Page 1

Crestron PROAMP(I)-7X400

PROCISE™ High-Definition Professional

Surround Sound Amplifier

Operations Guide

Page 2

This document was prepared and written by the Technical Documentation department at:

Crestron Electronics, Inc.

15 Volvo Drive

Rockleigh, NJ 07647

1-888-CRESTRON

Important Safety Instructions

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Do not use this apparatus near water.

• Clean only with dry cloth.

• Do not block any ventilation openings. Install in accordance

with the manufacturer's instructions.

• Do not install near any heat sources such as radiators, heat

registers, stoves, or other apparatus (including amplifiers) that

produce heat.

• Do not defeat the safety purpose of the polarized or groundingtype plug. A polarized plug has two blades with one wider than

the other. A grounding-type plug has two blades and a third

grounding prong. The wide blade or the third prong are

provided for your safety. If the provided plug does not fit into

your outlet, consult an electrician for replacement of the

obsolete outlet.

• Protect the power cord from being walked on or pinched

particularly at plugs, convenience receptacles, and the point

where they exit from the apparatus.

• Only use attachments/accessories specified by the

manufacturer.

• Use only with the cart, stand, tripod, bracket or

table specified by the manufacturer or sold with

the apparatus. When a cart is used, use caution

when moving the cart/apparatus combination to

avoid injury from tip-over.

• Unplug this apparatus during lightning storms or when unused

for long periods of time.

• Refer all servicing to qualified service personnel. Servicing is

required when the apparatus has been damaged in any way,

such as power-supply cord or plug is damaged, liquid has been

spilled or objects have fallen into the apparatus, the apparatus

has been exposed to rain or moisture, does not operate

normally, or has been dropped.

• Disconnect power prior to connecting or disconnecting

equipment.

• Do not install in direct sunlight.

• The apparatus must be installed in a way that the power cord

can be removed either from the wall outlet or from the device

itself in order to disconnect the mains power.

• Prevent foreign objects from entering the device.

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

DO NOT EXPOSE THIS APPARATUS TO RAIN OR

MOISTURE. THE APPARATUS SHALL NOT BE

EXPOSED TO DRIPPING OR SPLASHING. OBJECTS

FILLED WITH LIQUIDS, SUCH AS VASES, SHOULD

NOT BE PLACED ON THE APPARATUS.

WARNING:

TO PREVENT ELECTRIC SHOCK, DO NOT REMOVE

COVER. THERE ARE NO USER SERVICEABLE PARTS

INSIDE. ONLY QUALIFIED SERVICE PERSONNEL

SHOULD PERFORM SERVICE.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS: RISQUE DE CHOC ELECTRIQUE NE PAS OUVRIR

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product's enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions i n the

literature accompanying the appliance.

WARNING:

THIS IS AN APPARATUS WITH CLASS I

CONSTRUCTION. IT SHALL BE CONNECTED TO AN

ELECTRICAL OUTLET WITH AN EARTHING GROUND

TERMINAL.

IMPORTANT:

The PROAMP-7X400 and PROAMPI-7X400 can be used

with Class 2 output wiring.

Page 3

Regulatory Compliance

As of the date of manufacture, the PROAMP-7X400 and PROAMPI-7X400 have been tested and found to

comply with specifications for CE marking and standards per EMC and Radiocommunications Compliance

Labelling.

Federal Communications Commission (FCC) Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following conditions:

(1) This device may not cause harmful interference and (2) this device must accept any interference received,

including interference that may cause undesired operation.

CAUTION: Changes or modifications not expressly approved by the manufacturer responsible for compliance

could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna

Increase the separation between the equipment and receiver

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

Consult the dealer or an experienced radio/TV technician for help

Industry Canada (IC) Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

All brand names, product names and trademarks are the property of their respective owners.

©2010 Crestron Electronics, Inc.

Page 4

Page 5

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Contents

PROCISE™ High-Definition Professional Surround Sound Amplifier:

PROAMP(I)-7X400 1

Introduction ...............................................................................................................................1

Features and Functions................................................................................................1

Applications.................................................................................................................3

Specifications ..............................................................................................................4

Physical Description....................................................................................................5

Setup........................................................................................................................................10

Network Wiring.........................................................................................................10

Identity Code.............................................................................................................10

Installation.................................................................................................................11

Hardware Hookup .....................................................................................................12

Override Mode ..........................................................................................................15

Pairing .......................................................................................................................15

Programming Software............................................................................................................16

Earliest Version Software Requirements for the PC .................................................16

Programming with Crestron SystemBuilder..............................................................16

Programming with SIMPL Windows........................................................................16

Example Program......................................................................................................18

Uploading and Upgrading........................................................................................................19

Establishing Communication.....................................................................................19

Programs and Firmware ............................................................................................20

Program Checks ........................................................................................................20

Operation.................................................................................................................................22

Problem Solving......................................................................................................................23

Troubleshooting.........................................................................................................23

Check Network Wiring..............................................................................................23

Reference Documents................................................................................................24

Further Inquiries........................................................................................................24

Future Updates ..........................................................................................................24

Return and Warranty Policies..................................................................................................25

Merchandise Returns / Repair Service ......................................................................25

CRESTRON Limited Warranty.................................................................................25

Operations Guide – DOC. 6976A Contents • i

Page 6

Page 7

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

k

PROCISE™ High-Definition

Professional Surround Sound

Amplifier: PROAMP(I)-7X400

Introduction

The PROAMP-7X400 and PROAMPI-7X400 seven-channel amplifiers are the

perfect complement to the PSPHD PROCISE High-Definition Professional Surround

Sound Processor (sold separately), delivering 400 Watts per channel, with XLR

balanced inputs, Cresnet

monitoring through the PSPHD front panel.

The PROAMP-7X400 and PROAMPI-7X400 are functionally identical. For

simplicity within this guide, the term “PROAMP-7X400” is used except where

noted.

®

and Ethernet connectivity, and seamless control and

Features and Functions

• Professional 7-channel surround sound power amplifier

• 400 watts per channel at 8 Ohms

• Stable to 4 Ohms, all channels driven

• Perfect companion to the PSPHD PROCISE surround sound processor

• Affords native Crestron

• Provides the benefits of Class D amplifiers with the neutral sound

quality of Class AB amplifiers

• Infinitesimal noise and THD affords pure, natural audio reproduction

• Isolated channel power supplies ensure maximum dynamic impact

• DC coupling affords transparency and frequency response

• Inrush current limiting provides for gentle power-up

• Includes front panel signal, clip, and fault indicators for each channel

• Allows expanded monitoring of temperature, faults, and signal status

from PSPHD or control system

• Heavy duty detachable terminal blocks ease speaker wire termination

• 24k gold-plated XLR balanced inputs assure optimum signal transfer

• Premium 7-channel XLR interconnect kits available

• Includes optional rack ears and front/rear lifting handles

• Five-space 19" rac

®

system integration via Ethernet or Cresnet

-mountable

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 1

Page 8

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

The Power to Inspire

The PROAMP-7X400’s custom hybrid design achieves the warmth and neutrality of

a Class AB amplifier with all the efficiency benefits of modern Class D.

The PROAMP-7X400 delivers 400 Watts at 8 Ohms, and 700 Watts at 4 Ohms, per

channel. Twin 1.8 kVA toroidal power transformers direct pure, continuous power to

its seven mono amplifier channels, each with its own isolated power supply featuring

an immense 168,000 µF total capacitance for wide dynamic range and headroom.

Efficiency

An ultra-efficient circuit and chassis design enables the PROAMP-7X400 to produce

greater output power in considerably less space compared to other amplifiers. The

PROAMP-7X400 accomplishes its class-leading performance in a mere five rack

spaces while maintaining effective cooling with no need for extra clearance above or

below.

Pairing

Together, the PROAMP-7X400 and PSPHD processor possess the unique ability to

operate as one, affording functionality unattainable from any other amp/preamp

combination. Through a simple Ethernet connection, the two components become

paired, enabling seamless control and monitoring of the amplifier through the

PSPHD’s front panel. While the PROAMP-7X400 provides indication of signal and

fault conditions on its own faceplate, you can actually confirm the specific fault

condition, check the real internal temperature, and monitor the output level of each

amp channel on the face of the PSPHD. Pairing the two components also streamlines

remote control and monitoring through a Crestron control system, providing

programmers with a unified device interface for all functions.

Protect, Monitor, Control

To help ensure the most seamless user experience and long-lived operation from

your amplifier, the PROAMP-7X400 provides several ways to assume control of its

essential functions and keep tabs of its operating status and health. On its own, the

PROAMP-7X400 possesses the intelligence to protect itself from many types of

faults including over temperature, over current, over voltage, under voltage, and DC

offset on any channel. Its front panel indicators help alert the user to any fault

condition, and provide verification of signal activity and clipping. More detailed

status monitoring is available when paired with a PSPHD processor.

For the greatest flexibility, the PROAMP-7X400 includes both Cresnet and high-

speed Ethernet to enable direct control and monitoring via a Crestron control system

(in lieu of a PSPHD). Whether communicating with the control system directly or

via a PSPHD, the PROAMP-7X400 lets you control amplifier power, mute

individual channels, monitor temperature and signal status, and receive fault alerts,

all from a Crestron touchpanel, computer or mobile device. Signals from the

amplifier may also be utilized to enable custom automation, such as reducing audio

levels when clipping is sensed, or regulating climate control in the equipment room

in response to amp temperature.

Professional & Precise

The PROAMP-7X400 is designed to produc e pristine, accurate audio. A hybrid, DC

coupled topology preserves the audio signal throughout without coloring or adding

noise.

2 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

Page 9

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Applications

The following diagram shows a PROAMP-7X400 in a residential application.

PROAMP-7X400 in a Home Theater Application

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 3

Page 10

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

Specifications

Specifications for the PROAMP-7X400 are listed in the following table.

PROAMP-7X400 Specifications

SPECIFICATION DETAILS

Audio

(Typical of 7 Mono Channels)

Output Power

Power Bandwidth

Damping Factor

Frequency Response

S/N Ratio

Total Harmonic Distortion

(THD)

Intermodulation Distortion

(IMD)

Crosstalk

Gain

Input Sensitivity

Main Power 2 x 12 Amps @ 120 Volts AC, 60 Hz;

Default Net ID 9C

Minimum 2-Series Control System

Update File

Environmental

Temperature

Humidity

Heat Dissipation

(at 1/8 full power)

Enclosure

Chassis

Front Panel

Mounting

Dimensions

Height

Width

Depth

Weight (including rack ears, front

handles, & rear handles)

1, 2

400 Watts per channel at 8 Ohms

700 Watts per channel at 4 Ohms

5 Hz – 45 kHz at -3 dB

> 250

20 Hz to 20 kHz, ±0.1 dB

117 dB, A-weighted

0.02%

0.05%

105 dB

23 dB

4 V

produces 400 watts into 8 ohms

rms

Requires two independent 15 Amp circuits

Version 4.001.1012 or later

41° to 104°F (5° to 40°C)

10% to 90% RH (non-condensing)

At 8 Ohms: 650 BTU/Hr

At 4 Ohms: 1100 BTU/Hr

Metal, vented sides, ultra-quiet

speed-controlled fan cooling

Aluminum with plastic overlay

Freestanding or 5U 19-inch rack-mountable

(detachable feet, rack ears, and handles are

pre-installed)

9.24 in (235 mm) with feet

8.70 in (221 mm) without feet

19.00 in (483 mm) with ears

17.28 in (439 mm) without ears

21.14 in (537 mm) with front & rear handles

18.36 in (467 mm) without handles

108 lbs (49 kg)

(Continued on following page)

4 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

Page 11

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

PROAMP-7X400 Specifications (Continued)

SPECIFICATION DETAILS

PROAMP-7X400 Physical View (Front)

Available Accessories

CBL-PRO-XLR-2

CBL-PRO-XLR-6

PSPHD

1. The latest software versions can be obtained from the Crestron website. Refer to the NOTE following

these footnotes.

2. Crestron 2-Series control systems include the AV2 and PRO2. Consult the latest Crestron Product

Catalog for a complete list of 2-Series control systems.

Balanced Audio Interface Cable Kit

(two-foot cable length)

Balanced Audio Interface Cable Kit

(six-foot cable length)

PROCISE™ High-Definition Professional

Surround Sound Processor

NOTE: Crestron software and any files on the website are for authorized Crestron

dealers and Crestron Authorized Independent Programmers (CAIP) only. New users

may be required to register to obtain access to certain areas of the site (including the

FTP site).

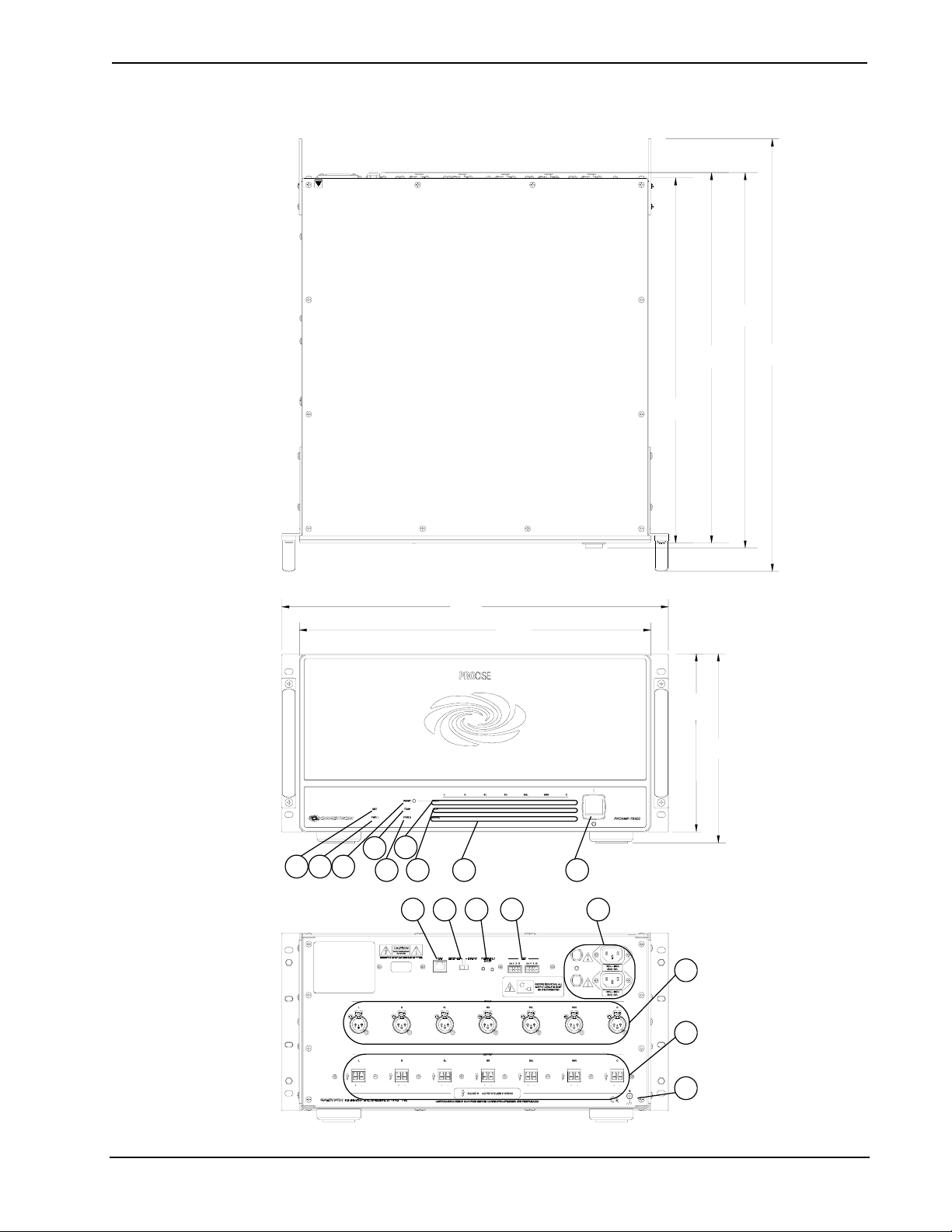

Physical Description

This section provides information on the connections, controls and indicators

available on your PROAMP-7X400.

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 5

Page 12

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

PROAMP-7X400 Physical View (Rear)

6 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

Page 13

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

PROAMP-7X400 Overall Dimensions

18.36 in

(467 mm)

19.00 in

(483 mm)

17.28 in

(439 mm)

17.86 in

(454 mm)

(221 mm)

18.12 in

(461 mm)

8.70 in

9.24 in

(235 mm)

21.14 in

(537 mm)

4

1 2 3

567 8 9

10 11 12 13 14

15

16

17

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 7

Page 14

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

Connectors, Controls & Indicators

#

CONNECTORS*,

CONTROLS &

INDICATORS

1 NET LED

2 PWR 1 LED

3 RESET BUTTON

4 TEMP LED

5 PWR 2 LED

6 FAULT LEDS

7 CLIP LEDS

8 SIGNAL LEDS

9 POWER

10

11

NETWORK/DIRECT

LAN

DESCRIPTION

(1) Amber LED, indicates communication with

Cresnet system

(1) Green LED, indicates power switch is

enabled and power is present at the upper

power input

(1) Miniature pushbutton, clears all channel

fault indications if condition is resolved

(1) Red LED, indicates an over-temperature

condition

(1) green LED, indicates power switch is

enabled and power is present at the lower

power input

(7) Red LEDs; indicate over-temperature,

over-current, over or under power supply

voltage, or DC offset condition on the

corresponding channel

(7) Amber LEDs, indicate a clipping condition

on the corresponding channel

(7) Green LEDs, indicate signal presence on

the corresponding channel

(1) Toggle switch, removes power from the

amp and resets microprocessor

(1) 8-wire RJ-45 with 2 LED indicators;

10/100BaseT Ethernet port;

Green LED indicates link status; Amber LED

indicates Ethernet activity;

Straight-thru LAN cable included for direct

connection to PSPHD

(1) Slide switch, selects whether connection

to PSPHD is via LAN or direct connection

12

13

(Continued on following page)

8 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

OVERRIDE/SETUP

(LED and button)

NET

(1) miniature pushbutton and (1) red LED,

used for touch-settable ID (TSID) in

conjunction with Crestron Toolbox™ software,

for activating Override mode for testing, and

for pairing with PSPHD

(2) 4-pin 3.5mm detachable terminal blocks;

Cresnet slave ports, paralleled;

24: Power (24 Volts DC)

Y: Data

Z: Data

G: Ground

NOTE: The NET port does not supply or

consume power.

Page 15

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Connectors, Controls & Indicators (Continued)

#

CONNECTORS*,

DESCRIPTION

CONTROLS &

INDICATORS

14

15

16

17

* Interface connectors for the NET and OUTPUT ports are provided with the unit.

POWER INPUT

INPUT

OUTPUT

GROUND

(2) IEC C14 male chassis plugs, main power

inputs 1 & 2;

Mate with removable power cords (included);

Each input includes a 15 Amp circuit breaker

(PROAMPI-7X400 has 8 Amp breakers);

Requires two independent AC feeds

(7) 3-pin XLR female;

Balanced line-level audio inputs;

Input Impedance: 24k Ohms balanced;

Maximum Input Level: 4 V

(7) 2-pin 7.62mm 41A detachable terminal

blocks;

Power amplifier outputs;

Wire Size: Terminals accept up to 10 AWG

(1) 6-32 screw, chassis ground lug

balanced

rms

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 9

Page 16

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

Setup

Network Wiring

When wiring the Cresnet and Ethernet network, consider the following:

• Use Crestron Certified Wire.

• Use Crestron power supplies for Crestron equipment.

• Provide sufficient power to the system.

CAUTION: Insufficient power can lead to unpredictabl e resul t s or damage

to the equipment. Please use the Crestron Power Calculator to help calculate

how much power is needed for the system (

www.crestron.com/calculators).

Cresnet

Ethernet

Net ID

For networks with 20 or more devices, use a Cresnet Hub/Repeater (CNXHUB) to

maintain signal quality.

For more details, refer to “Check Network Wiring” on page 23.

The PROAMP-7X400 can also use high-speed Ethernet for communications

between the device and a control system, computer, digital media server and other

IP-based devices.

For information on connecting Ethernet devices in a Crestron system, refer to the

latest version of the Crestron e-Control

available from the Crestron website (

®

Reference Guide (Doc. 6052), which is

www.crestron.com/manuals).

Identity Code

The Net ID of the PROAMP-7X400 has been factory set to 9C. The Net IDs of

multiple PROAMP-7X400 devices in the same system must be unique. Net IDs are

changed from a personal computer (PC) via Crestro n Tool b ox ™ (refer to

“Establishing Communication” on page 19).

When setting the Net ID, consider the following:

• The Net ID of each unit must match an ID code specified in the SIMPL™

Windows program.

• Each network device must have a unique Net ID.

• If an IP ID is set, Cresnet communication with the PSPHD is disabled. The

PROAMP-7X400 can use either a Cresnet connection or Ethernet

connection. It cannot use both.

For more details, refer to the Crestron Toolbox help file.

IP ID

10 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

The IP ID is set within the PROAMP-7X400’s table using Crestron Toolbox. For

information on setting an IP table, refer to the Crestron Toolbox help file. The IP IDs

of multiple PROAMP-7X400 devices in the same system must be unique.

When setting the IP ID, consider the following:

• The IP ID of each unit must match an IP ID specified in the SIMPL

Windows program.

• Each device using IP to communicate with a control system must have a

unique IP ID.

Page 17

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

• If an IP ID is set, Cresnet communication with the PSPHD is disabled. The

PROAMP-7X400 can use either a Cresnet connection or Ethernet

connection. It cannot use both.

Installation

Observe the following guidelines when installing the PROAMP-7X400:

WARNING: Failure to observe the following installation guidelines may result in

personal injury or damage to the equipment.

• The PROAMP-7X400 is very heavy. Two people should lift and install the

device.

• The installation location must be able to support the weight of the

PROAMP-7X400 (108 lbs (49.0 kg)) .

Ventilation

Rack Mounting

The PROAMP-7X400 should be used in a well-ventilated area. The venting holes

should not be obstructed under any circumstances.

To prevent overheating, do not operate this product in an area that exceeds the

environmental temperature range listed in the table of specifications. Consider using

forced air ventilation and/or incrementing the spacing between units to reduce

overheating. Consideration must be given if installed in a closed or multi-unit rack

assembly since the operating ambient temperature of the environment may be greater

than the room ambient temperature. Contact with thermal insulating materials should

be avoided on all sides of the unit.

The PROAMP-7X400 can be mounted in a rack or stacked wi t h other equipment.

Two “ears” are preinstalled so that the unit can be mounted in a rack.

WARNING: To prevent bodily injury when mounting or servicing this unit in a

rack, take special precautions to ensure that the system remains stable. The following

guidelines are provided to ensure your safety:

• Load the rack from the bottom to the top with the heaviest component at the

bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before

mounting or servicing the unit in the rack.

NOTE: The PROAMP-7X400 is shipped with “feet” installed so it can be stacked

with other equipment. If the PROAMP-7X400 is to be installed in a rack, remove the

feet using a #2 Phillips screwdriver. If rack mounting is not required, leave the feet

attached to the PROAMP-7X400.

NOTE: Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than direct

connections to the branch circuit (e.g. use of power strips).

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 11

Page 18

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

Use the following procedure and a #1 or #2 Philips screwdriver to install the

PROAMP-7X400 into a rack. Refer to the following illustration.

Rack Attachment for Rack Mounting

Rear Handles

Rack Ears

Stacking

Connect the Device

Front Handles

1. Remove the feet on the bottom of the amplifier.

2. Position the amplifier into the rack and secure the device to the rack by

screwing four rack screws (not included) into the top and bottom mounting

holes of the rack ears.

3. Remove the front handles.

4. Secure the amplifier to the rack by installing four more screws (not

included) into the middle mounting holes of the rack ears.

5. (Optional) Remove the rear handles.

Four “feet” are integrated into the PROAMP-7X400 so that if the unit is not rack

mounted, the feet can provide stability when the unit is placed on a flat surface or

stacked.

NOTE: No more than two PROAMP-7X400 units should be stacked.

Hardware Hookup

Make the necessary connections as called out in the illustration that follows this

paragraph. Refer to “Network Wiring” on page 10 before attaching the 4-position

terminal block connector. Apply power after all connections have been made.

WARNING: This amplifier is capable of delivering immense amounts of

undistorted power to your loudspeakers. Please use caution and adequate ear

protection if listening to content at high volume levels as continued exposure to high

sound pressure levels can cause permanent hearing impairment or loss.

12 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

Page 19

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

CAUTION: Keep the amplifier unplugged until all the input, network, and speaker

wiring is complete.

CAUTION: Do not bridge speaker outputs.

CAUTION: Check the speaker wires for shorts and frayed wiring around the

OUTPUT connectors.

NOTE: For optimum performance, Crestron recommends the optional

CBL-PRO-XLR-2 XLR Balanced Audio Interface Cable Kit (two-foot cable length)

or CBL-PRO-XLR-6 Balanced Audio Interface Cable Kit (six-foot cable length) to

connect to the PSPHD or other pre-amplifier.

Hardware Connections for the PROAMP-7X400

INPUT:

From PSPHD Or

Other Preamplifier

LAN:

10/100 Base-T Ethernet

to LAN Or PSPHD

NET:

To Cresnet Devices

POWER:

From Line Voltage

GROUND:

Tie To Preamplifier

Ground

NETWORK/DIRECT Switch

OUTPUT:

To Speakers

The NETWORK/DIRECT switch is used to select the connection between the

amplifier and a PSPHD. Move the switch to the appropriate position for the

connection to be used and connect the LAN port as described below:

• DIRECT: If using a direct connection to the PSPHD, connect an Ethernet

cable from the LAN port on the amplifier to the LAN port on a PSPHD.

• NETWORK: If using a network connection to the PSPHD, connect an

Ethernet cable from the LAN port on the amplifier to the local area

network. When using a network connection, the PSPHD and the amplifier

must be on the same subnet.

NOTE: Power must be cycled if the switch is moved.

For more information, refer to “Pairing” on page 15.

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 13

Page 20

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

PROCISE Amplifier

Connections

Connect a PROAMP-7X400 to a PSPHD Surround Sound Processor

Refer to the following diagram to properly connect the PROAMP-7X400 to a

PSPHD Surround Sound Processor.

Power Connections

NOTE: For optimum performance when connecting a source to a PROCISE

amplifier, Crestron recommends the optional CBL-PRO-XLR-2 Balanced Audio

Interface Cable Kit (two-foot cable length) or CBL-PRO-XLR-6 Balanced Audio

Interface Cable Kit (six-foot cable length).

When making connections to the PROAMP-7X400, two independent AC feeds are

required.

14 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

Page 21

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Override Mode

The Override mode turns on all amplifier channels and ignores any commands from

a control system or PSPHD (if connected). Use the Override mode to test the

amplifier prior to installation in a system. To use the Override mode:

1. With the amplifier powered on, press the OVERRIDE/SETUP button on

the rear of the PROAMP-7X400. The amplifier will be in the Override

mode and the associated LED will light.

2. Test the amplifier as needed.

3. Press OVERRIDE/SETUP to exit the Override mode. The LED will

extinguish.

Pairing

NOTE: Pairing is for use with the PSPHD only.

The PROAMP-7X400 can be paired with a PSPHD Surroun d So und Processor for

control and monitoring of the amplifier. Use the connection type that best fits the

application:

• DIRECT: Choose DIRECT for a quick installation test without

networking or LAN setup. The LAN port of the amplifier connects directly

to the LAN port of the PSPHD.

The following diagram shows a typical system arrangement where a

PSPHD is directly connected to the amplifier.

Control

System

Cresnet

PSPHD PROAMP

Ethernet

To later integrate with a control system program controlling via the LAN,

the pairing process must be executed again when the amplifier is installed

on a network. The original pairing must be removed and then re-paired.

If the amplifier and PSPHD are to be controlled by Cresnet, pairing does

not need to be repeated.

• NETWORK: Choose NETWORK if you already have a DHCP network

available and plan to eventually control the amplifier and PSPHD over a

LAN.

The following diagram shows a typical system arrangement where a

PSPHD is connected to the amplifier over an Ethernet network.

For details on pairing the PROAMP-7X400 with a PSPHD, refer to the latest version

of the PROAMP-7X400 Quickstart (Doc. 6977) and the PSPHD Operations Guide

(Doc. 6837) which are available for download from the Crestr on website.

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 15

Page 22

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

Programming Software

Have a question or comment about Crestron software?

Answers to frequently asked questions (FAQs) can be viewed in the Online Help

section of the Crestron website. To post a question or vie w questions you have

submitted to Crestron’s True Blue Support, log in at

First-time users will need to establish a user account.

Earliest Version Software Requirements for the PC

NOTE: Crestron recommends that you use the latest software to take advantage of

the most recently released features. The latest software is available from the Crestron

website.

Crestron has developed an assortment of Windows®-based software tools to develop

a controlled system. You can create a program to control the PROAMP-7X400 using

the Crestron programming tools SystemBuilder™ or SIMPL Windows. For the

minimum recommended software versions, visit the Version Tracker page of the

Crestron website (www.crestron.com/versiontracker).

www.crestron.com/support.

Configuration Manager

Programming with Crestron SystemBuilder

Crestron SystemBuilder is the easiest method of programming but does not offer as

much flexibility as SIMPL Windows. For additional details, download

SystemBuilder from the Crestron website and examine the extensive help file.

Programming with SIMPL Windows

NOTE: While SIMPL Windows can be used to program the PROAMP-7X400, it is

recommended to use SystemBuilder.

SIMPL Windows is Crestron’s premier software for programming Crestron control

systems. It is organized into two separate but equally important “Managers”.

Configuration Manager is the view where programmers “build” a Crestron control

system by selecting hardware from the Device Library.

NOTE: When paired with a PSPHD, the amplifier does not need to be added to the

SIMPL Windows program. Adding the amplifier to the program is recommended

when a paired PSPHD is not present in the system.

1. The PROAMP-7X400 must first be incorporated into the system.

a. To incorporate the PROAMP-7X400 (Cresnet) into the system, drag

the PROAMP-7X400 from the Cresnet Control Modules | Cresnet

Audio Modules folder of the Device Library and drop it in the System

Views.

16 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

Page 23

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Locating the PROAMP-7X400 (Cresnet) in the Device Library

b. To incorporate the PROAMP-7X400 (Ethernet) into the system, drag

the drag the PROAMP-7X400 from the Ethernet Control Modules |

Ethernet Audio Modules folder of the Device Library and drop it in the

System Views.

Locating the PROAMP-7X400 (Ethernet) in the Device Library

2. The system tree of the control system displays the device in the appropriate

slot(s) with a default Net ID or IP ID as shown in the following illustration.

NOTE: In the following illustration, there is both an Ethernet device in

Slot 8 and a Cresnet device in Slot 9. It is possible to have both types of

device attached to a control system as long as the control system has either

a built-in or expansion Ethernet interface. If Cresnet operation is desired,

the IP table for the PROAMP-7X400 must be empty.

PROAMP-7X400 Device, Slots 8 and 9

3. Additional PROAMP-7X400 devices are assigned different Net ID or IP ID

numbers as they are added.

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 17

Page 24

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

4. If necessary, double click a device to open the “Device Settings” window

and change the Net ID or IP ID, as shown in the following figures.

“Device Settings: Crestron PROAMP-7X400 (Cresnet)” Window

“Device Settings: Crestron PROAMP-7X400 (Ethernet)” Window

5. The ID code specified in the SIMPL Windows program must match the Net

ID or IP ID of each unit. Refer to “Identity Code” on page 10.

Program Manager

Program Manager is the view where programmers “program” a Crestron control

system by assigning signals to symbols.

The symbol can be viewed by double clicking on the icon or dragging it into Detail

View. Each signal in the symbol is described in the SIMPL Windows help file (F1).

Example Program

An example program for the PROAMP-7X400 is available from the Crestron

website (

18 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

www.crestron.com/exampleprograms).

Page 25

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Uploading and Upgrading

Crestron recommends using the latest programming software and that each device

contains the latest firmware to take advantage of the most recently released features.

However, before attempting to upload or upgrade it is necessary to establish

communication. Once communication has been esta bl i shed, files (for example,

programs or firmware) can be transferred to the control system (and/or device).

Finally, program checks can be performed (such as changing the device ID or

creating an IP table) to ensure proper functioning.

Establishing Communication

Use Crestron Toolbox for communicating with the PROAMP-7X400; refer to the

Crestron Toolbox help file for details. There are two methods of communication.

Indirect

TCP/IP

Indirect Communication

PC Running

Crestron Toolbox

PROAMP-7X400 connects to control system via Cresnet:

1. Establish communication between the PC and the control system as

described in the latest version of the 2-Series Control Systems Reference

Guide (Doc. 6256).

2. Use the Address Book in Crestron Toolbox to create an entry for the

PROAMP-7X400 using the expected communication protocol (indirect).

Select the Cresnet ID of the PROAMP-7X400 and the address book entry of

the control system that is connected to the PROAMP-7X400.

3. Display the PROAMP-7X400’s “System Info” window (click the

icon); communications are confirmed when the device information is

displayed.

NOTE: Required for operation with a PSPHD.

Ethernet Communication

Serial,

Ethernet

or USB

Control System

PROAMP-7X400

Cresnet

PC Running

Crestron Toolbox

NOTE: If the PROAMP-7X400 is connected directly to the PSPHD and the

NETWORK/DIRECT switch is set to DIRECT, the IP address is 192.168.238.239.

If the PROAMP-7X400 is connected to a LAN, DHCP is enabled. Use the Device

Discovery Tool in Crestron Toolbox to detect all Ethernet devices on the network

and their IP configuration. The tool is available in Toolbox version 1.15.143 or later.

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 19

Ethernet

PROAMP-7X400

Page 26

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

The PROAMP-7X400 connects to PC via Ethernet:

1. Enter the IP address, IP mask and default router of the PROAMP-7X400 via

Crestron Toolbox (Functions | Ethernet Addressing); otherwise enable

DHCP.

2. Confirm Ethernet connection between PROAMP-7X400 and PC. If

connecting through a hub or router, use CAT5 straight through cab les with

8-pin RJ-45 connectors. Alternatively, use a CAT5 crossover cable to

connect the two LAN ports directly without using a hub or router.

3. Use the Address Book in Crestron Toolbox to create an entry for the

PROAMP-7X400 with the PROAMP-7X400’s TCP/IP communication

parameters.

SIMPL Windows

Firmware

4. Display the “System Info” window (click the

PROAMP-7X400 entry.

icon) and select the

Programs and Firmware

Program or firmware files may be distributed from programmers to installers or from

Crestron to dealers. Firmware upgrades are available from the Crestron website as

new features are developed after product releases. One has the option to upload

programs via the programming software or to upload and upgrade via the Crestron

Toolbox. For details on uploading and upgrading, re fer to the SIMPL Windows help

file or the Crestron Toolbox help file.

If a SIMPL Windows program is provided, it can be uploaded to the control system

using SIMPL Windows or Crestron Toolbox.

Check the Crestron website to find the latest firmware. (New users may be required

to register to obtain access to certain areas of the site, including the FTP site.)

Upgrade PROAMP-7X400 firmware via Crestron Toolbox.

1. Establish communication with the PROAMP-7X400 and display the

“System Info” window.

2. Select Functions | Firmware… to upgrade the PROAMP-7X400 firmware.

Program Checks

Actions that can be performed on the PROAMP-7X400 vary depending on whether

it is connected via Cresnet or Ethernet.

Cresnet Connections

Ethernet Connections

20 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

For Cresnet connections, using Crestron Too l bo x, di splay the network device tree

(Tools | Network Device Tree) to show all network devices connected to the control

system. Right-click on the PROAMP-7X400 to display actions that can be performed

on the PROAMP-7X400.

For Ethernet connections, using Crestron Toolbox, display the “System Info window

(click the

performed on the PROAMP-7X400.

Be sure to use Crestron Toolbox to create the PROAMP-7X400 IP table.

1. Select Functions | IP Table Setup.

2. Add, modify or delete entries in the IP table. The PROAMP-7X400 can

3. A defined IP table can be saved to a file or sent to the device.

icon) and select the Functions menu to display actions that can be

have only one IP table entry.

Page 27

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Edit the control system’s IP table to include an entry for the PROAMP-7X400. The

entry should list the PROAMP-7X400’s IP ID (specified on the PROAMP-7X400’s

IP table) and the internal gateway IP address 127.0.0.1.

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 21

Page 28

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

Operation

Turn Power On or Off

Clear Fault Indicator

Reset Circuit Breaker

To turn the amplifier power on, move the switch on the front of the amplifier to the

position.

To turn the power off, move the switch on the front of the amplifier to the

position. The amplifier’s microprocessor will reset and continue to receive power.

In the event a channel detects overcurrent, over/under voltage, channel temperature,

or DC offset voltage, its FAULT LED will light. To clear the FAULT LED, press

the recessed RESET button on the front of the amplifier.

NOTE: Before pressing RESET, verify that the cause of the fault is no longer

present.

The amplifier is equipped with two circuit breakers that will open in the event an

internal short is detected. To reset a breaker, turn off the amplifier power as

described above, then press the breaker’s reset button on the rear of the amplifier.

NOTE: Before resetting the breaker, verify that the cause of the short is no longer

present.

22 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

Page 29

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Problem Solving

Troubleshooting

The following table provides corrective action for possible trouble situations. If

further assistance is required, please contact a Crestron customer service

representative.

PROAMP-7X400 Troubleshooting

TROUBLE POSSIBLE CAUSE(S) CORRECTIVE ACTION

Device does not

function.

Device does not

respond to

program control.

TEMP LED

illuminates.

FAULT LED

illuminates.

Device is not

communicating with the

network.

Device is not paired with

a PSPHD.

Device is in the Override

mode.

Excessive temperature

inside amplifier.

DC offset voltage on

speaker terminal.

Driving source level is

too high.

Operating temperature

is too high.

Both power plugs are

plugged into outlet on

the same circuit.

Device is not receiving

sufficient power.

Use Crestron Toolbox to poll

the network. Verify network

connection to the device.

Pair the amplifier with a

PSPHD.

OVERRIDE/SETUP to

Press

exit the

Provide better ventilation to

amplifier.

Remove DC source from

input signal. Press

turn off

Lower output level of audio

source. Press

off

Provide better ventilation to

amplifier.

Each power cord must be

plugged into a different

circuit.

Verify that each power cord is

plugged into a separate

circuit.

Override mode.

RESET to

FAULT LED.

RESET to turn

FAULT LED.

Check Network Wiring

Use the Right Wire

Strip and Tin Wire

Add Hubs

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 23

In order to ensure optimum performance over the full range of your installation

topology, Crestron Certified Wire and only Crestron Certified Wire may be used.

Failure to do so may incur additional charges if support is required to identify

performance deficiencies because of using improper wire.

When daisy-chaining Cresnet units, strip the ends of the wires carefully to avoid

nicking the conductors. Twist together the ends of the wires that share a pin on the

network connector and tin the twisted connection. Apply solder only to the ends of

the twisted wires. Avoid tinning too far up the wires or the end becomes brittle.

Insert the tinned connection into the Cresnet connector and tighten the retaining

screw. Repeat the procedure for the other three conductors.

Use of a Cresnet Hub/Repeater (CNXHUB) is advised whenever the number of

Cresnet devices on a network exceeds 20 or when the combined total length of

Cresnet cable exceeds 3000 feet (914 meters).

Page 30

PROCISE™ Surround Sound Amplifier Crestron PROAMP(I)-7X400

Reference Documents

The latest version of all documents mentioned within the guide can be obtained from

the Crestron website (www.crestron.com/manuals). This link will provide a list of

product manuals arranged in alphabetical order by model number.

List of Related Reference Documents

DOCUMENT TITLE

2-Series Control Systems Reference Guide

Crestron e-Control Reference Guide

PSPHD PROCISE™ High Definition Professional Surround Sound Processor

Further Inquiries

If you cannot locate specific information or have questions after reviewing this

guide, please take advantage of Crestron's award winning customer service team by

calling Crestron at 1-888-CRESTRON [1-888-273-7876].

You can also log onto the online help section of the Crestron website

(

www.crestron.com/onlinehelp) to ask questions about Crestron products. First-time

users will need to establish a user account to fully benefit from all available features.

Future Updates

As Crestron improves functions, adds new features and extends the capabilities of

the PROAMP-7X400, additional information may be made available as manual

updates. These updates are solely electronic and serve as intermediary supplements

prior to the release of a complete technical documentation revision.

Check the Crestron website periodically for manual update availability and its

relevance. Updates are identified as an “Addendum” in the Download column.

24 • PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 Operations Guide – DOC. 6976A

Page 31

Crestron PROAMP(I)-7X400 PROCISE™ Surround Sound Amplifier

Return and Warranty Policies

Merchandise Returns / Repair Service

1. No merchandise may be returned for credit, exchange or service without prior authorization

from CRESTRON. To obtain warranty service for CRESTRON products, contact an

authorized CRESTRON dealer. Only authorized CRESTRON dealers may contact the factory

and request an RMA (Return Merchandise Authorization) number. Enclose a note specifying

the nature of the problem, name and phone number of contact person, RMA number and

return address.

2. Products may be returned for credit, exchange or service with a CRESTRON Return

Merchandise Authorization (RMA) number. Authorized returns must be shipped freight

prepaid to CRESTRON, 6 Volvo Drive, Rockleigh, N.J. or its authorized subsidiaries, with

RMA number clearly marked on the outside of all cartons. Shipments arriving freight collect

or without an RMA number shall be subject to refusal. CRESTRON reserves the right in its

sole and absolute discretion to charge a 15% restocking fee plus shipping costs on any

products returned with an RMA.

3. Return freight charges following repair of items under warranty shall be paid by CRESTRON,

shipping by standard ground carrier. In the event repairs are found to be non-warranty, return

freight costs shall be paid by the purchaser.

CRESTRON Limited Warranty

CRESTRON ELECTRONICS, Inc. warrants its products to be free from manufacturing defects in mat erial s

and workmanship under normal use for a period of three (3) years from the date of purchase from

CRESTRON, with the following exceptions: disk drives and any other moving or rotating mechanical

parts, pan/tilt heads and power supplies are covered for a period of one (1) year; touchscreen display and

overlay components are covered for 90 days; batteries and incandescent lamps are not covered.

This warranty extends to products purchased directly from CRESTRON or an authorized CRESTRON

dealer. Purchasers should inquire of the dealer regard ing the nature and extent of the dealer's warranty, if

any.

CRESTRON shall not be liable to honor the terms of this warranty if the product has been used in any

application other than that for which it was intended or if it has been subjected to misuse, accidental

damage, modification or improper installation procedures. Furthermore, this warranty does not cover any

product that has had the serial number altered, defaced or removed.

This warranty shall be the sole and exclusive remedy to the original purchaser. In no event shall

CRESTRON be liable for incidental or consequential damages of any kind (property or economic damages

inclusive) arising from the sale or use of this equipment. CRESTRON is not liable for any claim made by a

third party or made by the purchaser for a third party.

CRESTRON shall, at its option, repair or replace any product found defective, without charge for parts or

labor. Repaired or replaced equipment and parts supplied under this warranty shall be covered only by the

unexpired portion of the warranty.

Except as expressly set forth in this warranty, CRESTRON makes no other warranties, expressed or

implied, nor authorizes any other party to offer any warranty, including any implied warranties of

merchantability or fitness for a particular purpose. Any implied warranties that may be imposed by law are

limited to the terms of this limited warranty. This warranty statement supersedes all previous warranties.

Trademark Information

All brand names, product names and trademarks are the sole property of their respective owners. Windows is a registered trademark

of Microsoft Corporation. Windows 95/98/Me/XP/Vista/7 and Windows NT/2000 are trademarks of Microsoft Corporation.

Operations Guide – DOC. 6976A PROCISE™ Surround Sound Amplifier: PROAMP(I)-7X400 • 25

Page 32

Crestron Electronics, Inc. Operations Guide – DOC. 6976A

15 Volvo Drive Rockleigh, NJ 07647 (2027298)

Tel: 888.CRESTRON 07.10

Fax: 201.767.7576 Specifications subject to

www.crestron.com change without notice.

Loading...

Loading...