Page 1

Lightweight Shunts

TM Series

J

9

Application

This lightweight range is specifically suitable for

applications where there are space and/or weight

limitations in the installation such as in portable equipment,

compact electronic instrumentation, mobile installations

such as tanks and aircraft etc.

In addition to ammeters, shunts can be used to measure

and/or monitor current in a wide range of measurement,

protection and control devices.

The TM series lightweight shunts are manufactured to

comply with the U.S.A. military specification MIL - S161B.

Standard outputs give 50mV potential drop.

By careful design and choice of materials, it has been

possible to produce a high performance shunt which is

mechanically strong, light in weight and of extremely

compact dimensions with the ability to withstand high

overloads without damage and possessing long term

calibration stability.

Features

✔ Compact space-saving design

✔ Accuracy +/- 0.25%

✔ Insulated base mounting

✔ USA Mil. spec MIL-S-61B

✔ Temperature coefficient 0.002% per 1°C

✔ High overload withstand

Specification

Ratings : 5-1200A

Accuracy: +/- 0.25%

Outputs: 50mV or 100mV

Refer to Factory for

other outputs

Overload withstand: 1.2 x rated current

continuously

5 Second Withstand: 10-150A = 10 x rated current

151-600A = 5 x rated current

601-1200A = 2 x rated current

Temperature Co-efficient: 0.002% per °C overall

Ambient temperature: Calibrated for 20°C, they can

be used in ambient range

-20°C to +60°C

Temperature Rise: A momentary rise up to

200°C will not affect the

performance of these shunts.

When mounted as

recommended in freely

circulating air the temperature

rise should not exceed 100°C.

Maximum Load

Indicator: 20mA

The TM series is designed to

comply with U.S. military

specification MIL-S-61B. Its

performance meets all

requirements including those

covering dielectric

withstanding voltage, voltage

drop, sustained load,

overload

Construction

The end blocks are machined from solid section, high

conductivity brass. They each carry two terminals, current

connection is made by either threaded studs or bolts

depending on the model, terminals for potential lead

connection are provided by 2 screws with spring and plain

washers.

The resistance elements are made from manganin sheet

for its low temperature co-efficient and long term stability

and strength, hard soldered into slots in the end blocks.

The shunt is mounted on a high strength black phenolic

base with integral fixing holes.

Installation

The heat generated by the current is dissipated by

conduction through the busbar or cable and by convection

in the air. The shunt temperature should not exceed

145°C. Conductors must be of adequate csa and contact

surface clean and level.

Ensure clamping bolts or nuts and washers are sufficiently

tight. Shunts above 100 amps should be mounted with

leaves vertical and longitudinal axis horizontal. Where this

is impractical, forced-air cooling may be necessary to limit

the temperature to 145°C.

Potential Leads

The resistance of the leads from the potential terminals

must be taken into account when the instrument is

calibrated. Details of standard lead lengths and

resistances are available on request.

Warning

Shunts are not fully insulated and protection against

accidental contact should be provided.

Contents

Page 2

Lightweight Shunts

TM Series

J

10

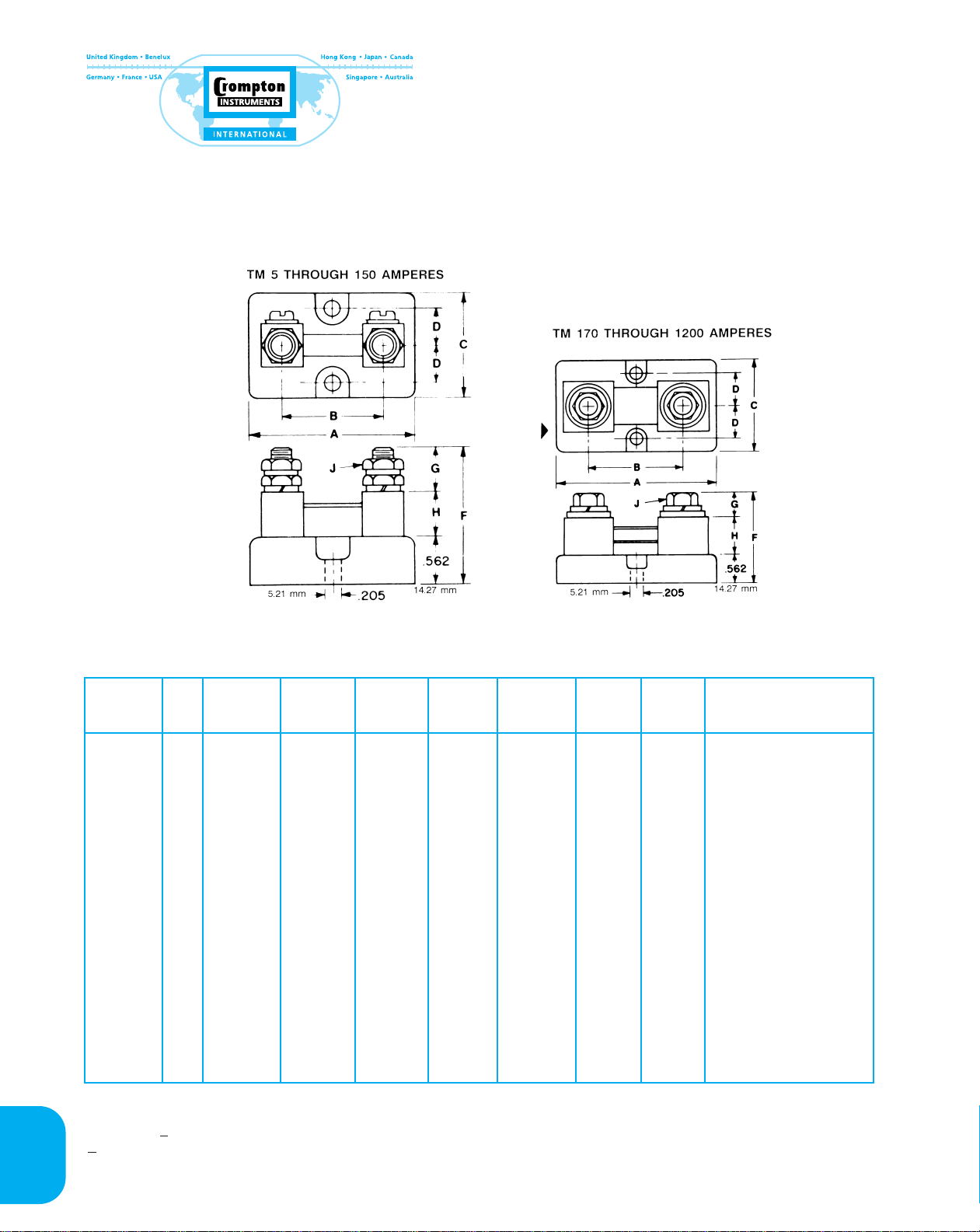

CATALOG AMP A B C D F G H J

No.

mm in mm in mm in mm in mm in mm in in mm mm in

TM-5-50 5 50.8 2 25.4 1 31.75 11⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-10-50 10 50.8 2 25.4 1 31.75 11⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-15-50 15 50.8 2 25.4 1 31.75 11⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-20-50 20 50.8 2 25.4 1 31.75 11⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-30-50 30 50.8 2 25.4 1 31.75 1

1

⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-50-50 50 50.8 2 25.4 1 31.75 1

1

⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-75-50 75 50.8 2 25.4 1 31.75 11⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-80-50 80 50.8 2 25.4 1 31.75 11⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-85-50 85 50.8 2 25.4 1 31.75 11⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-100-50 100 50.8 2 25.4 1 31.75 1

1

⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-150-50 150 50.8 2 25.4 1 31.75 1

1

⁄4 11.1 437 42.88 1.688 15.88 625 12.71⁄2 6.35-28

1

⁄4-28

TM-170-50 170 82.55 31⁄4 38.1 11⁄2 44.45 13⁄4 15.88 625 44.45 13⁄4 11.13 438 19.053⁄4 9.53-16 x 15.883⁄8-16 x 5⁄8

TM-200-50 200 82.55 31⁄4 38.1 11⁄2 44.45 13⁄4 15.88 625 44.45 13⁄4 11.13 438 19.053⁄4 9.53-16 x 15.883⁄8-16 x 5⁄8

TM-250-50 250 82.55 31⁄4 38.1 11⁄2 44.45 13⁄4 15.88 625 44.45 13⁄4 11.13 438 19.053⁄4 9.53-16 x 15.883⁄8-16 x 5⁄8

TM-300-50 300 82.55 31⁄4 38.1 11⁄2 44.45 13⁄4 15.88 625 44.45 13⁄4 11.13 438 19.053⁄4 9.53-16 x 15.883⁄8-16 x 5⁄8

TM-400-50 400 82.55 31⁄4 38.1 11⁄2 44.45 13⁄4 15.88 625 44.45 13⁄4 11.13 438 19.053⁄4 9.53-16 x 15.883⁄8-16 x 5⁄8

TM-450-50 450 82.55 31⁄4 38.1 11⁄2 44.45 13⁄4 15.88 625 44.45 13⁄4 11.13 438 19.053⁄4 9.53-16 x 15.883⁄8-16 x 5⁄8

TM-500-50 500 82.55 31⁄4 38.1 11⁄2 44.45 13⁄4 15.88 625 44.45 13⁄4 11.13 438 19.053⁄4 9.53-16 x 15.883⁄8-16 x 5⁄8

TM-600-50 600 82.55 31⁄4 38.1 11⁄2 44.45 13⁄4 15.88 625 44.45 13⁄4 11.13 438 19.053⁄4 9.53-16 x 15.883⁄8-16 x 5⁄8

TM-800-50 800 114.3 41⁄2 54.86 2.16 63.5 21⁄2 25.4 1 53.98 2.125 14.28 562 25.4 1 12.7-13 x 22.231⁄2-13 x 7⁄8

TM-1000-50 1000 114.3 41⁄2 54.86 2.16 63.5 21⁄2 25.4 1 53.98 2.125 14.28 562 25.4 1 12.7-13 x 22.231⁄2-13 x 7⁄8

TM-1200-50 1200 114.3 41⁄2 54.86 2.16 63.5 21⁄2 25.4 1 53.98 2.125 14.28 562 25.4 1 12.7-13 x 22.231⁄2-13 x 7⁄8

50 MV

Tolerances + 0.381 mm (0.015 in) for hole diameters, other tolerances

+ 0.762 mm (0.030 in) unless otherwise noted.

Dimensions are subject to change without notice.

Dimensions

Loading...

Loading...