Page 1

OPERATING INSTRUCTIONS

The LG-417 is activated by strategically located pressure pad. With a normal shooting grip,

your middle finger will naturally hit the pressure pad whether shooting right or left-handed.

A master ON/OFF switch is located on the left side of Lasergrip and is activated and deactivated

by pressing master switch firmly for less than two seconds. Turning the master switch OFF will

NOT increase battery life.

PLEASE READ ENTIRE OWNER’S MANUAL PRIOR TO INSTALLING AND USING YOUR NEW LASERGRIPS.

Crimson Trace

800-442-2406 or 503-783-5333

Fax: 503-783-5334

Customer Service E-Mail: customer@crimsontrace.com

www.crimsontrace.com

27-4178 RE V 010 01/11

www.crimsontrace.com

Fax: (503) 783-5334

Tel: (800) 442-2406

Wilsonville, OR 97070 USA

9780 SW Freeman Dr.

LG -41 7 fo r

GL O CK 17, 17 L , 1 9, 2 2 , 2 3, 3 1, 32 , 34, 3 5, 37, & 38

I N S TA L L A TI ON H A ND B O O K

THANK YOU FOR SELEC TING THE FINEST LASER

SI GH TI NG SY ST EM: CR IM SON T RA CE LA SE RGR IP S

AN D LA SE RGU AR D. WH EN I T CO ME S TO S PEE D,

ACCUR ACY AND SEC URIT Y, CRIMSON TR ACE IS THE

TOP CHOI CE OF LAW ENFOR CEME NT, MILITA RIES AND

LEGAL LY ARMED CITIZENS AROUND THE WORLD .

Page 2

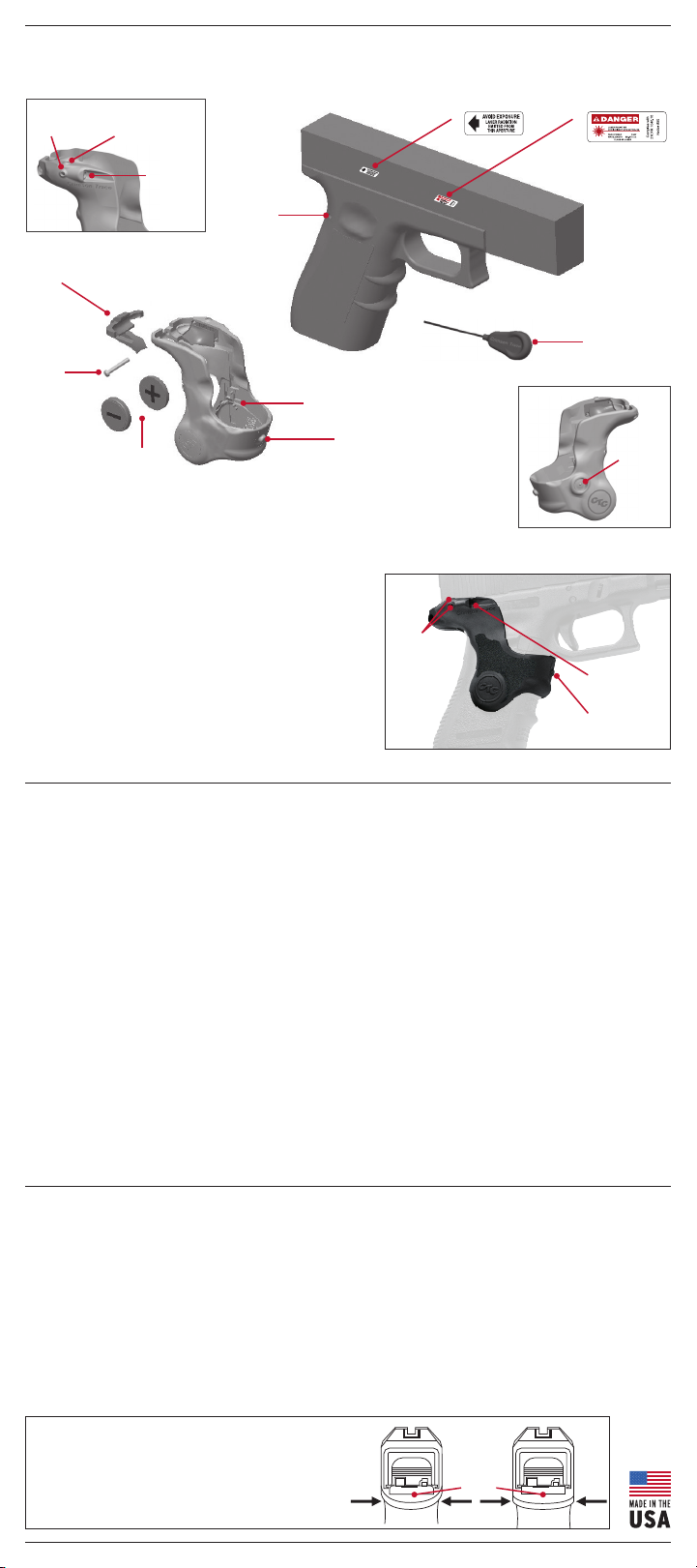

GLO CK 1 7, 1 7L, 1 9, 22 , 2 3 , 3 1, 32, 3 4 , 35, 37, & 38 [L G - 41 7]

Windage

Adjustment

Clamp

Stock Grip

Screw

Elevation

Adjustment

Batteries

Laser

Apertu re

Trigger

Housing Pin

Master ON/OFF Button

(on left side of Lasergrips)

BATTERIES

Two (2) CR2032 or DL2032 Lithium Cells.

PRODUCT SPECIFICATIONS

BEAM INTENSITY: 5mW peak, 633 nm, Class 3R laser

DOT SIZE: Approximately 0.5 inches diameter at 50 feet

BATTERIES: Two #2032 lithium batteries;

ACTIVATION: Front-located integrated momentary

WARRANTY: Three-year full warranty

This product complies with 21 CFR 1040.10

over four hours of illumination

pressure pad and master ON/OFF switch

Activation Pad

Windage and

Adjustment

Elevation

A.

B.

Armorer’s Tool

Laser

Aperture

Activation

Pad

Master

ON/OFF

Switch

INSTALLATION INSTRUCTIONS

1. Make sure firearm is unloaded. Remove magazine and double check that the chamber is empty.

(See “Four Basic Rules Of Firearm Safety” in Owner’s Manual).

2. Place one battery straight down into battery well on each Side, with the flat, (+) side visible.

3. Slide CTC Lasergrips® over the bottom of the firearm and push up until the Lasergrips pops into place.

4. Slide the clamp into the back of the Lasergrips. Insert screw (from right to left) and use armorer’s

tool to tighten down.

5. Lasergrips are default set at the factory to be in the “ON” position. Test the master on/off switch

(located on the left side of the Lasergrip) by pressing firmly for less than two seconds, and then

pressing the activation pad. The lasershould not activate. To turn back on, firmly press master on/off

switch less than two seconds.

6. Confirm that laser and iron sights are in alignment. Laser dot should rest on top of front site post

with correct iron sight picture. Lasergrips are sighted-in at the factory to 50 feet, but can be

fine-tuned to any point of impact by adjusting for windage and elevation. (See Laser Sight Owner’s

Handbook for complete sighting information.)

LASER SAFETY LABELING

IMPORTANT: LASER PRODUCTS MUST ONLY BE OPERATED WITH THE SAFETY LABEL APPLIED TO THE FIREARM.

Labels could not be affixed to the product but are supplied and must be installed as indicated below:

A. Attach the “Aperture” warning label with the arrow pointing to the laser aperture.

B. Attach the “Danger” warning label to the outside of the firearm.

Use caution when activating the laser to avoid direct eye exposure, which can result in permanent

eye damage. Follow all precautions as outlined by the firearms manufacturer. Keep this and all firearm

related products locked and secured from children or other unauthorized users.

NOTE: A SMALL NUMBER OF GLOCKS HAVE A SLIGHTLY

DIFFERENT FRAME CONFIGURATION DUE TO MANUFACTURING

TOLERANCES (SEE IMAGES) THE VAST MAJORITY OF THE

FRAMES WILL UTILIZE THE SMALL CLAMP (IMAGE 1).

If your Glock frame looks like image #1 use the SMALL (S) clamp.

If your Glock frame looks like image #2 use the LARGE (L) clamp.

Beaverta il

Image 1 Image 2

Loading...

Loading...