Page 1

Crestron 2-Series Control Systems

Reference Guide

Page 2

This document was prepared and written by the Technical Documentation department at:

Crestron Electronics, Inc.

15 Volvo Drive

Rockleigh, NJ 07647

1-888-CRESTRON

All brand names, product names and trademarks are the property of their respective owners.

©2006 Crestron Electronics, Inc.

Page 3

Crestron 2-Series Control Systems Reference Guide

Contents

2-Series Control Systems 1

Introduction ...............................................................................................................................1

Programming Tools & Utilities ................................................................................................. 3

SIMPL Windows......................................................................................................... 3

VisionTools Pro-e .......................................................................................................3

Crestron Toolbox......................................................................................................... 3

Viewport (Limited Use) .............................................................................................. 4

Establishing Communications with the Control System............................................................5

Serial Connection ........................................................................................................ 5

TCP/IP Connection ..................................................................................................... 9

Modem Connection................................................................................................... 11

Passthrough Mode (Viewport Only) .........................................................................12

Troubleshooting Communications........................................................................................... 13

2-Series Console Commands................................................................................................... 16

Introduction ............................................................................................................... 16

SIMPL Windows Symbols........................................................................................ 16

Command Groups .....................................................................................................18

Processor Groups....................................................................................................... 21

Command Structure................................................................................................... 22

2-Series Memory & Directory Structure .................................................................................23

Introduction ............................................................................................................... 23

Non-Volatile Random Access Memory (NVRAM) Disk .........................................25

NVRAMREBOOT.................................................................................................... 27

Running Programs from Compact Flash ................................................................... 28

2-Series Control System Error Messages ................................................................................ 29

Introduction ............................................................................................................... 29

Viewing Error Messages with the Front Panel.......................................................... 29

Viewing Error Messages with Crestron Toolbox...................................................... 30

Error Levels............................................................................................................... 31

Error Format.............................................................................................................. 31

Master-Slave Modes................................................................................................................ 32

Introduction ............................................................................................................... 32

Definitions................................................................................................................. 32

Master-Slave Operating Guidelines ..........................................................................33

Configuring the Control System................................................................................ 34

Configuration and Programming............................................................................... 37

Uploading.................................................................................................................. 41

Dynamic Host Configuration Protocol (DHCP)...................................................................... 42

Introduction ............................................................................................................... 42

Windows DHCP/DNS Server Configuration ............................................................ 42

Control System Configuration................................................................................... 43

Secure Sockets Layer (SSL) .................................................................................................... 46

Introduction ............................................................................................................... 46

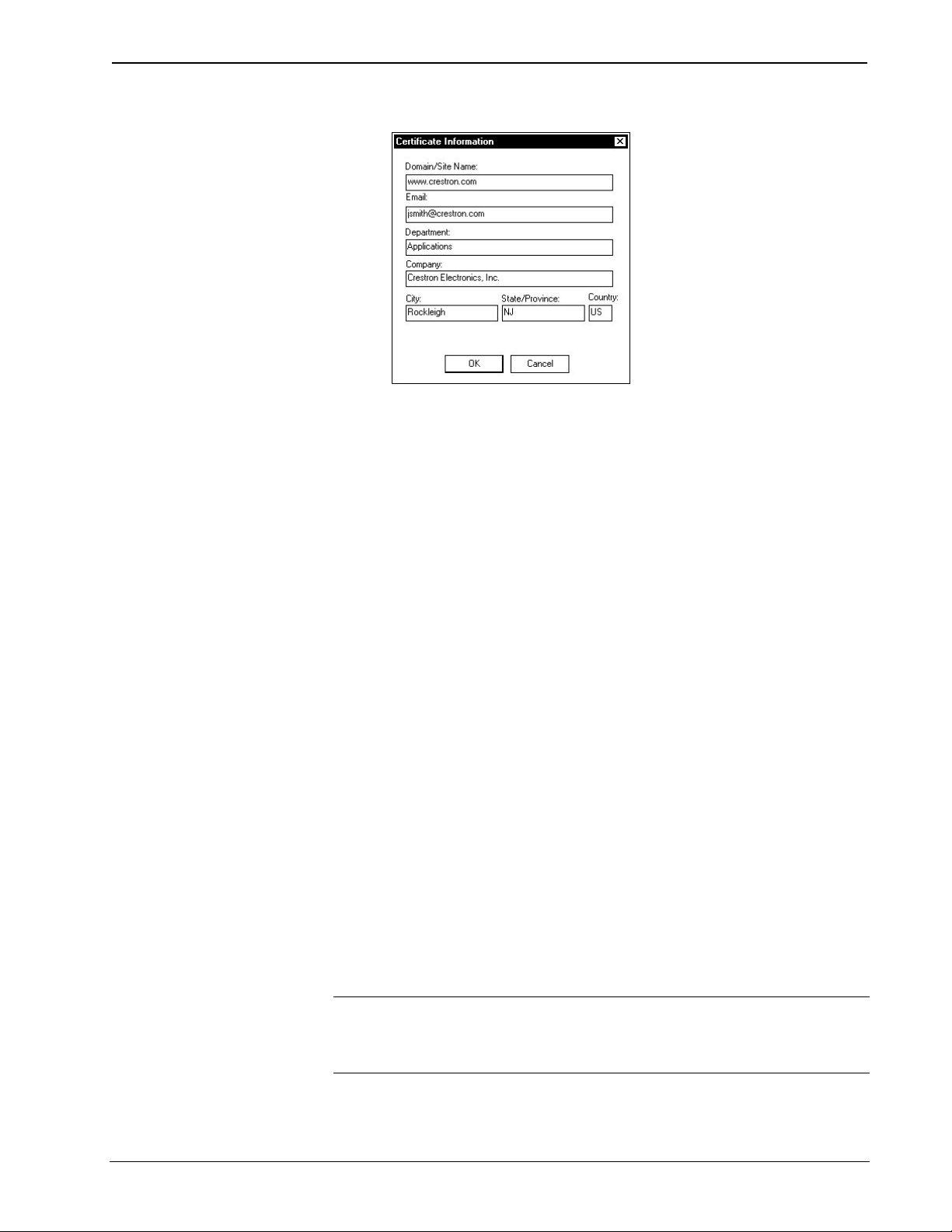

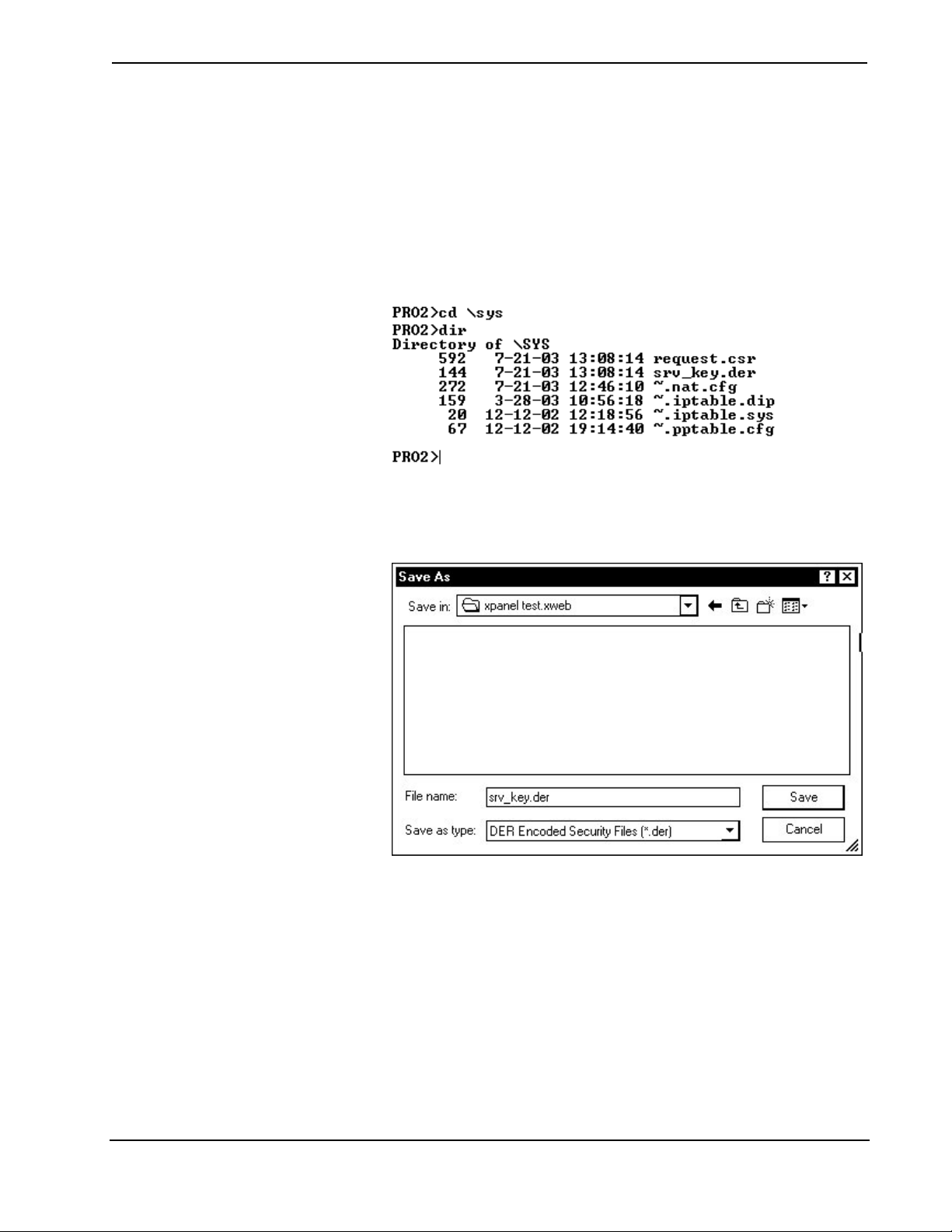

SSL Configuration..................................................................................................... 48

Uploading & Using Web Pages............................................................................................... 54

Crestron VisionTools Pro-e....................................................................................... 54

Reference Guide – DOC. 6256A Contents • i

Page 4

Crestron 2-Series Control Systems Reference Guide

Crestron Toolbox....................................................................................................... 54

SIMPL Windows....................................................................................................... 56

Web Page Basics ....................................................................................................... 56

Compiling and Uploading a Program ...................................................................................... 60

Compiling a Program in SIMPL Windows ............................................................... 60

Uploading a SIMPL Windows Program.................................................................... 60

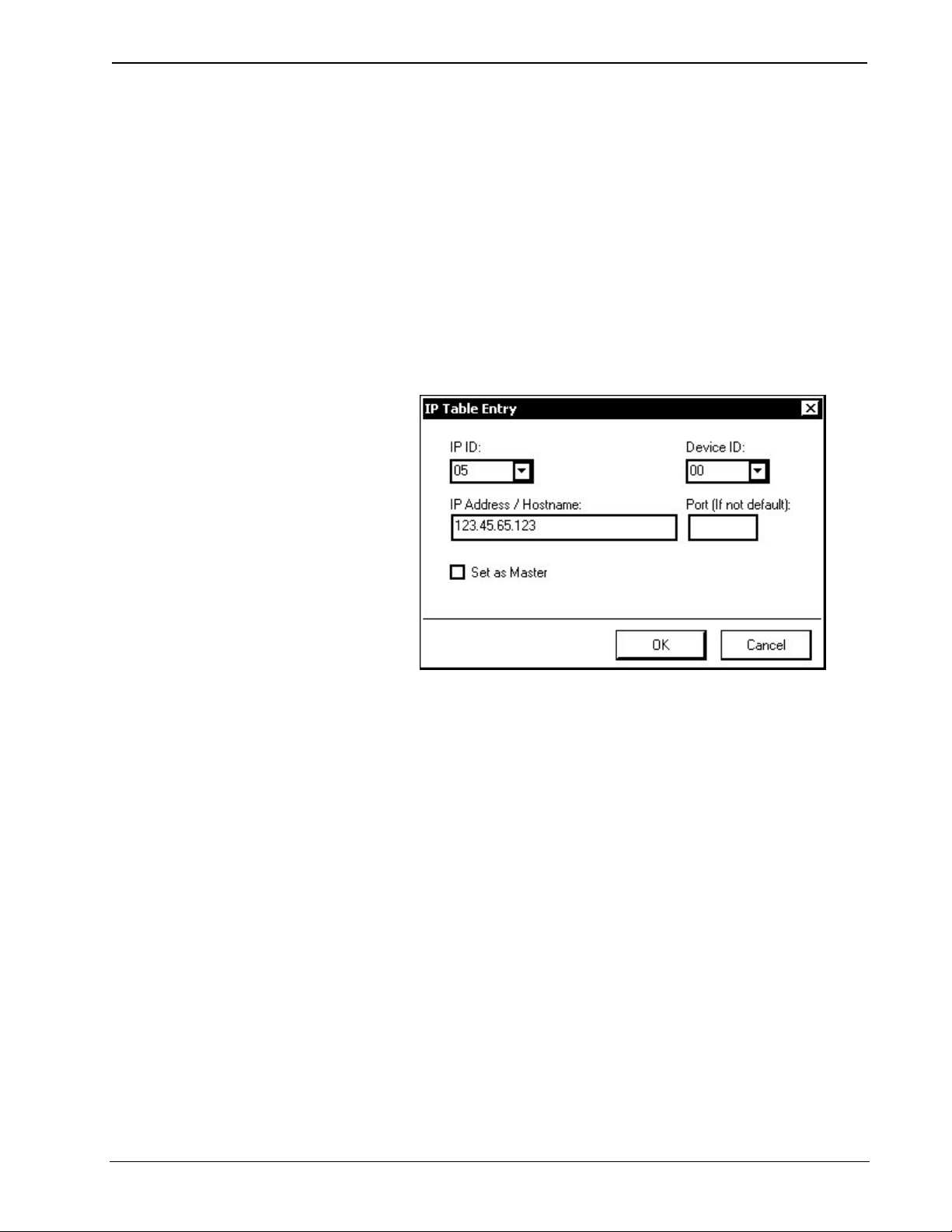

IP Tables.................................................................................................................... 61

Creating the Default IP Table from SIMPL Windows .............................................. 62

Creating and Modifying IP Tables with Crestron Toolbox....................................... 63

Uploading Touchpanel Projects............................................................................................... 65

Firmware Upgrade................................................................................................................... 67

Updating the Operating System............................................................................................... 69

Introduction ............................................................................................................... 69

Procedure................................................................................................................... 69

Test Manager........................................................................................................................... 71

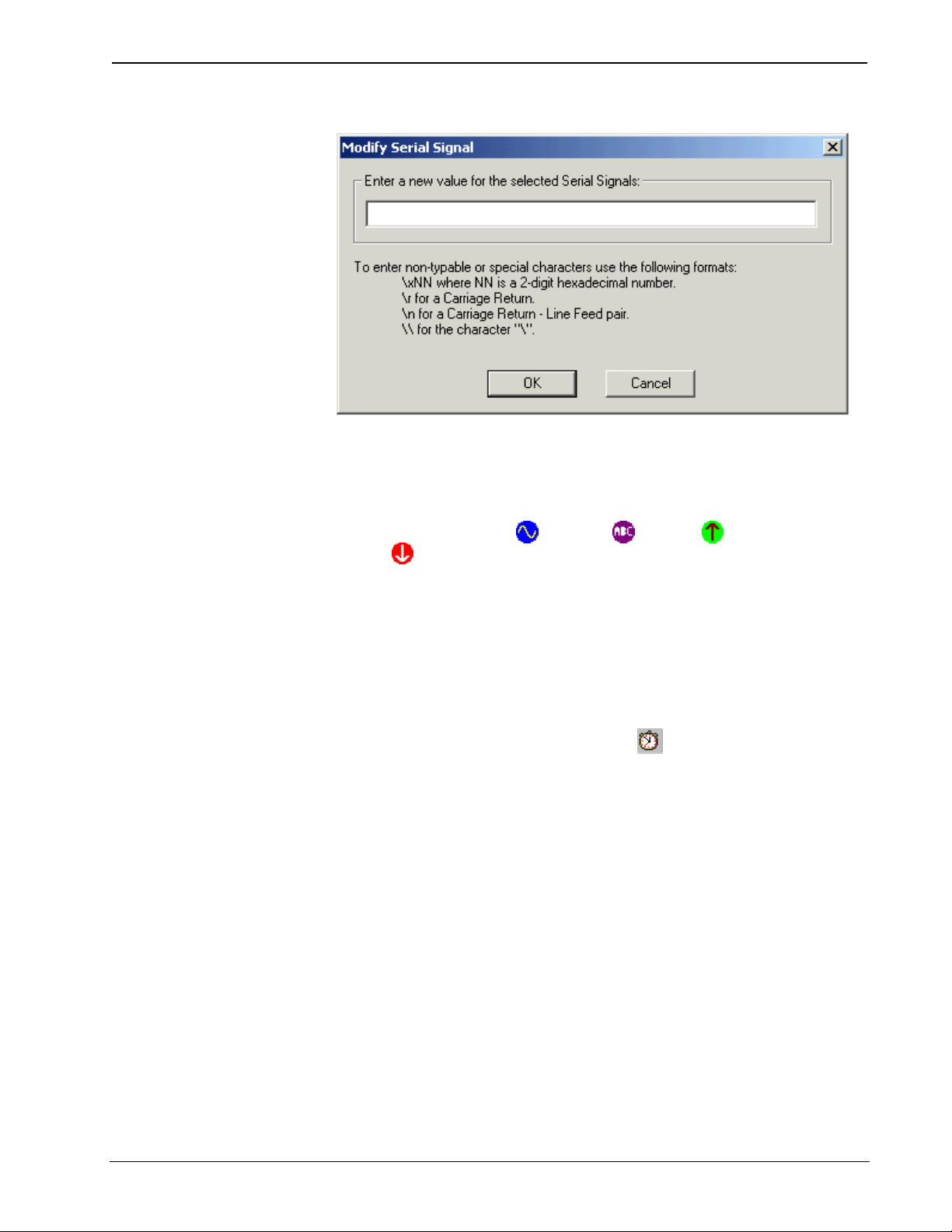

Incoming Data........................................................................................................... 71

Status Window ..........................................................................................................72

Trace Window........................................................................................................... 74

Network Analyzer.................................................................................................................... 75

Super-Debugger....................................................................................................................... 76

C2N-NPA8 Network Poll Accelerator .................................................................................... 77

Support Information ................................................................................................................79

Frequently Asked Questions .....................................................................................79

Watchdog Protection ................................................................................................. 80

Further Inquiries........................................................................................................ 80

Future Updates ..........................................................................................................81

Appendix A: Interfacing a Control System with a Modem ..................................................... 82

Quick Guide .............................................................................................................. 82

Cable Requirements (2-Series Control System to Modem) ......................................84

Cable Requirements (PC to Modem) ........................................................................85

Modem Configuration (Control System Modem) ..................................................... 85

Modem Communications Speed................................................................................ 86

Notes for QM-RMC and QM-RMCRX(-BA)........................................................... 86

2-Series Console Commands for Modem Configuration .......................................... 87

Appendix B: Passthrough Mode.............................................................................................. 89

Appendix C: Console Command Listing................................................................................. 91

Appendix D: Error Message Definitions ............................................................................... 123

Notice-Level Messages ...........................................................................................123

Warning-Level Messages........................................................................................ 123

Error-Level Messages.............................................................................................. 127

Appendix E: Super-Debugger Command Listing.................................................................. 152

Appendix F: Join Number Remapping (JNR) ....................................................................... 154

Introduction ............................................................................................................. 154

Programming........................................................................................................... 155

Uploading................................................................................................................ 172

Index...................................................................................................................................... 173

Software License Agreement................................................................................................. 178

Reference Guide – DOC. 6256A Contents • ii

Page 5

Crestron 2-Series Control Systems Reference Guide

2-Series Control Systems

Introduction

Crestron® control systems are at the center of every Crestron facility control system.

The 2-Series line of control systems share commonality across the product line and

offer a variety of development tools and techniques previously unavailable in

previous Crestron control systems. Crestron 2-Series control systems include the

AV2 and PRO2. Consult the latest Crestron Product Catalog for a complete list of all

2-Series control systems.

The common architecture shared by 2-Series control systems allows similar

programming tools, console commands, programming methods, and other practices

to be used across the product line. This document will discuss many of the tools,

features, and techniques used to program and troubleshoot a Crestron control system:

• Programming Tools & Utilities

• Establishing Communications with the Control System

• Troubleshooting Communications

• 2-Series Console Commands

• 2-Series Memory & Directory Structure

• 2-Series Control System Error Messages

• Master-Slave Modes

• Dynamic Host Configuration Protocol (DHCP)

• Secure Sockets Layer (SSL)

• Uploading & Using Web Pages

• Compiling and Uploading a Program

• Uploading Touchpanel Projects

• Firmware Upgrade

• Updating the Operating System

• Test Manager

• Network Analyzer

• Super-Debugger

• C2N-NPA8 Network Poll Accelerator

Reference Guide – DOC. 6256A 2-Series Control Systems • 1

Page 6

Reference Guide Crestron 2-Series Control System

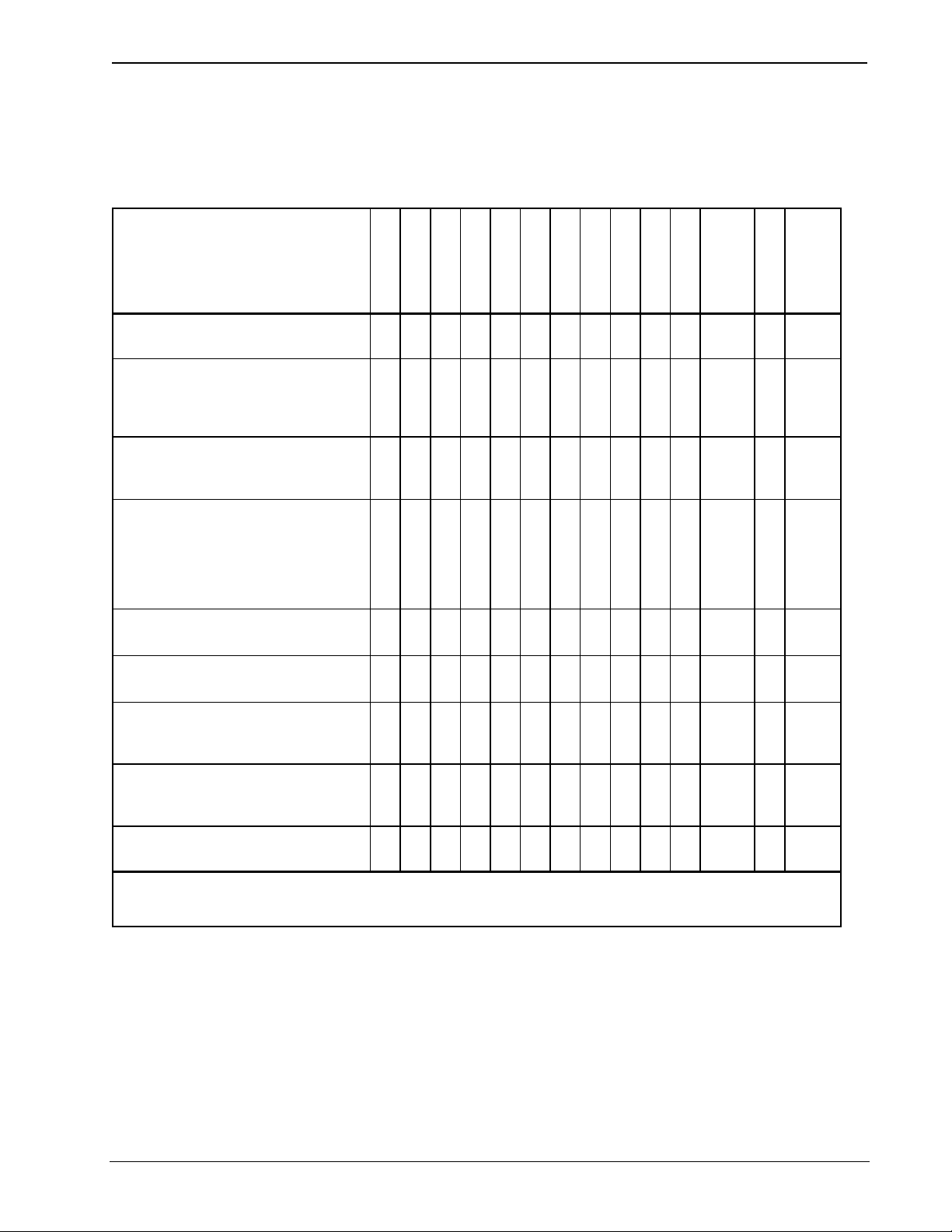

Each of the 2-Series control systems has unique features to meet a variety of system

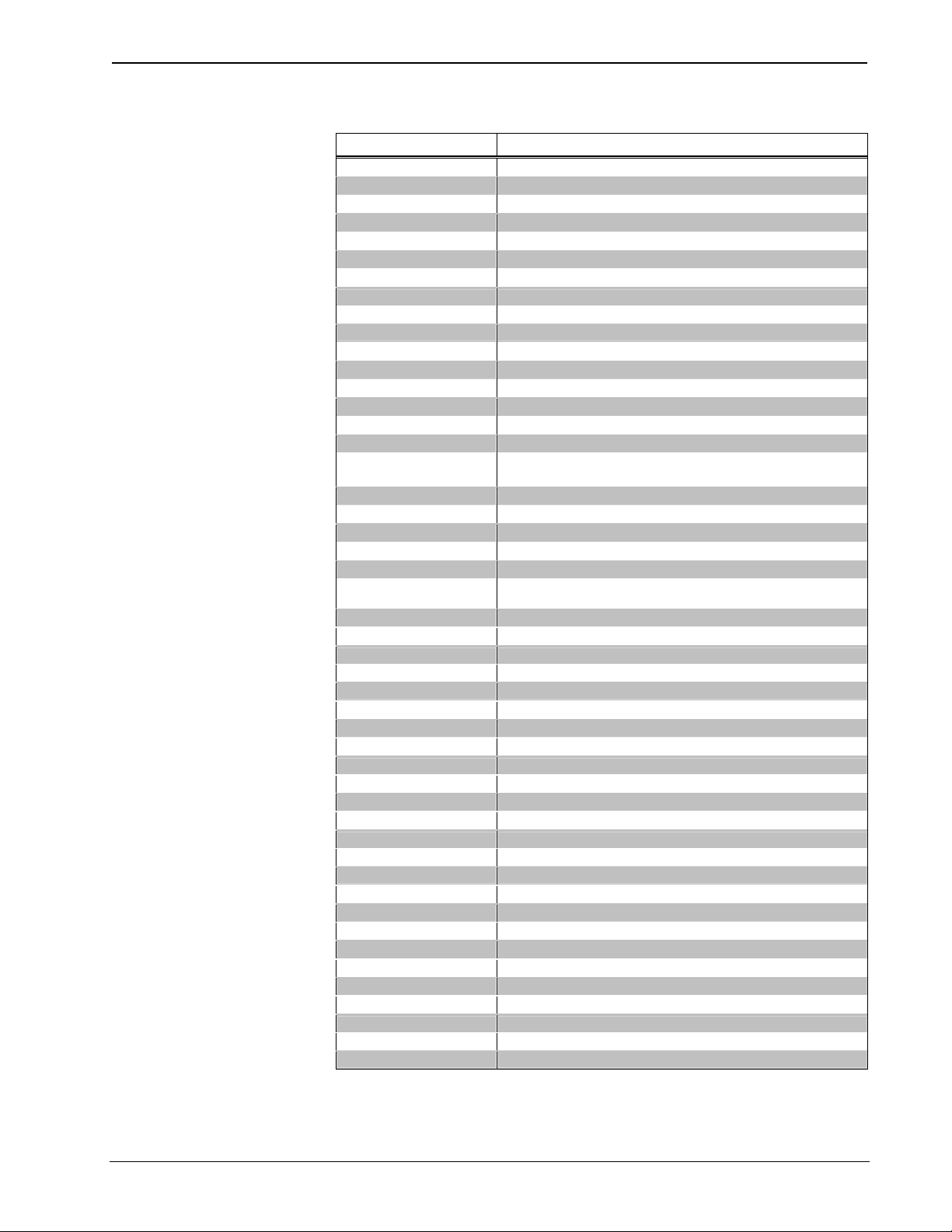

requirements. The following table lists all of the Crestron 2-Series control systems

and their key features.

2-Series Control Systems and Features

PRO2

AV2

RACK2

CP2E

CP2

MC2E

MC2W

MP2E

MP2

QM-RMC

QM-RMCRX(-BA)

CNX-DVP4

C2N-DVP4I

Processor:

2-Series Engine and Dual-bus Architecture XXXXXXXXXXX X X

4GB Compact Flash Memory Card Slot XXX X X

Cresnet:

Cresnet Port (Master/Slave) XXXXXXXXX X X X

Integrated Cresnet Network Hub XX

C2N-NPA8 Support via Com Port XX XXXXXX

C2N-NPA8 Support via Ethernet Port (a) (a) (a) XXX X(a)

Ethernet:

10/100 Ethernet Port w/SSL & DHCP (a) (a) (a) XXXXXX(a)

e-Control 2 Enabled (a) (a) (a) XXXXXX(a)

Built-in Firewall, NAT and Router (a) (a) (a) (a)

Integrated Control Ports:

Com (RS-232/422/485) 6+ 6+ (b) 332222 (b)

Com (RS-232 Only) 22 4

IR/Serial 8+ 8+ (b) 88444411 (b)

Versiport I/O 8+ 8+ (b) 884444 8+

Digital Input 44

Low-Voltage Relay 8+ 8+ (b) 884444 8+

Control Card Expansion Slots:

Y-Bus 3 (c) 12 2

Built-in Wireless:

1-way 418 or 434 MHz 1-way RF X

38 kHz RC5 Infrared (IR) via CNXRMIRD XXXX

Audio, Video and RGB:

Integrated AV Switcher/Processor XX X

Integrated QuickMedia Transport X

Integrated Digital Video Processor X

Power Supply:

Internal Univeral Power Supply XX X

External Power Supply Included XXXXXX

Separate Power Supply Required XXX X

Mounting:

EIA Rack Units (Ears Included) 224111111 2

Non-Rack Mount (d) (d) (e)

Notes:

a. Requires appropriate Z-bus card c. 3 Y-bus slots, requires optional CAGE2

b. Requires appropriate Y-bus card(s) d. Optional projector pole mount available

Z-Bus 114 1

e. Installs in CAEN automation cabinets

PAC2

2 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 7

Crestron 2-Series Control Systems Reference Guide

Programming Tools & Utilities

Many of the activities discussed in this document require the use of Crestron’s suite

of programming tools and utilities. They include:

Pro-e

®

• SIMPL™ Windows

• VisionTools

• Crestron Toolbox

• Test Manager

• Viewport (limited use)

The latest versions can be obtained from the Crestron website

(www.crestron.com

NOTE: Crestron software and any files on the website are for Authorized Crestron

dealers and Crestron Authorized Independent Programmers (CAIP) only. New users

may be required to register to obtain access to certain areas of the site (including the

FTP site).

®

/updates).

SIMPL Windows

SIMPL Windows is Crestron's software for programming Crestron control systems.

It provides a well-designed graphical environment with a number of windows in

which a programmer can select, configure, program, test, and monitor a Crestron

control system. SIMPL Windows offers drag and drop functionality in a familiar

Windows

®

environment.

VisionTools Pro-e

Crestron VisionTools Pro-e (also referred to as VT Pro-e) Windows-based software

is for drawing touchscreen pages by using two and three-dimensional graphics and

text as well as video and sounds (recorded as WAV files). A set of pages make up a

project. Each of these “projects” can be loaded in a Crestron touchpanel or used as a

set of web pages stored on a control system for remote access to control system

functions.

Crestron Toolbox

Crestron Toolbox is a replacement for Crestron Viewport. Crestron Toolbox is a

broad-based software package that accomplishes multiple system tasks, primarily

using an RS-232 or TCP/IP connection between a PC and one or more Crestron

control systems.

You can use Crestron Toolbox to:

• Observe system processes.

• Upload operating systems and firmware.

• Upload programs and touchpanel projects.

• Set or change device Network IDs.

• Change the serial number reported by a device.

Reference Guide – DOC. 6256A 2-Series Control Systems • 3

Page 8

Reference Guide Crestron 2-Series Control System

• Run scripts to automate tasks.

• Perform system diagnostics, and much more.

Crestron Toolbox allows you to perform these functions using simple graphical

views and click and drag methods.

Crestron Toolbox also contains the Network Analyzer and Test Manager (expected

2Q 2006) utilities.

Network Analyzer

The Network Analyzer utility helps to identify Cresnet® network problems that can

be caused by faulty devices, electrical shorts, or breaks in network wiring. Network

Analyzer takes a sample of the voltage levels on the Cresnet "Y" and "Z" wires.

Network Analyzer is launched from within Crestron Toolbox by clicking the

Network Analyzer icon

For more information on Network Analyzer, refer to “Network Analyzer” on page

75.

Test Manager

The Test Manager is a utility for testing and debugging a SIMPL Windows program,

by monitoring the status of selected signals in real time. Test Manager can test any

program that has been compiled and uploaded to the control system.

.

Test Manager is launched from within SIMPL Windows by clicking the Test

Manager button or by selecting Tools | Test Manager. Test Manager can also be

opened as a standalone program.

For more information on Test Manager, refer to “Test Manager” on page 71.

Viewport (Limited Use)

Where noted in this guide, the Crestron Viewport can be used to perform certain

functions

Viewport is available as a pull-down command from SIMPL Windows and VT Pro-e

(Tools | Viewport) or as a standalone utility. The Viewport utility performs multiple

system tasks, primarily via an RS-232 or TCP/IP connection between the control

system and a PC. It is used to observe system processes, upload new operating

systems and firmware, change system and network parameters, and communicate

with network device consoles and touchpanels, among many other tasks. Viewport

can also function as a terminal emulator for generic file transfer. All of these

functions are accessed through the commands and options in the Viewport menus.

NOTE: Except where noted, Crestron Toolbox should be used.

4 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 9

Crestron 2-Series Control Systems Reference Guide

Establishing Communications with the Control System

Whether uploading programs, troubleshooting, or performing diagnostics

communication between the control system and a PC must be established.

In electronic terms, a “console” provides a means of communication between an

operator and the central processing unit of a computer. Crestron Toolbox lets you

talk to the console of a 2-Series dual bus control system. Crestron Toolbox allows

the operator to establish, monitor, and troubleshoot communications directly with the

control system.

Depending on the control system’s capabilities, the following communication

protocols may be used to communicate with a control system:

• Serial communication (RS-232) with a PC via the COMPUTER port

on the control system

• Ethernet communication via CTP (Crestron Terminal Protocol –

reserved port number, default port is 41795) *

• Ethernet communication via Secure CTP over a SSL connection to port

41797 at the IP address of the processor*

• Telnet (default port is 23)*

• Cresnet for processors operating in the Cresnet slave mode (refer to

“Master-Slave Modes” on page 32)

* These methods are only available if the control system supports Ethernet.

Whether the intent is to use RS-232 or Ethernet, these methods initially require

connection of the control system to a PC via RS-232.

Another method for submitting a command to the console is to use the “Console” or

“User Program Commands “ symbols in SIMPL Windows in the control system

program. The Console symbol transmits and receives serial data to and from the

control system’s console. The User Program Commands symbol allows data typed at

the console to be sent to the program. For more information on the Console symbol,

refer to “Console Logic Symbol” on page 16. For more information on the User

Program Commands symbol, refer to “User Program Commands Symbol” on page

17.

Serial Connection

Complete the following steps to establish a serial connection between a PC and a

control system.

1. As shown in the following diagram, connect the COMPUTER port on the

control system to one of the COM ports (usually COM 1) on the PC. Use a

straight-through RS-232 cable with a DB9 male connector on one end and a

DB9 female connector on the other. Most commercially available cables are

acceptable; they should have at least five pins for transmit, receive, ground,

and hardware handshaking (pins 2, 3, 5, 7, 8).

NOTE: Most of the Crestron 2-Series control systems use a straightthrough RS-232 cable. However, some models use a null-modem cable.

Refer to your control system’s Operations Guide for cable details.

Reference Guide – DOC. 6256A 2-Series Control Systems • 5

Page 10

Reference Guide Crestron 2-Series Control System

Typical Connection Diagram for Establishing Communication

Control System

RS-232

NOTE: Certain control systems do not have a COMPUTER port and

require an alternate method for establishing serial communications. Refer to

your control system’s Operations Guide if the control system does not have

a COMPUTER port.

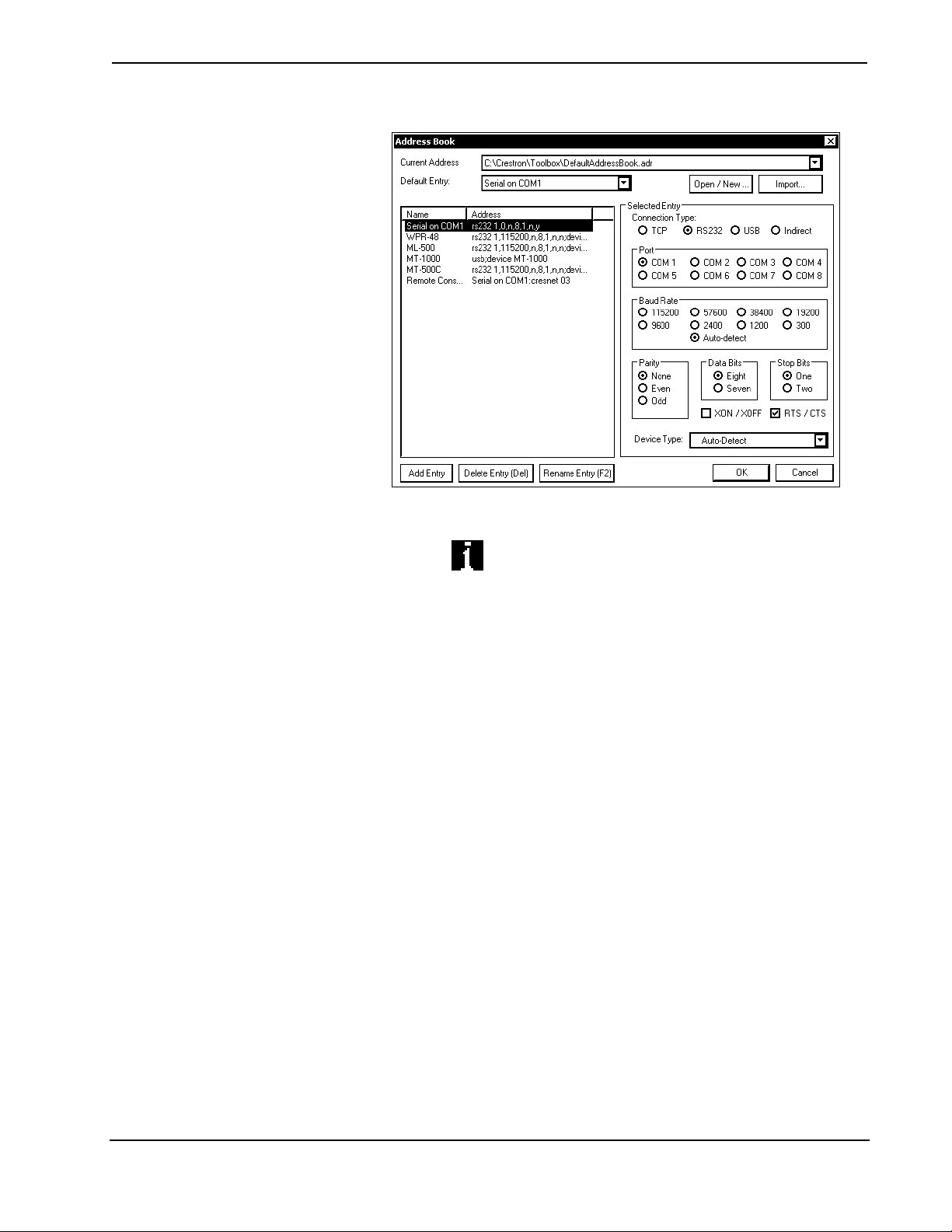

2. Open Crestron Toolbox and click Tools | Manage Address Book to display

a list of available devices. Select a connection to a control system (if an

entry for one exists), or Serial on COM1 as the connection type. Serial on

COM1 is an address book entry for PC-to-control system communications

that is included with Crestron Toolbox.

The default settings for the Serial on COM1 entry, which will work with

most 2-Series control systems, are as follows:

• Port = COM 1. If the PC is to communicate with a control system

through a different serial port, select the correct COM port (COM1

through COM8) to be used.

• Baud rate = Auto-detect.

• Parity = None.

• Number of data bits = 8.

• Number of stop bits = 1.

• Hardware handshaking (RTS/CTS) enabled.

• Software handshaking (XON/XOFF) not enabled.

NOTE: If using a direct serial connection, an 8-bit serial connection must be used

when transferring a binary file. If a 7-bit serial connection is used, the transfer will

fail.

6 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 11

Crestron 2-Series Control Systems Reference Guide

“Address Book” Window – Serial Setup

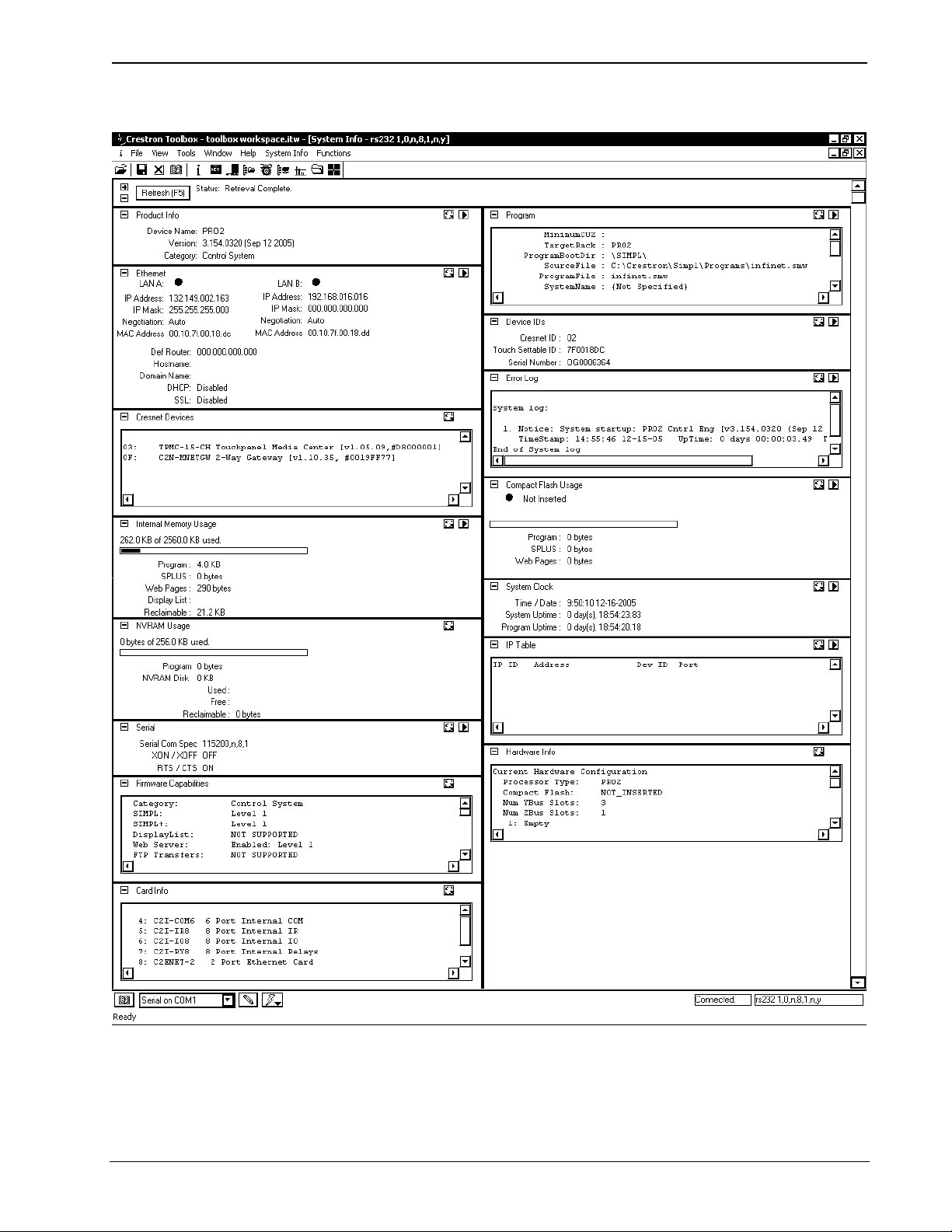

3. After setting the correct parameters, click OK to return to the Crestron

Toolbox main window.

4. Click the

entry for the control system or Serial on COM1 from the drop down list

(located on the bottom of the screen) if it is not already selected. If

communication is successful, the control system’s information is displayed

as shown in the following diagram.

icon to display the control system information. Select the

Reference Guide – DOC. 6256A 2-Series Control Systems • 7

Page 12

Reference Guide Crestron 2-Series Control System

“System Info” Window for PRO2

Once the system information is displayed a variety of functions are available to the

user. For more information, refer to the Crestron Toolbox help file.

8 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 13

Crestron 2-Series Control Systems Reference Guide

NOTE: Crestron Toolbox displays a customized list of functions depending on the

type of device with which it is communicating.

TCP/IP Connection

Before communicating with an Ethernet-enabled control system over TCP/IP, a static

IP address or the address/host name of the DHCP server (if DHCP is to be used)

must be obtained from the network administrator. The RS-232 connection previously

described must be used to configure the unit’s TCP/IP settings. After configuring the

IP information of the control system, further communications can be done over

TCP/IP. For more information, refer to the latest version of the Crestron e-Control

Reference Guide (Doc. 6052). The guide is available from the Crestron website

(www.crestron.com/manuals).

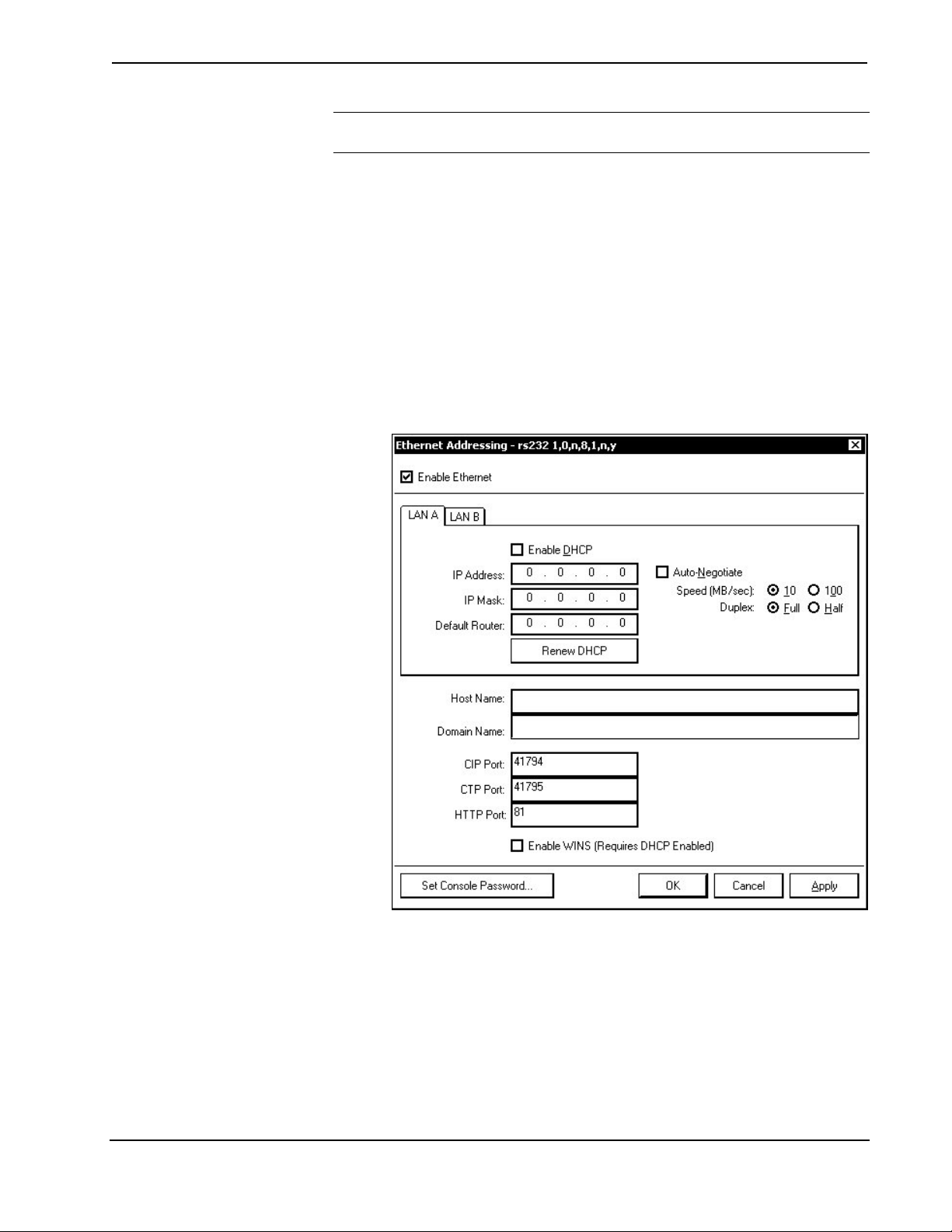

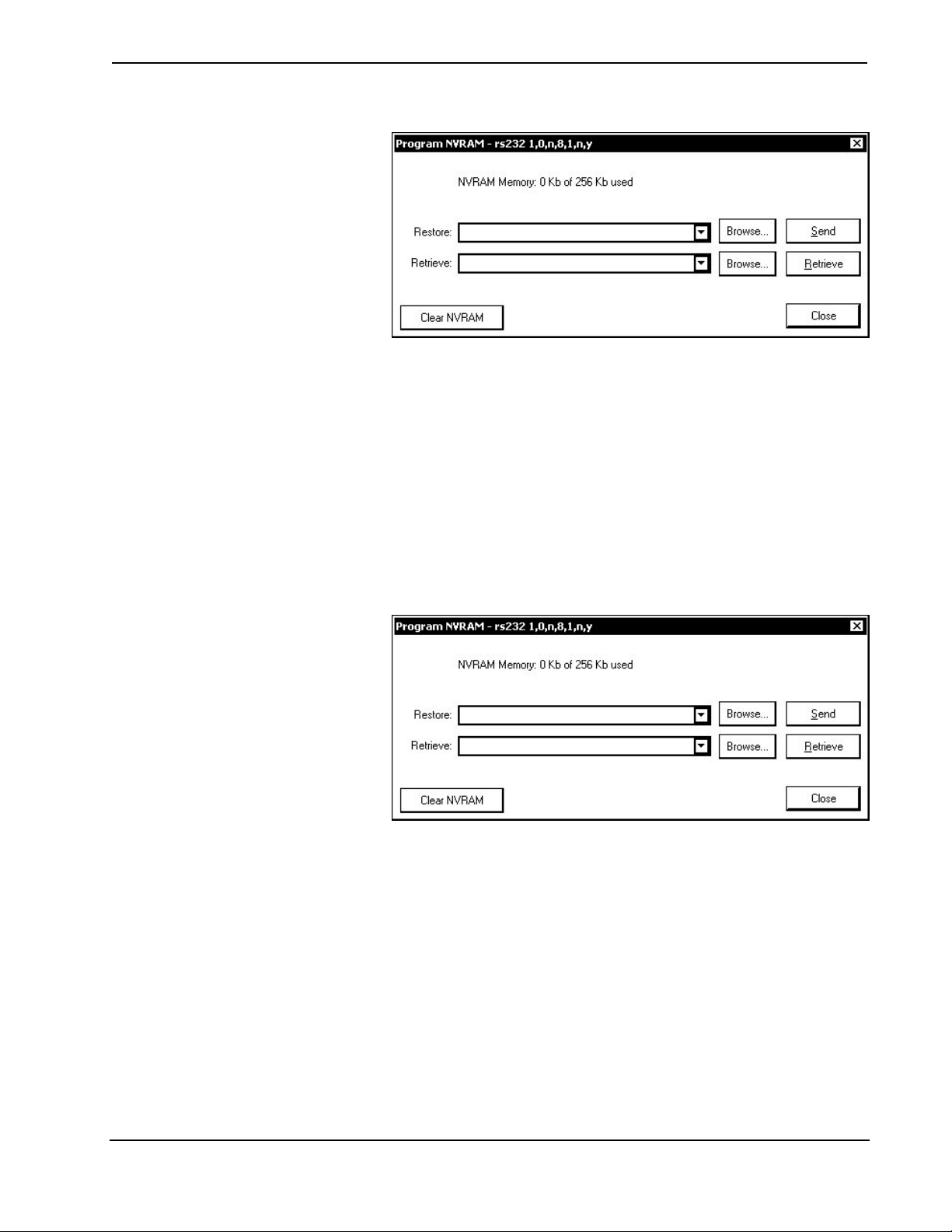

1. Select Functions | Ethernet Addressing… to open the “Ethernet

Addressing” window

“Ethernet Addressing” Window

2. Enable TCP/IP communications by checking Enable Ethernet and

configure for static or dynamic IP operation.

a) Static IP Operation

i. Clear (de-select) the Enable DHCP check box.

ii. Enter the static IP address and address mask in the address

fields. If applicable, enter the default gateway address. (If data

will not be routed outside the LAN, the default gateway can be

left blank.)

Reference Guide – DOC. 6256A 2-Series Control Systems • 9

Page 14

Reference Guide Crestron 2-Series Control System

The IP addresses of LAN A and LAN B cannot be the same.

iii. Enter the hostname in the Host Name field. The host name

identifies the control system on the network and is

automatically translated into the numerical IP address. The

host name can consist of up to 64 characters. Valid characters

are 0 – 9, A – Z (not case-sensitive), and the dash (hyphen

character). No other characters are valid. The host name

cannot begin with a dash or number.

If a host name is specified, you can enter this host name

instead of the IP address in the Address Book.

iv. The Domain Name is an additional qualifier that some

networks may need to resolve the name properly.

b) Dynamic IP Operation

i. Select the Enable DHCP check box to enable DHCP for

Windows 2000 Server.

ii. Select both the Enable DHCP and Enable WINS check

boxes for Windows NT 4.0 Server. The address of the WINS

server will be provided by the DHCP server.

iii. Enter the fully-qualified domain name (FQDN) of the control

system into the Host Name field. The host name identifies the

control system on the network and is automatically translated

into the numerical IP address. The host name can consist of up

to 64 characters. Valid characters are 0 – 9, A – Z (not casesensitive), and the dash (hyphen character). No other

characters are valid. The host name cannot begin with a dash

or number.

iv. If applicable, enter the domain into the Domain Name field.

This is only necessary if you are configuring DHCP on an

Ethernet connection to a control system that currently has a

static address. The domain name will be used to reconnect to

the control system after it reboots. With a serial connection,

the domain name does not need to be entered.

The domain name supplied by the DHCP server will overwrite

the domain name that is indicated in this field.

v. To request a new IP address from the DHCP server click the

Renew DHCP button.

NOTE: Other settings can be configured as well. Refer to the

Crestron Toolbox help file for more information.

3. Click OK to reboot the control system and set the new IP information.

Once the IP settings have been assigned, the control system can

communicate using the RS-232 connection or a TCP/IP connection.

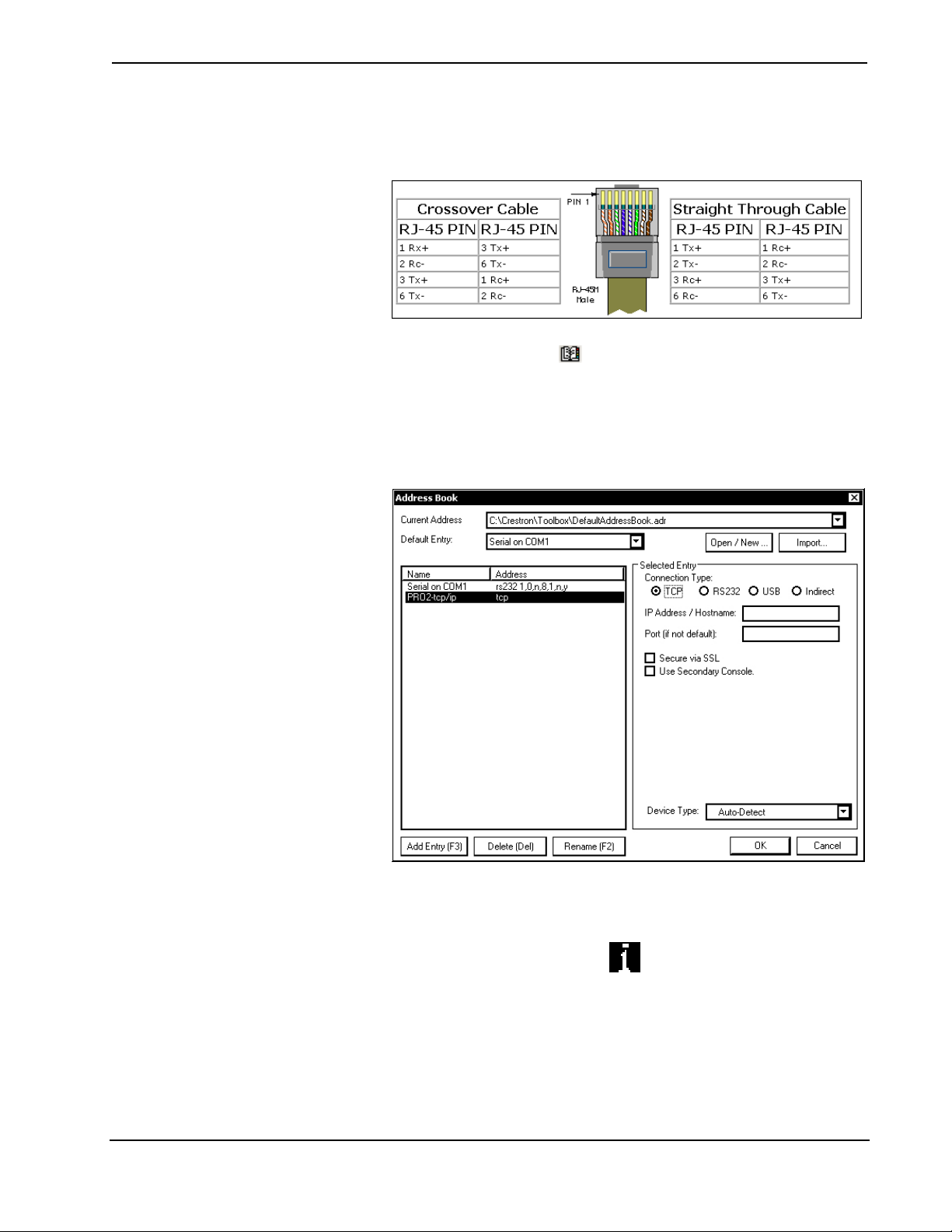

For TCP/IP, use CAT5 straight through cables with 8-pin RJ-45 connectors

to connect the LAN port on the control system and the LAN port on the PC

to the Ethernet hub. Alternatively, you can use a CAT5 crossover cable to

connect the two LAN ports directly, without using a hub. The following

10 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 15

Crestron 2-Series Control Systems Reference Guide

figure illustrates pinouts for straight through and crossover RJ-45 cables.

Pins 4, 5, 7, and 8 are not used.

RJ-45 Pinouts

4. Open the address book in Crestron Toolbox by selecting Tools | Manage

Address Book or clicking

5. Create a new entry for the control system by clicking Add Entry or

pressing F3.

6. Enter a name for the control system connection and select TCP as the

connection type.

“Address Book” Window - Entering New TCP-IP Entry

.

7. Enter the IP address or hostname of the control system that was created on

page 10.

8. Click OK to save the address book entry.

9. To verify the connection, click the

“System Info” window will be displayed.

icon. If the settings are correct, the

Modem Connection

In applications where remote access to a control system is required but a serial or

Ethernet connection cannot be used, a modem can be connected to the control system

for communication with a PC console over a standard telephone line.

Reference Guide – DOC. 6256A 2-Series Control Systems • 11

Page 16

Reference Guide Crestron 2-Series Control System

NOTE: This procedure requires the use of the Crestron Viewport.

For detailed instructions and information, refer to “Appendix A: Interfacing a

Control System with a Modem” on page 82.

Passthrough Mode (Viewport Only)

Viewport can be used to communicate with devices that are attached to a control

system’s serial port. For more information, refer to “Appendix B: Passthrough

Mode” on page 89.

12 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 17

Crestron 2-Series Control Systems Reference Guide

Troubleshooting Communications

Use the following checklist if communication cannot be established with the control

system.

1. If possible remove any cards that are in the card cage, Cresnet devices and

the Ethernet card (if applicable).

2. Verify that you are using the correct cables. As described previously, most

RS-232 connections between a control system and a PC require a straightthrough serial cable. That is, pin 1 on one end is connected to pin 1 on the

other end. Pin 2 connects to pin 2, etc. With a TCP/IP connection, a CAT5

cable with 8-pin RJ-45 connectors and the wiring shown on page 11 must

be used.

NOTE: If you are using a serial adapter, Crestron Toolbox should be used

to establish PC-to-control system communications.

3. If using a serial connection, verify that the correct COM port on the PC has

been selected. Some computers have more than one COM port; some may

be internal (e.g., for a modem). Consult the manufacturer’s documentation

for further information about the COM ports on your PC.

4. Check the MSG / ERR LED indicator on the front panel of the control

system. If this LED is illuminated before a program is loaded, unplug the

unit and reapply power after a few seconds. If the LED illuminates again,

call Crestron customer service.

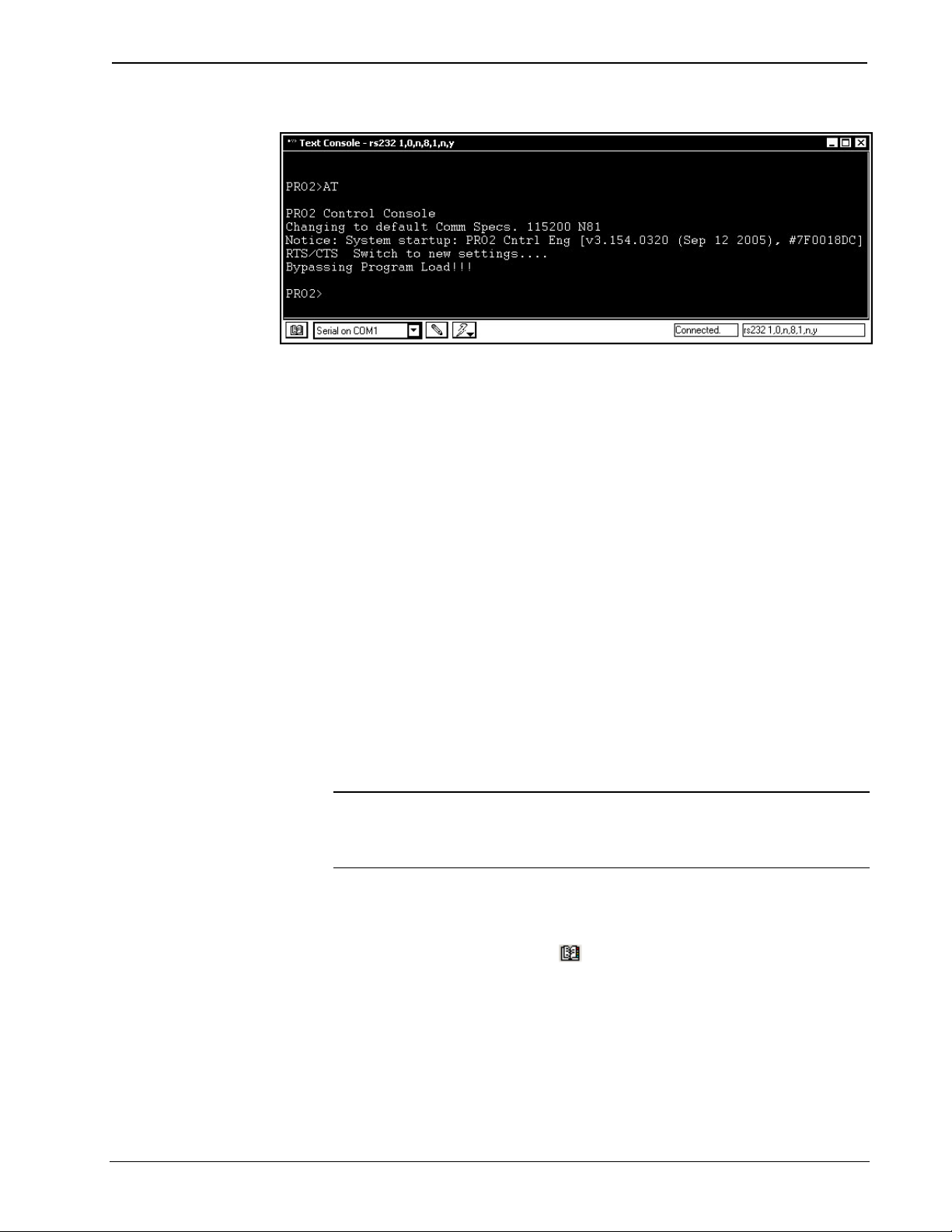

5. With a serial connection, reset the control system as follows:

a. Open Crestron Toolbox and open a text console connection to the

control system by clicking

system’s serial connection from the dropdown list on the bottom of the

page.

NOTE: The address book entry for the serial connection should

specify a 115200 baud rate. Do not select “Auto-Detect”.

b. Set the baud rate of the control system to 115200, as follows:

- Press and release the HW-R button on the unit’s front panel.

- Immediately press and hold the SW-R button for approximately

ten seconds. The Crestron Toolbox text console should display the

following message:

and selecting the entry for the control

Reference Guide – DOC. 6256A 2-Series Control Systems • 13

Page 18

Reference Guide Crestron 2-Series Control System

Crestron Toolbox Message (PRO2 Shown)

- Release the SW-R button.

c. If communication still cannot be established or the console is

displaying a <CS> prompt:

- Remove power from the control system.

- Press and hold the SW-R button on the front panel of the control

system.

- Reapply power to the control system while still holding the SW-R

button.

- The console should display the message previously shown.

- Release the SW-R button.

d. If communication still cannot be established, use the System Monitor

as described in the following paragraph.

If after performing all of the troubleshooting steps described in “Troubleshooting

Communications”, communication can still not be established or the control system

is still locked-up, perform the following to reload the control system’s firmware.

To erase and reinstall the control system firmware:

NOTE: This procedure will erase the control system’s firmware and reinstall it. If

problems persist before a SIMPL Windows program is loaded, contact Crestron’s

True Blue Technical Support Group. If the system locks up after a SIMPL Windows

program is loaded, there is probably an issue with the SIMPL Windows program.

1. Connect a serial cable (If using the QM-RMC or the QM-RMCRX(-BA),

use a null modem cable) from the control system to a PC.

2. Open the address book in Crestron Toolbox by selecting Tools | Manage

Address Book or clicking

3. Create a new address book entry with the following settings:

.

• Port = COM 1. If the PC is to communicate with a control system

through a different serial port, select the correct COM port (COM1

through COM8) to be used.

• Baud rate = 57600.

• Parity = None.

14 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 19

Crestron 2-Series Control Systems Reference Guide

• Number of data bits = 8.

• Number of stop bits = 1.

• Hardware handshaking (RTS/CTS) enabled.

• Software handshaking (XON/XOFF) not enabled.

4. Power down the control system.

5. In Crestron Toolbox, open a text console to the new address book entry.

6. While powering up the control system, press and hold ALT + K on the

keyboard (for the QM-RMC and QM-RMCRX(-BA), press Enter after

pressing ALT + K) until the following text (or similar) appears in the

Crestron Toolbox text console:

System Monitor [v1.001 (0001)]

12-19-01 16:25:23 32 MB RAM, 4MB FLASH

CS>

7. Increase the baud rate to 115200 by opening the “System Info” window,

selecting Functions | Serial Communications, and selecting 115200 as the

new baud rate. Click OK or Apply to set the new baud rate.

NOTE: Crestron Toolbox will automatically change the baud rate it uses to

communicate with the control system for the current session to ensure that

communications are maintained.

8. From the text console window, adjust the baud rate of the PC to control

system connection by clicking

rate.

9. At the control system prompt, type erase and press Enter. The following

text appears in the console window.

CS>erase

->25%->50%->75%->100%

Done

CS>

10. Send the new firmware file as described in “Firmware Upgrade” on page

67.

NOTE: The following processor firmware versions require the selection of

a CE*.CSU file that can be extracted from the .CUZ file using WinZip or

other ZIP file extraction tool:

• CNX-DVP4/C2N-DVP4DI: 2.006, 3.017

• MP2/MP2E: 3.016

• QM-RMC: 3.052

and selecting 115200 as the new baud

After extracting the CSU file, select it and click Open.

Once “Completed Successfully” appears in the text console window, close the text

console window.

Reference Guide – DOC. 6256A 2-Series Control Systems • 15

Page 20

Reference Guide Crestron 2-Series Control System

2-Series Console Commands

Introduction

The 2-Series processor is capable of understanding and responding to a set of

recognizable words known as console commands. The processor, in essence, is a

computer capable of interpreting commands received by the console via different

methods. Methods include:

• Serial communication (RS-232) with a PC via the COMPUTER port

on the control system

• Ethernet communication via CTP (Crestron Terminal Protocol –

reserved port number, default port is 41795) *

• Ethernet communication via Secure CTP over a SSL connection to port

41797 at the IP address of the processor*

• Telnet (default port is 23)*

• Cresnet for processors operating in the Cresnet slave mode (refer to

“Master-Slave Modes” on page 32)

* These methods are only available if the control system supports Ethernet.

Another method for submitting a command to the console is to use the “Console” or

“User Program Commands “ symbols in SIMPL Windows in the control system

program. The Console symbol transmits and receives serial data to and from the

control system’s console. The User Program Commands symbol allows data typed at

the console to be sent to the program.

NOTE: The method of transmitting each command to the control system varies

from command to command. Refer to “Appendix C: Console Command Listing” on

page 91 for a complete list of commands and their possible sources.

SIMPL Windows Symbols

Console Logic Symbol

Use the Console logic symbol to activate console commands via the SIMPL

Windows program. This feature is available for advanced programmers of SIMPL

Windows.

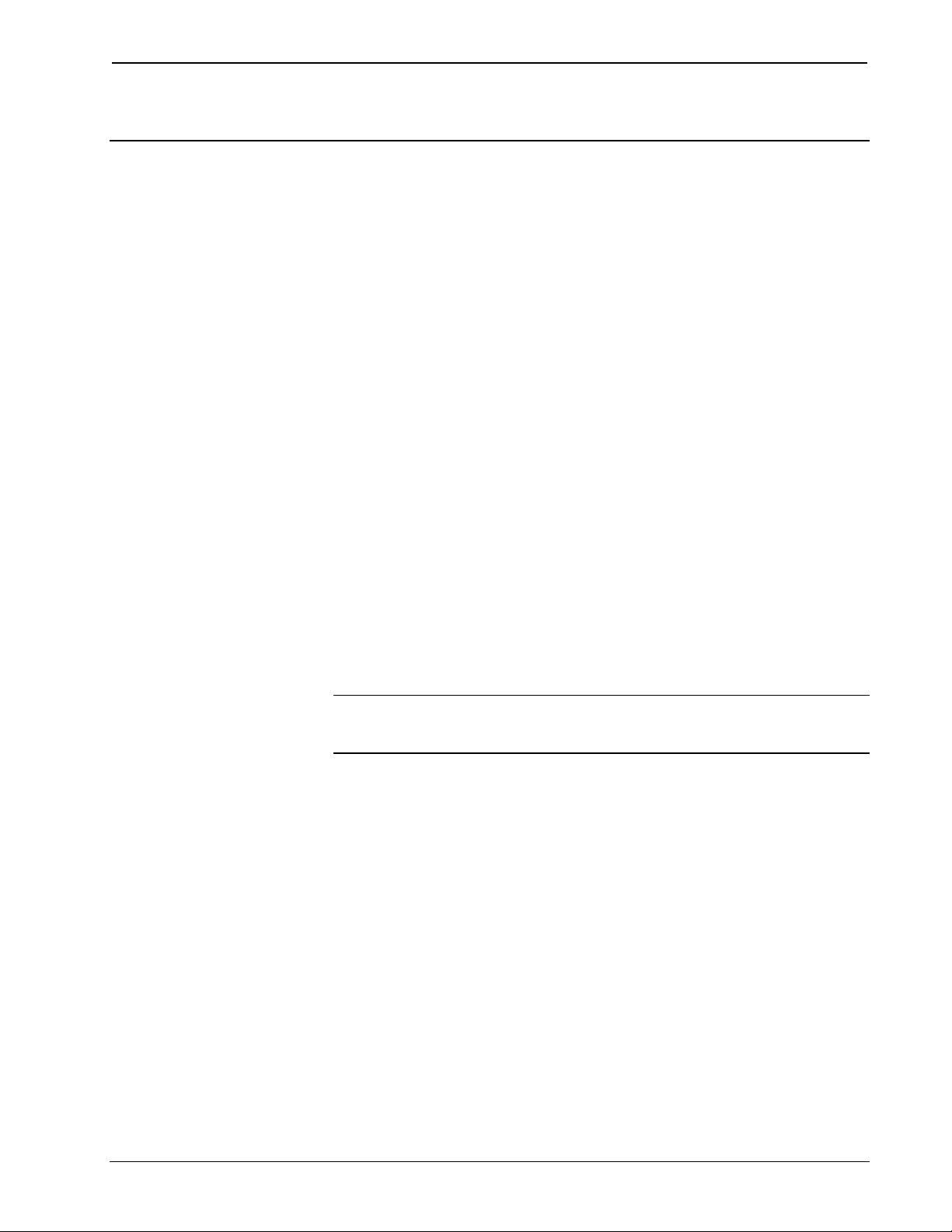

The Console logic symbol only appears in the System Control folder in the Symbol

Library, after enabling a special symbol set for display. To enable this set while in

SIMPL Windows, select Edit | Preferences, which opens the "SIMPL Windows

Preferences" window. In the Symbol Set area of the General tab, select Special as

shown in the following diagram.

16 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 21

Crestron 2-Series Control Systems Reference Guide

“SIMPL Windows Preferences” Window

After enabling viewing of special symbols, the Console symbol can be viewed as

shown in the following diagram.

The Console Logic Symbol in SIMPL Windows

When the program sends data on the TX$ signal of the Console symbol, the control

system interprets the console command just as if it was received via the RS-232 or

Ethernet console and outputs a serial string to the RX$ signal of the console symbol

which can be programatically interpreted.

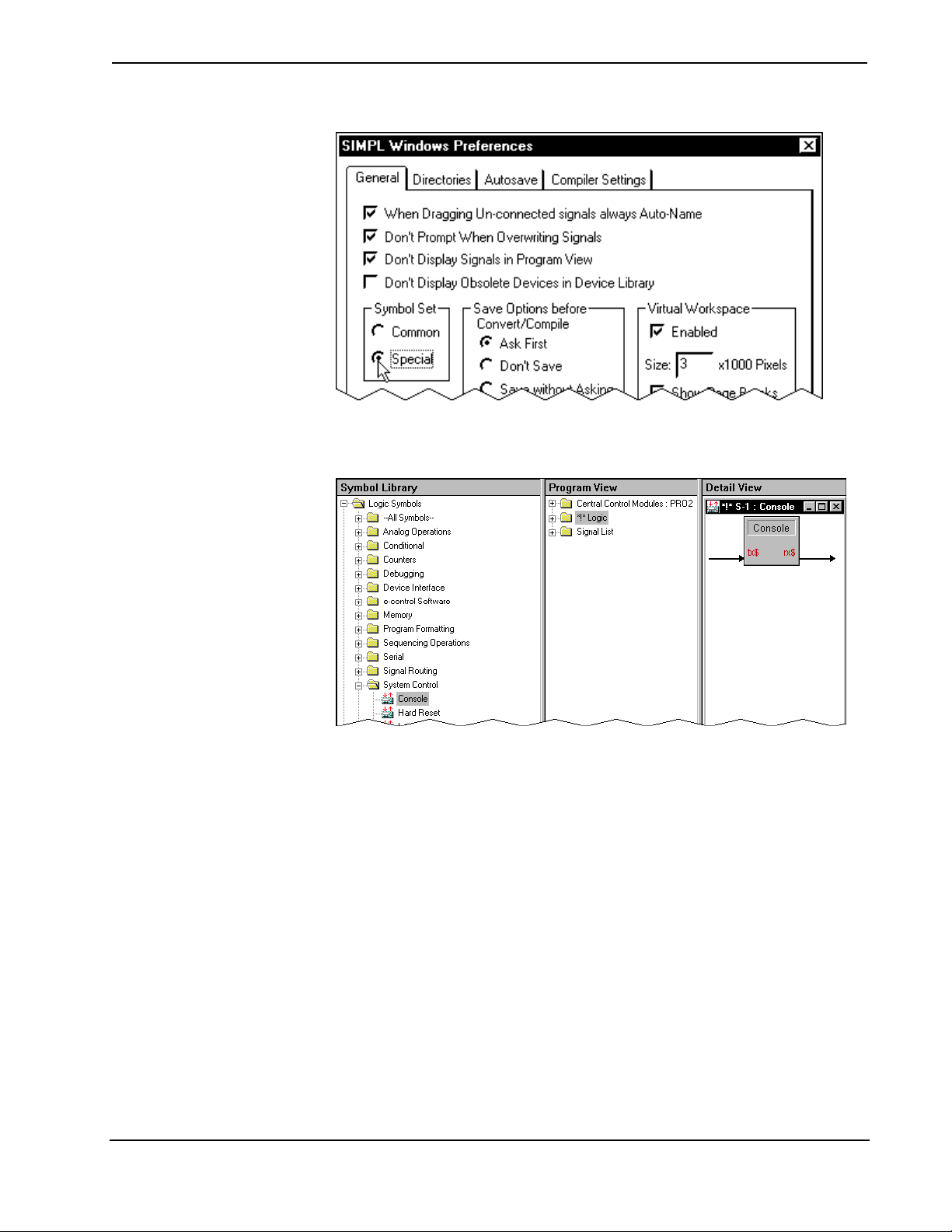

User Program Commands Symbol

Use the User Program Commands symbol to send data typed at the console to the

program. This feature is available for advanced programmers of SIMPL Windows.

The User Program Commands logic symbol only appears in the System Control

folder in the Symbol Library, after enabling a special symbol set for display. To

enable this set while in SIMPL Windows, select Edit | Preferences, which opens the

"SIMPL Windows Preferences" window. In the Symbol Set area of the General tab,

select Special as shown in the following diagram.

Reference Guide – DOC. 6256A 2-Series Control Systems • 17

Page 22

Reference Guide Crestron 2-Series Control System

“SIMPL Windows Preferences” Window

After enabling viewing of special symbols, the Console symbol can be viewed as

shown in the following diagram.

The User Program Commands Symbol in SIMPL Windows

The User Program Commands symbol receives data entered at the 2-Series console

prompt using the USERPROGCMD command. The syntax of the console command

requires double-quotes before and after the command string. The string may include

escape codes such as "\x".

The double quotes are stripped off and any escape codes are processed before

passing the string to the User Program Commands symbol. For example, if the user

types:

>USERPROGCMD "TURN ON DEBUG"

The string TURN ON DEBUG (without the double quotes) will be passed to the

User Program Commands symbol. The string can then be processed as desired.

Command Groups

Console commands are grouped logically. If the operator enters “help” from the

console, the 2-Series processor responds with a list of categories. It is possible to

find the same command in more than one category. Categories include:

• All – all 2-series console commands.

• Device – pertains to the unit itself.

• Ethernet – govern parameters that involve the Ethernet port(s).

• File – influence the internal file system.

• System – sets system-wide parameters.

18 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 23

Crestron 2-Series Control Systems Reference Guide

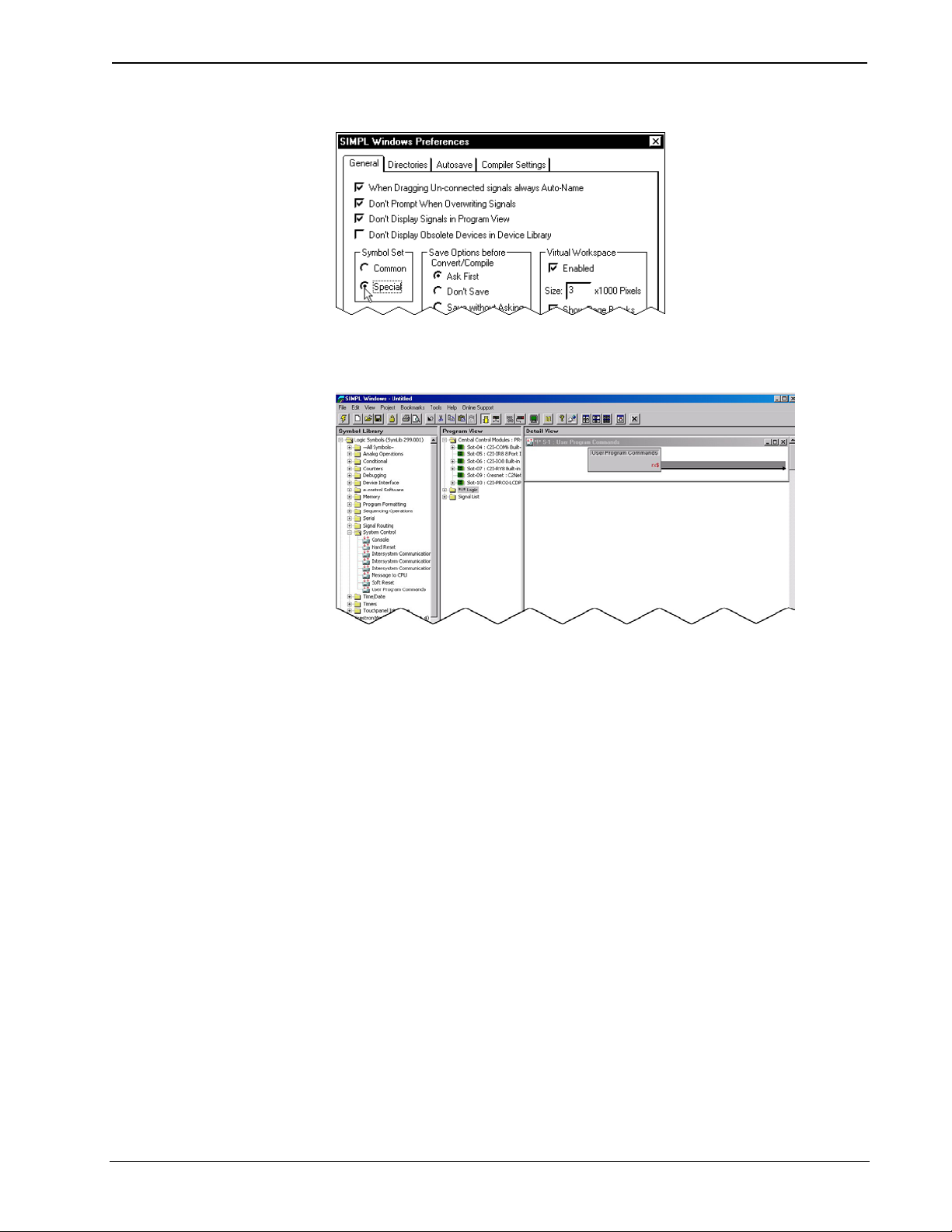

Commands are case insensitive and can be entered from the appropriate prompt (i.e.,

AV2, PRO2, DVP4DI, etc.). Help on individual commands is available by typing the

command followed by a "?" (i.e., ADDMASTER ?). The following table lists

acceptable commands alphabetically and provides a brief description of each

command. Refer to “Appendix C: Console Command Listing” on page 91 for

detailed information.

NOTE: The commands listed are not applicable to every processor. Refer to

“Appendix C: Console Command Listing” on page 91 to determine if the command

is applicable to your processor.

List of Acceptable Commands for the 2-Series Dual Bus Control System

COMMAND DESCRIPTION

ADDDNS Add a DNS server to the static list

ADDMASTER Add an entry to IP table to act as a master to the current system

ADDPORTMAP Add a port map to the NAT table

ADDSLAVE

AUTONEGOT Set auto negotiation for Ethernet device

BROADCAST Enable/disable the broadcasting of error messages

BYE Close user session

CALTOUCH Start DVP4 touchscreen calibration

CARDS Display cards detected in system

CD Change the file directory

CFAUTORUN

CFLOGERR Enable logging errors to compact flash

CFPROJDIRS Display a list of project directories on compact flash

CFTRANSFER Transfer a project to/from compact flash

CIPPORT Specify the port for the CIP interface

CLEARERR Clears the current error log

CNETID Set the Cresnet ID of the system

COMPACT Remove invalid files from system

COMCONSOLEMODE Sets operating mode of COM B

CTPPORT Specify the port for the CTP console

CURSOR Set the cursor option for the DVP4

DEFROUTER Set default router

DELETE Delete file(s)

DHCP Enable/disable dynamic IP address via DHCP

DIR Display files in directory

DOMAINNAME Enter a domain name to be used in DHCP

ECHO Enable/disable character echoing

EEPROM Displays the parameters stored in EEPROM

ERRLOG Prints the current error log

ESTATUS Displays the status and parameters for the Ethernet card

ETHERNET Enable/disable Ethernet

ETHERTEST Perform diagnostic test on the Ethernet card

FPPASSWORD Set front panel password

FREE Show available file space

GETCODE Retrieve the code needed for e-Control2 activation

GETFPLINE Show LCD front panel display on the console

HEAPFREE Show available RAM space

HELP Display help screens

Add an entry to IP table to act as a peer or slave to the current

system

Enables an automatic start of programs when compact flash is

inserted or extracted

(continued on next page)

Reference Guide – DOC. 6256A 2-Series Control Systems • 19

Page 24

Reference Guide Crestron 2-Series Control System

List of Acceptable Commands for the 2-Series Dual Bus Control System (Continued)

COMMAND DESCRIPTION

HOSTNAME Set the host name to be used in a DNS/DHCP environment

I2CERROR Enable reporting of I2C errors

ICMP Enable/disable response to ICMP ping requests

INFO Print software capabilities

INITIALIZE Clear internal file system

INPUT Set the DVP4 input resolution

IPADDRESS Set IP address

IPMASK Set IP subnet mask

IPTABLE Display IP table

ISDIR Check to see if path is a directory

KILLSOCKET Terminate a TCP console connection

LISTDNS Displays a list of DNS servers

MAKEDIR Create a file directory on compact flash

MESSAGE Display a message on front panel screen

MODEMINITSTRING Displays and changes the modem initialization string

NATENABLE Enable/disable Network Address Translator (NAT)

NATREMOTE

NPA Access Network Poll Accelerator Utilities

NVRAMCLEAR Clear the program portion of NVRAM

NVRAMDISK Establish and format a file disk in NVRAM

NVRAMGET Retrieve the contents of NVRAM using XMODEM from the system

NVRAMPUT Load the contents of NVRAM using XMODEM to the system

NVRAMREBOOT

OUTPUT Set the DVP4 output resolution

PASSWORD Set console password

PING Perform IP ping test on remote node

PROGRESET Reloads and restarts the program

PROGUPTIME Display the amount of time the program has been running

RAMFREE Show available file space in the ram file system

REBOOT Perform system reboot

REMDNS Remove a DNS server from the list

REMMASTER Remove a master entry from IP table

REMOVEDIR Delete a file directory on compact flash

REMPORTMAP Remove a port map from the NAT table

REMSLAVE Remove a peer/slave entry from the IP table

REPORTCRESNET Show all devices on the main Cresnet leg

RESTORE Restore factory defaults

RTSCTS Set/clear hardware handshaking

SAVEPARAM Save system parameters

SDEBUG Monitor packets to/from logic

SECURECIPPORT Set the secure (SSL) port for CIP

SECURECTPPORT Set the secure (SSL) port for CTP

SECUREWEBPORT Set the secure (SSL) webserver port

SELFTEST Initiate the self test procedure

SENDKEY Add e-Control2 activation key

SENDMODEMINITSTRING Sets/clears modem initialization

SERIAL Set serial communication parameters

SETUP Enter the DVP4 setup pages

Enable/disable configuring the Network Address Translator (NAT)

from the WAN (LAN A) port

Enables/disables storing special reboot information when the

processor unexpectedly reboots.

(continued on next page)

20 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 25

Crestron 2-Series Control Systems Reference Guide

List of Acceptable Commands for the 2-Series Dual Bus Control System (Continued)

COMMAND DESCRIPTION

SHOWEXTRAERRORS Enables extended error reporting

SHOWHW Display hardware configuration

SHOWPORTMAP Display the portmap from the NAT table

SSL Configure the SSL options

STANDBY Put the DVP4 into standby mode

STBYTO Set the standby timeout for DVP4

SYSTEM Xmodem download new firmware

TELNETPORT Enable/disable connections on the Telnet port (23)

TESTDNS Perform a DNS lookup on a given name

TIMEDATE Set the time and date

TOUCH Set the touch input for a DVP4

TYPE Display file contents

UPLOAD Load file into cresnet device

UPTIME Display the amount of time the system has been running

USERPROGCMD Send a string from the console to the user program

USERPASSWORD Enter the password to protect user pages

VERSION Print version to console

WEBINIT Initialize Webserver default file

WEBPORT Specify the port for the Webserver

WEBSERVER Enable/disable Webserver

WHO Display a list of the active console and gateway connections

XGETFILE Use Xmodem to retrieve file from system

XONXOFF Set/clear software handshaking

XPUTFILE Use Xmodem to transfer file to ROM

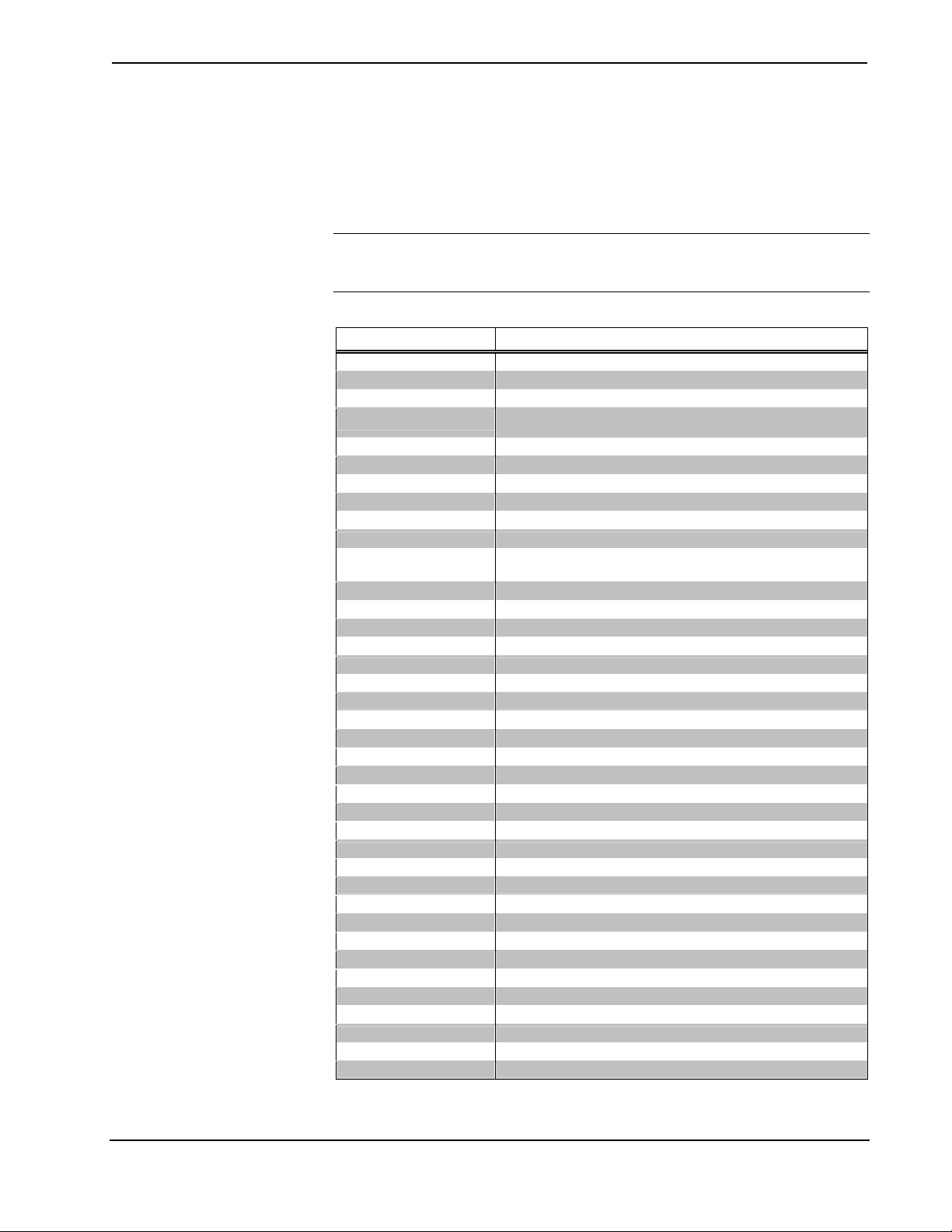

Processor Groups

At the time this document was released, Crestron offered 14 different 2-Series

processors. Selection of a processor depends on the application of the system.

Commands may only be supported on a ‘subset’ of 2-Series processors or processor

group. The table below lists the specific processors that belong to a processor group.

Breakdown of Processor Groups

PROCESSOR GROUP SPECIFIC PROCESSORS*

All 2-Series Processors

Audio Processors MP2 and MP2E

Ethernet Processors

Dual Ethernet Processors PRO2, AV2, PAC2, and RACK2

Compact Flash Processors PRO2, AV2, PAC2, RACK2, CNX-DVP4, and C2N-DVP4DI

Cresnet Processors

Display Processors CNX-DVP4 and C2N-DVP4DI

Plug-in Card Processors PRO2, AV2 (with card cage), PAC2, and RACK2

Front Panel Processors PRO2 and RACK2

QuickMedia Processors QM-RMC and QM-RMCRX(-BA)

* While not considered a 2-Series processor, there are console commands that can only be used when

a C2N-NPA8 is attached to the control system.

PRO2, AV2, PAC2, RACK2, CP2, CP2E, MP2, MP2E, MC2W,

MC2E, CNX-DVP4, C2N-DVP4DI, QM-RMC, and

QM-RMCRX(-BA)

PRO2, AV2, PAC2, RACK2, CP2E, MP2E, CNX-DVP4, C2NDVP4DI, QM-RMC, and QM-RMCRX

PRO2, AV2, PAC2, RACK2, CP2, CP2E, MP2, MP2E, MC2W,

MC2E, CNX-DVP4, C2N-DVP4DI, and QM-RMCRX(-BA)

Reference Guide – DOC. 6256A 2-Series Control Systems • 21

Page 26

Reference Guide Crestron 2-Series Control System

Command Structure

Details about each of the acceptable commands that can be interpreted by the

2-Series Dual Bus Control System can be found in “Appendix C: Console Command

Listing” on page 91. Commands are listed alphabetically. Each listing includes a

description of the command, a list of help menus that contain the command, the

proper syntax for entering the command, definitions of parameters that may be

included in the syntax, a list of possible sources

CUZ with which the command is recognized by the processor, and the specific

processor group

2

that supports the command. For a description of each detail listed

for a given command, refer to the SAMPLE COMMAND table shown below.

1. Possible sources refers to the methods by which console commands are delivered to the control

system, as explained on page 16.

2. Processor groups are defined in more detail with “Processor Groups” on page 21.

SAMPLE COMMAND

Description: Provides a textual description of the command.

Help Menu(s): Provides the category, which is used with the console HELP command.

Syntax: Provides the text characters required to execute the command.

Parameters: Provides a description of each parameter used in the syntax.

Possible Source: Indicates the method of console connection used for the sample command. Connection methods include:

RS-232 - a Crestron Toolbox connection to the computer port of the 2-Series processor.

CTP - an Ethernet connection to port 41795 at the IP address of the 2-Series processor.

Telnet - an Ethernet connection to port 23 at the IP address of the 2-Series processor.

User Program - a command entered using the SIMPL Windows Console symbol.

Secure CTP - SSL connection to port 41797 at the IP address of the 2-Series processor.

Minimum CUZ: Indicates the first version of firmware that supported the command. CUZ is the extension name for the

Processor Group: Since the 2-Series line has such a diverse feature set, some processors may not support all the

zipped file that holds the updated operating system for the 2-Series processor. As new features or

improvements are developed, the capabilities of the operating system are enhanced and the changes

are reflected in a later CUZ version number.

commands. This detail indicates the group to which the command belongs. Refer to the table in

”Processor Groups" on page 21 of this guide for the specific processors that belong to a processor

group.

1

for the command, the minimum

22 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 27

Crestron 2-Series Control Systems Reference Guide

2-Series Memory & Directory Structure

Introduction

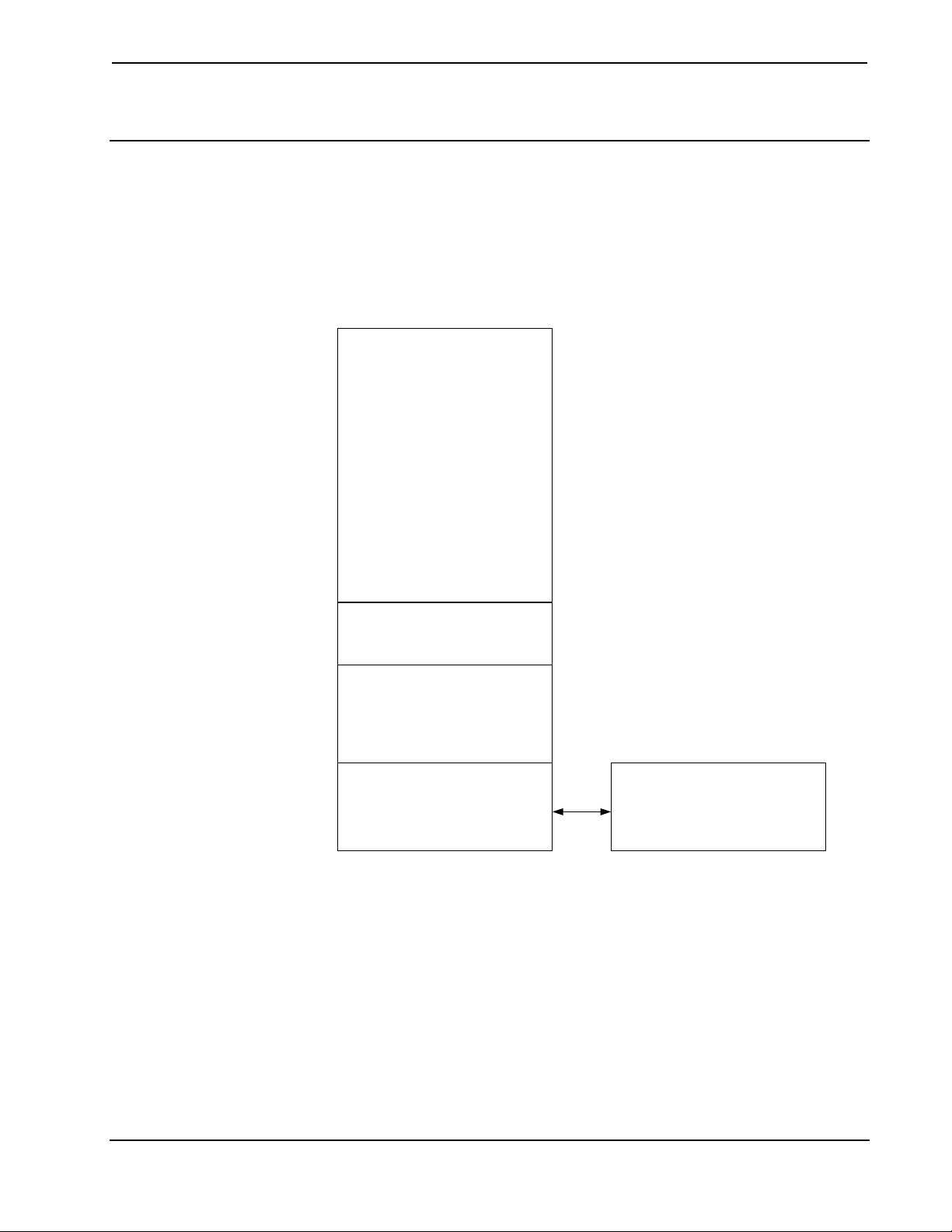

A 2-Series control system has 36MB of built-in memory (non-volatile and volatile).

The following diagram illustrates the memory structure of the 2-Series Control

System.

2-Series Memory Structure

32 MB SDRAM Volatile Memory

256 kB NVRAM

1.5 MB of operational memory

(CUZ file)

2.5.MB of Non-Volatile Memory

(SIMPL program storage, web files,

accessible directory structure)

The total of 36MB is specified as follows: 4MB flash (non-volatile), 32MB SDRAM

(volatile), and 256KB NVRAM (battery backed up). Flash memory contains the file

system inside the 2-series control engine. Non-volatile memory contains information

that is retained after the loss of electrical power. Volatile memory is lost after a

power failure. Refer to the lists below for a breakdown of memory usage for

program-related information stored in the unit.

Expandable to 4GB using flash

card

Flash

1. SIMPL Program

2. SIMPL+ Modules

3. Operating System (.cuz file)

Reference Guide – DOC. 6256A 2-Series Control Systems • 23

Page 28

Reference Guide Crestron 2-Series Control System

The 4MB flash memory consists of approximately 1.5MB used for firmware (.cuz

file), and approximately 2.5MB available for the SIMPL program and SIMPL+

modules. The files that reside in flash conform to a flat directory structure. The

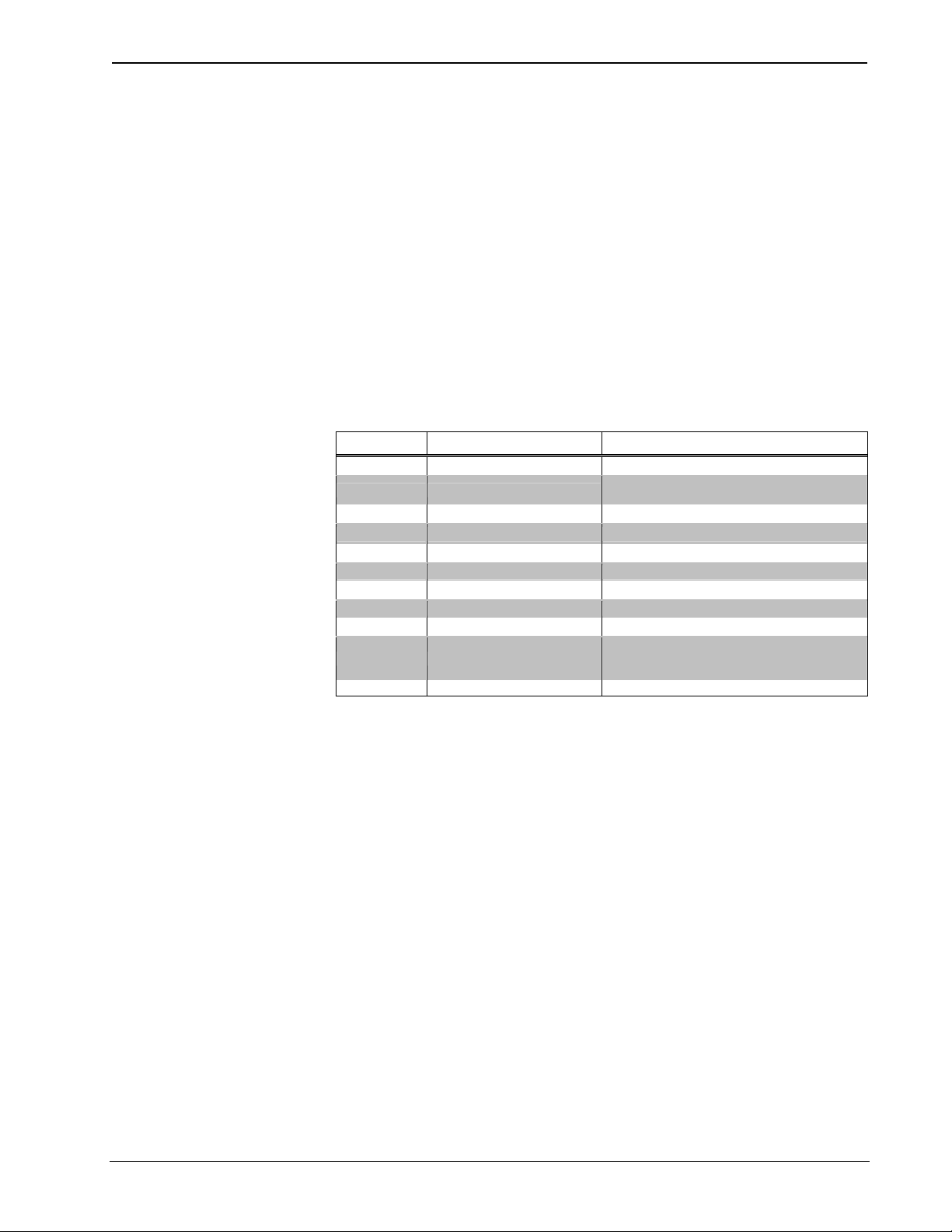

following table presents the structure of the overall file system.

The directory structure of the 2-series control system can be broken down into two

parts. The first part resides on the on-board flash memory (and discretionary

NVRAM memory when the NVRAMDISK option is enabled) and the second resides

on the optional external compact flash/microdrive card. Programs, data files, and

data can be stored in the on-board flash or on the compact flash card (if installed).

This section briefly describes the structure of the file system.

The files that reside in the internal flash/NVRAM conform to a flat directory

structure while the compact flash system contains a fully FAT32 compatible file

system to allow the same compact flash card to be used in a Windows environment.

The table, shown after this paragraph, presents the structure of the overall file

system.

Control System Directory Structure

TOP LEVEL SECONDARY LEVEL DESCRIPTION

\ Root of the file system

DISPLAY

SYS Contains various system configuration files

SETUP Directory for NAT configuration Web pages

HTML Web pages

SIMPL Control system program files

SPLUS SIMPL+ module files

USER Used for user-defined files

MAILBOX Directory contains the user mailbox file

CF0

NVRAM NVRAM disk is enabled

Legacy directory used in Crestron Isys® panels

to hold display lists

The mounting point for the compact flash files;

the 0 (or zero) refers to the on-board compact

flash slot

Although the file system names are case insensitive, the case is preserved to maintain

file checksums. The compact flash directory only appears when a compact flash card

is inserted into the system. The NVRAM directory only appears if an NVRAM disk

has been created. To reference files on the compact flash, prefix the “\CF0\” to any

fully qualified path from the Windows environment. For example, if the file in

Windows is “\MyDirectory\MySubdirectory\MyFile.ext”, the complete 2-Series path

for a file on the first compact flash slot (onboard) is:

“\CF0\MyDirectory\MySubdirectory\MyFile.ext”

When the SIMPL Windows program is stored on the compact flash, the files reside

in the directories \CF0\SIMPL and \CF0\SPLUS. When web pages are stored on the

compact flash, the directory is \CF0\HTML. Storing the program or web pages on

the compact flash gives those files precedence over files stored on internal flash.

That is to say, if you have different programs stored in both internal flash and

compact flash, the program on compact flash runs at boot-up.

Non-volatile (NVRAM)

1. SIMPL+ Variables (Default if no options are specified, or using

"nonvolatile" qualifier or #DEFAULT_NONVOLATILE)

24 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 29

Crestron 2-Series Control Systems Reference Guide

2. Signals explicitly written to NVRAM (by symbols such as Analog

RAM, Analog RAM from database, Serial RAM, Serial RAM from

database, Analog Non-volatile Ramp, Digital RAM, etc.)

Volatile (SDRAM)

1. Digital, analog and serial signal values

2. SIMPL+ Variables (if "volatile" qualifier is used, or

#DEFAULT_VOLATILE is used)

DRAM is used by the operating system for dynamic storage of variables, signals and

other constructs used at runtime. The actual amount of DRAM used at any given

time depends on the particular program that is running, i.e., usage is variable, or

dynamic, during normal operation.

NOTE: SDRAM is internal to operations and is not available to the programmer.

Non-Volatile Random Access Memory (NVRAM)

Disk

2-Series control systems are equipped with Non-Volatile Random Access Memory

(NVRAM). NVRAM contains information that is retained after the loss of electrical

power. Information that can be stored in NVRAM includes:

• SIMPL+ Global Variables (using "nonvolatile" qualifier or

#DEFAULT_NONVOLATILE)

• Signals explicitly written to NVRAM (by symbols such as Analog RAM,

Analog RAM from database, Serial RAM, Serial RAM from database,

Analog Non-volatile Ramp, Digital RAM, etc.)

• Portions of the NVRAM may be set aside for implementing an “NVRAM

Disk”. This can be used to provide file system access from SIMPL+.

NOTE: NVRAM values are position sensitive in the program. When saving the

NVRAM is crucial to your application, it is recommended to place all symbols and/or

modules that use NVRAM at the beginning of the program. When NVRAM (.nvr file)

is restored, all the values should line up with the program. If the program is modified,

and new logic that uses NVRAM is placed before any older symbols using NVRAM,

the previously stored values will not line up and presets will have to be re-entered. To

avoid concerns regarding the position of values within NVRAM, values can be stored

on a file on the NVRAM disk by writing a SIMPL+ module to read and write the

values to the file.

Setting Up an NVRAM Disk

Use Crestron Toolbox to set up a NVRAM disk on the processor. NVRAM disk

provides compact flash (CF) type file storage on systems without a CF slot. It also

works on systems with CF. The NVRAM disk’s storage capacity is limited in size.

Any space allocated to the NVRAM disk is not accessible by the SIMPL Windows

NVRAM symbols or SIMPL+ non-volatile variables.

Reference Guide – DOC. 6256A 2-Series Control Systems • 25

Page 30

Reference Guide Crestron 2-Series Control System

To set up an NVRAM disk, perform the following.

1. Open Crestron Toolbox and establish communications with the control

system as described on page 5.

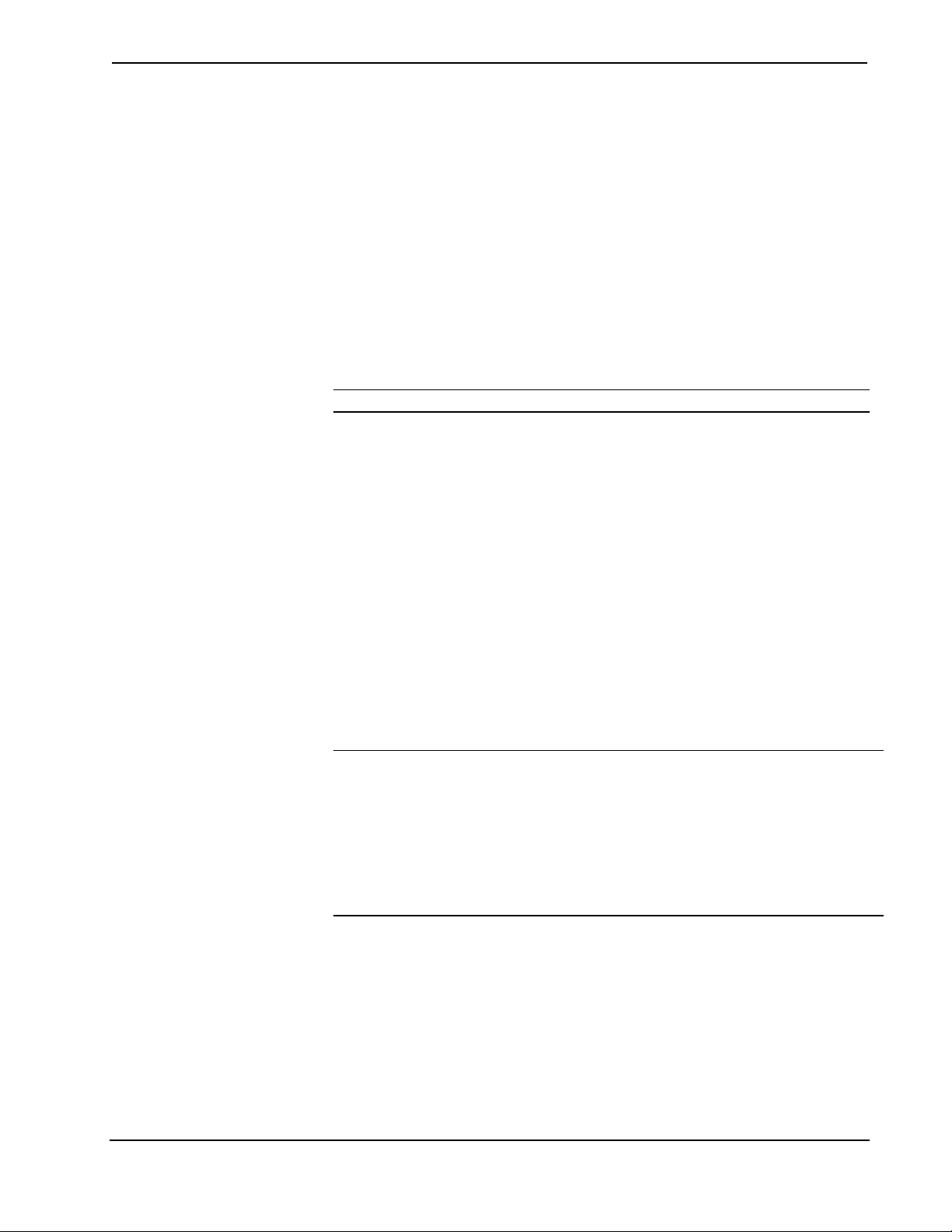

2. Select Functions | NVRAM Disk… to open the “NVRAM Disk” window.

“NVRAM Disk” Window

3. Enable the NVRAM Disk by selecting Enable NVRAM Disk.

4. Select the size of the NVRAM Disk.

5. Click OK or Apply to create the NVRAM Disk.

Files stored in NVRAM disk are accessed in the \NVRAM directory of the file

system. Entering the command without a parameter displays the current setting.

Each time the NVRAMDISK is enabled, the contents of the NVRAM disk are wiped

clean.

NOTE: The NVRAMDISK function (available in CUZ files later than 3.030), will fail

unless it can determine the amount of NVRAM used by the program, to ensure that the

NVRAM is not overwritten. Programs compiled in SIMPL Windows version 2.04.11

or later can provide this information. In the event of a failure of the NVRAMDISK

command, ensure that your program has been recompiled in an appropriate version of

SIMPL Windows and reloaded.

For more information on the NVRAMDISK command and other NVRAM-related

functions, refer to “Appendix C: Console Command Listing” on page 91.

Retrieving NVRAM Files from the NVRAM Disk

NVRAM files can be retrieved from the processor and saved to a local disk. To

retrieve NVRAM data from the processor and save to a file:

1. Open Crestron Toolbox and establish communications with the control

system as described on page 5.

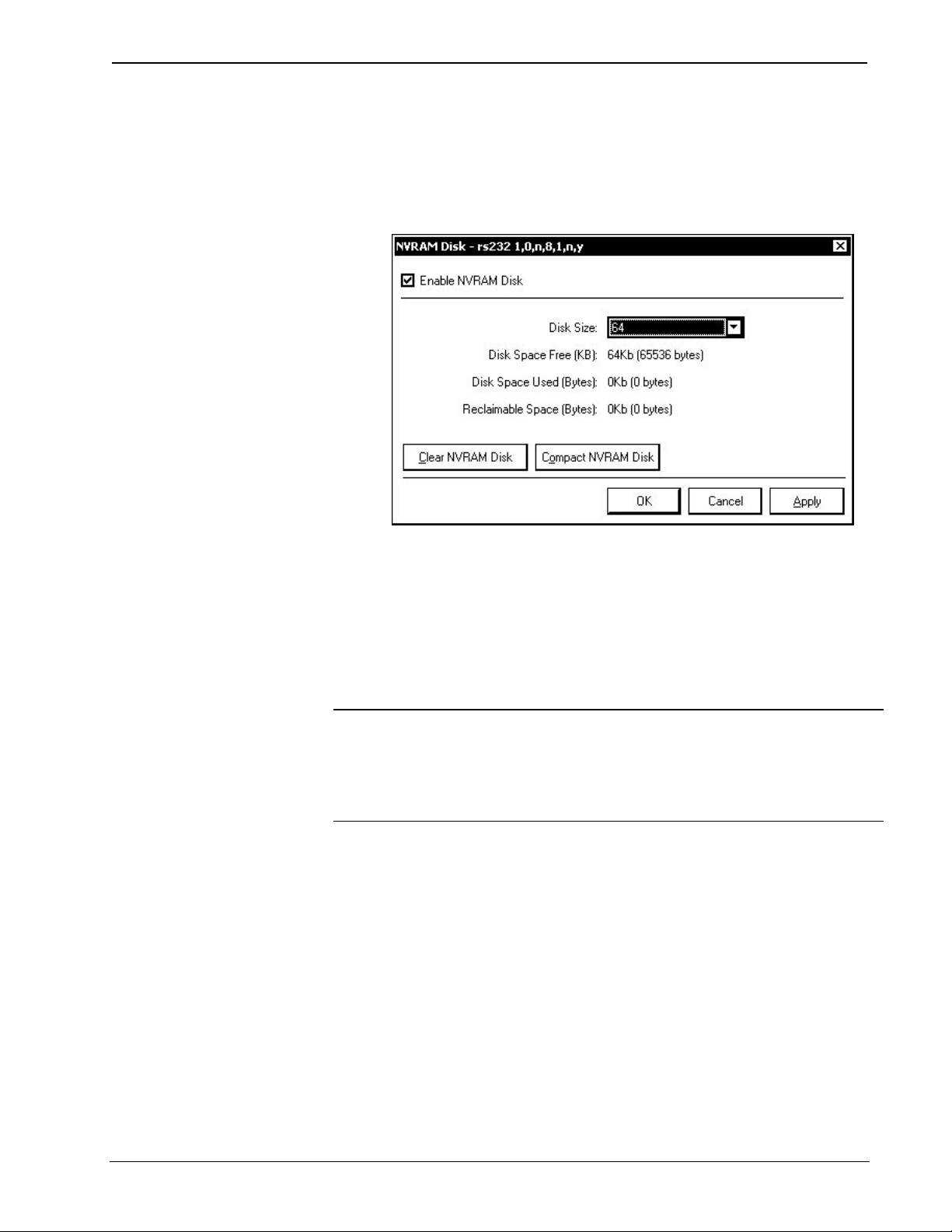

2. Select Functions | Program NVRAM… to open the “Program NVRAM”

window.

26 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 31

Crestron 2-Series Control Systems Reference Guide

“Program NVRAM” Window

3. Click the Browse button next to the Retrieve button and specify the name

and location of the file to be saved.

4. Click Retrieve. A status bar will display the progress of the file transfer.

Restoring NVRAM Files to the Control System

NVRAM files can be restored to the control system from a saved file. To restore

NVRAM data to the control system from a saved file:

1. Open Crestron Toolbox and establish communications with the control

system as described on page 5.

2. Select Functions | Program NVRAM… to open the “Program NVRAM”

window.

“Program NVRAM” Window

3. Click the Browse button next to the Send button and specify the name and

location of the file to be restored.

4. Click Send. A status bar will display the progress of the file transfer.

NVRAMREBOOT

When a control system unexpectedly reboots, the error that caused the reboot is not

stored to the error log since the log is erased when the control system reboots.

However, the information contained in the error log can be written to NVRAM by

using the NVRAMREBOOT command.

To use NVRAMREBOOT:

1. Use Crestron Toolbox to establish communications with the control system

as described on page 5.

Reference Guide – DOC. 6256A 2-Series Control Systems • 27

Page 32

Reference Guide Crestron 2-Series Control System

2. Open a text console window and type NVRAMREBOOT ON. This

command will write messages created during rebooting to NVRAM. If an

anomaly exists, this command will save the error even though the control

system has rebooted.

3. To view the contents of NVRAM, retrieve the file from NVRAM as

described in “Retrieving NVRAM Files from the NVRAM Disk” on page

26 and open the error log as described in “Viewing Error Messages with

Crestron Toolbox” on page 30. After the error log has been captured, turn

off the NVRAMREBOOT command by typing NVRAMREBOOT OFF.

Running Programs from Compact Flash

Certain 2-series control systems are equipped with a compact flash slot. On powerup or a hardware reset (HW-R), the control system first checks for a program on

compact flash (if installed) and then internal flash.

Crestron Toolbox can be used to control the actions of the control system when a

compact flash card is inserted into a running system.

To determine how the control system operates with a compact flash card installed:

1. Open Crestron Toolbox and establish communications with the control

system as described on page 5.

2. Select Functions | Compact Flash to display the “Compact Flash”

window.

“Compact Flash” Window

3. Click the Enable Auto-Run check box to enable the Auto-Run mode.

When operating in the Auto-Run mode, the control system will

automatically reset and run the Compact Flash program when the Compact

Flash card is inserted into the CF slot. If the Compact Flash is removed, the

program in internal Flash will automatically run.

When auto-run mode is disabled, a Program Reset must be sent to the

control system after the Compact Flash card is inserted or removed to run

the program.

4. Click OK or Apply for changes to the Auto-Run mode to take effect.

NOTE: Control systems are shipped with the Auto-Run mode enabled by default.

28 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 33

Crestron 2-Series Control Systems Reference Guide

2-Series Control System Error Messages

Introduction

This section provides a brief description of 2-Series error messages that one may

encounter. Error messages may be the result of hardware or software failure,

hardware incompatibility with software definitions, or a programming error. An error

is indicated by the MSG / ERR LED on the front panel of the control system.

Error messages created by the control system are written to an error log that is stored

in the control system’s RAM. If power is recycled or the processor is rebooted, the

error log will be erased. The error log can be saved to a compact flash card on

processors that can use a compact flash card.

NOTE: To save the error log in non-volatile memory, use the NVRAMREBOOT

console command to have the error log write to NVRAM. For more information,

refer to “NVRAMREBOOT” on page 27.

There are two ways to display the error log. Either use the front panel (if the 2-Series

control system is equipped with one) or use Crestron Toolbox.

Viewing Error Messages with the Front Panel

The front panels of select 2-Series control systems incorporate a reverse mode

(yellow on black) LCD screen, shown below. Access the error log by pressing the

MSG menu function button on the Main Menu (default LCD display).

Front Panel Displaying Main Menu

As shown in the sample below, the top line of the LCD screen provides a single error

message from the error log. The message indicates that the system expects a card to

be inserted into slot 1. The bottom line of the LCD screen provides commands. The

user can use NEXT or PREV to scroll through the entire error log. Some messages

may be too long to be displayed across the top line of the LCD screen; use << and

>> to scroll left and right, respectively.

The CLEAR button can to used to empty the error log and extinguish the MSG /

ERR front panel LED. A security message prompts the user to confirm the

command.

MSG Submenu with Sample Message

Reference Guide – DOC. 6256A 2-Series Control Systems • 29

Page 34

Reference Guide Crestron 2-Series Control System

Viewing Error Messages with Crestron Toolbox

Crestron Toolbox can be used with any 2-Series control system to view messages

stored in the error log.

To manage the Error Log with Crestron Toolbox:

1. Open Crestron Toolbox and establish communications with the control

system as described on page 5.

2. Select Functions | Error Log to open the “Error Log” window.

“Error Log” Window

The “Error Log” window opens with the latest version of the error log on

the control system.

To refresh the error log, click Retrieve Error Log from Device.

To clear the error log, click Clear Error Log in Device. The MSG / ERR

LED on the front panel (if present) will extinguish.

To save the error log, click Save As…, select a filename and directory, and

click OK.

To retrieve a saved error log, select Open…, select the file to be opened,

and click OK.

30 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 35

Crestron 2-Series Control Systems Reference Guide

Error Levels

The following table lists and defines the four levels of error messages that may

appear.

Error Message Levels

TYPE DEFINITION

Notice An event has occurred that is noteworthy, but will not affect program operation.

Warning An event has occurred that could affect program operation, but the program can

Error An event has occurred that indicates that the program is not operating as

Fatal An event has occurred that will prevent the program from running. The

The MSG/ERR LED on the front panel does not illuminate when Notice-level

errors occur.

still run normally. The MSG/ERR LED on the front panel will illuminate when a

Warning-level error occurs.

expected. The MSG/ERR LED on the front panel will illuminate when a Errorlevel error occurs.

MSG/ERR LED on the front panel will illuminate when a Fatal-level error occurs.

Error Format

Each error message has the following format:

Level: Message

Some messages have a suffix with additional information in parenthesis:

(Error#:Extended Error#:Reserved#)

Only the first two items (level and message) within the error format are of any

immediate value to the programmer.

• Level – defined on previous page.

• Message – varied and defined in “Appendix D: Error Message Definitions”

on page 123.

• Error# – unique identifier for Crestron use.

• Extended Error# – unique identifier for Crestron use.

• Reserved# – not yet defined; for future use.

NOTE: It is important to report the exact error message to a Crestron customer

service representative, as well as any Error# and Extended Error#. Also, try to be as

specific as possible regarding the events that lead to the error (i.e., pressing a certain

sequence of buttons, etc). Finally, provide the specific .cuz used.

For a detailed list of all error messages, refer to “Appendix D: Error Message

Definitions” on page 123.

Reference Guide – DOC. 6256A 2-Series Control Systems • 31

Page 36

Reference Guide Crestron 2-Series Control System

Master-Slave Modes

Introduction

Master-Slave mode is a network configuration that allows a Crestron 2-Series control

system to access ports on other Crestron 2-Series control systems over Cresnet or

Ethernet. By attaching a “slave” control system to a “master” control system, the

master control system can use ports it may not normally have (I/O, IR, RF, etc.).

In a master-slave environment, the master control system contains the SIMPL

Windows program that controls all Cresnet and Ethernet devices attached to it. The

slave control system turns off its processing capabilities and behaves exactly like any

other Cresnet or Ethernet device. It obeys the program in the master control system,

making its ports available for control by the master. By using slave systems, only

one master program has to be written to control multiple slave systems.

NOTE: If there is a need for a control system to run its own program but be able to

communicate with other control systems, use the Intersystem Communications

symbol for peer-to-peer communications between control systems over Ethernet or

serial communications. For more information on the Intersystem Communications

symbol, refer to the SIMPL Windows help file.

Depending on a control system’s communications capabilities, a control system may

function as a Cresnet master, a Cresnet slave, an Ethernet master, or an Ethernet

slave.

Definitions

Cresnet Master

When in the Cresnet master mode (the default mode for most control systems), a

master control system can control Cresnet and Ethernet devices (if equipped with

Ethernet capabilities) as well as control systems operating in the Cresnet slave mode.

Control systems with Cresnet and Ethernet capabilities can function as a Cresnet

master and Ethernet master simultaneously.

Cresnet Slave

A control system operating in the Cresnet slave mode operates as a Cresnet device

and makes its built-in ports (except for Cresnet and Ethernet) available to a master

control system. While operating in the Cresnet slave mode, any program that is

loaded into the control system will not run. When operating in Cresnet slave mode, a

control system can address any installed hardware, but it cannot address Cresnet or

Ethernet network devices.

Slave control systems with Cresnet and Ethernet abilities can be configured to

operate as either Cresnet or Ethernet slaves, not both. If a slave system is

accidentally configured as both, it will operate in the Cresnet slave mode.

Ethernet Master

When operating as an Ethernet master, a master control system can control Ethernet

and Cresnet devices (if equipped with Cresnet capabilities) as well as control

systems operating in the Ethernet slave mode.

32 • 2-Series Control Systems Reference Guide – DOC. 6256A

Page 37

Crestron 2-Series Control Systems Reference Guide

Control systems with Ethernet and Cresnet capabilities can function as an Ethernet

master and a Cresnet master simultaneously.

Ethernet Slave

A control system operating in the Ethernet slave mode operates as an Ethernet device

and makes its built-in ports (except for Ethernet and Cresnet) available to a master

control system. While operating in the Ethernet slave mode, any program that is

loaded into the control system will not run. When operating in the Ethernet slave

mode, the control system can address any installed hardware, but it cannot address

Cresnet or Ethernet network devices.

Slave control systems with Ethernet and Cresnet abilities can be configured to

operate as either Ethernet or Cresnet slaves, not both. If a slave system is configured

as both, it will operate in the Cresnet slave mode.

Master-Slave Operating Guidelines

Following are some general rules for master-slave configurations:

• A slave device cannot have its own network (Cresnet or Ethernet).

• 2-Series slave systems can only be controlled by a 2-Series master system.

• A control system with both Cresnet and Ethernet capabilities can operate as

an Ethernet master and a Cresnet master simultaneously.

• A control system with both Cresnet and Ethernet capabilities can be either

an Ethernet slave or a Cresnet slave. It cannot be both simultaneously. If it

is configured as both, it will operate in the Cresnet slave mode.

• A slave can be controlled by only one master control system. Only one

Cresnet master can exist in a network. Multiple Ethernet master systems can

exist in a network. However, an Ethernet slave only responds to one master.

• Any program loaded into a control system will not execute while a control

system is in the slave mode.

• While operating in the slave mode, Crestron Toolbox functions such as

firmware upgrades can still be performed. Passthrough mode operations

from Viewport can also be used on the slave control system.

NOTE: All control systems ship in the master mode except for the C2N-DVP4DI

and CNX-DVP4, which ship in the Cresnet slave setting.

Reference Guide – DOC. 6256A 2-Series Control Systems • 33

Page 38

Reference Guide Crestron 2-Series Control System

Configuring the Control System

System Requirements

To operate a control system as a master or slave device, the following control system

update files and programming software are required:

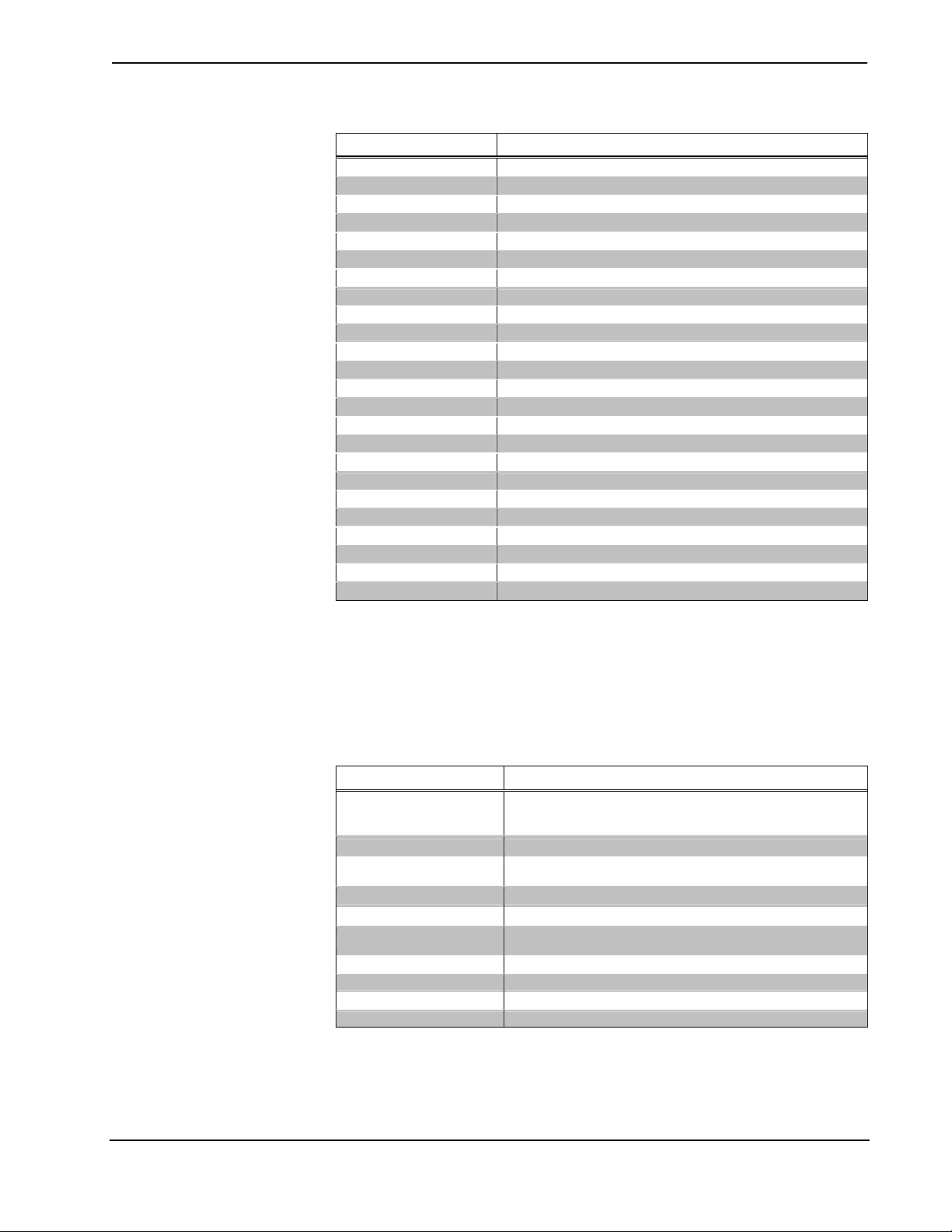

Software Requirements for Master-Slave Operations

SOFTWARE* VERSION NUMBER SUPPORTED MODES

2-Series Control

System Update Files

AV2

C2N-DVP4DI

CNX-DVP4

CP2

CP2E

MC2E

MC2W

MP2

MP2E

PAC2

PRO2

QM-RMC

QM-RMCRX(-BA)

RACK2

SIMPL Windows