Page 1

TABLE OF CONTENTS

Important Safety Instructions ........................... 2-3 Accessories .................................................... 24

Installatton Requirements .............................. 4-11 Fran_als ........................................................... 25

Installatton Instructions ................................ 12-19 Espa_ol ........................................................... 49

Reversmg Door ............................................ 20-23

c:_

Page 2

For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to prevent

property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in

....the vidnity °f th!s °! any °ther app!!ance:......................................................................................................................................................................................................................................................................................................................

AWARNING - RISK OF FIRE

Read all of the following instructions before installing and using this appliance:

* Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons covered

with rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place all materials in a

garbage container or make materials inaccessible to children.

* Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

* Install the clothes dryer according to the manufacturer's instructions and local codes.

* The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the

National Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian electrical code C22.I part 1.

* The gas service to the dryer must conform with local codes and ordinances and the latest edition of the National

Fuel Gas Code ANSI Z223.1, or in Canada, CAN/ACG BI49.1-2000. An individual manual shut-off valve must be

installed within 6 ft (i.83 m) of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

* The dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. i!2 (latest editions) for HONE

USE only. This dryer is not recommended for commercial applications such as restaurants, beauty salons, etc.

* Do not install a clothes dryer with flexible plastic or flexible foil venting material. Flexible venting materials are

known to collapse, be easily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase

the risk of fire.

* Do not stack a dryer on top of washer already installed on pedestal. Do not stack dryer on top of another dryer.

Do not stack washer on top of dryer. Do not stack washer on top of another washer. Do not stack dryer on top of

washer without use of manufacturer approved and correctly installed stacking kit appropriate for your model.

* The instructions in this manual and all other literature included with this dryer are not meant to cover every

possible condition and situation that may occur. Good safe practice and caution NUST be applied when installing,

operating and maintaining any appliance.

WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electrical switch; do not use any

phone in your building.

* Clear the room, building or area of all occupants.

* Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

* If you cannot reach your gas supplier, call the fire

department.

person move or lift the applianc e, ............

Save these instructions

for future reference.

Tools and materials needed for installation:

Pre-Installation Requirements

* Adjustable pliers * Carpenter's level

* Phillips, straight, & square bit * External vent hood

screwdrivers * 4-inch (!02 mm), rigid metal or

* Adjustable wrench semi-rigid metal exhaust duct work

* Pipewrench for gas supply (gas * 3-wire or 4-wire 240 volt cord kit

dryer) (electric dryer)

* @-resistant thread tape (for natural * 4 in. (!02 mm) clamp

gas or LPsupply, gas dryer)

* Gas line shutoff valve (gas dryer)

* _/2NPTunion flare adapters (x2)

and flexible gas supply line (gas

dryer)

Netal foil tape (not duct tape)

Page 3

Pleasereadallinstructionsbeforeusingthisdryer.

Exhaust Venting

Free-flowing, clear of lint buildup

4 inch (102 mm) rigid or semi-rigid ducting of

Recognize safety syrnboisr words

and labels

Safety items throughout this manual are labeled with

a WARNING or CAUTION based on the risk type as

described below:

Definitions

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DANGER indicates an imminently hazardous situation

which if not avoided will result in death or serious

injury, 240v Electric Supply (Electric Dryer)

CAUTION indicates a potentially hazardous situation E3 Test hinge and latch for function

which, if not avoided, may result in minor or moderate

injury. Electrical Power

IMPORTANT indicates installation, operation or

maintenance information which is important but not

hazard-related.

minimal length and turns

E_ NO foil or plastic venting material

E_ Approved vent hood exhausted to outdoors

Leveling

E_ Dryer is level, side-to-side and front-to-back

E3 Cabinet is setting solid on all corners

GasSupplyCGasDryer:

E_ Manual shutoff valve present in supply

E_ AIt connections sealed with approved sealer and

wrench tight

E_ Conversion kit for LPsystem

E_ Gas supply turned on

E3 No leaks present at all connections -

check with soapy water, NEVERcheck with flame

E3 Approved NEMA 10-30R or 14-30R service cord

with all screws tight on terminal block

E3 Approved strain relief installed

E3 Terminal access cover installed before initial

operation

Door Reversal

E3 Follow detailed instructions in this guide

E3 House power turned on

E3 Dryer plugged in

Final Checks

Installation Instructions and Use and Care

Guide read thoroughly

Door latches and drum tumbles when cycle

starts

Registration card sent in

Page 4

Becauseofpotentiallyinconsistentvoltagecapabilities,theuseofthisdryerwithpowercreatedbygaspowered

generators,solarpoweredgenerators,windpoweredgeneratorsoranyothergeneratorotherthanthelocalutility

companyisnotrecommended,

Electrical requirements for electric dryer

CIRCUIT - Individual 30 amp. branch circuit fused with 30 amp. time delay fuses or circuit breakers. Use separately

fused circuits for washer and dryer. DO NOT operate a washer and a dryer on the same circuit.

POWER SUPPLY- 3-wire or 4-wire, 240 volt, single phase, 60 Hz, Alternating Current.

through the neutral.

OUTLET RECEPTACLE- NEMA 10-3ORor NEMA 14-30R rece )tacie to be located so the power supply cord is accessible

when the dryer is in the installed position.

GROUNDING CONNECTION - See "Grounding requirements" in Electrical Installation section.

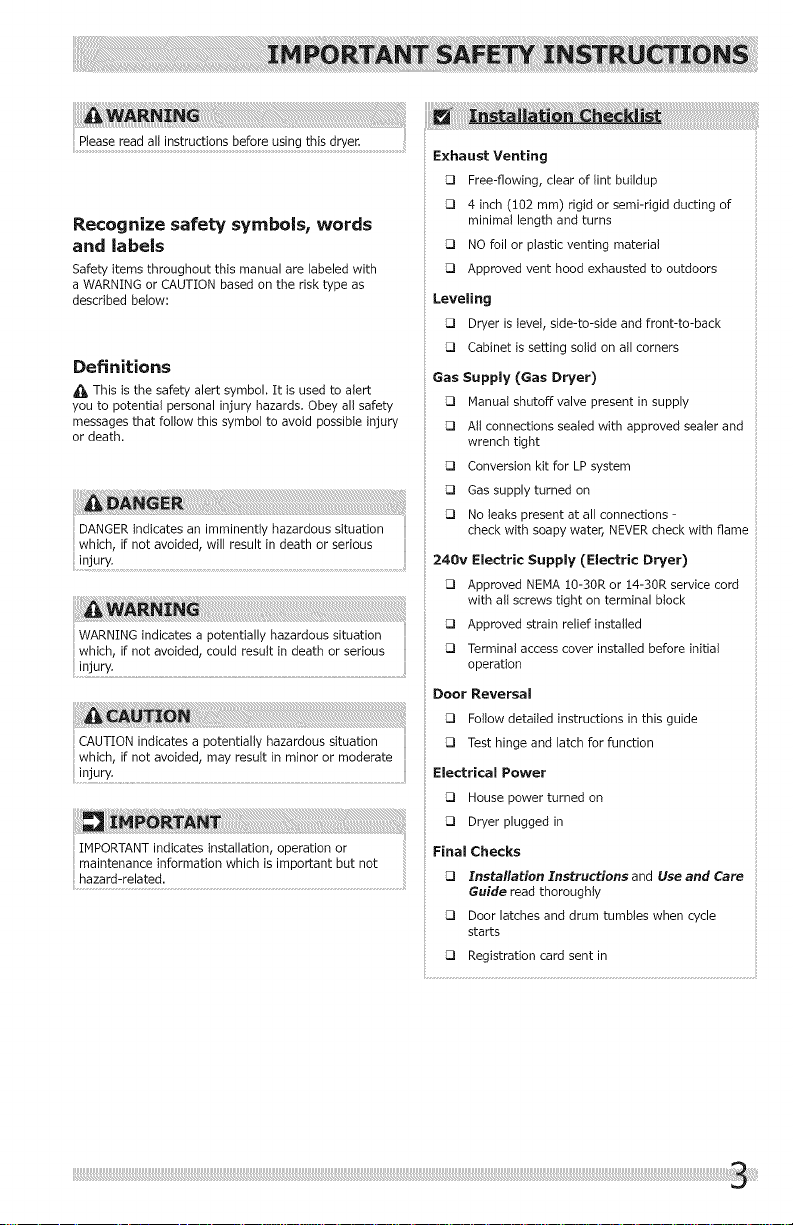

3-WIRE POWERSUPPLYCORDKIT (not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUSTemploy a 3-conductor power

supply cord NEMA 10-30 type SRDTrated at 240

volt AC minimum, 30 amp, with 3 open end spade

lug connectors with upturned ends or closed

loop connectors and marked for use with clothes

dryers. For 3-wire cord connection instructions see

ELECTRICALCONNECTIONS FOR A 3-WIRE SYSTEM.

4-WIRE POWER SUPPLYCORD KIT (not supplied)

4-wire receptacle

(NEMA type 14-30R)

The dryer MUST employ a 4-conductor power supply

cord NEMA 14-30 type SRDTor ST (as required) rated

at 240 volt AC minimum, 30 amp, with 4 open end

spade lug connectors with upturned ends or closed

loop connectors and marked for use with clothes

dryers. For 4-wire cord connection instructions see

ELECTRICALCONNECTIONS FORA 4-WIRE SYSTEM.

Page 5

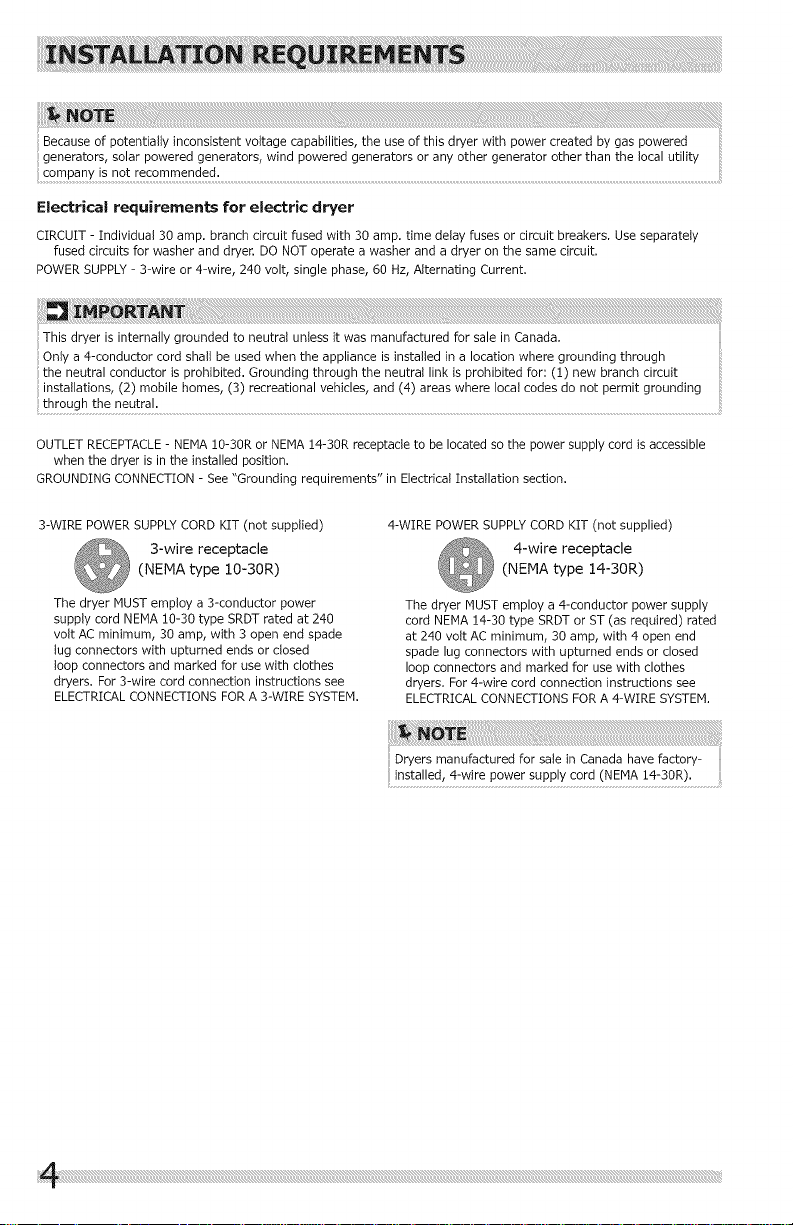

Electrical requirements for gas dryer

CIRCUIT - Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPLY- 2-wire, with ground, !20 volt, single

phase, 60 Hz, Alternating Current.

POWER SUPPLYCORD - The dryer is equipped with a 120

volt 3-wire power cord.

GROUNDING CONNECTION - See "Grounding

requirements" in Electrical Installation section.

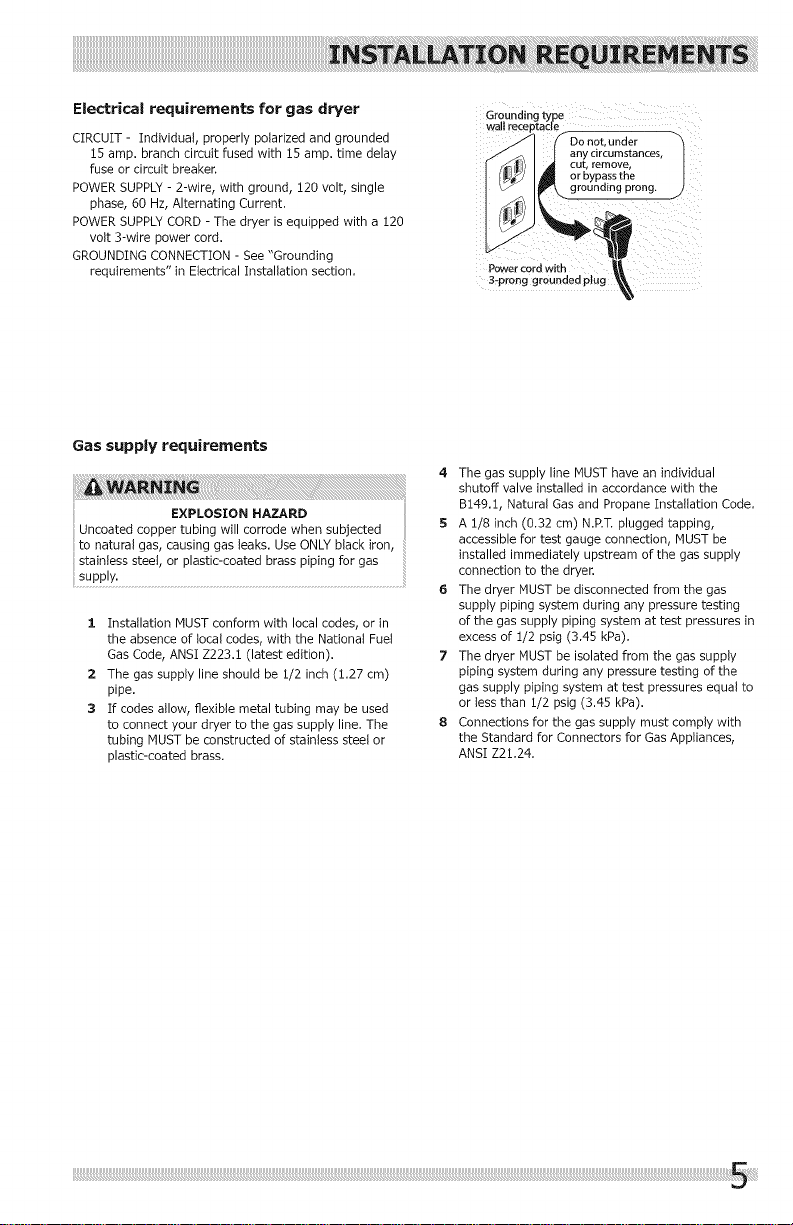

Gas supply requirements

; EXPLOSION HAZARD

Uncoated copper tubing will corrode when subjected

to natural gas, causing gas leaks. Use ONLY black iron,

stainless steel, or plastic-coated brass piping for gas

supply.

1 Installation MUST conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.I (latest edition).

2 The gas supply line should be 1/2 inch (1.27 cm)

pipe.

3 If codes allow, flexible metal tubing may be used

to connect your dryer to the gas supply line. The

tubing MUST be constructed of stainless steel or

plastic-coated brass.

Groundingtype

wal receptacle

/ _.\ I |anycircurnstances

_- Do not,under -"

\ I_ grounding prong.

h

B-pronggroundedpl

4. The gas supply line MUSThave an individual

shutoff valve installed in accordance with the

B!49.!, Natural Gas and Propane Installation Code.

5 A !/8 inch (0.32 cm) N.P.T.plugged tapping,

accessible for test gauge connection, MUST be

installed immediately upstream of the gas supply

connection to the dryer.

6 The dryer MUSTbe disconnected from the gas

supply piping system during any pressure testing

of the gas supply piping system at test pressures in

excess of !/2 psig (3.45 kPa).

7 The dryer MUSTbe isolated from the gas supply

piping system during any pressure testing of the

gas supply piping system at test pressures equal to

or tess than Z/2 psig (3.45 kPa).

8 Connections for the gas supply must comply with

the Standard for Connectors for Gas Appliances,

ANSI Z21.24.

Page 6

Exhaust system requirements

Use only 4 inch (i02 mm) diameter (minimum) rigid

or flexible metal duct and approved vent hood which

has a swing-out damper(s) that open when the dryer

is in operation. When the dryer stops, the dampers

automatically close to prevent drafts and the entrance

of insects and rodents. To avoid restricting the outlet,

maintain a minimum of !2 inches (30.5 cm) clearance

between the vent hood and the ground or any other

obstruction.

Failure to follow these instructions can create excessive

FIRE HAZARD

drying times and fire hazards.

The following are specific requirements for proper

and safe operationofyour dryer,

FIRE HAZARD

Do not install a clothes dryer with flexible plastic or

metal foil venting materials. Flexible venting materials

are known to collapse, be easily crushed and trap tint.

These conditions witt obstruct clothes dryer airflow and

increase the risk of fire.

If your present system is made up of plastic duct or

metal foil duct, replace it with a rigid or semi-rigid metal

duct. Also, ensure the present duct is free of any lint prior

to installing dryer duct.

Correct Incorrect

Correct

Page 7

Exhaust system requirements, continued

FIRE HAZARD FIRE HAZARD

A clothes dryer must be exhausted outdoors• Do not Exceeding the length of duct pipe or number of elbows

exhaust dryer into a chimney, a wall, a ceiling, an attic, allowed in the "MAXIMUM LENGTH" charts can cause

a crawl space or any concealed space of a building• A an accumulation of lint in the exhaust system• Plugging

clothes dryer produces combustible lint. If the dryer is

not exhausted outdoors, some fine lint will be expelled

into the laundry area• An accumulation of tint in any

area of the home can create a health and fire hazard.

The dryer must be connected to an exhaust outdoors.

Regularly inspect the outdoor exhaust opening and

remove any accumulation of lint around the outdoor

exhaust opening and in the surrounding area.

FIRE HAZARD

Do not allow combustible materials (for example:

clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT

be exhausted into a chimney, a wall, a ceiling,

or any concealed space of a building which can

accumulate lint, resulting in a fire hazard.

Do not screen the exhaust ends of the vent system,

or use any screws, rivets or other fasteners that

extend into the duct to assemble the exhaust

system. Lint can become caught in the screen, on

the screws or rivets, clogging the duct work and material.

creating a fire hazard as welt as increasing drying

..... * If nsta ngsem-rgdventng do not exceed8ft

t mes Use an approved vent hood to term nate the "2 4 m" duct len th

• _. ) g •

duct outdoors, and seal all ]omts wtth metal fotl duct .....

tape, All male duct pipe fittings MUST be instalied

downstream with the flow of air.

the system could create a fire hazard, as welt as

increase drying times.

MAXIMUM LENGTH

of 4" (102mm) RigidMetal Duct

9 VENT HOOD TYPE

0 64 ft. (19.5 m) 48 ft. (14.6 m)

1 52 ft. (15,9 m) 40 ft, (12.2 m)

2 44 ft. (13,5 m) 32 ft, (9.8 m)

3 36 ft. (11 m) 24 ft. (7.3 m)

4 28 ft. (9,5 m) 16 ft, (4.9 m)

(Preferred)

4" 2.5"

(102ram) Iouvered (6.35cm)

o Do not install flexible plastic or flexible foil venting

Page 8

Exhaust system requirements, continued

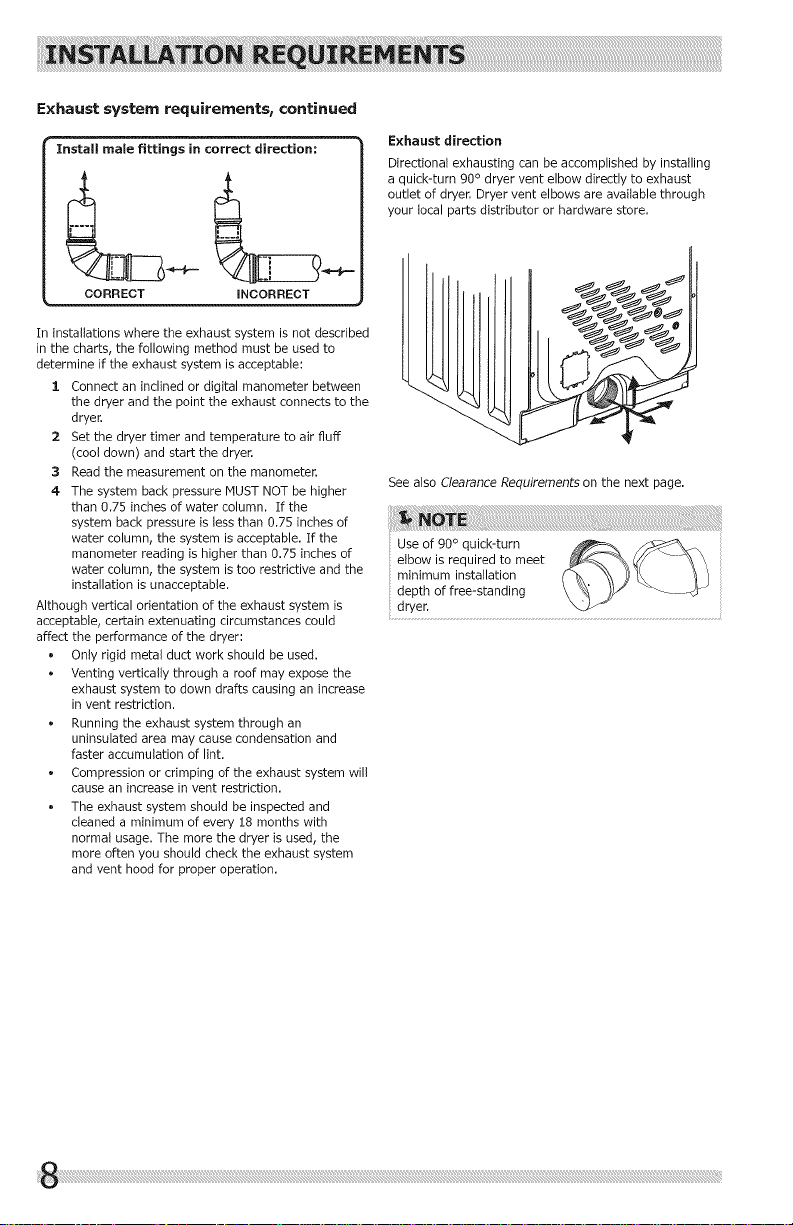

Install male fittings in correct direction:

CORRECT INCORRECT

In installations where the exhaust system is not described

in the charts, the following method must be used to

determine if the exhaust system is acceptable:

:1. Connect an inclined or digital manometer between

the dryer and the point the exhaust connects to the

dryer.

2 Set the dryer timer and temperature to air fluff

(cool down) and start the dryer.

3 Read the measurement on the manometer.

4 The system back pressure MUST NOT be higher

than 0.75 inches of water column. If the

system back pressure is tess than 0.75 inches of

water column, the system is acceptable. If the

manometer reading is higher than 0.75 inches of

water column, the system is too restrictive and the

installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could

affect the performance of the dryer:

• Only rigid metal duct work should be used.

• Venting vertically through a roof may expose the

exhaust system to down drafts causing an increase

in vent restriction.

• Running the exhaust system through an

uninsulated area may cause condensation and

faster accumulation of lint.

• Compression or crimping of the exhaust system will

cause an increase in vent restriction.

• The exhaust system should be inspected and

cleaned a minimum of every 18 months with

normal usage. The more the dryer is used, the

more often you should check the exhaust system

and vent hood for proper operation.

Exhaust direction

Directional exhausting can be accomplished by installing

a quick-turn 90 ° dryer vent elbow directly to exhaust

outlet of dryer. Dryer vent elbows are available through

your local parts distributor or hardware store.

See also Clearance Requirements on the next page.

Use of 90 ° quick-turn

elbow is required to meet

minimum installation

depth of free-standing

dryer.

Page 9

Manufactured or mobile home installation

1 Installation MUST conform to current Manufactured

Home Construction & Safety Standard, Title 24

CFR, Part 32-80 (formerly the Federal Standard

for Mobile Home Construction and Safety, Title 24,

HUD Part 280) or Standard CAN/CSAZ240 MH.

2 Dryer MUST be exhausted outside (outdoors, not

beneath the mobile home) using metal ducting

that wilt not support combustion. Metal ducting

must be 4 inches (10.i6 cm) in diameter with no

obstructions. Rigid metal duct is preferred.

3 If dryer is exhausted through the floor and area

beneath the mobile home is enclosed, the exhaust

system MUST terminate outside the enclosure with

the termination securely fastened to the mobile

home structure.

4 Refer to previous sections in this guide for other

important exhaust venting system requirements.

5 When installing a gas dryer into a mobile home, a

provision must be made for outside make up air.

This provision is to be not less than twice the area

of the dryer exhaust outlet.

6 Installer MUST anchor this (:!_)dryer or (2) dryer

mounted on pedestal to the floor with approved

Mobile Home Installation Kit - P/N :!_37067200,

Clearance requirememts

i i iiiiiiiii!ii!i iiii ii i ___________________________________________________________________:__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________ii ¸,......................................................................................................................................................................................................................

E×PLOSlON HAZARD DO NOT INSTALLYOUR DRYER:

Do not install the dryer where gasoline or other 1 In an area exposed to dripping water or outside

flammables are kept or stored. If the dryer is installed weather conditions.

in a garage, it must be a minimum of 18 inches (45.7

cm) above the floor. Failure to do so can result in 2 In an area where it will come in contact with

death, explosion, fire or burns, curtains, drapes, or anything that will obstruct

the flow of combustion and ventilation air.

3 On carpet. Floor MUST be solid with a maximum

Page 10

Clearance requirements, continued

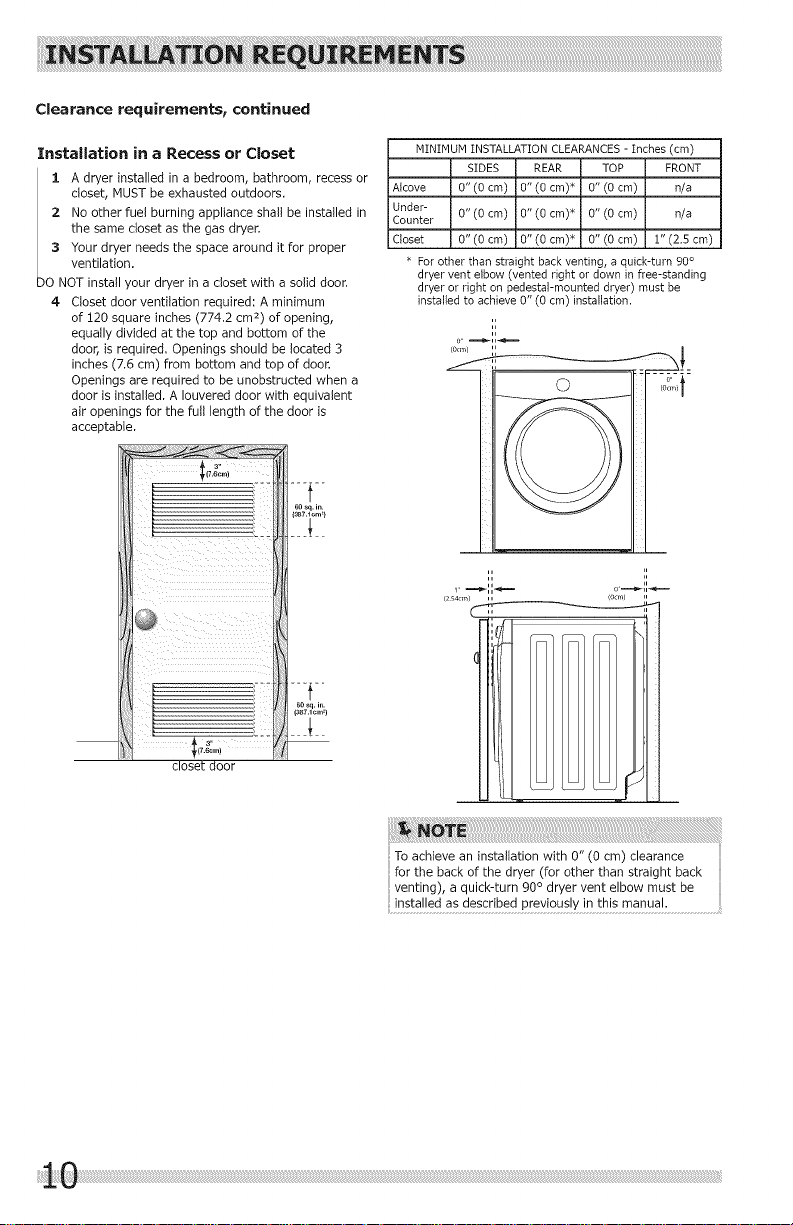

Installation in a Recess or Closet

:1. A dryer installed in a bedroom, bathroom, recess or

closet, MUST be exhausted outdoors.

2 No other fuel burning appliance shall be installed in

the same closet as the gas dryer,

I 3 Your dryer needs the space around it for proper

ventilation.

DO NOT install your dryer in a closet with a solid door,

4 Closet door ventilation required: A minimum

of 120 square inches (774.2 cm 2) of opening,

equally divided at the top and bottom of the

door, is required, Openings should be located 3

inches (7,6 cm) from bottom and top of door.

Openings are required to be unobstructed when a

door is installed, A Iouvered door with equivalent

air openings for the full length of the door is

acceptable.

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove 0" (0 cm) 0" (0 cm)* 0" (0 cm) n/a

Under- 0" (0 cm) 0" (0 cm)* 0" (0 cm) n/a

Counter

Closet 0" (0 cm) 0" (0 cm) _ 0" (0 cm) 1" (2.5 cm)

* For other than straight back venting, a quick-turn 90 °

dryer vent elbow (vented right or down in free-standing

dryer or right on pedestal-mounted dryer) must be

installed to achieve 0" (0 cm) installation.

0, -=-_, ,-_-=-

o :0!:,:,j

(2S4cm) (Ocm_

closet door

m

Toachieve an installation with O"(0 cm) clearance

for the back of the dryer (for other than straight back

venting), a quick-turn 90 ° dryer vent elbow must be

!nsta!!ed as descr!bed prev!ous!y !n th!s manua!. ...................................

i!!i!i!l!_!0 ill

Page 11

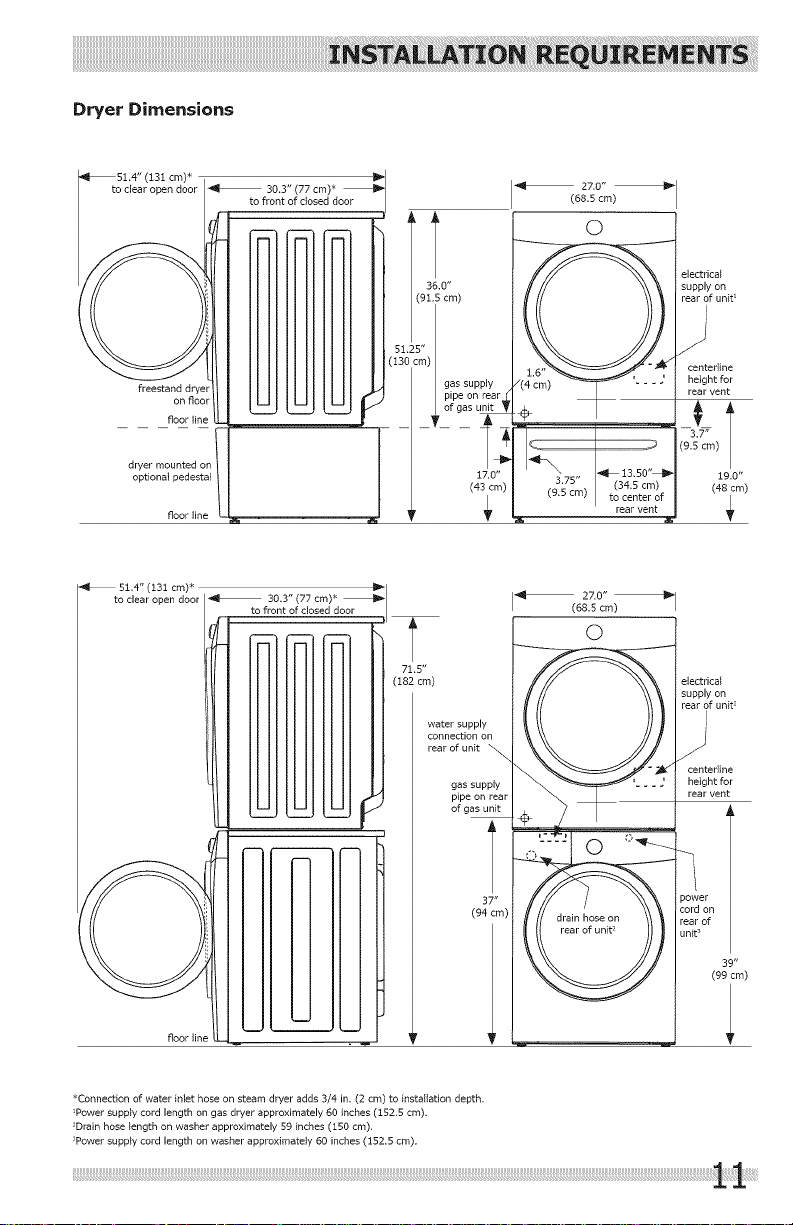

Dryer Dimensions

_ 51.4" (131 cm)*

o clear open door 41_ 30.3" (77 cm)*

freestand dryer

on floor

floorline

dryer mounted on

optional pedestal

floorline

51.4" (t31 cm) _

to clear open door

to front of c osed door

30.3" (77 cm)*

to front of closed door

27.0"

(68.5 cm)

'T o

"n)" gas supply " "

of gas unit

pipe on rear

- - - i....................................-

_!' (9.5 cm) t OeCaen;ernt f

27,0"

(68.5 cm_

0

71.5"

(182 cm)

water supply

connection on

rear of unit

gas supply

pipe on rear

of gas unit

electrical

supply on

r_f unit _

centefline

height for

rear vent

19.0"

(48;m)

electrical

supply on

rear of unit'

height for

floor]ine

*Connection of water inlet hose on steam dryer adds 3/4 in. (2 cm) to installation depth.

1Power supply cord length on gas dryer approximately 60 inches (152.5 cm).

2Drain hose length on washer approximately 59 inches (150 cm).

3Power supply cord length on washer approximately 60 inches (152.5 cm).

37"

(94 cm)

39"

(99 cm)

Page 12

Electrical installation

The following are specific requirements for proper and

safe electrical installation of your dryer. Failure to follow

* This appliance MUST be properly grounded.

ELECTRICAL SHOCK HAZARD

Electrical shock can result if the dryer is not properly

grounded. Follow the instructions in this manual for

proper grounding.

Do not use an extension cord with this dryer. Some

extension cords are not designed to withstand the

amounts of electrical current this dryer utilizes

and can melt, creating electrical shock and/

or fire hazard. Locate the dryer within reach of

the receptacle for the length power cord to be

purchased, allowing some slack in the cord. Refer to

the pre-instaltation requirements in this manual for

the proper power cord to be purchased.

Grounding requirements - Electric dryer (USA)

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

For a grounded, cord-connected dryer:

1 The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding witl reduce

the risk of electrical shock by a path of least

resistance for electrical current.

2 After you purchase and install a 3 wire or 4 wire

power supply cord having an equipment-grounding

conductor and a grounding plug that matches you

* A U.L.-approved strain relief must be installed onto

Fora permanently connected dryer:

ELECTRICAL SHOCK HAZARD

power cord. If the strain relief is not attached, the

cord can be pulled out of the dryer and can be cut

by any movement of the cord, resulting in electrical

shock.

Do not use an aluminum wired receptacle with a

copper wired power cord and plug (or vice versa).

A chemical reaction occurs between copper and

aluminum and can cause electrical shorts. The

proper wiring and receptacle is a copper wired

power cord with a copper wired receptacle.

wiring system, the plug MUST be plugged into

an appropriate, copper wired receptacle that is

properly installed and grounded in accordance with

all local codes and ordinances. If in doubt, call a

licensed electrician.

3 DO NOT modify the plug you've installed on this

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

1 The dryer MUSTbe connected to a grounded

metal, permanent wiring system; or an equipment

grounding conductor must be run with the circuit

conductors and connected to the equipment-

grounding terminal or lead on the appliance.

Page 13

Grounding requirements - Electric dryer (Canada)

2 Since your dryer is equipped with a power supply

cord having an equipment-grounding conductor and

a grounding plug, the plug must be plugged into

an appropriate outlet that is property installed and

grounded in accordance with all local codes and

ordinances. If in doubt, call a licensed electrician.

3 DO NOT modify the plug provided with this

For a grounded, cord-connected dryer:

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

1 The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance

for electrical current.

Grounding requirements = Gas dryer (USA and Canada)

1 The dryer is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle.

2 The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances. Tf

in doubt, call a licensed electrician.

3 DO NOT modify the plug provided with this

appliance. Tf it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Grounding lype

watl receptacle

f

anycircumstances,

Do not, under

nding prong, j

P_vercordwith _

3-prong grounded plug _

Page 14

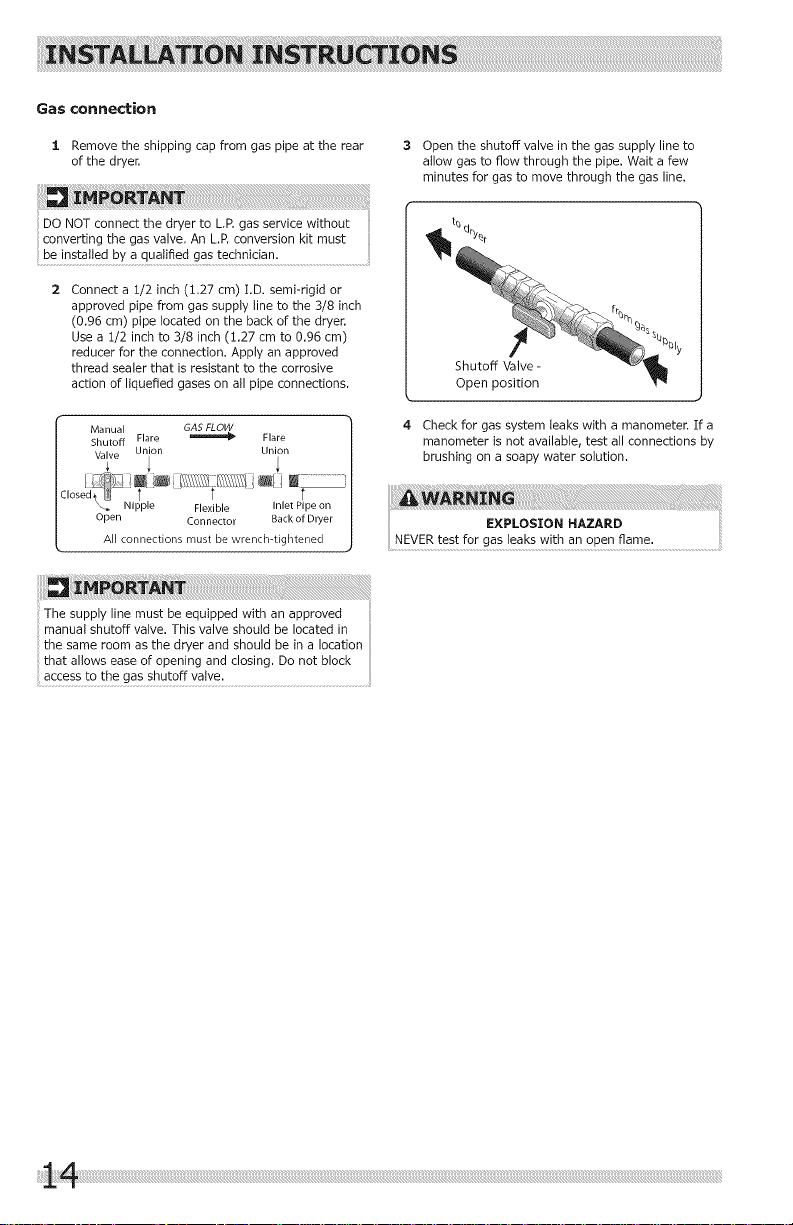

Gas connection

1 Remove the shipping cap from gas pipe at the rear 3 Open the shutoff valve in the gas supply line to

of the dryer, allow gas to flow through the pipe. Wait a few

DO NOT connect the dryer to LP, gas service without

converting the gas valve. An L.P.conversion kit must

be installed by a qualified gas technician.

2 Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or

approved pipe from gas supply line to the 3/8 inch

(0.96 cm) pipe located on the back of the dryer.

Use a 1/2 inch to 3/8 inch (1.27 cm to 0.96 cm)

reducer for the connection. Apply an approved

thread sealer that is resistant to the corrosive

action of liquefied gases on all pipe connections.

minutes for gas to move through the gas line.

Open position

Manua GAS FLOW "_

Shutoff Flare _ Flare |

Valve Union Union |

,o_/:_ed:l_Fi_'_i l\':_:::l_:_\\_/_'i l_/

: ,1_I t ' t t [

\. Nipple Flexible Inlet Pipe on |

Open Connector Back of Dryer |

AHconnections must be wrench-tightened J

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in

the same room as the dryer and should be in a location

that allows ease of opening and closing. Do not block

access to the gas shutoff valve.

4 Check for gas system leaks with a manometer. If a

manometer is not available, test all connections by

/

brushing on a soapy water solution.

EXPLOSION HAZARD

.EwRtestforgasleakswithanopen,ame.

Page 15

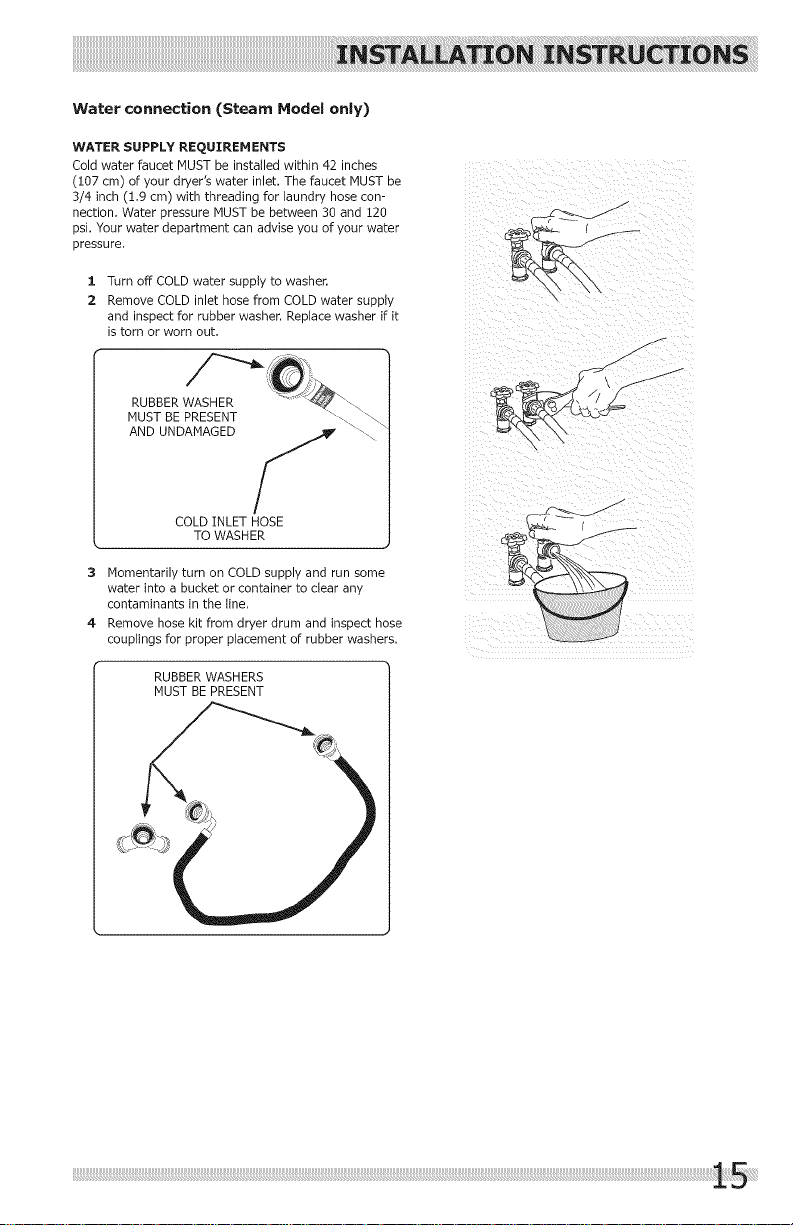

Water connection (Steam Model only)

WATER SUPPLY REQUIREMENTS

Cold water faucet MUST be installed within 42 inches

(i07 cm) of your dryer's water inlet. The faucet MUST be

3/4 inch (1.9 cm) with threading for laundry hose con-

nection. Water pressure MUST be between 30 and 120

psi. Your water department can advise you of your water

pressure.

1 Turn off COLD water supply to washer.

2 Remove COLD inlet hose from COLD water supply

and inspect for rubber washer. Replace washer if it

is torn or worn out,

RUBBER WASHER

MUST BE PRESENT

AND UNDAMAGED y

COLD INLET HOSE

TO WASHER

3 Momentarily turn on COLDsupply and run some

water into a bucket or container to clear any

contaminants in the line.

4 Remove hose kit from dryer drum and inspect hose

couplings for proper placement of rubber washers.

RUBBER WASHERS

MUST BE PRESENT

Page 16

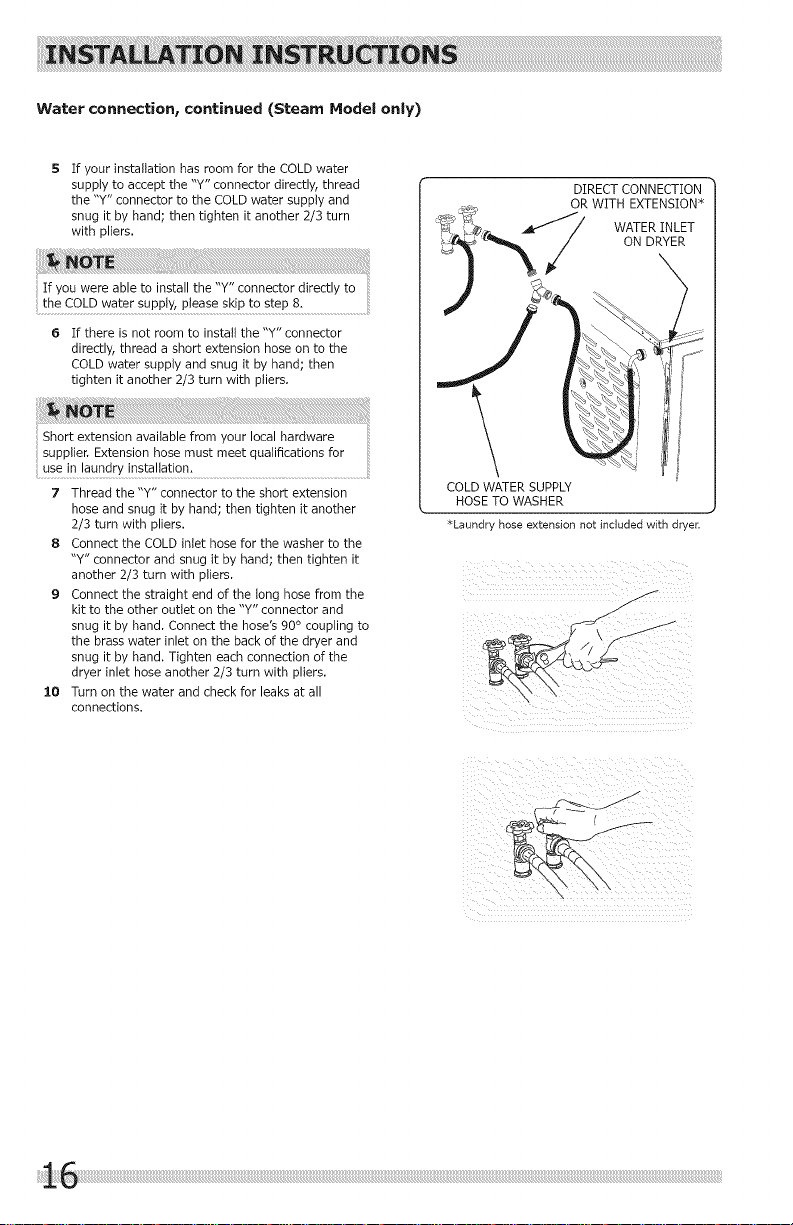

Water connec|:ion, continued (Steam Model only)

5 If your installation has room for the COLD water

supply to accept the "Y" connector directly, thread

the "Y" connector to the COLD water supply and

snug it by hand; then tighten it another 2/3 turn

with pliers.

ilIfyouwereab,etoinsta,,theYconnectordirect,ytoiii

the COLD water supply, please skip to step 8.

6 If there is not room to install the "Y" connector

directly, thread a short extension hose on to the

COLD water supply and snug it by hand; then

tighten it another 2/3 turn with pliers,

ii

DIRECT CONNECTION

i-_ _ / WATERINLET

_'% / ON DRYER

WiTHEXTENSION*

supplier. Extension hose must meet qualifications for

use in laundry installation.

7 Thread the "Y" connector to the short extension

hose and snug it by hand; then tighten it another

2/3 turn with pliers.

8 Connect the COLD inlet hose for the washer to the

"Y" connector and snug it by hand; then tighten it

another 2/3 turn with pliers,

9 Connect the straight end of the tong hose from the

kit to the other outlet on the "Y" connector and

snug it by hand, Connect the hose's 90° coupling to

the brass water inlet on the back of the dryer and

snug it by hand. Tighten each connection of the

dryer inlet hose another 2/3 turn with pliers.

10 Turn on the water and check for leaks at all

connections.

\

COLD WATER SUPPLY

HOSETO WASHER

*Laundry hose extensionnot includedwith dryer,

/ j

/

j/

Page 17

Electrical connection (non=Canada) - 3 wire cord

3-wire receptacle

(NEMA type 10-30R)

could result in personal injury or even death.

1 Turn off power supply to outlet.

2 Remove the screw securing the terminal block

access cover in the lower corner on the back of the

dryer.

3 Install a UL-approved strain relief according to the

power cord/strain relief manufacturer's instructions

in the power cord entry hole below the access

panel. At this time, the strain relief should be

loosely in place.

4 Thread an UNPLUGGED,UL-approved, 30 amp.

power cord, NEMA 10-30 type SRDT, through the

strain relief.

5 Attach the power cord neutral (center wire)

conductor to the SILVERcolored center terminal on

the terminal block. Tighten the screw securely.

6 Attach the remaining two power cord outer

conductors to the outer, BRASScolored terminals

on the terminal block. Tighten both screws

securely.

Do not make a sharp bend or crimp wiring/conductor

at connections.

7 Follow manufacturer's guidelines for firmly securing

the strain relief and power cord.

8 Reinstall the terminal block cover.

If moving dryer from a 4-wire system and installing it

in a 3-wire system, move the internal ground from the

center terminal back to the GREENscrew next to the

terminal block.

_-_ Accesscover

f_ black

If a terminal screw falls during cord installation, it can

be retrieved in the terminal screw recovery slot below

Line 2

(BRASS terminal)

Neutral

(SILVER terminal)

Line 1

(BRASS terminal)

-_ Internal ground

(GREEN screw)

Install

UL-approved

strain relief here

Terminal screw

recovery slot

the access panel.

DO NOT remove

internal ground in terminal

a 3-wire system]!

Neutral

Page 18

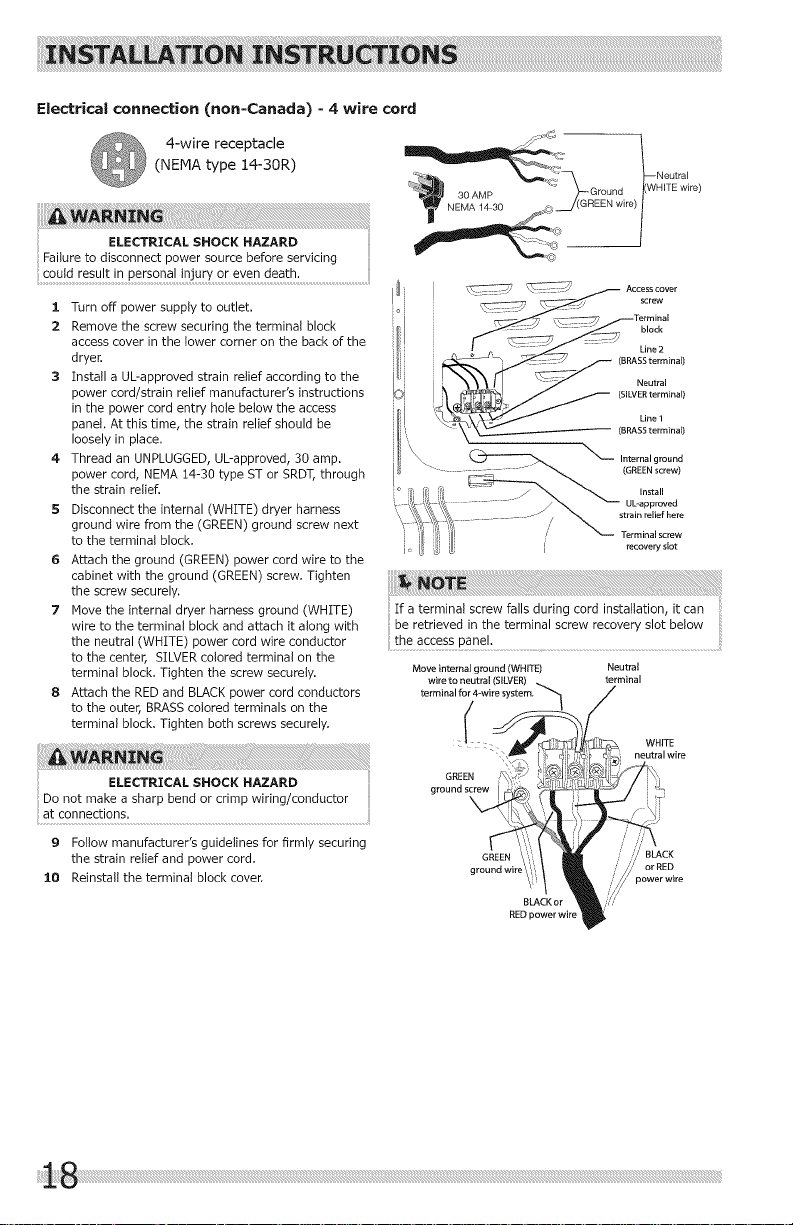

Electrical connection (non=Canada) = 4 wire cord

4-wire receptacle

(NEMA type 14-30R)

1 Turn off power supply to outlet.

2 Remove the screw securing the terminal block

access cover in the lower corner on the back of the

dryer.

3 [nstall a UL-approved strain retief according to the

power cord/strain relief manufacturer's instructions

in the power cord entry hole below the access

paneh At this time, the strain relief should be

loosely in place.

4 Thread an UNPLUGGED,UL-approved, 30 amp.

power cord, NEMA 14-30 type ST or SRDT,through

the strain relief.

5 Disconnect the internal (WHZTE) dryer harness

ground wire from the (GREEN) ground screw next

to the terminal block.

6 Attach the ground (GREEN) power cord wire to the

cabinet with the ground (GREEN) screw. Tighten

the screw securely.

7 Move the internal dryer harness ground (WHZTE)

wire to the terminal block and attach it along with

the neutral (WHZTE) power cord wire conductor

to the center, SILVERcolored terminal on the

terminal block. Tighten the screw securely.

8 Attach the RED and BLACKpower cord conductors

to the outer, BRASScolored terminals on the

terminal block. Tighten both screws securely.

Do not make a sharp bend or crimp wiring/conductor

at connections.

9 Follow manufacturer's guidelines for firmly securing

the strain relief and power cord.

10 Reinstall the terminal block cover.

If a terminal screw falls during cord installation, it can

be retrieved in the terminal screw recovery slot below

the access panel. ................

__ _r_Neutra]

t_"1_; 30AMP _%' )-_Ground. t(wH'TE w're)

T NEMA 14-30 4@_ /(GREEN w:re)l

(SILVER terminal)

Line 1

(BRASS terminal)

"_ Internal ground

(GREEN screw)

recoveryslot

Move internal ground (WHITE) Neutral

wire to neutral (SILVER) terminal

terminal for 4-wire !

',C"?

ground screw

GREEN BLACK

ground wirl

neutral wire

RED power win

Page 19

General installation

1 Connect the exhaust duct to the outside exhaust

system. Use of a 4" (102 ram) clamp (item A) is

recommended to connect the dryer to the exhaust vent

system. Use metal foil tape to seal all other joints.

2 Use a carpenter's level to level your dryer front-to-back

and side-to-side.

3 Use adjustable pliers to adjust the leveling legs so the

dryer is level front-to-rear and side-to-side, and stable

corner-to-corner.

4 Pressdown on alternate corners and sides and feel for

the slightest movement. Adjust the appropriate leg(s)

so the dryer sits solidly on the floor on ALL four legs,

Keepthe leveling leg extension at a minimum for best

performance of the dryer,

before plugging the power cord into an outlet. ........

5 Plugthe power cord into a grounded outlet.

Groundinc

Do not, und

any circumstances,

| grounding prongj)

3,prong grounded plug

6 Turn on the power at the circuit breaker/fuse box.

7 Read the Use & Care Guide provided with the dryer. It

contains valuable and helpful information that will save

you time and money.

8 If you have any questions during initial operation,

please review the "Avoid Service Checklist" in your Use

& Care Guide before calling for service.

9 Placethese instructions in a location near the dryer for

future reference.

Page 20

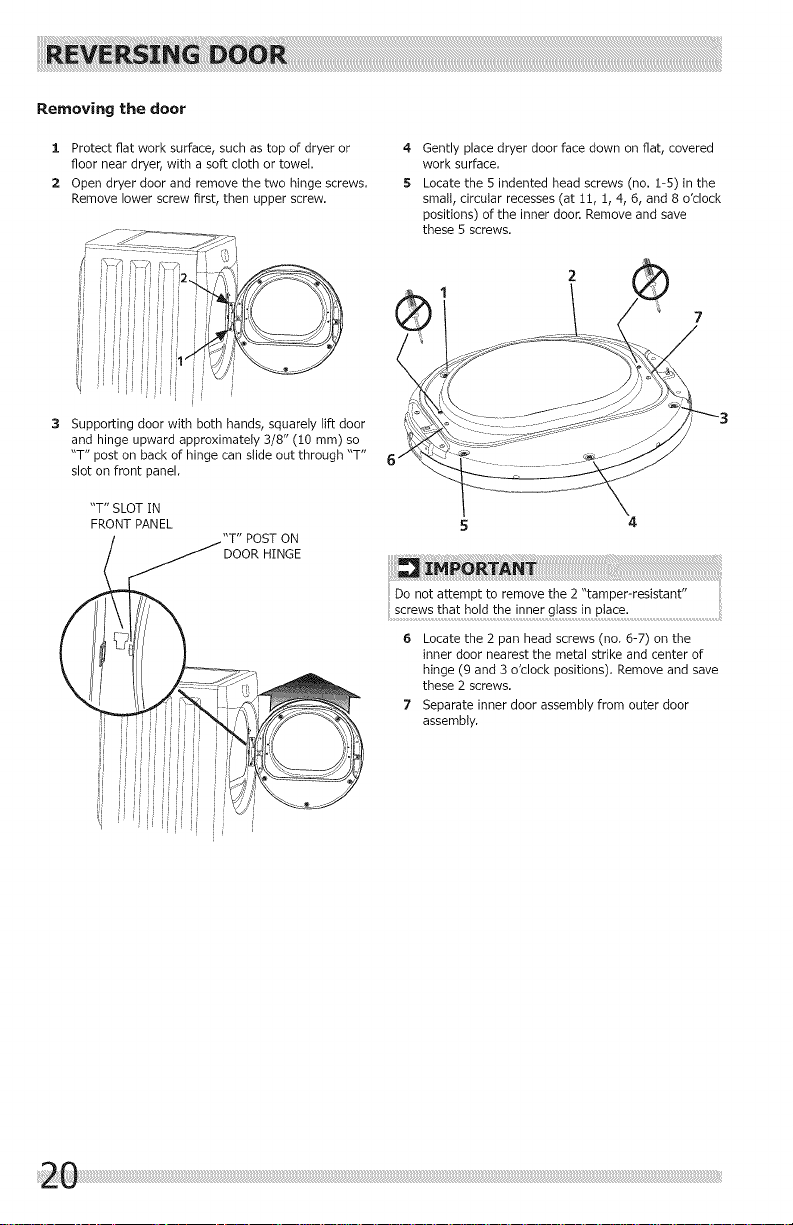

Removing the door

1 Protect fiat work surface, such as top of dryer or 4

floor near dryer, with a soft cloth or towel.

2 Open dryer door and remove the two hinge screws. 5

Remove lower screw first, then upper screw.

iil _i

i i il i _i!

il i i i i

iii !

i i!"

, i _ _ _i _

3 Supporting door with both hands, squarely lift door

and hinge upward approximately 3/8" (10 mm) so

"T" post on back of hinge can slide out through "T"

slot on front panel.

"T" SLOT IN

FRONT PANEL

POSTON

DOORHINGE

Gently place dryer door face down on fiat, covered

work surface.

Locate the 5 indented head screws (no. 1-5) in the

small, circular recesses (at 1i, 1, 4, 6, and 8 o'clock

positions) of the inner door. Remove and save

these 5 screws.

5 4

...............................................................

6 Locate the 2 pan head screws (no. 6-7) on the

inner door nearest the metal strike and center of

hinge (9 and 3 o'clock positions). Remove and save

these 2 screws.

7 Separate inner door assembly from outer door

assembly.

7

Page 21

Reversing the hinge

1 Carefully pull out the 2 small round hole plugs from

the front panel and save. Remove and save the

square "T" slot cover by sliding it up and pulling

it out. Move all 3 plugs to the opposite side of the

front )anel and insert.

ROUNOPwG.

_SQUARE PLUG ...___

_ROUND PLUG_

2 Turn inner door assembly over to expose retaining

tabs of metal strike. Grip tabs fully with pliers to

remove. Discard old metal strike.

3 Turn the inner door assembly back over and locate

the 2 pan head hinge screws. Remove and save the

2 screws and separate the hinge from inner door

assembly.

HINGE SCREWS

4 From the back side of the inner door, pinch the

retaining tabs of the plastic square plug to release

it. Save square plug for reinstallation.

5 Carefully remove the 2 round plugs from the inner

door and move them to the opposite holes and

reinstall.

OUT

IN

6 Rotate the hinge and move it to the opposite side

of the inner door. Attach it with the 2 pan head

screws removed previously. Reinstall plastic plug in

the square hole next to the hinge.

Page 22

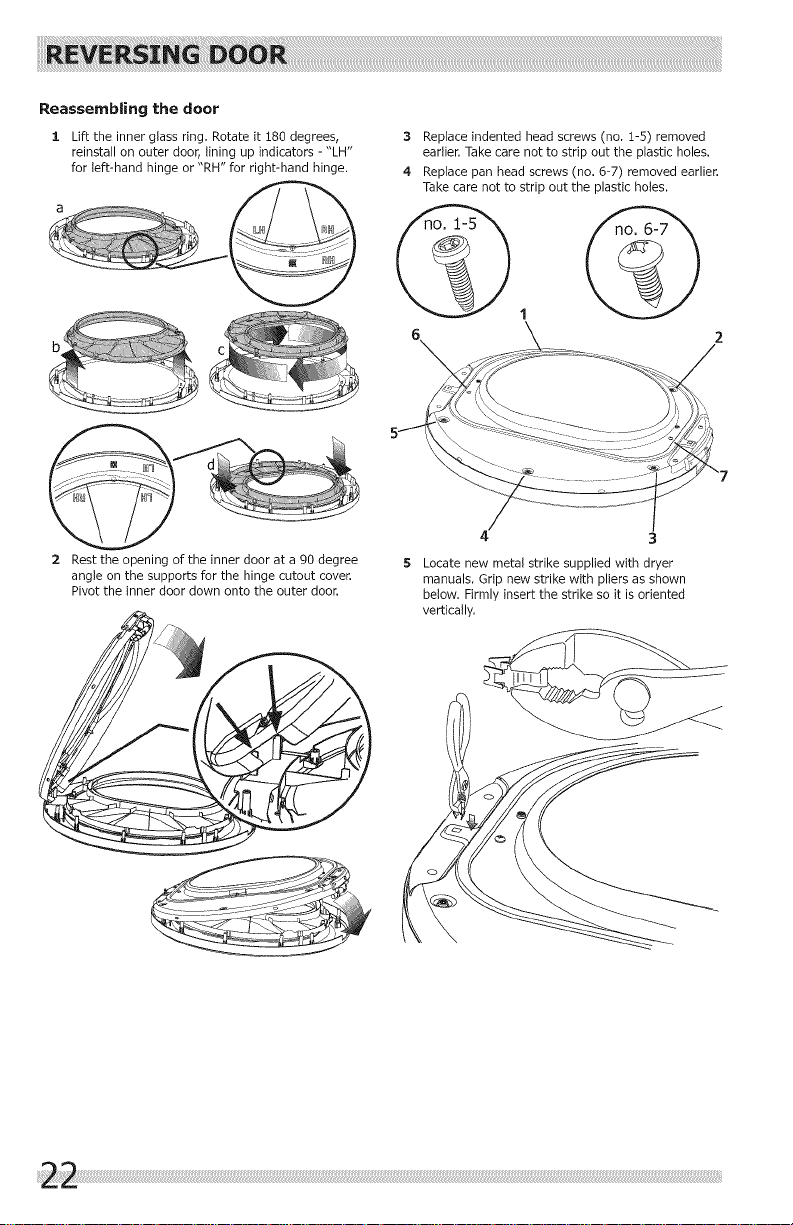

Reassembling the door

1 Lift the inner glass ring, Rotate it i80 degrees,

reinstall on outer door, lining up indicators - "LH"

for left-hand hinge or "RH" for right-hand hinge.

3 Replace indented head screws (no, i-5) removed

earlier. Take care not to strip out the plastic holes.

4 Replace pan head screws (no. 6-7) removed earlier.

Take care not to strip out the plastic holes.

2 Rest the opening of the inner door at a 90 degree

angle on the supports for the hinge cutout cover.

Pivot the inner door down onto the outer door.

4 /

3

Locate new metal strike supplied with dryer

manuals, Grip new strike with pliers as shown

below. Firmly insert the strike so it is oriented

vertically,

Page 23

Reattaching the door

1 Holding the door in both hands, squarely insert

the "T" post on the back of the hinge into the "T"

slot on the front panel and lower it to align the

mounting holes.

"T" POST ON FRONT PANEL

DOOR HINGE

2 While supporting the door, install the upper pan

head screw first and then the lower one.

1:_L'L'.\

"T" SLOT IN

Jl iiA:

3 Close the door and test operation of hinge, strike

and latch.

i [

i i

2ii

" ] i

LJ =

i i il i! _'

Correctly installed hinge screws will press hinge flush

to front panel. Any gap between hinge and front panel

will cause misalignment of strike to latch.

Page 24

MATCHING STORAGE PEDESTAL*

Classic White Pedestal - P/N CFPWD15W

Classic Silver Pedestal - P/N CFPWD15A

A storage pedestal accessory, specifically designed for this dryer

may be used to elevate the dryer for ease of use, This pedestal will

add about i5" (38 cm) to the height of your unit for a total height

of 5!.25" (130 cm).

_Other colors may be available. Contact the source where you purchased

your dryer.

DRYER STACKING KIT

P/N 8TACKIT4X

Depending on the model you purchased, a kit for stacking this dryer

on top of matching washer may have been included in the initial

purchase of your dryer. If your model did not include a stacking kit or

you desire another stacking kit, you may order one.

LP CONVERSION KIT

P/NPCK4200

Gasdryers intended for use in a tocation supplied with LP must use a

conversion kit prior to installation.

MOBILE HOHE INSTALLATION KIT

P/N137067200

Installation in a mobile home requires the use of a NOBILE HONE

INSTALLATION KIT.

DRYING RACK

P/N 137067300

Depending on the model you purchased, a drying rack may have

been included in the initial purchase of your dryer, If your model did

not include a drying rack or you desire another drying rack, you may

order one,

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A UNIVERSAL APPLIANCE WRENCH is available to aid in dryer/

washer/pedestal feet adjustment.

TOUCH UP PAINT PENS*

Classic White Touch Up Pen - P/N 5304468812

Classic Silver Touch Up Pen - P/N 5304471228

_Other colors may be available. Contact the source where you purchased

your dryer,

result in personal injury, property damage or

damage to the dryer.

_9

Replacement parts:

Ifreplacementspartsareneeded foryourdryer,contact

thesourcewhereyou purchasedyourwasheror referto

your Use and Care Guide for more information,

servicing-.......................................................................................................................................................................................

Page 25

Page 26

d'essence ou d'autres vaPeurs ou liquides inflammab!es & proxim!t@ de ce t appareit ou de tout autre appareit @lectrom@nager.

A AVERTISSEHENT

RISq D'I E

Lisez toutes les instructions de s@curit@ suivantes avant d'instalter et d'utiliser votre appareil :

• D@truisez le carton d'emballage et les sacs en plastique apr@s avoir d@ball@I'appareil. Les enfants pourraient les utile

ser pour jouer. Le carton recouvert de tapis, les couvertures et les feuilles de plastique peuvent @tre @ranches 5 I'air et

provoquer la suffocation. D@posez tousles mat@riaux d'emballage dans un conteneur 5 d@chets ou faites en sorte que les

enfants ne puissent y avoir acc@s.

® L'installation et I'entretien de cette s@cheuse doivent &tre r@aiis@s par un instaltateur qualifi@, un technicien de

service ou le fournisseur de gaz.

® Instaltez t'appareil conform@ment aux instructions du fabricant et aux codes Iocaux.

® I_'installation @tectrique de la s@cheuse dolt &tre conforme aux codes et aux r_glements Iocaux ainsi qu'5 ta route

derni@re @dition du National Electrical Code (ANSI/NFPA 70), ou au Canada, au Code canadien de I'@lectricit@

(C22,1,article 1).

• L'installation de gaz de ta s@cheuse dolt @tre conforme aux codes et aux r@glements tocaux ainsi qu% la toute

derni@re @dition du Fuet Gas Code (ANSI Z223.1), ou au Canada, au CAN/ACG B:L49.1-2000. Un robinet d'arr@t

manuel distinct dolt @tre install@ & moins de 1,83 m (6 pi) de la s@cheuse conform@ment au National Fuel Gas

Code, ANSI Z223,1/NFPA 54,

• La s@cheuse est ctass@e, en vertu des r@glements ANSI Z 21,5,1 ou ANSI/UL 2158 - CAN/CSA C22.2 N° 112

(demi&res versions), pour un USAGE DOMESTIQUE uniquement II n'est pas recommand@ d'utiliser cette s@cheuse

pour des usages commerciaux, comme des restaurants, des salons de coiffure, etc.

• N'installez pas une s@cheuse avec du mat@riel d'@vacuation en plastique ou en f:euille m@taltique flexible. Le mat@-

riel de ventilation flexible peut s'@craser facilement et emprisonner la charpie, Ces conditions nuiraient _ l'@coule-

ment d'air de votre s@cheuse et pourraient accro_tre le risque d'incendie.

• Ne superposez pas une s@cheuse sur une taveuse d@]_ instalt@e sur un socle. Ne superposez pas une taveuse sur

une s@cheuse. Ne superposez pas une laveuse sur une autre laveuse. Ne pas empiter tes s@che-linge au-dessus de

machine & laver sans utilisation du f:abricant approuv@ et install@ correctement kit de superposition correspondant

votre mod@te,

• Les instructions comprises dans ce guide et toute autre documentation foumie avec cet appareil ne sont pas

congues pour couvrir toutes les @ventualit@s ou situations qui pourraient survenir. Vous DEVEZ faire preuve de bon

sens et de prudence durant I'installation, t'utitisation et l'entretien de tout appareil m@nager.

QUE FAIRE SI VOUS DE_TECTEZUNE ODEUR DE GAZ :

• Ne mettez pas d'appareil en marche.

• Ne touchez _ aucun commutateur @lectrique; n'utiiisez

aucun t@t@phonede votre domicile.

• Evacuez ta pi&ce, le b_timent ou ta zone touch@e.

• En utilisant te t@l@phoned'un voisin, appetez imm@diate-

ment te fournisseur de gaz. Suivez ses instructions.

• Sivous ne pouvez joindre votre fournisseur de gaz,

appelez les pompiers.

Pour @viter tes blessures au dos ou d'autres types

de blessure, demandez l'aide d'autres personnes

pourd@placerousouJeverIaIaveuse/s@cheuse

Conservez ces instructions pour vous

y reporter uit rieurement,

Exigences avant I'installation

Outils et materiel n_cessaires & I'installation ;

• Pince r@glable

• Tournevis Phillips _ pointe plate et

pointe carr@e

• CI@_ molette

. CI@_ tuyau pour I'atimentation en gaz

• Ruban _ filetage r@sistant au GPL

(pour I'alimentation en gaz naturet

ou en GPL)

• Niveau de charpentier • Robinet d'arr@t pour conduite de

• Event ext@rieur gaz (s@cheuse_ gaz)

• Conduit d'@vacuation de 102 mm (4 " Deux raccords-unions _ @vasement

po) en m@talrigide ou semi-rigide de 1/2 po (1,3 cm) NPT et une

• Ensemble pour cordon d'alimenta- gaz (s@cheuse_ gaz)

tion de 240 V _ 3 ou 4 ills (s@cheu-

se @lectrique) * Ruban m@tallique (et non du ruban

• Collier de 10,2 cm (4 po)

conduite flexible d'alimentation en

conduits)

Page 27

Veuitteztirecesinstructionsaucompletavantd'utiliser

les4cheuse.

Sachez reconnaitre lee symboles, les

avertissemen_s et les _tiquettes de

s_curit_.

Les mesures de s4curit4 pr_sent_es dans ce guide sont

identifi_es par te mot AVERTISSEHENT ou A_q-ENTION

selon le type de risque pr4sent_ ci-dessous.

D4finitions

Voici le symbole d'avertissement concemant la

s_curit_. II est utilis_ pour vous avertir des risques de

blessures potentiels. Respectez tous tes messages qui

suivent ce symbole afin de pr4venir les blessures ou la

mort.

La mention DANGER indique un risque imminent qui

causera la mort ou de graves blessures, s'il n'est pas

La mention AVERTISSEMENTindiqueune situation

potentietlement dangereuse qui, si elle n'est pas _vit_e,

situation potentiellement dangereuse susceptible de

causer des blessures mineures ou moyennement graves

sie!len%stpas_V!t_e..........................................................................................................

Conduit d'dvacuation

Lair circule librement, il n'y a aucune

accumulation de cbarpie

Le conduit rigide ou semi-rigide de 102 mm (4

po) est le plus court et te plus direct possible

[I n'y a AUCUN mat4riel de ventilation en papier

d'aluminium ou en plastique

Le syst4me d'_chappement dolt 4vacuer l'air a

I'ext4rieur a I'aide d'un 4vent approuve

Hise _ niveau

La s4cheuse est au niveau lat_ralement et de

I'avant vers l'arri_re

IZi Leequatre coins de la caisse reposent

fermement sur le plancber

Alimentationau gaz(sdcheuseaugaz)

lZi Le conduit d'alimentation comporte un robinet

d'arr&t manuel

lZi Tous lee raccords sont 4tancb4ifi4s 5 I'aide de

joints certifi4s serr4s avec une cl4

lZi N4cessaire de conversion pour syst_me au GPL

I_ L'alimentation en gaz est ouverte

r] Aucun raccord ne pr4sente de fuite -

v4rifiez 5 t'aide d'eau savonneuse, ne faites

]AHA_S cette v4rification avec une flamme

Alirnentation 41ectrique de 240 V (sdch, _lect)

lZi Le cordon d'alimentation est certifi4 NEHA i0-

30R ou i4-30R et it fix4 solidement avec routes

les vie clans le bornier

IZi Un r4ducteur de tension certifi4 est install4

IZi Le couvre-borne est install4 avant la premiere

mise en marche

:Inversion de la porte

iS1 Suivez tee instructions d4taiil_es contenues dane

ce guide

V4rifiez que la charni&re et le loquet

fonctionnent correctement

Alimentation en 41ectricit4

Le syst&me 41ectrique de la maison est sous

tension

IZi La s4cheuse est brancb4e

Vdrifications finales

Vous avez tu enti_rement tes instructions

d'instaiiation et le Guide d'utiiisation et

d'entretien

La porte se verrouilte et te tambour tourne

Iorsqu'un cycle d4marre

151 La carte d'enregistrement est envoy_e

Page 28

Exigences _lectriques de ia s_cheuse _lectrique:

CIRCUIT - Circuit ind_pendant de 30 amperes avec fusible temporis_ ou disjoncteur de 30 A, Utilisez des circuits

ind_pendants pour la laveuse et ta s_cheuse. NE BRANCHEZ PAS la laveuse et ta s_cheuse sur le m_me circuit.

ALIMENTATION teLECTRIQUE - C_ble monophas_ _ trois ou quatre ills, 240 volts, 60 Hz; courant altematifl

terre par le fit d'alimentation neutre.

PRISE - Prise NEMA I0-30R ou NEMA 14-30R situ_e de mani&re _ permettre I'acc&s au cordon d'alimentation Iorsque

ta s_cheuse est _ sa position de fonctionnement.

CONNEXION DE HISE A LA TERRE - Consuttez la rubrique <<Exigences de raise _ la terre >>dans la section

d'installation _lectrique,

TROUSSEDECORDON D'ALIMENTATION,_TROIS FILS

(non fournie)

Prise _ 3 alv&oles

(NEMA type 10-30R)

La s#cheuse DOIT utiliser un cordon d'alimentation

trois ills NEMA !0-30 de type SRDT d'une capacit# de

240 volts (c.a.) et d'au moins 30 amperes, avec trois

connecteurs ouverts embrochables avec extr#mit_s

renvers#es, ou connecteurs _ boucle ferm#e,

sp_cialement indiqu_s pour une utitisation avec une

s_cheuse. Pour les instructions de raccordement du

cordon _ 3 ills, consultez ia section CONNEXIONS

12LECTRIQUES POUR UN SYSTEME _, TROIS FILS.

TROUSSEDE CORDON D'ALIMENTATION ,_QUATREFILS

(non fournie)

Prise _ 4 alv&oles

(NEMA type 14-30R)

La s#cheuse DOIT utiliser un cordon d'alimentation

quatre ills NEMA i4-30 de type SRDT d'une capacit#

de 240 volts (c.a.) et d'au moins 30 amperes,

avec quatre connecteurs ouverts embrochables

avec extr#mit#s renvers#es, ou connecteurs

boucle ferm#e, sp_cialement indiqu#s pour une

utilisation avec une s#cheuse. Pour tes instructions

de raccordement du cordon _ quatre ills, consultez

la section CONNEXIONS teLECTRIQUES POUR UN

SYSTEME A QUATRE FILS.

Les s_cheuses destinies _ la vente au Canada sont

munies d'un cordon d'alimentation _ 4 fits (NEMA 14-

30R).

Page 29

E×igences _lectriques de la s_cheuse gaz

CIRCUIT - Circuit ind#pendant de i5 amp6res, polaris_

et mis _ la terre, avec fusible temporis# ou disjoncteur

de i5 A.

ALINENTATION I_LECTRIQUE- C_ble monophas_ _ deux

flls mis _ la terre, i20 volts, 60 Hz; courant alternatif,

CORDON D'ALINENTATION - La s_cheuse est dot#e d'un

cordon d'alimentation de i20 volts _ trois fils,

CONNEXION DE MISE A LATERRE - Consuttez la rubrique

<<Exigences de raise _ la terre >>dans la section

d'instaltation _lectrique,

Exigences relatives & I'alimentatiom en gaz

Un tuyau en cuivre sans rev&tement se corrode Iorsqu'il

entre en contact avec le gaz naturel, entra_nant des

fuites, Utilisez SEULEMENT des tuyaux en fer noir, en

acier inoxydable ou encore en cuivre avec rev&tement

i L'instaltation DOlT @tre conforme aux codes

2 Le tuyau d'alimentation en gaz dolt &tre d'un

3 Si les codes le permettent, un tuyau m@tallique

RISQUE D'EXPLOSION

Iocaux ou au code national sur te combustible,

ANSI Z223.! (derni@re version), s'il n'existe pas de

codes Iocaux.

diam&tre int_rieur de !,27 cm (!/2 po).

flexible peut @tre utilis_ pour raccorder votre

s@cheuse au tuyau d'alimentation en gaz. Le tuyau

DOIT @tre fabriqu_ en acier inoxydable ou en laiton

avec rev@tement en plastique.

Prisemurale avec

raise & la terre

iNfecoupez pas, n,enleve,_

,_ pas et ne rnettez pas hors I

8circuit labroche de raise /

pm_ la terre de cette fiche. )

Cordon 61ectrk_uemuni _

d'unefiche_troisbroches_

ave=raise_la terre _,%

4 Le tuyau d'alimentation en gaz DOlT _tre muni d'un

robinet d'arr&t distinct conform_ment _ ta norme

BI49.I, Code d'installation du gaz naturel et du

propane.

5 Un orifice taraud_ de 0,32 cm (i/8 po) bouch_,

accessible pour le branchement de ta jauge d'essai,

DOlT _tre install_ directement en amont du

branchement du tuyau d'alimentation en gaz avec

la s_cheuse.

6 Cette s_cheuse DOlT &tre d_branch_e de ta

canalisation de gaz pendant toute v_riflcation de

pression de la canalisation de gaz _ des pressions

sup_rieures _ 3,45 kPa (!/2 tb/po2).

7 Cette s_cheuse DOlT _tre isol_e de la canalisation

de gaz pendant route v_rification de pression de

la canalisation de gaz _ des pressions _gales ou

inf_rieures _ 3,45 kPa (i/2 Ib/po2).

8 Les branchements d'alimentation en gaz doivent

_tre conformes _ la norme Connectors for Gas

Appliances (Raccords pour appareils au gaz) ANSI

Z21,24.

Page 30

E×igences du syst_rne d'_vacuation

Utilisez seutement des conduites m_taltiques rigides ou

flexibles d'au moins 10,2 cm (4 po) de diam&tre, et une

bouche d'_vacuation qui poss&de un ou des volets qui

s'ouvrent lorsque I'appareit est en fonction. Lorsque la

s_cheuse s'arr_te, les volets se ferment automatiquement

pour emp&cher les infiltrations d'air, d'insectes et de

rongeurs. Pour _viter de bloquer la sortie, gardez un

espace minimal de 30,5 cm (12 po) entre le bas de la

bouche d'_vacuation et le sol ou toute autre obstruction.

Le non-respect de ces instructions pourrait augmenter

R:SQOED::,CE,DiE

d_mesur_ment tes temps de s_chage et entra;ner des

Vous trouverez ci-dessous les exigences pour l'uti-

lisation adequate et s_curitaire de votre appareil,

N'installez pas une s#cheuse avec du mat#riet

d'#vacuation en plastique ou en feuille m#tallique

flexible. Le materiel de ventilation flexible peut

s'#craser facilement et emprisonner la charpie. Ces

conditions nuiraient _ I'#coutement d'air de votre

s_cheuse et pourraient accro_tre te risque d'incendie.

Si votre syst&me actuel utilise une conduite en plastique

ou en feuille m_taltique, remplacez-la par une conduite

m_taltique rigide ou semi-rigide. De plus, assurez-vous

que la conduite en place est tibre de charpie avant

d'installer la conduite de s_cheuse.

Correct Incorrect

Correct

Page 31

E×igences de systb_e d°_vacuation (suite)

Une s6cheuse doit _tre _vacu6e vers Fext_rieur.

N'_vacuez pas une s_cheuse dans une chemin6e, un

mur, un plafond, un grenier, un vide sanitaire ou dans

tout espace dos d'un b_timent. La s_cheuse produit

de la charpie inflammable1 Si la s6cheuse n'est pas

6vacu6e vers I'ext_rieur, de la charpie pourrait _tre

6vacu6e dans I'aire de buanderie. L'accumulation de

charpie dans toute piece de ta maison peut entra_ner

des risques pour lasant_ et des risques d'incendie.

La s_cheuse dolt &tre branch_e _ une _vacuation

ext_rieure. Inspectez r6guti6rement Fouverture de

I'_vacuation ext_rieure et retirez toute accumulation de

charpie pr6s de Fouverture et de la r_gion avoisinante.

RISQUE D'INCENDIE

• Ne laissez pas de mati_re combustible (par

exemple : des v_tements, des rideaux, du papier)

entrer en contact avec le syst_me d'_vacuation.

La s_cheuse NE DOIT PAS_tre _vacu_e clans une

chemin_e, un mur, un plafond, ou dans tout espace

confin_ d'un b_timent qui pourrait accumuter la

charpie, entrainant un risque d'incendie.

• Ne placez pas de grillage _ I'extr_mit_ du syst_me

d'_vacuation, ni de vis, de rivet ou autre fixation

de mani&re _ ce qu'its se prolongent dans la

conduite du syst&me d'_vacuation. De la charpie

pourrait s'accumuter sur te grillage, les vis ou

les rivets, et obstruer 1'6coulement d'air dans

le syst&me, entrainant un risque d'incendie et

I'augmentation des temps de s6chage. Utilisez

une bouche d'_vacuation approuv_e pour terminer

la conduite _ t'ext_rieur, et scellez tousles joints

avec du ruban m_tallique. Toutes les extr_mit_s

m_les des conduites doivent &tre instalt_es en aval

ii

relativement au sens de I'_coulement d'air.

Le fait de d6passer la Iongueur de conduites ou te

:: ::nombre de coudes indiqu6s dans les tableaux de

<<LONGUEURMAXIMALE >>peut entrainer l'accumutation

de charpie clans le syst6me. Toute obstruction au

:: ::syst6me d'6vacuation peut entra_ner un risque

::d'incendie, en plus d'accro_tre le temps de s6chage.

LONGUEUR MAXIMALE

o_ pour le conduit en m_tal rigide de 10,2 cm (4 po)

9 TYPE DE BOUCHE D'EVACUATION

o-

0 19,5 m (64 pi) 14,6 m (48 pi)

1 15.9 m (52 pi) 12,2 m (40 pi)

2 13.5 m (44 pi) 9.8 m (32 pi)

3 11 m (36 pi) 7.3 m (24 pi)

4 9.5 m (28 pi) 4,9 m (16 pi)

(De pr_f6rence)

10 cm 6.5 cm

(4 po) _, volets (2.5 po)

* N'installez pas de materiel de ventilation en

plastique ou en aluminium flexible.

. Si vous installez du materiel de ventilation semi-

rigide, il est n_cessaire que la tongueur du conduit

soit _gale ou inf_rieure _ 2,4 m (8 pi),

Page 32

E×igences de syst_rne d'_vacuation (suite)

EnstaHezies raccords m&les dans le bon sens :

CORRECT iNCORRECT

Pour une installation o0 le syst_me d'_vacuation n'est pas

d_crit dans les tableaux, la m_thode suivante dolt &tre

utilis_e pour v_rifier la conformit_ du syst&me :

::1. Branchez un manom&tre 5 tube inctin_ ou un

manom&tre num_rique entre la s6cheuse et le point

o0 I'_vacuation est raccord_e 5 la s_cheuse.

2 R_glez la minuterie de la s_cheuse, la temperature

duvetage (refroidissement), et mettez I'appareil

en fonction.

:3 Retevezle r6sultat du manom&tre.

4 La contre-pression du syst6me NE DOIT PAS_tre

sup6rieure 5 19 mm (0.75 po) de colonne d'eau.

Si la contre-pression du syst&me est inf_rieure

19 mm (0.75 po) de colonne d'eau, le syst6me

est conforme. Si ta lecture du manom_tre indique

une colonne d'eau sup_rieure 5 19 mm (0.75 po),

le syst&me est trop restreignant et n'est pas

conforme.

Bien que I'orientation verticale du syst6me d'_vacuation

soit acceptable, certaines circonstances pourraient influer

sur le rendement de I'appareil.

Seute une conduite m_tallique rigide dolt _tre

utitis_e.

L'_vacuation verticale par te toit peut entra;ner

le ph_nom_ne de contre-tirage, ce qui accro;t la

restriction du syst&me d'_vacuation.

L'acheminement de la conduite d'_vacuation

dans un endroit non isol_ peut entra;ner de la

condensation et l'accumutation plus rapide de

charpie.

Le fair de comprimer ou de pincer tesyst_me

d'_vacuation entra_nera I'augmentation de la

restriction dans lesyst&me.

Le syst_me d'_vacuation dolt &tre inspect_ et

v_rifi& au moins tousles 18 mois avec un usage

normal. Plus t'appareil est utitis_, plus la p_riode

de v_rification du syst&me et de la bouche

d'_vacuation dolt _tre raccourcie.

Direction d'_vacuation

It est possible de diriger I'_vacuation en posant un coude

de 90 ° _ courbe immediate directement _ ta sortie

d'_vacuation de ta s_cheuse. Les coudes pour _vacuation

de s_cheuse sont disponibles aupr_s du distributeur de

pi&ces de votre r_gion ou _ la quincaillerie.

Consultez _galement la section EXIGENCESDE

Dt_GAGEHENT_ ta page suivante.

L'utilisation d'un coude

90° _ courbe immediate

est n_cessaire pour

r_pondre aux exigences

de profondeur minimale

de ta s_cheuse autonome.

Page 33

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii !! !!i ii:i ! !i ! :i i i i i ii i ii ! i ! !i ! ! iii 6! i i ii i !

Installation darts une maison usin_e ou mobile

:1. [_'installation DOIT _tre conforme _ ta norme

Manufactured Home Construction and Safety

Standard, titre 24 CFR, article 32-80 (anciennement

d_sign_e comme la Federal Standard for Mobile

Home Construction and Safety, titre 24, HUD,

article 280) ou _ la norme CAN/CSAZ240 MH.

2 La s_cheuse DOIT _tre _vacu_e vers I'ext_rieur

(_ I'air tibre et non sous la maison mobile) avec

une gaine m_tallique ininflammable. La conduite

m_taltique dolt poss_der un diam&tre de 10,16 cm

(4 po) et ne contenir aucune obstruction. De

preference, utitisez une conduite m_taltique rigide.

3 Si la s_cheuse est _vacu_e par le plancher et que

I'espace sous la maison mobile est cloisonne, le

syst&me d%vacuation DOIT se terminer _ I'ext_rieur

E×igences de d_gagemen_

de la cloison et _tre fix6 solidement _ la structure

de la maison.

4 Reportez-vous aux sections pr6c_dentes de

ce guide retativement aux autres exigences

d%vacuation importantes.

5 Lors de I'installation d'une s_cheuse _ gaz dans

une maison mobile, des dispositions doivent _tre

prises pour permettre t'entr_e d'air d'appoint de

l'ext_rieur. Cette installation ne dolt pas mesurer

moins de deux lois la surface de la bouche

d%vacuation.

6 L'installateur DOIT ancrer (i) cette s_cheuse ou

(2) la monter sur un socle au sol avec une trousse

d'installation de maison mobile, n ° de pi&ce

137067200.

N'Jnstaltez pas la s_cheuse t_ o0 de I'essence ou autres

mati&res inflammables sont entrepos_es. Si la s_cheuse

est instatt_e dans un garage, elle doit &tre plac_e au

moins _ 45,7 cm (!8 po) du sol. Le non-respect de cette

recommandation peut entra_ner un choc _tectrique, une

exp!°si°n_ un incend!e °u m_me !a mort ?................................................................

RISQUE D'EXPLOSTON

N'[NSTALLEZ PAS VOTRE SECHEUSE :

& h, un endroit expos_ aux _coulements d'eau

ou aux alias des conditions m_t_orologiques

ext_rieures.

2 h, un endroit oO elle entrera en contact avec

des rideaux ou tout autre objet qui nuirait

ventilation.

:3 Sur un tapis. Le plancher DOlT &tre solide et

ii

pr6senter une pente inf6rieure _ 2,5 cm (1 po).

I%coutement de l'air de combustion ou de

Page 34

E×igences de d_gagement (suite)

Installation darts un Ertdroit en Retrait ou

une Armoire

1 Une s6cheuse instalt6e dans une chambre

coucher, une salie de bains, un renfoncement ou un

placard DOIT _tre 6vacu6e vers I'ext_rieur,

2 Aucun autre appareil _ combustion ne doit _tre

install6 dans le m_me placard que la s_cheuse,

3 Votre s_cheuse a besoin d'espace pour assurer une

ventilation ad6quate,

N'INSTALLEZ PAS votre s6cheuse dans un placard muni

d'une porte pleine

4 Porte de placard assurant une ventilation requise :

Une ouverture d'au moins 774,2 cm2 (i20 po2),

divis6e 6galement au-dessus et au-dessous de

la porte, est requise. Les ouvertures doivent _tre

situ_es _ 7,6 cm (3 po) du haut et du bas de la

porte, Les ouvertures ne doivent pas _tre obstru_es

Iorsqu'une porte est instalt6e. Une porte

persiennes dont les ouvertures sur I'ensemble de la

porte sont _quivalentes aux recommandations peut

_tre utilis_e,

DEGAGEMENTS MINIMAUX - Centim&tres (pouces)

COTES ARRIERE DESSUS AVANT

AIc6ve 0" (0 cm) 0" (0 cm)* 0" (0 cm) n/a

Sous le 0" (0 cm) 0" (0 cm) * 0" (0 cm) n/a

comptoir

Placard 0" (0 cm) 0"(0 cm) _ 0"(0 cm) 1" (2.5 cm)

• Pour toute installation autre qu'une _vacuation directe,

un coude de 90° _ courbe immediate dolt _tre utilis_

pour respecter I'exigence de 0 cm (0 po).

0..--_:;_--

..... =,i o- II

Porte de placard

installation autre qu'avec une sortie directe), un coude

de g0 ° _ courbe imm6diate dolt _tre install6, comme il

est d6crit pr6c6demment dans ce guide,

Page 35

Dimensions de S_cheuse

r 51.4" (131 cm)*

avec ta porte

grande ouverte

s_cheuse autonome

sur le plancher

plancher

s6cheuse mont6e sur

le socle optionnel

plancher

_ 51.4" (131 cm)*

avec ta porte

grande ouverte

30.3" (77 cm)*

partir de I'avant de la porte

orsqu e e est ferm_e

30.3" (77 cm)*

partir de I'avant de la porte

Iorsqu'elle est ferm_e

f

'T

_) en gaz _

71.5"

(182 cm)

I'arri&re de

V alimentation

I,'appareil _

a gaz T

17.0"

(43 cm)

raccord de

I'alimentation

en eau _ I'arri&e

de la laveuse _

alimentation er

gaz _ I'arri&re

de I'appareil

gaz

27.0"

(68.5 cm)

©

alimentation

_lectrique

I'arri&e de

heuse'

hauteur de {a

ligne centrale

de _vent arri_re

=-

C:: :::::::::::::::::::::::::::::::::::::::::::::::::

(34.5 cm)

3.75" du c6t_ jusqu'au

(9,5 cm) centre de I'_vent

27,0"

(68.5 cm_

arri&e

19.0"

(48 cm)

©

alimentation

61ectrique

I'arri&e de

la s6cheuse _

ligne centrale

de I'_vent arri&re

_L

37"

(94 cm)

plancher

*Le raccordement du tuyau d'arriv_e d'eau sur les modules _ }a vapeur ajoute 2 cm (3/4 po) _ la profondeur d'installation.

1Longueur du cordon d'alimentation de la s_cheuse _ gaz, environ 152,5 cm (60 po).

2Longueur du tuyau de vidange de la laveuse, environ 150 cm (59 po).

3Longueur du cordon d'alimentation de la laveuse, environ 152,5 cm (60 po).

I'an

la Is

39"

(99 cm)

Page 36

Installation _lectrique

Vous trouverez ci-dessous les exigences pour t'installation

#lectrique ad#quate et s#curitaire de votre appareit, Le

non-respect de ces instructions pourrait entra_ner le

risque de choc ou d'incendie.

• Cet appareil DOIT _tre ad_quatement mis _ la

terre. La mise _ la terre inadequate de las_cheuse

pourrait entratner des risques de choc _lectrique.

Suivez les instructions de ce guide pour une mise

ta terre adequate.

• N'utilisez pas de rallonge avec cet appareil. Certains

cordons pro!ongateurs ne sont pas con_us pour ...............................................................................................................................................................................

la quantit_ de courant _lectrique utitis_ par cette

s_cheuse et pourraient fondre, entra_nant des

risques de choc _lectrique ou d'incendie. Placezla , ............

s_cheuse _ une distance de la prise convenant _ Les s_cheuses aliment_es par une tension de 208 V

la tongueur de la rallonge, permettant d'installer la poss_deront des temps de s_chage plus longs qu'une

rallonge I_chement. Reportez-vous aux exigences de s6cheuse atiment_e par une tension de 240 V.

pr_instaltation de ce guide pour savoir quel cordon

d'atimentation acheter.

Un r6ducteur de tension certifi_ UL dolt &tre install6

sur te cordon d'alimentation. Site r6ducteur de

tension n'est pas installS, le cordon peut &tre

arrach_ de t'appareil ou coup_ par tout mouvement,

ce qui entra;nerait un risque de choc _lectrique.

N'utilisez pas une prise avec cSblage en aluminium

avec un cordon d'alimentation et une fiche avec fils

en cuivre (ou I'inverse). Une r_action chimique se

produit entre I'aluminium et le cuivre, ce qui pourrait

entra;ner un court-circuit. It faut utiliser un cordon,

une fiche et une prise avec des fils en cuivre.

Exigences de raise & la terre - S_cheuse _lectrique (E,-U.)

Un raccordement inad_quat du conducteur de mise 5 la

terre de 1'6quipement peut accro_tre les risques de choc

_lectrique. En cas de doute quant 5 la raise 5 la terre

de I'appareit, consultez un 51ectricien quatifi_.

Pour une s_cheuse avec cordon, mise _ la terre :

1 Cet appareit DOIT _tre mis _ la terre. En cas de

mauvais fonctionnement ou de panne, la mise

la terre diminue les risques de choc _tectrique en

fournissant au courant _lectrique une trajectoire de

moindre r6sistance.

2 Apr&s I'achat et I'instaltation d'un cordon

d'alimentation _ 3 ou 4 fils dot_ d'un fil de mise

la terre et d'une fiche de mise _ la terre qui

correspond _ votre syst&me de cSblage, la fiche

DOIT _tre branch_e dans un r_ceptacle cuivr6

install6 et mis _ la terre conform6ment aux codes

et r&glements locaux. En cas de doute, faites appel

un _lectricien qualifi6.

3 NE MODIFIEZ PASta fiche fournie avec cet

appareil. Si elle ne s'ins&re pas dans la prise,

demandez _ un 61ectricien qualifi6 d'installer la

prise adapt_e.

Pour une s_cheuse avec branchement permanent :

1 La s_cheuse DOIT _tre branch_e _ un syst&me de

c_bles m_taltiques permanents mis _ la terre; ou un

conducteur de mise _ la terre dolt &tre install_ avec

les conducteurs de circuit et branch_ _ la borne ou

au fil de mise _ la terre de l'appareil.

Page 37

E×igences de raise & la terre - S_cheuse _lectrique (Canada)

2 Puisque votre appareit est muni d'un cordon

d'alimentation avec filet fiche de raise _ la terre,

Un raccordement inad6quat du conducteur de raise 5 la terre

de 1'6quipement peut accroTtre les risques de choc _lectrique.

En cas de doute quant 5 la raise 5 la terre de I'appareil,

consultez un 61ectricien qualifi6.

Pour une s_cheuse avec cordon, mise _ la terre :

1 Cet appareil DOIT _tre mis _ ta terre. En cas de

mauvais fonctionnement ou de panne, ta raise

la terre diminue les risques de choc _lectrique en

fournissant au courant _lectrique une trajectoire de

moindre r_sistance.

la fiche dolt _tre branch_e dans un r_ceptacle

install_ et mis _ la terre conform_ment aux codes

et r&glements locaux. En cas de doute, faites appel

un _lectricien qualifi_.

3 NE MODIFIEZ PASta fiche fournie avec cet

appareil. Si elle ne s'ins_re pas dans la prise,

demandez _ un _lectricien qualifi_ d'installer la

prise adapt_e.

Exigences de raise _ la terre =S_cheuse _ gaz (E,=U. et Canada)

1 Cet appareit est muni d'une fiche _ trois broches

(raise _ la terre) pour assurer votre protection

contre les chocs _tectriques, Cette fiche doit &tre

branch_e directement dans une prise _ trois

alv_oles correctement raise _ ta terre.

2 La fiche dolt _tre branch_e dans un r_ceptacle

install6 et mis _ la terre conform_ment aux codes

et r&glements Iocaux, En cas de doute, faites appel

un _lectricien qualifi_.

3 NE MODIFIEZ PASta fiche fournie avec cet

appareit. Si etle ne s'ins&re pas dans la prise,

demandez _ un 61ectricien quaiifi6 d'installer la

prise adapt_e.

Prise murale avec

raise _ laterre

rf_ _ I j paset ne mettez pas hors

/Y_ _/ I A circuitlabrochedemise

1_ 1_1_ la terre de cette fiche )

_ .... pez pas, n'enlevez_

\

Page 38

Connexion de gaz

1 Retirez te capuchon d'exp_dition de la conduite de

gaz _ t'arri&re de !'appareil.

NE RACCORDEZPASla s_cheuse _ une alimentation

en propane liquide sans avoir pr6alablement converti la

soupape de gaz. Le n_cessaire de conversion au propane

liquide dolt &tre install6 par un technicien qualifi6.

2 Branchez un tuyau semi-rigide ou approuv_ d'un

diam&tre int_rieur de 1,27 cm (!/2 po) de ta

conduite d'alimentation de gaz au tuyau de 0,96 cm

(3/8 po) situ_ _ t'arri&re de I'appareil. Utilisez un

r_ducteur de !,27 cm _ 0,96 cm (1/2 po _ 3/8 po)

pour effectuer te raccordement. Utilisez du ruban

d'_tanch_it_ r_sistant _ Faction corrosive des gaz

I'_tat liquide _ chaque raccord.

Robinet Raccord- _ Raccord-

d'arr_t union _ union

l manuel._ _vas_ment _vasement,.

_. Duse Raccord Tuyau crent ree

Ouvert flexible raccord_ _ I'arri_re

I de la s_cheuse

Tous les raccords cloivent _tre serf,s au moyen d'une cl_

E'COULEMENT

La conduite d'atimentation doit &tre munie d'un robinet

d'arr_t approuv& Ce robinet dolt &tre situ_ darts la

m&me piece que la s_cheuse et plac_ de mani_re

&tre facilement accessible. Ne bloquez pas I'acc_s au

robinet d'arr&t de t'atimentation de gaz.

Ouvrez le robinet d'arr_t dans la conduite

d'alimentation de gaz pour permettre au gaz de

s'_couler clans te tuyau. Attendez quetques minutes

pour que le gaz s'_coule dans la conduite.

Robinet d'arr_t

en position ouverte

V_rifiez le syst_me avec un manom&tre pour

d_celer toute fuite. Si vous n'avez pas de

manom&tre, v_rifiez tes raccords en appliquant de

I'eau savonneuse sur les connexions.

Nev_rifiez ]AMAISla presencedefuites _ I'aided'une

flamme nue.

Page 39

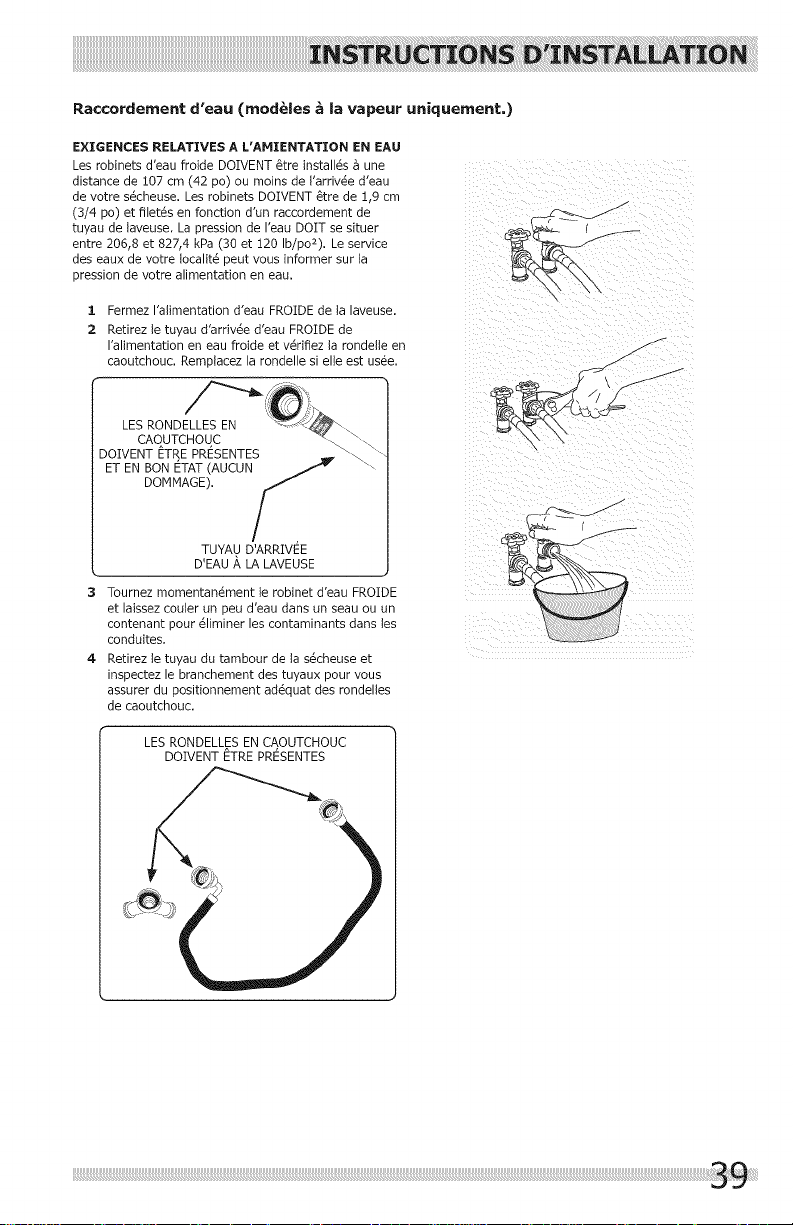

Raccordement d'eau (modbles b la vapeur uniquement)

EXIGENCES RELATIVES A L'AHIENTATION EN EAU

Les robinets d'eau froide DO[VENT_tre install_s _ une

distance de i07 cm (42 po) ou moins de {'arriv_e d'eau

de votre s_cheuse. Les robinets DOIVENT_tre de 1,9 cm

(3/4 po) et fi{et_s en fonction d'un raccordement de

tuyau de {aveuse. La pression de I'eau DOIT se situer

entre 206,8 eL 827,4 kPa (30 et 120 Ib/po2). Le service

des eaux de votre {ocalit_ peut vous informer sur {a

pression de votre alimentaUon en eau.

Fermez I'alimentation d'eau FROIDE de la laveuse.

Retirez te tuyau d'arriv_e d'eau FRO[DE de

I'alimentation en eau froide et v_rifiez {a rondelle en

caoutchouc, Remplacez la rondelle si elle est us#e.

LESRONDELLES EN

CAOUTCHOUC

DOIVENT ETP,E PEt_SENTES

ET EN BON ETAT (AUCUN

DOMMAGE). y,

TUYAU D'ARRIVEE

D'EAUA LA LAVEUSE

3 Tournez momentan_ment le robinet d'eau FROIDE

et laissez couter un peu d'eau dans un seau ou un

contenant pour _liminer les contaminants dans les

conduites,

4 Retirez le tuyau du tambour de la s_cheuse et

inspectez le branchement des tuyaux pour vous

assurer du positionnement ad_quat des rondelles

de caoutchouc.

LESRONDELLES EN CAOUTCHOUC

DOIVENT I_TREPRI_SENTES

Page 40

Raccordement d'eau, suite (modbies b la vapeur uniquement.)

5 Si votre installation offre suffisamment d'espace

pour installer directement un raccord en Y 5 votre

tuyau d'arriv#e d'eau FROIDE, vissez le raccord en

Y 5 votre tuyau d'arriv_e d'eau FROIDE et serrez-te

la main; ensuite, serrezqe avec une pince en le

toumant de 2/3 de tour.

Si vous n'avez pu installer te raccord en Y directement

votre tuyau d'arriv4e d'eau FROIDE, veuitlez passer

_ !'6tape 8:.......................................................................................................................................................................................

6 Si votre installation n'offre pas suffisamment

d'espace pour installer directement un raccord en Y,

vissez une petit tube-rallonge 5 votre tuyau d'arriv_e

d'eau FROIDE et serrez-le 5 la main; ensuite, serrez-

le avec une pince en le toumant de 2/3 de tour.

Le petit tube-raltonge peut 6tre achet4 chez le d4taillant

d'artictes de quincaillerie de votre r4gion. Le tube-

rallonge dolt r4pondre aux normes des installations des

appareils de buanderie.

7 Vissez te raccord en Y au petit tube-rallonge et

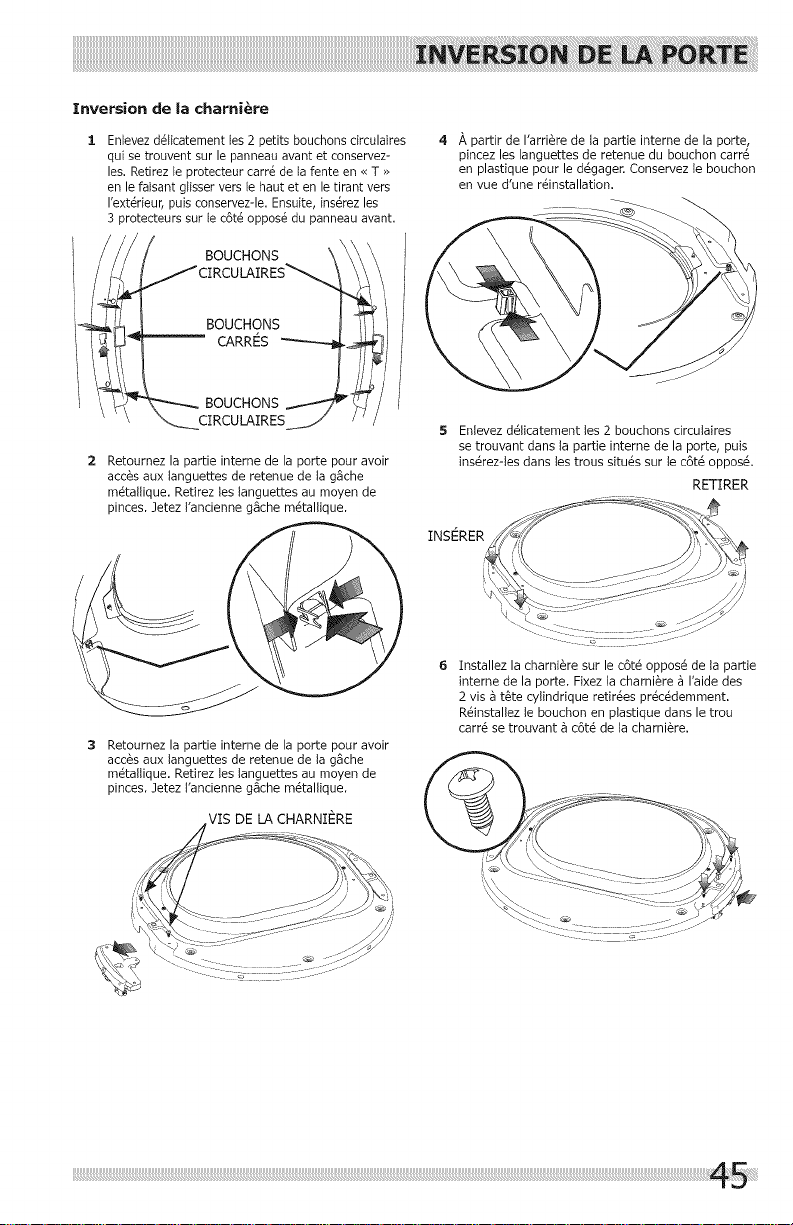

serrez-le _ la main; ensuite, serrez-le au moyen