Crestron electronic GLPS-HSW-FT, GLPS-SW-FT, GLPS-HDSW-FT, IPAC-GL1, GLPS-HSW User Manual

...Page 1

®

Crestron Green Light

Commercial Lighting Design Guide

Page 2

© 2009

Crestron Electronics Inc.

15 Volvo Drive

Rockleigh, NJ 07647

800.237.2041

www.crestron.com

For Residential Lighting Solutions, refer to Doc. 5999

All brand names, product names, and trademarks are the sole property of their respective owners.

Page 3

Crestron Commercial Lighting Design Guide

Contents

INTRODUCTION .................................................................. 1

C

RESTRON CONTROL TECHNOLOGY ..................................... 2

HE SINGLE SOLUTION CONTROL SYSTEM ........................... 2

T

S

YSTEM DESIGN ................................................................ 3

L

IGHTING SYSTEM DESIGN TYPES ....................................... 4

PECIFYING A LIGHTING SYSTEM ......................................... 8

S

EQUIRED LOAD SCHEDULE ITEMS .................................. 8

R

XAMPLE LOAD SCHEDULE WITH PANEL TERMINATIONS ....... 9

E

OMMERCIAL LIGHTING WIRING PLAN ............................ 10

C

QUIPMENT LIST SPECIFICATION ................................... 10

E

RDERING A CRESTRON COMMERCIAL LIGHTING SYSTEM ... 10

O

G

REEN LIGHT POWER SWITCHING ....................................... 11

SYSTEM

FEATURES ................................................... 11

GLPS-HSW ............................................................... 14

GLPS-SW .................................................................. 17

GLPS-HSW-FT .......................................................... 20

GLPS-SW-FT ............................................................. 22

GLPS-HDSW-FT ........................................................ 24

IPAC-GL1 .................................................................. 26

GLA-PWS50 .............................................................. 28

IMENSIONS ................................................................ 30

D

G

REEN LIGHT OPTIONS...................................................... 36

CAEN-

SERIES ENCLOSURES .......................................... 36

INSTALLATION ................................................. 38

CAEN

ENCLOSURE FRAMING ....................................... 38

CAEN

WIRING ......................................................... 39

CAEN

NIVERSAL MOUNTING PLATES .................................... 40

U

OVER EXTENSION KITS ............................................. 41

C

LIGHTING CONTROL MODULES .............................. 42

CLX

ERMINAL BLOCKS AND MODULES ................................ 44

T

RESNET® TERMINAL BLOCK FOR CAEN AUTOMATION

C

ENCLOSURES ........................................................... 46

C

RESTRON DIN RAIL PRODUCTS ........................................ 48

DIN-AP2 ............................................................... 50

DIN-1DIMU4 ......................................................... 51

DIN-8SW8 ............................................................ 52

DIN-4DIMFLV4...................................................... 52

DIN-2MC2 ............................................................ 52

DIN-AO8 ............................................................... 53

DIN-IO8 ................................................................ 53

DIN-BLOCK ........................................................... 54

DIN-PWS50 .......................................................... 54

DIN-HUB ............................................................... 55

NTERFACE EQUIPMENT ..................................................... 56

I

W

ALL MOUNT TOUCHPANELS .......................................... 57

T

ILT TOUCHPANELS ....................................................... 59

SERIES ISYS I/O WIFI TOUCHPANELS ....................... 60

TPMC

IRELESS TOUCHPANELS AND HANDHELDS ........................ 61

W

K

EYPADS ........................................................................ 62

C2N-DB

SERIES DECORATOR KEYPADS ............................ 62

DESIGNER SERIES KEYPADS ..................................... 63

CNX

AMEO™ ................................................................... 64

C

ILUX INTEGRATED LIGHTING CONTROL SYSTEM ..................... 66

ILUX FEATURES ........................................................ 67

IRELESS ILUX REMOTE ............................................ 67

W

ULTI-UNIT EXPANSION ............................................. 68

M

ONTROL SYSTEM INTEGRATION .................................. 69

C

ILUX EXPANSION MODULES ......................................... 70

W

ALL BOX DIMMERS AND SWITCHES .................................. 72

C

RESNET WALL BOX DIMMERS .................................... 73

RESNET WALL BOX SWITCHES ................................... 74

C

INFINET™ WIRELESS TECHNOLOGY ................................... 75

C

ONTROL PROCESSORS ..................................................... 78

PAC2

LIGHTING CONTROL PROCESSOR ............................. 78

PROFESSIONAL AUTOMATION MINI CONTROL SYSTEM 80

PAC2M

O

CCUPANCY AND PHOTOCELL SENSORS ............................... 83

GLS-ODT

GLS-LOL

I

NTEGRATED SHADE AND DRAPE CONTROLLERS .................... 84

& GLS-OIR ................................................. 83

& GLS-LCL ................................................. 83

C2N-SDC .............................................................. 84

C2N-SDC-DC ........................................................ 84

C2N-SSC-2 .......................................................... 84

I

NTEGRATED PARTNER MODULES ........................................ 85

A

PPENDIX A: ................................................................... 86

R

OOMVIEW® REMOTE ASSET MANAGEMENT ......................... 86

R

OOMVIEW SERVER EDITION ........................................... 86

OOMVIEW EXPRESS ..................................................... 89

R

A

PPENDIX B .................................................................... 90

G

REEN LIGHT DESIGNER SOFTWARE™: ............................. 90

A

PPENDIX C: TOUCHPANEL COMPARISON CHARTS ................. 92

T

ILT TOUCHPANELS ....................................................... 92

ALL MOUNT TOUCHPANELS .......................................... 93

W

IRELESS TOUCHPANELS & HANDHELD REMOTES ................ 94

W

A

PPENDIX D: GENERAL LIGHTING DESIGN CONSIDERATIONS .... 95

Page 4

Page 5

Crestron Commercial Lighting Design Guide Introduction

Introduction

Crestron is the world's leading manufacturer of advanced

control technologies. Our developments in combining

touchpanel technology with lighting control applications

were the very first of their kind.

Only Crestron brings the most comprehensive line of userinterfaces to lighting and dimming control, plus the ability

to remotely monitor, manage and control over standard IP

networks.

®

Cresnet

throughout a wide range of system design possibilities,

including traditional wiring with local intelligence or

distributed, high-voltage wiring with centralized and/or

distributed intelligence systems.

The wide range of Crestron multi-function user interfaces

replaces large banks of traditional switches, dimmers, and

timers. In addition to lighting, these user interfaces can

also control security, HVAC, and audio/video systems. Only

Crestron provides a single control wiring bus to all of its

components, simplifying installation and connection.

Each unique lighting control system reflects the needs and

desires of the inhabitants. Designing and constructing a

lighting and automation system to fill the requirements of

your client is a challenging task, and Crestron offers the

equipment and flexibility of design required for every

one-of-a-kind solution.

Crestron interfaces provide manual and automatic controls;

turning on exterior lights based on an astronomical clock,

providing a single button press to turn all lights on,

illuminating safe exits in case of emergency, and many

other lighting possibilities.

Crestron products allow the designer to continually expand

and change any lighting system. Crestron infiNET

wireless devices provide a simple retrofit solution to

expand a existing systems. Every Crestron lighting system

is completely modular and scalable, allowing virtually

unlimited configuration and expansion flexibility.

Crestron eliminates the need to walk from room to room

to adjust drapes, lights, temperature, and audio/video

components- total control is always at your fingertips

low-voltage wiring and/or RF control can be used

TM

Crestron Green Light™

Crestron Green Light is a complete line of lighting, HVAC,

and shade/drape control for both commercial and

residential applications, designed to maximize energy

conservation and cost savings.

Crestron Green Light solutions underscore the company's

ongoing commitment to environmental safety and energy

conservation. Only Crestron offers a fully integrated global

systems approach with the unique ability to monitor and

manage all environmental and AV systems on a single

platform that maximizes efficiencies and cost savings.

Crestron Green Light technology delivers total

environmental control throughout a home or commercial

facility to conserve energy and lower costs without

sacrificing comfort and convenience. Crestron systems

provide users the flexibility of both precise manual control

of all systems and devices, and customized levels of

automation to achieve advanced features such as daylight

harvesting and load shedding. Only Crestron can schedule,

monitor and manage all technology centrally and globally

from touchpanels and PCs.

Crestron Green Light products meet ASHRAE standards and

are fully CEC Title 24 compliant. Crestron is a member of

the U.S. Green Building Council (USGBC), the organization

responsible for creating the LEED Green Building Rating

System™. Crestron Green Light solutions take a wholebuilding approach to sustainability, and facilitate the

efficient operation of high performance green buildings.

Additionally, all Crestron Green Light products conform to

the European Union (EU) Directive 202/95/EC Restriction of

Hazardous Substances (RoHS).

Crestron Roomview™ software (appendix A) monitors

controls, schedules and tracks assets. Facility mangers can

perform remote system diagnostics and automate tasks

through event scheduling

Crestron Green Light™ Designer software (appendix B)

allows you to design and document a complete, energyefficient commercial lighting solution that combines

facility-wide lighting, shade/drape control with audio/video

integration and network management—all without

requiring extensive knowledge of Crestron products,

or any other Crestron software.

.

Doc. 4775A 1

Page 6

Introduction Crestron Commercial Lighting Design Guide

Crestron Control

Technology

View precise lighting levels, temperature and shade

positions in any room throughout the installation, graphically

and quantitatively, from any touchpanel or PC.

Monitor and track current and historical device usage

and intelligently manage resources.

Ethernet connectivity enables LAN or web-based system

control and management, and sends email advisories about

pre-determined events such as devices going off-line

or automatic load shedding.

Crestron control processors provide the total integration of

Crestron devices, non-Crestron devices, and subsystems

in any environment, for any purpose, anywhere. Crestron

control processors can connect to any digital, serial, or

analog system, and control by RF, IR, or hardwiring,

making them the most flexible, powerful control systems

ever devised.

Underlying the hardware are powerful, graphical

programming tools, specifically designed to establish total

control over any technology and make the user experience

uncomplicated, intuitive, and easy to use.

Crestron also provides true feedback for essential control

monitoring, function response to controls, and user inputs.

Single Solution Control

System- Crestron Exclusive

Crestron connects people with technology. As products and

systems become more complex, our solutions streamline and

simplify technology so people can enjoy its benefits.

We understand that our touchpanels, keypads, and handhelds

are how people interact with and experience the systems in

their homes, offices, schools and churches. We allow

individuals to create a comfortable environment, set a mood,

and enjoy technology.

With our wide range of interface products, slim profile wall

mount keypads and decorative faceplates, our products

enhance a décor, complement a lifestyle, or personalize a

room. Crestron offers the most brilliant graphics and intuitive,

customized interfaces. We integrate more of the technology

that people want and use everyday into our touchpanels; and

provide ergonomically designed and easy-to-use wireless

controllers, and flush-mount touchpanels of every size.

Tying all this technology together seamlessly is our exclusive

®

Cresnet

control system.

cable, connecting the user to a powerful and flexible

Crestron offers design solutions for every situation.

Selecting the proper equipment often depends on the kind

of installation. New construction, major renovation, or minor

renovation each present different design challenges.

Doc. 4775A 2

Page 7

Crestron Commercial Lighting Design Guide System Design

System Design

The applied lighting control strategy determines the basic methods used to

control the environment. When formulating an overall strategy, there are some

basic considerations:.

New construction and major renovations provide the opportunity to

easily run control cables from user interfaces to the control processor

when the walls are open.

Existing construction or minor renovations often make the task of

running cables more difficult, time consuming, expensive, or even

impossible (in historic landmarks, etc.). In this case, you may choose

to install a partialyl or completely wireless system

Light level control is achieved through dimming controls and daylight

management, where applicable, to adjust the lighting to the

appropriate level for different occupant activities

Occupancy sensing is used to switch the lighting on and off,

independent of time intervals or scheduled periods. This allows the

space to be responsive to individual use, and conserves energy

Scheduled lighting is determined by time of day, day of week,

vacation, outdoor lighting, and safety lighting requirements. An

astronomical clock (programmed with sunrise and sunset information)

is often used to provide natural lighting transitions

HVAC control should be part of the overall control strategy, permitting

additional economic and convenience benefits

Doc. 4775A 3

Page 8

Crestron Commercial Lighting Design Guide System Design

Lighting System Design Types

There are many ways in which a Crestron lighting control

system can be organized. Construction type, client

requirements, architectural restrictions, and many other

factors determine the best solution. In general, retaining

Crestron control design flexibility produces the most

reliable results.

Wireless Systems

The groundbreaking Crestron infiNET wireless technology

provides reliable 2-way communications throughout a

home or commercial structure without the need for

physical control wiring. Crestron infiNET products offer a

unique solution for retrofit projects. By replacing existing

controls with infiNET switches and dimmers, provisions

for automatic shutoff and overall control can be

implemented with minimal changes to the existing wiring.

Employing a 2.4 GHz mesh network topology, every

infiNET device functions as an RF repeater, increasing

effective range and reinforcing the complete network by

providing multiple redundant signal paths within the mesh

network. Adding more infiNET devices or repeaters to the

network effectively increases the range, strength, and

reliability of the network.

Advantages of RF wireless control start with reduced

capital and operating expenses. Wireless control can save

as much as 30 to 40 percent on installation and material

costs compared to a wired control system, making this

option attractive for retrofit as well as new construction.

Installation costs are reduced because RF devices can

be replaced one to one without involving control wiring.

Crestron infiNET Wireless System

Doc. 4775A 4

Page 9

Crestron Commercial Lighting Design Guide System Design

Centralized Wired Systems

A centralized system is one in which all the high-voltage

circuits are terminated within a Crestron automation

enclosure and operate under a central control system. In a

centralized design, the high voltage lighting, fans, motors

and switch circuits are individually wired directly to the

control modules in the Crestron automation enclosure.

The modules are controlled by low voltage or RF user

interfaces in the living area. This greatly simplifies the

high voltage wiring while creating a flexible and efficient

design using keypad and touchpanel interfaces.

A central processor, connected via a local area network to

the lighting modules and the user interfaces, is dedicated

to lighting, fans, motors, HVAC, and security. Processors

that are dedicated to other control systems can

communicate via Ethernet, RS-232 or RS-422 to the

central controller. This eliminates the need for additional

control that separate safety and environmental systems

and is a flexible, fully integrated design solution.

A Centralized Wiring System

Doc 4775A 5

Page 10

System Design Crestron Commercial l Lighting Design Guide

Decentralized Wired Systems

A decentralized system is the traditional wiring system

of individual lighting circuits with local control. In the

traditional distributed design wiring method, Crestron wall

box dimmers can be retrofitted into a project after routine

high voltage wiring is completed.

In addition to the traditional high voltage wiring, a low

voltage communication wire can be run from the dimmer

to the nearest Cresnet® connection (or an RF wireless

control can be used). This design offers the end user the

familiarity of a traditional control coupled with the power

and flexibility of automation. In a distributed design, the

user has the ability to operate the lighting in the event of

a temporary control system interruption.

A Decentralized Wiring System

Doc. Doc 4775A 6

Page 11

Crestron Commercial Lighting Design Guide System Design

Hybrid Systems

The most efficient and attractive lighting system designs

are a hybrid of centralized processing and distributed

dimmers. This provides the reliability of local control along

with sophisticated centralized control, and limits the

amount of wall clutter

A complete Crestron design is a blend of wireless and

wired, distributed and centralized design in which central

control intelligence and distributed local dimmers form a

reliable whole house lighting control solution.

Large rooms, stairways, and frequently used rooms are

often remotely controlled using the astronomical time

clock or whole house presets. This level of control

requires connection to a central dimming controller. Each

room is equipped with a low voltage or wireless keypad

for lighting preset selection and/or audio/video integration.

All of the dimmers in the system (grouped into the central

controller for wiring convenience) communicate with each

other through the Crestron control system, providing a

complete, integrated solution

A Hybrid Wiring System

Doc 4775A 7

Page 12

Crestron Commercial Lighting Design Guide Specifying a Lighting System

Specifying a Lighting

System

The Load Schedule

A lighting system design begins with a collection of

complete information. This includes a detailed floor plan

identifying all of the required elements. The first element

of design, the load schedule, is developed from the floor

plan. The load schedule lists the information on each

electrical load connected to every circuit in an electrical

panel. This primary source of information determines all

of the overall requirements:

Lighting types, required voltage and current,

dimmed or switched, fluorescent ballast types,

circuit number, normal or emergency, and

locations

The location and types of user interfaces used

(i.e., dimmers, switches, keypads, iLux™,

infiNET™, and touchpanels)

The control processor details (larger systems

should use a dedicated lighting control processor)

The window treatment details, which include

shade/blind motors and relay control (consult

the window treatment manufacturer for control

details).

Required Load Schedule Items

1. Control zone: Controlled circuits that do not need

to be physically wired together, but always operate

in tandem. For example, perimeter lights, sconce

lights and overhead lights all operating together

2. Location of controlled lighting zone, relevant to

building site/drawings, floor designation, and

room name

3. Fixture and/or lamp type of controlled lighting

zone, including any information describing custom

fixtures, undetermined fixtures, dimmable

transformers or fluorescent ballasts, and circuit

breaker numbers. This information can also contain

the number assigned to the controlled circuit

4. Load type of the controlled lighting zone: load types

include incandescent, magnetic low voltage,

electronic low voltage, neon/cold cathode, HID,

dimmable/non-dimmable fluorescent ballast, ceiling

fans, and switched 3-wire motor circuits. This

information is especially important for selecting the

correct Crestron module power rating and type

5. Dimming requirement for the controlled lighting

zone (i.e. whether the lighting level of the

loads/fixtures needs to be ramped up/down or

simply switched on/off). Indicate: “Yes” for

Dimming, and “No” for Non-Dim

6. Emergency designation for the controlled lighting

zone (yes/no; i.e. when a load needs to be assigned

to a separate emergency power feed). These items

are assigned to their own separate dimmer, so they

can be fed with emergency power

7. Voltage rating for the controlled lighting zone tells

the designer the voltage of the electrical feeds

required for that zone, and hence the required

rating for the associated Crestron module.

8. Fixture wattage (watts or power rating per fixture)

with regard to the controlled lighting zone: this is

used to determine the number of fixtures that can

be powered per each Crestron Dimmer Module

channel, in order not to overload the dimmer

beyond its power rating

9. Quantity of fixtures for the controlled lighting zone:

this is useful, along with item #6, in calculating the

total power rating (watts) for that particular

controlled circuit (item #9)

10. Total wattage, or power rating, of the controlled

lighting zone: This is required in order to determine

the total number of Crestron Lighting Module

channels required for that particular zone,

especially if the load of the total number of fixtures

exceeds the rating of a single module channel

A riser diagram is requied for commercial lighting

projects. The simgle lin or sier diagram indicates

system components connected to individual circuits

in the system. Components connected to a

common circuit are shown as being connected to a

single line, regardless of the number of conductors

actually used. The number of conductors in each

wiring segment is usually indicated by right angle

marks across the single line at that point or by other

appropriate means

NOTE: National and local electrical codes and the

functionality of each user interface must be taken

into consideration. Always install electrical devices

according to the national Electrical Code (NEC), local

codes, and with safety in mind.

Doc. 4775A 8

Page 13

Crestron Commercial Lighting Design Guide Specifying a Lighting System

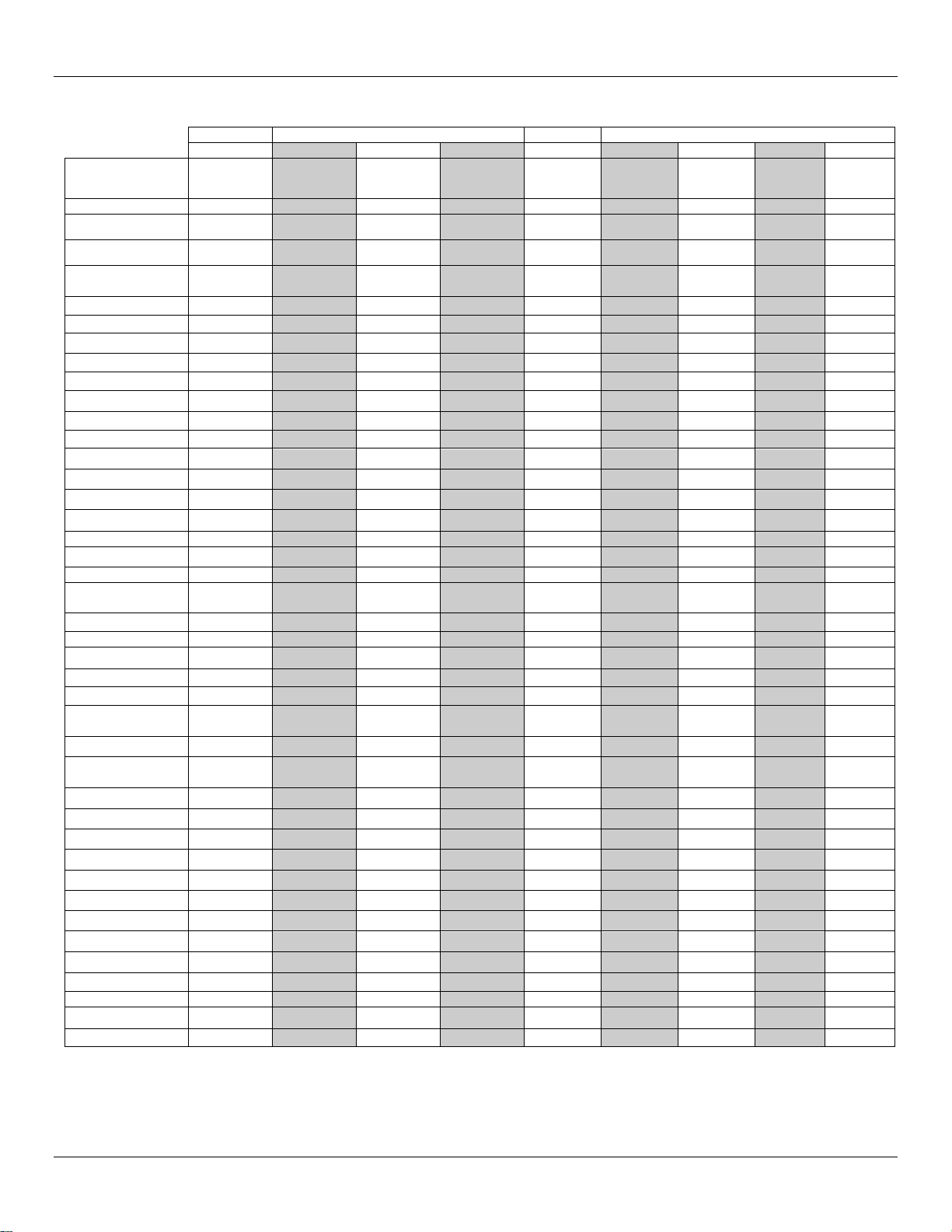

Example Load Schedule with Panel Terminations

Area Room

Main Floor Bathroom 1 Downlights 009 Downlights Incandescent yes no 100 1 100 Enclosure 1 2 CLX-1DIM8 1

Main Floor Bathroom 1 Downlights 2 008 Downlights Incandescent yes no 100 2 200 Enclosure 1 2 CLX-1DIM8 2

Main Floor Bathroom 1 Downlights 3 006 Downlights Incandescent yes no 100 2 200 Enclosure 1 2 CLX-1DIM8 3

Main Floor Bathroom 1 Drapes 019 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 4 CLX-1MC4 1

Main Floor Bathroom 1 Exhaust Fan 007 Exhaust Fan Switched no no 200 1 200 N / A N / A Interface 2 1

Main Floor Bathroom 2 Downlights 011 Downlights Incandescent yes no 100 1 100 Enclosure 1 2 CLX-1DIM8 4

Main Floor Bathroom 2 Downlights 2 010 Downlights Incandescent yes no 100 3 300 Enclosure 1 2 CLX-1DIM8 5

Main Floor Bathroom 2 Drapes 021 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 4 CLX-1MC4 2

Main Floor Bathroom 2 Exhaust Fan 012 Exhaust Fan Switched no no 200 1 200 N / A N / A Interface 4 1

Main Floor Bedroom Ceiling Fan 022 Ceiling Fan Ceiling Fan no no 100 1 100 Enclosure 1 6 CLX-1FAN4 1

Main Floor Bedroom Downlights 005 Downlights Incandescent yes no 250 2 500 Enclosure 1 2 CLX-1DIM8 7

Main Floor Bedroom Downlights 2 004 Downlights Incandescent yes no 100 4 400 Enclosure 1 3 CLX-1DIM4 1

Main Floor Bedroom Downlights 3 003 Downlights Incandescent yes no 100 1 100 N / A N / A Interface 6 1

Main Floor Bedroom Downlights 4 002 Downlights Incandescent yes no 100 1 100 N / A N / A Interface 5 1

Main Floor Bedroom Downlights 5 001 Downlights Incandescent yes no 100 2 200 Enclosure 1 3 CLX-1DIM4 2

Main Floor Bedroom Drapes 018 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 4 CLX-1MC4 3

Main Floor Bedroom Drapes 2 017 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 4 CLX-1MC4 4

Main Floor Bedroom Drapes 3 016 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 5 CLX-1MC4 1

Main Floor Foyer Downlights 013 Downlights Incandescent yes no 100 4 400 Enclosure 1 2 CLX-1DIM8 6

Main Floor Sauna Drapes 020 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 5 CLX-1MC4 2

Controlled Ckt

Name

Controlled

Ckt No. Fixture Load Type Dim Emergency

Fixture

Watts

Fixture

Total

Qty

Watts Enclosure Slot Module Output

*Calculation of load wattage includes transformer loss.

The complete diagram is available on line at:

http://www.crestron.com/dealer-tech_resources/application_diagrams.asp

.

Doc 4775A 9

Page 14

Specifying a Lighting System Crestron Commercial Lighting Design Guide

Commercial Lighting Wiring Plan

The wiring plan includes all enclosures and the

interconnecting wiring. The designer determines the

location of the enclosure(s), the route of keypad and

touchpanel connections to the enclosure(s), the route

of the interconnecting cable from the processor to the

other enclosure(s), and the high voltage load routes

to the enclosure or dimmer.

Ensure there are enough connectors and power (PAC2 offers

50W) in the main enclosure for all user interfaces. Each

enclosure filled with dimmers is connected to the main

enclosure and processor using low voltage wire. Dimmer

enclosures are distributed as needed.

Equipment List Specification

The equipment list is based on the requirements collected for

the lighting system in the load schedule. This is a sequential

process. The information gathered in previous steps is

required to complete the next. Once all the steps are done,

a complete Bill of Material for the system is created.

Module selection – based on the number and type

of loads

Automation enclosure selection – based on the

number of modules and the available space in the

enclosure

User interface selection – based on the user control

requirements

Wiring plan – based on the previous steps and the

layout of the environment

Control processor – based on the size of the system

(large systems should have a dedicated processor)

Network block selection – based on the layout and

distribution of the loads and user interfaces

Accessories selection – based on the required

accessories (telephone and alarm systems, HVAC

control, intercom systems, occupancy sensors, etc.)

Ordering a Crestron Commercial

Lighting System

These are the steps for ordering a Crestron commercial

lighting control system, regardless of the size.

Each system and module contains the appropriate installation

literature and operation guide.

Steps to order a lighting system:

STEP 1: Survey all controlled lights and loads. In hybrid

systems determine which loads are under local control and

which are to be wired to centralized modules

STEP 2: Determine the number and types of control modules

and terminal blocks needed to control lights and loads based

on the load schedule and wiring plan

STEP 3: Determine the number and type of automation

enclosures required

STEP 4: Determine the number of control processors and

related accessories required

STEP 5: Determine the number and types of keypads,

wall panels, iLux™ devices, infiNET™ wireless devices,

shade/drape controllers, and touchpanels

STEP 6: Determine the wiring accessories, cabling and

power supplies required

STEP 7: Place an order for identified Crestron items

Nearly all required documentation, such as load schedules

and wiring, equipment lists, engraving files and more can

be generated by using the Crestron D3 Pro Lighting and

Automation System Software.

Crestron ships all items to the job site for assembly and

wiring.

Note: Crestron Green Light Panels are shipped assembled

and are to be commissioned by Crestron.

Doc. Doc 4775A 10

Page 15

Crestron Commercial Lighting Design Guide Green Light Power Switching

SYSTEM FEATURES

Green Light Power

Switching

C

restron Green Light Power Switching is a family of switching

systems designed for control of lighting in office buildings,

warehouses, parking garages, sports facilities, public spaces,

and anywhere centralized switching is required. With a range

of panel sizes and configurations available, every system is

fully scalable to fit each installation perfectly. An extensive

selection of Crestron keypads, touchpanels, occupancy

sensors, photocells, shade controllers, and numerous other

peripheral options afford astounding design flexibility with

unparalleled capability for integration

Green Light Power Switching is simple to install and easy to

program. Native features include an astronomical time clock

to allow scheduling of events to occur around the rise and fall

of the sun. Other powerful, energy saving capabilities include

occupancy sensing to turn off lights when they are not

needed, daylight harvesting to harness natural light from

windows and skylights, and emergency override to assure

safe and reliable lighting of critical areas in the event of a

power outage or emergency condition.

Scalable and field-serviceable modular design

Switching control for all types of lighting loads and motors

up to 2 HP

All outputs rated at 16A @ 120V and 277V (347V also available)

Local front panel relay controls

3 high-performance relay types available

UL 508 Section 61C rated for electronic ballast

Available 0-10V fluorescent dimming control

Positive air gap at each output

Feed-through, main lug only, main circuit breaker options

CEC Title 24 listed

Astronomical time clock

Occupancy sensing and daylight harvesting

Emergency override capability

Easy programming via the IPAC-GL1 lighting processor

Extensively programmable via PC software

Wide selection of interface and computer control options

Optional shade and drape controllers

Crestron RoomView® remote management

Integration into building management systems

System design by Crestron

Factory assembled and tested

High-Performance Power Switching—Crestron GLEP Series

power switching panels feature field-replaceable switching

modules with a choice of relay technologies to address a

wider range of applications and budgets.

Our top of the line GLPS-HSW panels employ robust 50 Amp

mechanically-latching relays in combination with advanced

zero-cross arcless technology to achieve a relay lifetime of

one million cycles. For a higher density switching solution,

our GLPS-SW panels utilize the same rugged 50 amp relays

while putting more controlled circuits in less space. Either

panel supports both 120 and 277 voltages, and includes

main lugs and integrated branch circuit breakers.

GLPS-HSW Panel

For installations using a separate circuit breaker panel,

“

Crestron offers the Green Light Express series of

”

through

panels. Like their "main lug" panel counterparts

feed-

above, the GLPS-HSW-FT and GLPS-SW-FT panels feature

zero-cross arcless switching and standard high-inrush

switching respectively. Green Light Express also offers one

more relay option in the GLPS-HDSW-FT, utilizing heavy duty

Doc. 4775A 11

Page 16

Green Light Power Switching Crestron Commercial Lighting Design Guide

modular relays for an extra level of flexibility switching 120,

277, and 347 volt loads.

In addition to switching, some Green Light Power Switching

panels also allow the option to add dimming control for 0-10V

dimmable fluorescent ballasts

.

The IPAC-GL1 Control Processor—Crestron has been

manufacturing and innovating microprocessor-based control

systems for lighting and automation longer than anybody,

and all of that know-how has gone directly into the IPAC-GL1.

Right from its front panel, an entire system of lighting loads,

keypads, touchpanels, sensors, and scheduled events

can be programmed without ever having to connect a

computer.

Featuring the same 2-Series control engine as other Crestron

processors, the IPAC-GL1 allows advanced programming to

support all kinds of control options and interfaces, custom

functionality and extensive integration with third-party

systems. Crestron processors also deliver the most

comprehensive capabilities available for remote control

and management over an IP network.

Local Controls—Crestron Green Light simplifies installation by

providing local controls right on the front of each switching

module. Even before the lighting processor gets installed,

these simple controls can be used to switch each load on

and off for testing and operation during construction.

Emergency Override—Remote emergency override capability

allows a power loss sensor (GLS-PLS-120/277) or any

external contact closure to override the lighting system

program and set each circuit to its override preset state. In

a power failure situation using a backup power source, this

allows designated emergency lighting circuits to be turned on

immediately. Override settings can be made easily using the

local controls on the front of each switching module.

®

Cresnet

communicates with the IPAC-GL1, or other Crestron 2-Series

processor, via the Cresnet control network. This simple 4wire bus affords proven reliable digital control and flexible

system configuration, carrying data communications and 24

volt DC power to support a complete system of lighting

panels, keypads, touchpanels, sensors, and numerous other

Cresnet devices while connected to an IPAC-GL1 Integrated

Professional Automation Computer.

—Each Green Light Power Switching panel

Doc.4775A 12

Page 17

Crestron Commercial Lighting Design Guide Green Light Power Switching

A

A

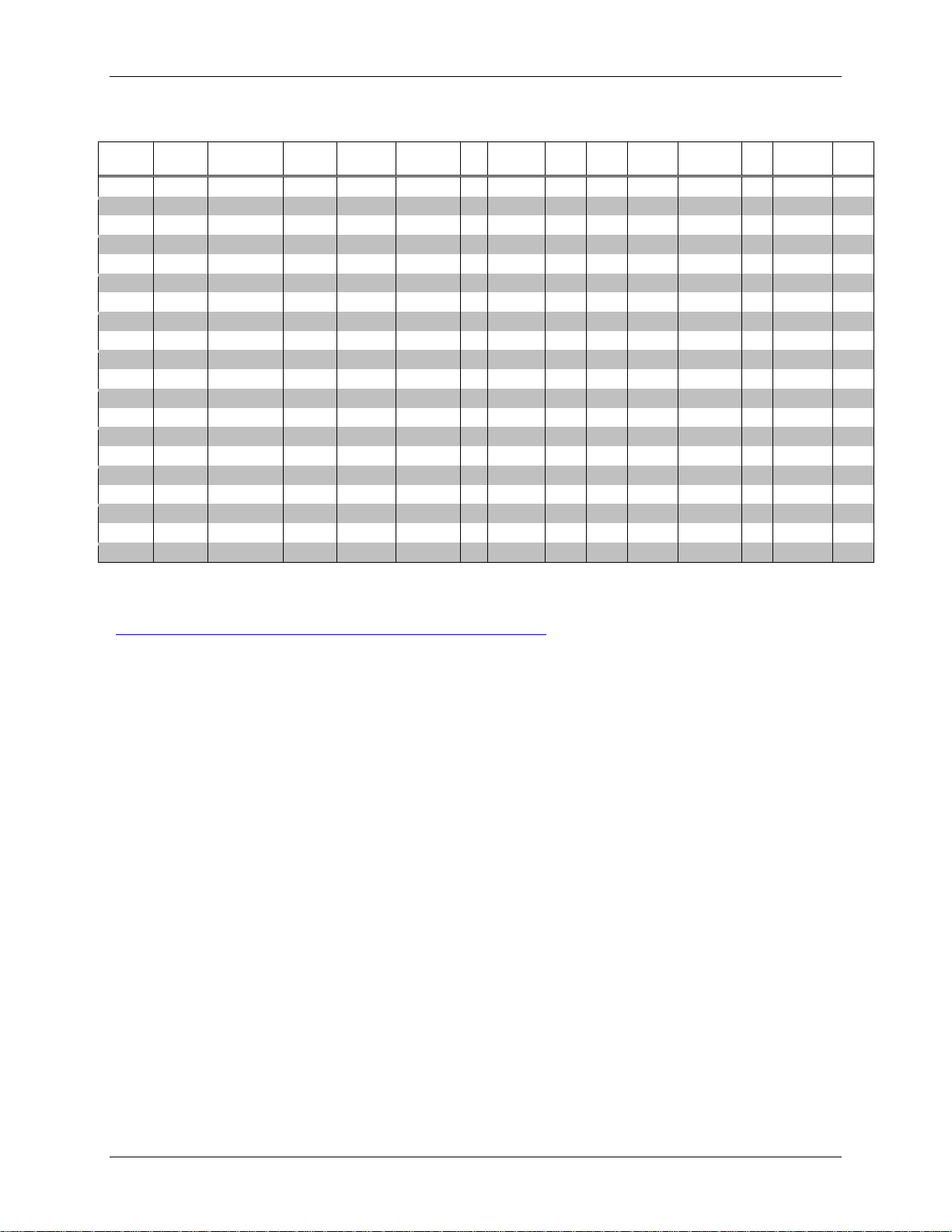

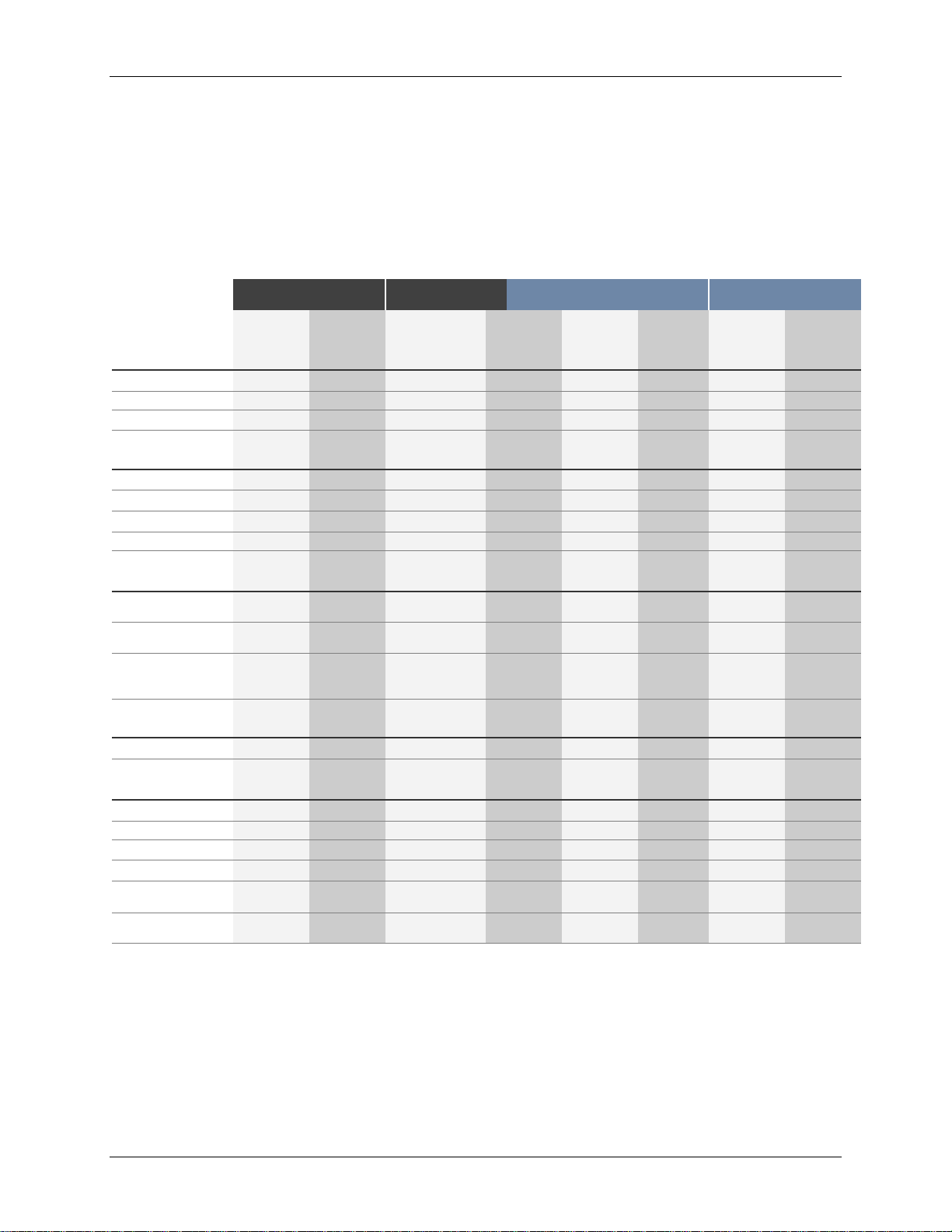

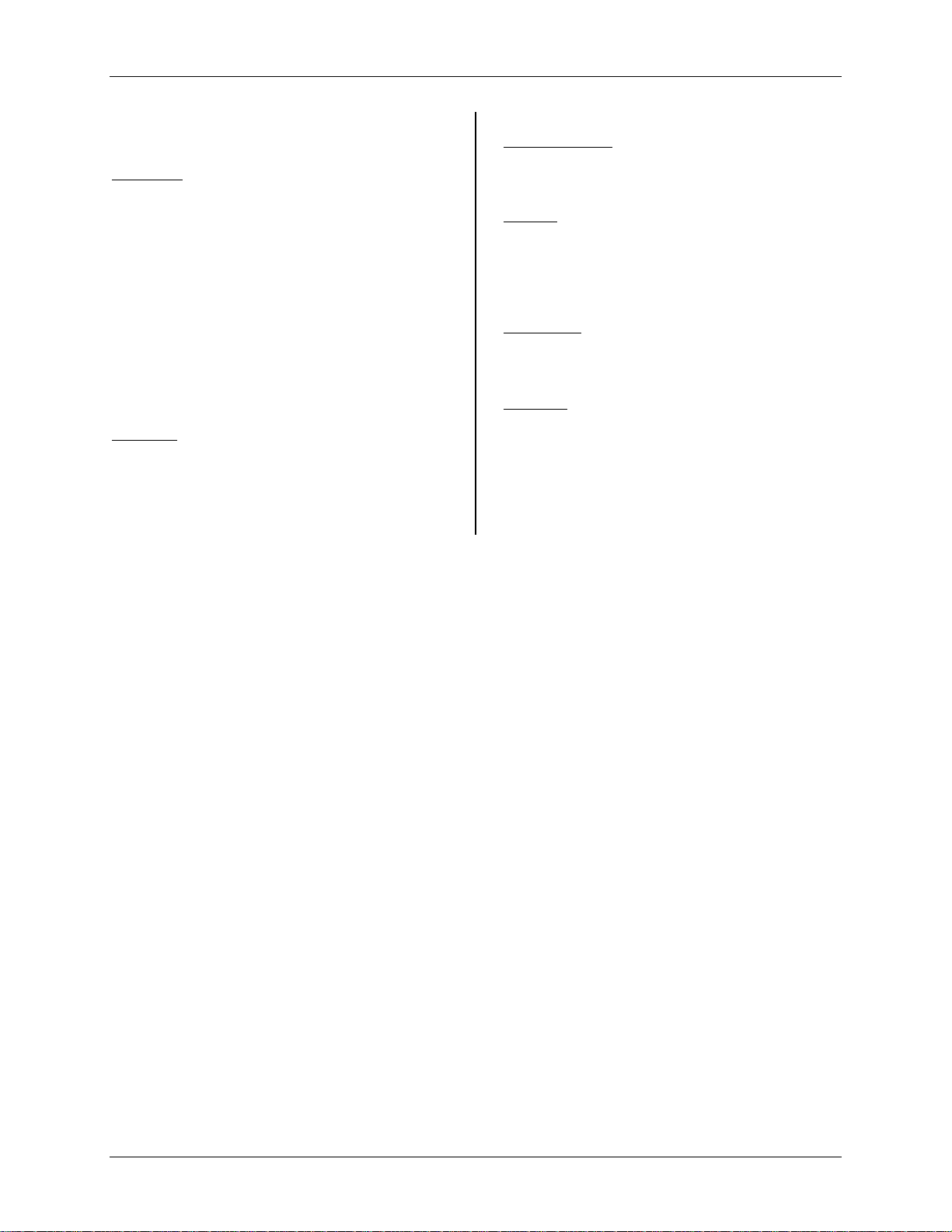

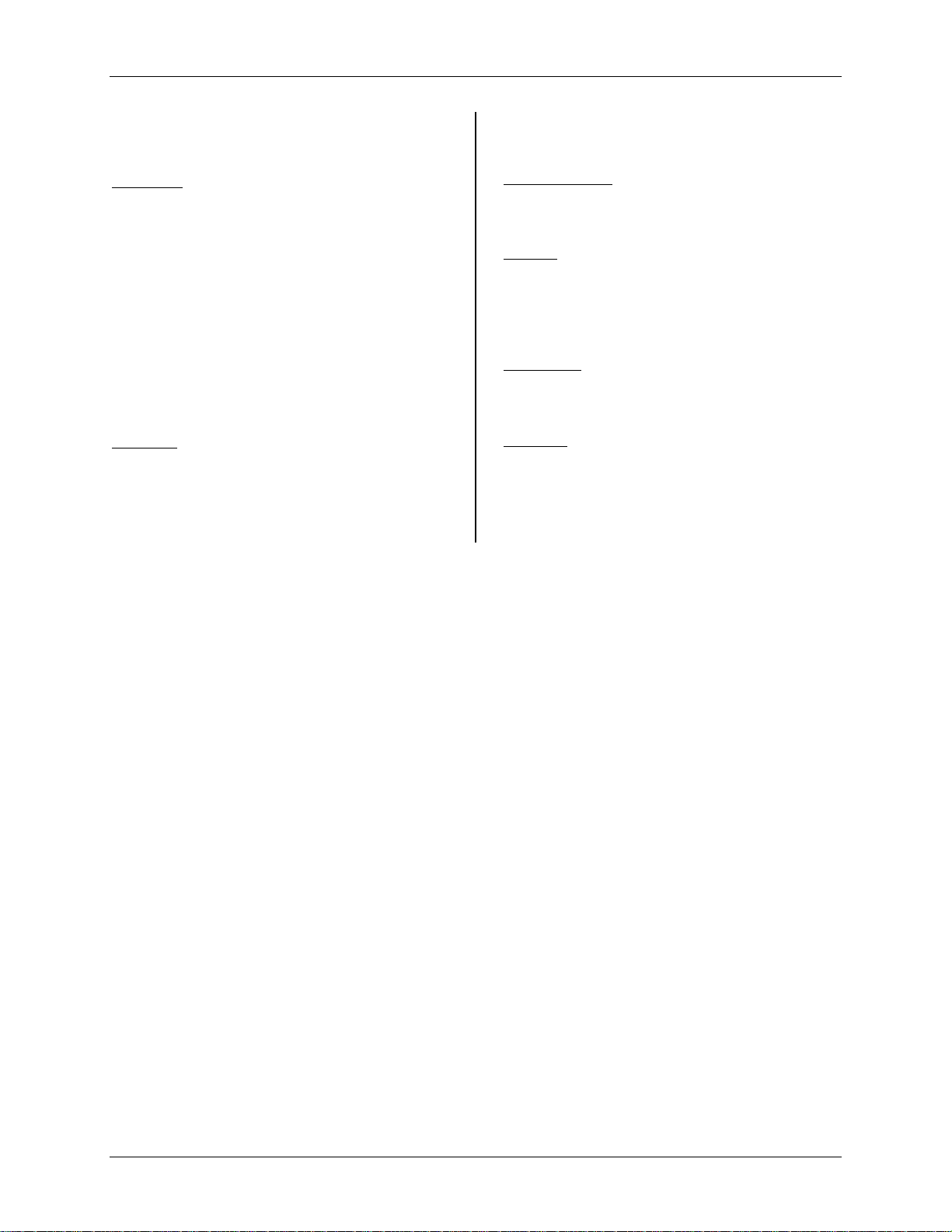

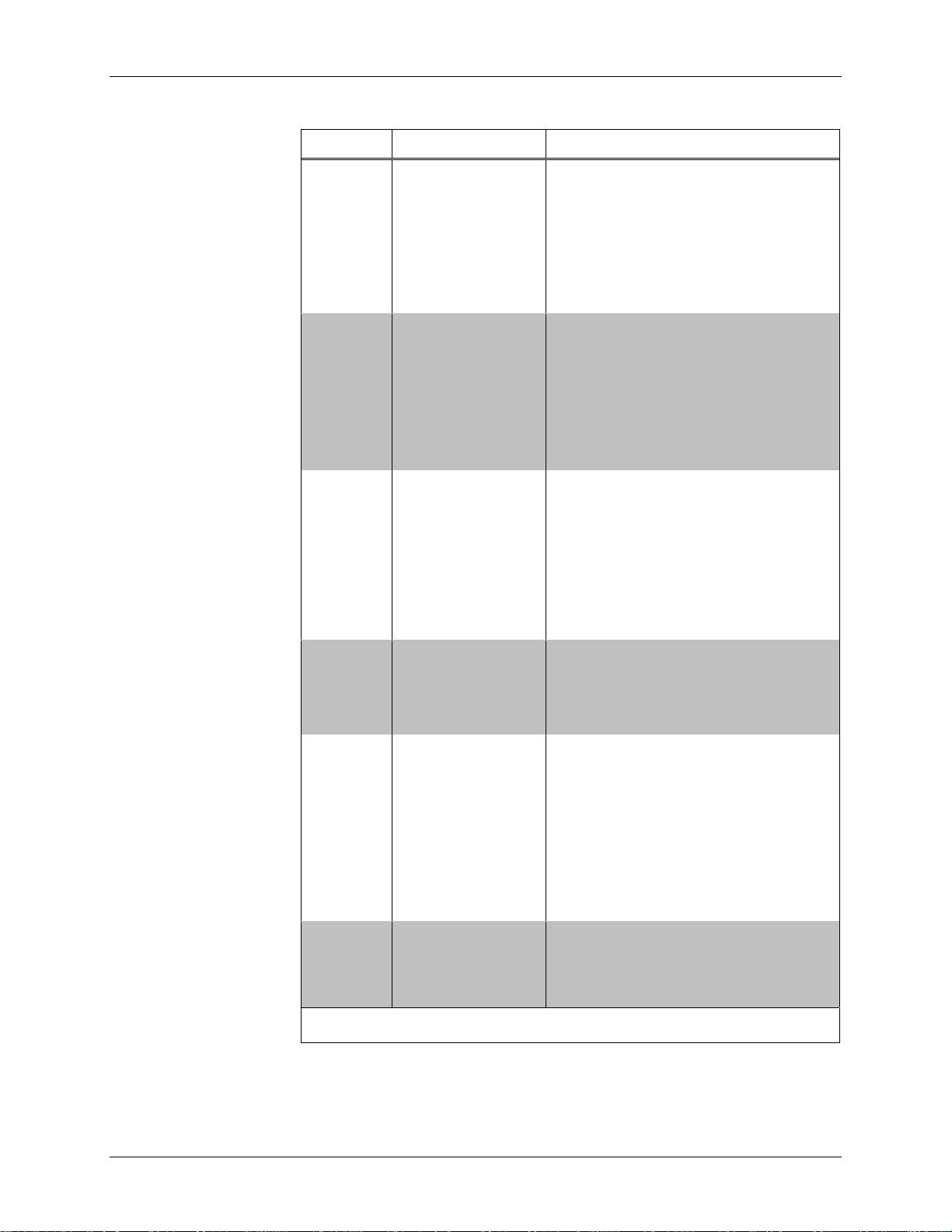

Crestron Green Light Power Switching Panels are available in five basic configurations. Use to the following cross-reference table to

begin specifying the configuration that fits your application.

This table represents the full line of Crestron Green Light and Green Light Express Power Switching panels, as well as Green Light

and Green Light Express Architectural Dimming panels. All are shown side-by-side for easy comparison. The Power Switching panels

are each fully detailed under their respective specifications pages within this document. For details about Architectural Dimming

panels, please refer to the Crestron Green Light™ Architectural Dimming Specification Guide, Doc. 4785 (future).

GREEN LIGHT GREEN LIGHT EXPRESS

Switching Relay Types

rcless High-inrush

Standard high-inrush

Modular high-inrush

2-pole available

Dimming Load Types

Incandescent, MLV

ELV

2-wire fluorescent

3-wire fluorescent

0-10V fluorescent

Ratings

Voltages

Output capacity lighting

loads

Output capacity, motor

loads@ 120/230/277 volts

Rated relay lifetime5 1,000,000 10,000 1,000,000 1,000,000 10,000 30,000 1,000,000

Circuit Breakers

Integrated branch breakers

vailable main breaker

Additional Features

Load state indicators

Local override

Emergency override

Mechanical override

Local control access door

option

Backup power supply

capable

Notes:

1.Please see Crestron Green Light™ Architectural Dimming Specification Guide, Doc. 4785 (future) for full description and specifications.

2. Supported via use of appropriate CLS-EXP expansion module.

3. 3-wire fluorescent loads require 2 control outputs per load.

4. Consult detailed specifications for ratings for ELV loads.

5. Relay lifetime based on number of cycles (on/off) with full electronic ballast load.

Power Switching Architectural Dimming Power Switching Architectural Dimming

GLPS-HSW

120/230/277 120/230/277 120/230/277 120/230/277 120/230/277

16A 16A 16A4 16A 16A 20A 16A4 8A

0.5/1/1 hp 1/2/2 hp 0.5/1/1 hp 0.5/1/1 hp 1/2/2 hp

GLPS-SW

GLPD-DIM

GLPS-HSW-FT GLPS-SW-FT

GLPS-HDSW-

FT

120/230/

277/347

0.5/1.5/1.5

hp

GLPD-DIM-FT GLPD-DIMX-FT

120/230/277 120/230/277

0.5/1/1 hp

Doc 4775A 13

Page 18

Green Light Power Switching Crestron Commercial Lighting Design Guide

GLPS-HSW Green Light Power Switching

Panels (MLO) Main Lug Only and (MCB) Main Circuit

Breaker Zero-Cross Arcless Relays

The GLPS-HSW Power Switching Panels come standard

with 20A branch circuit breakers, and accept 208Y/120 or

480Y/277 volt feeds terminating to main lugs provided. An

optional back-fed main circuit breaker may also be specified.

Four panel sizes are available, dubbed “Small,” “Medium,”

“Large,” and “Extra Large.” The panel size is ordinarily

determined according to the number of control circuits

specified, ranging from 8 to 42 circuits per panel. Each

control circuit is rated for 16A at 100-277V.

The GLPS-HSW panels utilize Crestron zero-cross arcless

relay technology, achieving a relay lifetime of one million

cycles. A high-current triac is employed to handle the

high-inrush current turn on, especially with certain load

types such as HID and electronic ballasts. Within

milliseconds, the continuous load is transferred to a

robust 50A mechanically-latching relay. All switching

occurs at the zero-cross point of the AC waveform under

microprocessor control. This is a complete solution

eliminating arcing at the physical relay contacts during

turn on and turn off, and supports switching of all types

of lighting loads up to 16A at 100V to 277V, as well as

motors up to 1 HP.

As an option, GLPS-HSW panels may be equipped with 0-10V

fluorescent dimming control substituted in place of some or

all switching circuits. Consult Crestron Sales Support

Services to specify this option.

The GLPS-HSW panels employ field-replaceable lighting

control modules, with 8 or 12 control circuits per module,

for excellent configurability and serviceability. Each module

includes local relay controls and load state indicators for each

circuit, plus additional controls and indicators for use during

system commissioning.

Individual hinged doors are provided on the front of each

GLPS-HSW panel for access to the circuit breaker panelboard

and the local controls on each module. As an option, the local

control access door may be omitted.

As part of a complete Green Light system, GLPS-HSW

panels connect to an IPAC-GL1 lighting control processor

(or other 2-Series control system) via the Cresnet

®

control network. An optional GLA-PWS50 (or equivalent)

power supply is also recommended for each panel to provide

backup power to the lighting modules.

Remote emergency override mode allows the lighting system

program to be overridden while each circuit is set to an

override preset state. The override preset for each circuit is

set using the local controls on the front of each lighting

module. Remote override mode is activated by an external

contact closure from a Crestron GLS-PLS-120/277 power

loss sensor or other device.

All low-voltage connections to a GLPS-HSW panel are made

via a connector block located near the bottom of the panel.

Connections are provided for Cresnet communications,

backup power supply, and emergency override.

Crestron Green Light Power Switching panels are configured

to order, factory assembled and tested prior to shipping. Each

panel is engineered to provide a clean and manageable

installation with provisions for wire termination and conduit

knockouts. On-site installation is fast and easy with all

termination points clearly labeled and accessible from

the front.

MODEL NUMBERS

Specifying and ordering a Crestron Green Light Power

Switching panel is facilitated using the following model

number system. Simply fill in the appropriate entry in each

position according to the steps that follow:

GLPS–HSW–MLO–30–120–10K –ND

GLPS-Relay Type-Feed Type-Number of Ckts-Voltage-AIC Rating-Door Option

The above example is for a “Main Lug Only” panel with 30

“HSW” zero-cross arcless relays, 120V / 10kAIC circuit

breakers, and no local control access door.

Relay Type: Enter “HSW” to specify zero-cross arcless

switching relays.

Notes: For other relay types, refer to the Selection Guide

0-10V fluorescent dimming is also available. Consult Crestron

Sales Support Services to specify this option.

Doc.4775A 14

Page 19

Crestron Commercial Lighting Design Guide Green Light Power Switching

Feed Type: Choose one of the following to specify the type of

feed:

MLO Main lug only

MCB60 60A back-fed main circuit breaker

MCB80 80A back-fed main circuit breaker

MCB100 100A back-fed main circuit breaker

MCB125 125A back-fed main circuit breaker

(available for 277V only)

Note: Main feeds are 3-phase, 4-wire; rated 225A @ 120/208V

or250A @ 277/480V. Consult Crestron Sales Support Services for

400Afeed and other main circuit breaker options.

Note: “Small,” “Medium,” “Large and “Extra Large” refer

to the default panel size per number of circuits. Consult

Crestron Sales Support Services for alternate configurations.

Voltage: To specify the circuit breaker voltage, enter “120”

for 120/208V or “277” for 277/480V.

AIC Rating: Choose one of the following values from the

appropriate column to specify the Ampere Interrupting

Capacity of the circuit breakers:

Number of Circuits: choose one of the following numeric

values from the appropriate column to specify the number

of controlled circuits in the panel:

GLPS-HSW-MLO GLPS-HSW-MCB

Small: 8, 12 8, 12

Medium: 16, 20, 24, 28, 30 16, 20, 24, 27, 30

Note: Consult Crestron Sales Support MCB options.

Door Option—Enter “ND” to omit the local control access

door. (The circuit breaker door cannot be omitted).

Large: 32 32

Extra Large: 36, 40, 42 36, 39

120 Volt 277 Volt

10K 18K

22K 35K

65K 65K

Doc 4775A 15

Page 20

Green Light Power Switching Crestron Commercial Lighting Design Guide

GLPS-HSW (Continued)

SPECIFICATIONS

Load Ratings

Switch Channels: 8 to 42 depending upon panel size and options,

each channel phase-independent

Maximum per Channel: 16 Amps @ 100 to 277 Volts AC, 50/60 Hz;

1/2 HP @ 120 Volts, 1 HP @ 277 Volts

Switched Load Types: Incandescent, Magnetic Low-Voltage,

Electronic Low-Voltage, Neon/Cold Cathode, Fluorescent Lamp

Ballast, High-Intensity Discharge, Motors

Dimmed Load Types (special order): 0-10 Volt 4-Wire Dimmable

Fluorescent Ballast

Rated Relay Lifetime: 1,000,000 cycles at full rated electronic ballast

load

Input Power

Line Power:120/208 VAC, 225 Amps maximum, 50/60 Hz

phase-to-neutral, or 277/480 VAC, 250 Amps maximum, 50/60 Hz

phase-to-neutralCresnet Power Usage (optional): 50 Watts (2.08

Amps @ 24 Volts DC) per panel, use Crestron GLA-PWS50 or

equivalent power supply

Circuit Breakers

Branch, 120V: 20A Square D

AIC rated as required

Branch, 277V: 20A Square D® EDB, EGB, EJB E-Frame type; 18k,

35k, or 65k AIC rated as required

Main, 120/208V (optional): 120/208V: 60A, 80A, or 100A Square D®

QOB Bolt-on type; 10k AIC rated (consult Crestron for additional

options)

Main, 277/480V (optional): 60A, 80A, 100A, or 125A Square D

EDB, EGB, EJB E-Frame type; 18k, 35k, or 65k AIC rated

Lightning Protection

Can withstand 6 kV / 3 kA surge, as per IEC 61000-4-5 and

ANSI/IEEE C62.41-1991

Enclosure

NEMA Type 1, IP20 rated protection, for indoor use only

Back Box: 16 Gauge galvanized steel, surface wall mount

Front Cover: 16 Gauge steel, grey powder coat finish

Environmental

Temperature: 32° to 104°F (0° to 40°C)

Humidity: 10% to 90% RH (non-condensing)

®

QOB Bolt-on type; 10k, 22k, or 65k

®

Small: 37-1/2 x 20-1/4 x 6-5/8 in (95.25 x 51.4 x 16.8 cm) HWD

Medium: 70 x 20-1/4 x 6-5/8 in (177.8 x 51.4 x 16.8 cm) HWD

Large: 78-15/16 x 20-1/4 x 6-5/8 in (200.5 x 51.4 x 16.8 cm) HWD

Extra Large: 90 x 20-1/4 x 6-5/8 in (228.6 x 51.4 x 16.8 cm) HWD

Weight

Fully loaded with modules, 277V circuit breakers, and wiring:

Small: 70 lb (31.8 kg) maximum

Medium: 140 lb (63.5 kg) maximum

Large: 165 lb (74.9 kg) maximum

Extra Large: 181 lb (82.1 kg) maximum

Testing & Compliance

UL Listed, FCC Part 15

Feed Wiring – 120/208V

Neutral and Main Lugs:

10-2/0 AWG (CU)

6-2/0 AWG (AL)

6-300 kcmil (CU or AL)

Neutral Bus:

14-4 AWG (CU)

12-4 AWG (AL)

Feed Wiring – 277/480V

Neutral and Main Lugs:

6-350 kcmil (CU or AL)

1/0-750 kcmil (CU or AL)

Neutral Bus:

14-6 AWG (CU or AL)

14-2/0 AWG (CU or AL)

Load Wiring

Load Outputs: 14-10 AWG

0-10V Dim Outputs: 28-12 AWG

Ground Bar: 14-10 AWG

Ground Lug: 14-4 AWG

Notes:

- For Feed wiring, use copper or aluminum conductors only.

- For Load wiring, use copper conductors only.

- All wiring rated 75ºC

Doc.4775A 16

Page 21

Crestron Commercial Lighting Design Guide Green Light Power Switching

GLPS-SW Green Light Power Switching

Panels (MLO) Main Lug Only and (MCB) Main Circuit

Breaker w/Standard High-Inrush Relays

The GLPS-SW Power Switching Panels come standard

with 20A branch circuit breakers, and accept 208Y/120 or

480Y/277 volt feeds terminating to main lugs provided. An

optional back-fed main circuit breaker may also be specified.

Three panel sizes are available, “Small,” “Medium,” and

“Large.” The panel size is ordinarily determined according

to the number of control circuits specified, ranging from 8 to

42 circuits per panel. Each control circuit is rated for 16A at

100-277V.

The GLPS-SW panels utilize robust 50A relays to handle all

types of lighting loads including electronic ballasts, as well

as motors up to 2 HP.

As an option, GLPS-SW panels may be equipped with 0-10V

fluorescent dimming control substituted in place of some or

all switching circuits. Consult Crestron Sales Support

Services to specify this option.

The GLPS-SW panels employ field-replaceable lighting

control modules, with 10 or 16 control circuits per module,

for excellent configurability and service-ability. Each module

includes local relay controls and load state indicators for each

circuit, plus additional controls and indicators for use during

system commissioning.

Individual hinged doors are provided on the front of each

GLPS-SW panel for access to the circuit breaker panelboard

and the local controls on each module. As an option, the local

control access door may be omitted.

As part of a complete Green Light system, GLPS-SW panels

connect to an IPAC-GL1 lighting control processor (or other 2Series control cystem) via the Cresnet control network. An

optional GLA-PWS50 (or equivalent) power supply is also

recommended for each panel to provide backup power to the

lighting modules.

Remote emergency override mode allows the lighting system

program to be overridden while each circuit is set to an

override preset state. The override preset for each circuit is

set using the local controls on the front of each lighting

module. Remote override mode is activated by an external

contact closure from a Crestron GLS-PLS-120/277 power

loss sensor or other devices.

All low-voltage connections to a GLPS-SW panel are made

via a connector block located near the bottom of the panel.

Connections are provided for Cresnet communications,

backup power supply, and emergency override. Crestron

Green Light Power Switching panels are configured to order,

and factory assembled and tested prior to shipping. Each

panel is engineered to provide a clean and manageable

installation with abundant provisions for wire termination and

conduit knockouts. On-site installation is fast and easy with

all termination points clearly labeled and accessible from

the front.

NUMBERS

MODEL

Specifying and ordering a Crestron Green Light Power

Switching panel is facilitated using the following model

number system. Simply fill in the appropriate entry in each

position according to the steps that follow:

GLPS - SW - MLO - 30 - 120 - 10K – ND

GLPS-Relay Type-Feed Type-Number of Ckts-Voltage-AIC Rating-Door Option

The above example is for a “Main Lug Only” panel with 30

“SW” standard high-inrush relays, 120V / 10kAIC circuit

breakers, and no local control access door.

Relay Type: Enter “SW” to specify standard high-inrush

switching relays.

Note: For other relay types, refer to the Selection Guide

0-10V fluorescent dimming is also available. Consult Crestron

Sales Support Services to specify this option.

Feed Type: Choose one of the following to specify the type

of feed:

MLO Main lug only

MCB60 60A back-fed main circuit breaker

MCB80 80A back-fed main circuit breaker

MCB 100 100A back-fed main circuit breaker

MCB 125 125A back-fed main circuit breaker

(available for 277V only)

Note: Main feeds are 3-phase, 4-wire; rated 225A @

120/208V or 250A @ 277/480V. Consult Crestron Sales

Doc. 4775A 17

Page 22

Green Light Power Switching Crestron Commercial Lighting Design Guide

Support Services for 400A feed and other main circuit

breaker options.

Number of Circuits: Choose one of the following numeric

values from the appropriate column to specify the number of

controlled circuits in

the panel:

Voltage: To specify the circuit breaker voltage, enter “120”

for 120/208V or “277” for 277/480V.

AIC Rating: Choose one of the following values from the

appropriate column to specify the Ampere Interrupting

Capacity of the circuit breakers:

GLPS-SW-MLO GLPS-SW-MCB

Small: 10, 16 10, 15

Medium: 20, 26, 30 20, 26, 27

Large: 32, 36, 40, 42 32, 36, 39

Note: “Small,” “Medium,” and “Large” refer to the default

panel size per number of circuits. Consult Crestron Sales

Support Services for alternate configurations.

Note: Consult Crestron Sales Support Services MCB options.

Door Option—Enter “ND” to omit the local control access

door. (The circuit breaker door cannot be omitted.)

120 Volt 277 Volt (

10K 18K

22K 35K

65K 65K

Doc.4775A 18

Page 23

Crestron Commercial Lighting Design Guide Green Light Power Switching

GLPS-SW (CONTINUED)

SPECIFICATIONS

Load Ratings

Switch Channels: 10 to 42 depending upon panel size and

options, each channel

phase-independent

Maximum per Channel: 16 Amps @ 100 to 277 Volts AC,

50/60 Hz; 1 HP @ 120 Volts,

2 HP @ 277 Volts

Switched Load Types: Incandescent, Magnetic Low-Voltage,

Electronic Low-Voltage, Neon/Cold Cathode, Fluorescent

Lamp Ballast, High-Intensity Discharge, Motors

Dimmed Load Types (special order): 0-10 Volt 4-Wire

Dimmable Fluorescent Ballast

Rated Relay Lifetime: 10,000 cycles at full rated electronic

ballast load

Input Power

Line Power:120/208 VAC, 225 Amps maximum, 50/60 Hz

phase-to-neutral, or 277/480 VAC, 250 Amps maximum,

50/60 Hz phase-to-neutral

Cresnet Power Usage (optional): 50 Watts (2.08 Amps @ 24

Volts DC) per panel, use Crestron GLA-PWS50 or equivalent

power supply

Circuit Breakers

Branch, 120V: 20A Square D® QOB Bolt-on type; 10k, 22k,

or 65k AIC rated as required

Branch, 277V: 20A Square D® EDB, EGB, EJB E-Frame type;

18k, 35k, or 65k AIC rated as required

Main, 120/208V (optional): 120/208V: 60A, 80A, or 100A

Square D® QOB Bolt-on type; 10k AIC rated (consult Crestron

for additional options)

Main, 277/480V (optional): 60A, 80A, 100A, or 125A Square

D® EDB, EGB,

EJB E-Frame type; 18k, 35k, or 65k AIC rated

Lightning Protection

Can withstand 6 kV / 3 kA surge, as per IEC 61000-4-5 and

ANSI/IEEE C62.41-1991

Enclosure

NEMA Type 1, IP20 rated protection, for indoor use only

Back Box: 16 Gauge galvanized steel, surface wall mount

Front Cover: 16 Gauge steel, grey powder coat finish

Environmental

Temperature: 32° to 104°F (0° to 40°C)

Humidity: 10% to 90% RH (non-condensing)

Dimensions

Small: 37-1/2 x 20-1/4 x 6-5/8 in (95.25 x 51.4 x 16.8 cm)

HWD

Medium: 70 x 20-1/4 x 6-5/8 in (177.8 x 51.4 x 16.8 cm)

HWD

Large: 78-15/16 x 20-1/4 x 6-5/8 in (200.5 x 51.4 x 16.8 cm)

HWD

Weight

Fully loaded with modules, 277V circuit breakers, and wiring:

Small: 70 lb (31.8 kg) maximum

Medium: 140 lb (63.5 kg) maximum

Large: 165 lb (74.9 kg) maximum

Testing & Compliance

UL Listed, FCC Part 15

Doc. 4775A 19

Page 24

Green Light Power Switching Crestron Commercial Lighting Design Guide

GLPS-HSW-FT Green Light Express

Feed-Through Power Switching Panels w/Zero-Cross

Arcless Relays

The GLPS-HSW-FT panels utilize Crestron zero-cross

arcless relay technology, achieving a relay lifetime of one

million cycles. A high-current triac is employed to handle

the high inrush current turn on, especially with certain

load types such as HID and electronic ballasts. Within

milliseconds, the continuous load is transferred to a

robust 50A mechanically-latching relay. All switching

occurs at the zero-cross point of the AC waveform under

microprocessor control. This is a complete solution,

eliminating arcing at the physical relay contacts during

turn on and turn off, and supports switching of all types of

lighting loads up to 16A at 100V to 277V, as well as

motors up to 1 HP.

As an option, GLPS-HSW-FT panels may be equipped with 010V fluorescent dimming control substituted in place of some

or all switching circuits. Consult Crestron Sales Support

Services to specify this option.

The GLPS-HSW-FT panels employ field-replaceable lighting

control modules, with 8 or 12 control circuits per module,

for excellent configurability and serviceability. Each module

includes local relay controls and load state indicators for each

circuit, plus additional controls and indicators for use during

system commissioning.

As part of a complete Green Light system, GLPS-HSW-FT

panels connect to an IPAC-GL1 lighting control processor

(or other 2-Series Control System) via the Cresnet control

network. An optional GLA-PWS50 (or equivalent) power

supply is also recommended for each panel to provide

backup power to the lighting modules.

Remote emergency override mode allows the lighting system

program to be overridden while each circuit is set to an

override preset state. The override preset for each circuit is

set using the local controls on the front of each lighting

module. Remote override mode is activated by an external

contact closure from a Crestron GLS-PLS-120/277 power

loss sensor or other devices

All low-voltage connections to a GLPS-HSW-FT panel are

made via a connector block located near the bottom of the

panel. Connections are provided for Cresnet communications,

backup power supply, and emergency override.

Crestron Green Light Express Power Switching panels are

configured to order, and factory assembled and tested prior

to shipping. Each panel is engineered to provide a clean and

manageable installation with abundant provisions for wire

termination and conduit knockouts. On-site installation is fast

and easy with all termination points clearly labeled and

accessible from the front.

MODEL NUMBERS

Specifying and ordering a Crestron Green Light Express

Power Switching panel is facilitated using the following

model number system. Simply

fill in the appropriate entry in each position according to the

steps that follow:

GLPS - HSW - FT - 32

GLPS – Relay Type – Feed Type – Number of Ckts.

The above example is for a “Feed-Through” panel with 32

“HSW” zero-cross arcless relays.

Relay Type: Enter “HSW” to specify zero-cross arcless

switching relays.

Notes: For other relay types, refer to the Selection Guide

0-10V fluorescent dimming is also available. Consult Crestron

Sales Support Services to specify this option.

Feed Type: Enter “FT” to specify “Feed-Through.”

Note: For other feed types, refer to the Selection Guide

Number of Circuits:

values to specify the number of controlled circuits in the

Panel:

Small: 8, 12, 16

Large: 20, 24, 28, 32

Note: “Small” and “Large” refer to the default panel size

per number of circuits. Consult Crestron Sales Support

Services for alternate configurations.

Choose one of the following numeric

Doc.4775A 20

Page 25

Crestron Commercial Lighting Design Guide Green Light Power Switching

GLPS-HSW-FT (Continued)

SPECIFICATIONS

Load Ratings

Switch Channels: 8 to 32 depending upon panel size and

options, each channel

phase-independent

Maximum per Channel: 16 Amps @ 100 to 277 Volts AC,

50/60 Hz; 1/2 HP @ 120 Volts, 1 HP @ 277 Volts

Switched Load Types: Incandescent, Magnetic Low-Voltage,

Electronic Low-Voltage, Neon/Cold Cathode, Fluorescent

Lamp Ballast, High-Intensity Discharge, Motors

Dimmed Load Types (special order): 0-10 Volt 4-Wire

Dimmable Fluorescent Ballast

Rated Relay Lifetime: 1,000,000 cycles at full rated electronic

ballast load

Input Power

Line Power: 120 or 277 VAC, 20 Amps maximum per circuit,

50/60 Hz

Cresnet Power Usage (optional): 50 Watts (2.08 Amps @ 24

Volts DC) per panel, use Crestron GLA-PWS50 or equivalent

power supply

Lightning Protection

Can withstand 6 kV / 3 kA surge, as per IEC 61000-4-5 and

ANSI/IEEE C62.41-1991

Enclosure

NEMA Type 1, IP20 rated protection, for indoor use only

Back Box: 16 Gauge galvanized steel, flush or surface wall

mount

Front Cover: 16 Gauge steel, grey powder coat finish

Environmental

Temperature: 32° to 104°F (0° to 40°C)

Humidity: 10% to 90% RH (non-condensing)

Dimensions

Small: 23-1/2 x 14-3/8 x 4 in (59.7 x 36.5 x 10.2 cm) HWD

Large: 38-1/4 x 14-3/8 x 4 in (97.2 x 36.5 x 10.2 cm) HWD

Doc 4775A 21

Page 26

Green Light Power Switching Crestron Commercial Lighting Design Guide

GLPS-SW-FT Green Light Express Feed-

Through

Power Switching Panels w/Standard High-Inrush Relays

The GLPS-SW-FT Power Switching Panels are designed for

use with a separate circuit breaker panel. Two "feedthrough" panel sizes are available, configurable with as few

as 8, or as many as 56 control circuits per panel. Each

control circuit is rated for 16A at 100-277V. Panels may be

deployed with a mix of 120V and 277V circuits within a single

cabinet.

The GLPS-SW-FT panels utilize robust 50A relays to handle

all types of lighting loads including electronic ballasts, as well

as motors up to 2 HP.

The GLPS-SW-FT panels employ field-replaceable lighting

control modules, with 8 control circuits per module, for

excellent configurability and serviceability. Each module

includes local relay controls and load state indicators for each

circuit.

As part of a complete Green Light system, GLPS-SW-FT

panels connect to an IPAC-GL1 lighting control processor (or

other 2-Series control system) via the Cresnet control

network. A GLA-PWS50 (or equivalent) power supply is also

required for each panel to provide operating power to the

lighting modules.

Remote emergency override mode allows the lighting system

program to be overridden while each circuit is set to an

override preset state. The override preset for each circuit is

set using the local controls on the front of each lighting

module. Remote override mode is activated by an external

contact closure from a Crestron GLS-PLS-120/277 power

loss sensor or other devices.

All low-voltage connections to a GLPS-SW-FT panel are

made via a connector block located near the bottom of the

panel. Connections are provided for Cresnet communications,

power supply, and emergency override.

Crestron Green Light Express Power Switching panels are

configured to order, and factory assembled and tested prior

to shipping. Each panel is engineered to provide a clean and

manageable installation with abundant provisions for wire

termination and conduit knockouts. On-site installation is fast

and easy with all termination points clearly labeled and

accessible from the front.

MODEL NUMBERS

Specifying and ordering a Crestron Green Light Express

Power Switching panel is facilitated using the following

model number system. Simply

fill in the appropriate entry in each position according to the

steps that follow:

GLPS - SW - FT - 56

GLPS – Relay Type – Feed Type – Number of Ckts.

The above example is for a “Feed-Through” panel with 56

“SW” standard high-inrush relays.

Relay Type: Enter “SW” to specify standard high-inrush

switching relays.

Note: For other relay types, refer to the Selection Guide on

Page 3.

Feed Type: Enter “FT” to specify “Feed-Through.”

Note: For other feed types, refer to the Selection Guide on

Page 3.

Number of Circuits: Choose one of the following numeric

values to specify the number of controlled circuits in the

panel:

Small: 8, 16, 24

Large: 32, 40, 48, 56

Note: “Small” and

rge” refer to the default panel size

“La

per number of circuits. Consult Crestron Sales Support

Services for alternate configurations.

Doc.4775A 22

Page 27

Crestron Commercial Lighting Design Guide Green Light Power Switching

GLPS-SW-FT

(Continued)

SPECIFICATIONS

Load Ratings

Switch Channels: 8 to 56 depending upon panel size and

options, each channel phase-independent

Maximum per Channel: 16 Amps @ 100 to 277 Volts AC,

50/60 Hz; 1 HP @ 120 Volts, 2 HP @ 277 Volts

Switched Load Types: Incandescent, Magnetic Low-Voltage,

Electronic Low-Voltage, Neon/Cold Cathode, Fluorescent

Lamp Ballast, High-Intensity Discharge, Motors

Dimmed Load Types (special order): 0-10 Volt 4-Wire

Dimmable Fluorescent Ballast

Rated Relay Lifetime: ,10,000 cycles at full rated electronic

ballast load

Input Power

Line Power: 120 or 277 VAC, 20 Amps maximum per circuit,

50/60 Hz

Cresnet Power Usage: 50 Watts (2.08 Amps @ 24 Volts DC)

per panel, use Crestron GLA-PWS50 or equivalent power

supply

Lightning Protection

Can withstand 6 kV / 3 kA surge, as per IEC 61000-4-5 and

ANSI/IEEE C62.41-1991

Enclosure

NEMA Type 1, IP20 rated protection, for indoor use only

Back Box: 16 Gauge galvanized steel, flush or surface wall

mount

Front Cover: 16 Gauge steel, grey powder coat finish

Environmental

Temperature: 32° to 104°F (0° to 40°C)

Humidity: 10% to 90% RH (non-condensing)

Dimensions

Small: 23-1/2 x 14-3/8 x 4 in (59.7 x 36.5 x 10.2 cm) HWD

Large: 38-1/4 x 14-3/8 x 4 in (97.2 x 36.5 x 10.2 cm) HWD

Doc 4775A 23

Page 28

Green Light Power Switching Crestron Commercial Lighting Design Guide

GLPS-HDSW-FT Green Light Express

Feed-Through Power Switching Panels w/Modular High-

Inrush Relays

The GLPS-HDSW-FT Power Switching Panels are designed

for use with a separate circuit breaker panel. Two "feedthrough" panel sizes are available, configurable with as few

as 8, or as many as 56 control circuits per panel.

The GLPS-HDSW-FT panels utilize individual, field-installable

modular relays. Panels are specified according to the number

of relay spaces. The relays are ordered separately. Each

space accommodates one single-pole relay (Model# GLRHD-1P). Allow 2 spaces for each double-pole relay (Model#

GLR-HD-2P).

Each control circuit is rated for 20A, supporting 120V, 277V,

and 347V lighting loads, as well as motors up to 2 HP. Panels

may be deployed with a mix of different voltages within a

single cabinet.

The GLPS-HDSW-FT panels include local relay controls and

load state indicators for each circuit.

As part of a complete Green Light system, GLPS-HDSW-FT

panels connect to an IPAC-GL1 lighting control processor

(or other 2-Series control system) via the Cresnet control

network. A GLA-PWS50 (or equivalent) power supply is also

required for each panel to provide operating power.

Remote emergency override mode allows the lighting system

program to be overridden while each circuit is set to an

override preset state. The override preset for each circuit is

set using the local relay controls. Remote override mode is

activated by an external contact closure from a Crestron

GLS-PLS-120/277 power loss sensor or other devices.

All low-voltage connections to a GLPS-HDSW-FT panel are

made via a connector block located near the bottom of the

panel. Connections are provided for Cresnet communications,

power supply, and emergency override.

Crestron Green Light Express Power Switching panels are

configured to order, and factory assembled and tested prior

to shipping. Each panel is engineered to provide a clean and

manageable installation with abundant provisions for wire

termination and conduit knockouts. On-site installation is fast

and easy with all termination points clearly labeled and

accessible from the front.

MODEL NUMBERS

Specifying and ordering a Crestron Green Light Express

Power Switching panel is facilitated using the following

model number system. Simply fill in the appropriate entry

in each position according to the steps that follow:

GLPS - HDSW - FT - 56

GLPS – Relay Type – Feed Type – Number of Ckts.

The above example is for a “Feed-Through” panel with

56 “HDSW” modular high-inrush relays.

Relay Type: Enter “HDSW” to specify modular high-inrush

switching relays.

Note: For other relay types, refer to the Selection Guide

Feed Type: Enter “FT” to specify “Feed-Through.”

Note: For other feed types, refer to the Selection Guide

Number of Circuits: Choose one of the following numeric

values to specify the number of controlled circuits in the panel:

Small: 8, 16, 24

Large: 32, 40, 48, 56

Note:

per number of circuits. Consult Crestron Sales Support

Services for alternate configurations.

“HDSW” relays must be ordered separately. Quantities

shown indicate the number of available relay spaces. Each

space accommodates one single-pole relay (Model# GLRHD-1P). Allow 2 spaces for each double-pole relay (Model#

GLR-HD-2P).

all” and “Large” refer to the default panel size

“Sm

Doc.4775A 24

Page 29

Crestron Commercial Lighting Design Guide Green Light Power Switching

GLPS-HDSW-FT (Continued)

SPECIFICATIONS

Load Ratings

Switch Channels: 8 to 56 single-pole, 4-28 double-pole,

depending upon panel size and relay combinations, each

channel phase-independent

Maximum per Channel: 20 Amps @ 100 to 347 Volts AC,

50/60 Hz; 1/2 HP @ 120 Volts, 1-1/2 HP @ 277 Volts

Switched Load Types: Incandescent, Magnetic Low-Voltage,

Electronic Low-Voltage, Neon/Cold Cathode, Fluorescent

Lamp Ballast, High-Intensity Discharge, Motors

Dimmed Load Types (special order): 0-10 Volt 4-Wire

Dimmable Fluorescent Ballast

Rated Relay Lifetime: 30,000 cycles at full rated electronic

ballast load

Input Power

Line Power: 120, 277, or 347 VAC, 20 Amps maximum per

circuit, 50/60 Hz

Lightning Protection

Can withstand 6 kV / 3 kA surge, as per IEC 61000-4-5 and

ANSI/IEEE C62.41-1991

Enclosure

NEMA Type 1, IP20 rated protection, for indoor use only

Back Box: 16 Gauge galvanized steel, flush or surface wall

mount

Front Cover: 16 Gauge steel, grey powder coat finish

Environmental

Temperature: 32° to 104°F (0° to 40°C)

Humidity: 10% to 90% RH (non-condensing)

Dimensions

Small: 23-1/2 x 14-3/8 x 4 in (59.7 x 36.5 x 10.2 cm) HWD

Large: 38-1/4 x 14-3/8 x 4 in (97.2 x 36.5 x 10.2 cm) HWD

Cresnet Power Usage: 50 Watts (2.08 Amps @ 24 Volts DC)

per panel, use Crestron GLA-PWS50 or equivalent power

supply

Doc 4775A 25

Page 30

Green Light Power Switching Crestron Commercial Lighting Design Guide

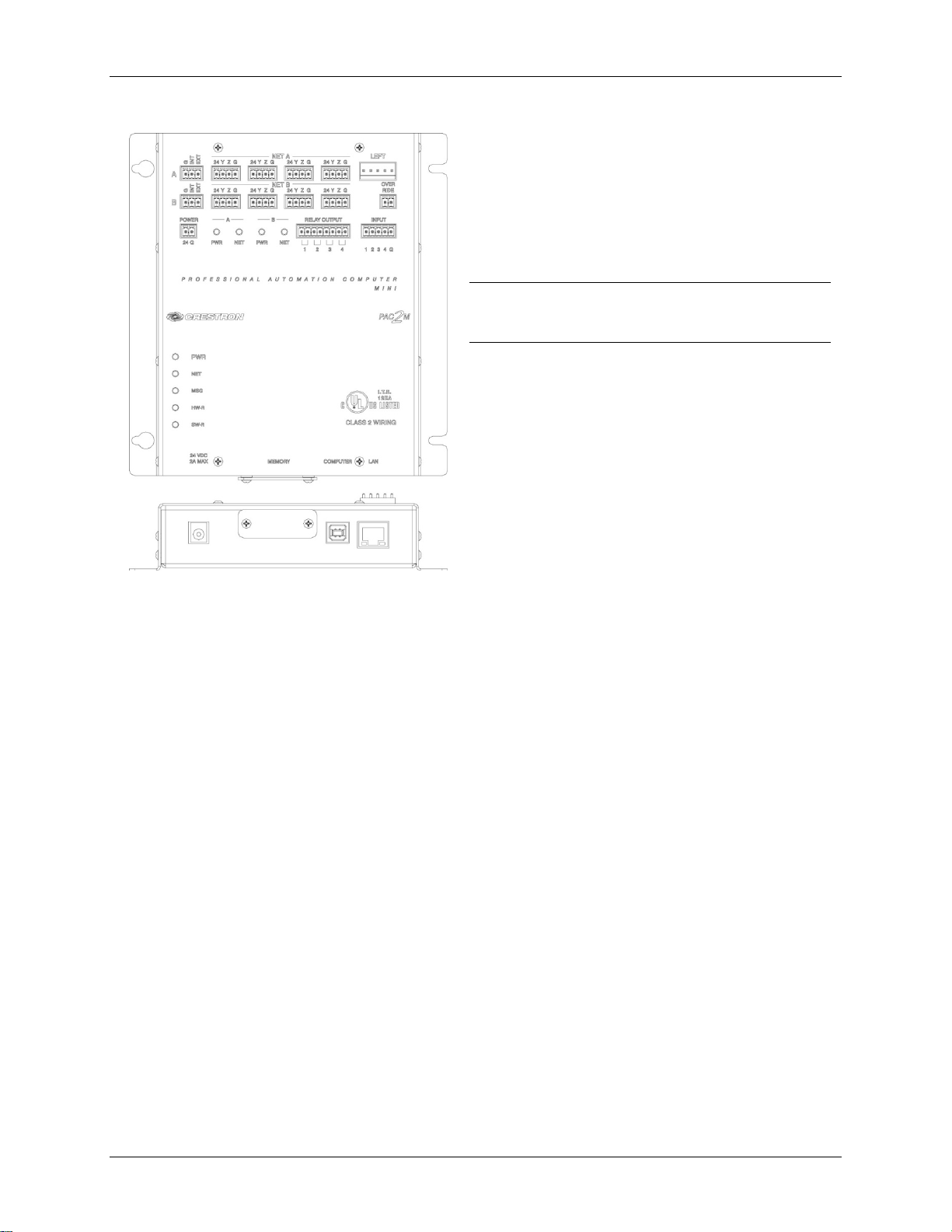

IPAC-GL1

Integrated Professional Automation

Computer for Green Light Power Switching

Wall mount lighting control processor

Crestron 2-Series control engine

Easy system programming via LCD front panel

7 programmable buttons with LED feedback

Customizable backlit button labels

CEC Title 24 listed

Astronomical time clock

Occupancy sensing and daylight harvesting

2 RS-232, 4 digital/analog input, & 4 relay control ports

Cresnet and 10/100 Ethernet communications

Onboard e-Control® Web server

RoomView® and SNMP remote management

SSL (Secure Sockets Layer) network protection

Extensively programmable via PC software

3-gang wall-mountable

Available in white or black

The Crestron IPAC is a 2-Series control processor designed

for wall mount installation. Its front panel controls and LCD

display deliver a user-friendly interface for out-of-the-box

system setup. Built-in Ethernet, Cresnet, RS-232, relay, and

sensor inputs provide direct connectivity for interfacing with

all kinds of devices, controls, and networks. The onboard e-

®

Control

Web server allows for complete integration as part

of a facility-wide managed control network.

—

Out-of-the-Box Lighting Control

The GL1 version of IPAC

comes preconfigured for use as the central control processor

for a Green Light Power Switching system. Right out of the

box, the IPAC-GL1 affords easy setup and programming for

a complete switching system consisting of:

Up to 210 switched circuits

16 keypads and 2 touchpanels

30 occupancy sensors and photocells

500 time clock events

Keypads with as many as 12 buttons each can be

programmed easily to control lighting loads and zones. As

well, the seven function buttons on the front panel of the

IPAC-GL1 may also be programmed for lighting control or a

variety of other common functions. Custom backlit labeling

of these buttons is facilitated using an assortment of preprinted labels or Crestron Engraver software.

Lights can be programmed to turn on and off automatically

using the built-in astronomical time clock feature. Lighting

events may be programmed to occur at specific times or at

an offset from sunrise or sunset. Occupancy sensors and

photocells may also be implemented to enable automatic

on/off lighting control based on room occupancy and ambient

light levels.

Custom programmability—with additional custom

programming, the IPAC-GL1 can support virtually any

functionality imaginable. It works seamlessly with the entire

line of Crestron touchpanels, wireless remotes, lighting

dimmers, shade controllers, thermostats, and more. It can

also interface with third-party devices and systems such as

security and access controls, surveillance cameras, and

HVAC for a fully integrated solution. Contact Crestron Sales

Support Services for more information.

The IPAC-GL1 is designed to be mounted in a standard

3-gang electrical box independent of the lighting panels,

allowing it to be installed wherever it is most advantageous

for the project.

Doc.4775A 26

Page 31