Page 1

Crestron QM-FTMC

FlipTop Media Center

Operations & Installation Guide

Page 2

This document was prepared and written by the Technical Documentation department at:

Crestron Electronics, Inc.

15 Volvo Drive

Rockleigh, NJ 07647

1-888-CRESTRON

All brand names, product names and trademarks are the property of their respective owners.

©2005 Crestron Electronics, Inc.

Page 3

Crestron QM-FTMC FlipTop Media Center

Contents

FlipTop Media Center: QM-FTMC 1

Introduction ..........................................................................................................1

Features and Functions...........................................................................1

QuickMedia Transport System...............................................................3

Specifications ......................................................................................... 4

Physical Description...............................................................................6

Industry Compliance ............................................................................14

Setup................................................................................................................... 14

Network Wiring ...................................................................................14

QM Network Wiring............................................................................15

Crestron Toolbox .................................................................................15

Identity Code........................................................................................ 16

Installation............................................................................................18

Hardware Hookup ................................................................................ 22

Ground Wire Connections....................................................................23

Configuration Software ......................................................................................24

Earliest Version Software Requirements for the PC ............................24

Configuring with SystemBuilder .........................................................25

Configuring with SIMPL Windows .....................................................31

Example Program.................................................................................42

Adjusting the QM-FTMC Microphone Inputs .....................................43

Uploading and Upgrading ..................................................................................46

Communication Settings ......................................................................46

Uploading a SIMPL Windows Program ..............................................49

Firmware Upgrade ...............................................................................52

Problem Solving.................................................................................................54

Further Inquiries...................................................................................55

Future Updates .....................................................................................55

Appendix A: International Receptacles..............................................................56

Appendix B: QuickMedia Installation and Compensation .................................57

Installation Notes .................................................................................57

Compensation.......................................................................................57

Compatibility Charts ............................................................................ 59

Return and Warranty Policies.............................................................................61

Merchandise Returns / Repair Service ................................................. 61

CRESTRON Limited Warranty ...........................................................61

Operations & Installation Guide – DOC. 6311A Contents • i

Page 4

Page 5

Crestron QM-FTMC FlipTop Media Center

FlipTop Media Center:

QM-FTMC

Introduction

Features and Functions

The QM-FTMC FlipTop Computer Center is part of the Crestron

MediaManager™ line of network devices, room control systems and signal

routing solutions. It is available in six different models.

Models

DESCRIPTION MODEL NUMBER COLOR

with Keypad

without Keypad

with Keypad

The international models accommodate a wide variety of international AC

adaptors. For simplicity within this guide, the color/button suffix and

international designation are omitted and QM-FTMC is used except where

noted.

Functional Summary

• Built-in engravable* keypad with 10 to 20 buttons and LEDs

• 3 X 1 video switch with sync sensing (one composite connector, one

S-video connector, one RGBHV connector)

• 3 X 1 audio switch (two stereo RCA, one stereo 1/8” mini jack) with

audio breakaway

• One Ethernet passthrough port

• One AC power passthrough

• Two Cresnet connectors (on bottom side)

• Two Microphone inputs with phantom power (on the bottom side)

• One QuickMedia RJ-45 connector (on the bottom side)

* As an option, custom-engraved buttons can be designed and obtained by using the

Crestron Engraver software. Version 2.2.2.3 and Crestron Database 16.3.4 or later are

available from the Crestron website (www.crestron.com).

QM-FTMC-B Black Domestic Models

QM-FTMC-BALUM Brushed Aluminum

QM-FTMC-NB-B Black Domestic Models

QM-FTMC-NB-BALUM Brushed Aluminum

QMI-FTMC-B Black International Models

QMI-FTMC-BALUM Brushed Aluminum

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 1

Page 6

FlipTop Media Center Crestron QM-FTMC

This Cresnet® device uses QuickMedia™ technology to facilitate an

uncomplicated connection of audio, video, and computer equipment. All media

and control signals are routed via a single QuickMedia cable for simple

installation. A complete integrated room solution is created with the addition of

a QuickMedia receiver (such as the QM-RMCRX-BA) and optional keypads or

touchpanels.

NOTE: The QM-FTMC is compatible with 2-Series control systems only.

The QM-FTMC is equipped with an auto-sense feature that allows the installer

to pass RGB, video, and S-video video signals (along with the appropriate audio

signals) through the system to check the wiring before a program has been

installed in the control system. Once a control program is running, this feature is

disabled.

QM-FTMC Block Diagram

2 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 7

Crestron QM-FTMC FlipTop Media Center

QuickMedia Transport System

Using a new, proprietary signal routing solution, signals such as composite

video, S-video, RGBHV, audio, and microphone are all transported using a

single cable solution called QuickMedia (QM).

The QM transport system port is capable of managing computer, video, and

audio signals simultaneously through one CresCAT-QM cable, simplifying

installations.

Routing CresCAT-QM cable is less expensive and much simpler than routing

multi-colored, multi-conductor coax cable. All Crestron products using the QM

transport system are capable of sending and receiving QM signals via

CresCAT-QM cable. Installation of any QM device is as simple as installing one

set of QM wires from output to input. Installations are flexible, affordable, and

fast.

The Crestron QuickMedia cable “CresCAT-QM” contains one CAT5E cable

and one Cresnet

CresCAT-QM Cable

NOTE: Do not untwist the two wires in a single twisted pair for more than

1/3-1/2" (0.84 – 1.27 cm) when making a connection. The twists are critical to

canceling out interference between the wires.

The QuickMedia transport mechanism performs delay compensation on each

video input to compensate for signal skew, and frequency/bandwidth

compensation for cable length. Signal skew occurs when part of the signal is

delayed with respect to other signal components. The amount of skew largely

depends on the length and design of the wire. Because CAT5 consists of twisted

pairs that are twisted together in the cable, unequal wire lengths are created.

The maximum aggregate cable length from QM transmitter to QM receiver is

limited by the loss of bandwidth over long distances and the amount of available

skew compensation. A cable rated at 15 ns of skew per 100 meters (328 ft.)

means that a cable will have no more than a 15 ns difference between the fastest

and slowest RGB signals over 100 meters of cable.

®

cable in siamese jackets.

To determine the allowable maximum length of installed cable, the installer

must first perform a calculation based on the skew rating of the cable. The use of

low-resolution signals may allow increased cable length but must be tested with

the sources to be used. To ensure sufficient bandwidth to support signal

resolutions up to 1600 x 1200, the maximum aggregate cable length should not

exceed 328 feet.

Skew compensation is primarily relevant to RGB sources; however, any/all

video or VGA signals may experience a loss of quality over very long lengths of

cable. This phenomenon is due to the added resistance and capacitance of longer

cable lengths, and is not particular to either Crestron and/or QuickMedia

systems.

The total accumulated skew from QM transmitter to QM receiver must not

exceed 15 ns (nanoseconds). Crestron recommends a cable with a rating of less

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 3

Page 8

FlipTop Media Center Crestron QM-FTMC

than or equal to 15 ns over its entire length. For example, if using a cable with a

rating of 15 ns/100 meters (100 meters = 328 feet), connecting the QM-FTMC

transmitter with 150 feet of cable to a QM-MD7x2 switcher, and then using

another 150 feet to connect the QM-RMCRX-BA receiver, the accumulated

skew over the entire 300 feet should not exceed 15 ns.

Specifications

Specifications for the QM-FTMC are given in the following table.

QM-FTMC Specifications

SPECIFICATION DETAILS

Cresnet Power Usage 8 Watts (0.33 Amp @ 24 VDC)

Default Network ID 0A

Video Formats Composite, S-video, RGBHV, RGsB, YPBPR

Video Detection Within 2 seconds

Firmware QM-FTMC.V.3.05.upg or later

2-Series Control System

Update Files

Connectors

Computer Input (1) DB15HD female, video sensing on H-sync

Computer Audio (1) 3.5mm mini-jack, computer soundcard type

Composite Video (1) RCA (yellow), video sensing

Composite Video Audio (2) RCA (red and white)

S-video

S-video Audio (2) RCA female (red and white)

QuickMedia Output (1) RJ-45 CAT5E/CAT6

Ethernet (1) RJ-45 connector

Cresnet (2) 4-pin terminal blocks

Ground (1) Ground Terminal

Microphone (2) 5-pin terminal blocks

Video

Types Composite, S-video, Component and RGB

Video Sensing

Gain 0 dB (unity gain, 75 Ohm termination)

Maximum Input Voltage 1.0 V

Input Impedance 75 ohms

Bandwidth

(Composite &

S-video)

Max Resolution/Refresh

Rate (RGB)

H and V Sync (RGB) 5.0 V

1,2

Version 3.125.CUZ (for QM-RMCRX-BA) or

later

(1) Mini-DIN 4-pin female, video sense on

luminance signal

Automatic sensing of composite, S-video

(luminance), RGB (H-Sync), component (G/Y)

p-p

> 100 MHz (-3 dB) at unity gain

1600 x 1200 @ 60 Hz vertical rate with

CAT5/5E/6 cable length of 100 meters and

skew rating ≤ 15 ns / 100 meters

max into 1 KΩ

p-p

Specifications continued on next page.

4 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 9

Crestron QM-FTMC FlipTop Media Center

QM-FTMC Specifications (continued)

SPECIFICATION DETAILS

Audio

Analog-Digital Conversion 24 bit / 48 kHz

Maximum line-level input 2 V

Input Impedance 10k ohms

Bandwidth 20 Hz to 20 kHz

Operating Temperature and

Humidity

Dimensions and Weight

(Domestic Models)

Dimensions and Weight

(International Models)

Accessories QM-FTCMK Cable Management Kit

International Adaptors for

QMI-FTMC Models

/ 6 dBV (Video)

RMS

/ 0 dBV (PC)

1 V

RMS

-60 to -20 dBV (Balanced Mic)

41º to 104º F (5º to 40º C)

10 to 90% relative humidity

(non-condensing)

Width: 6.75 in (17.13 cm)

Height: 5.39 in (13.68 cm) with top closed

Depth: 5.71 in (14.49 cm)

Weight: 4.05 lbs (1.84 kg)

Width: 8.50 in (21.58 cm)

Height: 5.58 in (14.17 cm) with top closed

Depth: 6.67 in (16.95 cm)

Weight: 4.80 lbs (2.18 kg)

QMI-FTCMK International Cable

Management Kit

FT-BTNB-L Button Kit

FT-BTNB-L-BLANK Button Kit

FT-BTNB-S Button Kit

FT-BTNB-S-BLANK Button Kit

Refer to Appendix A on page 56

1. The latest software versions can be obtained from the Crestron website. Refer to the NOTE

following these footnotes.

2. Crestron 2-Series control systems include the AV2 and PRO2. Consult the latest Crestron Product

Catalog for a complete list of 2-Series control systems.

NOTE: Crestron software and any files on the website are for Authorized

Crestron dealers and Crestron Authorized Independent Programmers (CAIP)

only. New users may be required to register to obtain access to certain areas of

the site (including the FTP site).

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 5

Page 10

FlipTop Media Center Crestron QM-FTMC

Physical Description

Refer to the physical views shown below.

QM-FTMC Open View

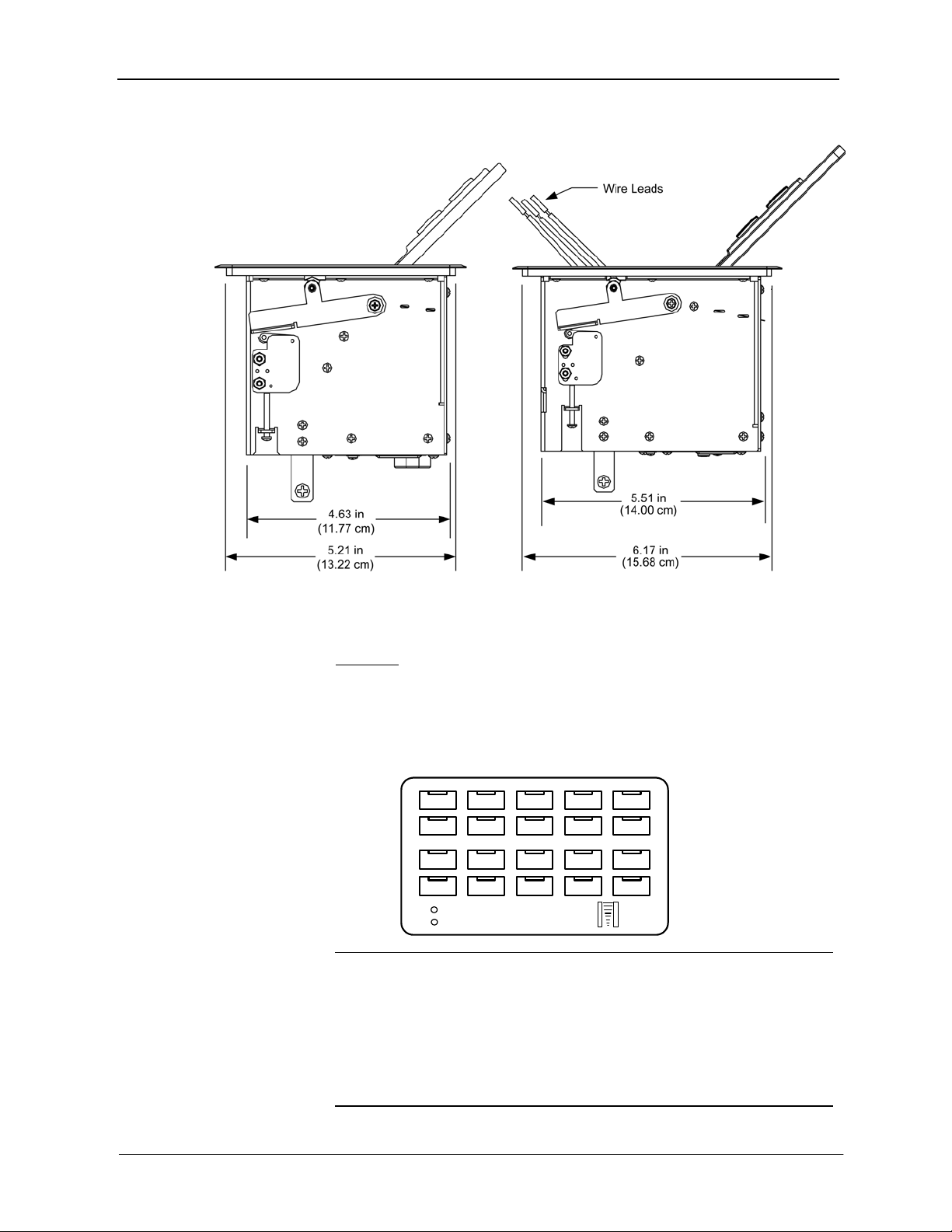

QM-FTMC Physical Dimensions - Top View QMI-FTMC Physical Dimensions - Top View

6 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 11

Crestron QM-FTMC FlipTop Media Center

QM-FTMC-NB – Top View

NOTE: The physical dimensions of the NB models are identical to the models

with keypad.

QM-FTMC Physical Dimensions - Front View QMI-FTMC Physical Dimensions - Front View

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 7

Page 12

FlipTop Media Center Crestron QM-FTMC

QM-FTMC Bottom View QMI-FTMC Bottom View

QM-FTMC Physical Dimensions - Back View QMI-FTMC Physical Dimensions - Back View

8 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 13

Crestron QM-FTMC FlipTop Media Center

QM-FTMC Physical Dimensions - Side View QMI-FTMC Physical Dimensions - Side View

Controls and Ports (Top)

Buttons

.

The QM-FTMC can have 10 to 20 engravable, replaceable, programmable

buttons. All buttons are functionally identical and have light emitting diodes

(LEDs) that serve as user feedback indicators. The illumination of each LED

(on/off) is independently addressable, and programmable using SIMPL

Windows.

Row 1

Row 2

Row 3

Row 4

12 345

678910

11 12 13 14 15

16 17 18 19 20

PWR

NET

NOTE: Numbers in this illustration are for programming purposes only. Refer

to page 40 for button programming information.

NOTE: The QM-FTMC is shipped with a set of ten buttons. Additional

buttons may be added by ordering button kits (refer to page 18).

NOTE: NB models do not have buttons, LEDs, or bar graphs.

NOTE: These button units do not support audio WAV files.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 9

Page 14

FlipTop Media Center Crestron QM-FTMC

AC Outlet

125V – 50/60Hz 10A

The yellow RCA connector is used for connecting a composite video source to

The 3-prong grounded AC outlet is rated at 125 VAC @ 10 Amps, 50 – 60 Hz.

The international version (QMI-FTMC) has a bezel that accepts an adaptor

receptacle and three wires that connect to the adaptor; blue, brown, and green

with a yellow stripe.

The international AC outlet is rated 250 VAC @ 10 Amps, 50 – 60 Hz.

Refer to “Appendix A” on page 56 for a complete list of international

receptacles and applicable countries.

VIDEO

the presentation system. A corresponding set of stereo RCA audio inputs (red and

white) are provided for the video source’s audio program. This port can

automatically detect the presence of a composite video signal and is 75 Ω

terminated, maximum input 1 V

p-p

.

S-VIDEO

This 4-pin mini DIN-type female connector is used for connecting an S-video source

to the presentation system. A corresponding set of stereo RCA audio inputs (red and

white) are provided for the video source’s audio program. This port can

automatically detect the presence of a luminance video signal (Y) on pin 3. Refer to

the following table for pin assignments.

• 75 Ω terminated

• Maximum input 1 V

S-Video DIN Connector Pin Assignments

PIN DESCRIPTION

1 Ground

2 Ground

3 Luminance

4 Chrominance

p-p

.

10 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 15

Crestron QM-FTMC FlipTop Media Center

COMPUTER

This female DB15HD connector is used for connecting a computer’s RGB video

output to the presentation system. A corresponding 3.5mm mini-jack is provided

for the computer sound card output. This port can automatically detect the

presence of an H-sync video signal to support RGBHV and RGBS, and

component video detection by sensing the green video signal on pin 2 to support

RGsB and Y, P

activity in the following locations.

• Horizontal sync on RGB

• Green Video path on RGB

• Composite video

SIGNAL DETECTED SIGNAL REPORTED

Green & H Sync RGB

Green & No H Sync Component

Composite Composite

Refer to the following table for the DB15HD connector pin-assignments.

, PR. Video sensing is accomplished by detecting electrical

B

• 75 Ω terminated (R,G,B)

• Maximum input voltage 1 V

• Maximum H and V Sync: 5.0 V

p-p

into 1 kΩ

p-p

RGB DB15HD Pin Assignments

PIN FUNCTION PIN FUNCTION

1 Red Video 9 No Connect

2 Green Video 10 Ground

3 Blue Video 11 No Connect

4 Reserved 12 Monitor Sense 1

5 Ground 13 Horizontal Sync

6 Red Ground 14 Vertical Sync

7 Green Ground 15 Monitor Sense 2

8 Blue Ground

The computer audio connector provides an unbalanced stereo line-level audio

input (maximum input level 1 V

rms

).

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 11

Page 16

FlipTop Media Center Crestron QM-FTMC

Ports (Underside)

MIC 1 / MIC 2

These two 5-pin 3.5 mm detachable terminal blocks provide two microphone

and line level audio inputs.

• Balanced microphone input level: -60 to -20 dBV nominal

NET

24 Y Z G

NET

24 Y Z G

• Balanced line input level: -28 to +12 dBV, 4 V

• Unbalanced input level: -34 to +6 dBV, 2 V

• Microphone input impedance: 10 kΩ,

RMS

maximum

RMS

maximum

accepts balanced microphones 60 to 600 Ω

• Line input impedance: 22 kΩ (balanced), 11 kΩ (unbalanced)

• Phantom power: 10 mA (total) at 48 VDC, software enabled for both

inputs

• Mic level indicators (via software): 20 dB below clipping (Norm), 6 dB

below clipping (Overload)

• Mic Input Gain: 0 to 100% (0 to 40 dB) plus mute

• Gate level (threshold): 0 to 100%

• Attack: 1 to 100 ms

• Decay (release): 1 to 5000 ms

• Analog to Digital conversion: 24-bit, 48 kHz

NET (x2)

These two 4-pin terminal block connectors, located on the bottom side of the

QM-FTMC, are for connection to the Cresnet network. One connector is used to

connect to the Cresnet network while the second connector can be used to connect

another Cresnet device. Cresnet power to the QM-FTMC is supplied through either

of these connectors. For more information, refer to “Network Wiring” on page 14.

QM

This eight-pin RJ-45 transport port, located on the bottom side of the QM-FTMC,

allows connection of the QuickMedia cable. It carries audio, video, and microphone

signals over CresCAT-QM cable to a QuickMedia receiver or switcher. For more

1

8

12 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

information on QuickMedia refer to page 3.

NOTE: When transmitting S-video, luminance uses the green video pathway,

and chrominance uses the red video pathway. When transmitting composite

video, the signal is carried on the blue video pathway.

NOTE: Always use Crescat-QM cable to make QuickMedia connections.

NOTE: Crescat-QM siamese cable includes four additional wires for making

Cresnet connections.

Page 17

Crestron QM-FTMC FlipTop Media Center

RJ-45 QuickMedia Connector Pin Assignments

RJ-45 MALE CONNECTOR

125V – 50/60Hz 10A

RJ-45 PIN

NUMBER

1 WHITE/ORANGE - RGB RED (- CHROMINANCE) (-PR)

2 ORANGE + RGB RED (+ CHROMINANCE) (+PR)

3 WHITE/GREEN - RGB GREEN (- LUMINANCE) (-Y)

4 BLUE + AUDIO

5 WHITE/BLUE - AUDIO

6 GREEN + RGB GREEN (+ LUMINANCE) (+Y)

7 WHITE/BROWN - RGB BLUE (- COMPOSITE) (-PB)

8 BROWN + RGB BLUE (+ COMPOSITE) (+PB)

AC Power

Connect the six-foot (183 cm) grounded AC line cord to supply AC power to

the outlet on the topside of the QM-FTMC.

The international version (QMI-FTMC) is equipped with a standard IEC-320

electrical appliance coupler. The IEC (International Electrotechnical

Commission) is the international standards and conformity assessment body

for all fields of electrotechnology.

WIRE COLORS

(EIA 568B)

QM ASSIGNMENT

RGB, COMPOSITE, COMPONENT

S-VIDEO, AND AUDIO

Indicators

PWR (Power)

This LED illuminates when 24 volts DC is supplied to the QM-FTMC from

Cresnet.

NET

This LED illuminates when communication between the control system and the

QM-FTMC is established (the unit is polled on the network). Illumination

indicates that the SIMPL Windows program currently loaded has a network

device defined at the same Net ID as the QM-FTMC.

Bargraphs

Two sets of eight-segment programmable red LEDs are provided that can be

programmed to display audio level settings. The LEDs display is proportional to

the input and can be set from zero to 100%. Refer to “Buttons” on page 40 for

programming details.

NOTE: Indicators are not included with NB models.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 13

Page 18

FlipTop Media Center Crestron QM-FTMC

SETUP LED and Pushbutton

The QM-FTMC is Touch-Settable ID-ready. A SETUP pushbutton and

associated LED are located on the bottom of the unit next to the Cresnet

connectors. The SETUP pushbutton and its associated LED are used for setting

a units network ID during the initial configuration of a Cresnet system or when

the device is being added/replaced.

Industry Compliance

As of the date of manufacture, the QM-FTMC has been tested and found to

comply with specifications for CE marking and standards per EMC and

Radiocommunications Compliance Labelling.

NOTE: This device complies with part 15 of the FCC rules. Operation is

subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Setup

Network Wiring

CAUTION: In order to ensure optimum performance over the full range of

your installation topology, Crestron Certified Wire, and only Crestron Certified

Wire, may be used. Failure to do so may incur additional charges if support is

required to identify performance deficiencies as a result of using improper wire.

CAUTION: Use only Crestron power supplies for Crestron equipment. Failure

to do so could cause equipment damage or void the Crestron warranty.

CAUTION: Provide sufficient power to the system. Insufficient power can lead

to unpredictable results or damage to the equipment. Please use the Crestron

Power Calculator to help calculate how much power is needed for the system

(http://www.crestron.com/calculators

When calculating the length of wire for a particular Cresnet run, the wire gauge

and the Cresnet power usage of each network unit to be connected must be taken

into consideration. Use Crestron Certified Wire only. If Cresnet units are to be

daisy-chained on the run, the Cresnet power usage of each network unit to be

daisy-chained must be added together to determine the Cresnet power usage of

the entire chain. If the unit is a home-run from a Crestron system power supply

network port, the Cresnet power usage of that unit is the Cresnet power usage of

the entire run. The wire gauge and the Cresnet power usage of the run should be

used in the following equation to calculate the cable length value on the

equation’s left side.

).

Cable Length Equation

40,000

Where:

L <

R x P

14 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

L = Length of run (or chain) in feet.

R = 6 Ohms (Crestron Certified Wire: 18 AWG (0.75 MM

P = Cresnet power usage of entire run (or chain).

2

))

Page 19

Crestron QM-FTMC FlipTop Media Center

Make sure the cable length value is less than the value calculated on the right

side of the equation. For example, a Cresnet run drawing 20 watts should not

have a length of run more than 333 feet.

NOTE: All Crestron certified Cresnet wiring must consist of two twisted pairs.

One twisted pair is the +24V conductor and the GND conductor, and the other

twisted pair is the Y conductor and the Z conductor.

NOTE: When daisy-chaining Cresnet units, strip the ends of the wires carefully

to avoid nicking the conductors. Twist together the ends of the wires that share a

pin on the network connector, and tin the twisted connection. Apply solder only

to the ends of the twisted wires. Avoid tinning too far up the wires or the end

becomes brittle. Insert the tinned connection into the Cresnet connector and

tighten the retaining screw. Repeat the procedure for the other three conductors.

NOTE: For larger networks (i.e., greater than 28 network devices), it may

become necessary to add a Cresnet Hub/Repeater (CNXHUB) to maintain signal

quality throughout the network. Also, for networks with lengthy cable runs, it

may be necessary to add a Hub/Repeater after only 20 devices.

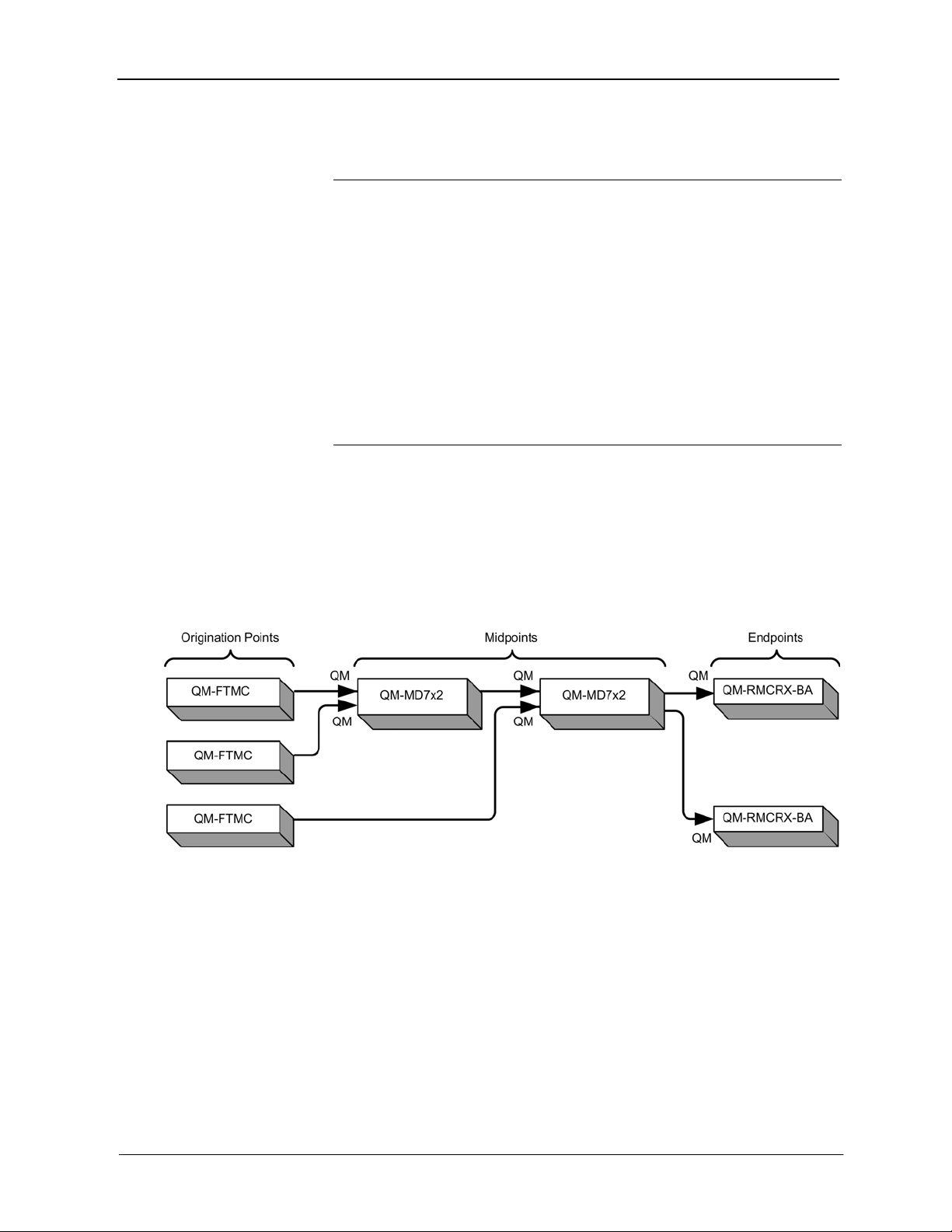

QM Network Wiring

When connecting multiple QM devices, the route between a QM origination

point (e.g., QM-FTMC) and a QM endpoint (e.g., QM-RMCRX-BA) cannot

have more than two midpoints (e.g., QM-MD7x2 or other QM switchers). Refer

to the following diagram when configuring a QM network. Refer to Appendix B

on page 57 for additional QuickMedia installation information.

QM Network Topology

Crestron Toolbox

The Crestron Toolbox (replacement for Crestron Viewport, you may continue to

use Viewport if desired) is a broad-based software package that accomplishes

multiple system tasks, primarily using an RS-232 or TCP/IP connection between

a PC and one or more Crestron control systems.

You can use the Crestron Toolbox to:

• Observe system processes.

• Upload operating systems and firmware.

• Upload programs and touchpanel projects.

• Set or change device Network IDs.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 15

Page 20

FlipTop Media Center Crestron QM-FTMC

• Change serial numbers.

• Run scripts to automate tasks.

• Perform system diagnostics, and much more.

The Crestron Toolbox allows you to perform these functions using simple

graphical views and click and drag methods.

Identity Code

Every piece of equipment and user interface within the network requires a

unique identity code (Net ID). These codes are two-digit hexadecimal numbers

from 03 to FE (Net ID 02 is reserved for master control units). The Net IDs

reside within all Cresnet devices (hardware) and must match the Net ID as

specified in the software (SIMPL Windows) that runs the system. Refer to

“Setting the Net ID in Device Settings” on page 33 for details of the SIMPL

Windows procedure.

The Net ID of the QM-FTMC has been factory set to 0A. The Net IDs of

multiple QM-FTMCs in the same system must be unique. Net IDs can be

changed from a personal computer (PC) using SystemBuilder

Toolbox.

NOTE: For detailed information on establishing communication between the

PC and control system, refer to “Communication Settings” on page 46. If

communication cannot be established, refer to the “Troubleshooting

Communications” section in the latest version of the 2-Series Control System

Reference Guide (Doc. 6256), which is available from the Crestron website

(http://www.crestron.com/manuals).

™

or Crestron

The Crestron Toolbox provides several methods to easily set or change device

Net IDs for any device on the network. The following method permits you to

change the Net ID of any device in the network through the “Network Device

Tree” window.

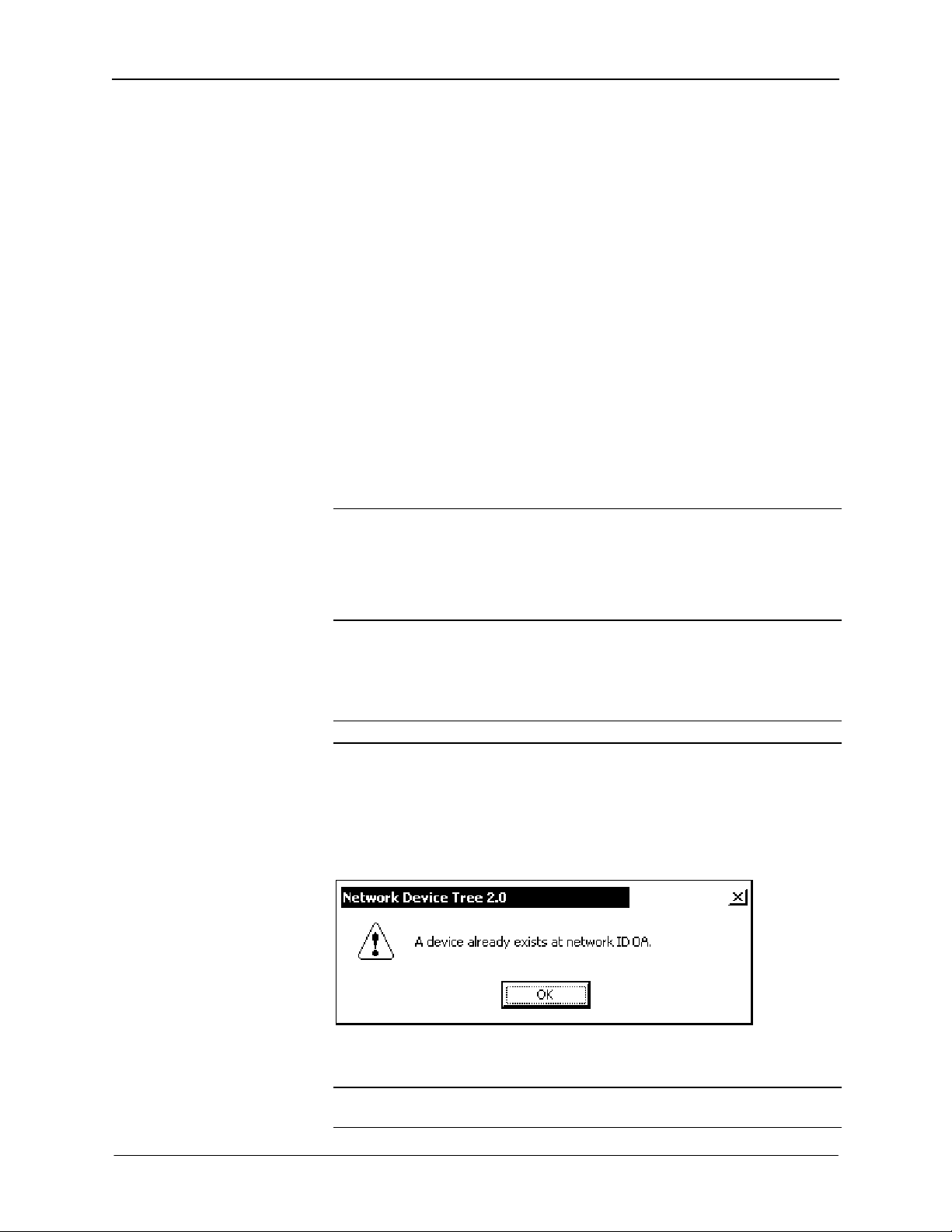

NOTE: This method prevents you from setting duplicate IDs.

This method permits you to manually set the Net ID for any device in the

network, can be used to set any known Net IDs that may require changing, and

may also be used for non-TSID equipment. This method will not permit you to

choose an ID already in use by another device. A warning message will appear

if you attempt to use an ID that is already in use.

Duplicate Net ID Warning Message

This method does not change the Net ID as assigned in SIMPL windows. Refer

to page 33 for the SIMPL Windows ID change procedure.

NOTE: You may also use SystemBuilder to perform Network ID setup. Refer

to page 30 for Net ID setup details using SystemBuilder.

16 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 21

Crestron QM-FTMC FlipTop Media Center

1. Ensure that all network devices are connected to the control system.

2. Open Crestron Toolbox and establish communications (refer to page

46).

3. Select the Network Device Tree

Device Tree.

Network Device Tree

4. Right-click on the device Net ID, and when the sub-menu appears,

select Change Network ID from the sub-menu.

Network Device Tree – Sub-Menu

icon, or select Tools | Network

5. Enter a new Net ID and press Enter.

Enter New Net ID

Repeat this procedure for each additional network device requiring a Net ID

change.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 17

Page 22

FlipTop Media Center Crestron QM-FTMC

Installation

NOTE: This section does not apply to NB models.

The QM-FTMC is shipped with ten large blank buttons. You can order a variety

of button kits (sold separately) to add as many as 20 engraved or blank buttons.

Button Kits

KIT NUMBER DESCRIPTION

FT-BTNB-L One large button engraved as desired

FT-BTNB-L-BLANK One large button not engraved

FT-BTNB-S Two small buttons with divider engraved as desired

FT-BTNB-S-BLANK Two small buttons with divider, not engraved

Button Installation

To replace the large buttons with small buttons, follow this procedure.

A 1/16" Allen (hexhead) wrench is required to remove the button faceplate.

1. Remove the four Allen screws that secure the button faceplate.

2. While holding adjacent buttons in place, carefully pull the button(s) to

be replaced from the rubber membrane.

3. Carefully press the two small replacement buttons in place, making

sure LED window faces up. Use care not to dislodge the membrane and

circuit board.

NOTE: The removable buttons fit snugly on the rubber membrane and must be

removed carefully to avoid pulling the membrane from the unit.

4. The divider bar slips into the slots on the back of the faceplate.

5. Replace the faceplate.

Button Installation

18 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 23

Crestron QM-FTMC FlipTop Media Center

QM-FTCMK Cable Management Plate

The QM-FTMC is shipped with a blank bottom plate. A cable management plate

is available to provide a pullout cable solution for the computer input and LAN

pass-through cables. The kit contains two 6-foot cables (computer and computer

audio).

• Order the QM-FTCMK Cable Management Kit for domestic models.

• Order the QMI-FTCMK Cable Management Kit for international

models.

Parts Supplied with Optional Cable Management Kit

PART DESCRIPTION QUANTITY

Small Cable Bushing, 5/16 inch ID, 0.5 inch OD 4

Large cable Bushing, 0.55 inch ID, 0.80 inch OD 2

Cable Support Plate 1

Tie Wrap 3

Computer RGB Cable, VGA to VGA, 6 ft long 1

Computer Audio Cable, 3.5 mm Stereo, 6 ft long 1

Tools Required:

• Phillips screwdriver

• Small flat-blade screwdriver (for connecting the VGA cable)

The cable support plate must be installed before mounting the QM-FTMC to a

surface. The cables are looped through the cable support plate.

1. Remove the blank bottom plate and retain the four #4 x ¼ LG black

mounting screws (the QMI-FTCMK includes four #4 x ¼ screws).

2. Place the bushings on the cables (six bushings supplied). Use the large

bushing for the VGA cable.

3. Thread the cables through the appropriate slot on the plate.

4. Snap the bushings into the plate slots.

5. Feed all the excess cable through the opening.

6. Attach the plate using the four #4 x ¼ LG black mounting screws

retained in step 1 (use the four #4 x ¼ screws included with the

QMI-FTCMK).

7. Connect the cables to the appropriate connector on the front of the

QM-FTMC.

8. The cables may be secured to the bottom bar using the supplied tie

wraps.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 19

Page 24

FlipTop Media Center Crestron QM-FTMC

Cable Management Plate Installation

Cable Loops Through the Cable Plate

NOTE: Ensure that the cables have sufficient clearance to enable smooth

movement. Allow approximately 40 inches (102 cm) from the top surface of the

FlipTop box.

Mounting to Surface

The QM-FTMC is designed to mount in a horizontal surface, such as a desk top,

lectern, or podium. The following diagram illustrates the required opening size

to accommodate the QM-FTMC. A cutout template (4006405 or 4006874) is

included.

20 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 25

Crestron QM-FTMC FlipTop Media Center

Cutout Dimensions

QM-FTMC (4006405) QMI-FTMC (4006874)

NOTE: Before inserting the QM-FTMC in the mounting hole, ensure that all

required cables have been installed.

Mounting Parts Supplied with the QM-FTMC

PART DESCRIPTION QUANTITY

Screw #6-32, Pan Head, Phillips 8

Screw #10, Pan Head, Phillips 4

Mounting Bracket 2

1. Install the eight supplied #6-32 screws, but do not tighten (four on the

front side and four on the rear side). These will be used to secure the

front and rear mounting brackets.

2. Position the QM-FTMC in the mounting hole.

Mounting Bracket Screw Locations

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 21

Page 26

FlipTop Media Center Crestron QM-FTMC

3. Install the four #10 screws in the mounting brackets (two screws per

bracket). Refer to the following diagram.

4. Slide the mounting brackets over the #6-32 screws and tighten the

#6-32 screws.

5. Turn the four #10 screws equally until they contact the underside of the

mounting surface.

NOTE: Do not over-tighten the #10 screws as this may damage the surface

and/or the unit.

Mounting Bracket Installation

NOTE: Be careful not to press the buttons while closing the FlipTop, even

though the buttons are disabled when the FlipTop begins to close and all pressed

buttons are released.

Hardware Hookup

Refer to the following hookup diagram and, aside from attaching power last,

complete the connections in any order.

NOTE: To prevent overheating, do not operate this product in an area that

exceeds the environmental temperature range listed in the specifications table.

Consideration must be given if installed in a closed or multi-unit rack assembly,

inside a closed desk, or in a closed podium since the operating ambient

temperature of these environments may be greater than the room ambient.

22 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 27

Crestron QM-FTMC FlipTop Media Center

Contact with thermal insulating materials should be avoided on all sides of the

unit.

NOTE: The maximum continuous current from equipment under any external

load conditions shall not exceed a current limit that is suitable for the minimum

wire gauge used in interconnecting cables. The ratings on the connecting unit's

supply input should be considered to prevent overloading the wiring.

Underside Connections

Ground Wire Connections

Proper grounding is required. Connect the ground from the QM transmitter

(QM-FTMC) to earth ground. Connect the Cresnet shield at the

QM-RMCRX-BA to the chassis ground provided on the QM-RMCRX-BA. The

QM-RMCRX-BA chassis must also be connected to an earth ground (building

steel). Refer to the following grounding diagram.

Ground Wire Connections

NOTE: Do not connect the shield to earth ground at the QM-FTMC.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 23

Page 28

FlipTop Media Center Crestron QM-FTMC

Configuration Software

Have a question or comment about Crestron software?

Answers to frequently asked questions (FAQs) can be viewed in the Online Help

section of the Crestron website. To post a question or view questions you have

submitted to Crestron’s True Blue Support, log in at http://support.crestron.com.

First-time users will need to establish a user account.

Use the Crestron programming tool Crestron SystemBuilder™ to create a

control program for a QuickMedia control system.

The flexibility of SIMPL Windows requires a much greater degree of

programming expertise and is not recommended for this application. However,

SIMPL Windows information is included in this guide. Use the advanced

techniques available in SIMPL Windows to customize the job only if necessary.

Earliest Version Software Requirements for the PC

NOTE: Crestron recommends that you use the latest software to take advantage

of the most recently released features. The latest software is available from the

Crestron website.

NOTE: Crestron software and any files on the website are for Authorized

Crestron dealers and Crestron Authorized Independent Programmers (CAIP)

only. New users are required to register to obtain access to certain areas of the

site (including the FTP site).

The following are the earliest useable software version requirements for the PC:

• (Optional but highly recommended) SystemBuilder version 2.0

(Requires SIMPL Windows, VT Pro-e and Crestron database and

Crestron Engraver).

• SIMPL Windows version 2.06 or later. Library 332 and SIMPL+ Cross

Compiler version 1.1 are required. Library 346 for NB versions.

• Crestron Database version 17.2 or later (17.3 for NB versions).

Required by SIMPL Windows.

• Crestron Toolbox version 1.0 or later.

• Crestron Engraver version 2.3.3 or later (only required if using

SystemBuilder).

• Crestron RoomView

NOTE: The NB versions may be programmed with the regular QM FlipTop

devices, but will not match during SystemBuilder verification procedure in the

finish stage.

®

version 6.0 (required for room management).

24 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 29

Crestron QM-FTMC FlipTop Media Center

p

Configuring with SystemBuilder

The easiest method of

rogramming, but does not

offer as much flexibility as

SIMPL Windows.

Crestron SystemBuilder offers automatic programming for such residential and

commercial applications as audio distribution, home theater, video conferencing, and

lighting. The interface of this tool guides you through a few basic steps for

designating rooms and specifying the control system, touchpanels, devices, and

functionality. Crestron System Builder then programs the system, including all

touchpanel projects and control system logic.

Crestron SystemBuilder is fully integrated with Crestron's suite of software

development tools, including SIMPL Windows, VT Pro-e, Crestron Database,

User IR Database, and User Modules Directory. Crestron System Builder

accesses these tools behind the scenes, enabling you to easily create robust

systems.

NOTE: Modifications to the program that are made outside of SystemBuilder

(for example, in VT Pro-e or SIMPL Windows) are not preserved when you

reenter SystemBuilder.

SystemBuilder

After entering the appropriate information in each step, SystemBuilder creates

the control system logic and touchpanel pages, ready to upload to the controller.

NOTE: Crestron SystemBuilder version 2.0 or higher is required.

The following information is a general procedure for setting up a QuickMedia

system using SystemBuilder. Refer to the SystemBuilder help file for more

detailed instructions.

Creating a QuickMedia System in SystemBuilder

1. Open SystemBuilder and select File | New. Select a Blank System.

SystemBuilder – “New” Blank System Option

2. Select the plug-in for a QuickMedia system.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 25

Page 30

FlipTop Media Center Crestron QM-FTMC

SystemBuilder – “Plug-in Selection” Window

3. Select the control processor.

NOTE: You can select any 2-Series or QM control processor as the master.

SystemBuilder – Select a Control Processor (As the Master)

4. Specify the audio configuration. Choose from the various dialogs

(stereo program, speech, etc.) and click Next. Click Finish to continue

to the next step.

®

5. Add RoomView

if desired.

6. Select the device and then click the Assign QuickMedia Devices and

Routing button

located on the menu bar, and drag the

QM devices from the library on the right side, to the QM system on the

left side.

26 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 31

Crestron QM-FTMC FlipTop Media Center

SystemBuilder – Menu Bar, Assign Quick Media Devices and Routing

As devices are added from the library (on the right) to the system (on

the left), they are automatically assigned sequential Net IDs.

SystemBuilder – Equipment Room and Library

7. The QM-FTMC has three default programming modules already

prepared in SystemBuilder. When you choose the QM-FTMC, the

following notice is displayed. Click Yes to select one of the default

modules.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 27

Page 32

FlipTop Media Center Crestron QM-FTMC

Default Programming Notice

Choosing Yes allows you to select one of the three default programming

selections. Click the appropriate selection:

• Program and Speech – Dual Volume Control

• Program and Speech – Single Volume Control

• Program Only Volume Control

Click OK when finished.

Default Programming Example – Program and Speech, Dual Volume Control

8. Setup the QM network cable routing. Right-click on the connector and

select the routing to the desired device. The connectors that are

displayed in the following diagram have an exclamation mark (!) if

they are selectable for routing.

28 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 33

Crestron QM-FTMC FlipTop Media Center

Routing Example – Right-Click on QM Connector

9. Build the program. The “Finish” window affords an opportunity to

set/reset network IDs and verify hardware network IDs.

10. After completing your SystemBuilder program, click the Build and

Upload System button

SystemBuilder – “Finish” Window

.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 29

Page 34

FlipTop Media Center Crestron QM-FTMC

Setting Net IDs in SystemBuilder

SystemBuilder provides a convenient method of selecting and assigning Net IDs

to devices.

1. Ensure that all network devices are connected to the control system.

2. After completing your SystemBuilder program, click the Build and

Upload button

SystemBuilder – “Finish” Window

.

3. On the “Finish” window, click the Set Network IDs… button to assign

the network IDs. SystemBuilder provides three methods for assigning

Net IDs.

• Drag and drop a device from the program tree on the left onto the

device in the network tree on the right.

• Right-click a device the program tree on the left and select Setup

from the sub-menu.

• Right-click on a device in the network tree on the right and set the

Net ID directly.

30 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 35

Crestron QM-FTMC FlipTop Media Center

SystemBuilder – “Set Network IDs” Window

Configuring with SIMPL Windows

NOTE: While SIMPL Windows can be used to configure the QM-FTMC,

Crestron recommends SystemBuilder software for configuring and tuning a

QuickMedia system.

NOTE: The following are acceptable file extensions for programs that include

a QM-RMCRX-BA and QM-FTMC, developed for specific control system

types:

.smw projectname.smw (source file)

.spz projectname.spz (compiled file for 2-Series)

.usp projectname.usp (source code module for SIMPL+)

.ir projectname.ir (user IR)

.umc projectname.umc (user macro)

.ush projectname.ush (completed SIMPL+)

SIMPL Windows is the Crestron graphical, Windows®-based development tool

for programming control systems. The SIMPL Windows interface provides two

workspaces: the Configuration Manager, for configuring the control system,

touchpanels, and controlled network devices; and Program Manager, for

designing the logic and functionality of the control system.

In addition, you can use the powerful Crestron Toolbox utility to accomplish

multiple system tasks, such as uploading the program to the control system and

performing diagnostic functions. Together with the Crestron Database, these

tools provide you with the essential components you need to program the

QM-RMCRX-BA and QM-FTMC. Crestron software is available from the

Crestron website, registration is required for downloading.

NOTE: Crestron software and any files on the website are for Authorized

Crestron dealers and Crestron Authorized Independent Programmers (CAIP)

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 31

Page 36

FlipTop Media Center Crestron QM-FTMC

only. New users may be required to register to obtain access to certain areas of

the site (including the FTP site).

NOTE: The information in this section assumes that the reader has knowledge

of SIMPL Windows. If not, refer to the extensive help information provided

with the software.

NOTE: In the following example, a QM-RMCRX-BA is used as the

QuickMedia receiver for the QM-FTMC.

In Configuration Manager, drag the QM-RMCRX-BA from the Control Systems

folder of the Device Library to System Views.

QM-RMCRX-BA in the Device Library

System View of QM-RMCRX-BA

C2Net-Device Slot in Configuration Manager

The C2Net-Device slot (05) enables the QM-RMCRX-BA to control up to 252

Cresnet devices. Each Cresnet device is assigned a unique identifier called a Net

ID, which is a hexadecimal value ranging from 03 to FE.

To view the list of supported devices, expand the control system in the bottom

pane of System Views and double-click the C2Net-Device slot, the desired Net

ID, or right-click and select Add Item from the submenu. Then select the device

you want to add. Alternatively, you can drag the device from the Cresnet

Control Modules folder onto the Net ID. Supported devices include network

control modules, lighting modules and a variety of Crestron wired touchpanels.

In Program Manager, the C2Net-Device symbol contains no signals; to program

a controlled Cresnet device, expand C2Net-Device in Program View. Then drag

the device to Detail View.

Locate the QM-FTMC in the Cresnet Control Modules.

32 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 37

Crestron QM-FTMC FlipTop Media Center

QM-FTMC Control Module

Within this module are three slots, Basic Controls, Microphone Controls, and

Buttons. Drag and drop the QM-FTMC module onto the C2Net-Device slot.

This symbol has default Net ID 0A.

C2Net-Device, Slot 5

Setting the Net ID in Device Settings

Double-click the QM-FTMC icon in the upper pane to open the “Device

Settings” window. This window displays QM-FTMC device information. The

Net ID can be changed in this window using the Net ID tab, as shown in the

following figure.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 33

Page 38

FlipTop Media Center Crestron QM-FTMC

“Device Settings” Window

NOTE: This procedure sets the Net ID for the QM-FTMC in the program only.

It does not automatically set the Net ID for the QM-FTMC itself. SIMPL

Windows automatically changes Net ID values of a device added to a program if

a duplicate device or a device with the same Net ID already exists in the

program. Always ensure that the hardware and software settings of the Net ID

match. For Net ID hardware setting details, refer to “Identity Code” on page 16.

Symbols in Programming Manager

Three symbols make up the QM-FTMC: Basic Controls, Microphone Controls,

and Buttons. These symbols may be opened in Detail View. Following each

symbol, a table lists the symbol input and output signals, respectively, and their

functional descriptions.

Basic Controls

The Basic Controls module is built into slot 01 of the QM-FTMC.

The QM-FTMC provides the following video inputs:

• One RCA input labeled VIDEO, which accepts one composite video

source.

• One RGB video input labeled COMPUTER, which accepts one

computer or component video source.

• One mini-DIN input labeled S-VIDEO, which accepts one S-video

source.

The QM-FTMC provides the following stereo line level program audio inputs:

• Two RCA inputs labeled VIDEO L and R.

• Two RCA inputs labeled S-VIDEO L and R.

• One mini phone jack input labeled COMPUTER AUDIO.

In addition to the stereo program audio, the QM-FTMC provides two

microphone/line-level inputs.

The QM-FTMC provides one QM output that transmits three channels of video

together with the stereo program audio and one or both microphones via

CresCAT-QM. The built-in switcher can switch any video source independent

of the program audio source.

34 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 39

Crestron QM-FTMC FlipTop Media Center

QM-FTMC Symbol – Detail View of Basic Controls

QM-FTMC Basic Controls - Signal Descriptions

SIGNAL TYPE

AND NAME

Digital output:

<RGB Detect>

Digital output:

<Composite Detect>

Digital output:

<SVideo Detect>

Digital output:

<YPbPr Detect>

DESCRIPTION

Indicates that TTL H-sync is detected on the

COMPUTER input. The feedback remains high for as

long as video is detected.

High/1 = Computer video detected

Low/0 = No video detected

Indicates that video sync levels are detected on the

VIDEO input. The feedback remains high for as long

as video is detected.

High/1 = Composite video detected

Low/0 = No video detected

Indicates that video sync levels are detected on the SVIDEO input. The feedback remains high for as long

as video is detected.

High/1 = S-Video detected

Low/0 = No video detected

Indicates that G/Y-sync is detected on the

COMPUTER input. The feedback remains high for as

long as video is detected.

High/1 = Component video detected

Low/0 = No video detected

Continued on the following page

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 35

Page 40

FlipTop Media Center Crestron QM-FTMC

QM-FTMC Basic Controls - Signal Descriptions (continued)

SIGNAL TYPE

AND NAME

Analog input:

<VidInputSelect>

Analog output:

<VidInputSelect_F>

Analog input:

<AudInputSelect>

Analog output :

<AudInputSelect-F>

Analog input:

<CompForRGB-Aud>

Analog output:

<CompForRGB_Aud-F>

Analog input

<CompForComposite_Aud>

Analog output:

<CompForComposite_Aud-F>

Analog input:

<CompForSVideo-Aud>

Analog output:

<CompForSVideo_Aud-F>

DESCRIPTION

Selects the video source that will be switched to

the QM output.

Valid analog values range from 0d to 3d as

follows:

0d = No source

1d = COMPUTER (RGB or component on three

channels)

2d = VIDEO (on one channel) and S-VIDEO (on

two channels)

3d = VIDEO (on one channel) and S-VIDEO (on

two channels)

A value of 2d or 3d switches both the VIDEO and

S-VIDEO sources to the QM output.

The final video source selection is completed at

the QM receiver. Here a value of 2d selects

VIDEO; a value of 3d selects S-VIDEO.

Out of range values are ignored.

Indicates the video source(s) present at the QM

output.

Selects the program audio source to be switched

to the QM output.

Valid analog values range from 0d to 3d as

follows:

0d = No source (mute audio)

1d = COMPUTER AUDIO

2d = VIDEO L and R

3d = S-VIDEO L and R

Out of range values are ignored.

Indicates the audio source present on the stereo

program channel of the QM output.

Sets the source gain compensation for the

COMPUTER AUDIO source.

Valid analog values range from -100d (-10dB) to

+100d (+10dB), adjustable in increments of 0.1dB

(1d = 0.1dB).

Indicates the source gain compensation being

applied to the COMPUTER AUDIO source.

Sets the source gain compensation for the VIDEO

audio source.

Valid analog values range from -100d (-10dB) to

+100d (+10dB), adjustable in increments of 0.1dB

(1d = 0.1dB).

Indicates the source gain compensation being

applied to the VIDEO audio source.

Sets the source gain compensation for the SVIDEO audio source.

Valid analog values range from -100d (-10dB) to

+100d (+10dB), adjustable in increments of 0.1dB

(1d = 0.1dB).

Indicates the source gain compensation being

applied to the S-VIDEO audio source.

NOTE: Use an Analog Initialize to send a decimal input signal to the symbol.

NOTE: Returned values match values that were selected for the <VidInput

Select> and <AudInput Select> inputs.

36 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 41

Crestron QM-FTMC FlipTop Media Center

Microphone Controls

The Microphone Controls module is built into slot 02 of the QM-FTMC. The

unit provides two microphone/line level inputs labeled MIC 1/LINE 1 and MIC

2/LINE 2, with muting, phantom power, noise gating, and level monitoring. In

addition, auto-compensation models provide four bands of equalization (160Hz,

500Hz, 1.2kHz, and 3kHz).

The microphone audio is routed to the MIC 1 and MIC 2 channels of the QM

output together with video and stereo program audio.

QM-FTMC Symbol – Detail View of Microphone Controls

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 37

Page 42

FlipTop Media Center Crestron QM-FTMC

The parameters that are associated with QM inputs are stored in the transmitter.

Input compensation and Mic EQ are examples of this. This information is then

transmitted along with the digital audio. The DSP that does the compensation

and EQ are in the receiver, but the settings now travel with the audio signal.

When you have switchers in-between the transmitter and receiver, the program

does not have to keep track of the routes and recall the preset in the receiver for

these functions. Now the receiver automatically gets this information when the

route is made, with no programming required. In addition we send the Cresnet

ID (or a user defined number for systems with multiple Cresnets), which will be

used by the receiver to automatically recall the video peaking/gain/skew

parameters.

QM-FTMC Microphone Control - Signal Descriptions

SIGNAL TYPE

AND NAME

Digital inputs:

<Mic1Mute>

<Mic2Mute>

Digital outputs:

<Mic1Mute-F>

<Mic2Mute-F>

Digital inputs:

<Mic1GatingEnable>

<Mic2GatingEnable>

Digital outputs:

<Mic1GatingEnable-F>

<Mic2GatingEnable-F>

Digital outputs:

<Mic1Gate>

<Mic2Gate>

Digital outputs:

<Mic1Nominal>

<Mic2Nominal>

Digital outputs:

<Mic1Clip>

<Mic2Clip>

Digital input:

<PhantomEnable>

DESCRIPTION

Mutes the MIC 1/LINE 1 or MIC 2/LINE 2 audio for as

long as the input is high.

High/1 (level sensitive) = Mute audio; Low/0 = Un-mute

audio

Indicates that the corresponding MIC/LINE input is

muted.

High/1 = Mic audio is muted; Low/0 = Mic audio is not

muted

Enables noise gating for MIC 1/LINE 1 or MIC 2/LINE

2, for as long as the input is high.

Gating eliminates unwanted background noise that

could prove distracting when amplified. The noise gate

will not pass an audio signal unless it is above the

threshold, set by the <GatingLevel> input.

High/1 (level sensitive) = Enable gating; Low/0 =

Disable gating

Indicates the current status of the noise gate for the

corresponding MIC/LINE input.

High/1 = Gating is enabled; Low/0 = Gating is disabled

Indicates that the signal level on MIC 1/LINE 1 or MIC

2/LINE 2 has exceeded the <GatingLevel>.

High/1 = Gating level exceeded; Low/0 = Gating level

not exceeded

Indicates that the signal level on MIC 1/LINE 1 or MIC

2/LINE 2 has exceeded the nominal level.

The nominal indication is reported at 10% of the

maximum level supported by the hardware, or 20dB

below the input clip level.

High/1 = Nominal level exceeded;

Low/0 = Nominal level not exceeded

Indicates that the signal level on MIC 1/LINE 1 or MIC

2/LINE 2 has exceeded 50% of the maximum level

supported by the hardware, or 6dB below the input clip

level. This signifies a mic level that is too hot.

High/1 = Mic signal clipping;

Low/0 = Mic level not clipping

Enables the 48V phantom power supply for as long as

the input remains high. (Phantom power is required by

condenser microphones, but should be disengaged for

dynamic microphones.)

High/1 (level sensitive) = Enable phantom power;

Low/0 = Disable phantom power

Continued on the following page

38 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 43

Crestron QM-FTMC FlipTop Media Center

QM-FTMC Microphone Control - Signal Descriptions (continued)

SIGNAL TYPE

AND NAME

Digital output:

<PhantomEnable-F>

Analog inputs:

<Mic1GatingLevel>

<Mic2GatingLevel>

Analog outputs:

<Mic1GatingLevel-F>

<Mic2GatingLevel-F>

Analog inputs:

<Mic1Gain>

<Mic2Gain>

Analog outputs:

<Mic1Gain-F>

<Mic2Gain-F>

Analog input:

<AttackTime>

Analog output:

<AttackTime-F>

Analog input:

<DecayTime>

Analog output:

<DecayTime-F>

Analog inputs:

<Mic1EQTrim1>

through

<Mic1EQTrim4>

Analog outputs:

<Mic 2EQTrim1-F>

through

<Mic 2EQTrim4-F>

DESCRIPTION

Indicates that phantom power has been enabled.

High/1 = Phantom power is on; Low/0 = Phantom

power is off

Sets the threshold for gating. The noise gate is enabled

for as long as the <GatingEnable> input is high. Valid

gating values range from 0% to 100%.

Once the microphone audio rises above

<GatingLevel> the gate opens, allowing the signal to

pass through.

If the <MicNominal> feedback pulses while the

<MicGate> feedback remains low, this indicates a

threshold that is set too high.

Indicates the gating level for the corresponding

MIC/LINE input.

Adjusts the gain of the MIC 1/LINE 1 or MIC 2/LINE 2

input.

Valid values range from 0% to 100%. This maps into

the following range:

Mic level input: -60dBV to -20dBV

Line level input: -28dBV to +12dBV

Indicates the gain being applied to the corresponding

MIC/LINE input.

Sets the time, in milliseconds, that it takes for the noise

gate to fully open after the signal exceeds the

<GatingLevel>. This prevents short spikes in the input

signal level, such as coughing, from opening the gate.

The attack time applies to both microphones.

Valid analog values range from 0d (0ms) to 100d

(100ms), with 10d to 40d being the most usable range.

Out of range values are ignored.

Indicates the attack time.

Sets the time, in milliseconds, over which the noise

gate will close. This prevents the sound from stopping

too abruptly—for example, during brief pauses in

speech.

The decay time applies to both microphones.

Valid analog values range from 0d (0ms) to 5000d

(5000ms, or 5s), with 1000d to 3000d (1000s to 3000s,

or 1s to 3s) being the most usable range.

Out of range values are ignored.

Indicates the decay time.

Sets the four MIC 1 EQ trims (at 160Hz, 500Hz,

1.2kHz, and 3kHz).

Valid analog values range from -120d (-12dB) to +120d

(+12dB), adjustable in increments of 0.1dB (1d =

0.1dB).

A trim of 0d (0dB) means that the signal will pass

unaffected.

Indicates the trim being applied to each band of the

MIC 1 equalizer.

Continued on the following page

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 39

Page 44

FlipTop Media Center Crestron QM-FTMC

QM-FTMC Microphone Control - Signal Descriptions (continued)

SIGNAL TYPE AND

NAME

Analog inputs:

<Mic 2EQTrim1>

through

<Mic 2EQTrim4>

Analog outputs:

<Mic 2EQTrim1-F> through

<Mic 2EQTrim4-F>

DESCRIPTION

Sets the four MIC 1 EQ trims (at 160Hz, 500Hz,

1.2kHz, and 3kHz).

Valid analog values range from -120d (-12dB) to +120d

(+12dB), adjustable in increments of 0.1dB (1d =

0.1dB).

A trim of 0d (0dB) means that the signal will pass

unaffected.

Indicates the trim being applied to each band of the

MIC 2 equalizer.

NOTE: Phantom power is applied to the connectors of both microphone inputs.

It cannot be switched on an individual microphone input.

NOTE: <AttackTime> and <DecayTime> are applied to both microphone

inputs.

NOTE: The gating level indicators will still function even if the gating function

is not enabled.

NOTE: Nominal indication is reported at 20 dB below input clip level. Clip

indication is reported at 6 dB below input clip level.

NOTE: Returned values match values that were selected for the

<Mic1GatingLevel>, <Mic2GatingLevel>, <Mic1Gain>, <Mic2Gain>,

<AttackTime> and <DecayTime> inputs.

NOTE: Refer to page 43 for adjustment details of the microphone inputs.

Buttons

The Buttons module is built into slot 03 of the QM-FTMC. It consists of a

keypad 10 to 20 buttons with LED indicators, and two bargraphs. The button

presses are fixed and map to <press> outputs on the symbol detail, as follows:

Row 1

Row 2

Row 3

Row 4

NOTE: Numbers in this illustration are for programming purposes only.

NOTE: Not applicable to NB models.

The buttons on rows 1 and 2 can be combined vertically to form one larger

button. For example, the button caps for buttons #1 and #6 can be replaced with

one larger button cap. Similarly, the vertical pairs on rows 3 and 4 can be

combined to form one larger button. For example, buttons #13 and #18 can be

12 345

678910

11 12 13 14 15

16 17 18 19 20

PWR

NET

40 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 45

Crestron QM-FTMC FlipTop Media Center

combined. No other combinations are valid. That is, two buttons cannot be

combined horizontally; the buttons on rows 2 and 3 cannot be combined.

QM-FTMC Symbol – Detail View of Buttons

QM-FTMC Buttons - Signal Descriptions

SIGNAL TYPE AND

NAME

Digital Outputs:

Button presses/vertical pair

<Press1>, <Press6>

Button presses/vertical pair

<Press2>, <Press7>

Button presses/vertical pair

<Press3>, <Press8>

Button presses/vertical pair

<Press4>, <Press9>

Button presses/vertical pair

<Press5>, <Press10>

Button presses/vertical pair

<Press11>, <Press16>

Button presses/vertical pair

<Press12>, <Press17>

Button presses/vertical pair

<Press13>, <Press18>

Button presses/vertical pair

<Press14>, <Press19>

Button presses/vertical pair

<Press15>, <Press20>

DESCRIPTION

Indicates that the corresponding button has been

pressed. The signal remains high for the duration of the

button press.

If the FlipTop cover is not fully open the buttons are

disabled and the unit will not report any button presses,

and will release any button that is already pressed. The

status of the cover is given by the <FlipTopOpen>

output.

If two buttons are combined to form one larger button,

the same signal should be attached to both button

presses.

High/1 = Button pressed; Low/0 = Button released

Continued on the following page

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 41

Page 46

FlipTop Media Center Crestron QM-FTMC

QM-FTMC Buttons - Signal Descriptions

SIGNAL TYPE AND

NAME

Digital Inputs:

<fb1> through <fb20>

Digital output:

<FlipTopOpen>

Analog input:

<Bargraph1>

Analog input:

<Bargraph2>

DESCRIPTION

Activates the corresponding LED for as long as the

input is high.

If two buttons are combined, then only the LED for the

top button in the vertical pair will be visible.

High/1 (level sensitive) = Activate LED feedback;

Low/0 = Turn off LED

Indicates that the FlipTop cover is fully open. The

feedback remains high for as long as the cover is open.

If the cover is not fully open the signal will go low, the

keypad buttons will be disabled and the unit will not

report any button presses.

High/1 = FlipTop open; Low/0 = FlipTop not fully open

Sets the levels that will be displayed on the left

bargraph. The bargraph is an 8-segment LED and is

proportional to the input.

Valid values range from 0% to 100%.

Sets the levels that will be displayed on the right

bargraph. The bargraph is an 8-segment LED and is

proportional to the input.

Valid values range from 0% to 100%.

Example Program

An example program for the QM-FTMC is available from the “Example

Program” section of the Crestron website

(www.crestron.com/exampleprograms

). Search for QM-FTMC.ZIP.

42 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 47

Crestron QM-FTMC FlipTop Media Center

Adjusting the QM-FTMC Microphone Inputs

Once a QM-FTMC is installed and configured, settings for gain, gating level,

attack time, and decay time should be set using the SystemBuilder finish tab.

NOTE: Crestron recommends that you use the latest software to take advantage

of the most recently released features. The latest software is available from the

Crestron website.

Definitions

The QM-FTMC allows for adjustments to be made to microphone input signals.

The following are definitions of terms that are commonly used when making

adjustments.

Attack Time

The time it takes (in milliseconds) from when an input signal rises above the

gating level until the microphone output signal is enabled.

Clipping

A condition in which a signal level exceeds the maximum level (the clipping

level) a circuit can handle. This is usually caused by improper gating parameters

and gain settings.

Decay Time

The time (in milliseconds) from when an input signal falls below the gating

level until the microphone output signal is muted.

Gain

An adjustable amplification to accommodate varying input signal levels.

Gating

Gating is a function that mutes a microphone signal when the input sound level

is below a user-set threshold (gating level).

The following diagram demonstrates clipping, attack time, decay time, and

gating level.

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 43

Page 48

FlipTop Media Center Crestron QM-FTMC

Visual Representation of Gating Level, Clipping Level, Attack Time, and Decay Time

SIGNAL LEVEL

MICROPHONE

INPUT

SIGNAL

Mic On

Clipping Level

Gating Level

Mic Off

TIME

SIGNAL LEVEL

QM

OUTPUT

SIGNAL

Attack Time

Gating Level

Reached

Mic On

Attack Time Decay Time

Decay Time

Gating Level Reached

Mic Off

TIME

44 • FlipTop Media Center: QM-FTMC Operations & Installation Guide - DOC. 6311A

Page 49

Crestron QM-FTMC FlipTop Media Center

Setting Microphone Gain

The QM-FTMC provides variable gain on microphone inputs. The following

procedure is used to set the optimal gain for a microphone input.

Use the Realtime Mode in SystemBuilder to control phantom power, gain and

gate settings, and to monitor the gate, normal, and clip level indicators. For

information on using SystemBuilder software, refer to the extensive help

information provided with the software.

NOTE: The input gain is independent of the system’s output volume level.

1. To adjust the input gain, set the gain and noise gate to their lowest

settings. Disable the “Mute” function by removing the check from the

Mute checkbox.

2. Connect a microphone and enable phantom power if required.

3. Increase the gain while providing a “normal” sound level input to the

microphone. When the “Norm” indicator shows fairly consistent

activity, you’ve reached a good signal level for the QM-FTMC.

NOTE: The "clip" indicator shows that the signal is clipping. Let your ears be

the judge, but when the clip indicator is active, you are approaching or have

reached distortion in your QM-FTMC signal. Occasional clip indications on

loud input are expected, but constant clip indicator activity is a sign that the gain

may be set too high.

4. Set the system output volume to a desirable listening level and verify

the gain settings by listening to the system output. Some minor gain

adjustment may be required for the “best sound” in any specific

configuration.

Setting the Gating Level

The QM-FTMC provides an input level gating function that will mute a

microphone signal when the input sound level is below a user-set threshold. This

function can be enabled or disabled via software commands.

Use the Realtime Mode in SystemBuilder to control phantom power, gain and

gate settings, and to monitor the gate, normal, and clip level indicators. For

information on using SystemBuilder software, refer to the extensive help

information provided with the software.

The following procedure sets the optimal “gate level” for the microphone inputs:

1. Follow the “Setting Microphone Gain” procedure on page 45 to set the

gain for each microphone input.

2. Set the noise gate level, attack and decay times to minimum. Disable

the “Mute” function by removing the check from the Mute checkbox.

3. While providing a level to the microphone that is equivalent to the

background noise that should be gated out, increase the noise gate level

until the Gated indicator turns off. When the input sound levels are at

or below the established noise gate level, the microphone output signal

will be gated off.

4. Set the “attack time” to the minimum level and the “decay time” to the

maximum level. These settings provide the shortest time to enable the

Operations & Installation Guide – DOC. 6311A FlipTop Media Center: QM-FTMC • 45

Page 50

FlipTop Media Center Crestron QM-FTMC

microphone output when an input is above the gating level, and the

longest time before disabling the microphone after such an input.

NOTE: The “attack” and “decay times” are applied to both microphone inputs.

5. Set the system output volume to a desirable listening level. While

providing realistic voice input and background noise levels, adjust the

gating level and attack/decay times to eliminate undesired input while

providing the best content quality.

Uploading and Upgrading

NOTE: Crestron recommends using the latest programming software and that

each device contains the latest firmware to take advantage of the most recently

released features. Please check the Crestron website

(http://www.crestron.com/updates) for the latest versions of software and

firmware. New users are required to register to obtain access to this site.

Assuming a PC is properly connected to the entire system, Crestron

programming software allows the programmer to upload programs and projects

to the system and touchpanel and firmware to the wall plates after their

development. However, there are times when the files for the program and

projects are compiled and not uploaded. Instead, compiled files may be

distributed from programmers to installers, from Crestron to dealers, etc. Even

firmware upgrades are available from the Crestron website as new features are

developed after product releases. In those instances, one has the option to upload

via the programming software or to upload and upgrade via the Crestron

Toolbox.

The following sections define how one would upload a SIMPL Windows