presi6ndelsistemadetubedadesuministro

de gas para presiones de prueba iguales o mayores a 14" de

presi6n de columna de agua (aproximadamente 1/2" psig).

Si fuera necesario revisar la presi6n de gas en el colector,

conecte el man6metro (medidor de agua) uotro dispositivo de

presi6n al orificio posterior derecho del quemador superior.

Usando una manguera de caucho con un diametro interior de

aproximadamente 1/4",sostenga fuerte la tubeda hacia abajo

sobre elorificio. Encienda lavalvula del quemador.

Para unarevisi6n exactadela presi6n, tenga porlo menosotros

dos (2) quemadores superiores. AsegQrese que la presi6n del

suministro de gas (entrada) se encuentra por Io menos una

pulgada por encima de la presi6n especificada en el colector de

lacocina. La presi6ndelsuministrodegas nuncadebeencontrarse

por encima de 14"de la columna de agua. Cuando se encuentra

debidamente ajustado paraGas Natural, lapresi6n en elcolector

es 4" (para PL/Gas Propano, la presi6n en el colector es 10").

5. Lea estos detalles de la cone×i6n ei_ctrica

primero y iuego conecte ia electricidad a ia

estufa.

Antes de realizar cualquier tarea de

mantenimiento, desconecte el suministro el6ctrico en el

interruptor, fusible o cable del suministro de energia

el6ctrica.

Requisitos del sistema electrico: Un circuito de derivaci6n

individual polarizado, con toma de tierra, protegido por un

interruptor de 15Ao unfusible de retardo de tiem po. Consulte la

placa de datos tecnicos en laque se indica la tensi6n adecuada.

Precauciones a tenet en cuenta sobre alargadores de cables:

Debido a los peligros potenciales de seguridad bajo algunas

condiciones, le recomendamos no hacer usodeningOncable de

extensi6n. Sin embargo, si a pesar de esto elige usar un cable

de extensi6n, esabsolutamente necesario que sea un cable de

extensi6n tipo cableado atierradetres cables con aprobaci6n UL

yque el promedio de carga de corriente del cable en amperios

sea equivalente o mayor al promedio del circuito de derivaci6n.

Estos cables de extensi6n pueden obtenerse a traves de su

organizaci6n de servicio local.

13

Page 14

LEACONDETENIMIENTO.Parasuseguridad

personal,esteproductodebeserdebidamenteconectadoauna

tomadetierra.

Instruccionesparala toma de tierra

El cable del suministro electrico de esta aplicaciOn esta

equipado con un enchufede 3patillas(para toma detierra) que

coincida con un enchufe de pared estandar con toma de tierra

de 3 patillas para minimizar la posibilidad de que se produzcan

descargas electricas. El cliente debera encargar a un tecnico

electricista la revision del enchufe de la pared y del circuito

para asegurarsede que elenchufe se encuentra debidamente

conectado a tierra y polarizado. En lugares en los que haya un

enchufe de pared estandar de dos patillas, el cliente tendra

responsabilidad directa ylaobligaciOn de reemplazarlo por un

enchufe de pared de tres patillas debidamente cableado a

tierra.

M_todo prefeddo ('f-No torte, retire o derive_

J bajo ninguna circunstancia, I

_la patilla de la toma de|

i !'errade'enchufe" J

I_ Cable de

Enchufe de suministro

pared con el_ctrico con

toma de enchufe con

tierra toma de tierra

6. Montaje de las Cabezas, de ias Tapas de los

Quemadores y de ias Rejiilas de los

Quemadores:

Es muy importante asegurarse de que todas las cabezas, las

tapas de los quemadores superiores y las rejillas de los

quemadores superiores esten instaladas correctamente y en

sus lugares correctos.

Nota: Las cabezas del quemador de la superficie estan

sujetas a la cubierta de coccion.

La cubierta de coccion no es desprendible. No intente

quitar o levantar la cubierta de coccion.

RECUERDE--NO PERMITAQUE PENETREN

DERRAMES DE ALIMENTOS, AGENTES DE LIMPIEZA O

NINGUN OTRO MATERIAL EN LAABERTURA DEL

SOPORTE DE LA TOBERA DE GAS. Siempre mantenga

las tapas de los quemadores y las cabezas de los

quemadores en su lugar cuando use los quemadores.

BAJO NINGUNA ClRCUNSTANCIA, CORTE, RETIRE O

DERIVE LA TERCERA PATILLA (DE TOMA DE TIERRA)

DEL CABLE DEL SUMINISTRO DE ENERGiA ELleCTRICA.

Ajuste elfuego hasta que pu,edagirar la perilla de manera rapida

desde LITE hacialaPOSICION MAS BAJAsin extinguir elfuego.

El fuego debe ser tan pequeSo como sea posible sin apagarlo.

14

Page 15

7. Funcionamiento de los Controles Superiores

del Gas:

1. Coloque el utensilio de cocina sobre elquemador superior.

2. Optima la perilla de control superior y girela a la izquierda

para sacarla de la posici6n 'OFF'. (Vet Fig. 1).

3. Suelte la perillaygire ala posiciOn"LITE". Nota: Los cuatro

encendedores superiores electr6nicos emitiran chispas al

mismo tiempo. Sin embargo, solamente elquemadorque

usted esta girando se encendera.

4. Verifique visualmente si el quemador tiene una llama.

5. Gire laperilla de control a la izquierda al tama_o deseado

de llama. No es necesario colocar las perillas de control

en un ajuste particular. Use los ajustes indicadores de la

perilla para regular la llama como sea necesario. NO cocine

con la perilla de control en laposici6n 'LITE'. (El encendedor

electrOnico continuara emitiendo chispas si la perilla se

deja en laposici6n 'LITE'.)

Fig. 1

8. Ajuste la configuraci6n "LOW" ("BAJA") de la

v_lvula del quemador de superficie (s61o en

v_lvulas de flujo lineal):

Pruebe para comprobar si la configuraci6n "LOW" ("BAJA")

debe set ajustada

a. Presione haciaadentro ygire elcontrol haciaLITEhasta queel

quemadorseencienda.

b. Presione,hacia adentro y gire rapidamente la perillahacia la

POSICION MAS BAJA.

c. Si el quemador se apaga, Ileveel controlhacia la posici6n de

OFF (APAGADO).

d. Retire laperillade control del quemador desuperficie.

e. Inserteundestornilladorde hojadelgada en lavalvulahuecay

enganche el tornillo ranurado dentro. El tama_o de la llama

puedeseraumentadoodisminuidogirandoeltornillo. Girea la

izquierdaparaaumentareltama_odelallama.Girealaderecha

para disminuir el tama_o de lallama.

Tama6o del arco de encendido

del quemador

Nota: El ajuste de la mezcla de aire no es necesario en

quemadores de superficie.

--_ 5/8" 4--

Cubierta

Operaci6n en Quemadores del Homo y

Ajustes de Homo

9. Quemadores de ignici6n el_ctrica

La operaci6n de los encendores electricos debe ser revisada

luego que lacocina ylos conectores de la linea de suministro han

sido cuidadosamente revisados para descartar fugas y que la

cocina ha sido conectada a la corriente el6ctrica. El quemador

de! homo esta equipado con un sistema de control electrico asi

como un encendedor de quemador de horno el6ctrico. Si su

modelo esta equipado con un quemador de asado central

superior, tambien contara con un encendedor de quemador

electrico. Estos sistemas de control no requieren ajustes.

Cuando el homo es configurado para operar, la corriente fluira

hacia el encendedory tendra un resplandorde manera similar a

una bombilla de luz. Cuando elencendedor ha alcanzado una

temperatura suficiente para encender el gas, lavalvula del homo

controlada electricamente se abrira y el fuego aparecera en el

quemadordel homo. Hay unlapso detiempode 30 a60segundos

luegoqueeltermostatoseenciendeantesquela llamaaparezca

enelquemadordel homo.Cuandoel hornoalcanza laconfiguraci6n

del dial,elencendedor resplandeciente se apagara. La llama del

quemador desaparecera pot20 a 30 segundos despues que el

encendedor seAPAGUE. Para mantener cualquier temperatura

de homo dada, este ciclo continuara tanto como el dial (o

visualizador) este config urado para operar.

Aq

desuperficJe

Despues de retirar todos los materiales del empaque y la

literatu radel homo:

a) Fije el homo en HORNEAR (BAKE) a 300°F. Vea la Guia

para Uso y Cuidado para conocer las instrucciones de

funcionamiento.

b) En 60 segundos, el quemador del homo se encendera.

Revise que exista un fuego adecuado, y permita que el

quemador cure plasu ciclo una vez. Lleve loscontroladores

hacia off (APAGADO).

c) Si sumodelo esta equipado con unasador central superior,

fije el horno en ASAR. Vea la Guia de Uso y Cuidado para

conocer las instrucciones de funcionamiento.

d) En 60 segundos el quemador de asar debe encenderse.

Revise si existe una llama adecuada. Lleve los controles

hacia off (APAGADO).

15

Page 16

10. Obturador de Aire - Quemador del homo

12.Aseg_rese que la cocina est_ nivelada.

Nivele la cocina colocando un nivelador de manera horizontal

sobre un soporte para hornos. Revise diagonalmente desde la

parte anterior hacia atras, luegonivele lacocina ya seaajustando

las patas de nivelaci6n o colocando cu_as debajo de las

esquinas de la cocina seg0n sea necesario.

Quernador a la altura

la cintura (modelos

auto lirnpiables)

idel homo '-

(extralble! .......

_ Obturador de aire

Obturador !

de aire I

_r del

homo (extraible)

la Iongitudaproximada de la llama del quemador de homo es 1

pulgada (interiorclaro, flama azul). Para determinar si la llama del

quemador de homo es laadecuada, retire el fondo del homo y el

deflectordelquemadory fije elhomo en laopci6n homear a300°F.

Para retirarelfondo del homo, retirelostornillos de ajustedel homo

enlaparteposteriordelfondodelhomo.Jalehaciaarriba,desenganche

elfrentedelfondodel marcoanteriordel homo,yjale labasedel homo

haciaafueradeeste. Retireeldeflectordelquemadorde maneraque

la llamadelhomo pueda serobservada.

Silallama esdecoloramarillo, aumente eltama_ode laaberturadel

obturadordeaire(Veaeltama_o"2" enelgr_ficodeabajo).Si lallama

esdeazulclaro, reduzca eltama_o de laabertura delobturador de

aire.Paraajustaruntomillo decierreflojo (veaelgr_fico"3"de abajo),

vuelva acolocar elobturador deaire, y ajuste el tornillo de cierre.

Reemplace elfondo del homo.

13. Luego que la instalaci6n ha sido terminada,

asegurese que todos los controles son dejados

en ia posici6n de OFF (APAGADO).

Cuidado, Limpieza y Mantenimiento

Refierase a la Gu[a de Uso y Cuidado para conocer las

instrucciones de limpieza.

Si es necesario retirar la cocina para la limpieza o

mantenimiento, cierre el suministro de gas. Desconecte el

suministro de gas y elsuministro electrico. Si no tiene acceso

al suministro de gas o electrico, levante la unidad levemente

en el frente yseparelo de lapared. Jale s61oIo necesario para

desconectar el suministro de gas y de electricidad. Termine

de retirar la unidad para realizar el servicio tecnico y la

limpieza. Vuelva a instalar en el orden inverso asegu randose

de nivelar la cocina y revise las conexiones de gas para

descartar la existencia de fugas. Vea la pagina 3, paso 1 para

conocer las instrucciones sobre un adecuado aseguramiento

en el piso.

Antes de ilamar al servicio t_cnico

Lea las secciones "Antes de Ilamar" e instrucci6n sobre

funcionamiento en su GuiadeUso y Cuidado. Puede ayudarle

a ahorrar tiempo y dinero.

La lista incluye problemas comunes que no son resultado de

una manipulaci6n o materiales defectuosos en este artefacto.

Refierase a la garant[a en su Gu[a de Uso y Cuidado para

obtener nuestro n0mero telef6nico gratuito de servicio tecnico

y nuestra direcci6n. S[rvase Ilamarnos o escribirnos en caso

de dudas acerca del producto para su cocina y/o cualquier

requerimiento de partes.

/ del homo

11. Obturador de aire - Quemador de asado

La Iongitud aproximada de lallama del quemador de asado es 1

pulgada (interiorclaro, flama azul). Paradeterminar silaIlama del

quemador de asado es laadecuada, el homo en laopci6n asar.

Si lallama esde color amarillo, aumente eltama_o de laabertura

del obturador de aire (Vea eltama_o "2" enelgr_fico de abajo).

Si la llama es deazul claro, reduzca eltama_o de laabertura del

obturador de aire. Paraajustar untornillo de cierre flojo (vea el

gr_fico "3" de abajo), vuelva a colocar el obturador de aire, y

ajuste el tornillo de cierre.

Ubicaci6n del N6mero de Modelo y de Serie

En los homos de quemador sellado, la placa de identificaci6n

esta ubicada sobre la superficie derecha del marco anterior del

homo en elcaj6n para almacenar o calentar; o elarea del panel

inferior.

AI solicitar las partes o realizar pedidos sobre su cocina,

siempre asegOrese de incluir el nOmero de modelo y de serie

y un nOmero o letra de Iotede la placa de datos tecnicos que

se encuentra en su cocina. Su placa de datos tecnicos

tambien le indica el promedio de sus quemadores, el tipo de

combustible y la presi6n en la cual la cocina fue ajustada al

salir de la fabrica.

Ubicaci6n de la placa de datos

t_cnicos: Abra el caj6n para

almacenar o calentar que se encuentra en

16

la parte derecha del bastidor de la cocina.

Loading...

Loading...