Page 1

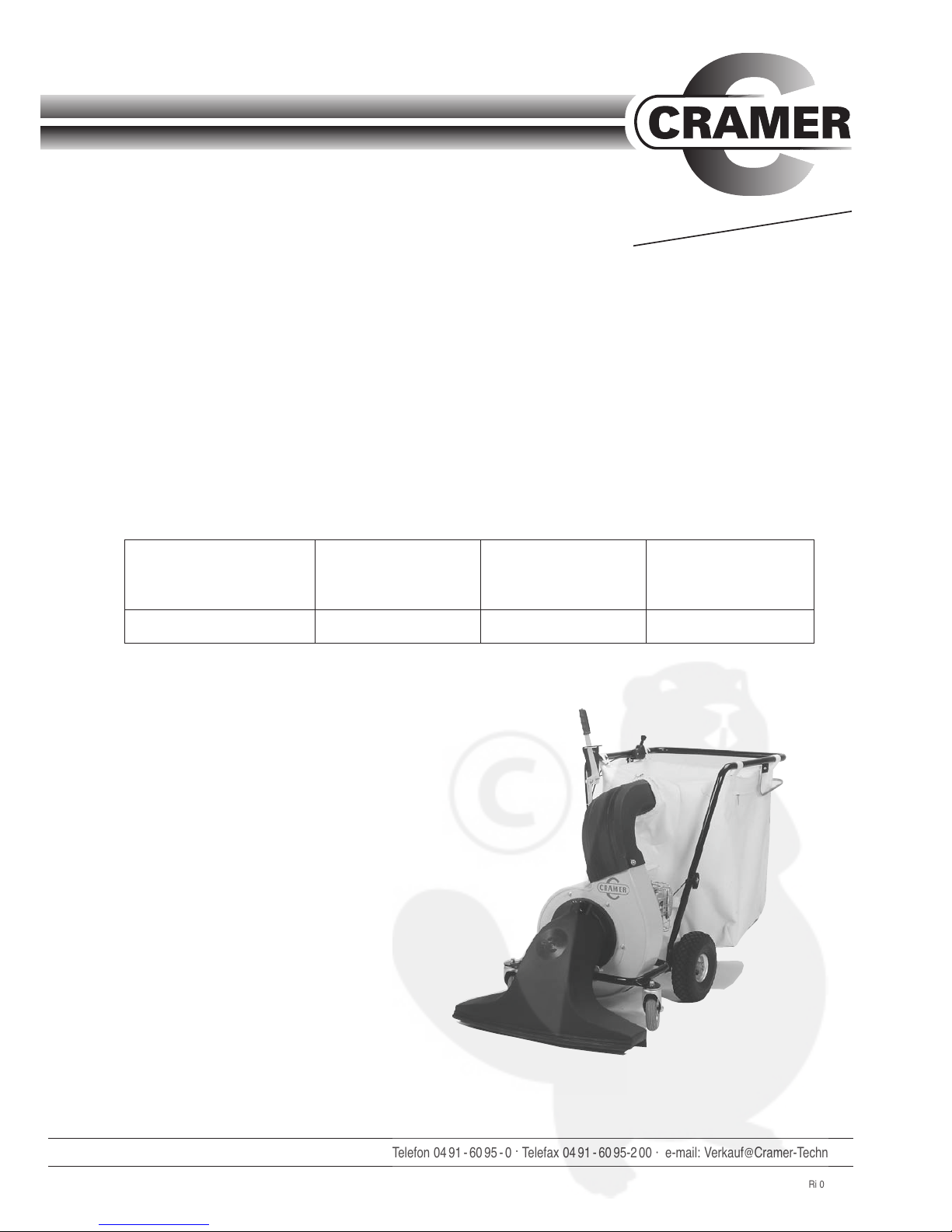

FOLIAGE- and WASTEVACUUM-CLEANER

Operating Instructions

Design: 03

CRAMER-TECHNIK GmbH .Postfach 12 69 .D-26762 Leer .Telefon 04 91- 6095 -0 .Telefax 04 91- 6095-2 00 · e-mail: Verkauf@Cramer-Technik.de

Contents:

1. Scope of Application

2. Description

3. Safety Instructions

4. Operation

5. Maintenance Instructions

6. Spare Parts

7. Troubleshooting

8. Technical Data

9. Spare Parts Drawing

10. Spare Parts List

Ri 02/18/01

You have purchased

the following model

(as marked)

Maschine-Nr.

LS 5000 LS 5000 H

LS 3500

T

op

-

T

echnique for the Gar

den

Page 2

1. Scope of Application

(The digits in text correspond to the item numbers on spare part list.)

- This machine is approved for use as a foliage and

garden waste vacuum (by converting the machine into a foliage blower) as described in these

operating instructions.

- The machine must not be used for any other purpose. The manufacturer shall not be liable for

damage resulting from improper use of the equipment. In such cases the user shall bear sole responsibility.

- Proper use includes observation of the operating,

maintenance and repair instructions given by the

manufacturer.

- Only personnel who are familiar with the machine

and possible dangers should be allowed to operate or repair the machine.

- The relevant accident prevention regulations and

generally recognized safety rules shall be observed.

- Unauthorized changes to the machine relieve the

manufacturer from any liability for damages that

might result therefrom.

2. Description

The machine comes pre-assembled except for the

foliage bag (8) and the suction nozzle (25/32). The

suction nozzle and bag should be fitted as shown in

Fig. 1.

The vacuum body has 4 wheels (9/36/46a+b/47);

hard rubber steering wheels at the front (9/47) to

resist damage by thorns, cushion tyred wheels at

the rear (36/46).

The drive consists of a 2.6 or 3.75 kW Honda petrol

engine. Model LS 3500 does not have a wheel

drive, model LS 5000 features a wheel drive. The

working width is 80 cm. A hand lever (27) is provided on the steering handle to adjust the suction

height of the nozzle (3).

The machine can be converted into a foliage blower

(see 4. Operation for further details).

For further technical data please refer to the table in

Section 7.

3. Safety Instructions

1. Always check machine for roadworthiness and

operating safety prior to use.

2. Observe all valid safety and accident prevention regulations in addition to these operating

instructions.

3. Read and understand these operating and

maintenance instructions and make sure that

you are familiar with the control elements and

their proper use.

4. Do not allow personnel to use the machine until

they have read these instructions. Save

instructions for future reference and ordering of

spare parts.

5. Make yourself familiar with all features and

control elements and with their functions prior

to operating the machine.

6. Persons below the age of 14 should not use the

machine.

7. Keep persons, especially children and pets,

away from the working area of the machine.

8. To operate this machine the manufacturer

recommends wearing the following:

- safety glasses or other suitable eye protection;

- sturdy shoes;

- no loose fitting clothing that might get caught

in the machine.

9. Protect the machine against rolling away and

use by unauthorized personnel.

10. Prior to starting the machine make sure that

there is enough fuel in the tank. Never refill fuel

in enclosed buildings when the engine is running or hot. Wipe off all spilt fuel before starting,

or wait until spilt fuel vapours have vanished.

11. Except when filling petrol, the petrol cap should

always be firmly fitted on the tank. When handling fuel, avoid naked flames, smoking and

sparks. Store fuel in appropriate containers

only.

12. Prior to carrying out cleaning, repairs or inspections make sure that all moving parts have

Vac assembly

Please see enclosed mounting

instructions

Fig. 1

Page 3

completely stopped. The engine ignition lever

should be set to »0« position so that the engine

cannot be started accidentally. In addition, the

gas lever must be in »Stop« position.

13. Never leave the machine unattended while the

engine is running.

14. Never run the engine in closed rooms: Danger of

intoxication!

15. Do not place hands or feet under the suction

nozzle or near rotating parts.

16. The area to be vacuumed should be clear of stones, wires etc. which could be picked up by the

rotor and flung in any direction, causing injury to

the operator or bystanders.

17. Do not vacuum materials that could clog the

rotor.

18. Always switch off the engine and wait until the

rotor has stopped completely before doing the

following:

1. Removing the foliage bag or clearing a blockage in the infeed channel, or

2. Removing the suction nozzle or clearing a

blockage in the suction nozzle

3. Repairs, adjustments or removal of foreign

items.

19. When using the foliage vacuum as a foliage blower, the protective cover at the rotor inlet has to

be properly fitted. The blower should not be pointed at persons.

20. The foliage bag should be cleaned at regular

intervals to guarantee proper filter performance.

21. Never empty the foliage bag when the engine is

running.

22. Never replace the suction nozzle or suction tube

while the engine is running.

23. Use only manufacturer’s approved accessories

and original spare parts.

24. Only qualified personnel should be allowed to

carry out repairs and maintenance.

4. Operation

As mentioned in section 2 the machine is pre-assem-

bled in the works with the exception of the foliage bag

and suction nozzle.

Fit the suction nozzle (3) and foliage bag (8) as shown

in Fig. 1, paying particular attention to the adjustment

of the Bowden cable (25/32) for the switch bar (31) to

prevent slipping of the engine clutch.

The engine is started by means of a recoil starter,

after first having set the ignition lever to »1« and the

gas lever to »start«. For further information, please

refer to the attached instructions of Honda.

The suction power of the rotor (51) is largely depen-

dent upon the height of the suction nozzle, (3) i.e. the

heavier the material to be picked up, the lower it

should be (right down for moist foliage and higher for

dry foliage).

The front and sides of the foliage bag (8) are fitted

with air-permeable filter material. The upper and rear

surface is less permeable out of consideration for the

operator. When large volumes of air are sucked in, i.e.

with a high position of the suction nozzle, additional filter surfaces can be created by opening the zips on

the right and left.

The foliage bag is full when the machine tends to tip

backwards, lifting the suction nozzle (3) at the front. In

this case the foliage bag (8) should be emptied by

opening the circumferential zip on the back and emptying it by means of the handle provided on the front

side. The opened part of the bag can be folded up out

of the way by means of a Velcro fastener.

Model LS 3500 has to be pushed over the surfaces to

be cleaned. Model LS 5000/LS 5000 H has a self-propelled drive which is started by means of the switch

bar (31) on the steering handle. Model LS 5000/LS

5000 H features free-wheeling ball bearings for curve

negotiating ability (38).

How to convert the foliage vaccum (3) into a foliage

blower: Unscrew the suction nozzle and the outlet

connecting piece (7). To cover the two openings, fit

the guard (59) supplied as an accessory. Then pull

back the locking plate (24) at the back to release the

lock and turn the rotor body (51) by approx. 90 deg.

(in counter-clockwise direction seen from the front of

the machine).

Caution:

rotation in the wrong direction might

damage cable to contact switch (5).

5. Maintenance Instructions

Strong vibrations arise when vac is on. It is therefore necessary to check screw tightness after a

few working hours.

Always set the ignition lever of the engine to »0« prior

to carrying out maintenance or repairs. To clean the

foliage bag (8), release the bag from the outlet (7)

connecting piece and undo the retaining straps. The

filter material of the foliage bag will eventually become

clogged. In this case, turn the bag inside out and

shake it out completely, or wash foliage bag in a water

bath or by rinsing with water; industrial cleaning is

also possible.

From time to time the suction nozzle (3) at the front of

the machine should be dismantled and the blower

rotor (14) inspected for damage caused by foreign

items.

Check the air pressure of the rear wheels (36/46a+b)

occasionally according to the technical data.

The drive engine should be serviced as described in

Page 4

the attached instructions of Honda.

All bearing points of the foliage vacuum have self-

lubricating ball bearings and do not have to be lubricated.

Model LS 5000/LS 5000 H: check drive after a longer

period of working time (depending on the type of

ground the vac is used on). Loosen the four screws

holding the bottom plate to uncover the complete

driving mechanism (45/66). Wear may have loosened the wheel driving chain (41/74). To adjust

distance again, loosen shaft bearings (42) and turn

bearings (42) in slot. Tighten screws carefully.

The air filter of the drive engine should be cleaned or washed out frequently because handling

foliage always involves a lot of dust.

6. Spare parts

A spare parts drawing and spare parts list is attached. Please identify the required spare parts

according to the drawing and state the article numbers given in the spare parts list on all orders.

7. Troubleshooting

8. Technical Data

Model 3500 Model 5000 Model 5000 H

Drive: Petrol engine type Honda Petrol engine type Honda Petrol engine type Honda

3.5 HP/2.6 kW 5 HP/3.75 kW 5 HP/3.75 kW

Consumption: 1.1 l/h 1.5 l/h 1.5 l/h

Noise level

without load: 66 db(A) 66 db(A) 66 db(A)

full load: 91 db(A) 91 db(A) 91 db(A)

Tyres

front: dia. 180 x 45 dia. 180 x45 dia. 180 x45

rear: dia. 300 x400-4 dia. 300 x400-4 dia. 300 x400-4

Air pressure, rear tyres: 1,8 bar 1,8 bar 1,8 bar

Weight (kg): 67 70 75

Dimensions:

L(mm) 157 157 157

W (mm) 70 70 70

H (mm) 105 105 105

Bag capacitiy: 240 240 240

Working width (cm): 80 80 80

Wheel drive: no yes yes

Fault: Cause: Solution:

1. Engine won’t start – Ingnition switch on engine in – Turn ignition switch to

»0« position »1« position

2. No engine power – Fuel tank empty – Refill fuel

– Sparking plug defective – Exchange sparking plug

– Fuel line blocked or – Empty fuel line and tank

water in petrol and refill new petrol

– Air filter soiled – Clean (rinse) air filter

3. Engine gets too hot – Carburettor not adjusted – Adjust carburretor acc. to

correctly Honda instructions

– Insufficient engine oil – Top up with engine oil

4. No suction power – Foliage bag too full – Empty foliage bag

– Filter area of foliage bag – Wipe filter areas

soiled (dry clean if necessary)

– Suction nozzle blocked – Clean suction nozzle

5. Wheel drive slip – Gear clutch is slipping – Shorten Bowden cable for

switch bar by shifting

clamping piece

Page 5

9. Spare Parts Drawing

Page 6

10. Spare Parts List

LS 3500 LS 5000 LS 5000 H

Item Description No. of drawing Art.-No. Art.-No. Art.-No.

1 Rubber strip 670.01-01-006 99.5.7000 99.5.7000 99.5.7000

2 Clamping strip 670.01-01-005 99.5.7001 99.5.7001 99.5.7001

3 Suction nozzle LS 99.5.7002 99.5.7002

4 Star-grip nut M10x25 99.5.7078 99.5.7078 99.5.7078

5 Contact switch 99.5.7004 99.5.7004

6 Hexagon bolt DIN 933-M10x25 99.5.7005 99.5.7005 99.5.7005

7 Outlet connecting piece 99.5.7006 99.5.7006

8 Foliage bag 99.5.7007 99.5.7007

9 Steering wheel assy (steel-rim) 99.5.7008 99.5.7008

10 Lock nut DIN 985-M12 99.5.7009 99.5.7009 99.5.7009

11 Plastic bushing 670.01-01-002 99.5.7010 99.5.7010 99.5.7010

12 Washer DIN 125-Ø13 99.5.7011 99.5.7011 99.5.7011

13 Hexagon bolt DIN 933-M12x35 99.5.7012 99.5.7012 99.5.7012

14 Rotor (20 mm ø) LS 5000 670.01-11 99.5.7013 99.5.7013

15 Feather key DIN 6886-A5x5x63 99.5.7014 99.5.7014 99.5.7014

16 Top pulley SPZ 50x1 99.5.7015 99.5.7015

17 Taper bushing PN 20-1610 99.5.7016 99.5.7016

18 Bottom pulley SPZ 150x1 99.5.7017 99.5.7017

19 V-belt XPZ 687 99.5.7018 99.5.7018

20 Flange bearing RA 20 99.5.7019 99.5.7019

21 Tension spring 99.5.7020

22 Feather key A5x5x25 99.5.7048 99.5.7048

23 Tightener 670.01-09 99.5.7021

23a Tightener 675.01-09 99.5.7088

24 Locking plate 670.01-25 99.5.7022 99.5.7022 99.5.7022

25 Bowden cable (gas lever) 99.5.7023

26 Adjusting rod 670.01-12 99.5.7024 99.5.7024 99.5.7024

27 Adjusting lever 670.01-13 99.5.7025 99.5.7025 99.5.7025

28 Handle 30x4 99.5.7026 99.5.7026 99.5.7026

29 Compression spring 590.01-01-009 99.5.7027 99.5.7027 99.5.7027

29a Washer DIN 125-Ø8.4 99.5.7028 99.5.7028 99.5.7028

29b Hexagon bolt DIN 933-M8x35 99.5.7029 99.5.7029 99.5.7029

29c Washer (plastic) 99.5.7030 99.5.7030

29d Nut DIN 985-M8 99.5.7031 99.5.7031 99.5.7031

30 Gas lever assy 99.5.7032

31 Switch bar 670.01-14 99.5.7033 99.5.7033

32 Bowden cable (drive) 99.5.7034

32a Adjustment-screw 99.5.7077 99.5.7077

33 Circlip DIN 471-20x1.2 99.5.7035 99.5.7035 99.5.7035

35a Shaft with sprocked wheel 675.01-16 99.5.7090

35b Shaft with sprocked wheel 670.01-16 99.5.7100

36 Cushion-tyred wheel (plastic-rim) 99.5.7038

39 Washer DIN 9021-Ø8.4 99.5.7041 99.5.7041

40 Hexagon bolt DIN 933-M8x20 99.5.7042 99.5.7042

41 Chain 670.01-01-008 99.5.7043

42 Flange bearing RA 20 99.5.7019 99.5.7019

43 Sprocket wheel 670.01-10-002 99.5.7045 99.5.7045

44 Split taper pin DIN 1481-4x16 99.5.7046 99.5.7046

45 Gearbox 670.01-10-004 99.5.7047

46 Cushion tyred wheel (steel-rim) 99.5.7060 99.5.7060

46a Cushion tyred wheel (steel-rim) right with bearing and free-wheel 99.5.7101 99.5.7101

46b Cushion tyred wheel (steel-rim) left with bearing and free-wheel 99.5.7102 99.5.7102

47 Steering wheel (plastic-rim) 99.5.7061

48 axle 660.01-06 99.5.7062

49 Rotor ø 18 mm LS 3500 660.01-07 99.5.7075

50 Distance-bush 660.01-01-002 99.5.7076

51 Housing 670.03-02 99.5.7071 99.5.7071 99.5.7071

52 Frontplate housing 670.02-20 99.5.7067 99.5.7067 99.5.7067

53 Motorplate LS 3500 660.02-02 99.5.7072

54 Motorplate LS 5000 670.02-05 99.5.7073 99.5.7073

55 Screw for protection DIN 603-M8x20 99.5.7070 99.5.7070 99.5.7073

56 Starlock-cap D20 99.5.7079

57 Washer DIN 125-Ø21 99.5.7080

58 Split taper pin DIN 1481-6x40 99.5.7081

59 Safety-guard 670.02-18 1429 423 1429 423 1429 423

60 Suction tube with accessories 670.01-28 1429 417 1429 417 1429 417

66 Gearbox 675.01-10 99.5.7089

68 Chain protection wheel shaft 675.01-15 99.5.7091

69 Bowden cable (drive) 675.01-14 99.5.7092

70 Operating handle 675.01-06 99.5.7093

72 Shaft for blower 675.01-12 99.5.7095

73 Pulley guide incl. sprocket 675.01-08 99.5.7096

74 Chain - Gearbox 675.01-01-003 99.5.7097

75 Chain for rotor drive 675.01-01-004 99.5.7098

76 Regulating device (operating handle) 675.01-13 99.5.7099

77 Sprocket - Gearbox H (pos. 66) 675.01-10-003 99.5.7104

Loading...

Loading...