Page 1

Crestron Lighting

Control System

Design Guide

Page 2

This document was prepared and written by the Technical Documentation department at:

Crestron Electronics, Inc.

15 Volvo Drive

Rockleigh, NJ 07647

1-888-CRESTRON

All brand names, product names and trademarks are the property of their respective owners.

2003 Crestron Electronics. Inc.

Page 3

Crestron Lighting Control System

Contents

Lighting Control System Design 1

Introduction ...............................................................................................................................1

Types of Lighting System Designs............................................................................................ 1

Centralized Design ......................................................................................................2

Distributed Design....................................................................................................... 3

Complete Crestron Home Design................................................................................ 4

Requirements for Design ........................................................................................................... 5

Step 1: Define the Load Schedule ...............................................................................5

Step 2: Module Selection............................................................................................. 8

Step 3: Enclosure Selection....................................................................................... 12

Step 4: User Interface Selection ................................................................................14

Step 5: Wiring Plan ...................................................................................................23

Step 6: Control Processor Selection ..........................................................................24

Step 7: Network Block Selection...............................................................................28

Step 8: Accessories Selection.................................................................................... 29

Basic Lighting System Interconnections .................................................................................30

Ordering a Crestron Lighting Control System......................................................................... 31

Hardware ...................................................................................................................31

Programming............................................................................................................. 31

Example Lighting System........................................................................................................32

Merchandise Returns / Repair Service ......................................................................38

CRESTRON Limited Warranty.................................................................................38

Design Guide – DOC. 5999A Contents • i

Page 4

Page 5

Crestron Lighting Control System

Lighting Control System Design

Introduction

A lighting control system is as unique as the home it supports.

Crestron offers the equipment and flexibility of design required for every one-of-a-

kind solution to home automation needs. The designer can create a complete lighting

system consisting of traditional wiring with local intelligence, up to a system that

incorporates distributed, high-voltage wiring with centralized and/or distributed

intelligence. Cresnet low-voltage wiring is used for control throughout this wide

range of system design possibilities.

In a typical home with traditional wiring, a wall switch completes a simple circuit to

an overhead light. Adding additional lighting controls to the room requires that banks

of switches, dimmers, or timers replace the single switch.

In larger homes, businesses, and institutions, a multi-function user interface replaces

the large banks of traditional switches, dimmers, and timers. In addition to lighting,

these user interfaces can also be used to control security, HVAC, and audio/video

systems.

The system control can be located near the user interface, the controlled circuits, or

can be centralized at some other remote location.

Crestron D3 Pro software is a comprehensive design and development tool that

provides a programming environment for all lighting, HVAC and security needs. It

contains many features to facilitate a successful installation, including an

astronomical clock that allows the scheduling of events based on time of day or

sunrise and sunset. Keypads and touchpanels are easily designed and programmed,

and communication among Crestron control equipment is simplified.

Types of Lighting System Designs

Crestron offers centralized and distributed lighting control system components. A

centralized system is one in which all the high-voltage circuits are terminated within

a Crestron home automation enclosure. A distributed system is the traditional wiring

system of individual lighting circuits with local control. The most efficient lighting

systems are a combination of centralized processing and distributed dimmers. This

provides the reliability of local control along with sophisticated central control.

Design Guide – DOC. 5999A Lighting Control System Design • 1

Page 6

Control System Crestron Lighting

Centralized Design

The high-voltage lighting, fans, motors and switch circuits are individually wired

directly to the modules in the Crestron home automation enclosure. The modules are

controlled by low voltage user interfaces in the living area. This greatly simplifies

the high-voltage wiring while creating a flexible and efficient design using keypad

and touchpanel interfaces.

A central processor, connected via a local area network to the lighting modules and

the user interfaces, is dedicated to lighting, fans, motors, HVAC, and security. Other

processors that are dedicated to other home control systems can communicate via

Ethernet, RS-232 or RS-422 to the lighting processor. This eliminates the need for

additional controls for other home systems, separating home safety and life support

systems from information and entertainment systems, providing a flexible design

solution and a fully integrated home control.

Lighting Layout in a Centralized Design

2 • Lighting Control System Design Design Guide – DOC. 5999A

Page 7

Crestron Lighting Control System

Distributed Design

In the traditional distributed design wiring method, Crestron wall box dimmers can

be retrofitted into a project after routine high-voltage wiring is completed.

In addition to the traditional high-voltage wiring, a low-voltage communication wire

is run from the dimmer to the nearest Cresnet connection. This design offers the end-

user the familiarity of a traditional control coupled with the power and flexibility of

automated control. In a distributed design, the user has the security of operating the

lighting in the event of a temporary control system interruption.

Lighting Layout in a Distributed Design

Design Guide – DOC. 5999A Lighting Control System Design • 3

Page 8

Control System Crestron Lighting

Complete Crestron Home Design

A complete Crestron home design is a blend of distributed and centralized design in

which central control intelligence and distributed local dimmers form a reliable

whole house lighting control solution.

Large rooms, stairways, and frequently used rooms are often remotely controlled

using the astronomical time clock or whole-house presets. This level of control

requires connection to a central dimming controller. Each room is equipped with a

low voltage keypad for preset selection and audio/video integration. All the dimmers

in the system (grouped into the central controller for wiring convenience)

communicate with each other through the Crestron control system, providing a

complete Crestron home design.

Lighting Layout in a Complete Crestron Home Design

4 • Lighting Control System Design Design Guide – DOC. 5999A

Page 9

Crestron Lighting Control System

Requirements for Design

Lighting system design begins with a collection of complete information. The

successful lighting system plan begins with a lighting load schedule that you define

and compile based on the information contained in a detailed floor plan that

identifies the elements of the load schedule design, the location and types of user

interfaces used (i.e., local dimmers, keypads or touchpanels), the control processor

details (large systems should use a dedicated lighting control processor), and the

optional window treatment details, which include shade/blind motors and relay

control (consult manufacturer for details). The following eight steps, performed in

this sequence, is the recommended design procedure.

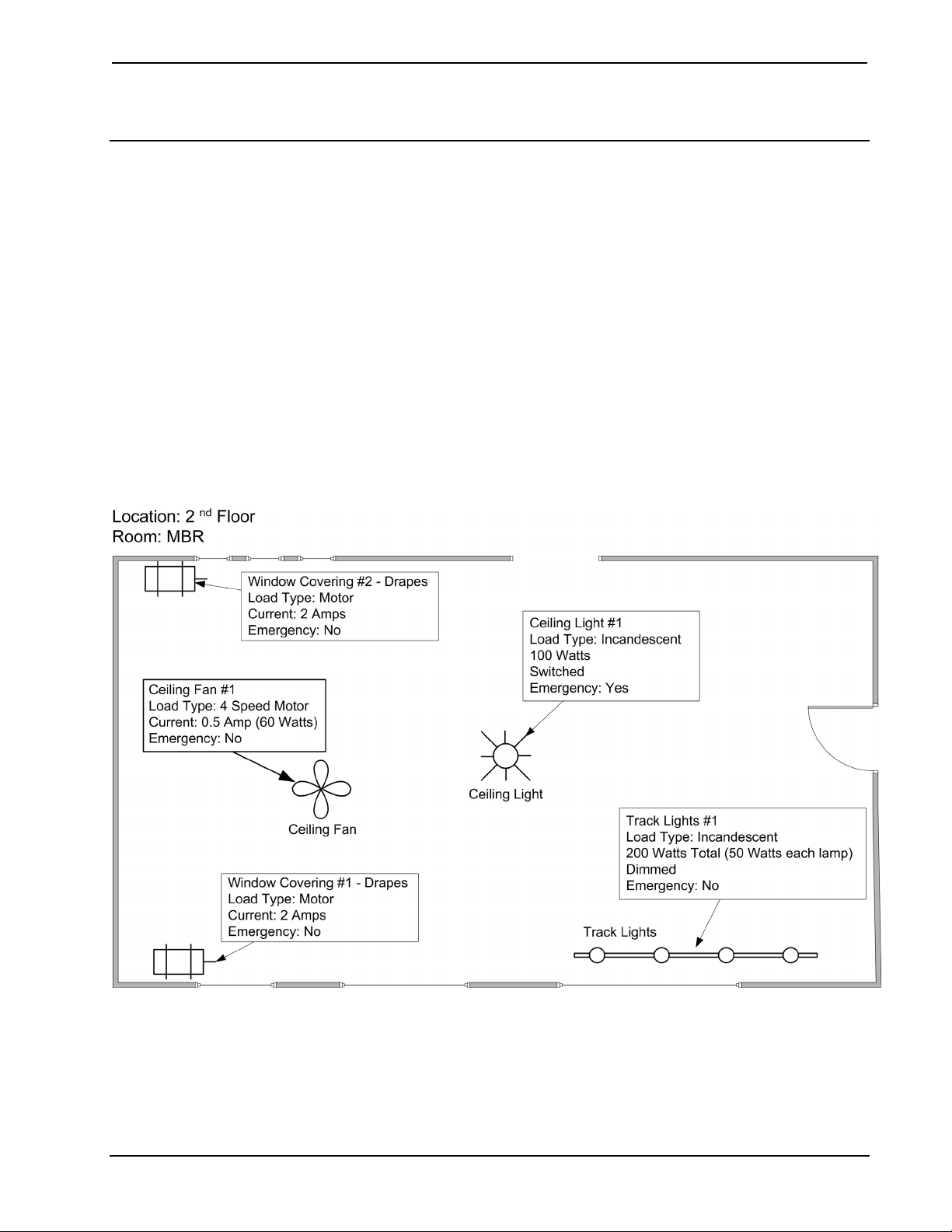

Step 1: Define the Load Schedule

A load schedule lists the information on each load connected to every circuit in an

electrical panel. This is the primary source of information required for lighting

control system design.

Simplified Room Specifications Example

Design Guide – DOC. 5999A Lighting Control System Design • 5

Page 10

Control System Crestron Lighting

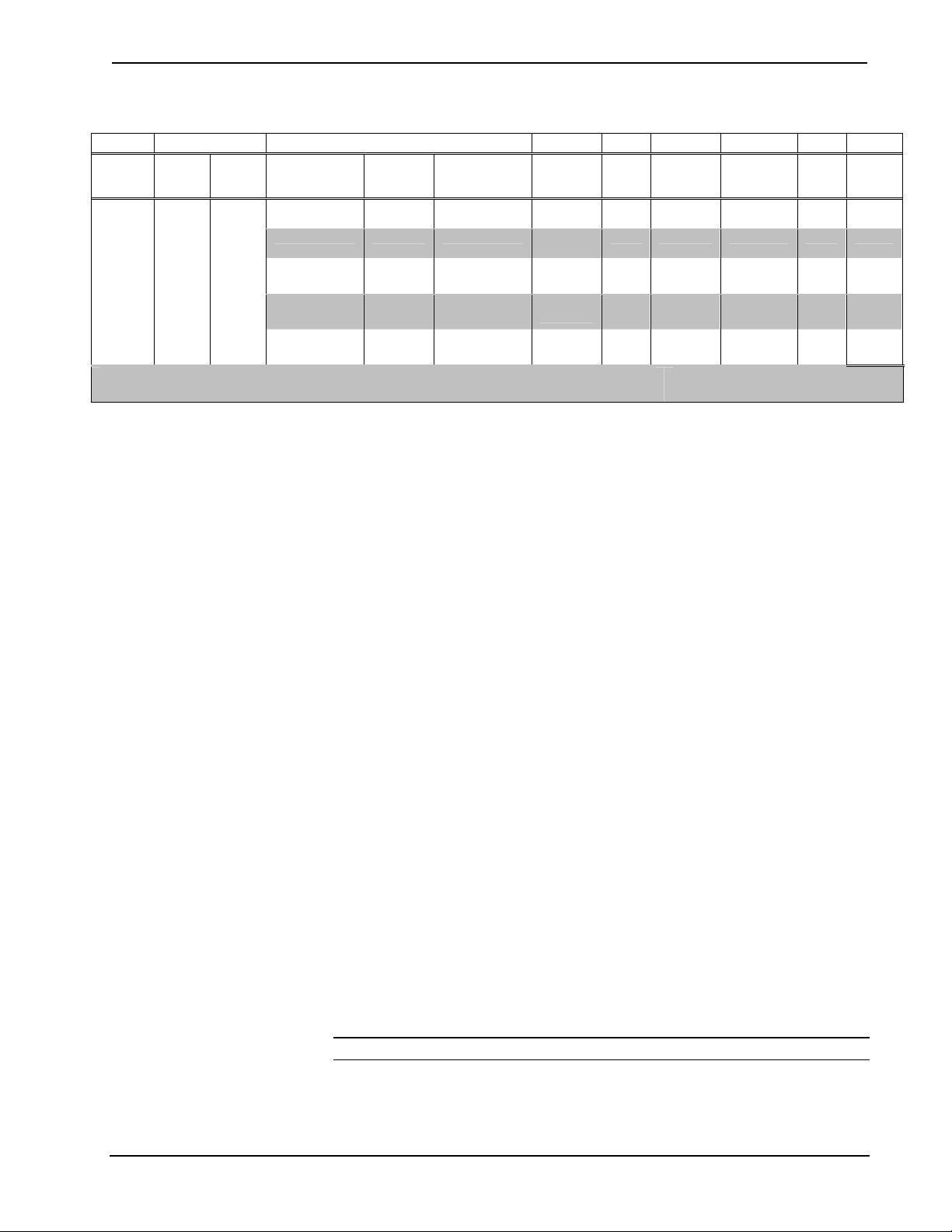

Example of a Load Schedule (Based on the room example in the previous illustration)

1 2 3 4 5 6 7 8 9

Control

Zone

1 Floor 2 MBR

Area Room Controlled Circuit

name

Ceiling 1 Ceiling Light Incan-

Track 2 Track Light Incan-

Ceiling Fan 3 Ceiling Fan Ceiling

Drape Motor 1 4 Drape Motor 1 3-wire

Drape Motor 2 5 Drape motor 2 3-wire

Controlled

Load Schedule Items

1. Control Zone: Controlled circuits that are not physically wired together, but

Circuit

Number

Fixture Type Load Type DIM Emergency

Lighting?

N Yes 100/120 1 100

descent

Y No 50/120 4 200

descent

N No 60/120 1 60

Fan

N No 240/120 1 240

Motor

N No 240/120 1 240

Motor

Total Wattage For Floor 2 MBR 840

Fixture

Wattage and

Voltage

Fixture

Qty

always operating in tandem. For example, perimeter lights, sconce lights

and overhead lights all operating together.

Total

Watts

2. Location of controlled lighting zone, relevant to building site/drawings,

floor designation, and room name.

3. Fixture and/or lamp type of controlled lighting zone, including any

information describing custom fixtures, undetermined fixtures, dimmable

transformers or fluorescent ballasts, and circuit breaker numbers. This

information can also contain the number assigned to the controlled circuit.

4. Load Type of the controlled lighting zone. Load types include incandescent,

magnetic low voltage, electronic low voltage, neon/cold cathode, HID,

dimmable/non-dimmable fluorescent ballast, ceiling fans, and switched 3wire motor circuits. This information is especially important for selecting

the correct Crestron module power rating and type.

5. Dimming requirement for the controlled lighting zone (i.e. whether the

lighting level of the loads/fixtures needs to be ramped up/down or simply

switched on/off). Indicate: “Yes” for Dimming, and “No” for Non-Dim.

6. Emergency designation for the controlled lighting zone (Yes/No; i.e. when

a load also needs to be assigned to a separate emergency power feed). These

items are assigned to their own separate dimmer, so it can be fed with

emergency power.

7. Fixture Wattage (Watts or Power-Rating per Fixture) with regard to the

controlled lighting zone. This is used to determine the number of fixtures

that can be powered per each Crestron Dimmer Module channel, in order

not to overload the dimmer beyond it’s own power rating. Volts rating for

the controlled lighting zone tells the designer the voltage of the electrical

feeds required for that zone, and hence the required rating for the associated

Crestron module. It is recommended, due to electrical codes, to avoid

mixing different voltages in a single enclosure.

NOTE: At the present time, all Crestron load voltage is 120 VAC.

6 • Lighting Control System Design Design Guide – DOC. 5999A

Page 11

Crestron Lighting Control System

8. Quantity of fixtures for the controlled lighting zone. This is useful, along

with item #6, in calculating the total power rating (watts) for that particular

controlled circuit (item #9).

9. Total Wattage, or Power Rating, of the controlled lighting zone. This is

required in order to determine the total number of Crestron Lighting

Module channels required for that particular zone, especially if the load of

the total number of fixtures exceeds the rating of a single module channel.

NOTE: National and local electrical codes and the functionality of each userinterface must be taken into consideration. Always install electrical devices

according to the national Electrical Code (NEC), local codes, and with safety in

mind.

Equipment List Specification

The equipment list is based on the requirements collected for the lighting system in

the load schedule. This is a sequential step-by-step process. The information

gathered in previous steps is required to complete following steps. Once all the steps

are completed, a complete bill-of-material for the system is created. The seven steps

are as follows:

• Module selection – based on the number and type of loads

• Enclosure selection – based on the number of modules and

locations

• User interface selection – based on the user control requirements

• Wiring plan – based on the previous steps and the layout of the

environment

• Control processor – based on the size of the system (large systems

should have a dedicated processor)

• Network block selection – based on the layout and distribution of

the loads

• Accessories selection – based on the required accessories (third

party telephone and alarm systems, etc.)

NOTE: Crestron D3 Pro software is the ideal tool for specifying an equipment list.

A fully documented help file supports the easy-to-use screens and views. It offers the

designer a starting place for determining modules and enclosures. The Crestron D3

Pro software can also generate a load schedule report. Refer to the latest version of

the Crestron D3 Pro Reference Guide (Doc. 5998) available from the Crestron web

site (www.crestron.com) for detailed information about D3 Pro.

Design Guide – DOC. 5999A Lighting Control System Design • 7

Page 12

Control System Crestron Lighting

Step 2: Module Selection

The enclosure mounted Crestron modules, connected to the appropriate terminal

block, perform pre-determined functions with various types of light sources, motors

and non-lighting loads. Modules have a Cresnet link for control processor

communication and a module override connection. Six different modules are

available. The type of load, number of circuits, required current load capacity, and

economic considerations are all determining factors when choosing modules. The

number and type of modules is determined from the load schedule. The number of

required modules will determine the size and type of enclosure(s) in the next step.

Each module is wired via the terminal block to a circuit breaker (provided by others).

The power provided to the module is distributed to all of its outputs. Each module

contains relays that provide an individual air gap for each controlled high voltage

circuit. Module selection can be done manually or by the D3 Pro software.

NOTE: A module terminal block (CLT-Series device) must also be ordered for each

module. The corresponding CLT terminal block is installed in the enclosure for high

voltage wire termination. Each terminal block includes a terminal rail for mounting

the terminal block in the enclosure. Terminal rails and blocks do not occupy a

module space within an enclosure.

CLX-2DIM2 Module Specifications

Oversized heat-sink fins on the face of the module provide superior heat dissipation,

eliminating heat related failures. The modules incorporate spit-bobbin transformers

and ground reference electronics for superior performance. AC line noise

interference and lamp flicker are eliminated by an innovative zero-crossing detection

technique and unique Crestron firmware. The red LEDs on the side of the module

indicate the presence of voltage to the module output. The brightness of the LED

corresponds to brightness of the lights. The green and amber Cresnet

communications LEDs indicate both power and communication.

Module Specifications

CLX-2DIM2 has two input feeds and two large capacity dimmers. This module

handles larger loads like chandeliers, landscape lights, and loads using many

transformers or 2-wire ballasts. Each output circuit is limited to 1920 watts (16A).

Load Type Incandescent, magnetic low-

voltage, neon and cold cathode

lighting, and 2-wire fluorescent

ballasts

Module Output 2 controlled circuits, 16A per

controlled circuit, 32A total

Heat Dissipation

Terminal Block

Input Voltage

Size (H x W x D)

Temperature Range

Humidity Range

Weight

170 BTU/Hr (with full load)

CLT-2DIM2

Two 120 VAC 60 Hz, singlephase (same phase)

7 3/8 x 6 7/8 x 3

32 – 104° F

10 – 90% RH (non condensing)

3 lbs.

8 • Lighting Control System Design Design Guide – DOC. 5999A

Page 13

Crestron Lighting Control System

CLX-1DIM4 is a workhorse module with one input feed and four controlled

dimmers. Ideal for a small mix of loads where some loads are 500W or more. The

single input feed limits the total output of all four controlled dimmer circuits to 1920

watts (16A).

CLX-1DIM4 Module Specifications

Load Type Incandescent, magnetic low-

voltage, neon and cold

cathode lighting, and 2-wire

fluorescent ballasts

Module Output 4 controlled circuits,16A per

controlled circuit, 16A total

Heat Dissipation

Terminal Block

Input Voltage

Size (H x W x D)

Temperature

Range

Humidity Range

Weight

98 BTU/Hr (with full load)

CLT-1DIM4

120 VAC 60 Hz, single-phase

7 3/8 x 6 7/8 x 3

32 – 104° F

10 – 90% RH (non

condensing)

3 lbs.

CLX-1DIM8 Module Specifications

CLX-1DIM8 is best used for multiple small incandescent loads. It is economical to

use only six or seven channels on the module with small loads, while leaving some

channels unconnected. The single input feed limits the total output of all eight

controlled dimmer circuits to 1920 watts (16A).

Load Type Incandescent, magnetic low-

voltage, neon and cold cathode

lighting, and 2-wire fluorescent

ballasts

Module Output 8 controlled circuits, 16A per

controlled circuit, 16A total

Heat Dissipation

Terminal Block

Input Voltage

Size (H x W x D)

Temperature

101 BTU/Hr (with full load)

CLT-1DIM8

120 VAC 60 Hz, single-phase

7 3/8 x 6 7/8 x 3

32 – 104° F

Range

Humidity Range

Weight

10 – 90% RH (non condensing)

3 lbs.

Design Guide – DOC. 5999A Lighting Control System Design • 9

Page 14

Control System Crestron Lighting

The CLX-4HSW4 switching module can switch four 16A lighting circuits as well as

½ HP (maximum) motors. Loads are switched on and off, but not dimmed. The

maximum load is four controlled circuits per module and 1920 watts (16A) per

controlled circuit (64A maximum total).

CLX-4HSW4 Module Specifications

Load Type INC, MLV, NCC and non-dim

fluorescent, non-dim H.I.D.

Module Output 4 controlled circuits, 16A (1/2

HP) per controlled circuit, 64A

total

Heat Dissipation

Terminal Block

Input Voltage

Size (H x W x D)

Temperature Range

Humidity Range

Weight

42 BTU maximum

CLT-4HSW4

Four 120 VAC 60 Hz, singlephase (same phase)

7 3/8 x 6 7/8 x 3

32 – 104° F

10 – 90% RH (non condensing)

3 lbs.

CLX-1MC4 Module Specifications

The CLX-1MC4 controls up to four 10A (½ HP) maximum bi-directional motors.

High-voltage window treatment motor controls are assigned to CLX-1MC4. The

single input feed limits the total output of all eight controlled dimmer circuits to

1920 watts (16A).

Load Type

Module Output 4 controlled circuits,

Heat Dissipation

Terminal Block

Input Voltage

Size (H x W x D)

Temperature Range

Humidity Range

Weight

3-wire bi-directional motors

10A (1/2 HP) per motor load (5A

each direction), 16A total

22 BTU/Hr

CLT-1MC4

120 VAC 60 Hz,

single-phase

7 3/8 x 6 7/8 x 3

32 – 104° F

10 – 90% RH (non condensing)

3 lbs.

10 • Lighting Control System Design Design Guide – DOC. 5999A

Page 15

Crestron Lighting Control System

T

L

l

i

T

r

t

G

g

The CLX-1FAN4 controls up to four independent ceiling fans with four preset

speeds in addition to off. The maximum load is four 2A ceiling fans motors per

module. Lights for ceiling fans are assigned to a DIM type module and are wired

independently.

CLX-1FAN4 Module Specifications

Load Type

Module Output 4 controlled circuits, 2A per

Terminal Block

Input Voltage

Size (H x W x D)

Temperature

Range

Humidity Range

Weight

Ceiling fan (1 per controlled circuit)

controlled circuit, 8A total

4 speeds plus off.

CLT-1FAN4

120 VAC 60 Hz,

single-phase

7 3/8 x 6 7/8 x 3

32 – 104° F

10 – 90% RH (non condensing)

3 lbs.

Terminal Blocks (CLT-Series)

he Crestron terminal block is mounted within an enclosure and has two functions.

1. Terminates the circuit feed (HOT and NEUTRAL) supplied by circuit

breaker and distributes the controlled circuits (LOAD) to the fixtures.

2. Serves as a test point and interface to the lighting module. Bypass

jumpers on the terminal block allow the testing of circuits and protect

the module during installation.

eft and right wiring labels are provided with each terminal block. The wiring

abels are positioned in between the terminal block and enclosure to provide

dentification of each terminal block section.

he left-side labels are common for both single and double-width enclosures. The

ight-side labels are only used in double-width enclosures because the modules and

erminal blocks along the right side must be inverted when installed.

rounding terminal blocks (provided with the CAEN enclosures) permit the

round wire termination.

CLT-Series Specifications

Item Specification

Line Voltage Wiring

Terminal Block

Grounding Terminal

Block

Use copper conduct ors only – rated 75° C

Accepts one 14 to 10 AWG wire. Wires should be

stripped to ½ inch. Tighten terminal blocks to 9 in/lbs

14 to 10 AWG – Tighten to 35 in/lbs

8 AWG – Tighten to 40 in/lbs

6 to 4 AWG – Tighten to 45 in/lbs

Design Guide – DOC. 5999A Lighting Control System Design • 11

Page 16

Control System Crestron Lighting

Step 3: Enclosure Selection

Crestron home automation enclosures contain the control devices of the lighting

control system (excluding the user interfaces). These enclosures also provide a

centralized location in which to install other home automation equipment. Crestron

enclosures are constructed of 16-gauge galvanized steel and are UL and C-UL listed.

Enclosures can be flush mounted or surface mounted.

The wide range of sizes, mounting options, and convenient electrical knockouts,

ensure mounting location flexibility, efficiency and an orderly installation.

NOTE: CAEN-Series enclosures are required to install CLX-Series lighting

modules.

The lighting designer identifies the CAEN-Series enclosure(s) required, based on the

number of module spaces counted in step 2 and the AC power distribution of the

system. Enclosures may be all centrally located in one area or distributed throughout

the home. Distributing the enclosures throughout the home reduces the run-length of

high-voltage wires to the loads.

Enclosures have a specific number of module spaces for CLX-Series modules, the

control processor, and CAEN-UMP mounting plates.

Enclosures that do not contain a PAC2 control processor require a CAEN-BLOCK

communications link, which is installed in the bottom of the enclosure and not

installed in a module slot. Therefore the CAEN-BLOCK is not included in the

calculation of enclosure size.

Consider selecting enclosures with excess room to accommodate system

improvements and expansion. Crestron recommends selecting an enclosure that has

at least one more space than needed, allowing for changes in modules or lighting

fixtures. A larger enclosure also enhances air-cooling.

The CAEN-7x2 is the largest and most economical enclosure, containing up to 12

modules and a PAC2 processor. Without the PAC2, this enclosure can hold up to 14

modules (assuming a fully loaded enclosure with 14 CLX-1DIM8s, a maximum of

112 dimmers).

There are occasions when a separate enclosure is desired for the PAC2. The

processor can be located in a more accessible location with better temperature

control and easier access to the wiring. In this situation, Crestron recommends using

the CAEN-2x1 enclosure for the PAC2.

Single-width enclosures fit between 16” on-center stud framing. Using several

CAEN-7x1 enclosures, flush mounted between the studs, creates a clean, in-wall

installation. When surface mounting the enclosures, allow at least 6” (15cm) side-toside clearance between enclosures.

The design of the CAEN-Series enclosures separates high-voltage and low-voltage

wiring when the control processor is installed. The low-voltage openings in the

bottom of the enclosure are insulated to protect low-voltage wires from cuts and

scrapes. The airflow through the perforated cover assists in the dissipation of heat.

Refer to the following tables for a listing of dimensions and maximum number of

modules that can be contained in each CAEN-Series enclosure.

12 • Lighting Control System Design Design Guide – DOC. 5999A

Page 17

Crestron Lighting Control System

CAEN-Series Specifications

CAEN Specifications 7x2 7x1* 4x2 4x1* 2x1*

Module Capacity

Required Flush Mount

25 ½” x 62” 14 ⅜” x 62” 25 ½” x 38 ⅞” 14 ⅜” x 38 ⅞” 14 ⅜” x 23 ½”

Opening (W) x (H)

Construction

Regulatory Approvals

Mounting

CAEN-Series Dimensions (Front and Side Views)

W1

W3

W6

H2

H3

W3

W2

W4

H1

W5

14 7 8 4 2

16 gauge galvanized sheet metal

Cover is painted metal with ventilation holes

UL and C-UL listed

Surface or flush mounted

*Single-width enclosures fit between standard 16” on-center studs

CAEN

Dimensions

1

H1

H2

H3

W1

W2

W3

W4

W55

W6

D1

Cover Thickness

Cover Height

Cover Width

Weight2 Empty3

Weight Full4

D1W3

1. Length is in inches.

2. Weight is in pounds.

3. Weight Empty includes the cover.

4. Weight Full is with the maximum number of modules installed.

5. The lower keyholes are not symmetrically spaced in single-width enclosures.

7x2 7x1 4x2 4x1 2x1

62 38 ⅞ 23 ½

2 11/16 2 ⅛

56 32 ⅞ 34 18 ⅝

26 ½ 15 ⅜ 26 ½ 15 ⅜

25 ½ 14 ⅜ 25 ½ 14 ⅜

2 ½ 1 ¾ 2 ½ 1 ¾

20 ½ 10 ⅞ 20 ½ 10 ⅞

20 ½ 9 ⅞ 20 ½ 9 ⅞

2 ½ 2 ¾ 2 ½ 2 ¾

4 ⅛

1

/16

62 ¾ 39 ⅝ 24 ¼

27 ¼ 16 ⅛ 27 ¼ 16 ⅛

65 42 43 28 19

155 88 95 55 31

Design Guide – DOC. 5999A Lighting Control System Design • 13

Page 18

Control System Crestron Lighting

Step 4: User Interface Selection

User interfaces (keypads, dimmers, switches, and touchpanels) provide the link

between the control devices in the enclosure and the user. Typically these interfaces

are prominently and strategically located throughout a lighting design.

NOTE: Due to the variety of touchpanels, dimmers, switches and keypads,

specifications for each type are not provided as part of this guide. Instead obtain the

latest copy of the individual operation guide from the Crestron website

(www.crestron.com).

The lighting designer specifies the type of user interface required for each location,

based on function and user preference.

Keypads, touchpanels, dimmers and switches are available in a wide variety of

choices, including number of buttons, color of trim, color of the buttons, back

lighting and even custom engraving on each button.

The entire line of award-winning Crestron touchpanels can be used to enhance the

most demanding design.

C2N-DB Series Wall Panels

The C2N-DB6/8/12-series Decorator Wall Panels are wall-mounted, single-gang

user interfaces that can be part of a Crestron solution. The panels are standard

Cresnet devices providing fingertip control when the control system is properly

programmed using Crestron’s SIMPL Windows, Application Builder, or D3 Pro

software. The number in the product’s name corresponds to the number of buttons on

the panel. Each of these panels is available in three colors: almond, black, and white.

A letter at the end of the product name, ‘A’, ‘B’, or ‘W’, denotes the color; e.g.,

C2N-DB12B is a black, 12-button unit.

Faceplates are not supplied; the wall panels accept decorator style faceplates that can

be obtained in any store selling lighting supplies and accessories, making it easy for

the wall panels to match the appearance of the site’s other switch and outlet styles.

Custom-engraved keys can be designed and obtained by using the Crestron Engraver

software. Version 2.1.0.1 or later is available from the Downloads | Software

Updates section of the Crestron website (www.crestron.com).

All buttons on the wall panel are functionally identical and have light emitting diodes

(LEDs) that serve as user feedback indicators. Each LED’s illumination (on/off) is

independently addressable, and is programmable using SIMPL Windows. The

intensity level for the button LEDs can be set from 0 to 100%.

14 • Lighting Control System Design Design Guide – DOC. 5999A

Page 19

Crestron Lighting Control System

6, 8, and 12 button C2N-DB Series Wall Panels

Physical View of the C2N-DB Wall Panel

Side View

with buttons installed

1.53 in

(3.89 cm)

1.07 in

(2.72 cm)

4.16 in

(10.57 cm)

Front View

with buttons removed

1.79 in

(4.55 cm)

Rubber

Membrane

Back View

1.67 in

(4.24 cm)

2.70 in

(6.86 cm)

Cresnet

port

Design Guide – DOC. 5999A Lighting Control System Design • 15

Page 20

Control System Crestron Lighting

CNX Series Keypads

Crestron keypads are a wall-mounted user interface. The keypads feature oversized

buttons that provide positive feedback. The user can have the ability to control

individual lights or groups of lights and create a predetermined “lighting scene” for

particular activities. Keypads are Cresnet devices and programmable using SIMPL

Windows or the Crestron D3 Pro software. The product name corresponds to the

number of keypad buttons. For example, CNX-B6 is a six-button keypad and a

CNX-B12 is a 12-button keypad.

The CNX-B series keypads have a uniquely stylish shape and faceplates are

available for the most common groupings; single, double, or three gang plate

arrangements. Keypads are available with the following features:

• Available with 2, 4, 6, 8, or 12 buttons.

• Colors include white, almond, or black.

• Metal faceplate options:

- Black Chrome - Brushed Gold

- Polished Black - Polished Gold

- Polished Brass - Stainless Steel

• Primed faceplate available.

• All keypads can be custom engraved.

• All keypad buttons are backlit capable and have an LED that serves as a

user feedback indicator. Status LEDs are controlled via SIMPL

programming or the Crestron D3 Pro software. The illumination of each

LED is independently addressable and programmable. Each LED can be

programmed to dim at night and return to full intensity during the day.

• Each keypad requires 3 watts of power.

• Crestron keypads can be ganged in one, two or three gang configurations

and are mounted in standard electrical junction boxes. Custom multi-gang

plates are required.

Physical View of the CNX-B12 Keypad

1.07 in

(2.71 cm)

4.76 in

(12.10 cm)

2.91 in

(5.57 cm)

1.54 in

(3.90 cm)

16 • Lighting Control System Design Design Guide – DOC. 5999A

Page 21

Crestron Lighting Control System

Wall Dimmers

The CLW-DIM is a stand-alone wall box dimmer that can also act as a Cresnet

device that reports to a Crestron control processor. The CLW-DIM has four preset

lighting levels that can be adjusted (refer to note below). The CLW-DIM also

includes two isolated, non-polarized Cresnet wires (plus a ground wire) for

connecting to the Cresnet network over a twisted pair wire with shield.

NOTE: The four preset levels are noted as Button 1-High, Button 1-Low, Button

Preset 2, and Button Preset 3. Preset “Button 1-High” is usually used for turning

lights on to full brightness while preset “Button 1-Low” is usually used for turning

the lights off. Although “1-High” and “1-Low” are usually used for “On” and “Off”

respectively, the light level for each preset can be customized by the user. Refer to

the CLW-DIM, DIMS, & SLVD Operation Guide (Doc. 5995) for more information

on installation and customizing light levels.

The CLW-DIM features a three-position mode selection switch. In the absence of

Cresnet communications, the dimmer can still be used to control lighting.

The CLW-DIMS is similar to the CLW-DIM with the added capability of working

with a slave unit

The CLW-SLVD is a slave unit that when used in conjunction with the CLW-DIMS

acts as an additional dimmer control point in a multi-dimmer / single circuit

application. It does not connect to a Cresnet system and cannot be used without a

CLW-DIMS. The CLW-SLVD does not have a mode selection switch and is not

programmable. It emulates the operation of the CLW-DIMS to which it is connected.

The CLW-DIM, CLW-DIMS, and CLW-SLVD are available in white (designated by

part numbers ending in “W”), almond (designated by part numbers ending in “A”,

and black (designated by part numbers ending in “B”). Each dimmer can be covered

with a decorative faceplate (not supplied).

The CLW-DIM, CLW-DIMS, and CLW-SLVD mount in a standard wallbox and are

covered using a decorator-style faceplate (not included).

CLW-DIM, CLW-DIMS, & CLS-SLVD Specifications

SPECIFICATION DETAILS

Power Requirements Line Power (120 VAC, 60 Hz)

Load Type Incandescent, Tungsten-Halogen, Magnetic Low Voltage

Load Ratings

Incandescent/Tungsten Halogen 1000 W (800 W)

Magnetic Low Voltage 1000 VA / 750 W (800 VA / 600 W)

Operating Temperature and

Humidity

32°F to 104°F (0°C to 40°C)

10 to 90% Relative Humidity (Non-Condensing)

NOTE: VA ratings are for input power to the transformer. If you do not know the

input power requirement of the transformer, use the bulb’s wattage rating to

determine proper rating.

NOTE: Operating temperature affects load ratings. Refer to the Load Rating

specification in the table above for specific operating temperatures. Ratings are given

for 32°F to 86°F (0°C to 30°C) and 32°F to 104°F (0°C to 40°C) operation. Ratings

for 32°F to 104°F (0°C to 40°C) are in parentheses.

Design Guide – DOC. 5999A Lighting Control System Design • 17

Page 22

Control System Crestron Lighting

Derating

In a multi-gang installation, several dimmers are grouped in one horizontal wall box.

When this is the case, the inner heat sink section is removed to permit the installation

of a one-piece multi-gang wallplate. Removing the heat sink reduces the current

carrying capability of the dimmers due to reduced heat dissipation. The following

table provides the derating information for this application.

Application No Heat Sink Removed

– Single Unit

One Heat Sink Removed

– Two Gang

Both Heat Sinks Removed

– Three or more Gang

Incandescent and Tungsten

Halogen

Magnetic Low Voltage 1000 VA / 750 W

1000 W (800 W) 600 W (450 W) 400 W (300 W)

(800 VA / 600 W)

For additional installation information, refer to the CLW-DIM, DIMS & SLVD

Installation Guide (Doc. 5995).

Physical View of CLW-DIM and CLW-DIMS (clockwise from top; Top, Side, and Front)

600 VA / 450 W

(450VA / 300 W)

400 VA / 300 W

(300 VA / 200 W)

18 • Lighting Control System Design Design Guide – DOC. 5999A

Page 23

Crestron Lighting Control System

Physical View of CLW-SLVD (clockwise from top; Top, Side, and Front)

Design Guide – DOC. 5999A Lighting Control System Design • 19

Page 24

Control System Crestron Lighting

Switches

The CLW-SW wall box switch can also act as a Cresnet device reporting to a

Crestron control processor. The CLW-SW includes two isolated, non-polarized

Cresnet wires (plus a ground wire) for connecting to a Cresnet system over a twisted

pair wire with shield. In the absence of Cresnet communications, the switch can still

be used to control a load.

Refer to the CLW-SW, CLW-SWS, & CLS-SLVS Installation Guide (Doc. 6134)

for more installation information.

The CLW-SWS is similar to the CLW-SW with the added capability of working

with a slave unit (CLW-SLVS) in a multi-switch / single circuit application.

The CLW-SLVS is a slave unit that when used in conjunction with the CLW-SWS

acts as an additional switch control point in a multi-switch / single circuit

application. It does not connect to a Cresnet system and cannot be used without a

CLW-SWS. The CLW-SLVS does not have a mode selection switch and is not

programmable. It emulates the operation of the CLW-SWS to which it is connected.

The CLW-SW, CLW-SWS, and CLW-SLVS are available in white (designated by

part numbers ending in “W”), almond (designated by part numbers ending in “A”),

and black (designated by part numbers ending in “B”). These switches can be

covered with a decorative faceplate (not supplied).

CLW-SW, CLW-SWS, & CLS-SLVS Specifications

SPECIFICATION DETAILS

Power Requirements Line Power (120 VAC, 60 Hz)

Switch Type Single-Pole, Single-Throw

Load Type Incandescent, Tungsten Halogen, Fluorescent,

Load Ratings

Incandescent / Tungsten Halogen 1000 W (800 W)

Magnetic Low Voltage 1000 VA / 750 W (800 VA / 600 W)

Neon / Cold Cathode 1000 VA / 750 W (800 VA / 600 W)

Electronic Low Voltage 1000 W (800 W)

Fluorescent / HID

(High Intensity Discharge)

General Purpose Fan 3.0 A (3.0 A)

Minimum Load 40W / 0.5A

Operating Temperature and Humidity 32°F to 104°F (0°C to 40°C)

Electronic Low Voltage, Magnetic Low Voltage,

General Purpose Fan

8 A (6.5 A)

10 to 90% Relative Humidity (Non-Condensing)

NOTE: VA ratings are for input power to the transformer. If you do not know the

input power requirement of the transformer, use the bulb’s wattage rating to

determine proper rating.

NOTE: Operating temperature affects load ratings. Refer to the Load Rating

specification in the table above for specific operating temperatures. Ratings are given

for 32°F to 86°F (0°C to 30°C) and 32°F to 104°F (0°C to 40°C) operation. Ratings

for 32°F to 104°F (0°C to 40°C) are in parentheses.

20 • Lighting Control System Design Design Guide – DOC. 5999A

Page 25

Crestron Lighting Control System

NOTE: Refer to the latest version of the Installation Guide (Doc. 6134) for derating

information in multi-gang applications, available on the Crestron website,

www.crestron.com.

Physical View of CLW-SW/SWS (clockwise from top; Top, Side, and Front)

Physical View of CLW-SLVS (clockwise from top; Top, Side, and Front)

Design Guide – DOC. 5999A Lighting Control System Design • 21

Page 26

Control System Crestron Lighting

Touchpanel Selection

CT-1000

TPS-2000L

Crestron touchpanels are graphical user interfaces that provide the user with visual

control and feedback.

Touchpanels are an elegant, efficient and practical solution to room control. A

touchpanel can control lighting, audio and video, HVAC, and security.

Touchpanel pages can provide convenient control of every individual light in the

residence from a single location. The integration of touchpanels and lighting control

is a primary feature of Crestron lighting systems. The designer can create a complex

control environment while presenting the user with easy and intuitive controls.

For example, a "Good Night" button can be programmed to dim the lights, gently

quiet the music, notify the alarm system, and set a nighttime temperature. All with

one touch.

Designed using VT-Pro-e software, these user interfaces can be customized to

provide complete control of the lighting control system and the entire home

automation system.

Consult lightingsolutions@crestron.com

Physical Views of Series 1000 Touchpanel

4.86 in

(12.34 cm)

4.76 in

(12.10 cm)

for additional information.

1.59 in

(4.04 cm)

1.36 in

(3.47 cm)

22 • Lighting Control System Design Design Guide – DOC. 5999A

Page 27

Crestron Lighting Control System

Physical Views of TPS-2000L Touchpanel

3.43 in

(8.71 cm)

3.07 in

6.73 in

(17.10 cm)

4.76 in

(12.10 cm)

(7.79 cm)

Crestron touchpanels are available as either wired or wireless units, with screens

from 3.8” diagonal to 15” diagonal. Many Crestron touchpanels also feature buttons

that can be custom engraved and programmed to provide quick access to

programmed functions. The built-in speakers can play .WAV files provided by the

programming.

Step 5: Wiring Plan

The wiring plan includes all enclosures and the interconnecting wiring.

The designer determines the location of the enclosure(s), the route of keypad and

touchpanel connections to the enclosure(s), the route of the interconnecting cable

from the processor to the other enclosure(s), and the high voltage load routes to the

enclosure or dimmer.

Ensure there are enough connectors and power (PAC2 offers 50W) in the main

enclosure for all the user interfaces. Each enclosure filled with dimmers is connected

to the main enclosure and processor using low voltage wire. Dimmer enclosures are

distributed as needed.

Design Guide – DOC. 5999A Lighting Control System Design • 23

Page 28

Control System Crestron Lighting

Wiring Plan Details

Location Device Type Crestron Device

Room 1 DIM1 – Wall dimmer – 100 Watts CLW-DIM

Room 2 DIM4 – Wall dimmer – 150 Watts CLW-DIM

Room 2 DIM5 – Wall dimmer – 150 Watts CLW-DIMS

Room 2 SW1 – Wall Box switch – Low voltage/outdoor CLW-SW

Room 2 Touchpanel TPS-1000

Room 3 DIM2 – Wall dimmer – 100 Watts CLW-DIM

Room 3 DIM3 – Wall Dimmer – 100 Watts CLW-DIMS

Room 4 DIM6 – Wall dimmer – 200 Watts CLW-DIM

Room 5 DIM7 – Wall dimmer – 120 Watts CLW-DIM

Room 5 KP1 – Wall Keypad – Fan Motor Speed CLX-1FAN4

Step 6: Control Processor

The PAC2 has been specifically designed for the Crestron automation enclosure and

the Crestron lighting system, although other Crestron processors can also be used.

The PAC2 can be placed in its own enclosure for simplification of low-voltage

wiring. The PAC2 occupies one module space in single-width enclosures and two

module spaces in double-width enclosures.

24 • Lighting Control System Design Design Guide – DOC. 5999A

Page 29

Crestron Lighting Control System

)

The PAC2 processor provides 50W of power for keypads and touchpanels. Each

keypad in the CNX-B series uses 3-watts, therefore only 15 keypads can be

connected without adding another power supply. Make sure there is sufficient power

in the system design to accommodate all the keypads, touchpanels, voltage drops,

and wire runs. Additional power supplies should not be mounted on CAEN-UMP

plates in an enclosure that contains dimmer units because this introduces low-voltage

in the high-voltage section of the enclosure. If required, an extra power supply,

attached to a CAEN-UMP plate, can be added to a separate CAEN enclosure.

Crestron recommends the C2N-SPWS300 Power Supply; a 300-watt system power

supply designed for large Cresnet control systems. It operates with an input of 100 to

240 VAC, 4A (maximum) and a noise rating less than 150mV. The C2N-SPWS300

provides regulated 24 VDC, 300 W to Cresnet system components. The C2NSPWS300 is capable of delivering a nominal 75 watts of power at 24 volts DC on

any of its eight channels.

The PAC2 connects all the user interfaces:

• Keypads and wall switches

• touchpanels

• contact closures

• emergency switches

• override switches

• backup Cresnet controller input

• output relays

• fault indicator

• computer data port

The PAC2 enables the customer to efficiently control not only the lighting in their

home, but also other systems such as HVAC and security.

Physical View of the PAC2

Top View

24 Y Z G 24 Y Z G 24 Y Z G 24 Y Z G

24 Y Z G 24 Y Z G 24 Y Z G 24 Y Z G

24 Y Z G 24 Y Z G 24 Y Z G 24 Y Z G

24 Y Z G 24 Y Z G 24 Y Z G 24 Y Z G

I/O

S4

1 2 3 4 5 6 7 8 G

NET A

NET B

NET E

NET F

OVER

RIDE

(35.56 cm)

LEFT

BACKUP

NET INPUT

24 Y Z G

14.00 in

POWER

1 2

G

G

INT

EXT

POWER

3 4

G

G

INT

EXT

FAULT

F G

RIGHT

24 Y Z G 24 Y Z G 24 Y Z G 24 Y Z G

INT

EXT

24 Y Z G 24 Y Z G 24 Y Z G 24 Y Z G

24 Y Z G 24 Y Z G 24 Y Z G 24 Y Z G

INT

EXT

24 Y Z G 24 Y Z G 24 Y Z G 24 Y Z G

RELAY OUTPUT

S5

1 2 3 4 5 6 7 8

NET C

NET D

NET G

NET H

7.40 in

(18.80 cm

NET

ERR

LNK

ACT

LAN A LAN B

HW-R

PWR

SW-R

Design Guide – DOC. 5999A Lighting Control System Design • 25

Page 30

Control System Crestron Lighting

The on-board 36MB memory is enhanced with a 4GB expansion slot that supports

off-the-shelf Type II compact flash memory and the IBM Microdrive

hard disk

drive, for on-board storage of program and touchpanel files, room and equipment

profiles, upgrades, databases, and schedules.

Crestron's unique dual bus system, with its high-speed I/O bus architecture, provides

blazing fast throughput, system wide. The two 40Mb/s Y-BUS expansion slots offer

the option of installing any of the CNX-series cards listed in Crestron’s 2003 Product

Catalog, and all C2-series control cards. The 300Mb/s Z-BUS expansion slot is

designed for super high-speed control card applications such as 10/100 Ethernet,

available via Crestron’s single-port C2ENET-1 and dual-port C2ENET-2 Ethernet

cards.

The PAC2 offers eight programmable analog and digital inputs as well as digital

outputs. There are eight normally open relays, isolated with MOV suppression.

The 32 Cresnet connectors that comprise the built-in 8-segment Cresnet hub are

located on the top of the PAC2 (NET A – NET H). When powered by the internal or

external power supply, they expand the number of Cresnet devices that can be

connected to the PAC2. Each group of four connectors can electrically support up to

32 Cresnet devices. When powered by the internal power supply, there is a

maximum of 50 watts (DC) available for all network devices connected to the PAC2.

The LEDs indicate communication on the Cresnet link.

The PAC2 provides external connections for both a back-up processor and

emergency override closure signals. In the absence of Cresnet or in case of a power

failure, a signal is generated to switch power and communication of the Cresnet

system to a back-up processor. When the override connection receives a contact

closure, a signal is passed to the lighting modules via the fifth wire of the

interconnect cable, and the lights are turned on to a programmed preset emergency

level. They remain at this level until that contact closure is opened.

The PAC2 also provides true secure network communications, which is required for

today's corporate networks, automated residence systems, and the Internet. The Dual

Port 10/100 BaseT Ethernet card (C2ENET-2) will support dynamic and static IP

addressing and full duplex TCP/IP and UDP/IP. It offers a WAN port for Internet

and remote-location communications and a LAN port for local in-home use. A builtin firewall delivers network security with the Network Address Translator (NAT)

and router functions. The built-in Web Server uses memory storage on a compact

flash card for remote access and control. Refer to the PAC2 Operations Guide (Doc.

5941) for more detailed information.

PAC2 2-Series Automation Control System Specifications

SPECIFICATION DETAILS

CPU 32-Bit Motorola ColdFire® Processor

Processor Speed 257 MIPS (Dhrystone 2.1 Benchmark)

On-board Memory 36MB (4MB flash, 32MB DRAM, 256KB

NVRAM)

Expandable Memory Compact Flash Slot (up to 4GB) accepts

standard

Type II Compact Flash or IBM Microdrive®

Dual Bus Architecture

Y-BUS 40 Mb/s Parallel

Communications

Z-BUS 300 Mb/s Parallel

Communications

Table continued on the following page.

2 Expansion Card Slots

1 Expansion Card Slot

26 • Lighting Control System Design Design Guide – DOC. 5999A

Page 31

Crestron Lighting Control System

PAC2 2-Series Automation Control System Specifications (continued)

SPECIFICATION DETAILS

Ethernet (Optional Z-BUS

cards)

Ports/Connectors

NET

COMPUTER

I/O

RELAY OUTPUT

POWER

OVERRIDE

BACKUP NET INPUT

FAULT

LEFT / RIGHT

Power Requirements 100-240 VAC, 2.4 A, 50/60 Hz

Network Power Fuse Rating 4 A, 250 V (1¼” x ¼” Slow Blow Fuse Series)

Reset Buttons HWR - Initiates system hardware reset

Environmental Temperature 41° to 113°F (5° to 45°C)

Humidity 10% to 90% RH (non-condensing)

Dimensions & Weight Height: 3.75 in (9.52 cm)

Dynamic/Static IP Addressing

Full and Half Duplex TCP/IP and UDP/IP

Built-in Firewall for Security (Dual Port Only)

Built-in Network Address Translator (Dual Port

Only)

Built-in Web Server

Built-in Router –(Dual Port Only)

33 – Cresnet 4-wire interface (32 on the built-in

hub/repeater, and 1 on the front panel)

(Expandable via Cresnet Poll Accelerator)

1 – DB9F PC interface

8 – Programmable digital/analog inputs & digital

outputs

8 – Normally open, isolated relays (MOV

suppression)

4 – Internal and External power

2 – External contact closure

1 – External 2-Series control system backup

1 – To external 2-Series control system for fault

indication

2 – Lighting module interface

Internal Universal Power Supply

50 watts 24 VDC regulated maximum available

for Cresnet devices

SWR – Program Restart / Program Bypass

Width: 14.00 in (35.56 cm)

Depth: 7.40 in (18.80 cm)

Weight: 8.00 lb (3.60 kg)

Design Guide – DOC. 5999A Lighting Control System Design • 27

Page 32

Control System Crestron Lighting

Step 7: Network Block Selection

A CAEN-BLOCK, required in each enclosure that does not contain a PAC2

processor. The CAEN-BLOCK provides module connection and Cresnet

communications.

The unit has a left and right connector for communication with the CLX-Series

modules. Refer to CAEN Block Installation Guide (Doc. 5994) for additional

information.

The four passive Cresnet ports provide a convenient way to connect devices and

enclosures together. The power for each Cresnet port comes from the incoming

Cresnet line. Verify that the incoming Cresnet line has sufficient power for all

connected devices.

Two OVERRIDE ports are activated from dry closure switches. When a switch

contact closure is received between the "G" connection and the "L" or "R"

connections, the respective left or right column of modules will set the lights to the

programmed override state.

CAEN-BLOCK

LEFT

ZY24 G

CRESTRON

SINGLE WIDTH CABINET

DOUBLE WIDTH CABINET

NET

ZY24 G

ZY24 G G L R

ZY24 G

RIGHT

OVER RIDE

G L R

CAEN-BLOCK

Network Block Dimensions & Weight

Dimensions

Weight

2 in (H) x 6 in (W) x 1 ¾ in (D)

3.4 oz

This unit is a pass-through device with a Cresnet power factor of zero.

28 • Lighting Control System Design Design Guide – DOC. 5999A

Page 33

Crestron Lighting Control System

Step 8: Accessories Selection

The Crestron complete line of universal accessory mounting plates are provided for

designers who wish to integrate custom items into the CAEN enclosure, including

any non-Crestron equipment (third-party products such as phone and alarm systems).

This simplifies adding items to the enclosure.

Ensure that the addition of any items to the CAEN enclosure is done in accordance

with all National and local electrical codes. Additional CAEN enclosures can be used

with CAEN-UMP plates(s) to facilitate any required separation codes.

CAEN-UMP is available in a variety of sizes, and occupies the same area as one, two

or four Crestron lighting modules. Plate size corresponds to the number of module

spaces and their arrangement within the enclosure.

CAEN-UMP-Series Specifications (Shown with a CAEN-7x2 enclosure)

CAEN-UMP 2 x 2 2 x 1 1 x 2 1 x 1

1

15

1x1 1x1

1x2

2x1 2x1

Height

Width

Depth

Weight

Number of

Module Positions

Occupied

14 in 6 15/16 in 14 in 6 15/16 in

22.6 oz 12.0 oz 12.4 oz 6.6 oz

4 2 2 1

/8 in 7 7/16 in

5

/8 in

2x2

Design Guide – DOC. 5999A Lighting Control System Design • 29

Page 34

Control System Crestron Lighting

Basic Lighting System Interconnections

A Crestron Lighting System

30 • Lighting Control System Design Design Guide – DOC. 5999A

Page 35

Crestron Lighting Control System

Ordering a Crestron Lighting Control System

Hardware

These are the steps for ordering a Crestron lighting control system, regardless of the

size. Each system and module contains the appropriate installation literature and

operation guide.

Steps to order a lighting system:

STEP 1: Survey all lights and loads to be controlled.

STEP 2: Determine the number and types of modules and terminal blocks

needed to control lights and loads based on the load schedule and

wiring plan.

STEP 3: Determine the number and type of CAEN enclosures required

STEP 4: Determine the number of keypads, wall panels, and touchpanels.

STEP 5: Determine the wiring accessories, cabling and power supplies required.

STEP 6: Determine the number of control processors required.

STEP 7: Determine the number of CAEN-BLOCKs required for all components

and locations.

STEP 8: Determine the number and type of accessory plates required.

STEP 9: Place an order for Crestron items as identified in steps 2-8.

Crestron ships all items to the jobsite for assembly and wiring.

Programming

The lighting system designer finalizes the implementation of the lighting control

system with the Crestron D3 Pro System Programming software package or with

SIMPL Windows for the more advanced Cresnet programmers.

Crestron D3 Pro Software provides all the tools necessary to create a complete

Crestron Lighting System for residential applications. The lighting system includes

the control system program, touchpanel screens and keypad programming,

documentation, and real-time lighting adjustment capabilities. As with all Crestron

software, the D3 Pro software provides extensive right-click and drag-and-drop

functionality, in addition to convenient keyboard shortcuts for frequently used

functions and commands.

D3 Pro is organized into six views of the lighting system, each displaying a program

detail area, a toolbox of devices such as interfaces, fixtures, and modules, and a

system directory of devices arranged by location. You can add a device to your

system simply by selecting it from the toolbox and dragging it to a room in the

system directory. The available devices differ depending on the view, but all the

views have a general toolbox that allows you to add areas and rooms at any time.

Refer to the latest version of the Crestron D3 Pro Reference Guide (Doc. 5998)

available from the Crestron web site (www.crestron.com) for detailed information

about D3 Pro.

Design Guide – DOC. 5999A Lighting Control System Design • 31

Page 36

Control System Crestron Lighting

Example Lighting System

This example is based on the following typical wiring plan.

32 • Lighting Control System Design Design Guide – DOC. 5999A

Page 37

Crestron Lighting Control System

Enter the information into D3 Pro, and the software can generate the following load schedule reports.

Load Schedule

Project: AV Sample Residence Dealer: Crestron

Creator: Crestron D3 Pro v1.2.1

Description:

Date: 11/4/2003 System Number: 1

Area Room

Main

Bathroom 1 Downlights 009 Downlights Incandescent yes no 100 1 100

Floor

Main

Bathroom 1 Downlights 2 008 Downlights Incandescent yes no 100 2 200

Floor

Main

Bathroom 1 Downlights 3 006 Downlights Incandescent yes no 100 2 200

Floor

Main

Bathroom

Floor

Main

Bathroom 1 Exhaust Fan 007 Exhaust

Floor

Main

Bathroom 2 Downlights 011 Downlights Incandescent yes no 100 1 100

Floor

Main

Bathroom 2 Downlights 2 010 Downlights Incandescent yes no 100 3 300

Floor

Main

Bathroom

Floor

Main

Bathroom 2 Exhaust Fan 012 Exhaust

Floor

Main

Floor

Main

Floor

Main

Floor

Main

Floor

Main

Floor

Main

Floor

Main

Floor

Main

Floor

Main

Floor

Main

Floor

Main

Floor

Bedroom Ceiling Fan 022 Ceiling Fan Ceiling Fan no no 100 1 100

Bedroom Downlights 005 Downlights Incandescent yes no 250 2 500

Bedroom Downlights 2 004 Downlights Incandescent yes no 100 4 400

Bedroom Downlights 3 003 Downlights Incandescent yes no 100 1 100

Bedroom Downlights 4 002 Downlights Incandescent yes no 100 1 100

Bedroom Downlights 5 001 Downlights Incandescent yes no 100 2 200

Bedroom Drapes 018 Drapes 3-Wire Motor no no 200 1 200

Bedroom Drapes 2 017 Drapes 3-Wire Motor no no 200 1 200

Bedroom Drapes 3 016 Drapes 3-Wire Motor no no 200 1 200

Foyer Downlights 013 Downlights Incandescent yes no 100 4 400

Sauna Drapes 020 Drapes 3-Wire Motor no no 200 1 200

Controlled Ckt

Name

Drapes 019 Drapes 3-Wire Motor no no 200 1 200

1

Drapes 021 Drapes 3-Wire Motor no no 200 1 200

2

Controlled Ckt

No. Fixture Load Type Dim Emergency

Switched no no 200 1 200

Fan

Switched no no 200 1 200

Fan

*Calculation of load wattage includes transformer loss.

Fixture

Watts

Fixture

Qty

Total

Watts

Design Guide – DOC. 5999A Lighting Control System Design • 33

Page 38

Control System Crestron Lighting

Load Schedule w/ Panel Terminations

Project: AV Sample Residence Dealer: Crestron

Creator: Crestron D3 Pro v1.2.1

Description:

Date: 11/4/2003 System Number: 1

Area Room

Main

Bathroom 1 Downlights 009 Downlights Incandescent yes no 100 1 100 Enclosure 1 2 CLX-

Floor

Main

Bathroom 1 Downlights 2 008 Downlights Incandescent yes no 100 2 200 Enclosure 1 2 CLX-

Floor

Main

Bathroom 1 Downlights 3 006 Downlights Incandescent yes no 100 2 200 Enclosure 1 2 CLX-

Floor

Main

Bathroom 1 Drapes 019 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 4 CLX-

Floor

Main

Bathroom 1 Exhaust Fan 007 Exhaust

Floor

Main

Bathroom 2 Downlights 011 Downlights Incandescent yes no 100 1 100 Enclosure 1 2 CLX-

Floor

Main

Bathroom 2 Downlights 2 010 Downlights Incandescent yes no 100 3 300 Enclosure 1 2 CLX-

Floor

Main

Bathroom 2 Drapes 021 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 4 CLX-

Floor

Main

Bathroom 2 Exhaust Fan 012 Exhaust

Floor

Main

Bedroom Ceiling Fan 022 Ceiling

Floor

Main

Bedroom Downlights 005 Downlights Incandescent yes no 250 2 500 Enclosure 1 2 CLX-

Floor

Main

Bedroom Downlights 2 004 Downlights Incandescent yes no 100 4 400 Enclosure 1 3 CLX-

Floor

Main

Bedroom Downlights 3 003 Downlights Incandescent yes no 100 1 100 N / A N / A Interface 6 1

Floor

Main

Bedroom Downlights 4 002 Downlights Incandescent yes no 100 1 100 N / A N / A Interface 5 1

Floor

Main

Bedroom Downlights 5 001 Downlights Incandescent yes no 100 2 200 Enclosure 1 3 CLX-

Floor

Main

Bedroom Drapes 018 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 4 CLX-

Floor

Main

Bedroom Drapes 2 017 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 4 CLX-

Floor

Main

Bedroom Drapes 3 016 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 5 CLX-

Floor

Main

Foyer Downlights 013 Downlights Incandescent yes no 100 4 400 Enclosure 1 2 CLX-

Floor

Main

Sauna Drapes 020 Drapes 3-Wire Motor no no 200 1 200 Enclosure 1 5 CLX-

Floor

Controlled

Ckt Name

Controlled

Ckt No. Fixture Load Type Dim Emergency

Switched no no 200 1 200 N / A N / A Interface 2 1

Fan

Switched no no 200 1 200 N / A N / A Interface 4 1

Fan

Ceiling Fan no no 100 1 100 Enclosure 1 6 CLX-

Fan

Fixture

Watts

Fixture

Total

Qty

Watts Enclosure Slot Module Output

*Calculation of load wattage includes transformer loss.

The following three pages contain the complete application diagrams of this example

system, Circuits and Interfaces, Module Wiring, and PAC2 Connections, divided up

to fit the space available. The complete diagram is available on line at:

http://www.crestron.com/dealer-tech_resources/application_diagrams.asp

1DIM8

1

2

1DIM8

3

1DIM8

1

1MC4

4

1DIM8

5

1DIM8

2

1MC4

1

1FAN4

7

1DIM8

1

1DIM4

2

1DIM4

3

1MC4

4

1MC4

1

1MC4

6

1DIM8

2

1MC4

.

34 • Lighting Control System Design Design Guide – DOC. 5999A

Page 39

Crestron Lighting Control System

Circuits and Interfaces

Design Guide – DOC. 5999A Lighting Control System Design • 35

Page 40

Control System Crestron Lighting

Module Wiring

36 • Lighting Control System Design Design Guide – DOC. 5999A

Page 41

Crestron Lighting Control System

PAC2 Connections

Design Guide – DOC. 5999A Lighting Control System Design • 37

Page 42

Control System Crestron Lighting

Return and Warranty Policies

Merchandise Returns / Repair Service

1. No merchandise may be returned for credit, exchange, or service without prior authorization

from CRESTRON. To obtain warranty service for CRESTRON products, contact the factory

and request an RMA (Return Merchandise Authorization) number. Enclose a note specifying

the nature of the problem, name and phone number of contact person, RMA number, and

return address.

2. Products may be returned for credit, exchange, or service with a CRESTRON Return

Merchandise Authorization (RMA) number. Authorized returns must be shipped freight

prepaid to CRESTRON, 6 Volvo Drive, Rockleigh, N.J., or its authorized subsidiaries, with

RMA number clearly marked on the outside of all cartons. Shipments arriving freight collect

or without an RMA number shall be subject to refusal. CRESTRON reserves the right in its

sole and absolute discretion to charge a 15% restocking fee, plus shipping costs, on any

products returned with an RMA.

3. Return freight charges following repair of items under warranty shall be paid by CRESTRON,

shipping by standard ground carrier. In the event repairs are found to be non-warranty, return

freight costs shall be paid by the purchaser.

CRESTRON Limited Warranty

CRESTRON ELECTRONICS, Inc. warrants its products to be free from manufacturing defects in materials and

workmanship under normal use for a period of three (3) years from the date of purchase from CRESTRON, with

the following exceptions: disk drives and any other moving or rotating mechanical parts, pan/tilt heads and power

supplies are covered for a period of one (1) year; touchscreen display and overlay components are covered for 90

days; batteries and incandescent lamps are not covered.

This warranty extends to products purchased directly from CRESTRON or an authorized CRESTRON dealer.

Purchasers should inquire of the dealer regarding the nature and extent of the dealer's warranty, if any.

CRESTRON shall not be liable to honor the terms of this warranty if the product has been used in any application

other than that for which it was intended, or if it has been subjected to misuse, accidental damage, modification, or

improper installation procedures. Furthermore, this warranty does not cover any product that has had the serial

number altered, defaced, or removed.

This warranty shall be the sole and exclusive remedy to the original purchaser. In no event shall CRESTRON be

liable for incidental or consequential damages of any kind (property or economic damages inclusive) arising from

the sale or use of this equipment. CRESTRON is not liable for any claim made by a third party or made by the

purchaser for a third party.

CRESTRON shall, at its option, repair or replace any product found defective, without charge for parts or labor.

Repaired or replaced equipment and parts supplied under this warranty shall be covered only by the unexpired

portion of the warranty.

Except as expressly set forth in this warranty, CRESTRON makes no other warranties, expressed or implied, nor

authorizes any other party to offer any warranty, including any implied warranties of merchantability or fitness for

a particular purpose. Any implied warranties that may be imposed by law are limited to the terms of this limited

warranty. This warranty statement supercedes all previous warranties.

Trademark Information

All brand names, product names, and trademarks are the sole property of their respective owners. Windows is a registered

trademark of Microsoft Corporation. Windows95/98/Me/XP and WindowsNT/2000 are trademarks of Microsoft Corporation.

38 • Lighting Control System Design Design Guide – DOC. 5999A

Page 43

Crestron Lighting Control System

This page intentionally left blank.

Design Guide – DOC. 5999A Lighting Control System Design • 39

Page 44

Crestron Electronics, Inc. Design Guide – DOC. 5999A

15 Volvo Drive Rockleigh, NJ 07647 11.03

Tel: 888.CRESTRON

Fax: 201.767.7576 Specifications subject to

www.crestron.com change without notice.

Loading...

Loading...