Page 1

CR-3040 Pro

V1.3

Page 2

Page 3

Content

Dear Consumers,

Thank you for choosing our products. For the best experience, please read

the instructions before operating the Printer. Our teams will always be

ready to render you the best services. Please contact us by the phone

number or e-mail address provided at the end when you encounter any

problem with the Printer.

For a better experience in using our product, you can also learn how to

use the Printer in the following ways:

View the accompanied instructions and videos in the storage card.

Visit our official website www.creality.com to find relevant software/hard

ware information, contact details and operation and maintenance

instructions.

目录

A

B

Notes

使用须知

Equipment Introduction

设备简介

Spare Parts

零部件清单

尊敬的创想三维用户:

感谢您选择、使用创想三维的产品。为了您使用方便,请您在使用之前仔细阅读

该说明书,并严格按照说明书的指示进行操作。

创想三维团队时刻准备为您提供优质的服务。在使用过程中无论遇到什么问题

请按照说明书结尾所提供的电话、邮箱与我们进行联系。

为了您能够更好地体验我们的产品,您还可以从以下方式获取设备操作知识:

随机使用说明:你可以在存储卡内找到相关使用说明及视频。

创想三维官网:www.cxsw3d.com 您可以登陆创想三维官网寻找相关软硬件、

联系方式、设备操作、设备保养等信息。

C

Use A 3D Printer

使用3D打印机

Wire Connection

电路接线

Trouble Shooting

故障检修

Page 4

NOTES

1. Do not use the printer in the way which are not described herein to avoid persond injury or property damage.

2. Do not place the printer near any heat source or flammable or explosive objects. We suggest placing it in a well-ventilated, low-dust environment.

3. Do not expose the printer to violent vibration or any unstable environment, as this may cause poor print quality.

4. Do not use any other power cable except the one supplied. Do use a grounded three-prong power outlet.

5. Please do not open the plastic cover during usage, otherwise the printing will be interrupted.

6. Do not wear cotton gloves when operating the printer. Such cloths may become tangled in the printers moving parts leading to burns, possible bodily injury,

or printer damage.

7. There is the residual temperature of nozzle after printing, timely clean up filaments on the nozzle with other tools. Do not touch the nozzle to prevent scalding.

8. Clean the printer frequently. Always turn the power off when cleaning, and wipe with a dry cloth to remove dust, adhered printing plastics or any other material

off the frame, guide rails, or wheels. Use glass cleaner or isopropyl alcohol to clean the print surface.

9. Children under 10 years should not use the printer without supervision.

10.The printing environment temperature is recommended to be 18-30℃. Excess temperature or low temperature will influence the printing quality.

11. Users should comply with the laws and regulations of the corresponding countries and regions where the equipment is located (used), abide by professional

ethics, pay attention to safety obligations, and strictly prohibit the use of our products or equipment for any illegal purposes. Creality will not be responsible for

any violators' legal liability under any circustance.

12. Tips:Do not plug or unplug the power cord when power on.

1、请勿尝试任何使用说明中没有描述的方法来使用本机,避免造成意外的人身伤害和财产损失;

2、请勿将本机放置在易燃易爆物品或高热源附近,请将本机放置在通风、阴凉、少尘的环境内;

3、请勿将打印机放置在振动较大或者其他不稳定的环境内,机器晃动会影响打印机打印质量;

4、请勿在安装过程中使用其他产品电源线代替,请使用本机附带的电源线,电源插头需接插在带有地线的三孔插座;

5、请勿在打印机工作时打开打印机面盖,以免影响打印;

6、请勿在操作打印机时戴棉手套,以防可动部件对人身部件造成卷入挤压和切割伤害;

7、在打印完毕后及时利用喷头的余温借助工具将喷头上的耗材清理干净,清理时请勿直接用手触摸喷头,以防出现烫伤;

8、常做产品维护,定期在断电的情况下,用干布对打印机做机身清洁,拭去灰尘和粘结的打印材料、导轨上的异物;

9、年龄在10岁以下的儿童,请勿在没有人员监督的情况下使用本机,以免造成人身伤害;

10、建议打印环境温度为18-30度,过高或过低的环境温度,都会影响打印质量

11、使用者应遵守设备所在地(使用地)相应国家、地区法律法规,恪守职业道德,注意安全义务,严禁将我司的产品或设备使用在任何非法用途上。如有违反者所应承

担的相关法律责任我司概不负责;

12、温馨提示:请勿带电插拔电线。

使用须知

Page 5

Equipment Introduction

设备简介

1

2

3

13

4

5

6

7

8

1

2

3

4

Top door

上门

Top cover

上盖

Touch screen

触摸屏

Nozzle kit

喷头套件

Front door

5

前门

Hotbed plate

6

热床板

Storage card slot and USB port

7

存储卡卡槽及USB接口

Universal wheel

8

万向轮

9

10

11

12

14

15

Extruder

9

挤出机

Filament sensor

10

断料检测模块

Right door

11

右门

Filament holder and trays

12

料架及料盘

Air filtration system

13

空气过滤系统

Power switch

14

电源开关

Power port

15

电源接口

Page 6

Equipment Parameters

设备参数

Model | 型号 CR-3040 Pro

Molding size | 成型尺寸

Number of nozzle | 喷头数量

Nozzle diameter | 喷嘴直径

Precision | 精度

Filament | 打印材料

File format | 支持格式

File transfer| 打印方式

Slicing software | 可兼容切片软件

Power specification | 电源规格

Total power | 总功率

Hotbed temperature | 热床温度

Filament sensor| 断料检测

Dual Z-axis screw rod | 双Z轴丝杆

Language | 语言

Computer operating system| 电脑操作系统

Print speed | 打印速度

Basic Parameters 基本参数

300*300*400mm

FDMMolding technology | 成型技术

1

0.4mm

±0.1mm

Φ1.75mm PLA/ABS

STL/OBJ/AMF

Storage card/USB |存储卡脱机打印或联机打印

3D Creator Slicer, Repetier-Host, Cura, Simplify3D | 创想三维切片软件、Repetier-Host、Cura、Simplify3D

Input | 输入:AC 100-240V 50/60Hz Output | 输出:DC 24V

500W

≤110°C

≤280°CNozzle temperature| 喷嘴温度

Yes | 有

Yes | 有

Chinese/English | 中英切换

Windows XP/Vista/7/8/10/MAC/Linux

≤180mm/s, 30-60mm / s normally | ≤180mm/s, 正常为30-60mm/s

Page 7

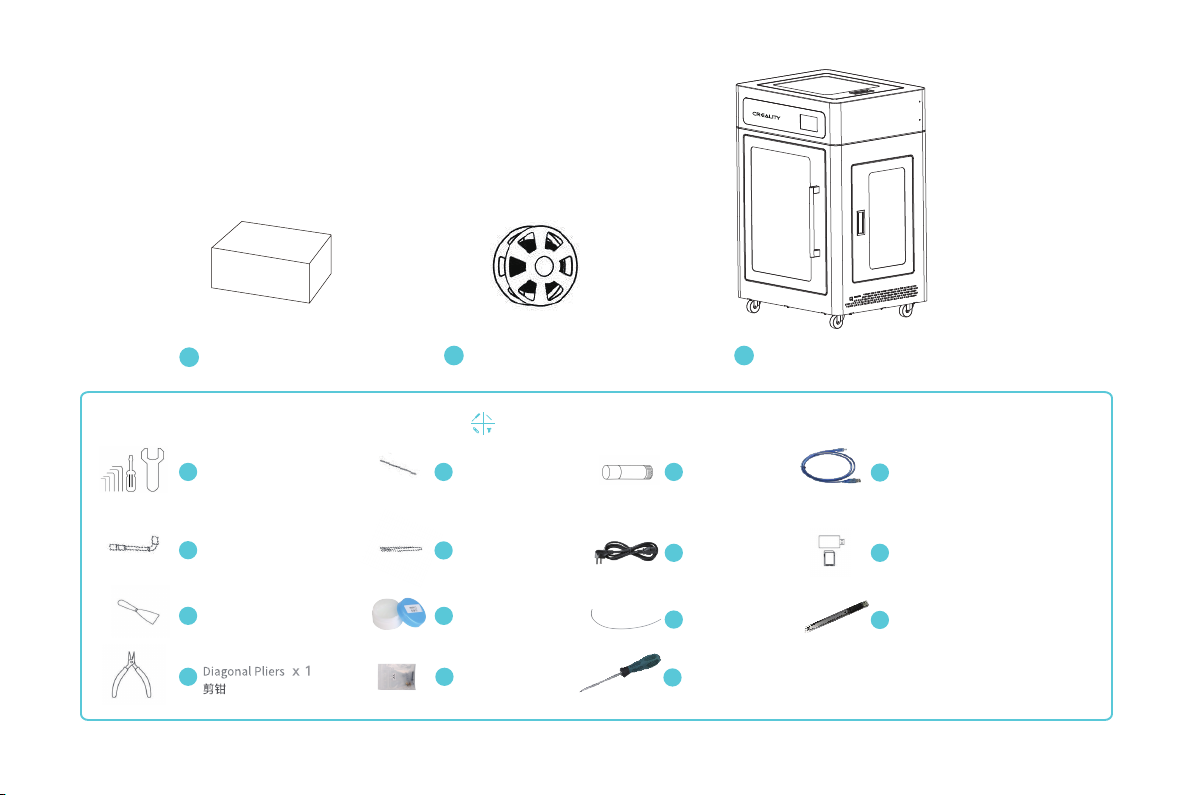

Spare Parts

零部件清单

1

Tool Kit|工具包

x 1

2

Filament|耗材

x 1

3

3D printer |3D打印机

Tool list 工具包清单

Wrench and screwdr-

4

iverx 1 扳手和螺丝刀

Sleeve x 1

8

套筒

Spade x 1

12

铲刀

16

Tips: the above accessories are for reference only, please refer to the physical accessories! 注意:以上配件仅供参考,请以实物为准!

Needle x 1

5

通针

Tweezers x 1

9

镊子

Greasex 1

13

润滑膏

Spare parts x 1

17

备品

Solid glue x 2

6

固体胶

Power cord x 1

10

电源线

Teflon tube x 1

14

铁氟龙管

Cross Screwdriver x 1

18

十字螺丝刀

x 1

USB cablex 1

7

USB线

Storage cardand card readerx 1

11

存储卡和读卡器

Utility knifex 1

15

美工刀

Page 8

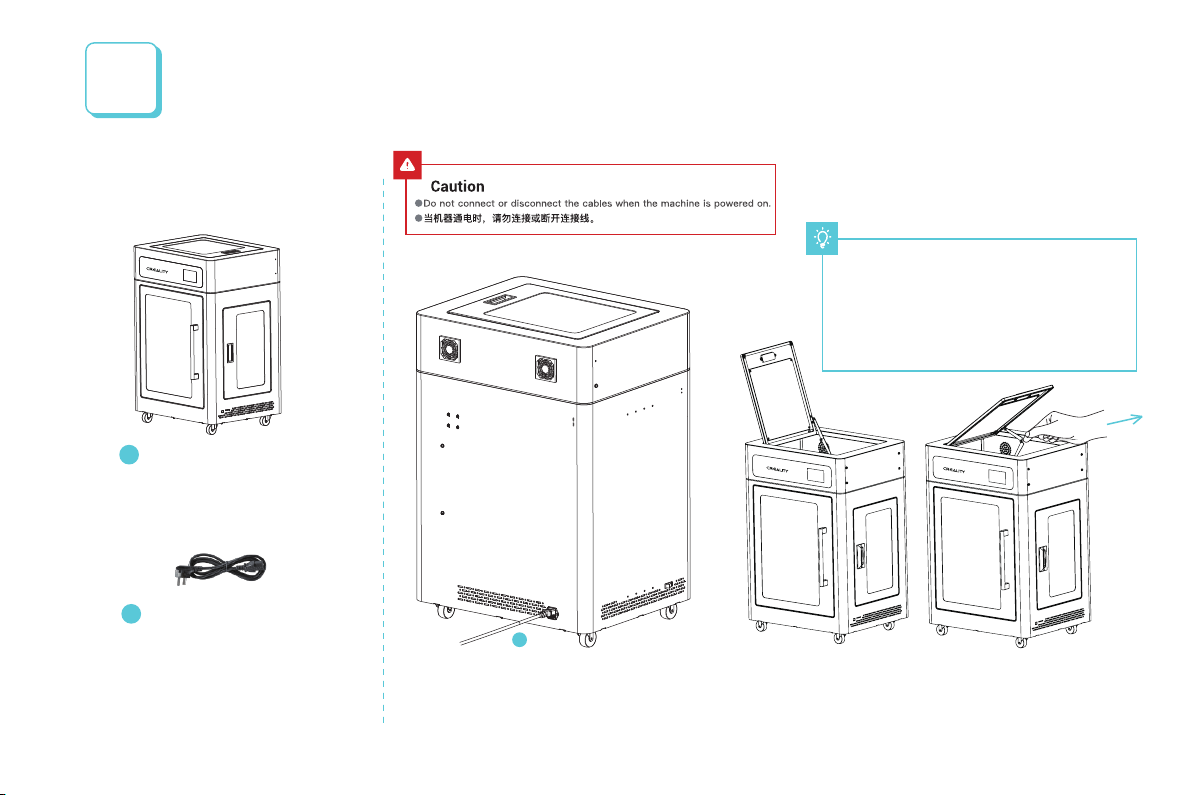

1

3

3D printer|打印机

10

Power cord |电源线

Start the 3D Printer 启动3D打印机

Turn the power switch to the I position to start the equipment.将电源开关拨至I档,即启动设备。

1. The hinge automatically supports the door

panel when opening;

2. Hold the door panel and move the hinge

outward to close it.

1. 开启时铰链自动支撑上门板;

2. 关闭时需用手往外拉铰链即可关闭上门板。

x 1

x 1

10

Page 9

2

Preheat

预热

29 0 29 0

29 0 29 0

0~280℃

280

81

110

38

29 0 29 0

29 0 29 0

200

0

81

0

38

Page 10

3

Preheat

预热

方法1、

29 0 29 0

方法2、

注意:界面仅供参考,实际以机器

UI为准。

29 0 29 0

29 0 29 0

0~280℃

280

81

110

38

29 0 29 0

200

Page 11

4165

2

Page 12

coming

awailing

Tips: How to replace the filament?

1.Cut filament near the Extruder and slowly feed in the new

filament to the material tube.

2.After preheating the nozzle, push the filament a little forward

and quickly withdraw the filament, and then feed in the new

filament.

Page 13

6

29 0 29 0

Level the Platform

调平平台

1、在初始调平时,稍微拧紧平台底部的四个调平螺母。

2、设置“调平模式”,点击数字①-⑤。

29 0 29 0

0.132

0.105

0.043

0.040

0.080

0.132

0.105

0.043

0.040

0.080

-0.015

-0.827

-0.365

-0.084

-0.033

-0.015

-0.827

-0.365

-0.084

-0.033

-0.005

-0.022

-0.067

-0.044

-0.035

-0.005

-0.022

-0.067

-0.044

-0.035

-0.057

-0.097

-0.022

-0.092

-0.092

-0.057

-0.097

-0.022

-0.092

-0.092

-0.055

-0.132

-0.087

-0.067

-0.085

-0.055

-0.132

-0.087

-0.067

-0.085

Notes:

Page 14

7

Move the nozzle near the top of the leveling screw, twist the screw left or right to adjust the distance between the nozzle and

the platform. The distance is as thick as a piece of A4 paper. Level the four corners of platform in order, click ① to check

whether the gap between the nozzle and the platform is proper or not.

①

Page 15

8

Page 16

9

Level the Platform

调平平台

Auto-leveling

If you need to realize the auto-leveling, you can have a setting:

29 0 29 0

自动调平

如果您需要自动调平,可以在下面界面中进行设置:

29 0 29 0

29 0 29 0

0.132

0.105

0.043

0.040

0.080

0.132

0.105

0.043

0.040

0.080

-0.015

-0.827

-0.365

-0.084

-0.033

-0.015

-0.827

-0.365

-0.084

-0.033

-0.005

-0.022

-0.067

-0.044

-0.035

-0.005

-0.022

-0.067

-0.044

-0.035

-0.057

-0.097

-0.022

-0.092

-0.092

-0.057

-0.097

-0.022

-0.092

-0.092

-0.055

-0.132

-0.087

-0.067

-0.085

-0.055

-0.132

-0.087

-0.067

-0.085

Notes:

Page 17

10

Page 18

11

G

G

G

29 0 29 0

195 195 45 45

29 0 29 0

G

SD卡

G

G

G

G

6.lnsert the storage card→Click print control→ Select the file to be printed.

插入存储卡→点击打印控件→选择要打印的文件

storage card!

shugen

test

huba

1

shugen

test

test

huba

1

test

2/20

test

2/20

打印

Page 19

Notes for printing ABS Materials

打印ABS材料注意事项

-1.84

100

240

110

1. Turn off the energy-saving ,

turn off the energy-fan ;

-1.84

100

240

110

1.关掉节能模式到OFF,关掉风扇到OFF;

2. The user shall turn off the printing cooling in the

design of ABS slice parameters.

2.用户在打ABS 切片参数设计上做要求关闭打印冷却。

Page 20

24V

5V

PT100 line

PT100线

BL-touch

Nozzle controllable fan

喷头可控风扇 机箱排气风扇

Case exhaust fan

Case fan

机箱风扇 喷头常开风扇

Normally open fan of the nozzle

Page 21

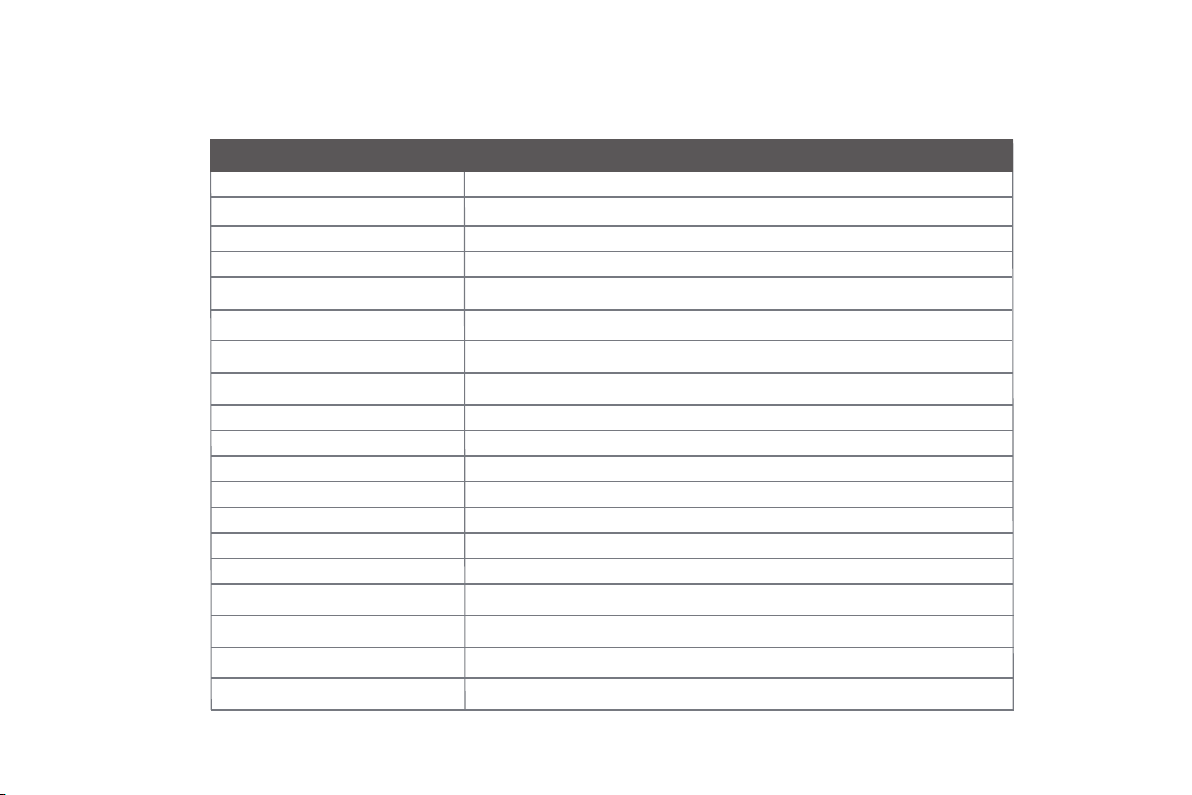

Trouble shooting

Workflow Fault diagnosis Fault cause Fault handling Result feedback

Start

Print from

storage card

File identification

Y/N

N

or not

Y

Resume printing function,

BLTOUCH probes can be retracted.

Y/N

Y

Return

“Home”

Y/N

Print or not

N

Y

Heat the

hot bed

Hot bed is

N

Y/N

heated or not

Y

Heat the

nozzle

The nozzle is

N

Y/N

heated or not

Y

Y/N

Y

Finish

Dislocation

Y

or not

Filament-push

N

or not

The E motor

N

rotates or not

Y

Printing wh en

filament-push

N

N

Y

Display error

codes or not

Other documents are

Y Y

printed normally or not

N

N

Beyond

Y Y

“Home”

N

The display of

Y

temp is normal or not

N

N

The display of humidity

N

is normal or not

Y

Y

N

or not

The filament is

normal or not

The gear rotates

Y Y Y

N

Storage-card

File naming

Slic er

BLTOUCH

Shaft motor

Limit switch

Hot bed

Thermistor

Heating tube

Thermistor

Slicer\

Synchronous belt

1.Wipe Storage-card

2. Format Storage-card

3. Replace Storage-card

Change the file name to English and

number format

1.Move model position and slice again

2.Using repair software to repair the model

1.Manually put back the probe

1.Reconnect circuit

2. Check by substitution

3. Check whether the push rod is at the

origin of the motor

1.Reconnect circuit

2. Check by substitution

1.Reconnect circuit

1.调平操作

1.Reconnect circuit

1.Reconnect circuit

1. Reconnect circuit and lock the screws of

1.调平操作

thermistor

1.Slice again

2. Adjusting the tension of synchronous belt

Coupling 1.Fasten the coupling

Others

N

Filament

E motor

1.Remove surface defects of filaments

2.Replace the filament

1.Reconnect circuit

2. Check by substitution

Process

result

Problem solved

Component damage, replace

continuously

Unknown malfunction, please

contact the after-sales

Page 22

故障检修

工作流程 故障诊断 故障原因 故障处理

开始

由存蓄

卡打

印

是/否

否

是

断电续打BLTOUCH

探针可以缩回

文件是否

识别

否

是否乱码是 是

否

其他文件是否

打印正常

存储卡

文件名

是

切片

1.擦拭存储卡

2.格式化存储卡

3.更换存储卡

1.文件名修改为英文和数字格式

1.移动模型位置并重新切片

2.使用修复软件修复模型

结果反馈

是/否

是

回零

是/否

是

热床加热

是/否

是

喷嘴加热

是/否

是

出丝打印

是/否

是

完成

是否运动

否

热床是否

否

加热

喷嘴是否

否

加热

是否错位 是

是

否

是否出料

否

E电机是否

否

转动

是

是

是

是

否

否

越过零点

否

温度是否

正常

否

温度显示

是否正常

挤出齿轮

是否转动

否

是

耗材是否

正常

BLTOUCH

轴电机

是

否

否

否

限位开关

热床

热敏电阻

加热管

热敏电阻

切片/同步带

联轴器 1.紧固联轴器

是

其他

否

耗材

E电机

1.手动拨回探针

1.检查电机、线路

2.用替换法检查

3.检查推料杆是否在电机端原点

1.检查限位开关、线路

2.用替换法检查

1.检查线路

1.调平操作

1.检查线路

1.检查线路

1.检查线路、松紧锁定热敏电阻

1.调平操作

螺钉

1.重新切片

2. 调整同步带松紧

1.去除耗材表面瑕疵

2.更换耗材

1.检查线路

2.用替换法检查

处理结果

解决故障

部件损坏连续更换

未知故障联系售后

Page 23

Page 24

Add:18F,JinXiuHongDu Building, Meilong Blvd., Longhua Dist.,

Shenzhen, China 518131

深圳市创想三维科技股份有限公司

深圳市龙华区民治街道新牛社区梅龙大道锦绣鸿都大厦18F

邮箱:kefu@creality.com

Loading...

Loading...