Page 1

Crestron QM-MD4X4

4X4 QuickMedia™ Matrix Switcher

Operations Guide

Page 2

This document was prepared and written by the Technical Documentation department at:

Crestron Electronics, Inc.

15 Volvo Drive

Rockleigh, NJ 07647

1-888-CRESTRON

All brand names, product names and trademarks are the property of their respective owners.

©2007 Crestron Electronics, Inc.

Page 3

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Contents

4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 1

Introduction ...............................................................................................................................1

Features and Functions................................................................................................ 1

Applications.................................................................................................................2

Internal Block Diagram ............................................................................................... 4

Specifications ..............................................................................................................6

Physical Description.................................................................................................... 7

Industry Compliance .................................................................................................11

Setup ........................................................................................................................................ 12

Network Wiring......................................................................................................... 12

QuickMedia Wiring................................................................................................... 12

Identity Code ............................................................................................................. 13

Supplied Hardware.................................................................................................... 13

Hardware Hookup .....................................................................................................15

Programming Software............................................................................................................17

Earliest Version Software Requirements for the PC .................................................17

Programming with Crestron SystemBuilder.............................................................. 17

Programming with SIMPL Windows........................................................................ 17

Example Program...................................................................................................... 19

Uploading and Upgrading........................................................................................................ 20

Establishing Communication.....................................................................................20

Programs and Firmware ............................................................................................20

Program Checks ........................................................................................................21

Operation .................................................................................................................................22

Operating Modes .......................................................................................................22

System Mode Operation-Viewing Signal Routing..................................................... 22

Local Mode Operation-Switching Signal Routing ....................................................22

Problem Solving ...................................................................................................................... 24

Troubleshooting......................................................................................................... 24

Check Network Wiring..............................................................................................25

Reference Documents................................................................................................26

Further Inquiries........................................................................................................ 26

Future Updates ..........................................................................................................26

Return and Warranty Policies.................................................................................................. 27

Merchandise Returns / Repair Service ......................................................................27

CRESTRON Limited Warranty.................................................................................27

Operations Guide – DOC. 6546A Contents • i

Page 4

Page 5

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

g

4X4 QuickMedia™ Matrix

Switcher: QM-MD4X4

Introduction

The QM-MD4X4 is a 4X4 QuickMedia matrix switcher designed to provide versatile

routing of up to four inputs from QuickMedia Wall Plates and FlipTop boxes to any

of four QuickMedia receivers. All signal routing is provided over inexpensive

CAT5e type cable* via Crestron's exclusive QuickMedia transport, supporting the

distribution of high-resolution RGB, video, stereo audio and microphone signals up

to a total of 450 feet end-to-end. Audio breakaway capability allows audio signals to

be routed independent of video signals.

Features and Functions

• Four input by four output QuickMedia matrix switcher

• QuickMedia technology carries high-resolution RGB, video, stereo

audio and microphone signals up to 450 feet using either Crescat-QM-P

or Crescat-QM-NP QuickMedia cable from Crestron

• Audio breakaway can route audio signals independent of video signals

• Expands number of inputs and outputs of existing QuickMedia systems

• Front panel buttons can be used to operate switcher; buttons can be

custom labeled

• Front panel buttons can be disabled for security

• Control system program can operate the switch via digital, analog, and

serial control

• QuickMedia ports include Cresnet

distribution to simplify termination of QuickMedia and Cresnet wirin

Up to two QuickMedia Matrix Switchers and Distribution Centers may be cascaded

in a given QuickMedia signal path* to support larger system configurations. For

instance, a QM-MD4X4 may be used to expand the input capacity of a QM-MD7X2,

or multiple QM Matrixes can be combined to support applications such as roomcombining with numerous inputs and outputs.

* For QuickMedia wiring use CresCAT-QM-P, CresCAT-QM-NP, CresCAT-IM-P, or quality

CAT5e/CAT6 cable with a delay skew of ≤15ns per 100m; the maximum aggregate cable length and

delay skew between any QM transmitter (origination point) and QM receiver (endpoint) is 450 ft

(137 m) and 22 ns; a maximum of two QM midpoint devices may be inserted in a given QM signal

path; exceptions apply, refer to each respective product manual for full detail.

®

ports with 24VDC power

®

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 1

Page 6

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Complete system operation can be made transparent to the end-user with all signal

routing occurring smoothly under the command of the MediaManager control

system. Control and monitoring of the QM-MD4X4 is also possible independent of

the control system using its front panel pushbuttons and LEDs. Customizable label

strips are provided to easily designate inputs and outputs by name using Crestron

Engraver software or standard 3/8" tape labels. For security, the front panel controls

can be locked out.

Every QuickMedia port on the rear panel is accompanied by a Cresnet port with 24V

DC power distribution built in to simplify termination of the QuickMedia and

Cresnet wiring.

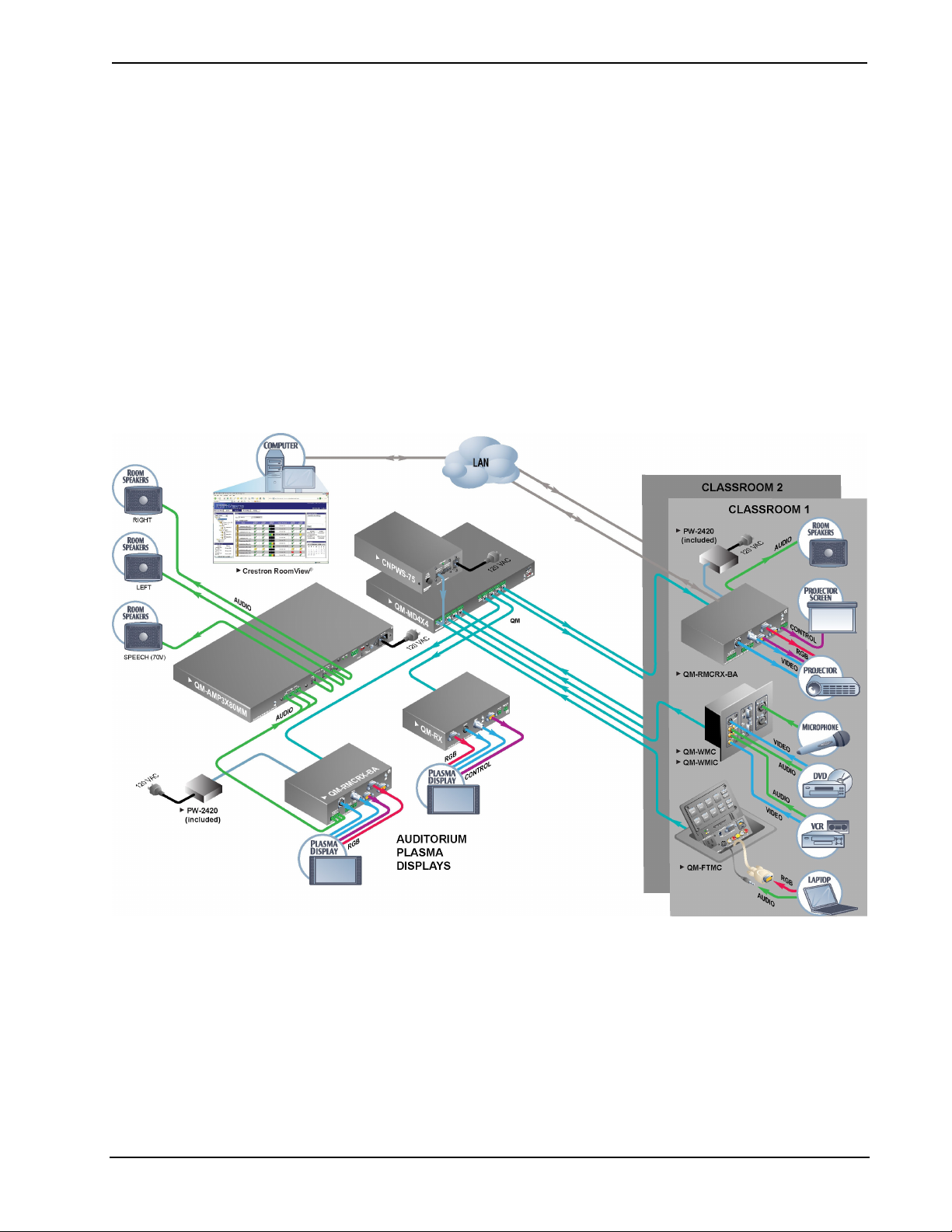

Applications

The following diagrams show a QM-MD4X4 in a lecture hall application and a

business application.

QM-MD4X4 in a Lecture Hall Application

2 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 7

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

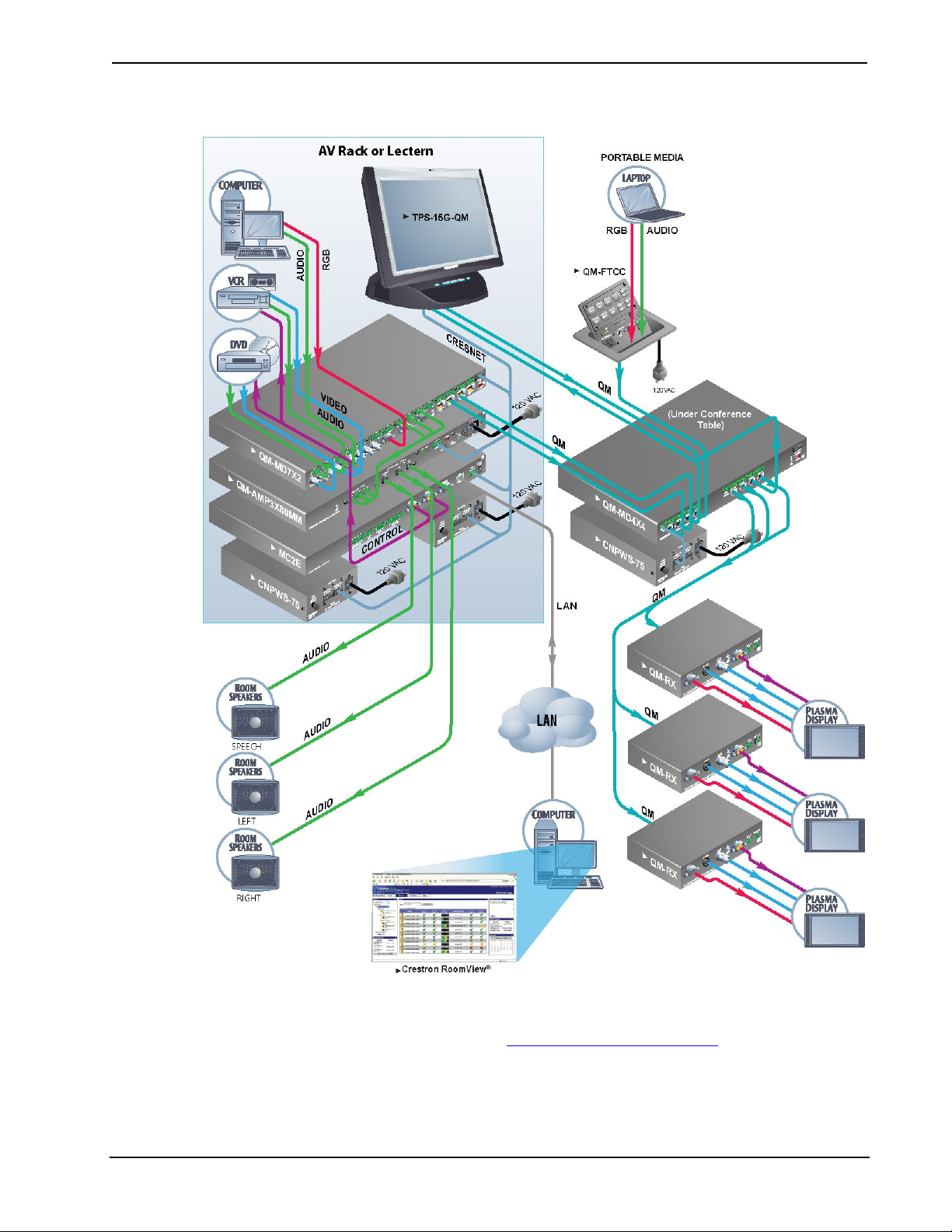

QM-MD4X4 in a Business Application

For more information on this and other QM applications, refer to the latest revision

of the Crestron MediaManager Applications Guide (Doc. 6244) which is available

from the Crestron website (http://www.crestron.com/manuals

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 3

).

Page 8

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Internal Block Diagram

The following diagram represents the switching abilities of the QM-MD4X4. The

QM-MD4X4 can be operated locally (local mode) using buttons on the front panel,

or remotely from a control system (system mode). For more information, refer to

“Operating Modes” on page 22.

Internal Block Diagram of the QM-MD4X4

4 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 9

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

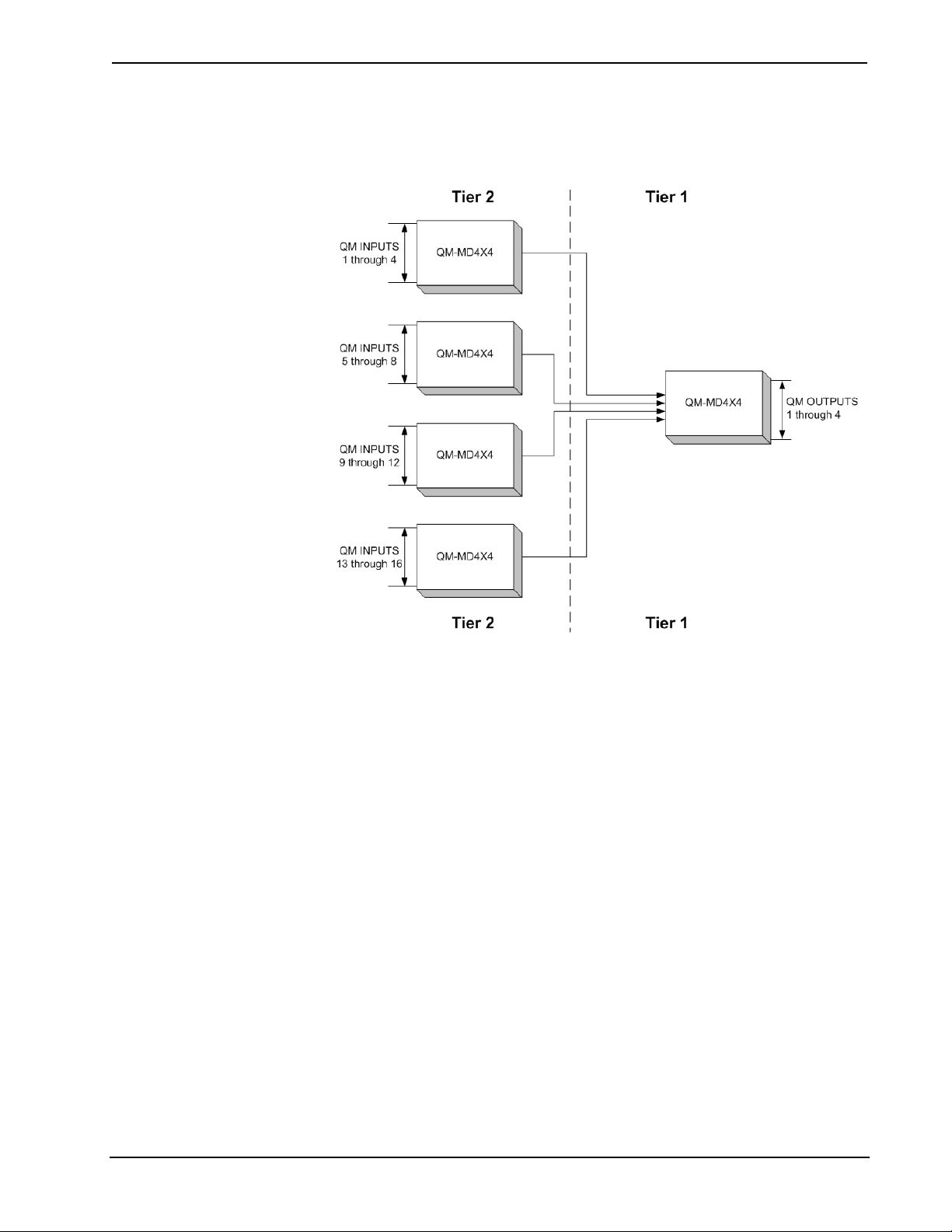

Up to two tiers of QM-MD4X4s can be cascaded to provide up to 16 QM inputs

through one QM-MD4X4 as shown in the following block diagram.

Multiple QM-MD4X4s Cascaded to One QM-MD4X4

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 5

Page 10

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Specifications

Specifications for the QM-MD4X4 are listed in the following table.

QM-MD4X4 Specifications

SPECIFICATION DETAILS

4X4 Video/RGB Matrix

Gain

Crosstalk

4X4 Audio Matrix

Gain

Power Requirements

Cresnet Power Usage

Default NET ID 32

Minimum 2-Series Control

System Update File

Environmental

Temperature

Humidity

Heat Dissipation

Enclosure

Chassis

Faceplate

Mounting

Dimensions

Height

Width

Depth

Weight 4.6 lbs (2.1 kg)

1. The latest software versions can be obtained from the Crestron website. Refer to the NOTE following

these footnotes.

2. Crestron 2-Series control systems include the AV2 and PRO2. Consult the latest Crestron Product

Catalog for a complete list of 2-Series control systems.

1, 2

Routes any (4) QM inputs to any of (4) QM

outputs

0dB

-60dB

Routes any of (4) QM inputs to any of (4)

QM outputs with selectable audio-followvideo or audio breakaway

0dB

15 Watts (0.62 Amps @ 24 Volts DC)

Version C2-V3.093.CUZ or later

41° to 104°F (5° to 40°C)

10% to 90% RH (non-condensing)

50 BTU/Hr

Steel, black matte powder coat finish,

vented top and sides

Extruded aluminum, black matte powder

coat finish with polycarbonate label overlay

Freestanding or 1U 19-inch rack-mountable

(adhesive feet and rack ears included)

1.70 in (4.32 cm)

19.0 in (48.26 cm) with ears;

17.07 in (43.35 cm) without ears

10.14 in (25.75 cm)

NOTE: Crestron software and any files on the website are for authorized Crestron

dealers and Crestron Authorized Independent Programmers (CAIP) only. New users

may be required to register to obtain access to certain areas of the site (including the

FTP site).

6 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 11

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Physical Description

This section provides information on the connections, controls and indicators

available on your QM-MD4X4.

QM-MD4X4 Physical View (front)

QM-MD4X4 Physical View (rear)

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 7

Page 12

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

QM-MD4X4 Overall Dimensions

10.14 in

(25.75 cm)

17.07 in

(43.35 cm)

1 2 3 4 5 6 7 8 9 10

1112 1311

1

# CONNECTORS

,

CONTROLS, &

INDICATORS

1 PWR LED

2 NET LED

3 AUDIO BREAK

(1) green LED, indicates 24 Volts DC power

supplied from Cresnet control network

(1) yellow LED, indicates communication with

Cresnet system

(1) recessed pushbutton & red LED, enables

audio breakaway in Local mode, indicates

audio breakaway in System mode

14

15

DESCRIPTION

1.70 in

(4.32 cm)

(continued on following page)

8 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 13

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Connectors, Controls, & Indicators (continued)

# CONNECTORS1,

CONTROLS, &

INDICATORS

4 A

5 V

6 SYS

7 LOCAL

8 ENTER

DESCRIPTION

(1) pushbutton & red LED, selects audio

routing in Local mode when audio breakaway

is enabled, selects audio routing view in

System mode

(1) pushbutton & red LED, selects video

routing in Local mode when audio breakaway

is enabled, selects video routing view in

System mode

(1) pushbutton & red LED, activates Cresnet

system control mode

(1) recessed pushbutton & red LED,

activates local front panel control mode

(1) pushbutton & red LED, implements

routing set by IN and OUT buttons in Local

mode

9 IN 1 through 4

10 OUT 1 through 4

11 24/G

(continued on following page)

(4) pushbuttons & red LEDs, select inputs to

be routed in Local mode, select routing view

for a given input in System mode

(4) pushbuttons & red LEDs, select output

destination(s) in Local mode, select routing

view for a given output in System mode

(2) 2-pin 5mm detachable terminal blocks

providing (1) power connector per (4)

Cresnet ports;

Receive 24 Volts DC from external Cresnet

power supplies;

Maximum Load: 75 watts each

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 9

Page 14

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Connectors, Controls, & Indicators (continued)

# CONNECTORS1,

DESCRIPTION

CONTROLS, &

INDICATORS

12 QM IN 1 through 4

1

2,3

8

13 QM OUT 1 through 4

1

8

14 NET

15

SETUP

(LED and button)

1. Interface connectors for NET and 24/G ports are provided with the unit.

2. To determine which is pin 1 on the cable, hold the cable so that the end of the eight pin modular jack

is facing away from you, with the clip down and copper side up. Pin 1 is on the far left.

3. The eight-pin RJ-45 QuickMedia transport port accepts CAT5E/CAT6 carrying audio, video and

microphone signals. The QM input port conforms to the 568B wiring standard. Refer to the following

table for connector pinouts.

RJ-45 PIN

NUMBER

1 WHITE/ORANGE

2 ORANGE

3 WHITE/GREEN

4 BLUE

5 WHITE/BLUE

6 GREEN

7 WHITE/BROWN

8 BROWN

4. For QuickMedia wiring, use CAT-QM-P, CresCAT-QM-NP, CresCAT-IM-P, or quality

CAT5e/CAT6 cable with a delay skew of ≤15ns per 100m; the maximum aggregate cable length and

delay skew between any QM transmitter (origination point) and QM receiver (endpoint) is 450 ft

(137m) and 22 ns; a maximum of two QM midpoint devices may be inserted in a given QM signal

path. (exceptions apply, refer to each respective product manual for full detail).

WIRE COLORS

(EIA 568B)

(4) 8-wire RJ-45 female and (4) 4-pin 3.5mm

detachable terminal blocks comprising (4)

QuickMedia input ports with Cresnet;

Connect to Cresnet and QM output ports of

other QuickMedia devices via CresCAT-QM

cable4

2,3

(4) 8-wire RJ-45 female and (4) 4-pin 3.5mm

detachable terminal blocks comprising (4)

QuickMedia output ports with Cresnet;

Connect to Cresnet and QM input ports of

other QuickMedia devices via CresCAT-QM

cable4

(1) 4-pin 5mm detachable terminal block;

Cresnet slave port; connects to Cresnet

control network

Pin 1 (24) Power

Pin 2 (Y) Data

Pin 3 (Z) Data

Pin 4 (G) Ground

(1) miniature pushbutton & red LED, used for

touch-settable ID (TSID)

QM ASSIGNMENT: RGB

- RGB RED

+ RGB RED

- RGB GREEN

+ DIGITAL AUDIO

- DIGITAL AUDIO

+ RGB GREEN

- RGB BLUE

+ RGB BLUE

QM ASSIGNMENT:

COMPOSITE, S-VIDEO,

COMPONENT AND AUDIO

- CHROMINANCE (- Pr)

+ CHROMINANCE (+ Pr)

- LUMINANCE (- Y)

+ DIGITAL AUDIO

- DIGITAL AUDIO

+ LUMINANCE (+ Y)

- COMPOSITE (- Pb)

+ COMPOSITE (+ Pb)

10 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 15

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Industry Compliance

As of the date of manufacture, the QM-MD4X4 has been tested and found to comply

with specifications for CE marking and standards per EMC and

Radiocommunications Compliance Labelling.

NOTE: This device complies with part 15 of the FCC rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful interference and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy

and if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 11

Page 16

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Setup

Network Wiring

When wiring the network, consider the following:

• Use Crestron Certified Wire.

• Use Crestron power supplies for Crestron equipment.

• Provide sufficient power to the system.

CAUTION: Insufficient power can lead to unpredictable results or damage

to the equipment. Please use the Crestron Power Calculator to help calculate

how much power is needed for the system (www.crestron.com/calculators

• For larger networks, use a Cresnet Hub/Repeater (CNXHUB) to maintain

signal quality.

For more details, refer to “Check Network Wiring” on page 25.

).

QuickMedia Wiring

The Crestron QuickMedia cable (sold under the name “CresCAT-QM”) contains one

CAT5E cable and one Cresnet cable in Siamese jackets. Installation of any QM

device is as simple as installing CresCAT-QM wires from the output of one device to

the input of another. Installations are flexible, affordable and fast. For more

information, refer to the latest revision of the Crestron MediaManager Applications

Guide (Doc. 6244), which is available for download from the Crestron website.

CresCAT-QM Cable

CresCAT-QM

Cable

NOTE: Do not untwist the two wires in a single pair for more than 1/3-1/2”

(0.84-1.27 cm) when making a connection. The twists are critical to canceling out

interference between the wires.

The aggregate cable length of a signal path originating at a QM transmitter and

terminating at a QM receiver must not exceed 450 feet (137 meters). Video signals

may experience a loss of quality over very long lengths of cable. This phenomenon is

12 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 17

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

due to the added resistance and capacitance of longer cable lengths and is not

peculiar to either Crestron and/or QuickMedia systems. To ensure sufficient

bandwidth, the maximum aggregate cable length should not exceed 450 feet. The use

of lower-resolution signals may allow increased cable length but must be tested by

the installer with the sources to be used. The QM pin assignment is based on the

EIA/TIA 568B RJ-45 Jack standard.

NOTE: When transmitting S-video, luminance uses the green video pathway and

chrominance uses the red video pathway. When transmitting composite video, the

signal is carried on the blue video pathway.

NOTE: When using CresCAT-QM-P or CresCAT-QM-NP wiring, four additional

wires are included for making Cresnet connections.

When connecting multiple QM devices, the route between a QM origination point

(transmitter) and a QM endpoint (receiver) cannot have more than two midpoints

(e.g. QM-MD4X4 or other QM switchers). Refer to the following diagram when

configuring a QM network.

NOTE: The aggregate length from transmitter to receiver cannot have a delay skew

or more than 22 ns.

QM Network Topology

Origination Points Endpoints

QM

QM-TX

QM

QM-FTDC

QM-WMC

Midpoints

QM

QM

QM

QM-MD4X4QM-MD4X4

TPS-12G/15G-QM-L

TPS-12G/15G-QM-L

QM

Identity Code

The Net ID of the QM-MD4X4 has been factory set to 32. The Net IDs of multiple

QM-MD4X4 devices in the same system must be unique. Net IDs are changed from

a personal computer (PC) via the Crestron Toolbox™ (refer to “Establishing

Communication” on page 20).

When setting the Net ID, consider the following:

• The Net ID of each unit must match an ID code specified in the SIMPL™

Windows

®

program.

• Each network device must have a unique Net ID.

For more details, refer to the Crestron Toolbox help file.

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 13

Page 18

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Installation

Ventilation

Rack Mounting

The QM-MD4X4 should be used in a well-ventilated area. The venting holes should

not be obstructed under any circumstances.

To prevent overheating, do not operate this product in an area that exceeds the

environmental temperature range listed in the table of specifications. Consider using

forced air ventilation and/or incrementing the spacing between units to reduce

overheating. Consideration must be given if installed in a closed or multi-unit rack

assembly since the operating ambient temperature of the rack environment may be

greater than the room ambient temperature. Contact with thermal insulating materials

should be avoided on all sides of the unit.

The QM-MD4X4 can be mounted in a rack or stacked with other equipment. Two

“ears” are provided with the QM-MD4X4 so that the unit can be rack mounted.

These ears must be installed prior to mounting. Complete the following procedure to

attach the ears to the unit. The only tool required is a #2 Phillips screwdriver.

WARNING: To prevent bodily injury when mounting or servicing this unit in a

rack, take special precautions to ensure that the system remains stable. The following

guidelines are provided to ensure your safety:

• When mounting this unit in a partially filled rack, load the rack from the

bottom to the top with the heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before

mounting or servicing the unit in the rack.

NOTE: If rack mounting is not required, rubber feet are provided for tabletop

mounting or stacking. Apply the feet near the corner edges on the underside of the

unit.

NOTE: Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than direct

connections to the branch circuit (e.g. use of power strips).

To install the ears:

1. There are screws that secure each side of the QM-MD4X4 top cover. Using

a #2 Phillips screwdriver, remove the three screws closest to the front panel

from one side of the unit. Refer to the diagram following step 3 for a

detailed view.

2. Position a rack ear so that its mounting holes align with the holes vacated

by the screws in step 1.

3. Secure the ear to the unit with three screws from step 1, as shown in the

following diagram.

14 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 19

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Ear Attachment for Rack Mounting (this image shows a 1RU device)

4. Repeat procedure (steps 1 through 3) to attach the remaining ear to the

opposite side.

Stacking

Connect the Device

Hardware Connections for the QM-MD4X4

POWER:

24 VDC TO

QM INPUTS

1 - 4

Four “feet” are provided with the QM-MD4X4 so that if the unit is not rack

mounted, the rubber feet can provide stability when the unit is placed on a flat

surface or stacked. These feet should be attached prior to the hookup procedure.

Hardware Hookup

Make the necessary connections as called out in the illustration that follows this

paragraph. Refer to “Network Wiring” on page 12 before attaching the 4-position

terminal block connector. Apply power after all connections have been made.

When making connections to the QM-MD4X4, use Crestron power supplies for

Crestron equipment.

QM INPUTS:

QUICKMEDIA PORT CARRIES AUDIO,

VIDEO, RGB, AND MICROPHONE

SIGNALS

POWER:

24 VDC TO

QM OUTPUTS

1 - 4

QM OUTPUTS:

QUICKMEDIA PORT CARRIES AUDIO,

VIDEO, RGB, AND MICROPHONE

SIGNALS

GROUND

CRESNET:

CONNECT TO THE

CRESNET

CONTROL

NETWORK

NOTE: Ensure the unit is properly grounded.

NOTE: For optimum performance, Crestron strongly recommends using

CresCAT-QM cable, available from Crestron. Other high-quality/low skew

CAT5e/CAT6 wiring may also be used with varying performance.

The required 24 VDC power for each group of QM inputs and QM outputs can be

supplied in a variety of ways. The following wiring diagram suggests one method of

applying 24 VDC power to the QM ports. In this configuration, the C2N-SPWS300

can supply up to 75 watts of power to each group of QM ports to ensure that

sufficient power is available for QM devices that are connected to the QM-MD4X4.

The C2N-SPWS300 can also supply the power required by the QM-MD4X4.

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 15

Page 20

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Suggested Power Connections for QM-MD4X4

QUICKMEDIA RECEIVER/PROCESSOR

QM-RMCRX-BA

300 WATT POWER SUPPLY

C2N-SPWS300

Label the Buttons

QM-MD4X4

NOTE: The QM-MD4X4 can only be powered by the 4-position terminal block

connector labeled “NET”.

NOTE: Cresnet data is fed through the NET connector that is internally wired to the

4-position mini-terminal block connector at each QM connector.

NOTE: In the configuration shown, the C2N-SPWS300 can operate in the “PWR

ON” position or the “PWR OFF SLAVE” position. For more information, refer to

the latest revision of the C2N-SPWS300 System Power Supply Operations Guide

(Doc. 8190).

NOTE: Power to the QM ports on the QM-MD4X4 can be applied using other

configurations. The total power usage of each port group must not exceed the port

group’s available input power. For example, if 75 watts is supplied to QM inputs 1

through 4, the total power consumption for those ports cannot exceed 75 watts.

Use Crestron Engraver software to print custom labels for the QM-MD4X4’s front

panel buttons and LEDS. Crestron recommends printing on 100-pound paper. Paper

weighing less than 100 pounds will tend to crumple while sliding in, while paper

weighing more than 100 pounds may not fit.

Labels can also be created using a 3/8” label maker.

16 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 21

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Programming Software

Have a question or comment about Crestron software?

Answers to frequently asked questions (FAQs) can be viewed in the Online Help

section of the Crestron website. To post a question or view questions you have

submitted to Crestron’s True Blue Support, log in at http://support.crestron.com

First-time users will need to establish a user account.

Earliest Version Software Requirements for the PC

NOTE: Crestron recommends that you use the latest software to take advantage of

the most recently released features. The latest software is available from the Crestron

website.

Crestron has developed an assortment of Windows-based software tools to develop

a Cresnet system. The following are the minimum recommended software versions

for the PC:

.

Software

TASK REQUIRED SOFTWARE VERSION

Program control system to

operate QM-MD4X4.

Upload program and firmware. Crestron Toolbox 1.06.24 or later.

Simplified programming with

wizards for QuickMedia systems

(optional but recommended)

Create labels for front panel

buttons.

SIMPL Windows version 2.08 or later with

SIMPL+ Cross Compiler version 1.1 or later

and Library update 497 or later; Also

requires Crestron Database version 19.1.0

or later

Crestron SystemBuilder™ version 3.5 or

later with Systembuilder Templates version

3.5 or later. Refer to software release notes

or Crestron website for other required

Crestron software packages.

Crestron Engraver 3.8.0.0 or later.

Programming with Crestron SystemBuilder

Crestron SystemBuilder is the easiest method of programming but does not offer as

much flexibility as SIMPL Windows. For additional details, download

SystemBuilder from the Crestron website and examine the extensive help file.

Programming with SIMPL Windows

NOTE: While SIMPL Windows can be used to program the QM-MD4X4, it is

recommended to use SystemBuilder and Digital Media Tools software for

configuring a QuickMedia system.

SIMPL Windows is Crestron’s premier software for programming Crestron control

systems. It is organized into two separate but equally important “Managers”.

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 17

Page 22

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Configuration Manager

Configuration Manager is the view where programmers “build” a Crestron control

system by selecting hardware from the Device Library.

• To incorporate the QM-MD4X4 into the system, drag the QM-MD4X4

from the Cresnet Control Modules | QM Series folder of the Device Library

and drop it in the System Views.

Locating the QM-MD4X4 in the Device Library

• The system tree of the control system displays the device in the appropriate

slot with a default Net ID of 32 as shown in the following illustration.

C2Net Device, Slot 5

• Additional QM-MD4X4 devices are assigned different Net ID numbers as

they are added.

• If necessary, double click a device to open the “Device Settings” window

and change the Net ID, as shown in the following figure.

18 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 23

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

“QM-MD4X4 Device Settings” Window

• The ID code specified in the SIMPL Windows program must match the Net

ID of each unit. Refer to “Identity Code” on page 13.

Program Manager

Program Manager is the view where programmers “program” a Crestron control

system by assigning signals to symbols.

The symbol can be viewed by double clicking on the icon or dragging it into Detail

View. Each signal in the symbol is described in the SIMPL Windows help file (F1).

Example Program

An example program for the QM-MD4X4 is available from the Crestron website

(www.crestron.com/exampleprograms

).

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 19

Page 24

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Uploading and Upgrading

Crestron recommends using the latest programming software and that each device

contains the latest firmware to take advantage of the most recently released features.

However, before attempting to upload or upgrade it is necessary to establish

communication. Once communication has been established, files (for example,

programs or firmware) can be transferred to the control system (and/or device).

Finally, program checks can be performed (such as changing the device ID or

creating an IP table) to ensure proper functioning.

Establishing Communication

Use Crestron Toolbox for communicating with the QM-MD4X4; refer to the

Crestron Toolbox help file for details. There is a single method of communication:

indirect communication.

Indirect Communication

PC RUNNING

CRESTRON TOOLBOX

SERIAL,

ETHERNET

OR USB

CONTROL SYSTEM

CRESNET

QM-MD4 X4

• QM-MD4X4 connects to control system via Cresnet.

• Establish communication between the PC and the control system as

described in the latest version of the 2-Series Control Systems Reference

Guide (Doc. 6256).

• Use the Address Book in Crestron Toolbox to create an entry for the

QM-MD4X4 using the expected communication protocol (Indirect). Select

the Cresnet ID of the QM-MD4X4 and the address book entry of the control

system that is connected to the QM-MD4X4.

• Display the QM-MD4X4’s “System Info” window (click the

icon);

communications are confirmed when the device information is displayed.

Programs and Firmware

Program or firmware files may be distributed from programmers to installers or from

Crestron to dealers. Firmware upgrades are available from the Crestron website as

new features are developed after product releases. One has the option to upload

programs via the programming software or to upload and upgrade via the Crestron

Toolbox. For details on uploading and upgrading, refer to the SIMPL Windows help

file or the Crestron Toolbox help file.

SIMPL Windows

If a SIMPL Windows program is provided, it can be uploaded to the control system

using SIMPL Windows or Crestron Toolbox

Firmware

Check the Crestron website to find the latest firmware. (New users may be required

to register to obtain access to certain areas of the site, including the FTP site.)

To upgrade QM-MD4X4 firmware via Crestron Toolbox:

• Establish communication with the QM-MD4X4 and display the “System

Info” window.

• Select Functions | Firmware… to upgrade the QM-MD4X4 firmware.

20 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 25

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Program Checks

Using Crestron Toolbox, display the network device tree (Tools | Network Device

Tree) to show all network devices connected to the control system. Right-click on

the QM-MD4X4 to display actions that can be performed on the QM-MD4X4.

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 21

Page 26

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Operation

Operating Modes

The QM-MD4X4 operates in either the System mode or the Local mode.

System Mode

Local Mode

Viewing Source Routing

Viewing Output Routing

Switching functions controlled by control system program. Press the SYS button to

activate System mode (accompanying LED will light).

• When in System mode, pressing input or output buttons shows

source/destination information.

Switching functions controlled by front panel buttons. Press LOCAL to activate

Local mode (accompanying LED will flash).

• Local mode may not be available if the buttons on the front panel are locked

by the control system. If the buttons are locked, the LOCAL LED will

rapidly flash three times and turn off when LOCAL is pressed. The front

panel can only be unlocked with control system programming.

System Mode Operation-Viewing Signal Routing

Press an input signal button to display all of the outputs that are connected to it.

Press an output signal button to display the input signal that is connected. All outputs

that are receiving the same input signal are also displayed.

The AUDIO BREAK LED will illuminate if there is any difference between the

audio and video route for any signal. The A and V LEDs indicate which portion of a

signal is displayed. Press A or V to select the portion to display.

NOTE: The AUDIO BREAK button has no function when the QM-MD4X4 is

operating in the System mode.

Local Mode Operation-Switching Signal Routing

Signals coming in to the QM-MD4X4 can be switched to individual or multiple

output locations. Additionally, the audio and video portions of an input signal can be

switched simultaneously or separately.

Switching Audio & Video

Simultaneously

22 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

1. Press LOCAL to place the QM-MD4X4 in the Local mode (the LOCAL

LED is flashing slowly).

2. Press AUDIO BREAK to turn off the audio break function. The AUDIO

BREAK LED will turn off and the V LED will be on.

NOTE: If any outputs have different audio and video sources, the audio

inputs will switch to match the video inputs.

3. Press the button corresponding to the input to be switched. The LED of the

selected input will light.

4. Press the button(s) corresponding to the output(s) to be switched. The

LED(s) of the selected output(s) will light.

Page 27

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

To disable routing to a specific output, press the corresponding output

button again. The LED will turn off.

If a button press will result in changing the current routing, the ENTER

LED will flash rapidly.

5. Press ENTER to make the connection(s) shown on the front panel. The

ENTER LED will turn off.

Changes made on the front panel are made only after the ENTER button is

pressed. If you do not press ENTER, the connection is not made.

NOTE: If ENTER has not been pressed, you can go back and “undo”

changes made to the current routing.

Switching Audio & Video

Separately

1. Press LOCAL to place the QM-MD4X4 in the Local mode (the LOCAL

LED is flashing slowly).

2. Press AUDIO BREAK to turn on the audio break function. The AUDIO

BREAK and A LEDs will turn on.

3. Press the button corresponding to the audio portion of the input to be

switched. The LED of the selected input will light.

4. Press the button(s) corresponding to the output(s) to be switched. The

LED(s) of the selected output(s) will light.

To disable audio routing to a specific output, press the corresponding output

button again. The LED will turn off.

If a button press will result in changing the current routing, the ENTER

LED will flash rapidly.

5. Press ENTER to make the audio connection(s) shown on the front panel.

The ENTER LED will turn off.

Changes made on the front panel are made only after the ENTER button is

pressed. If you do not press ENTER, the connection is not made.

NOTE: If ENTER has not been pressed, you can go back and “undo”

changes made to the current routing.

6. Press V to switch the video portion of a signal. The A LED will turn off and

the V LED will turn on.

7. Press the button corresponding to the video portion of the input to be

switched. The LED of the selected input will light.

8. Press the button(s) corresponding to the output(s) to be switched. The

LED(s) of the selected output(s) will light.

To disable video routing to a specific output, press the corresponding output

button again. The LED will turn off.

If a button press will result in changing the current routing, the ENTER

LED will flash rapidly.

9. Press ENTER to make the video connection(s) shown on the front panel.

The ENTER LED will turn off.

Changes made on the front panel are made only after the ENTER button is

pressed. If you do not press ENTER, the connection is not made.

NOTE: If ENTER has not been pressed, you can go back and “undo” and

changes made to the current routing.

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 23

Page 28

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Problem Solving

Troubleshooting

The following table provides corrective action for possible trouble situations. If

further assistance is required, please contact a Crestron customer service

representative.

QM-MD4X4 Troubleshooting

TROUBLE POSSIBLE CAUSE(S) CORRECTIVE ACTION

Device does not

function.

PWR LED does

not illuminate.

NET LED does

not illuminate.

Connected QM

devices are not

receiving power.

Poor picture

quality.

Device is not

communicating with the

network.

Device is not receiving

power from a Crestron

power source.

Device is not receiving

sufficient power.

QM-MD4X4 is not

receiving power.

QM-MD4X4 Net ID is

not set to match the Net

ID of the SIMPL

Windows program.

Power is not supplied to

the 24/G connector.

Faulty Cresnet wiring or

faulty Cresnet device.

Cables improperly

connected.

Incorrect skew settings

in the QM-RMCRX-BA

device.

Use Crestron Toolbox to poll

the network. Verify network

connection to the device.

Use the provided Crestron

power source. Verify

connections.

Use the Crestron Power

Calculator to help calculate

how much power is needed

for the system.

Verify that cables plugged

into the NET ports are

secure.

Using Crestron Toolbox, poll

the network. Verify that the

Net ID for the QM-MD4X4 is

set to match the ID specified

in the SIMPL Windows

program.

Apply sufficient power to the

24/G connector.

Remove each Cresnet

connection on the affected

input or output until power is

restored to the remaining

devices.

Verify that all cables are

secure.

Use QM Tools software to set

correct skew settings for each

QM-RMCRX-BA in the

system.

24 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 29

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Check Network Wiring

Use the Right Wire

Calculate Power

In order to ensure optimum performance over the full range of your installation

topology, Crestron Certified Wire and only Crestron Certified Wire may be used.

Failure to do so may incur additional charges if support is required to identify

performance deficiencies because of using improper wire.

CAUTION: Use only Crestron power supplies for Crestron equipment. Failure to

do so could cause equipment damage or void the Crestron warranty.

CAUTION: Provide sufficient power to the system. Insufficient power can lead to

unpredictable results or damage to the equipment. Please use the Crestron Power

Calculator to help calculate how much power is needed for the system

(www.crestron.com/calculators).

When calculating the length of wire for a particular Cresnet run, the wire gauge and

the Cresnet power usage of each network unit to be connected must be taken into

consideration. Use Crestron Certified Wire only. If Cresnet units are to be daisychained on the run, the Cresnet power usage of each network unit to be daisychained must be added together to determine the Cresnet power usage of the entire

chain. If the unit is home-run from a Crestron system power supply network port, the

Cresnet power usage of that unit is the Cresnet power usage of the entire run. The

wire gauge and the Cresnet power usage of the run should be used in the following

equation to calculate the cable length value on the equation’s left side.

Cable Length Equation

Strip and Tin Wire

Add Hubs

L = Length of run (or chain) in feet

R = 6 Ohms (Crestron Certified Wire: 18 AWG (0.75 MM ))

or 1.6 Ohms (Cresnet HP: 12 AWG (4 MM ))

P = Cresnet power usage of entire run (or chain)

2

2

L <

40,000

Where:

R x P

Make sure the cable length value is less than the value calculated on the right side of

the equation. For example, a Cresnet run using 18 AWG Crestron Certified Wire and

drawing 20 watts should not have a length of run more than 333 feet. If Cresnet HP

is used for the same run, its length could extend to 1250 feet.

NOTE: All Crestron certified Cresnet wiring must consist of two twisted pairs. One

twisted pair is the +24V conductor and the GND conductor and the other twisted

pair is the Y conductor and the Z conductor.

When daisy-chaining Cresnet units, strip the ends of the wires carefully to avoid

nicking the conductors. Twist together the ends of the wires that share a pin on the

network connector and tin the twisted connection. Apply solder only to the ends of

the twisted wires. Avoid tinning too far up the wires or the end becomes brittle.

Insert the tinned connection into the Cresnet connector and tighten the retaining

screw. Repeat the procedure for the other three conductors.

For larger networks (i.e., greater than 28 network devices), it may become necessary

to add a Cresnet Hub/Repeater (CNXHUB) to maintain signal quality throughout the

network. Also, for networks with lengthy cable runs it may be necessary to add a

Hub/Repeater after only 20 devices.

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 25

Page 30

4X4 QuickMedia™ Matrix Switcher Crestron QM-MD4X4

Reference Documents

The latest version of all documents mentioned within the guide can be obtained from

the Crestron website (www.crestron.com/manuals). This link will provide a list of

product manuals arranged in alphabetical order by model number.

List of Related Reference Documents

DOCUMENT TITLE

2-Series Control Systems Reference Guide

C2N-SPWS300 System Power Supply Operations Guide

MediaManager Applications Guide

Further Inquiries

If you cannot locate specific information or have questions after reviewing this

guide, please take advantage of Crestron's award winning customer service team by

calling the Crestron corporate headquarters at 1-888-CRESTRON [1-888-273-7876].

For assistance in your local time zone, refer to the Crestron website

(www.crestron.com/offices

You can also log onto the online help section of the Crestron website

(www.crestron.com/onlinehelp

users will need to establish a user account to fully benefit from all available features.

) for a listing of Crestron worldwide offices.

) to ask questions about Crestron products. First-time

Future Updates

As Crestron improves functions, adds new features and extends the capabilities of

the QM-MD4X4, additional information may be made available as manual updates.

These updates are solely electronic and serve as intermediary supplements prior to

the release of a complete technical documentation revision.

Check the Crestron website periodically for manual update availability and its

relevance. Updates are identified as an “Addendum” in the Download column.

26 • 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 Operations Guide – DOC. 6546A

Page 31

Crestron QM-MD4X4 4X4 QuickMedia™ Matrix Switcher

Return and Warranty Policies

Merchandise Returns / Repair Service

1. No merchandise may be returned for credit, exchange or service without prior authorization

from CRESTRON. To obtain warranty service for CRESTRON products, contact an

authorized CRESTRON dealer. Only authorized CRESTRON dealers may contact the factory

and request an RMA (Return Merchandise Authorization) number. Enclose a note specifying

the nature of the problem, name and phone number of contact person, RMA number and

return address.

2. Products may be returned for credit, exchange or service with a CRESTRON Return

Merchandise Authorization (RMA) number. Authorized returns must be shipped freight

prepaid to CRESTRON, 6 Volvo Drive, Rockleigh, N.J. or its authorized subsidiaries, with

RMA number clearly marked on the outside of all cartons. Shipments arriving freight collect

or without an RMA number shall be subject to refusal. CRESTRON reserves the right in its

sole and absolute discretion to charge a 15% restocking fee plus shipping costs on any

products returned with an RMA.

3. Return freight charges following repair of items under warranty shall be paid by CRESTRON,

shipping by standard ground carrier. In the event repairs are found to be non-warranty, return

freight costs shall be paid by the purchaser.

CRESTRON Limited Warranty

CRESTRON ELECTRONICS, Inc. warrants its products to be free from manufacturing defects in materials

and workmanship under normal use for a period of three (3) years from the date of purchase from

CRESTRON, with the following exceptions: disk drives and any other moving or rotating mechanical

parts, pan/tilt heads and power supplies are covered for a period of one (1) year; touchscreen display and

overlay components are covered for 90 days; batteries and incandescent lamps are not covered.

This warranty extends to products purchased directly from CRESTRON or an authorized CRESTRON

dealer. Purchasers should inquire of the dealer regarding the nature and extent of the dealer's warranty, if

any.

CRESTRON shall not be liable to honor the terms of this warranty if the product has been used in any

application other than that for which it was intended or if it has been subjected to misuse, accidental

damage, modification or improper installation procedures. Furthermore, this warranty does not cover any

product that has had the serial number altered, defaced or removed.

This warranty shall be the sole and exclusive remedy to the original purchaser. In no event shall

CRESTRON be liable for incidental or consequential damages of any kind (property or economic damages

inclusive) arising from the sale or use of this equipment. CRESTRON is not liable for any claim made by a

third party or made by the purchaser for a third party.

CRESTRON shall, at its option, repair or replace any product found defective, without charge for parts or

labor. Repaired or replaced equipment and parts supplied under this warranty shall be covered only by the

unexpired portion of the warranty.

Except as expressly set forth in this warranty, CRESTRON makes no other warranties, expressed or

implied, nor authorizes any other party to offer any warranty, including any implied warranties of

merchantability or fitness for a particular purpose. Any implied warranties that may be imposed by law are

limited to the terms of this limited warranty. This warranty statement supersedes all previous warranties.

Trademark Information

All brand names, product names and trademarks are the sole property of their respective owners. Windows is a registered trademark

of Microsoft Corporation. Windows95/98/Me/XP/Vista and WindowsNT/2000 are trademarks of Microsoft Corporation.

Operations Guide – DOC. 6546A 4X4 QuickMedia™ Matrix Switcher: QM-MD4X4 • 27

Page 32

Crestron Electronics, Inc. Operations Guide – DOC. 6546A

15 Volvo Drive Rockleigh, NJ 07647 (2016915)

Tel: 888.CRESTRON 10.07

Fax: 201.767.7576 Specifications subject to

www.crestron.com change without notice.

Loading...

Loading...