CRESTRON GREEN LIGHT™ Power Switching

Introduction

CRESTRON GREEN LIGHT power switching cabinets come pre-configured with GLXP modules already installed.

The cabinets only require installation and wiring of feed and load circuits.

Industry Compliance

The cabinet and modules are Listed to applicable UL Standards and requirements by Underwriters Laboratories Inc.

Application

The following diagram shows CRESTRON GREEN LIGHT cabinets in a lighting application that is controlled by

an IPAC system.

CRESTRON GREEN LIGHT Power Switching Cabinets in a Typical Lighting Application

(E227280 (cabinet) and E103692 (modules))

Crestron Electronics, Inc. Installation Guide – DOC. 6672B

15 Volvo Drive Rockleigh, NJ 07647 (2020570)

Tel: 888.CRESTRON 10.08

Fax: 201.767.7576 Specifications subject to

www.crestron.com change without notice.

Power Switching CRESTRON GREEN LIGHT™

Physical Description

This section shows the exterior and interior dimensions of the CRESTRON GREEN LIGHT cabinet.

External Dimensions of CRESTRON GREEN LIGHT Power Switching Cabinets

20"

(508 mm)

H2

H1

H3

1

2

2

(64 mm)

"

15"

(381 mm)

5

Ø

16

(8 mm)

5

Ø

(16 mm)

"

"

8

OPTIONAL DOOR

(169 mm)

TECHNICAL KNOCKOUTS, 50 TOTAL

3

(FOR

4

TYPICAL TOP & BO T TOM

" (19 mm) &

1

" (13 mm) CONDUIT)

2

KNOCKOUT

3

(FOR

" (19 MM) CONDUIT)

4

TYPICAL BOTH SI D ES

5

6

"

8

7

Ø

16

(12 mm)

"

External Dimensions of CRESTRON GREEN LIGHT Power Switching Cabinets

DIMENSION 12 Breaker 30 Breaker 42 Breaker 42 Breaker (Short)

H1

H2

H3

37 1/2” 953 mm) 70” (1.8 m) 90” (2.3 m) 78 15/16” (2 m)

3” (77 mm) 3 5/8” (93 mm) 3 5/8” (93 mm) 3 5/8” (93 mm)

32 7/8” (836 mm) 59 3/8“ (1.5 m) 79 3/8” (2.0 m) 66" (1.7 m)

2 • CRESTRON GREEN LIGHT Power Switching Installation Guide – DOC. 6672B

CRESTRON GREEN LIGHT™ Power Switching

Interior Dimensions of CRESTRON GREEN LIGHT Cabinets (120/208 VAC, left; 277/480 VAC, right)

H1

(207 mm)

1

6

"

4

(159 mm)

7

1

1

"

8

8

(48 mm)

8

"

7

1

"

8

(48 mm)

H1

7

"

3

8

(99 mm)

8"

(204 mm)

2"

(51 mm)

2"

(51 mm)

Interior Dimensions of CRESTRON GREEN LIGHT Cabinets

120 Service 277 Service

DIMENSION 12 Breaker 30 Breaker 42 Breaker 12 Breaker 30 Breaker 42 Breaker

H1

8 3/4”

(223 mm)

15 1/8”

(385 mm)

18 1/8”

(461 mm)

Installation Guide – DOC. 6672B CRESTRON GREEN LIGHT Power Switching • 3

7 1/16”

(180 mm)

12 1/16”

(310 mm)

15 1/16”

(383 mm)

Power Switching CRESTRON GREEN LIGHT™

Installation

Observe the following when installing the cabinet:

• The cabinet must be mounted by a licensed electrician in accordance with all national and local codes.

Refer to the diagram below for specific requirements.

• The cabinet is designed for surface mounting on a wall.

• Cabinets are intended for indoor use only.

• The ambient temperature range should be 32°F to 104°F (0°C to 40°C). The relative humidity should range

from 10% to 90% (non-condensing). Allow adequate clearance in front of the cover for servicing.

Mounting Location

WALL

MAXIMUM HEIGHT OF

HIGHEST BREAKER

(FROM GROUND)

6'-7"

(2.01 m)

3'

(0.9 m)

MINIMUM REQUIRED

CLEARANCE

4 • CRESTRON GREEN LIGHT Power Switching Installation Guide – DOC. 6672B

CRESTRON GREEN LIGHT™ Power Switching

Wiring

NOTE: All wiring must be installed in accordance with all local and national electrical codes.

NOTE: Refer to the torque settings specified on pages 6, 7 and 8.

CRESTRON GREEN LIGHT cabinets are shipped with GLXP modules installed and prewired to the branch circuit

breakers. The following must be performed after installation:

• Connect incoming feed conductors to the breaker panel (section A of the following diagram)

• Connect load wiring to GLXP module outputs (section B of the following diagram)

• Connect control wiring (section C of the followi ng diagram)

FEED:

3-PHASE 4-WIRE

TO LOADS:

2W + GND 16A (MAX)

A

B

CLASS 2

WIRING ONLY

C

CLASS 2

WIRING ONLY

Installation Guide – DOC. 6672B CRESTRON GREEN LIGHT Power Switching • 5

Power Switching CRESTRON GREEN LIGHT™

Feed Wiring (Section A)

Feed Wiring for MLO (left) and MCB (right) Applications

Refer to the following table for information on wiring the feed to the panel.

Feed Wire Information

120 Volt Models

TERMINAL CONNECTOR MAX

WIRE RANGE

Neutral and

Main Lugs

Neutral Bus 14-10 AWG(CU) or

WARNING: Failure to properly tighten lugs may result in poor electrical connection and overheating of the terminals.

10-2/0 AWG (CU) or

6-2/0 AWG (AL)

6 - 300 kcmil (CU or AL)

12-10 AWG (AL)

8 AWG (CU or AL)

6-4 AWG (CU or AL)

Use copper or aluminum conductors only – rated 75°C.

TORQUE Max

Current

15 lb-ft

(20.3 Nm)

21 lb-ft

(28.5 Nm)

20 lb-in

(2.3 Nm)

25 lb-in

(2.8 Nm)

35 lb-in

(4.0 Nm)

225

Amps

CONNECTOR MAX

WIRE RANGE

6-350 kcmil (CU or AL)

1/0-750 kcmil (CU or AL)

14-6 AWG (CU or AL)

14-2/0 AWG (CU or AL)

277 Volt Models

TORQUE Max

275-300 lb-in

(31.1-33.9 Nm)

24-35 lb-in

(2.7-4.0 Nm)

40-50 lb-in

(4.5-5.6 Nm)

Current

250

Amps

6 • CRESTRON GREEN LIGHT Power Switching Installation Guide – DOC. 6672B

CRESTRON GREEN LIGHT™ Power Switching

Load Wiring (Section B)

CAUTION: Bypass jumpers are provided on each output to allow testing and to protect the module during

installation. The jumper shorts the L and SW terminals so that the load circuit is energized when the branch breaker

is on. Do not remove the bypass jumper until all feed and load wiring has been completed, and the circuits have been

tested for electrical faults.

NOTE: Use copper conductors only – rated 75°C.

Wire Gauge and Torque Values

TERMINAL CONNECTOR MAX WIRE RANGE TORQUE STRIP LENGTH

LOAD OUTPUTS 14-10 AWG 4.43 lb-in

DIM CONTROL

(GLXP-DIMFLV8 only)

GROUND BAR 14-10 AWG 35 lb-in

GROUND LUG 14-4 AWG 45-25 lb-in

28-12 AWG 4.43 lb-in

(0.5 Nm)

(0.5 Nm)

(4.0 Nm)

(5.1-2.8 Nm)

1. Each output has a label with the number of the controlling circuit breaker printed on it. With the

corresponding circuit breaker turned off, connect the controlled circuit (LOAD) wires to the output per the

markings on the module as shown in the following diagrams. Terminals for load wiring accept one 10 – 14

AWG wire.

5/16”

(8 mm)

5/16”

(8 mm)

5/16”

(8 mm)

3/4"

(19 mm)

Load Wiring for GLXP-SW10, GLXP-SW16, GLXP-HSW8, GLXP-HSW12, and GLXP-DIMFLV8 (Jumper Installed)

1

NEUTRAL

BUS

L

CIRCUIT BREAKER (20A MAX)

TO NEUTRAL BUS (PREWIRED)*

TO BRANCH BREAKER (PREWIRED)

JUMPER (PREWIRED)

TO LOAD

N

TO LOADS

L

1.2000

2

3

4

* A NEUTRAL connection is only present on OUTPUT 1.

Installation Guide – DOC. 6672B CRESTRON GREEN LIGHT Power Switching • 7

Power Switching CRESTRON GREEN LIGHT™

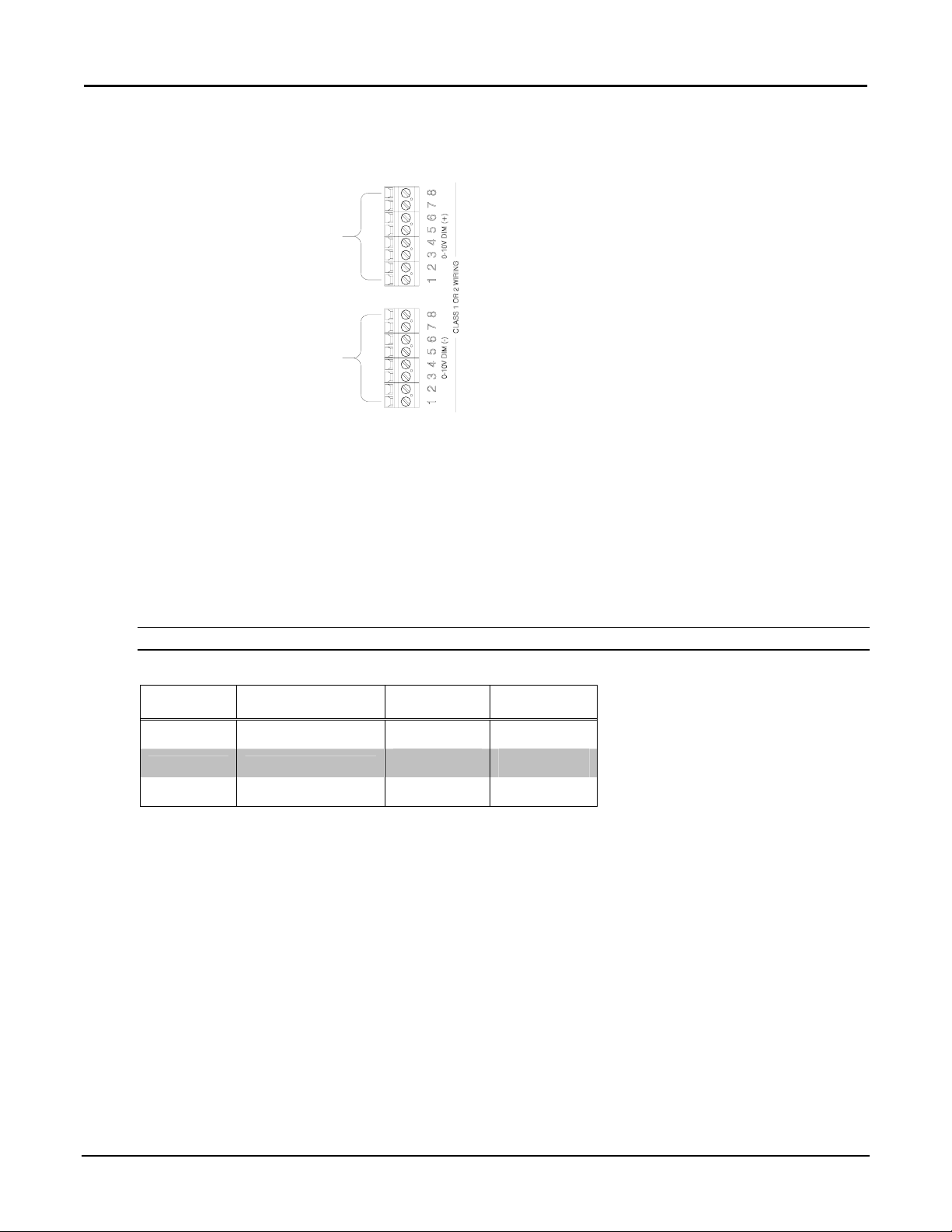

The GLXP-DIMFLV8 also requires wiring the terminals for 0-10 VDC control wire. Refer to the following

diagram when connecting the dimmable ballast. Each control wire terminal accepts one 12 – 28 AWG wire.

0-10 VDC Control Wiring for GLXP-DIMFLV8 Only

TO + ON 4-WIRE LOADS (PURPLE)

TO - ON 4-WIRE LOADS (GRAY)

2. Test the circuit for electrical faults by turning on each circuit breaker, checking that the breakers do not

trip, and that power is delivered to the proper loads.

3. Turn off the circuit breaker(s) and remove all jumpers.

4. Turn on the circuit breakers.

Control Wiring (Section C)

The bottom of the cabinet contains Cresnet® connections for interfacing to the rest of the Crestron® control system.

It also provides an override input which can be tied to devices such as the GLS-PLS-120/277 phase-loss sensor, or

other devices that provide a dry contact closure (manual switch, fire alarm relay, etc.).

NOTE: Interface connectors for NET (x2), POWER (x1), and OVERRIDE (x1) ports are pr ovided.

Wire Gauge and Torque Values

TERMINAL CONNECTOR MAX

WIRE RANGE

NET 12 AWG

POWER 26-12 AWG

OVERRIDE 26-12 AWG

TORQUE STRIP

LENGTH

4.43 lb-in

(0.5 Nm)

4.43 lb-in

(0.5 Nm)

4.43 lb-in

(0.5 Nm)

1/4”

(6 mm)

1/4”

(6 mm)

1/4”

(6 mm)

8 • CRESTRON GREEN LIGHT Power Switching Installation Guide – DOC. 6672B

CRESTRON GREEN LIGHT™ Power Switching

Connector Wiring

RED

BLUE

WHITE

TO CONTROL SYSTEM AND

NET:

OTHER CRESNET DEVICES

BLACK

POWER:

24 VDC JUMPERED FROM NET

PORT or EXTERNAL SUPPLY.

PROVIDES CRESNET POWER

TO THE MODULES

OTHER DEVICES RECEIVING

OVERRIDE:

FROM DEVICE PROVIDING

CONTACT CLOSURE & TO

OVERRIDE SIGNAL

NET Port Wiring

When wiring the supplied NET connectors for connection to a Crestron control system or other device on the

Cresnet network, use Crestron certified wire such as CRESNET-NP or CRESNET-P.

To ensure optimum performance over the full range of your installation topology, use Crestron certified wire.

Failure to do so may incur additional charges if support is required to identify performance deficiencies because

of using improper wire.

When daisy-chaining connections between NET ports, strip the ends of the wires carefully to avoid nicking the

conductors. Twist together the ends of the wires that share a pin on the network connector, insert the connection

into the Cresnet connector, and tighten the retaining screw. Repeat the procedure for the other three conductors.

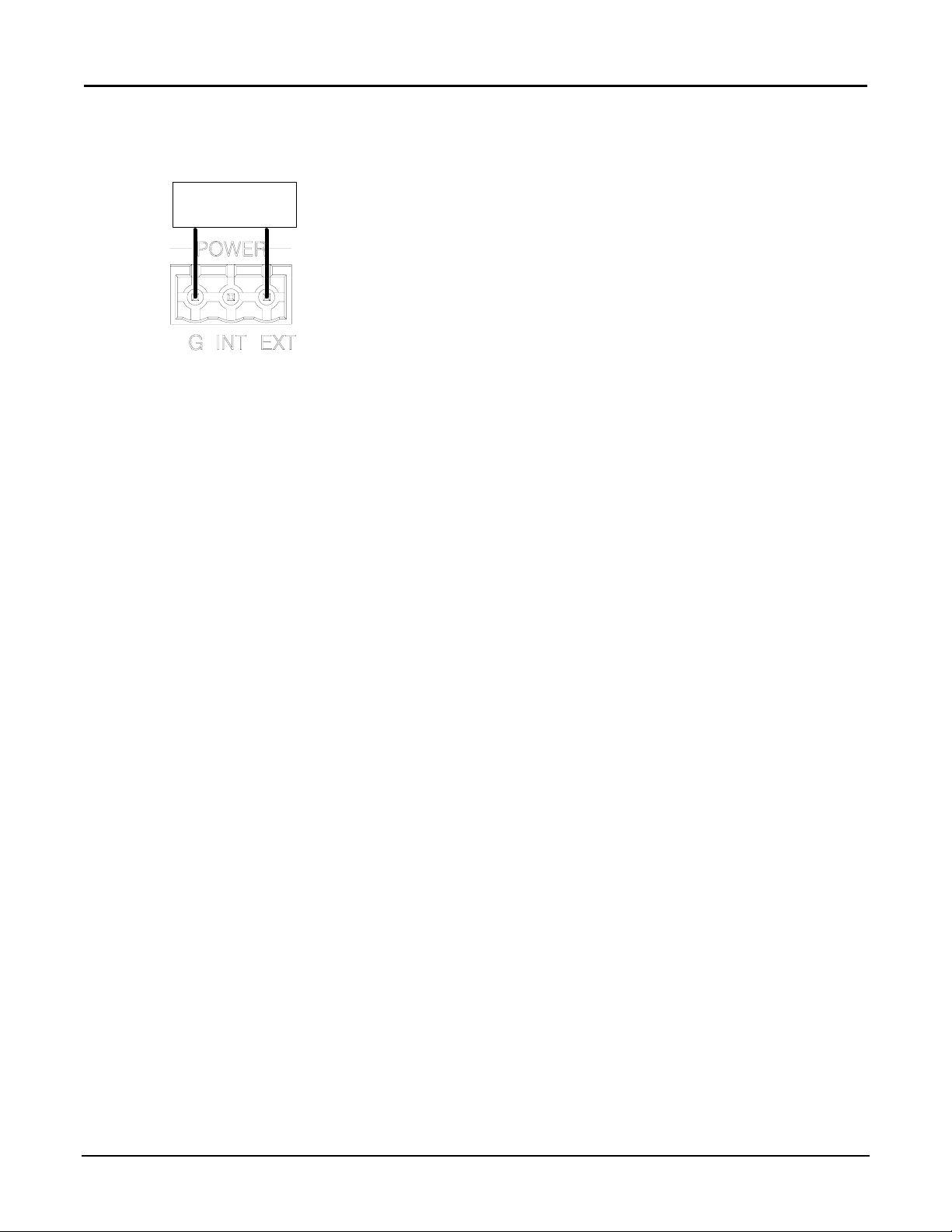

POWER Port Wiring

Low voltage (24 VDC) power must be supplied to the modules either internally via devices connected to the

NET port or externally via a Cresnet power supply connected to the POWER port.

To power the modules internally from line power, install a jumper from the INT pin on the supplied POWER

connector to the EXT pin on the POWER connector as shown in the following diagram.

Providing Cresnet Power Internally

When a lighting module is powered from line power, the module’s PWR LED will illuminate.

Installation Guide – DOC. 6672B CRESTRON GREEN LIGHT Power Switching • 9

Power Switching CRESTRON GREEN LIGHT™

To power the modules externally from a Cresnet 24 VDC power supply, connect the external power supply to

the EXT and G pins on the POWER supplied connector as shown in the following diagram.

Providing Cresnet Power Externally

CRESTRON 24 VDC

POWER SUPPLY

G 24

When properly connected and receiving 24 VDC power externally, the green LED next to the MODULES port

will light.

When a lighting module is powered from a Cresnet power supply in the absence of line power, the module’s

PWR LED will flash.

OVERRIDE Port Wiring

Low-voltage input devices such as the Crestron GLS-PLS-120/277 phase-loss sensor or any device that

provides a dry contact closure can be connected to the supplied OVERRIDE connector on the bottom of the

cabinet.

10 • CRESTRON GREEN LIGHT Power Switching Installation Guide – DOC. 6672B

CRESTRON GREEN LIGHT™ Power Switching

Testing

Manual Control

A lighting module can be manually controlled from its front panel.

GLXP-SW and GLXP-HSW Modules:

The state of each output can be manually controlled from the front panel.

To toggle the output between off and on, tap the appr opriate ON/OFF button. The corresponding LED

illuminates and the output state is shown on the NET ID display (“oF” for off, “On” for on) for two seconds

after the button is released.

NOTE: The control system program may change the settings if the Override mode is not enabled.

GLXP-DIMFLV8 Modules:

The lighting level of each of the outputs can be manually controlled from the front panel.

To toggle the light between off and 100% (on), tap an output’s ON/OFF button. The corresponding LED

illuminates and the output level is shown on the NET ID display (“oF” for off, “On” for on) for two seconds

after the button is released.

To ramp the lighting level up or down (until it reaches a limit), press and hold the output’s ON/OFF button. To

change the ramp direction, release the output’s ON/OFF button, then press and hold it again. The

corresponding LED illuminates and the output level is shown on the NET ID display as a percentage (01-99)

for two seconds after the button is released.

NOTE: The control system program may change the settings if the Override mode is not enabled.

Override Mode

The Override mode overrides the control system program and sets all of the output states to the stored override

values. For instructions on saving override setti ngs, refer to “Save Override Settings” below.

To enable Override mode, press and release the OVR button. The OVR LED flashes slowly.

NOTE: If the Override mode was enabled from an external device (i.e. a contact closure is present on the

OVERRIDE terminals), the OVR LED will flash quickly. Pressing the OVR button has no effect.

To disable Override mode, press the OVR button again. The OVR LED extinguishes and the outputs return to the

states set by the control system program.

NOTE: If override states have not been stored, the factory default override state is all loads on.

Save Override Settings

The state of each output can be saved as an override setting, which can be automatically recalled when the Override

mode is enabled.

NOTE: The control system program has a setting that can prevent locally saving the override state. If this setting is

enabled, the display shows “Er” when trying to save override states. For more information, refer to the SIMPL

Windows help file.

To save the state of all of the outputs as an override setting, press and hold the OVR button for three seconds. The

OVR LED blinks to indicate the new override settings have been stored.

Installation Guide – DOC. 6672B CRESTRON GREEN LIGHT Power Switching • 11

Power Switching CRESTRON GREEN LIGHT™

System Operation and Commissioning

This cabinet has been designed as a component of a programmed Crestron system. System commissioning by an

authorized Crestron representative

Once the cabinet has been wired and the modules have been tested, contact Crestron at 1-888-CRESTRON

[1-888-273-7876] to schedule commissioning.

must be performed to ensure system operation.

12 • CRESTRON GREEN LIGHT Power Switching Installation Guide – DOC. 6672B

CRESTRON GREEN LIGHT™ Power Switching

Problem Solving

Troubleshooting

The following table provides corrective action for possible trouble situations. If further assistance is required, please

contact a Crestron customer service representative.

Troubleshooting

TROUBLE POSSIBLE CAUSE(S) CORRECTIVE ACTION

Module(s) does not

function.

Module’s PWR LED is

flashing.

Unit cannot be taken out of

Override mode

Fluorescent lamps stay at

minimum intensity (0-10V

dimmable fluorescents only).

Fluorescent lamps stay at

maximum intensity (0-10V

dimmable fluorescents only).

Power not delivered to the

module.

System commissioning not

complete.

AC power not present on L1.

Short (contact closure) exists

between G and OVR terminals

on any of the OVERRIDE

terminals present at bottom of

the cabinet.

+ or - wires are reversed or

shorted.

+ or - wires are not connected.

If the module is powered internally, verify that

the circuit breaker connected to the first

channel on the module is on and delivering

power to the module.

If module is powered externally, verify that the

POWER port is correctly wired and receiving

power.

Arrange for system commissioning.

Check that the branch breaker feeding L1 has

not tripped. Note that unit will continue to

function, but will draw power from the backup

Cresnet power supply.

Determine the reason for the short. Remove or

remedy the short (e.g. GLS-PLS-120/277 phaseloss sensor may not have been installed

properly, or actual phase-loss has been

detected).

Verify polarity of + and - wires at ballasts and

GLXP-DIMFLV8.

Verify polarity of + and - wires at ballasts and

GLXP-DIMFLV8.

Further Inquiries

If you cannot locate specific information or have questions after reviewing this guide, please take advantage of

Crestron's award winning customer service team by calling Crestron at 1-888-CRESTRON [1-888-273-7876].

You can also log onto the online help section of the Crestron website (

questions about Crestron products. First-time users will need to establish a user accoun t to fully benefit from all

available features.

Installation Guide – DOC. 6672B CRESTRON GREEN LIGHT Power Switching • 13

www.crestron.com/onlinehelp) to ask

Power Switching CRESTRON GREEN LIGHT™

Appendix A: Setting Module Net IDs

The following procedure will normally be performed by an authorized Crestron representative as part of the System

Commissioning phase. For system wiri ng and basic te sti n g as desc ri bed on pages 5 and 11, it is not necessary to

perform this step. Only perform this step if instructed by an authorized Crestron representative, or when replacing

modules on a system that have already been commissioned (in the latter case the Net ID should be set to match the

Net ID of the module being replaced).

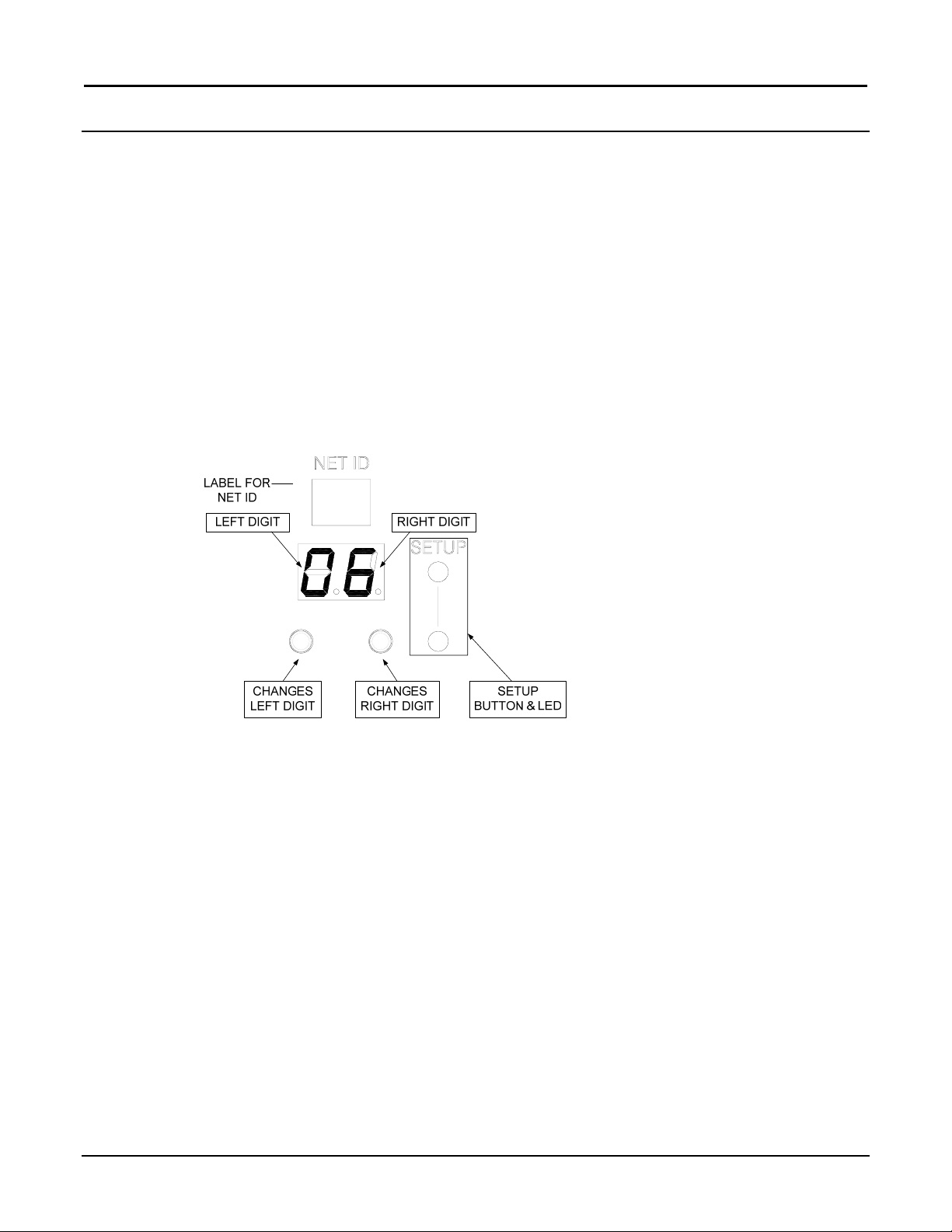

The Net ID of each module in the cabinet can be changed from the front panel of each module. The Net IDs of each

module in the system must be unique.

To set the Net ID using the front panel:

1. Press the recessed SETUP button to enter the Setup mode. The SETUP LED illuminates.

2. As shown in the following diagram, press the left button under the NET ID display to chang e th e left digit

of the Net ID or press the right button under the NET ID display to change the right digit of the Net ID

number.

Changing the Net ID

3. When the desired Net ID is displayed, press the SETUP button to exit the Setup mode. The SETUP LED

extinguishes.

If the SETUP button is not pressed, the Setup mode will time out after one minute activity and the Net ID

will revert back to its original value.

14 • CRESTRON GREEN LIGHT Power Switching Installation Guide – DOC. 6672B

CRESTRON GREEN LIGHT™ Power Switching

Appendix B: Module Specifications

Specifications for the GLXP modules are listed in the following table.

GLXP Module Specifications

SPECIFICATION GLXP-SW10 GLXP-SW16 GLXP-HSW8 GLXP-HSW12 GLXP-DIMFLV8

Description

Number of Outputs

Cresnet Power

Usage*

Input Voltage 100 – 277 VAC

Supported Load

Types

Maximum Load

Lighting

Motor

Environmental

Temperature

Humidity

Heat Dissipation

10 Channel

Switch Module

10 16 8 12 8

5 Watts 5 Watts 5 Watts 5 Watts 5 Watts

50/60 Hz

Incandescent,

Magnetic Low

Voltage,

Electronic Low

Voltage,

Neon/Cold

Cathode,

Fluorescent

Ballast, HID,

Motor

16 A per output

1 HP @ 120V

2 HP @ 230/277V

32º to 104º F

(0º to 40º C)

10% to 90% RH

(non-condensing)

10 BTU/Hr

16 Channel

Switch Module

100 – 277 VAC

50/60 Hz

Incandescent,

Magnetic Low

Voltage,

Electronic Low

Voltage,

Neon/Cold

Cathode,

Fluorescent

Ballast, HID,

Motor

16 A per output

1 HP @ 120V

2 HP @ 230/277V

32º to 104º F

(0º to 40º C)

10% to 90% RH

(non-condensing)

10 BTU/Hr

8 Channel High-

Inrush Switch

Module

100 – 277 VAC

50/60 Hz

Incandescent,

Magnetic Low

Voltage,

Electronic Low

Voltage,

Neon/Cold

Cathode,

Fluorescent

Ballast, HID,

Motor

16 A per output

½ HP @ 120V

1 HP @ 230V,

1 HP @ 277V

32º to 104º F

(0º to 40º C)

10% to 90% RH

(non-condensing)

10 BTU/Hr

12 Channel High-

Inrush Switch

Module

100 – 277 VAC

50/60 Hz

Incandescent,

Magnetic Low

Voltage,

Electronic Low

Voltage,

Neon/Cold

Cathode,

Fluorescent

Ballast, HID,

Motor

16 A per output

½ HP @ 120V

1 HP @ 230V,

1 HP @ 277V

32º to 104º F

(0º to 40º C)

10% to 90% RH

(non-condensing)

10 BTU/Hr

8 Channel 0-10V

Fluorescent

Dimmer Module

100 – 277 VAC

50/60 Hz

Dimmable

Loads:

0-10 VDC

dimmable

fluorescent

ballasts (i.e.

Advance Mark 7

or other ballasts

that comply with

the specifications

for control by DC

voltage in ANSI

C82.11:2002 and

IEC60929:2006)

Non-Dim Loads:

Incandescent,

HID, magnetic low

voltage (MLV),

electronic low

voltage (ELV),

neon/cold

cathode, and

fluorescent

ballasts, motor

16 A per output

½ HP @ 120V

1 HP @ 230V,

1 HP @ 277V

32º to 104º F

(0º to 40º C)

10% to 90% RH

(non-condensing)

10 BTU/Hr

* Power usage will be zero whenever AC power is present on circuit 1 on the module. Use of Cresnet power is optional.

Installation Guide – DOC. 6672B CRESTRON GREEN LIGHT Power Switching • 15

Power Switching CRESTRON GREEN LIGHT™

Return and Warranty Policies

Merchandise Returns / Repair Service

1. No merchandise may be returned for credit, exchange or service without prior authorization from

CRESTRON. To obtain warranty service for CRESTRON products, contact an authorized

CRESTRON dealer. Only authorized CRESTRON dealers may contact the factory and request an

RMA (Return Merchandise Authorization) number. Enclose a note specifying the nature of the

problem, name and phone number of contact person, RMA number and return address.

2. Products may be returned for credit, exchange or service with a CRESTRON Return Merchandise

Authorization (RMA) number. Authorized returns must be shipped freight prepaid to

CRESTRON, 6 Volvo Drive, Rockleigh, N.J. or its authorized subsidiaries, with RMA number

clearly marked on the outside of all cartons. Shipments arriving freight collect or without an RMA

number shall be subject to refusal. CRESTRON reserves the right in its sole and absolute

discretion to charge a 15% restocking fee plus shipping costs on any products returned with an

RMA.

3. Return freight charges following repair of items under warranty shall be paid by CRESTRON,

shipping by standard ground carrier. In the event repairs are found to be non-warranty, return

freight costs shall be paid by the purchaser.

CRESTRON Limited Warranty

CRESTRON ELECTRONICS, Inc. warrants its products to be free from manufacturing defects in materials and

workmanship under normal use for a period of three (3) years from the date of purchase from CRESTRON,

with the following exceptions: disk driv es and any other moving or rotating mechanical parts, pan/tilt heads and

power supplies are covered for a period of one (1) year; touchscreen display and overlay components are

covered for 90 days; batteries and incandescent lamps are not covered.

This warranty extends to products purchased directly from CRESTRON or an authorized CRESTRON dealer.

Purchasers should inquire of the dealer regarding the nature and extent of the dealer's warranty, if any.

CRESTRON shall not be liable to honor the terms of this warranty if the product has been used in any

application other than that for which it was intended or if it has been subjected to misuse, accidental damage,

modification or improper installation procedures. Furthermore, this warranty does not cover any product that

has had the serial number altered, defaced or removed.

This warranty shall be the sole and exclusive remedy to the original purchaser. In no event shall CRESTRON

be liable for incidental or consequential damages of any kind (property or economic damages inclusive) arising

from the sale or use of this equipment. CRESTRON is not liable for any claim made by a third party or made by

the purchaser for a third party.

CRESTRON shall, at its option, repair or replace any product found defective, without charge for parts or labor.

Repaired or replaced equipment and parts supplied under this warranty shall be covered only by the unexpired

portion of the warranty.

Except as expressly set forth in this warranty, CRESTRON makes no other warranties, expressed or implied,

nor authorizes any other party to offer any warranty, including any implied warranties of merchantability or

fitness for a particular purpose. Any implied warranties that may be imposed by law are limited to the terms of

this limited warranty. This warranty statement supersedes all previous warranties.

Trademark Information

All brand names, product names and trademarks are the sole property of their respective owners. Windows is a registered trademark of

Microsoft Corporation. Windows95/98/Me/XP/Vista and WindowsNT/2000 are trademarks of Microsoft Corpora tion.

16 • CRESTRON GREEN LIGHT Power Switching Installation Guide – DOC. 6672B

Loading...

Loading...