Page 1

2008/2009 Product Directory

Heating Solutions

Cl/SfB

Uniclass L7522

EPIC L22

(56)

Page 2

Our heating technology has been developed with today’s

lifestyles in mind, so attention to style as well as efficiency and

economy are paramount. At Creda we never forget, however, that

safety is the number one concern.

With a renowned safety record, ease of installation or upgrade,

virtually no maintenance and low cost of ownership, electric

heating continues to grow in popularity in the UK and across

the world.

As electricity generation gets ever greener, the world is turning to

electric heating. In the UK our heating products are designed to

comply with Part L of the Building Regulations which focuses on

reducing carbon emissions and the conservation of fuel and

power. For more details on meeting these regulations see pages

6 & 7 of this brochure. For advice on helping to save the Earth by

saving energy and saving money too - see the guide at the back

of this brochure.

Our advanced heating control options assist in achieving the best

possible SAP ratings. (SAP is the Standard Assessment

Procedure for energy ratings and is also used within Part L).

As pioneers in electric heating, we continue to lead the

field with innovative and contemporary product design,

backed by nationwide after-sales suppor t and a dedicated

specification team.

We are here to help you develop the most ef fective, economical

and environmental heating solution.

Welcome to the fuel of the future!

Eco-Response storage radiant heaters offer advanced heating

technology with rapid response, touch temperature control.

Creda Heating

Introducing the fuel of the future!

2

“

For over 40 years Creda

has been dedicated to

heating the nation. In the

future low carbon electricity

will make electric heating

the first choice for a lower

carbon footprint and low

lifetime cost of ownership.

”

TPRIII Electronic pilot plus panel heaters with plug-in

timer options or 4 zone central control.

Proline II Ladder style electric towel rails with fast

response heating technology.

Page 3

3

Index

Creda Heating Introducing the fuel of the future! 2

Creda Heating A low carbon future 4

Creda Heating Design applica

tion suppor

t 5

Meeting Part L The quic

k start guide! 6-7

Eco-Response Intelligent heating tec

hnology / Storage radiant heaters 8-9

Contour100 Electronic panels 10-11

TPRIII E Electronic pilot plus panel heaters 12-13

TPRIII M / MT Mechanical thermostatic panel heaters 14

TPRIII NC No controls panels 15

Newera Style Panel heaters 16

Newera Electronic Panel heaters 17

Newera Plus Panel heaters 17

RF Electronic radio frequency panels and control options 18-19

Control Options 20-21

Sensair Automatic Electric storage fan heaters 22

TSR Supaslim Combi Storage fan heaters 23

TSR Sensor Plus & Slimline Electric storage heaters 24

TSF Turbo Commercial storage fan heaters 25

Storage Heater Accessories 26

Outline Thermostatic integral control towel rails 27

Proline II PL Fast response electric ladder towel rails 28-29

TD Traditional style electric towel rails 30

Solarail and LRC Electric towel rails 31

CDF Compact Downflow fan heaters 32

PH2 Electric plinth heaters for base units 33

Soleglow Underfloor electric heating 34

Sunplus Outdoor patio heaters 35

Sunquartz Shortwave infra-red radiant heaters 36

Ceramic Emitters Long wave infra-red heaters 37

Sunslim Commercial radiant heaters 38

Suntube Tubular heaters 39

Sunfan High level fan heater 40

Sunscreen Warm air curtains 41

Creda Heating Cable and connection points

42-43

Sizing Guide Storage and panel hea

ter

s 44

Sizing Guide Commercial space heater

s 45

Design Request Applica

tion Design Survey Information Sheet 46

Good Practice Helping you sa

ve energy 47

Introduction

Advanced control

heating systems43

Electric storage

heating3

Towel rails &

bathroom warmers

Underfloor heating

& fan heaters

Commercial

space heating

T

echnical

information

+44 (0) 1733 456789 www.creda-heating.co.uk

Page 4

Creda Heating

A low carbon future

4

“

a low carbon future.

”

Low carbon electricity, generated here in

the UK and not imported from around the

world, gives us security of energy supplies

and contributes to reducing the devastating

impact of climate change.

Low carbon electricity provides low carbon

heating from electric panel and storage

heaters. Creda are at the forefront of these

developments with the latest technology,

advanced energy-saving controls and

contemporary styling to suit the homes

of today.

Part L and SAP

(Standard Assessment Procedure)

The April 2006 revision to Part L of the Building Regulations

requires that all new buildings do not exceed a Target Carbon

Emission Rate (TER) as measured by a Standard Assessment

Procedure (SAP). For more details on how to comply see our

‘quick start’ guide on pages 6 & 7 of this brochure.

Every day, across the country, we design electric heating systems

that improve SAP scores and achieve full compliance with Part L

of the Building Regulations for buildings of all shapes and sizes.

See page 5 for information on how!

Decent Homes and Sustainable Communities

By 2010, the government has committed to bring 95% of all social

housing in the UK into a decent condition and the remainder are

to be improved soon after.

The new Housing and Regeneration Bill has also committed the

government to building 3 million new affordable and sustainable

homes by 2020. The provision of modern facilities are along with

the building improvements required to meet this legal obligation,

brings energy efficiency to the fore. Improved air-tightness

combined with new heating systems, kitchen and bathroom

facilities and effective ventilation strategies will all be needed.

Our sister brand Redring has a successful track record in

providing affordable hot water and showering into Decent Homes

projects (see www.redring.co.uk) and Xpelair are experts in the

field of low carbon ventilation, with the Xpelair Carbonlite

boasting a range of low energy and long-life product

(see www.xpelair.co.uk). Here at Creda we are the

heating experts.

Warmth is a pre-requisite of decent housing and low carbon

electricity is the route to sustainable communities. We believe

electricity is the fuel of the future; homes built today may well last

60 to 100 years, so we must build for the future today!

Creda electric heating can meet and exceed the needs of the

Decent Homes Standard. Our website provides on-line help,

tutorials and CPD accredited courses for those wishing to

ensure their development is compliant with the regulations.

Creda on the web

Visit www.creda-heating.co.uk for downloads, brochures, product

specifications and more information on Part L, SAP and the

Decent Homes Standard.

Creda continues to invest in the bright future of electric

heating. The 2008 Energy Bill promoted the production

of heating from low carbon electricity, as ever more

central generation flows from low carbon sources.

+44 (0) 1733 456789 www.creda-heating.co.uk

Page 5

Creda Heating

Design application support

5

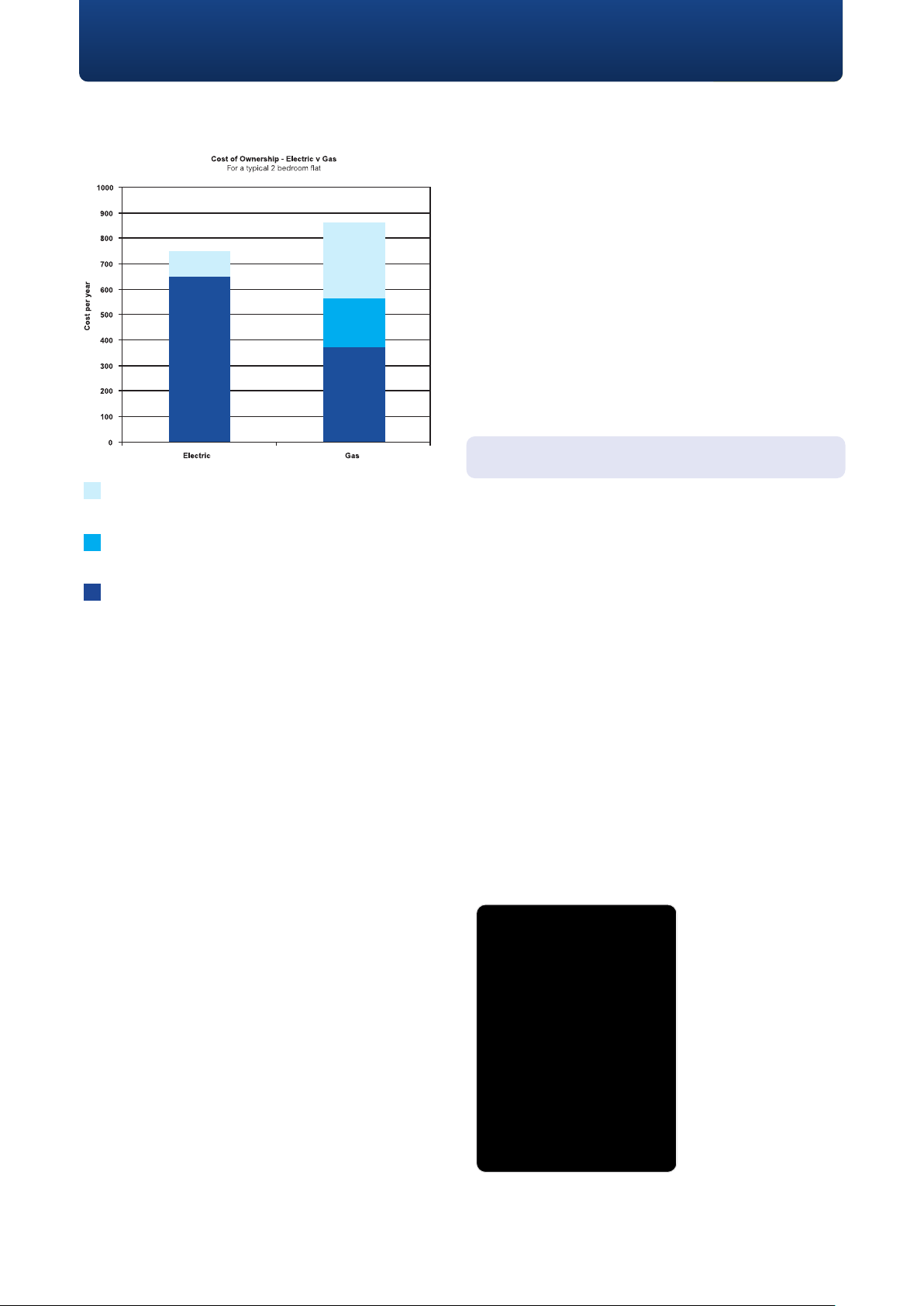

Electric heating is cheaper than gas

Annualised installation costs (based on manufacturers’ quoted average lifetimes

and typical installation costs for 6 electric panels or 6 wet-radiators and a

gas boiler).

Annual safety check and maintenance costs (to comply with manufacturers’

conditions of guarantee - using lowest priced British Gas service contract to

include boiler, controls and radiator s).

Annual fuel costs (based on guidance from the Energy Saving Trust publication

CE185 and Npower standard gas and electricity prices on Feb 10th 2008).

Low carbon electricity from renewable sources makes electric

heating the fuel of the future; but already electric heating is

cheaper than gas.

In recent times all energy prices have risen but none more so than

gas. Creda electric heating is now cheaper over its entire lifetime

than gas, when all the facts are considered.

Electric heating products cost less to buy in the first place and

are quick and easy to install or upgrade. They offer total flexibility

in the building design, with no complicated pipe runs, which also

leave gaps in the building fabric; a problem when air-tightness is

a key factor in improving the carbon footprint of a building and

meeting Part L of the building regulations. Once installed, electric

heating requires virtually no maintenance. Unlike gas there is no

legal requirement for an annual landlord safety certificate.

Year in and year out, electric heating provides instant, responsive

and safe heating on demand. Recent calculations have shown

that when all these factors are taken into account there is a

minimum overall cost saving of at least 13% a year in comparison

to gas central heating.

Apartments and flats often favour electric heating for all these

reasons. It is the simplest and most cost effective solution for

many hotels, gyms, crèches, nurseries, surgeries, care homes,

offices and shops all over the UK.

Application design

We have over 40 years experience in designing and supporting

electrical heating installations. We are able to offer an expert

application design service for all our products, helping new and

existing customers alike to specify Creda products into real

buildings and live projects, either off-plan, commenced new-build

or refurbishments.

In recent times the proliferation of environmental legislation and

revisions to Building Regulations, all designed to reduce carbon

intensity and improve energy efficiency, have made the design

process more complex. We are here to help with two levels of

design service.

Level 1:

Our standard design service is free of charge and will provide a

clear and simple indication of the products required and the

associated costs. This service can be provided from basic plans

and drawings.

Level 2:

Our enhanced design service incurs a very competitive fee to

cover third-party costs and a small contribution to the work of our

accredited SAP assessors. In return a dedicated assessor will

provide schematic designs and confirmation of regulatory

compliance including Part L of the Building Regulations and a

SAP score, as well as the product requirements and costs to

achieve this. Full architectural drawings are required to complete

this service and work cannot commence without them.

For further information send a description of your project,

contact details and drawings to aedesign@applied-energy.com

Technical services

Our technical services call centre is staffed by a team trained in

diagnosing and rectifying potential concerns over the phone.

If for any reason they are unable to solve a problem by phone,

they will brief an engineer on your behalf prior to the service visit

to ensure that, wherever possible, the problem is fixed first time.

The team also provides advice on product selection, application,

installation and operation; ensuring maximum value is gained from

selecting a Creda heating product.

For further information:

Tel: 08709 000430 Fax: 08709 000530

The Building Centre

Building specifiers within easy reach of Central London can see a

permanent exhibition of selected Creda products at the Building

Centre in Store Street, WC1E 7BT. The centre also offers a full

library support and literature distribution service for visitors, to

assist them in identifying the most appropriate products for any

given application.

Details of the Building Centre can be seen by the following the

link at www.creda-heating.co.uk

+44 (0) 1733 456789 www.creda-heating.co.uk

Page 6

Meeting Part L

The quick start guide!

6

What changed?

All the old methods of compliance have been abolished and

replaced with a Target Carbon Emission Rate (TER).

Whatever fuel type you choose for the heating and hot water of

your new building - gas, oil, LPG or electric - you have to show

that the overall carbon emission rate is less than the target for that

building type.

There are also new minimum standards for U-values and airtightness, which must be tested on completion of the building.

However, even meeting all the minimum standards will not

guarantee a pass.

The biggest change is that under the new rules the whole building

is taken into consideration. Every factor that can influence carbon

emissions is relevant and it’s the whole building that must pass.

So just building to minimum standards may not guarantee a pass

because the whole building may still exceed the target

carbon emission rate.

What’s my target?

The target is set in terms of Kilograms of carbon dioxide for every

square metre of the building, over the course of a year

(KgCO2/m

2

/yr).

A range of sample buildings is used to set the target, which is

then adjusted for the size and shape of the actual design and the

heating and hot water plan.

The complex calculation of both the target and the actual score of

your new building can be performed within special SAP 2005

approved software. (The government’s adopted Standard

Assessment Procedure). An accredited SAP assessor is required

to complete this.

The targets created under Part L 2006 demand a 20% reduction

in carbon emissions compared with the previous rules. This new

tougher target was set to improve the country’s energy efficiency

and dependence on imported fuel and to reduce the devastating

effects of climate change.

The tougher target applies to all relevant buildings, all products

and all fuel types. It’s the whole building that must comply, not any

given product or building service.

Block Assessment

Part L 2006 has important rules for setting and achieving the

targets in flats and apartments. So called ‘Block Assessment’

allows for all the flats or apartments in a building to be assessed

in one go.

Each flat or apartment can be dealt with as the developer or

specifier feels appropriate for meeting the overall TER, across the

different floors and sides of the building. Any given flat or

apartment does not have to meet an individual TER as long as the

whole building does.

This allows the developer or specifier flexibility in how to achieve

the target. For example, mechanical ventilation with heat recover y

(see picture above) may be installed which would create carbon

savings which can be shared out across the whole building.

It also reduces running costs and becomes a major selling

feature. For more advice on saving energy see the guide at the

back of this brochure.

Can you comply using electric heating and hot water?

Ye s.

The only test for compliance is that the building does not exceed

the target carbon emission rate. We continue to supply electric

heating and hot water solutions into fully compliant buildings.

Electric heating has also been shown to have lower lifetime costs

of ownership than gas, is easier and quicker to install,

is maintenance free, offers great design flexibility and has lower

initial capital costs.

Electric heating is the fuel of the future. Low carbon electricity

from UK sources produces low carbon heating only with

electric products.

How do I reduce the carbon emission rate of a building?

There are a number approaches that are proving most effective at

reducing the carbon emission rate of a building. We recommend

you consider the following options. In isolation or in combination,

all of these options have been used in conjunction with modern

electric heating.

Electric heating continues to grow in popularity. In April 2006 the

revision to Part L of the Building Regulations meant the way you comply

for new buildings changed. This is the quick-start guide to complying

with Part L.

“

”

Xpelair Xcell 270

+44 (0) 1733 456789 www.creda-heating.co.uk

Page 7

Meeting Part L

The quick start guide!

7

1 Improve the air-tightness:

It is now mandatory to test the air-tightness of a building on its completion.

There are minimum levels required under the new regulations but improving

on these has been shown to be one of the best ways to reduce the carbon

emission rate and therefore comply with Part L. Electric heating is helpful in

this regard as it results in less holes and gaps in the building fabric than gas

heating systems. The regulations require a minimum air-tightness of 10 cubic

metres per hour per square metre of floor area at 50 Pascals of pressure.

(10m

3

/h/m2@ 50Pa). Many developments can now achieve 7 or 5 and some

even 3m3/h/m2 @ 50Pa.

2 Install mechanical ventilation with heat recovery:

Used in conjunction with improved air-tightness, so called MVHR recovers

otherwise wasted heat and is a great advantage to the ventilation strategy.

There are specific provisions within SAP (Appendix Q) which show how using

MVHR can reduce the carbon emissions rate and help compliance with Part L.

Xpelair offers leading MVHR systems as part of the Carbonlite range,

see www.xpelair.co.uk.

3 Improve the building fabric:

There are minimum U-values for all elements of the building fabric. U-values are

a measure of how much heat energy can escape through a given element of a

building. However, simply meeting these alone does not guarantee compliance.

By exceeding the minimum requirement significant improvements can be made

on the carbon emission rate. It is possible to show compliance with Part L just

by improving building fabric U-values. However, a combination of improved airtightness, MVHR and modest improvements in building fabric U-values has

proved most cost effective in many building developments. Consider reducing

U-values for roofs to 0.14, walls to 0.3, floors to 0.2 and glazing to 1.8 but,

generally speaking, the lower the better.

4 Consider glazing as a percentage of the building

floor area:

The regulations assume that glazing coverage is equivalent to 25% of the floor

area, which is more than most developments. Where this can be sensibly

reduced it will improve the carbon emission rate of the building. If the

specification of glazing is also improved the impact is increased. Consider gas

filled or triple glazing.

5 Go renewable:

The installation of solar thermal hot water systems, heat-pumps

or micro wind-turbines can have a number of major benefits. Often the

installation of some of these products can turn an otherwise non-compliant

building into a fully compliant one. However, many developers now also

see this as the preferred route to meeting other planning requirements or

aspirational targets for the use of micro-generation technologies. They can

significantly reduce running costs and can be a great selling point. Redring

offers one of the most efficient solar thermal hot water systems in the UK see www.redring.co.uk - and Xpelair has a world-class micro wind-turbine

(see www.xpelair.co.uk).

6 Improve the lighting plan:

In some buildings the carbon impact of the lighting can be significant and

expert advice can assist in demonstrating compliance with Part L.

Modular lighting strategies should be considered. The traditional rules of thumb

based on the number of rooms should give way to a recommended number of

lighting points by square metre of floor area. It is good practice to install low

energy fittings as standard indoors, with consideration given to highly effective

control. Externally the regulations require a maximum 150W with automatic

switch-off via PIR, photocell and timers.

7 Controllability reduces emissions:

It has been shown that easy to use, highly responsive heating systems actually

reduce carbon emissions. When heating responds quickly it tends, in practice,

to be used more effectively. Where controls are simple to use, people make

better use of them. Modern electric heating is highly controllable and

responsive. This is recognised within SAP. We offer leading edge electric

heating with our Eco-Response technology. Integrated and sensitive thermostats

within Creda electric heating products allow precise control room by room,

ensuring solar gain is taken into account in maintaining a desired temperature

and reducing carbon emissions.

8 Background heat:

By ensuring there is a low level background heat throughout the common

walkways, like stairwells and landings in apartment blocks, adjoining walls are

only considered semi-exposed for calculation purposes, reducing heat losses

and improving the carbon emission rate. We offer modern electric heating

solutions designed for this purpose.

9 Size the cylinder:

The regulations now assume a 170l water cylinder. By ensuring the cylinder is

not oversized for its application, heat losses are reduced. If the cylinder size is

reduced below 170l then the carbon emission rate is improved. Redring offers

cylinders at 90, 125, 150 and 170 litre capacities, as well as larger sizes

where necessary. See www.redring.co.uk for a full range of instant water

heating products that have no standing losses at all!

Creda Eco-Response

Redring LWSS Stainless Steel Cylinder

+44 (0) 1733 456789 www.creda-heating.co.uk

Page 8

“

Eco-Response offers advanced

electric heating for the future,

challenging expected norms

with superior efficiency and

controllability.

Eco-Response

Intelligent heating technology

Key features

• Economical use of energy utilising the best of stored and direct acting

heating technologies

• Contemporary design - looks good in any home

• Unobtrusive - takes up no more space than a traditional wet radiator

• One-touch electronic controls with child lock facility

• Simple ‘+ or -’ touch temperature control for accuracy and flexibility

• Rapid response to changing temperature demands

• Pre-wired with 2 x 1.6 metre lengths of cable for storage and direct acting

power supplies - for ease of connection

• Designed for rapid assembly to keep installation costs down

• Requires no annual maintenance

• Optional central controller for 4 zone pilot wire linked heating system

8

The Creda Eco-Response has been developed to help meet the

needs of Part L 2006 Building Regulations and provides enhanced

SAP scores.

Specifiers will benefit from the ‘integrated storage/direct acting heater’ category within

table 4a of SAP 2005 which rewards the enhanced controllability of Eco-Response with

a 100% efficiency rating, placing this leading technology in heating type 2 with a

responsiveness weighting of 0.75.

Model Reference Nominal Charge Input Rating Input Rating Number Number Weight

Output Acceptance (Off Peak) (Radiant Elt.) of Elements of Bricks

ER300 75 773301 0.7kW 9.1kWh 1.3kW 0.28kW 2 8 65kg

ER400 75 773302 1.1kW 13.65kWh 1.95kW 0.34kW 3 12 94kg

ER500 75 773303 1.5kW 18.2kWh 2.6kW 0.39kW 4 16 124kg

PW E4ZC 75 770916 4 zone pilot wire central controller

Product Selector

Warmth where it's needed, when it's needed...

in a single room or across the house. A constant low level

of background heat prevents the fabric of the building from

cooling. On demand, this fast-acting appliance raises the

temperature to meet your needs, providing total control and

the peace of mind that comes with low running costs.

”

Stored heat - maintains low level background heat

to keep the fabric of the building warm, utilising

economy off-peak electricity

Simple integral control on top of the heater - allows

easy adjustment to achieve the user’s preferred

comfort temperature

Radiant heat - rapidly raises temperature to

required comfort level on demand

PART L and SAP 2005

+44 (0) 1733 456789 www.creda-heating.co.uk

Advanced control

heating systems

Average carbon saving of up to 300kg

per annum when compared to

auto slimline storage heaters*

*Based on a semi-detached house

with a floorspace of 130m

2

300kg

saving

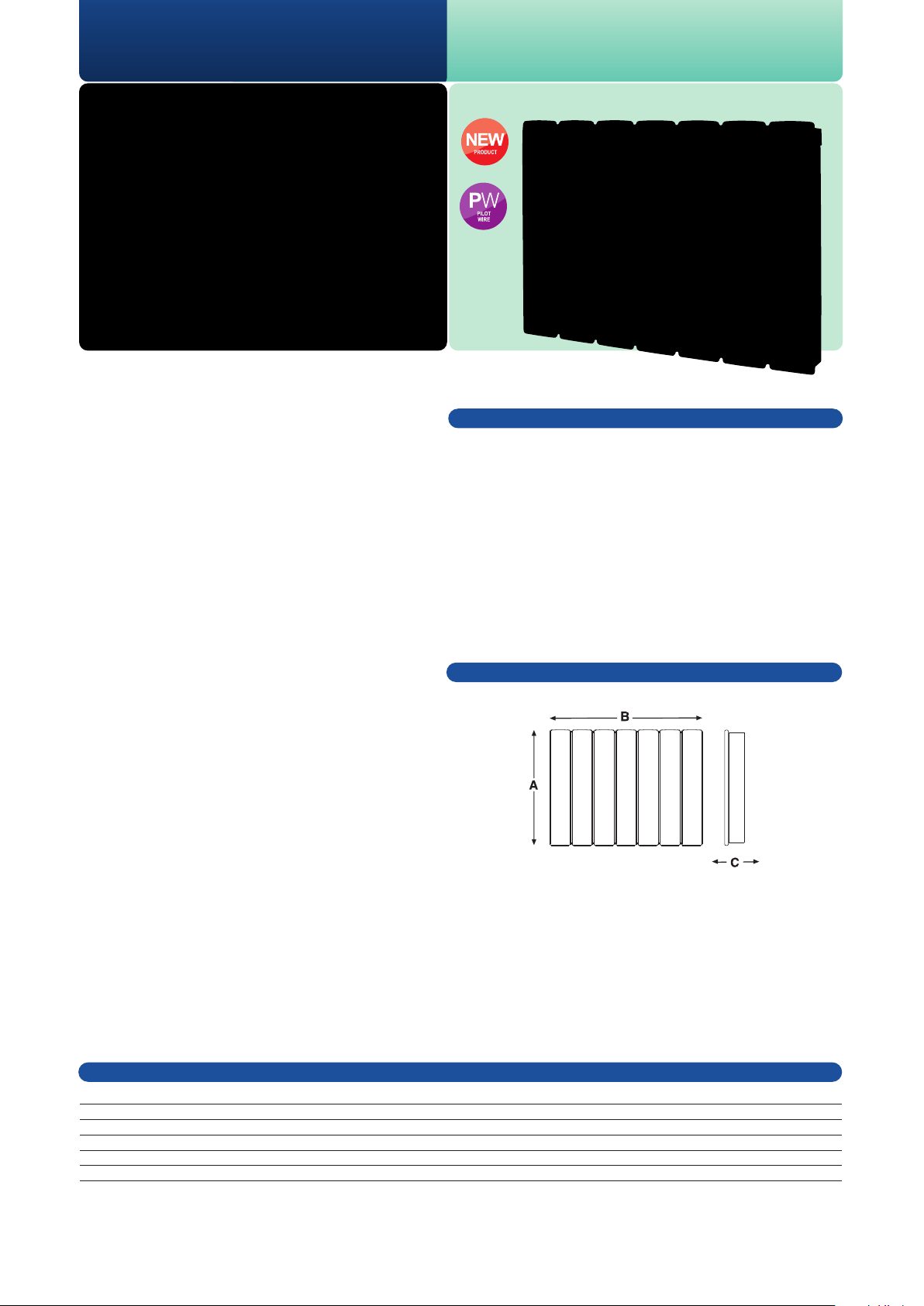

Page 9

With a conventional ‘wet’

heating system, when

heating goes off,

building shell cools.

It is smarter to

maintain low level

background heat.

The building shell has

to then be warmed

again before room

feels comfortable.

The room temperature

can be raised quickly

and efficiently when

needed.

This takes time and

energy - slow response.

Economical.

Responsive.

Intelligent.

• Elements (Storage) - 650W incoloy sheathed, mineral

filled elements

• Element (Direct Acting) - cable-on-foil thin facia panel

• Thermostat (Input) - integral electronic charge limiter

Maximum core temperature 670

o

C/690oC at full charge

• Thermostat (Output) - integral electronic thermostat with child

lock facility

• Thermal Insulation - Carbowool 128kg/m

2

, Microtherm G

and calcium silicate

• Energy Retention Cells - high density bonded magnetite

• Protection (Storage) - automatic reset core limit thermostat and

manual over-temperature cut out

• Protection (Direct Acting) - automatic reset limit thermostat and

automatic reset over-temperature cut out

• Finish - white polyester and zinc coated steel with grey base

• Cable (Storage) - 1.6m 2.5mm

2

3 core

• Cable (Direct Acting) - 1.6m 0.75mm

2

2 core

• Supply - 230/240V AC single phase

9

Model Height A Width B Depth C Feet Position D

ER300 712mm 600mm 130mm+10mm 295mm

ER400 712mm 830mm 130mm+10mm 523mm

ER500 712mm 1060mm 130mm+10mm 751mm

Minimum clearance required

• 75mm either side of heater

• 150mm in front of the heater

• 250mm directly above the heater

4 zone pilot wire central controller

Allows 7 day programming of comfort/setback time

settings of multiple pilot wire linked heaters in up to

4 separate zones.

Ref: 75 770916

Conventional heater

Dimensions

12 3

12 3

Technical Specification

Eco-Response

+44 (0) 1733 456789 www.creda-heating.co.uk

Eco-Response

Storage radiant heaters

Advanced control

heating systems

Matching TPRIII E

Electronic panel

heaters also available

for pilot wire linked

heating systems

(See page 12-13).

Control options

Page 10

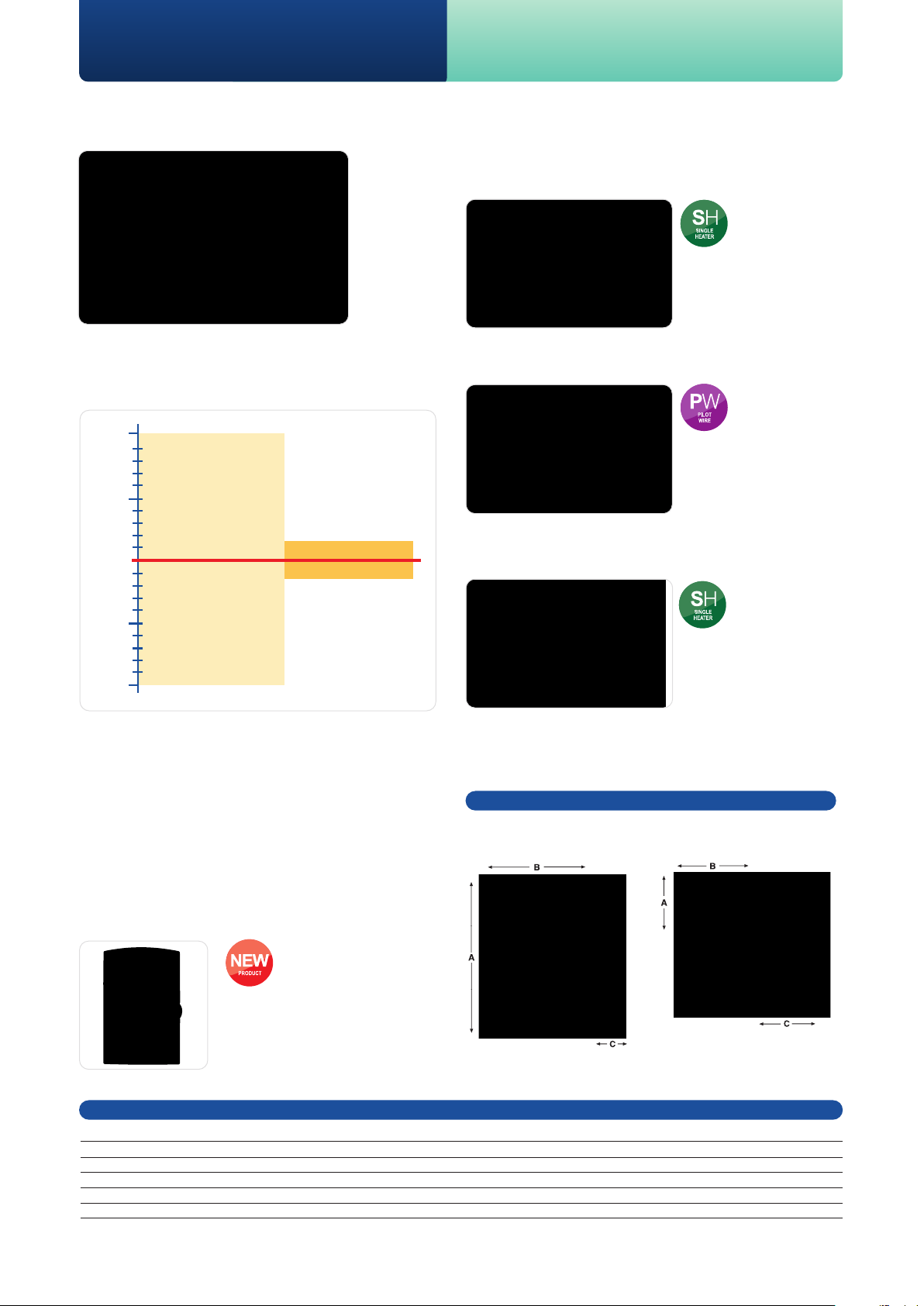

Contour100

Electronic panel heater

Model Reference Rating Height A Width B Depth C Weight

CEP 500E 75 775101 0.5kW 536mm 503mm 104mm 12kg

CEP 750E 75 775102 0.75kW 536mm 503mm 104mm 12kg

CEP 1000E 75 775103 1kW 536mm 671mm 104mm 15kg

CEP 1500E 75 775104 1.5kW 536mm 741mm 104mm 17.5kg

CEP 2000E 75 775105 2kW 536mm 911mm 104mm 22kg

10

Product Selector

Contour100 panel heaters incorporate electronic

thermostatic controls which allow very precise regulation

of room temperatures.

Key features

• Contemporary radiator styling

• Electronic thermostatic control, accurate to +/-0.3

O

C

• Convected heat for rapid warm up

• Silent operation

• Pre-set background temperature at 5

O

C below thermostat setting

(when connected to a programming unit supporting setback feature)

• IPX4 rated (splashproof)

• Being electronic, control is totally silent and reliable

• Hidden thermostat range limiter feature - for additional economy

• Range of optional plug-in electronic timer modules, including:

- 24 hour digital timer

- Single zone 7 day pilot wire programmer

- Runback timer

• Compatible with Creda 4 zone pilot wire central controller

Dimensions

Technical Specification

“

The all new Contour100 panel

heater range offers high quality build

and panel finish with contemporary

radiator styling.

”

+44 (0) 1733 456789 www.creda-heating.co.uk

Advanced control

heating systems

• Elements - finned, mineral-filled sheath type

• Thermostat - electronic with 5ºC setback control capability

• Finish - white powder coated steel and thermoplastic

• Protection - auto reset thermal cutout

• Cable - 1.2 metres, 4 core (live, neutral, pilot and earth)

• IP rating - IPX4 (splashproof)

• Supply - 230/240V AC single phase

Page 11

Contour100

Electronic panel heater

11

+44 (0) 1733 456789 www.creda-heating.co.uk

Both Contour100 and TPRIII E electronic panel heaters

feature highly accurate electronic thermostats (+/-0.3OC),

providing superior comfort and operating efficiency.

As the room temperature nears the desired set point, power

to the elements is reduced. The room temperature is closely

monitored to an accuracy of less than 0.3ºC, minimising

overshoot and temperature drift, resulting in better energy

efficiency and user comfort.

Advanced control

heating systems

+2OC

MECHANICAL

THERMOSTATS

MAY OVERSHOOT

BY UP TO 2

O

C

ELECTRONIC

THERMOSTATS

ARE ACCURATE

TO ±0.3

O

C

SET TEMPERATURE

Contour100 Electronic panel features

• High quality build and panel finish

• Forward angled facing grille to assist heat circulation

• Electronic thermostat for accuracy

-2OC

-1

O

C

+0.3

O

C

+1

O

C

-0.3

O

C

4 zone pilot wire central controller

Allows 7 day programming of comfort/setback

time settings of multiple pilot wire linked

heaters in up to 4 separate zones (see page 20).

Control options

Control options

A range of optional plug-in control modules, which can be

removed from the heater for easy programming, provide the

flexibility for TPRIII to meet a wide range of control specifications:

• TPR E24T 24 hour digital timer. Provides 24 hour programmable on/off control

• TPR E7DT single zone, pilot wire programmer controls up to 10 slave heaters.

Provides 7 day programmable on/off control

• TPR ERBT runback timer. Provides installer programmable runback time up to

4 hours (in 30 minute increments). Can be locked into heater

Dimensions

Plug-in timer module

Model Reference Product Description Height A Width B Depth C

TPR E24T 75 770912 24 hour plug-in timer module 50mm 70mm 145mm

TPR E7DT 75 770913 7 day single zone plug-in timer module 50mm 70mm 145mm

TPR ERBT 75 770914 4 hour run back timer plug-in module 50mm 70mm 145mm

PW E16A 75 770915 16 amp pilot wire interface unit 86mm 86mm 22mm

PW E4ZC 75 770916 4 zone pilot wire central controller 132mm 86mm 38mm

Product Selector

4 zone pilot wire controller

Page 12

TPRIII E

Electronic pilot plus panel heaters

Model Reference Loading Height A Width B Depth C Weight

TPRIII 500E 75774440 0.5kW 430mm 450mm 108mm 5.2kg

TPRIII 750E 75774441 0.75kW 430mm 620mm 108mm 6.6kg

TPRIII 1000E 75774442 1kW 430mm 620mm 108mm 6.6kg

TPRIII 1250E 75774443 1.25kW 430mm 690mm 108mm 7.1kg

TPRIII 1500E 75774444 1.5kW 430mm 690mm 108mm 7.1kg

TPRIII 2000E 75774445 2kW 430mm 860mm 108mm 8.5kg

12

Product Selector

TPRIII Electronic pilot plus panel heaters incorporate

electronic thermostatic controls to allow precise regulation

of room temperatures - essential when comfort,

economy and energy efficiency need to be considered in

equal measure. To meet the needs of most applications the

TPRIII Electronic pilot plus panel heaters can also be

controlled by a new range of plug-in timers or by pilot

wired signalling from a 4 zone pilot wire central controller.

Key features

• Front facing grille for best possible heat projection

• Styling to complement Eco-Response radiators with pure white finish

• Electronic thermostatic control - +/-0.3ºC, completely silent operation

• Pre-set background temperature at 5ºC below thermostat setting

(when connected to a programming unit supporting setback feature)

• Optional plug-in electronic timer modules, including:

- 24 hour digital timer

- Single-zone pilot wire programmer

- Runback timer

• Compatible with Creda 4 zone, wall mounted pilot wire signalling

multi-heater programmers

• IPX4 rated (splashproof)

• Hidden thermostat range limiter feature - for additional economy

• Simple detachable wall bracket for easy installation

Dimensions

• Element - finned, mineral-filled sheathed type

• Thermostat - electronic with fixed 5ºC setback facility

• Finish - white powder coated steel and thermoplastic

• Protection - auto reset thermal cut-out

• IP rating - IPX4 (splashproof)

• Cable - 1.2 metres, 4 core cable (live, neutral, pilot and earth)

• Supply - 230/240V AC single phase

Technical Specification

“

The TPRIII Electronic pilot plus panel

heater range - unites smooth styling with

superior control performance options

to give flexible heating solutions.

”

+44 (0) 1733 456789 www.creda-heating.co.uk

Advanced control

heating systems

Page 13

TPRIII E

Electronic pilot plus range controls

13

+44 (0) 1733 456789 www.creda-heating.co.uk

TPRIII E Electronic panel heaters will accept the same range of plug-in timer

modules as Contour100 electronic panel heaters (featured on page 11).

Advanced control

heating systems

Dimensions

Model Reference Product Description Height A Width B Depth C

TPR E24T 75 770912 24 hour plug-in timer module 50mm 70mm 145mm

TPR E7DT 75 770913 7 day single zone plug-in timer module 50mm 70mm 145mm

TPR ERBT 75 770914 4 hour run back timer plug-in module 50mm 70mm 145mm

PW E16A 75 770915 16 amp pilot wire interface unit 86mm 86mm 22mm

PW E4ZC 75 770916 4 zone pilot wire central controller 132mm 86mm 38mm

Product Selector

Plug-in timer module

4 zone pilot wire controller

240v mains supply

TPRIII E Electronic rotary thermostat

Improved economy may be achieved by limiting the thermostat rotational

range, by means of the mechanical ‘peg and hole’ feature hidden beneath a

removable cap on the thermostat knob.

Pilot wire auxiliary interface unit

The PW E16A pilot wire auxiliary interface unit enables heaters without

electronic controls to be central programmed, for on/off time periods only,

as part of a pilot wire linked heating system.

(Max. 3kW. Requires a 38mm deep metal box or surface patress).

Pilot wire heating system

The PW E4ZC central controller allows 7 day programming for comfort and setback

temperature periods of multiple pilot wire linked heaters in up to four separate zones.

• 4 Separate heating zones

• Heater modes - Comfort/Setback, Comfort/Frost or Comfort/Off

• Wall mounted mains powered controller with capacitor back up (approx. 4 hrs)

Control Options

PW E16A Interface unit

Zone 3 Zone 4

Zone 1 Zone 2

Page 14

TPRIII M / MT

Mechanical thermostatic panel heaters

Model Reference Loading Height A Width B Depth C Weight

Thermostat only models

TPRIII 500M 75 774440 0.5kW 430mm 450mm 108mm 4.8kg

TPRIII 750M 75 774401 0.75kW 430mm 620mm 108mm 6.2kg

TPRIII 1000M 75 774402 1kW 430mm 620mm 108mm 6.2kg

TPRIII 1250M 75 774403 1.25kW 430mm 690mm 108mm 6.6kg

TPRIII 1500M 75 774404 1.5kW 430mm 690mm 108mm 6.6kg

TPRIII 2000M 75 774405 2.kW 430mm 860mm 108mm 8.0kg

Timer models 24hr

TPRIII 500MT 75 774410 0.5kW 430mm 450mm 108mm 4.8kg

TPRIII 750MT 75 774411 0.75kW 430mm 620mm 108mm 6.2kg

TPRIII 1000MT 75 774412 1.kW 430mm 620mm 108mm 6.2kg

TPRIII 1250MT 75 774413 1.25kW 430mm 690mm 108mm 6.6kg

TPRIII 1500MT 75 774414 1.5kW 430mm 690mm 108mm 6.6kg

TPRIII 2000MT 75 774415 2.kW 430mm 860mm 108mm 8.0kg

Timer model 7 day

TPRIII 2000MT7 75 774435 2.kW 430mm 860mm 108mm 8.0kg

14

Product Selector

Technical Specification

Popular with specifiers and contractors to complement

Creda electric storage heaters, TPRIII mechanical

thermostatic panels are most commonly used to warm

bedrooms, bathrooms, kitchens and other areas which only

require heating for short periods of the day. Cost effective,

they offer an efficient way to extend an existing heating

system. The ranges come with control options to fulfil the

widest range of applications, from single room background

heating through to commercial applications.

Key features

• TPRIII (MT) models have programmable 24 hour timers

• TPRIII (MT7) model has a programmable 7 day timer

• TPRIII (NC) models with no built-in controls

• Full or half power output selection on thermostatic models

• Adjustable thermostat (5-30

O

C) on thermostatic models

• Convected heat for rapid warm-up. Suitable for domestic or

commercial use

• IPX4 rated (splashproof)

+44 (0) 1733 456789 www.creda-heating.co.uk

Dimensions

• Element - mineral-filled sheathed type

• Thermostat - capillary type (MT models only)

• Finish - white powder coated steel

• Protection - auto reset thermal cut-out

• IP rating - IPX4 (splashproof)

• Supply - 230/240V AC single phase

“

TPRIII mechanical thermostat panel

heaters offer a versatile choice of

models with built-in timer options or

panels with no controls at all.

”

• Frost protection setting on thermostatic models

• 2kW model available with 7 day timer

• Front heat outlet grille for efficient heat circulation

• Lockable dust cover (on thermostatic models)

• Detachable hinged wall mounting bracket for fast installation and easy cleaning

Advanced control

heating systems

Page 15

TPRIII NC

‘No controls panel heaters’

+44 (0) 1733 456789 www.creda-heating.co.uk

15

Model Reference Loading Height A Width B Depth C Weight

No controls models

TPRIII 500NC 75 774300 0.5kW 430mm 450mm 108mm 4.8kg

TPRIII 750NC 75 774301 0.75kW 430mm 620mm 108mm 6.2kg

TPRIII 1000NC 75 774302 1kW 430mm 620mm 108mm 6.2kg

TPRIII 1250NC 75 774303 1.25kW 430mm 690mm 108mm 6.6kg

TPRIII 1500NC 75 774304 1.5kW 430mm 690mm 108mm 6.6kg

TPRIII 2000NC 75 774305 2kW 430mm 860mm 108mm 8.0kg

Product Selector

TPRIII M mechanical thermostat without timer

(500W - 2000W models).

TPRIII Thermostatic panel heater ranges

Advanced control

heating systems

TPRIII MT mechanical thermostat with 24hr timer

(500W - 2000W models).

TPRIII MT7 mechanical thermostat with 7 day timer

(available in 2000W model only).

TPRIII No controls panel heater range

TPRIII NC a range of panel heaters without any integral controls for use in applications

where external control of temperature and time programming is required.

Technical Specification

Dimensions

• Element - mineral-filled sheathed type

• Finish - white powder coated steel

• Protection - auto reset thermal cut-out

• IP rating - IPX4 (splashproof)

• Supply - 230/240V AC single phase

Page 16

Newera Style

Panel heaters

16

+44 (0) 1733 456789 www.creda-heating.co.uk

Model Reference Rating Height A Width B Depth C

PPH750 75 772601 0.75kW 615mm 497mm 135mm

PPH1000 75 772602 1kW 615mm 645mm 135mm

PPH1500 75 772603 1.5kW 615mm 941mm 135mm

PPH2000 75 772604 2kW 615mm 1163mm 135mm

MBPRG 75 770907 Newera MB programmer

MBIF 75 770908 Newera MB interface

PW E4ZC 75 770916 4 zone pilot wire central controller

Safety and comfort feature highly in

the design of the Newera Style,

manufactured from composite material to

provide a lower surface temperature

without loss of convected heat with a

unique outlet grille design that helps

prevent wall discolouration.

Key features

• Unique grille design to keep walls free

of dust marks

• Composite construction for lower surface

temperature without loss of convected heat

• Twin electronic thermostats for comfort

and setback

• Mains borne and pilot wire control options

• IP24 rated (splashproof)

Control options

Newera Style and Newera Electronic panel heaters

may be connected as a centrally controlled system

using the optional mains borne accessories.

The MB programmer communicates with the heaters

and controls a comfort or setback thermostat as per

the times set in the programmer.

MB Programmer Ref: 75 770907

MB Interface Ref: 75 770908

Allows 7 day programming of comfort/setback time

settings of multiple pilot wire linked heaters in up to

4 separate zones.

4 zone pilot wire central controller

Ref: 75 770916

Integral twin electronic thermostats for setting

comfort and setback temperatures.

• Elements - finned, metal sheathed mineral

filled type

• Thermostats - twin electronic

• Protection - two level thermal safety overheat

• Supply - 230/240V AC single phase

Technical Specification

Dimensions

Product Selector

“

The Newera Style provides

a contemporary option for

fully controllable heating in

every room, with accurate

twin electronic thermostats

providing flexible control.

”

Advanced control

heating systems

Page 17

Newera Electronic and

Newera Plus Panel heaters

17

+44 (0) 1733 456789 www.creda-heating.co.uk

Model Reference Rating Height A Width B Depth C

EPH500 75 772401 0.5kW 450mm 370mm 78mm

EPH1000 75 772402 1kW 450mm 445mm 78mm

EPH1250 75 772403 1.25kW 450mm 520mm 78mm

EPH1500 75 772404 1.5kW 450mm 590mm 78mm

EPH2000 75 772405 2kW 450mm 740mm 78mm

PW E4ZC 75 770916 4 zone pilot wire central controller

MBPRG 75 770907 Newera MB Programmer

MBIF 75 770908 Newera MB Interface

HPH750 75 772301 0.75kW 450mm 370mm 78mm

HPH1000 75 772302 1kW 450mm 445mm 78mm

HPH1250 75 772303 1.25kW 450mm 520mm 78mm

HPH1500 75 772304 1.5kW 450mm 590mm 78mm

Product Selector

Newera Electronic

The Newera Electronic range provides style,

flexibility and ease of use in buildings of

any size. Built-in twin electronic thermostats

allow control of comfort and setback

temperatures. So panels can be used

individually or can be linked to provide

complete heating systems. A 7 day

programmer can be added for the

convenience of hassle-free heating matched

to the way you use the space throughout

the week.

Key features

• Twin electronic thermostats for comfort and setback

• Can be used with mains borne or pilot wire

controllers as part of a complete heating system

• Compact, attractive design occupying minimum

wall space

• Mains borne and pilot wire control options

• Hinged wall mounting bracket to allow easy

access for cleaning and decorating

• IP24 rated (splashproof)

Technical Specification

Dimensions

Electronic

Models only

“

The Newera Electronic and Plus panel heater ranges

provide a choice of control options or stand alone heaters

in sleek designs.

”

• Elements - finned, metal sheathed mineral

filled type

• Thermostats - twin Electronic

(Newera Electronic only)

• Thermostat - single mechanical

(Newera Plus only)

• Protection - two level thermal safety overheat

• Supply - 230/240V AC single phase

Newera Plus

A simple robust stand alone thermostatic

panel heater. The Newera Plus range offers

a low cost heating solution ideal for hotels

or student accommodation.

Single mechanical thermostat

Key features

• Single mechanical thermostat, stand alone heating

• Excellent value and simple to operate

• Robust construction and easy to install

• Compact - takes up minimal wall space

• Hinged wall mounting bracket to allow easy access

for cleaning and decorating

• Ideal for conservatories, extensions, hotels and

student accommodation

• IP24 rated (splashproof)

Advanced control

heating systems

Page 18

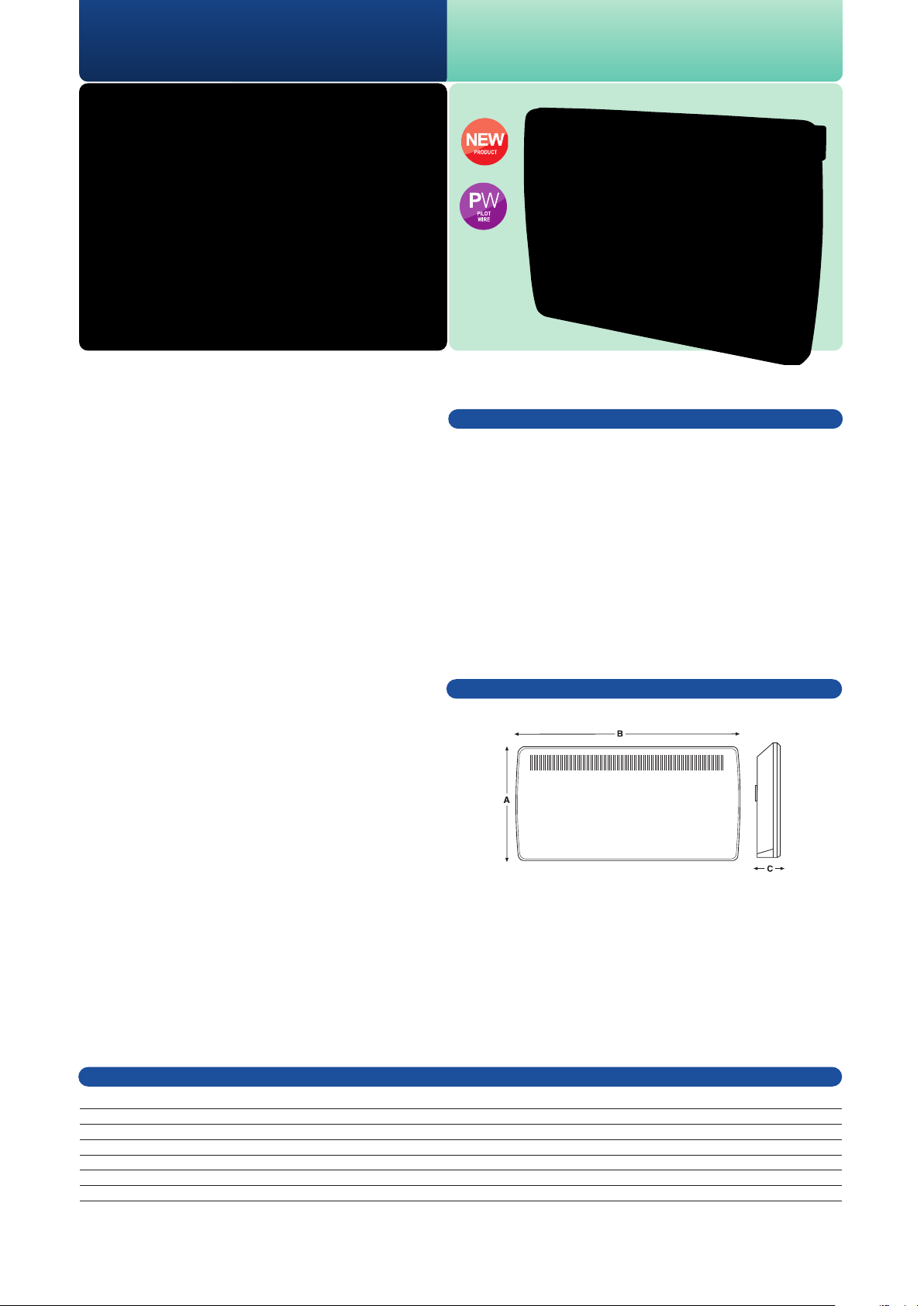

RF Electronic radio frequency

controlled panels

+44 (0) 1733 456789 www.creda-heating.co.uk

18

Model Reference Product Description Rating Height A Width B Depth C

RF/E408 85510 RF 400mm panel heater 0.8kW 400mm 645mm 80mm

RF/E410 85520 RF 400mm panel heater 1kW 400mm 735mm 80mm

RF/E412 85530 RF 400mm panel heater 1.2kW 400mm 915mm 80mm

RF/E415 85540 RF 400mm panel heater 1.5kW 400mm 1,095mm 80mm

RF/E420 85550 RF 400mm panel heater 2kW 400mm 1,365mm 80mm

RF/E406S 85820 RF 400mm panel heater (splashproof) 0.6kW 400mm 555mm 80mm

RF/E410S 85840 RF 400mm panel heater (splashproof) 1kW 400mm 735mm 80mm

RF/E208 85610 RF 200mm panel heater (plinth) 0.8kW 200mm 1,095mm 80mm

RF/E210 85620 RF 200mm panel heater (plinth) 1kW 200mm 1,275mm 80mm

RF/E212 85630 RF 200mm panel heater (plinth) 1.2kW 200mm 1,545mm 80mm

RF/E215 85640 RF 200mm panel heater (plinth) 1.5kW 200mm 1,725mm 80mm

• Elements - Finned, metal sheathed mineral-filled type

• Finish - Cream powder coated steel and thermoplastic

• Protection - Two level thermal safety overheat

• Supply - 230/240V AC single phase

Product Selector

Designed to offer economical, stylish and safe heating

solutions, these compact panels can be used in

conjunction with tailored accessories to provide the perfect

heating solution.

A digital electronic thermostat uses integral drift

compensation to ensure a stable and consistent room

temperature and an on/off switch allows flexibility when

heating is not required.

The RF panel range includes standard 400mm panels,

200mm plinth panels and splash-proof models to provide

a complete heating solution for every room, including

the bathroom.

Key features

• Local or central control meets Building Regulations Part L

(when used with Creda Saver or Zone Controllers)

• Electronic thermostat with drift compensation for accurate room

temperature control

• RF/E406S and RF/E410S models are IP24 rated (splashproof)

• Non-wired signalling for total flexibility and ease of insulation

Technical Specification

Dimensions

“

The RF range offers a combination

of slimline, flexible heater panels

with non-wired control solutions;

ideal for use in domestic and

commercial applications.

”

Advanced control

heating systems

Page 19

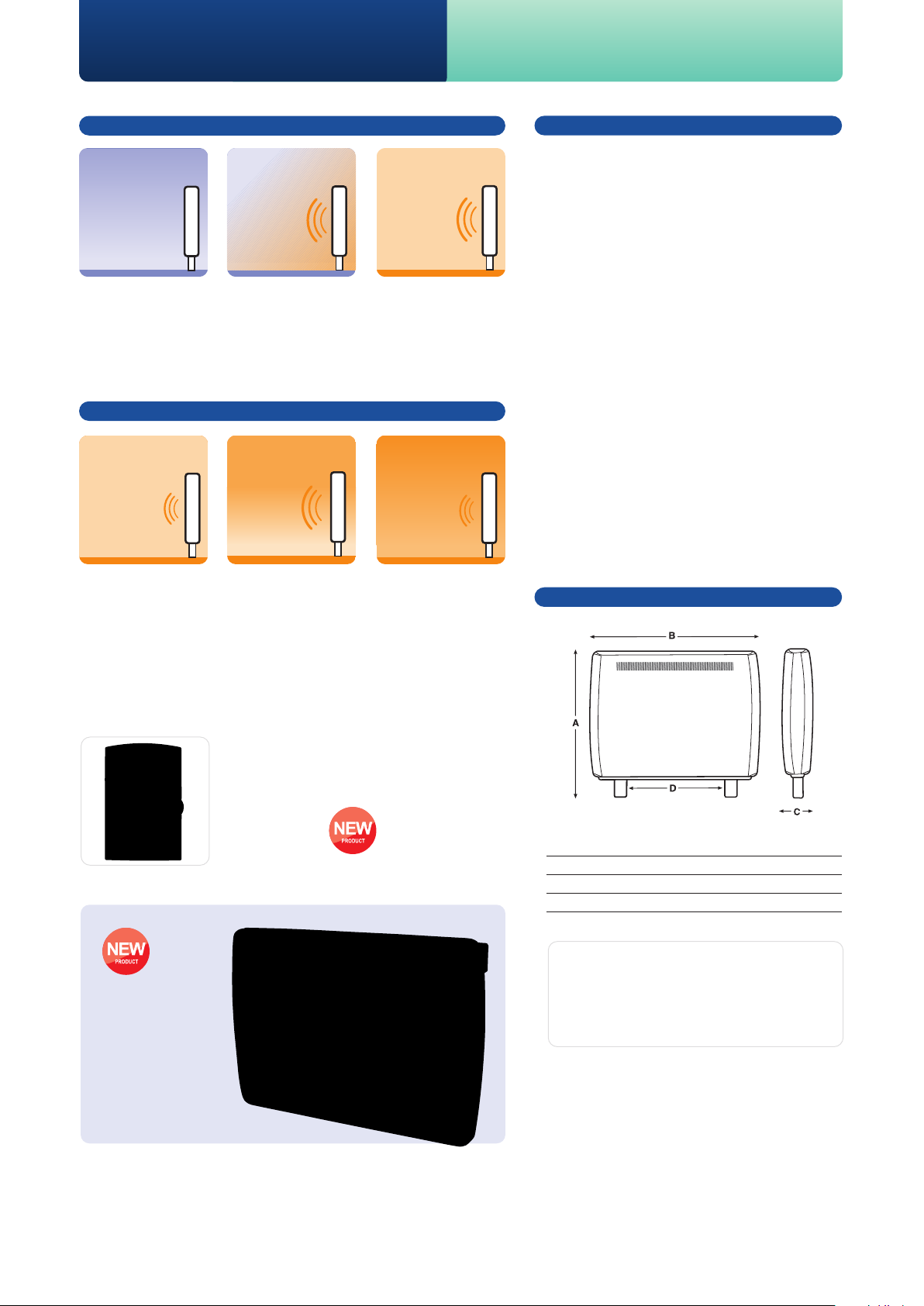

A choice of innovative control options is

available to suit both domestic and

commercial applications.

Electronic thermostat:

• All RF panels feature integral electronic thermostat

• Drift compensation to maintain a stable room

temperature

• Double pole on/off switch and overheat protection

• LCD display when element is energised

Creda Saver:

• Optional plug-in, programmable cartridge with

15 pre-set programmes

• Comfort mode thermostat on heater

• Integral setback thermostat

(Comfort thermostat on panel)

Creda Zone Receivers:

• Optional plug-in receivers for heaters, to enable

control via Creda Zone controllers

• Integral thermostat for setback

• Automatic start up when communication is restored

• 433 MHz operating band

(Creda Zone 1 and 6 zone controllers)

• 868 MHz operating band

(Creda Zone 8 zone controller)

New Creda Zone 8:

• New controller for up to 8 zones (868 MHz)

• Time and temperature adjustment 24 hours a day,

7 days a week

• Frost protection setting (5-15°C)

• Setback temperature (5-20°C)

• Comfort temperature setting (5-30°C)

• Individual zone & measured zone temperature

LCD display

• Can be wall mounted or freestanding for hand

held programming

• Battery operated (2 x AAA)

Creda Zone 1 and 6:

• Single or 6 zone controllers (433 MHz)

• Time and temperature adjustment 24 hours a day,

7 days a week

• Frost protection setting (5-15°C)

• Fall back temperature (5-30°C)

• Comfort temperature setting (5-30°C)

• Individual zone & measured zone temperature

LCD display

• Can be wall mounted or freestanding for hand

held programming

• Battery operated (3 x AAA)

RF

Panel heater control options

+44 (0) 1733 456789 www.creda-heating.co.uk

19

Model Reference Product Description

CZ8N 75770918 Creda Zone 8 RF controller (868 MHz)

CZRN 75770919 Plug-in receiver (868 MHz)

CZ6 85710 Creda Zone 6 RF controller (433 MHz)

CZ1 85715 Creda Zone 1 RF controller (433 MHz)

CZR 85711 Plug-in receiver (433 MHz)

CZS 85712 Plug-in Creda Saver

CZC 85713 Cover for controls

Product Selector

Advanced control

heating systems

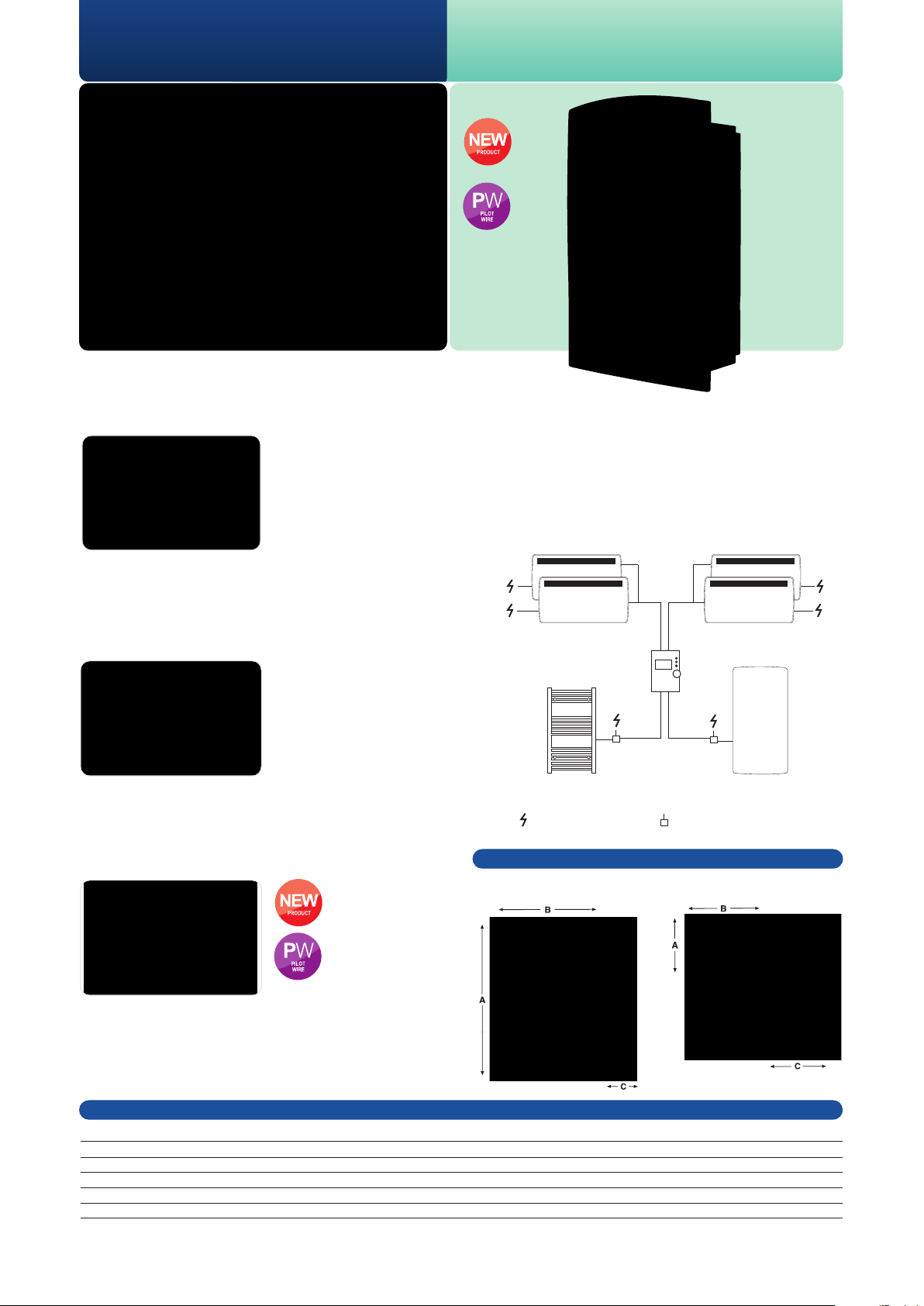

Page 20

Control Options

20

+44 (0) 1733 456789 www.creda-heating.co.uk

The performance and economy of Creda heating products

can be further enhanced by use of control options best

suited to the type of installation and lifestyle requirements.

Creda controller for 4 zone pilot wire linked heating system

Auxiliary heater interface for pilot wire linked heating system

Plug-in 7 day heater module for single zone pilot wire linked system

Plug-in 24 hour timer module for single heater control

Plug-in runback timer module for single heater control

Pilot wire signalling - ideal control system option

for new build applications

4 zone wall mounted central controller mains powered with 4hr backup

Number of heaters - up to 20 in the same zone

Controller features:

TIME - individual 7day programming of multiple

time periods

MODES - on/off, comfort/setback or comfort/frost.

Also with manual override selection and holiday

functions

Panel Heater features - integral electronic

thermostat for comfort temperature selection with a fixed

5

O

C setback from comfort, and frost protection at 5OC

Outline towel rails feature - integral thermostat for

comfort temperature, fixed 3-4

O

C setback from comfort

and frost at 7

O

C. Also has manual override, 2hr boost

and thermostat range restriction options

EcoResponse Storage

Radiant Heaters

Contour100

Electronic

Panel Heaters

TPRIII E Electronic

Panel Heaters

Newera Style

Electronic Panel

Heaters

Newera Electronic

Panel Heaters

Outline Thermostatic

Towel Rails

Proline II PL

Electric Ladder

Towel Rails

TD Traditional Style

Electric Towel Rails

Solarail Electric

Towel Rails

Immersion heater

downflow fan heater or

plinth heater (3kW max)

Contour100

Electronic

Panel Heaters

Pilot Wire Controller

Ref: 75 770916

Model: PW E4ZC

Pilot Wire Interface

Ref: 75 770915

Model: PW E16A

7 Day Timer Pilot Wire

Ref: 75 770913

Model: TPR E7DT

24 Hour Timer

Ref: 75 770912

Model: TPR E24T

Run Back Timer

Ref: 75 770914

Model: TPR ERBT

Pilot wire signalling - ideal control system option

for new build applications

16amp interface unit - for auxiliary heaters without

any integral controls

Number of heaters - single unit with up to 3kW

maximum loading

Interface features - on/off switching only as

signalled by the central controller

Installation - requires a 46mm deep single gang

metal back box for flush mounting

Pilot wire signalling - ideal control system option

for new build applications

Single zone plug-in module controller mains powered by panel with 12hr backup

Number of heaters - up to 10 slave panels pilot

wire linked in a single zone

Timer features - 4 on/off time periods for weekdays

and 4 for weekends. Also has key lock and ‘advance to

next programme’ functions

Single heater control - not system linked

24 hour plug-in timer module - mains powered

by panel with 12hr backup

Number of heaters - single heater control only

Timer features - 4 on/off time periods in 24hrs

Additional features: key lock and ‘advance to next

programme’ functions

Single heater control - not system linked

Runback plug-in timer module - mains powered

by panel

Number of heaters - single heater control only

Timer features - on/off fixed runback time from

1/2hr up to a 4hr period (1/2hr increments selected at

installation)

Special function - an alternative selection that

switches from comfort to setback for an initial 24hr

period, followed by comfort to frost

TPRIII E Electronic

Panel Heaters

Contour100

Electronic

Panel Heaters

TPRIII E Electronic

Panel Heaters

Contour100

Electronic

Panel Heaters

TPRIII E Electronic

Panel Heaters

Page 21

Control Options

21

+44 (0) 1733 456789 www.creda-heating.co.uk

Plug-in timer module for single zone mains borne panel heating system

Central controllers for 1 or 6 zone radio frequency panel systems

Central controller for 8 zone radio frequency panel systems

Plug-in single heater 7 day programmable timer module (with setback)

RF remote thermostat / programmer kits for auxiliary appliances

Mains borne signalling - no additional signal

cabling required ideal for retro fit installations

Single zone plug-in programmer - powered by

panel with battery backup

Number of heaters - any number of panels each

with an receiver interface unit fitted

Controller features - 3 separate time clocks with

hourly on/off period selection over 24hrs. Each can be

allocated to one or more days of the week

Panel heater features - integral twin linked

electronic comfort and setback thermostats

Radio frequency signalling - 433MHz wireless

signalling ideal for retro fit installations

Single or 6 zone RF programmers - wall mounted

or free standing, battery powered (2 x AA batteries)

Number of heaters - any number of RF panels with

plug-in 433MHz receiver modules fitted

Controller features: full time and temperature

adjustment with override and holiday functions.

TIME - 7day, multiple time period setting for each zone

TEMPERATURE - level settings: frost (5-15

O

C),

setback (5-30OC) and comfort (5-30OC)

Panel heater features - integral digital electronic

thermostat

Radio frequency signalling - 868MHz wireless

signalling ideal for retro fit installations

8 zone RF programmer - compact wall mounted or

free standing, battery powered (2 x AAA batteries)

Number of heaters - any number of RF panels with

plug-in 868MHz receiver modules fitted

Controller features: full time and temperature

adjustment with override and holiday functions.

TIME - 7day, multiple time period setting in each zone

TEMPERATURE - level settings (frost 5-15

O

C),

(setback 5-30OC) and (comfort 5-30OC)

Panel heater features - integral digital electronic

thermostat

Radio frequency signalling - wireless signalling

between thermostat/programmer unit and the receiver

at the heater

Number of heaters - multiple heaters with receivers

fitted up to a maximum total loading of 2kW

Thermostat unit features - push on/off rotary

control (5

O

C -30OC) with 30 minute boost

Thermostat with programmer unit 4 programmable on/off time periods for weekdays and

weekends. LCD display with 12hr backup memory

MB Programmer

Ref: 75 770907

Model: PW E4ZC

MB Receiver interface

Ref: 75 770908

Model: PW E4ZC

Newera Style

Electronic Panel

Heaters

Newera

Electronic Panel

Heaters

RF Single Zone

Programmer

Ref: 85715

Model: CZ1

RF Plug-in (433MHz)

Receiver Module

Ref: 85711

Model: CZR

RF Single Zone

Programmer

Ref: 85715

Model: CZ1

RF 6 Zone

Ref: 85710

Model: CZ6

RF Electronic

Panel Heaters

RF Electronic

Plinth Heaters

RF Plug-in (868MHz)

Receiver Module

Ref: 75 770919

Model: CZ RN

RF 8 Zone

Programmer

Ref: 75 770918

Model: CZ 8N

RF Electronic

Panel Heaters

RF Electronic

Plinth Heaters

Credasaver Plug-in

Programmer

Ref: 85712

Model: CZS

RF Electronic

Panel Heaters

RF Electronic

Plinth Heaters

RF Thermostat &

Receiver Kit

Ref: 75 770917

Model: RFRTK

RF Thermostat &

Programmer & Receiver

Ref: 75 770920

Model: RFRTK7

RF Receiver

Ref: 75 770920

Model: RFRTK7

Towel rails, Plinth Heaters and other

heaters without controls

Single heater control - not system linked

7 day plug-in programmer module -

mains powered by the panel heater

Number of heaters - single heater control only

Programmer features:

15 pre-set programmes over a 7 day period.

Integral setback thermostat (5-20

O

C)

Panel heater features - integral digital electronic

thermostat for comfort setting (5-30

O

C)

Page 22

Model Reference Rating Direct Charge Net Storage Weight Number Number of Remaining Useful Heat* (Fan Off)

Storage Acting Acceptance (7 hrs) of Elements Core Bricks After 17hrs (Static) Discharge

SFH18AW 70305 2.5kW 1.5kW 17.6kWh 14.9kWh 121kg 3 12 40%

SFH24AW 70315 3.4kW 1.5kW 23.5kWh 20kWh 158kg 4 16 40%

SFHA Sensair Automatic

Electric storage fan heaters

22

+44 (0) 1733 456789 www.creda-heating.co.uk

Product Selector

Technical Specification

Dimensions

Key features

• Combines electric storage fan heating,

direct acting heating and fanned heat output

with simple controls

• Fully automatic heat storage - no user adjustment

required on input controls

• High performance insulation works more

effectively than a conventional storage heater

• Heat output is via a quiet two speed fan

• Boost setting for high speed room heat up

• Fan can be switched off without altering

thermostat setting

• Operates on virtually any tariff and takes better

advantage of extended or split tariffs

• Fanned heating avoids heat stratification

• Lockable controls cover

• Negative pressure air movement through the

storage core avoids hotspots and heat leakage

• Elements (storage) - mineral insulated stainless

steel sheathed

• Insulation - opacified silicaceous aerogel and

mineral fibre mat

• Storage Core - high density iron oxide compound

• Fan Unit - two speed crossflow fan

• Controls (Output) - regulated by fan, activated

by integral adjustable thermostat

• Controls (Input) - hydraulic head temperature

compensated, room and storage core temperature

sensitive, auto-set charge control

• Protection - two level thermal safety overheat

• Supply - 230/240V AC single phase

“

The ultimate combination

of storage and direct

fan heating. Able to

regulate input with direct

acting heat flexibility, the

SFHA Sensair is more

effective at retaining heat

than a conventional

storage heater.

Able to operate on virtually any tariff

and with superior high performance

insulation levels, it achieves higher SAP

and NHER ratings than manual input

storage heaters.

”

Model Height A Width B Depth C

SFH18AW 705mm 788mm 187mm

SFH24AW 705mm 1016mm 187mm

Electric storage

heating

Page 23

23

+44 (0) 1733 456789 www.creda-heating.co.uk

Model Reference Rating Direct Charge Net Storage Weight Number Number of

Storage Acting Acceptance (7hrs) of Elements Core Bricks

TSR12CW 79348 1.7kW 1/0.5kW 11.8kWh 12.6kWh 78kg 2 8

TSR18CW 79358 2.5kW 1.5/0.75kW 17.6kWh 18.5kWh 114kg 3 12

TSR24CW 79368 3.4kW 2/1kW 23.5kWh 25.0kWh 149kg 4 16

TSR12ACW 75 772001 1.7kW 1/0.5kW 11.8kWh 12.6kWh 78kg 2 8

TSR18ACW 75 772002 2.5kW 1.5/0.75kW 17.6kWh 18.5kWh 114kg 3 12

TSR24ACW 75 772003 3.4kW 2/1kW 23.5kWh 25.0kWh 149kg 4 16

TSR Supaslim Combi

Storage fan heaters

Effectively two heaters in one, the built-in

fan can provide heat on its own or in

combination with the storage heater for a

rapid boost to room temperature.

Key features

• Combines economic tariff rate storage heater

with a fast and responsive Warmflow fan heater

for instant room heating

• The slimmest storage combination heater available

• Sensamatic fully automatic storage heater output

ensures room comfort levels are maintained

throughout the day without user intervention

• The Warmflow fan heater has manually

adjustable room temperature sensing thermostatic

control accurate to within 0.5°C

• Warmflow gives better heat distribution, helping

to avoid heat stratification

• Quiet, low velocity Warmflow fan

• All controls are concealed behind a lockable flap

• CW range manually adjustable hydraulic

charge control thermostat

• ACW range has hydraulic input charge

control thermostat providing auto-set

input charge control

• Fan heater ratings can be set on full or

half load (installation option)

• Automatic fan heater switch-off during off-peak

tariff periods (installation override option)

• Elements (storage) - mineral insulated stainless

steel sheathed

• Insulation - opacified silicaceous aerogel and

mineral fibre mat

• Storage Core - high density iron oxide compound

• Fan Unit - crossflow

• Controls - hydraulic head temperature

compensated, room and storage core temperature

sensitive, auto-set charge control

• Protection - two level thermal safety overheat

• Supply - 230/240V AC single phase

Technical Specification

Dimensions

Product Selector

Model Height A Width B Depth C

TSR12CW/ACW 760mm 560mm 170mm

TSR18CW/ACW 760mm 788mm 170mm

TSR24CW/ACW 760mm 1016mm 170mm

“

The Creda Supaslim

Combi heater is designed

to combine economic and

has efficient storage

heating using low-cost

tariff electricity with an

independently thermostatcontrolled fan heater.

”

Electric storage

heating

Page 24

Working on any low-cost tariff, these

heaters monitor the room temperature and

energy stored within the heater core to

avoid overcharging. This can save up to

15% of the energy used by ordinary

storage heaters.

Key features

• Multi-sense two thermostatic sensor control

system for heat storage and room

temperature control

• The only storage heater available that

automatically monitors and controls heat output

through a thermostatic sensor

• Controls couldn’t be simpler - one for input

and one for output

• Multi-sense system enables energy savings

of up to 15%

• Multi-sense operates exclusively at maximum

efficiency on all economy tariff periods

• Automatic control means little if any control

adjustment - just set and forget

• All Multi-sense sensors are mounted within

the heater

• Lockable controls cover

TSR Slimline (MW) models offer the same

range of sizes and outputs but with simple

manual input and output controls.

* TSR6AW/MW have no user controls and

are IPX2 rated (drip-proof)

• Elements (storage) - mineral insulated stainless

steel sheathed

• Insulation - opacified silicaceous aerogel and

mineral fibre mat

• Storage Core - high density iron oxide compound

• Controls* (Output) - manually adjustable

thermostat controlling output damper.

• Controls (Input) - hydraulic charge control

thermostat, manually adjustable

• Protection - two level thermal safety overheat

• Supply - 230/240V AC single phase

Model Reference Rating Charge Charge Weight Number Number of

Storage Acceptance (7 hrs) Acceptance (8 hrs) of Elements Core Bricks

TSR6AW 79331 0.9kW 6.3kWh 7.2kWh 41kg 1 4

TSR12AW 79341 1.68kW 11.8kWh 12.6kWh 77kg 2 8

TSR18AW 79351 2.5kW 17.6kWh 18.5kWh 110kg 3 12

TSR24AW 79361 3.4kW 23.5kWh 25kWh 145kg 4 16

TSR6MW 79334 0.9kW 6.3kWh 7.2kWh 41kg 1 4

TSR12MW 79344 1.68kW 11.8kWh 12.6kWh 77kg 2 8

TSR18MW 79354 2.5kW 17.6kWh 18.5kWh 110kg 3 12

TSR24MW 79364 3.4kW 23.5kWh 25kWh 145kg 4 16

Model Height A Width B Depth C

TSR6A/MW 705mm 335mm 170mm

TSR12A/MW 705mm 560mm 170mm

TSR18A/MW 705mm 788mm 170mm

TSR24A/MW 705mm 1016mm 170mm

TSR Sensor Plus & Slimline

Electric storage heaters

24

+44 (0) 1733 456789 www.creda-heating.co.uk

Product Selector

Technical Specification

Dimensions

“

The Multi-sense system in

the TSR Sensor Plus

(AW models) automatically

controls heat storage to

maintain the desired room

temperature.

”

Electric storage

heating

Page 25

25

+44 (0) 1733 456789 www.creda-heating.co.uk

Model Reference Rating Direct Acting Charge Charge Weight Number of

Element Load Acceptance (7hrs) Acceptance (8hrs) Core Bricks

TSF24K 70369KS 3.6kW 0.7kW 25.2kWh 28.8kWh 137kg 18

TSF32K 70379KS 4.8kW 1.1kW 33.6kWh 38.4kWh 176kg 24

TSF42K 70389KS 5.7kW 1.5kW 39.9kWh 45.6kWh 215kg 30

TSF Turbo

Commercial storage fan heaters

The heater retains up to 40% of its total

stored heat after 17 hours, allowing the

thermostatically controlled 2-speed

centrifugal fan to deliver rapid and

uniform heat.

Key features

• Smooth, rounded, modern appearance, compatible

with today’s home and office décor

• TSF Turbo uses economy tariff electricity,

operating particularly well on special daytime

economy periods

• Available in 3.6kW, 4.8kW and 5.7kW models

• More controllable, providing heat quickly

when required

• In-built direct element for out of season heating

using day rate electricity

• Fanned heat is faster and more even in distribution,

particularly near ground level

• Easy to use manual controls for room thermostat

and economy charge

• Single or 3 phase installation capability

User controls

• Charge input control

• Neon switch for fan

• Neon switch for direct acting element

• Heat output control

• Insulation - opacified silicaceous aerogel and

mineral fibre mat

• Storage Core - high density iron oxide compound

• Storage Elements - mineral insulated stainless

steel sheathed

• Protection - two level thermal safety overheat

• Supply - 230/240V AC single phase

Technical Specification

Dimensions

Product Selector

Model Height A Width B Depth C

TSF24K 672mm 776mm 250mm

TSF32K 672mm 926mm 250mm

TSF42K 672mm 1076mm 250mm

“

Creda TSF Turbo storage

fan heaters provide

controlled output space

heating with maximum

economy and flexibility.

”

Electric storage

heating

Page 26

Storage Heater

Accessories

26

+44 (0) 1733 456789 www.creda-heating.co.uk

Useful shelves for utilising space above

the heater and rail attachment to warm

towels and clothes.

TSR towel rails

• Available for TSR 6, TSR 12 and TSR18

auto and manual models

• Warms and drys towels safely

• Matching white finish

• Quick and easy to fit

• Supply complete with fixings

Storage heater shelves

• Available in four widths to cover all sizes of TSR

storage heaters and SFHA storage fan heaters

• Matching white finish

• Quick and easy to fit

• Supply complete with fixings

Heater Guard Options

“

Creda are also able to offer a choice of

heater accessories to complement the storage

heater ranges.

”

A range of guards, designed to protect against

accidental contact with the hot surface of the heater,

is available for Creda heaters from our suppliers:

Norfolk Industries, 95 Oak Street, Norwich NR3 3BP.

Please contact them direct:

Tel: 01603 667957 Fax: 01603 624265

Dimensions

Electric storage

heating

Model Reference Product Description Rating Height A Width B Depth C

TR6 79130WS Storage heater towel rail attachment TSR6A and TSR6M 226mm 391mm Ø10mm

TR12 79140WS Storage heater towel rail attachment TSR12A and TSR12M 226mm 618mm Ø10mm

TR18 79150W Storage heater towel rail attachment TSR18A and TSR18M 226mm 826mm Ø10mm

SHS6 79032S Storage heater shelf TSR6 140mm 405mm 93mm

SHS12 79042S Storage heater shelf TSR12 140mm 630mm 93mm

SHS18 79052S Storage heater shelf TSR18 and SFHA18 140mm 858mm 93mm

SHS24 79062S Storage heater shelf TSR24 and SFHA24 140mm 1086mm 93mm

Product Selector

Rail

Shelf

Page 27

Key features

• 300W, 500W and 750W output rails

• High quality white or chrome finish

• Integral controls (Controls must be positioned

outside of zones 0, 1 & 2)

• Digital electronic thermostat with range restriction

and lock facility

• Pilot wire control compatible

• IP24 rated (splashproof)

Integral control features

• Push button - On/off with neon indicator

• Rotary - Thermostat with frost protection setting

• Rotary - Variable boost - time set 15 minutes,

30 minutes,1 hour or 2 hours

Control options

Outline towel rails can be pilot wire linked

to a flash controller as part of a complete

heating system.

27

+44 (0) 1733 456789 www.creda-heating.co.uk

Outline

Thermostatic integral control towel rails

Model Reference Product Description Rating Height A Width B Depth C

OTRC300 75 772710 Outline 30 (chrome) 300W 855mm 550mm 85mm

OTRC500 75 772711 Outline 50 (chrome) 500W 1,300mm 550mm 85mm

OTRW500 75 772701 Outline 50 (white) 500W 815mm 550mm 85mm

OTRW750 75 772702 Outline 75 (white) 750W 1,225mm 550mm 85mm

PW E4ZC 75 770916 4 zone pilot wire central controller

Product Selector

Dimensions

“

Outline heated towel rails

are of the popular ladder

style and, with outputs of

up to 750W, they provide

background heating as well

as warm dry towels.

”

Towel rails &

bathroom warmers

Technical Specification

• Element - cartridge type

• Control - digital electronic thermostat

with boost facility

• Protection - thermal cut-out

• Supply - 230/240V AC single phase

Page 28

Proline II PL

Fast response electric ladder towel rails

Product Selector

Model Reference Description Rating Height A Width B Depth C Weight

Straight rail models

PL180SW 75 774502 Straight white 180W 610mm 453mm 80mm 4.4kg

PL220SW 75 774503 Straight white 220W 610mm 602mm 80mm 7.9kg

PL260SW 75 774504 Straight white 260W 843mm 453mm 80mm 5.5kg

PL360SW 75 774505 Straight white 360W 843mm 602mm 80mm 9.5kg

PL180SC 75 774512 Straight chrome 180W 610mm 453mm 80mm 5.4kg

PL220SC 75 774513 Straight chrome 220W 610mm 602mm 80mm 7.9kg

PL260SC 75 774514 Straight chrome 260W 843mm 453mm 80mm 5.5kg

PL360SC 75 774515 Straight chrome 360W 843mm 602mm 80mm 9.5kg

“

The new Proline II range of

dry element ladder style

towel rails provide much

faster heat up than fluid

filled models and are

lighter and easier to install,

with no chance of leaks.

”

28

+44 (0) 1733 456789 www.creda-heating.co.uk

Towel rails &

bathroom warmers

Featuring a patented fast response

technology and outstanding performance.

Proline II towel rails are available in a

choice of 16 models with chrome or white

finishes and both and straight options.

Key features

• Fast response technology for a quicker warm up

than conventional towel rails

• Provides more heat from a lower output so more

energy efficient

• Even heat distribution - no cold spots

• Compact, slimline design

• Dry element technology - no leakage, no rusting

• Lightweight for faster, easier installation

• IPX4 rated (splashproof)

180W

260W

220W

360W

Four sizes each in white or chrome, straight or curved rails

Page 29

29

+44 (0) 1733 456789 www.creda-heating.co.uk

Proline II PL

Fast response electric ladder towel rails

Technical Specification

Dimensions

• Element - silicone coated dry element type

• Control - cycling cutout

• Protection - Two auto re-set temperature limiters

• Supply - 230/240V AC single phase

Towel rails &

bathroom warmers

Fluid-filled

towel rail

New dry

element rails

Fast even heat distribution in minutes

Control Options

RFRTK7 RF remote thermostat

and programmer kit.

Enables thermostatic and time control

using wireless signalling between the

remote wall mounted thermostat and

the receiver unit at the appliance

(Also available thermostat kit only

see page 21).

Product Selector

Model Reference Description Rating Height A Width B Depth C Weight

Curved rail models

PL180CW 75 774552 Curved white 180W 610mm 453mm 90-100mm 4.4kg

PL220CW 75 774553 Curved white 220W 610mm 602mm 90-100mm 7.9kg

PL260CW 75 774554 Curved white 260W 843mm 454mm 90-100mm 5.5kg

PL360CW 75 774555 Curved white 360W 843mm 602mm 90-100mm 9.5kg

PL180CC 75 774562 Curved chrome 180W 610mm 453mm 90-100mm 4.4kg

PL220CC 75 774563 Curved chrome 220W 610mm 602mm 90-100mm 7.9kg

PL260CC 75 774564 Curved chrome 260W 843mm 453mm 90-100mm 5.5kg

PL360CC 75 774565 Curved chrome 360W 843mm 602mm 90-100mm 9.5kg

RF Thermostat kits

RFRTK 75 770917 RF remote ther mostat kit 2kW

RFRTK7 75 770920 RF thermostat and programmer 2kW

RFRI 75 770921 RF additional receiver unit only 2kW

Pilot wire interface unit

PW E16A 75 770915 Pilot wire auxiliar y interface unit 3kW

PW E16A Pilot wire auxiliary interface unit

Enables heaters without electronic controls

to be central programmed, for on/off time